Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1058results about How to "High carbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge-based activated carbon and preparation method thereof

The invention relates to a sludge-based activated carbon and a preparation method thereof. In the invention, according to composition of sludge, a certain amount of biomass material (such as corn straw, wheat straw, peanut shell and the like) is appropriately added, mixing to be uniform is carried out, and carbon content of agricultural waste such as crop straw, peanut shell and the like is relatively higher, thus adsorption capacity of the activated carbon is improved (can be improved) when the crop straw and the peanut shell are added into sludge. Activating agent with certain concentration (such as ZnCl2, KOH, KCO3 and the like) is added into the sludge which is mixed to be uniform, impregnating and activating treatment is carried out, and then high temperature activation is carried out, thus the sludge-based activated carbon can be obtained. The sludge-based activated carbon provided by the invention has the advantages of simple process, low cost, and high specific surface area; meanwhile, a way is provided for recycling sludge and treating the agricultural waste, and hazard-free treatment, reduction and reutilization on waste treatment are realized.

Owner:BEIJING UNIV OF TECH

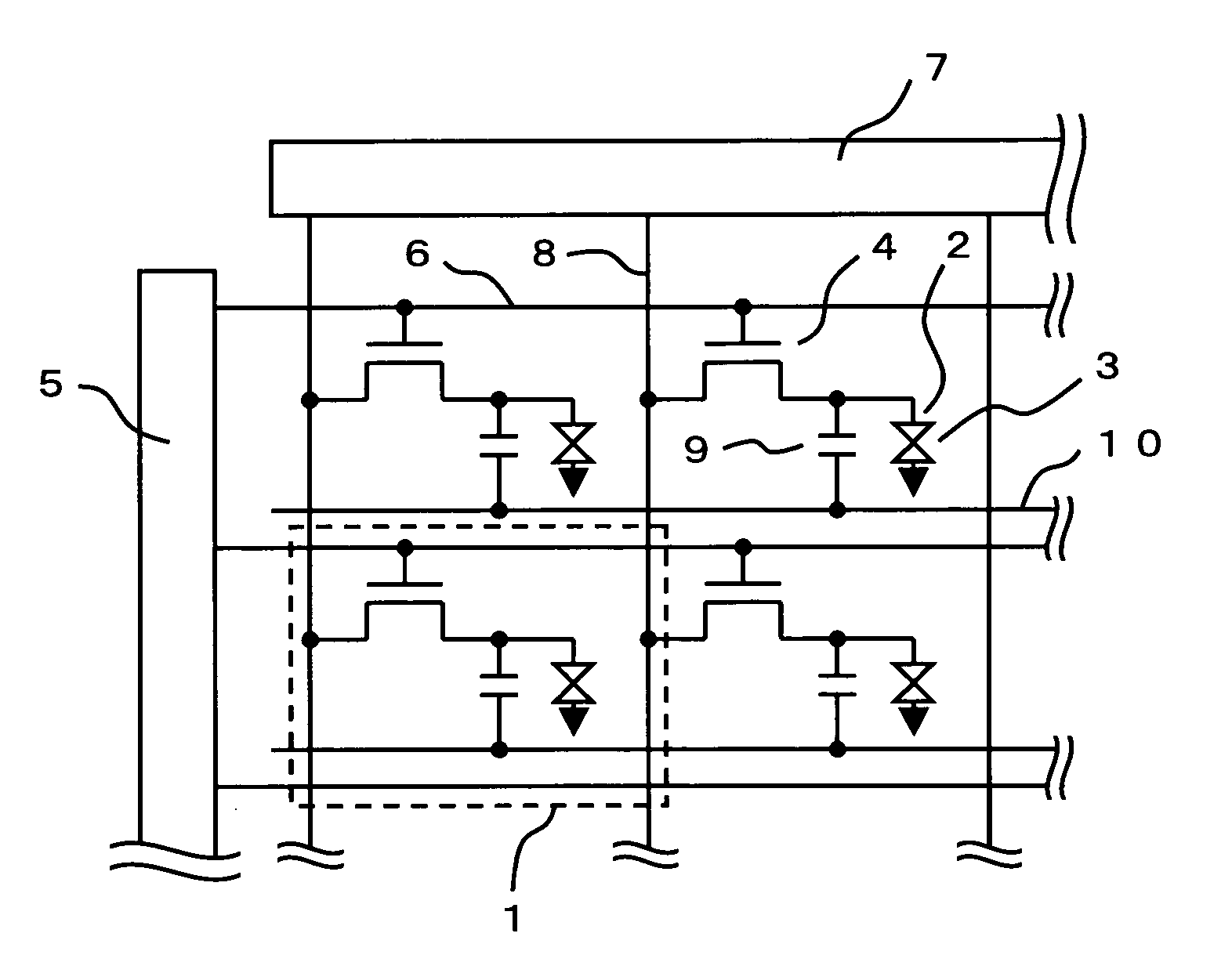

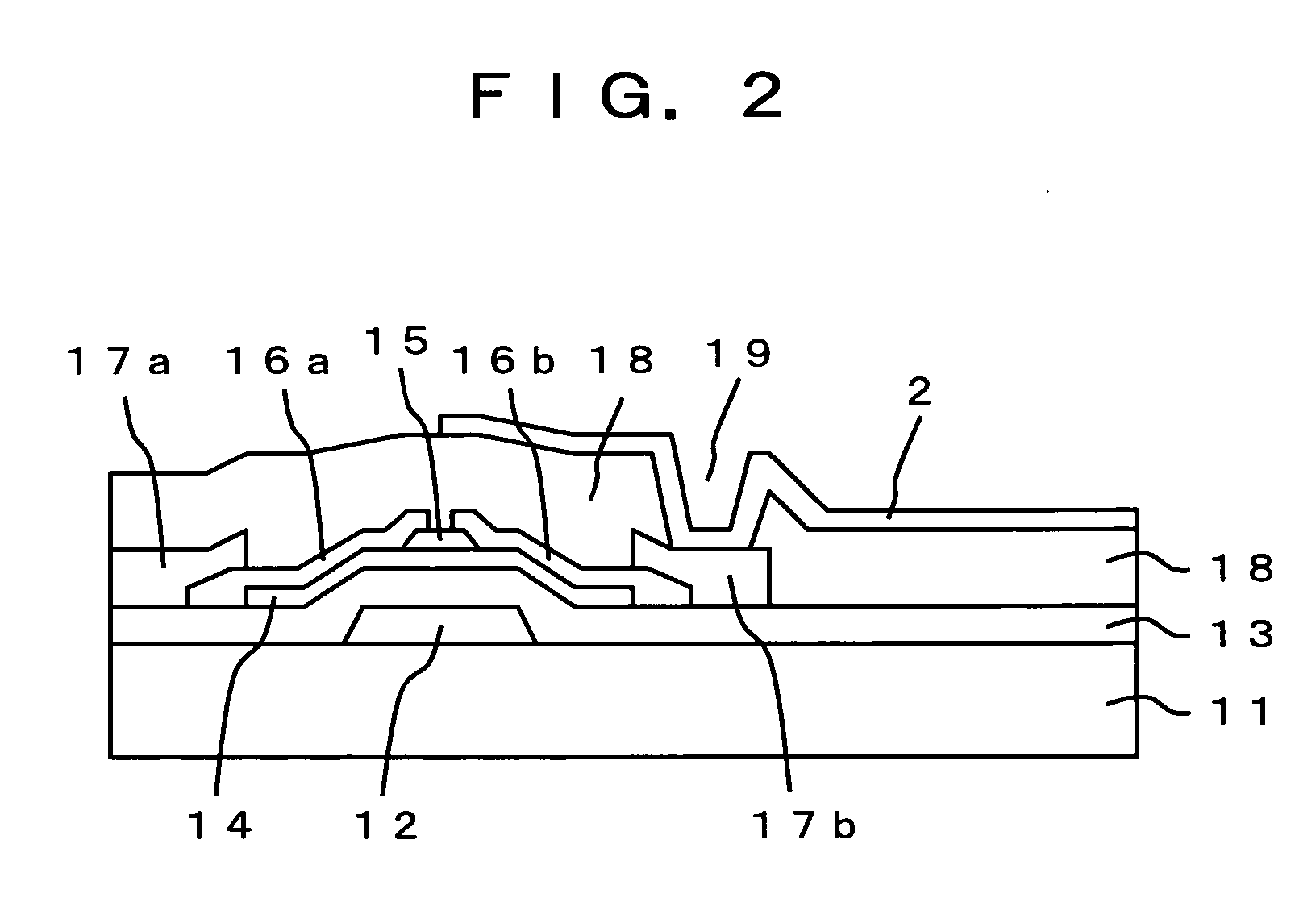

Liquid crystal display device and dielectric film usable in the liquid crystal display device

ActiveUS20070092661A1Efficient processLow dielectric constantLiquid crystal compositionsSemiconductor/solid-state device manufacturingVisibilityLiquid-crystal display

The present invention provides a liquid crystal display device with high image visibility at low power consumption and produced at low cost by using an interlayer dielectric film, which has low dielectric constant, high heat-resistant property, high optical transmissivity, high film thickness and high flattening property produced at low cost. An organic siloxane dielectric film is used as an interlayer dielectric film of the liquid crystal display device. A ratio of nitrogen content to silicon content (Ni content / Si content) in the interlayer dielectric film is controlled to 0.04 or more in the element ratio. The limiting film thickness to suppress and limit the cracking caused by the thickening of the interlayer dielectric film is set to 1.5 μm or more.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

