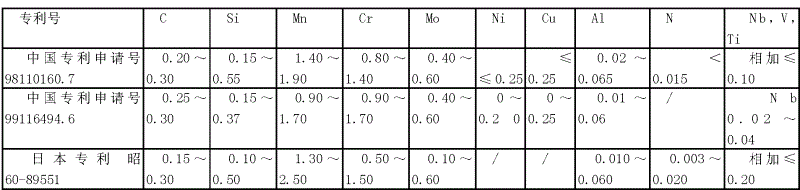

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce Mn content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1000 MPa low-carbon hot-galvanized dual-phase steel and preparation method thereof

ActiveCN105950998AGood mechanical propertiesGood formabilityHot-dipping/immersion processesMechanical propertyImpurity

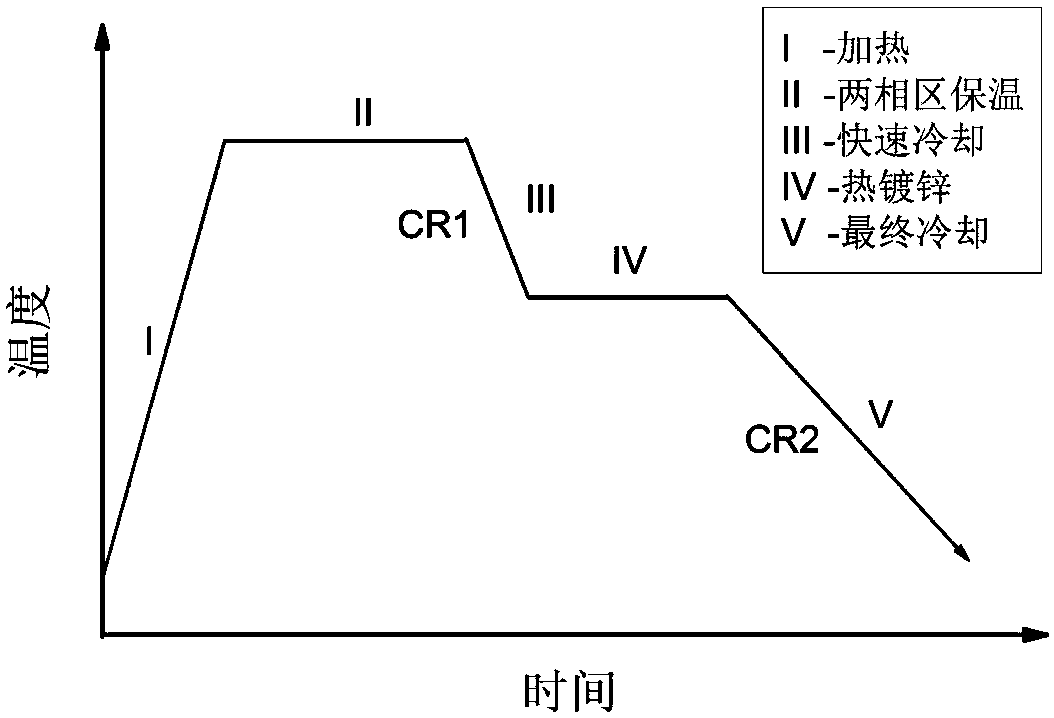

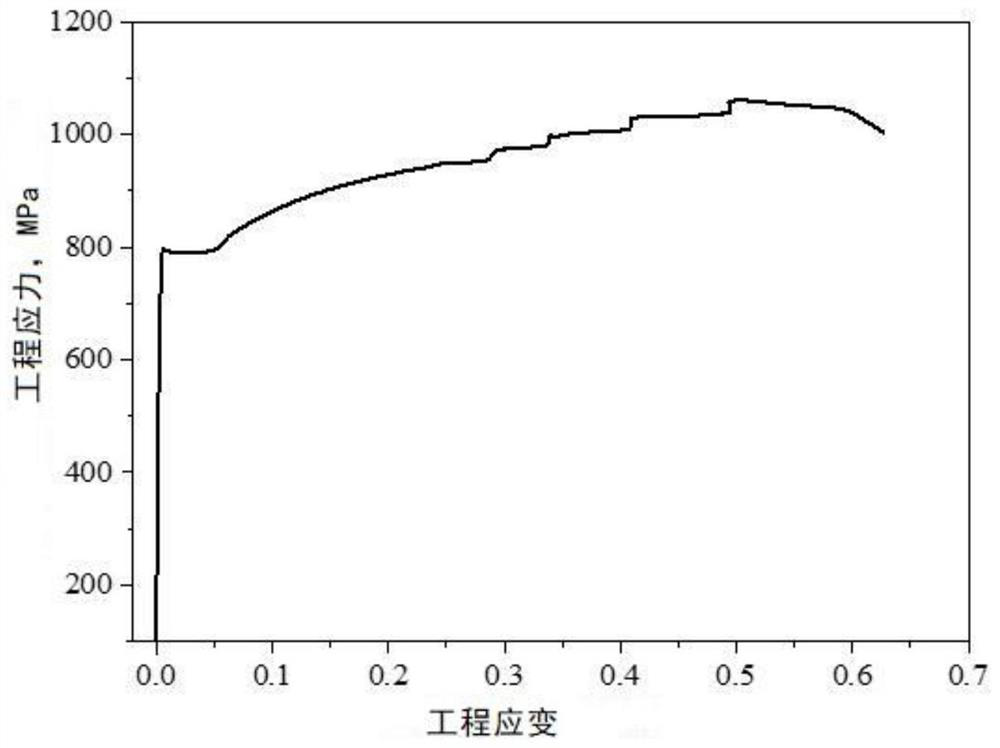

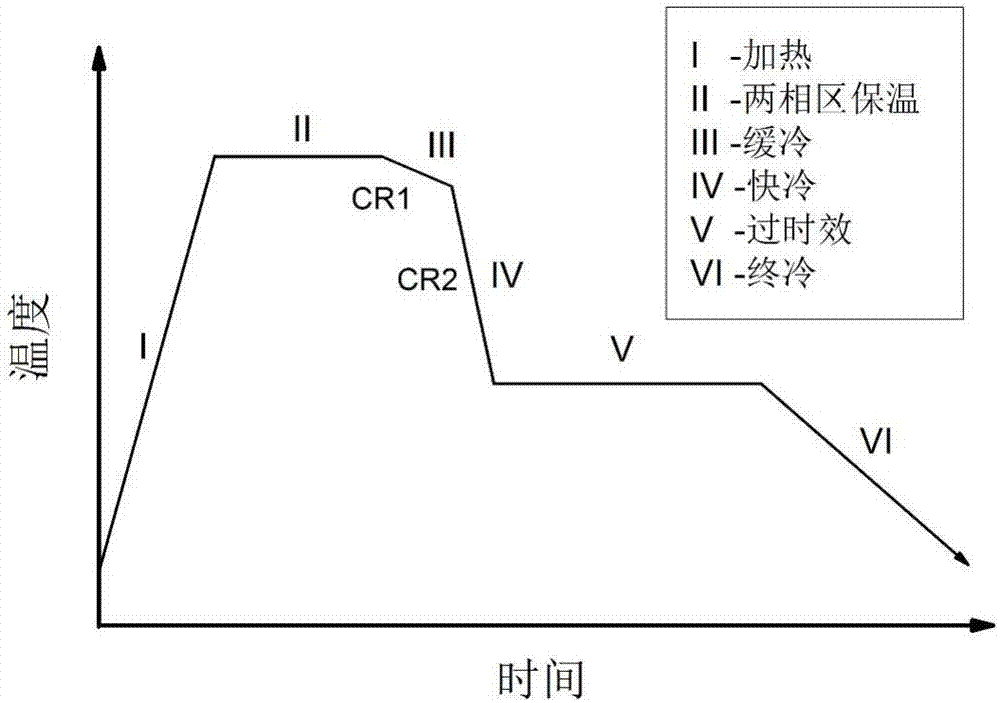

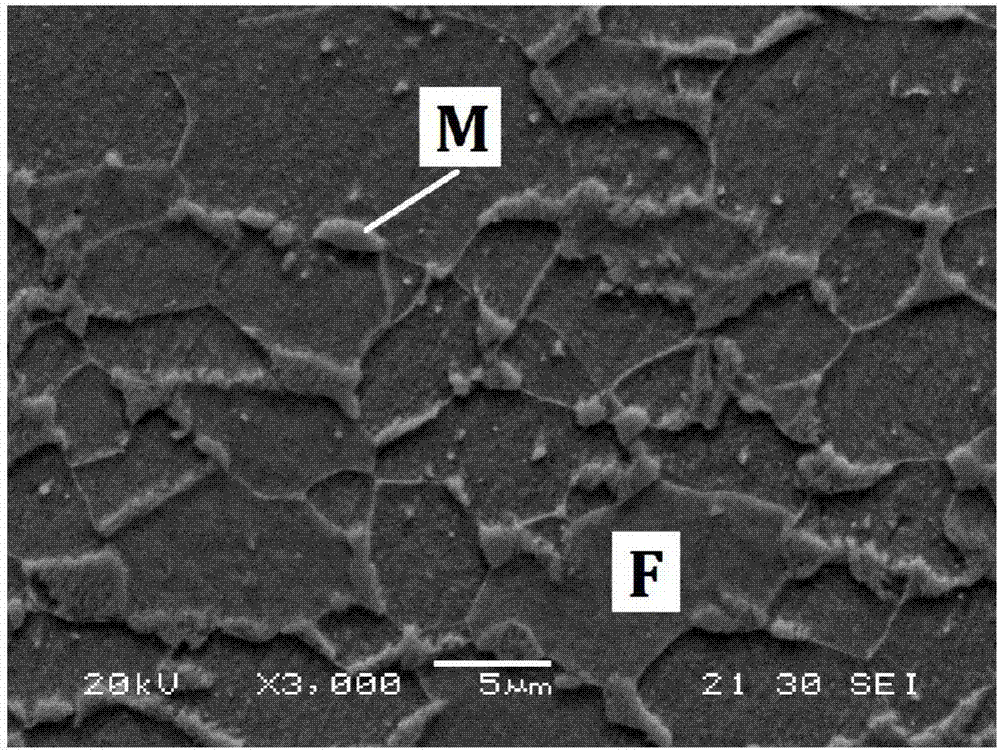

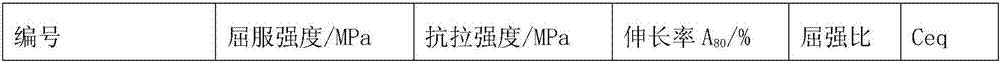

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cr5 series hot work die steel

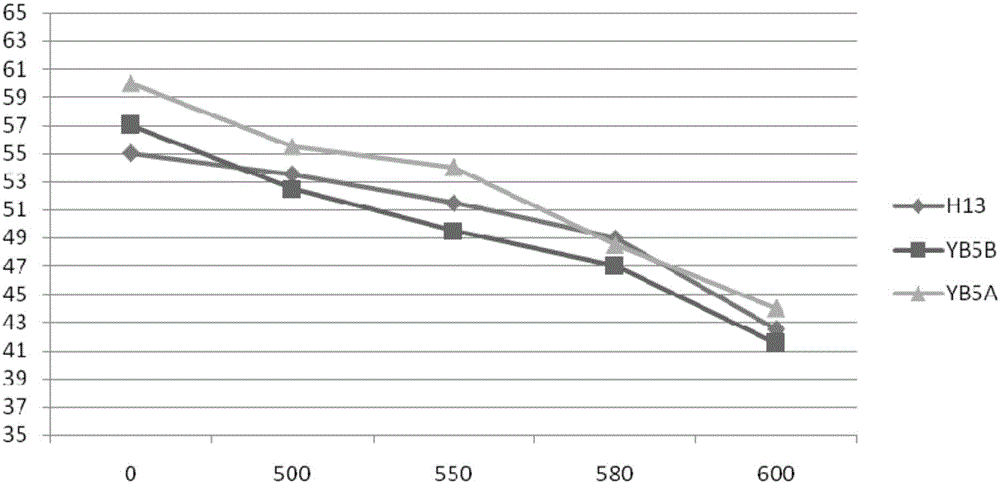

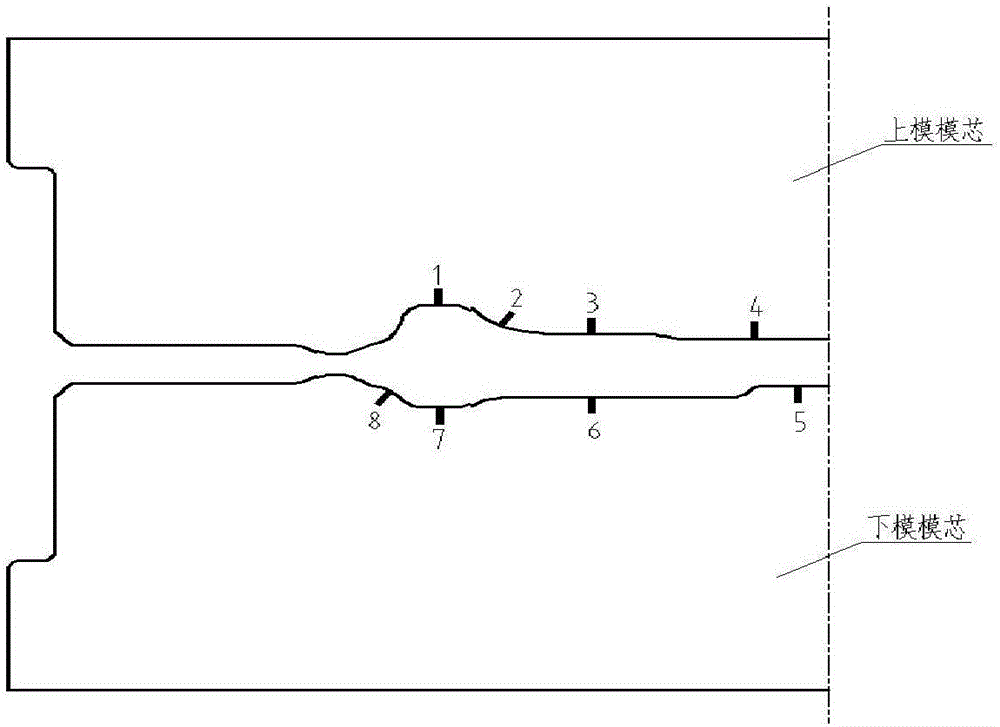

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

High-manganese ultralow temperature steel welding wire and welding process thereof

ActiveCN107186382AReduce Mn contentReduce Ni contentWelding/cutting media/materialsSoldering mediaSteelmakingShielding gas

The invention discloses a high-manganese ultralow temperature steel welding wire. The high-manganese ultralow temperature steel welding wire comprises the chemical components, by mass, of 0.2%-0.4% of C, 18.0%-27.0% of Mn, less than or equal to 0.15% of Si, less than or equal to 0.005% of S, less than or equal to 0.02% of P, 1.0%-3.0% of Ni, 2.0%-4.5% of Cr, 0.2%-0.5% of Cu, 0.01%-0.06% of N and the balance Fe and residual elements commonly existing in steelmaking. A welding process of the high-manganese ultralow temperature steel welding wire adopts tungsten pole argon arc welding, the groove is in a V shape, the heat input amount is 4-21KJ, and protective gas adopts high-purity argon. The high-manganese ultralow temperature steel welding wire is made of an alloy with the high Mn content, the Ni content is decreased by a large margin, and accordingly the material cost is reduced significantly. According to the welding process, preheating before welding and heat treatment after welding are not needed, the process is simple and easy to implement. The strength, plasticity and toughness of the formed weld metal are well matched, and the formed weld metal has good toughness especially in the ultralow temperature environment of -196 DEG C.

Owner:NANJING IRON & STEEL CO LTD

Tensile strength-780 MPa-stage vanadium-contained cold-rolled dual-phase steel and preparation method thereof

The invention relates to high-strength steel and a preparation method thereof, in particular to tensile strength-780 MPa-stage vanadium-contained cold-rolled dual-phase steel and a preparation method thereof. The tensile strength-780 MPa-stage vanadium-contained cold-rolled dual-phase steel comprises the following components in percentage by weight: 0.09-0.14% of C, 0.10-0.60% of Si, 1.30-1.80% of Mn, 0.10-0.60% of Cr, 0.01-0.06% of Al, 0.02-0.07% of V, P not more than 0.02%, S not more than 0.015%, N not more than 0.006%, and the balance of Fe and inevitable impurities. The tensile strength-780 MPa-stage vanadium-contained cold-rolled dual-phase steel is low in production cost and excellent in welding performance and mechanical performance, and reaches the yield strength of 430-480 MPa, the tensile strength of 805-840 MPa and the elongation of 15-18%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

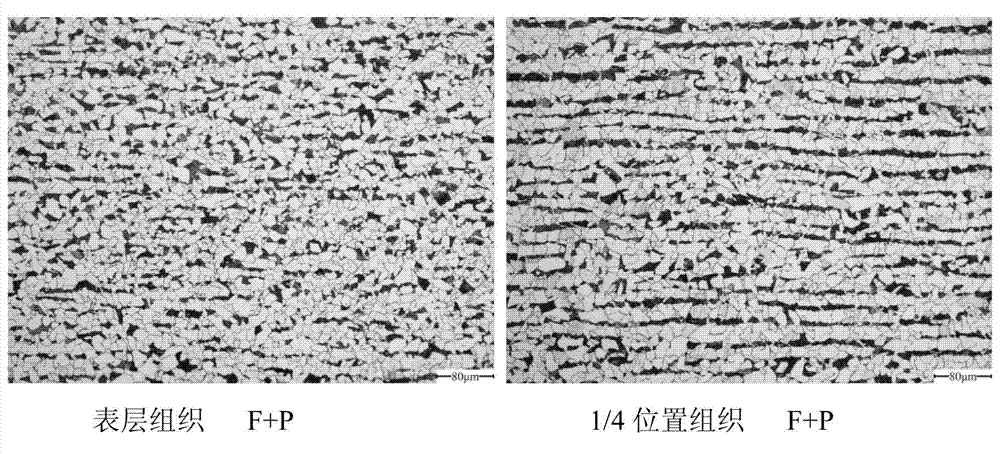

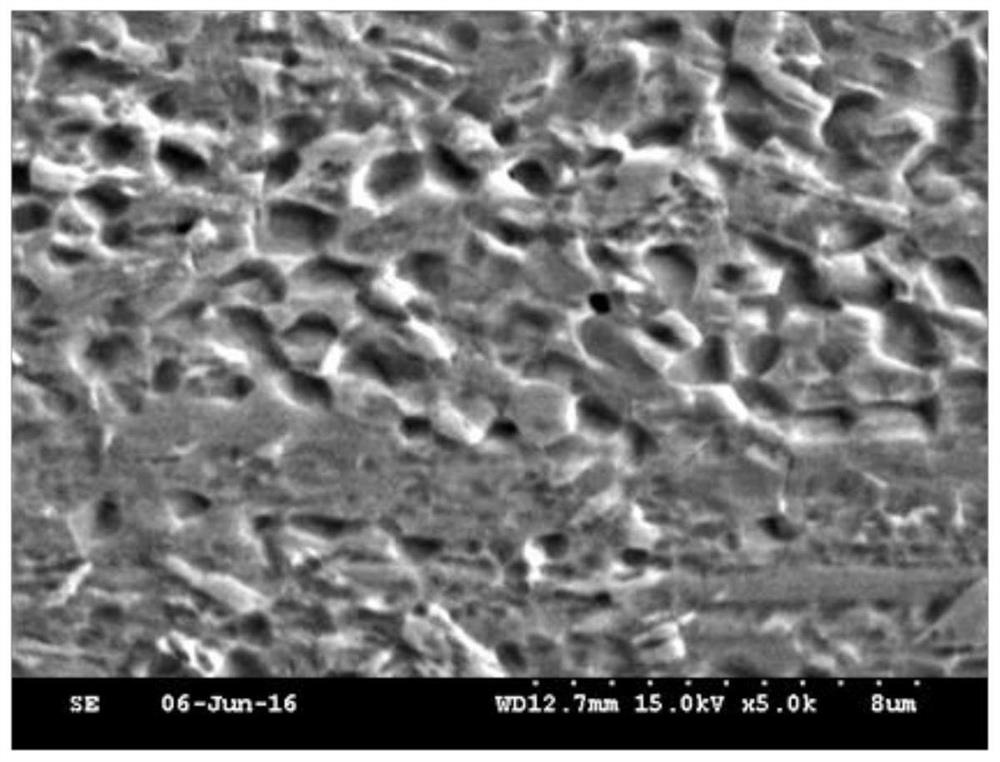

Resource-saving Q345 low-alloy series steel plate and production method thereof

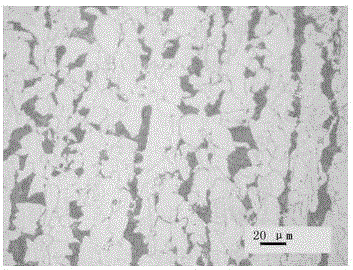

InactiveCN103045939AImprove performanceGuaranteed final performanceHeat treatment process controlAlloyPearlite

