Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

513results about How to "Well-formed weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

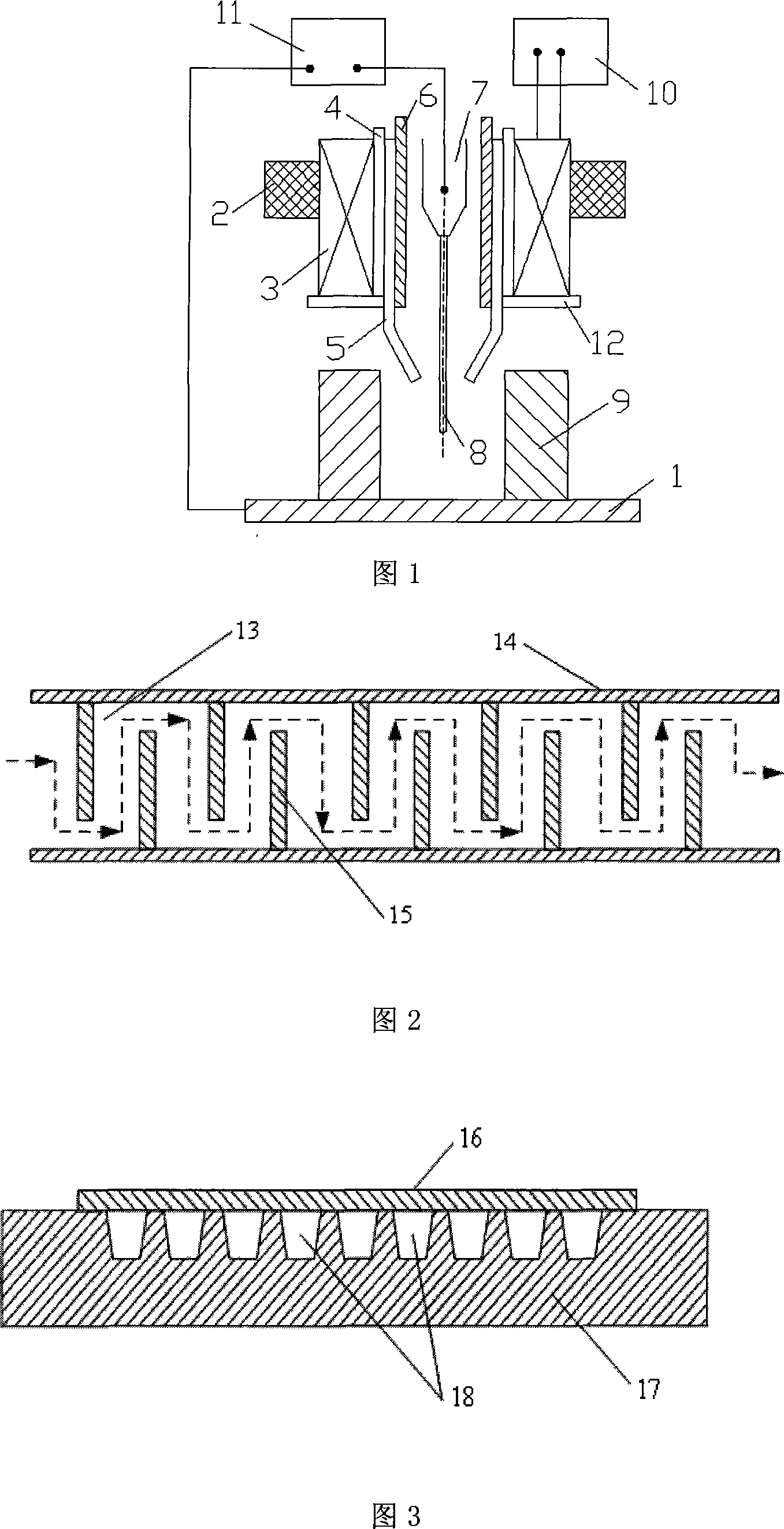

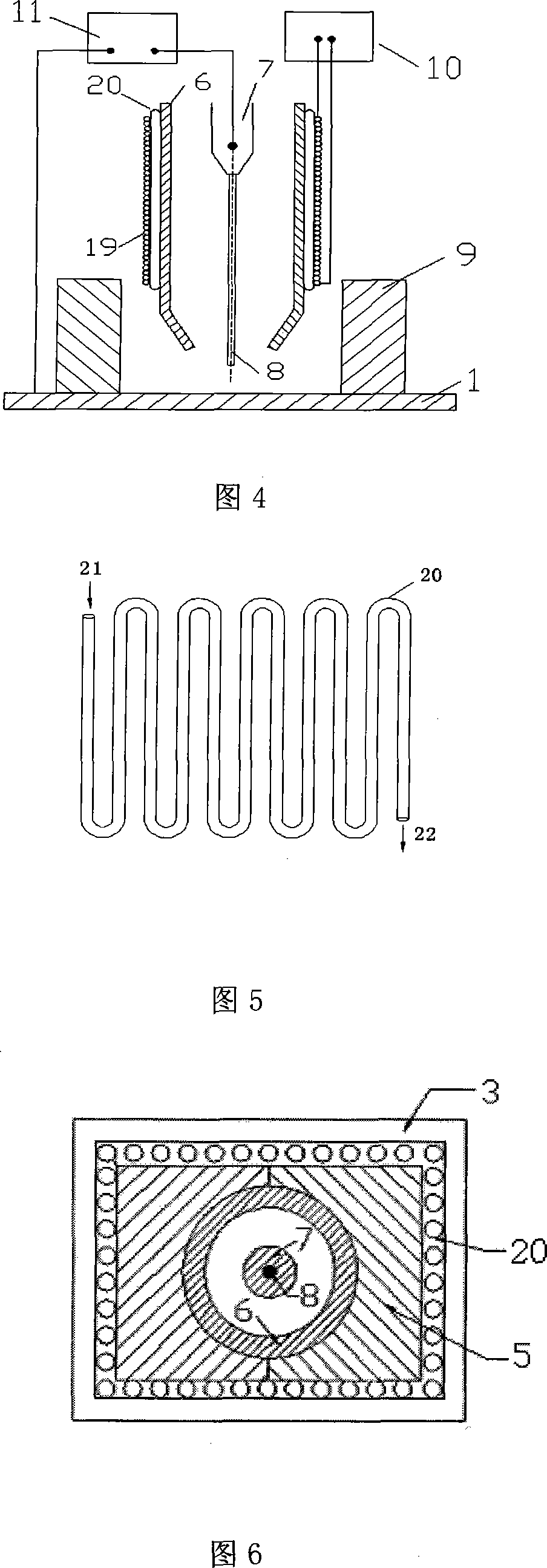

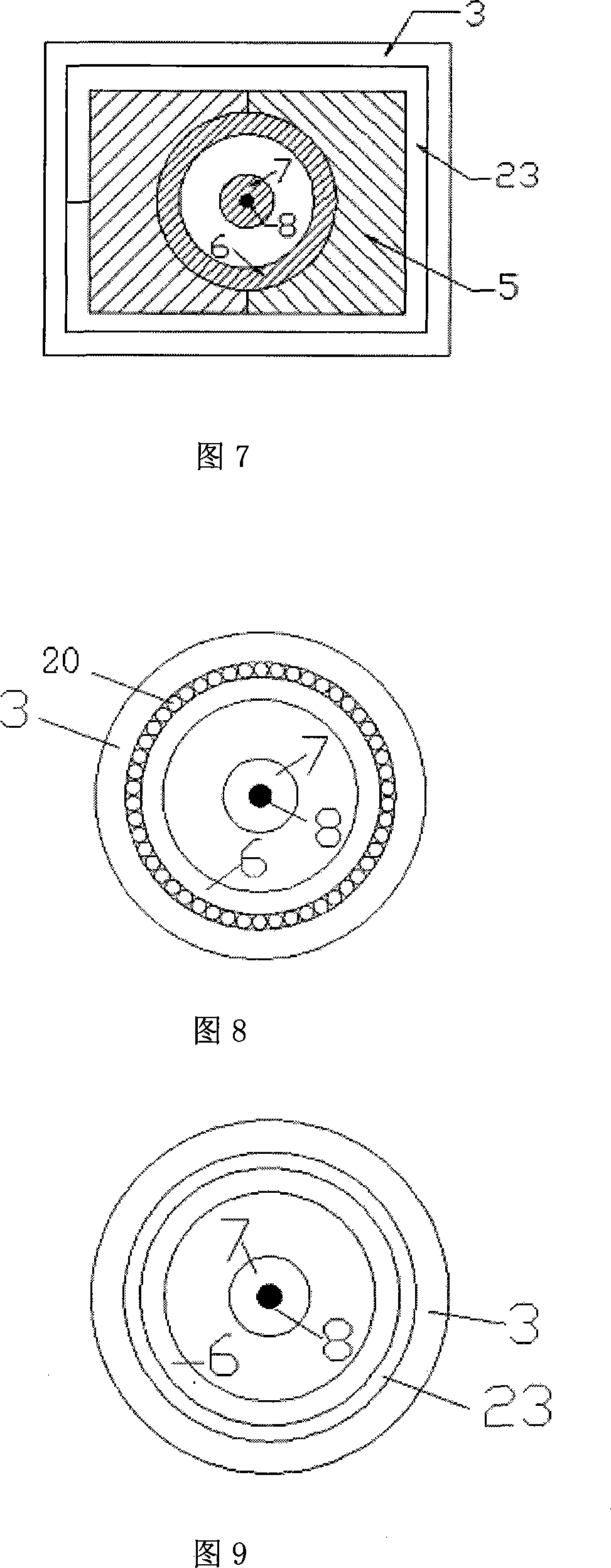

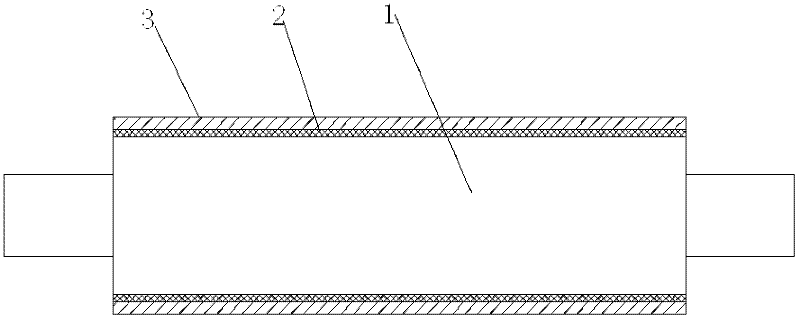

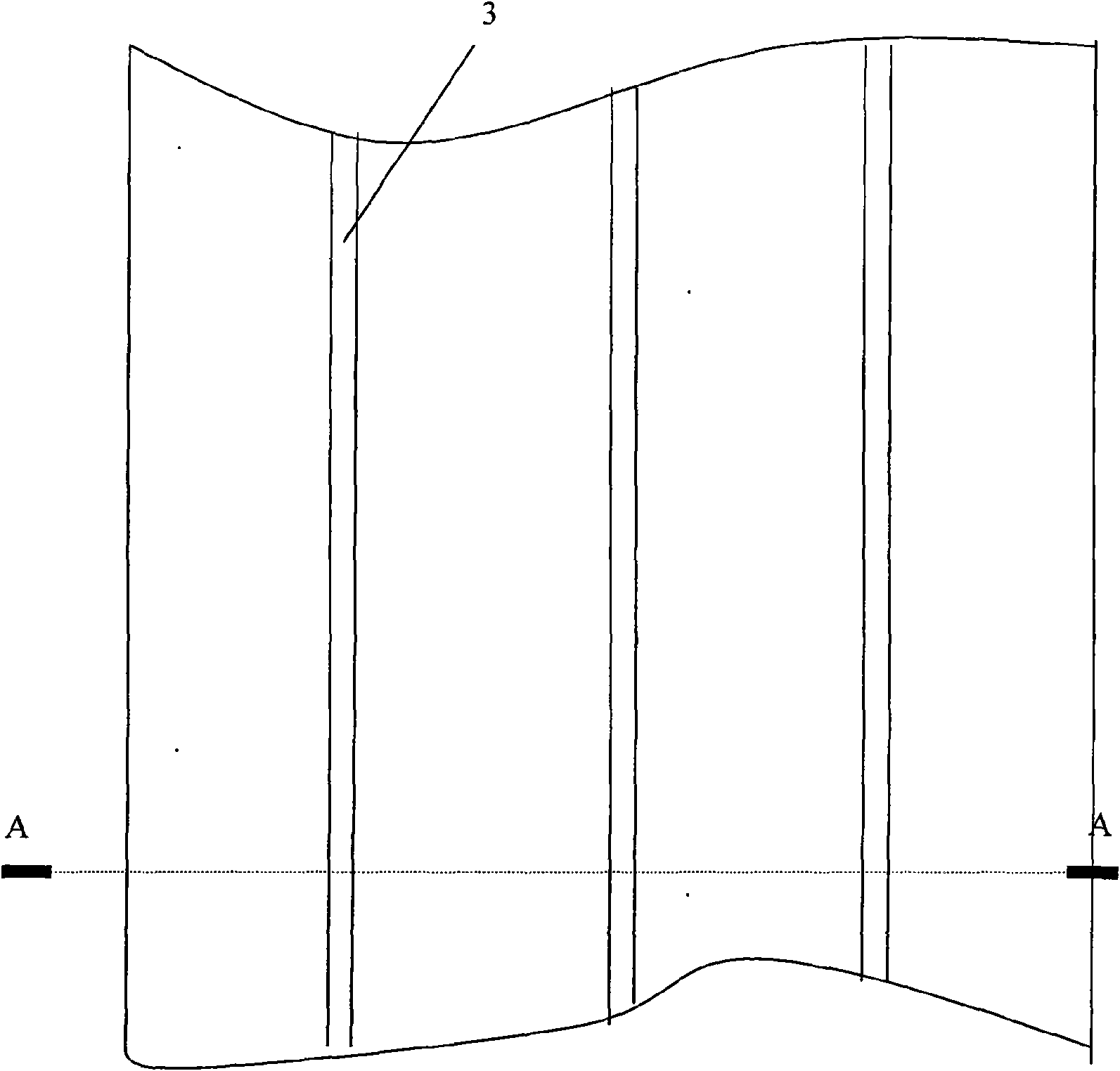

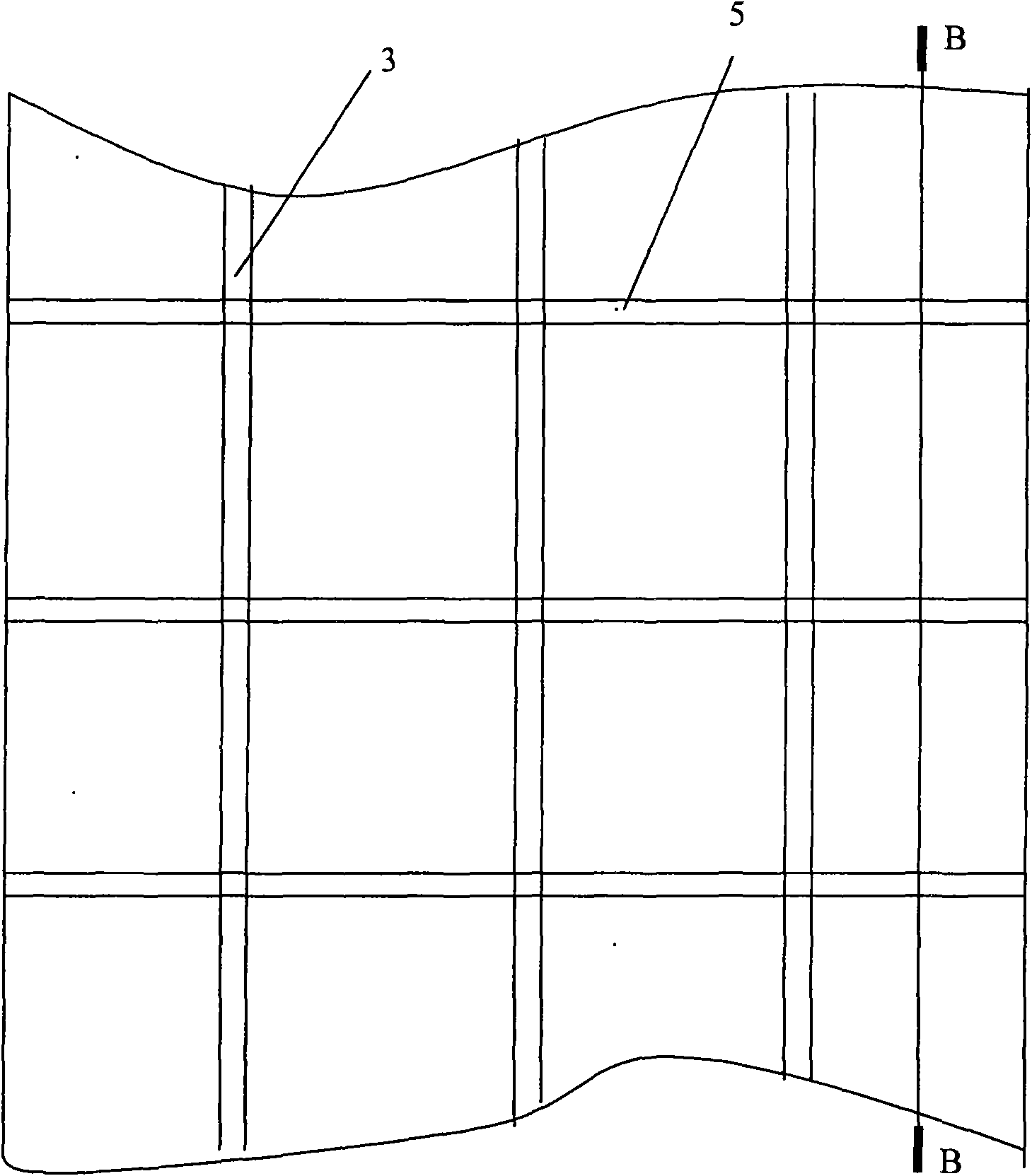

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

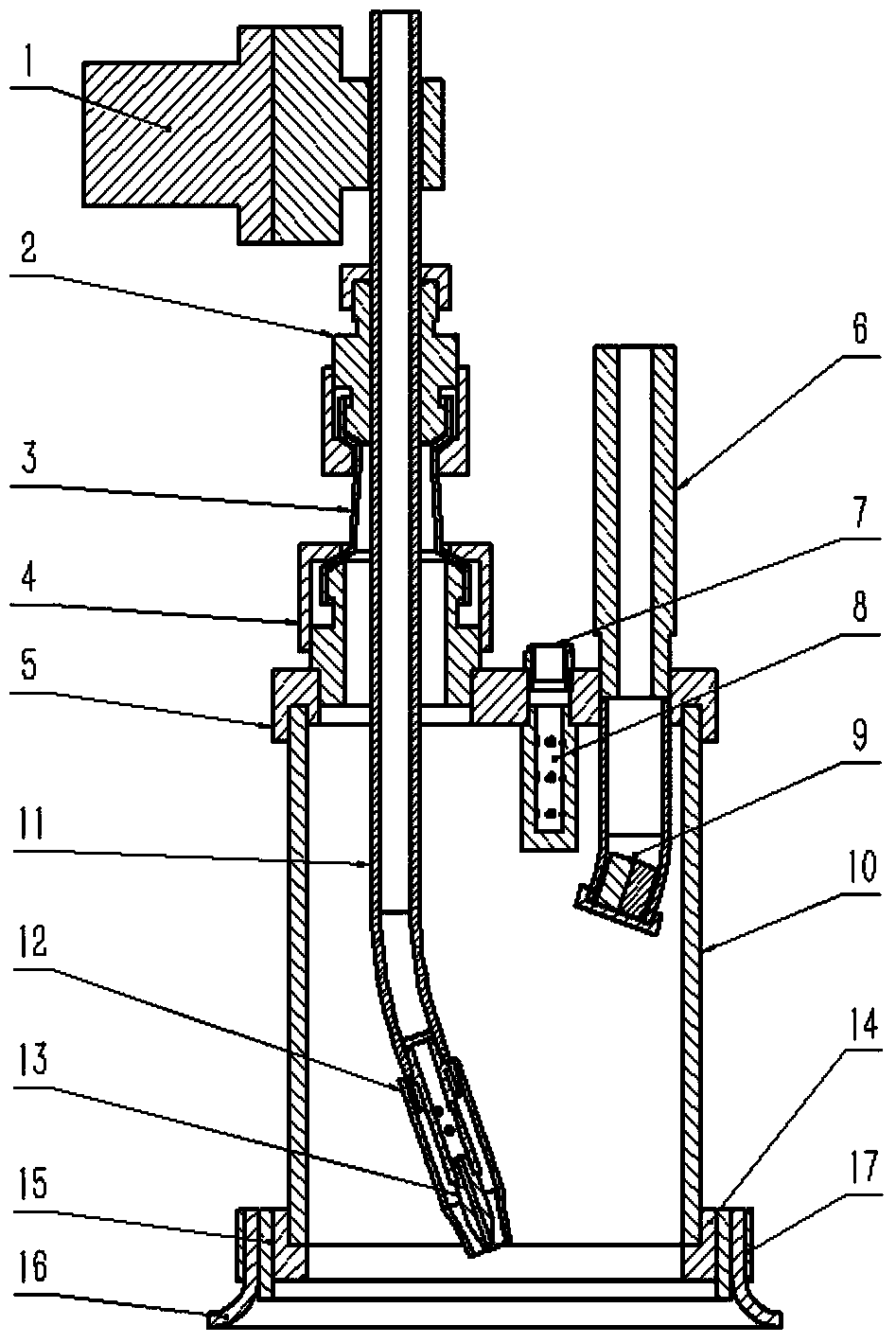

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

Girth welding method of duplex stainless steel bimetal composite pipe

InactiveCN101362249ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/soldering/cutting articlesCarbon steelDouble phase

The invention discloses a method for girth welding for double-phase stainless steel bimetal composite tubes. The method comprises the following steps of: firstly, groove processing: the double-phase stainless steel bimetal composite tube consists of a double-phase stainless steel lining tube and a carbon steel base tube, the welding surface of the base tube is processed into a V-shaped groove at an angle of 45-55 degree, and the lining tube is 2-3 mm longer than the base tube; secondly, caulk welding: the connection ports between the base tube and the lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 65-80 A; thirdly, backing welding: the connection ports of lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 60-90 A; fourthly, base tube welding: the connection ports of the base tube are welded through arc welding, and double-phase stainless steel welding wires are adopted. The procedures and the steps are simple, the used welding material is in a small amount, the welding qualification rate is high, the welding defect can be reduced or avoided, and the production efficiency can be greatly improved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

