Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improved stability against tempering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

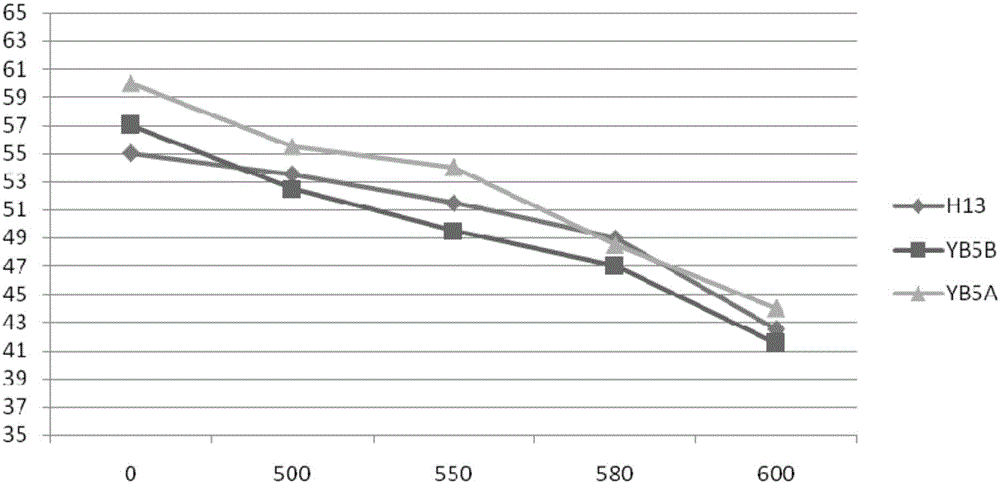

Cr5 series hot work die steel

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

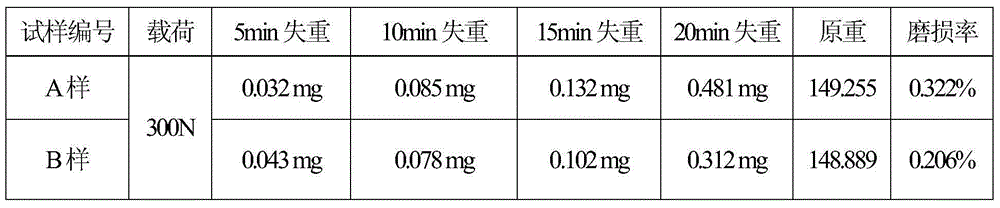

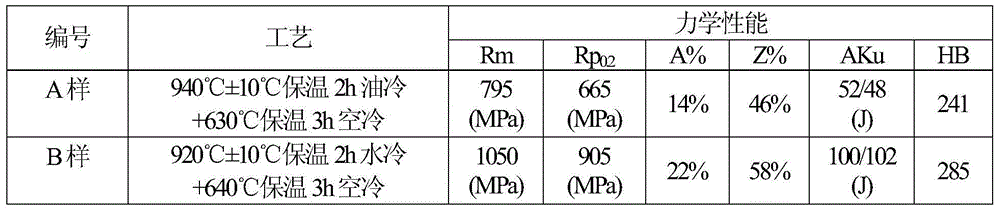

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

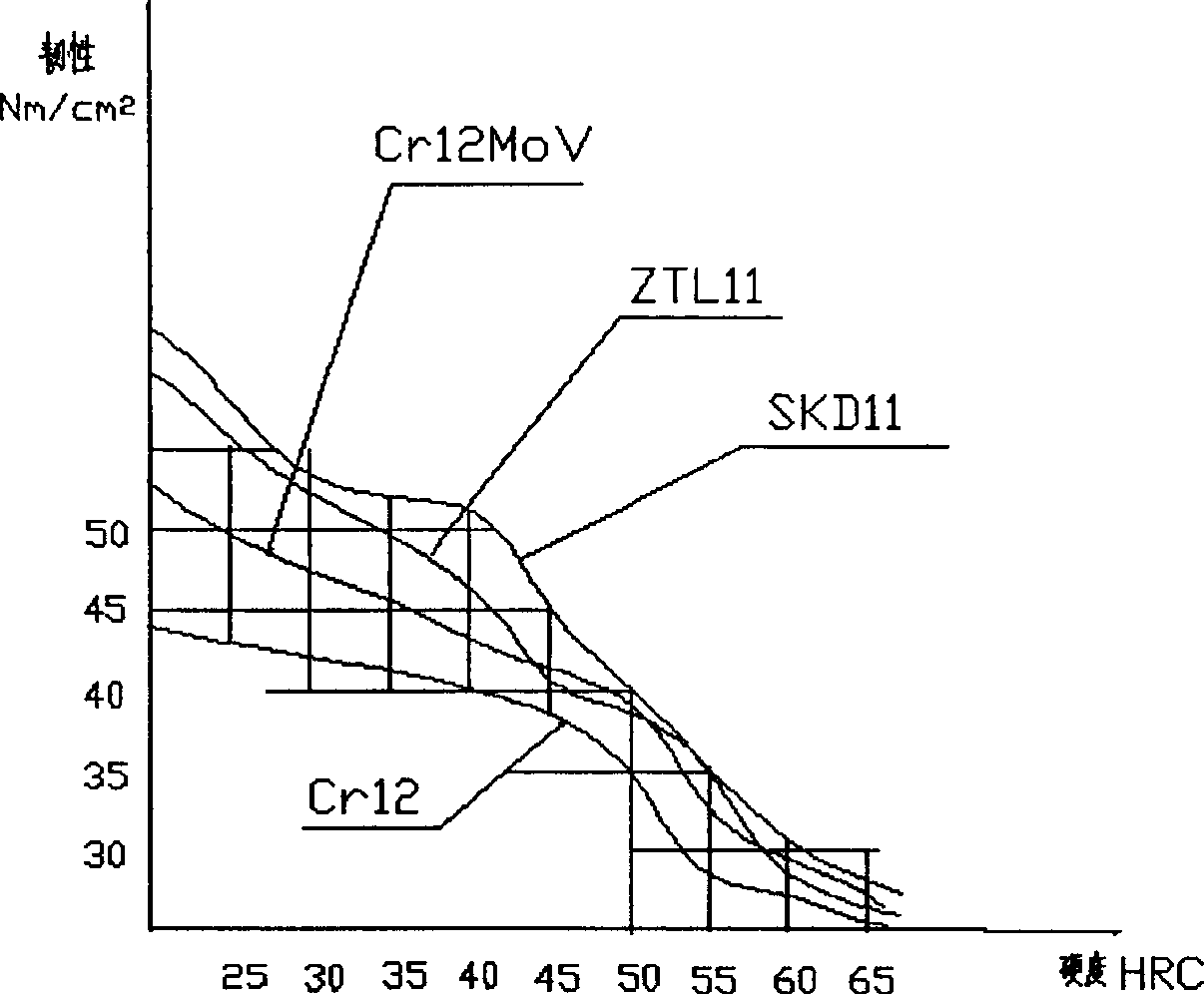

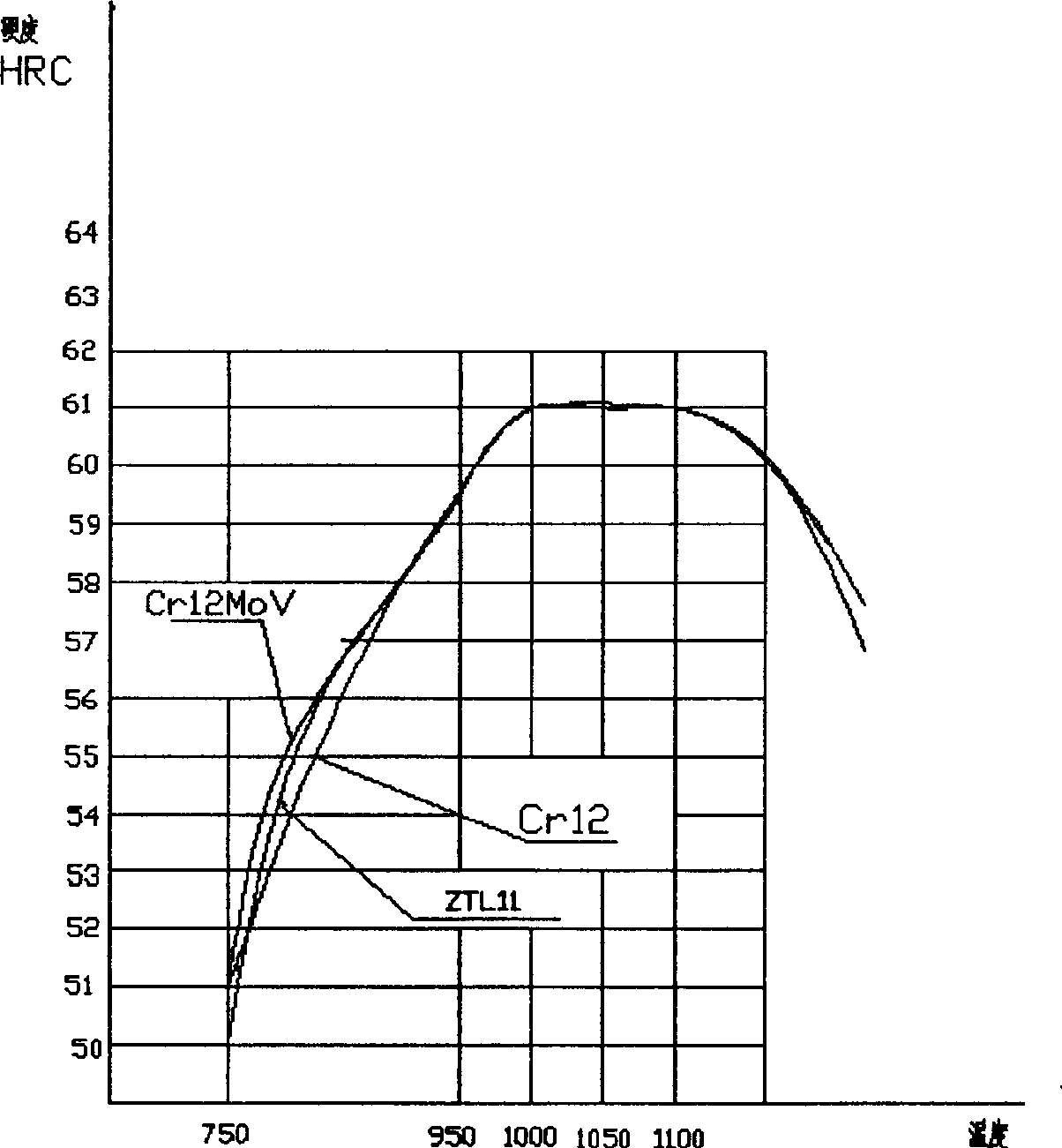

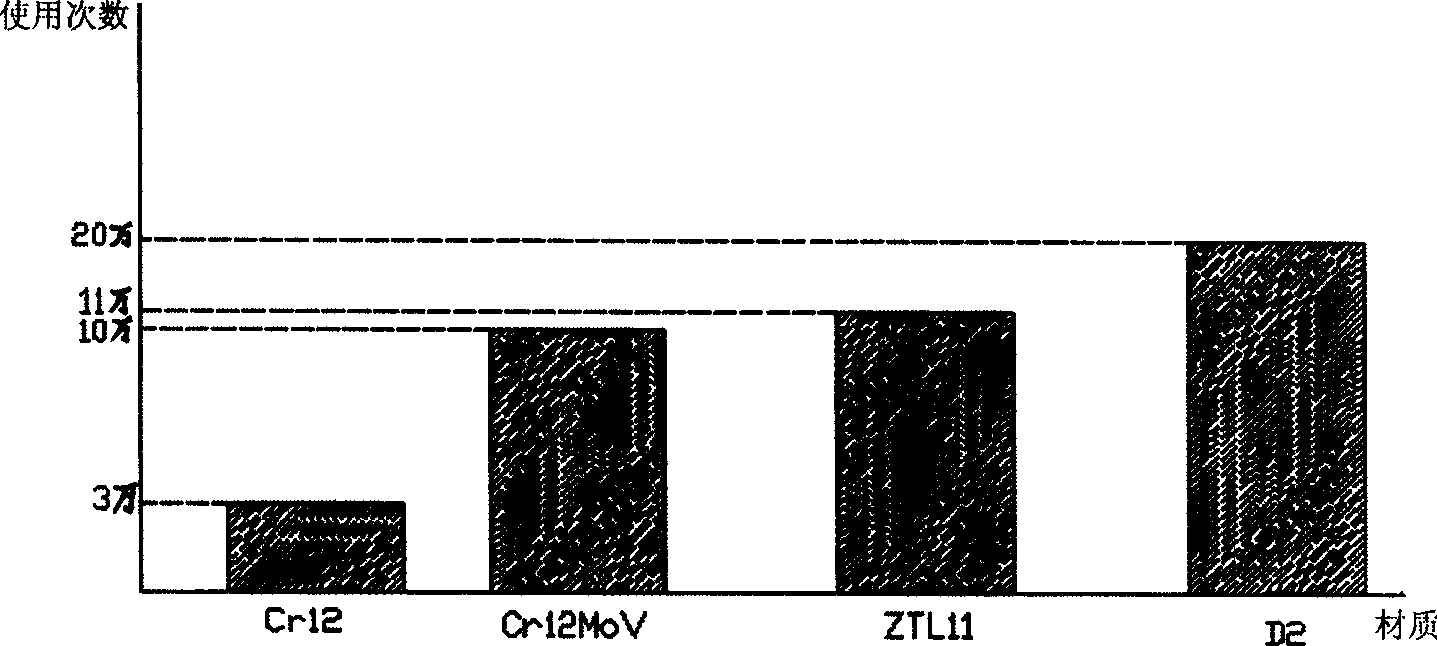

Cold working die steel material and production technology thereof

InactiveCN101381844AImprove wear resistanceEasy to processProcess efficiency improvementElectric furnaceTrace elementPrice ratio

The invention provides a cold-working die steel material, which comprises the following trace elements in percentage by weight: 0.95 to 1.05 percent of C, 0.35 to 0.45 percent of Mn, 0.55 to 0.65 percent of Si, 7.55 to 8.5 percent of Cr, 0.45 to 0.55 percent of Mo, 0.35 to 0.45 percent of V, less than or equal to 0.025 percent of S, and less than or equal to 0.025 percent of P. The cold-working die steel material has simple technical process and easily-controlled operation, adopts alloying and modification treatment, has good hardenability, stable temper resistance, higher wear resistance and good processability, can improve work efficiency, reduce production cost, reduce or avoid moulds from breaking and cracking, and has long service life, high performance-price ratio and wide application.

Owner:尚宗文

High-performance hydrogen sulfide corrosion resistant oil drill rocker and its heat treatment process

InactiveCN101117683AGuaranteed hardenabilityGuaranteed sulfur resistanceDrilling rodsFurnace typesMechanical propertyPetroleum

The present invention relates to a high-performance hydrogen sulfide corrosion resistant petroleum drill pipe with a weight percentage of components as follows: C 0.20-0.32 percent, Si 0.1-0.5 percent, Mn 1.0-1.5 percent, Cr 0.5-1.5 percent, Mo 0.8-1.2 percent, P less than or equal to 0.015 percent, S less than or equal to 0.01 percent and the remainders are Fe and unavoidable impurities. The drill pipe of the present invention has a higher content of Mn, which