Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

336results about How to "Lower phase transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

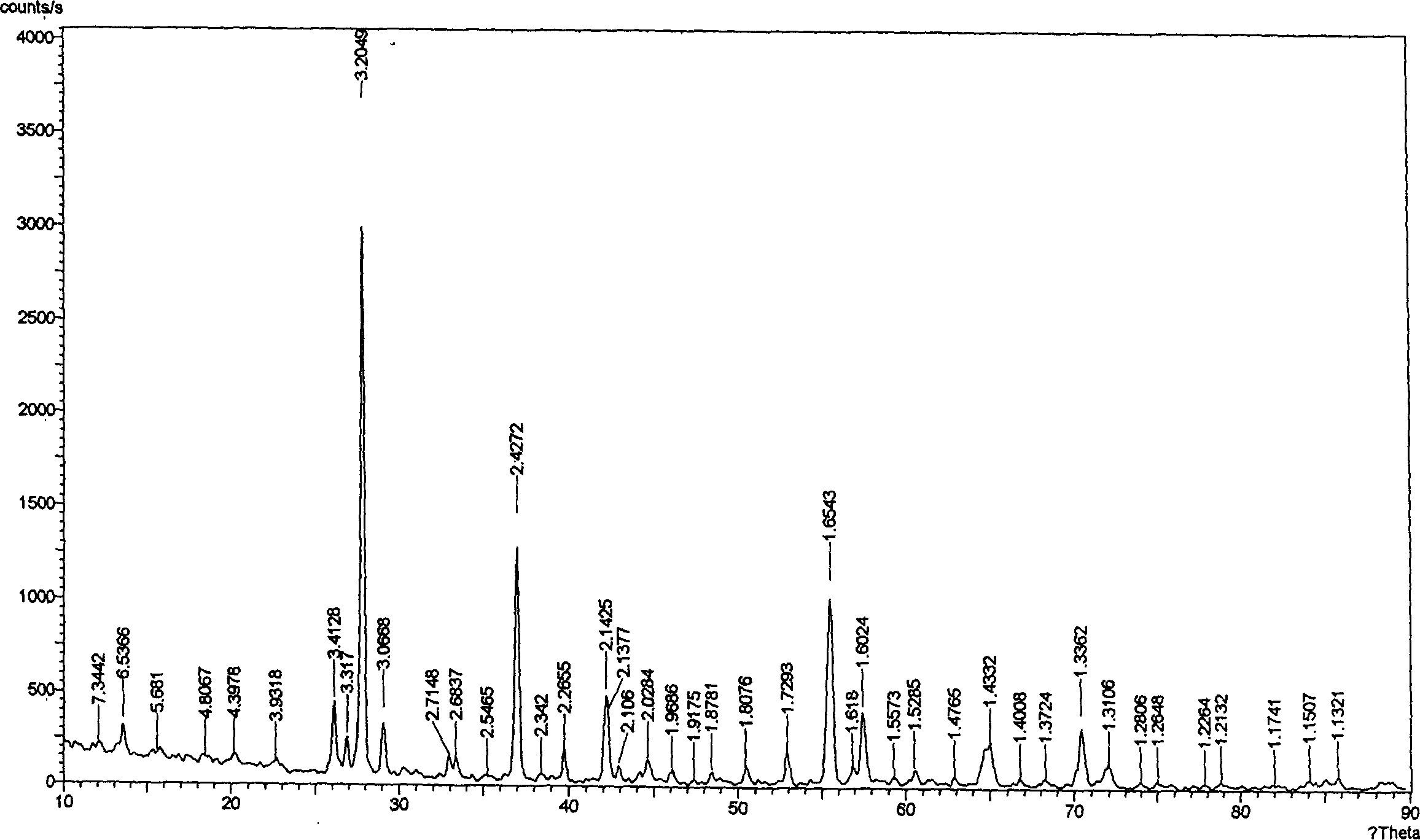

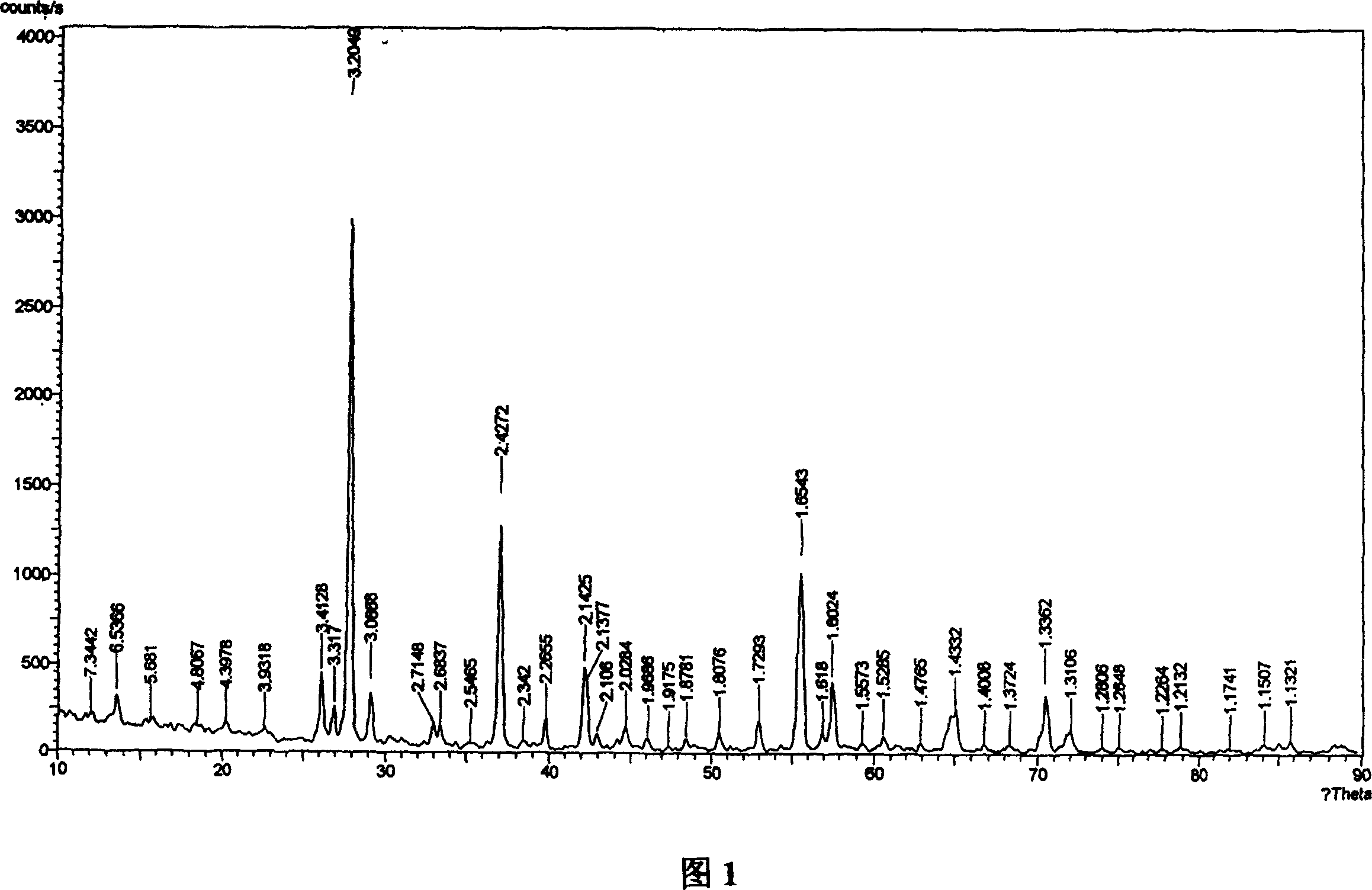

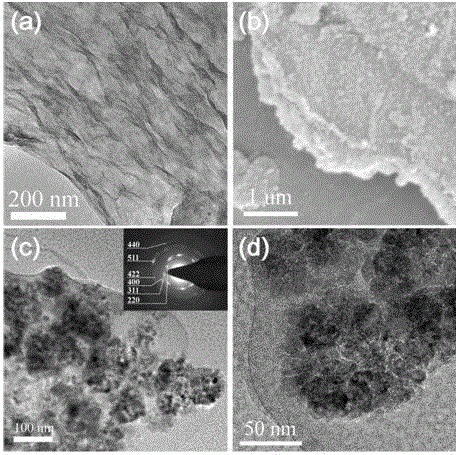

Process for preparing vanadium dioxide nano powder

A process for preparing VO2 nanoparticles includes such steps as proportionally adding V2O5 and oxalic acid to reactor, adding water, stirring at 40-70 deg.C while reaction, evaporating to obtain solid vanadium oxalate, vacuum heating to 350-500 deg.C, holding the temp for 20-40 min for thermodecomposing, and cooling. It is possible to add MoO3 or N5H37W6O24 for preparing the doped product.

Owner:SICHUAN UNIV

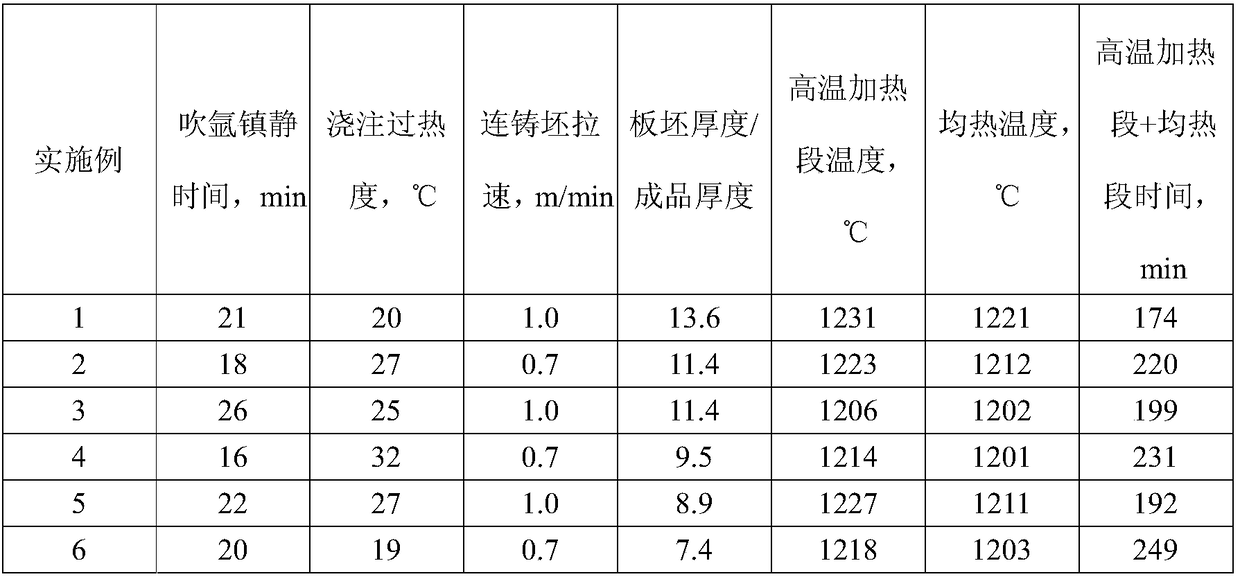

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

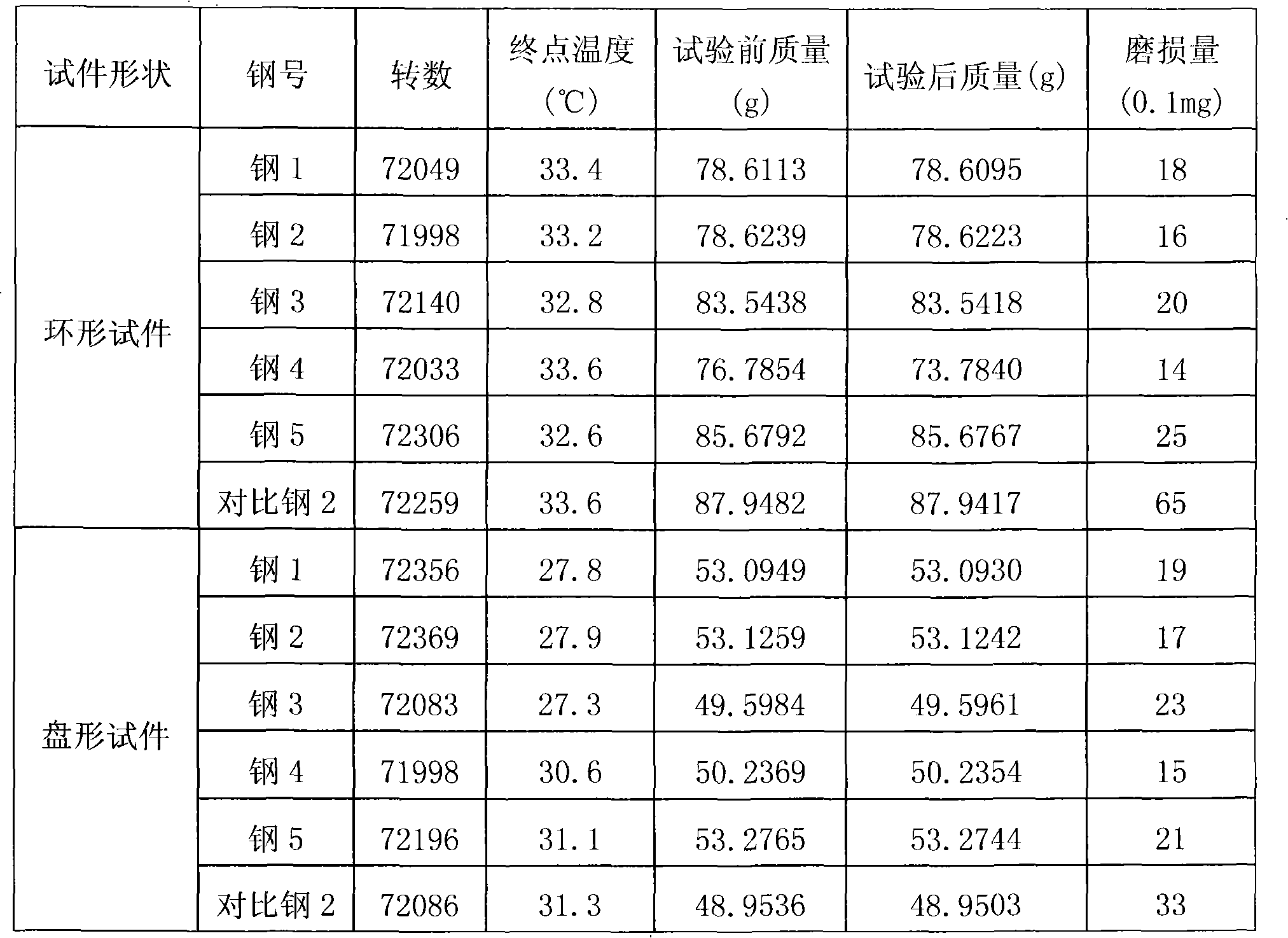

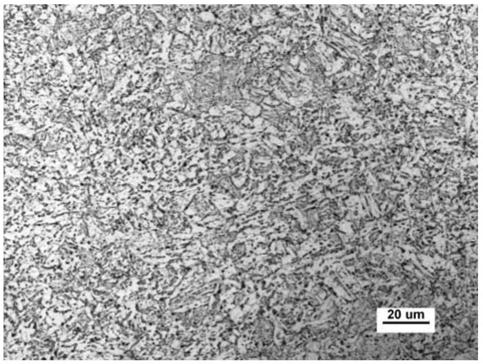

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

Titanium micro-alloyed 400MPa grade high-strength steel bar and production method thereof

