Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Achieve solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel base alloy and stainless steel valve with nickel base alloy layer sealing surface, and production method thereof

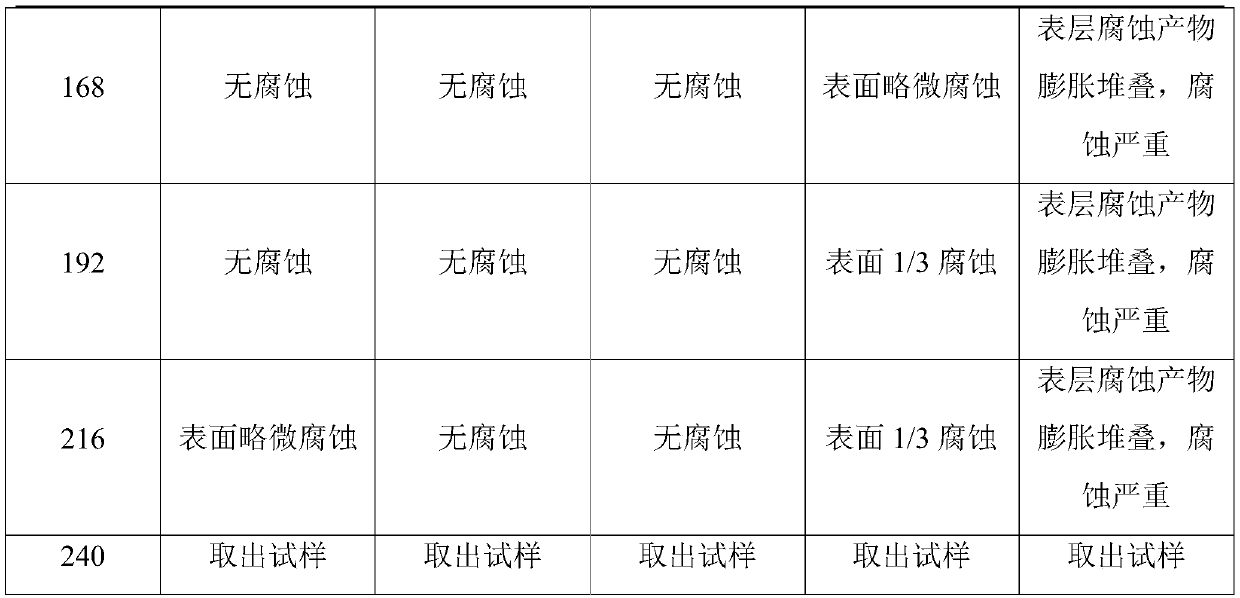

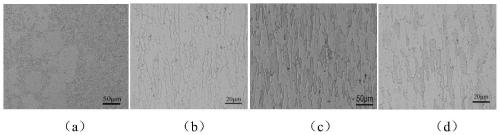

ActiveCN101368239AHigh dilution rateHigh hardnessMetallic material coating processesMetal silicideMetal