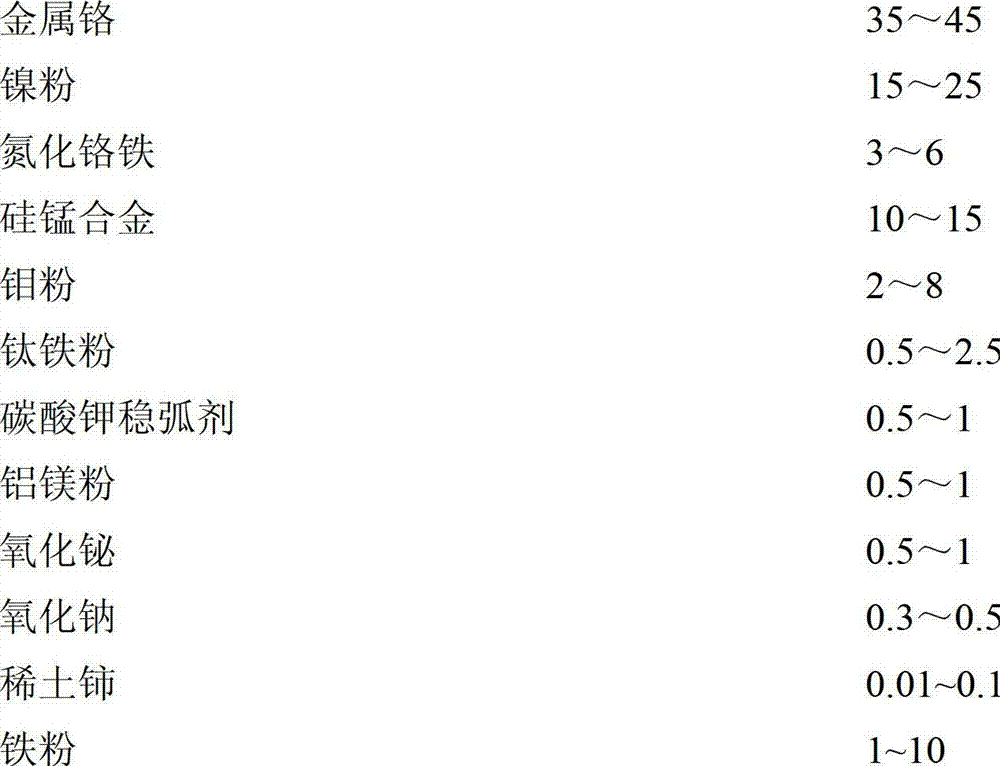

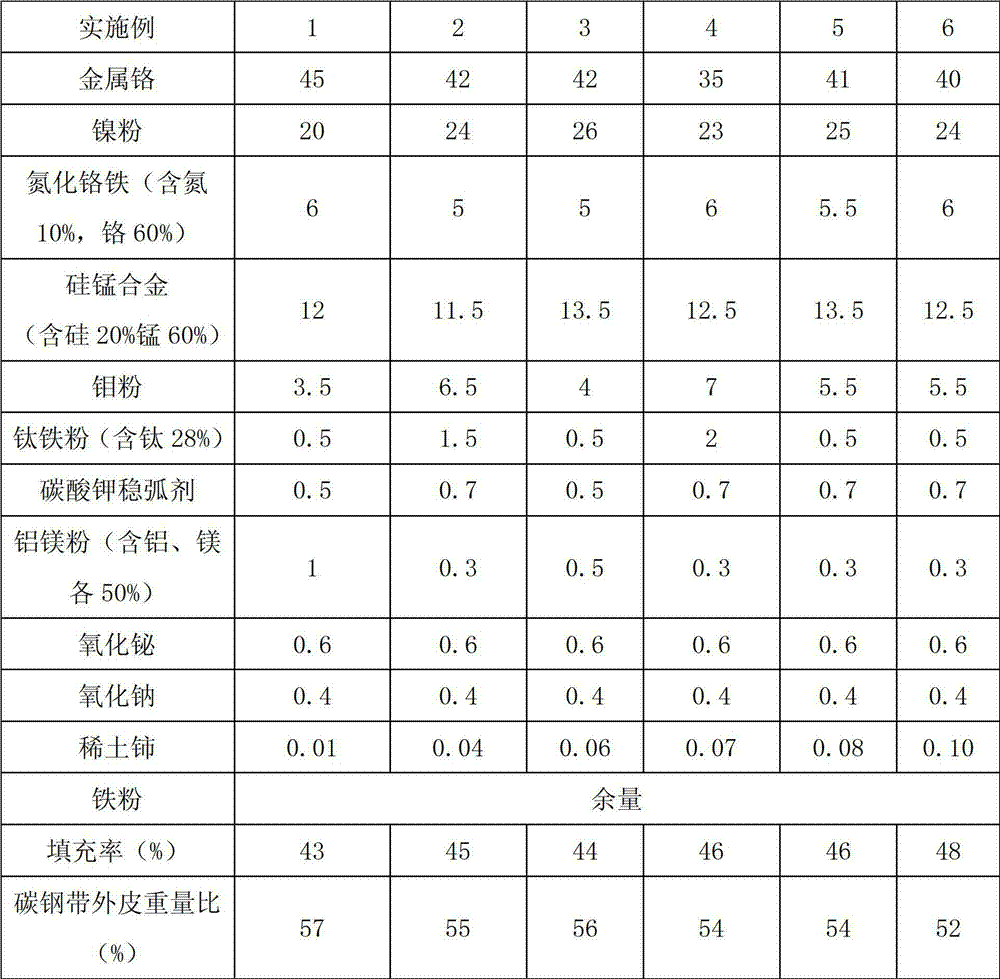

Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

ActiveCN103042321AEffective combinationGood wire qualityWelding/cutting media/materialsSoldering mediaCeriumMechanical property

The invention relates to a metal powder-cored type nitrogen austenite stainless steel flux-cored wire and a method for manufacturing the same. The metal powder-cored type nitrogen austenite stainless steel flux-cored wire comprise a carbon steel cored shell and powder filled in the shell, and is characterized in that the powder comprises, by weight, from 35% to 45% of metal chromium, from 15% to 25% of nickel powder, from 3% to 6% of ferrochromium nitride, from 10% to 15% of silicon-magnesium alloy, from 2% to 8% of molybdenum powder, from 0.5% to 2.5% of ferrotitanium powder, from 0.5% to 1% of potassium carbonate arc stabilizers, from 0.5% to 1% of aluminum-magnesium powder, from 0.5% to 1% of bismuth oxide, from 0.3% to 0.5% of sodium oxide, from 0.01% to 0.1% of rare-earth cerium and from 1% to 10% of iron powder, and the weight of the powder ranges from 40% to 50% of the total weight of the wire. Compared with the prior art, the metal powder-cored type nitrogen austenite stainless steel flux-cored wire has the advantages that weld metal has excellent mechanical properties such as good toughness and high strength after the wire is applied to welding high-nitrogen steel, and a corrosion resistant effect is good.

