A medium-strength heat-resistant magnesium alloy

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloys, can solve the problems of backward application of magnesium alloys, poor heat resistance, and high alloy cost, and achieve the effects of hindering the growth of aging precipitates, good thermal stability, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

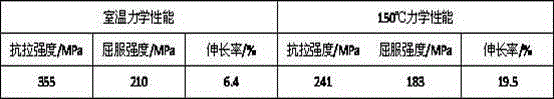

[0008] Example 1 The chemical composition of the magnesium alloy is: 8.24% by weight of aluminum, 0.41% by weight of zinc, 0.15% by weight of manganese, 0.034% by weight of silver, 0.016% by weight of cerium, 0.0011% by weight of calcium, and the rest For magnesium and unavoidable impurities in the casting process. Magnesium alloy ingots were prepared by semi-continuous casting. After homogenization annealing, forging, rolling and aging treatment, tensile tests were done at room temperature and 150°C to obtain tensile strength, yield strength and elongation. The specific data are shown in the table 1.

Embodiment 2

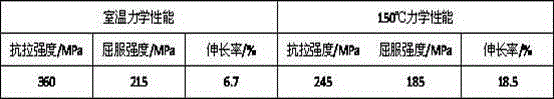

[0009] Example 2 The chemical composition of the magnesium alloy is: 8.22% by weight of aluminum, 0.4% by weight of zinc, 0.14% by weight of manganese, 0.032% by weight of silver, 0.015% by weight of lanthanum, 0.0032% by weight of calcium, and the rest For magnesium and unavoidable impurities in the casting process. After the magnesium alloy ingot is prepared by the semi-continuous casting method, after homogenization annealing, forging, rolling and aging treatment, the tensile test at room temperature and 150°C is carried out to obtain the tensile strength, yield strength and elongation. The specific data are shown in the table 2.

Embodiment 3

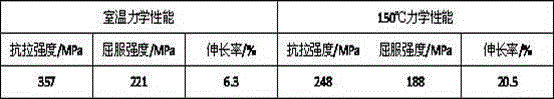

[0010] Example 3 The chemical composition of the magnesium alloy is: 8.02% by weight of aluminum, 0.44% by weight of zinc, 0.12% by weight of manganese, 0.030% by weight of silver, 0.019% by weight of neodymium, 0.015% by weight of calcium, and the rest For magnesium and unavoidable impurities in the casting process. After the magnesium alloy ingot is prepared by the semi-continuous casting method, after homogenization annealing, forging, rolling and aging treatment, the tensile test at room temperature and 150°C is carried out to obtain the tensile strength, yield strength and elongation. The specific data are shown in the table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com