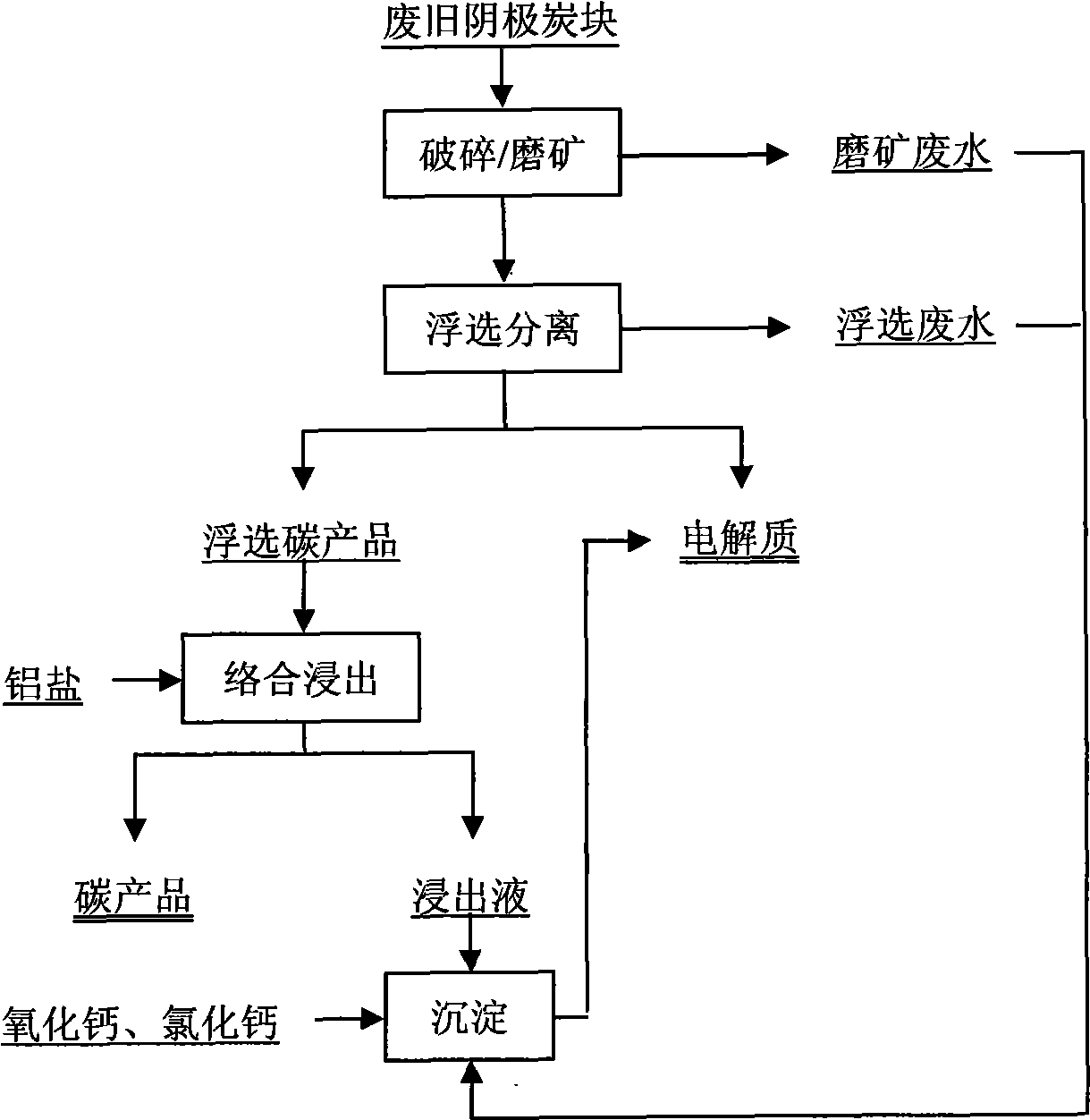

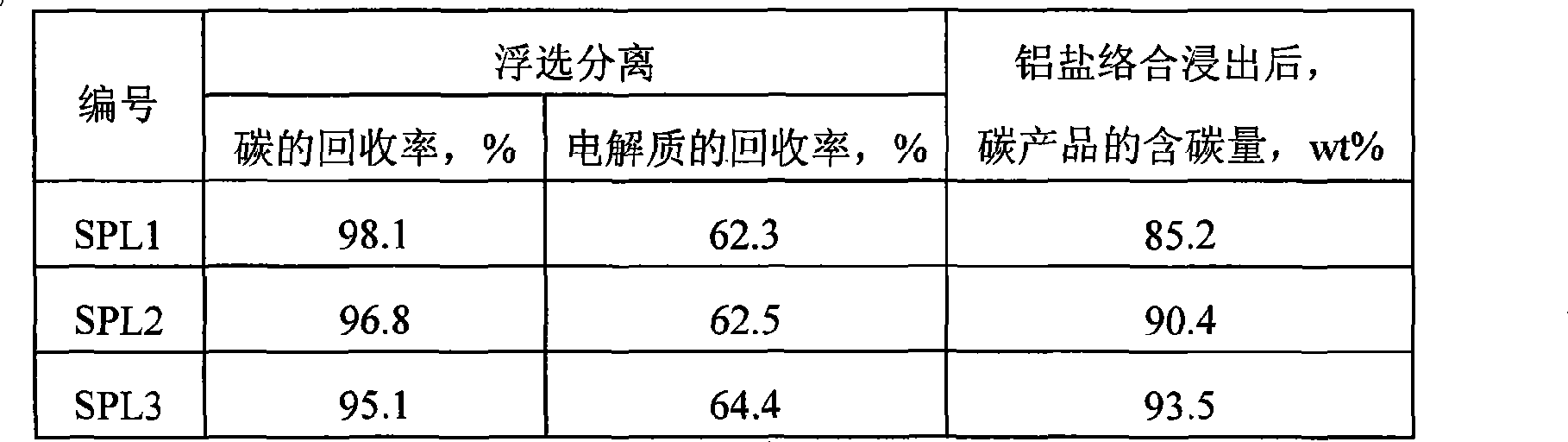

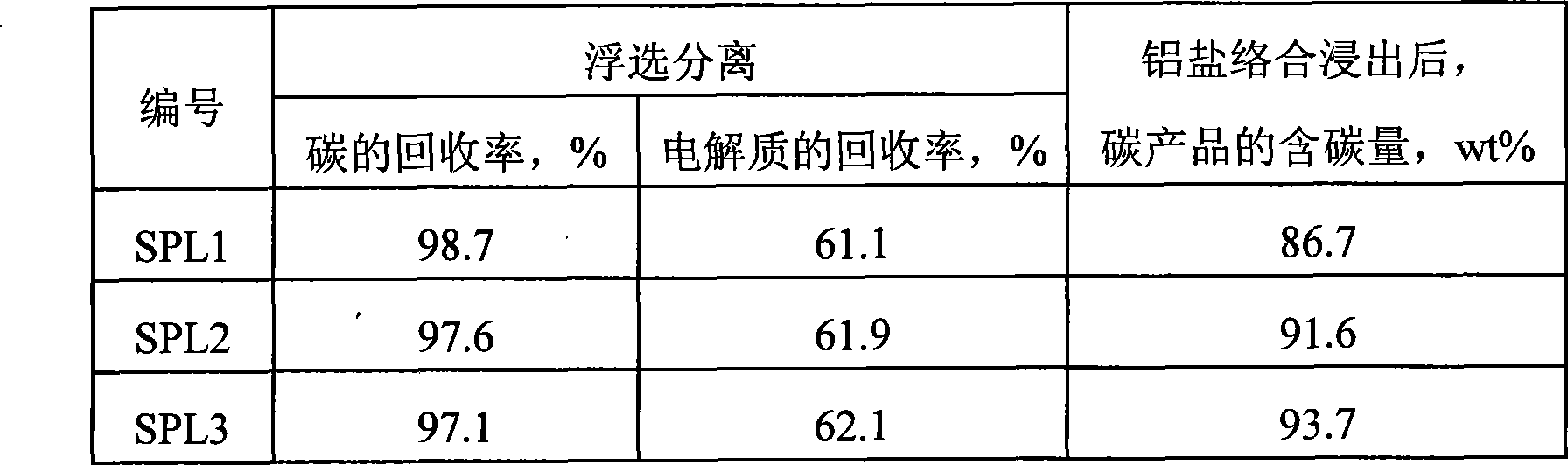

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

Method for smelting ultra-low carbon steel

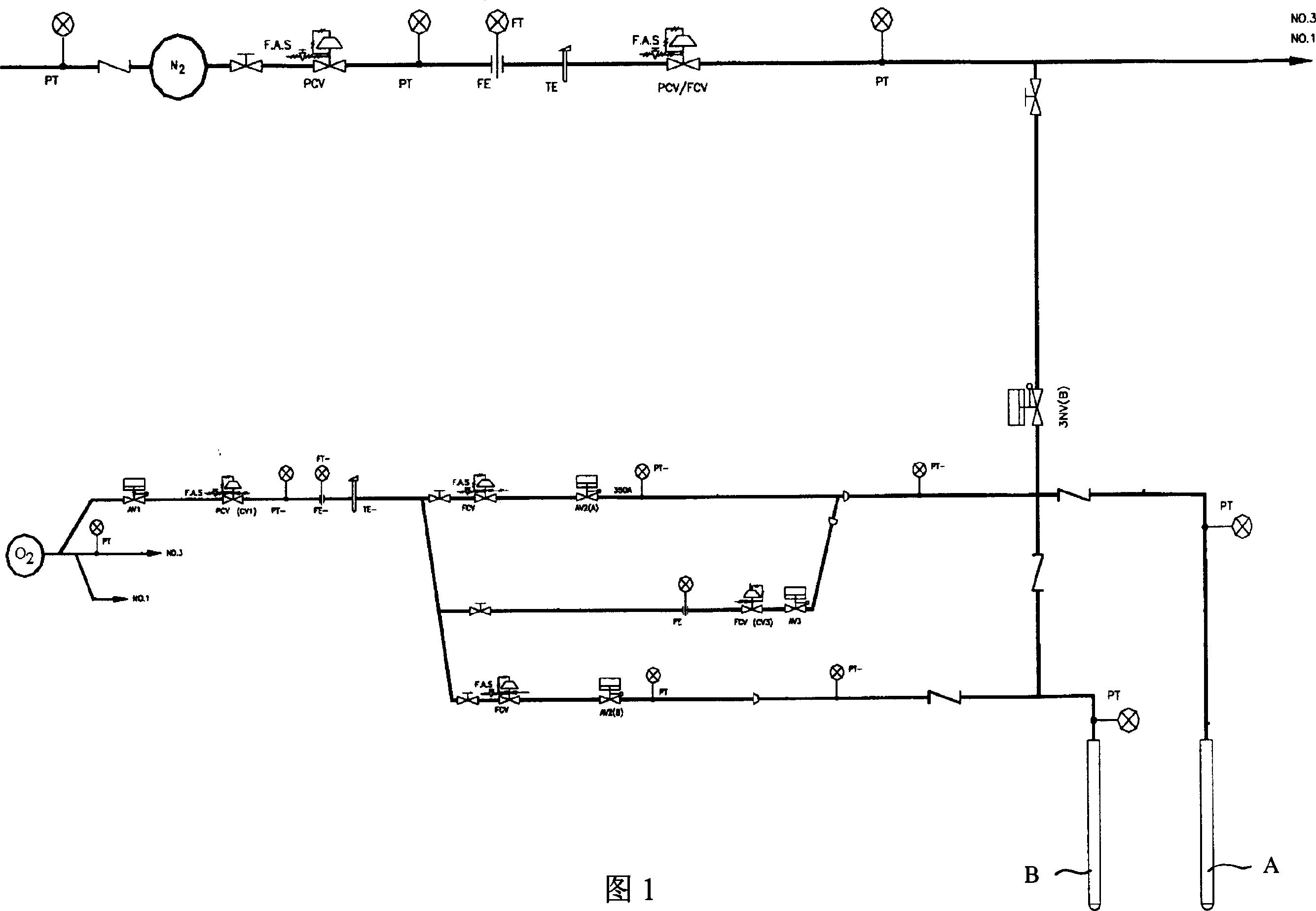

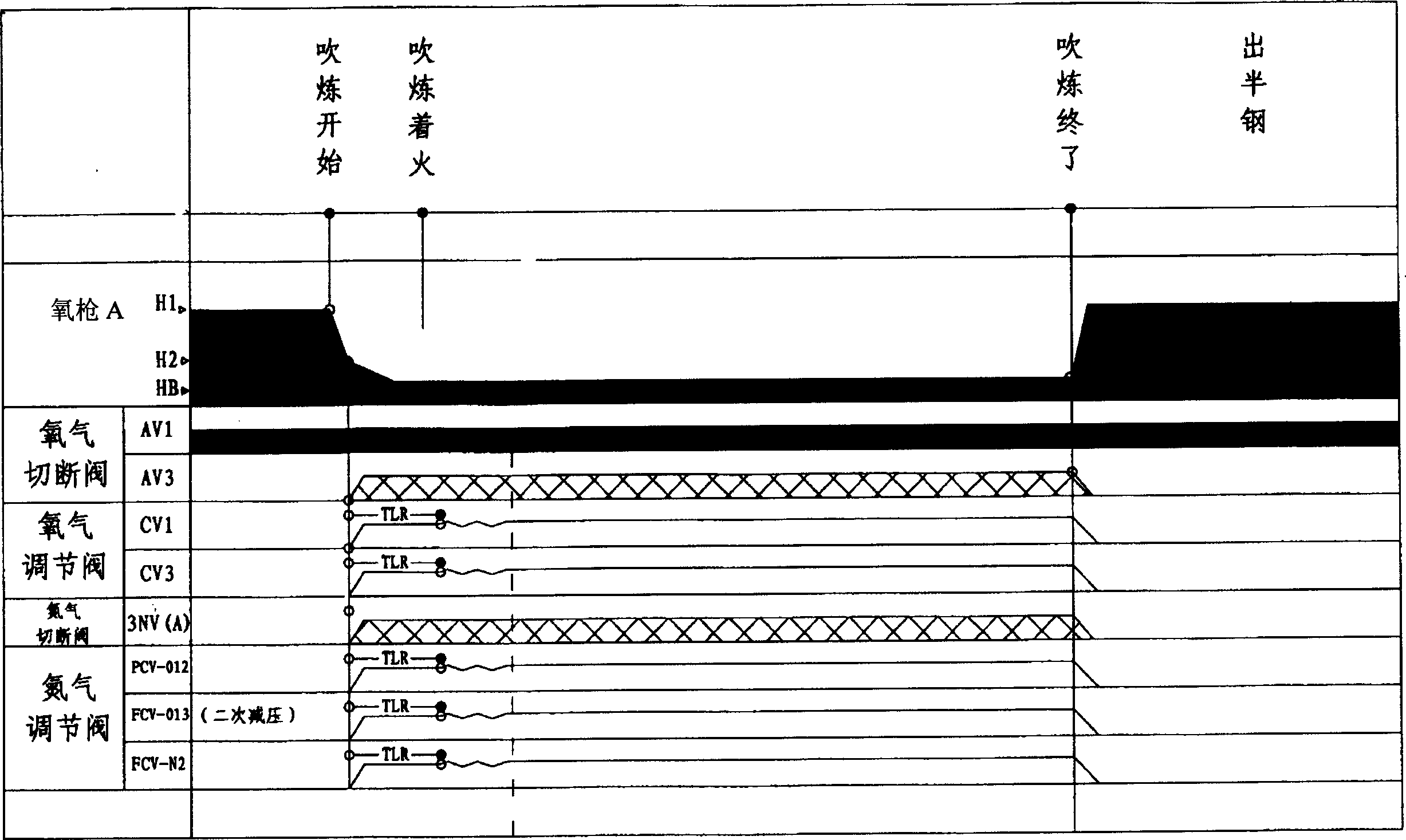

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

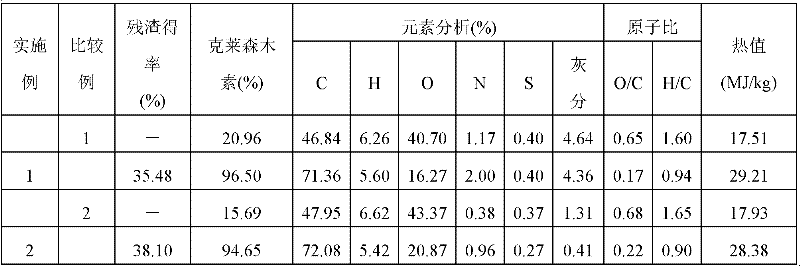

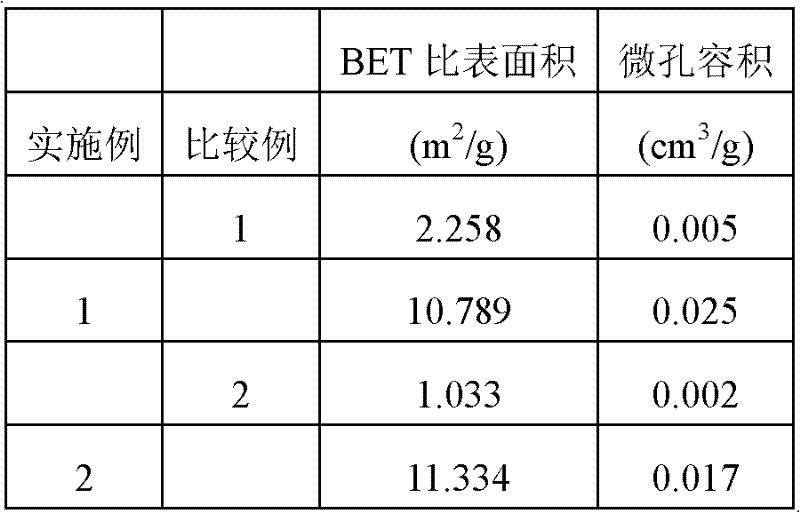

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

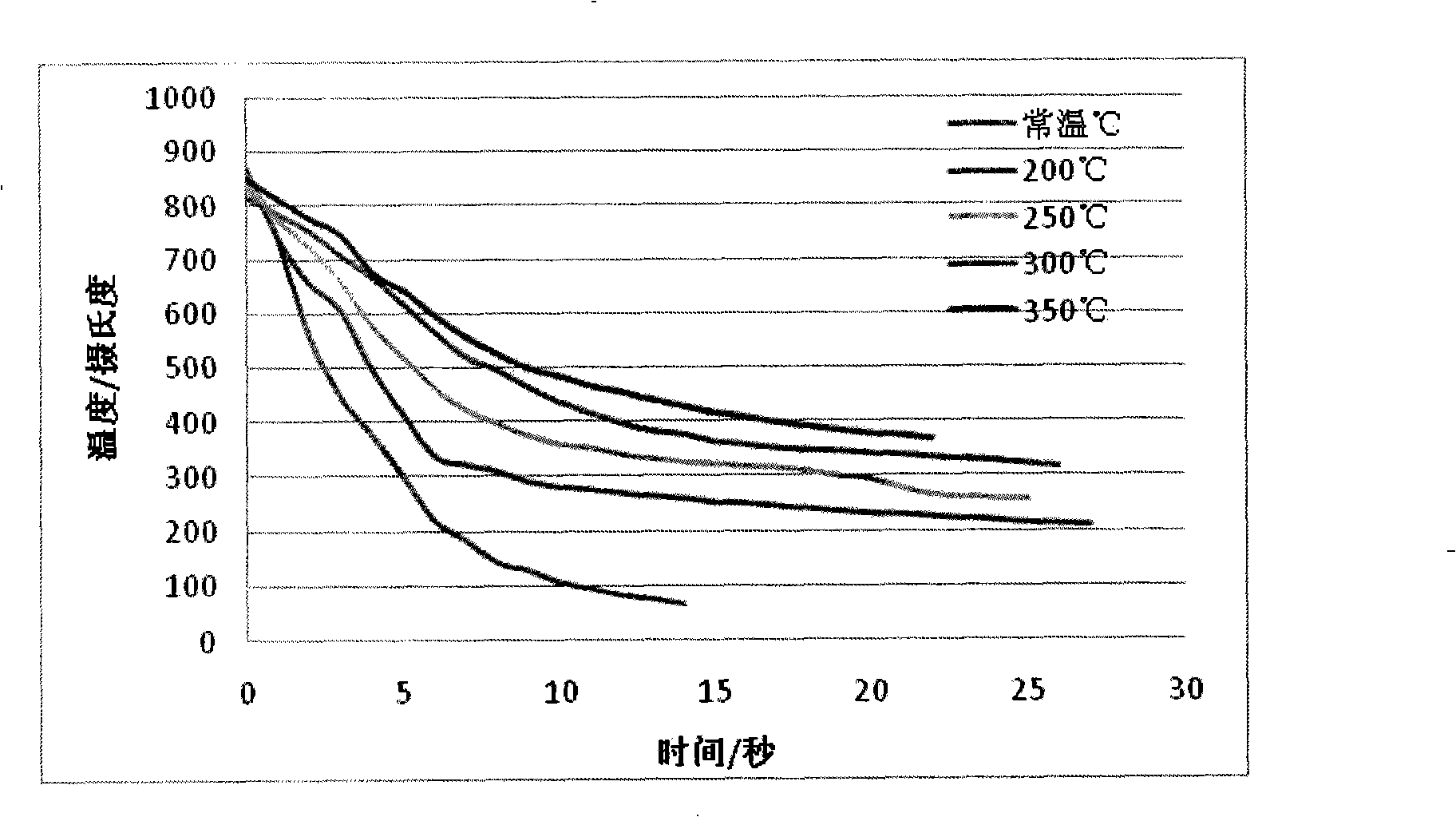

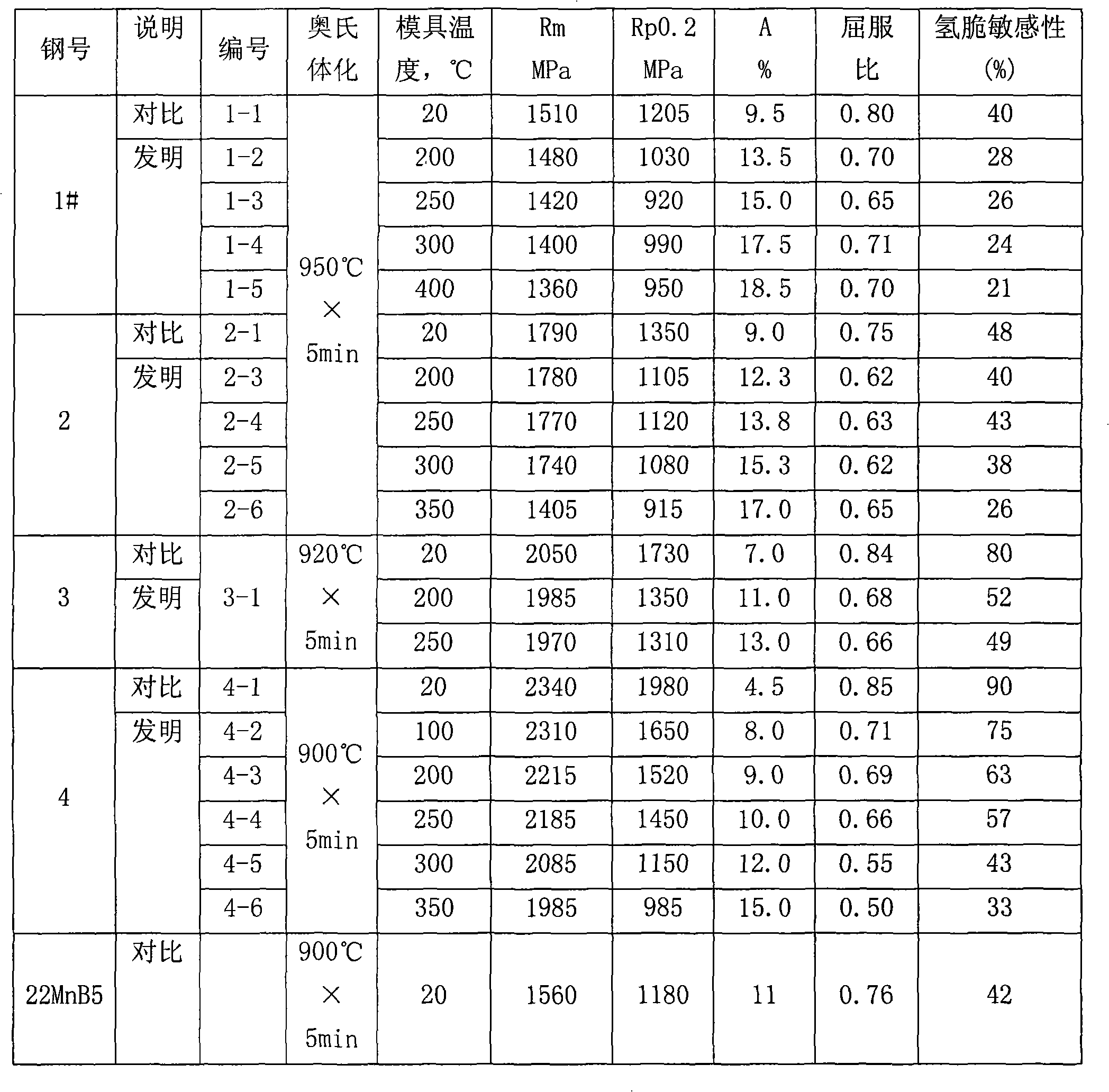

High-safe high-precision producing method of thermoforming martensitic steel parts

InactiveCN101280352AGuaranteed Hardenability RequirementsLow yield ratioShaping toolsHot stampingSheet steel

The invention provides a high security, high accuracy and thermal forming martensite steel part preparing method, which belongs to the field of obtaining controlling and cooling technology of the hot stamping forming part of the alloy steel plate, the martensite works as the matrix structure of the alloy steel plate. The method adopts the processes as follows: a steel plate is heated to 20 to 250 DEG C above the Ac3 temperature, therefore an austenite structure can be obtained, then the steel plate is transferred to the stamping die for forming by stamping; simultaneously, the temperature of the stamping die is controlled in a range of 100 to 400 DEG C, 5 to 60 seconds later after stamping forming, the formed component parts can be taken out of the stamping die. The method has the advantages that a well ductility and security can be obtained, and the anti-susceptibility of the steel can be greatly enhanced.

Owner:CENT IRON & STEEL RES INST

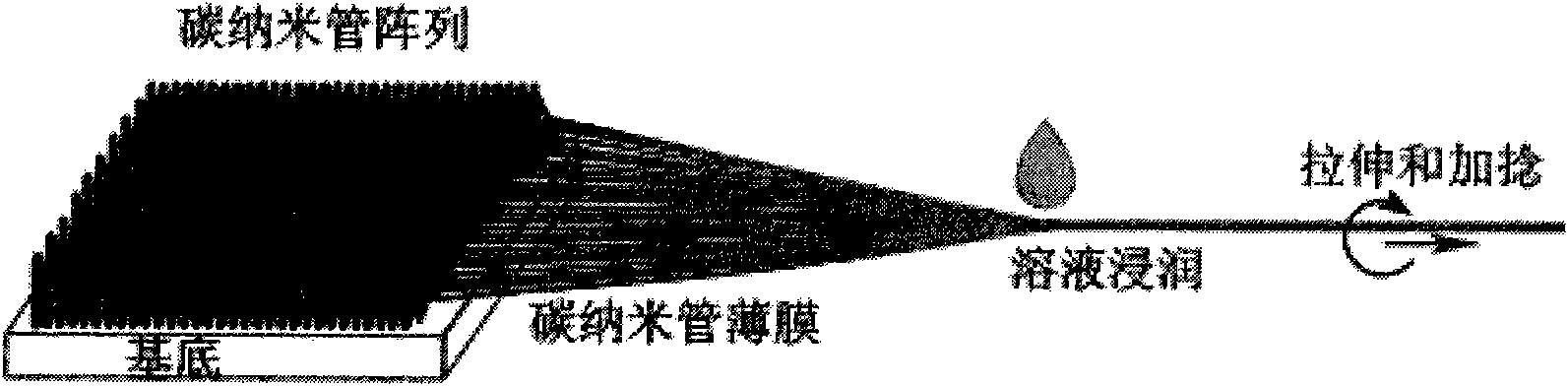

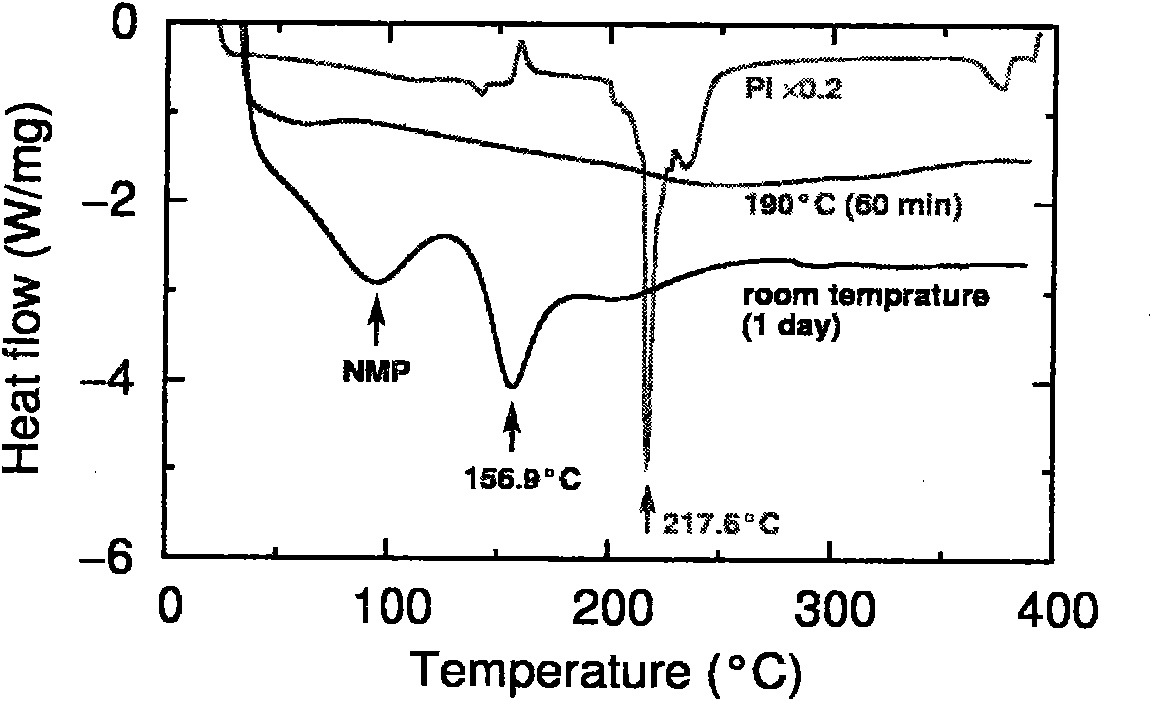

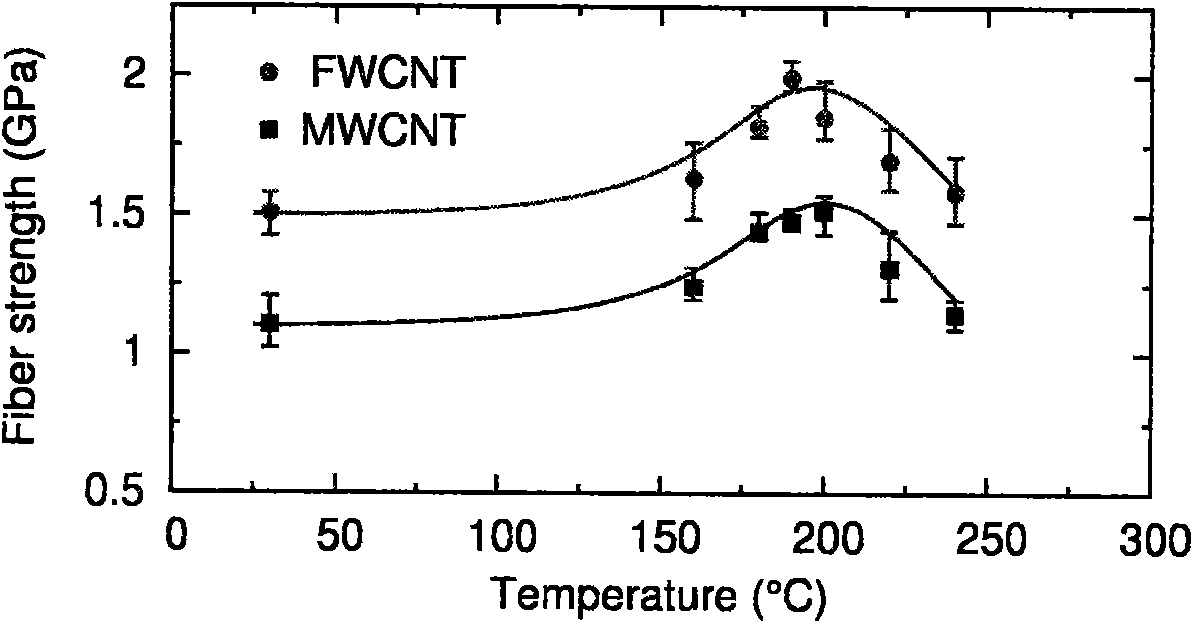

Preparation method of high-performance carbon nanotube fiber

ActiveCN101967699AExcellent mechanical propertiesReduce dosageYarnArtificial filament chemical after-treatmentYarnMechanical properties of carbon nanotubes

The invention relates to a preparation method of a high-performance carbon nanotube fiber, which comprises the following specific steps of: drawing a carbon nanotube film from a spinning carbon nanotube array; then, immersing the carbon nanotube film in a thermosetting polyamic acid / N-methyl pyrrolidone solution, and twisting to form a carbon nanotube / polyamic acid composite fiber; subsequently, curing the carbon nanotube / polyamic acid composite fiber so that polyamic acid in the composite fiber forms polyimide with a net type crosslinking structure; and finally preparing the carbon nanotube / polyimide composite fiber. The invention has the advantages of simple and easy process, low cost and easy realization of large-scale production; moreover, the prepared carbon nanotube composite fiber has excellent mechanical performance, the strength can reach 2.06 GPa, the tenacity is superior to that of carbon fiber, and the conducting property is maintained unchanged as compared with that of pure carbon nanotube fiber; meanwhile, the carbon nanotube composite fiber also has the operability of common yarn, so that the requirements on subsequent treatment processes of stretching, stranding, weaving and the like can be satisfied.