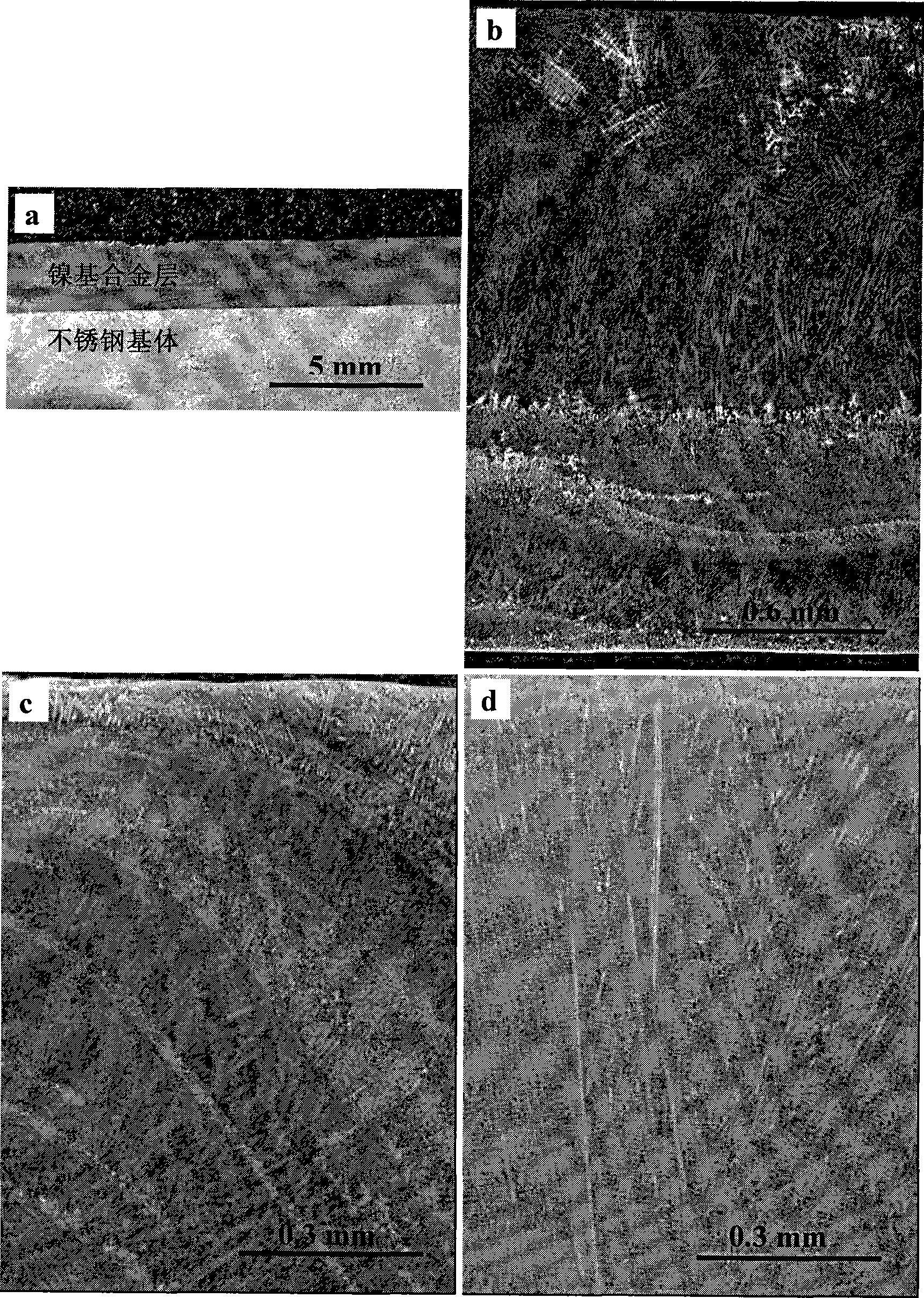

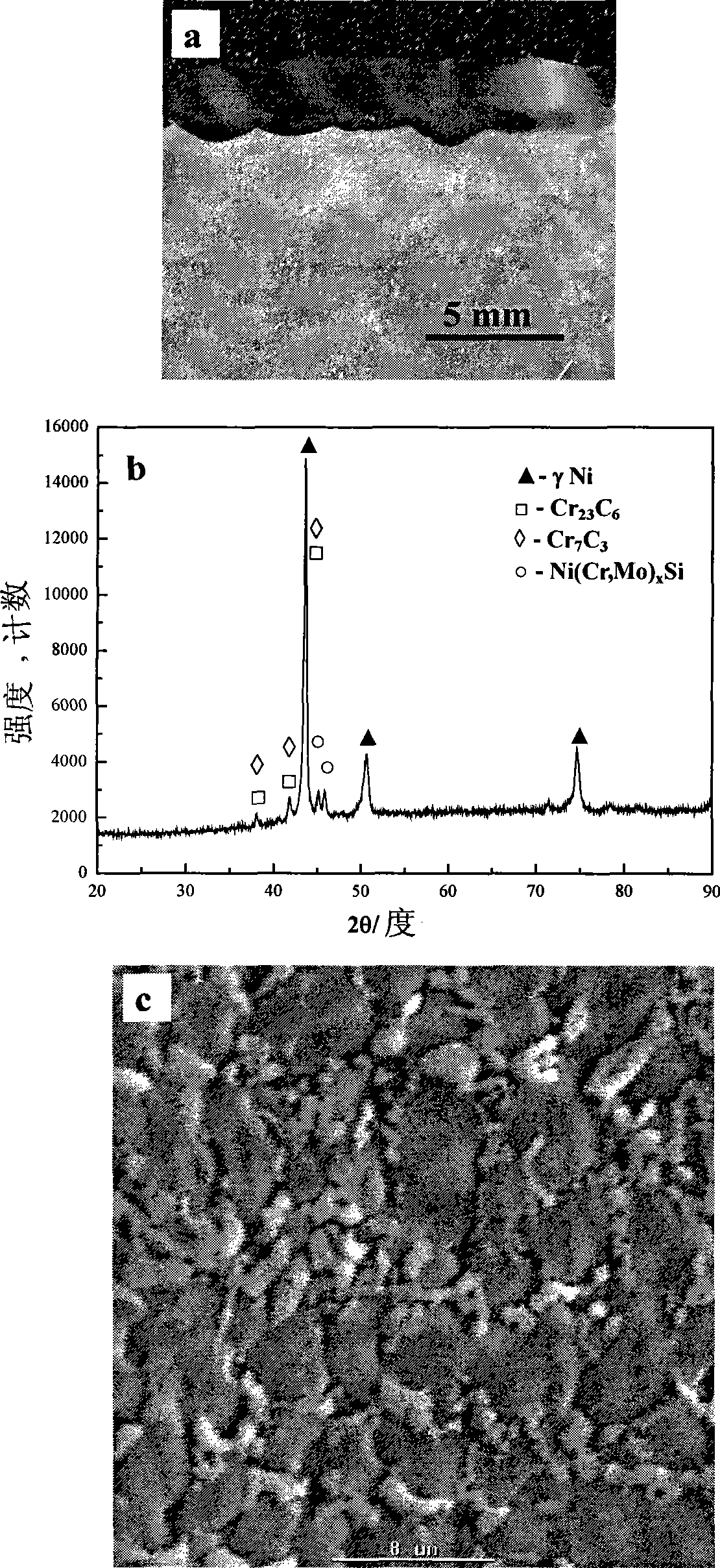

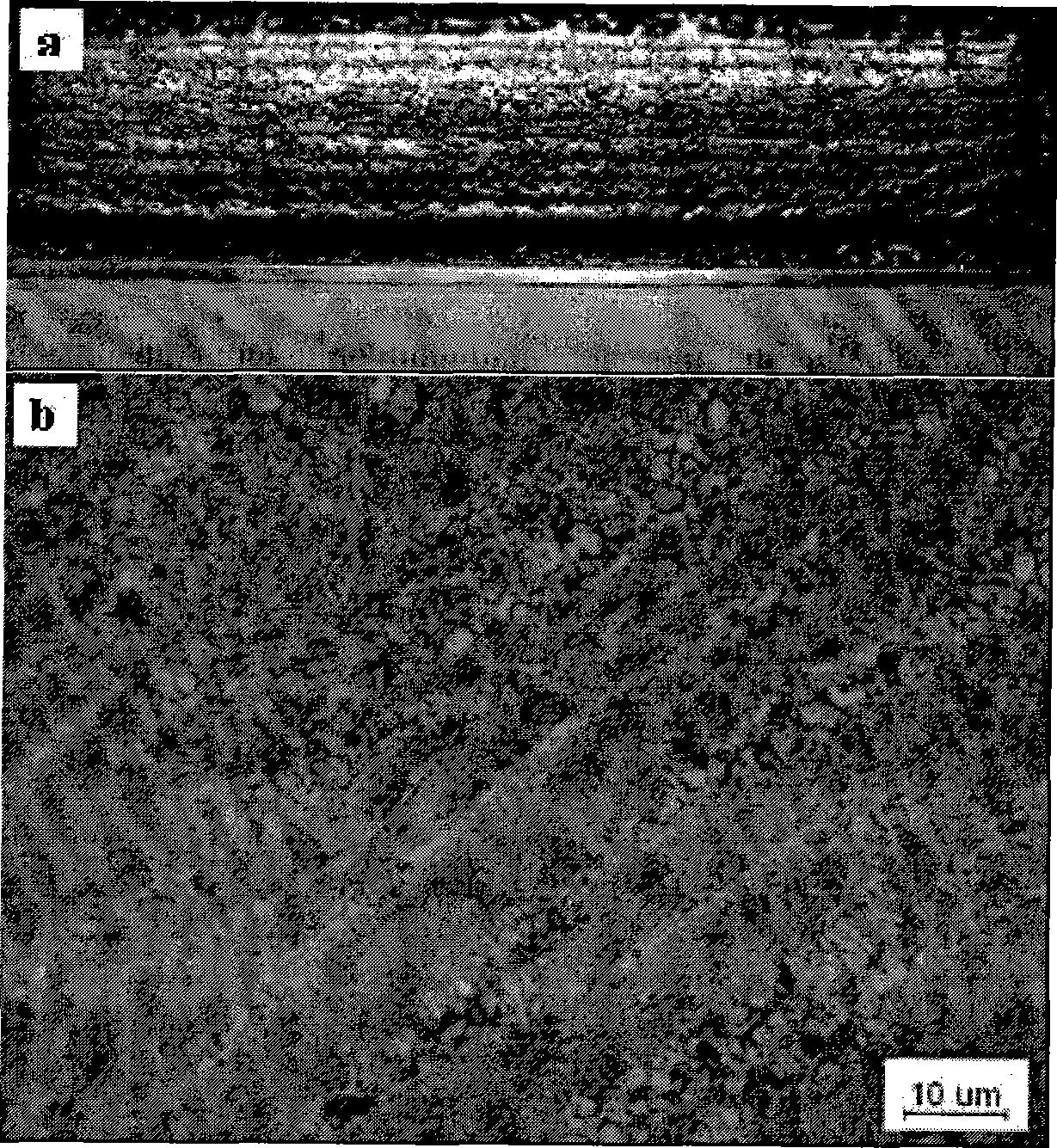

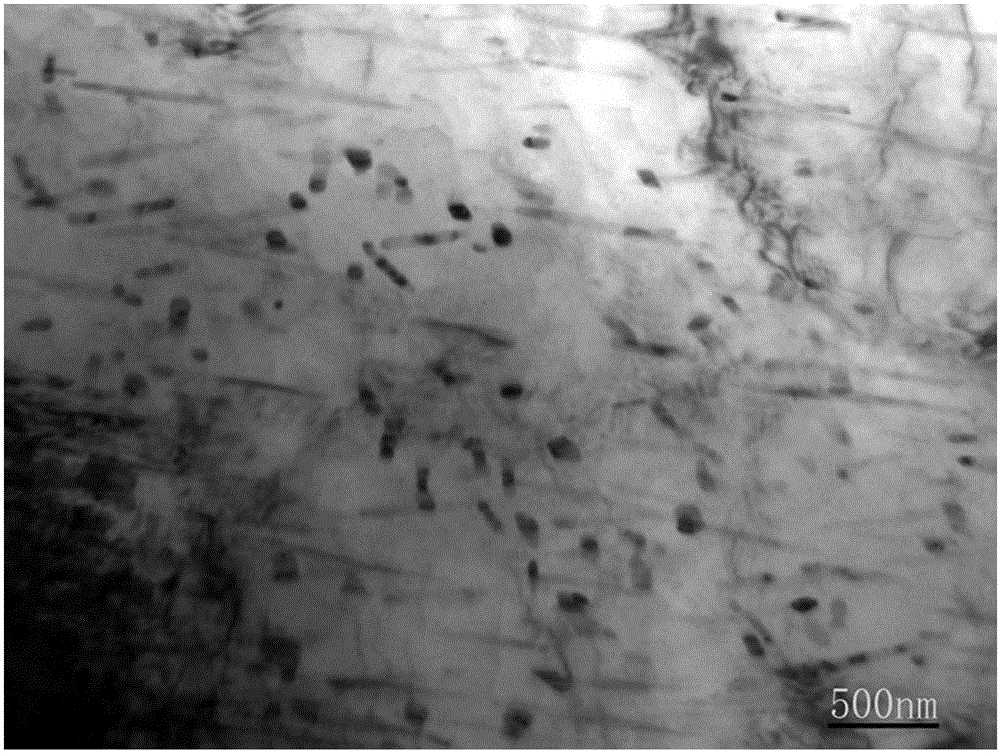

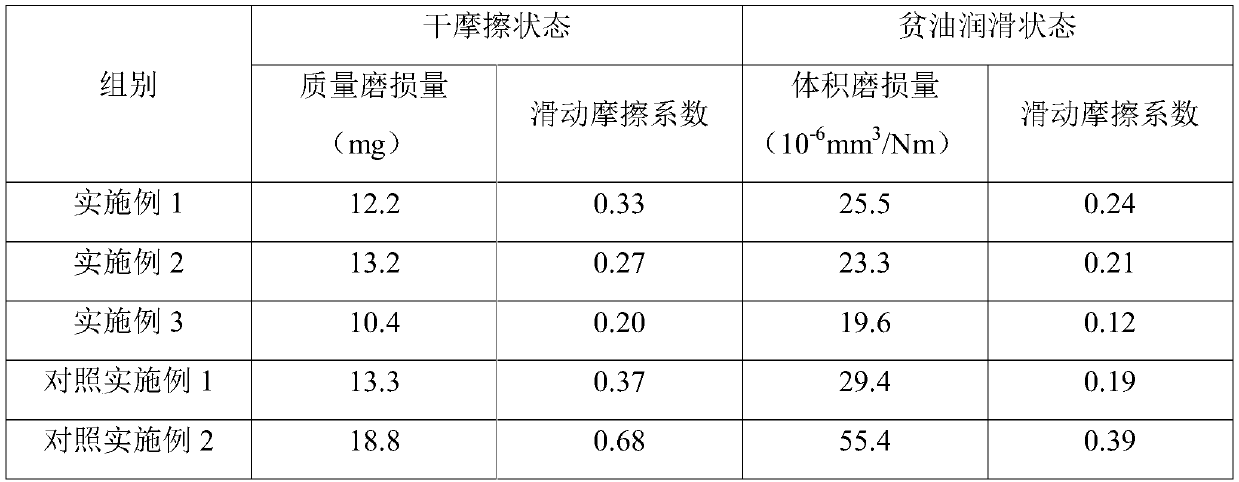

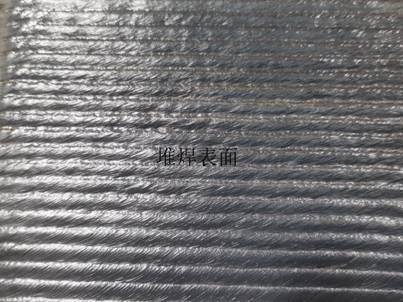

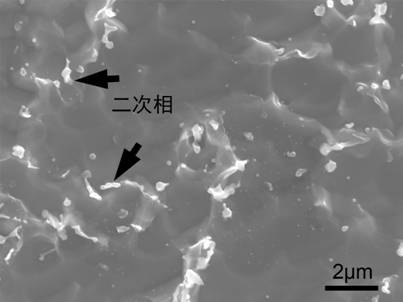

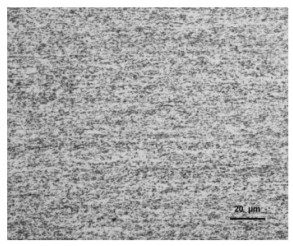

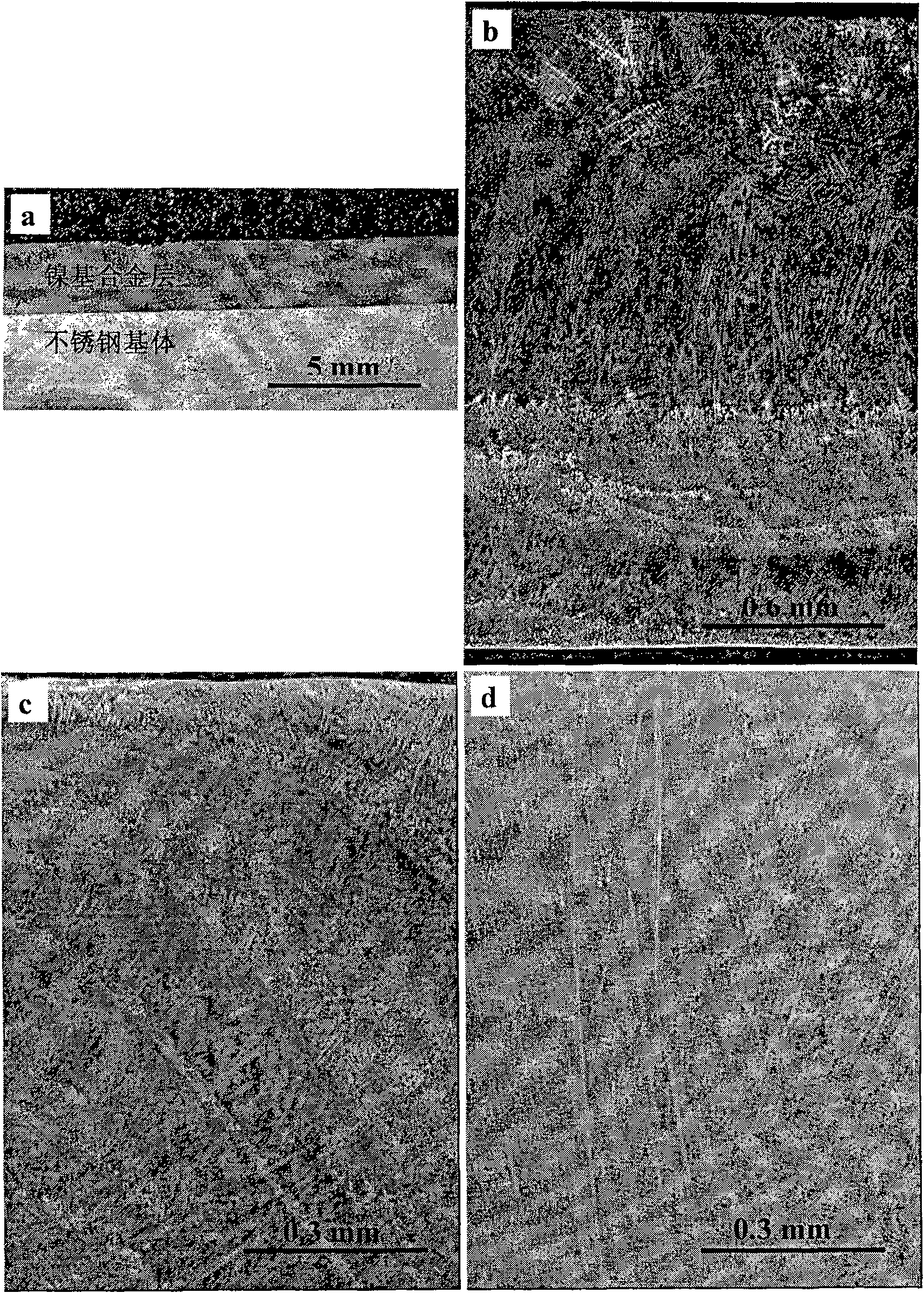

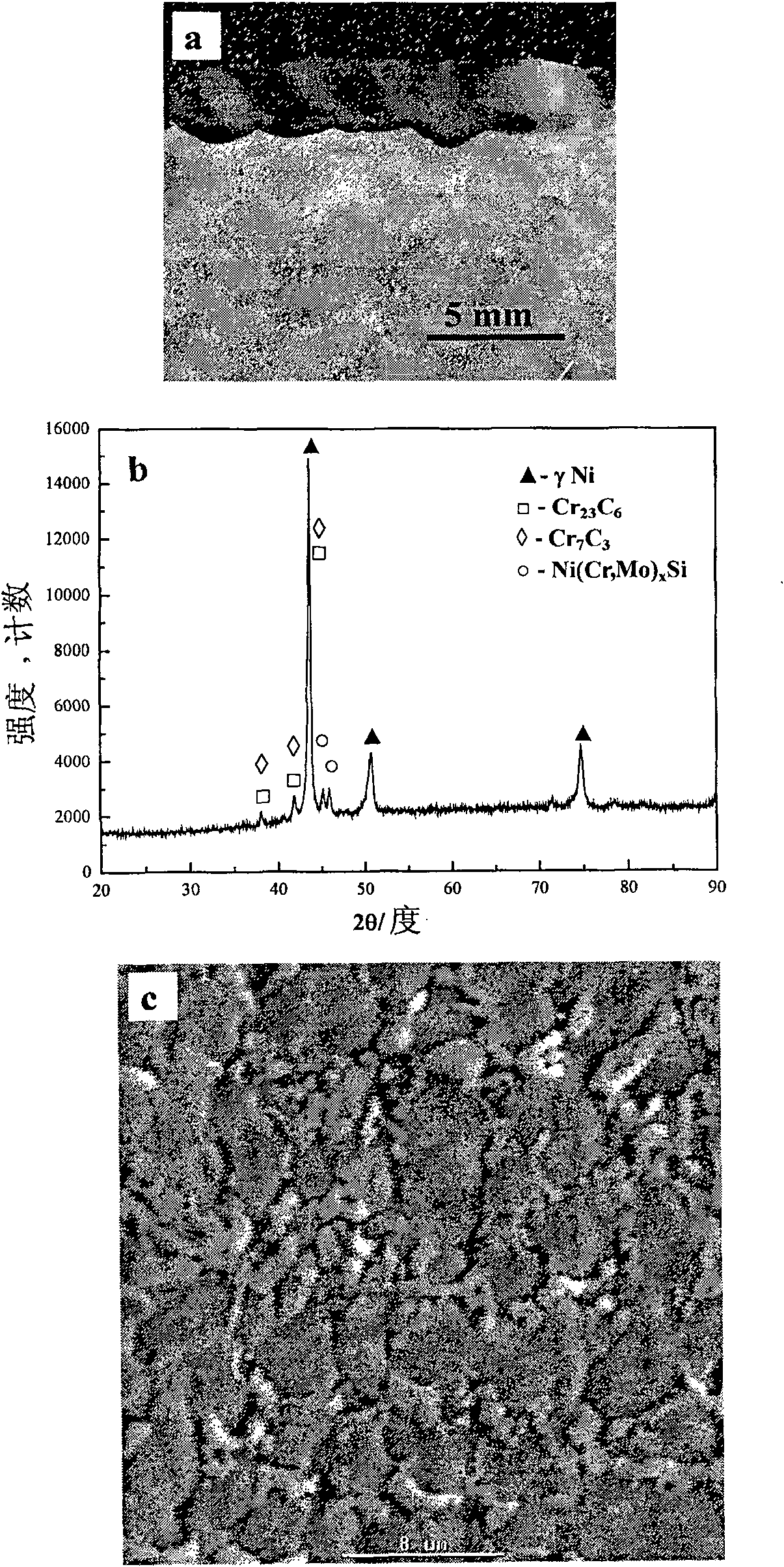

The invention relates to a nickel-based alloy, a stainless steel valve provided with a seal surface of a nickel-based alloy layer and a preparation method. The components and the contents of the nickel-based alloy used on the seal surface of the nickel-based alloy layer are respectively: 1.0 to 1.5wt percent of C, 17.5 to 19.5wt percent of Cr 7.0 to 9.0wt percent of Mo, 3.5 to 4.5wt percent of W, 1.5 to 2.5wt percent of Nb, 2.0 to 3.0wt percent of Si and the rest is Ni. The stainless steel valve provided with a seal surface of a nickel-based alloy layer is lead the powder of the nickel-based alloy to form a seal surface nickel-based alloy on the stainless steel valve through a laser plating method. The nickel-based alloy layer and a stainless steel matrix are completely metallurgically bonded without the defects like cracks, air holes, and the like. The alloy layer comprises nickel-based solid solution dendrites, the metallic carbides between the dendrites, the metal silicides, and the like. The reinforced layer of the nickel-based alloy has higher rigidity (HRC43-49) and excellent properties for anti-heat and shock and can be used for preparation the alloy reinforced layer on the seal surface of the stainless steel which has strict demands on the alloy components (B and Co are excluded).

Owner:有研金属复材技术有限公司

High-strength and high-elasticity-modulus casting Mg-RE alloy and preparation method thereof