can guarantee an upset end with a thickness of over 30mms to be fully hardened, thereby guaranteeing the sulfur-resistant performance of the upset end. The drill pipe of the present invention has a higher content of Mo, which can improve the backfire-preventive stability of the material, thereby raising the backfire temperature, reducing the residual stress and guaranteeing the sulfur-resistant performance. Simultaneously, the invention can make the pipe body with a different wall thickness and the upset end have the same cooling speed by controlling the outer water injection of the upset end and pipe body of the steel pipe, reducing the water injection outside the pipe body or increasing the water injection outside the upset end of the drill pipe, to ensure that the pipe body and the upset end have the same quenching structure, and the same mechanical property can be achieved after the backfire.

Owner:BAOSHAN IRON & STEEL CO LTD

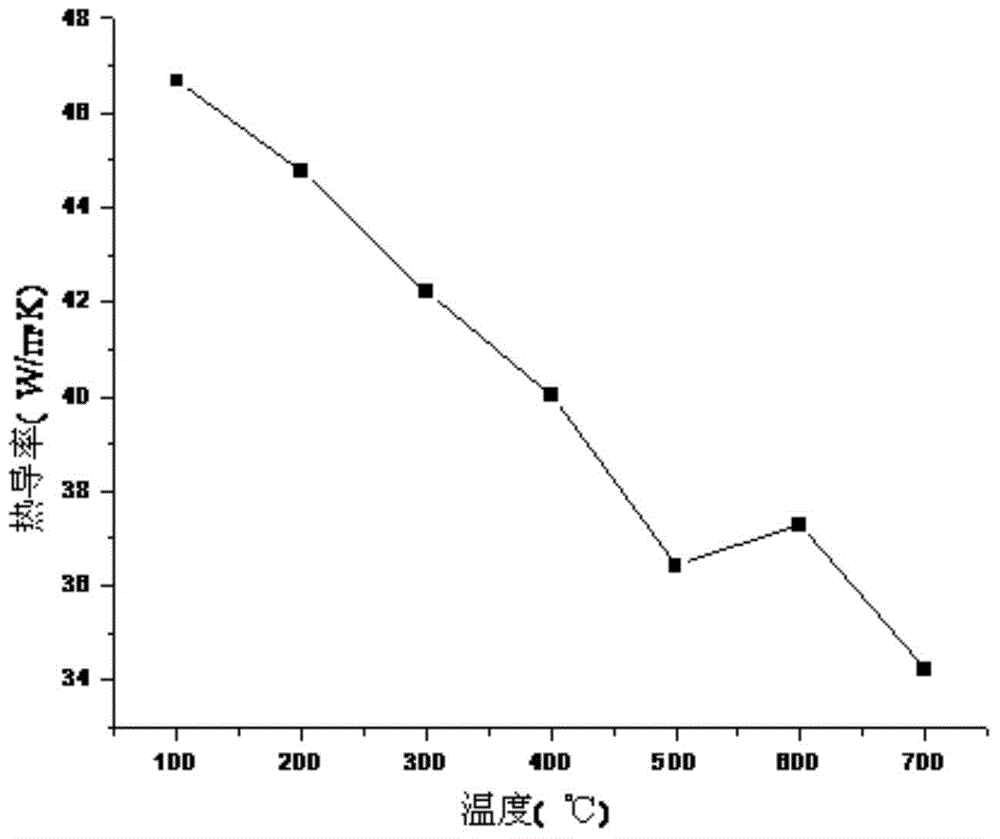

High wear-resistant hot-stamping die steel and manufacturing method thereof

The invention discloses a high wear-resistant hot-stamping die steel and a manufacturing method thereof. The high wear-resistant hot-stamping die steel is prepared from the following chemical elements in percentage by weight: 0.4-0.6 percent of C, less than 0.40 percent of Si, less than 0.40 percent of Mn, 1.5-2.0 percent of W, 3.0-4.0 percent of Mo, less than 0.50 percent of Cr, 3.0-4.0 percent of V and the balance of Fe and other inevitable impurities. The invention also discloses the manufacturing method of the high wear-resistant hot-stamping die steel. The manufacturing method comprises the following steps: electric furnace smelting, electroslag remelting, primary annealing, high-temperature homogenizing, forging, secondary annealing and heat treatment, wherein in the heat treatment step, quenching is carried out at temperature of 1060-1100 DEG C and tempering is carried out at temperature of 560-620 DEG C. the high wear-resistant hot-stamping die steel is high in heat conductivity, strong in rigidity and strength, excellent in impact toughness and wear resistance and good in machinability, thermal fatigue resistance and temper resistance stability.