Owner:北方材料科学与工程研究院有限公司 +2

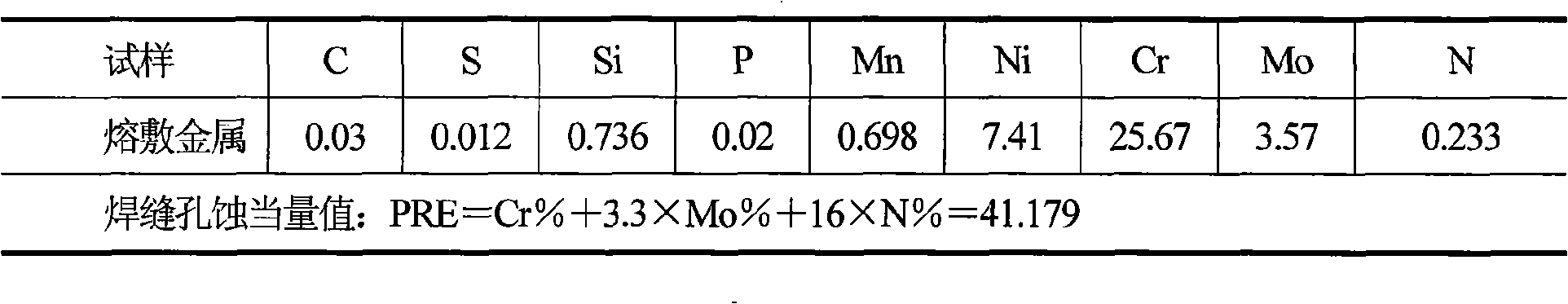

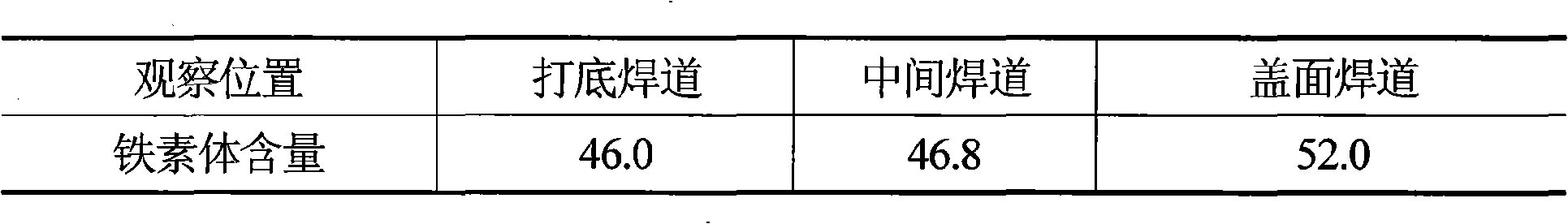

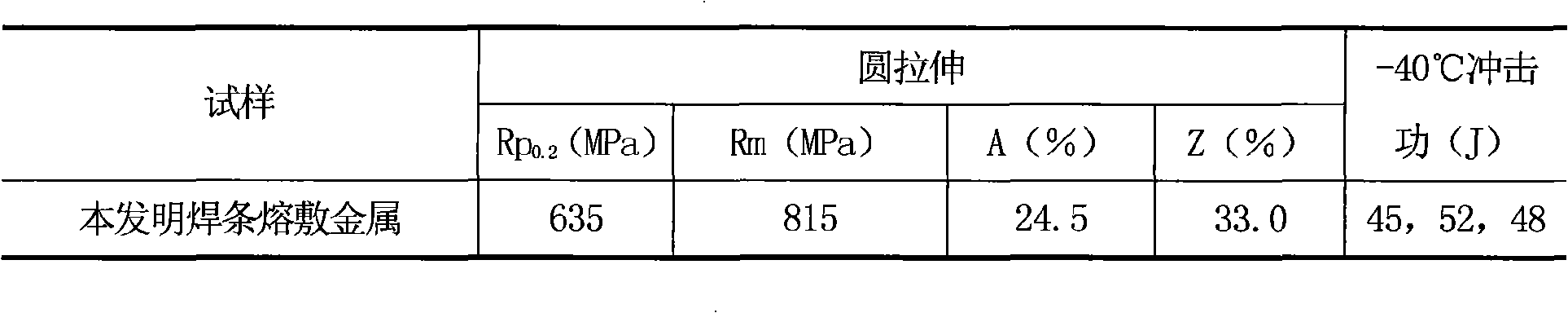

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

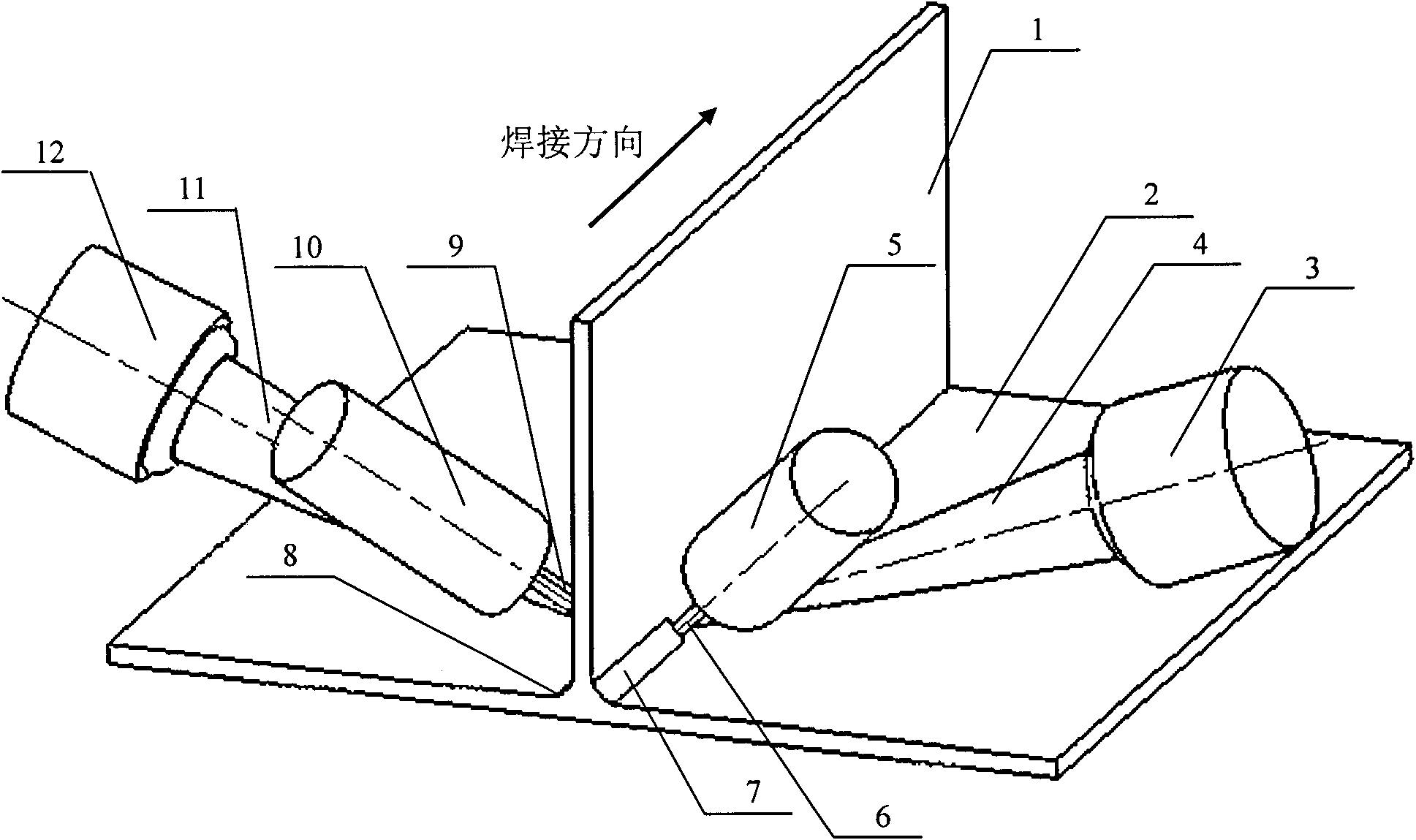

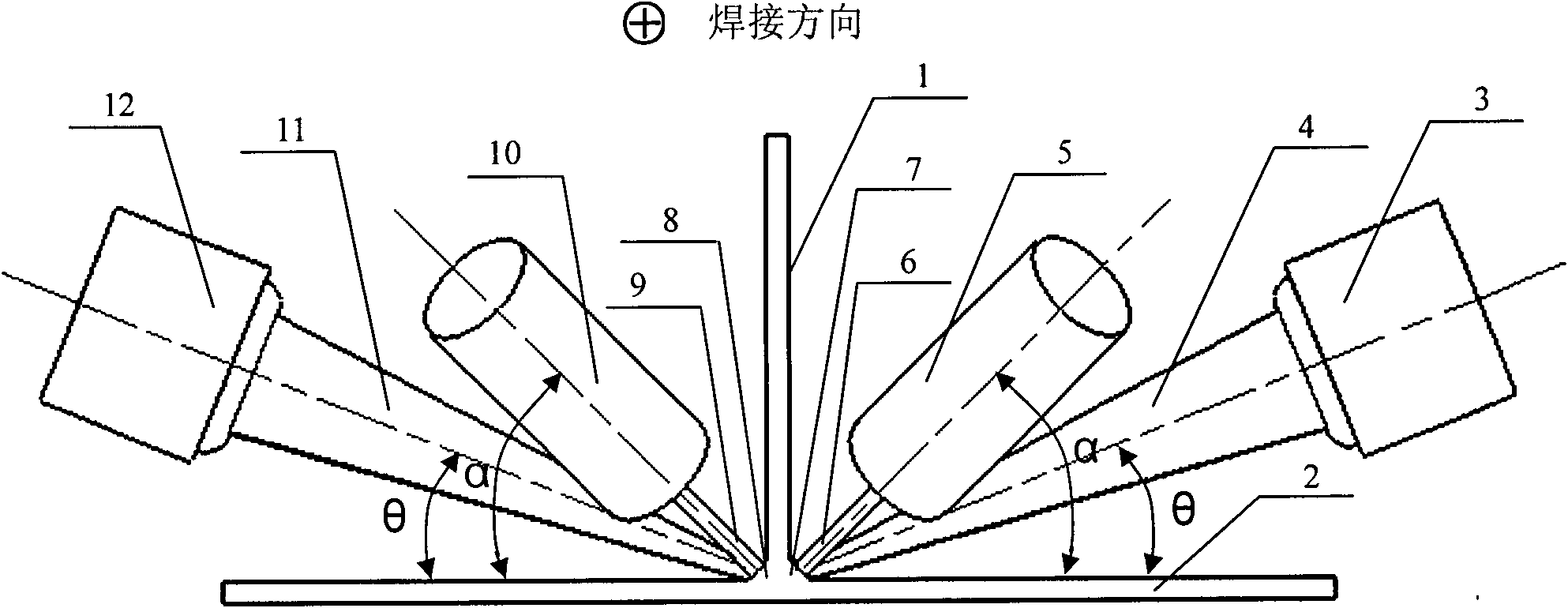

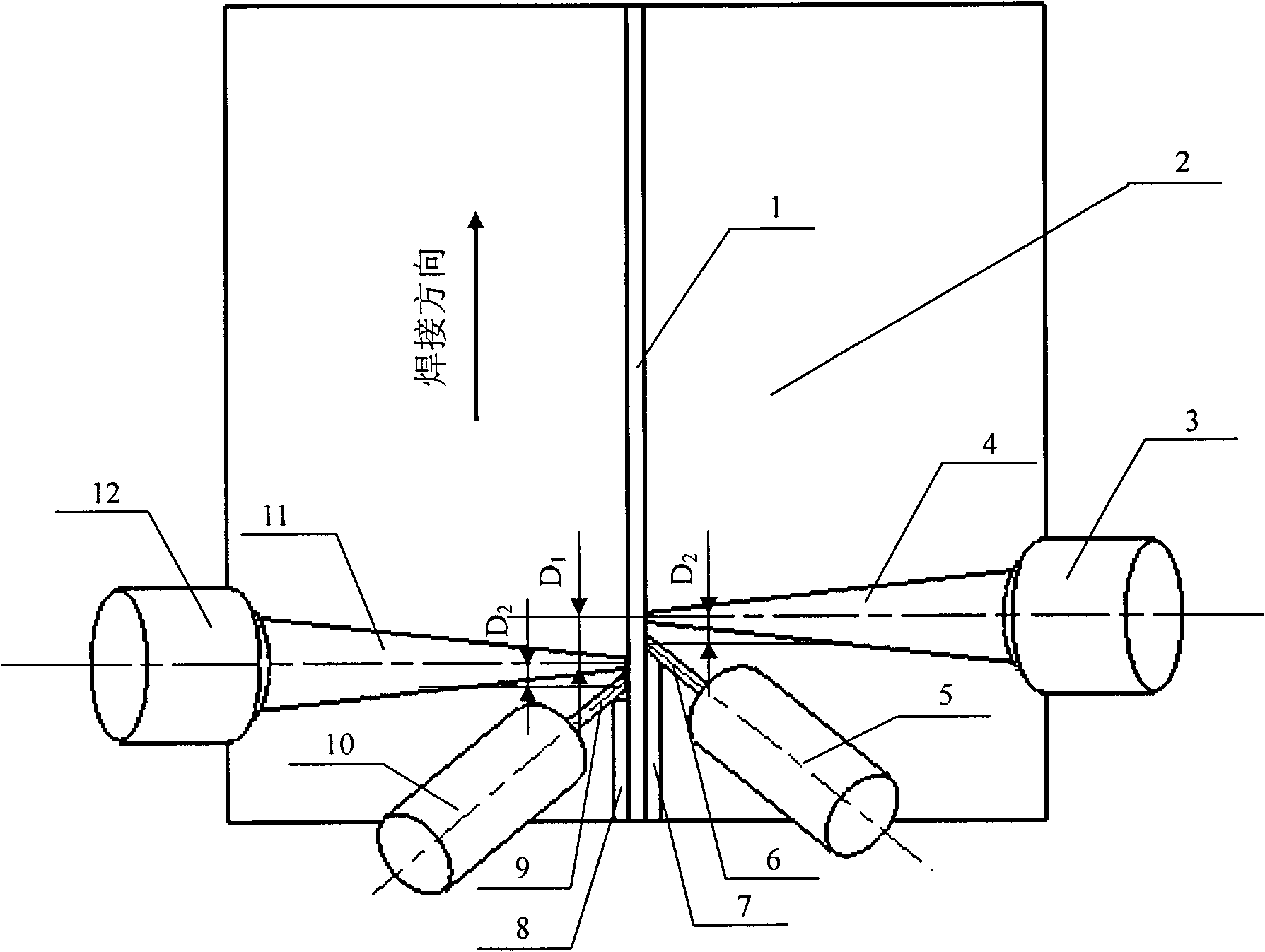

Non-splash, low-deformation, high-quality and high-efficiency welding method for T-shaped joint of aluminum alloy sheet

The invention discloses a non-splash, low-deformation, high-quality and high-efficiency welding method for a T-shaped joint of an aluminum alloy sheet, which belongs to the technical field of low-deformation, high-quality and high-efficiency welding of a light metal sheet. The method mainly comprises the following steps of: controlling a short-circuited transferred arc composite heat source to perform double side welding from both sides of a rib plate 1 by using two relatively independent laser-precision waveforms, wherein precision waveform control electric arc ensures that welding current is mainly maintained at a very small value when a molten dropping liquid bridge is fractured by tension by controlling current and voltage waveforms during molten drop short circuiting transfer so as to prevent welding splash when short circuiting transfer occurs; and controlling the distance between two laser beams 4 and 11 and a welding wire filling speed within certain ranges and reasonably matching included angles between arc welding guns 5 and 10 and a substrate 2 and included angles between the laser beams 4 and 11 and the substrate 2 so as to obtain the non-splash, low-deformation and low-weight gain T-shaped joint. The welding method of the invention is suitable for high-quality welding of T-shaped joints for aluminum alloy and other light metal sheets.

Owner:HARBIN WELDING INST LTD

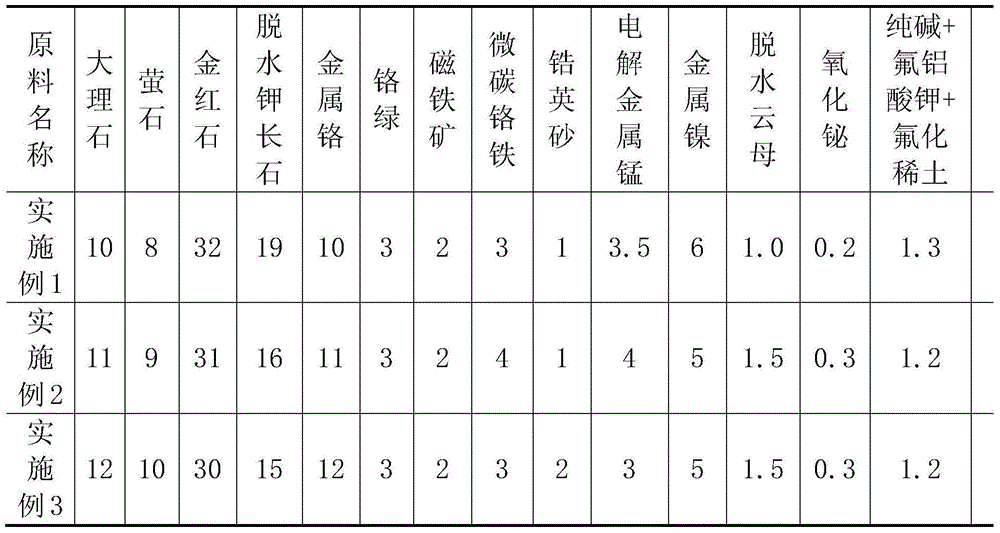

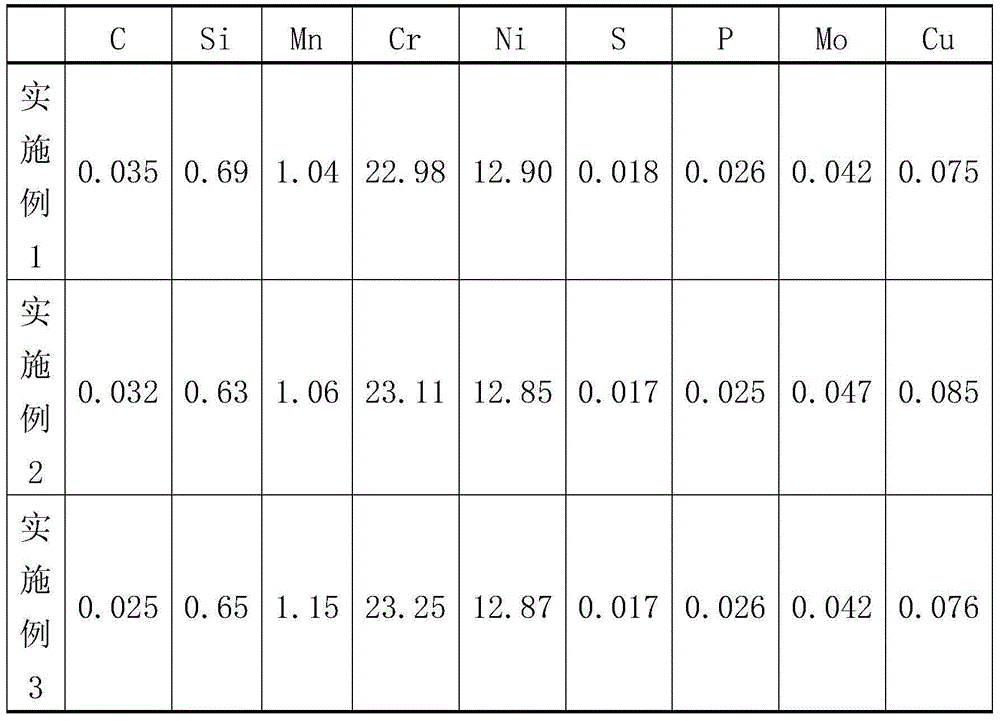

E309L stainless steel lengthened welding electrode capable of being used for large-current welding

ActiveCN105215580ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPotassiumRare earth

Provided is an E309L stainless steel lengthened welding electrode capable of being used for large-current welding. A coating contains marble, fluorite, rutile, dehydrated potassium feldspar, dehydrated mica, bismuth oxide, chrome green, magnetite, sodium carbonate, micro-carbon ferro chrome, electrolytic manganese metal, zircon sand, potassium fluoroaluminate, rare earth fluoride, chromium metal and metallic nickel, blending and even stirring are conducted according to the ratio of the coating, 