The invention discloses a high-strength and high-elasticity-modulus casting Mg-RE alloy and a preparation method thereof. The casting Mg-RE alloy comprises 8-14wt% of Gd, 2-6wt% of Y, 1-5wt% of Zn, 0.5-2.5wt% of Si, 0.4-1wt% of Zr, the impurity elements of Fe, Cu and Ni and the balance of Mg, wherein the total content of the impurity elements of Fe, Cu and Ni is smaller than 0.02wt%. The preparation method includes the steps of smelting and heat treatment. According to the preparation method, Si is added and reacts with Mg and RE in an MG alloy to generate a high-elasticity-modulus Si-containing phase, meanwhile, Zn is added and reacts with Mg and RE in the Mg alloy to generate a stable eutectic phase, in this way, the crystallization range of an alloy melt is reduced, melt fluidity is improved, and accordingly through the following corresponding heat treatment process, the alloy has high room-temperature strength and elasticity modulus.

Owner:SHANGHAI JIAO TONG UNIV

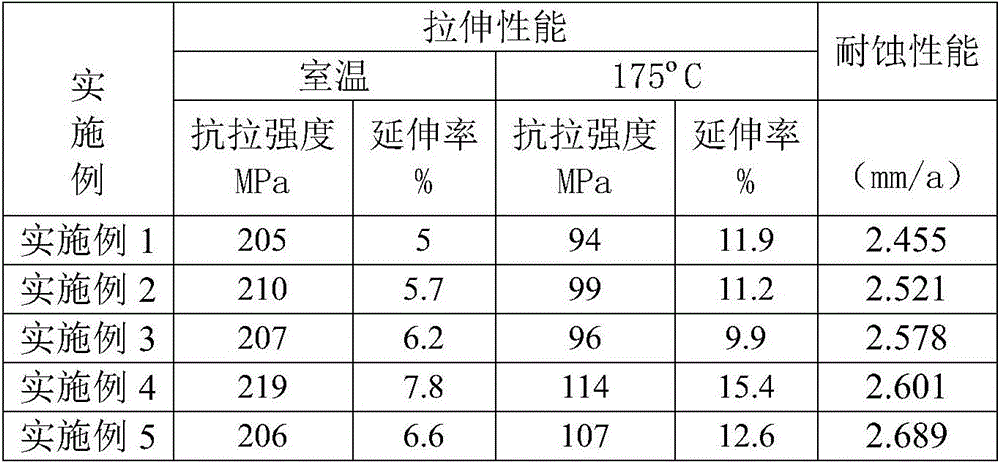

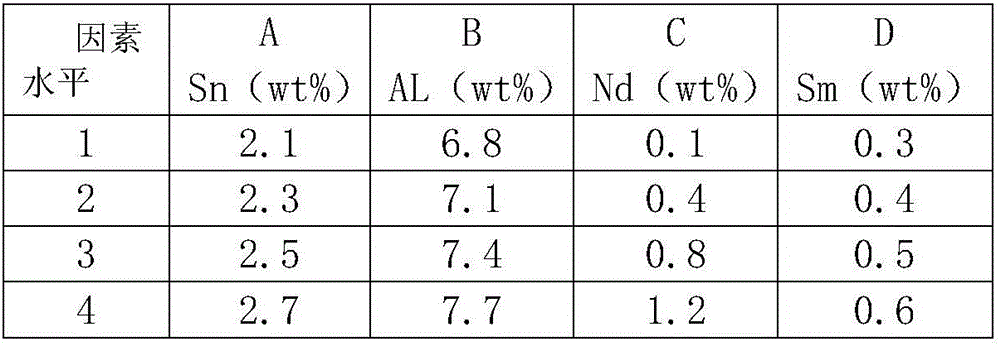

Multielement heat and corrosion resisting magnesium alloy and preparation method

The invention discloses a multielement heat and corrosion resisting magnesium alloy and a preparation method. The alloy comprises the following components in percentage by mass: 5.8-7.8% of Al, 2.2-3.2% of Sn, 0.2-1.0% of Zn, 0.2-2.0% of RE, 0.1-0.3% of Mn, and the balance of Mg and inevitable impurities with the total quantity of not more than 0.2%. Tin, neodymium and / or samarium are added in a magnesium aluminum substrate material to form high-melting-point particle phases Nd5Sn3 and Sm5Sn3, and zinc is added to further refine the high-melting-point particle phases, so that the strong plasticity, the heat resistance and the corrosion resistance of the alloy are improved; meanwhile, remained tin and magnesium are combined to generate Mg2Sn to further improve the performances of the alloy; manganese is added to reduce harm from impurity elements to improve the corrosion resistance; and the ratio among the elements is adjusted to obtain the heat and corrosion resisting magnesium alloy.