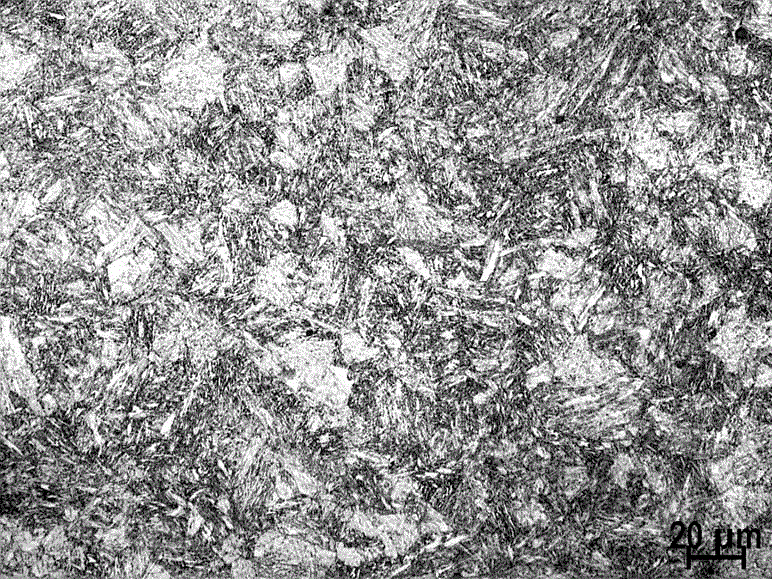

The invention discloses a resource-saving Q345 low-alloy series steel plate and a production method thereof. The steel plate comprises the following chemical components in percent by weight: 0.15 to 0.18 percent of C, 0.15 to 0.50 percent of Si, 1.10 to 1.25 percent of Mn, not more than 0.030 percent of P, not more than 0.035 percent of S, 0 to 0.045 percent of Alt, not more than 0.44 percent of carbon equivalent, and the balance of Fe and inevitable impurities. The production process of the steel plate comprises 150 t converter, LF external refining, slab continuous casting, slab heating, steckel mill controlled rolling, controlled cooling, thermal straightening, cooling, shearing and mark warehousing. The resource-saving Q345 low-alloy series steel plate, produced by the production method, has the yield strength of 360 to 420 MPa, the tensile strength of 500 to 550 MPa, and the elongation of 24 to 32%, and acicular ferrite with the thickness of 3 to 6 mm, polygonal ferrite, degenerate perlite and a small amount of granular bainite are arranged on the surface layer of the steel plate.

Owner:ANYANG IRON & STEEL

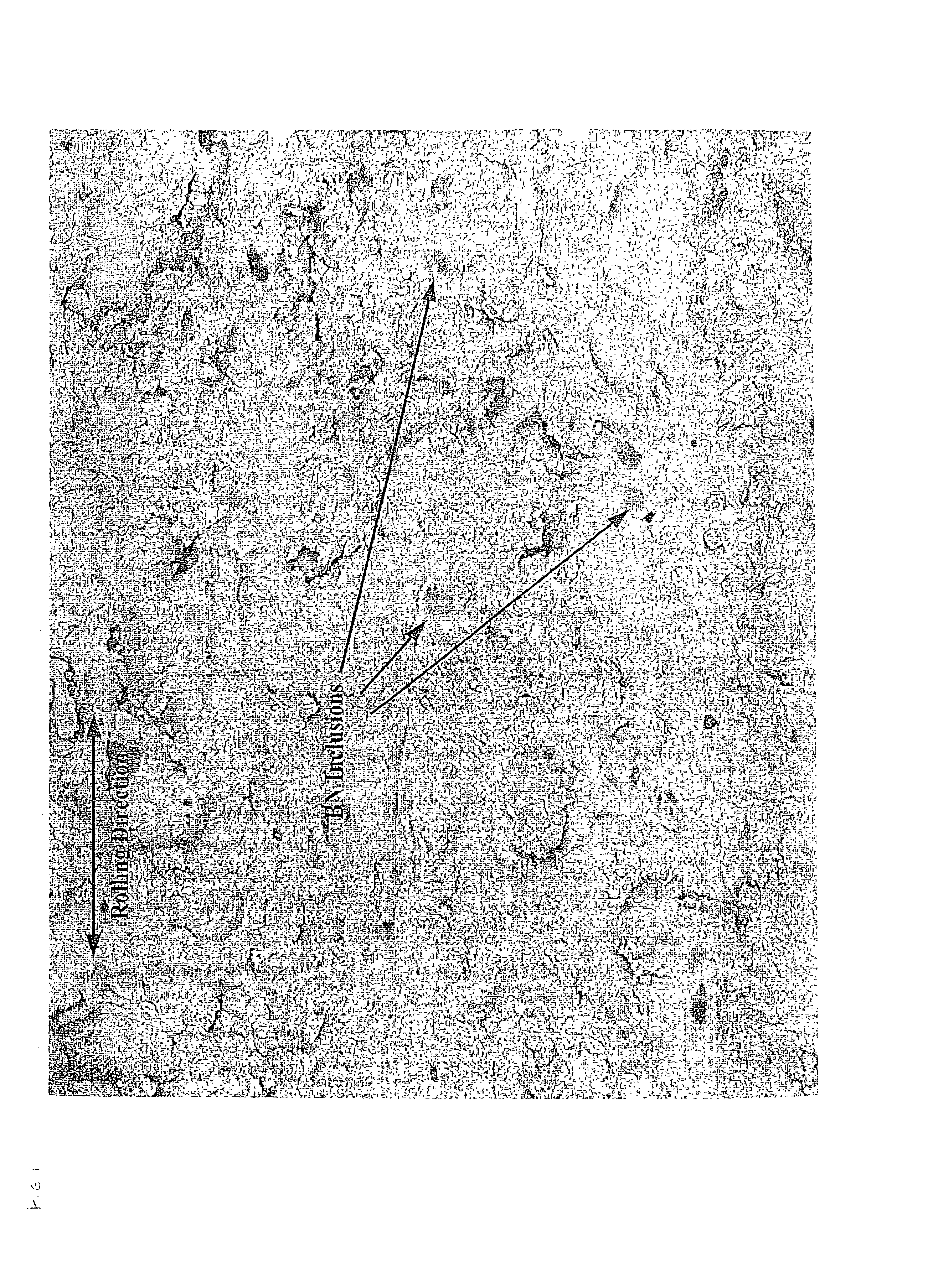

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

The invention relates to a quench-and-temper steel alloy for use in casing for oil and gas wells wherein such casing is exposed to low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, and a sulphur range by weight of less than 0.002%. The steel alloy has a quench-and-temper micro-structure and features precipitated spheroidal molybdenum carbides in manganese- and carbon-rich bands. The steel alloy also has, by weight, a chromium range of less than 0.50%, an aluminum range of less than or equal to 0.08% and a calcium range of less than or equal to 0.0045%.

Owner:IPSCO ENTERPRISES

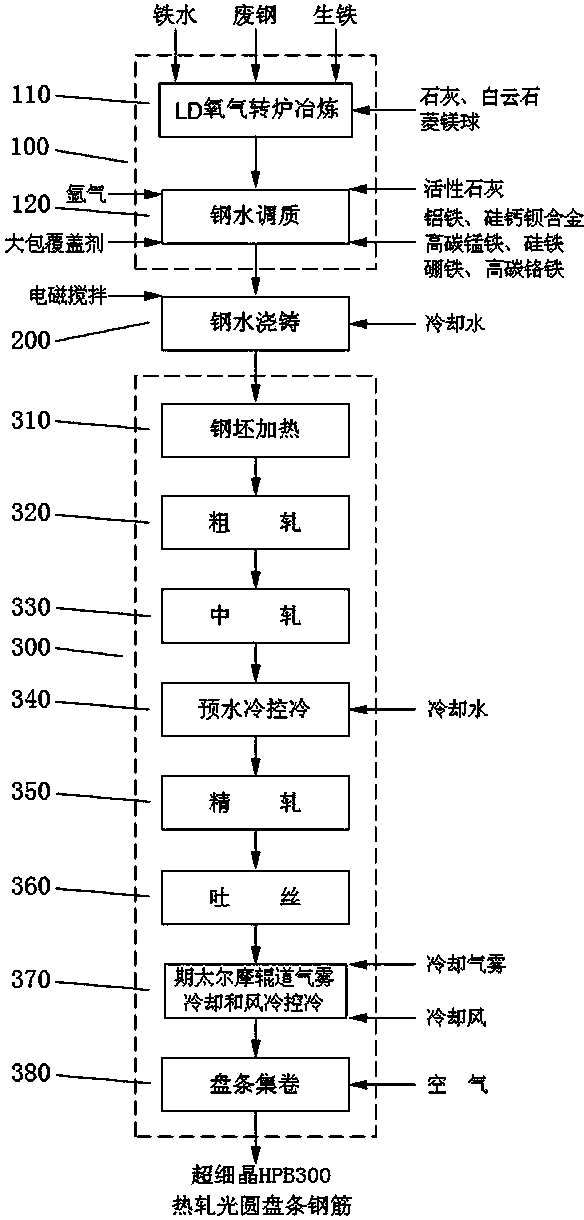

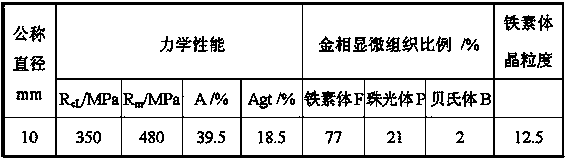

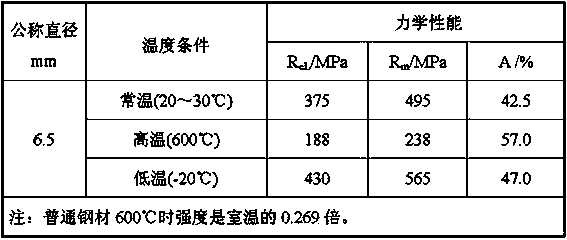

Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

The invention discloses an ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and a preparation method thereof. The ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar comprises the following components in percentage by weight: 0.15-0.18% of C, 0.10-0.16% of Si, 0.16-0.28% of Mn, 0.080-0.120% of Cr, 0.0010-0.0020% of B, less than 0.030% of S, less than 0.045% of P and the balance of Fe. The reinforcing steel bar is prepared from molten iron, steel scrap and pig iron through steps of molten steel smelting, molten steel pouring and billet controlled rolling and controlled cooling. According to the reinforcing steel bar, a small amount of ferromanganese, ferroboron and high carbon ferro-chrome alloy into the steel-making step, so that the alloying cost is remarkably lowered. By adopting low-temperature controlled rolling before spinning and a stelmor roller aerial fog cooling process after spinning, the reinforcing steel bar has the advantages of low cost, good toughness, excellent high- and low-temperature performance, low stress time-validity and the like.

Owner:WUKUN STEEL

Cr alloying steel without yield platform and preparation method thereof

ActiveCN110453146AImprove plasticityOvercoming Discontinuous Yield PhenomenonChemical compositionSheet steel

The invention discloses Cr alloying steel without a yield platform. The Cr alloying steel comprises, by mass, 0.03-0.3% of C, 1.0-9.0% of Cr, 0.01-2.0% of Mn, 0.01-2.0% of Al, 0.01-2.0% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, the balance being Fe and inevitable impurities; and the sum of the weight percentages of Al and Si is greater than or equal to 1.5%. A casting blank is obtained after molten steel smelting, and a hot-rolled coil with good plasticity can be directly used after the casting blank is heated and hot-rolled; austenite with moderate stability is obtained after annealing the hot rolled coil, and the preparation of a high-performance steel plate is finished; and a hot-rolled plate can also be subjected to on-line or off-line heat treatment, the hot-rolled plate is austenitized or partially austenitized by a heating furnace and then cooled to room temperature, the hot-rolled plate is heated and then annealed or directly annealed to obtainthe austenite with moderate stability, and the preparation of the high-performance hot-rolled plate is finished. According to the preparation method, the hot-rolled coil can be subjected to cold rolling again so as to obtain a cold-rolled steel plate with the required performance.

Owner:SHOUGANG CORPORATION

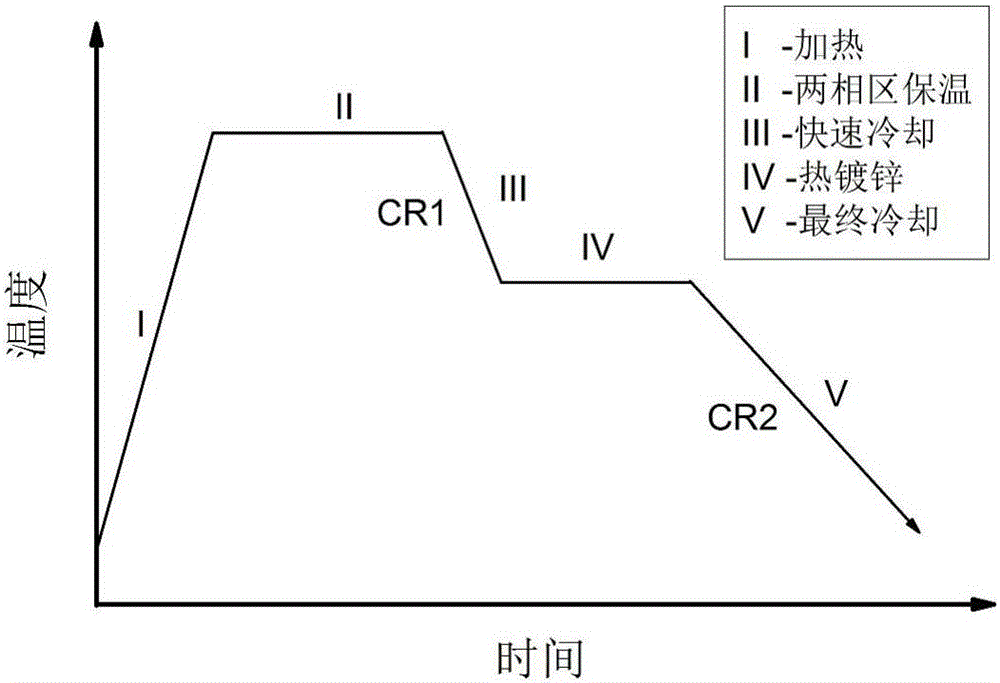

800 MPa-grade low-carbon hot-galvanized dual-phase steel and preparation method thereof

The invention belongs to the technical field of preparation of high-strength steel, and in particular, relates to 800 MPa-grade low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel comprises the following components in percentage by weight: 0.05-0.10% of C, 0.20-0.60% of Si, 1.30-1.80% of Mn, 0.10-0.60% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.05-0.10% of V, P not more than 0.015%, S not more than 0.005%, N not more than 0.006%, and the balance of Fe and inevitable impurities. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel is low in production cost, high in forming performance and welding performance and excellent in galvanizing performance and mechanical performance, and reaches the yield strength of 450-520 MPa, the tensile strength of 805-840 MPa and the elongation of 15-18%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