Owner:SUZHOU CREATIVE CARBON NANOTECH

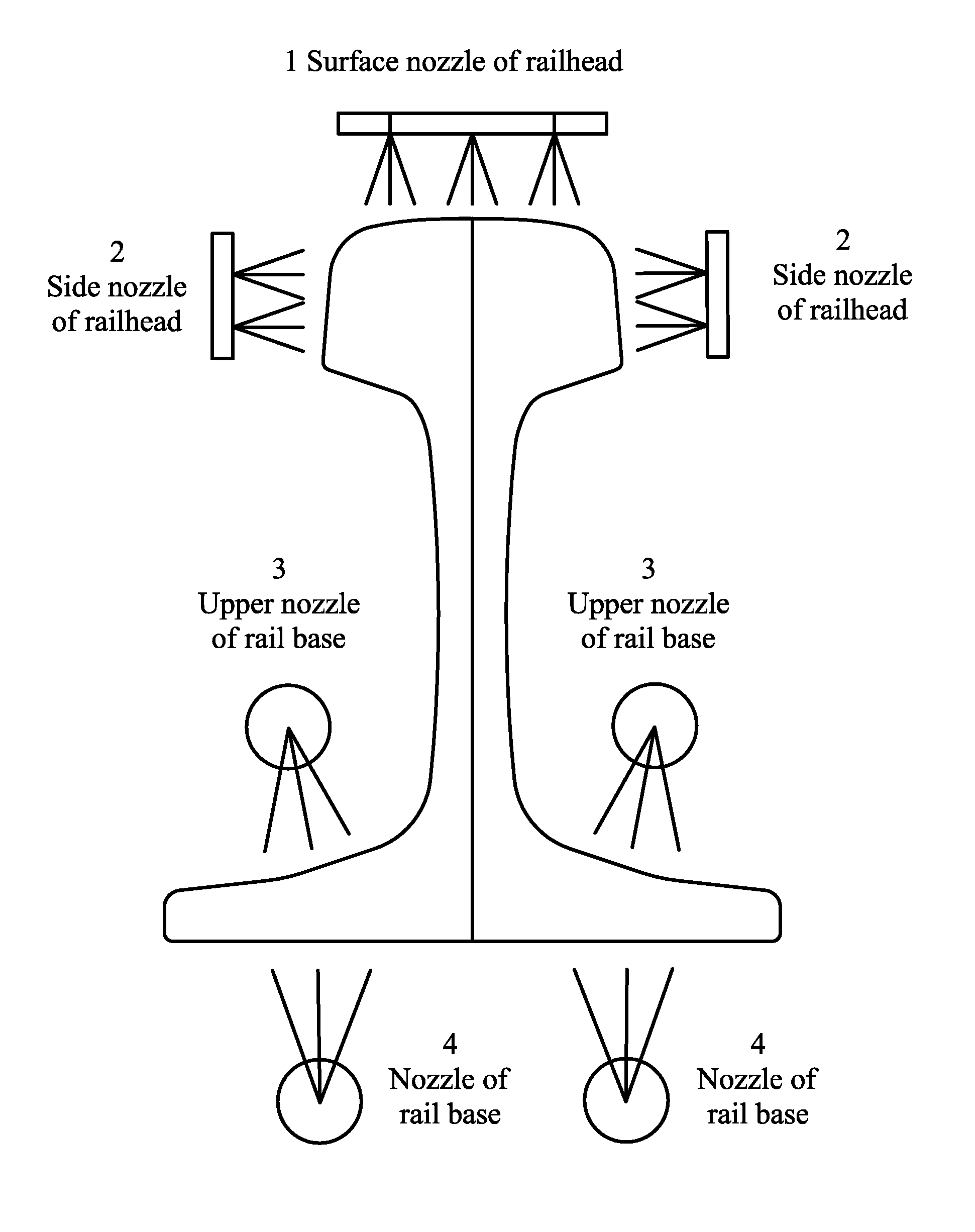

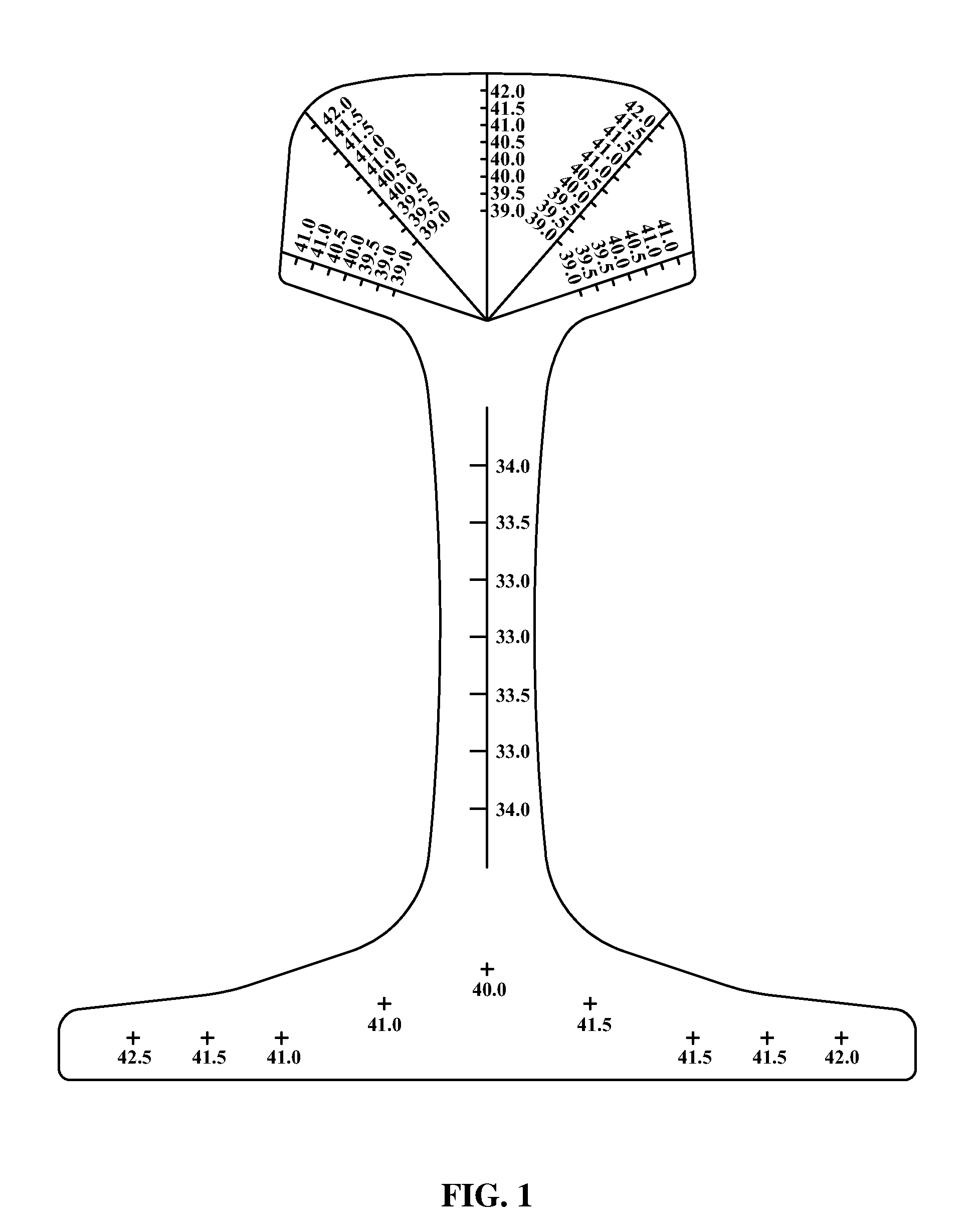

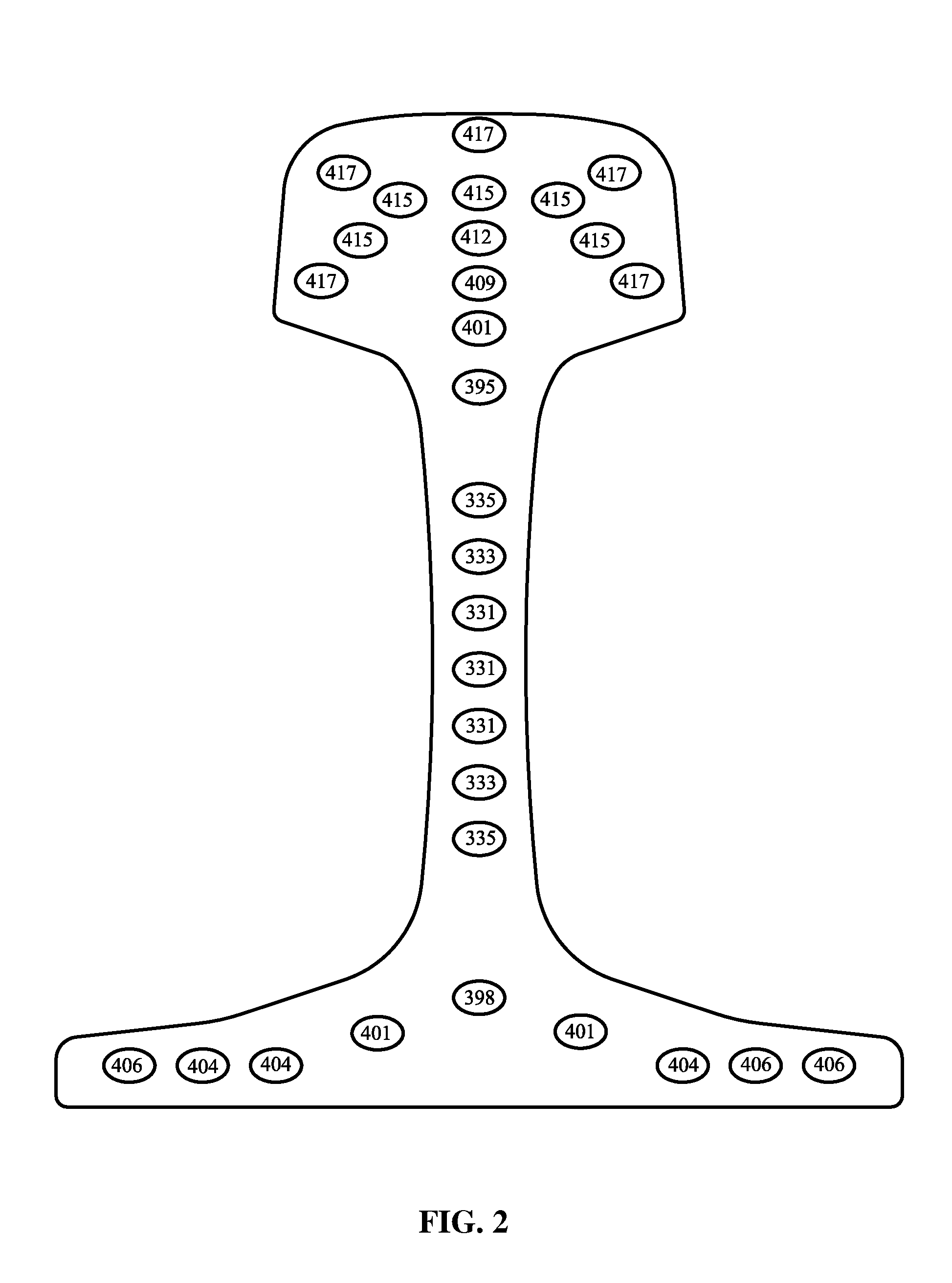

High carbon content and high strength heat-treated steel rail and method for producing the same

ActiveUS20110253268A1Excellent wear resistance and plasticityGreat potentialFurnace typesMetal rolling arrangementsAluminiumHigh intensity

A high carbon content and high strength heat-treated steel rail including by weight 0.80-1.20% carbon, 0.20-1.20% silicon, 0.20-1.60% manganese, 0.15-1.20% chromium, 0.01-0.20% vanadium, 0.002-0.050% titanium, less than or equal to 0.030% phosphorus, less than or equal to 0.030% sulfur, less than or equal to 0.010% aluminum, less than or equal to 0.0100% nitrogen, and iron. The steel rail has excellent wear resistance and plasticity and can satisfy the requirement for overloading. A method for producing the steal rail by heating a slab to a heating temperature, multi-pass rolling, and accelerated cooling, wherein a maximum heating temperature (° C.) of said slab is equal to 1,400 minus 100[% C], [% C] representing the carbon content (wt. %) of said slab multiplied by 100.

Owner:PANZHIHUA IRON AND STEEL +2

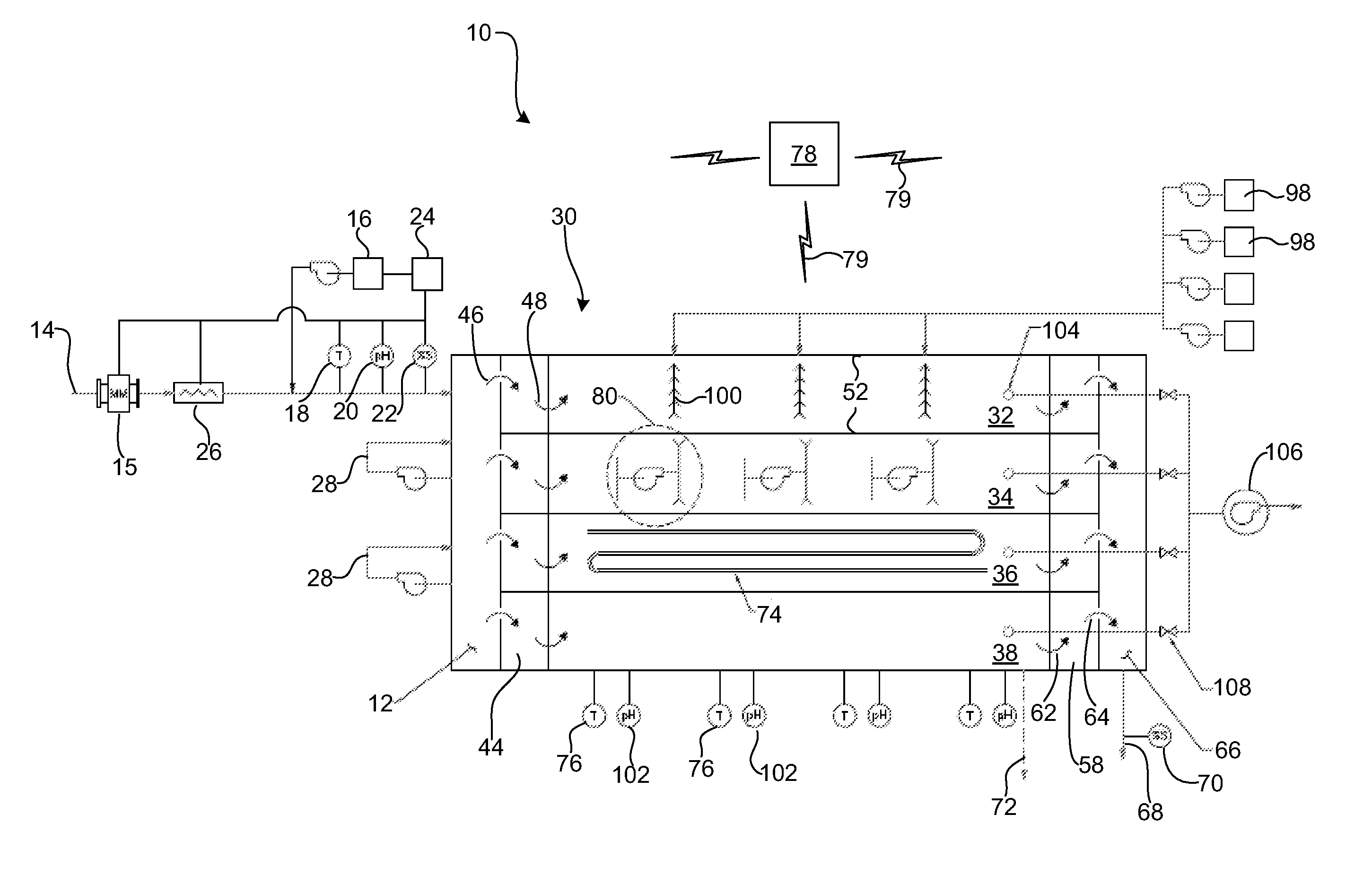

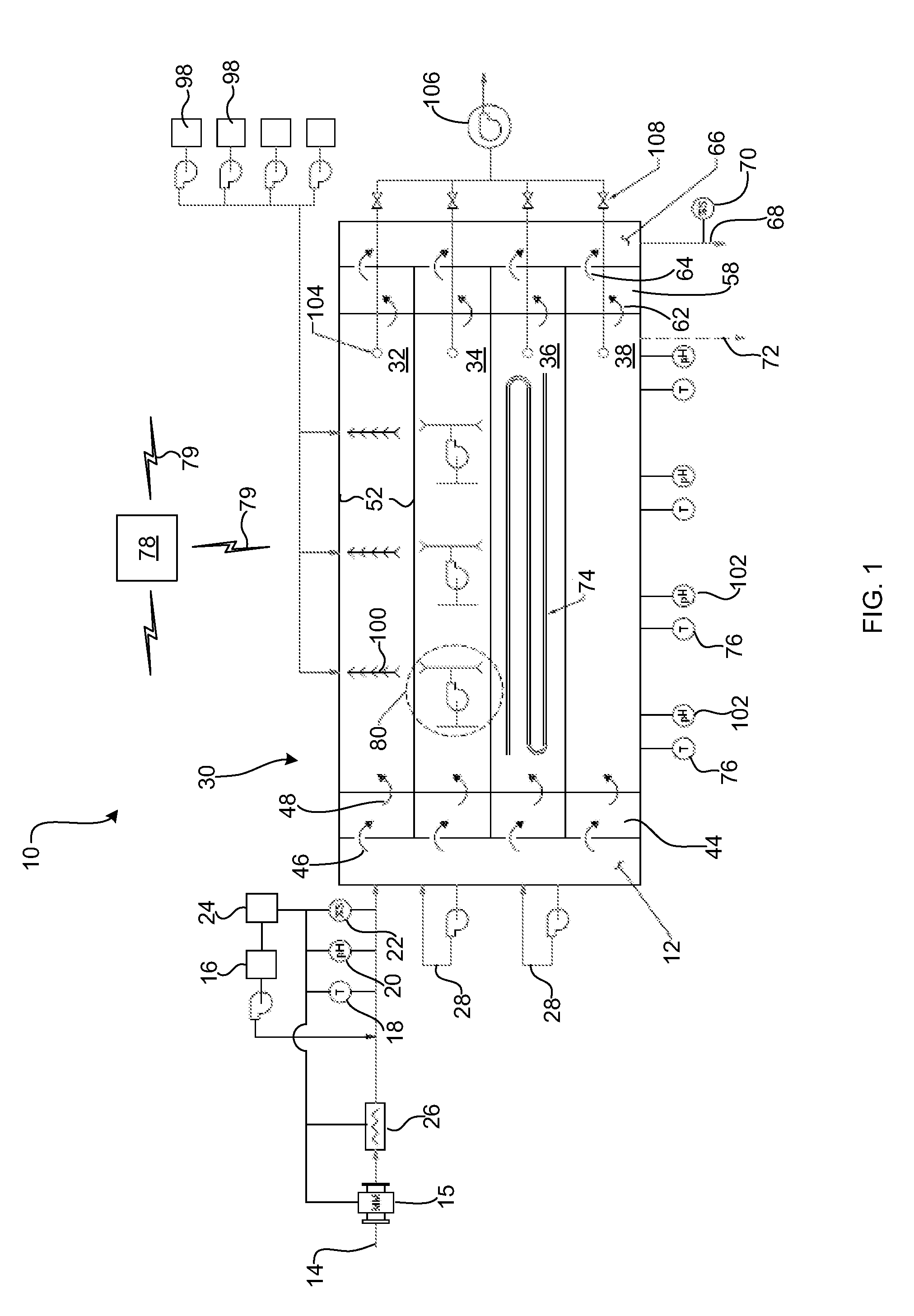

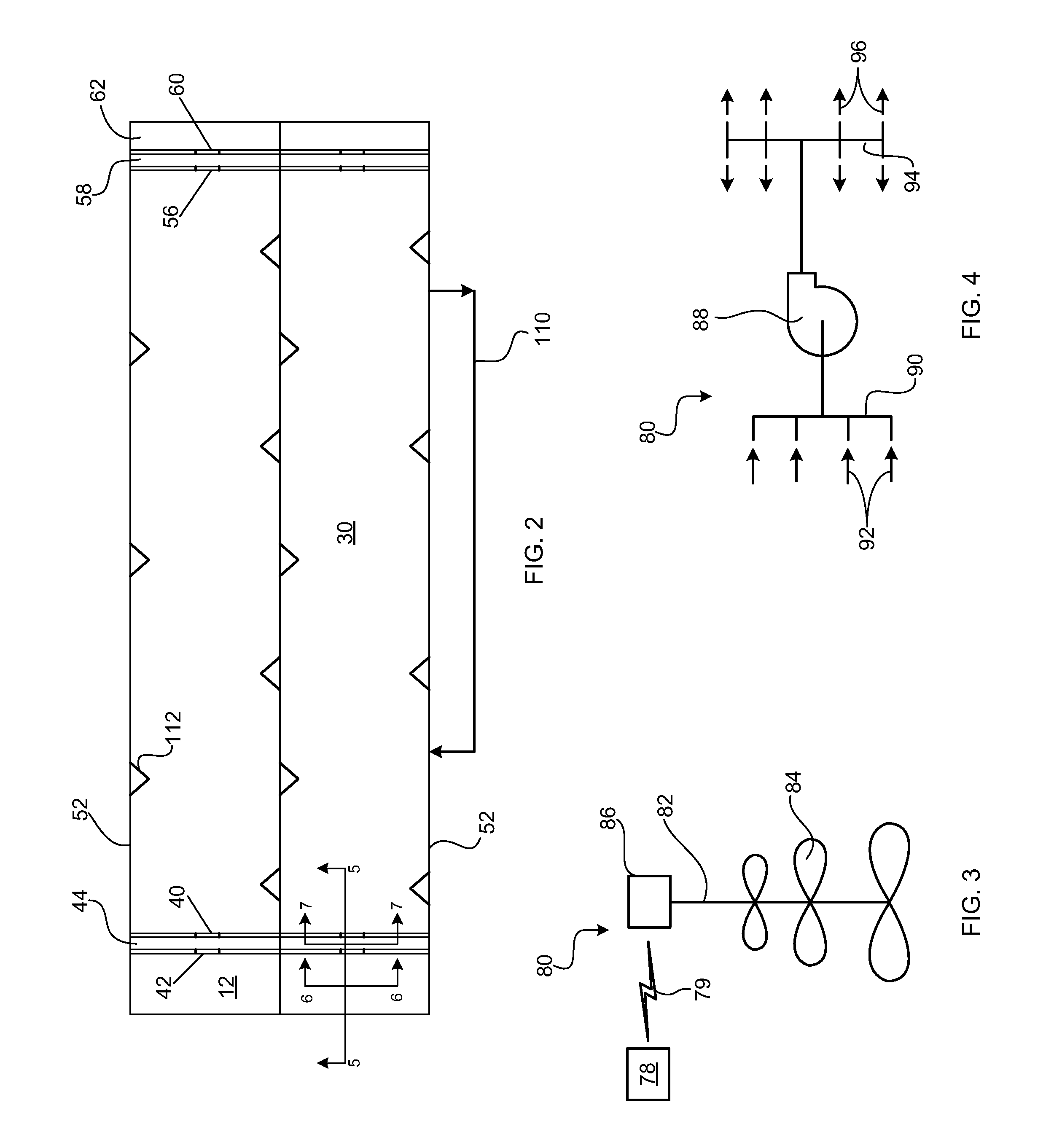

Anaerobic digester design and operation

ActiveUS20100032370A1High carbon contentHigh nitrogen contentBiological substance pretreatmentsIon-exchanger regenerationControl systemDigestion Treatment

An apparatus for the anaerobic digestion of solid waste is disclosed. The apparatus includes a pre-digestion treatment chamber and an anaerobic digester chamber coupled to the pre-digestion treatment chamber. A liquid suspension of solid waste is pretreated under aerobic conditions by heating to a desired pre-digestion temperature. One or more chemical or biological additives are added to the suspension of solid waste to improve the anaerobic digestibility of the solid waste. This may include enzymes to destruct poorly digestible solids and / or materials to provide a desired C:N ratio in the solid waste. The apparatus may include mixers, heaters, chemical or biological additives as needed, various sensors and probes, and a control system to monitor and control the anaerobic digestion process and maintain microbial health of the digester.