Owner:BAOSHAN IRON & STEEL CO LTD

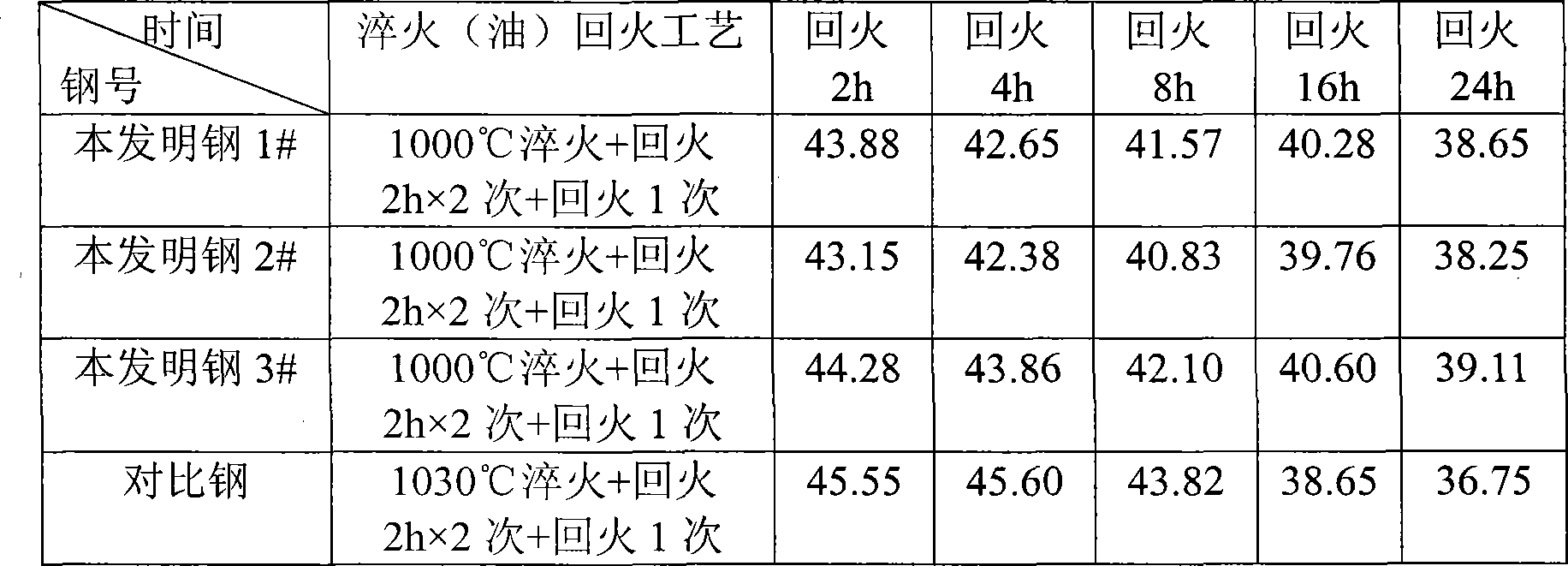

Cr3 series hot work die steel and heat treatment method thereof

The invention provides a Cr3 series hot work die steel. The hot work die steel comprises, by weight percentage, 0.38%-0.50% of C, 0.15%-0.70% of Si, 0.30%-0.90% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S, 2.80%-3.50% of Cr, 1.40%-2.00% of Ni, 1.80%-2.60% of Mo, 0.10%-0.50% of V, 0.020%-0.10% of Al, 0.02%-0.20% of Nb and the balance Fe. According to the chemical component formula of the Cr3 series hot work die steel (remembered as YD3 series die steel), compared with existing Cr3Mo3(4Cr3Mo3SiV, H10) series hot work die steel, C, Mn and Cr of the YD3 series die steel are equivalent in content, the content of Mo, V and Si is reduced, the Ni element is added, the Nb element is added, the Al element is added, and therefore toughness is improved.

Owner:YINGKOU SPECIAL STEEL FORGING

Molybdenum-free low-cost hot working die steel

The invention belongs to the field of tool and die, specifically to a molybdenum-free low-cost hot die steel. The chemical compositions of the steel (weigh%) are: C: 0.38-0.42%, Si: 0.9-1.1%, S<=0.030%, P<=0.030%, Mn: 0.3-0.5%, W: 1.9-2.2%, Cr: 4.8-5.2%, V: 0.25-0.45%, Nb: 0.08-0.15% and Fe and unavoidable impurities: the residue. The steel of the invention can be used as a substitute for high-alloy-containing H13, has similar comprehensive performance to H13, superior temper resistance, no molybdenum and low chromium; the rational alloy ratio saves cost more than 20%, compared with H13 steel, thus having better economical benefit.

Owner:CENT IRON & STEEL RES INST

Compressor 38CrMoAl steel treatment technology

InactiveCN104911607ALower the critical pointHigh surface hardnessSolid state diffusion coatingStress concentrationHardness

The invention discloses a compressor 38CrMoAl steel treatment technology, and relates to a 38CrMoAl steel treatment hardening and tempering and surface hardening heat treatment technology. The problems of shallowness, low hardness, poor wear and acid-salt corrosion resistance and low hardening and tempering treatment mechanical performances of a hardened layer generated through traditional surface heat treatment of 38CrMoAl steel are solved in the invention. The heat treatment technology comprises the steps of 38CrMoAl steel forging and stamping molding, hardening and tempering, and surface hardening treatment. The technology disclosed in the invention can completely avoid the disadvantages of shallowness, low hardness after finish grinding, and low hardening and tempering treatment mechanical performances of traditional nitridized hardened layers, improves the surface hardness to above HRc70, improves the wear resistance by 50%, and improves the acid-salt corrosion resistance by above 40%. The mechanical performances improve by 40-50%, the bending fatigue life prolongs by above 100 times, the bending fatigue strength improves by 100%, and the fatigue strength stress concentration susceptibility is substantially inhibited.

Owner:SHENYANG TURBO MASCH CORP

Cr1-series hot work die steel and heat treatment method thereof

The invention provides Cr1-series hot work die steel. The Cr1-series hot work die steel is characterized by comprising, by weight, 0.40%-0.48% of C, 0.17%-0.40% of Si, 0.80%-1.20% of Mn, 0-0.020% of P, 0-0.010% of S, 0.80%-1.60% of Cr, 1.00%-1.70% of Ni, 0.80%-1.60% of Mo, 0.05%-0.30% of V, 0.010%-0.050% of Al, 0.02%-0.20% of Nb and the balance Fe. According to the chemical component formula of the novel Cr1-series hot work die steel, the material name is YD1. Compared with existing Cr1-series (5CrNiMo and 5CrNiMoV) hot work die steel, the YD1-series die steel reduces the content of carbon, the contents of the Mn and Cr are increased, the content of the Mo is greatly increased, the content of the Ni is slightly decreased, and the Nb element and Al element are added. Hence, high-temperature strength and creep resistance are improved, and toughness is also improved.

Owner:YINGKOU SPECIAL STEEL FORGING

Stainless steel bCr13Mo gas nitriding process

InactiveCN101139693AStrong penetrating powerImproved stability against temperingSolid state diffusion coatingNitrogenHardness

The invention provides a gas nitriding process for stainless steel bCr13Mo, which is a surface treatment method in the field of heat treatment. As bCr13Mo is liable to forming a dense Cr2O3 passivated layer, nitriding is difficult by an ordinary way. The invention adds small amount of NH4Cl during nitriding to heat NH4Cl, which dissolves HCl to react with bCr13Mo so as to damage the passivated layer of bCr13Mo, hence N atoms can rapidly permeate into bCr13Mo. During the process, the dissolution rate of ammonia maintains at about 25%, the nitriding temperature is 520 DEG C. Before carburization ends, the temperature can be improved to 530 DEG C to carry out certain time of de-nitrogenizing, so as to reduce the surface hardness of the bCr13Mo and increase the depth of the nitrided layer. The actual time can be managed according to the requirement of the work piece. Generally the time under 520 DEG C is about 10 hours, that under 530 DEG C is about 2 hours, and then the work piece is discharged to cool rapidly.

Owner:WUJIANG TIANDIREN VACUUM FURNACE

Low-chromium low-cost hot working die steel

ActiveCN101240399AComprehensive performance is quiteImproved stability against temperingChromiumChemical composition

The invention belongs to the field of tool and die, specifically to a low-chromium low-cost hot die steel. The chemical compositions of the steel (weigh%) are: C: 0.38-0.42%, Si: 0.9-1.1%, S<=0.030%, P<=0.030%, Mn: 0.3-0.5%, W: 0.9-1.2%, Mo: 0.45-0.55%, Cr: 2.8-3.2%, V: 0.25-0.45%, Nb: 0.08-0.15% and Fe and unavoidable impurities: the balance. The steel of the invention can be used as a substitute for high-alloy-containing H13, has similar comprehensive performance to H13, superior temper resistance, low cost and low chromium; the rational alloy ratio saves cost more than 20%, compared with H13 steel, thus having better economical benefit.

Owner:CENT IRON & STEEL RES INST

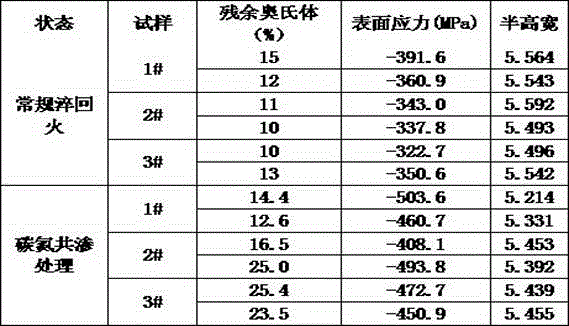

Carbonitriding heat treatment technique under new atmosphere

ActiveCN106637060AAdd depthAddressing Prone Non-Horse OrganizationsSolid state diffusion coatingFurnace typesCarbon potentialCharge layer

The invention discloses a carbonitriding heat treatment technique under a new atmosphere. The technique comprises the following steps that (a), a multi-purpose chamber furnace suitable for carburizing treatment is selected; (b), a nitrogen, methyl alcohol, ammonia gas and dimethylmethane carburizing medium is adopted, and an oxygen probe is adopted to control the carbon potential, so that control over the carbon potential of the atmosphere in the furnace is achieved; (c), according to a charging mode, charging layers are chosen according to the heights of workpieces, and gaps are kept between the workpieces of each layer to guarantee the uniformity of infiltration layers; (d), according to technological parameters, the carbonitriding temperature is 815 DEG C-825 DEG C, the carbon potential is 1.20%-1.30%, and strong infiltration is conducted for 3 h-3.5 h; in the diffusion period, the temperature is 815 DEG C-825 DEG C, the carbon potential is 1.10%-1.20%, and diffusion is conducted for 3 h-3.5 h; KR-218 fast bright quenching oil is used for quenching, and cooling is conducted for 8 min-15min; and air cooling is conducted after tempering; and (e), steel foil is used for carbon determination during strong infiltration of each furnace. According to the carbonitriding heat treatment technique under the new atmosphere, a carbonitriding layer with a certain depth can be obtained in a relatively short time, and higher hardness is achieved.

Owner:LUOYANG LYC BEARING

Flux-cored wire used for repairing continuous casting hollow foot roller sleeve, and cladding process of flux-cored wire

InactiveCN109604858AImproved high temperature fatigueImproved impact wear resistanceMetallic material coating processesWelding/cutting media/materialsNiobiumChromium nitride

The invention discloses a flux-cored wire used for repairing a continuous casting hollow foot roller sleeve, and a cladding process of the flux-cored wire. The flux-cored wire is prepared from self-fluxing alloy powder and a particle modificator; and the self-fluxing alloy powder is prepared from a mixture of carbon, chrome, nickel, silicon, boron, molybdenum, cobalt, niobium and tantalum, and thebalance of iron. A cladding method comprises the steps: 1, the surface of a roller sleeve base body is subjected to lathe polishing in a machining mode; 2, the flux-cored wire is cladded on the outersurface of the continuous casting hollow foot roller sleeve base body; and 3, a clad layer is polished to enable the roughness of the outer surface of the clad layer to reach 6.3. Through a coaxial lateral powder feeding method, a metallurgically bonded alloy coating is formed on the surface of the continuous casting hollow foot roller sleeve of a plate blank; and the iron-based flux-cored wire prepared from the self-fluxing alloy powder and the particle reinforced modificator, namely chromium nitride is selected as the coating, after cladding, a nitride is contained in the coating, and the properties of overall high-temperature fatigue resistance, impact abrasion resistance and corrosion resistance of a continuous casting roller are improved.