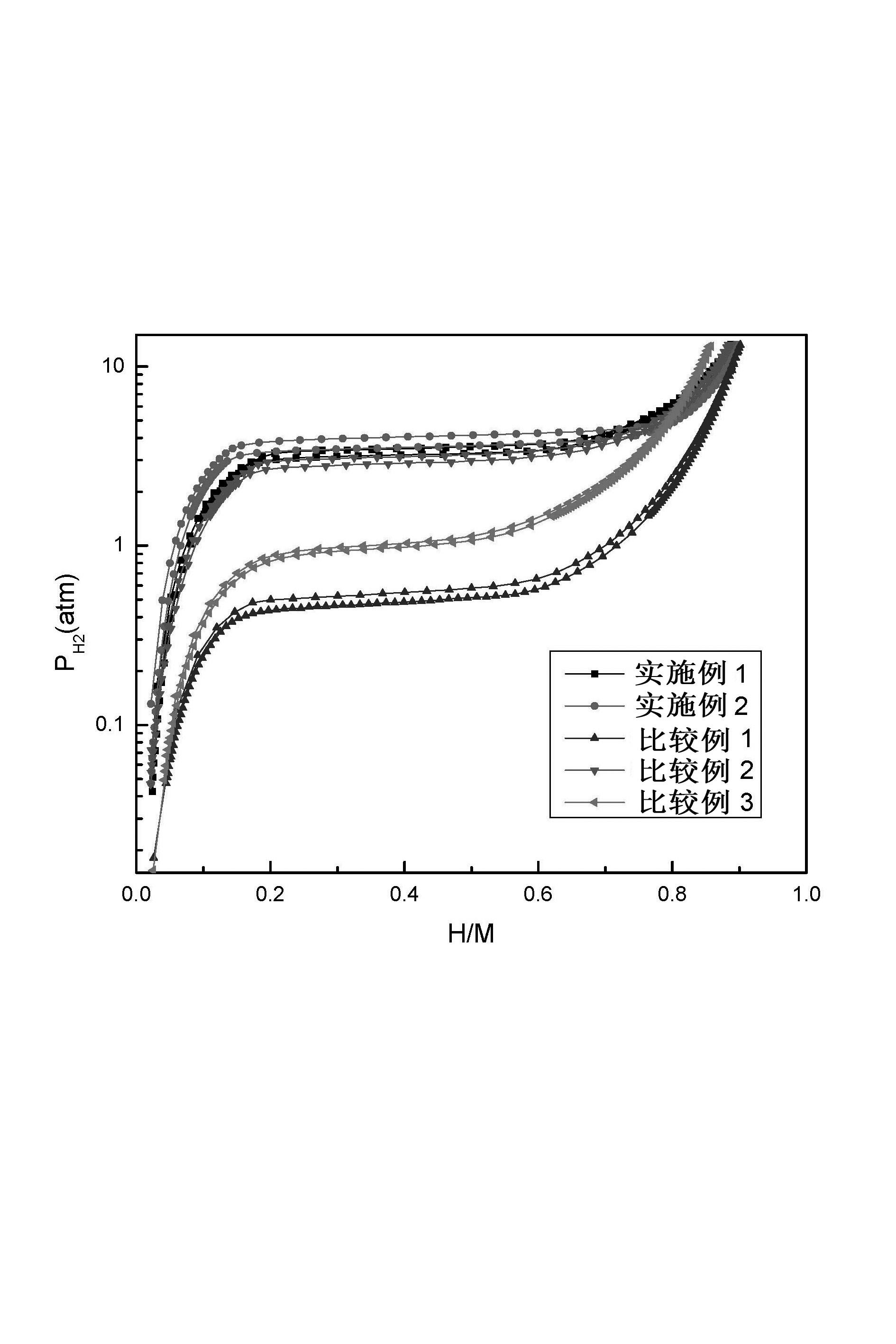

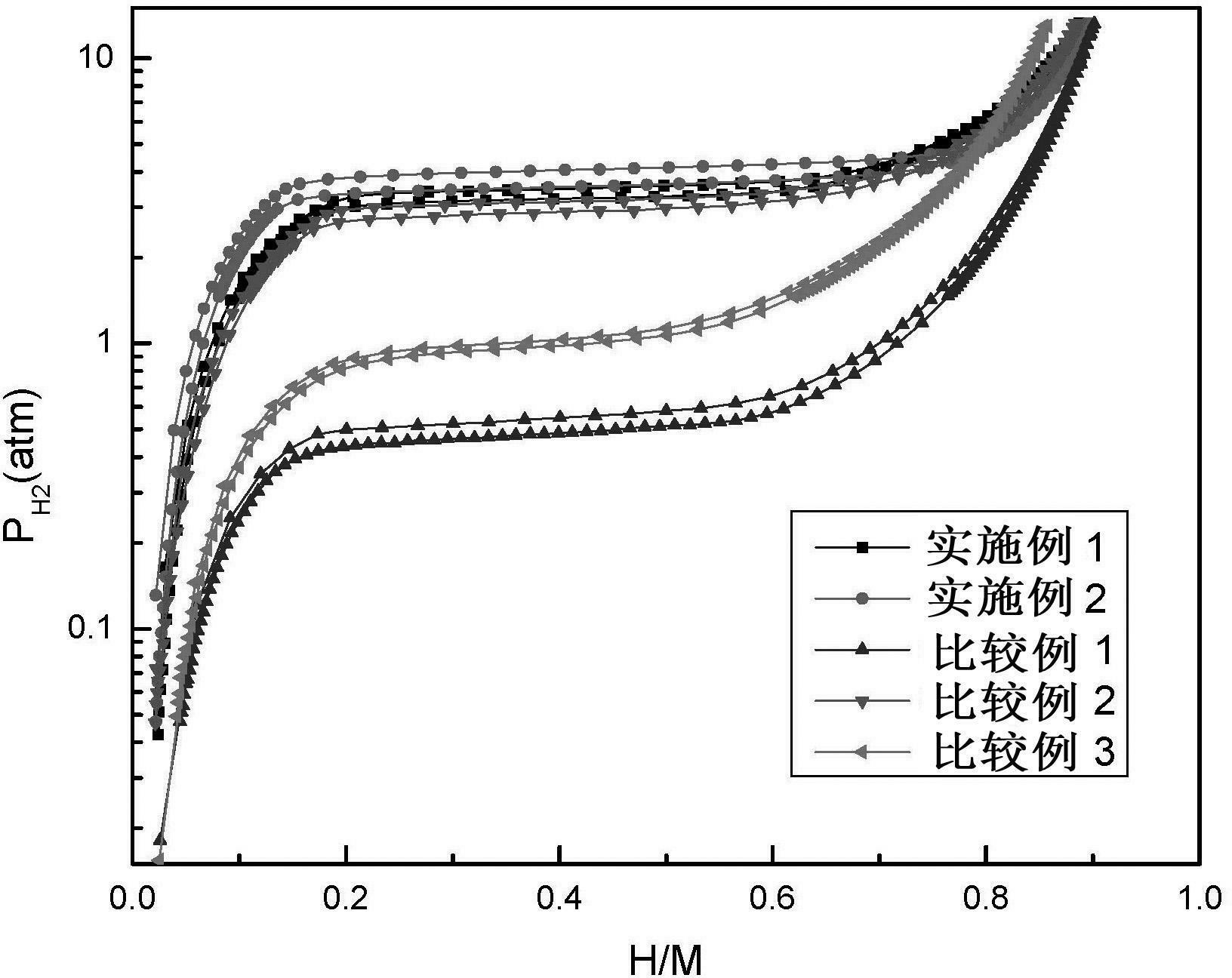

Low temperature power type hydrogen storage alloy for nickel-metal hydride battery

ActiveCN102644007AImprove electrochemical performanceIncreased self-dischargeCell electrodesSelf-dischargeVoltage

The invention discloses a low temperature power type hydrogen storage alloy for a nickel-metal hydride battery. An alloy general formula is MlNiaCobMncAld, wherein a, b, c and d show molar ratio, the number range is 3.9<=a<=4.8, 0.3<=b<=0.6, 0<=c<=0.1, 0.1<=d<=0.4, 5.0<=a+b+c+d<=5.3. The Ml is composed of La and one of elements of Ce, Pr, Nd, Sm, Gd, Dy, Y and Zr, the La content is 40-80wt% of the Ml, and corresponding La is 10-26wt% of the content of the alloy. The alloy has excellent low temperature performance and high discharge voltage, simultaneously Mn content in the alloy composition is low, and the low temperature power type hydrogen storage alloy has excellent self discharge performance.

Owner:XTC HYDROGEN ENERGY SCI & TECH (XIAMEN) CO

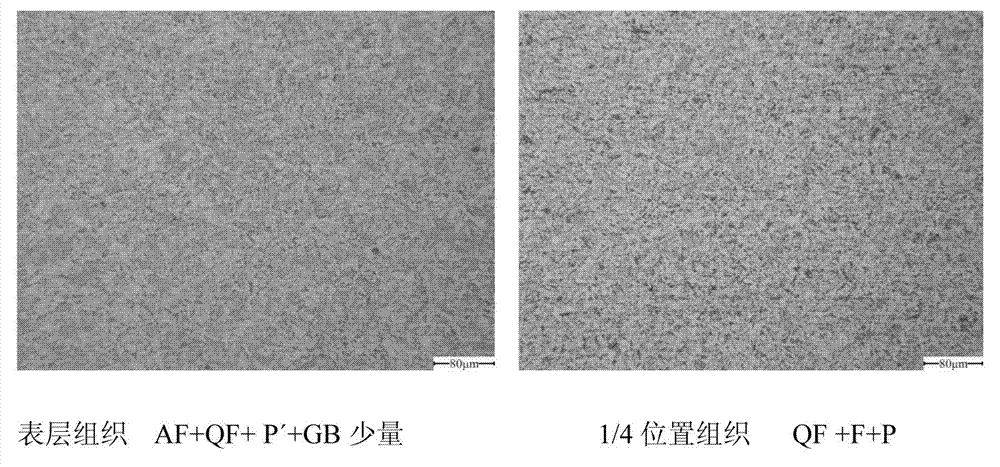

High-hardenability and high-strength ultra-thick marine steel plate and production method thereof

The invention relates to a high-hardenability and high-strength ultra-thick marine steel plate. The high-hardenability and high-strength ultra-thick marine steel plate is 60-150 mm thick and is composed of the chemical components of, by weight percentage, 0.04-0.08% of C, 4-9% of Mn, 0.10-0.25% of Si, 0.01-0.03% of Als, 0.2-0.5% of Mo, 0.025-0.050% of Nb, less than or equal to 0.04% of S, less than or equal to 0.007% of P, and Fe and impurity elements as balance. The high-hardenability and high-strength ultra-thick marine steel plate can solve the phenomenon of non-uniformity of thickness direction texture and performance, expand the thickness specification to 150 mm with low-temperature toughness still meeting the operating requirements at -80 DEG C and obtain low yield ratio under equal yield strength conditions, specifically, the parts of 1 / 4 and 1 / 2 thickness of the steel plate reach a yield strength not lower than 690 MPa, a yield ratio not higher than 0.86, an elongation percentage not lower than 20%, and a -80 DEG C low-temperature impact energy greater than 100 J.

Owner:NANJING IRON & STEEL CO LTD

Wheel steel with tensile strength being at level of 590 MPa and production method

The invention discloses wheel steel with the tensile strength being at level of 590 MPa and a production method. The wheel steel with the tensile strength being at level of 590 MPa comprises, by weight, 0.05%-0.09% of C, no more than 0.1% of Si, 1.4%-1.7% of Mn, no more than 0.015% of P, no more than 0.008% of S, 0.04%-0.055% of Nb, no more than 0.0025% of O, no more than 0.0040% of N, 0.015%-0.045% of Als, and the balance Fe and inevitable impurities. The production method comprises the following steps of converter smelting, LF refining, continuous casting of a slab, heating of the slab, descaling with high-pressure water, controlled rolling, cooling for controlled rolling, and curling. A hot-rolled curled plate produced through the method is reinforced through Nb, the C content is decreased, the welding performance and forming performance of the wheel steel are improved, and industrial production is achieved.

Owner:HEBEI IRON AND STEEL

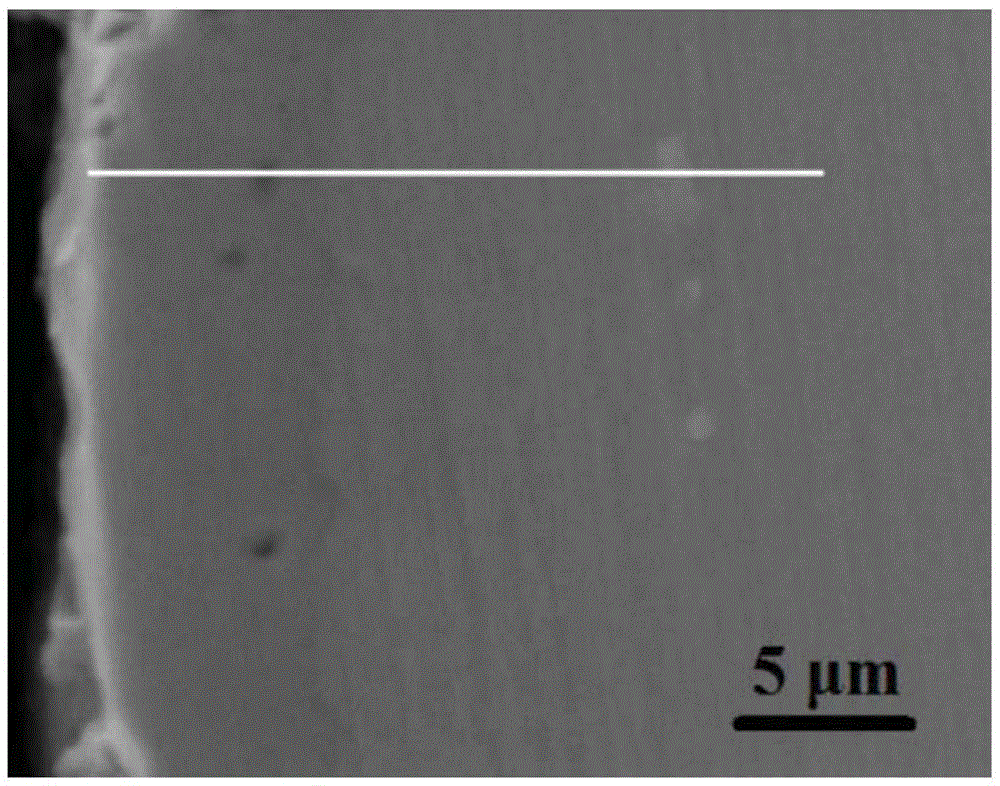

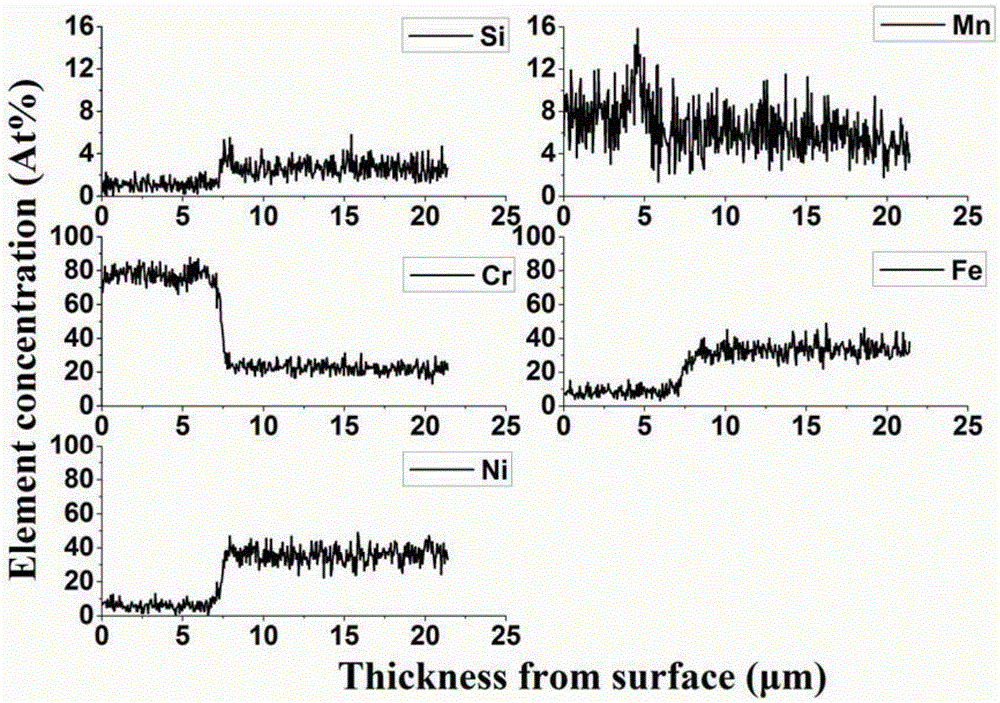

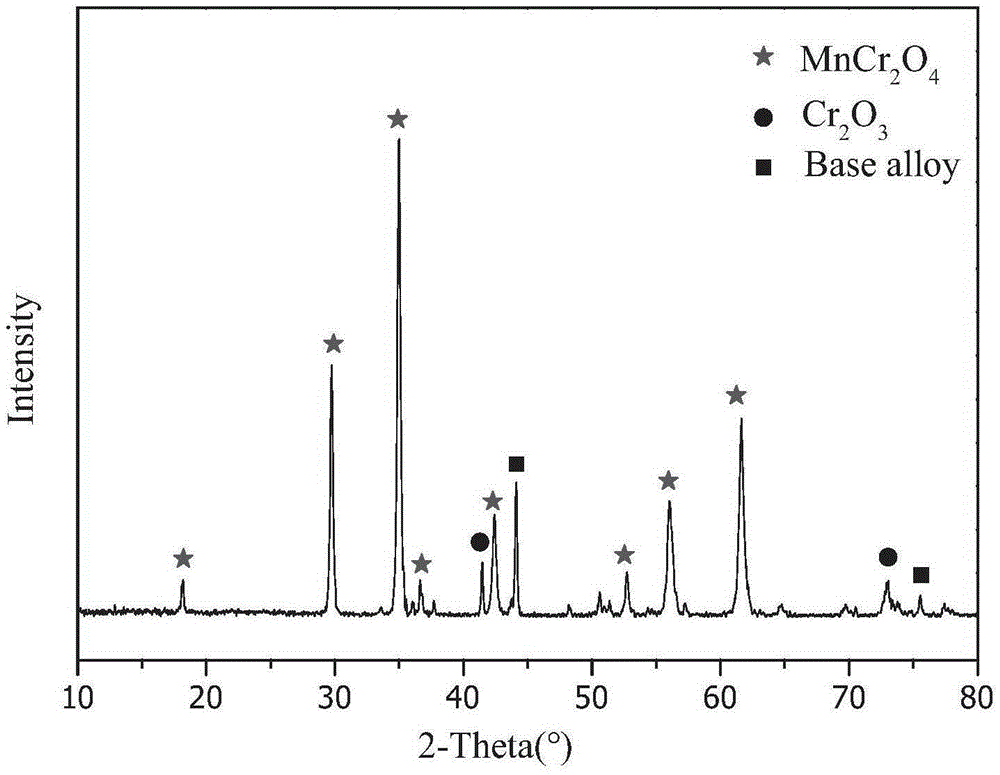

Preparation method for forming spinel coating on surface of alloy

ActiveCN106756775AControl concentration distributionThe overall thickness is thinSolid state diffusion coatingTectorial membraneSpinel

The invention relates to a preparation method for forming a spinel coating on the surface of an alloy. Mn and Cr alloy elements are infiltrated into the surface of the alloy by adopting the elemental co-infiltration process, the concentration of the surface elements, especially Mn, is increased, and then the surface of the material is subjected to in-situ oxidation through the low oxygen partial pressure method, to preferentially generate a dense manganese chrome spinel protective film. The protective film can effectively improve the high temperature oxidation resistant, anti-carburizing and anti-coking performances of the material, thereby prolonging the service life or coke cleaning period of the material.

Owner:EAST CHINA UNIV OF SCI & TECH

Low alloy structural steel with low cost and thick specification and production method thereof

The invention discloses low alloy structural steel with low cost and thick specification. The low alloy structural steel comprises the following components by weight percent: 0.17%-0.20% of C, 0.15%-0.30% of Si, 0.35%-0.55% of Mn, less than or equal to 0.025% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, and the rest of Fe and inevitable impurities. A production method of the structural steel comprises the following steps: (1) continuous casting to obtain billet; (2) soaking the cast billet; (3) high-pressure descaling, and finish rolling, wherein the sum of reduction rates of F1 and F2 is greater than or equal to 98% and is less than or equal to 105%, and F1 and F2 cooling water amount is 70%-80% of normal water amount, F3 or F4 is nominal, and the outlet temperature is 840-870 DEG C; (4) setting the laminar flow cooling speed to be 40-83 DEG C / s, the coiling temperature to be 540-570 DEG C, and the head coiling temperature to be 580-600 DEG C; (5) cooling. The production method disclosed by the invention basically eliminates phenomena such as mixed crystal and cold bending cracking, has good coiling shape, and is suitable for being widely applied to the field of steel production.