Owner:WATER SOLUTIONS TECH LLC

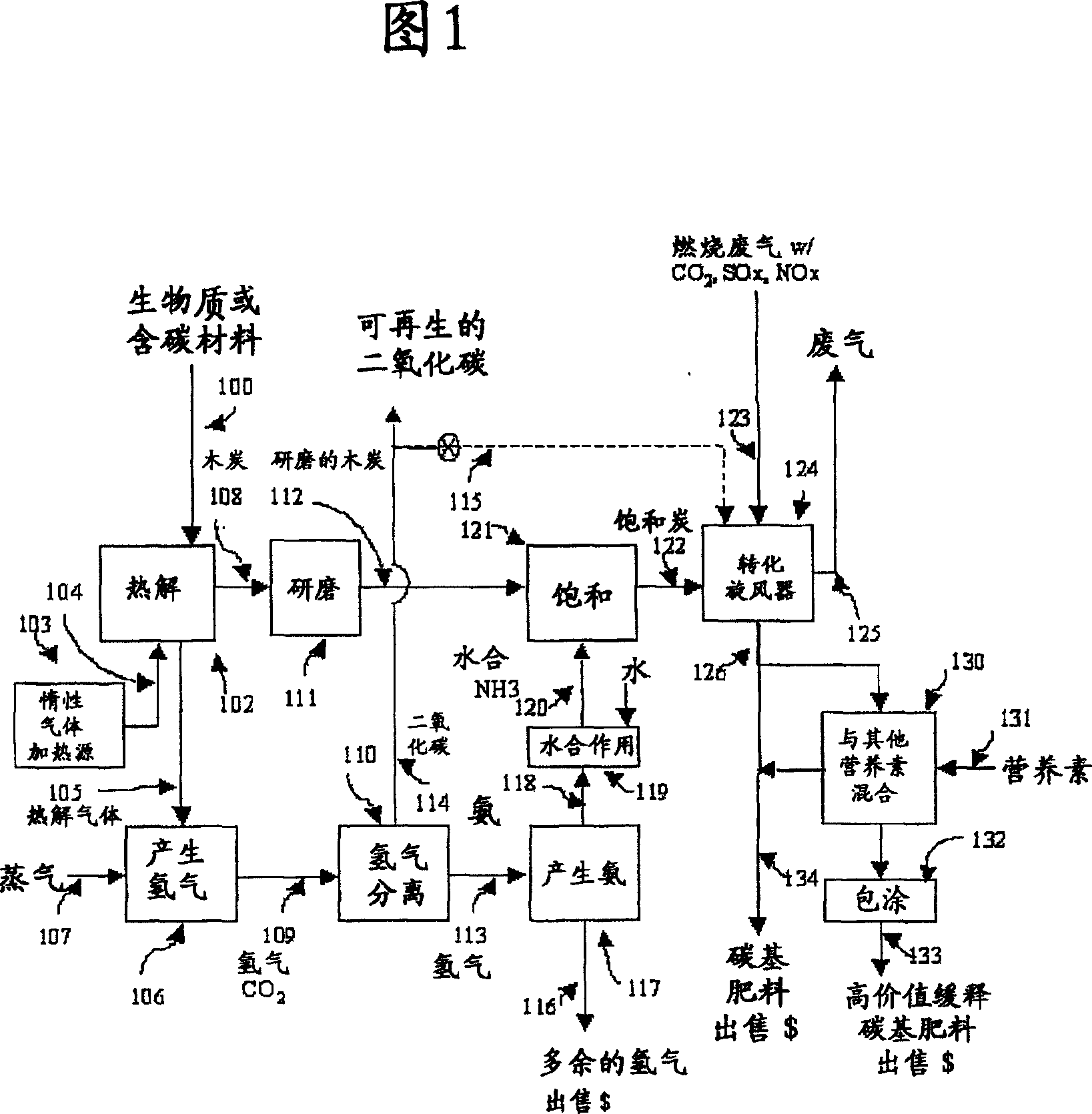

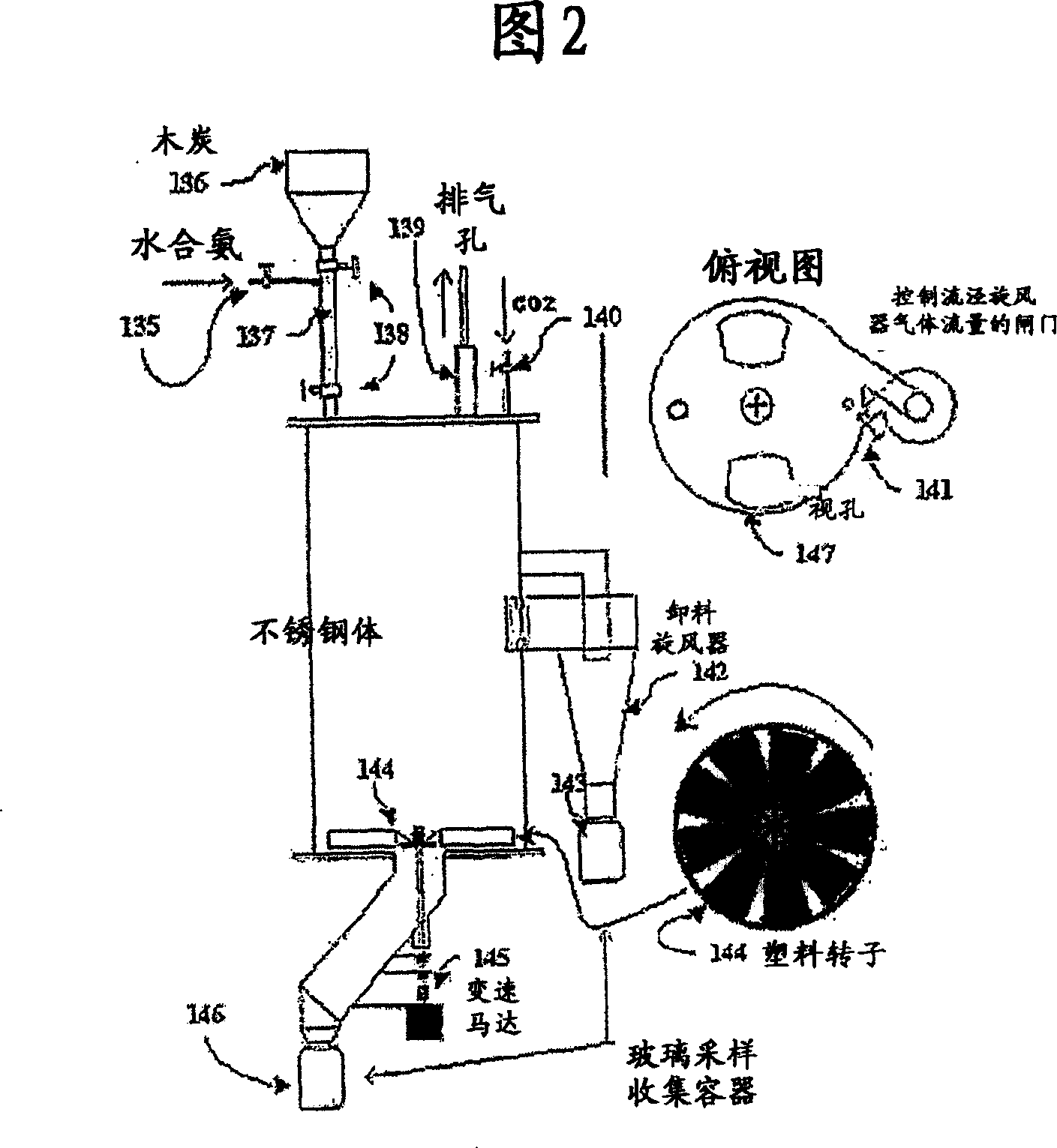

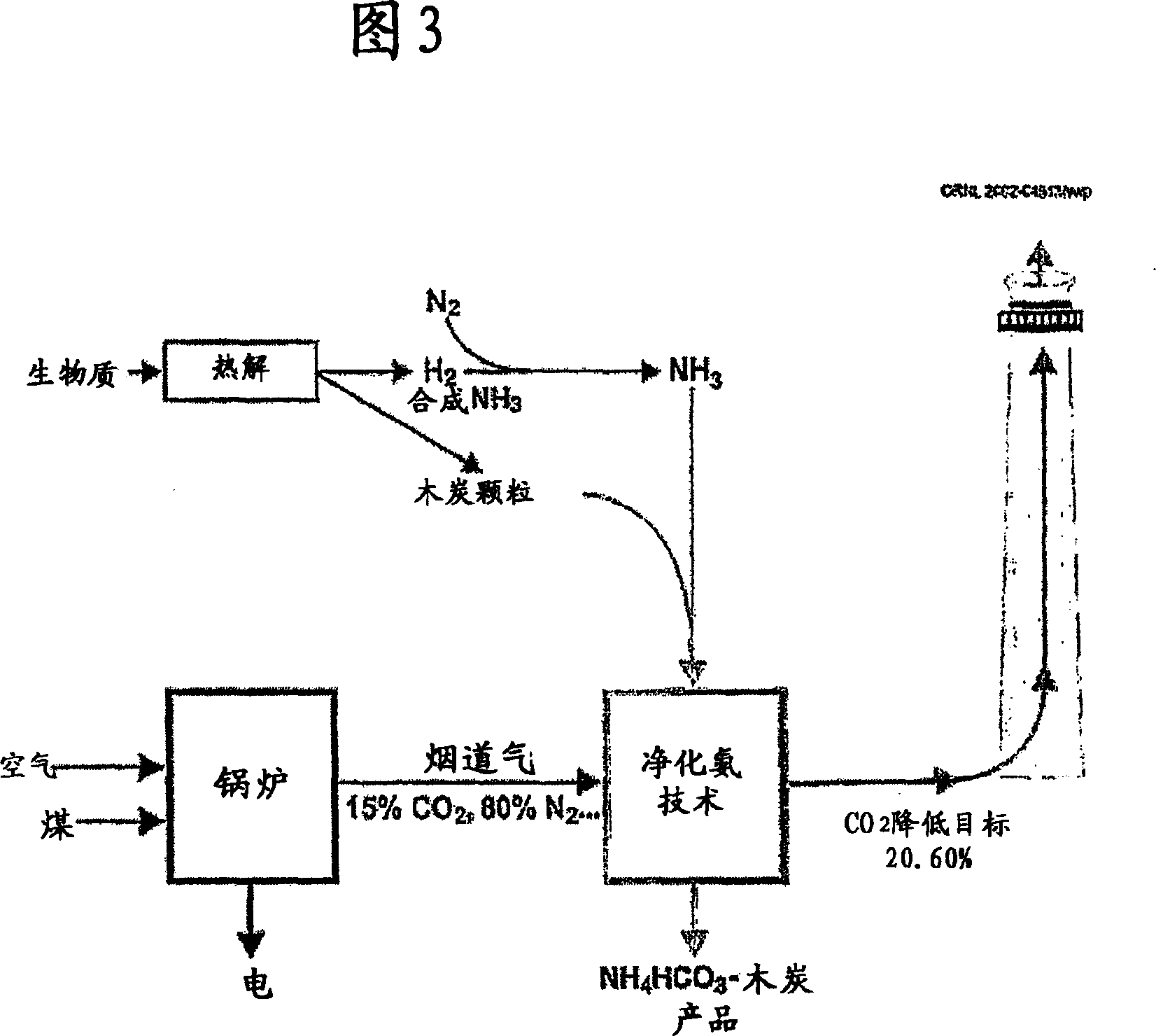

Production and use of a soil amendment made by the combined production of hydrogen, sequestered carbon and utilizing off gases containing carbon dioxide

InactiveCN1997590AHigh carbon contentReduce churn rateNitrous oxide captureMethane captureBiofuelCo product

This invention relates a series of steps to provide an economical production of a carbon based fertilizer and soil amendment made during the capture of greenhouse gases from the combustion of fossil and non fossil fuels. The invention uses biomass and other carbonaceous sources through pyrolytic conversion to gases and charcoal, to allow for the further production of co-products, such as hydrogen and ammonia. The invention also relates to the combination of hydrated ammonia, combustion flue gas exhaust, and charcoal, provide for the conversion of the charcoal into a valued added soil amendment to return essential trace minerals and plant nutrients to the soil. The ability to produce a large volume carbon co-product while removing mandated emissions and producing renewable based hydrogen provides an economic gain to a large number small and large businesses and increase the chance of achieving significant reductions in greenhouse gas emissions.

Owner:丹尼·马歇尔·戴 +1

Preparation for carbon fiber paper used for gas diffusion layer of proton exchange membrane fuel cell

InactiveCN101591868ASimple methodLow costFinal product manufactureCell electrodesCarbon nanotubeCarbon black

The invention relates to a preparation for carbon fiber paper used for a gas diffusion layer of a proton exchange membrane fuel cell, which comprises the following steps: (1) carrying out water treatment on asphalt base carbon fiber, and carrying out activation treatment on PAN base pre-oxidized fiber; (2) chopping the fibers; (3) mixing the chopped fibers, and then carrying out wet papermaking forming to obtain raw paper; (4) dispersing carbon nano tubes and / or conductive carbon black grains in resin solution; (5) spraying the resin solution on the upper surface and the lower surface of the raw paper, drying the raw paper and then thermally pressing the raw paper into a semi-finished product; and (6) thermally treating the semi-finished product to obtain the carbon fiber paper. The preparation has simple process and low cost, and is suitable for industrialized production; and the carbon fiber paper has good electric conductivity, high porosity, smooth surface, compact structure and proper flexibility and rigidity.