Owner:JILIN UNIV

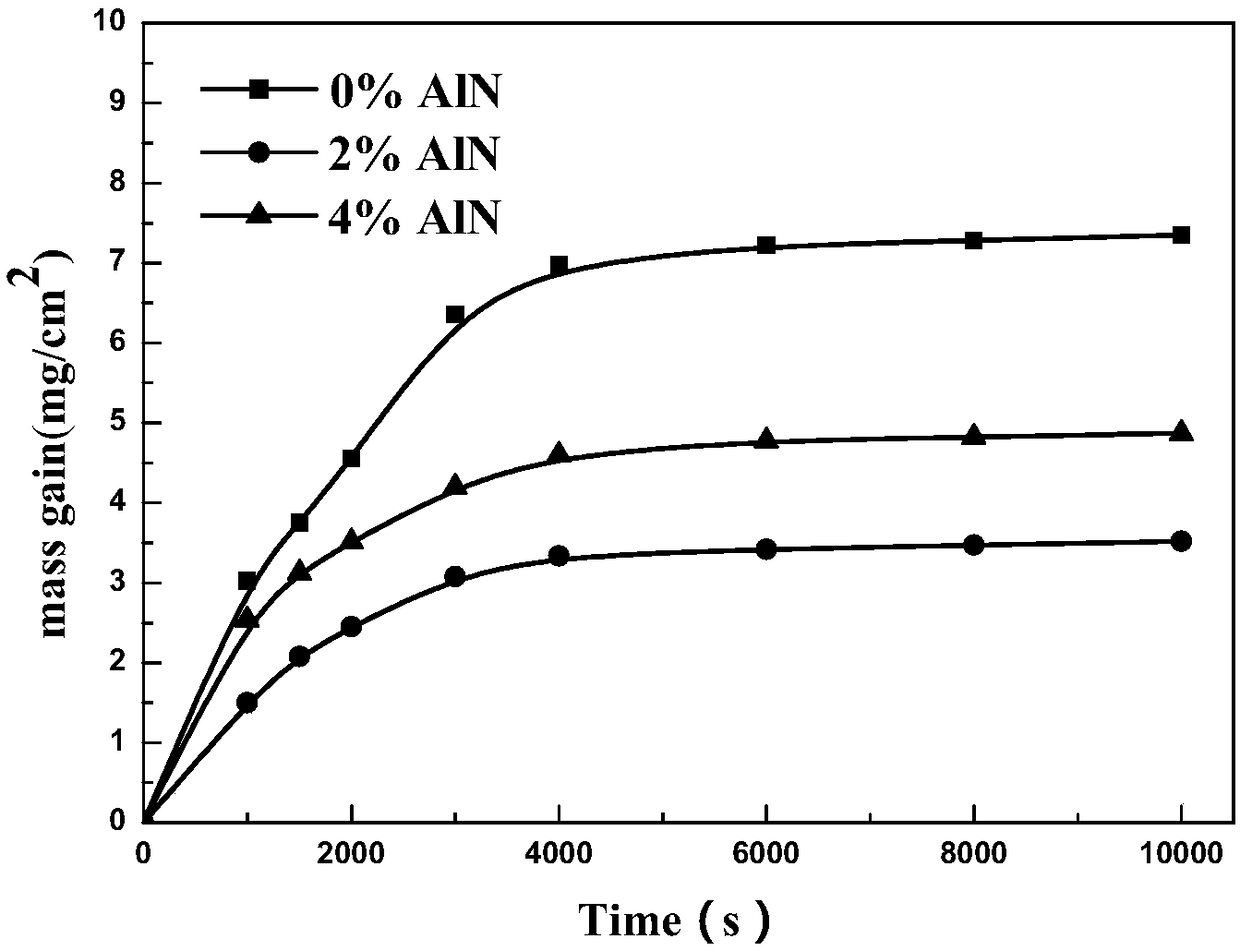

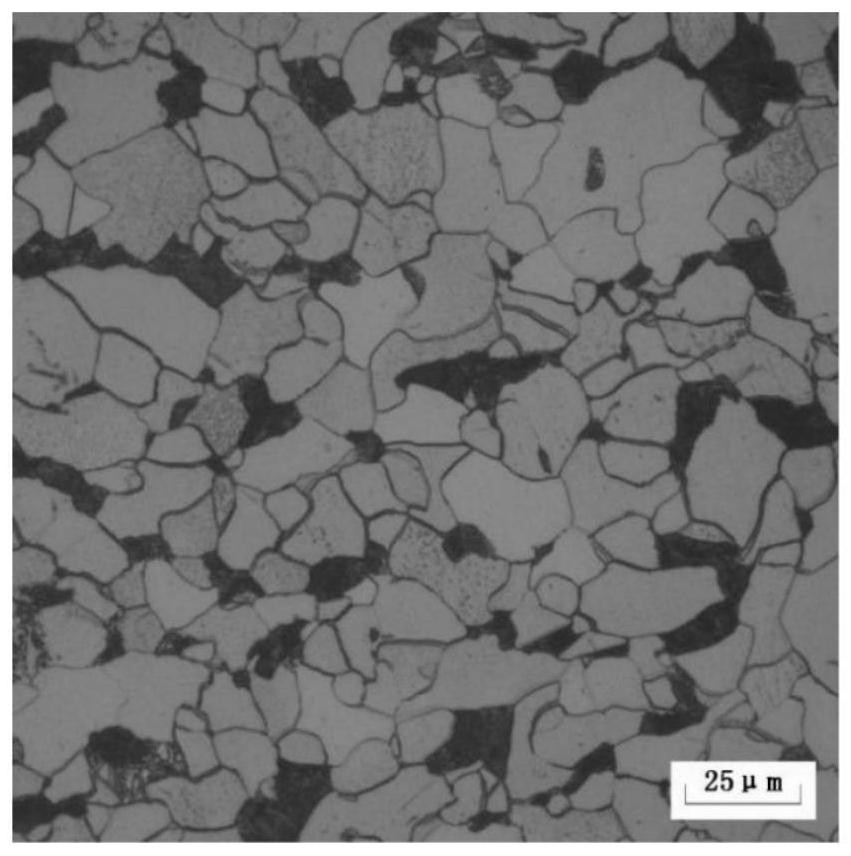

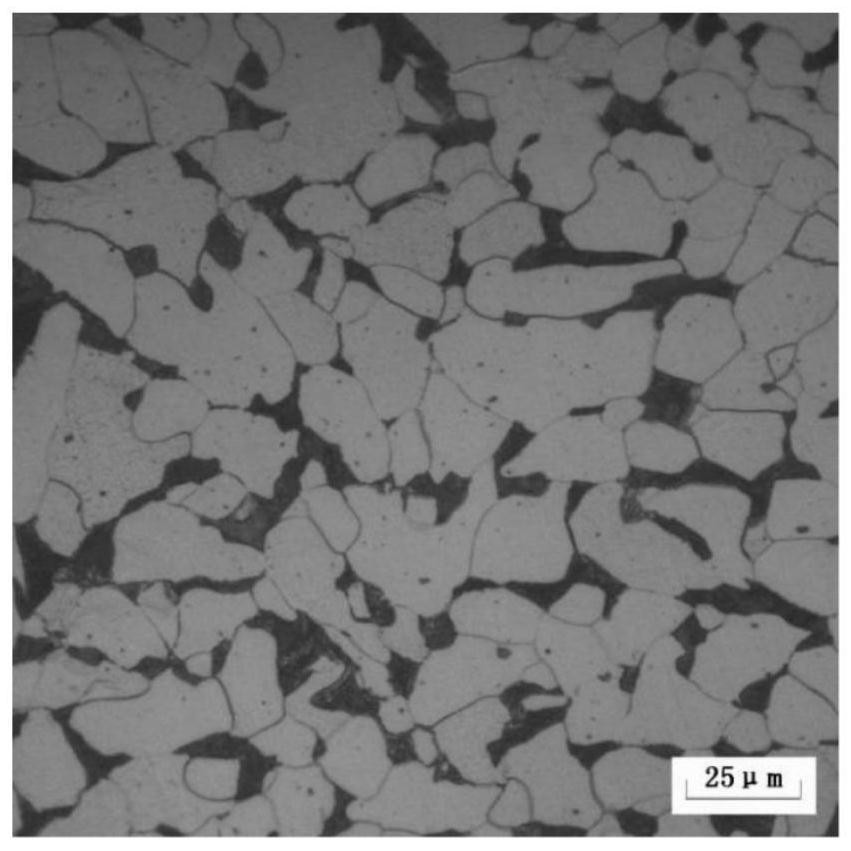

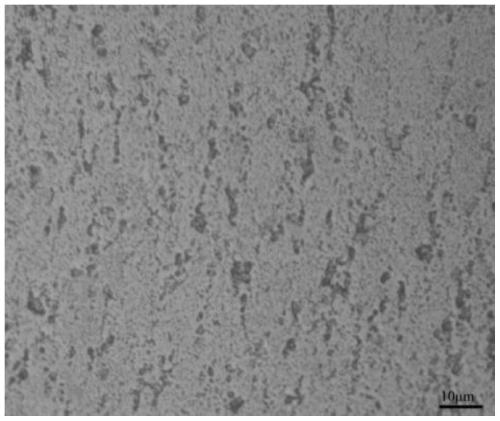

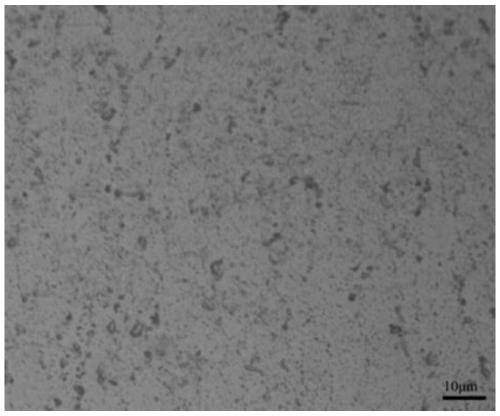

Novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and preparation method thereof

ActiveCN108642402AHeat treatment window widthReduced tendency to overheat during heat treatmentMicro structureOxidation resistant

The invention discloses novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and a preparation method thereof. Aluminum high-speed steel prepared by the preparation method adopts a novel powder metallurgical high-speed steel direct preparation process to lead in (0.05-5.0) AlN micro powder, and a material mixture is subjected to processes such as wet-milling, pelletizing, isostatic cool pressing and forming, hydrogen gas deoxidizing, hot-pressing composite sintering and vacuum thermal treatment, so that micro-level dispersion distribution of aluminum nitride particles is realized, and therefore, the defects that a conventional casting process easily generates a ledeburite structure, an aluminum nitride strengthening phase is difficulty led in by agas-atomizing-hot isostatic pressing method, and the like are overcome. The novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel is short in process flow, islow in production cost, is low in impurity content, is high in compactness, and is remarkably improved in wear resistance, oxidization resistance and a micro structure after aluminum nitride is led in, and is novel mould material among conventional high-speed steel, a hard alloy and a ceramic material.

Owner:XIANGTAN UNIV

A kind of anti-oxidation iron-based superalloy and preparation method thereof

InactiveCN102286694AIncrease working temperatureIncrease productivityNuclear fusionOxidation resistant

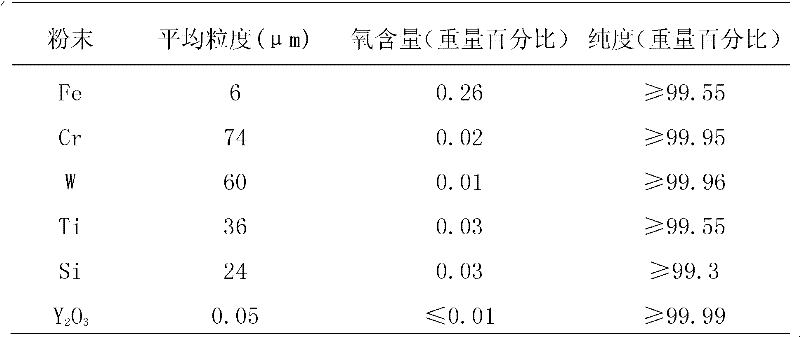

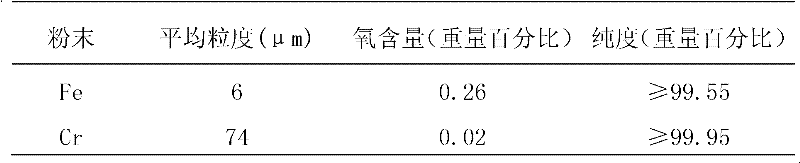

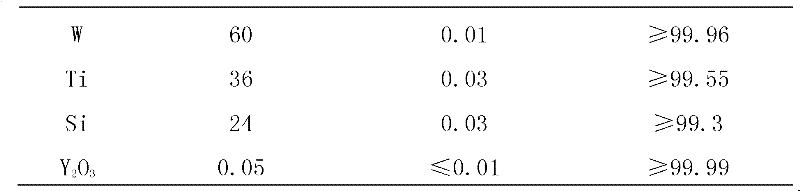

An anti-oxidation iron-based superalloy and a preparation method thereof, which belong to superalloys and a preparation method thereof, solve the problem of unsatisfactory oxidation resistance of existing iron-based superalloys under high-temperature conditions, so as to improve serviceability and broaden high-temperature application fields. The anti-oxidation iron-based superalloy of the present invention has the composition mass percentages of: 12%≤Cr≤14%, 2%≤W≤3%, 0.3%≤Ti≤0.4%, 0.2%≤Si≤2%, 0.25%≤ Y2O3≤0.3%, the balance is Fe; it is made by mechanical alloying, molding and vacuum sintering, and the matrix of the final sintered body is α-(Fe, Cr) single-phase solid solution with uniformly distributed oxides in the matrix. The invention has high production efficiency and low cost, and the prepared anti-oxidation iron-based superalloy has reduced oxidation weight gain and improved anti-oxidation ability under the atmospheric condition of 850°C; the tensile strength at room temperature is ≥600MPa, and the elongation rate is ≥25%, which meets the requirements of automobiles. Requirements for the use of high-temperature structural parts such as engines and gas turbines, nuclear fission fuel cladding tubes, and first wall structural materials of nuclear fusion reactors.