Owner:武汉钢铁有限公司

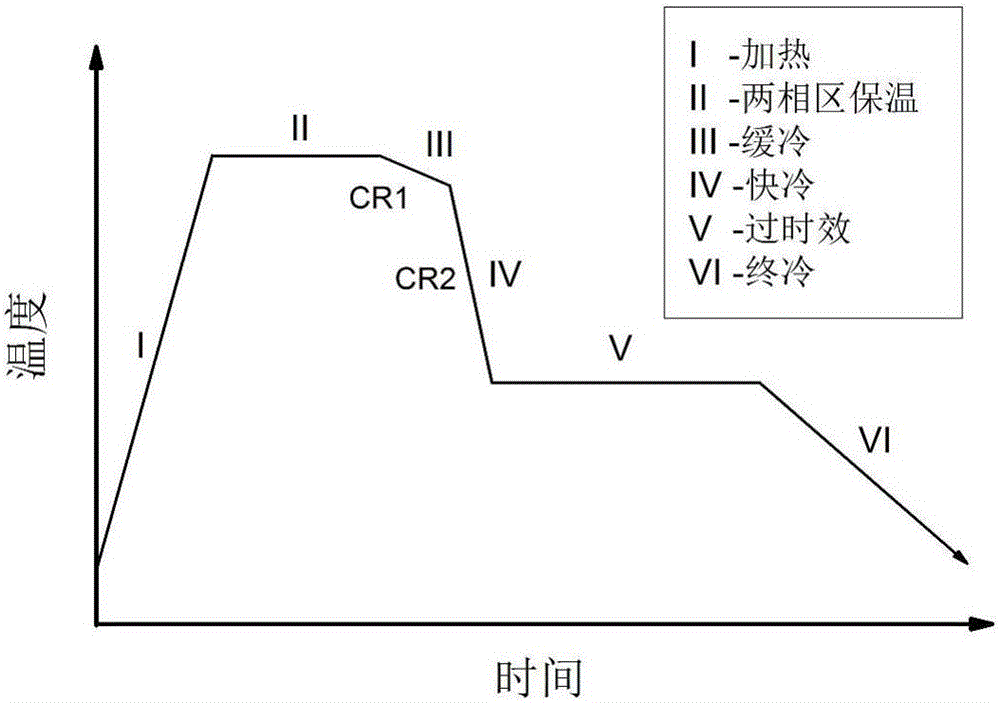

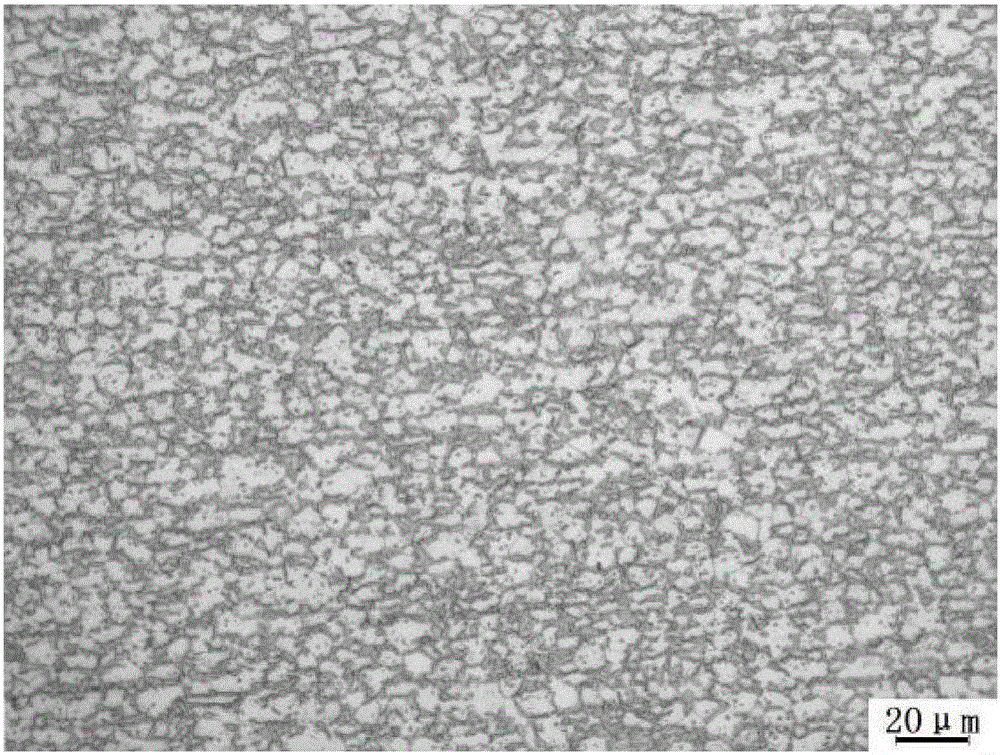

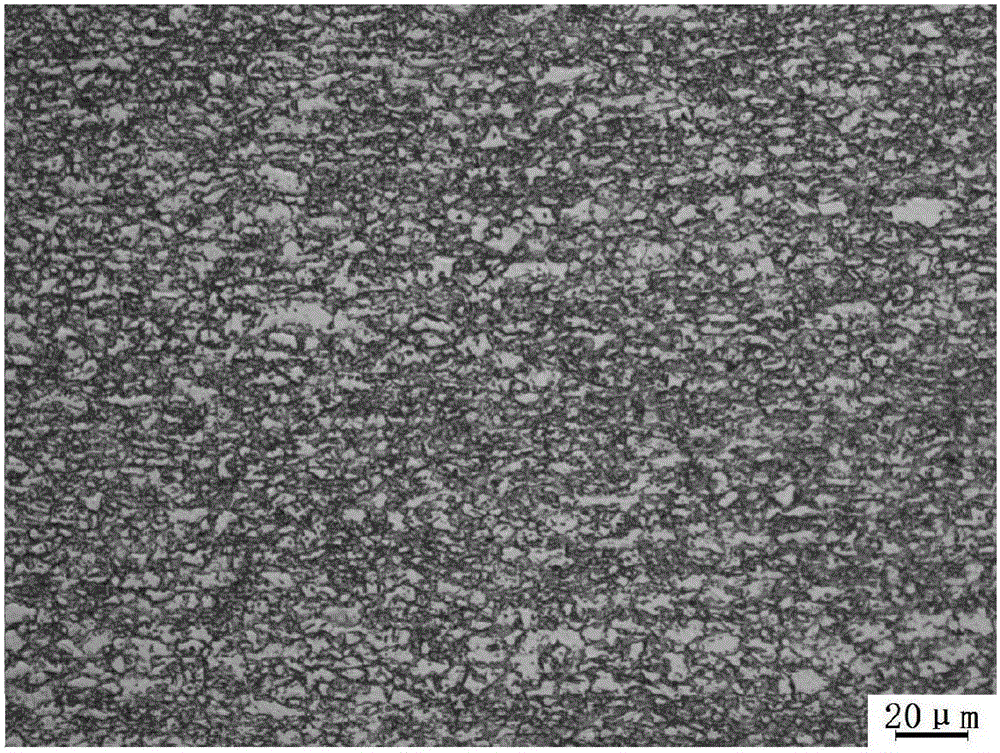

Cold-rolling medium Mn steel with low Mn content and high product of strength and ductility, and preparation method for same

The invention provides cold-rolling medium Mn steel with a low Mn content and a high product of strength and ductility, and a preparation method for the same. The steel contains, by weight, the chemical components including 0.15%-0.6% of C, 3.0%-6.0% of Mn, 1.0%-3.0% of Al, 0.0%-2.0% of Si, 0%-5.0% of Cr, 0%-2.0% of Ni and the balance being Fe and inevitable impurities. Preparation of the cold-rolling medium Mn steel with the high product of strength and ductility comprises the steps that molten steel is smelted by a converter, and a continuous casting blank is obtained through continuous casting; the continuous casting black is heated by a heating furnace, and a hot-rolling plate roll is obtained after hot rolling; the hot-rolling roll is treated with softening annealing by a bell furnace, and cold and hard belt steel is obtained after cold rolling; and the cold and hard belt steel is treated with continuous annealing, and the finished product of the cold-rolling medium Mn steel withthe high product of strength and ductility is obtained. The cold-rolling medium Mn steel and the preparation method provided by the invention have the beneficial effects that the Mn steel has the highproduct of strength and ductility on the premise that good ductility is ensured during cold rolling; and the significance of practical application is high.

Owner:SHOUGANG CORPORATION

Hot continuous rolled steel plate and production method thereof

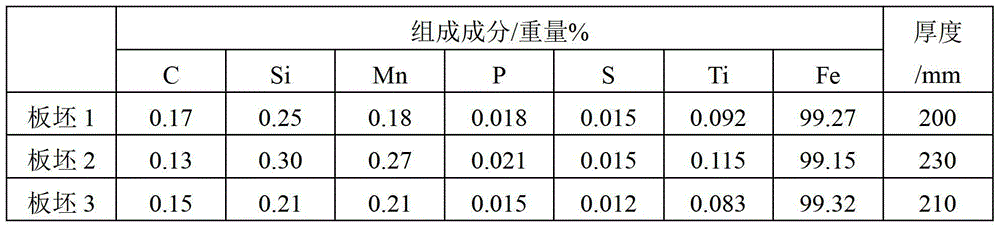

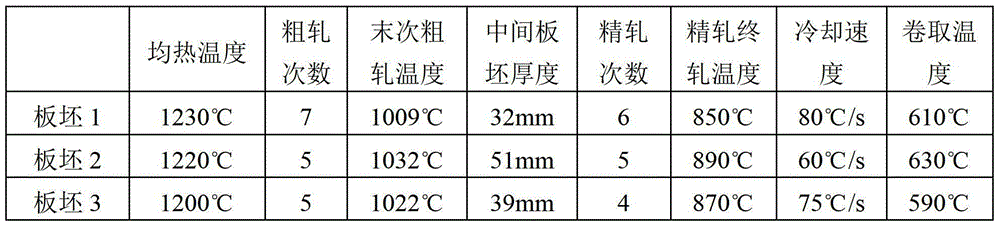

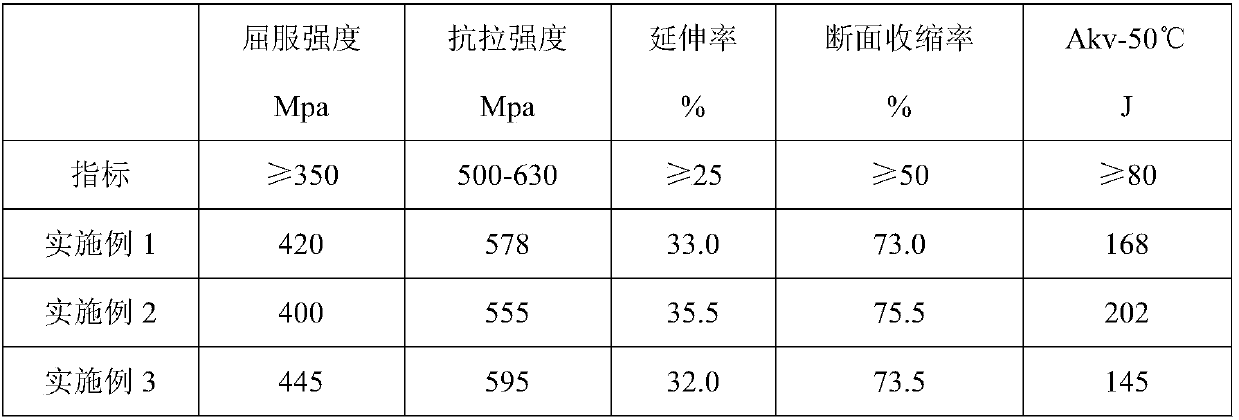

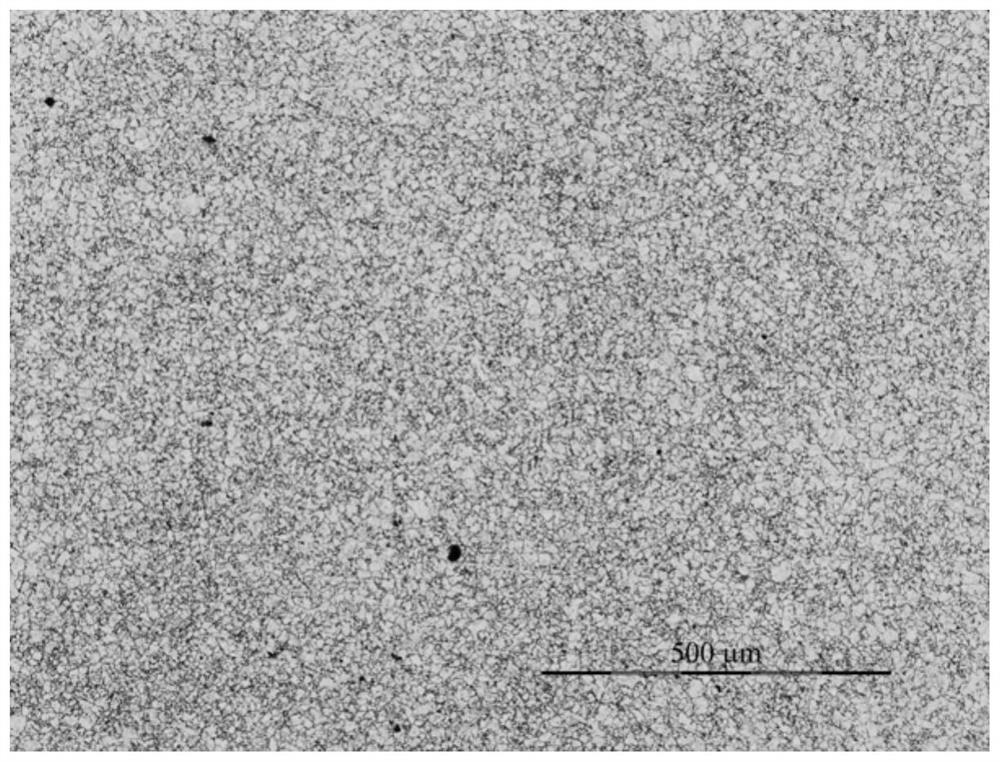

InactiveCN104060161AReduce Mn contentMake up for loss of strengthRoll mill control devicesMetal rolling arrangementsSheet steelREL

The invention discloses a production method of a hot continuous rolled steel plate, the method includes sequential rough rolling, finish rolling, cooling and coiling of a plate blank, and the plate blank comprises the following components by weight: 0.1-0.2 wt% of C, less than or equal to 0.45 wt% of Si, 0.15-0.5 wt% of Mn, less than or equal to 0.025 wt% of P, less than or equal to 0.025 wt% of S, 0.08-0.2 wt% of Ti, and 98.6-99.7 wt% of Fe; and the cooling speed is 50 to 100 DEG C / s. The invention also discloses the hot continuous rolled steel plate prepared by the method. The yield strength ReL of the hot continuous rolled steel plate is greater than or equal to 345MPa, the tensile strength Rm is 470-630MPa, and the elongation rate A is greater than or equal to 21.0%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Normalized cryogenic steel at temperature of -50 DEG C and manufacturing method thereof

The invention provides a steel for normalizing -50°C low temperature. The composition of the steel plate is as follows by weight percentage: C: 0.09%-0.15%, Si: 0.16%-0.50%, Mn: 0.60%-1.18%, Ni: 0.10 %~0.50%, Mo: 0.01%~0.09%, Cr: 0.15%~0.30%, V: 0.06%~0.10%, Ti: 0.015%~0.030%, S: ≤0.005%, P: ≤0.008%, remainder The amount is Fe and unavoidable impurities, Ceq≤0.36. Manufacturing method: converter smelting, refining, continuous casting, slow cooling of slab, cleaning, rolling, heat treatment. Adopting the invention to produce low-temperature steel has yield strength ≥ 350MPa, tensile strength 500-630MPa, elongation ≥ 25%, and the strength is about 15% higher than that of 09MnNiDR steel of the same level.

Owner:ANGANG STEEL CO LTD

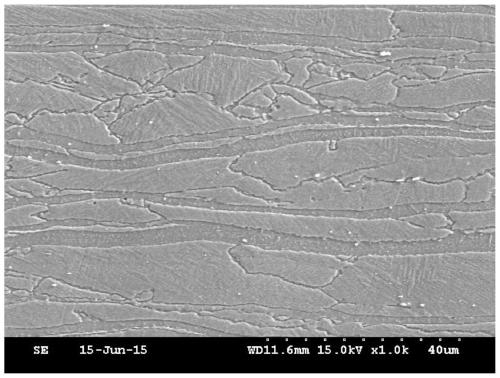

Economical Nb-containing cold-rolling medium manganese steel and preparation method thereof

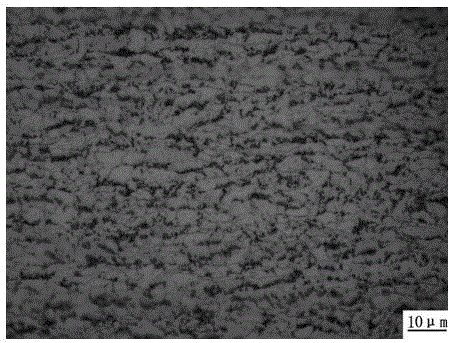

The invention discloses economical Nb-containing cold-rolling medium manganese steel and a preparation method thereof. The economical Nb-containing cold-rolling medium manganese steel is prepared fromthe following chemical components in percentage by mass: 0.15 to 0.20 percent of C, less than or equal to 0.20 percent of Si, 3.8 to 4.2 percent of Mn, 0.10 to 0.20 percent of Nb, less than or equalto 0.01 percent of P, less than or equal to 0.01 percent of S, and the balance Fe. According to the economical Nb-containing cold-rolling medium manganese steel and the preparation method thereof provided by the invention, the process parameters are reasonably controlled, no any noble metal element is added on the basis of traditional medium manganese steel, meanwhile, the Mn content is reduced, so that on one hand, the smelting and continuous casting performances are improved, and the occurrence of segregation and cracks is reduced; on the other hand, through the reasonable matching of the reduction of the Mn content and a hot rolling process, the deformation resistance during cold rolling is reduced, so that the processes such as intermediate annealing are reduced, and the technologicalprocess is shortened; and a large number of metastable austenite, ultra-fine ferrite and carbide structures are obtained through a reversal transformation annealing process, so that the strength and the plasticity of the steel are improved, and the development demands of high strength and plasticity, good welding performance, resource conservation, cost reduction and the like of the steel for an automobile are met.