The invention discloses a hot-rolled 400MPa grade high-strength steel bar for reinforced concrete and a production method for the steel bar, and belongs to the technical field of micro-alloying of ferrous metallurgy. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.16 to 0.25 percent of C, 0.20 to 0.80 percent of Si, 1.20 to 1.50 percent of Mn, 0.02 to 0.06 percent of Ti, less than or equal to 0.01 percent of N, less than or equal to 0.045 percent of S, less than or equal to 0.045 percent of P, and the balance of Fe and inevitable impurities. The preparation method for the steel bar comprises the following steps of: a, smelting crude molten steel, tapping, deoxidizing and alloying; b, refining, finely regulating the components, and pouring; and c, hot rolling, wherein titanium is alloyed in the tapping process and after deoxidizing or in the refining process. By using the principle that the titanium plays a role in precipitation and reinforcement in the steel, the mechanical properties of the steel such as yield strength and tensile strength are improved, and the property requirement of the 400MPa grade high-strength steel bar is met..

Owner:PANZHIHUA GANGCHENG GROUP

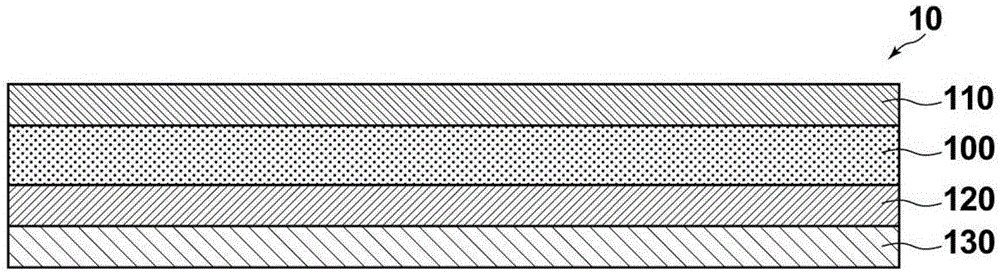

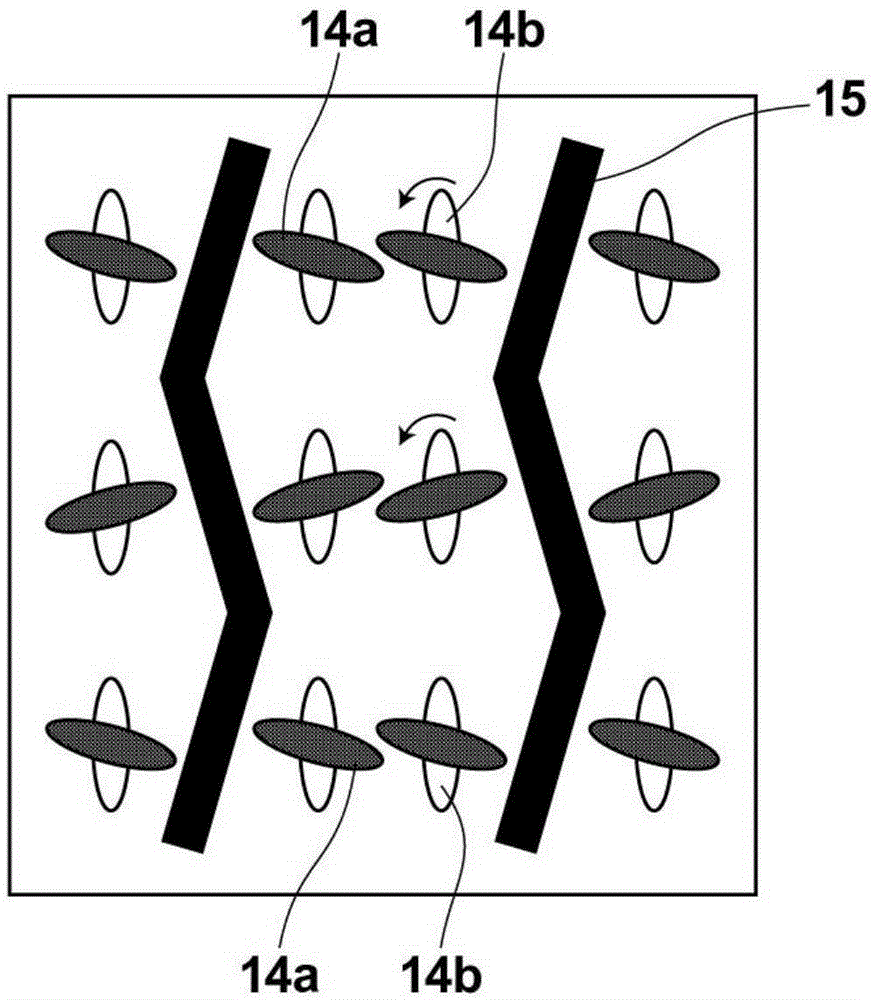

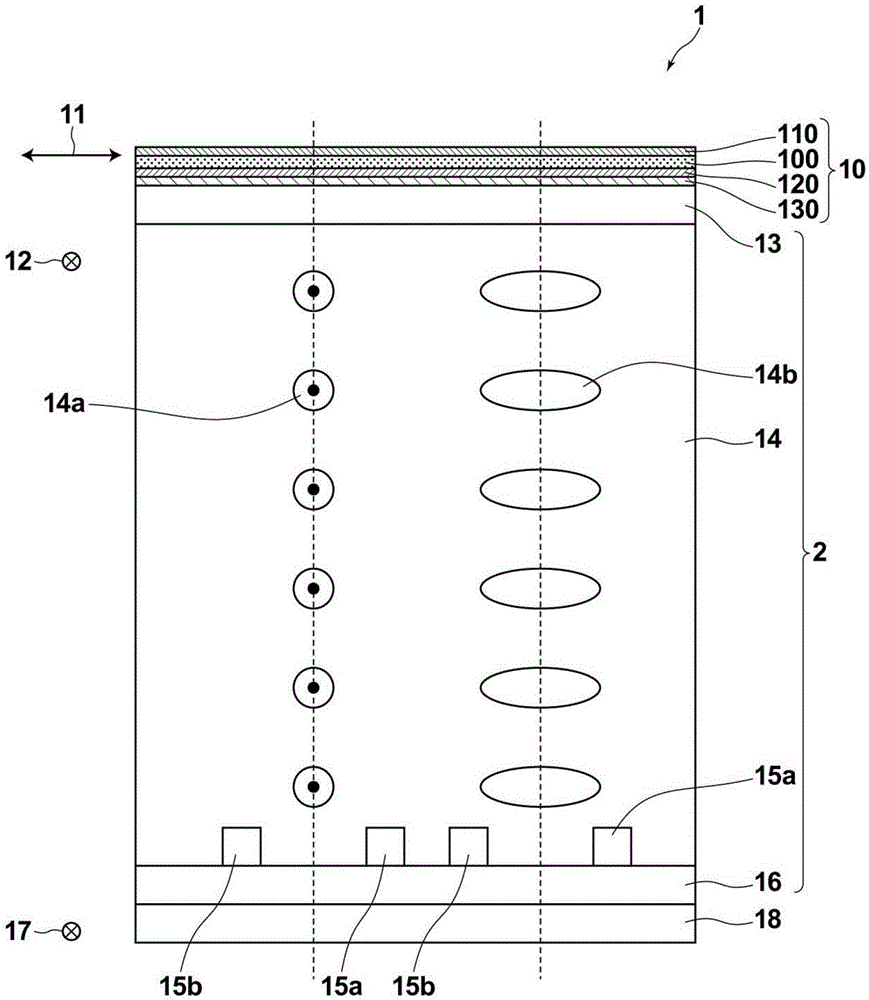

Optically anisotropic layer, method for producing the optically anisotropic layer, a laminate, polarizing plate, display device, liquid crystal compound, method for producing the liquid crystal compound, and carboxylic acid compound

ActiveCN105524625AExcellent reverse wavelength dispersionExcellent manufacturing adaptabilityLiquid crystal compositionsOrganic chemistryDisplay deviceCarboxylic acid

An optically anisotropic layer is formed by a liquid crystal compound represented by General Formula 1, in which the long axes of the molecules are oriented. wherein L1 and L2 independently represent a linking group having a carbonyl group; F1 and F2 independently represent an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or a halogen atom; n and m independently represent an integer from 0 to 4; a and b independently represent an integer from 1 to 4; T1 and T2 independently represent a spacer portion including a straight chain or branched alkylene or alkylene oxide group having 2 to 20 carbon atoms; and Ar represents a divalent group having at least one aromatic ring selected from a group consisting of aromatic hydrocarbon rings and aromatic heterocycles, the number of [Pi] electrons in the Ar group being 8 or greater.

Owner:FUJIFILM CORP

Porous geopolymer-based phase-change energy storage material

InactiveCN103641433AGood dispersionLow thermal conductivitySolid waste managementCement productionSlurryMetakaolin

The invention discloses a porous geopolymer-based phase-change energy storage material. The existing basic geopolymer-based porous materials all have no phase-change energy storage function. The porous geopolymer-based phase-change energy storage material is composed of slurry and a composite foaming agent in the weight ratio of (9-38): 1, wherein the slurry is composed of 20-50 parts of water glass, 20-50 parts of mineral waste residue, 10-20 parts of coal ash, 10-20 parts of metakaolin, 0.1-1.5 parts of polypropylene fiber, 0.3-1.0 part of redispersible latex powder, and 0.005-0.03 part of phase change microcapsule; the composite foaming agent is composed of 24-35 parts of hydrogen peroxide, 64-75 parts of water, 0.5-1 part of foam stabilizer and 1-1.5 parts of animal foaming agent. The porous geopolymer-based phase-change energy storage material provided by the invention maintains the advantages of the existing basic geopolymer-based porous materials such as even foam bore diameter, low heat conductivity coefficient, high solidification speed, high production efficiency and low cost, and wide raw material source; the porous geopolymer-based phase-change energy storage material is also capable of absorbing and releasing energy; therefore, the effects of energy saving and environmental protection can be achieved truly and the shortcomings of the similar materials are made up. The porous geopolymer-based phase-change energy storage material is a fireproof and durable basic geopolymer-based porous material which is capable of realizing phase-change energy storage.

