Nickel base alloy and stainless steel valve with nickel base alloy layer sealing surface, and production method thereof

A nickel-based alloy, stainless steel technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of thickness limitation, difficult to combine coating performance with metallurgical combination of coating and matrix, and can not guarantee the continuity of cladding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A nickel-based alloy layer is prepared by multi-layer single-pass laser cladding on a 1Cr18Ni9Ti stainless steel substrate with the nickel-based alloy of the present invention.

[0030] The composition and content of the nickel-based alloy powder used in Example 1 are (wt.%): C: 1.38, Cr: 18.5, Mo: 8.2, W: 3.9, Nb: 2.0, Si: 2.6, Ni: the balance. The nickel-based alloy powder is prepared through a gas atomization process, and the particle size of the powder ranges from -100 mesh to +325 mesh.

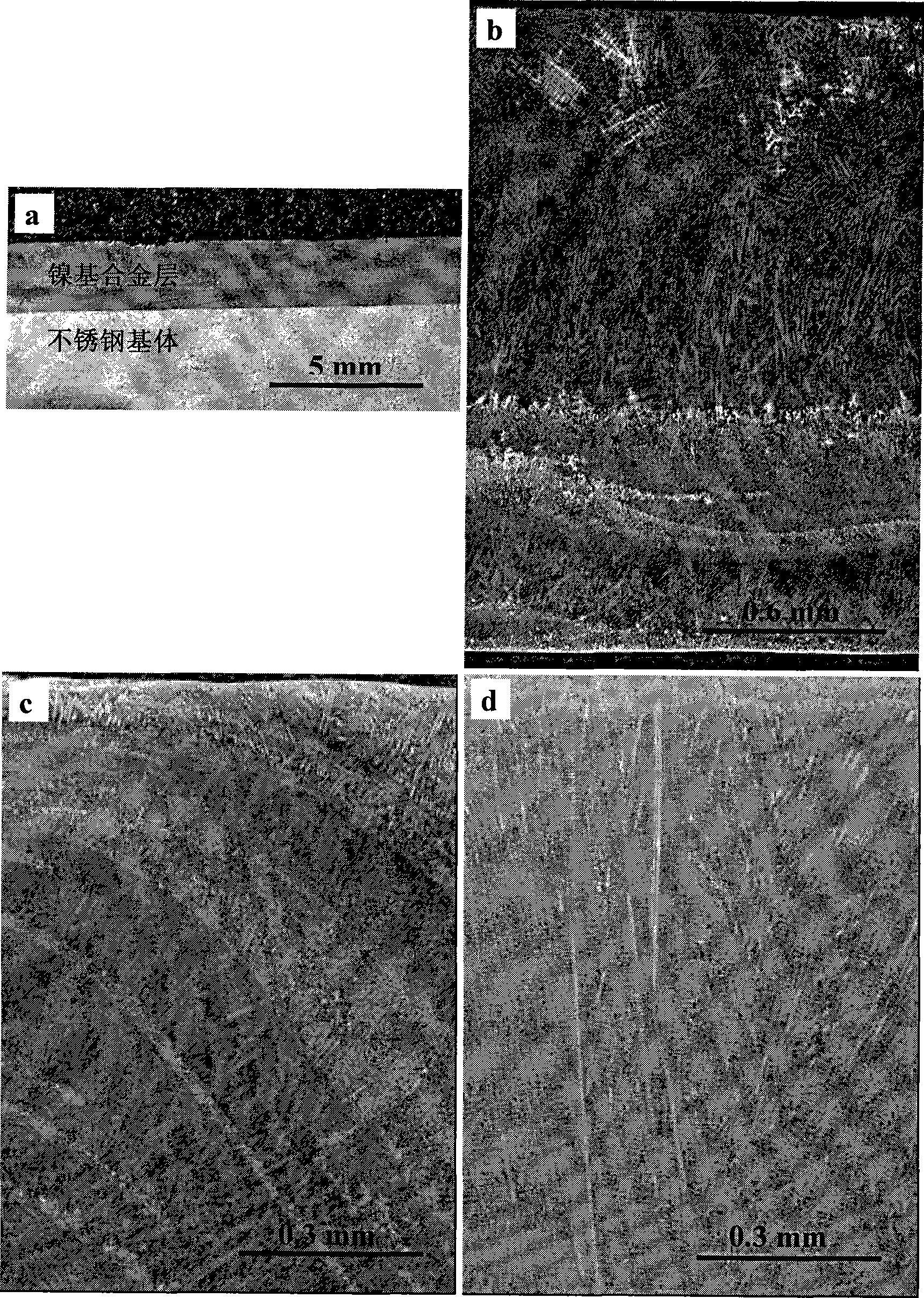

[0031] A nickel-based alloy layer was prepared on a 1Cr18Ni9Ti stainless steel substrate by laser cladding gas-atomized nickel-based alloy powder by multi-layer single-pass reciprocating scanning. The process parameters of laser cladding are: laser power 3.0kW, spot diameter 3.0mm, powder feeding rate 5.7g / min, powder feeding carrier gas (argon) flow rate 2L / min, cladding path length 50mm. figure 1 a (ie figure 1 The figure marked a in the four figures, figure 1 b...

