Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Weld microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

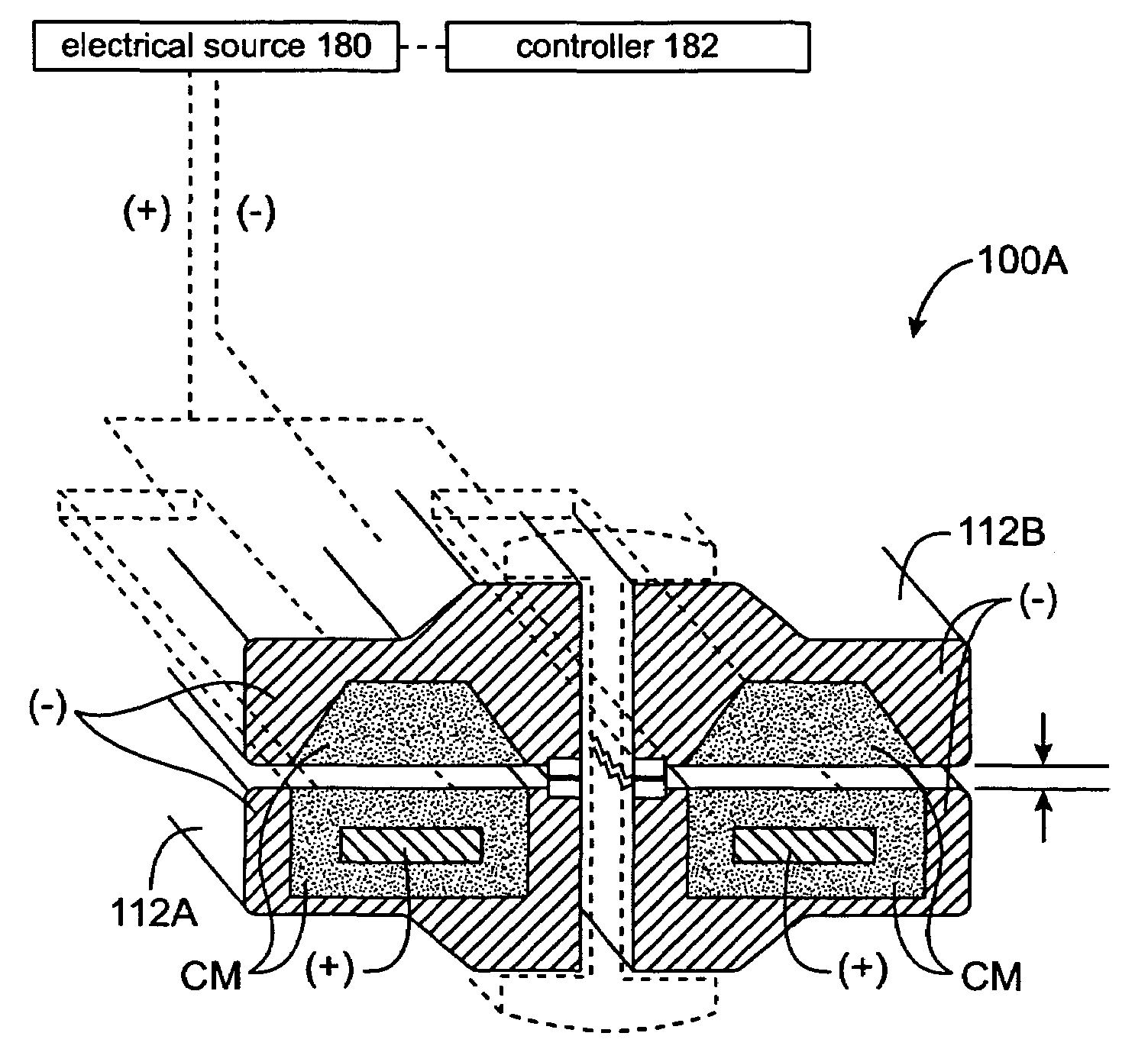

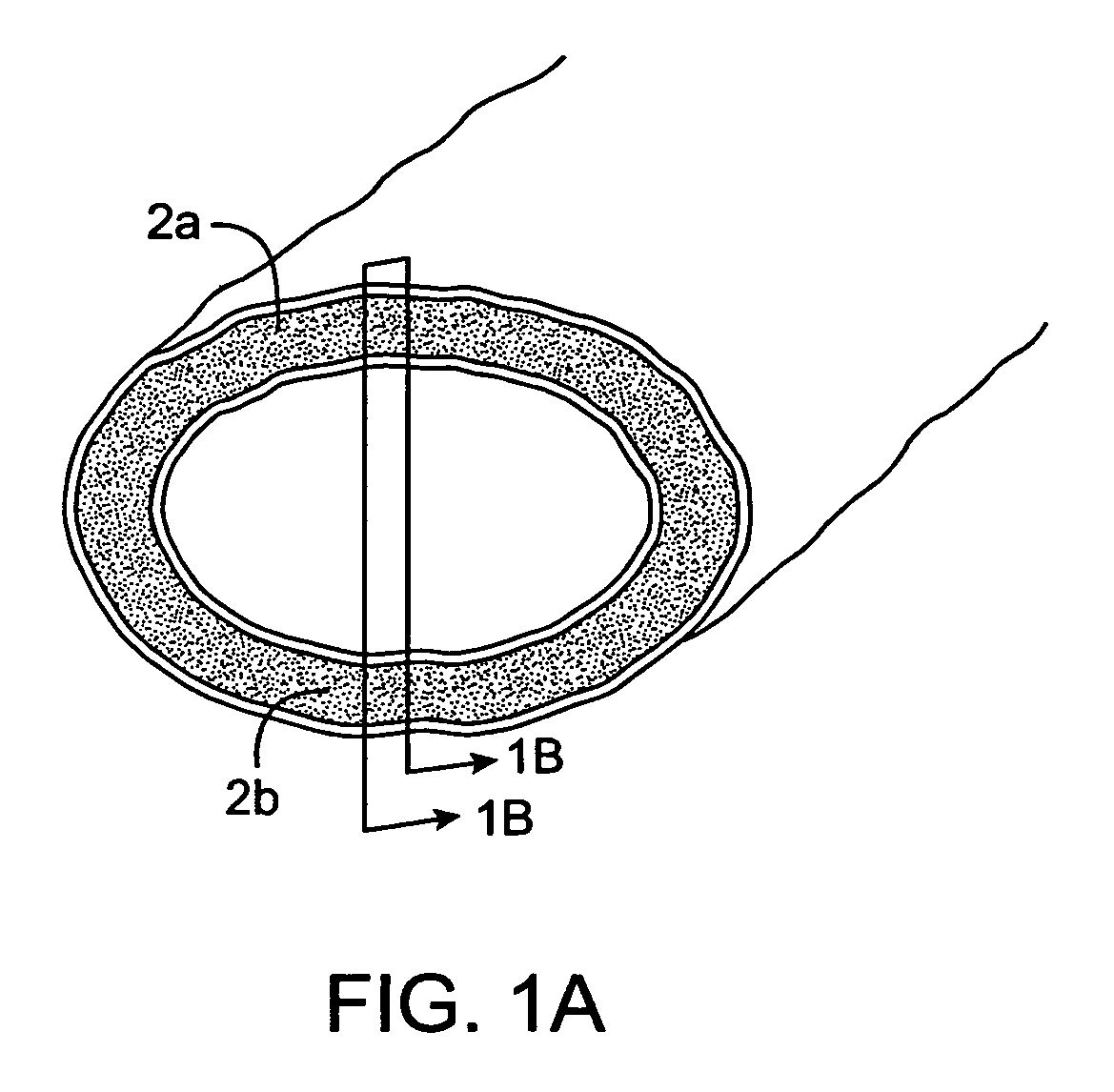

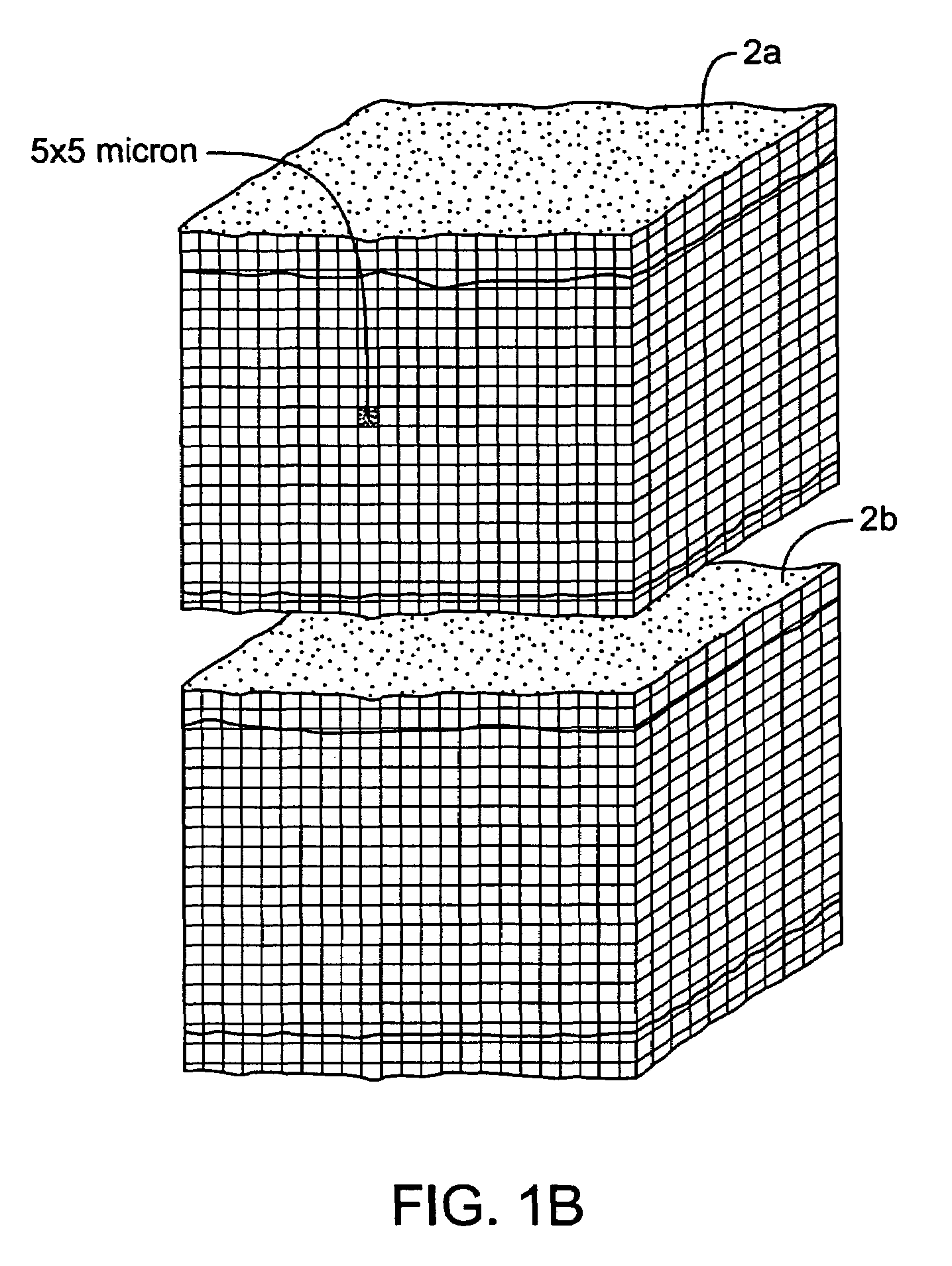

Electrosurgical instrument and method of use

InactiveUS7112201B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface. In another mode of operation, a conductive-resistive matrix can induce a “wave” of Rf energy density to sweep across the tissue to thereby weld tissue.

Owner:ETHICON ENDO SURGERY INC

Aluminum alloy welding wire for aerospace and preparation method of aluminum alloy welding wire for aerospace

InactiveCN105779831AHigh tensile strengthImprove plasticityMetallic material coating processesCrack resistanceToughness

The invention relates to an aluminum alloy welding wire for aerospace and a preparation method of the aluminum alloy welding wire for aerospace. The aluminum alloy welding wire for aerospace is characterized by comprising the following chemical components in percentages by mass: 6.2-7.0% of Cu, 0.06-0.10% of Ti, 0.1-0.5% of Cr, 0.05-0.2% of V, 0.1-0.5% of Mn, 0.5-1.5% of Sc, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.2% of Mg, less than or equal to 0.2% of Fe, less than or equal to 0.2% of Si, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for aerospace comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for aerospace provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common 5556, 5654, 2319 or 2325 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