Owner:广西启利新材料科技股份有限公司

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

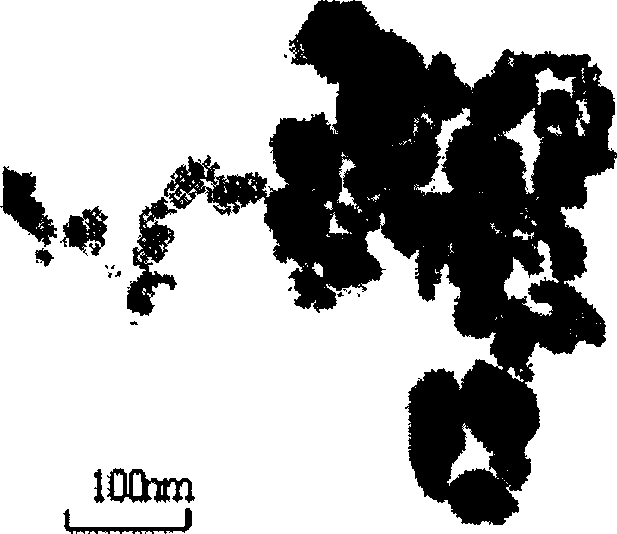

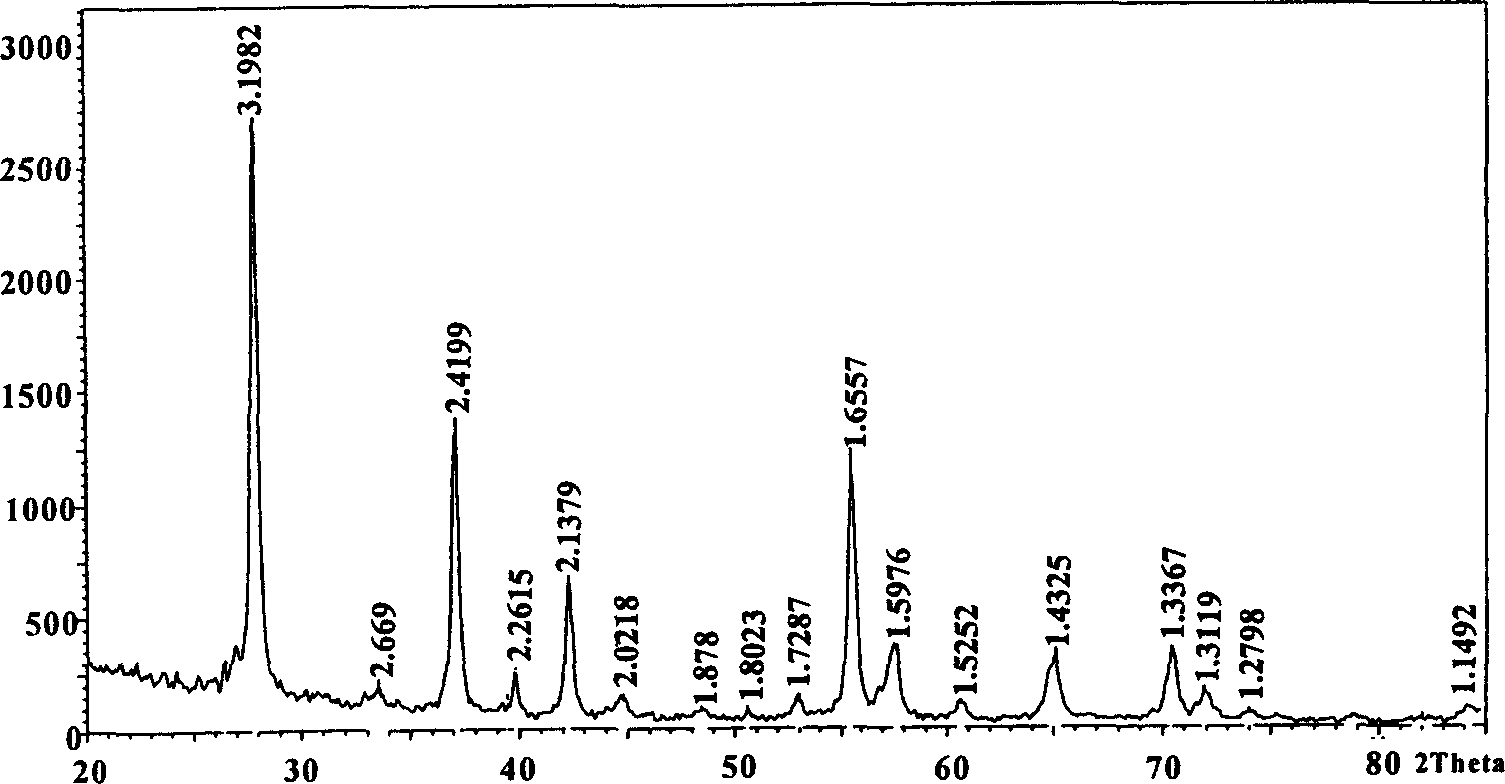

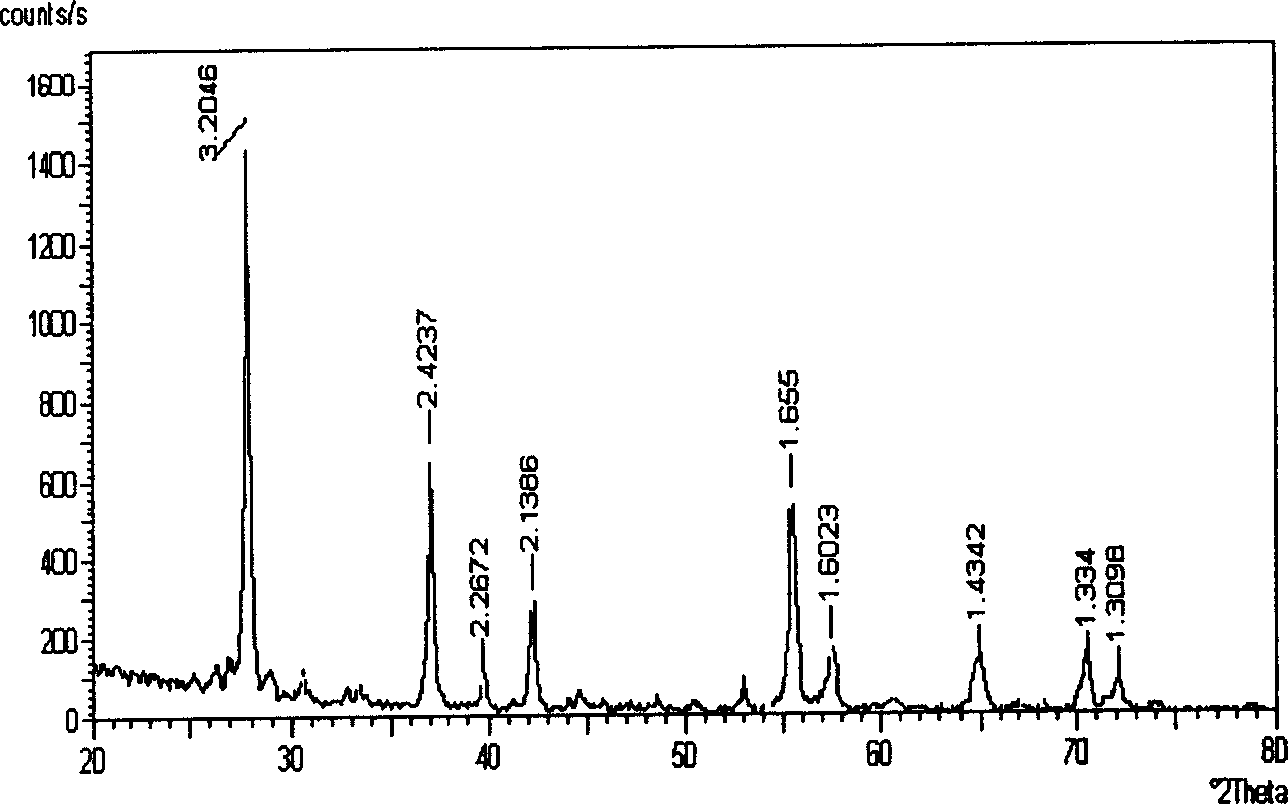

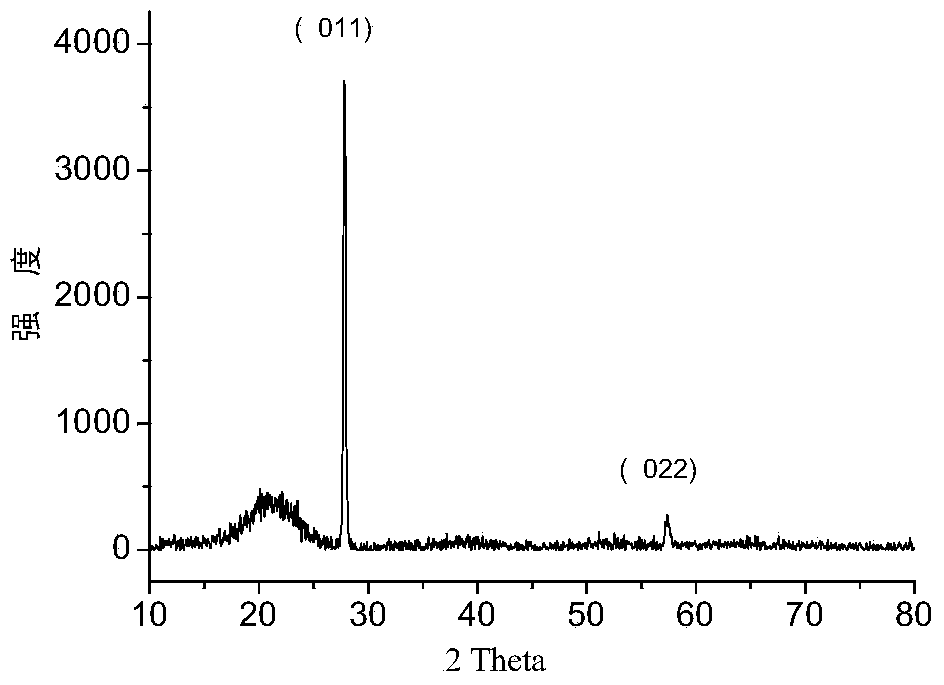

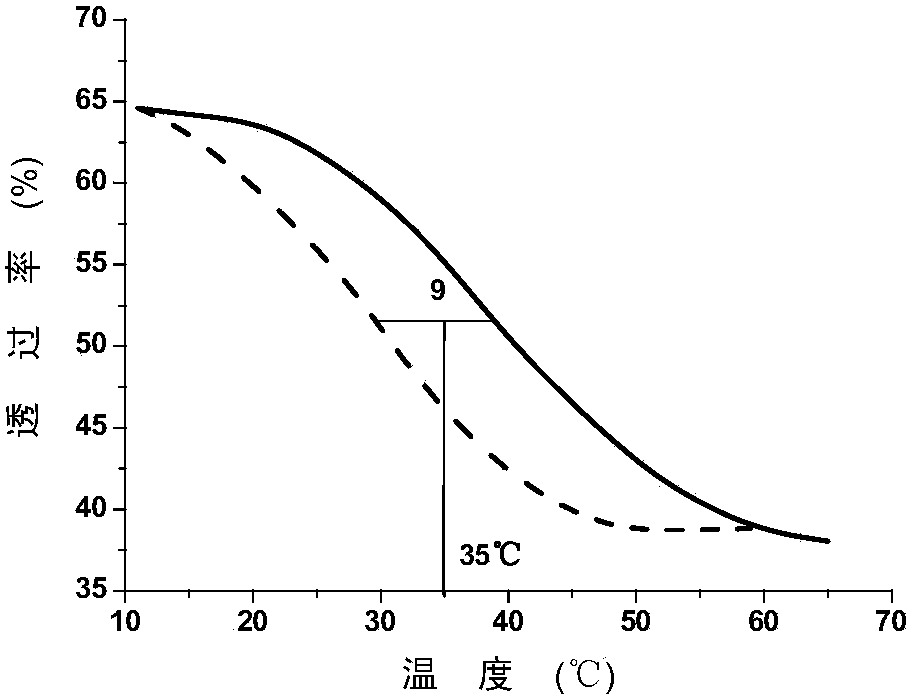

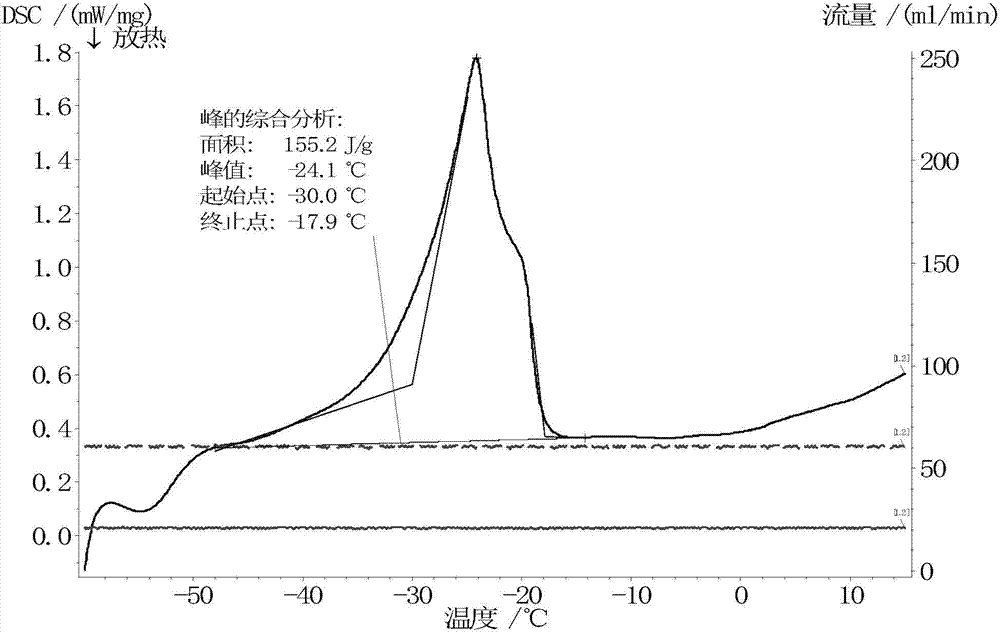

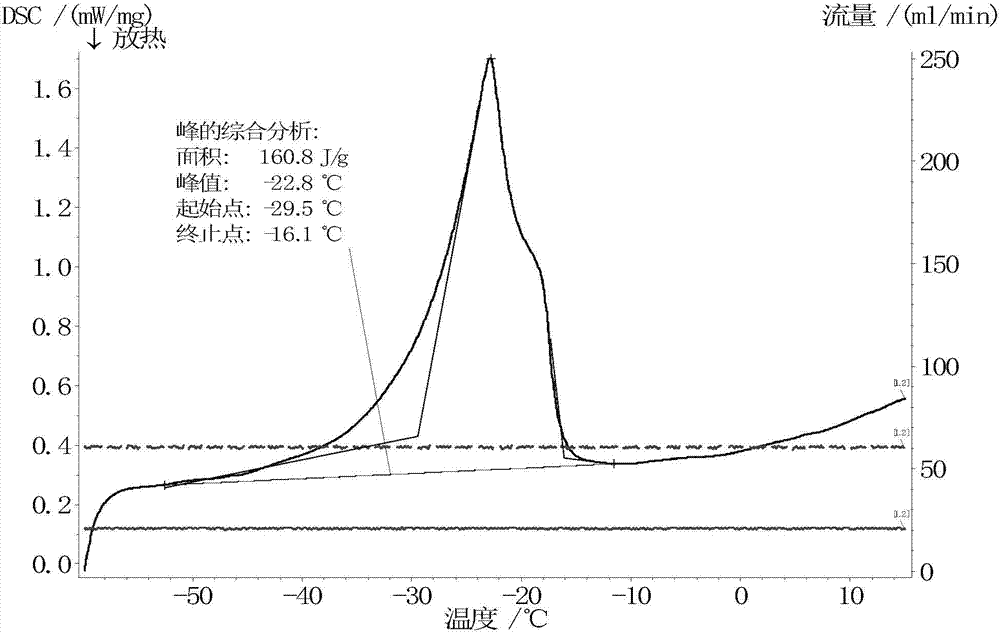

Composite mixed vanadium dioxide nano powder material and its preparation process

InactiveCN1693211AImprove transmittanceLower phase transition temperatureVanadium oxidesVanadium dioxideOxalate

A process for preparing the doped composite VO2 nanoparticles with low phase-change temp (25-30 deg.C) and improved physical propoerties includes such steps as preparing the metal element and non-metal element doped solid vanadium oxalate as precursor from V2O5 and oxalic acid, and vacuum thermodecomposing. Its molecular formula is V1-xMxO2-yZy, where x=0-0.08, y=0-0.1, M is metal element and Z is non-metal element.