Embodiment 2

[0033] Embodiment 2: Using the nickel-based alloy of the present invention to prepare a nickel-based alloy layer on a 1Cr18Ni9Ti stainless steel substrate by multi-layer and multi-track overlapping laser cladding.

[0034] The nickel-based alloy powder used in Example 2 is the same as that used in Example 1.

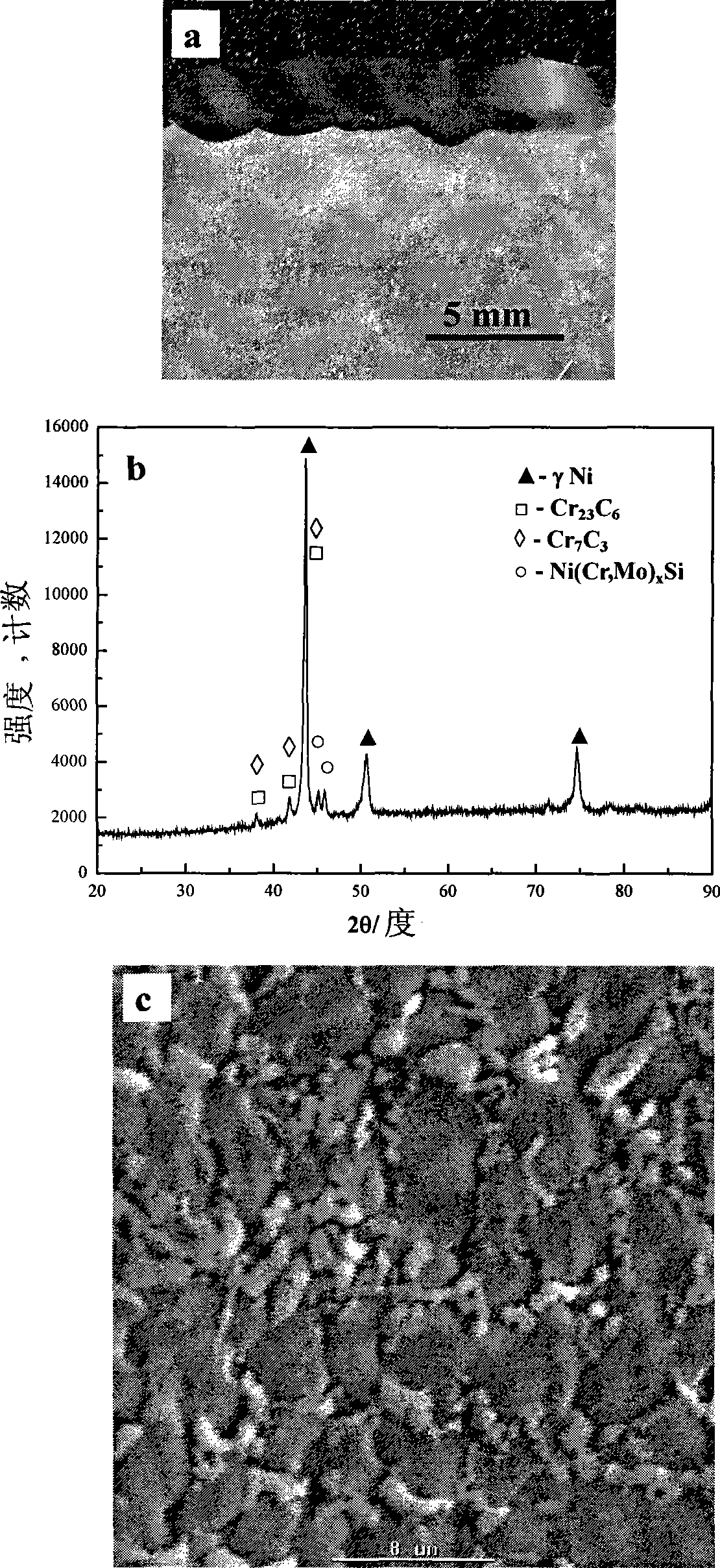

[0035] Multi-layer and multi-lap laser cladding nickel-based alloy layers were prepared on the 1Cr18Ni9Ti stainless steel substrate by using multi-pass bonding. The laser cladding process parameters of this embodiment 2 are: laser power 3.0kW, spot diameter 3.0mm, scanning speed 6mm / s, powder feeding rate 5.7g / min, powder feeding carrier gas (argon) flow rate 2L / min , cladding track length 50mm, cladding track spacing 2.8mm, a total of 3 layers of cladding, 6 laps in each layer, the size of the obtained cladding layer is 50mm (length) × 18mm (width) × 2.3mm (thickness) , The cladding layer hardness is HRC48. figure 2 a (ie figure 2 The figure marked a in the three f...