Owner:HUAZHONG UNIV OF SCI & TECH

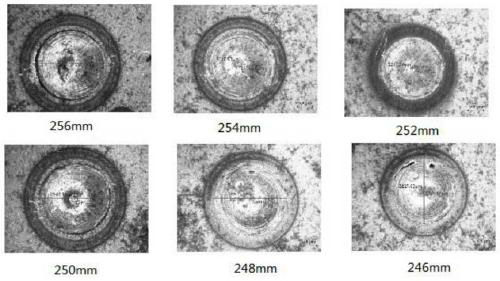

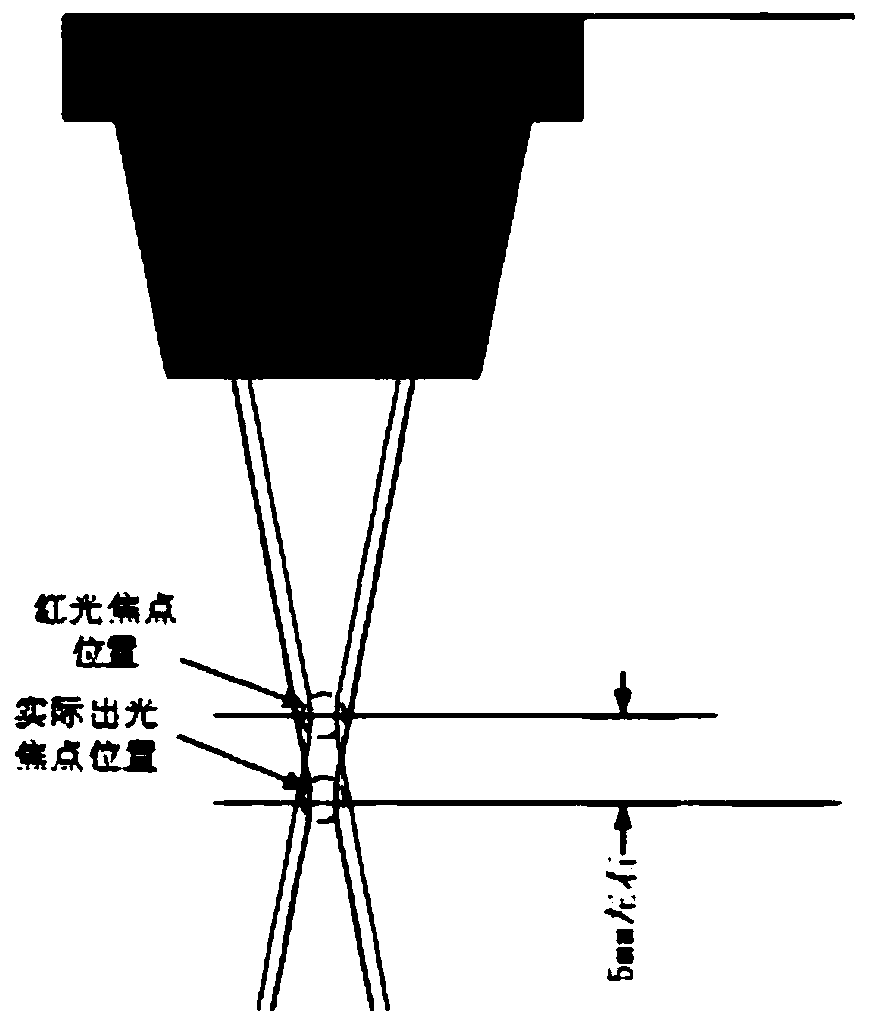

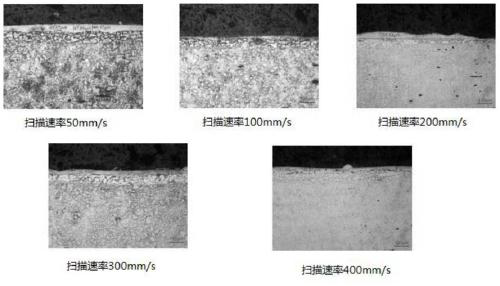

Process for preparing cladding layer on surface of copper base body by utilizing high-speed laser cladding technology

The invention discloses a process for preparing a cladding layer on the surface of a copper base body by utilizing a high-speed laser cladding technology. The process is characterized in that a lasercoaxial powder feeder is used for feeding a cladding alloy material to the surface of the copper base body, meanwhile, layer-by-layer high-speed laser cladding is performed by using an optical fiber laser or an optical fiber coupling semiconductor laser, wherein the process parameters of the laser in the cladding operation process are as follows, the focal length of a focusing lens is 250-300 mm,the cladding power is 2000-8000 W, the diameter of a light spot is 0.3-1.2 mm, the cladding scanning speed is 100-400 mm / s, and the lap joint rate is 65%. According to the preparation process of the obtained cladding layer, by utilizing the laser with the high scanning speed and adopting the specific cladding alloy powder for cooperation, the process parameters of the high-speed laser are determined, on the premise that subsequent other treatment is not needed, the cladding layer with the compact structure, without cracks and air holes and with extremely low dilution rate can be formed the surface of the copper base body, good metallurgical bonding between the cladding layer and the surface of the copper base body can be formed.

Owner:唐山中科量子激光科技有限公司

Aluminum-based material and preparation method thereof

InactiveCN109706350AHigh hardnessImprove wear resistanceFoundry mouldsMetallic material coating processesWear resistantAlloy substrate

The invention discloses an aluminum-based material. Aluminum nitride, zirconium oxide and tantalum oxide particles are uniformly distributed in an aluminum alloy substrate, MoS2, Al2O3 and SiC are distributed on part of a surface layer of the aluminum alloy substrate, the hardness of aluminum nitride, zirconium oxide and tantalum oxide is high, the hardness and wear-resisting performance of the substrate are significantly improved, and fluorinated graphite powder can improve the anti-friction property. The surface of the substrate is coated with a Mn-Cr coating in a fusion mode to effectivelyimprove the wear-resisting performance and corrosion resistance of the alloy surface. The dispersion strengthening of strengthening phases of Si, Cu, Cr, Ni, Hf, Fe, Ag, Ca, Li, Ba and other elementsin the alloy improves the mechanical properties of the material. A preparation method enables mixed powder to be located in the center of a master alloy solution during casting through a method by adhering the mixed powder to a pure aluminum metal wire, the rapid diffusion and homogenization of micro powder particles is facilitated, the production efficiency is improved, wear-resistant materials are locally added by friction stir machining, and the material utilization ratio is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Method for efficiently forming copper-nickel-silicon alloy strip through continuous casting and rolling

InactiveCN107326214AGood plasticityImprove solid solution strengtheningMetal rolling arrangementsAlloy elementCopper

The invention provides a method for continuously casting and rolling high-efficiency forming copper-nickel-silicon alloy strips, comprising the following steps: taking copper source, nickel source and silicon source as raw materials, successively melting, continuous casting, cooling and casting to obtain copper The nickel-silicon alloy slab and the copper-nickel-silicon alloy slab are sequentially rolled, aged, cooled and finished cold rolled to obtain a copper-nickel-silicon alloy strip. The examples show that the copper-nickel-silicon alloy slab with high surface quality and dense columnar grain structure obtained by the present invention has an elongation rate greater than 45% at room temperature and has excellent plasticity; Continuous casting and rapid solidification can effectively improve the solid solution strengthening and precipitation strengthening effects of alloy elements; the invention has a simple process, can effectively reduce energy consumption, reduce costs, and improve production efficiency and product yield.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Composite material and preparation method thereof

InactiveCN109929986AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingSilicon oxideBoron nitride

The invention discloses a composite material. Boron nitride particles, silicon oxide particles, tungsten trioxide particles and molybdenum disulfide particles are uniformly distributed in an aluminumalloy matrix, wherein the antifriction property can be improved through the molybdenum disulfide particles. The surface of the matrix is provided with three-layer gradient deposition layers, so that the wear resistance and the hardness of the alloy surface can be effectively improved. Dispersion strengthening is realized through strengthening phases of elements such as Zn, Sr, Ho, Cu, Au, Mg, Pd,Si, Al, Ni, W and Fe in an alloy, so that the mechanical property of the material is improved. The invention further discloses a preparation method of the composite material. According to the preparation method, a ceramic layer is formed through laser deposition, aluminum oxide particles can be driven to grow in the deposition layers, the hardness and the wear resistance are further improved by combining ultrasonic surface rolling, through the ceramic surface of the composite material, the composite material simultaneously achieves the characteristics of ceramic high temperature resistance andmetal low temperature resistance, so that the composite material can be applied to the field of machining of parts requiring the high temperature resistance and the low temperature resistance simultaneously, and the surface nitriding process can enhance the corrosion resistance of the composite material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Multi-component alloy cast iron preparation method

InactiveCN103484794ASimple preparation processEase of mass productionThermal insulationRoom temperature

The invention relates to a multi-component alloy cast iron preparation method, which is characterized by comprising: carrying out smelting of hot metal in an electric furnace, wherein hot metal comprises the following chemical components, by mass: 3.05-3.45% of C, 0.75-1.05% of Mn, 1.10-1.35% of Si, 0.03-0.07% of N, less than 0.06% of S, less than 0.08% of P, and the balance of Fe and inevitable trace impurities; discharging out of the electric furnace when the hot metal temperature is 1450-1480 DEG C; adding an inoculant along with the hot metal flow during the hot metal discharging process, wherein the amount of the inoculant is 0.8-1.2% of the mass of the hot metal; adding alloy wires into the hot metal by using a wire feeding machine after the hot metal enters a hot metal ladle, wherein the alloy wire addition amount is 2.5-3.5% of the mass of the hot metal in the hot metal ladle, and the size of the alloy wire is phi 2.5-4.0mm; carrying out pouring casting molding on the hot metal when the hot metal temperature is reduced to 1335-1370 DEG C; and opening the box, carrying out air cooling on the cast, heating the cast to achieve a temperature of 200-260 DEG C, carrying out thermal insulation for 6-10 h, and carrying out air cooling to achieve a room temperature to obtain the multi-component alloy cast iron cast with excellent performances.

Owner:BEIJING UNIV OF TECH

Preparation method for Cu-Ni-Si-Ma alloy strip

The invention provides a preparation method for a Cu-Ni-SI-Ma alloy strip. The method comprises the following steps that a copper source, a nickel source, a silicon source and a magnesium source serve as the raw materials and are sequentially subjected to melting, continuous casting, cooling and billet drawing to obtain a Cu-Ni-SI-Ma alloy rod billet; the Cu-Ni-Si-Ma alloy rod billet is directly subjected to continuous extrusion molding to obtain a Cu-Ni-Si-Mg alloy strip billet; and then rolling and ageing treatment are sequentially conducted to obtain the Cu-Ni-Si-Mg alloy strip. Embodiments show that the elongation, under the room temperature, of the Cu-Ni-Si-Mg alloy rod billet prepared through the preparation method is greater than 45%, and excellent plasticity is achieved; and melting and continuous casting in combination of cooling enforcement measures are adopted, continuous casting and fast solidification can be achieved, the solution strengthening and precipitation strengthening effects of alloy elements are effectively improved, and the method for continuous casting, continuous extruding, rolling and efficient molding of the Cu-Ni-Si-Mg alloy strip is provided.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Nickel-based welding wire, manufacturing method of nickel-based welding wire and welding process of nickel-based welding wire

ActiveCN114505619AGuaranteed high temperature oxidation resistanceGuaranteed solid solution strengtheningNuclear energy generationWelding/cutting media/materialsHeat transfer tubeDuctility

The invention provides a nickel-based welding wire, a manufacturing method of the nickel-based welding wire and a welding process of the nickel-based welding wire, relates to the technical field of welding materials, and aims to solve the problem of poor welding effect of a heat transfer tube made of an Incoloy800H material. The nickel-based welding wire comprises an outer skin and a flux core filled in the outer skin. The outer skin is an Inconel 625 belt, and the flux core comprises, by mass, 28.0%-32.0% of Co, 19.0%-23.0% of Cr, 7.0%-9.0% of Mo, 1.5%-3.5% of Nb, 1.0%-1.5% of Cu, 1.5%-3.5% of W, 0.6%-1.0% of B, 0.4%-0.6% of La and the balance Ni. According to the nickel-based welding wire provided by the invention, a joint part can keep relatively high tensile strength and ductility under normal-temperature and high-temperature conditions.