Owner:SICHUAN UNIV

Method for preparing temperature-adjusting humidity-adjusting material

InactiveCN101624435ALower phase transition temperatureIncrease moisture contentOther chemical processesViscous liquidPolyethylene glycol

The invention relates to a method for preparing a temperature-adjusting humidity-adjusting material, which is characterized by adopting the following steps: (A) adding activated meerschaum, artificial zeolite, gelatin and urea into deionized water sequentially and stirring to react for 4-6h at the temperature of 50-60 DEG C; (B) adding acrylic acid, polyethylene glycol, ammonium persulphate and the deionized water into a reactant in the step (A) sequentially and stirring for 3-5h at 50-60 DEG C; and (C) cooling a mixture formed in the step (B) to room temperature, forming viscous liquid, drying at the temperature of 80-90 DEG C and preparing the temperature-adjusting humidity-adjusting material. Compared with the prior humidity-adjusting material, the invention has the following outstanding advantages of quick response of the temperature and the humidity, low phase change temperature of the material, high moisture content, quick heat absorption, good kept balance of the temperature and the humidity, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

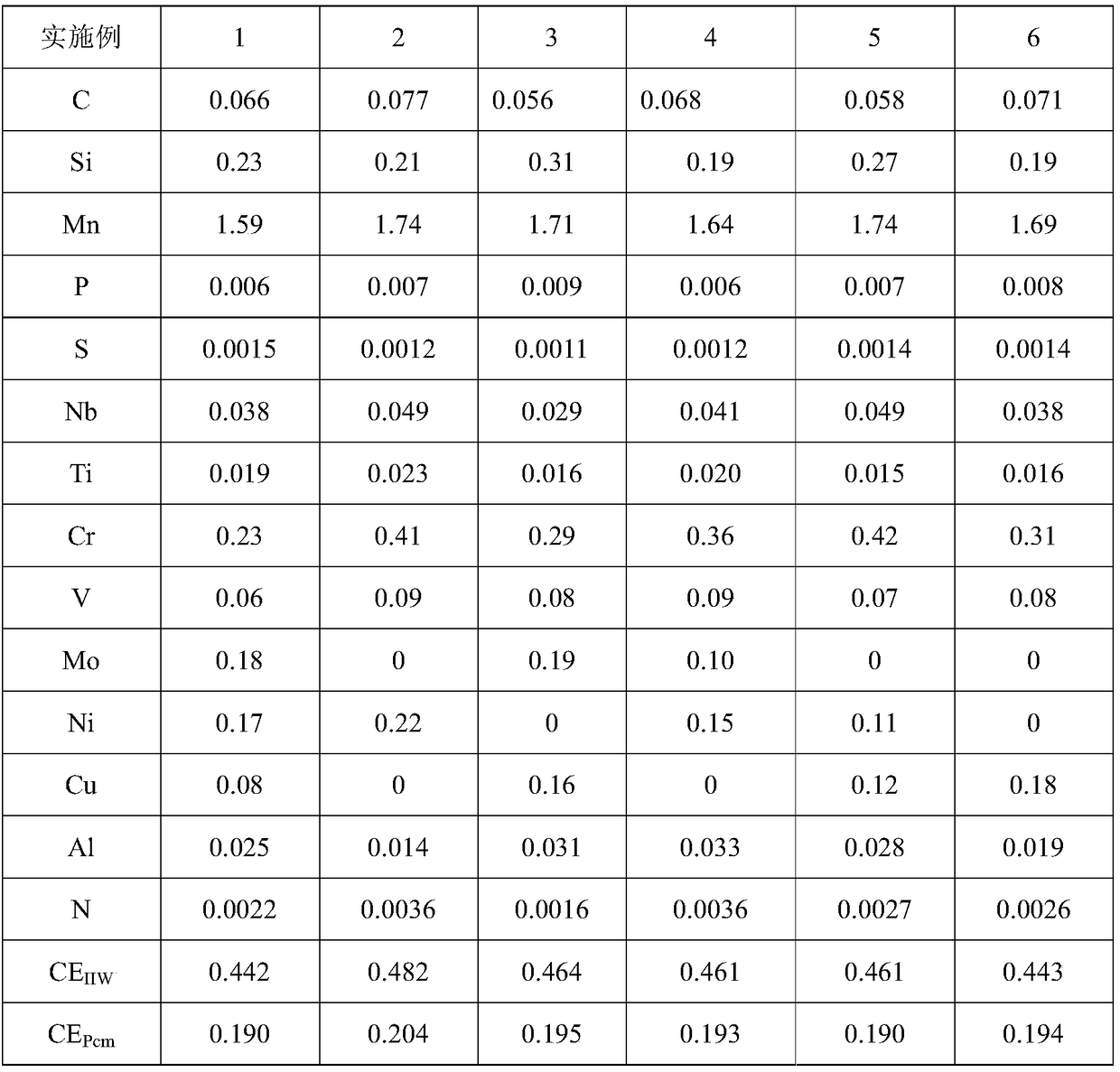

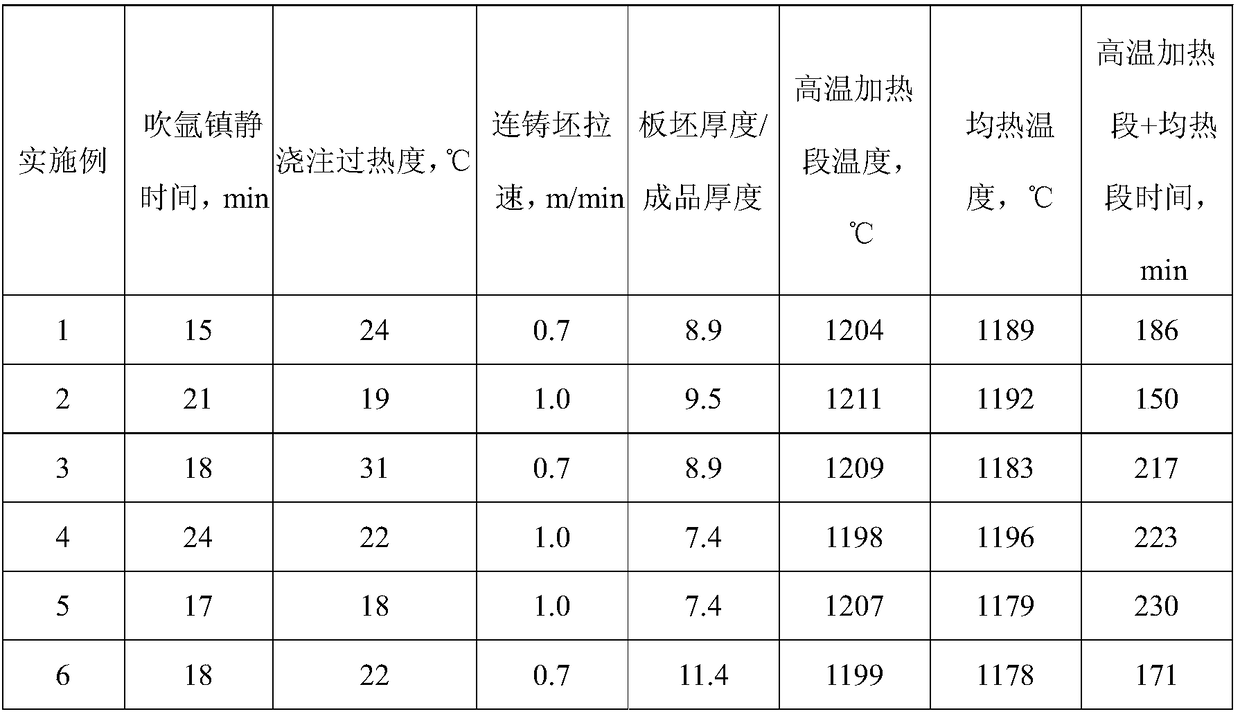

Wide and heavy steel plate for high-strength high-toughness and low-yield-ratio hot-bending bend and production method of wide and heavy steel plate

The invention provides a wide and heavy steel plate for a high-strength high-toughness and low-yield-ratio hot-bending bend and a production method of the wide and heavy steel plate. The steel plate comprises, by weight percentage, 0.055%-0.080% of C, 0.16%-0.30% of Si, 1.76%-1.95% of Mn, 0.051%-0.080% of Nb, 0.010%-0.025% of Ti, 0.09%-0.13% of V, 0.25%-0.45% of Cr, 0.20%-0.35% of Mo, less than 0.25% of Ni, less than 0.25% of Cu, 0.010%-0.035% of Al, not larger than 0.010% of P, not larger than 0.002% of S, 0.001%-0.004% of N and the balance iron and inevitable impurities, wherein (Mo+Ni+Cr+Cu) is controlled within the range of 0.6%-1.0%, CEIIW is controlled within the range of 0.50%-0.55%, and CEPcm is controlled within the range of 0.19%-0.23%. The production method includes the steps ofmolten iron pretreatment, converter smelting, external refining, continuous casting, heating, rolling, cooling and heat treatment. The microstructure of the wide and heavy steel plate is a compositestructure of bainite and ferrite, and the performance meets the requirement of manufacturing X90-grade hot-bending bends with ultra-wide and thick walls in a low-temperature environment.

Owner:ANGANG STEEL CO LTD

Titanium microalloyed 500-MPa high-strength steel bar and production method thereof

The invention discloses a 500-MPa high-strength steel bar for reinforced concrete and a production method thereof, belonging to the technical field of microalloying in ferrous metallurgy. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.18-0.25% of C, 0.20-0.80% of Si, 1.20-1.50% of Mn, 0.06-0.12% of Ti, at most 0.01% of N, at most 0.045% of S, at most 0.045% of P, and the balance of Fe and inevitable impurities. The preparation method of the steel bar comprises the following steps: a. crude smelting, tapping, deoxidizing and alloying; b. refining and composition fine adjustment, and casting after satisfying the steel bar composition requirement; and c. hot rolling; wherein the titanium is alloyed in the tapping process after deoxidizing or in the refining process. By using the principle that the titanium in steel reinforces the precipitation, the invention enhances the mechanical properties of the steel, and satisfies the performance requirements for 500-MPa high-strength steel bars and even anti-seismic steel bars.

Owner:PANZHIHUA GANGCHENG GROUP

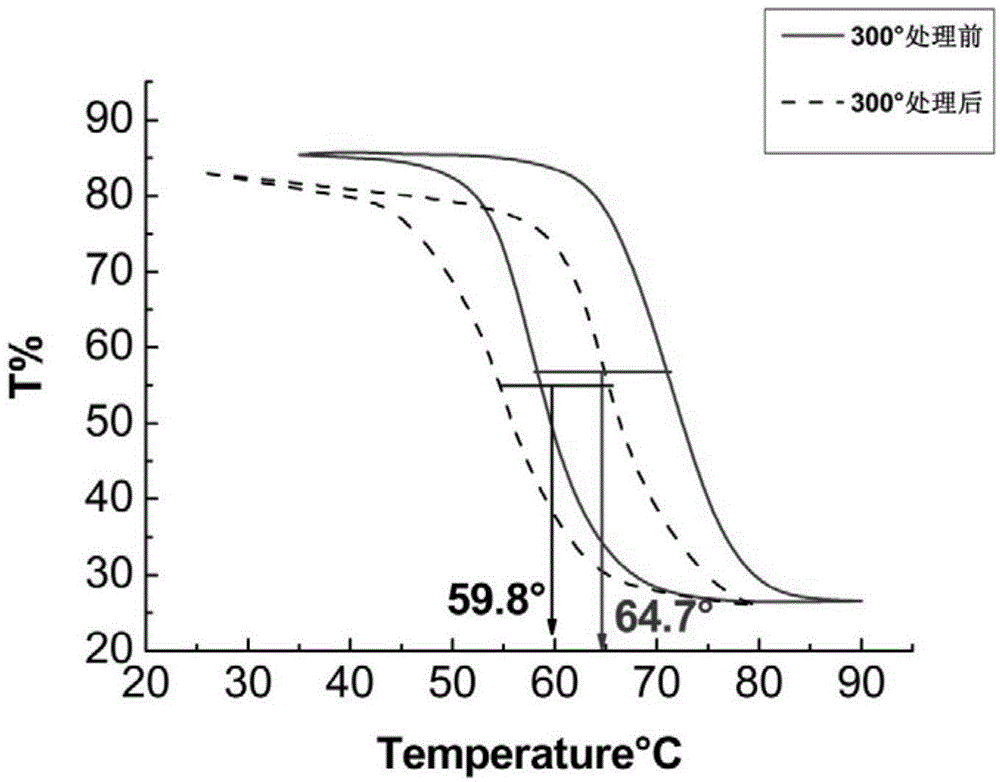

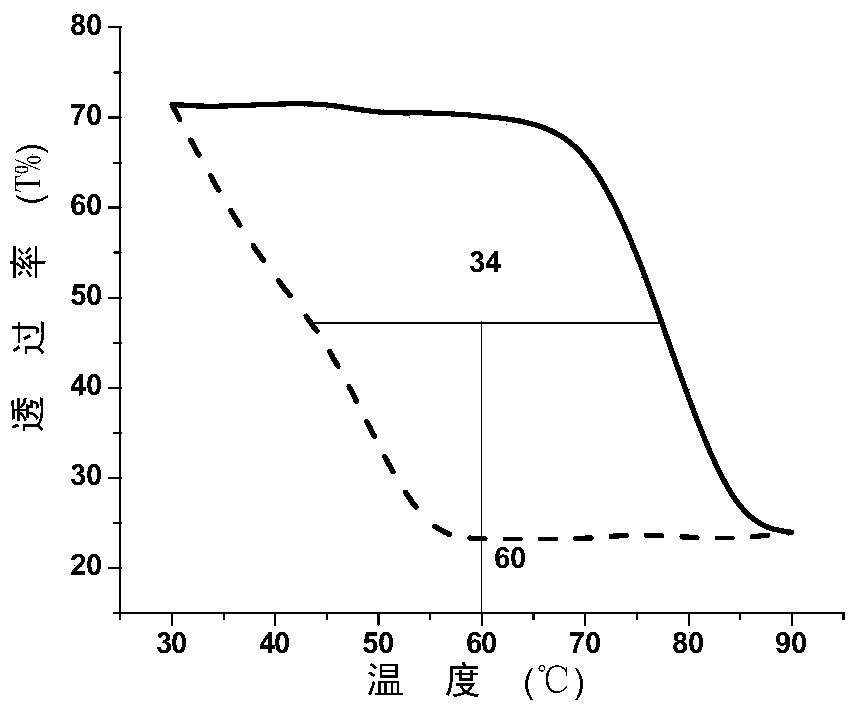

Method for reducing phase change temperature of vanadium dioxide film

InactiveCN104445990ALower phase transition temperatureGood optical performanceHeat-exchange elementsCoatingsVanadium dioxidePhase change temperature