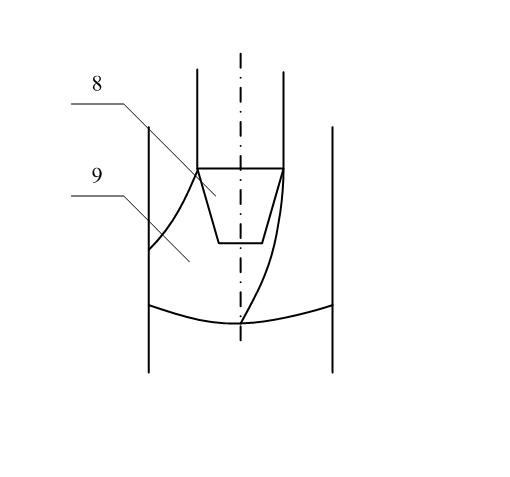

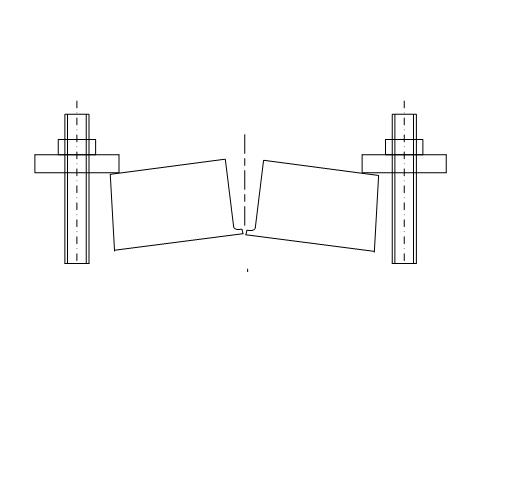

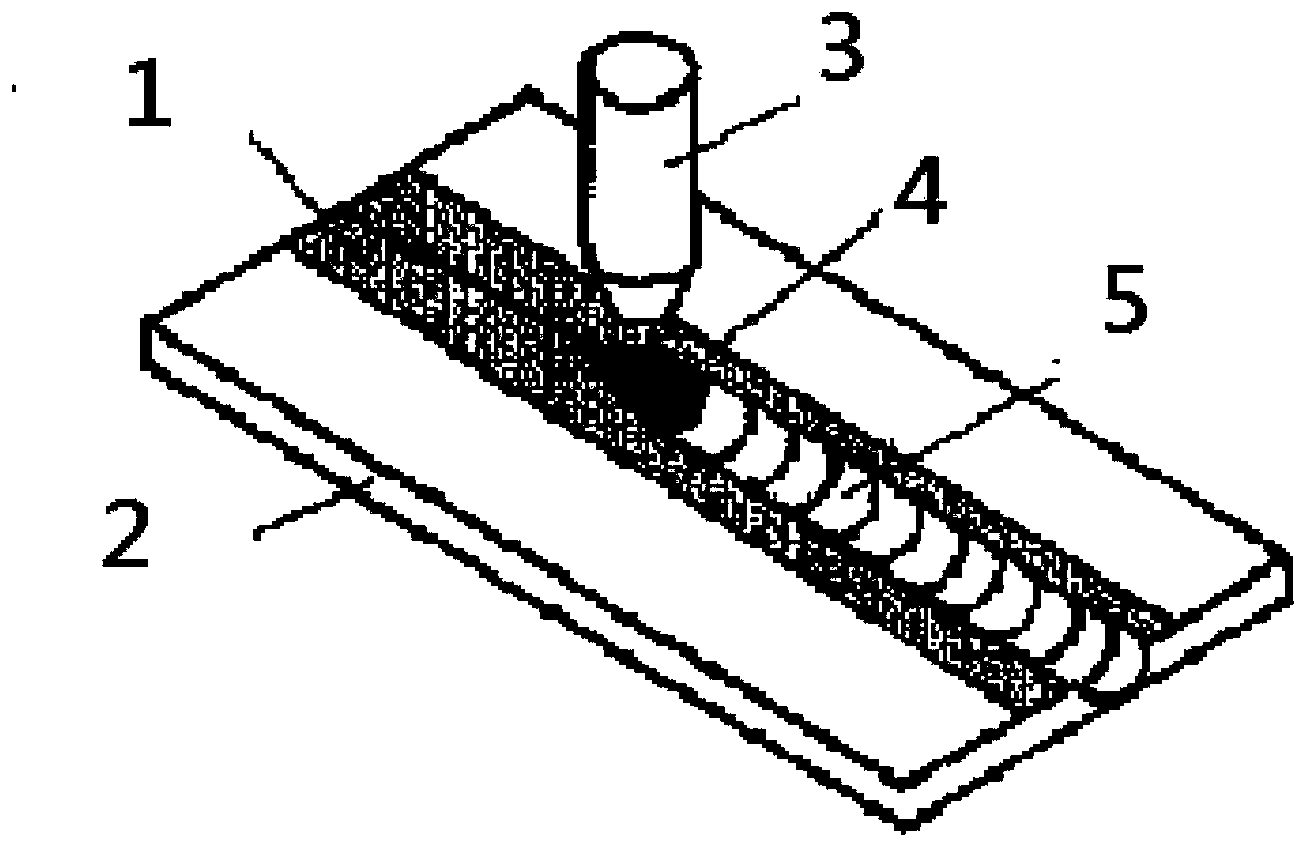

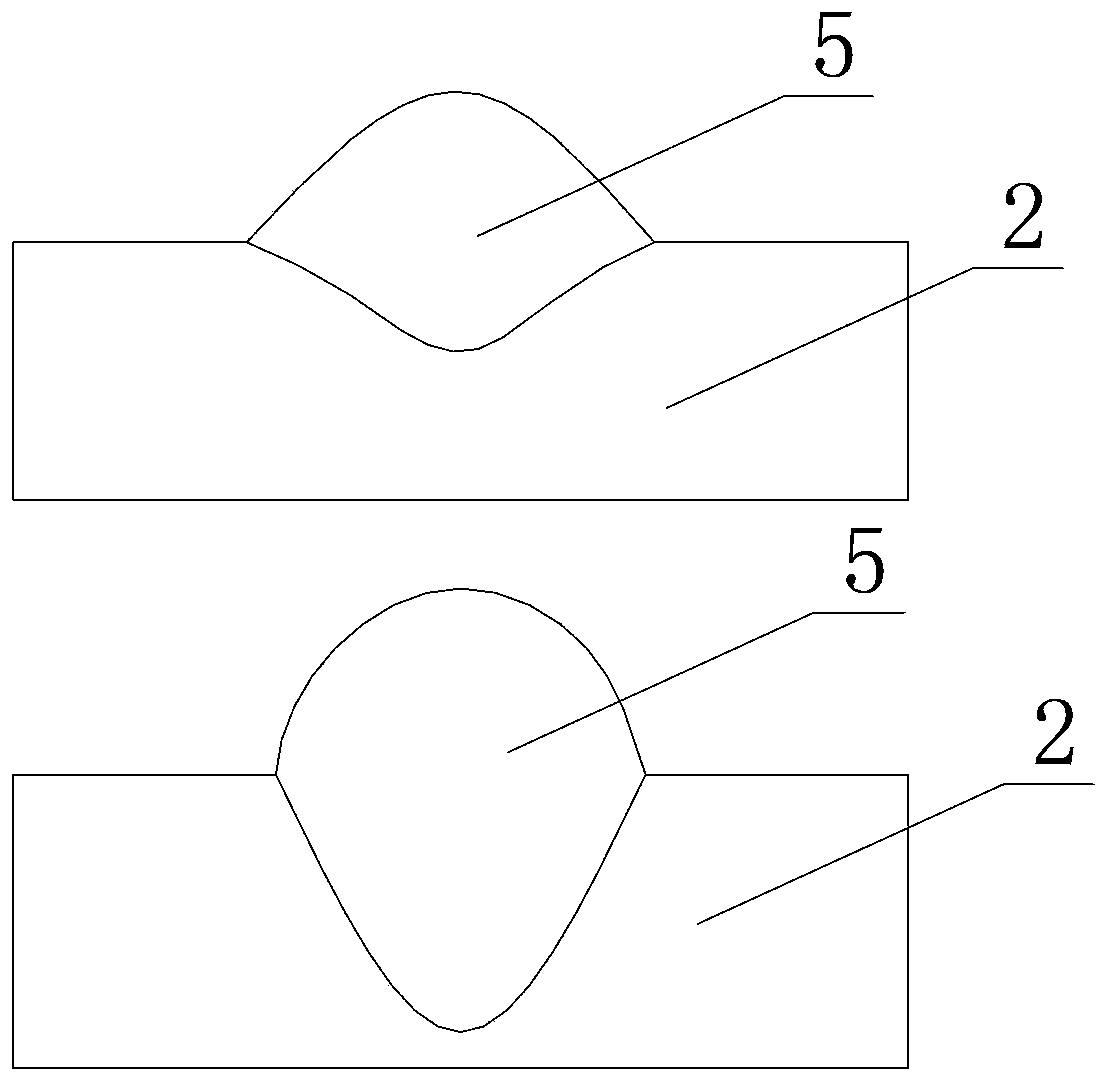

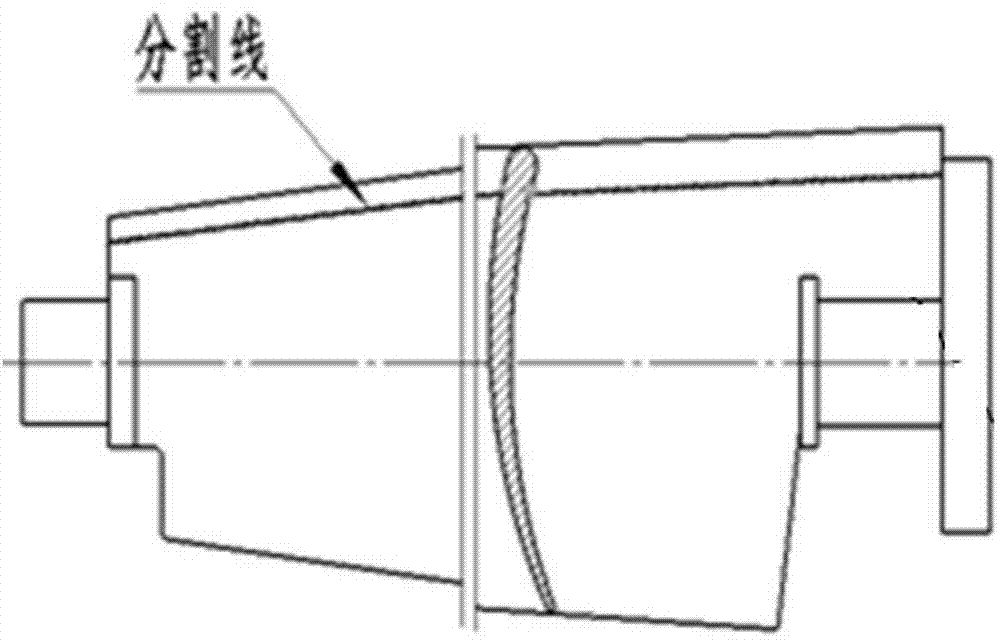

Magnetic control TIG (Tungsten Inert Gas) welding process for narrow gap of thick plate titanium alloy

InactiveCN102601501AImprove performanceWeld firmlyArc welding apparatusWelding/cutting media/materialsThick plateResidual deformation

The invention discloses a TIG (Tungsten Inert Gas) welding process for a narrow gap of a thick plate titanium alloy, which comprises six items adopted in the welding process, namely form of a welding gun, welding line spreading form, form of a welding groove, locking form before welding, selection of welding engineering parameters and selection of protective atmosphere in the welding process. The welding process solves the technical problem of the automatic TIG welding process for the narrow gap of the thick plate titanium alloy, realizes automatic TIG welding of the narrow gap of the thick plate titanium alloy, and has the characteristics of less time of weld beads, narrow heat affected zone and high welding efficiency. The residual stress and residual deformation of the welding joint are small, the weld structure is fine, and the welding performance is high.

Owner:HARBIN INST OF TECH AT WEIHAI

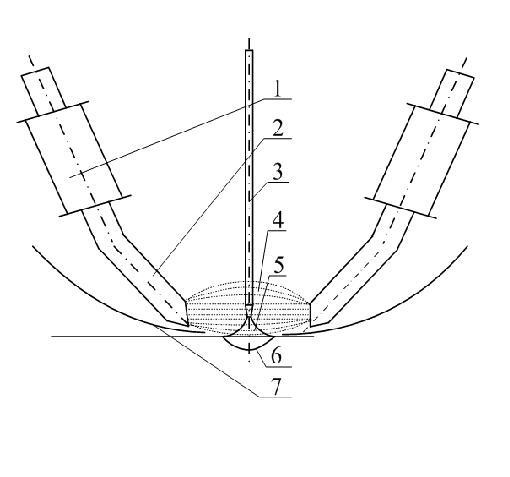

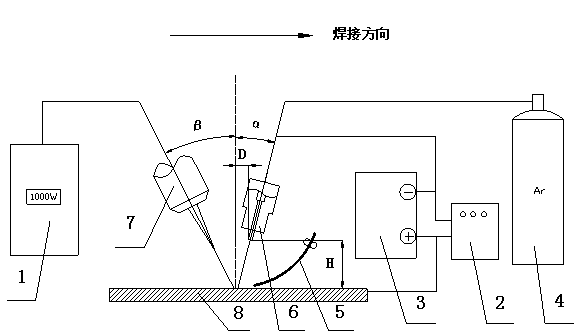

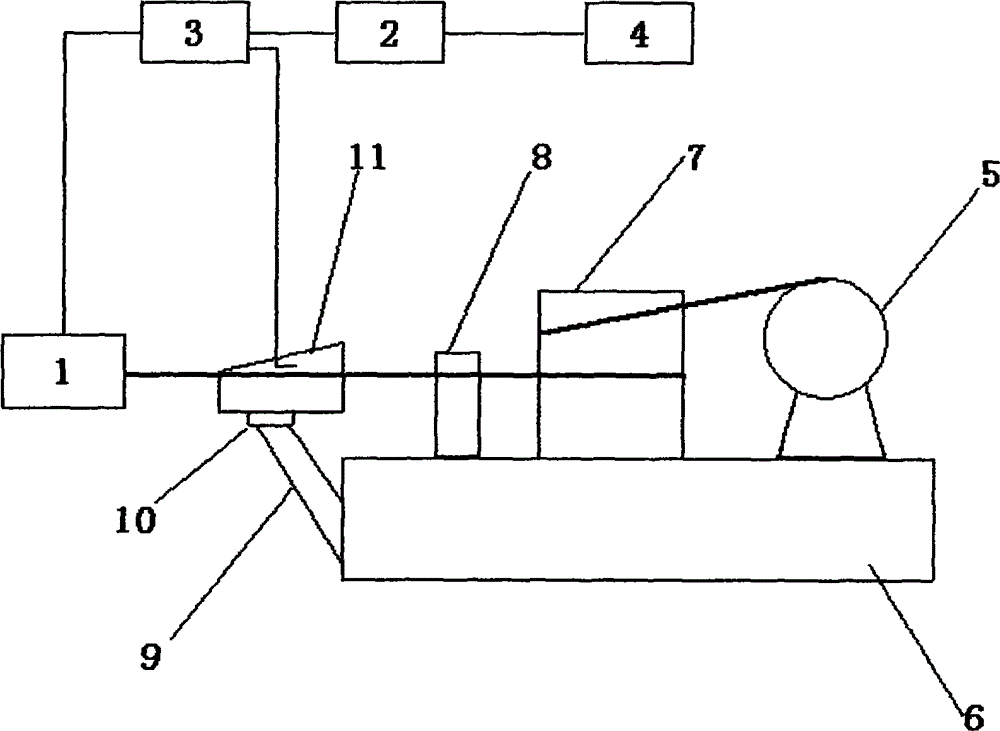

Laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process

InactiveCN103192187AGood compound effectReduce laser powerWelding/soldering/cutting articlesLaser beam welding apparatusAnti stressMolten bath

The invention discloses a laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process. The process comprises the following steps of: constructing a laser high-frequency alternating-current pulse TIG hybrid welding system, and gathering an TIG arc and a semiconductor laser beam on the same welding position of a welded workpiece 8 in the same welding direction, to form a molten bath, wherein an inclined angle alpha of 10-40 degrees is formed between the TIG arc tungsten electrode tip end and a vertical direction, the semiconductor laser beam forms an included angle beta of 10-30 degrees with the vertical direction, the TIG arc tungsten electrode tip end keeps a vertical distance H of 2-4mm with the surface of the welded workpiece 8, and the TIG arc tungsten electrode tip end and the semiconductor laser beam keep a horizontal distance D of 2-5mm with an action point of the surface of the welded workpiece 8. The process disclosed by the invention can refine weld microstructure, remarkably reduce or eliminate pores in melting area and effectively improve mechanical performance and anti-stress corrosion performance of a high-strength aluminous alloy welding joint, and the process is quite practical.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Lorentz-force-based laser welding pool control method

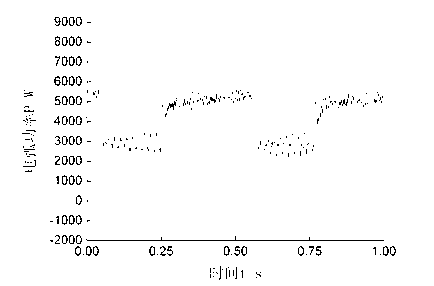

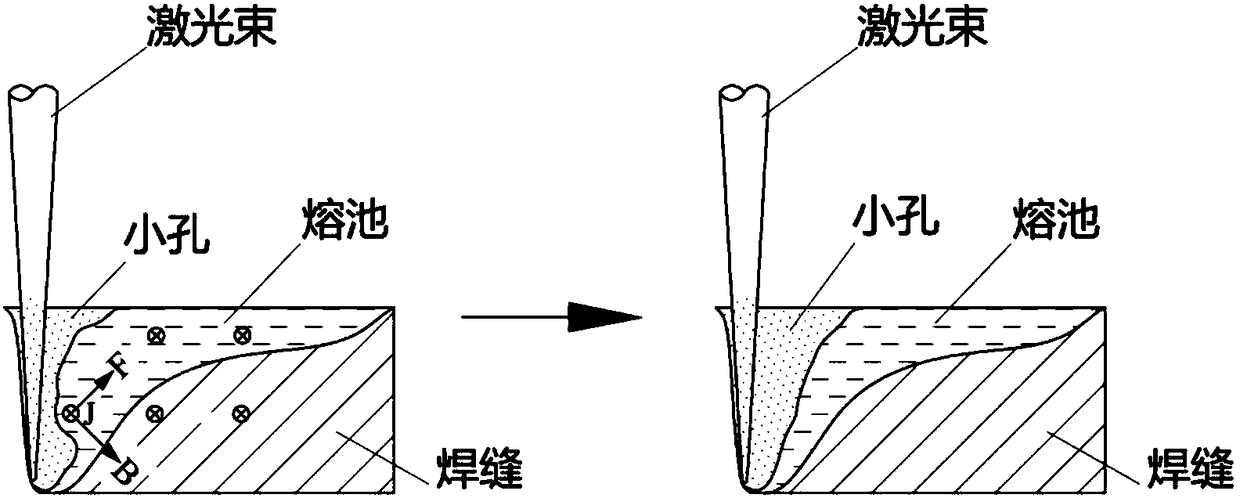

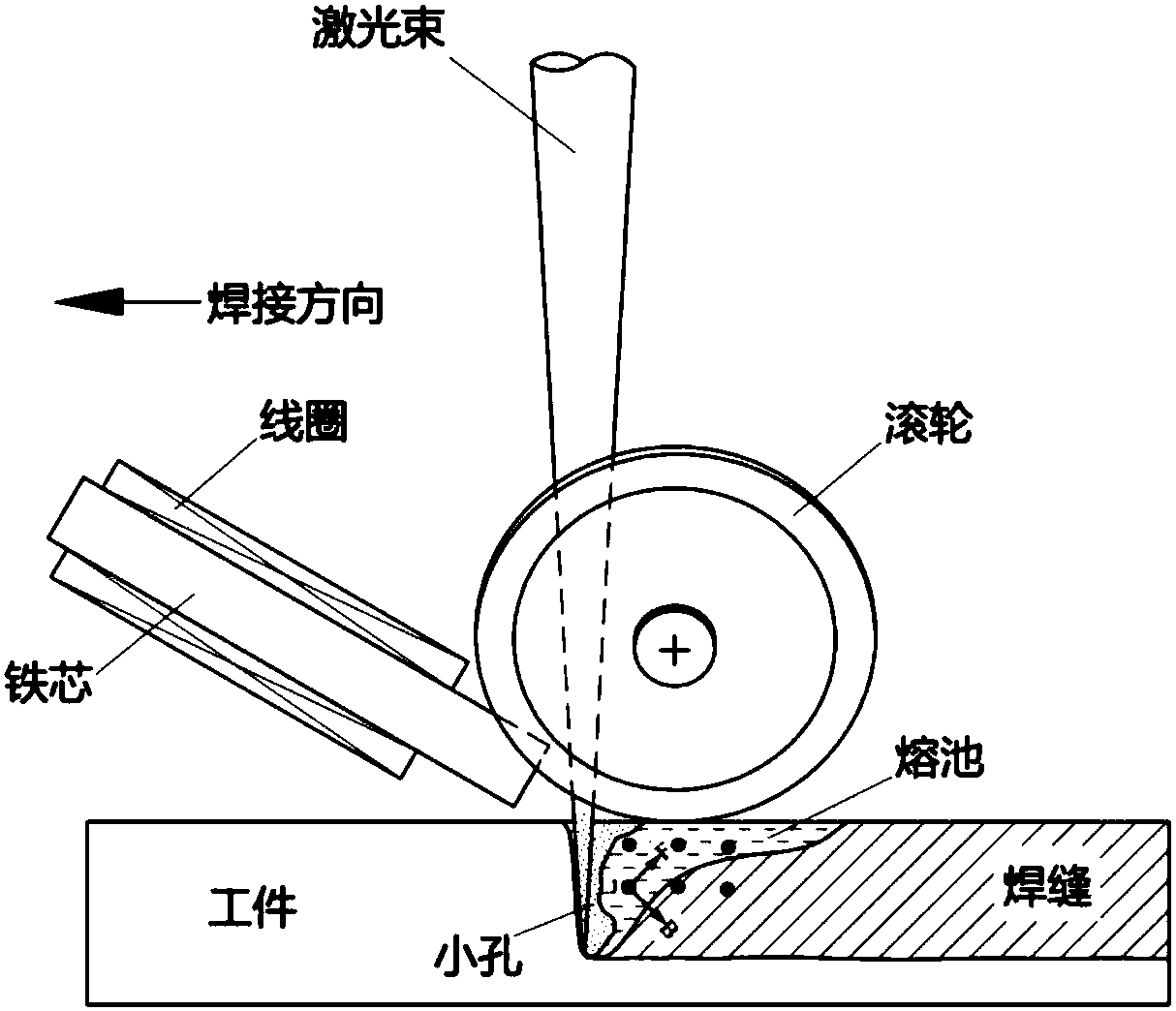

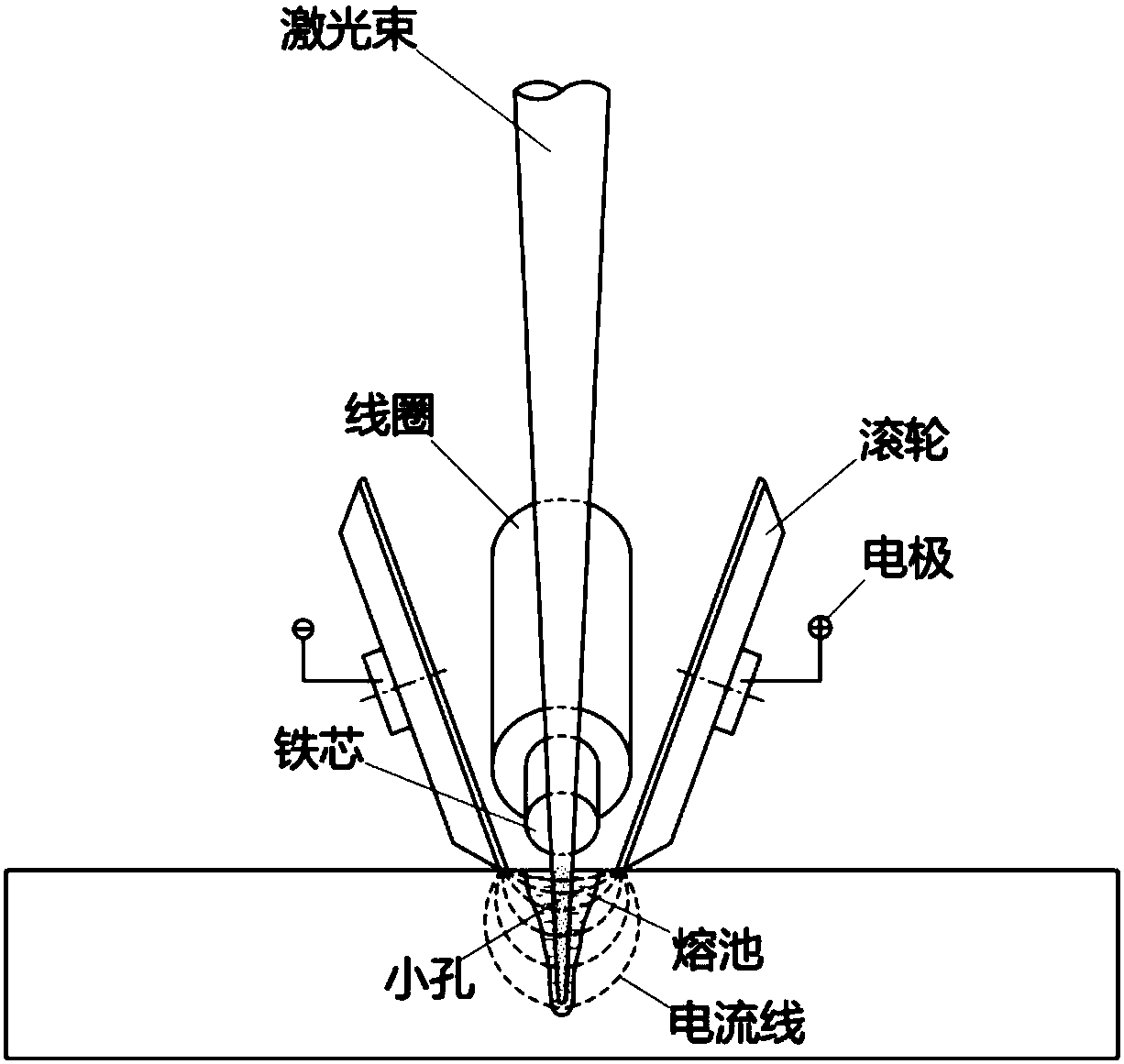

ActiveCN108247226AAffecting the physical laws of interactionImprove controllabilityLaser beam welding apparatusEngineeringStressed state