Owner:XIAN THERMAL POWER RES INST CO LTD

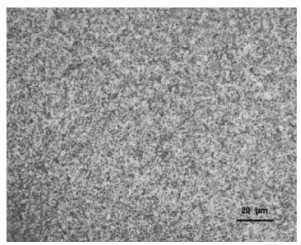

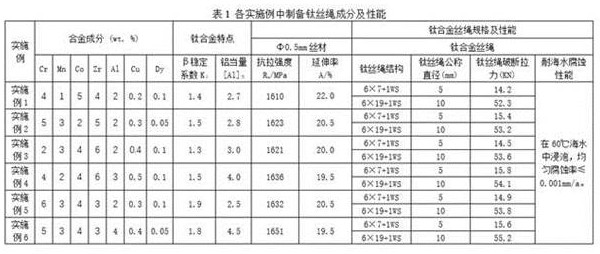

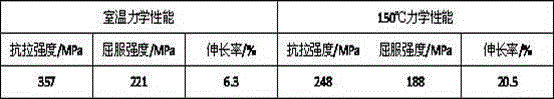

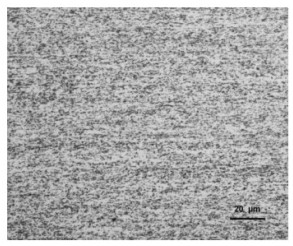

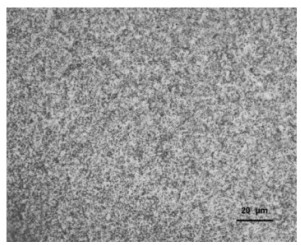

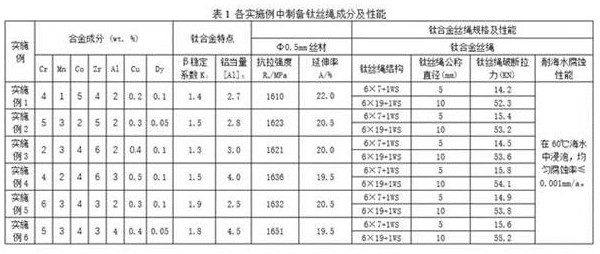

Light ultrahigh-strength and corrosion-resistant weldable titanium alloy wire rope for crane and preparation method of titanium alloy wire rope

ActiveCN113249993AImprove corrosion resistanceImprove antifouling performanceTextile cablesTitanium alloyUltimate tensile strength

The invention discloses a light ultrahigh-strength and corrosion-resistant weldable titanium alloy wire rope for a crane. Alloy comprises the following components in percentage by weight of 2.0 to 6.0 percent of Cr, 1.0 to 3.0 percent of Mn, 2.0 to 5.0 percent of Co, 2.0 to 6.0 percent of Zr, 2.0 to 4.0 percent of Al, 0.2 to 0.5 percent of Cu, 0.05 to 0.10 percent of Dy, less than 0.3 percent of total content of impurity elements C, H, O and N, and the balance of Ti. The titanium alloy wire rope disclosed by the invention has high specific strength, good plasticity and toughness and excellent corrosion resistance and antifouling property, and the weight is reduced by 40% or above; and the titanium alloy wire rope has good technical application and market prospects in the fields of hoisting equipment under the environmental conditions of ports, coasts, ocean platforms and coastal areas.

Owner:XINXIANG UNIV

Tough corrosion-resistant titanium alloy and method for preparing same

The invention provides tough corrosion-resistant titanium alloy and a method for preparing the same. The tough corrosion-resistant titanium alloy comprises, by weight, 5.56-6.75% of Al, 0.08-0.14% ofRu, 3.5-4.5% of V, higher than 0% and lower than or equal to 50% of Zr and the balance Ti. The tough corrosion-resistant titanium alloy and the method have the advantages that the strength and the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved by means of alloying, infinite solid solution can be formed by the Zr and the Ti, and accordingly solid solution can be strengthened; the Zr is negative in initiating passive potential as compared with the Ti, and still can be passivated even in environments under weak oxidization conditions, accordingly, the capacity of generating dense oxidation films on surfaces can be improved, and the corrosion resistance of the surfaces can be enhanced; the stability of alpha phase can be greatly improved by the element Al,the beta-alpha transition temperatures can be greatly increased by the element Al, tiny alpha phase can be obtained after the tough corrosion-resistant titanium alloy is quenched, and fine grains canbe strengthened; the trace element Ru is added into the tough corrosion-resistant titanium alloy, and accordingly the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved.

Owner:YANSHAN UNIV

Wear resisting material and preparation method thereof

ActiveCN109868386AImprove wear resistanceImprove surface wear resistanceAnodisationOxide ceramicMicro arc oxidation

The invention discloses a wear resisting material. Aluminum nitride, aluminum oxide, molybdenum disilicide and graphite powder particles are uniformly distributed in an aluminum alloy basal body; a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy basal body; the aluminum nitride, the aluminum oxide and the molybdenum disilicide are high in hardness to prominently improve the hardness and the wear resistance of the material; and through graphite powder, the antifriction can be improved. Through the composite micro-arc oxidation layer on the surface, the alloy surface wear resistance and corrosion resistance can be effectively improved. Strengthening phases of such elements as Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo and Fe in an alloy are in dispersion strengthening to improve mechanical performances of the material. In a preparation method, through a mode of attaching mixed powder on a pure aluminum metal wire, the mixed powder is positioned in the center of mother alloy liquid during casting, so that the quick dispersion and the homogenization of micropowder particles are facilitated, and the production efficiency is improved; and micro-arc oxidation film forming parameters and conditions are optimized, so that the hardness and the smoothness degree of oxide ceramic films are improved, the film thickness is reduced, and the wear resistance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

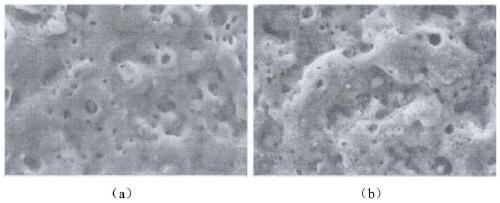

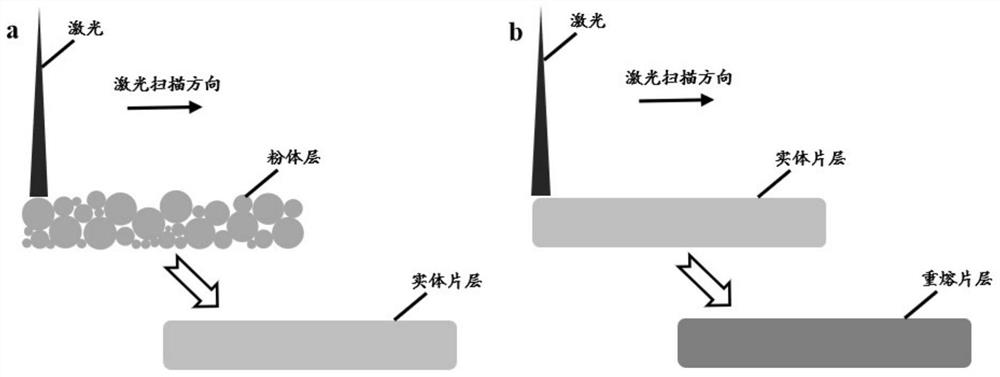

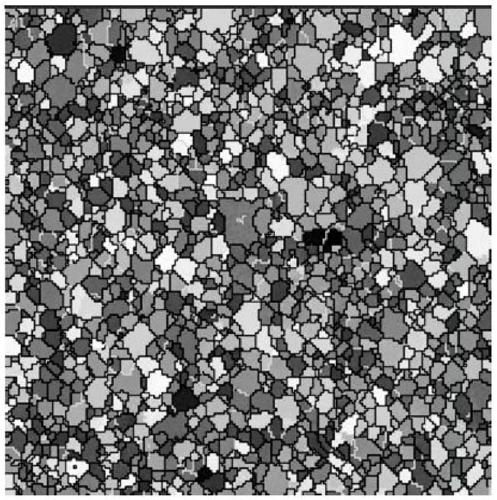

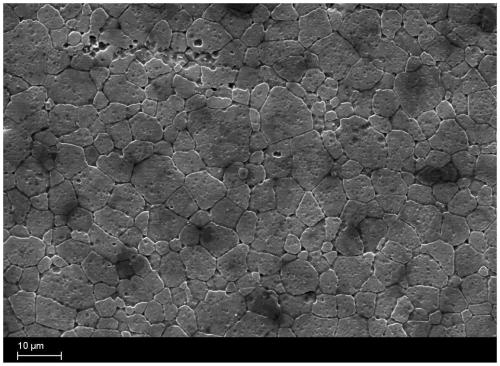

Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

ActiveCN112176213AAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMg composite

The invention discloses a laser additive manufacturing method of an in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. The method comprises the following steps of (1) mixingZnO ceramic powders and AlSi10Mg aluminum alloy powders, and carrying out ball milling to obtain ZnO / AlSi10Mg composite powders; (2) carrying out additive manufacturing forming on the composite powders by adopting a selective laser melting process to form a solid sheet layer; (3) carrying out laser scanning on the solid sheet layer again to form a remelting sheet layer; (4) repeating the steps (2)and (3), and finally forming to obtain the in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. A laser is used for exciting Al and ZnO to generate aluminothermic reactions between the Al and ZnO to generate Al2O3 ceramic particles in situ, the overall process design of the method is improved, selective laser melting and laser remelting scanning are matched, the prepared aluminum-based composite material is high in density and fine in microstructure, the in-situ synthesized Al2O3 particles are nanoscale in size and are uniformly distributed, and the phase interfaces ofthe Al2O3 particles are well combined with an aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Multi-element small-amount degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN111286656AImprove corrosion resistanceImprove antibacterial propertiesCorrosionSolid solution strengthening

The invention discloses a multi-element small-amount degradable antibacterial magnesium alloy. The multi-element small-amount degradable antibacterial magnesium alloy is prepared from the following components of, in percentage by weight, 0.4 %-1.2 % of Ca, 0.8 %-1.2 % of Zn, 0.3 %-2.0 % of Ag, 0.02 %-0.2 % of Se, 0.05 %-0.15 % of Mn, and the balance Mg and inevitable impurities, wherein the Se element is added in a manner of Ag2Se. The invention further discloses a preparation method of the novel antibacterial multi-element wrought magnesium alloy. According to the alloy and the method, a castingot is prepared through the multi-element alloying component design, through the high-purity raw material and through the vacuum-atmosphere protection smelting method, so that the purity of the alloy is guaranteed; then turning, the homogenizing treatment, the extrusion and the heat treatment are carried out, so that solid solution strengthening, fine grain strengthening and second phase strengthening are realized, and the mechanical property of the alloy is improved; and the corrosion resistance and the antibacterial property of the alloy are improved through the formation of a CaZnAg phase and the addition of Se.