15-20% of sodapotash water glass is added and evenly stirred according to the total weight of the coating, the coating and an ER308L welding wire are put in an oil pressure type welding electrode extrusion press to produce and prepare the lengthened welding electrode, and no coating cracks or flushing can happen when the large current is 170-180 A and the welding core length is 450 mm; though an ER308L welding core is adopted, the cladding metal chemical components meet the requirement of E309L chemical components through the coating transition alloy method, and therefore the welding electrode has good welding process performance and is stable in electric arc, convenient to operate, good in weld appearance during welding, and sediments are easily separated.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

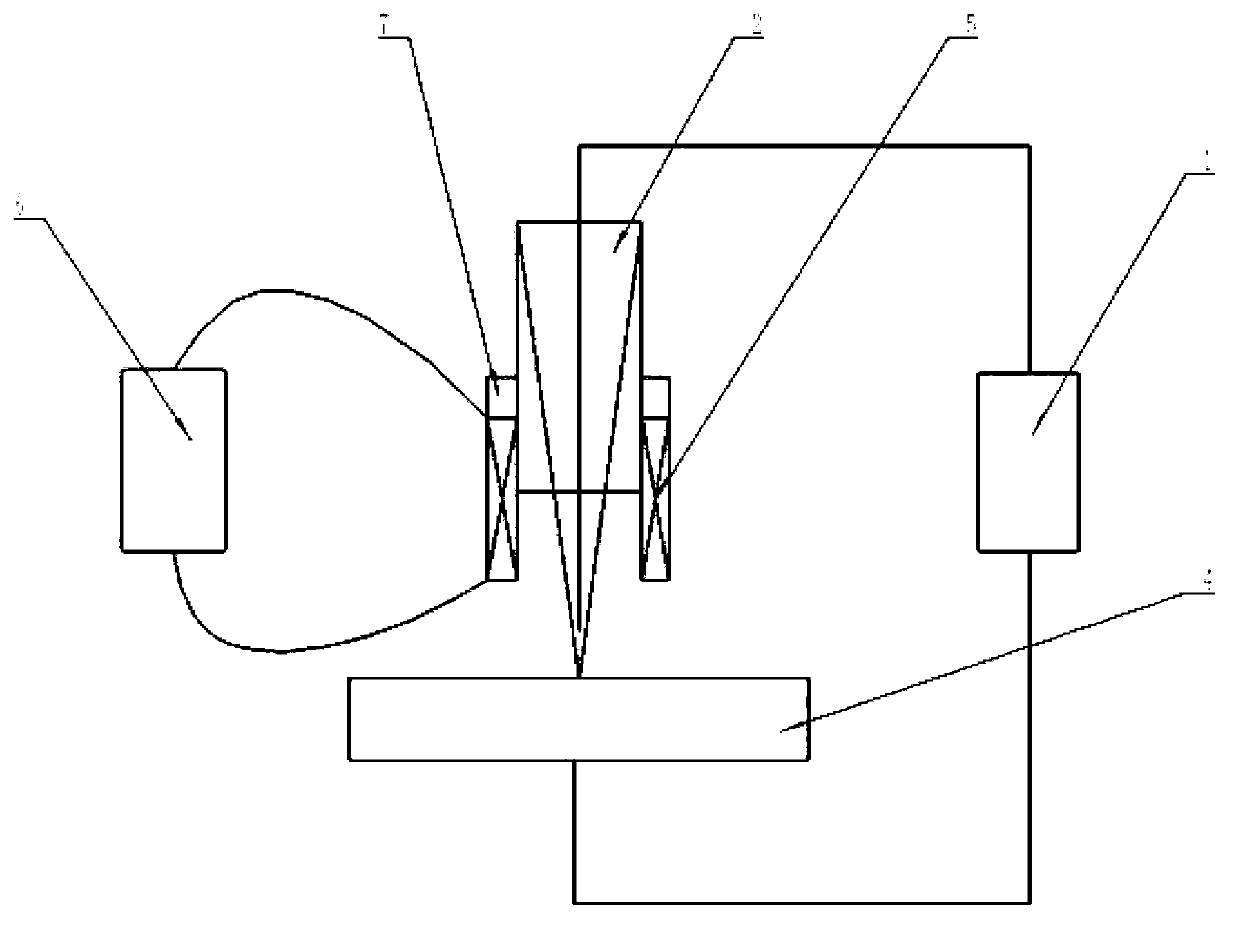

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

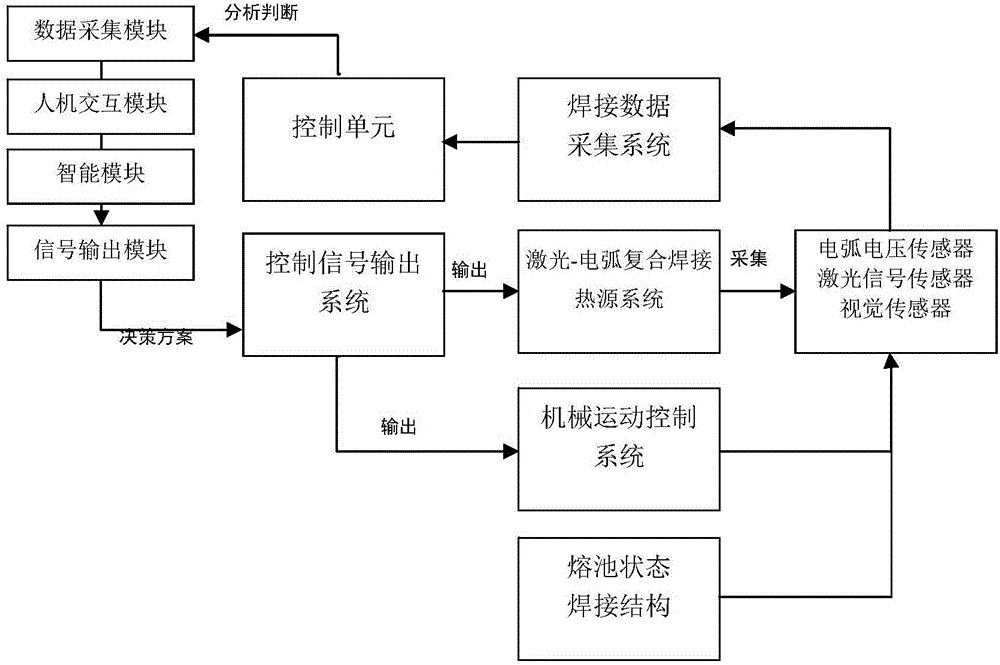

Laser-electric arc composite welding real-time regulation and control system and regulation and control method thereof

ActiveCN106825953ARealize intelligent analysisGuaranteed stabilityLaser beam welding apparatusControl signalData acquisition module

The invention discloses a laser-electric arc composite welding real-time regulation and control system and a regulation and control method thereof. The regulation and control system comprises a laser-arc composite welding heat source system, a sensing system, a welding data collection system, a control unit, a control signal output system and a welding mechanical-movement control system. According to the laser-electric arc composite welding real-time regulation and control system and the regulation and control method thereof, information is collected through the sensing system, is input to the welding data collection system and is converted into respective digital signals, the digital signals are input into a data collection module of a control unit and are input into a human-computer interaction module through classification, the simple digital signals are converted into referable relative variable signals, then the relative variable signals are input into an intelligent module to be calculated, when the calculated result data deviates from a set range of the intelligent module, the electric arc current, the laser energy, the movement speed and the like are regulated and controlled in real time so that the welding comprehensive evaluation value is returned to the set range again, and therefore the purposes of stabilizing the welding process and improving the welding quality can be achieved.