Owner:DONGHUA UNIV

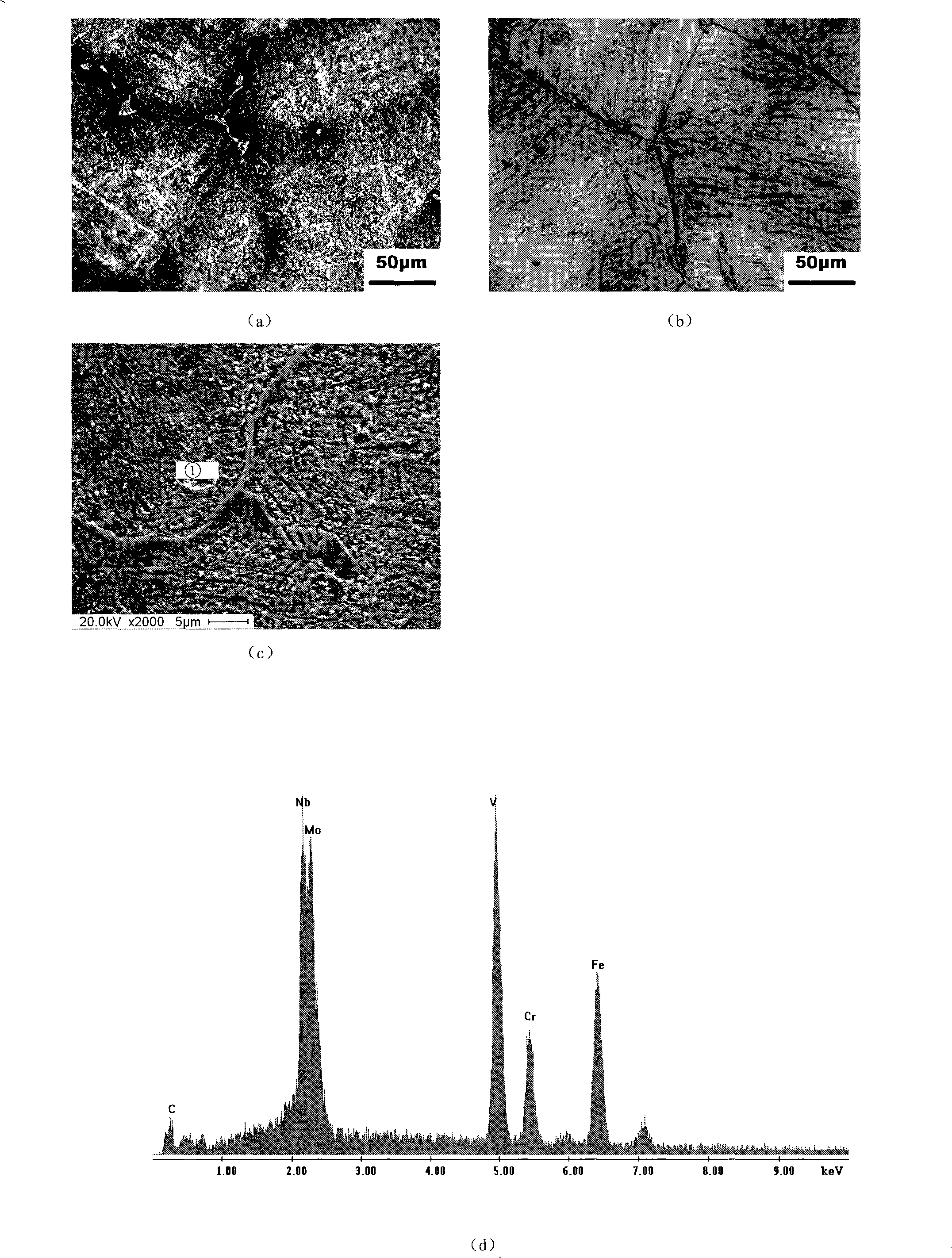

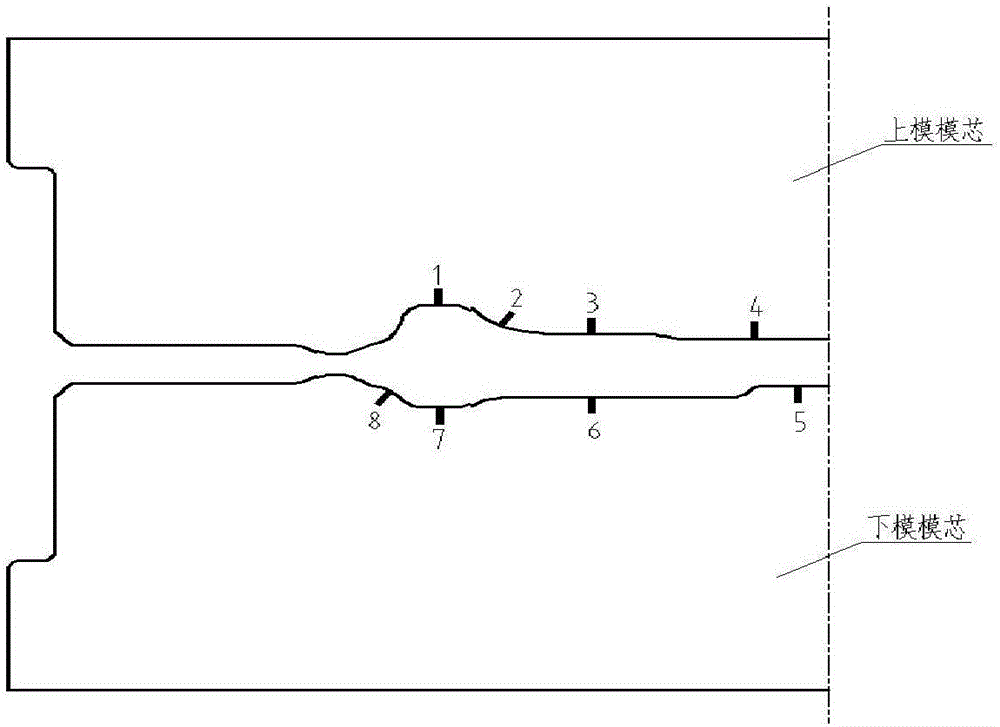

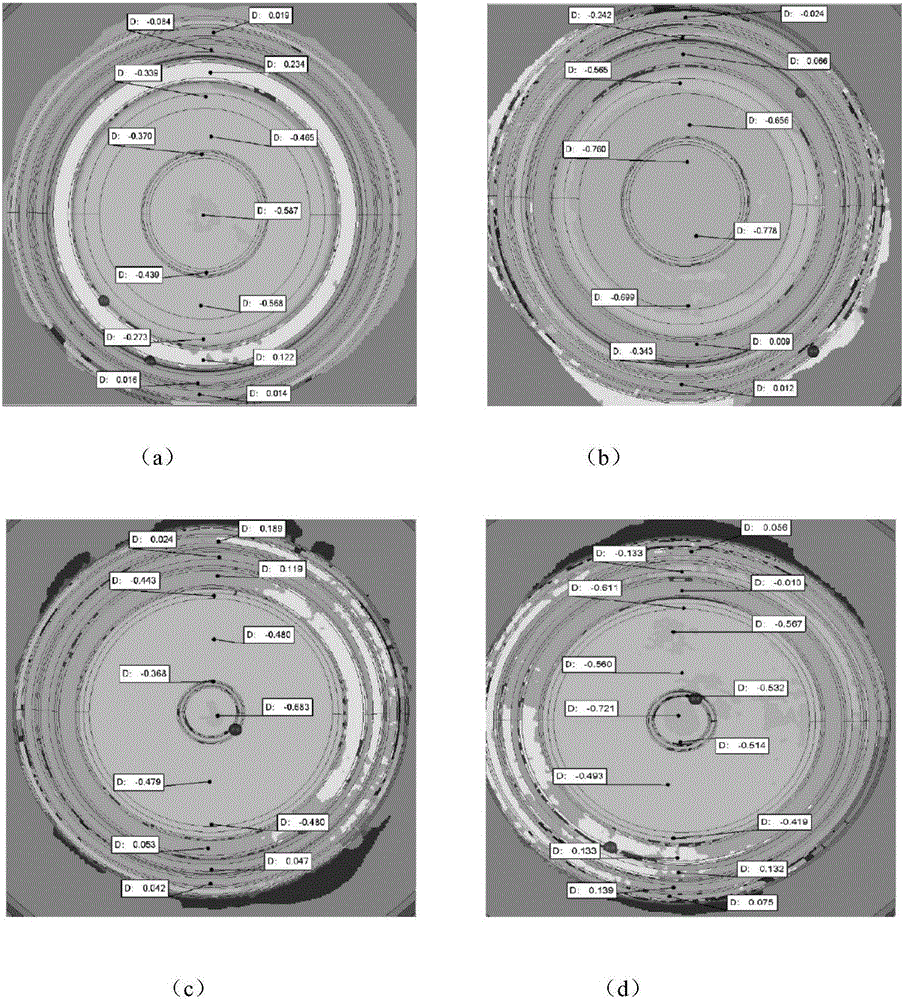

Large-section high-performance hot work die steel for die casting and preparation technology thereof

The invention relates to large-section high-performance hot work die steel for die casting and a preparation technology thereof and belongs to the technical field of an alloy steel preparation technology. The steel is characterized in that main alloy elements in alloy chemical components comprise, by weight, 0.35-0.65% of C, 0.30-1.00% of Si, 0.30-1.00% of Mn, 3.50-5.50% of Cr, 2.00-3.00% of Mo, 0.40-0.80% of V, P being less than or equal to 0.02%, S being less than or equal to 0.01%, 1.00-2.00% of Ni, Nb being greater than or equal to 0.15%, and the balance Fe. The preparation process of the hot work die steel comprises the following steps: burdening, smelting, casting and electroslag remelting; heat treatment by high-temperature heat diffusion, hot working by multi-directional forging and controlled cooling after forging; refining and heat treatment of proeutectoid carbide and isothermal annealing treatment; and heat treatment by quenching and tempering, namely austenitizing by heating to 950-1100 DEG C, oil cooling or mist cooling, and tempering at 540-630 DEG C for two to three times. The hot work die steel provided by the invention has advantages of high hardenability, high thermal stability, high toughness and good resistance to thermal fatigue.

Owner:RUGAO HONGMAO HEAVY FORGING

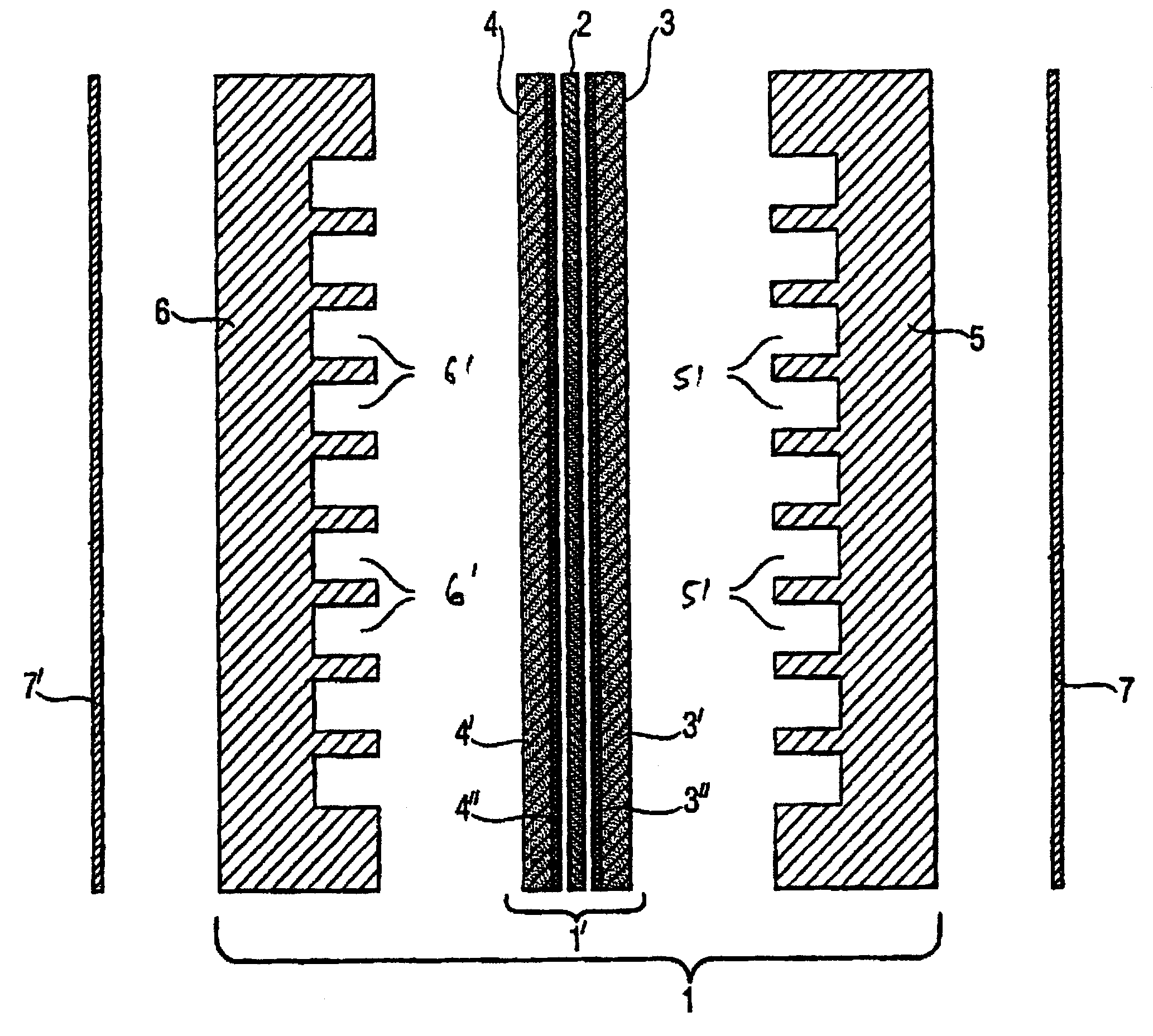

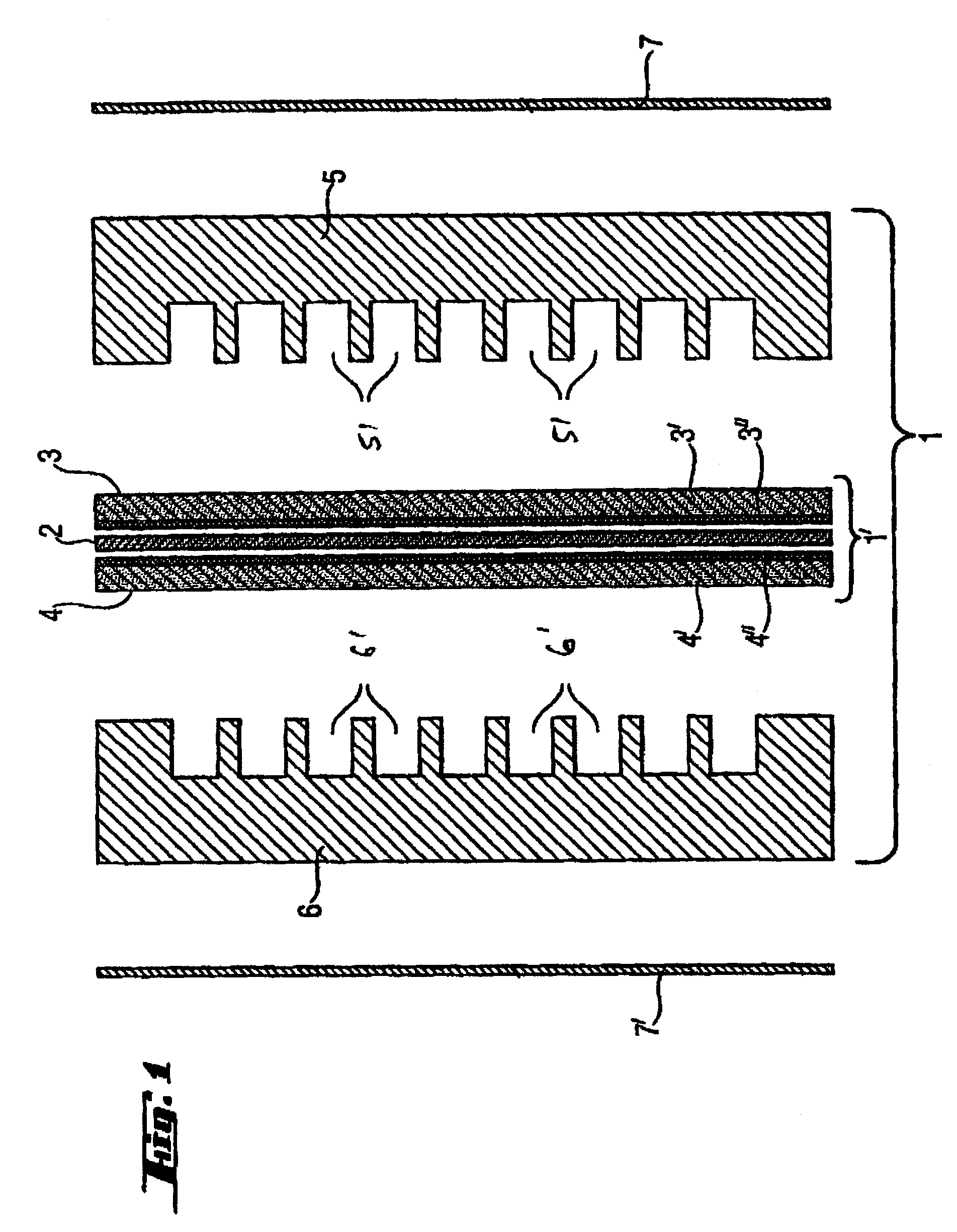

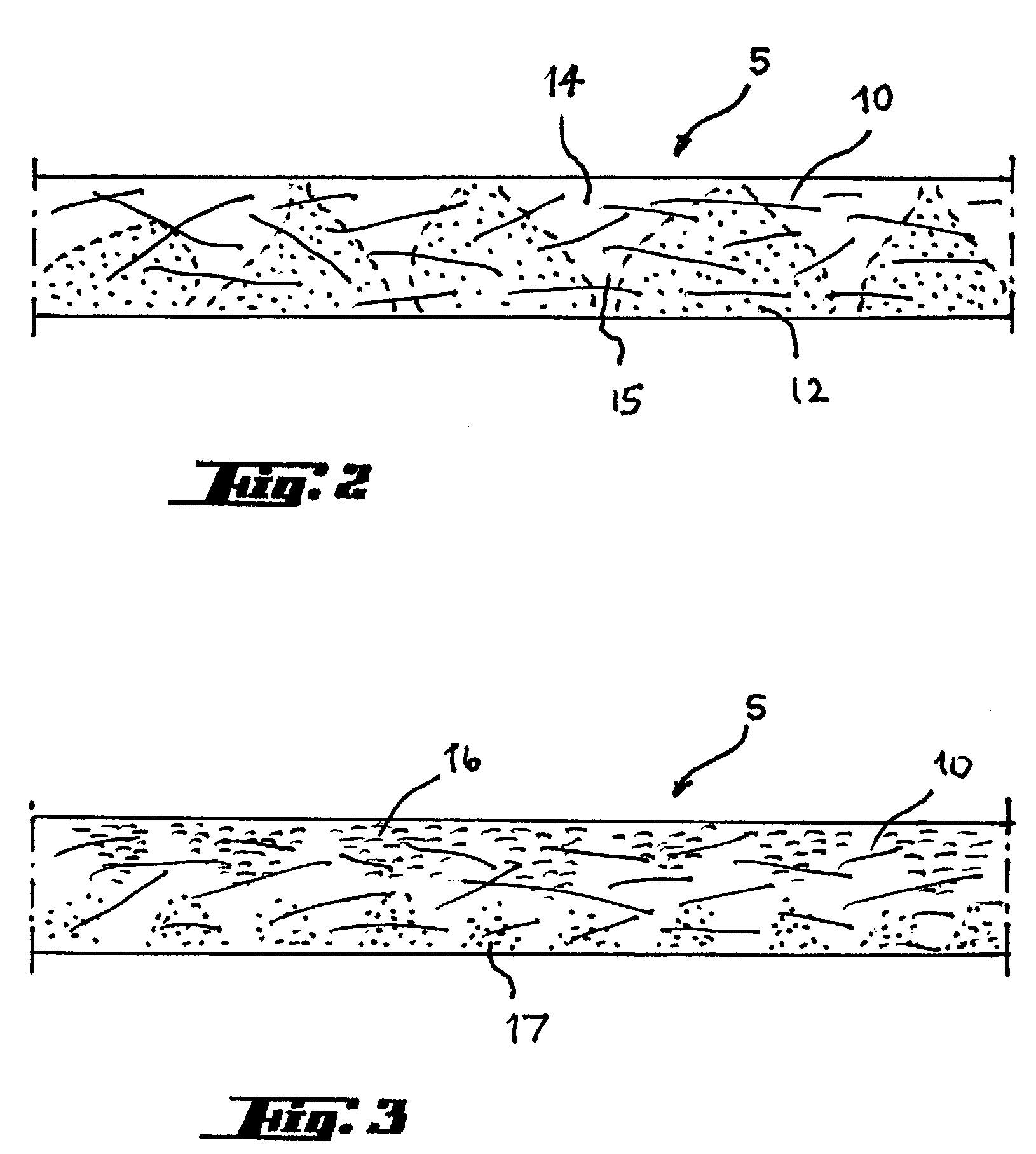

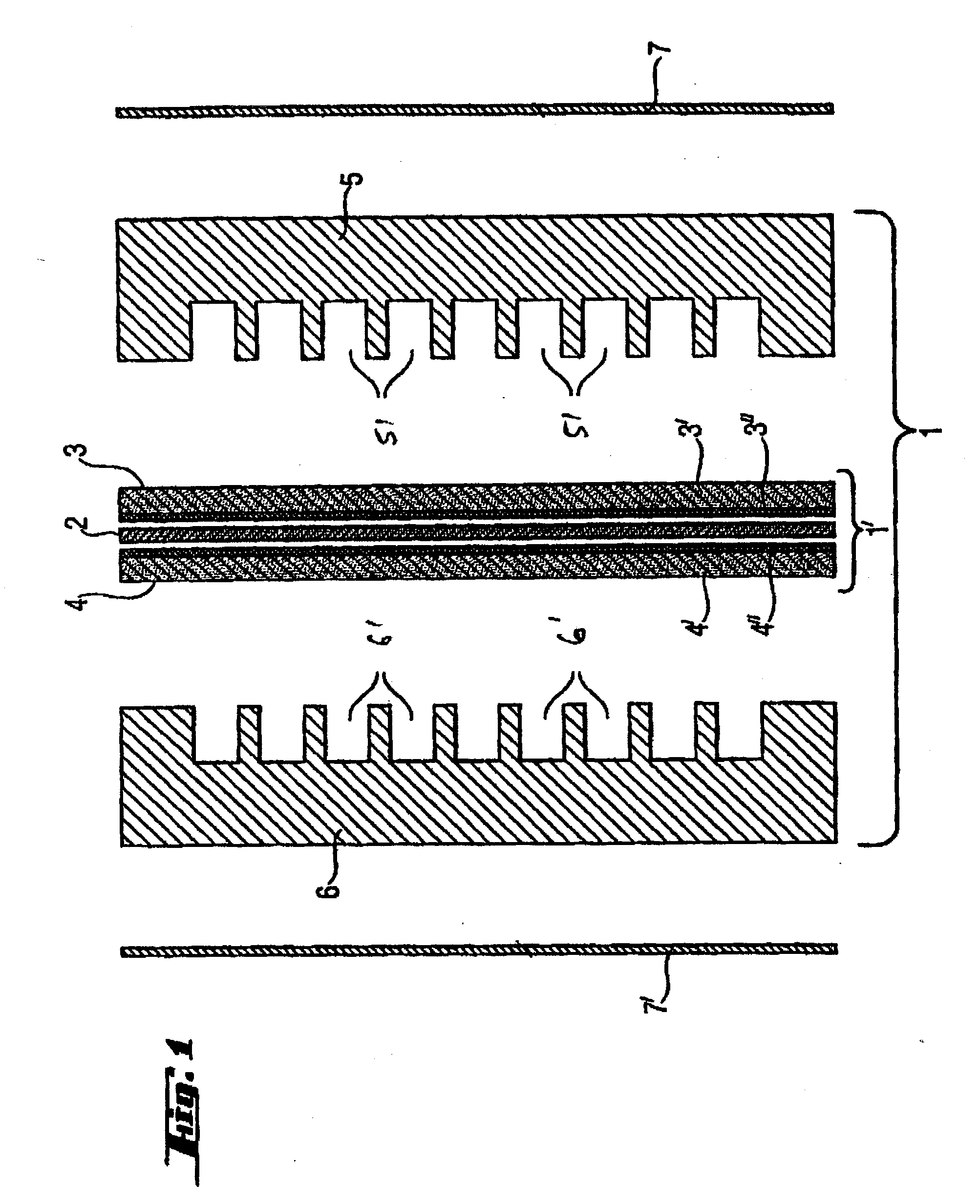

Carbon fiber electrode substrate for electrochemical cells

ActiveUS7144476B2High carbon contentImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCarbon fibers

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

Carbon fiber electrode substrate for electrochemical cells

ActiveUS20030194557A1Improve conductivityContinuous processabilityNon-fibrous pulp additionNatural cellulose pulp/paperPorosityFiber