Owner:JILIN UNIV

Preparation method for high-hardness manganese-iron alloy material

InactiveCN107190211AAchieve solid solution strengtheningImprove performanceProcess efficiency improvementRare-earth elementHardness

The invention discloses a preparation method for a high-hardness manganese-iron alloy material. The preparation method comprises the following steps: S1, Fe is added into a smelting furnace and is heated to be completely melted; S2, Mn, Cr, Zr, Mo, Cd, W, V, graphite, diamond, WC, Cr2B, La2O3, Nd(OH)3, Eu2O3,Yb2O3, PrCl3, PrSi2, YSi2 and TbN are added into the Fe melted in the S1, and are uniformly mixed with the melted Fe to obtain an alloy melt; S3, the alloy melt in the S2 is refined, and a refining agent is added in the refining process; S4, the alloy melt refined in the S3 is cast to obtain a casting; and S5, the casting cooled in the S4 is tempered and cooled to obtain the alloy material. According to the preparation method for the high-hardness manganese-iron alloy material, by adding Cr and rare earth elements, the manganese-iron alloy is high in strength and good in toughness and wear resistance, and the comprehensive performance of the copper alloy is greatly improved.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

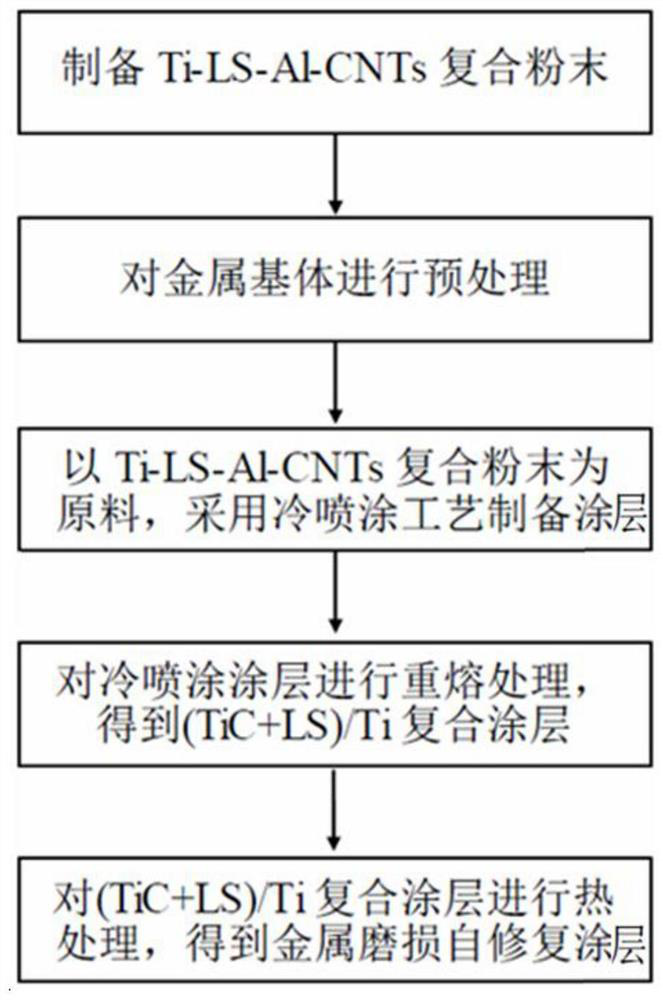

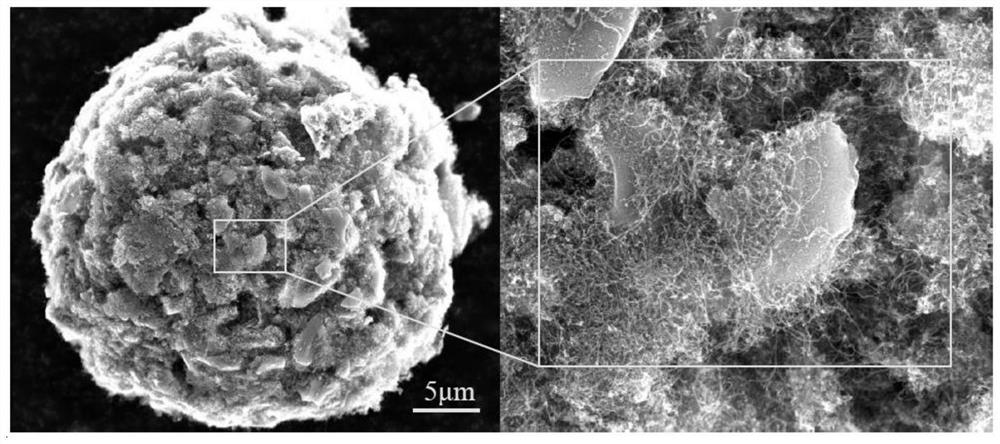

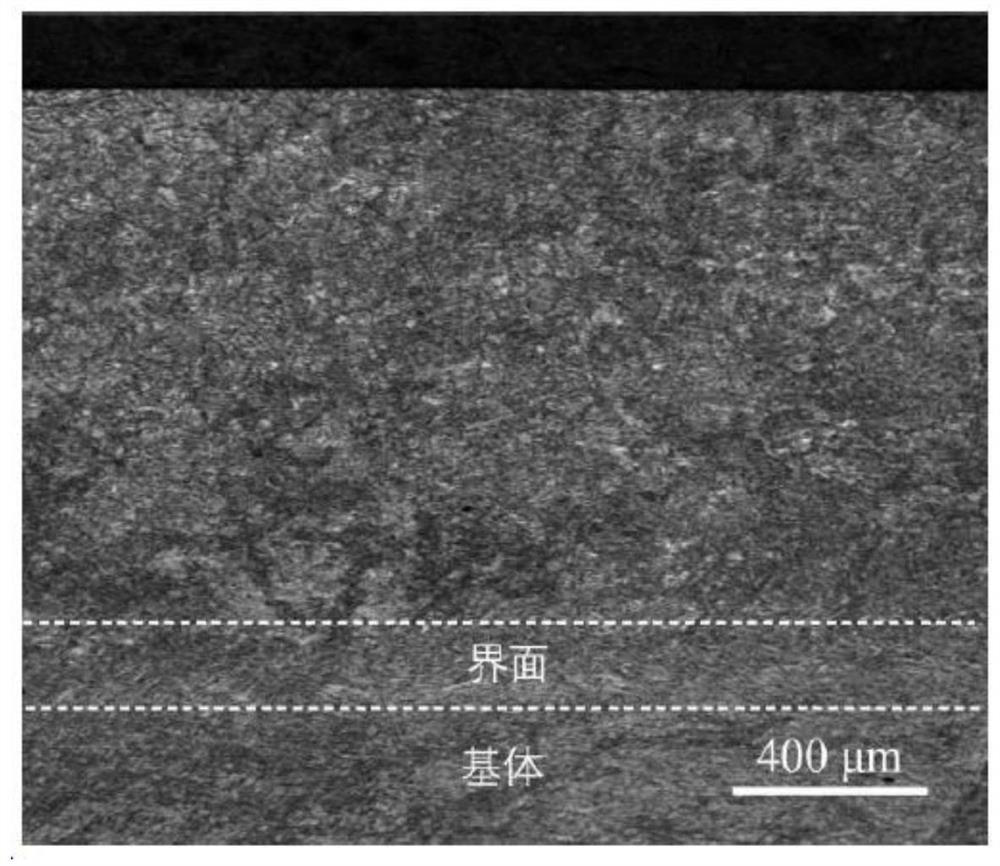

Composite powder for preparing self-repairing coating, preparation method of composite powder, titanium-based wear-resistant self-repairing coating and preparation method of titanium-based wear-resistant self-repairing coating

ActiveCN112974799AEvenly distributedHigh hardnessMaterial nanotechnologyTransportation and packagingAl powderCarbon nanotube

The invention provides composite powder for preparing a self-repairing coating, a preparation method of the composite powder, a titanium-based wear-resistant self-repairing coating and a preparation method of the titanium-based wear-resistant self-repairing coating. The preparation method of the composite powder comprises the following steps: firstly, mixing powder materials (layer silicate mineral powder, Al powder and Ti powder), a nitrate solution, a dispersing agent and a binder, and performing ball milling to obtain slurry; secondly, carrying out spray drying to obtain spherical composite powder particles; and finally, performing chemical vapor deposition treatment in an environment containing carbon source gas to form a carbon nanotube coating layer on the surface of the spherical composite powder, thereby obtaining spherical composite powder coated with carbon nanotubes (namely CNT). The composite powder is used as a raw material, and the wear-resistant self-repairing coating is prepared on the surface of a metal matrix through the steps of matrix surface pretreatment, cold spraying, re-melting treatment, heat treatment and the like. The titanium-based wear-resistant self-repairing coating provided by the invention has high hardness and good wear resistance, and has a wear self-repairing function in oil lubrication, dry friction and vacuum environments.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +1

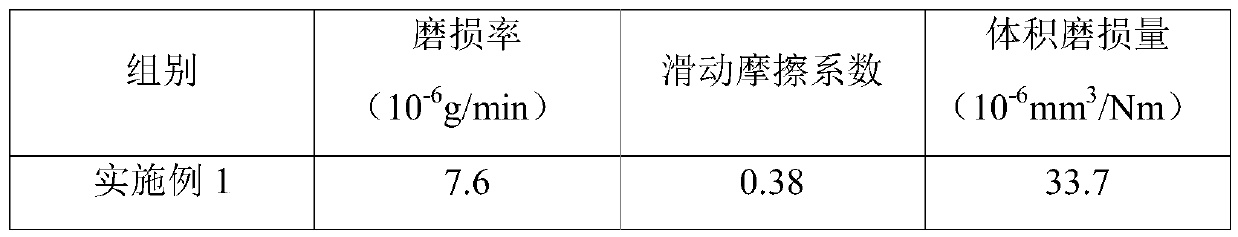

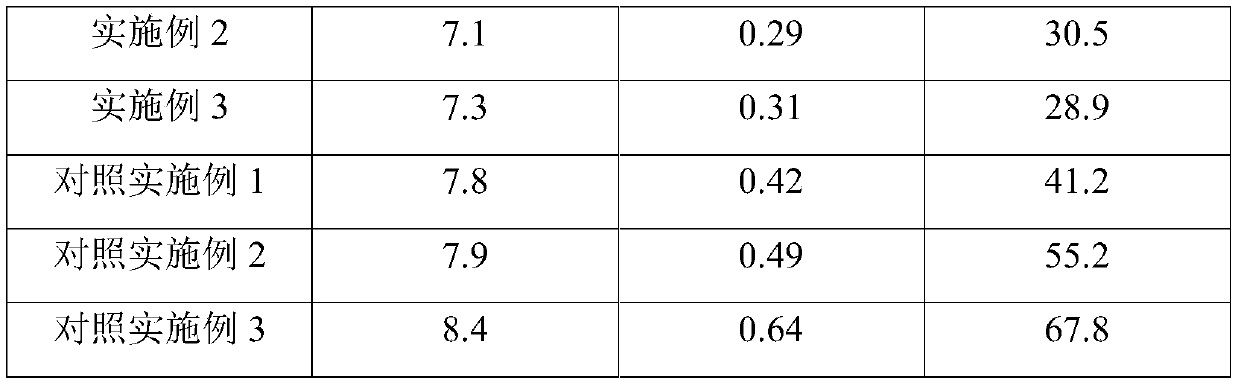

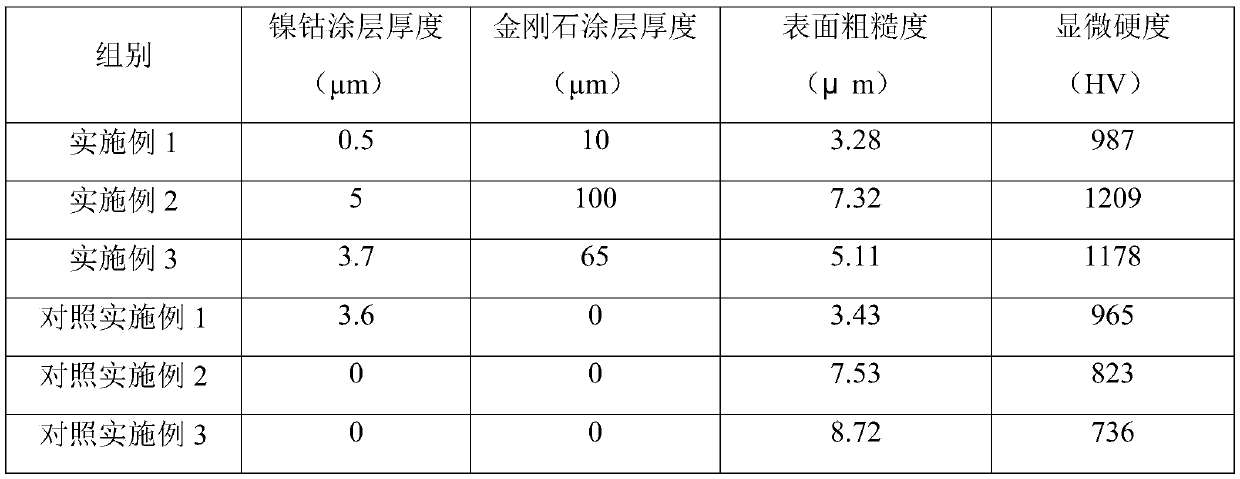

Low-wear-rate material and preparation method thereof

InactiveCN109852851AReduce the phenomenon of agglomeration and segregationPromote growthLiquid/solution decomposition chemical coatingChemical vapor deposition coatingChemical platingNiobium