Owner:MAANSHAN IRON & STEEL CO LTD

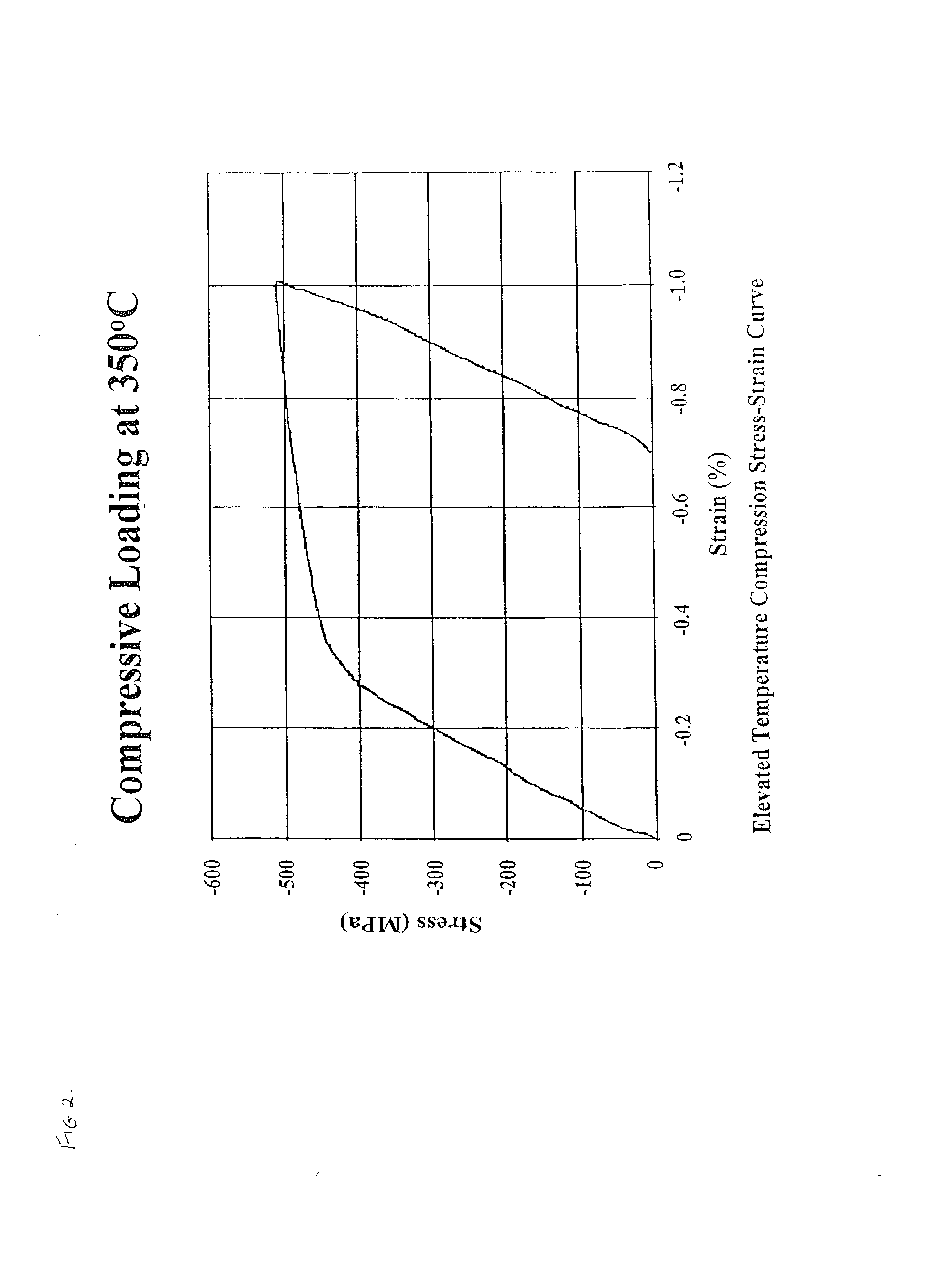

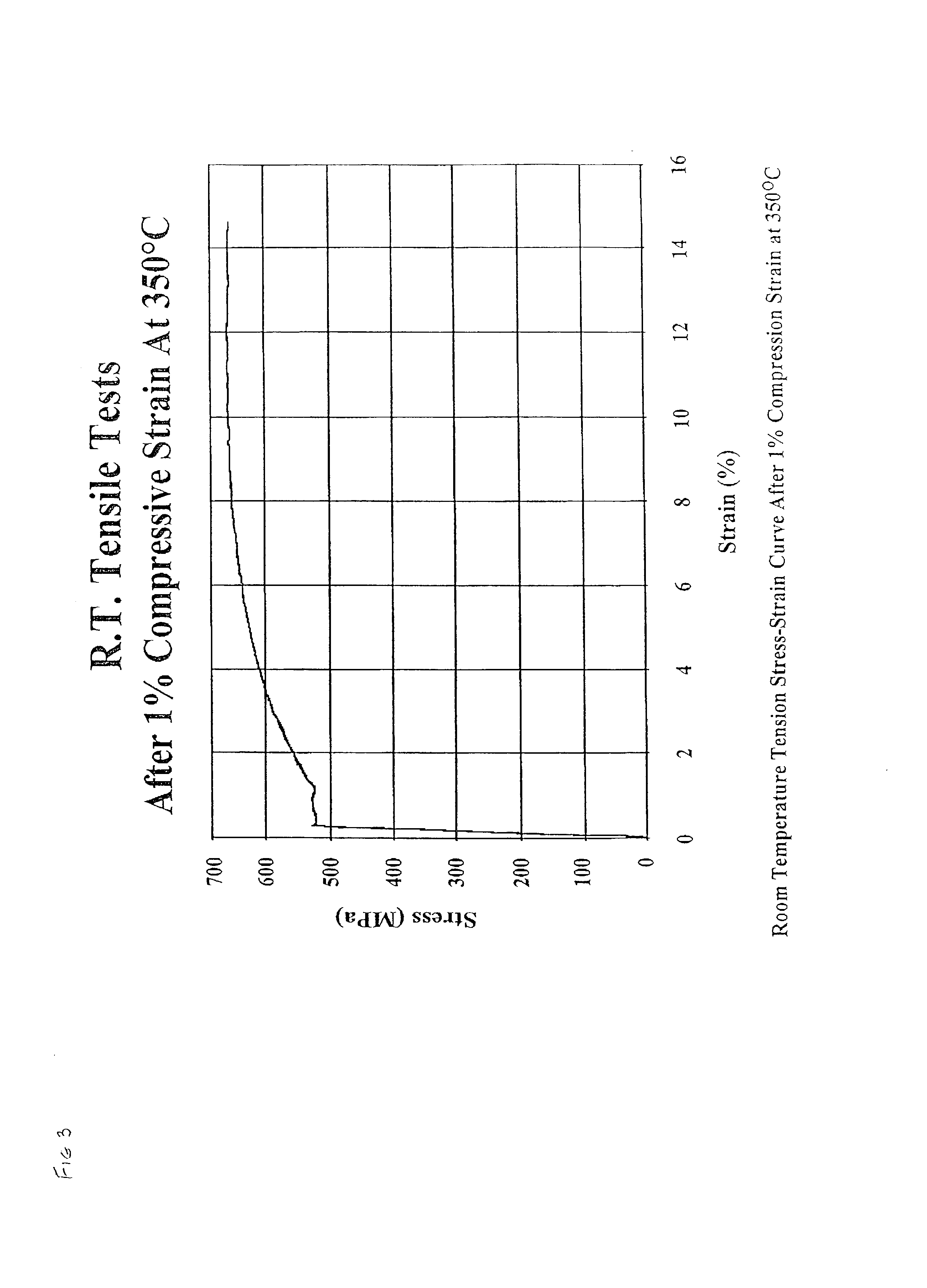

High-strength high-ductility spring steel used in high-temperature and high-pressure conditions and production method of high-strength high-ductility spring steel used in high-temperature and high-pressure conditions

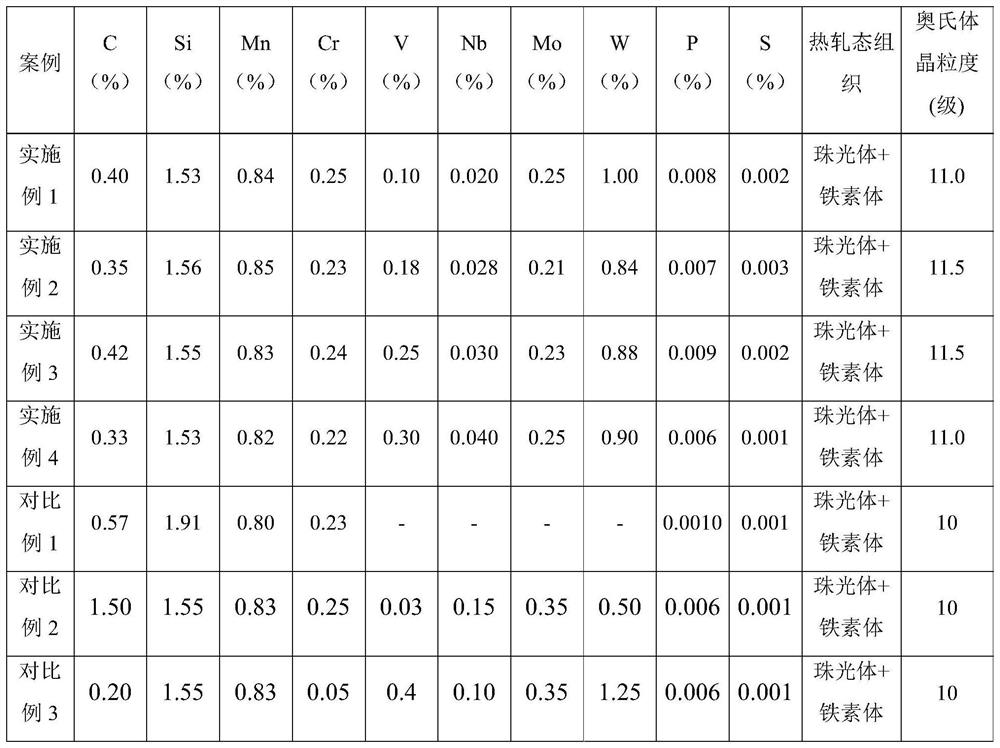

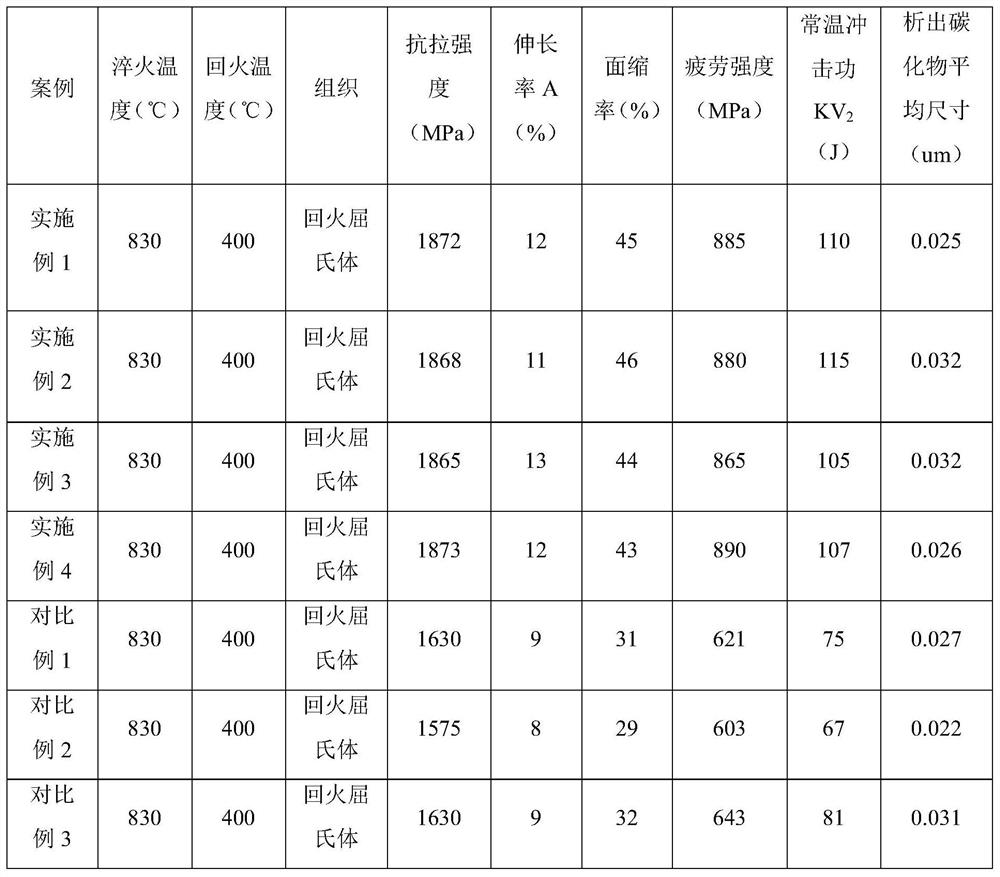

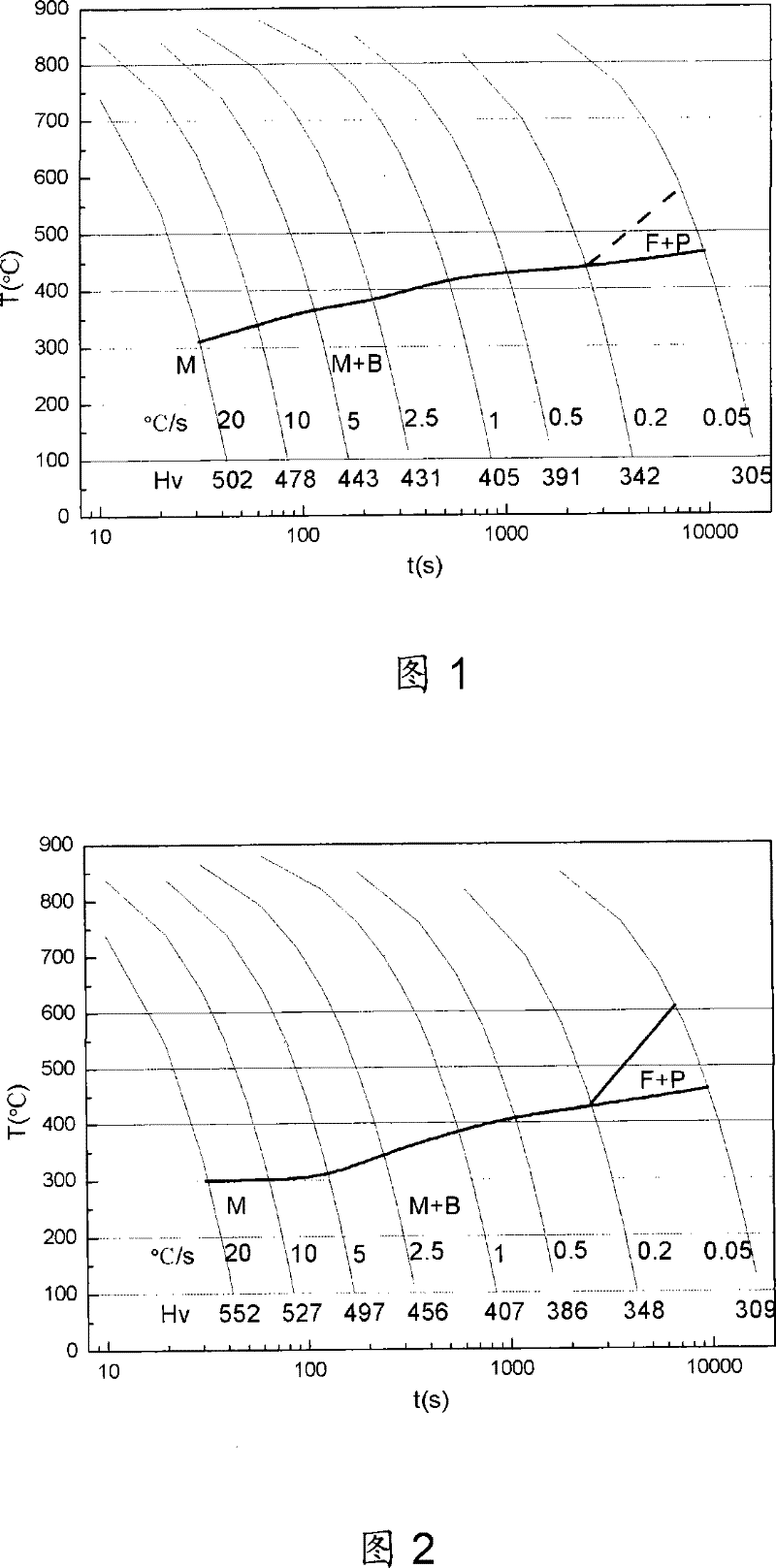

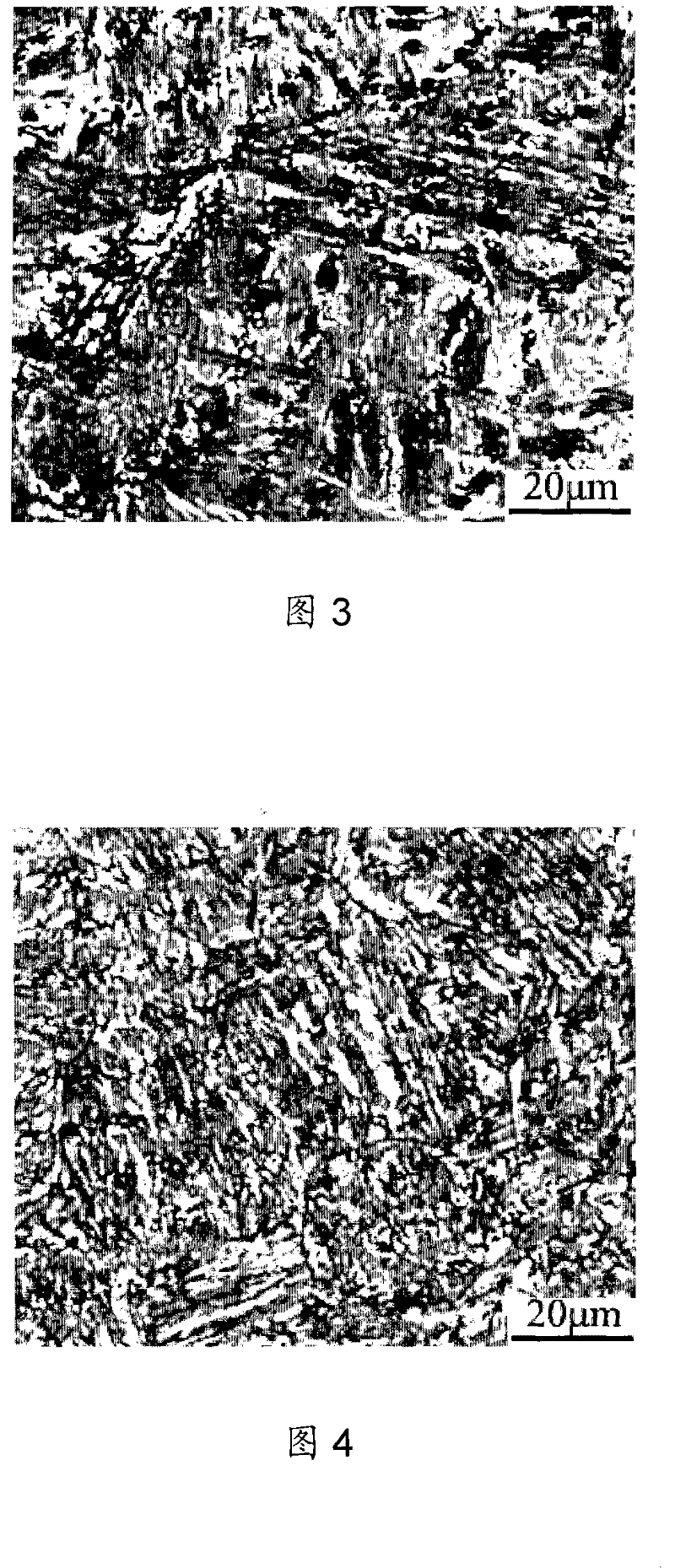

The invention discloses high-strength high-ductility spring steel used in high-temperature and high-pressure conditions and a production method of the high-strength high-ductility spring steel used inthe high-temperature and high-pressure conditions, and belongs to the technical field of metal smelting. The spring steel comprises the following components in percentage by weight: 0.30%-0.50% of C,1.30%-1.80% of Si, 0.80%-1.00% of Mn, 0.10%-0.30% of Cr, 0.10%-0.30% of V, 0.020%-0.040% of Nb, 0.10%-0.30% of Mo, 0.60%-1.20% of W, 0.015% of trace P, 0.010% of trace S and the balance Fe and impurities. The chemical component proportions meet the following condition: Meq=[C]-(0.10[Cr]+0.20[V]+0.03[Nb]+0.05[W]+0.08[Mo]). The steel has good heat-resistant performance, so that the use requirementsof springs under the high-temperature conditions are met.