Owner:北京奥邦新材料有限公司

Medium-carbon alloy cast steel shots and manufacturing method thereof

The invention relates to medium-carbon alloy cast steel shots and a manufacturing method thereof. Each medium-carbon alloy cast steel shot comprises the following chemical components in percentage by mass: 0.35 to 0.45 percent of carbon, 0 to 0.2 silicon, 0.45 to 0.5 percent of manganese, 0.8 to 1.2 percent of chrome, 0 to 0.015 percent of sulfur, 0 to 0.020 percent of phosphor and the balance of iron and inevitable impurities. The manufacturing process comprises the following steps of: mixing and smelting, namely, smelting the raw material composition mixed proportionally into liquid steel, pouring the liquid steel into a tundish and performing deoxygenation by adopting an deoxidant; preparing shots by a centrifugally forming method, namely, pouring deoxygenized liquid steel into a centrifugal disc which rotates at a high speed, throwing out the liquid steel under the action of a centrifugal force to make the liquid steel fall into a cooling water pool, and taking the liquid steel out and drying the cooled steel to obtain formed cast steel shots; and performing heat treatment, namely, heating the formed cast steel shots until the temperature reaches 860 to 880 DEG C, performing cold quenching after keeping the temperature for 20 to 40 minutes, tempering for 40 to 80 minutes at the temperature of between 350 and 500 DEG C, and after tempering, cooling rapidly by a steel plate vibrating screen water cooling method to produce the medium-carbon alloy cast steel shots. The medium-carbon alloy cast steel shots and the manufacturing method thereof have the advantages of guaranteeing the high rigidity of the steel shots, avoiding crack generated in the centrifugally forming process and the heating tempering process, improving the toughness and the like.