The invention discloses a low-wear-rate material. Titanium nitride, titanium oxide, nickel oxide and niobium diselenide mixture particles are evenly distributed in an aluminum alloy substrate, a nickel-cobalt clad layer and a diamond coating are distributed on the surface of the aluminum alloy substrate, the hardness of titanium nitride and nickel oxide is high, the hardness and the low-wear-rateperformance of the material are remarkably improved, and the anti-wear performance can be improved due to titanium oxide and niobium diselenide. By means of the composite coatings on the surface, thewear rate of the alloy surface can be effectively reduced, and the hardness can be effectively improved. Strengthening phases of Dy, P, Bi, Sn, Nb, Cr, Fe, Zn, Pt, Th and other elements in alloy are in dispersion strengthening. In a preparation method, mixed powder adheres to aluminum-selenium metal wires, the mixed powder is located in the center of mother alloy liquid during casting, rapid diffusion and homogenization of micro-powder particles are facilitated, chemical plating and CVD film forming parameters and conditions are optimized, the hardness and the smooth degree of the coatings areimproved, the film thickness is reduced, and the low-wear-rate performance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Extra-thick structural steel with high strength and good low-temperature toughness and production method thereof

ActiveCN114231834AHigh strengthImprove low temperature toughnessChemical compositionEngineering structures

The invention provides super-thick structural steel with high strength and good low-temperature toughness, which belongs to the technical field of steel rolling and comprises the following chemical components: less than or equal to 0.12% of C, 0.20-0.50% of Si, 1.00-2.00% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.020-0.050% of Al, less than or equal to 1.00% of Cu, less than or equal to 1.00% of Cr, less than or equal to 1.00% of Ni, less than or equal to 0.80% of Mo and the balance of Fe and inevitable impurities. The extra-thick structural steel is excellent in mechanical property, high in strength, excellent in low-temperature toughness and suitable for being used as engineering structural steel in alpine regions. The invention further provides a production method of the extra-thick structural steel with high strength and good low-temperature toughness.

Owner:SHOUGANG CORPORATION

High-strength aluminum alloy material and preparing method thereof

InactiveCN109763039AImprove mechanical propertiesGood mechanical propertiesFoundry mouldsFoundry coresPre coolingMechanical property

The invention discloses a high-strength aluminum alloy material. The material comprises, by weight percent, 0.6 to 0.8% of Fe, 0.95 to 1.25% of Cr, 2 to 6% of Zn, 0.05 to 0.08% of Pt, 2 to 6% of Sn, 0.2 to 0.8% of Bi, 0.01 to 0.04% of Th, 0.1 to 0.5% of Sb, 0.01 to 0.04% of Dy, 0.01 to 0.04% of P and the balance Al. Solute atoms fused into the solid solution enable strength and hardness of the alloy solid solution to be increased, according to the preparing method, pre-cooling casting chilling action is adopted, refined crystalline strengthening of elements is promoted, during casting, an Al-Sr alloy is adopted for carrying out the metamorphic reaction, and the volume fraction of the alpha phase crystal form can be effectively improved, through hot extrusion and rolling process after casting, the microstructure is improved, the mechanical property of the aluminum alloy can be improved, and the material can be widely applied to the manufacturing field.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

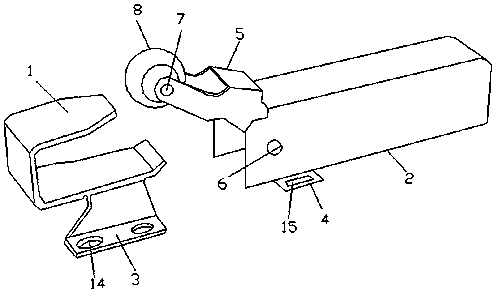

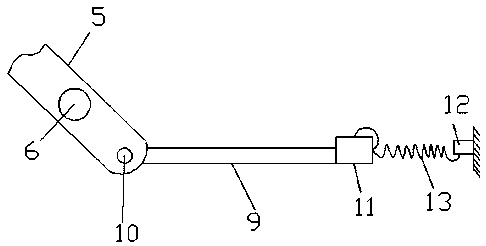

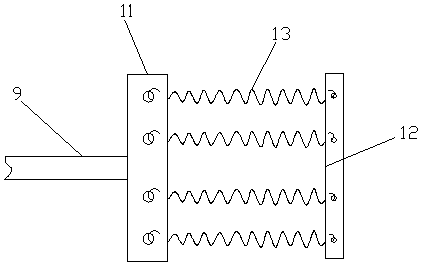

Door closing device for aluminum-coated wooden door

InactiveCN110454023AHigh tensile strengthHigh yield strengthWing openersWing closersSoftware engineeringAluminium

Owner:ANHUI KATA DOOR & WINDOW

A kind of wear-resistant material and preparation method thereof

The invention discloses a wear-resistant material, in which aluminum nitride, aluminum oxide, molybdenum disilicide, and graphite powder particles are evenly distributed in an aluminum alloy matrix, and a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy matrix, aluminum nitride, oxide Aluminum and molybdenum disilicide have high hardness, which can significantly improve the hardness and wear resistance of the material, and graphite powder can improve friction reduction. The composite micro-arc oxidation layer on the surface can effectively improve the wear resistance and corrosion resistance of the alloy surface. Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo, Fe and other elements in the alloy strengthen phase dispersion strengthening to improve the mechanical properties of the material. In the preparation method, the mixed powder is adhered to the pure aluminum wire, so that the mixed powder is located in the center of the master alloy liquid during casting, which is conducive to the rapid diffusion and homogeneity of the micro-powder particles, improves production efficiency, and optimizes the parameters of micro-arc oxidation film formation And conditions, improve the hardness and smoothness of the oxide ceramic film, reduce the film thickness, and effectively improve the wear resistance of the material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Zirconium-containing TB7 titanium alloy and preparation method thereof

InactiveCN108913944AImprove corrosion resistanceAchieve solid solution strengtheningSolid solutionUltimate tensile strength

The invention provides a zirconium-containing TB7 titanium alloy which is prepared from, by mass, 16%-60% of Ti, 9%-50% of Zr and 30%-35% of Mo. In the titanium alloy, the zirconium element and Ti canform an infinite solid solution, therefore, solution strengthening is achieved, the initiating passive potential of the zirconium element is more negative than Ti, passivation can still be generatedeven in the weak oxidation environment, the ability of generating a compact oxidation film on the surface is improved, and corrosion resistance of the alloy is improved. According to records of embodiments, compared with Ti-32Mo alloy, in the TB7 titanium alloy, the tensile strength can be improved by 13.84% or more and can reach up to 42.95%, and the corrosion resisting strength can be improved by 11.62% or more and can reach up to 38.97%.

Owner:YANSHAN UNIV

Aluminum alloy, preparation method thereof and die casting

The invention relates to an aluminum alloy which comprises the following components including 0.9%-1.4% of iron, 0.5%-0.9% of magnesium, 0.2%-0.5% of manganese, 0.15%-0.3% of silver, 0.2%-0.3% of scandium, 0.3%-0.5% of yttrium and the balance aluminum. The invention further relates to a preparation method of the aluminum alloy. The invention also relates to a die casting which is made of the aluminum alloy.

Owner:惠州市田宇中南铝合金新材料科技有限公司

Nickel base alloy and rustless steel valve possessing nickel base alloy layer seal surface and its preparation method

ActiveCN100575519CHigh dilution rateHigh hardnessMetallic material coating processesCarbideMetal silicide

Owner:有研金属复材技术有限公司

A medium-strength heat-resistant magnesium alloy

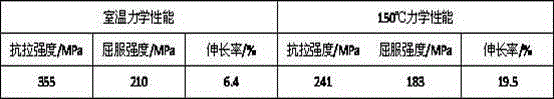

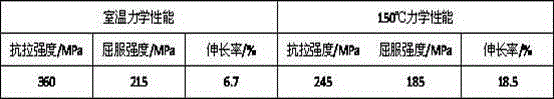

The invention involves a medium -to -strong heat -resistant magnesium alloy.The quality of the alloy is scored: aluminum: 7.5-9.0%, silver: 0.02-0.80%, zinc: 0.35-0.55%, rare earth: 0.01-0.10%, calcium: 0.001-0.020%, manganese: 0.05-0.20%, the rest ofFor magnesium and irregular impurities.Adding rare earth elements can significantly improve the intensity of magnesium alloy; adding appropriate amounts of silver and calcium can effectively improve the high temperature performance of the alloy.This alloy is ≥350MPa in the T5 state temperature, the yield strength ≥210MPa, and the elongation rate ≥6%;The structural parts of high -temperature service conditions in the field of automobile industry are required to meet the requirements of aviation, aerospace and automotive industry.

Owner:湖南镁宇科技有限公司

In situ self-generated nano al 2 o 3 Laser additive manufacturing method for reinforced aluminum matrix composites

ActiveCN112176213BAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMg compositeHigh density

The invention discloses an in-situ self-generated nano-Al 2 o 3 A laser additive manufacturing method for strengthening an aluminum-based composite material, the method comprising the following steps: (1) mixing ZnO ceramic powder and AlSi10Mg aluminum alloy powder and ball milling to obtain a ZnO / AlSi10Mg composite powder; (2) preparing the composite powder The laser selective melting process is used for additive manufacturing forming to form a solid sheet; (3) The laser re-scans the solid sheet to form a remelted sheet; (4) Repeat steps (2) and (3) to finally form the original self-generated nano-Al 2 o 3 Reinforced aluminum matrix composites. In the present invention, laser is used to excite Al and ZnO to generate aluminum thermal reaction between them in situ. 2 o 3 Ceramic particles, and by improving the overall flow process design of the method, combining laser selective melting and laser remelting scanning, the aluminum matrix composite material obtained has high density, fine microstructure, and in-situ self-generated Al 2 o 3 The particle size is nanoscale, uniformly distributed, and its phase interface is well combined with the aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Lightweight, super-high-strength, corrosion-resistant, weldable titanium alloy wire rope for cranes and preparation method thereof

ActiveCN113249993BHas an ultra-fine grain structureHigh strengthTextile cablesMarine terraceTitanium alloy

The invention discloses a lightweight ultra-high-strength corrosion-resistant weldable titanium alloy wire rope for cranes. The weight percentage of the alloy is: Cr: 2.0-6.0%, Mn: 1.0-3.0%, Co: 2.0-5.0%, Zr: 2.0~6.0%, Al: 2.0~4.0%, Cu: 0.2~0.5%, Dy: 0.05~0.10%, the total content of C, H, O and N impurity elements is less than 0.3%, and the balance is Ti. The titanium alloy wire rope of the present invention has high specific strength and good plastic toughness, and has excellent corrosion resistance and antifouling performance at the same time, and the weight is reduced by more than 40%; it is suitable for lifting equipment in port coasts, ocean platforms and coastal areas And other fields have good technical application and market prospects.

Owner:XINXIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com