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

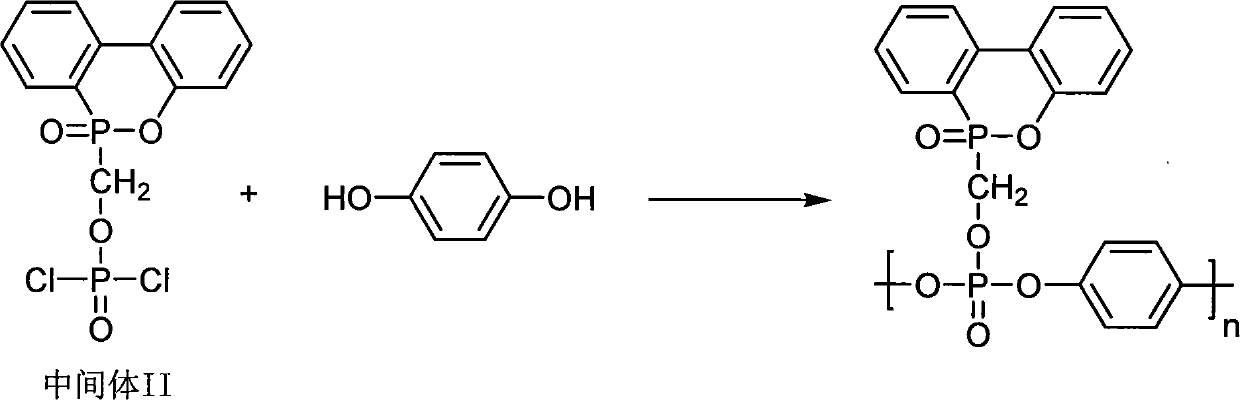

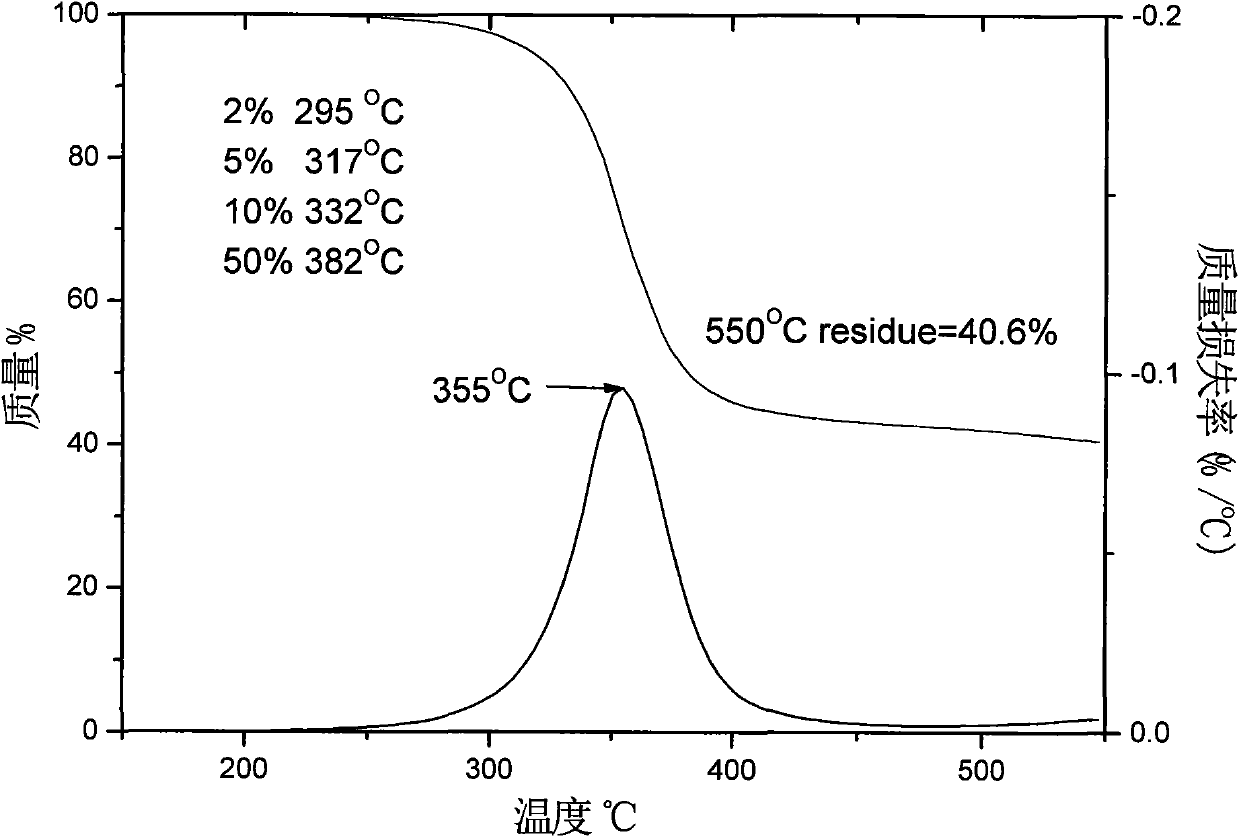

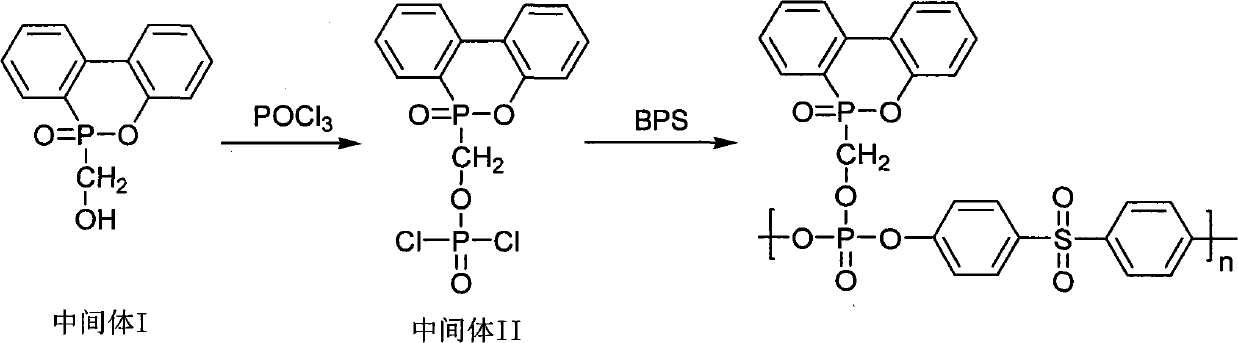

Poly-phosphate flame retardant containing DOPO side-chain structure and preparation method thereof

InactiveCN101838538AImprove thermal stabilityGood char formationGroup 5/15 element organic compoundsPolyesterSide chain

The invention discloses a poly-phosphate flame retardant containing a DOPO side-chain structure and a preparation method thereof, belonging to the technical field of polymeric organic phosphorus flame retardant structures and the preparation method thereof. The flame retardant is characterized by comprising the following repeating unit structure: wherein n=5-50. The preparation method of the poly-phosphate flame retardant comprises the following steps of: reacting an intermediate I containing the DOPO structure with phosphorus oxychloride to obtain an intermediate II containing phosphorus oxychloride, and fusing and polymerizing the intermediate II and a bisphenol compound to obtain the poly-phosphate flame retardant containing the DOPO side-chain structure. The preparation method is simple, and through adjusting Ar categories and ratios, the phosphorus content can be controlled at 11.5-15.5% and the sulfur content can be controlled at 0-5.9%. The flame retardant has the characteristics of favorable thermal stability, high decomposition temperature, favorable char-forming property, and the like, and can be used for flame retardance modification of materials, such as polyester, polyamide, polycarbonate and blends thereof, and the like, with higher processing temperature.

Owner:DALIAN UNIV OF TECH

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

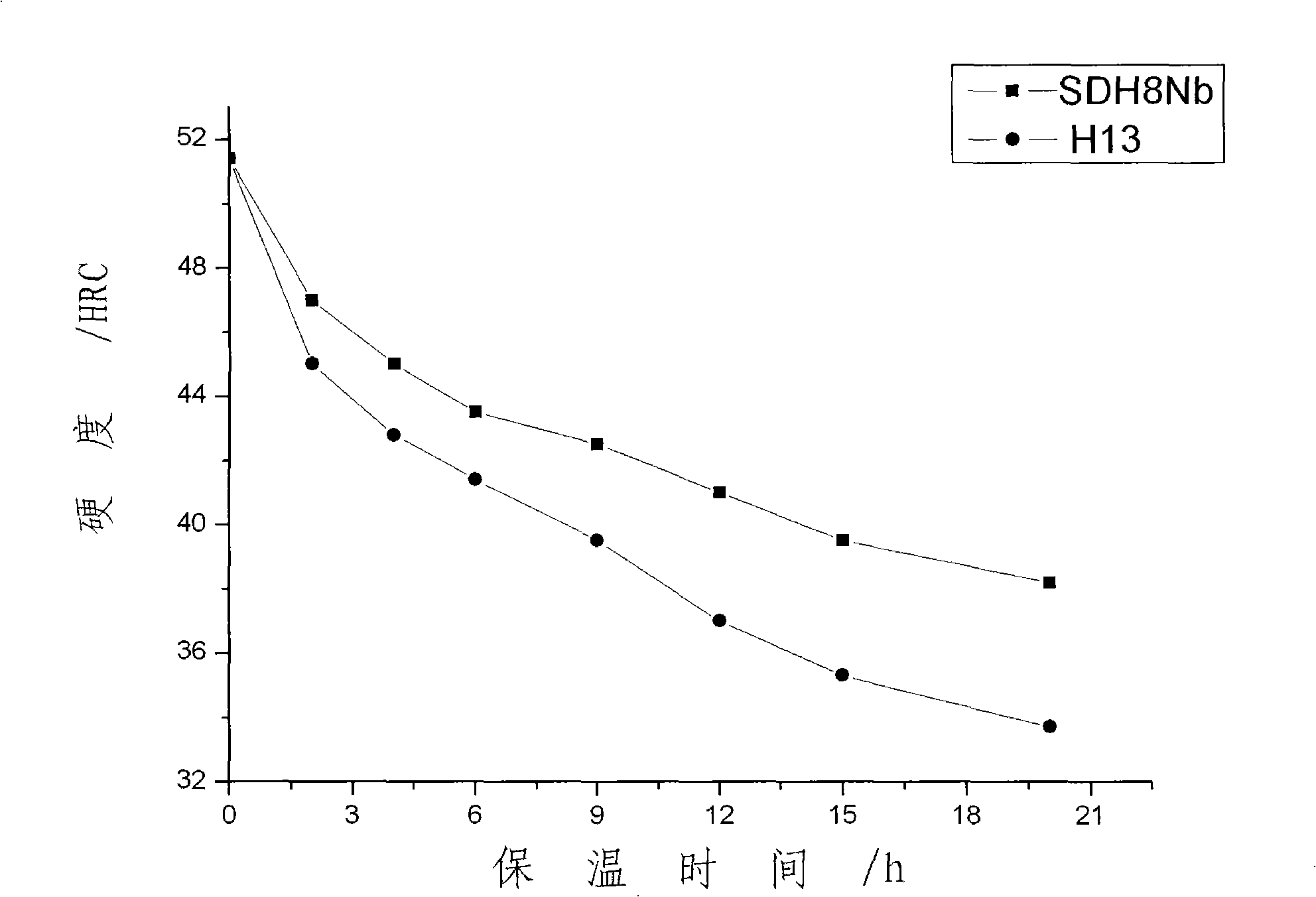

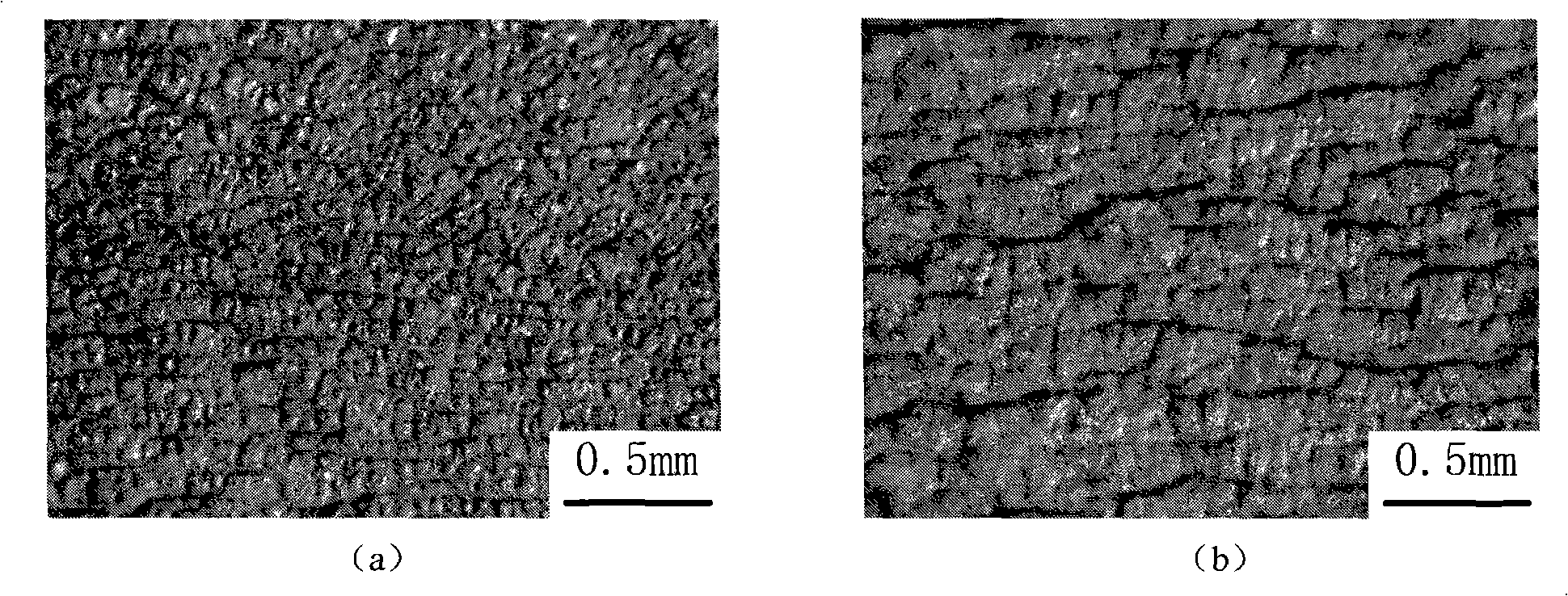

Niobium microalloyed high strength hot work die steel and preparation thereof

The invention relates to niobium microalloyed high-strength hot working die steel, belonging to the alloy steel manufacturing process technical field. The compositions by weight percentage of the steel are: 0.3 to 0.6 percent of C, 0.1 to 0.5 percent of Si, 0.1 to 0.5 percent of Mn, 4.0 to 6.5 percent of Cr, 1.0 to 3.5 percent of Mo, 0.4 to 1.4 percent of V, 0.02 to 0.10 percent of Nb, less than 0.03 percent of P, less than 0.03 percent of S, and the balance being Fe. The process for preparing the hot working die steel comprises the following steps of: batching, smelting, secondary refining and electroslag remelting; homogenizing the mixture for 5 to 10 hours at a temperature of between 1210 and 1300 DEG C, and forging, annealing, quenching and tempering the mixture; heating up the mixture to a temperature of between 1000 and 1100 DEG C for austenization, after performing 'step heating' at a temperature of 650 DEG C and at a temperature of 800 DEG C, then performing secondary tempering to the processed mixture, and finally acquiring the hot working die steel. The die steel has the advantages of good thermal resistance, good thermal stability and good thermal fatigue performance.