The invention provides a Lorentz-force-based laser welding pool control method and belongs to the technical field of laser processing. According to the method, current and a magnetic field which are perpendicular to each other are applied to a laser welding pool to generate Lorentz force following the ampere left-hand law in the welding pool; the stress state, the flow behavior and the solidification process of a melt are actively controlled through the Lorentz force. The backward Lorentz force is applied to the welding pool to make a welded tiny hole be deepened and stretched, so that metal vapor / plume in the tiny hole escape smoothly. A solution in the welding pool flows smoothly. The effects of increasing the weld penetration depth increase, improving the welding stability and optimizing welding formation are achieved. If AC or pulse wave modulation is conducted on parameters of the applied current and the applied magnetic field, the Lorentz force can have the effects of stirring, vibrating and directionally driving the solution in the welding pool. The adjustment functions of the weld microstructure and performance can be achieved while the welding defects such as pores, cracks, undercut and poor formation are controlled.

Owner:BEIJING UNIV OF TECH

Welding method of laser brazing of X 80 pipeline steel

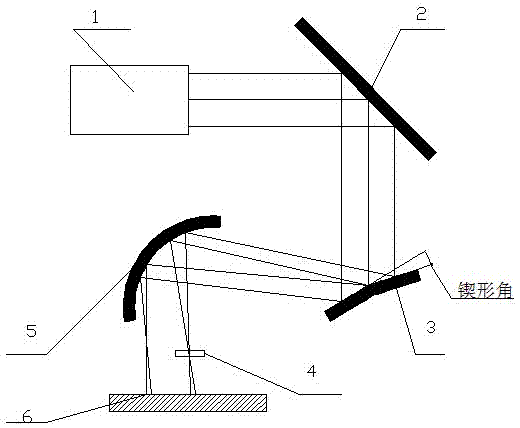

ActiveCN103192149AAvoid multiple processesUniform preheating effectSoldering apparatusWedge angleEnergy dispersion

The invention relates to a welding method of laser brazing of X 80 pipeline steel and belongs to the advanced manufacturing technology field. High energy laser source is utilized as unified preheating light source and welding light source to perform steps which comprises laser-bounce, transverse beam splitting, energy distribution and inward refocusing are performed on laser through a reflecting mirror, a spectroscope and a focusing mirror, the purpose of laser transverse beam energy distribution is achieved by adjusting the position of the spectroscope, distance between a front laser beam and a rear laser beam is adjusted by adjusting the size of a wedge angle of the spectroscope to form into the front laser beam and the rear laser beam, the front laser beam is served as a preheating light beam, the rear laser beam is served as a welding beam, and energy dispersion of the preheat light beam is performed through a concave lens when the preheating beam is utilized to preheat. The welding method of the laser brazing of the X 80 pipeline steel solves the problem that nonuniform weld microstructure caused by common welding is easy to cause electrochemical corrosion.

Owner:邳州市博睿投资管理有限公司

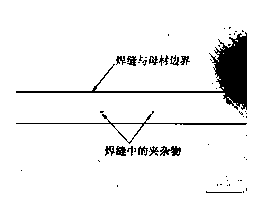

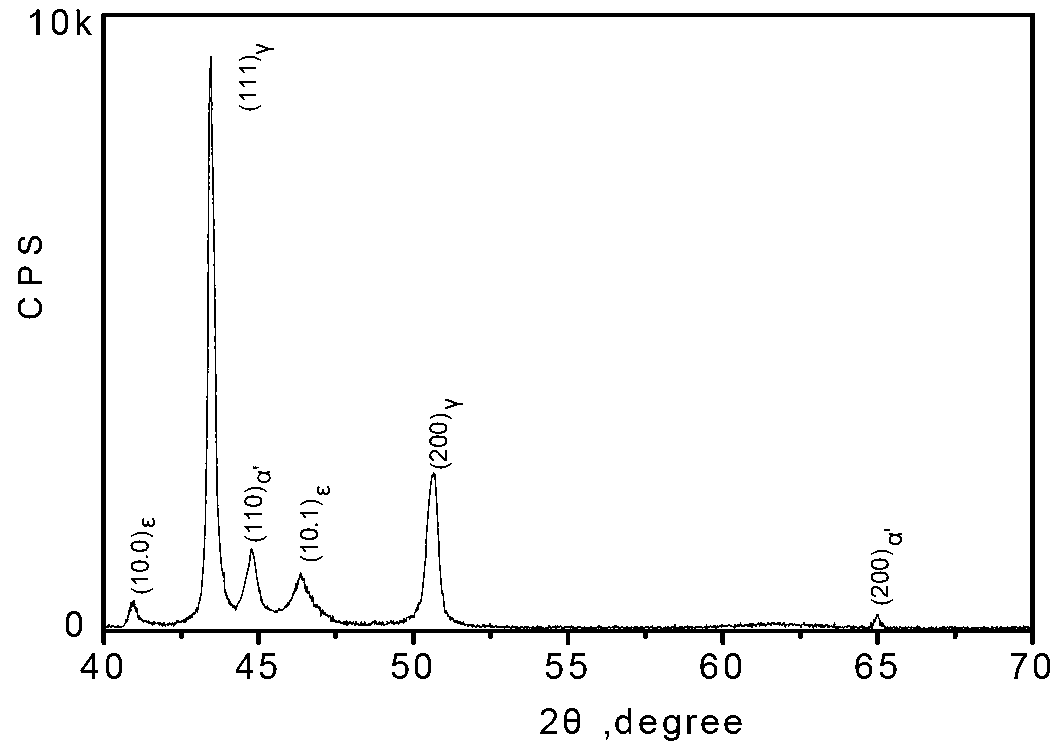

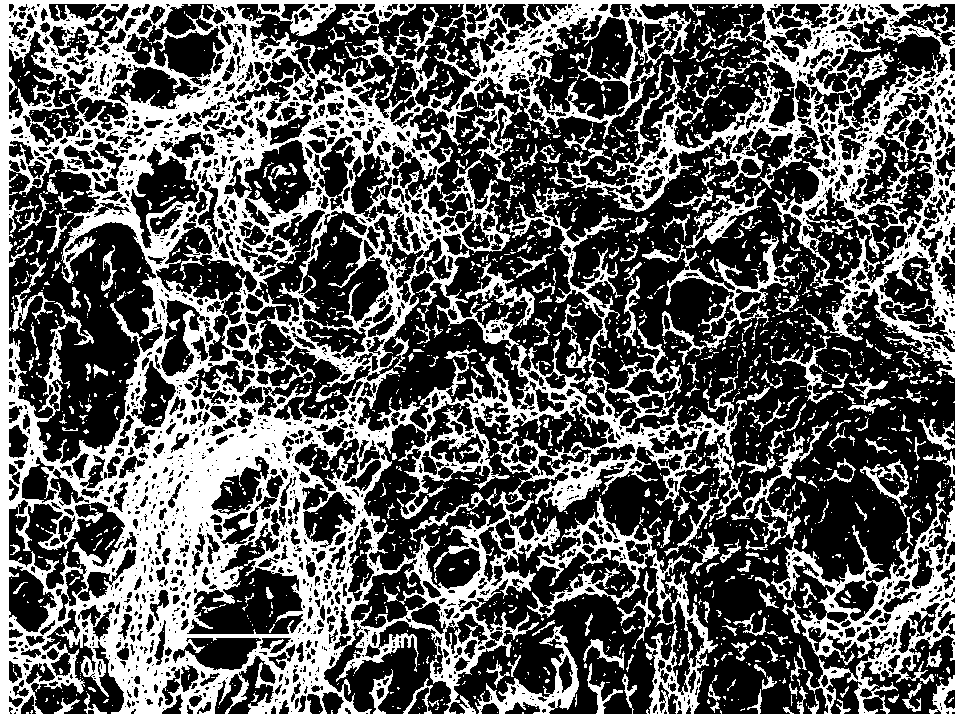

Electron beam welding method for dissimilar materials of nickel-aluminum bronze alloy and TC4 titanium alloy

InactiveCN101920391AHigh tensile strengthGood metallurgical bondElectron beam welding apparatusWelding defectTitanium alloy

The invention discloses an electron beam welding method for dissimilar materials of a nickel-aluminum bronze alloy and a TC4 titanium alloy, belongs to the field of dissimilar material fusion welding, and aims to solve the problem that an intermetallic compound layered structure is easily produced in the electron beam welding of the dissimilar materials of the nickel-aluminum bronze alloy and the TC4 titanium alloy. Different from the conventional welding method, the electron beam welding method is performed on the abutting surfaces of the TC4 titanium alloy and the nickel-aluminum bronze alloy respectively by deviating a certain distance to a nickel-aluminum bronze alloy side by using a superposition welding method. On the one hand, excellent metallurgical bonding can be formed on the welding line of the TC4 titanium alloy and the nickel-aluminum bronze alloy, and a joint does not have any welding defects, such as pores, cracks and the like; and on the other hand, the intermetallic compound layered structure formed by the welding line and the nickel-aluminum bronze alloy side can be weakened or eliminated, and continuously distributed weld microstructures can be obtained, so that the tensile strength of the joint can be improved to over 70 percent of that of the mother metal of the nickel-aluminum bronze alloy. The welding method in the invention is suitable for welding the conventional plate-like and tubular mother metals.

Owner:HARBIN INST OF TECH

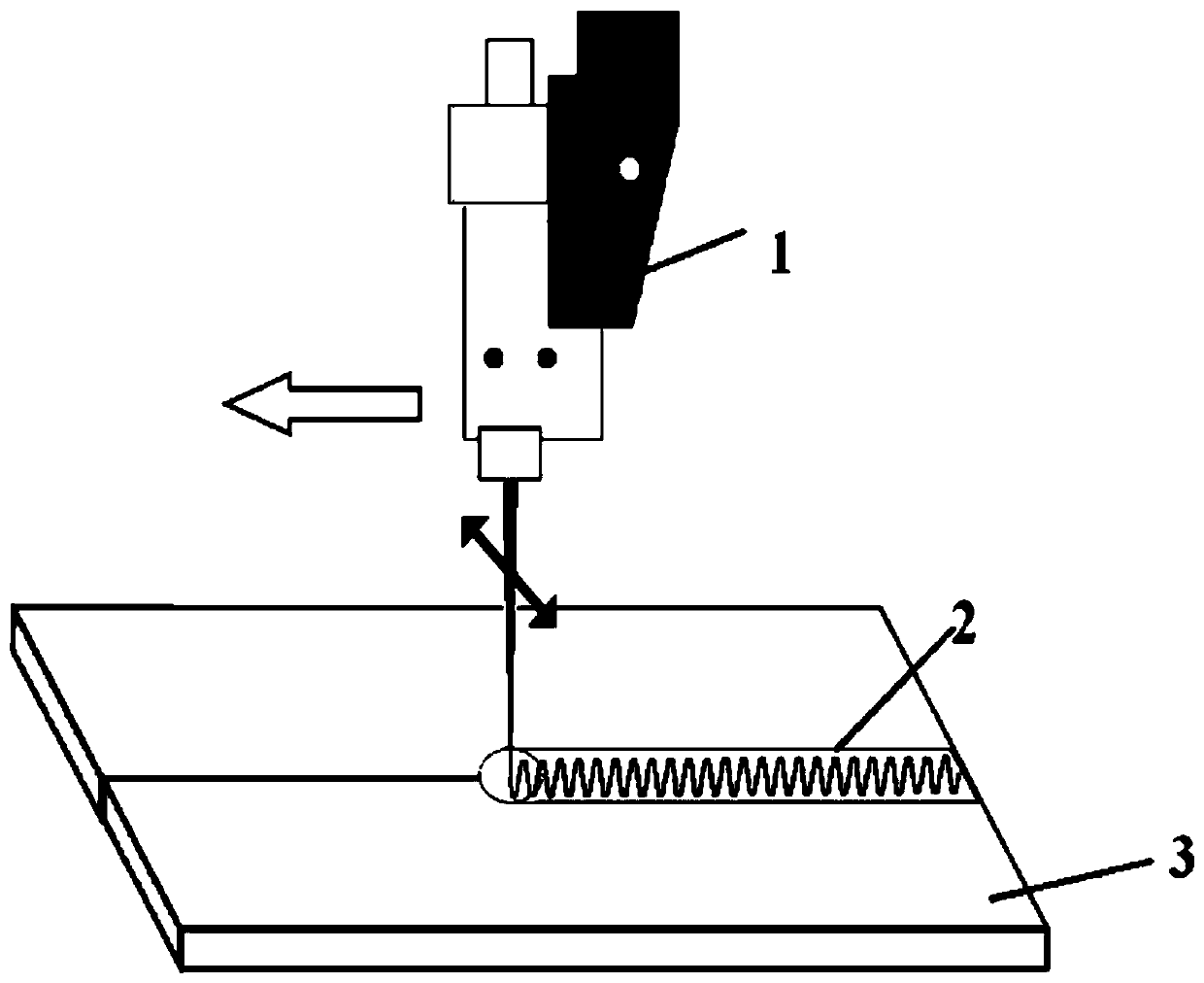

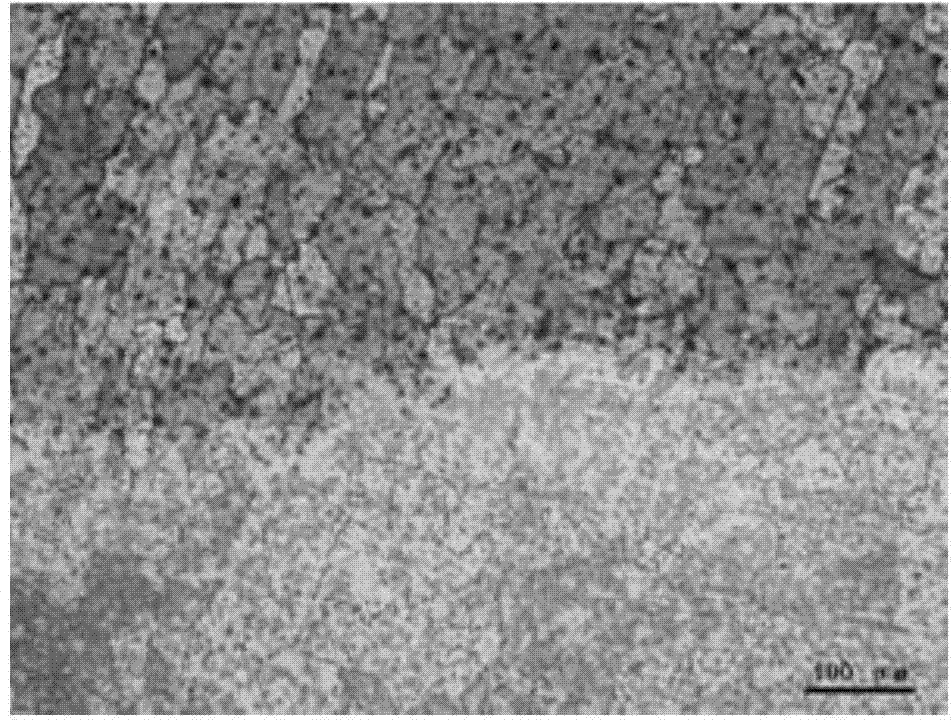

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

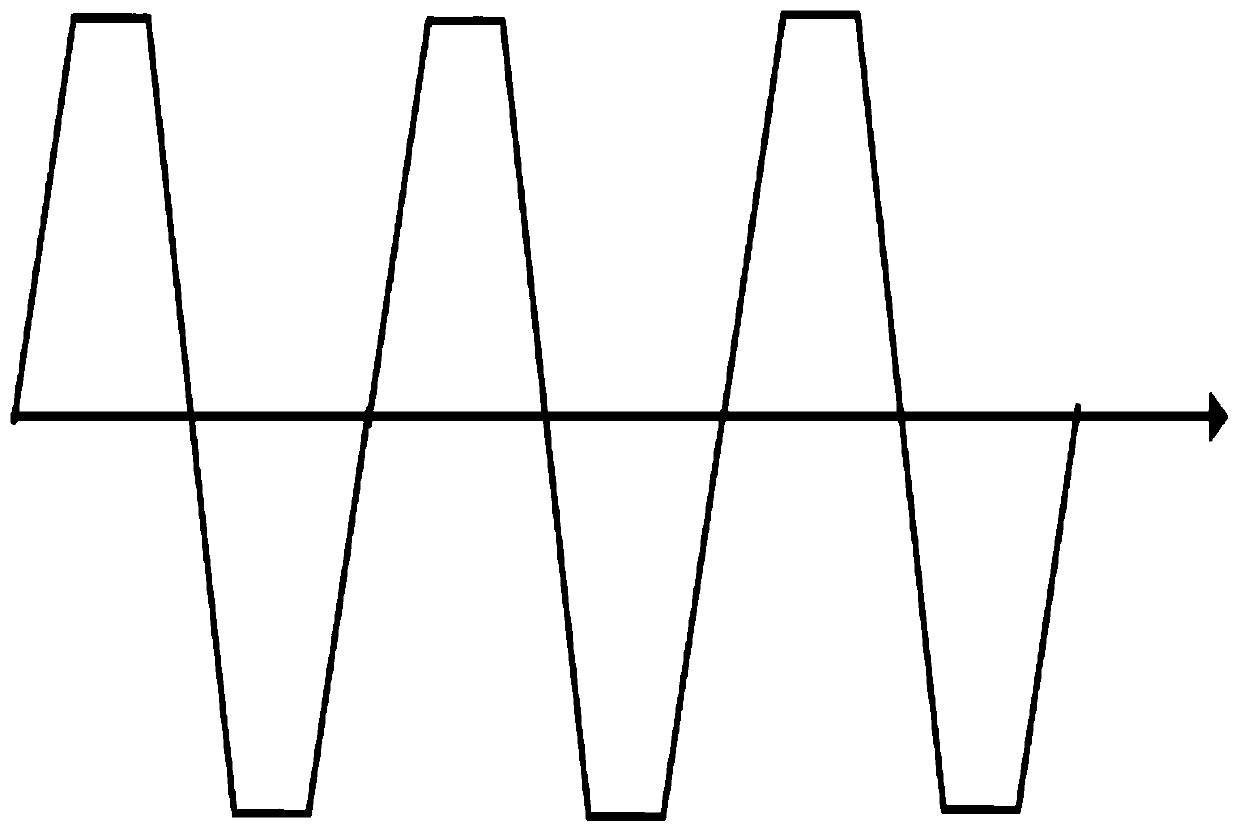

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

Aluminum alloy welding wire for high speed train and preparation method of aluminum alloy welding wire for high speed train