Owner:DALIAN UNIV OF TECH

Gas-shielded flux-cored wire with recyclable welding slag

InactiveCN102139424ALow diffusible hydrogen contentReduce sensitivityWelding/cutting media/materialsSoldering mediaCrack resistanceHydrogen

A gas-shielded flux-cored wire with recyclable welding slag belongs to the welding field. In the invention, the skin of the gas-shielded flux-cored wire is made from a mild steel strip, and welding slag powder is partially or completely instead of natural rutile, thus the purposes of saving the resource and reducing the cost are achieved. The powder of the flux-cored wire comprises the following chemical components in percentage by weight: 15-35% of the welding slag powder of the flux-cored wire (including 20-65% of TiO2, 5-15% of MnO, 5-15% of MgO, 5-15% of SiO2, 1-10% of Fe2O3 and 1-10% of Al2O3), 15-35% of TiO2, 2-7% of Si, 3-8% of Mn, 0.5-5% of Al-Mg, 0-5% of Na, 0-5% of K, 1-5% of Mg and the balance of ferrous powder. When the flux-cored wire manufactured by adopting the welding slag powder is applied to welding, the gas-shielded flux-cored wire has the advantages of excellent technical performance of welding and omnibearing welding adaptability, attractive appearance good humidity resistance, low content of diffusible hydrogen in a welding seam, excellent crack resistance, high connection strength and good low-temperature impact toughness.

Owner:BEIJING UNIV OF TECH

Gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates

ActiveCN106270957AHigh strengthGuaranteed toughness and plasticityArc welding apparatusWelding/cutting media/materialsEngineeringSlow cooling

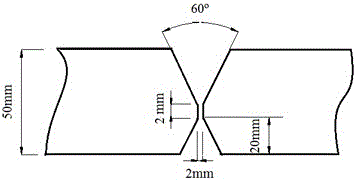

The invention provides a gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates. Welding base materials are Rm1000-1100 MPa engineering machine quenched and tempered steel plates in equal-thickness flat plate butt joint, a groove is a double-side V-shaped asymmetric groove, the angle of the groove is 60 degrees, a truncated edge is 2-3 mm long, and an assembly gap is 2 mm wide. According to welding materials, bottoming welding wires are 700 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm, and filling and surface covering welding wires are 1000 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm. The welding method includes the welding steps that bottoming welding is conducted, filling welding is conducted, surface covering welding is conducted, slow cooling is conducted after welding, and joint areas in the range of 300 mm on the two sides of a weld joint are covered with asbestos cloth. Preheating is not needed, after-heating is not conducted, strength and toughness of a joint are ensured, the variety of welding gas and replacement frequency of equipment and the welding wires are reduced, the high-strength advantage of high-strength steel can be fully achieved, and maneuverability is high.

Owner:武汉钢铁有限公司

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

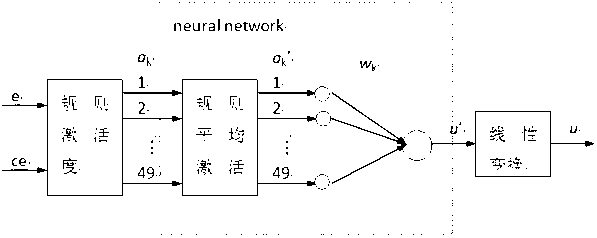

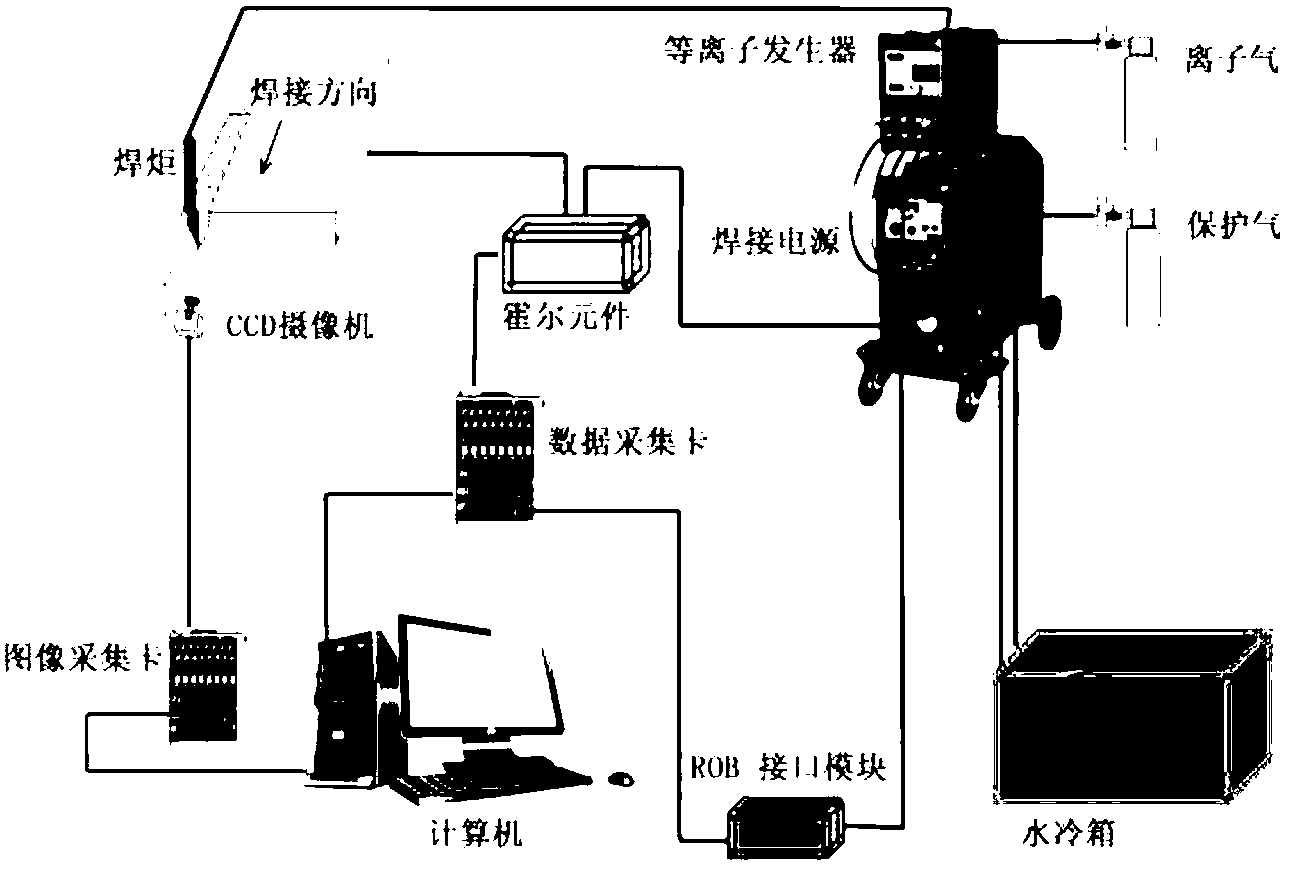

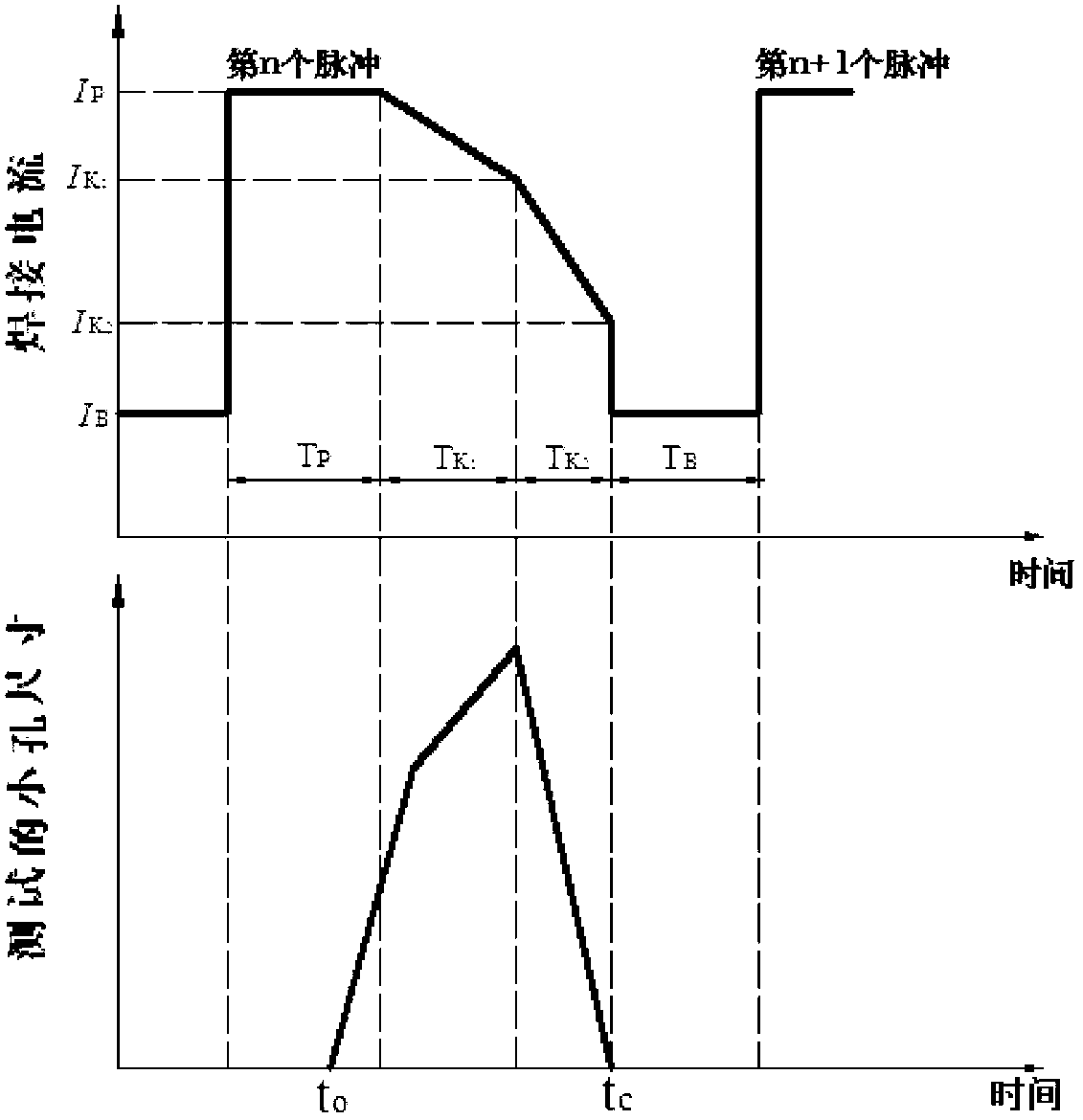

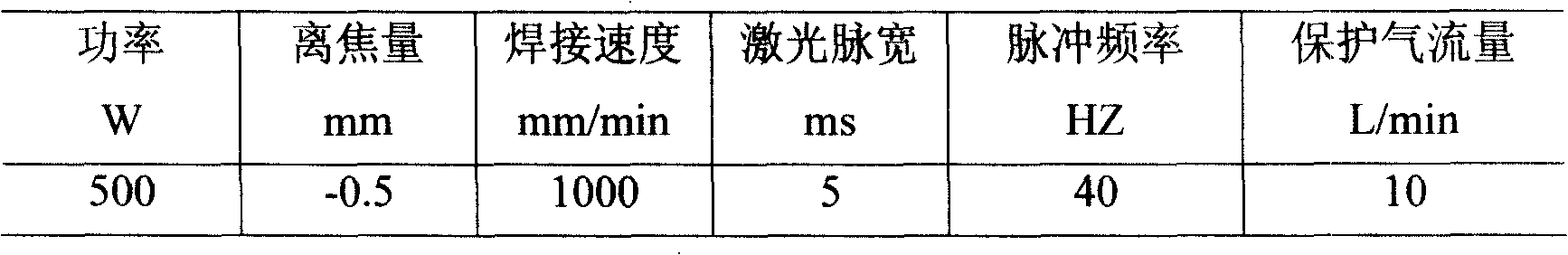

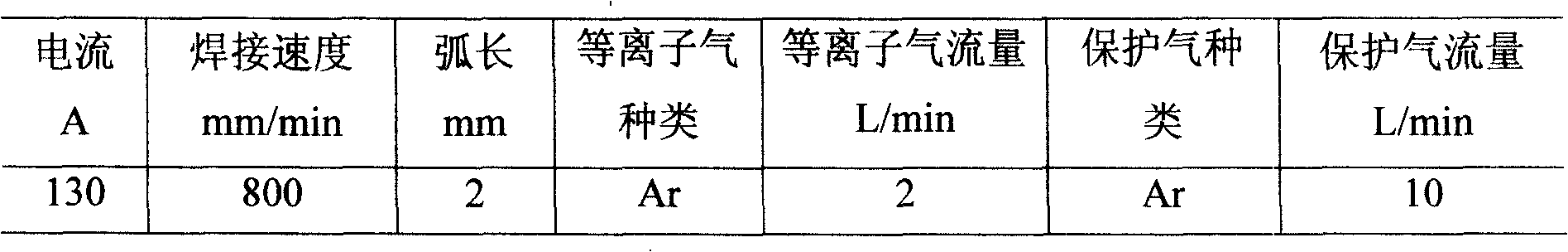

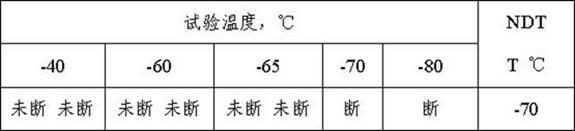

Controlled perforation plasma-arc welding system and process on basis of back small-hole visual inspection