The invention discloses a method for reducing the phase change temperature of a vanadium dioxide film. The method comprises the following steps: 1) preparing an M-phase vanadium dioxide film with a phase change function, wherein the M-phase vanadium dioxide film is formed on a substrate; 2) putting an M-phase vanadium dioxide film sample prepared in the step 1) into an annealing device, vacuumizing the annealing device till the vacuum degree is 200-2000 Pa, keeping the vacuum degree, or vacuumizing till the vacuum degree is 200-2000 Pa, subsequently introducing inert gas to the standard atmospheric pressure, heating to be 280-320 DEG C, keeping the temperature for 0.5-3 hours, and natural cooling to be the room temperature in a furnace, thereby obtaining the vanadium dioxide film with reduced phase change temperature. By adopting the method, the phase change temperature of a pure vanadium dioxide film can be reduced, and the phase change temperature of a doped vanadium dioxide film can also be reduced, so that the method has a very wide application range. In addition, the method is low in treatment temperature, simple in process, good in safety and wide in application prospect in the field of high-end photoelectric functional materials.

Owner:WUHAN UNIV OF TECH

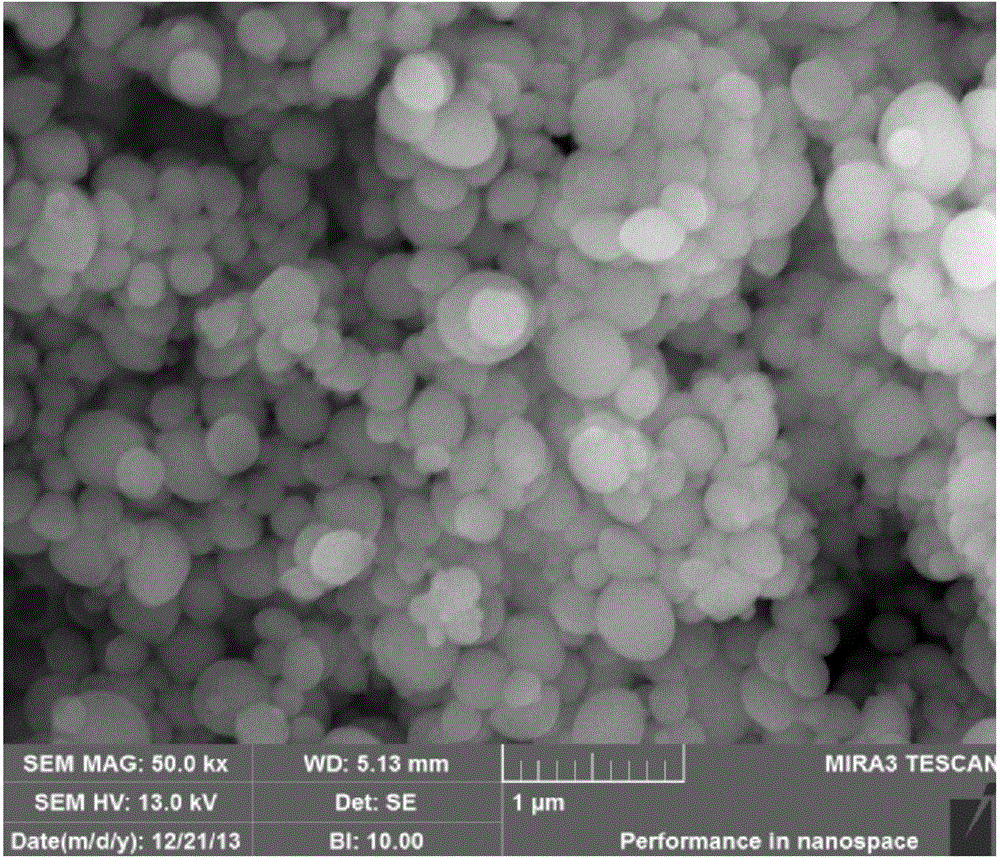

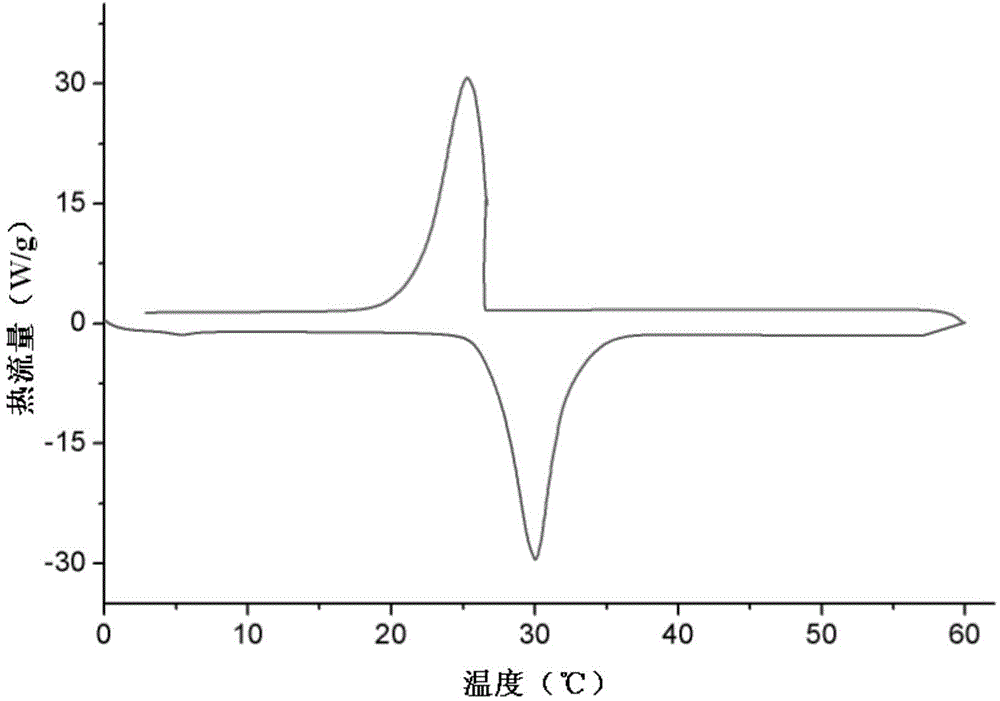

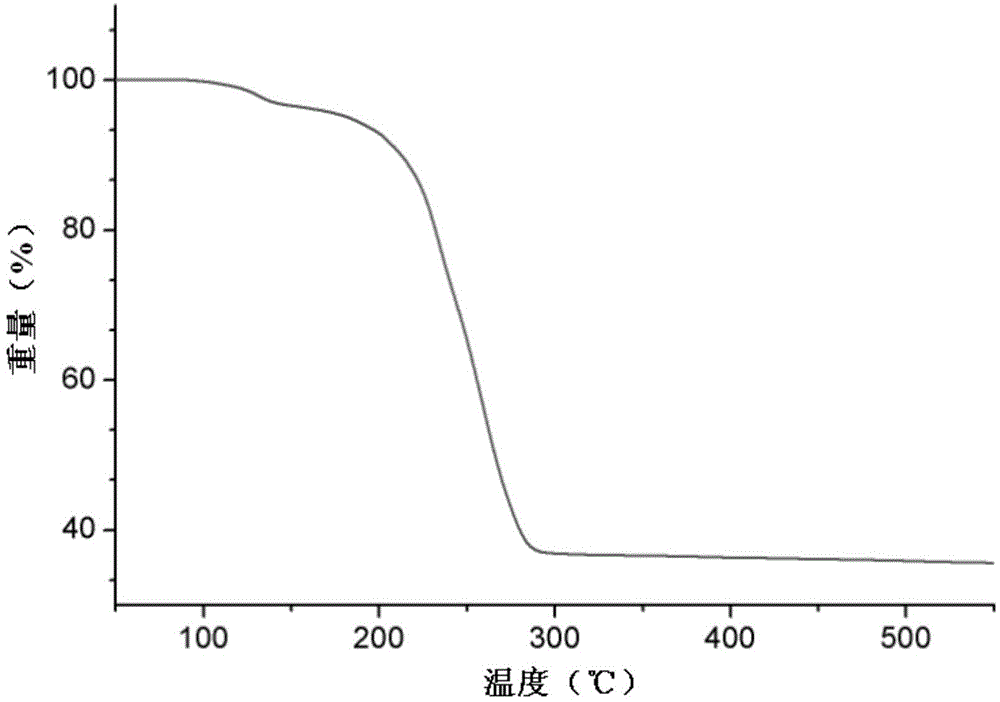

Low-temperature phase-change thermal storage microcapsule as well as preparation method and application thereof

ActiveCN104610924AGood formabilityGood coating effectHeat-exchange elementsMicroballoon preparationFilling materialsPhase change

The invention provides a low-temperature phase-change thermal storage microcapsule as well as a preparation method and an application thereof. The microcapsule has a core-shell structure and belongs to low temperature thermal storage materials. The preparation method includes the following steps: by taking the n-octadecane as a thermal storage medium, dispersing the n-octadecane into the water solution, and adding an emulgator to emulsify to obtain an emulsion; by taking phenyl trimethoxysilane as a polymeric monomer, with the help of the O / W miroemulsion template effect, hydrolytically polymerizing the phenyl trimethoxysilane on the surface of the n-octadecane micro droplets to obtain the silicon dioxide, and then finishing the cladding and self-assembling process; and finally, washing and drying to obtain the microcapsule. The method disclosed by the invention has the characteristics of being simple in process and easy to control. The microcapsule disclosed by the invention has an integral spherical shape, a smaller particle size and good uniformity; and the microcapsule also has a higher thermal storage density, which can be applied in the fields of temperature self-operating fabrics, wall filling materials, solar energy development and utilization and industrial waste heat recovery.

Owner:XI AN JIAOTONG UNIV

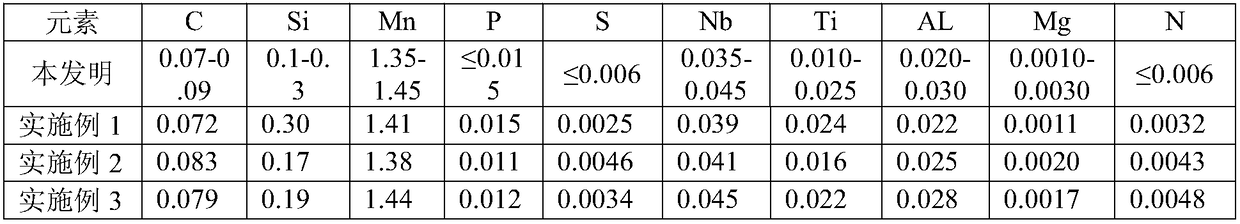

Low-cost X65 pipeline steel based on magnesium treatment, and manufacturing method thereof

The invention discloses a low-cost X65 pipeline steel based on magnesium treatment, and a manufacturing method thereof. A purpose of the present invention is mainly to solve the technical problem of high manufacturing cost of the existing X65 pipeline steel. According to the present invention, the low-cost X65 pipeline steel comprises the following chemical components by weight: 0.07-0.09% of C, 0.1-0.3% of Si, 1.35-1.45% of Mn, less than or equal to 0.006% of S, less than or equal to 0.015% of P, 0.035-0.045% of Nb, 0.010-0.025% of Ti, 0.0010-0.0030% of Mg, 0.020-0.030% of Al, less than or equal to 0.006% of N, and the balance of Fe and unavoidable impurities. According to the present invention, the metallographic structure of the hot-rolled steel plate comprises fine-grained ferrite, acicular ferrite and pearlite, and the elongation A after break of the hot-rolled steel plate having the thickness of 10.0-15.0 mm is more than or equal to 24%.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Movable heat storage and discharge device based on pulsating heat pipes and heat storage and discharge method thereof

PendingCN106767082AGuaranteed uptimeSimple structureHeat storage plantsEnhanced heat transferCooling chamber

The invention provides a movable heat storage and discharge device based on pulsating heat pipes and a heat storage and discharge method thereof. The heat storage and discharge device comprises a shell, a heating chamber, a phase-change material chamber, a cooling chamber and the pulsating heat pipes, wherein the heating chamber, the phase-change material chamber, the cooling chamber and the pulsating heat pipe are all arranged in the shell; the heating chamber, the phase-change material chamber and the cooling chamber are separated by stainless steel partitions; at least one group of pulsating heat pipes pass through the partitions and are arranged in the shell; the parts, which are arranged in the heating chamber and the cooling chamber, of the pulsating heat pipes include straight pipe sections and elbows, and the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are straight pipe sections; the parts, which are arranged in the heating chamber, of the pulsating heat pipes are evaporating sections, the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are insulation sections, and the parts, which are arranged in the cooling chamber, of the pulsating heat pipes are condensation sections; and fluid inlets and outlets are formed in one end of the cooling chamber and the heating chamber. Phase-change heat transfer of working media in the pulsating heat pipes and phase-change heat storage of phase-change materials are used, so that waste heat is absorbed, stored, transferred and released, thereby effectively recycling the waste heat.

