Welding device for internally-clad stainless steel tube of clad steel plate

A technology for stainless steel pipes and clad steel plates, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of poor performance of stainless steel welds, unqualified corrosion resistance of inner clad stainless steel welds, unqualified corrosion resistance, etc. problems, to achieve the effect of excellent corrosion resistance, improved welding quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

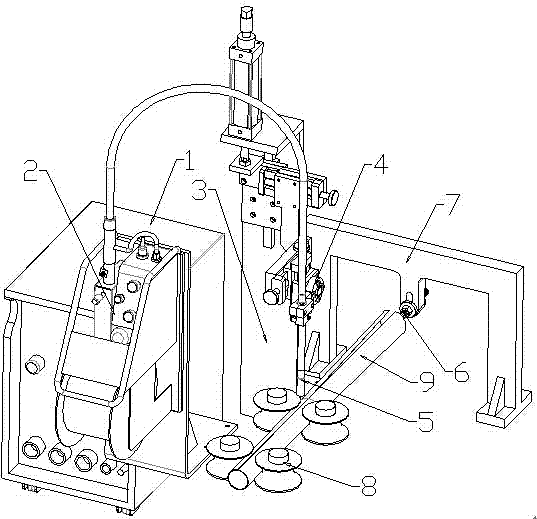

[0009] The specific embodiments of the present invention will be described with reference to the drawings, such as figure 1 As shown, the welding device for the stainless steel pipe in the composite steel plate includes MIG welding power source 1, automatic wire feeder 2, welding torch support 3, three-dimensional gun holder 4, MIG welding torch 5, welding tool 6, welding support 7, and sizing roll 8; The MIG welding gun 5 is installed on the three-dimensional gun frame 4 through the gun clamp, the three-dimensional gun frame 4 is installed on the welding gun holder 3, the sizing roller 8 is installed below the MIG welding gun 5, and the welding tool 6 The welding tool installed between the rollers of the sizing roller 8 6 One end is installed on the welding support 7, and the steel pipe 9 to be welded enters the welding tool 6 from the straight seam pipe production line, and enters between the sizing rollers 8, and the MIG The welding gun 5 is welding.

[0010] In the ordinary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com