InactiveCN103264216AState transitions are smoothHigh sensitivityPlasma welding apparatusVision sensorVisual perception

The invention discloses a controlled perforation plasma-arc welding system on the basis of back small-hole visual inspection. The controlled perforation plasma-arc welding system comprises a welding machine system, an electric parameter acquisition system, a visual sensor system and a regulation and control system. The invention further discloses a controlled perforation plasma-arc welding process on the basis of the back small-hole visual inspection. The controlled perforation plasma-arc welding process includes the following steps: (1) starting: selecting appropriate current waveform parameters according to texture and plate thickness of materials to be perforated; and (2) starting welding after the parameters are selected and set, acquiring current waveforms and back small-hole images in real time, transmitting the information to a computer, calculating the size of a small hole, and calculating deviation of the size of the small hole and a set value until welding is finished. The controlled perforation plasma-arc welding system and process on the basis of the back small-hole visual inspection enables a one-pulse and one-hole welding mode to be expanded from welding of stainless steel sheets with thickness less than 4mm to welding of middle thickness plates with 8mm thickness, guarantees perforation of workpieces, enables the size of the small hole to be maintained at a value nearby a predetermined value, and effectively prevents a furnace hearth from collapsing and being burnt through.

Owner:SHANDONG UNIV

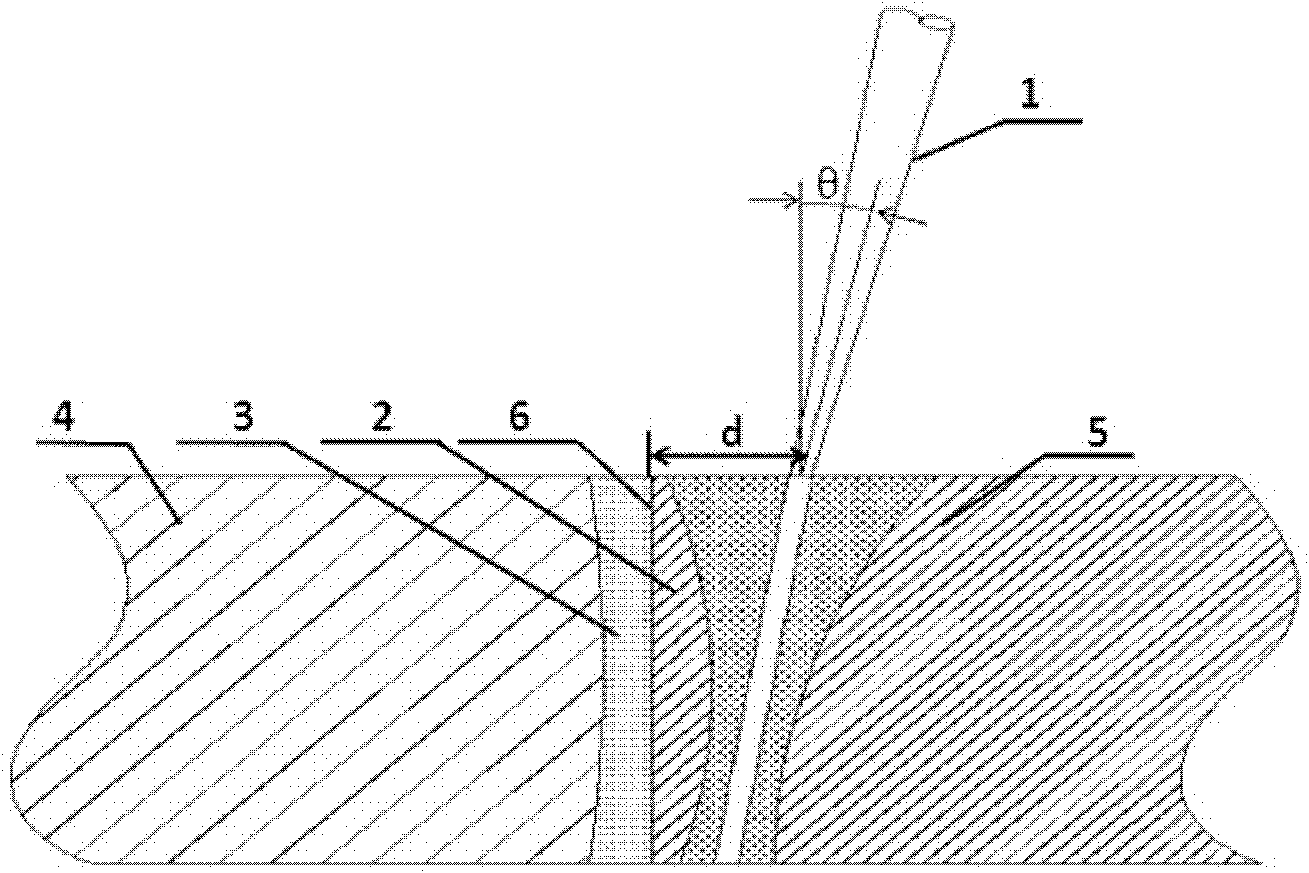

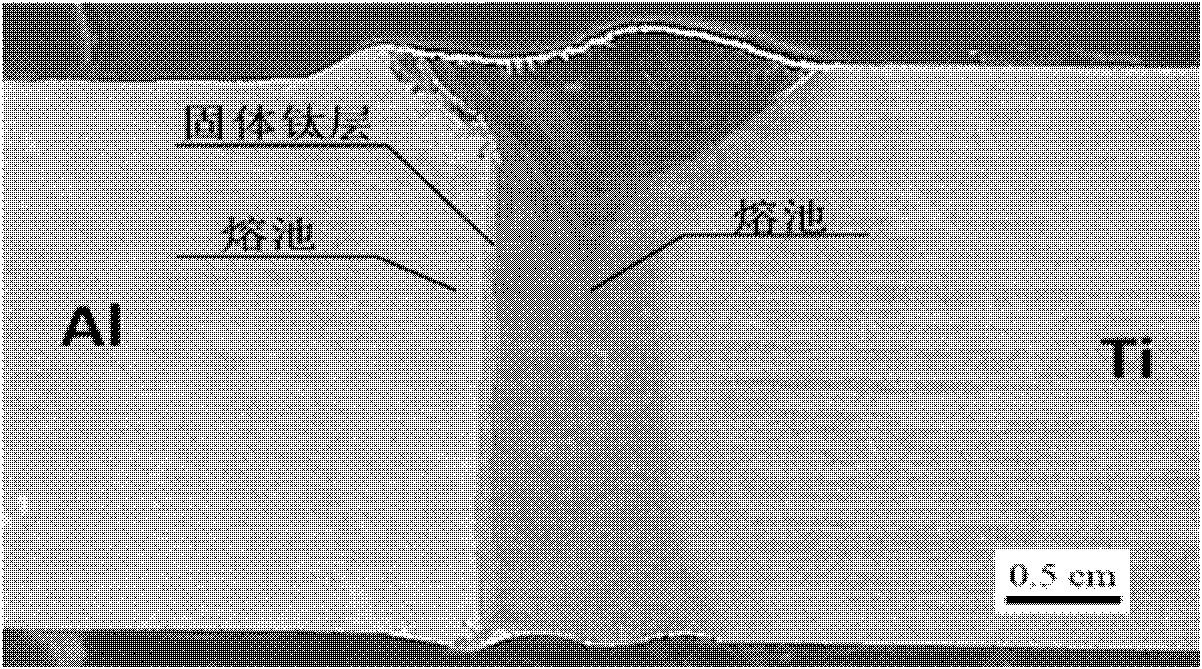

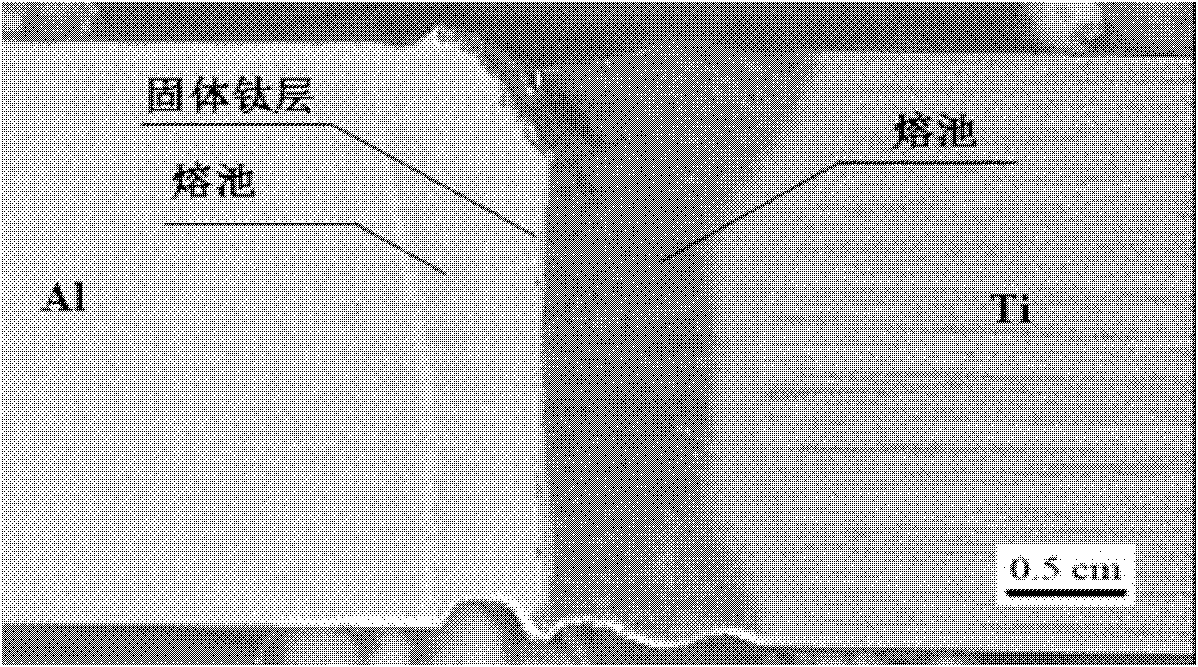

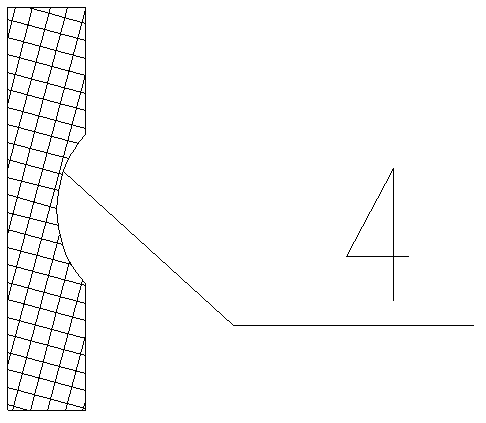

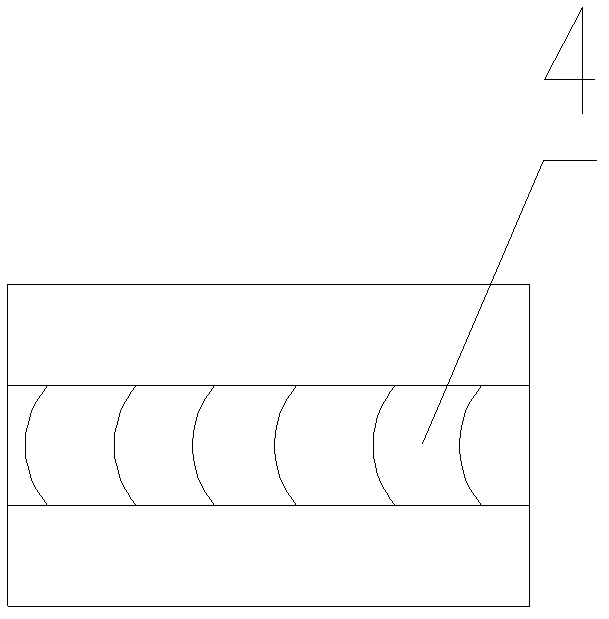

Laser penetration brazing method for dissimilar alloy

InactiveCN102145420AThe effect of improving wettabilityUncontrollable formationSoldering apparatusAlloyMaterials processing

The invention discloses a laser penetration brazing method for dissimilar alloy and belongs to the technical field of laser material processing. The method comprises the following steps of: during welding, allowing a focused laser beam (1) to act on one side of a high-melting-point parent material (5) to realize penetration fusion welding; and controlling a distance d of the laser beam (1) and an interface (6) on the surface of the high-melting-point parent material and an included angle theta between the laser beam (1) and a normal line, forming a high-melting-point parent material solid state intermediate layer (2) on the high-melting-point parent material side close to the interface (6), melting a low-melting-point parent material (4) through the heat conduction of the high-melting-point parent material solid state intermediate layer (2), and spreading and soaking the high-melting-point parent material (5) on a melted low-melting-point parent material layer (3) to realize the laser penetration brazing of the dissimilar alloy. The laser energy utilization rate and welding efficiency are obviously improved, and the welding of a dissimilar alloy plate with a certain thickness can be realized. The influence of mixing two kinds of metal liquid states at the interface to generate a complex and brittle intermetallic compound on joint quality is avoided.