InactiveCN105772981AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

Welding material for butt fusion welding transition layer of titanium-steel composite board and preparation method of welding material

ActiveCN103567661AFusion welding butt joint realizationActive connectionWelding/cutting media/materialsWelding/soldering/cutting articlesTitaniumFusion welding

The invention provides a welding material for a butt fusion welding transition layer of a titanium-steel composite board and a preparation method of the welding material. The welding material comprises the components in percentage by weight as follows: 3.15%-3.35% of Mn, 18%-27% of Cr, 0.01%-0.015% of Cu, 0.35%-0.55% of Ti, 0.03%-0.04% of Co, 1.8%-2.0% of Nb, 0.2%-0.6% of Ta, smaller than or equal to 0.02% of C, smaller than or equal to 0.025% of Si, smaller than or equal to 0.002% of P, smaller than or equal to 0.75% of Fe and the balance of Ni, wherein the sum of the weight percentages of the components is 100%. The diameter of the welding material is small, weld microstructures of a titanium layer and a steel layer of the titanium-steel composite board can be effectively connected through manual TIG (tungsten inert gas) welding or MIG (metal inert gas) welding, butt fusion welding of the titanium-steel composite board is realized, and a welded joint has excellent strength and toughness; and the welding material is simple in preparation method, low in cost and suitable for batch production.

Owner:西安宝泰激光科技有限公司

Active agent for laser welding of ferrite stainless steel and using method for active agent

InactiveCN102699575AConvenient coatingImprove absorption rateWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention discloses an active agent for the laser welding of ferrite stainless steel and a using method for the active agent. The method comprises the following steps of: respectively weighing and mixing 3 to 7 weight parts of ZrO2, 0.9 to 1.5 weight parts of CaO, 1 to 3 weight parts of MgO and 1 to 3 weight parts of carbonate, and fully grinding a mixture into the active agent; adding the obtained active agent into a solvent according to the weight ratio of 1:(0.3-0.8), and preparing paste; grinding the surface of a workpiece to be welded, and washing the workpiece by using absolute ethyl alcohol to remove oil stains from the surface; coating the paste on the surface of the pretreated workpiece to be welded; and after a coating is fully dried, performing the laser welding. Tests show that a ferrite stainless steel plate can be welded under lower power by the active agent under the conditions of the same welding parameters; the weld penetration can be remarkably improved; and a weld microstructure can be refined, and the number of isometric crystals of a weld zone can be increased. When the active agent is used for the laser welding, the using method is easy and convenient to operate and low in cost, and the welding efficiency can be greatly improved.

Owner:TIANJIN UNIV

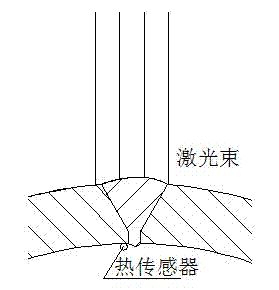

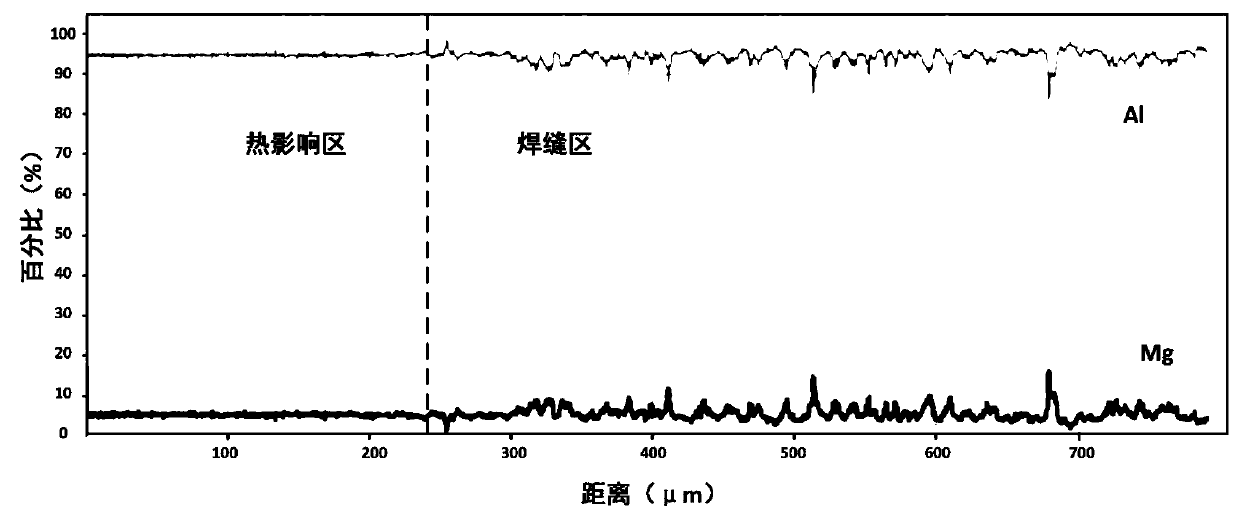

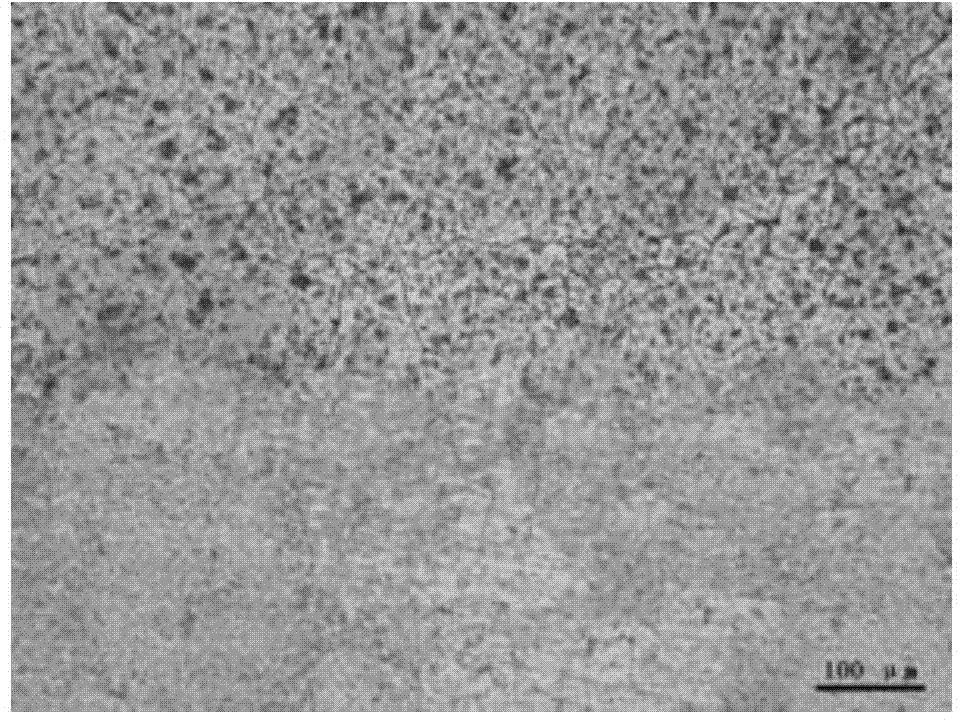

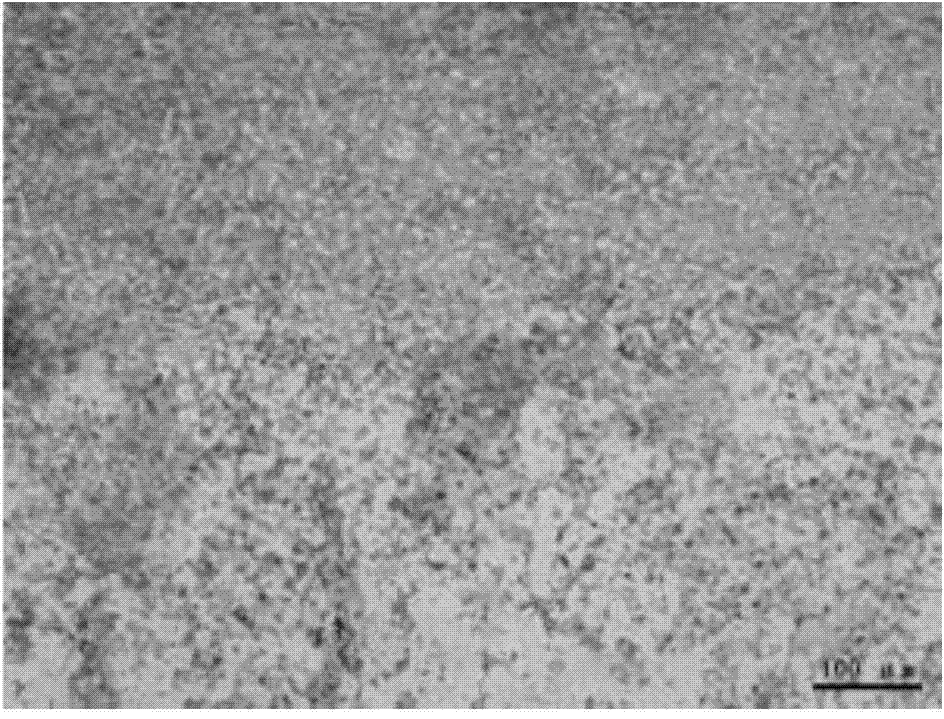

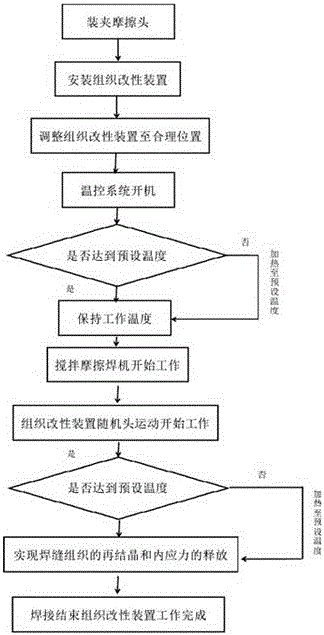

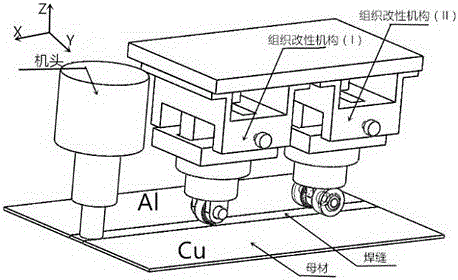

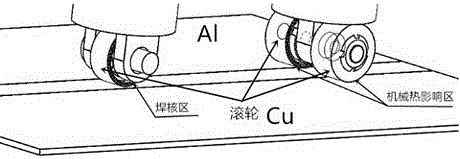

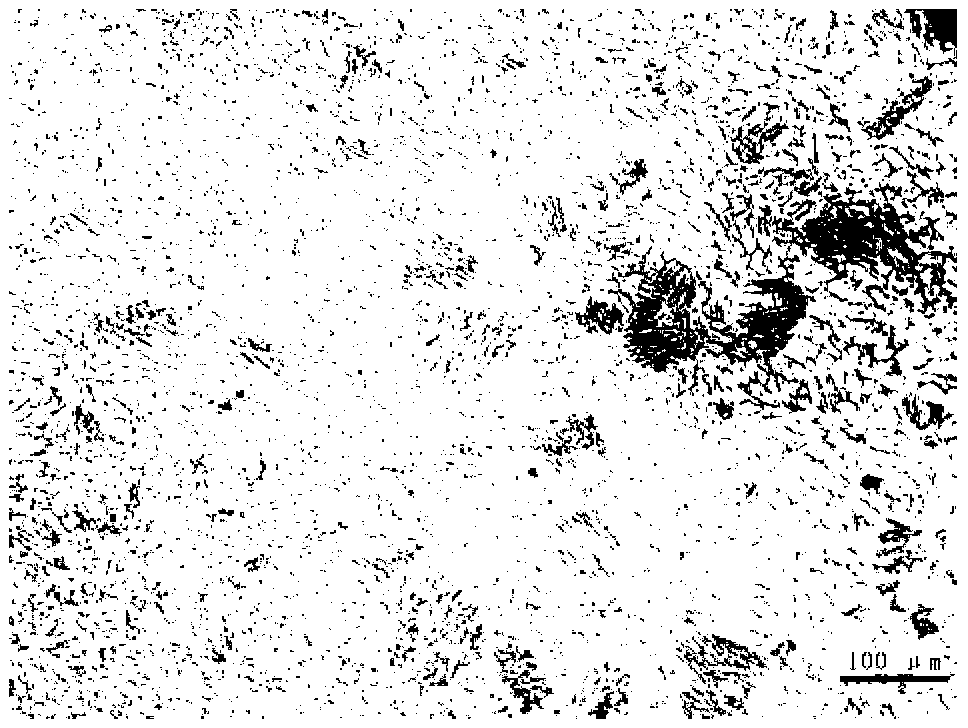

Method for improving weld microstructure of Al/Cu friction stir welding in follow-up manner

ActiveCN106181020AImprove mechanical propertiesImprove conductivityNon-electric welding apparatusTemperature controlWorking pressure

Owner:山东因泽智能设备有限公司

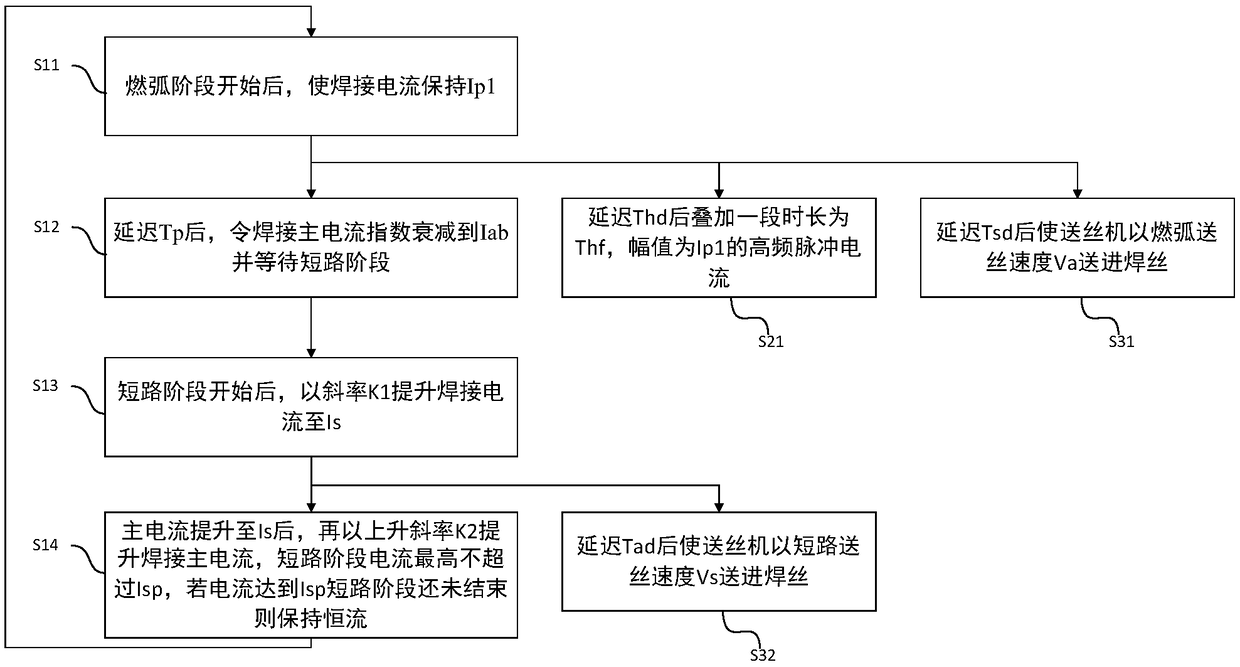

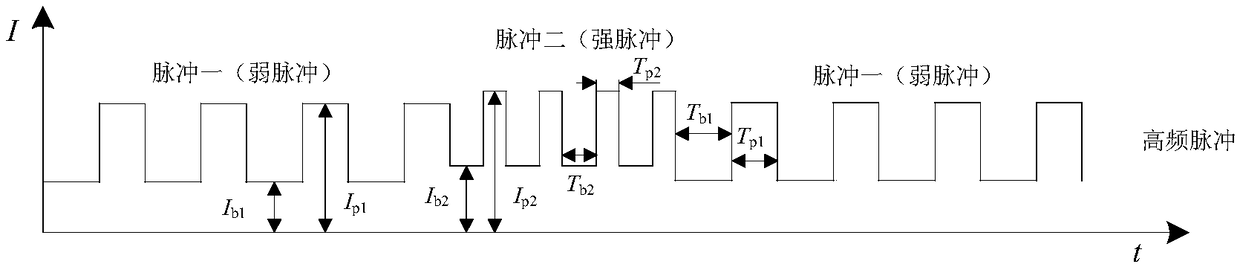

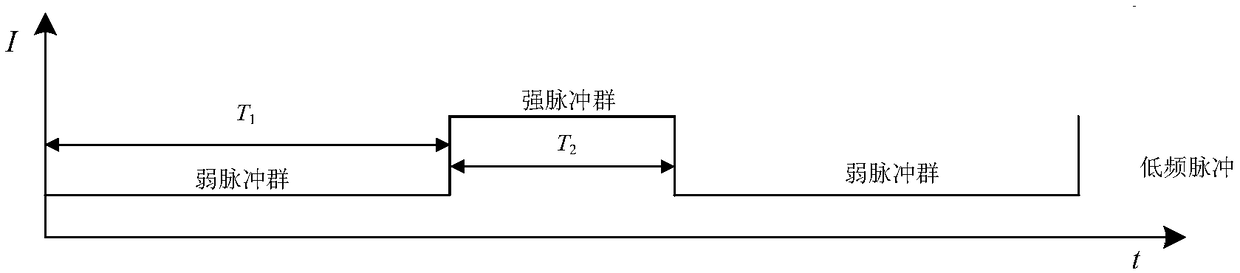

Short-circuit transient welding method and system

The invention relates to a short-circuit transient welding method and a system, which belong to the field of welding power supplies and welding automation equipment. According to the method, on the basis of a welding main current of a welding arcing stage, a high-frequency impulse is overlapped, so that the welding quality is improved by utilizing a high-frequency effect. At a short-circuit stage,a wire feed speed of a wire feeder is changed, so that wire feeding is slowed down; or a welding wire is withdrawn for assisting globular transfer. The invention additionally aims to provide the short-circuit transient welding system for implementing the welding method. The system adopts an alternate wire-feed method, meanwhile, a short-circuit state or an arcing state in a welding process can bedetected, and an appropriate welding current is output. In addition, at an arcing stage, a high-frequency impulse with the frequency being larger than 20kHZ can be overlapped. The researches show that by utilizing an electric arc with a high-frequency effect for welding, the welding stability and the electric arc stiffness can be greatly improved, and in addition, the high-frequency electric archas an effect on refining grains, so that weld microstructures and joint performances are favorably improved.