Owner:SHANGHAI MARITIME UNIVERSITY

Method for preparing alumina powder with small particle diameter

InactiveCN1669931ASimple processSmall particlesAluminium oxide/hydroxide preparationAluminium hydroxide preparationAlcoholCarbonate

This invention relates to a method for producing the small size aluminum oxide powder, which comprises the following steps: 1) preparing aluminium salt solution in the concentration of aluminium ion of 0.3-3.5 mol / L and PH of 1-5 by deionized water, 2) preparing the ammonium acid carbonate solution in the concentration of 1-3 mol / L and PH of 8-10 adjusted by ammonial solution, 3) adding additive into the ammonium acid carbonate solution, 4) heating the ammonium acid carbonate solution to the temperature of 20-80 Deg. C, adding the aluminium salt solution into the ammonium acid carbonate solution, stirring and adjusting the PH of deposition in 8-10 by adding ammonial solution, 5) after adding all aluminium salt solution, stirring 1-5 h followed, 6) stopping and stewing or centrifugal sedimentating, pouring the supernatant fluid, washing the deposition by deionized water or ethyl alcohol 1-3 times, dewatering and drying to get the puffy powder, 7) incandescing the powder under the temperature of 900-1400 Deg. C at last one time of 5 min to 10 h to get the dispersed alpha-aluminum oxide powder.

Owner:SOUTHEAST UNIV

Low temperature phase change cool storage agent and preparation method thereof

ActiveCN102942905APlay a thickening roleHigh latent heat valueHeat-exchange elementsCold chainCool storage

The invention discloses a low temperature phase change cool storage agent and a preparation method thereof. The low temperature phase change cool storage agent comprises, by mass, 8% to 19.5% of ammonium chloride, 0.1% to 2% of dipotassium phosphate, 0.1% to 1% of sodium hydroxyethyl cellulose, 0.05% to 0.1% of nano-titanium dioxide and the balance deionized water. The preparation method includes adding the ammonium chloride, the dipotassium phosphate and the nano-titanium dioxide in the deionized water, uniformly mixing to obtain a solution, heating the solution to 70 DEG C to 80 DEG C, then slowly adding the sodium hydroxyethyl cellulose in the solution under high speed stirring, and uniformly stirring to obtain the low temperature phase change cool storage agent. Compared with low temperature phase change cool storage agents and preparation methods in prior art, the low temperature phase change cool storage agent and the preparation method thereof have the advantages that the low temperature phase change cool storage agent is low in phase transition temperature, free of salt crystal separation, high in phase change potential heat value, free of potential heat value decay after overturn circulation and the like, raw materials are easy to obtain, the production is easy, the low temperature phase change cool storage agent is safe and non-toxic, and the low temperature phase change cool storage agent has a potential application value in food fresh keeping and biological vaccine cold chain transportation.

Owner:SHANGHAI CHUANGSHI MEDICAL TECH (GRP) CO LTD +1

Ultrahigh-strength gas protection welding wire containing V and manufacturing method thereof

InactiveCN104551441APlay a role in solid solution strengtheningPlay a role in precipitation strengtheningArc welding apparatusWelding/cutting media/materialsChemical elementUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

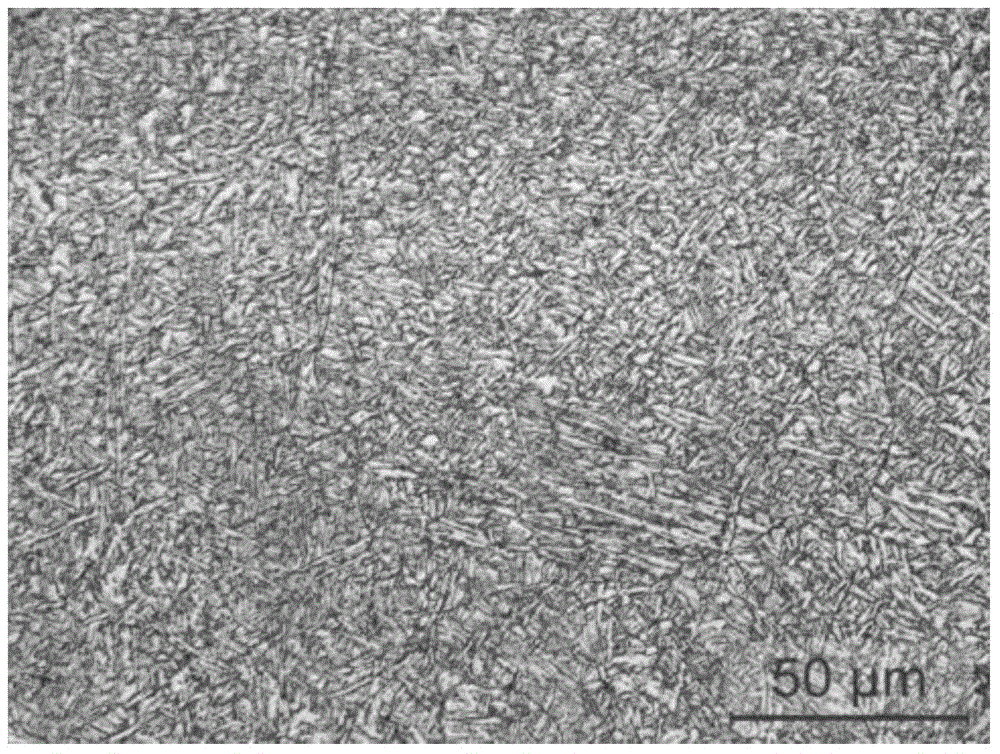

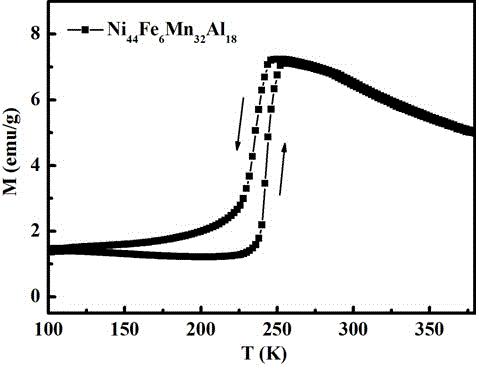

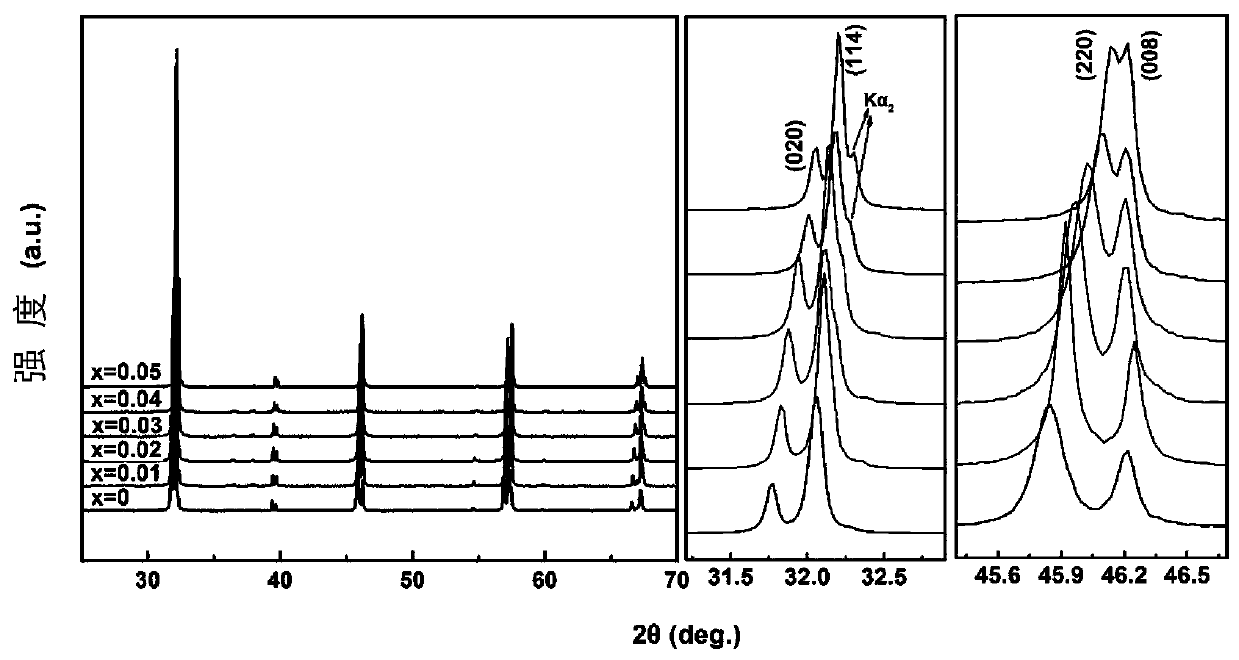

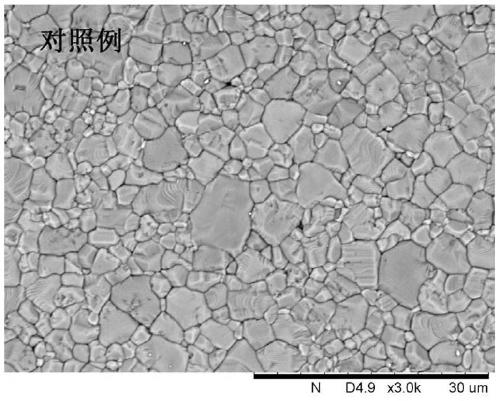

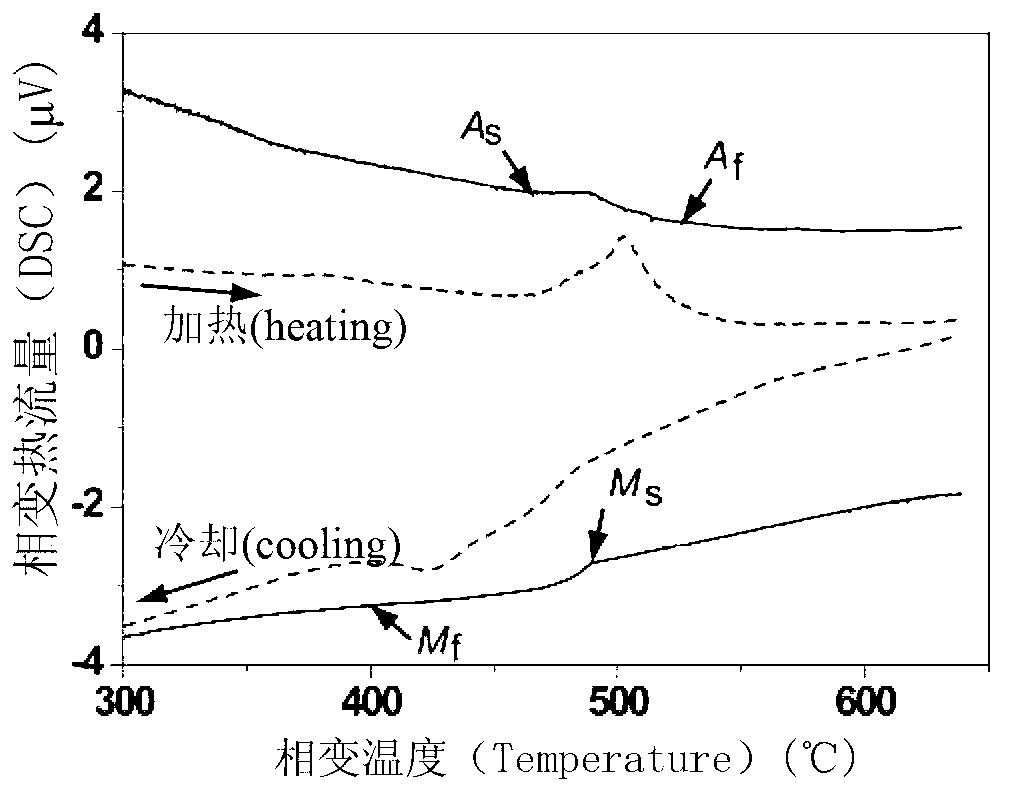

Ni-Fe-Mn-Al alloy material and preparation method thereof

InactiveCN103981397AValence electron reductionLower phase transition temperatureHeat-exchange elementsShape-memory alloyMixed materials

The invention provides a Ni-Fe-Mn-Al alloy material, which has a chemical formula of Ni<50-x>Fe<x>Mn<50-y>Al<y> (2=<x=<9, 16<=y<=18). The preparation comprises the following steps: (1) weighting pure elements according to the ratio of the chemical formula, mixing the pure elements together; (2) placing the mixed material in a water-cooling copper crucible, and repeatedly smelting the mixed material through a conventional electric arch smelting method so as to obtain a uniform alloy casting ingot. The obtained polycrystalline casting ingot can be made into Ni<50-x>Fe<x>Mn<50-y>Al<y> rapidly-quenched strips with a certain texture through a melt quick quenching method. Compared to that of the conventional Ni-Mn base ferromagnetic shape-memory alloy, the binding strength among the crystals of the Ni-Fe-Mn-Al alloy is higher, and thus the mechanical property of the Ni-Fe-Mn-Al alloy is better. The Ni-Fe-Mn-Al alloy is prepared through a conventional method, the raw materials are cheap, and furthermore, the Ni-Fe-Mn-Al alloy has a strong magneto-thermal effect under a low magnetic field, so the Ni-Fe-Mn-Al alloy can be applied to the magnetic refrigeration field.