Owner:淄博大亚金属科技股份有限公司

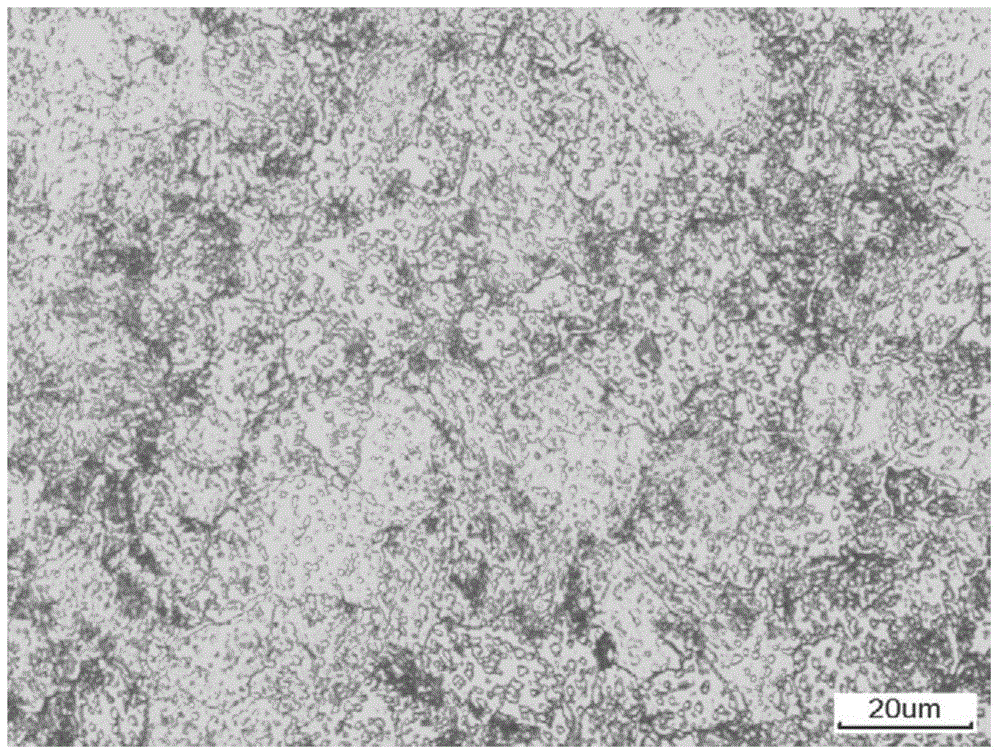

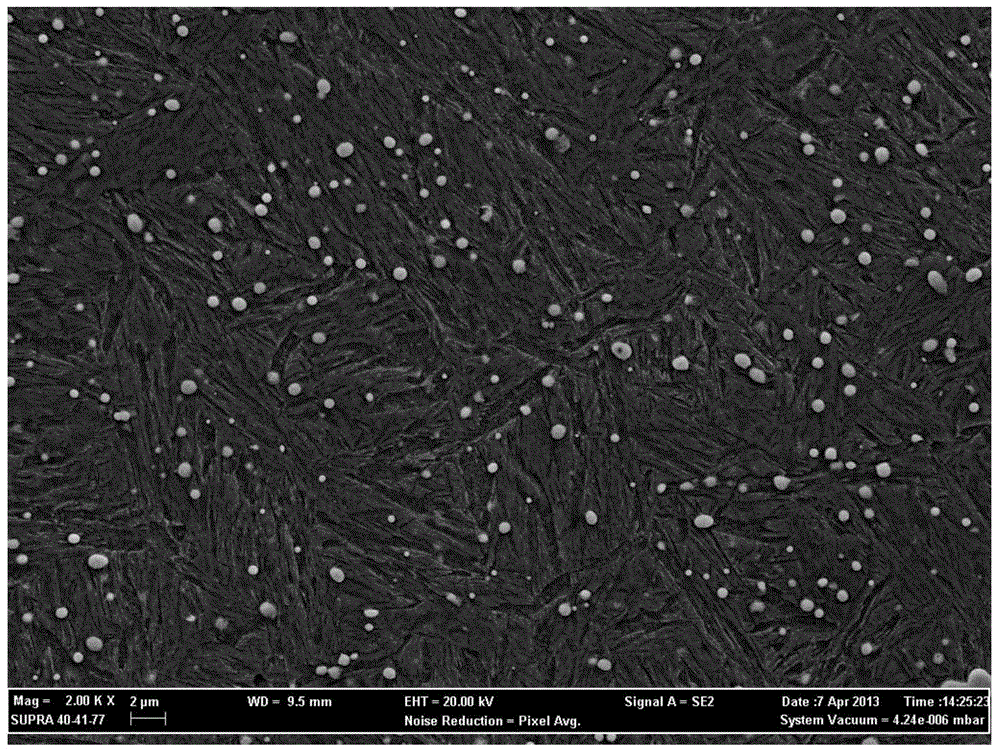

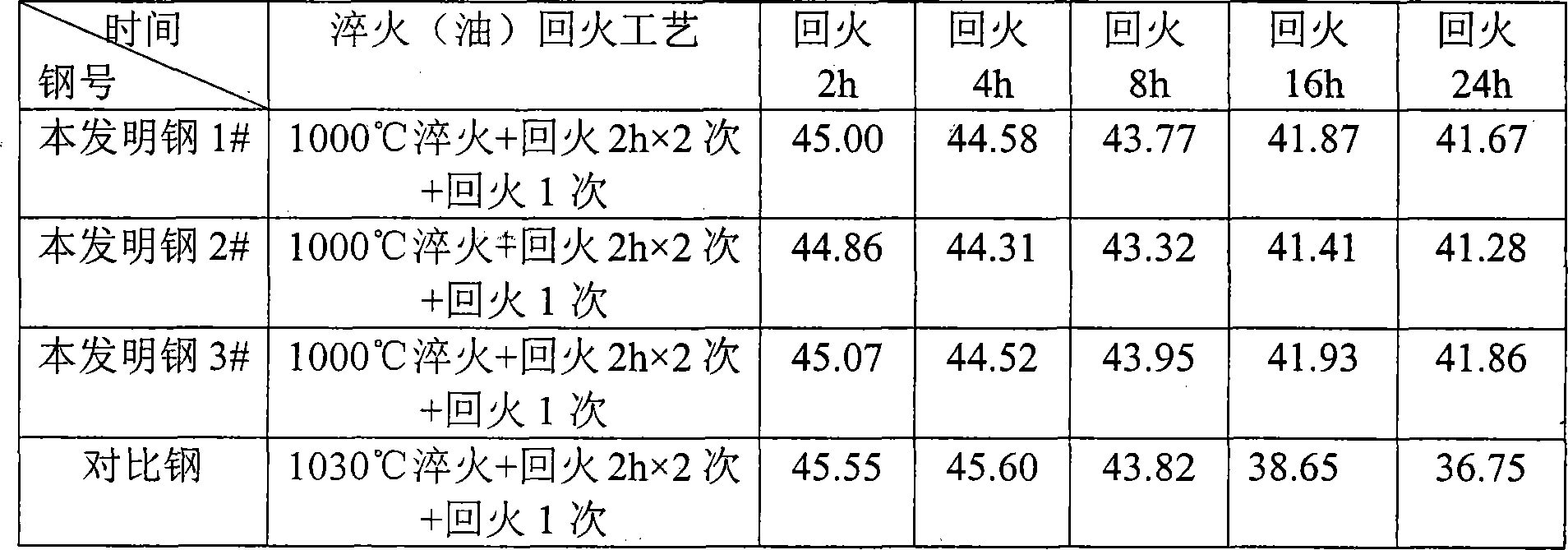

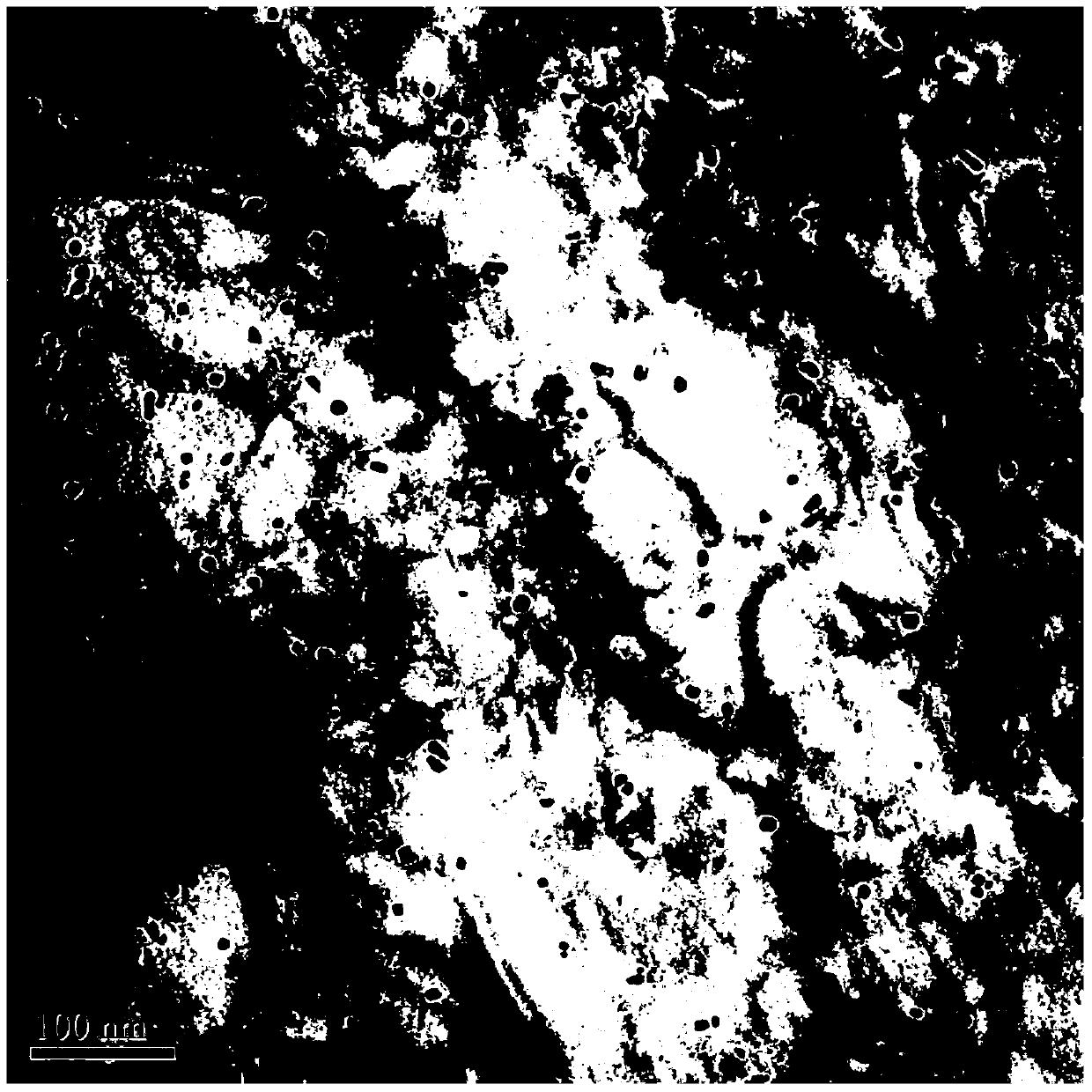

Intermetallic compound and carbonitride co-hardened powder metallurgy high-speed steel and preparation method thereof

The invention discloses intermetallic compound and carbonitride co-hardened powder metallurgy high-speed steel, which is prepared by the following steps: strengthening a steel matrix by using an intermetallic compound generated in situ and additional carbonitride, and obtaining the intermetallic compound and carbide co-hardened powder metallurgy high-speed steel by a powder metallurgy method. Theintermetallic compound and carbonitride co-hardened powder metallurgy high-speed steel is obtained by adding specific stable carbonitride and alloy elements and co-strengthening the material by addingthe carbonitride and the in-situ generated intermetallic compound. Due to less carbon in the intermetallic compound and the matrix, the material can keep excellent red hardness and knife sticking resistance, and meanwhile, the addition of the stable high-hardness carbonitride can achieve the effects of obviously refining grains and improving the wear resistance.