Owner:BEIJING UNIV OF TECH

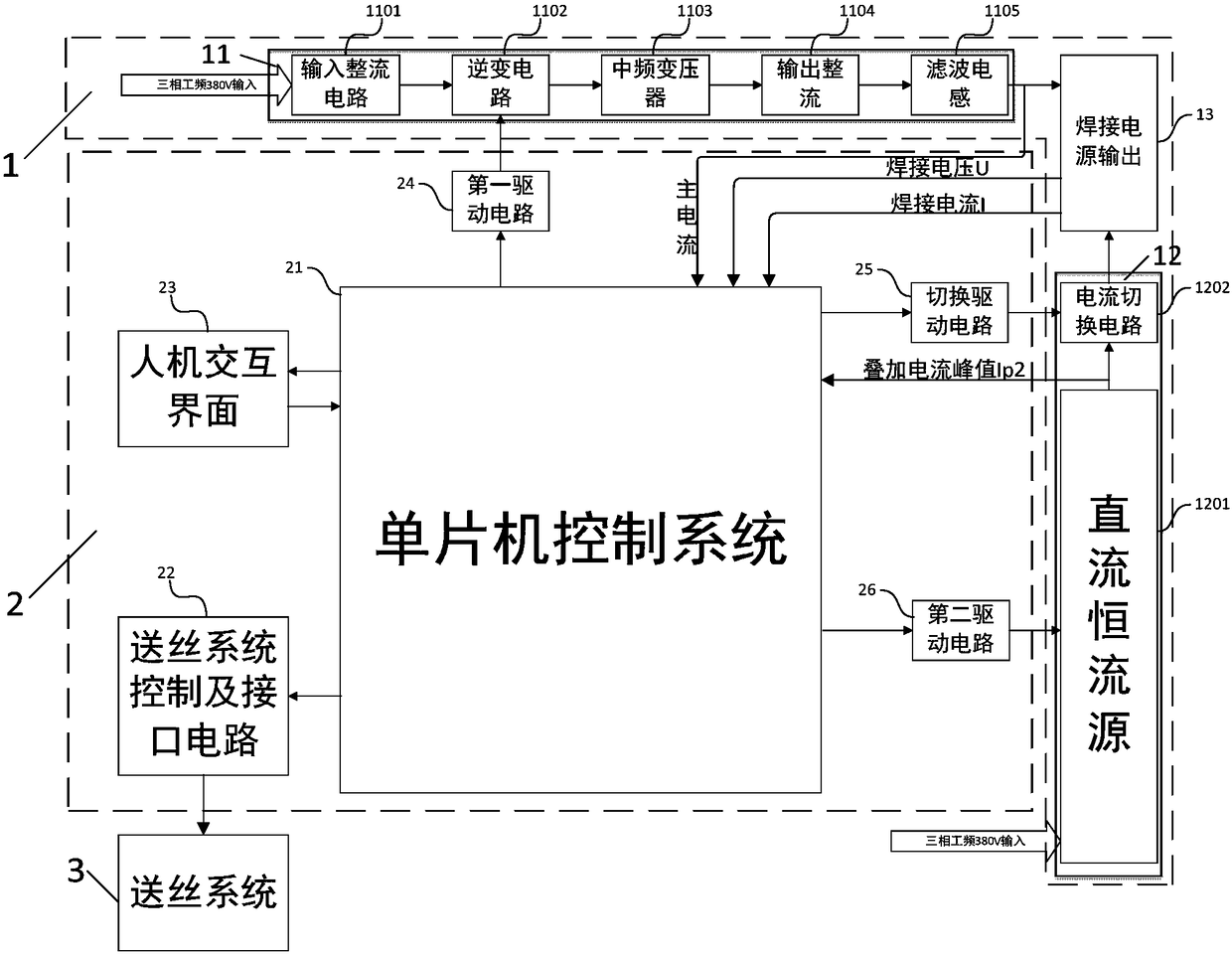

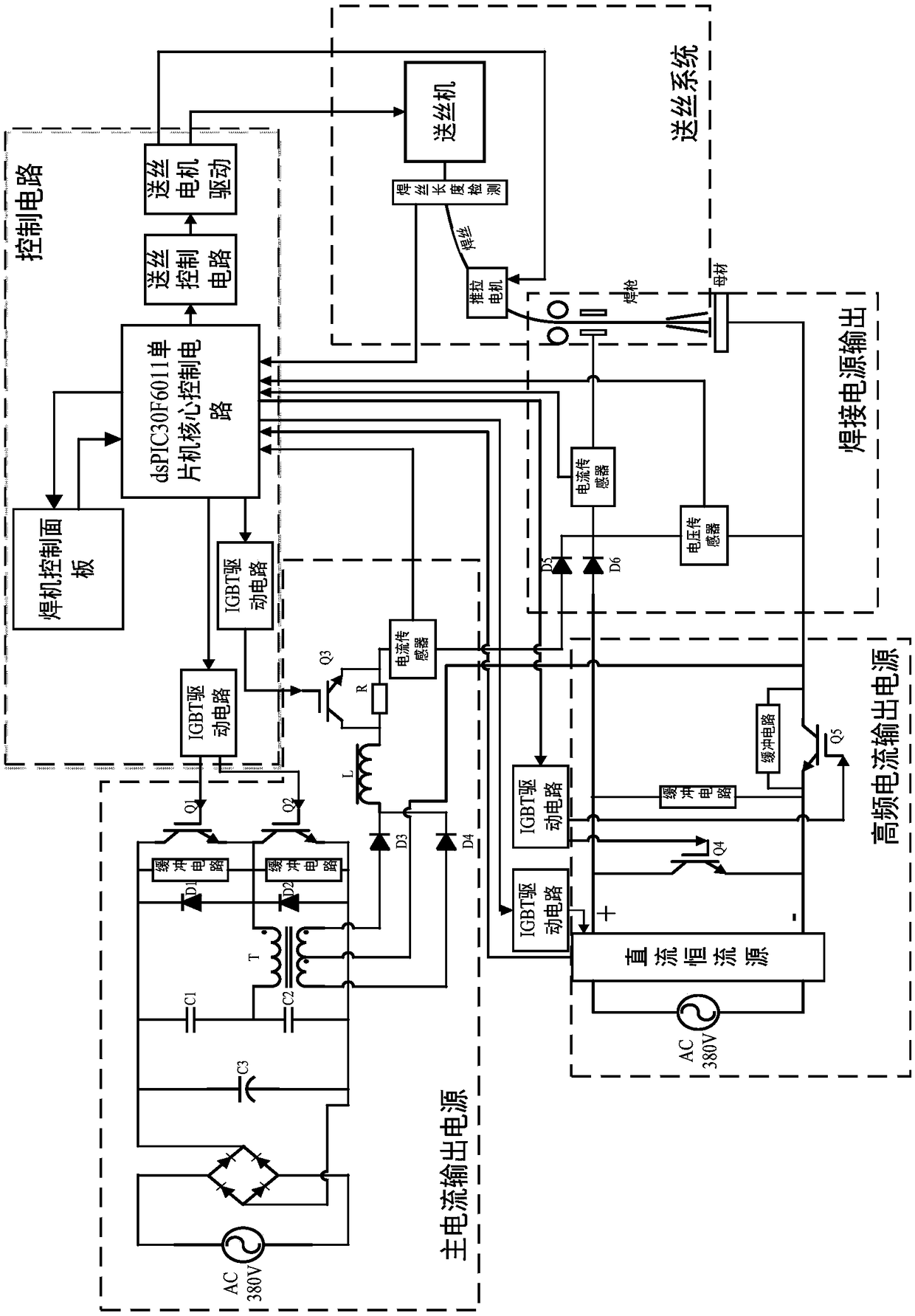

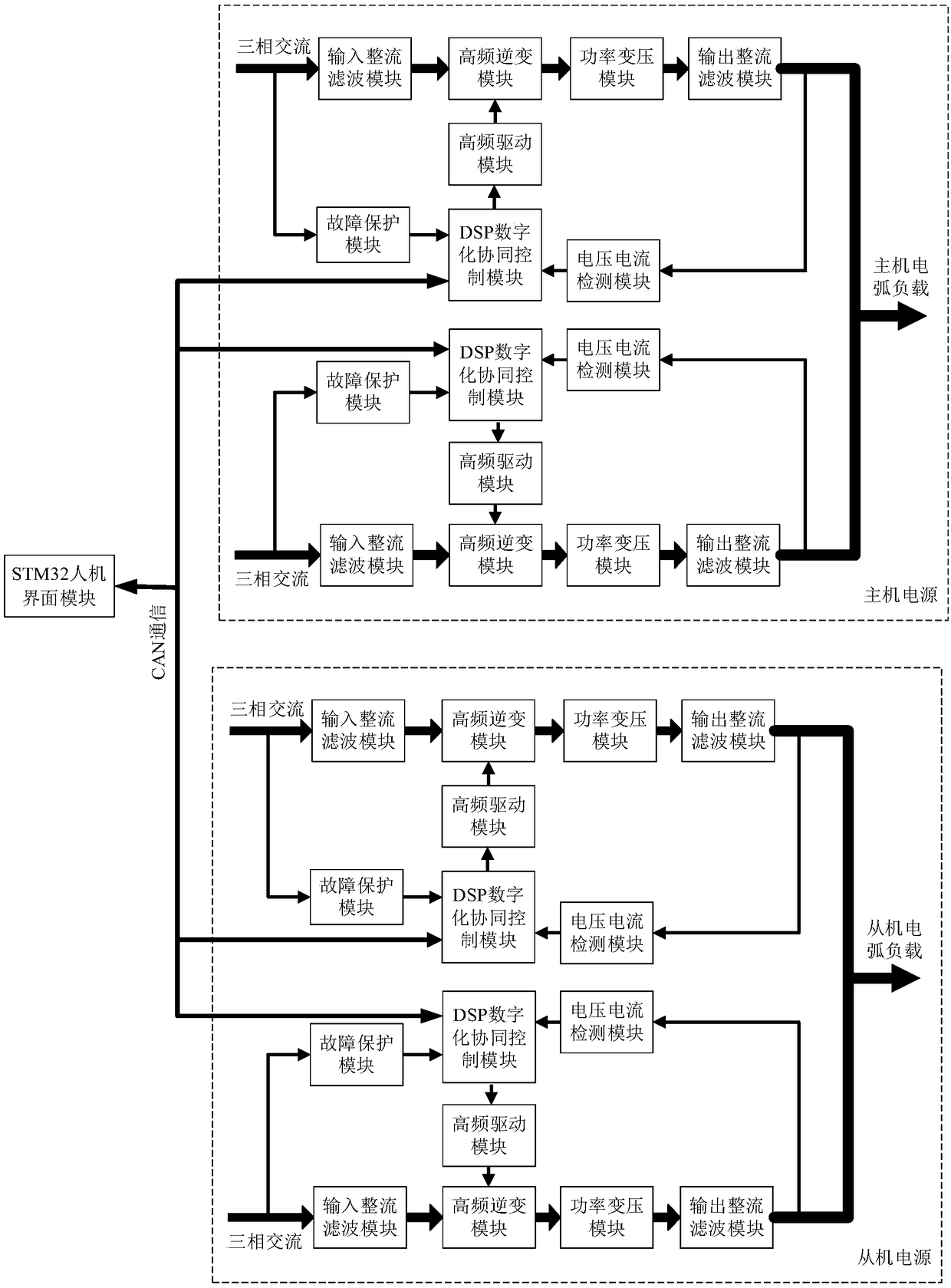

High-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and control method thereof

ActiveCN108746944AImprove welding efficiencyEasy to achieve one-time forming weldingArc welding apparatusDouble phaseWelding power supply

The invention discloses a high-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and a control method thereof. The power supply system comprises an STM32 human-computer interface module, a host power supply and a slave power supply, wherein the STM32 human-computer interface module is connected to DSP digital synchronic control modulesin the host power supply and the slave power supply; the host power supply provides current for a previous wire; the slave power supply provides current for a latter wire; and the host power supply,as well as the slave power supply, consists of two parallel main circuits and a control circuit. The power supply system can realize seven high-and-low-frequency pulse phase modes; two host and slavelow-frequency modulation double phases act on a high-power twin arc for double-wire melt dripping to arouse resonance of a molten pot; the temperature gradient of a temperature field of the molten potis optimized; double-arc interference is reduced; and the welding stability is improved, the weld microstructure is optimized, and the weld forming quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