Owner:TAIYUAN UNIV OF TECH

Lanthanum-doped silver niobate lead-free anti-ferroelectric energy storage ceramic material and preparation method thereof

ActiveCN109650885AHigh energy storage densityImprove energy storage efficiencyLanthanumEnergy storage

The invention relates to a lanthanum-doped silver niobate lead-free anti-ferroelectric energy storage ceramic material and a preparation method thereof. The lanthanum-doped silver niobate lead-free anti-ferroelectric energy storage ceramic material has a single perovskite structure, and has a general formula of Ag1-3xLaxNbO3, wherein x is greater than or equal to 0.01 and smaller than or equal to0.08, preferably x is greater than or equal to 0.03 and smaller than or equal to 0.04.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

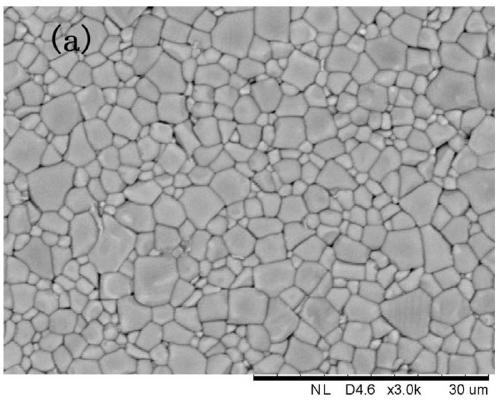

X80 wide and heavy steel plate with good low-temperature toughness and for hot bends and production method thereof

The invention provides an X80 wide and heavy steel plate with good low-temperature toughness and for hot bends and a production method thereof. The steel plate is prepared from 0.055%-0.080% of C, 0.16%-0.35% of Si, 1.55%-1.75% of Mn, 0.025%-0.050% of Nb, 0.011%-0.025% of Ti, 0.05%-0.09% of V, 0.21%-0.45% of Cr, less than 0.20% of Mo, less than 0.25% of Ni, less than 0.20% of Cu, 0.010%-0.035% ofAl, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.001%-0.004% of N, and the balance of Fe and inevitable impurities. The production method comprises the steps of hot metal pretreatment, converter smelting, external refining, continuous casting, heating, rolling, cooling and heat treatment. A microstructure is a combination of bainite and ferrite.

Owner:ANGANG STEEL CO LTD

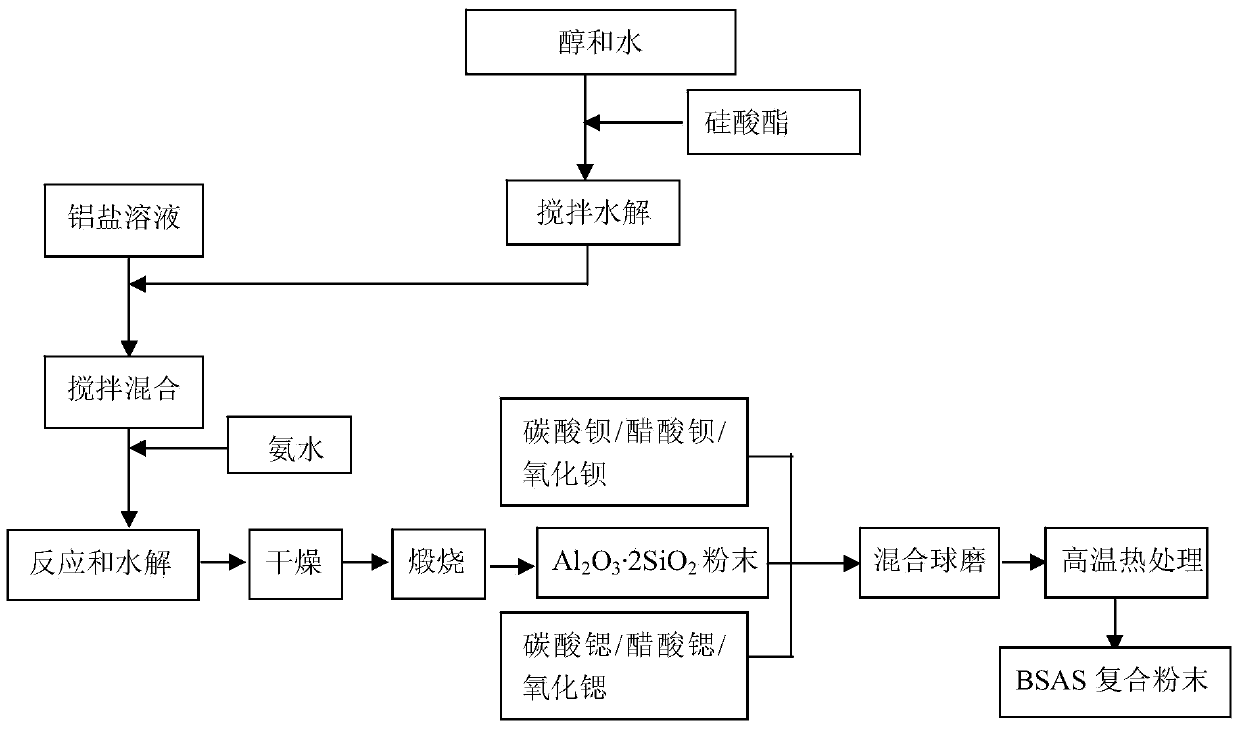

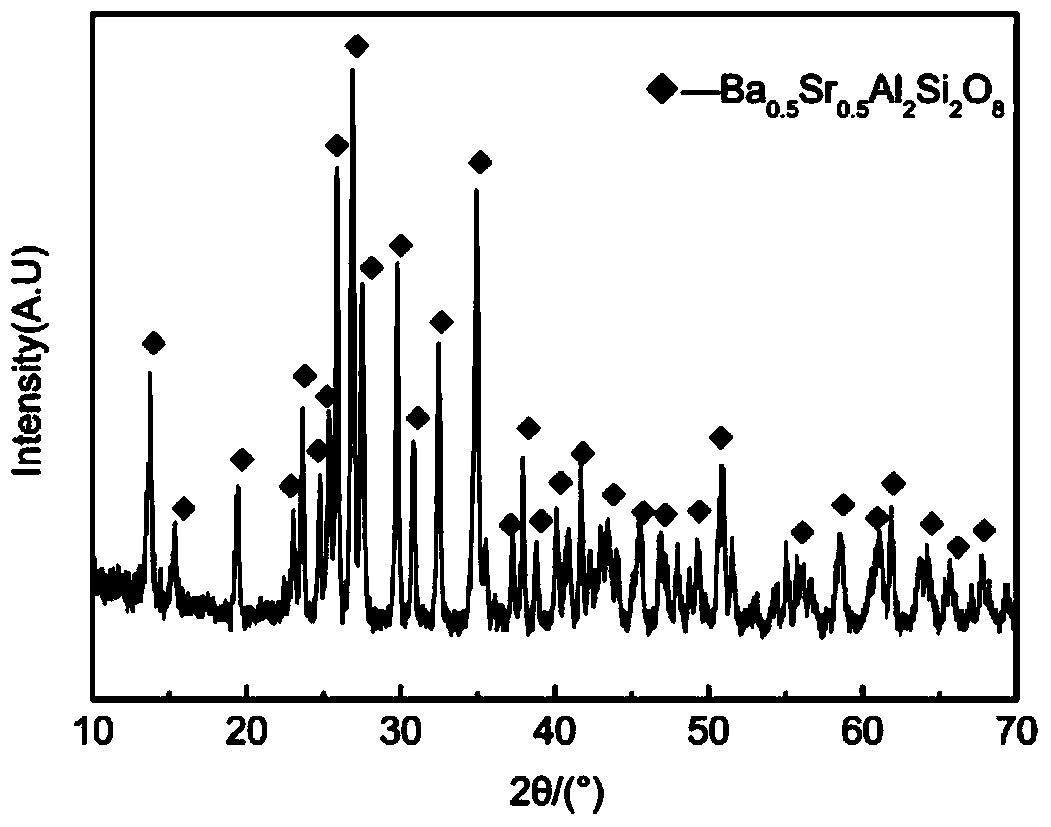

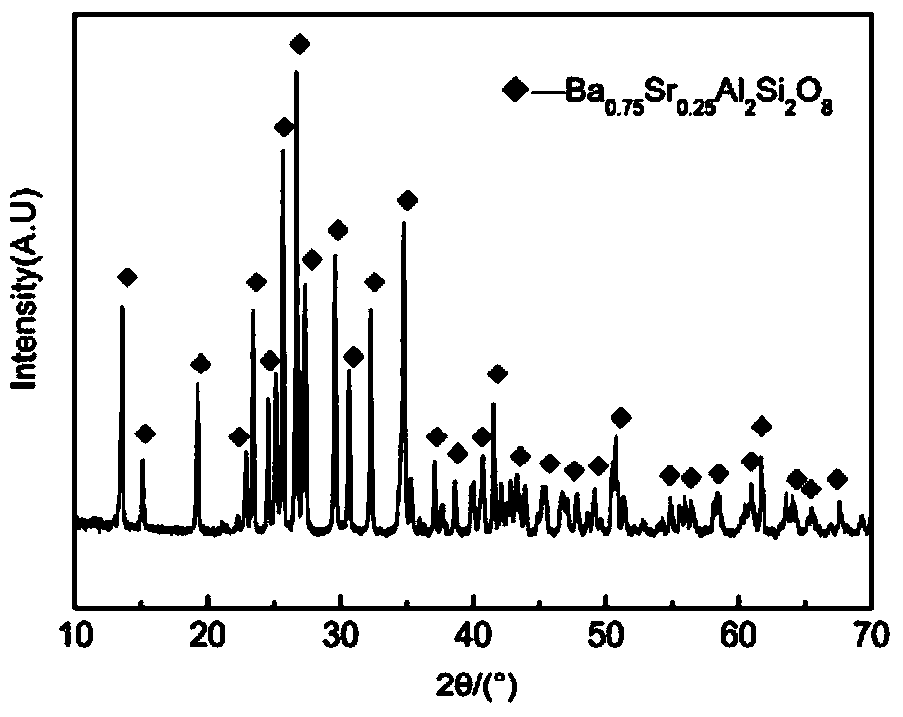

Preparation method of BSAS composite ceramic powder

ActiveCN104003697AProcess raw materials are cheapThe process is simple and easy to controlComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

Submerged arc welding wire for superstrength pipeline steel and production method thereof

InactiveCN102069320AHigh strengthIncrease contentArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingCopper plating

The invention relates to a submerged arc welding wire for superstrength pipeline steel and a production method thereof. The technical scheme is that: the submerged arc welding wire comprises the following components in percentage by weight: 0.04 to 0.06 percent of C, 1.40 to 2.00 percent of Mn, 0.70 to 1.10 percent of Mo, 2.00 to 2.60 percent of Ni, 0.80 to 1.20 percent of Cr, 0.10 to 0.30 percent of Cu, less than or equal to 0.0005 percent of B, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe and inevitable impurities. The production method comprises the following steps of: adding 0.01 to 0.5 weight percent of composite additive when the components are smelted, forming a square billet in a pouring way, hot-rolling the square billet to form a steel wire rod with the diameter of Phi 5.5 to Phi 7.5mm, removing oxide skin from a surface, drawing the steel wire rod to form the welding wire with the diameter of Phi 3.2 to Phi 4.0mm and performing copper plating, wherein the composite additive is added in form of cored wire. The welding wire produced by the method is welded together with an SJ105 welding flux so as to achieve the tensile strength sigmab of more than or equal to 910MPa and the impact toughness Akv at -30 DEG C of more than or equal to 84J of a weld metal, and is suitable for the submerged arc welding of X120 pipeline steel with superstrength.

Owner:WUHAN UNIV OF SCI & TECH

Composite mixed vanadium dioxide nano powder material and its preparation process

InactiveCN1321067CImprove transmittanceLower phase transition temperatureVanadium oxidesOxalateVanadium dioxide

A process for preparing the doped composite VO2 nanoparticles with low phase-change temp (25-30 deg.C) and improved physical propoerties includes such steps as preparing the metal element and non-metal element doped solid vanadium oxalate as precursor from V2O5 and oxalic acid, and vacuum thermodecomposing. Its molecular formula is V1-xMxO2-yZy, where x=0-0.08, y=0-0.1, M is metal element and Z is non-metal element.

Owner:SICHUAN UNIV

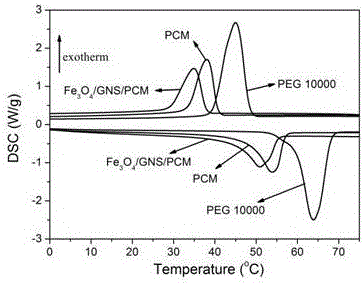

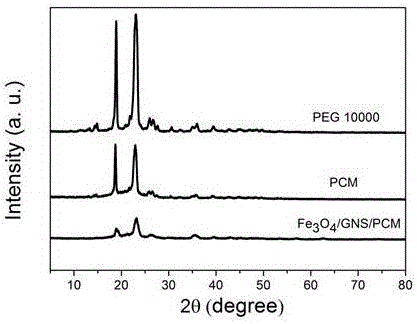

Magnetic thermal-photothermal double-drive energy conversion and storage polymer nano composite phase-change energy-storage material and preparation method thereof

ActiveCN106010458AExcellent phase change heat storage performanceLower phase transition temperatureMaterial nanotechnologyHeat-exchange elementsIonOxide

The invention discloses a magnetic thermal-photothermal double-drive energy conversion and storage polymer nano composite phase-change energy-storage material and a preparation method thereof, and belongs to the technical field of energy conversion and storage. The polymer nano composite phase-change energy-storage material takes nano magnetic based graphene as an energy converter, takes a polyurethane organic polymer as a phase-change material energy-storage device, and achieves conversion and storage of magnetic energy and optical energy. The nano magnetic based graphene is obtained by one-step reduction of a metal ion and graphene oxide through a solvothermal method, and the polyurethane organic polymer is obtained by polymerization of polyethylene glycol and an isocyanate type organic compound. Then, the nano magnetic based graphene and the polyurethane organic polymer are composited and hybridized to finally obtain the polymer nano composite shapely phase-change energy-storage material. The product has the advantages of magnetic thermal-photothermal double-drive energy conversion and storage performance, high thermal conductivity coefficient, large energy storage density and good shape fixing performance, and has wide application prospects in the field of energy conversion and storage.