Owner:CENT SOUTH UNIV

Method for manufacturing pipeline assembly from shape memory alloy

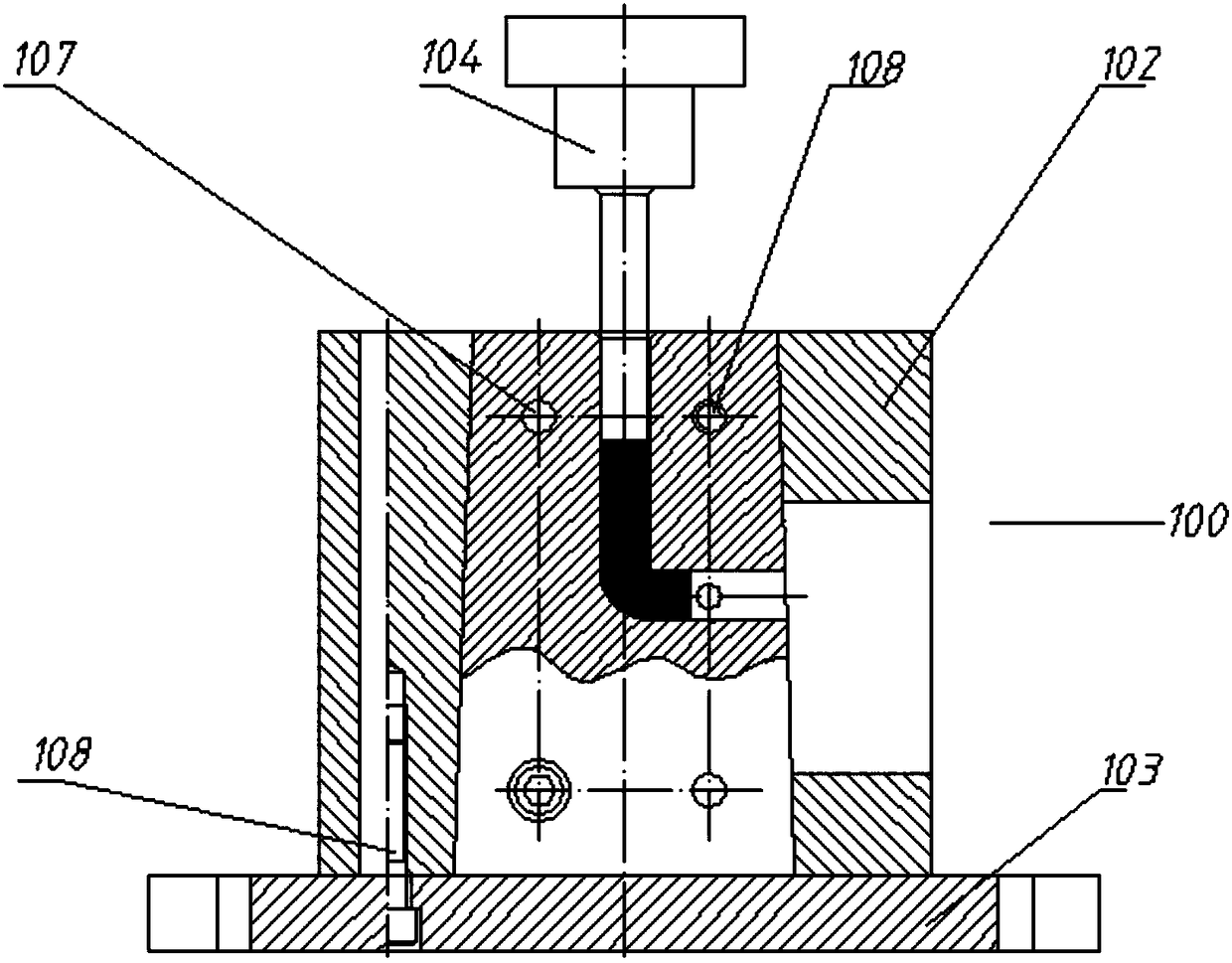

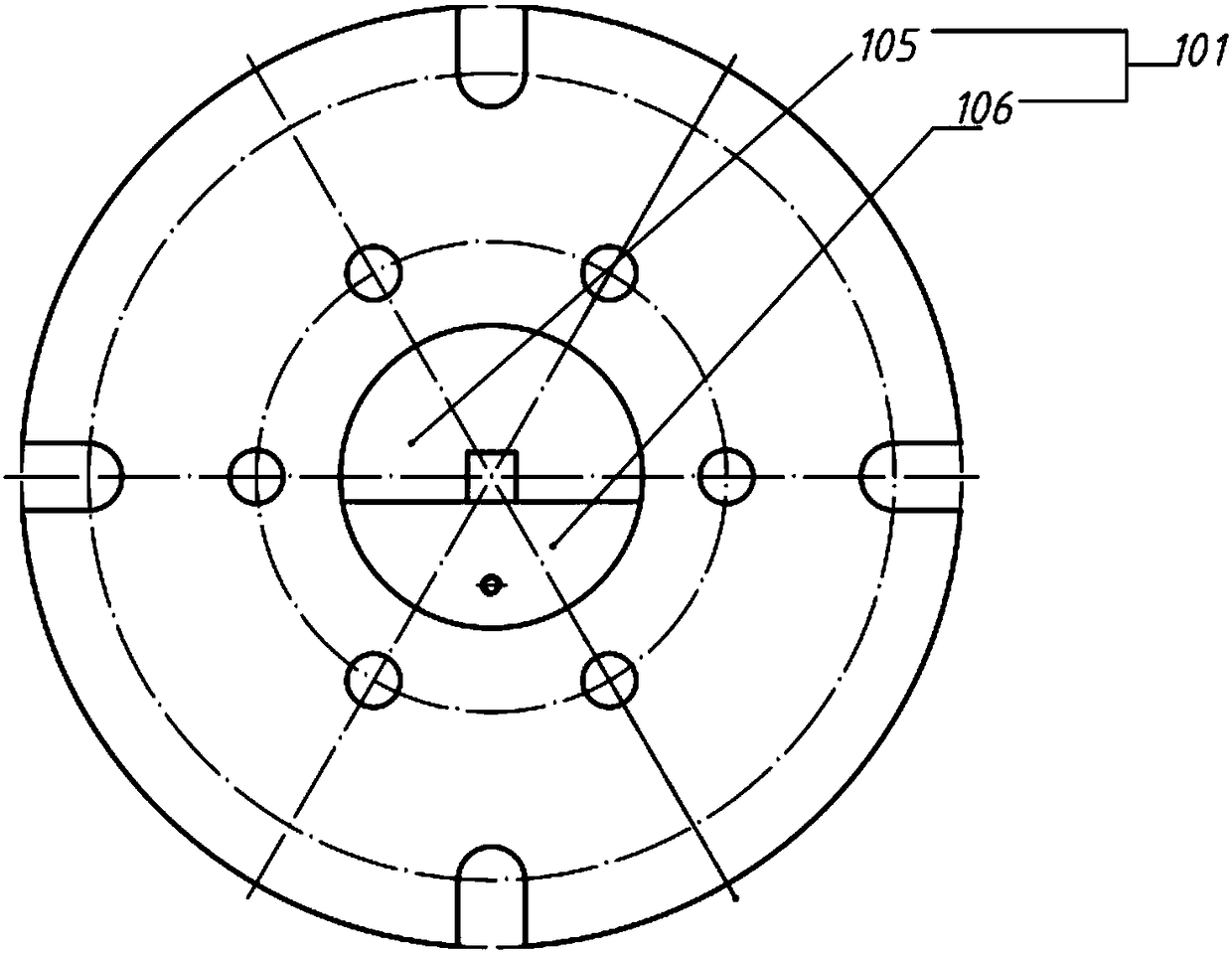

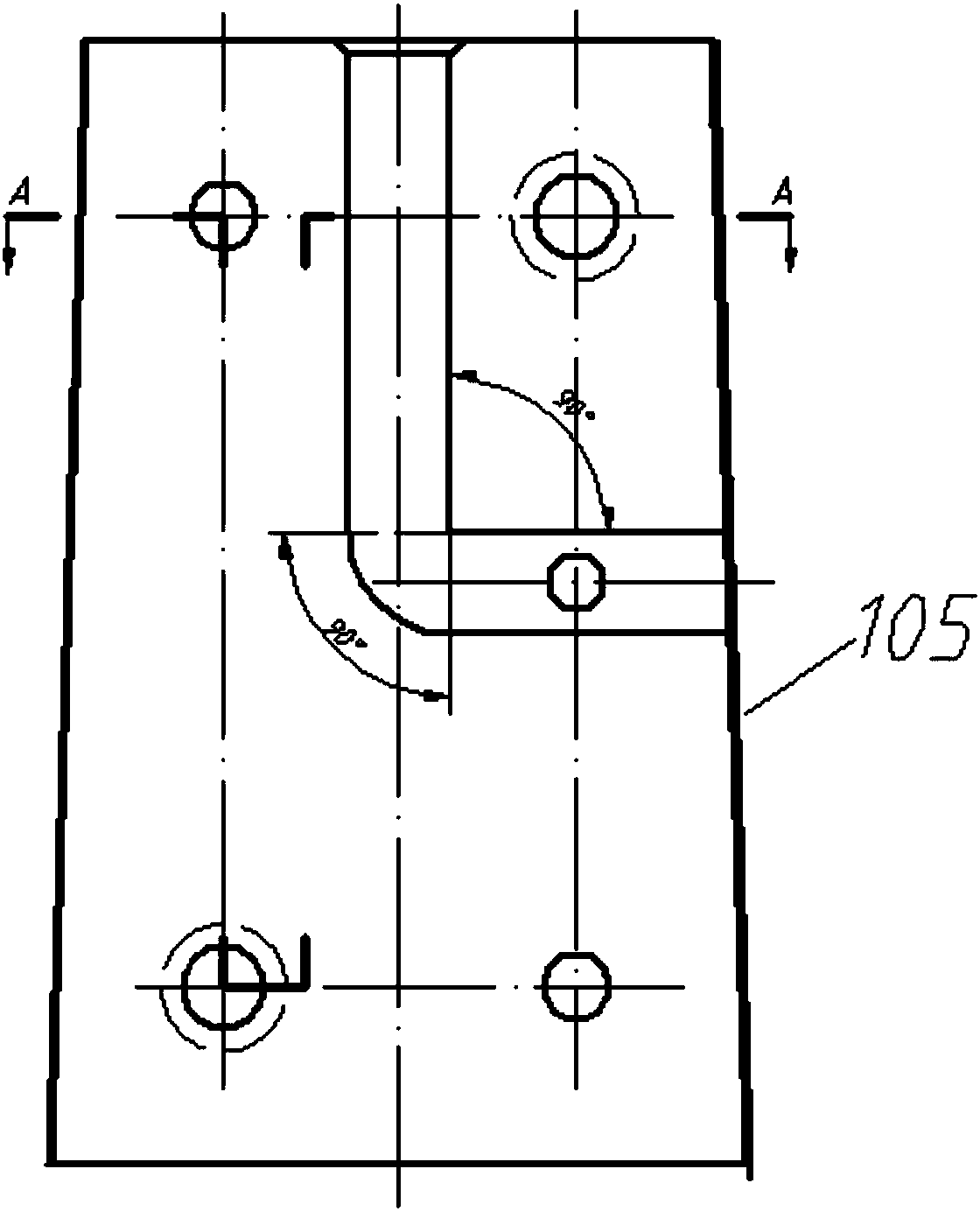

ActiveCN108723110AHigh material strengthIncreased strength and recoveryExtrusion diesShearing deformationCrystallite

The invention relates to a method for manufacturing a pipeline assembly from shape memory alloy. The method adopts an equal-diameter bending extrusion mould to form an equal-diameter bending extrusionmethod for processing the shape memory alloy; the method can realize large shearing deformation of a test sample under relatively low load and relatively load stress in case of not changing the crosssection area of the material; in a deforming process, crystalline grains are greatly refined by processing and hardening, dynamic recovery and re-crystallizing of block materials; and finally, a sub-microcrystal or nano structure is finally formed, so that the material strength is improved; and according to the research, the strength and the recovery rate of iron-based shape memory alloy can be remarkably improved by ECAP deformed refined crystalline grains. Therefore, the method belongs to the technical field of metal material refining.

Owner:江苏华晨气缸套股份有限公司

Low-cost hot working die steel

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

High-temperature-resistant and high-toughness hot work die steel and preparation method thereof

InactiveCN111057950AImprove toughnessAvoid performance incompatibility problemsElectric arc furnaceHot work

The invention relates to the technical field of special steel forgings, in particular to high-temperature-resistant and high-toughness hot work die steel and a preparation method thereof. The hot workdie steel comprises the following components of, in percentage by weight, 0.38 %-0.40% of C, 0.25 %-0.40 % of Si, 0.45 %-0.55 % of Mn, 4.75 %-5.3 % of Cr, 1.7 %-1.9 % of Mo, 0.60 %-0.80 % of V, 0.30%-0.50 % of Ni, less than or equal to 0.002 % of S, less than or equal to 0.0015 % of P, and the balance Fe. The preparation method comprises the following steps of electric arc furnace smelting, external refining, casting, atmosphere protection electroslag remelting, forging, quenching oil cooling treatment and spheroidizing annealing treatment. According to the steel and the method, the raw material proportion of the hot work die steel is optimized, and the content of Si, V, Mo, Ni and other elements is limited within an accurate adjustment and control range, so that the adding amount of corresponding Si, V, Mo, Ni and other elements can be accurate, and the problem that all properties of the die steel are incompatible is solved; and the high-performance hot work die steel can be directly manufactured by selecting the numerical value of the content within the range, so that the finished product rate is remarkably increased.