Owner:MAANSHAN IRON & STEEL CO LTD

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751BImprove compactnessImprove uniformityMetal rolling arrangementsIngotMaterials science

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weiThe invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0ght percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electri.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when beingc stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when beingraised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; andraised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; andd. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the sted. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5el is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

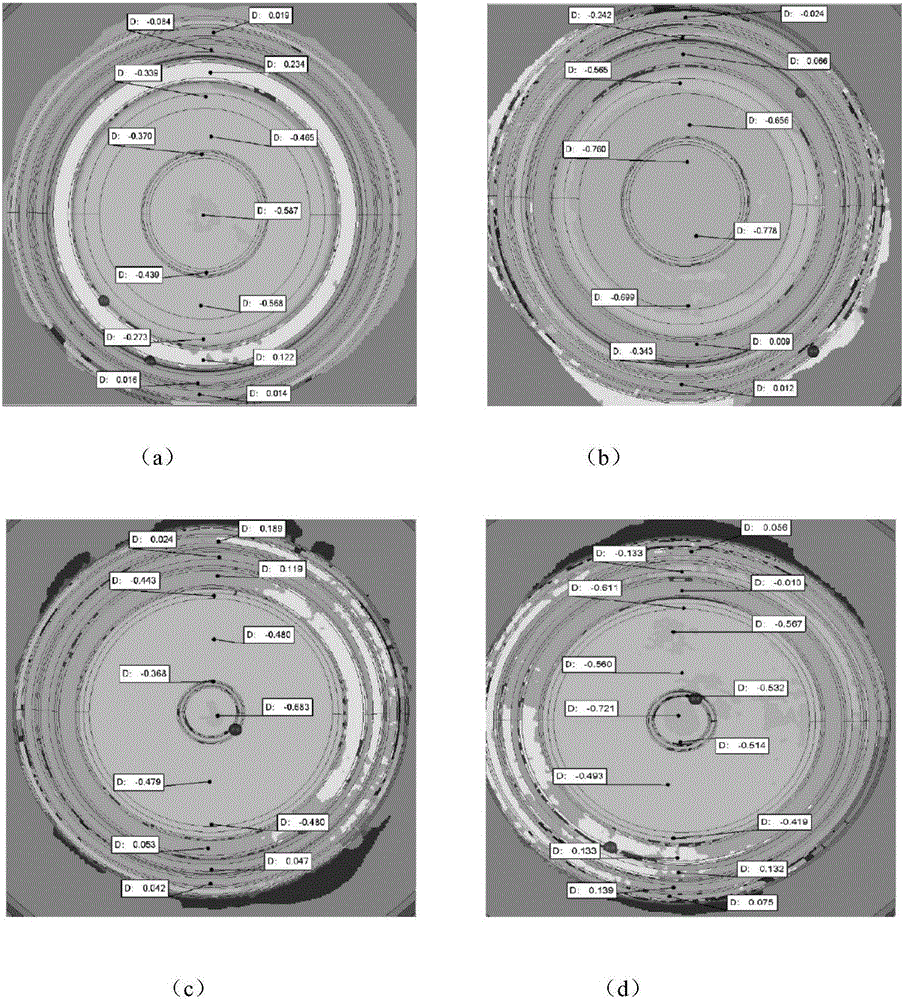

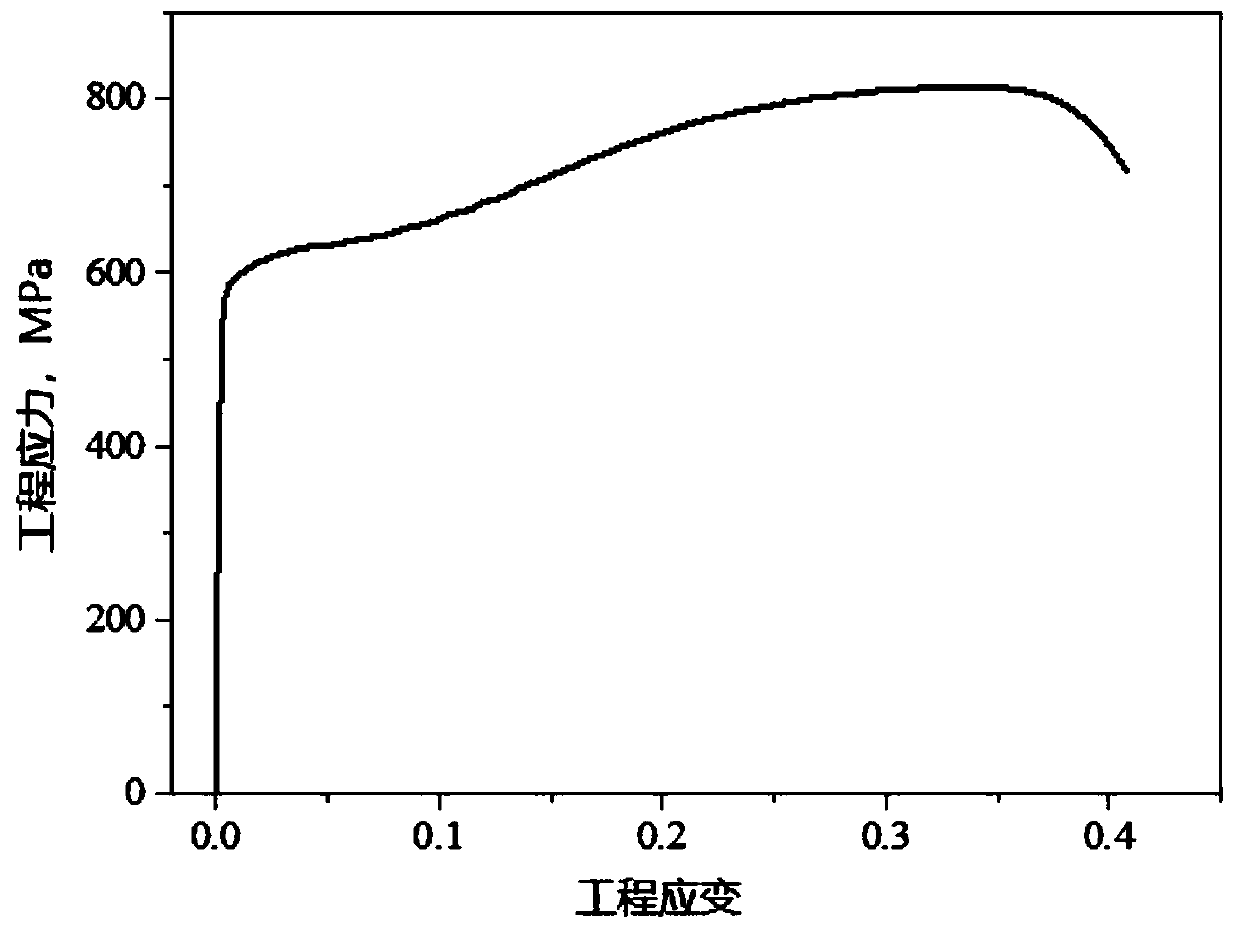

Hot-rolled medium manganese steel with high product of strength and elongation and relatively low Mn content and preparation method thereof

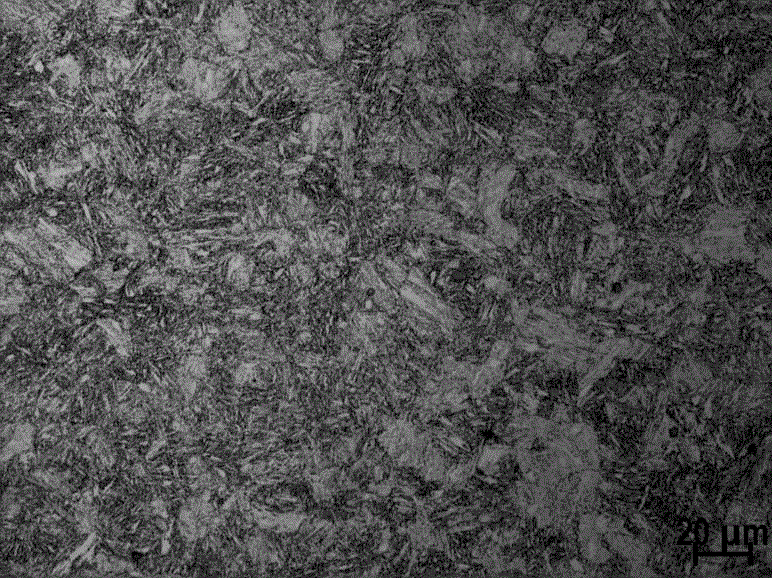

The invention provides hot-rolled medium manganese steel with high product of strength and elongation and relatively low Mn content and a preparation method thereof. The hot-rolled medium manganese steel comprises the following chemical components of, in percentage by weight, 0.19-0.5% of C, 3.0-7.0% of Mn, 1.0-3.0% of Al, 0-2.0% of Si, 0-5.0% of Cr, 0-2.0% of Ni and balance Fe and inevitable impurities. The preparation method of the hot-rolled medium manganese steel with high product of strength and elongation comprises the following steps of carrying out smelting on molten steel in a converter and obtaining a continuous casting billet by adopting a continuous casting mode; heating the continuous casting billet through a heating furnace and then obtaining a hot rolled coil after being subjected to hot rolling; and carrying out annealing on the hot rolled coil in a bell-type furnace and obtaining finished product of the hot-rolled medium manganese steel with high product of strength and elongation. According to the hot-rolled medium manganese steel with high product of strength and elongation and relatively low Mn content and the preparation method thereof, the hot-rolled medium manganese steel has higher product of strength and elongation at the same time under the premise that the good toughness is ensured, and has good practical application significance.

Owner:SHOUGANG CORPORATION

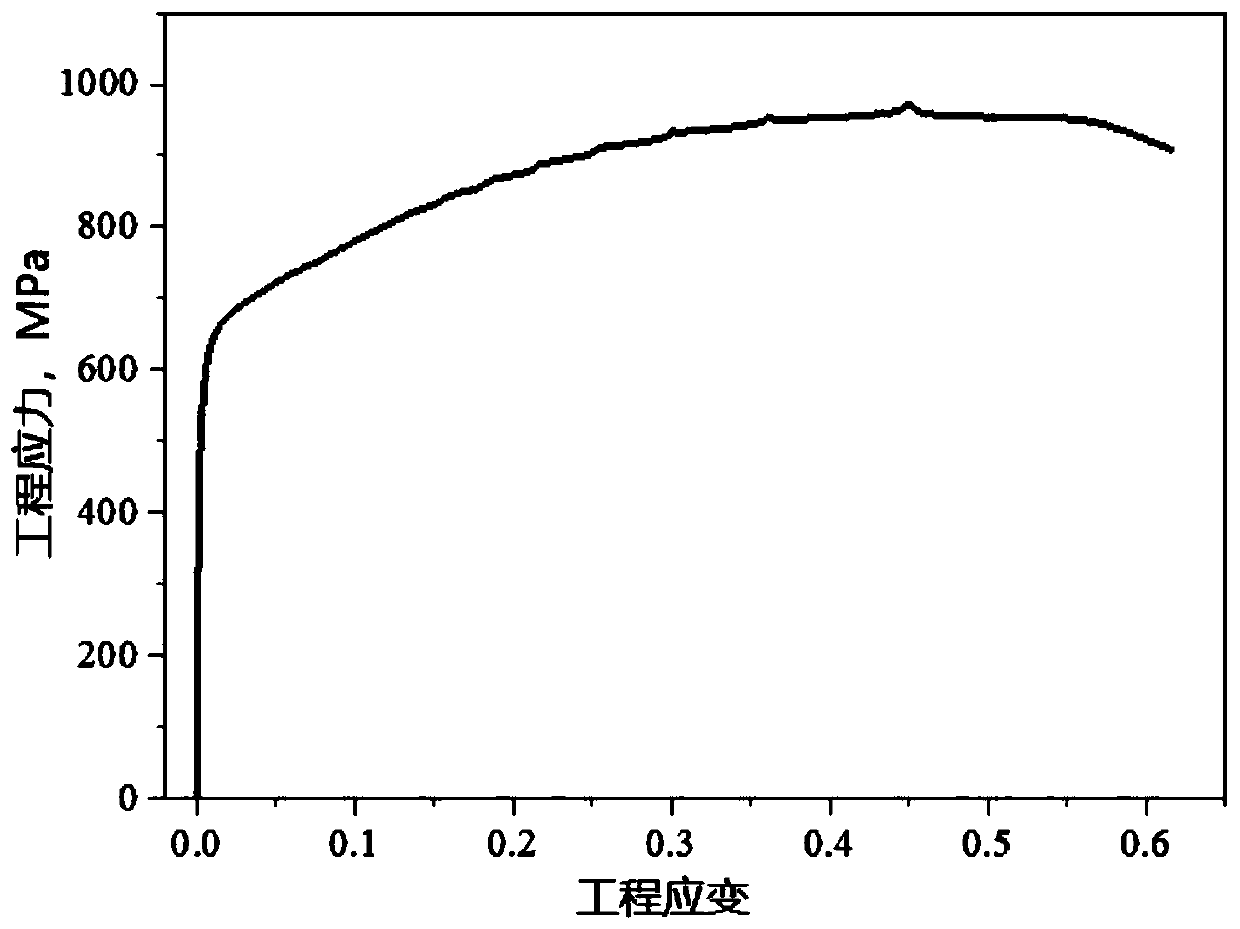

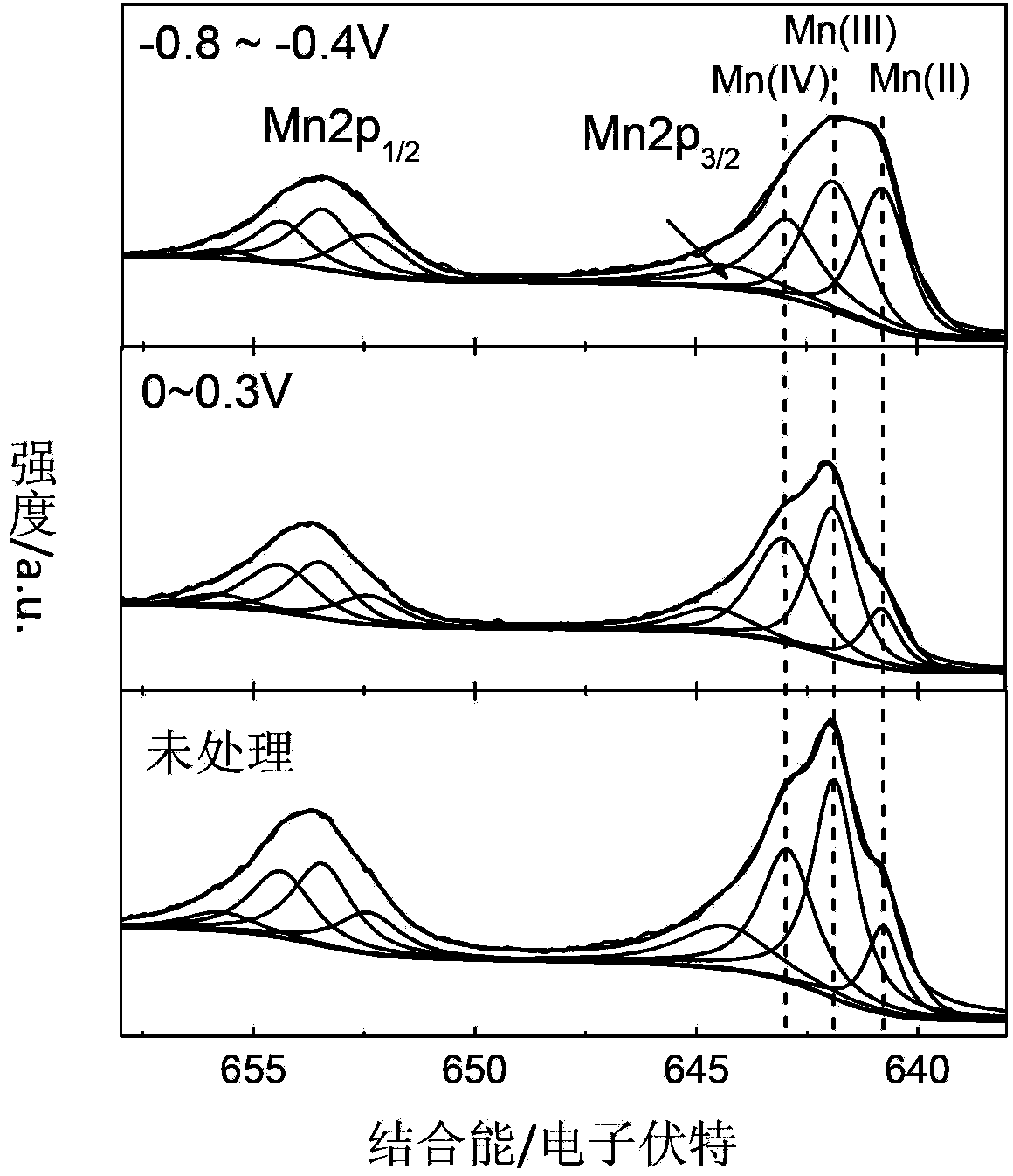

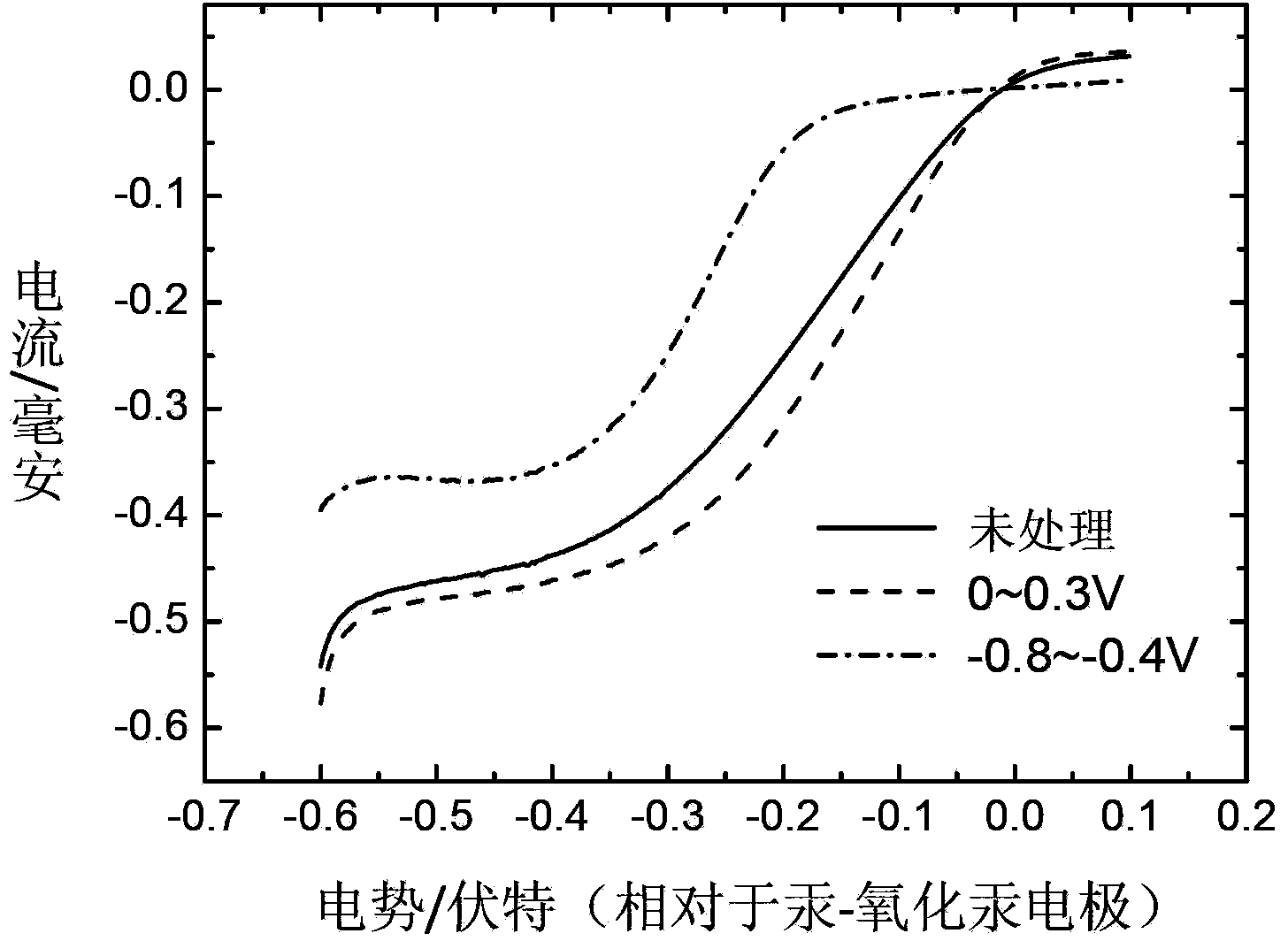

Method for increasing oxygen reduction activity of MnOx catalyst in electrode

ActiveCN103877972AIncrease Mn contentReduce Mn contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOxygenOxygen reduction reaction