Embodiment 3

[0037] Embodiment 3: Using the nickel-based alloy of the present invention to prepare a nickel-based alloy layer on a 0Cr18Ni10Ti stainless steel substrate by overlapping multiple layers of laser cladding.

[0038] The nickel-based alloy powder used in Example 3 is the same as that used in Example 1.

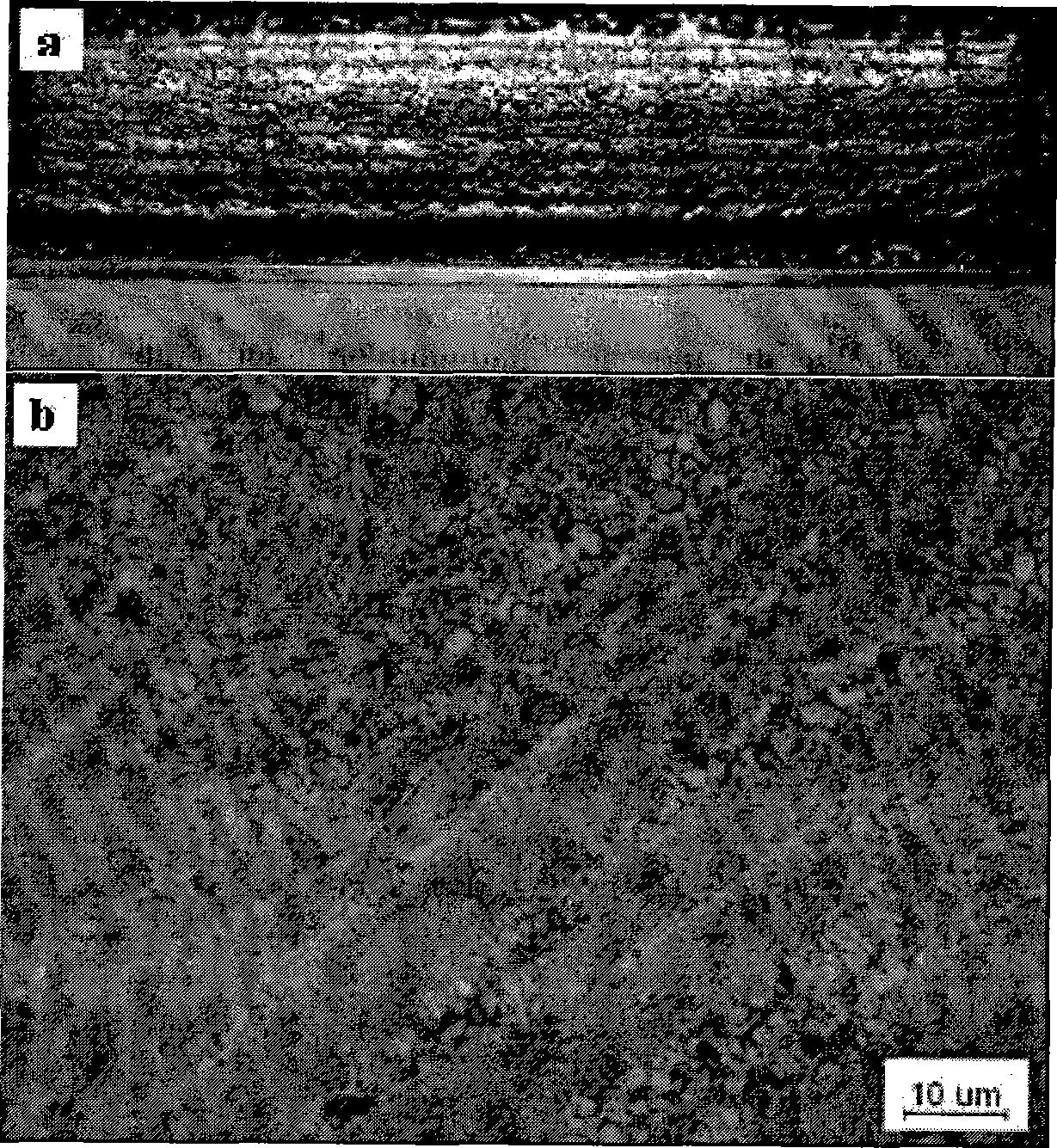

[0039] A multi-layer and multi-layer lapped laser cladding layer was prepared on a 15mm thick 0Cr18Ni10Ti stainless steel substrate by using a multi-layer lap method. The laser cladding process parameters used in this embodiment 3 are: laser power 1.8kW, spot diameter 3.0mm, scanning speed 4mm / s, powder feeding rate 4.8g / min, powder feeding carrier gas (argon) flow rate is 2L / min, cladding track length 105mm, cladding track spacing 2.0mm, a total of 4 cladding layers, 10 laps in each layer, the size of the obtained cladding layer is 105mm (length) × 20mm (width) × 3.5mm (thickness ). image 3 a (ie image 3 The figure marked a in the three figures, image 3 b is the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com