Owner:潘少俊

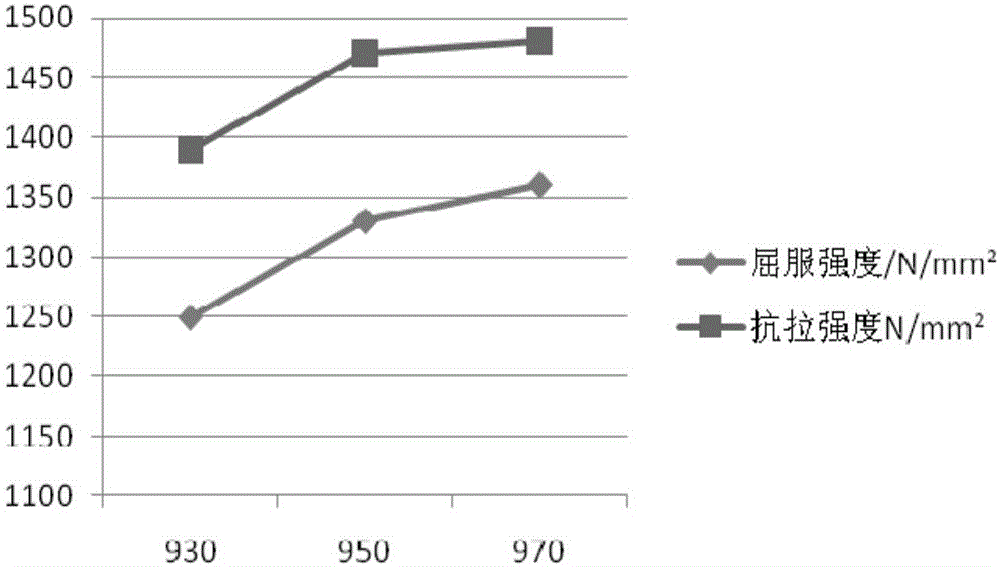

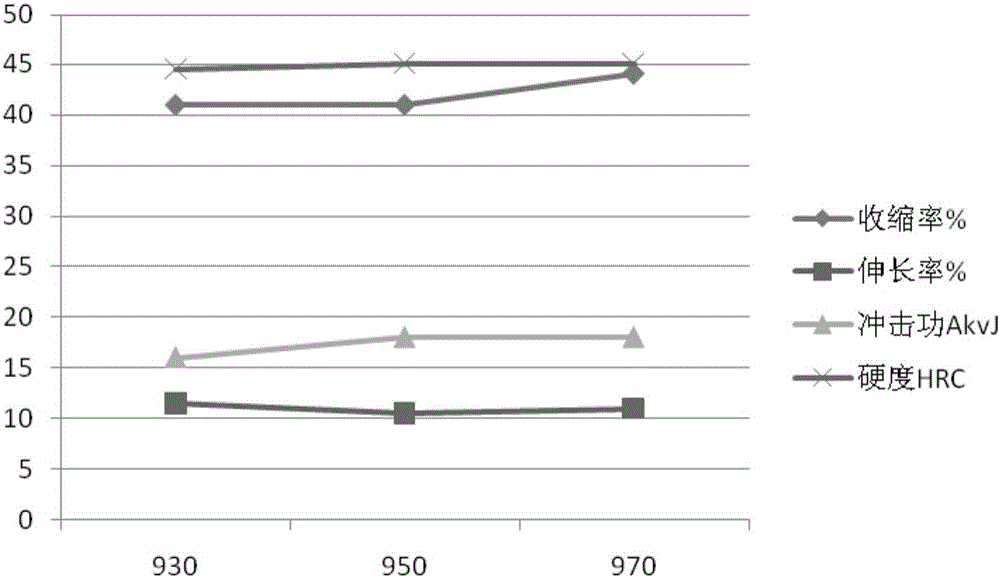

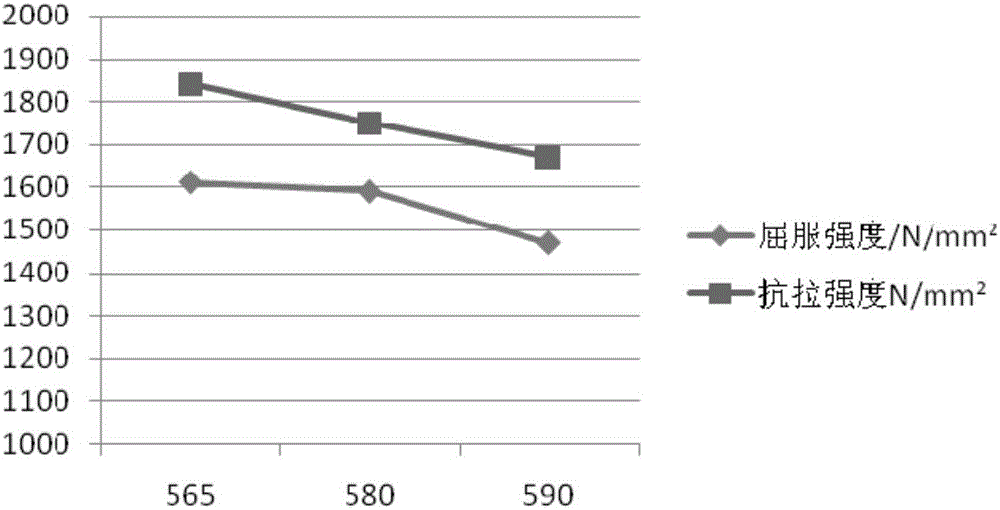

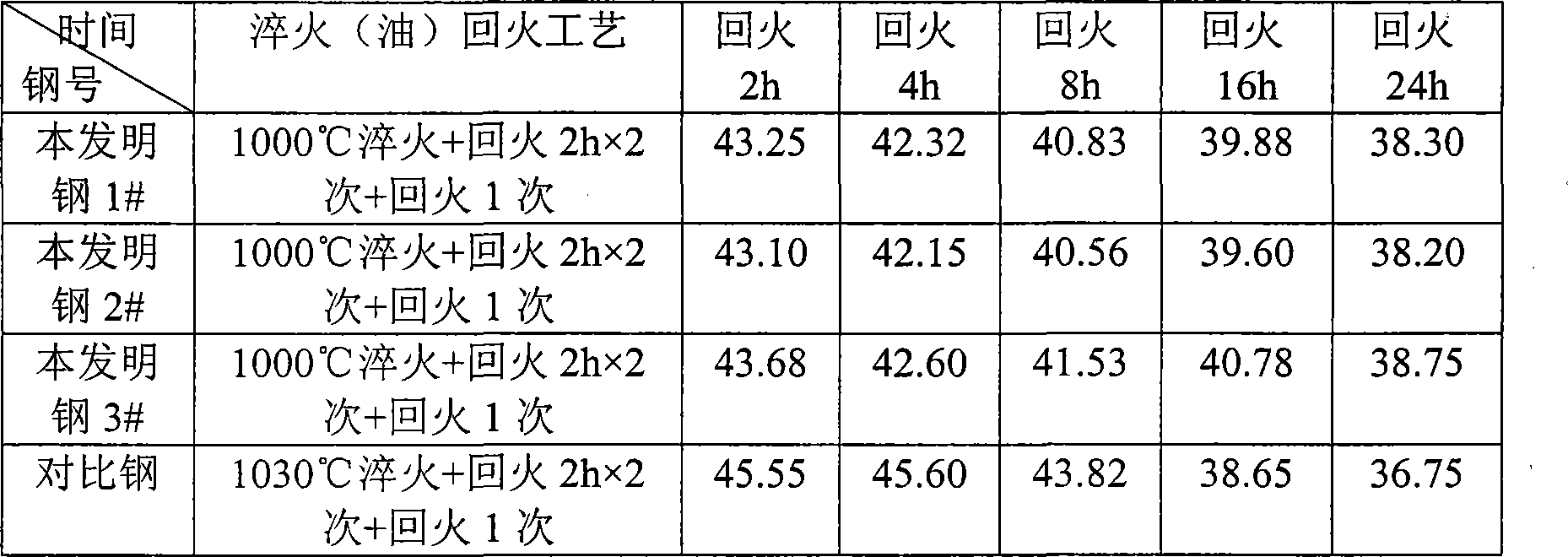

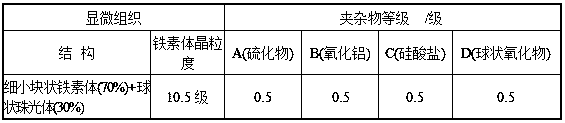

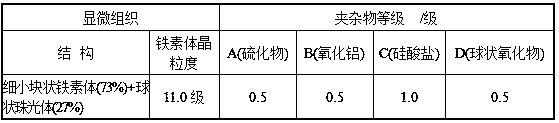

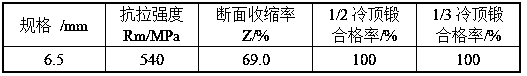

A kind of preparation method of steel hot-rolled round wire rod for 10.9 high-strength bolts

ActiveCN106929623BHigh strengthImproved stability against temperingManufacturing convertersProcess efficiency improvementMachining deformationHardness

The invention discloses a preparation method of a hot-rolled steel coil rod for a 10.9-level high-strength bolt. The preparation method comprises the following steps of A, pretreatment and desulfurization of molten iron; B, smelting of molten steel; C, deoxygenation alloying; D, LF furnace refining of the molten steel; E, casting of the molten steel; F, billet heating; and G, controlled rolling and controlled cooling. According to the preparation method of the hot-rolled steel coil rod for the 10.9-level high-strength bolt, the prepared hot-rolled steel coil rod is high in cleanliness and good in hardenability and has proper strength and hardness as well as excellent plastic toughness and cold heading machining deformation capacity, the 10.9-level high-strength bolt can be produced through cold heading machining directly without spheroidizing annealing, manufacturing procedures and energy consumption are reduced, and production cost is reduced.

Owner:WUKUN STEEL

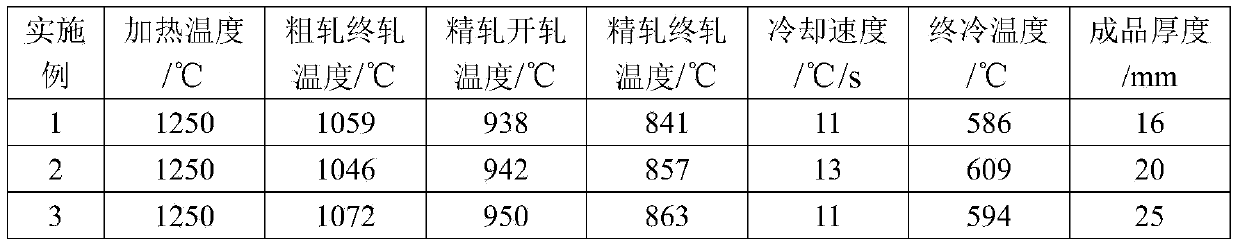

Low-molybdenum high-titanium 590MPa-grade fire-retardant steel plate for building and preparation method of steel plate

ActiveCN104046902ASmall and uniform tissueImproved stability against temperingTemperature control deviceSteel platesSheet steel

The invention discloses a low-molybdenum high-titanium 590MPa-grade fire-retardant steel plate for building. The fire-retardant steel plate comprises the following chemical components in percentage by weight: 0.04-0.12% of C, 0.10-0.35% of Si, 0.6-1.2% of Mn, 0.015-0.045% of Al, 0.10-0.50% of Cr, 0.01-0.25% of Mo, 0.015-0.035% of Nb, 0.05-0.12% of Ti, no more than 0.004% of N, no more than 0.003% of O, no more than 0.015% of P, no more than 0.005% of S, and the balance of Fe and inevitable impurities being less than or equal to 0.05%. The invention further provides a preparation method of the corresponding fire-retardant steel plate. The fire-retardant steel plate contains less precious metals Mo and Nb, does not contain Ni, nano-carbide precipitation of cheap metal Ti is creatively utilized and strong and dispersively distributed TiC is obtained, so that the high-temperature strength can be effectively enhanced, the welding performance can also be improved, and the alloy cost can be greatly lowered. The low-molybdenum high-titanium 590MPa-grade fire-retardant steel plate is produced by adopting controlled rolling and controlled cooling technology, is free from follow-up thermal treatment, simple in production operation, low in technological cost, and high in production efficiency.

Owner:LAIWU IRON & STEEL GRP

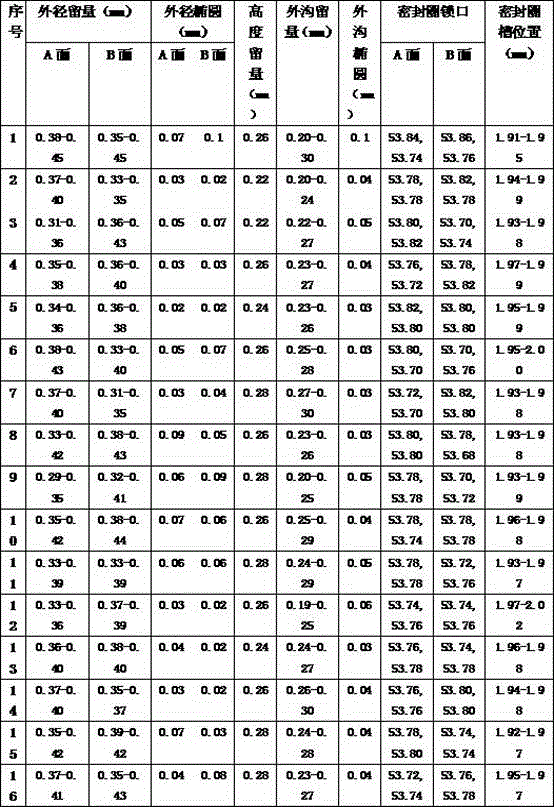

Main valve element for reversing valve

InactiveCN106286885AImprove performanceImprove organizational stabilityServomotor componentsMultiple way valvesMechanical engineeringToughness

The invention relates to a main valve element for a reversing valve. The main valve element comprises a lower valve sleeve, a valve element and an upper valve sleeve internally provided with a piston. The lower valve sleeve is inserted into the upper valve sleeve to be connected with the upper valve sleeve. The valve element is located in the lower valve sleeve and stretches into the piston. The upper valve sleeve is provided with an opening which is covered with an end cover. The upper valve sleeve, the lower valve sleeve and the valve element are all made of alloy steel. The alloy steel comprises 0.10-0.15% of C, 1.5-2.0% of Cr, 0.22-0.35% of Si, 0.8-1.2% of Mn, 0.045-0.06% of Al, 0.03-0.05% of N, 0.25-0.35% of Mo, 0.025-0.04% of Cu, 0.005-0.022% of S, 0.08-0.15% of V, 0.08-0.15% of RE, no more than 0.015% of P and the balance Fe. The main valve element is high in toughness and good in anti-tempering stability, cold-hot-fatigue resistance and high-temperature abrasion resistance.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