Owner:SHANGHAI UNIV

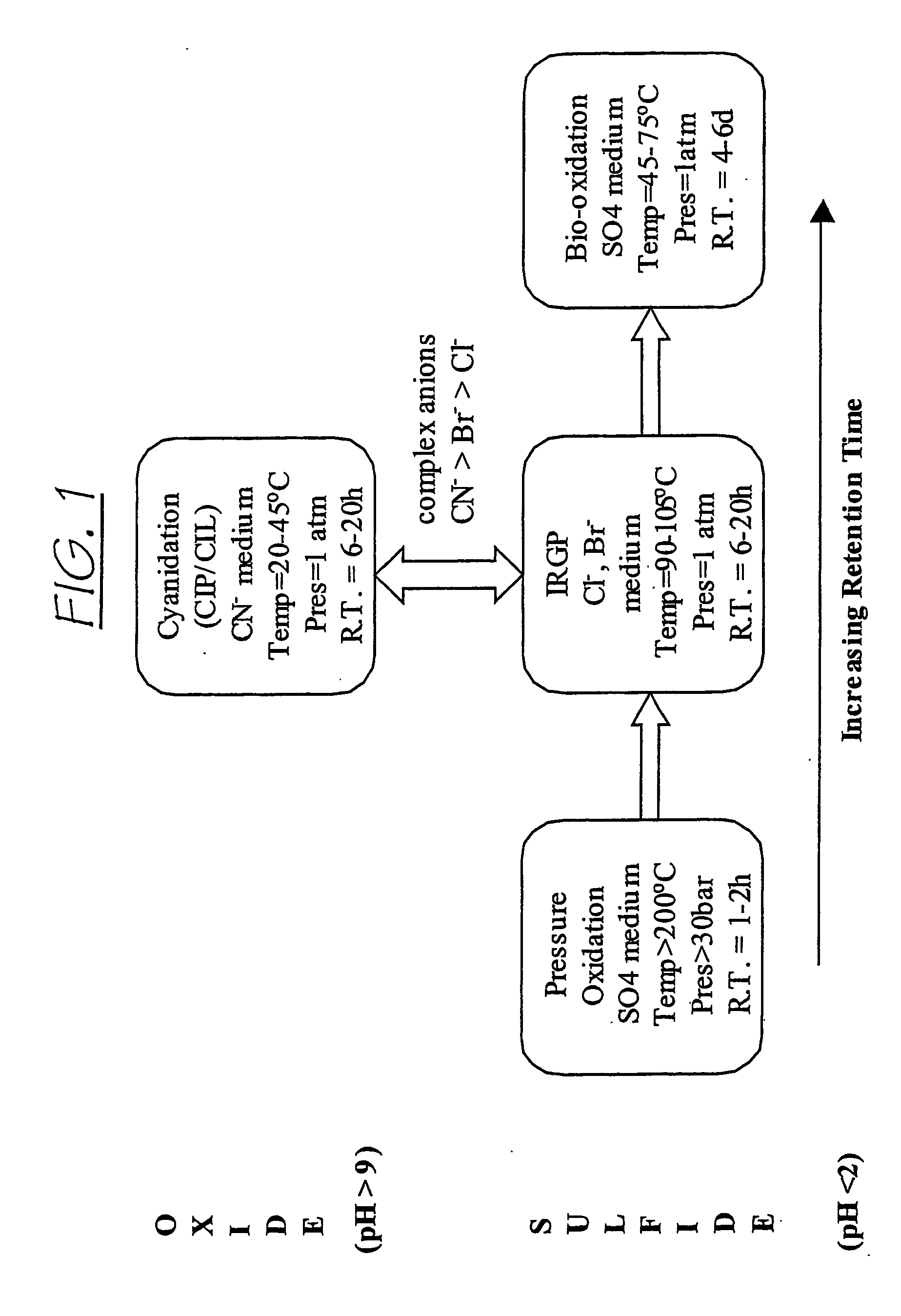

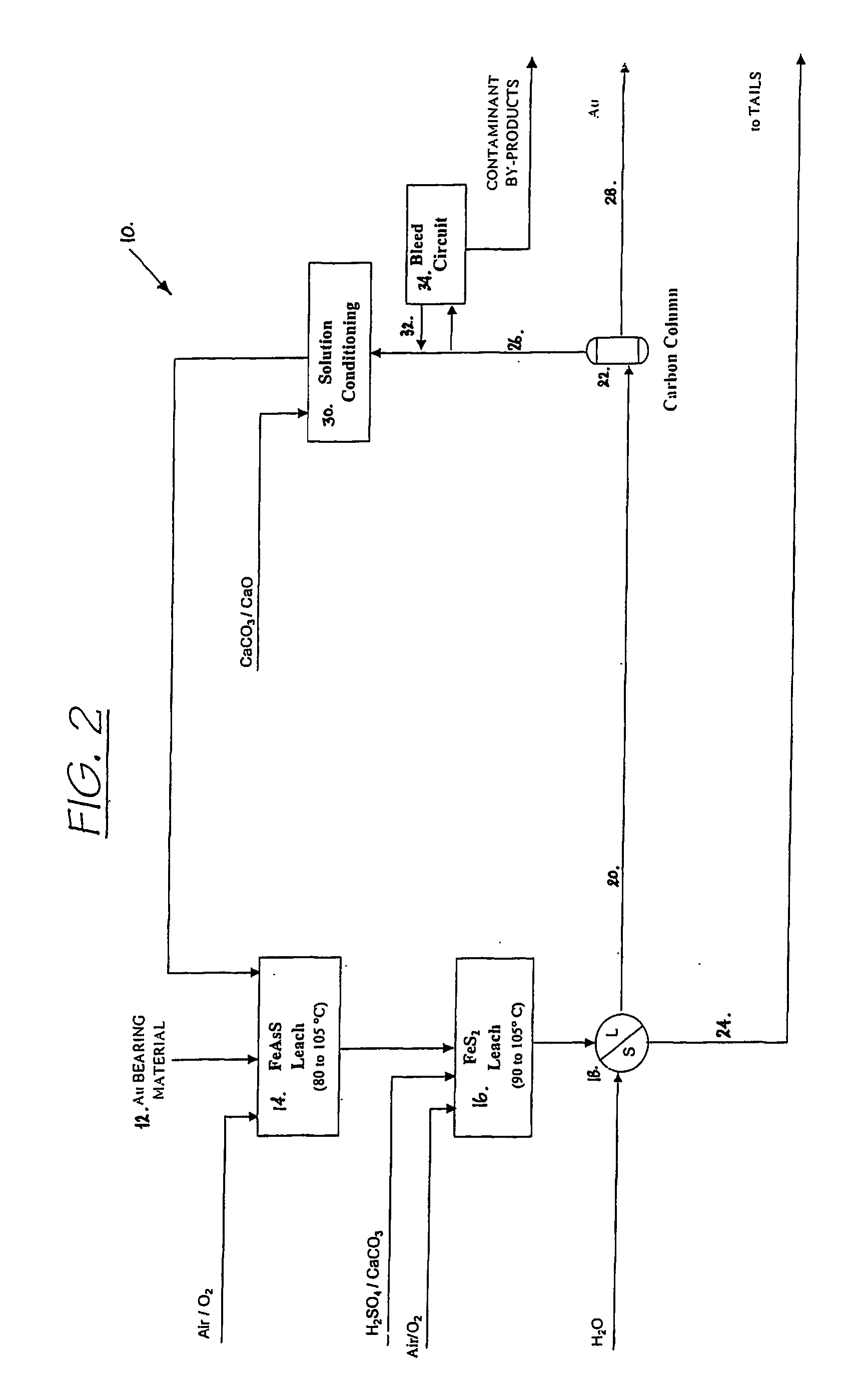

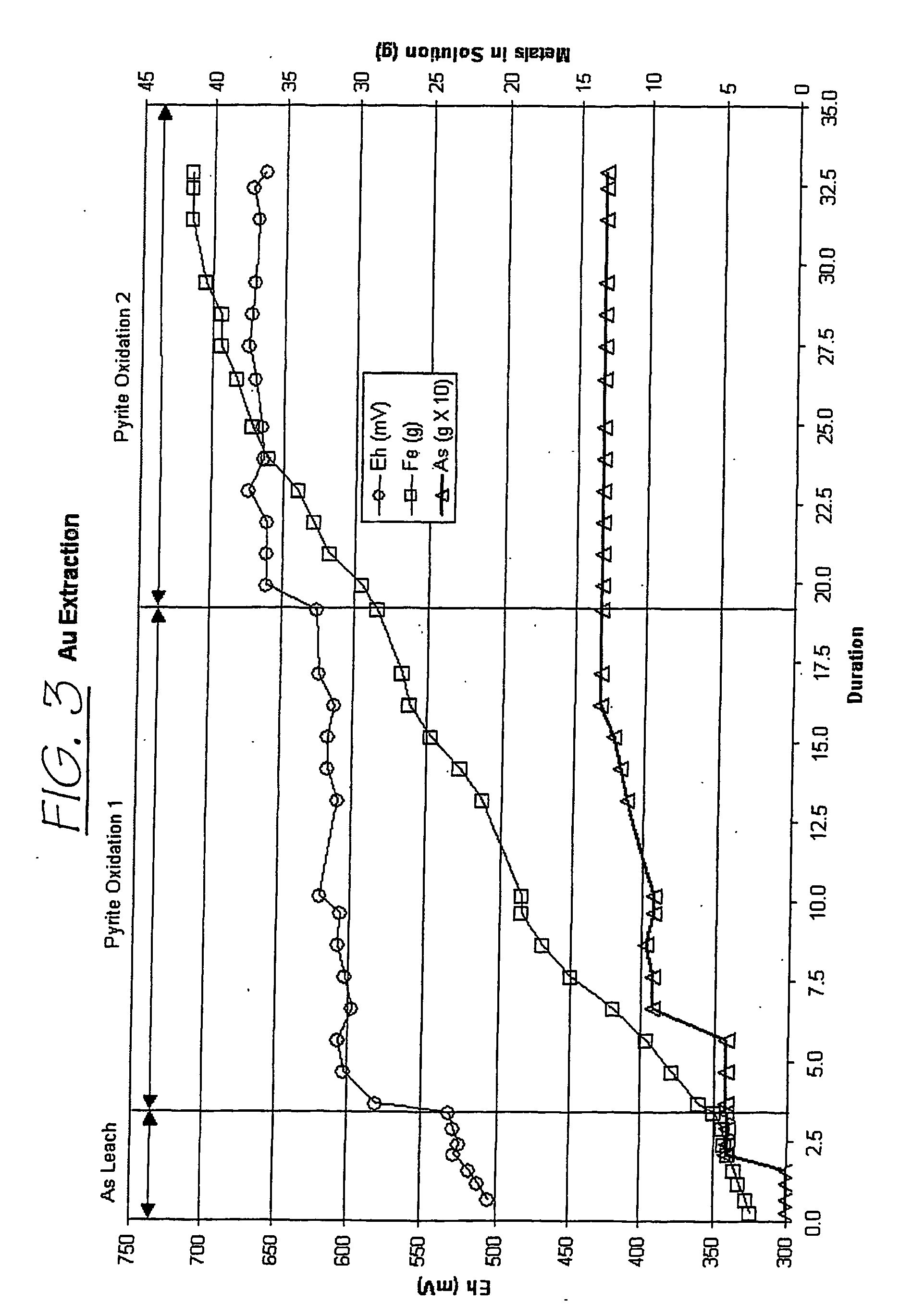

Recovering metals from sulfidic materials

InactiveUS20070014709A1Facilitate precious metal dissolution precious metalFacilitate precious metal subsequent precious metal recoveryPhotography auxillary processesSolvent extractionOxidation stateSulfide

A process for recovering a precious metal from a sulfidic material comprises the steps of preparing an acidic aqueous halide solution having an oxidation potential sufficient to oxidise the sulfidic material and render the precious metal soluble in the solution, adding the material to the acidic aqueous halide solution so that the sulfidic material is oxidised and the precious metal is solubilised and separating the precious metal from the oxidised sulfidic material. In addition, a process for removing a contaminant from a contaminated sulfidic material comprises the steps of mixing the material in an aqueous solution wherein a multi-valent species of a relatively high oxidation state oxidises the contaminant to render it soluble in the solution, produces a contaminant refined material, and is reduced to a relatively lower oxidation state; and removing the contaminant from the solution whilst regenerating the multi-valent species to its relatively high oxidation state.

Owner:INTEC INT PROJECTS

Aluminium oxide carrier containing magnesium and phosphor and preparing method

InactiveCN101069853AStrong anti-coking abilityHigh activityMetal/metal-oxides/metal-hydroxide catalystsLarge poreChemistry

The present invention discloses an aluminium oxide carrier which contains magnesium and phosphorus, also can contain potassium and its preparation method. The magnesium, phosphorus and potassium can be added in the process of preparation. Said carrier is low in acidity and has large pore volume and large specific surface area. The catalyst prepared by using said carrier has the features of strong anti-coking property and good stability.

Owner:林方 +3

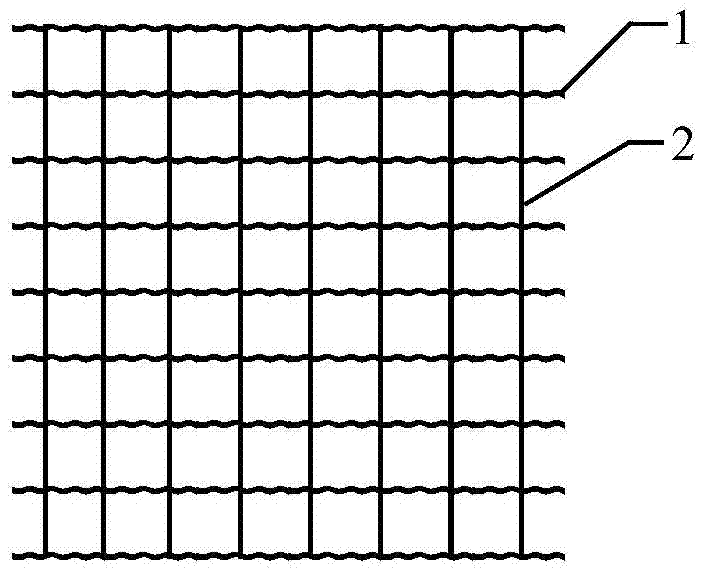

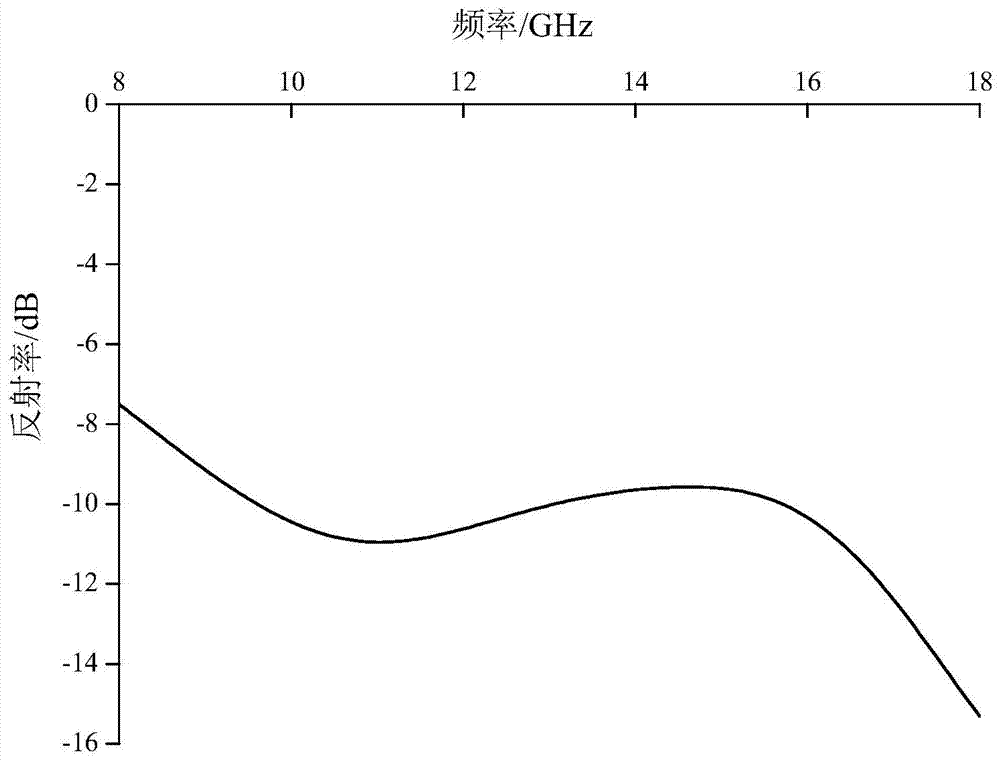

Silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic and preparation method thereof

ActiveCN103922776AIncreased interlaminar shear strengthImprove mechanical propertiesCarbon fibersMicrowave

The invention discloses a silicon carbide fibre-reinforced silicon carbide composite microwave-absorbing ceramic. The microwave-absorbing ceramic consists of continuous silicon carbide fibre-reinforced silicon carbide composite material; wherein silicon carbide fibre cloth overlaid layer by layer is used as reinforcement; the silicon carbide fibre cloth is connected into a whole in a way of sewing with carbon fibres in Z direction; the band width, of which the reflectivity is lower than -8dB in frequency band of 8GHz to 18GHz, is 6.5 GHz to 10 GHz at normal temperature; and the density is lower than 2.1 / cm <3>. The method for preparing the microwave-absorbing ceramic comprises the following steps: weaving the continuous silicon carbide fibres into silicon carbide fibre plain cloth; sewing the plain cloth into a whole body in a Z direction by carbon fibres to prepare a preformed body; dipping, pyrolyzing and densifying the preformed body repeatedly by using precursor dipping and pyrolysis technology, thus obtaining the microwave-absorbing ceramic. The product provided by the invention has advantages of simple structure, wide absorbing frequency band, light weight, thin thickness, good mechanical property, etc.

Owner:NAT UNIV OF DEFENSE TECH

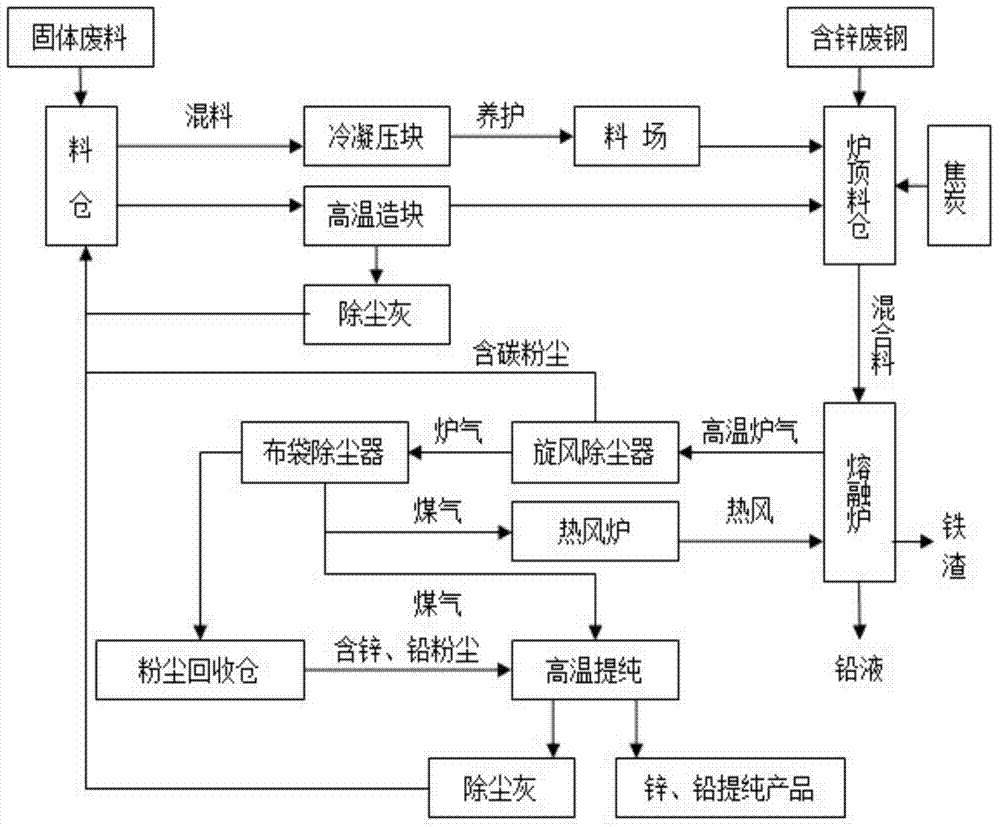

Process method for processing solid waste of steelworks by utilizing smelting furnace

The invention relates to a process method for processing iron-containing solid waste of steelworks by utilizing a smelting furnace. The process method comprises the following steps: with blast furnace dust containing zinc and lead, revolving furnace sludge, electric furnace fly ash, slag metal, waste metal and the like as principal raw materials, carrying out condensation agglomeration and high-temperature agglomeration, and carrying out operations such as maintaining or cooling and granulation so as to obtain finished agglomerates; after mixing the finished agglomerates with coke, sending the mixture into the smelting furnace to be subjected to high-temperature smelting, simultaneously adding the waste such as zinc-containing waste into the smelting furnace in a certain proportion to finally generate high-temperature mixed gas, separating elements such as carbon from the mixed gas by utilizing a cyclone dust collector at the top of the furnace, recycling carbon-containing dust again, further separating the residual mixed gas by utilizing a bag-type dust collector so as to obtain zinc-rich and lead-rich dust, and recycling the zinc-rich and lead-rich dust and applying the zinc-rich and lead-rich dust to the high-temperature agglomeration, the hot air preheating of the smelting furnace and a smelting furnace purification process; then purifying the collected zinc-rich and lead-rich dust, so as to obtain high-purity zinc and lead products; regularly opening a lead discharging hole in the bottom of the smelting furnace, and collecting lead liquid so as to simultaneously obtain wet lead and products such as molten iron and furnace slag.

Owner:卢龙宏赫废料综合利用有限公司

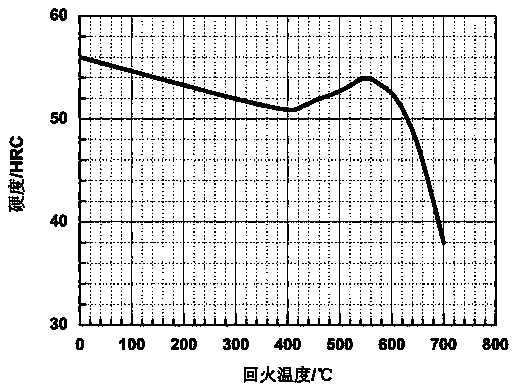

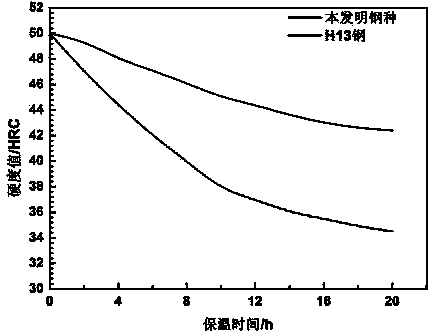

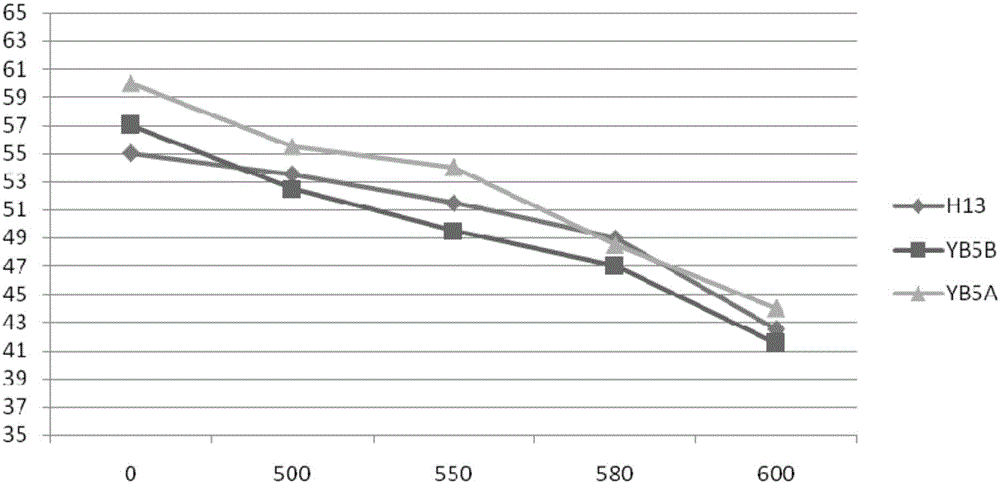

Cr5 series hot work die steel

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

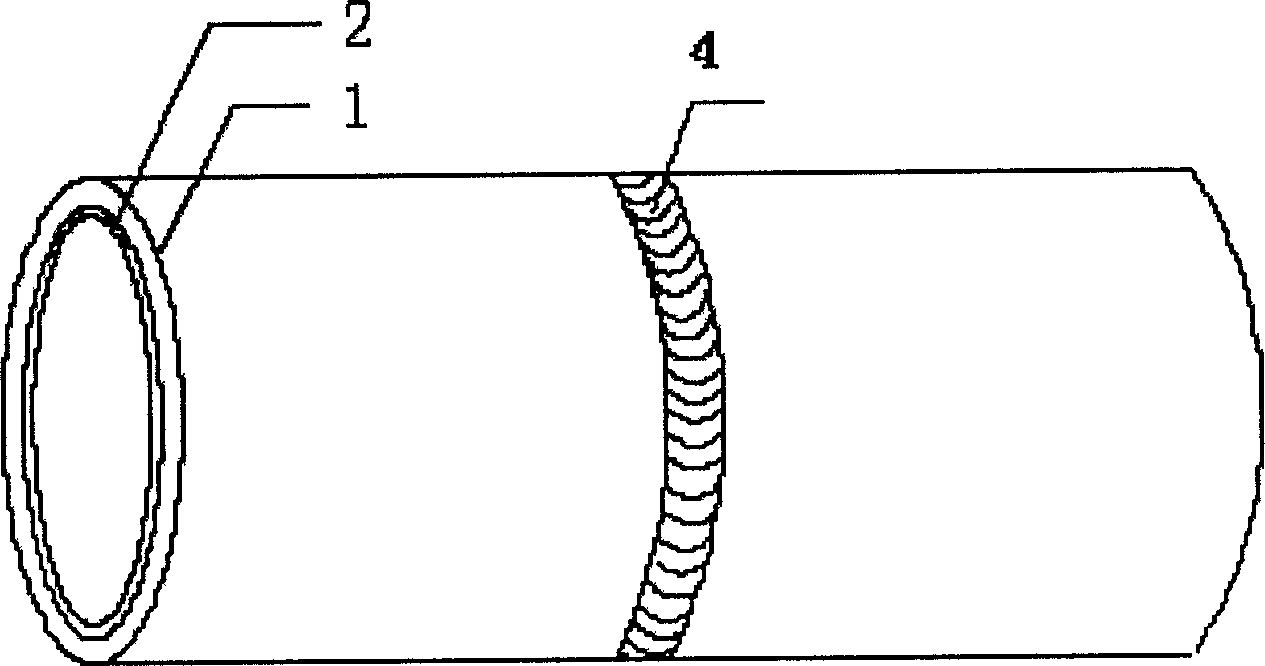

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

InactiveCN102527767AReduce processing difficultyImprove deburring speedEngineeringEddy-current testing

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

Converter oxide and nitrogen top-blown dephosphorizing method

InactiveCN1552919AHigh carbon contentInhibition of decarburization reactionsManufacturing convertersSputteringSlag

An oxygen-nitrogen top blowing converter process for desulfurization is carried out by blowing oxygen-nitrogen at its top while blowing nitrogen or inertial gases at its bottom to desulfurise. Its top blowpipe controls oxygen blowing to desulfurise in two modes, with mixed gases at some ratio or with pure oxygen switched with pure nitrogen, in order to inhibit sputtering and to enhance stirring in smelting pool when sputter occurs by excessive oxidation, so that balance of (P) / [P] in dynamics is improved. It desulfurises better when bottom blowing is weak, can inhibit decarbonise reaction effectively with >70% recovery of Mn in molten iron, also, strengthen blowing at top to stir strongly and shorten pre-treat time, increase rate of desulfurization, control slag elimination in procedure effectively to prevent sputtering, and increase stability and security.

Owner:BAOSHAN IRON & STEEL CO LTD

Powder metallurgy production method of internal helical gear

The invention relates to a powder metallurgy production method of an internal helical gear. The powder metallurgy production method comprises the following steps: 1) preparing metal powder raw materials in proportion; 2) putting the prepared metal powder raw materials into a mould of a powder extrusion moulding machine for moulding by rotary extrusion to form a mould green compact; 3) putting the mould green compact into a high temperature mesh belt furnace for sintering treatment; and 4) putting a sintered product into a carburizing furnace for carburizing treatment. The powder metallurgy production method helps produce the internal helical gear with easy production and operation, less cost, high production efficiency, high material utilization rate and high product accuracy.