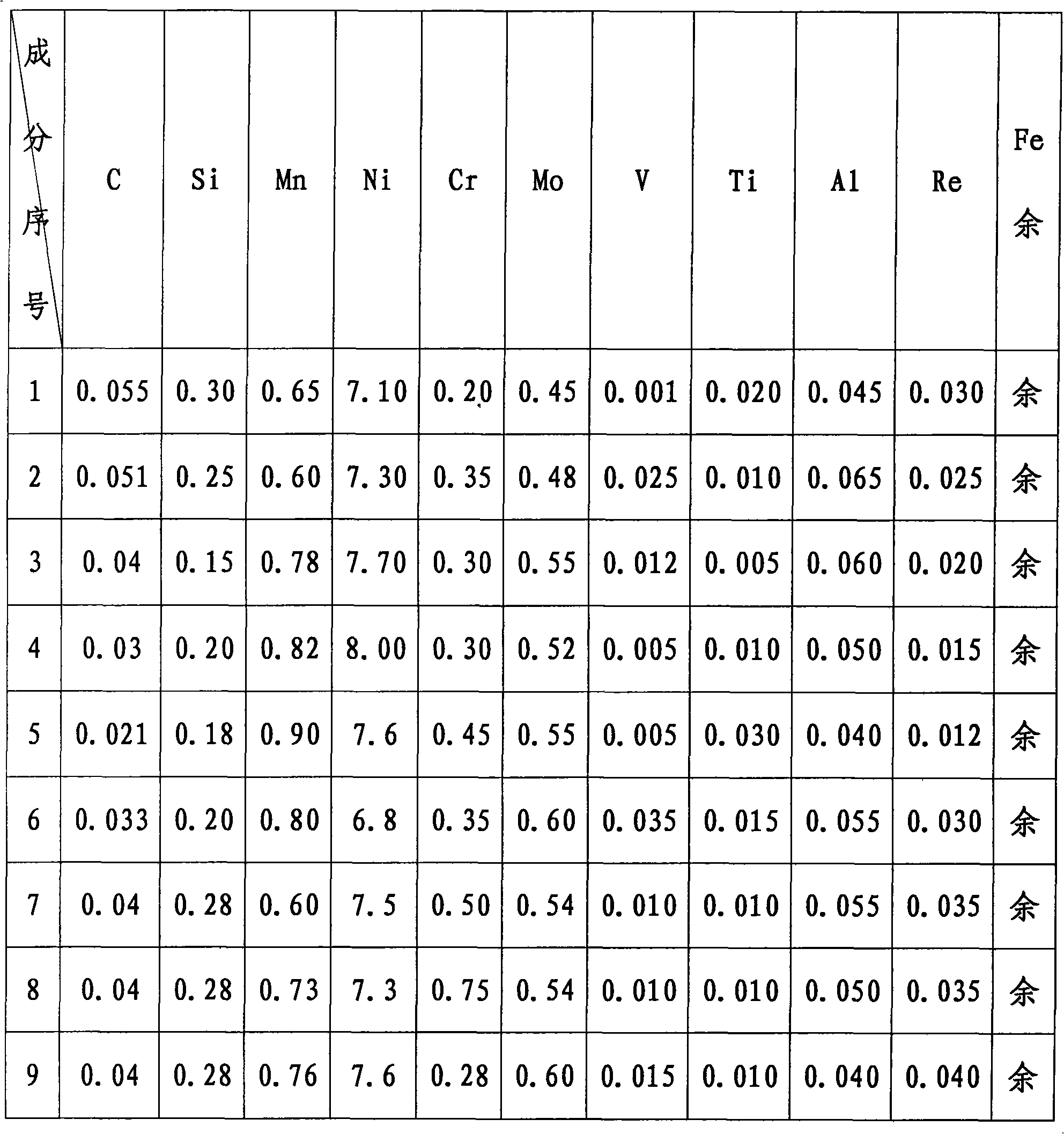

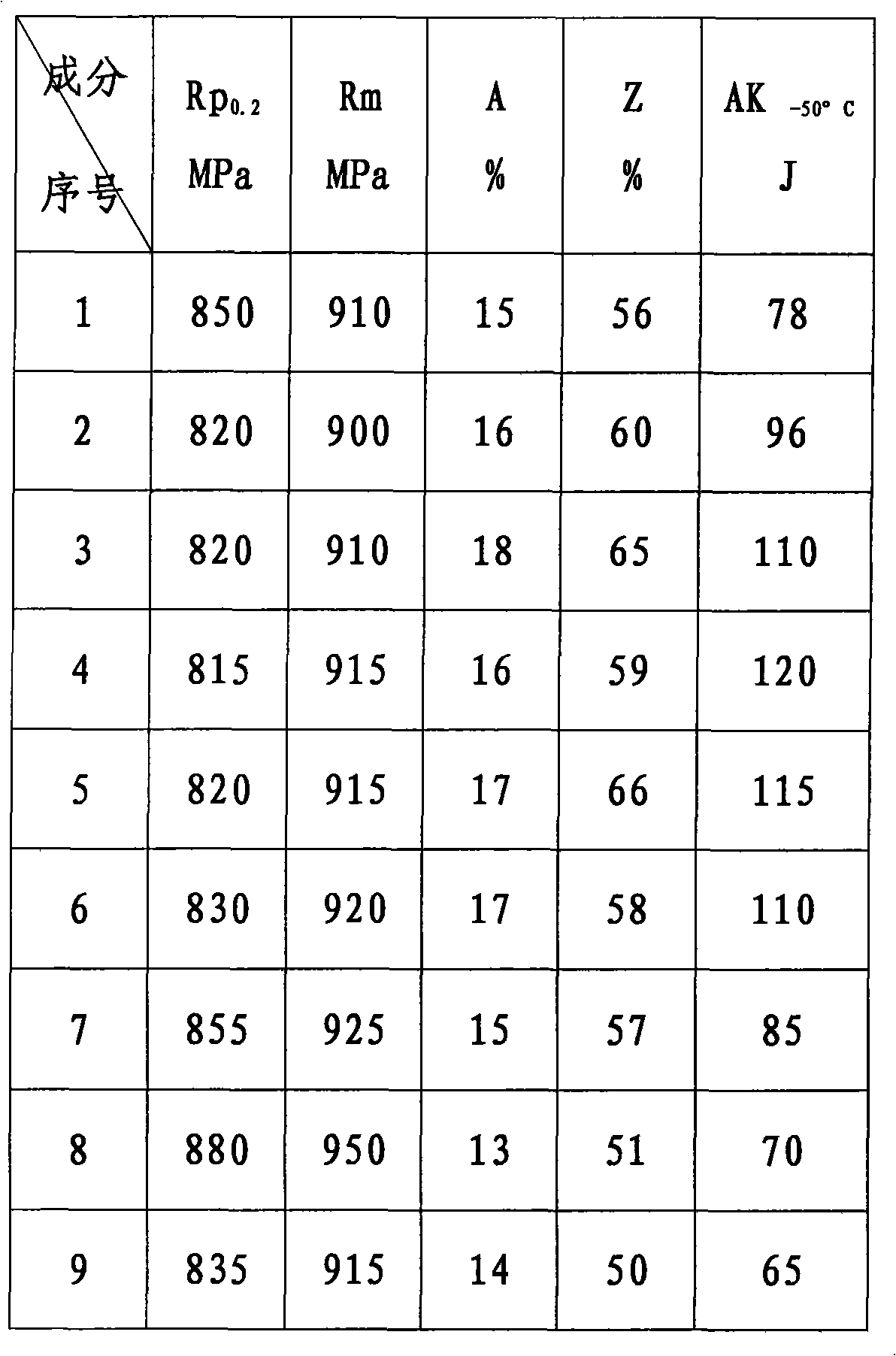

Low-carbon high-nickel content 785 MPa grade gas shielded welding wire

InactiveCN101524795ALower phase transition temperatureStress-inducing effectWelding/cutting media/materialsSoldering mediaHydrogen contentSoldering

The invention belongs to the welding material field and mainly relates to low-carbon high nickel content 785 MPa grade gas shielded arc welding soldering wire which is used for high-tensile steel welding. The gas shielded arc welding soldering wire comprises components: 0.02-0.055% of C, less than or equal to 0.30% of Si, 0.6-0.9% of Mn, less than or equal to 0.80% of Cr, 6.8-8.0% of Ni, 0.45-0.60% of Mo, less than or equal to 0.035% of V, less than or equal to 0.075% of AI plus Ti, less than or equal to 0.04% of Re, and the rest of iron. The soldering wire adopts MIG welding, and can reach the following effects: (1) deposited metal and welding microstructure take bainite and martensite mixed microstructure as the main, have low phase transition temperature, can reduce the welding heat stress, thus reducing hydrogen induced cracking sensitivity; (2) deposited metal and welding microstructure contain a small quantity of remaining austenite and adverse transformation austenite; as this kind of austenite has high nickel content, moderate carbon content and strong stability, the austenite can become hydrogen trap to reduce diffusive hydrogen content and also can reduce the capability of diffusive hydrogen which assembles at the lower part of the last welding layer to form the hydrogen induced cracking through interlayer diffusion.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Quality control method for high-frequency resistance welded pipe welding area

InactiveCN103240515AReduce inclusionsHomogenization of ingredientsWelding electric supplyTubular articlesWeld seamElectric resistance welding

A quality control method for a high-frequency resistance welded pipe welding area includes the steps: firstly, heating a surface to be welded to reach the temperature T (DEG C)=1538-113wc by induction for 5-10s; secondly, arranging two inert gas sprayers of surfaces to be welded of two sides of a welding seam of a welded pipe respectively; thirdly, simultaneously spraying inert gas to the surfaces to be welded by the sprayers during welding until the welding seam is completely fused under the action of pressure to effectively reduce non-metallic inclusion of the welding seam; fourthly, performing local heat treatment for the welding seam by means of induction heating after welding, controlling the heating temperature to range from 920 DEG C to 940 DEG C and performing air cooling to obtain uniform weld microstructures; and fifthly, performing bulk heat treatment for the welding seam after local heat treatment, reducing internal stress of the welding area, stabilizing the microstructures to obtain a high-quality resistance welding joint, and reducing sensitivity of the welding seam to stress corrosion and groove corrosion. Gas flow is 5-10L / min, and the quality control method has the advantages of convenience in implementation and popularization, and remarkable effects.

Owner:XI'AN PETROLEUM UNIVERSITY

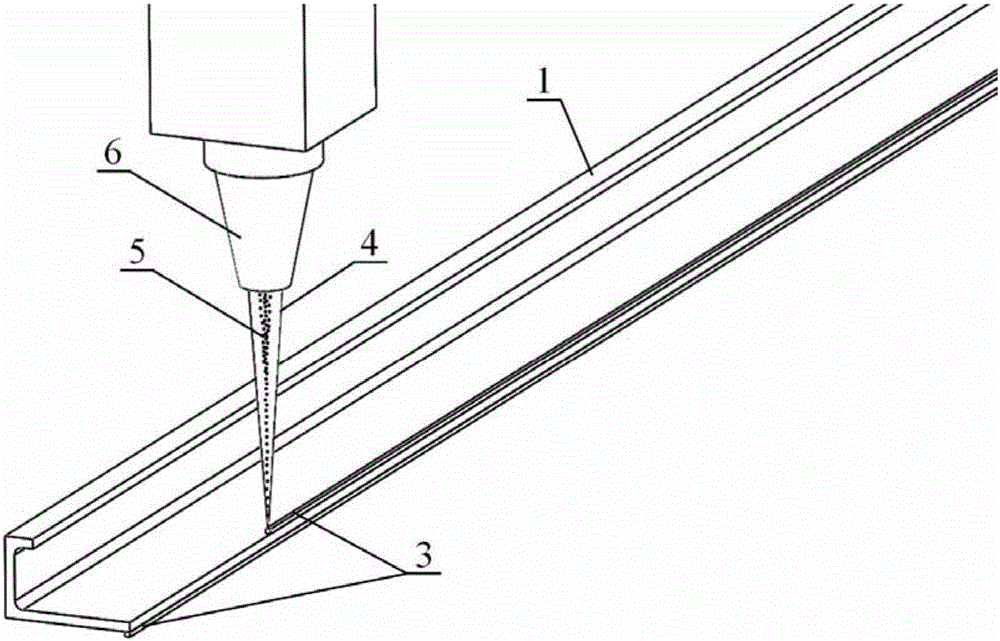

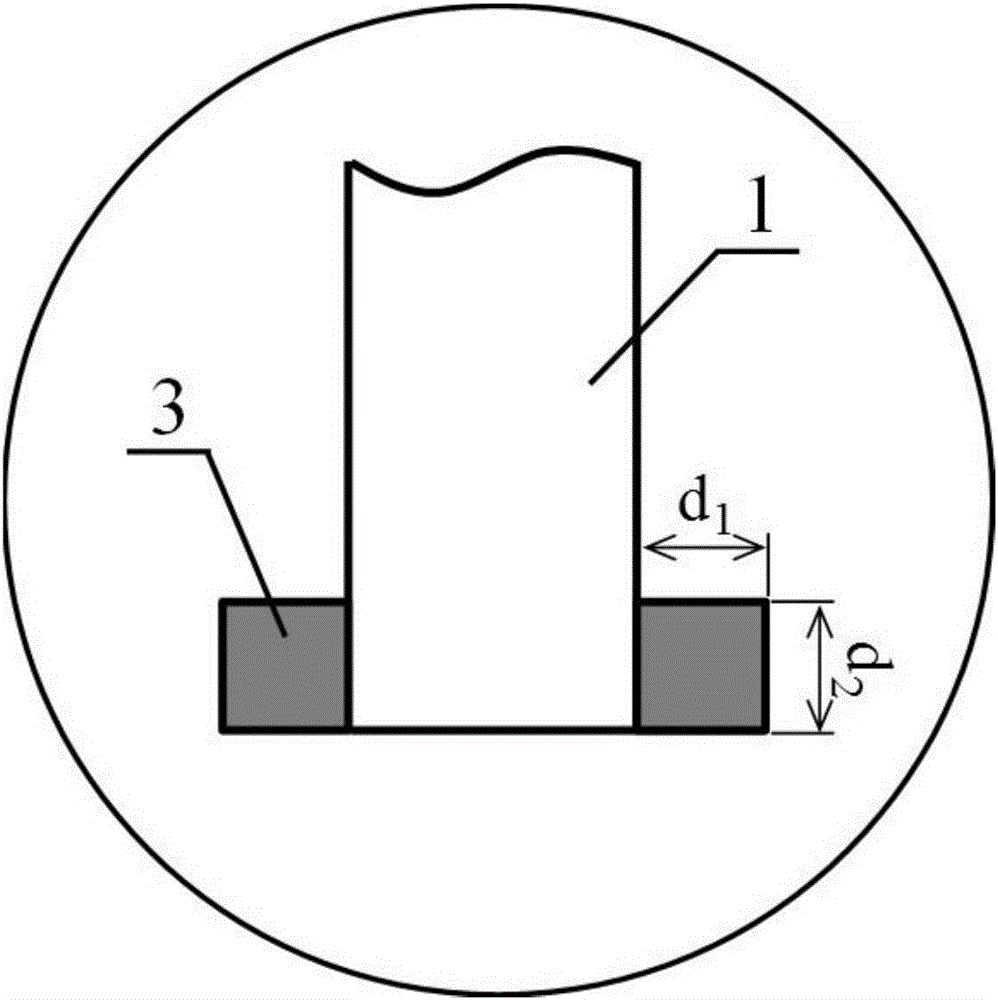

3D additive-manufacturing bilateral laser welding method for T-shaped structure

ActiveCN105710536AImprove mechanical propertiesEvenly regulatedLaser beam welding apparatusMelting tankAlloy

Owner:HARBIN INST OF TECH

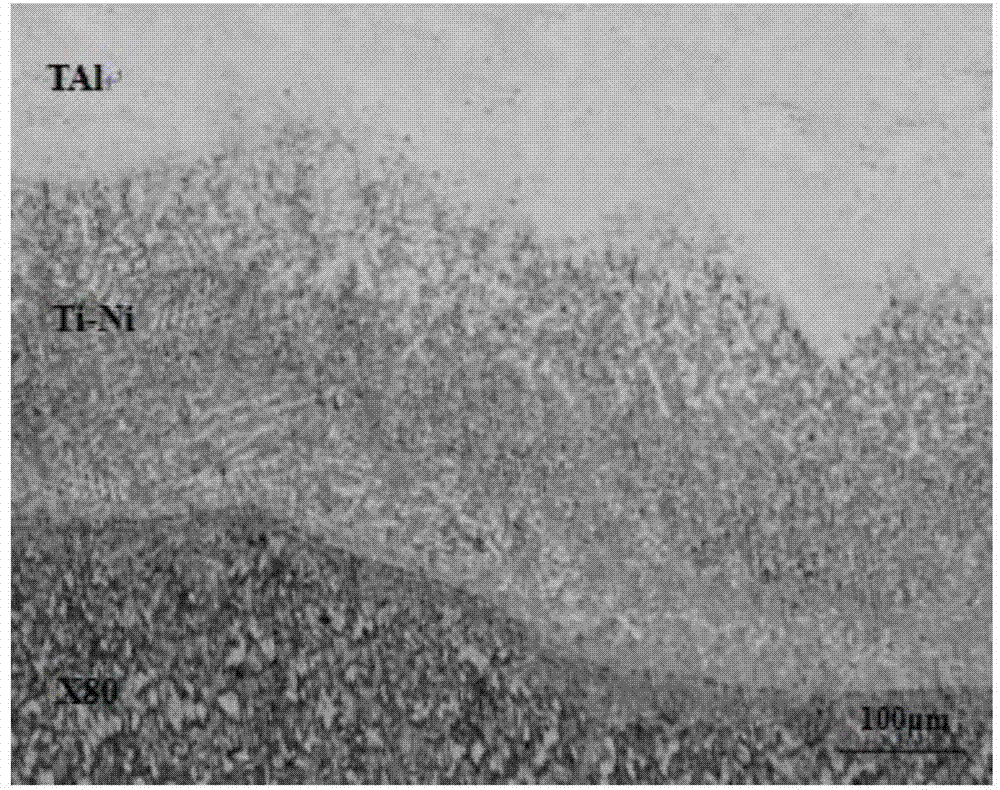

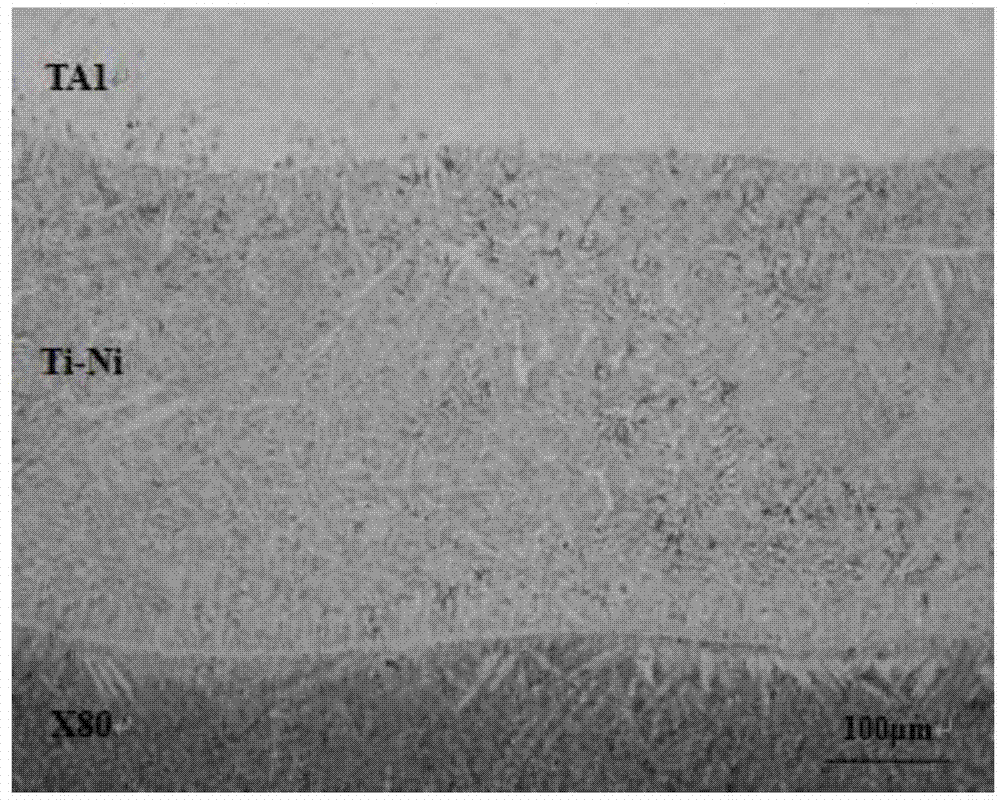

Ti-Ni welding wire for welding Ti-pipeline steel composite board and preparation method of Ti-Ni welding wire

InactiveCN103567664ARealize fusion welding butt jointEffective connectionWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyTitanium

The invention provides a Ti-Ni welding wire for welding a Ti-pipeline steel composite board and a preparation method of the Ti-Ni welding wire. The Ti-Ni welding wire comprises the components in percentage by weight as follows: 52%-58% of Ni, smaller than or equal to 0.04% of C, smaller than or equal to 0.007% of N, smaller than or equal to 0.035% of O, smaller than or equal to 0.001% of H and the balance of Ti, wherein the sum of the weight percentages of the components is 100%. The Ti-Ni welding wire for welding the Ti-pipeline steel composite board can effectively connect weld microstructures of a Ti layer and a pipeline steel layer of the composite board, so that butt fusion welding of the Ti-pipeline steel composite board is realized, and a welded joint has excellent strength and toughness; the diameter of the Ti-Ni welding wire is small, and both manual TIG (tungsten inert gas) welding and MIG (metal inert gas) welding can be adopted; and the variety of welding material alloys is small, the preparation technology is simple, and the Ti-Ni welding wire is suitable for mass production.

Owner:XIAN UNIV OF TECH

Metal flux-cored wire for 25Cr2Ni4MoV steel and preparing method

ActiveCN107649798AImprove mechanical propertiesAccelerated corrosionWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

The invention discloses a metal flux-cored wire for 25Cr2Ni4MoV steel and a preparing method. The metal flux-cored wire comprises a flux core and welding scale; the flux core is composed of componentsincluding, by mass percent, 1% to 4.0% of ferrosilicon powder, 6.0% to 15.0% of ferromanganese powder, 20.0% to 30.0% of nickel powder, 8% to 15% of chromium powder, 5% to 15% of FeMo powder, 1% to 5% of vanadium iron powder, 1% to 5% of copper powder, 1% to 2% of rare-earth powder and the balance iron. The sum of mass percents of the above components is 100%. The preparing method comprises the steps that raw material powder is matched according to the proportion, and is mixed and dried, the powder is added into a U-shaped groove formed through rolling of low-carbon steel strip, the powder issubject to grinding and closing, drawing, straightening and coiling into a disc, and seal packaging is carried out. The flux-cored wire is attractive in welding seam forming, the martensitic stainless steel weld microstructure can be obtained, the welding joint has the excellent mechanical property, and the preparing method is simple, suitable for an automatic welding machine and batched production.