Owner:BEIJING UNIV OF TECH

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

Low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding

InactiveCN109623194AReduce manufacturing costAvoid microstructureWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

The invention discloses a low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding. The low-hydrogen welding rod for the ultra-low-temperature high-manganese steel manual arc welding comprises a welding rod core and a coating, wherein chemical components of the welding rod core comprise 0.30-0.75 wt% of C, 20-26 wt% of Mn, 6.5-8.5 wt% of Ni, 3.0-5.5 wt% of Cr, 2.5-4.0 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S, and the balance Fe and inevitable impurities; and chemical components of the coating comprise 35-40 wt% of marble, 16-22 wt% of fluorite, 3-5 wt% of quartz sand, 3-6 wt% of zircon sand, 4-10 wt% of titanic schorl, 5-10 wt% of ferrotitanium, 5-8 wt% of low carbon ferromanganese, 3-6 wt% of silicon iron, 1-2 wt% of rare earth ferrosilicon, 2-3 wt% of synthetic mica, and 1-2 wt% of sodium carbonate, wherein the sum of the weight percentages of all the components is 100%. The low-hydrogen welding metal has excellent low-temperature toughness and the strength which is matched with the ultra-low-temperature high-manganese steel, and can meet the technical requirements for the strength and the ultra-low-temperature toughness of the ultra-low-temperature high-manganese steel to be welded.

Owner:NANJING IRON & STEEL CO LTD +1

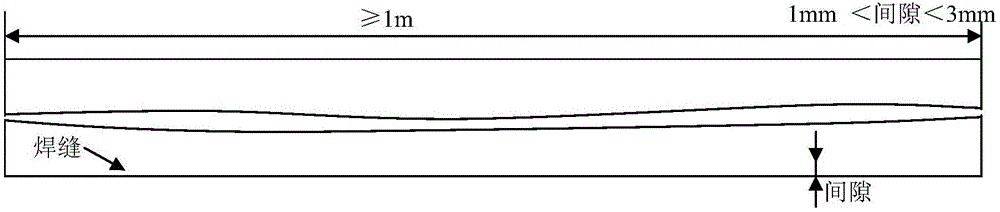

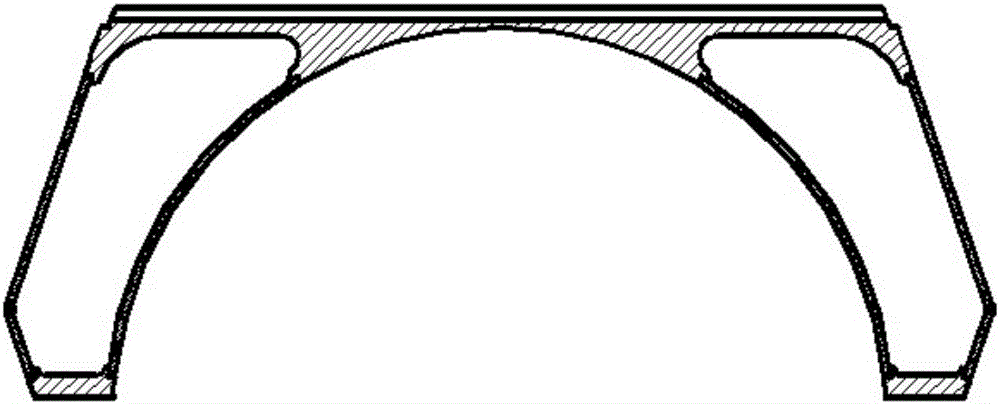

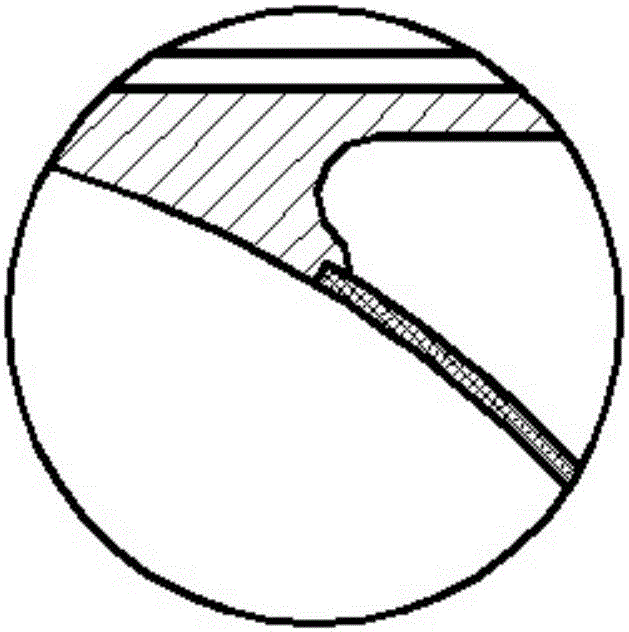

Large tank singe-face-weld double-face-forming method and weld joint forming pad

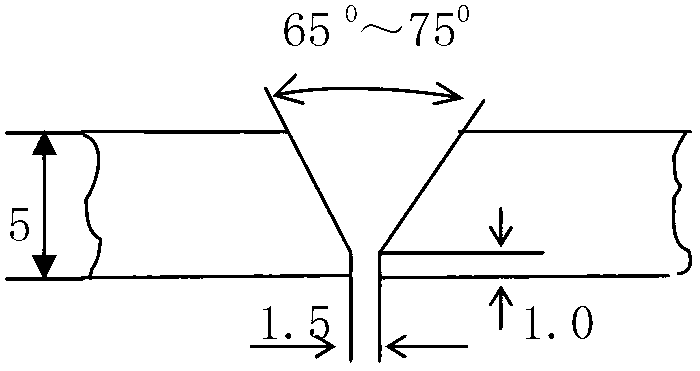

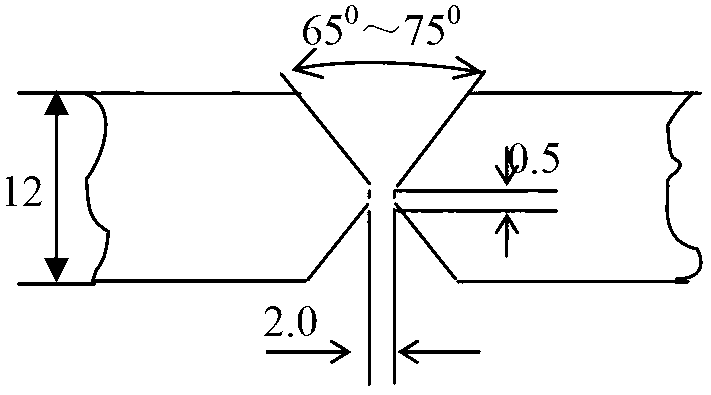

InactiveCN102489830AHigh technical levelReduce consumptionWelding accessoriesEngineeringWeld penetration

The invention provides a large tank singe-face-weld double-face-forming method, which comprises arranging a weld joint forming pad on the back face of a weld joint of a weld part, wherein the weld joint forming pad is provided with a weld joint forming groove with the shape matched with that of the weld joint; fixedly and tightly attaching the weld joint forming pad on the back face of the weld joint to enable the center of the weld joint to align at the center of the weld joint forming groove; welding the front face of the weld joint; using large weld current for weld penetration of a weld part at one step; and enabling a weld puddle to be cooled and solidified on the weld joint forming groove. Compared with a traditional double-face-weld method, the weld joint is formed by one step, weld quality is better, production efficiency is improved, and production cost is reduced.

Owner:CHONGQING POLYCOMP INT

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

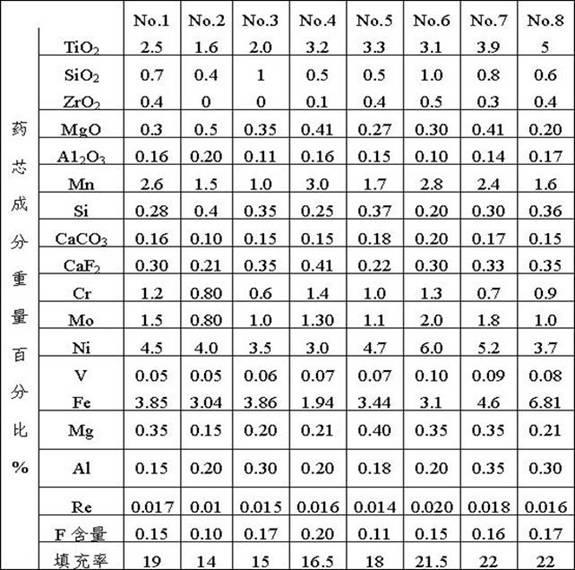

Flux-cored wire, preparation and application thereof

ActiveCN102161137AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaHigh intensityToughness

The invention discloses a flux-cored wire, which consists of a sheath and a flux core, wherein the sheath is made from low-carbon steel; the flux core is 14 to 22 percent based on the mass of the flux-cored wire; based on the total mass, the flux core comprises the following components in percentage by mass: 1.6 to 5.0 percent of TiO2, 0.4 to 1 percent of SiO2, 1.0 to 3.0 percent of Mn, 0.2 to 0.4 percent of Si, 0.20 to 0.50 percent of MgO, 0.10 to 0.20 percent of Al2O3, 0.10 to 0.20 percent of CaCO3, 0.21 to 0.41 percent of CaF2, 0.6 to 1.4 percent of Cr, 0.8 to 2.0 percent of Mo, 3 to 6 percent of Ni, 0.05 to 0.10 percent of V, 0.01 to 0.02 percent of Re, 0.15 to 0.35 percent of Mg, 0.15 to 0.35 percent of Al, and the balance of Fe. The flux-cored wire provided by the invention has the advantages of high intensity, toughness and crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Self-protecting flux-cored wire containing polyvinylidene resin

InactiveCN101279409AHigh and stable impact toughnessAdd a small proportionWelding/cutting media/materialsSoldering mediaSlagHazardous substance

The invention relates to a self-shielded flux-cored wire containing polyvinylidene fluoride resin, which comprises a shuck manufactured by adopting the home-made SPCC common mild-carbon steel strip. The invention is characterized in that flux core of the common mild-carbon steel strip consists of villaumite, carbonate, oxide, Manganese (Mn), Silicon (Si), Aluminum (Al), Magnesium (Mg), Nickel (Ni) and ferrous powder jointly; wherein, the components of the flux core include 20 percent to 45 percent of the villaumite, 4 percent to 13 percent of the carbonate, 4 percent to 15 percent of the oxide, 1 percent to 5 percent of Mn, 1 percent to 3 percent of Si, 3 percent to 8 percent of Al, 3 percent to 7 percent of Mg, 0 percent to 5 percent of Ni and ferrous powder serving as the rest. The invention has the advantages that the defects that the pore sensitivity of the self-shielded flux-cored wire is high and the impact toughness of the deposited metal is not excellent; when the multi-layer welding is carried out, the surface blowhole is not generated, the complete slag coverage is achieved, the slag can be easily detached, the weld can be formed well and the impact toughness of the deposited metal is high and stable; the concentration of the hazardous substances in the welding fume is lowered and the invention is beneficial to the health of the welder.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