In the prior art, MnOx catalysts have good oxygen reduction activity under alkaline conditions, and have advantages of low cost, simple preparation and the like, but Mn in the usually-prepared MnOx is mixed valence, and the low valence Mn has poor oxygen reduction reaction activity. The present invention relates to a method for increasing oxygen reduction activity of a MnOx catalyst, wherein the method specifically comprises: under an alkaline condition, carrying out an electrochemistry treatment on a MnOx catalyst through cyclic voltammetry scanning or linear scanning or constant potential to increase the high valence Mn (IV) content in the MnOx catalyst so as to increase the oxygen reduction activity of the catalyst. The method has advantages of simpleness, easy performing, stability, reliability and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

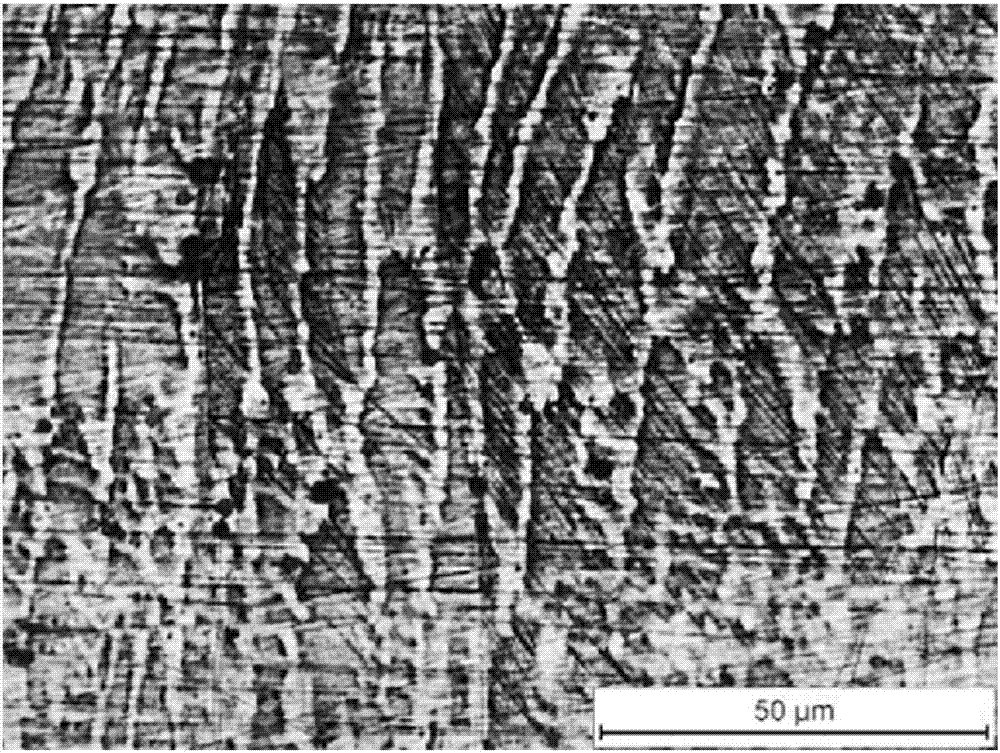

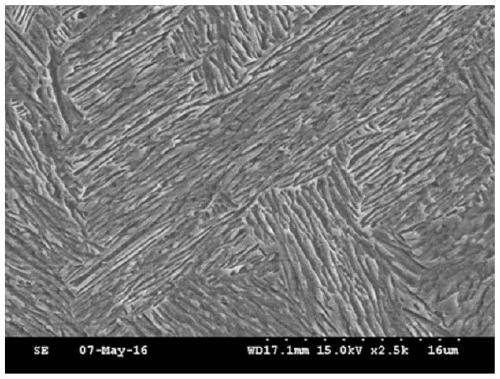

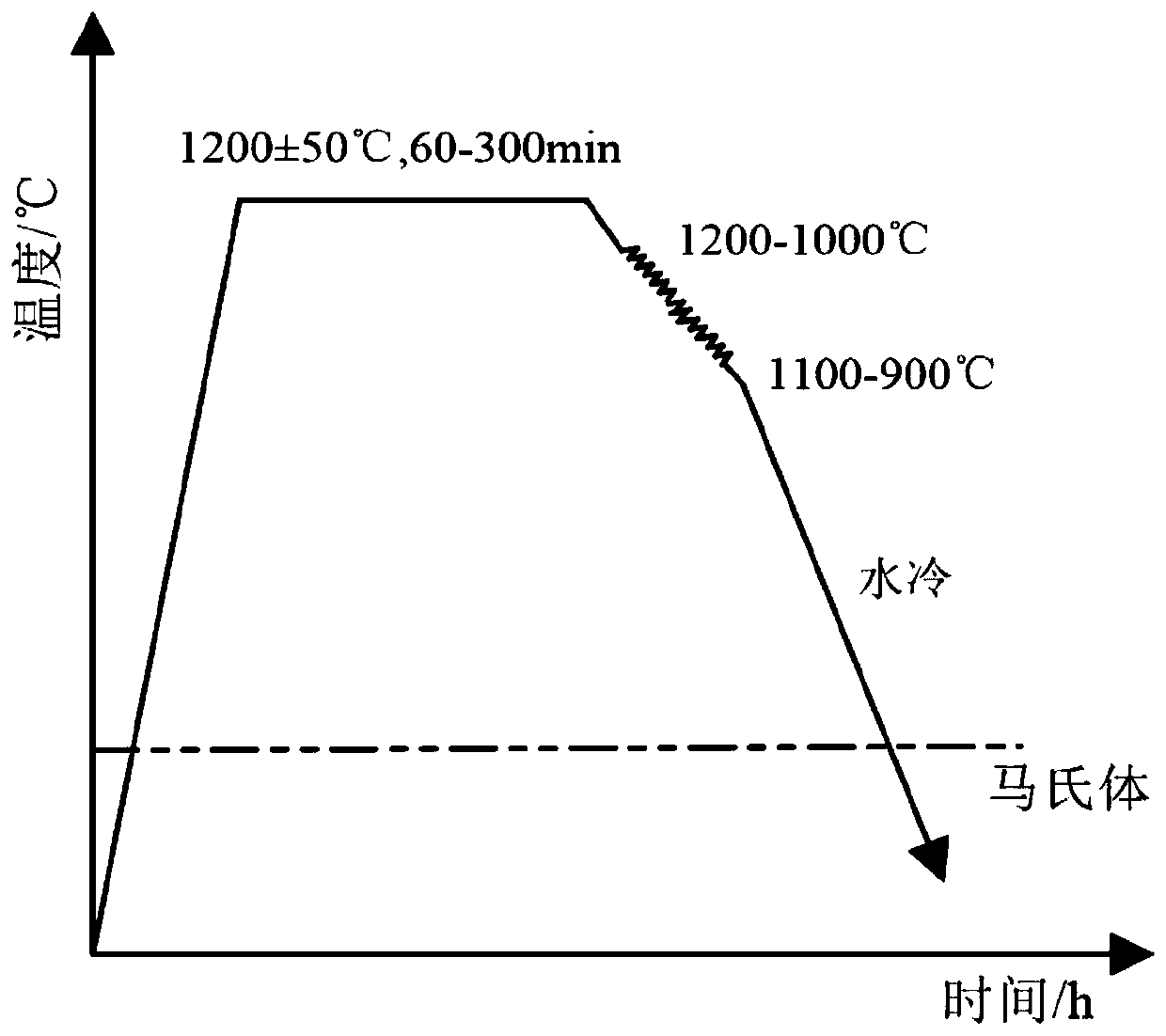

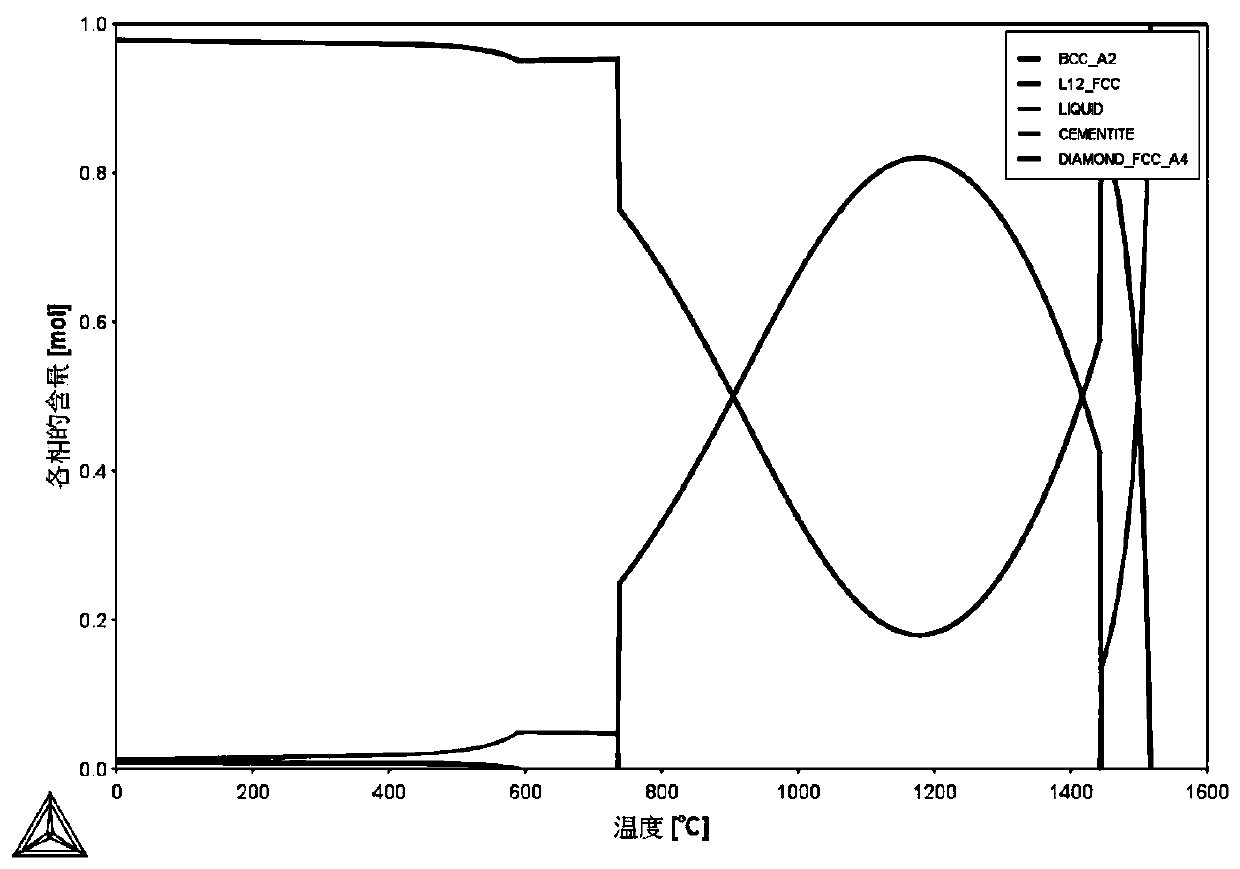

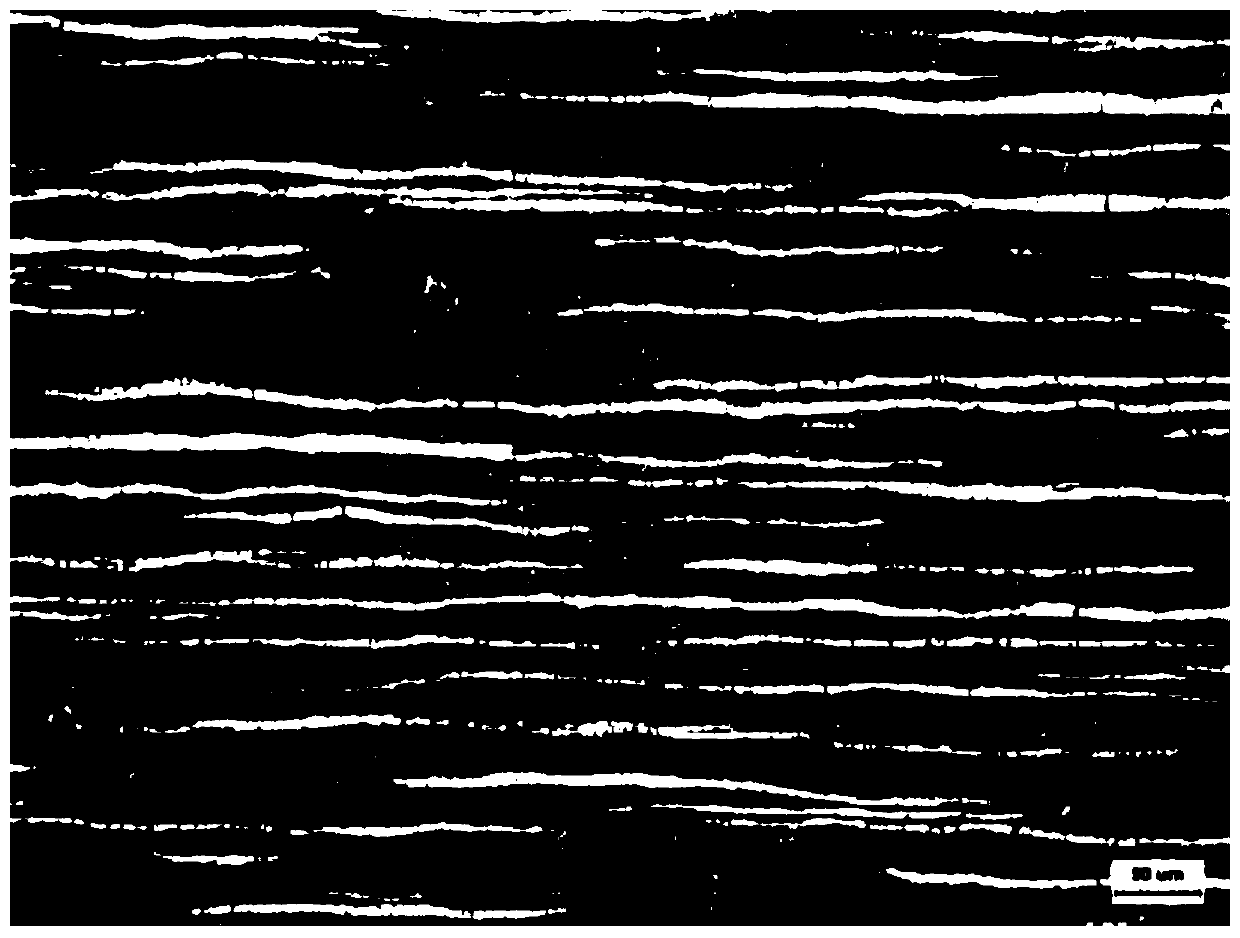

Ultrahigh-strength, ultrahigh-toughness and low-density double-phase lamellar steel plate and preparation method thereof

ActiveCN110551878AHigh strengthImprove toughnessFurnace typesHeat treatment furnacesDouble phaseAlloy

The invention relates to an ultrahigh-strength, ultrahigh-toughness and low-density double-phase lamellar steel plate. The steel plate comprises the following alloy components in percentage by mass: 0.200-0.320% of C, 0.600-2.000% of Mn, 0.200-0.600% of Si, 2.000-4.000% of Al, 0.300-1.200% of Ni, 0.001-0.005% of B, P not more than 0.012%, S not more than 0.005%, and the balance of Fe and inevitable impurities; the inevitable impurities comprise H, N and the like, wherein H is not more than 2.0 ppm, and N is not more than 45 ppm; the steel plate consists of double phases of ferrites and martensites; the ferrites are high-temperature delta ferrites; the martensites are batten martensites; the delta ferrites are distributed in the batten martensites in a lamellar mode; and the volume fractionof the ferrites is not more than 30%. The invention further comprises a preparation method; a high-temperature two-phase area (ferrite+austenite two-phase area) rolling process; the steel plate is quenched to a room temperature online after rolling; a lamellar structure obtained by rolling is retained at the room temperature; and a ferrite+martensite two-phase lamellar structure is obtained at the room temperature, so that the steel plate achieves excellent mechanical performances: the yield strength in the rolling direction is not lower than 1000 MPa, the tensile strength is not lower than 1600 MPa, the ductility is not lower than 8.0%, and the Charpy impact work average value of a V type gap on the surface of a -40 DEG C steel plate is not lower than 350 J.