Owner:西安华瑞力宏焊材技术有限公司

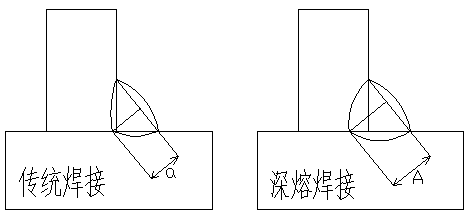

Deep penetrating fillet welding process for hydraulic support structure piece mid-thickness plate welding

ActiveCN110681956ASolve the problem of shallow fusion and poor fusionSave weld metalArc welding apparatusShielding gasWelding power supply

The invention relates to a deep penetrating fillet welding process for hydraulic support structure piece mid-thickness plate welding. The process comprises the steps of cleaning a to-be-welded area, connecting a welding gun to a welding power supply, preparing welding shielding gas and a solid welding wire, and welding by using a welder. According to the process, the method is reasonable and feasible, weld metal is greatly saved under the same load bearing capacity, welding workload is reduced, the weld joint fusion is improved, the filling material is saved, the welding time is reduced, the weld joint strength is improved, the technical problems that an existing hydraulic support mostly adopts multi-layer and multi-pass welding of a mid-thickness plate, the welding number is excessive, the welding workload is increased, the welding defect probability is increased, the welding failure rate is increased, the welding heat for a weldment is increased, the weld microstructure is coarse, the strength and toughness are reduced, and the product quality and the enterprise production benefit are influenced are solved, and compared with the prior art, the process has good market prospect anddevelopment space.

Owner:PINGDINGSHAN COAL MINE MACHINERY EQUIP CO LTD

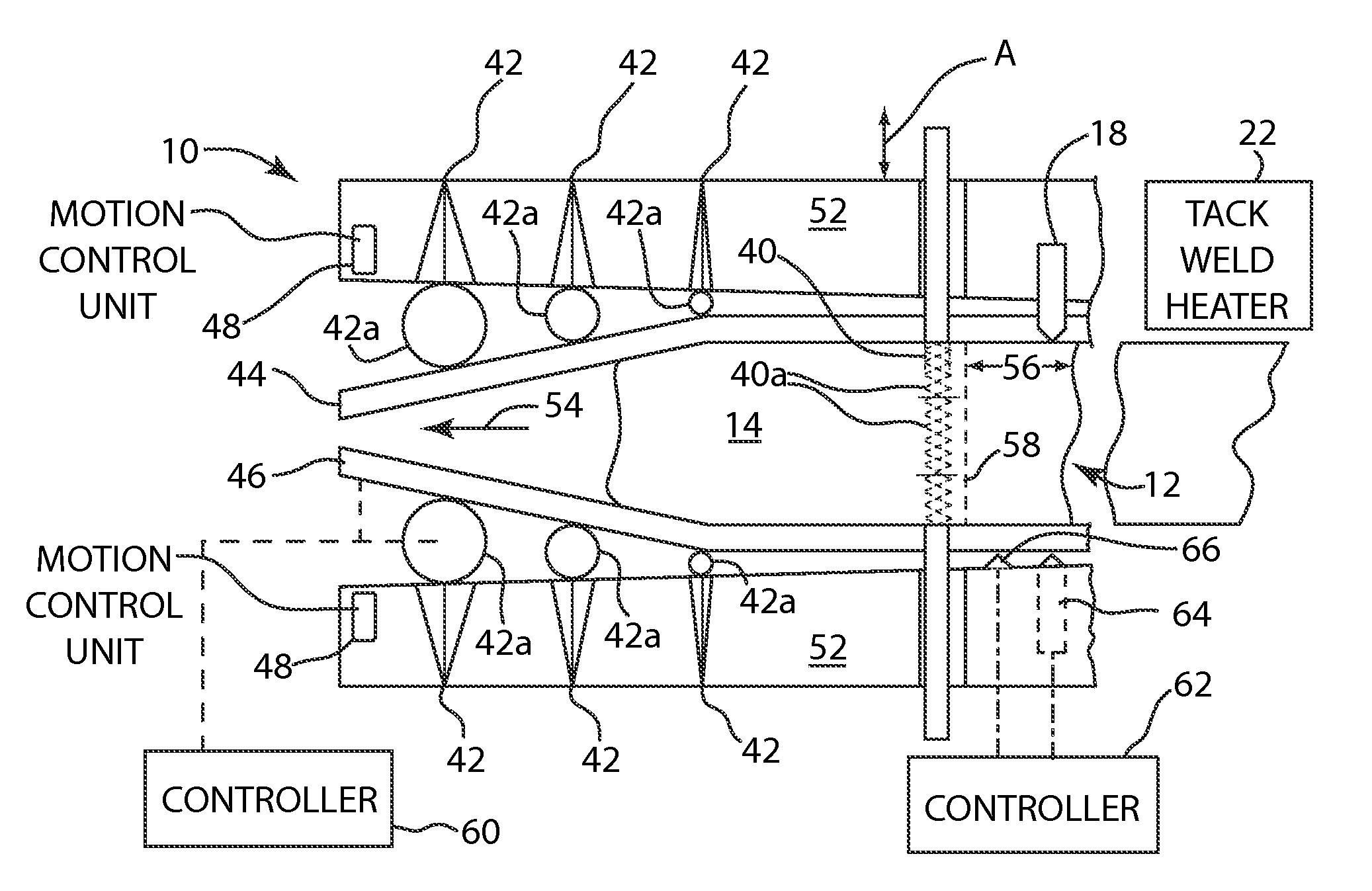

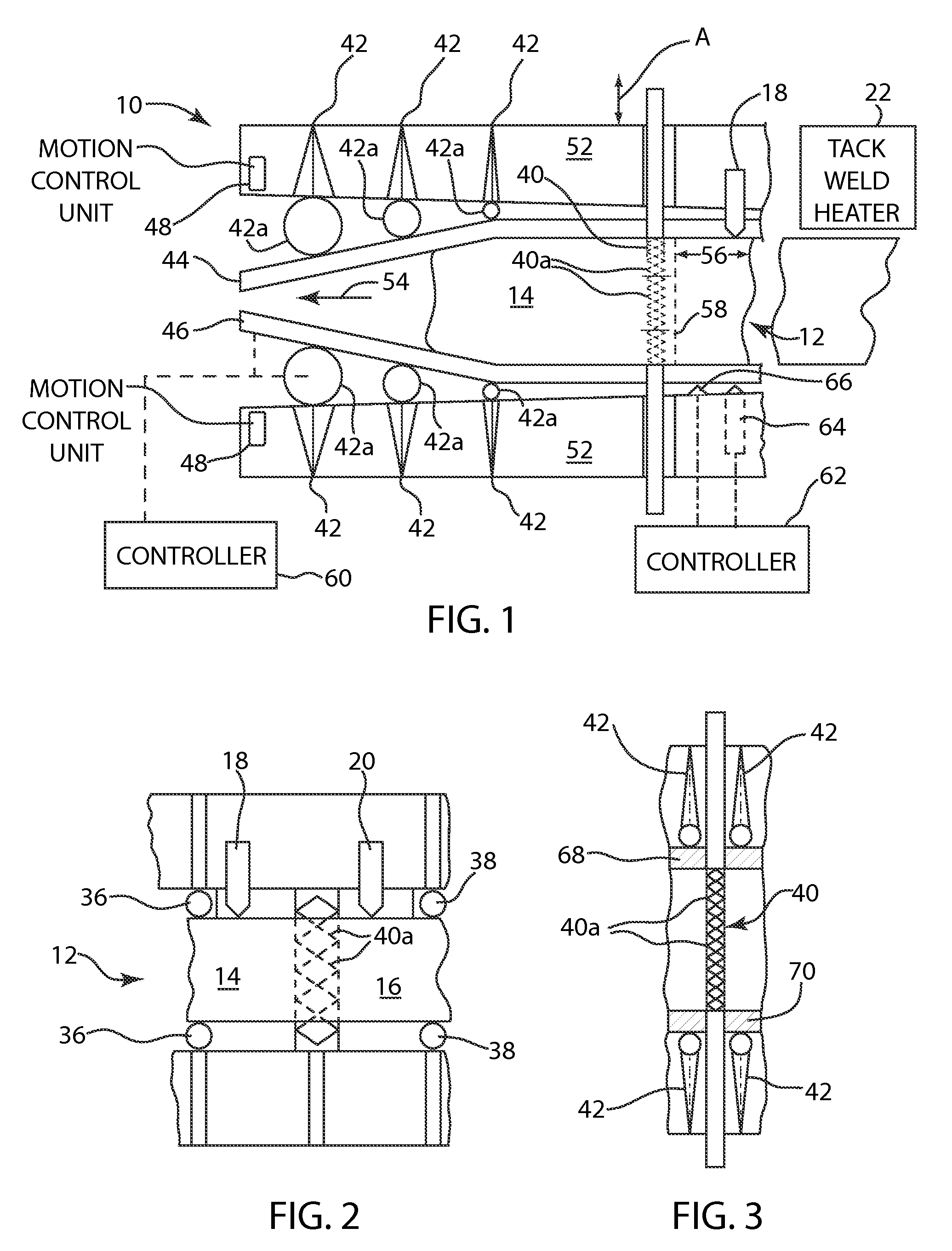

Thermal stir welding apparatus

InactiveUS7980449B2Welding/cutting auxillary devicesFeeding apparatusEngineeringMechanical engineering

A welding method and apparatus are provided for forming a weld joint between first and second elements of a workpiece. The method includes heating the first and second elements to form an interface of material in a plasticized or melted state interface between the elements. The interface material is then allowed to cool to a plasticized state if previously in a melted state. The interface material, while in the plasticized state, is then mixed, for example, using a grinding / extruding process, to remove any dendritic-type weld microstructures introduced into the interface material during the heating process.

Owner:NASA

Active agent used for aluminum alloy MIG (metal-inert gas) welding and application method of active agent

ActiveCN103785972AIncrease weld penetrationImprove performanceArc welding apparatusWelding/cutting media/materialsActive agentStain

The invention relates to an active agent used for aluminum alloy MIG (metal-insert gas) welding and an application method of the active agent. The active agent is prepared by powder particles including, by weight, 40%-55% of B203, 25%-40% of NaF, 10%-15% of Si02 and 0% to 5% of MgC03 with the particle size ranging from 60 to 80 micrometers and the fineness ranging from 95% to 99%. The application method includes: performing burdening on the active agent according to the weight, blending a mixture with an organic solution after the mixture is well blended, and stirring the same into paste; carefully polishing base metal with a stainless steel wire brush till the polished metal is exposed and using acetone to scrub the surface of a work piece to remove surface oil stains; covering the prepared paste on the surface of the welding work piece till metal luster is covered; performing normal MIG welding after the organic solution is volatilized. By the application of the active agent, welding line grains can be refined, weld microstructure can be improved, weld penetration can be increased, property of welded joint can be improved, and operation easiness can be achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

Formula of iron-based shape memory alloy electrode and manufacturing method of iron-based shape memory alloy electrode

InactiveCN103056554AReduce residual stressReduce distortionWelding/cutting media/materialsSoldering mediaShape-memory alloyWeld seam

The invention discloses a formula of an iron-based shape memory alloy electrode and a manufacturing method of the iron-based shape memory alloy electrode. The formula of the electrode comprises the formula of an electrode welding core and the formula of an electrode coating. The electrode welding core comprises chemical components as follows: C, Mn, Si, N, Cr, V, Nb, Ti, Zr, N and Fe; and the formula of the electrode coating is the formula of an acidic electrode coating, a basic low-hydrogen electrode coating or a stainless electrode coating. The manufacturing method comprises the following steps of manufacturing the iron-based shape memory alloy welding core, preparing the electrode coating and extruding and coating the electrode. The weld microstructure of the electrode after the welding is the iron-based shape memory alloy, the residual tensile stress of a welded seam can enable the alloy to induce gamma-to-epsilon martensite phase transformation, and the phase transformation deformation loosens the residual tensile stress of the weld seam to decrease the residual tensile stress to be lower than the yield strength (because the driving force inducing the phase transformation is lower than the yield strength) and reduce the welding deformation. Therefore, the fatigue strength of the weld seam is high, and the comprehensive mechanical property of a welded joint is guaranteed.

Owner:DALIAN MARITIME UNIVERSITY

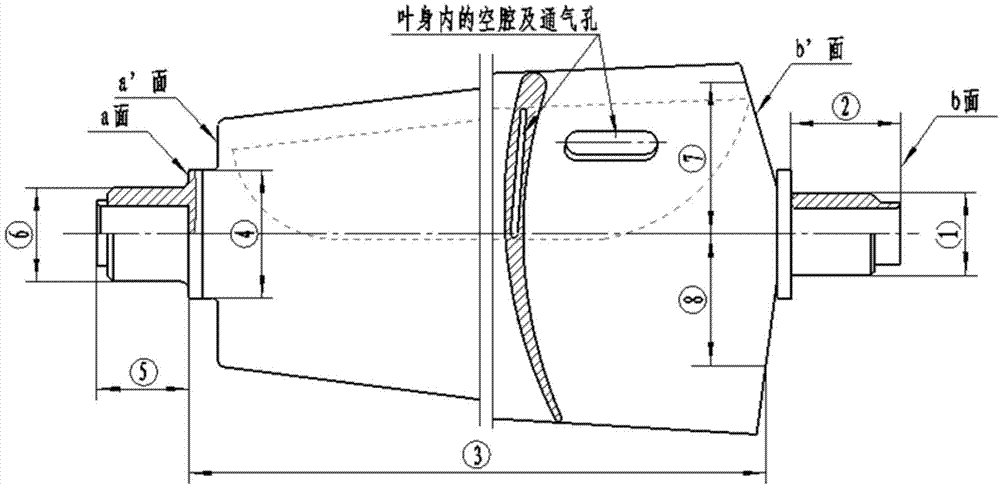

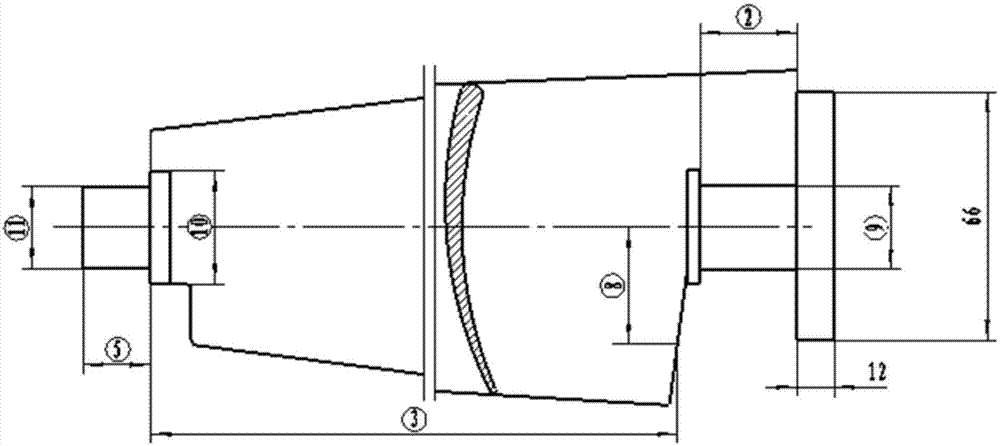

Forming method of aeroengine hollow guide vane

ActiveCN103586647AAdvancedImprove pass rateEngine componentsNon-electric welding apparatusAviationFirst pass yield

The invention provides a forming method of an aeroengine hollow guide vane. The method includes: forging a vane body blank and an exhaust edge insert blank respectively, machining fitting faces of the vane body blank and fitting faces of the exhaust edge insert blank, and connecting the vane body blank and the exhaust edge insert blank for formation by means of friction stir welding. Through the application of the method, the problem that the hollow structure of the large-sized hollow guide vane cannot be formed by the existing forging technologies is solved; compared to the background techniques, the method is significantly advanced. Through the application of the novel technique double-side symmetric friction stir welding, first pass yield during the forming process of hollow vanes is increased greatly, production efficiency is improved, and production cost is reduced. Experiments show that after the application of the method, weld microstructure is compact with no obvious defects such as pores and inclusion, the production process is easy to mechanize, first weld yield is increased from 25.54% to 92.25%, and weld strength is increased by more than 50%.

Owner:AECC AVIATION POWER CO LTD

Micro-vibration welding device and method

InactiveCN104625338AImprove efficiencySmall sizeElectrode vibration holdersElectrode accessoriesSpray nozzleMechanical engineering

The invention relates to the technical field of welding technologies, in particular to a micro-vibration welding device and method capable of effectively accelerating globular transfer, improving the deposition rate and improving the weld microstructure. The micro-vibration welding device is provided with an arc welding power source, a conducting rod, a wire, an electrode clamping body, a welding wire feeding mechanism and a nozzle, and is characterized by further comprising a micro-vibration mechanism connected with the electrode clamping body, the micro-vibration mechanism comprises a vibration generation component, a vibration transferring component and a power source for vibration, the vibration generation component and the vibration transferring component are connected, the vibration transferring component is provided with a guide rod and a buffering body connected with the vibration generation component, the buffering body is arranged at the tail end of the guide rod and abuts against the electrode clamping body, and the front end of the guide rod is connected with the vibration generation component. Compared with the prior art, the welding quality can be obviously improved.

Owner:张锴

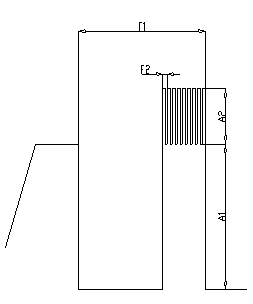

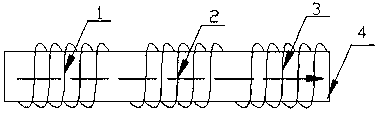

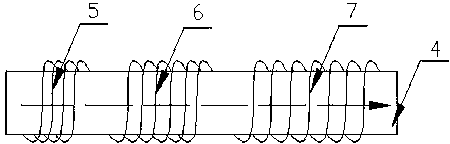

Pipe induction heating equipment inductor

InactiveCN105506239AReduce residual stressSimple structureIncreasing energy efficiencyFurnace typesExtensibilityInductor windings

The invention relates to the technical field of pipe induction heating equipment annealing technologies, especially a pipe induction heating equipment inductor. The inductor comprises a first inductor winding, a second inductor winding and a third inductor winding, and is characterized in that: the first inductor winding, the second inductor winding and the third inductor winding are wound on the outer surface of a workpiece along the workpiece operation direction in order, wherein the first inductor winding, the second inductor winding and the third inductor winding have different and increasing turns of induction heating coils. The pipe induction heating equipment inductor provided by the invention adopts three inductor windings with different turns of induction heating coils to eliminate the residual stress of products after solution annealing, improves multiple indicators of the weld microstructure, grain structure and extensibility, greatly upgrades the product quality, and obviously enhances the heat treatment work efficiency and product quality to meet market demands.