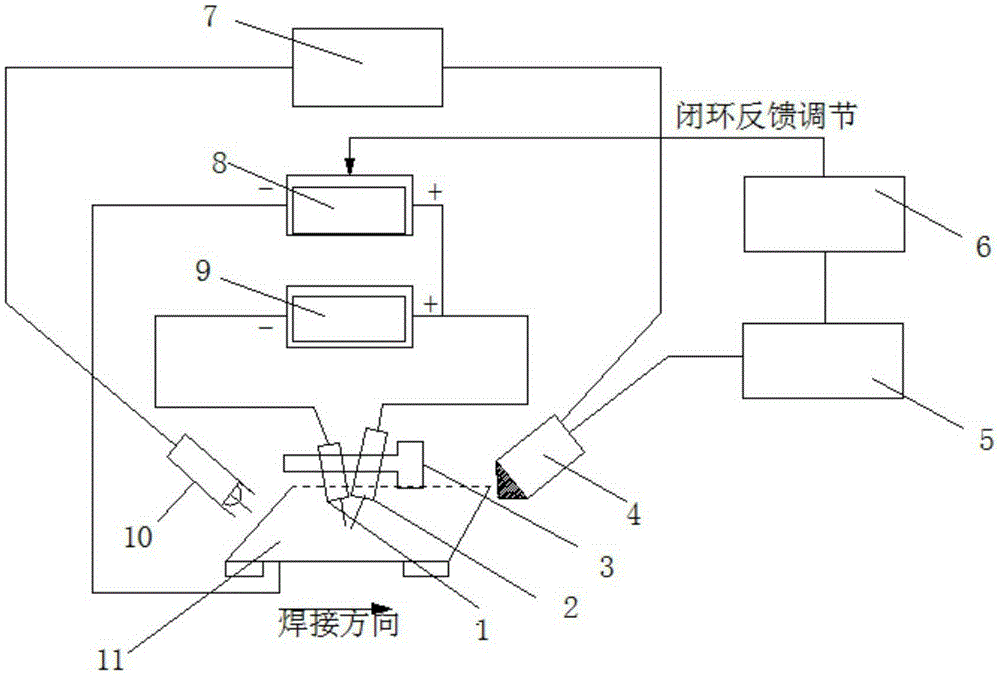

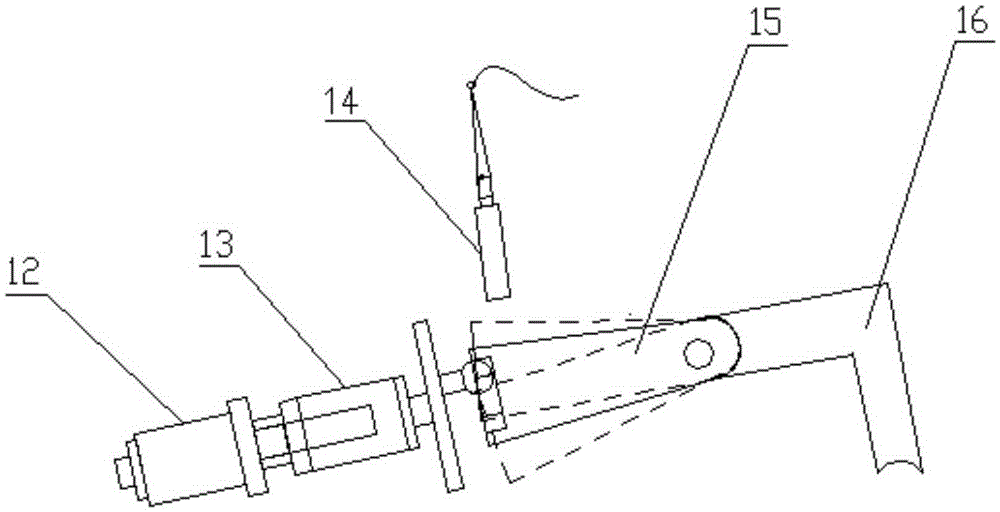

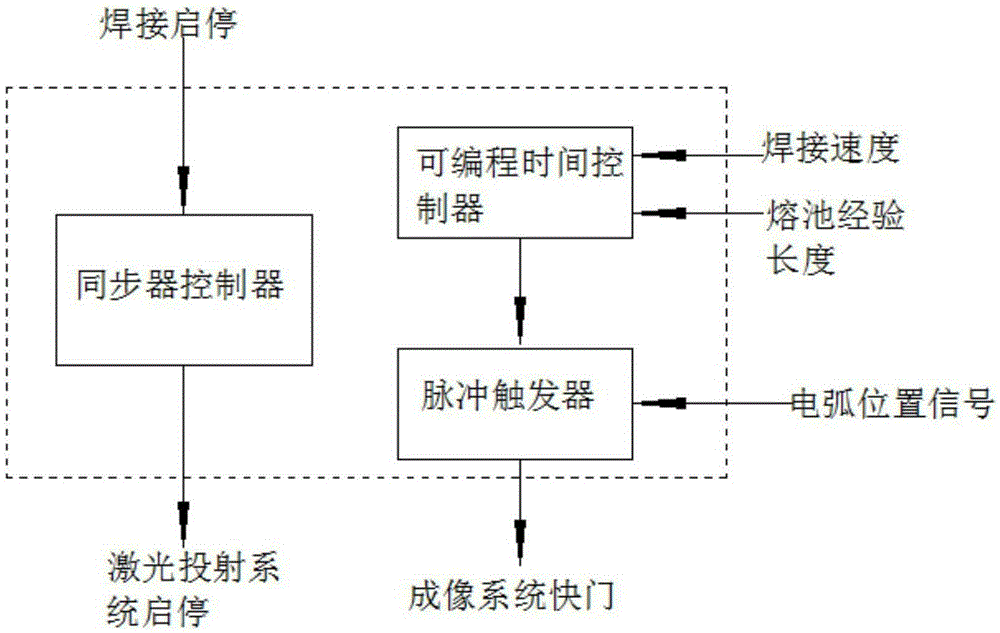

Real-time detecting method and device for surface topography of swing arc MAG welding molten pool

InactiveCN105290576AReduce distractionsImprove collection qualityArc welding apparatusUsing optical meansEngineeringTopography

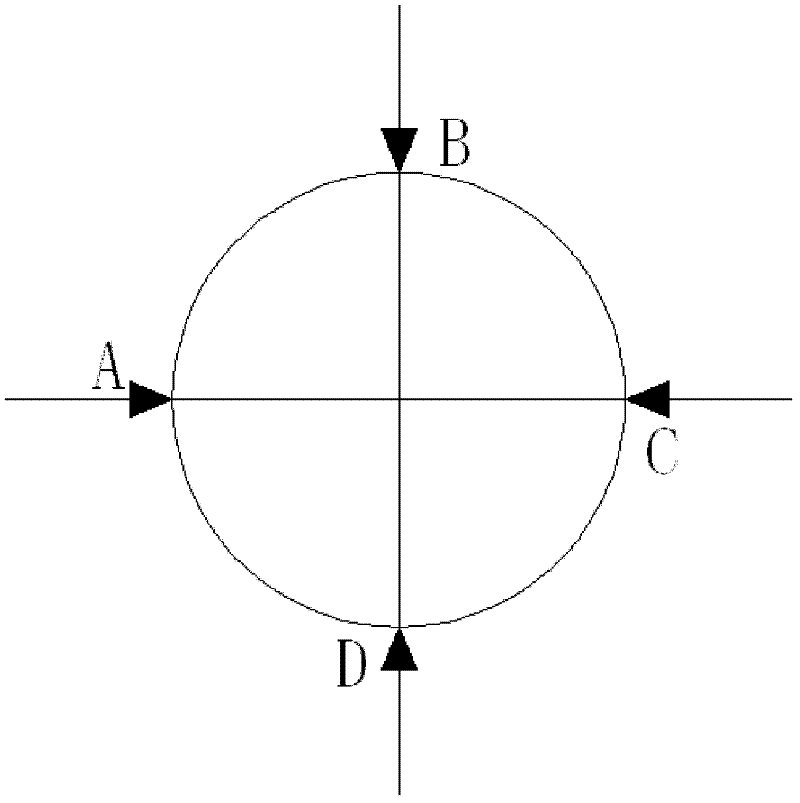

The invention discloses a real-time detecting method and a device for a surface topography of a swing arc MAG welding molten pool. The device mainly comprises a double-gun swing positioner, a laser projecting system, an imaging system, a molten pool detecting control system, an image information processor and a molten pool control system. The double-gun swing positioner is used for controlling synchronous swing of a MAG welding gun and a TIG welding gun and positioning an arc position. The method is characterized in that the TIG welding gun is placed beside the MAG welding gun, and a stable coupling arc is formed by the TIG welding gun and the MAG welding gun to provide excellent arc light environment for the detection of the molten pool. In the welding process, when the TIG welding gun and the MAG welding gun swing to the most left side or the most right side of a welding lane (the interference of the arc on the molten pool is the lowest), an arc positioning device in the double-gun swing positioner emits the pulse to the molten pool detecting control system to control the imaging system to acquire images so as to obtain the topography of the swing molten pool. On the aspect of signal source, the device and the method effectively reduce such interference factors as splashing and smoke in the MAG welding, optimize the molten pool detecting method, and promote the molten pool control technology.

Owner:XIANGTAN UNIV

Vacuum electron beam welding method for special-shaped thin-walled metal plate welding structure cabin

InactiveCN106392294AAvoid cutting effectReduced solder assembly requirementsElectron beam welding apparatusPower flowSlag

The invention belongs to a vacuum electron beam welding method aiming at a special-shaped thin-walled metal plate welding structure cabin. The vacuum electron beam welding method comprises the following steps: firstly, preparation before welding; secondly, welding and assembling; thirdly, electron beam welding; fourthly, quality inspection after welding. The vacuum electron beam welding method has the advantages that: chemical cleaning and mechanical cleaning are performed before welding, so that the defects, such as air holes and slag inclusion, are formed by welding seams because of oil contamination and oxidant on the surface of a workpiece can be effectively avoided; pre-welding is performed by using a focalized small current electron beam, so that the welding and assembling requirements of the cabin can be reduced, and an electron beam cutting effect caused by an overlarge butt gap can be avoided; meanwhile, a welding seam can also be preheated, and the possibility of the air holes and cracks of a joint can be reduced; the formation of a welding seam surface can be improved by performing typical welding by using a focalized large current electron beam, so that one-time welding formation can be realized, and the welding deformation caused by modification welding is avoided. The formation of the welding seam can be improved and the possibility of air holes of the joint can be reduced by using scanning electron beam current.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Self-protection flux-cored wire for underwater wet-method welding

ActiveCN104057214AEasy arc startGood mechanical propertiesWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

Method for manufacturing composite straightening roll by overlaying

ActiveCN102430839ASurfacing less smoke and dustEasy to remove slagArc welding apparatusWelding/cutting media/materialsMetal workingMaterials science

The invention discloses a method for manufacturing a composite straightening roll by overlaying, comprising the steps of: at first, manufacturing a straightening roller body tempered by 42 CrMo; then overlaying a transitional layer which is 2-4mm thick on the straightening roller body; and then manufacturing a deposited metal working layer on the transitional layer through submerged arc overlaying. The roll surface of the straightening roll manufactured by the method for manufacturing the composite straightening roll by overlaying has the advantages of corrosion resistance, high temperature resistance, abrasion resistance and steel adhering resistance.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Method for decreasing laser welding pores

InactiveCN107186339AStable working conditionGood effectLaser beam welding apparatusPorosityButt joint

The invention provides a method for decreasing laser welding pores, and relates to the technical field of laser welding. The method for decreasing the laser welding pores comprises the steps of (1) placing two metal to-be-welded parts in a horizontal butt joint manner to form a to-be-welded workpiece; (2) clamping and fixing the two ends of the metal to-be-welded workpiece; (3) preheating the metal to-be-welded workpiece through laser beams; and (4) starting a control switch, introducing a protective gas, igniting electric arcs for 1 s to 2 s, emitting laser, combining laser emitted by a laser A and a laser B into one laser beam, and moving a high pressure air rifle which injects acetone together with the laser A and the laser B. According to the method, a device utilized in the method comprises the two lasers, firstly, the material surface is subjected to preheating treatment, an oxide film generated on the surface is scrubbed through acetone, and then, the two lasers emit the two laser beams to melt the material for welding, so that metal weld joint porosity is obviously decreased, and porosity of 8% to 10% during laser welding is decreased to zero.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

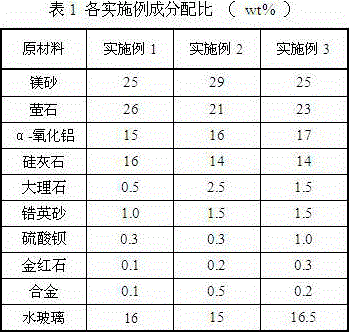

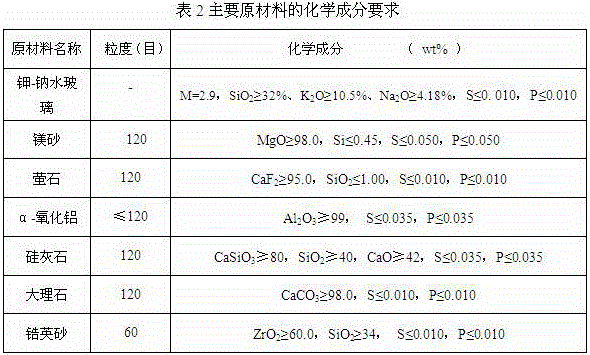

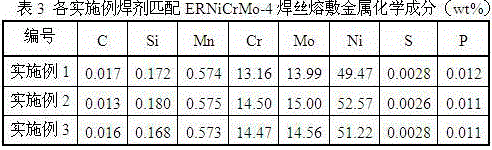

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Cored welding strip applied in resurfacing welding and preparation method thereof

InactiveCN101596653AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaSteel beltDrug powder

The invention discloses a novel resurfacing welding cored welding strip which consists of a steel tube circled by steel strips and drug powder wrapped in the steel tube, the steel strips comprises an upper steel strip and a lower steel strip which can be purchased in the market. The shape of the steel tube circled by steel strips is that the longitudinal cross section is long flat form or rectangle-like shape, the longitudinal length is determined at will, and the steel tube can be cut out at will or winded into a tray according to requirements. The transverse edges of the upper steel strip and the lower steel strip are connected at the upper steel strip side in a related joint form, and the drug powder is filled in the steel tube circled by the steel strips evenly with the filling rate being 20-80%. According to the different types of resurfacing metals, the content of alloy element in the resurfacing welding cored welding strip is different. The cored welding strip has simple production equipment and technique, and low production cost, thus overcoming the defect that alloy welding filament used for filament resurfacing welding is difficult to produce and the problems of large investment on production equipment, high production cost and expensive price in cored welding filament production.

Owner:SHANDONG UNIV

Welding process method of brass H62

ActiveCN102699496AReduce evaporationImprove welding qualityArc welding apparatusWelding/soldering/cutting articlesSurface layerEngineering

The invention discloses a welding process method of brass H62, which uses a welding wire Scu6810A and a soldering flux CJ301, and uses a manual argon tungsten-arc welding method. The welding process method of the brass H62 comprises the following steps of: firstly, machining a groove of a welding piece, wherein a groove angle is 32.5-37.5 degrees; controlling a truncated edge within a range of 0-1.5 mm; cleaning the welding surface of a welding piece and a welding wire; coating soldering flux paste of the soldering flux CJ301 on the groove of the clean welding piece and an area within a 30-mm range near the groove, as well as the surface of the welding wire; assembling the welding piece with an assembly clearance of 1.5-3.0 mm; pre-heating the welding piece to 200-300 DEG C before welding; welding a welding bead at a bottom layer by using a high-frequency arc striking technology; cleaning the surface of the welding bead at the bottom layer after the welding bead at the bottom layer is welded; coating the CJ301 soldering flux paste on the surface of the welding bead at the bottom layer; welding a filling layer, cleaning the surface of the filling layer after the filling layer is welded, and coating the CJ301 soldering flux paste after cleaning the surface of the filling layer; welding a cover surface layer; welding a weld joint and then pickling, and washing the weld joint with water; and drying with hot air.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com