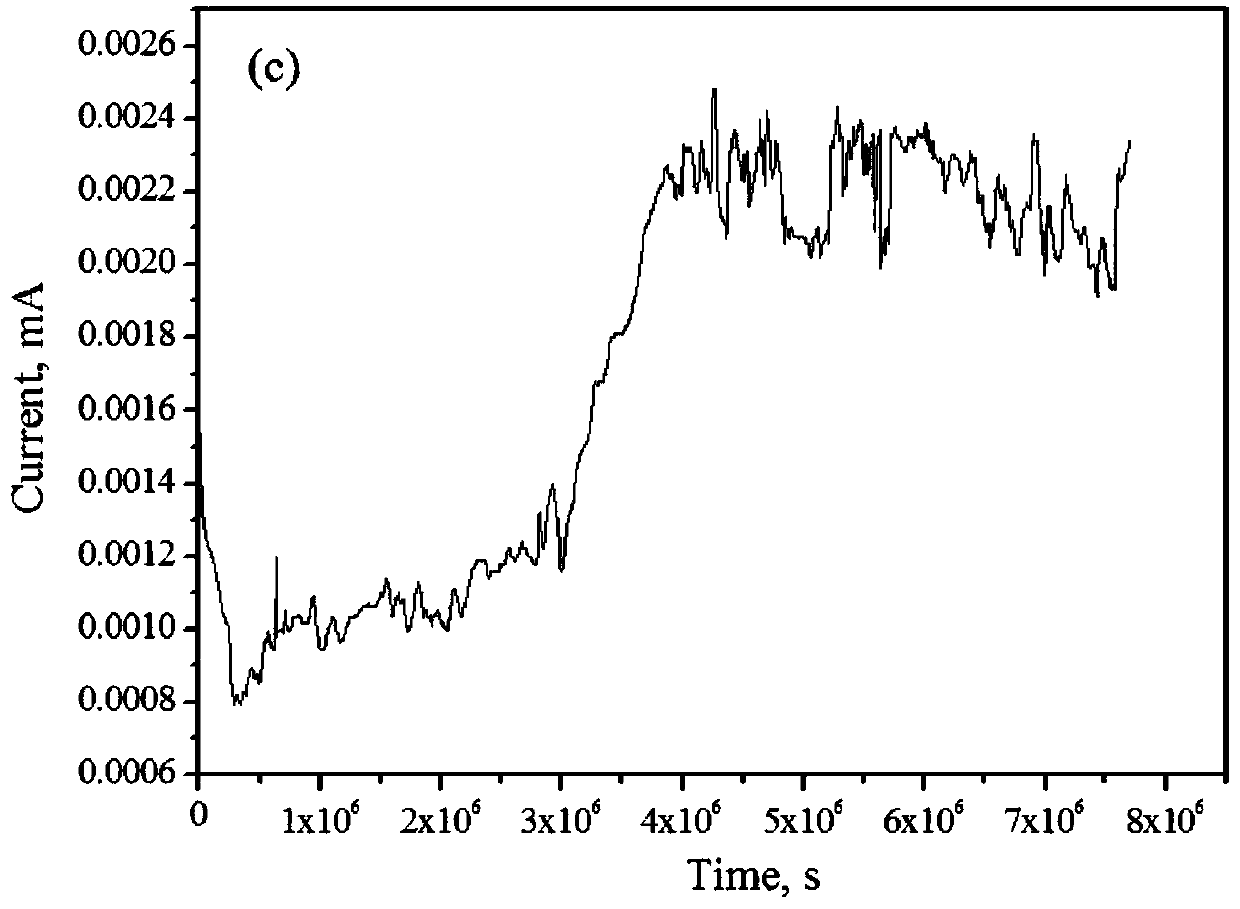

Steel for high strength fastener for marine environment

The invention relates to steel for a high strength fastener for a marine environment. The steel is prepared from the following raw materials in percent by weight: 0.08-0.20% of C, 0.10-1.0% of Si, 0.3-1.0% of Mn, less than or equal to 0.005% of S, less than or equal to 0.005% of P, 0.2-1.2% of Cr, 4.5-9.5% of Ni, 0.3-1.0% of Mo, less than or equal to 0.15% of V and the balance Fe and other inevitable impurities. The hydrogen diffusion coefficient D of the steel is smaller than or equal to 10<-8>mm<2> / s. A hydrogen trap type of the steel is a reversible hydrogen trap, and the hydrogen escape activation energy Ea is smaller than 30 kJ / mol. Starting from an essential attribute design of a material, the average hydrogen content in the steel is reduced, and process and influence of hydrogen atoms taking part in hydrogen induced delayed fracture in an irreversible hydrogen trap are eliminated, so that the hydrogen induced delayed fracture problem of the high strength fastener for the marineenvironment is controlled effectively.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Preparation method for high-hardness manganese-iron alloy material

InactiveCN107190211AAchieve solid solution strengtheningImprove performanceProcess efficiency improvementRare-earth elementHardness

The invention discloses a preparation method for a high-hardness manganese-iron alloy material. The preparation method comprises the following steps: S1, Fe is added into a smelting furnace and is heated to be completely melted; S2, Mn, Cr, Zr, Mo, Cd, W, V, graphite, diamond, WC, Cr2B, La2O3, Nd(OH)3, Eu2O3,Yb2O3, PrCl3, PrSi2, YSi2 and TbN are added into the Fe melted in the S1, and are uniformly mixed with the melted Fe to obtain an alloy melt; S3, the alloy melt in the S2 is refined, and a refining agent is added in the refining process; S4, the alloy melt refined in the S3 is cast to obtain a casting; and S5, the casting cooled in the S4 is tempered and cooled to obtain the alloy material. According to the preparation method for the high-hardness manganese-iron alloy material, by adding Cr and rare earth elements, the manganese-iron alloy is high in strength and good in toughness and wear resistance, and the comprehensive performance of the copper alloy is greatly improved.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

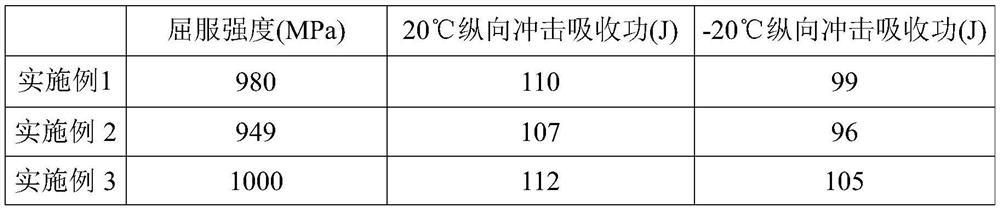

High-strength and high-toughness steel for drill rod joint and preparation method thereof

InactiveCN112048669AGrain refinementImproved stability against temperingAlloy elementElectric furnaces

The invention discloses high-strength and high-toughness steel for a drill rod joint and a preparation method thereof. The high-strength and high-toughness steel is prepared from the following chemical components in percentage by mass: 0.35 to 0.38 percent of C, 0.20 to 0.30 percent of Si, 0.90 to 1.10 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent ofS, 0.90 to 1.20 percent of Cr, 0.25 to 0.35 percent of Mo, 0.05 to 0.15 percent of Ni, 0.01 to 0.04 percent of Nb, 0.010 to 0.030 percent of Ti, and the balance of Fe and inevitable impurities. The preparation method comprises the procedures of electric furnace smelting, LF refining, VD vacuum degassing, continuous casting, rolling, segmented forging and pressing, normalizing, quenching and tempering, wherein in the LF refining process, niobium is added into molten steel to control the niobium content to be 0.01 to 0.04 percent by weight; and after the VD vacuum degassing, a titanium wire is fed for titanium alloying to control the titanium content to be 0.010 to 0.030 percent by weight. According to the preparation method, a reasonable alloy element component design is adopted to obtain the steel for the drill rod joint with the yield strength of larger than or equal to 920 MPa, the longitudinal impact absorption energy of larger than or equal to 100 J at the temperature of 20 DEG C,the longitudinal impact absorption energy of larger than or equal to 90 J at the temperature of 20 DEG C below zero, and the performance requirement of an ultra-deep well on the drill rod joint is met.

Owner:NANJING IRON & STEEL CO LTD

Manufacturing method of blank of bearing steel rolling body for wind driven generator yawing pitch bearing

ActiveCN106636579AImproved stability against temperingImproved impact toughness and contact fatigue lifeWind drivenWind force

The invention discloses a manufacturing method of a blank of a bearing steel rolling body for a wind driven generator yawing pitch bearing. The manufacturing method comprises the following steps that (a), a bearing steel bar are heated to 1000-1150 DEG C and fed into a hot header to be cut, upset and molded; (b), a molded product is cooled to 550-700 DEG C with a liquid medium, after the molded product is taken out of the liquid medium, the molded product continues to be subjected to blast cooling to 200-350 DEG C, and then stack cooling is conducted; (c), a product obtained in the step (b) is moved into a balling annealing furnace; and (d), a product obtained in the step (c) is cooled to 690-730 DEG C and subjected to isothermal balling, after heat preservation is conducted for 5-10 h, the product is cooled to under 620 DEG C at the speed of 25 DEG C / h or below, and the product is fetched out of the furnace and cooled in the air. The tempering resisting stability of the product is improved, impact toughness is greatly improved, and the contact fatigue life is greatly prolonged; and the level of network carbides can be controlled under the second level.

Owner:CHANGSHU LONGTENG ROLLING ELEMENT CO LTD +1

Cast steel shot and manufacture method thereof

InactiveCN104451392AHigh hardnessImprove toughnessAbrasion apparatusManufacturing technologyQuenching

The invention relates to a cast steel shot and a manufacture thereof. The cast steel shot comprises the chemical compositions in percent by mass: 0.30-0.40% of C, 0.1-0.2% of Si, 0.5-0.65% of Mn, 1.0-1.2% of Cr, 0-0.01% of S, 0-0.01% of P, and the balance iron and unavoidable impurity. The manufacture technology comprises: preparing materials and melting, namely melting the prepared raw material compositions to form molten steel, pouring into a tundish, and employing a deoxidizer for deoxidization; forming a shot, namely, pouring deoxidized molten steel into a centrifugation disk rotating at a high speed, tossing out the pill under the centrifugal effect, dropping into a cooling pool, fishing out and baking to dry, so as to obtain a formed as-cast steel shot; and performing heat treatment, namely, heating the formed as-cast steel shot to 870-880 DEG C, keeping for 30-40 min, performing water-cooling quenching, performing tempering processing at 400-500 DEG C for 50-80 min, after tempering, employing a steel-plate vibrating-screen water cooling process to perform rapid cooling, so as to prepare the cast steel shot. The method guarantees the steel shot to have high hardness and also prevents the steel shot from generating cracks in the process of centrifugation forming and heating quenching, thereby increasing the toughness and other advantages of the steel shot.

Owner:李玉清

Manufacturing method of medium-carbon alloy cast steel shots

The invention relates to medium-carbon alloy cast steel shots and a manufacturing method thereof, which is characterized in that, each medium-carbon alloy cast steel shot comprises the following chemical components in percentage by mass: 0.35 percent of carbon, 0.11 percent of silicon, 0.45 percent of manganese, 1.2 percent of chrome, 0.015 percent of sulfur, 0.020 percent of phosphor and the balance of iron and inevitable impurities. The manufacturing process comprises the following steps of: mixing and smelting, namely, smelting the raw material composition mixed proportionally into liquid steel, pouring the liquid steel into a tundish and performing deoxygenation by adopting an deoxidant; preparing shots by a centrifugally forming method, namely, pouring deoxygenized liquid steel into a centrifugal disc which rotates at a high speed, throwing out the liquid steel under the action of a centrifugal force to make the liquid steel fall into a cooling water pool, and taking the liquid steel out and drying the cooled steel to obtain formed cast steel shots; and performing heat treatment, namely, heating the formed cast steel shots until the temperature reaches 860 to 880 DEG C, performing cold quenching after keeping the temperature for 20 to 40 minutes, tempering for 40 to 80 minutes at the temperature of between 350 and 500 DEG C, and after tempering, cooling rapidly by a steel plate vibrating screen water cooling method to produce the medium-carbon alloy cast steel shots. The medium-carbon alloy cast steel shots and the manufacturing method thereof have the advantages of guaranteeing the high rigidity of the steel shots, avoiding crack generated in the centrifugally forming process and the heating tempering process, improving the toughness and the like.

Owner:淄博大亚金属科技股份有限公司

Low-chromium low-cost hot working die steel

ActiveCN101240399BComprehensive performance is quiteImproved stability against temperingChemical compositionHot working

Owner:CENT IRON & STEEL RES INST

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041BImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium,0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com