Owner:LUOYANG NEW FIRE ENERGY SAVING TECH PROMOTION

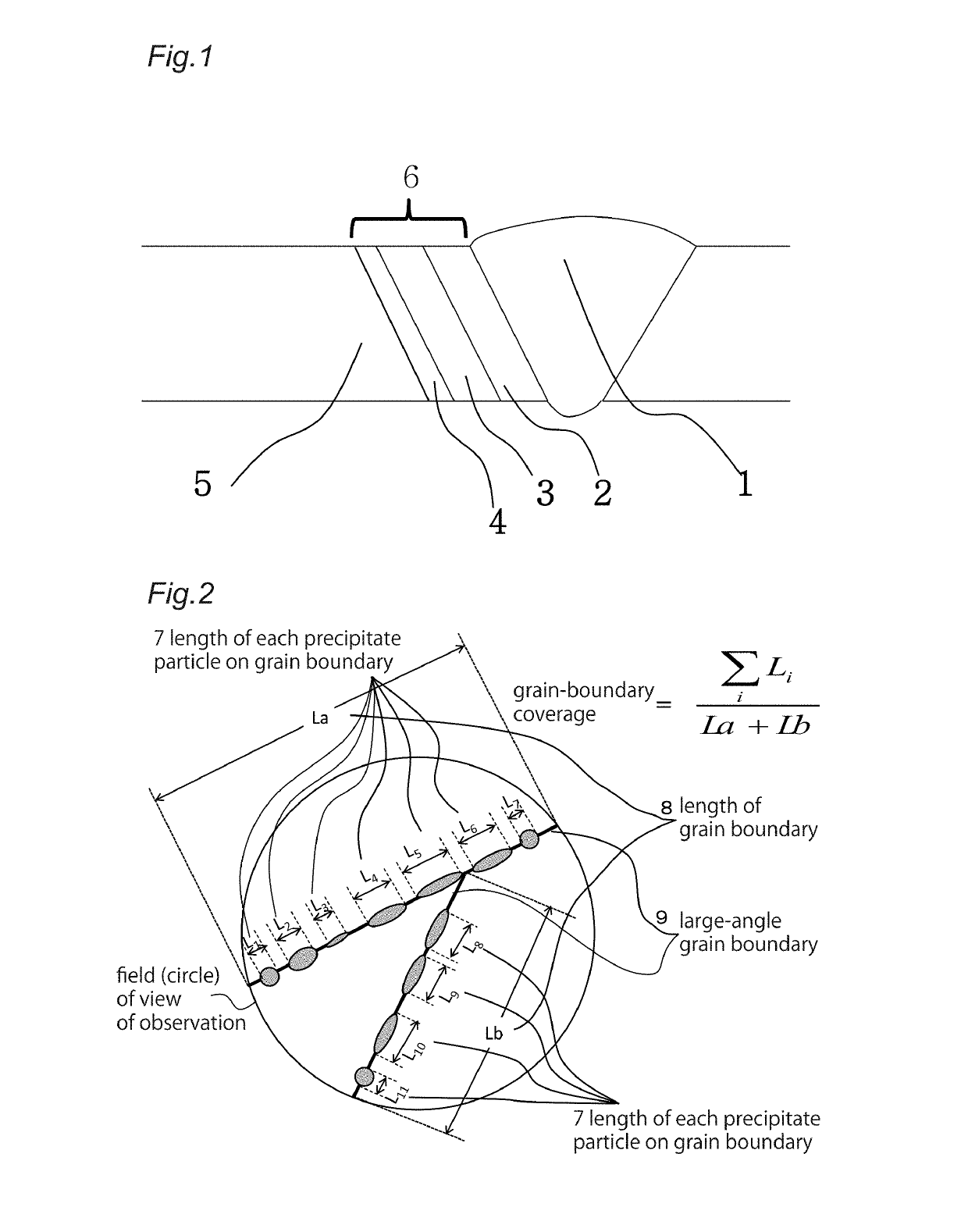

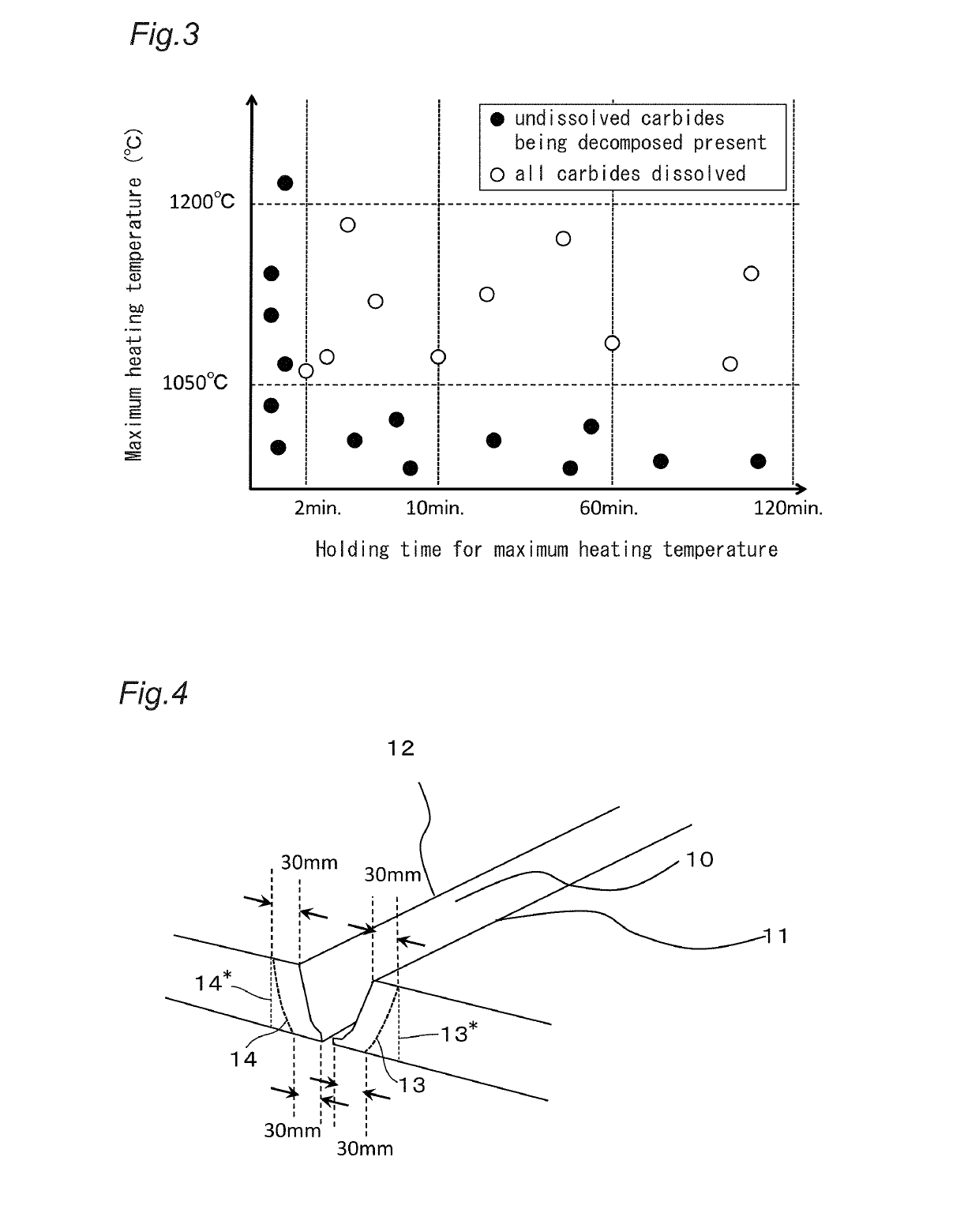

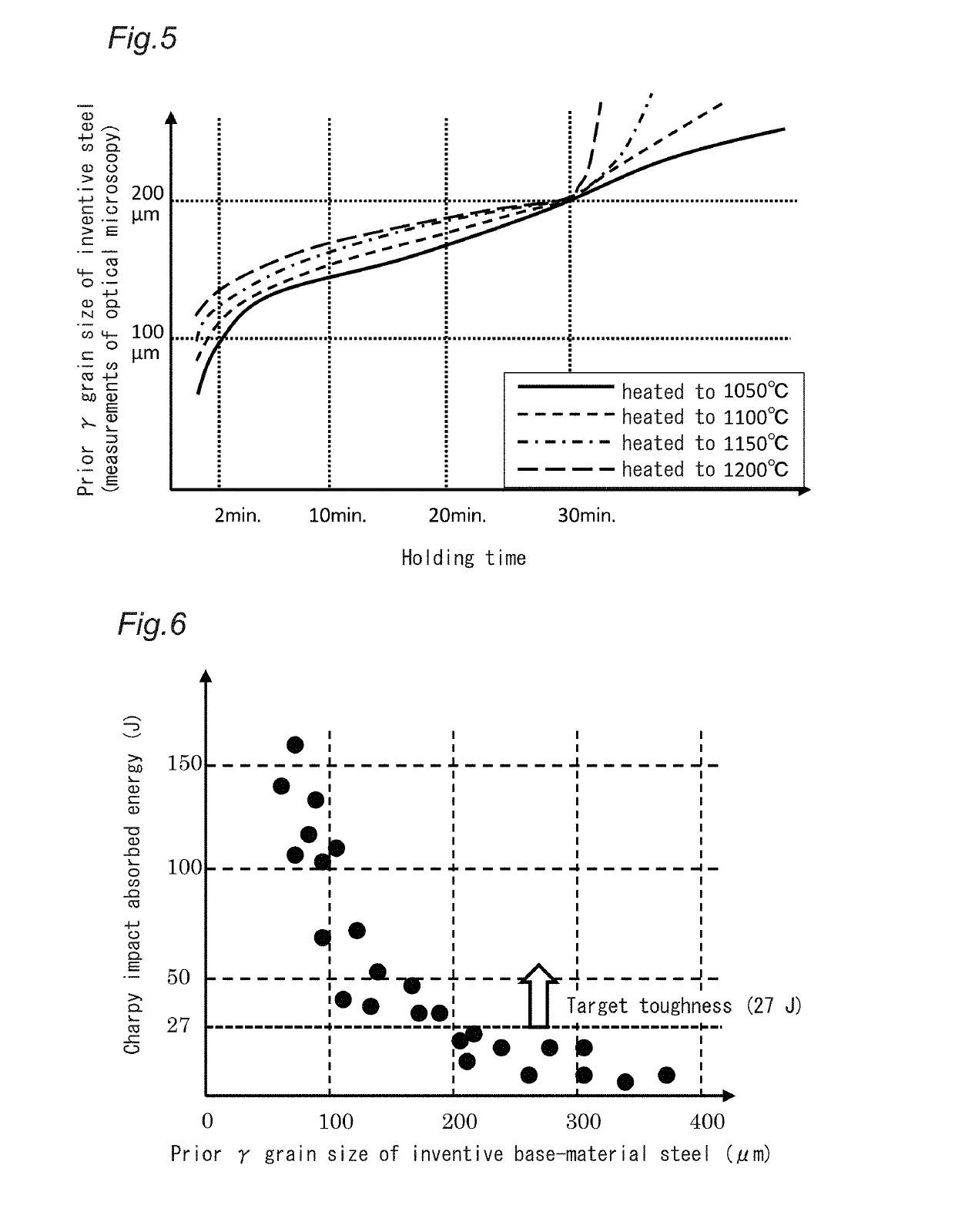

Method of Manufacturing Welded Structure of Ferritic Heat-Resistant Steel and Welded Structure of Ferritic Heat-Resistant Steel

ActiveUS20190210137A1Prevent Type IV damageGood on-site operabilityArc welding apparatusFurnace typesMetalWeld metal

A method of manufacturing a welded structure of a ferritic heat-resistant steel is provided that prevents Type IV damage and that has good on-site operability without adding a high B concentration. The method includes: the step of preparing a base material including 8.0 to 12.0% Cr, less than 0.005% B and other elements; the step of forming an edge on the base material; a pre-weld heat treatment step in which a region located between a surface of the edge and a position distant from the surface of the edge by a pre-weld heat treatment depth of 30 to 100 mm is heated to a temperature of 1050 to 1200° C. and is held at this temperature for 2 to 30 minutes; a welding step in which the edge is welded to form the weld metal; and a post-weld heat treatment step in which a region located between the surface of the edge and a position distant from the surface of the edge by a distance not smaller than the pre-weld heat treatment depth and not greater than 100 mm is heated to a temperature of 720 to 780° C. and is held at this temperature for a time period not shorter than 30 minutes and satisfying the following formula, (1):(Log(t)+12)·(T+273)<13810 (1).

Owner:NIPPON STEEL CORP

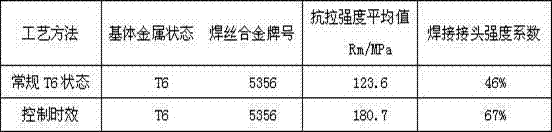

Thermal treatment process for improving weld structure performance of aluminum alloy battery box body

ActiveCN102345079AImprove tissue performanceReduce manufacturing costSolution treatmentSolid solution strengthening

The invention discloses a thermal treatment process for improving the weld structure performance of an aluminum alloy battery box body, which is characterized by comprising the steps of: promoting a solid solution strengthening phase in an alloy to separate out through first high-temperature short ageing from an ageing control process, wherein an extruded section online solid solution treatment process is as follows: the section mold stripping hole temperature is 520-540 DEG C, online air cooling and quenching are carried out, and a high-temperature ageing process is carried out at a temperature of 195-205 DEG C for 1.5-2 hours; secondly, under the cooling condition provided by a welding procedure special tool, enabling a weld structure to generate different levels of secondary solid solution quenching effects; and finally, carrying out low-temperature ageing treatment at a temperature of 160-170 DEG C for 5-6 hours. By adopting the technical scheme disclosed by the invention, on the basis of no reduction of strength of a base material, the structure performance level of a weld heat affected zone of an aluminum alloy extruded member can be improved.

Owner:天津锐新昌科技股份有限公司

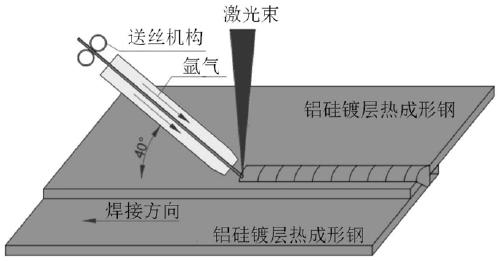

Laser wire feeding welding method for aluminum-silicon-coated hot formed steel

The invention provides a laser wire feeding welding method for aluminum-silicon-coated hot formed steel. A well formed aluminum-silicon-coated hot formed steel laser wire feeding lap weld can be obtained by adopting a high-strength steel welding wire to perform laser wire feeding welding on the aluminum-silicon-coated hot formed steel. For the laser wire feeding welding method provided by the invention, by selecting a high-strength steel welding wire as a proper filling material, a laser wire feeding process is controlled to dilute an aluminum coating dissolved in the weld through the fillingmaterial, such that a weld microstructure is controlled, a high-quality lap joint welding head is obtained, and meanwhile, the laser wire feeding welding method is also suitable for aluminized siliconhot formed steel welding for an automobile. Compared with a traditional laser lap joint method, by adopting the laser wire feeding welding method provided by the invention, without removing an aluminum-silicon coating on the surface of the hot formed steel, the lap welding process flow is simplified, and the production efficiency is improved; and meanwhile, due to the fact that the welding wire is dissolved, the problem of surface collapse easily caused by self-welding is solved, and the weld is full, such that the strength of the lap joint welding head is improved, that is the mechanical property of the lap joint is improved.

Owner:SHANGHAI UNIV OF ENG SCI

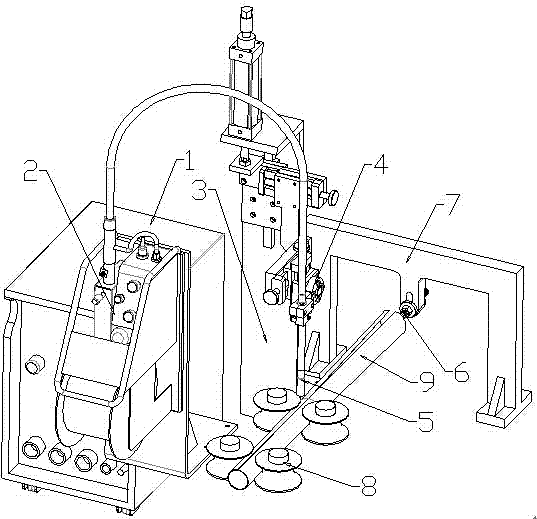

Welding device for internally-clad stainless steel tube of clad steel plate

InactiveCN104708182AImprove quality and efficiencyIncrease productivityArc welding apparatusSS - Stainless steelEngineering

The invention relates to welding equipment, in particular to a welding device for an internally-clad stainless steel tube of a clad steel plate. The welding device comprises an MIG welding power source, an automatic wire feeder and an MIG welding gun. The MIG welding gun is mounted on a three-dimensional gun rack through a gun clamp, and the three-dimensional gun rack is mounted on a welding gun support. Sizing rolls are mounted below the MIG welding gun, and a welding fixture is mounted between the sizing rolls. One end of the welding fixture is mounted on a welding support, a steel tube to be welded enters the welding fixture from a straight-seam tube manufacturing production line and enters the position between the sizing rolls, and the steel tube is welded by the MIG welding gun. The welding device for the inner composite stainless steel tube of the clad steel plate is in butt joint with a common straight-seam tube manufacturing production line or a spiral tube manufacturing production line, open arc automatic welding is conducted from the outer surface of the steel tube, one-time welding is achieved, and the welding quality and the production efficiency are improved. Weld joint single-face welding and double-face forming of dissimilar metal welding are achieved. The quality of a welding joint is improved, particularly, the weld microstructure of a stainless steel composite layer face achieves two-phase organization, and therefore the corrosion resistance is better than that of a base material.

Owner:WUXI QINENG WELDING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com