Owner:NORTHEASTERN UNIV

WC series steel bond hard alloy

The invention relates to a WC series steel bond hard alloy. The mass percentage of hard phase WC is 65-85wt%, and the mass percentage of binding phase high manganese steel. The alloy comprises the following components in mass percent: 61-80wt% of W, 2.2-5.1wt% of Mn, 0.6-1.5wt% of Ni, 0.5-1.5wt% of Cr, 0.4-1.0wt% of Mo, 4.0-6.0wt% of C and the balance of Fe. The purposes of purifying grain boundary and strengthening the binding phase, improving the bonding strength effect of the two phases and thus improving the strength and hardness of the alloy are reached by adding alloy elements such as Cr and Mo, the promotion of alloy performance is realized, low product porosity and good surface quality are obtained, and the alloy is high in strength and hardness and has excellent abrasion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

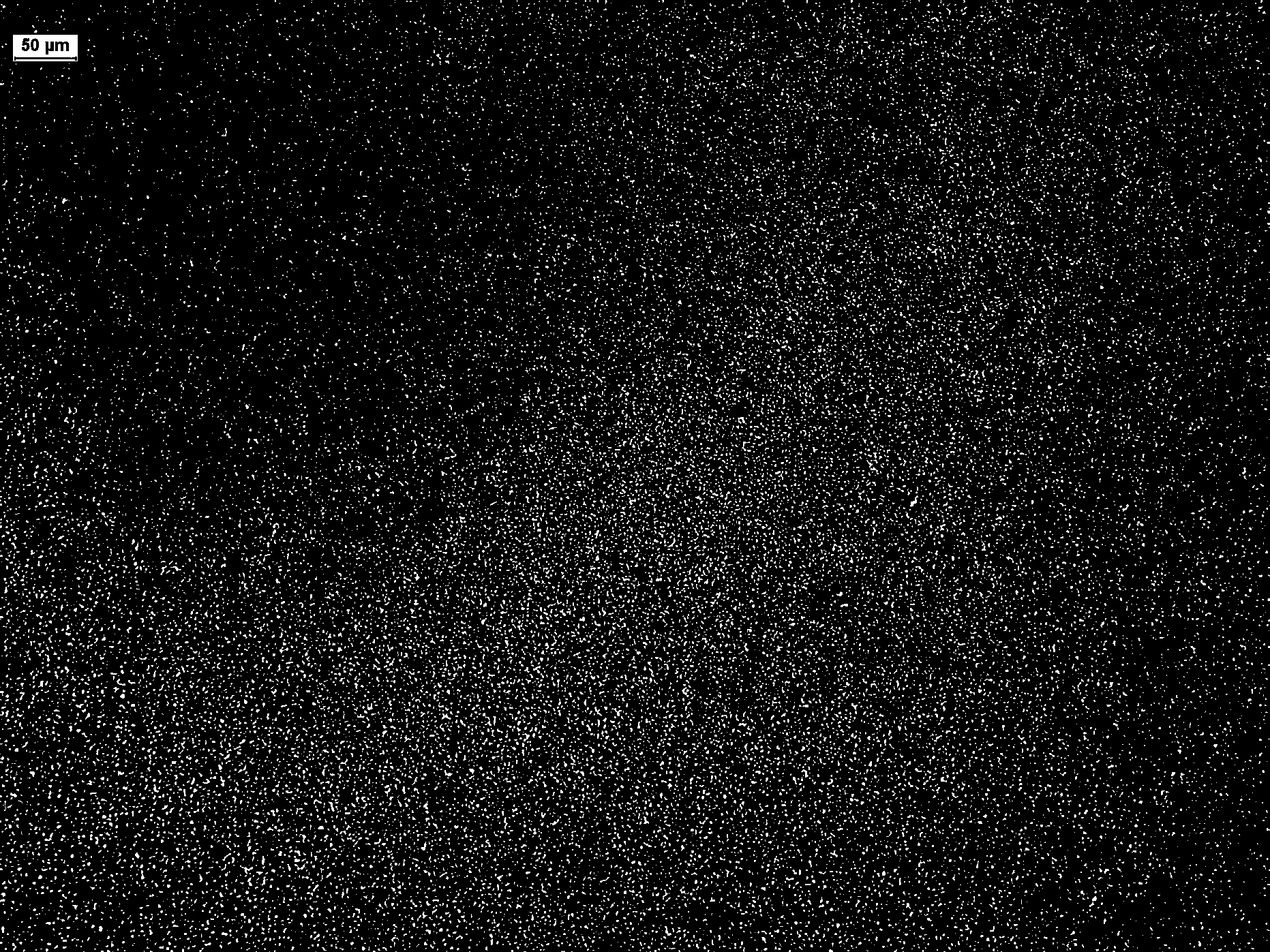

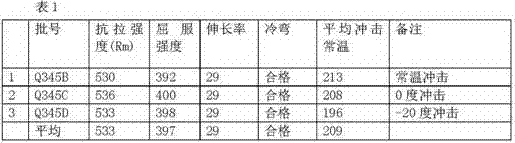

Method for controlling medium-thick plate Q345 steel flaw detection defects

The invention discloses a method for controlling medium-thick plate Q345 steel flaw detection defects. The method comprises the steps that the component weight ratio of Q345 steel is optimized, the method is applicable to the steel Q345B / C / D, the thickness H is smaller than or equal to 30 mm, and the steel is prepared from, by weight, 0.16 of C, 0.30 of Si, 1.15 of Mn, 0-0.018 of P, 0-0.008 of S, 0.025 of Al, 0.015 of Ti and 0.0020 of Ca; the [MnS] impurities in steel are controlled, the technological process comprises molten iron desulphurization, 120t revolving furnace, LF-slab continuous casting-heating furnace, medium plate rolling and ACC-collection, wherein the sulphur content [S] in molten iron is reduced to be smaller than 0.002% through molten iron desulphurization pretreatment, and the revolving furnace tapping [N] content is smaller than 0.002%; 2, the molten steel temperature and component accuracy are improved through the revolving furnace, and the revolving furnace tapping temperature is larger than 1620 DEG C; 3, LF slagging and desulfurization are carried out to remove impurities, AL-Ca refining agent is added in LF refining, 200 kg of AL-Ca refining agent is added after revolving furnace tapping, the LF refining final slag Al2O3 content is larger than 30%, the power supply time is controlled to be within 15 min, and the molten steel nitrogen content is smaller than 0.0040%; and 4, continuous protection casting is carried out, and the tundish molten steel temperature is controlled to be 1535-1515 DEG C during continuous casting.

Owner:XINJIANG BAYI IRON & STEEL

A kind of cold-rolled high-strength plastic product medium manganese steel with lower Mn content and preparation method thereof

The invention provides a cold-rolled high-strength plastic product medium-manganese steel with low manganese content and a preparation method thereof. The weight percentages of the chemical components are: C: 0.15-0.6%, Mn: 3.0-6.0%, Al: 1.0 -3.0%, Si: 0.0-2.0%, Cr: 0-5.0%, Ni: 0-2.0%, and the balance is Fe and unavoidable impurities. The preparation of cold-rolled high-strength plastic-laminated medium-manganese steel includes the following steps: the molten steel is smelted in a converter and then continuously cast to obtain a continuous casting slab; the continuous casting slab is heated in a heating furnace and then hot rolled to obtain a hot-rolled coil; After softening and annealing in a bell furnace, cold rolling is performed to obtain a chilled steel strip, and the chilled steel strip is subjected to continuous annealing treatment to obtain a finished product of cold-rolled high-strength plastic medium-manganese steel. The invention enables the cold-rolled medium-manganese steel to have high strength-plastic product under the premise of ensuring good toughness, and has good practical application significance.

Owner:SHOUGANG CORPORATION

A kind of tensile strength 590mpa level cold-rolled dual-phase steel and its preparation method

The invention belongs to the technical field of high-strength steel, and in particular, relates to tensile strength 590 MPa-grade cold-rolled dual-phase steel and a preparation method thereof. The tensile strength 590 MPa-grade cold-rolled dual-phase steel comprises the following components in percentage by weight: 0.06-0.10% of C, 0.26-0.60% of Si, 1.20-1.60% of Mn, 0.10-0.45% of Cr, 0.02-0.06% of Al, P not more than 0.020%, S not more than 0.015%, N not more than 0.006%, and the balance of Fe and inevitable impurities. The cold-rolled dual-phase steel is low in production cost, excellent in forming performance and low in yield strength and yield ratio; and in addition, the contents of C and Mn are reduced, and little Cr is used for replacing Mn, excellent hardenability of the steel is guaranteed, the carbon equivalent is lower, and the welding performance and the forming performance are better.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

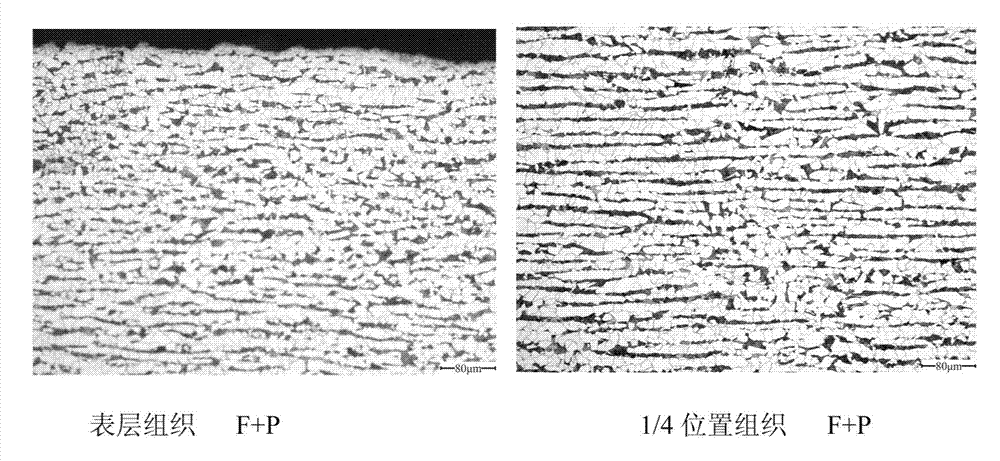

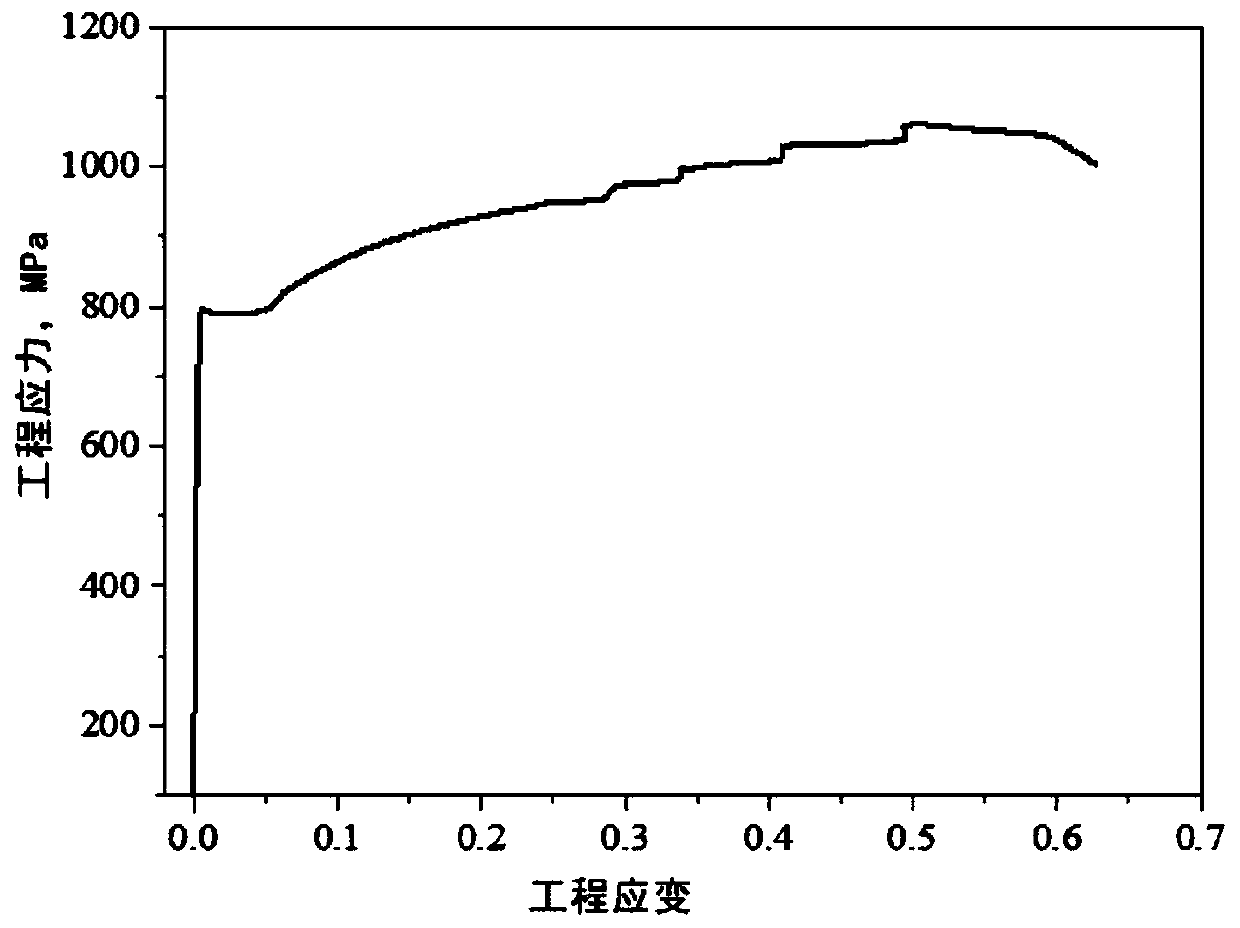

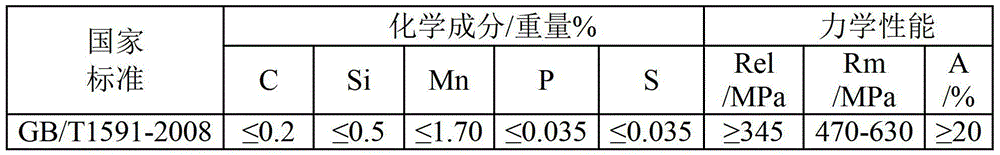

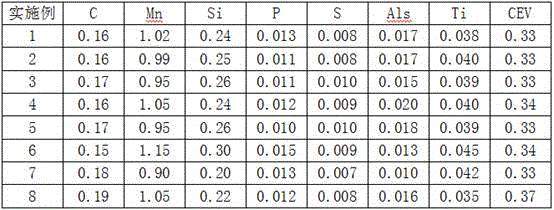

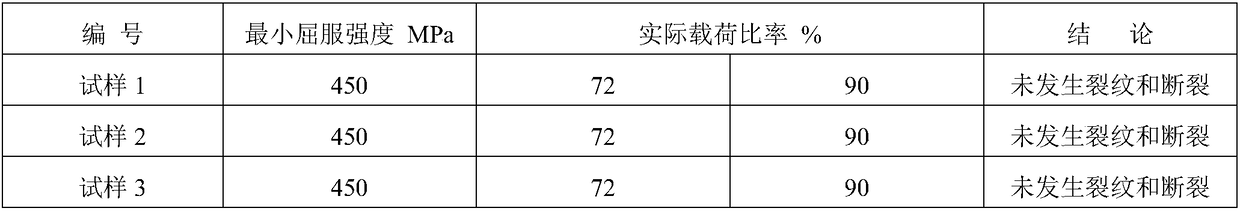

Ti-microalloyed Q345B steel plate and production method thereof

The invention discloses a Ti-microalloyed Q345B steel plate and a production method thereof. The Ti-microalloyed Q345B steel plate comprises the following chemical components by weight: 0.15 to 0.19% of C, 0.9 to 1.15% of Mn, no more than 0.010% of S, no more than 0.015% of P, 0.2 to 0.3% of Si, 0.01 to 0.02% of Als and 0.035 to 0.045% of Ti, with the balance being iron and unavoidable impurities. CEV is no more than 0.37%. According to the invention, on the basis of C and Mn steel, the content of Mn is reduced and microalloying reinforcement effect of Ti is utilized, so the mechanical properties of the steel plate meet requirements of Q345B, and the steel plate has better welding performance compared with conventional steel plates prepared from C and Mn; and the Ti-microalloyed steel plate has lower cost and is more suitable for promotion and application. The method provided by the invention employs controlled-rolling controlled-cooling technology for rolling and utilizes microalloying reinforcement of Ti, so the produced steel plate has yield strength of 378 to 401 Mpa, tensile strength of 488 to 522 Mpa, elongation percentage of 21.5 to 28.5%, impact toughness at 20 DEG C of 164 to 213 J and carbon equivalent of no more than 0.37% and meets requirements prescribed in Standard GB / T1591-2008 in China.

Owner:TANGSHAN IRON & STEEL GROUP

Acidic-corrosion-resistant X65MS pipeline steel and preparation method thereof

InactiveCN108265225AAppropriate yield ratioModerate elongationFurnace typesMetal rolling arrangementsMo elementCorrosion resistant

The invention discloses acidic-corrosion-resistant X65MS pipeline steel which comprises the following components in percentage by weight: 0.04-0.06% of C, 0.10-0.20% of Si, 1.20-1.40% of Mn, no more than 0.010% of P, no more than 0.002% of S, 0.030-0.040% of Nb, 0.010-0.020% of Ti, 0.020-0.040% of Al, 0.20-0.30% of Cr, 0.10-0.20% of Cu and 0.10-0.20% of Ni. The invention further discloses a preparation method of the acidic-corrosion-resistant X65MS pipeline steel. According to the acidic-corrosion-resistant X65MS pipeline steel and the preparation method, the Mn content is lowered, no expensive Mo element is added, and the alloy cost is relatively low, thereby being beneficial to wide popularization and application.

Owner:BAOTOU IRON & STEEL GRP

1000 Mpa grade high-strength metastable austenite-martensite stainless steel

ActiveCN109881123AGood resistance to pitting corrosionImprove toughnessMartensitic stainless steelAustenitic stainless steel

The invention relates to the technical field of stainless steel manufacturing, in particular to 1000 Mpa grade high-strength metastable austenite-martensite stainless steel. The 1000 Mpa grade high-strength metastable austenite-martensite stainless steel is prepared from the following components in percentage by mass: 0.03%-0.1% of C, 0.2%-1.0% of Si, 3.0%-5.0% of Mn, 13.0%-15.5% of Cr, 1.0%-3.0%of Ni, greater than or equal to 0.2% and less than or equal to 0.6% of Mo, less than or equal to 0.045% of P, less than or equal to 0.030% of S, 0.05%-0.15% of N, less than or equal to 0.30% of Ti, less than or equal to 0.30% of Nb, less than or equal to 0.3% of V, and the balance of Fe and inevitable impurity elements. The 1000 Mpa grade high-strength metastable austenite-martensite stainless steel has the beneficial effects that compared with traditional high-strength Cr13 series of martensite stainless steel, the intensity and toughness comprehensive performance is more excellent, and the corrosion resistance is high; and compared with martensite precipitation-hardening stainless steel, the machining difficulty is low, and the alloy and the manufacturing cost both have obvious advantages.

Owner:福建青拓特钢技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com