Owner:扬州保来得科技实业有限公司

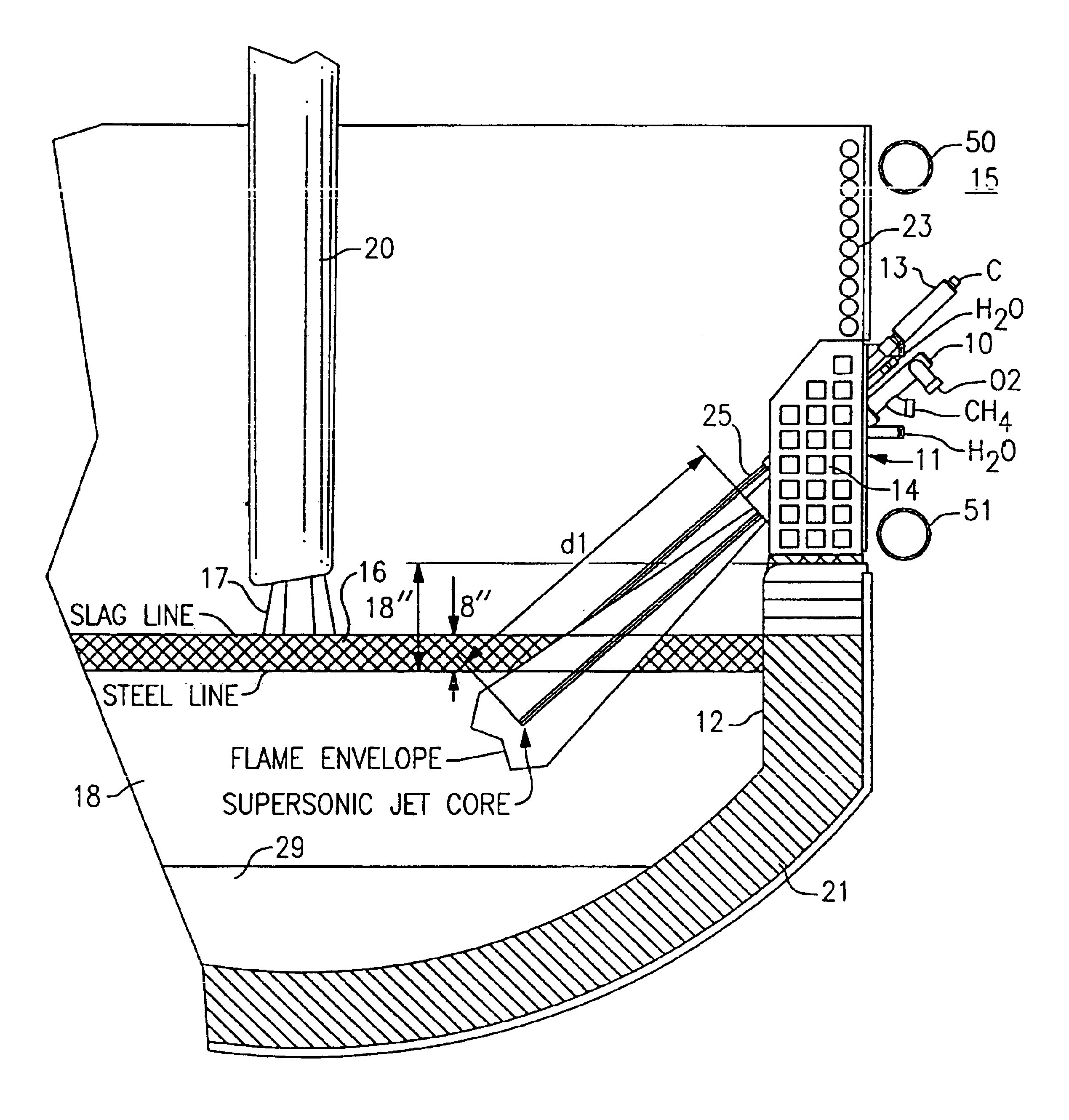

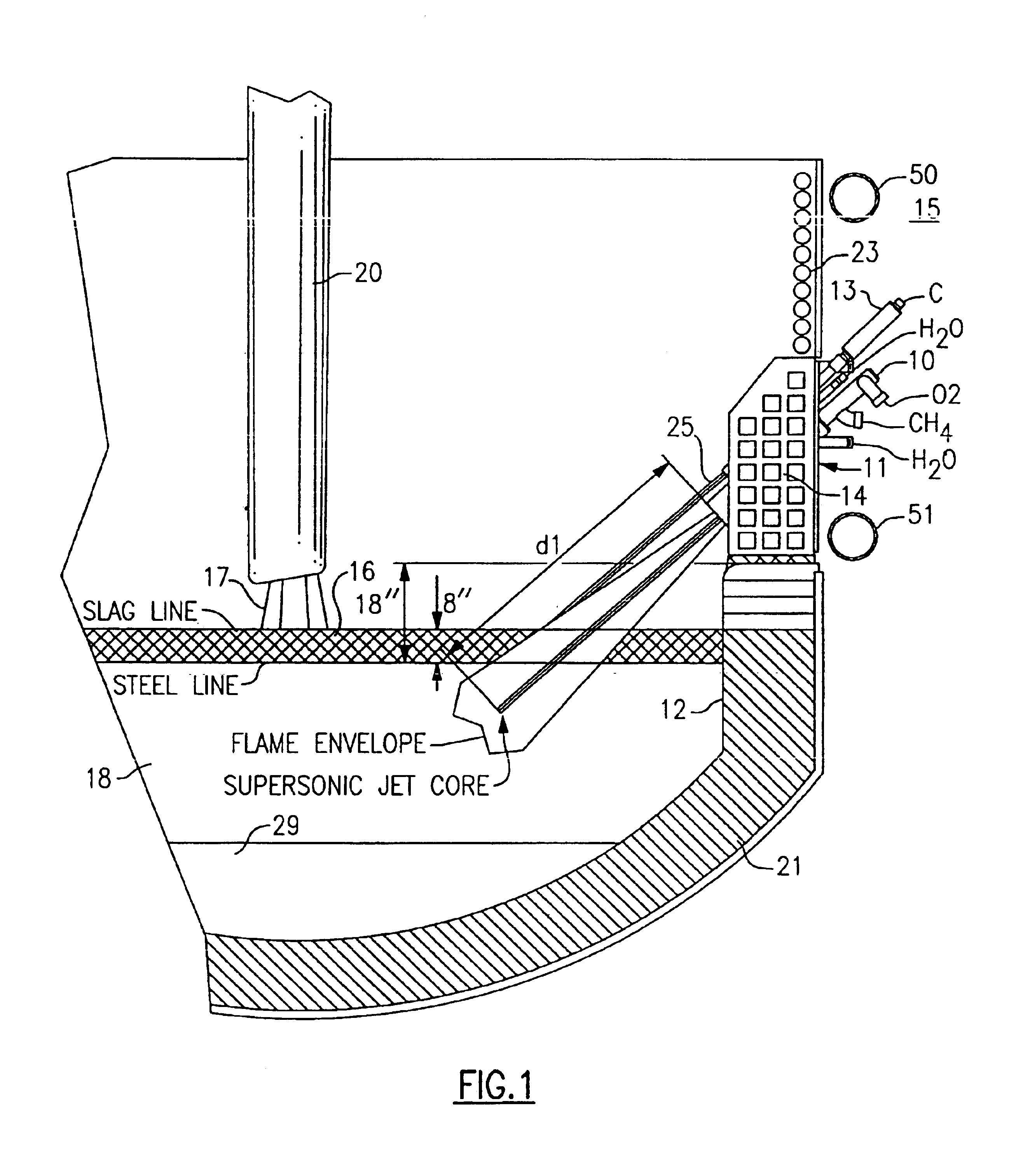

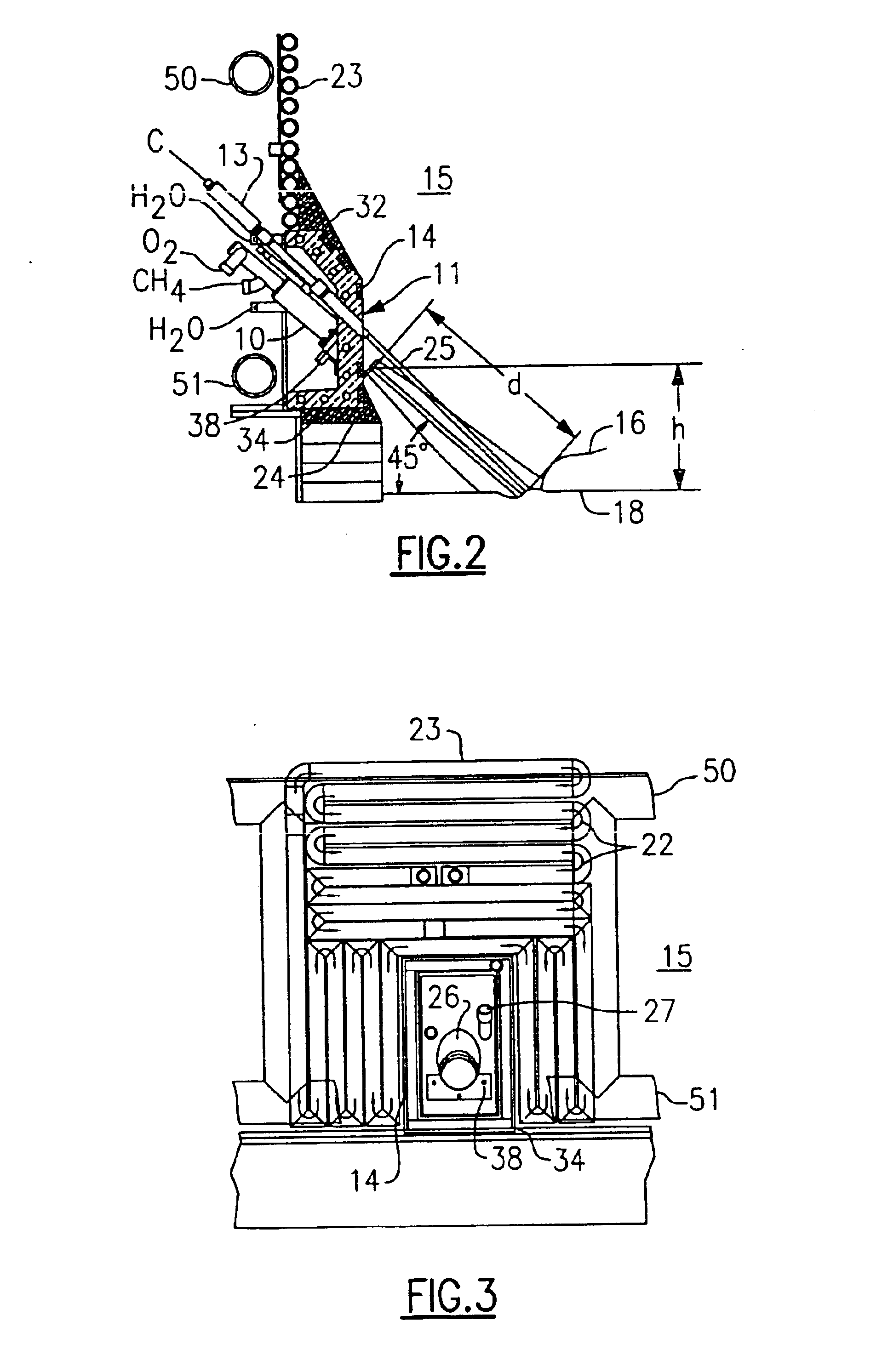

Method for particulate introduction for metal furnaces

InactiveUS6805724B2Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

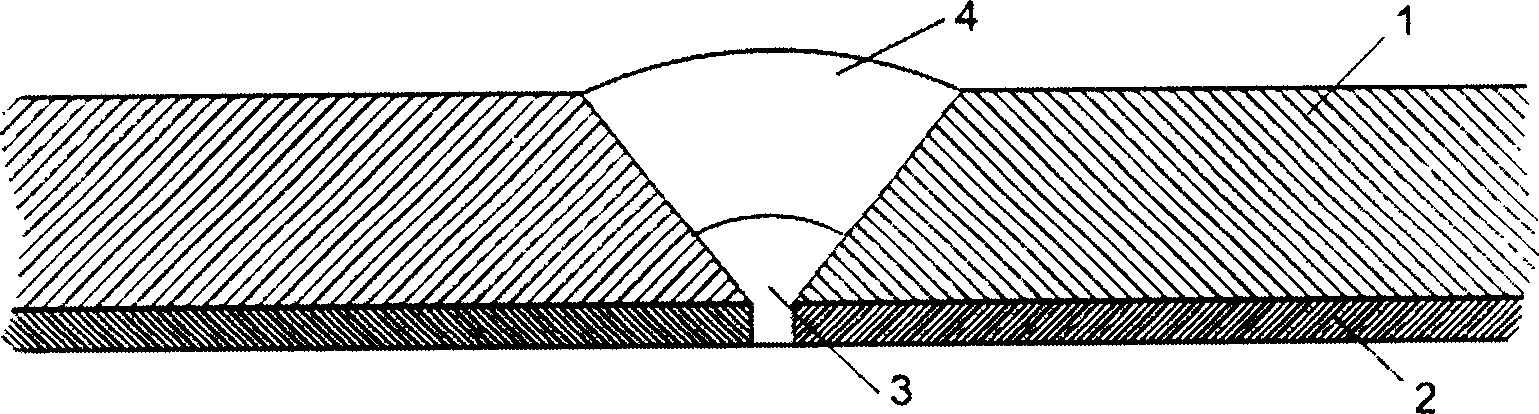

Welding method for ultra-thin composite layer low-carbon steel - austenitic stainless steel multiple tube adaptor

ActiveCN1546267AHigh carbon contentGuaranteed mechanical propertiesArc welding apparatusWelding/cutting media/materialsCarbon steelWeld seam

The invention discloses a welding method for low carbon steel-austenite stainless steel compound pipe of ultra-thin stainless composite bed. The character is: the welding is completed with transition layer welding seam and base layer welding, it hasn't single stainless steel composite bed seam; the welding rod for low carbon steel base layer seam is the same to the one for mother metal; the first welding for stainless steel composite layer and the transition layer between the stainless composite layer and the low carbon steel base layer use argon tungsten-arc welding with back argon filling protection, or uses manual arc welding; the welding wire or welding rod use stainless steel in order to form the transition welding seam; after the transition welding seam is completed, the second time uses manual arc welding to weld the low carbon steel base layer, the welding rod uses low carbon steel in order to form base layer welding seam.

Owner:XI AN JIAOTONG UNIV +1

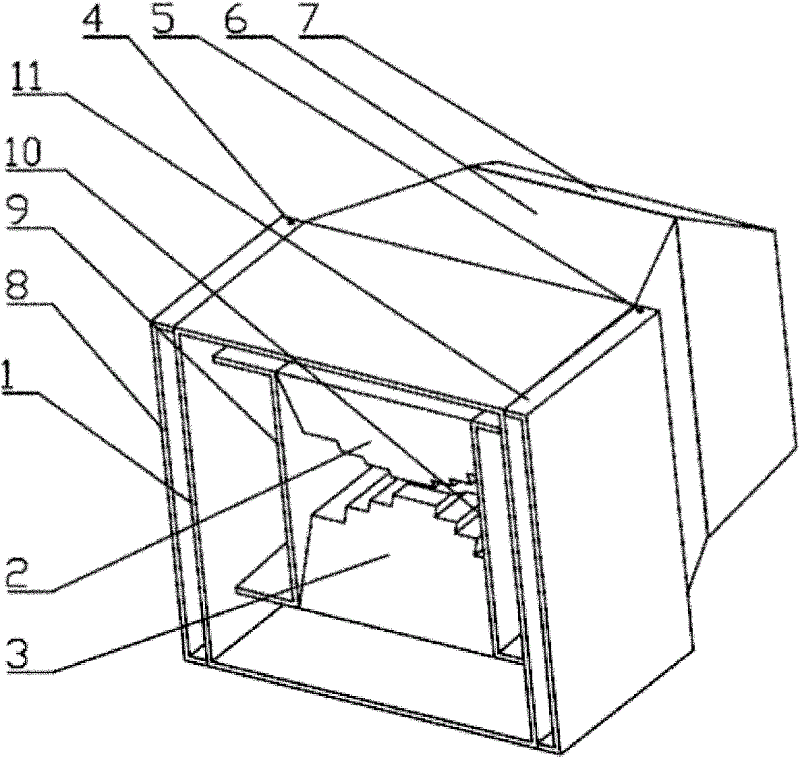

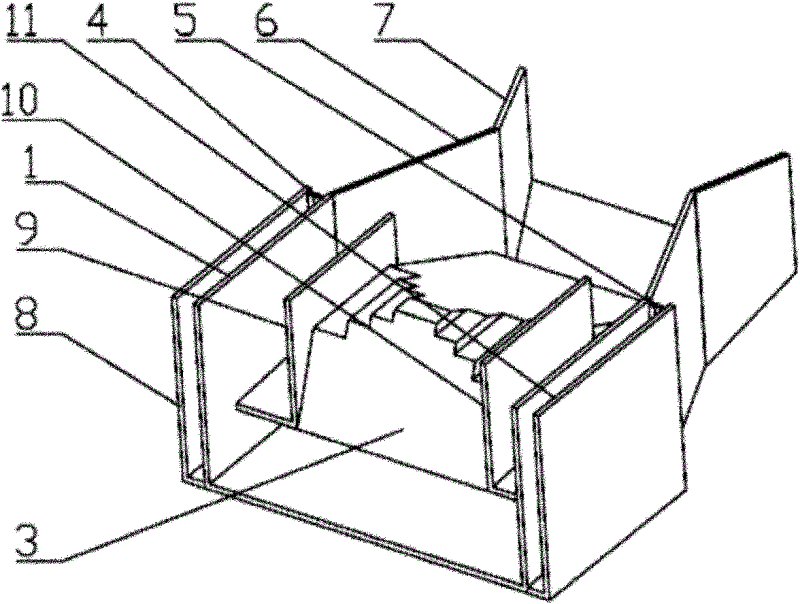

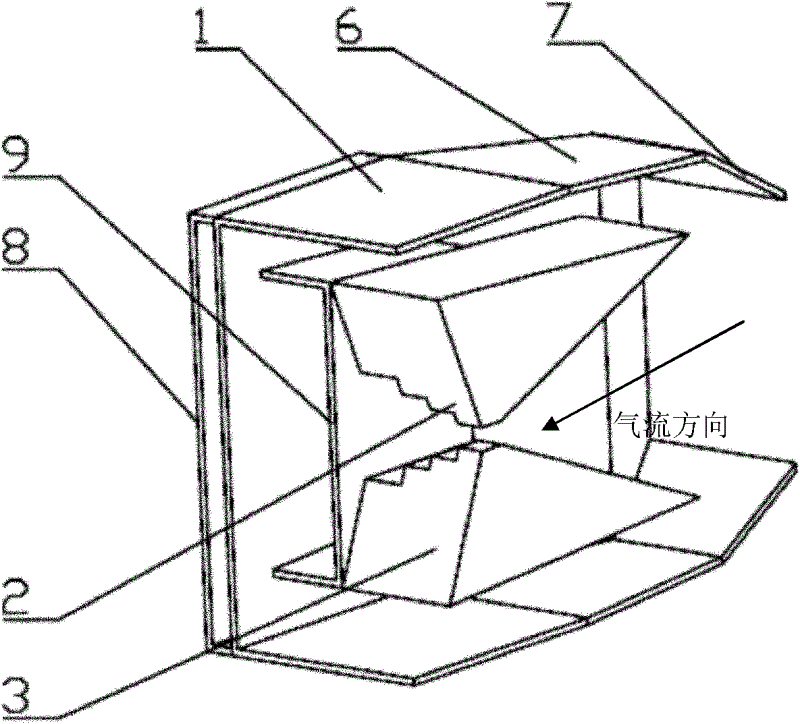

Pulverized coal decoupling combustor with low nitrogen oxide discharge and pulverized coal decoupling combustion method with low nitrogen oxide discharge

InactiveCN102620291ASeparation perimeter lengthSmall steering anglePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationProcess engineeringCoal

The invention relates to a pulverized coal decoupling combustor with low nitrogen oxide discharge and a pulverized coal decoupling combustion method with low nitrogen oxide discharge. The method is implemented through the following two stages: a) stage 1, firstly separating mixed airflow of pulverized coal and air into a concentrated part and a dilute part by virtue of the pulverized coal decoupling combustor provided by the invention, igniting the concentrated pulverized coal airflow, then feeding the concentrated pulverized coal airflow into a hearth, and performing combined combustion on the concentrated pulverized coal airflow and the dilute pulverized coal airflow; and b) stage 2, mixing the mixed airflow with secondary air in the hearth, and fully combusting the pulverized coal semicoke generated in the stage 1 under conditions of rich oxygen and high temperature which is insufficient to generate thermal NOx, wherein in the stage 1, the pulverized coal is pyrolyzed, gasified and gas-fired under reducing atmosphere, volatile components are fully separated out, products of pyrolysis and gasification are utilized to convert fuel-type NOx into more stable N2. According to the invention, an integration design of pulverized coal condensation, stable combustion and low nitrogen oxide discharge can be realized, the equipment structure is compact, the pulverized coal condensation effect is good, the stable combustion capability is strong, and the potential of inhibiting NOx from generating is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Intermediate phase asphalt and preparation method thereof

InactiveCN103194254AHas a streamlined structureHigh aromaWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansResource utilizationDistillation

The invention provides intermediate phase asphalt and a preparation method thereof. The preparation method comprises the following steps that A, mixing coal liquefaction residuals with an extraction solvent, stirring, extracting, and carrying out centrifugal separation to form an extraction liquid; B, carrying out atmospheric or reduced pressure distillation on the extraction liquid to form an extraction refined substance; and C, carrying out a polymerization reaction on the extraction refined substance at constant 400-450 DEG C and at constant 0.1-3.0MPa in an inert gas atmosphere for 5-16 hours to form the intermediate phase asphalt. According to the preparation method, under the condition that no catalyst is added, the intermediate phase asphalt in a good streamline structure is prepared, and serves as a carbon precursor for further preparing various carbon materials; the flow of a whole technical process is relatively simple; operation is convenient and safe; utilization potential of asphalt substances in the coal liquefaction residuals is fully exerted; the application field of the coal liquefaction residuals is expanded; and the resource utilization ratio is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com