Owner:DALIAN UNIV OF TECH

Copper-aluminum-iron-manganese high-temperature shape memory alloy and preparation method thereof

The invention relates to a copper-aluminum-iron-manganese high-temperature shape memory alloy and a preparation method thereof. The invention relates to a high-temperature shape memory alloy. The invention provides a copper-aluminum-iron-manganese high-temperature shape memory alloy with high martensitic phase-transformation temperature, stable extra-large shape memory effect and excellent stability thereof, good plasticity, and low cost. The invention also provides a preparation method thereof. The copper-aluminum-iron-manganese high-temperature shape memory alloy is composed of, by mass, 75- 83% of copper, 9-13% of aluminum, 3-6% of iron, and 2-9% of manganese. According to the invention, copper, aluminum, iron, and manganese raw materials are placed into a smelting furnace; the furnace is vacuumed, and argon is filled in; smelting is carried out under an argon atmosphere, such that a copper-aluminum-iron-manganese high-temperature shape memory ingot is obtained; the obtained copper-aluminum-iron-manganese high-temperature shape memory ingot cut into a sample; the obtained copper-aluminum-iron-manganese high-temperature shape memory ingot sample is subjected to a heat treatment, and is subjected to ice-water quenching, such that the copper-aluminum-iron-manganese high-temperature shape memory alloy is obtained.

Owner:XIAMEN UNIV

Preparation method of intelligent temperature control color changing vanadium oxide film

InactiveCN103695874ALower phase transition temperatureHigh chemical activityLiquid/solution decomposition chemical coatingTemperature controlColor changes

The invention relates to a preparation method of an intelligent temperature control color changing vanadium oxide film, which is characterized by comprising the following steps: (1) preparing tungstenic sol; (2) preparing sol comprising vanadium ions; (3) preparing tungsten-doped vanadium oxide sol, i.e. adding the tungstenic sol obtained in the step (1) into the sol comprising vanadium ions, which is obtained in the step (2), so as to obtain the tungsten-doped vanadium oxide sol; and (4) preparing a tungsten-doped vanadium oxide film, i.e. plating the tungsten-doped vanadium oxide sol obtained in the step (3) on the surface of a washed substrate and then carrying out annealing processing in the inert atmosphere or under the vacuum condition so as to obtain the tungsten-doped vanadium oxide film with an intelligent temperature control color changing function. The method disclosed by the invention has low energy consumption, adopts a simple preparation process, has high safety and has wide application prospect in the field of photoelectronic functional materials.

Owner:WUHAN UNIV OF TECH

Low-temperature composite phase change cold storage agent and preparation method thereof

InactiveCN104232025ALower phase transition temperatureLarge latent heat value of phase changeHeat-exchange elementsGlycerolMagnetic stirrer

The invention discloses low-temperature composite phase change cold storage agent and a preparation method thereof. The low-temperature composite phase change cold storage agent is composed of 15-16.5% of sodium chloride, 12.5% of glycerol and rest of water by weight. The preparation method for the low-temperature composite phase change cold storage agent includes steps that S1, preparing 20-22% of sodium chloride solution according to the mass percent; S2, preparing 50% of glycerol according to the mass percent; S3, pouring the solution of the S1 and the solution of the S2 into a vessel according to the ratio of 3: 1 to mix, and using a magnetic stirrer to stir uniformly. The low-temperature composite phase change cold storage agent is low in phase change temperature, large in phase change latent heat, easy to prepare, low in cost, low in use concentration, small in volume change in the phase change process, safe to use, non-toxic, odorless, pollution free, and small in corrosivity.

Owner:GUANGZHOU UNIVERSITY

Preparing method for polyethylene glycol/nano-silicon dioxide composite phase change material

InactiveCN106554754AImprove thermal conductivityLower phase change enthalpyHeat-exchange elementsPhase change enthalpyEnd-group

The invention provides a preparing method for a polyethylene glycol / nano-silicon dioxide composite phase change material. Firstly, polyethylene glycol and a silane coupling agent are subjected to the reaction, prepolymer with a siloxane end group is generated; after the prepolymer and ethyl orthosilicate are mixed uniformly, the PEG-SiO2 sol system is prepared through the acid catalysis hydrolysis-condensation reaction, gel is obtained through volatilization of a solvent, and the polyethylene glycol / nano-silicon dioxide composite phase change material is obtained through drying. By means of the polyethylene glycol / nano-silicon dioxide composite phase change material prepared through the method, the heat conductivity of a compound system can be greatly improved, and the phase change enthalpy and the phase change temperature are obviously reduced.

Owner:李博琪

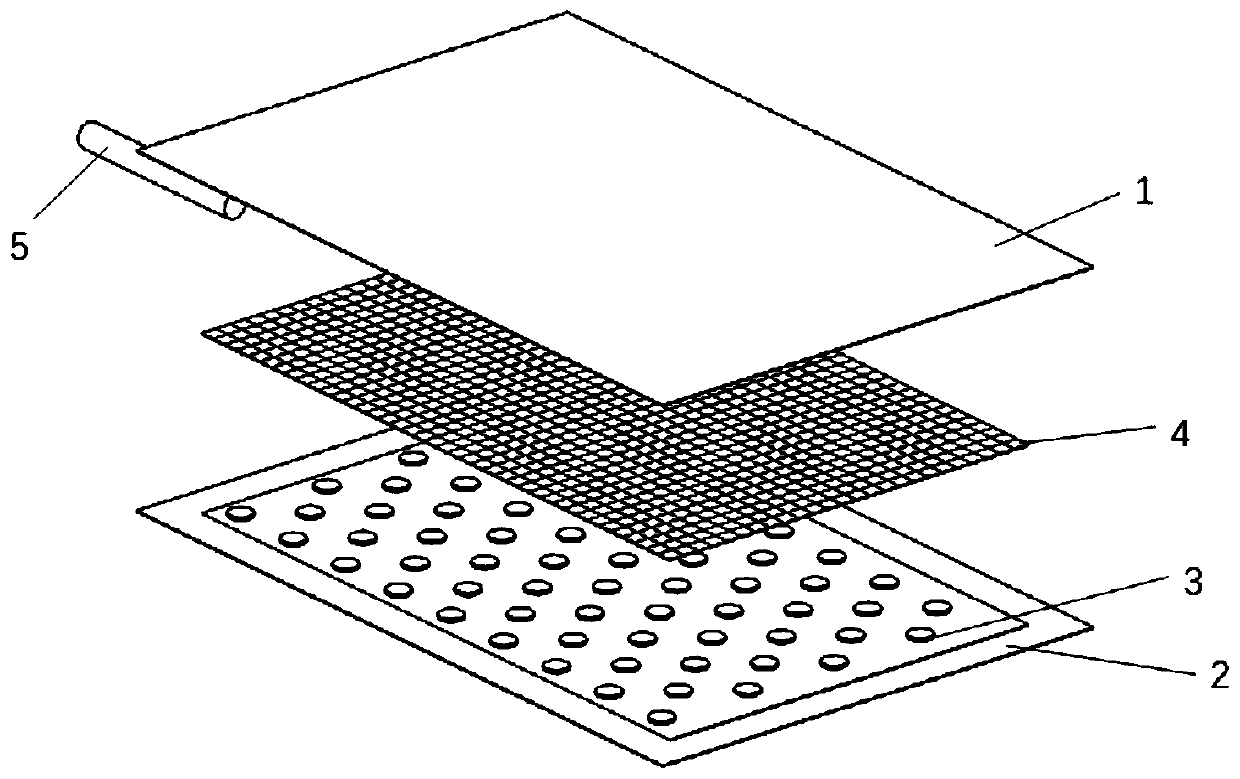

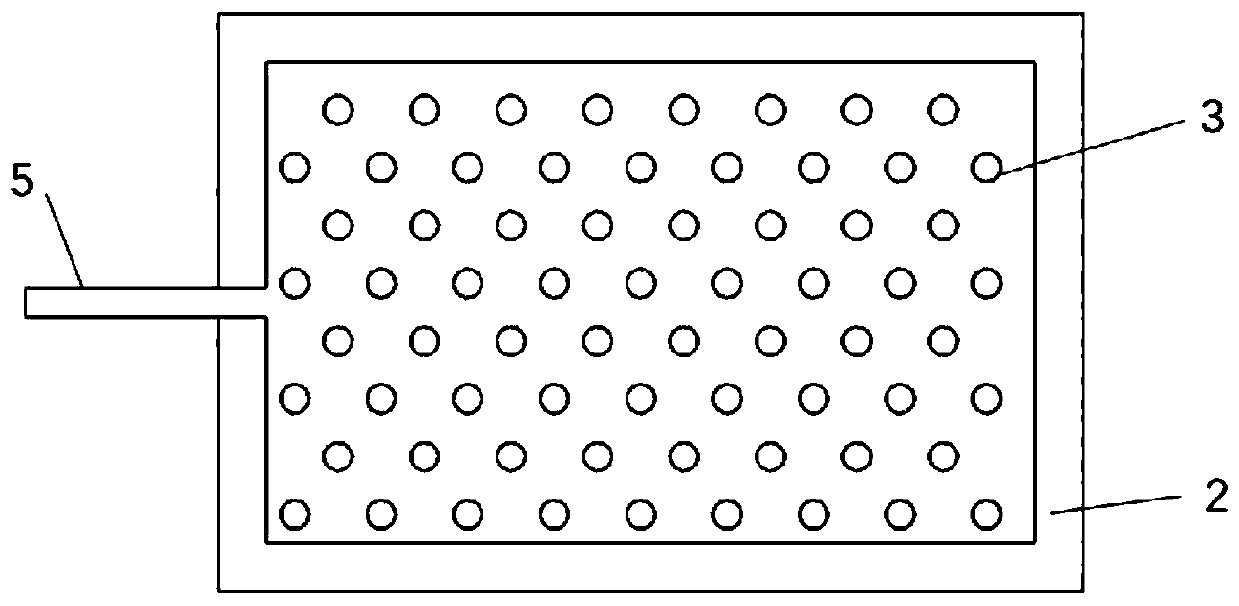

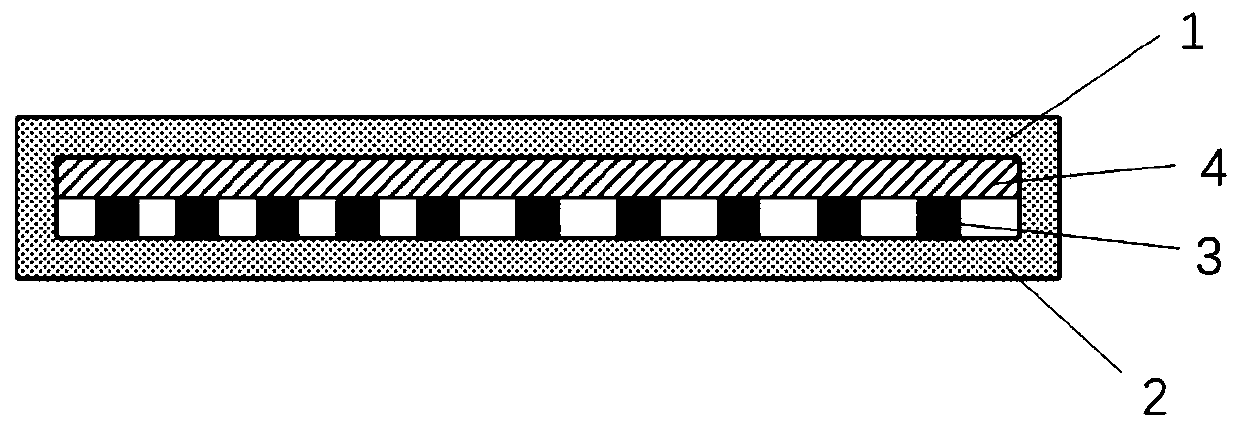

Ultrathin flexible flat-plate heat pipe

PendingCN110425918AHigh thermal conductivityImprove thermal conductivityIndirect heat exchangersCopper wirePliability

The invention discloses an ultrathin flexible flat-plate heat pipe. The flat-plate heat pipe comprises an upper flexible composite cover plate, a lower flexible composite cover plate, a flexible red copper wire mesh and a supporting column structure growing on the lower flexible cover plate; each of the upper cover plate and the lower cover plate is formed by three layers of materials, the middlelayer is provided with a high-thermal-conductivity flexible graphite film, and ultra-thin copper foil layers are obtained on the two sides of the flexible graphite film through physical vapor deposition / electrolytic deposition; a closed cavity is formed between the cover plates through edge sealing, and the sealed cavity after vacuumizing is filled with working liquid; and circular micro-columnsformed on the inner side of the lower flexible cover plate through electrolytic deposition / 3D printing / mold extrusion form flexible flat-plate heat pipe supporting columns. The flexible red copper wire mesh subjected to hot pressing sintering on the upper flexible cover plate serves as a capillary core structure of the heat pipe. The ultrathin flexible flat-plate heat pipe has the advantages ofbeing small in size, light in weight, high in heat conductivity and good in flexibility, so that the surface adaptability is strong.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com