Cr5 series hot work die steel

A hot work die steel, a series of technologies, applied in the field of iron-based alloys, can solve problems such as collapse, die wear, poor thermal strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

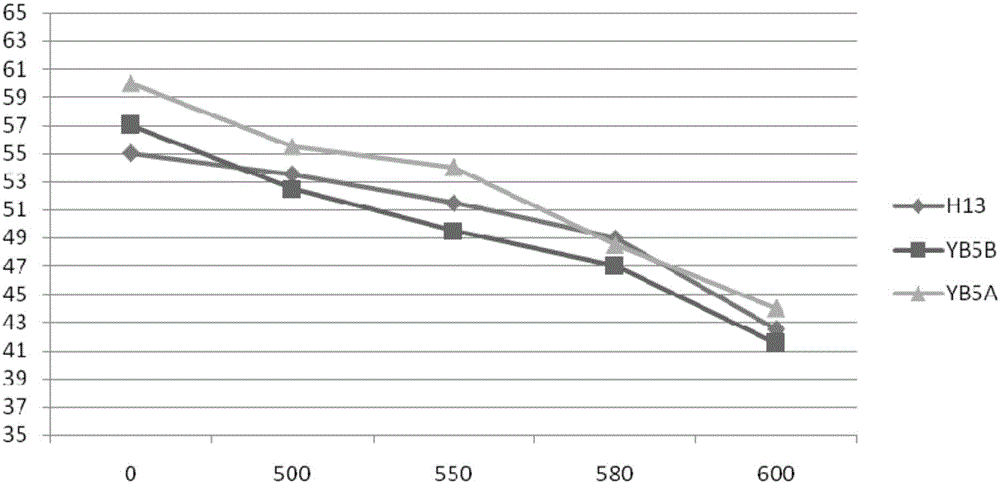

[0109] The preparation method of Cr5 series hot working die steel is characterized in that it comprises steps: electric furnace smelting, LF furnace refining (LADLE FURNACE is the ladle refining furnace), vacuum degassing (VD), mold casting, annealing, electroslag remelting (ESR ), slow cooling, annealing, forging, normalizing, spheroidizing annealing, hydrogen expansion, roughing, inspection, finishing, quenching and tempering, finishing, inspection, and production.

[0110] By controlling the composition of molten steel, the prepared mold steel contains C0.44%, Si0.40%, Mn0.60%, P0.010%, S0.002%, Cr5.20%, Ni1. 60%, Mo 0.90.%, V 0.60.%, W 0.55%, Co 0.09%, Al 0.10%, Nb 0.040%, the balance Fe. The obtained product is YB5A steel.

Embodiment 2

[0112] The method of smelting is with embodiment 1. By controlling the composition of molten steel, the prepared mold steel contains C 0.43%, Si 1.00%, Mn 0.40%, P 0.012%, S0.0015%, Cr4.80%, Ni1.40.% in weight % , Mo1.00%, V0.50%, W0.80%, Co0.090.%, Al0.010%, Nb0.030%, the balance Fe. The obtained product is YB5B steel.

Embodiment 3

[0114] The method of smelting is with embodiment 1. By controlling the composition of molten steel, the prepared die steel contains 0.43% C, 0.40% Si, 0.60% Mn, 0.009% P, 0.001% S0, 5.20% Cr, 1.60% Ni, Mo1. 10%, V 0.60%, W 0.55.%, Co 0.53%, Al 0.20%, Nb 0.025%, the balance Fe. The obtained product is YB5C steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com