Large tank singe-face-weld double-face-forming method and weld joint forming pad

A single-sided welding and double-sided forming technology, which is applied in the field of welded seam forming gaskets, can solve the problems of high technical level requirements for workers, low weld quality, improper operation, etc., and achieve reduced production costs, good welding quality, and weld seams. Fair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

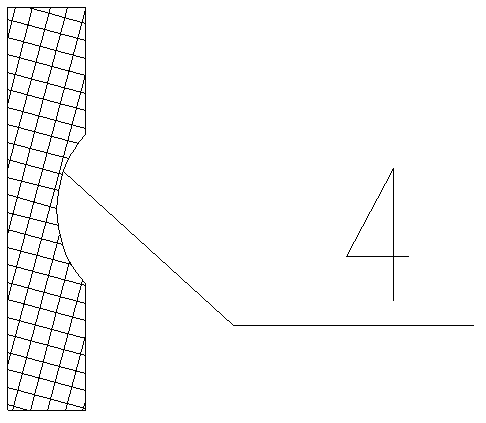

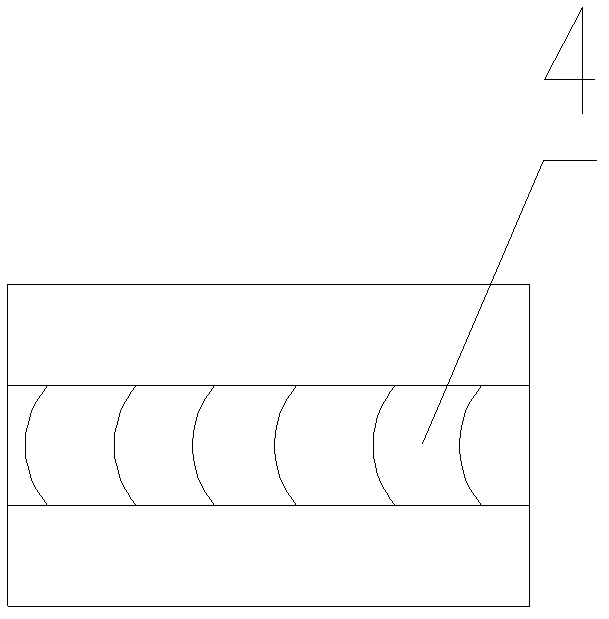

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] A double-sided forming method for single-sided welding of a large tank body, comprising the following steps: 1) firstly, a weld forming liner is arranged on the back of the weld of a welded piece, and the weld forming liner has a welding liner suitable for the shape of the weld. 2) Then weld the front side of the weld, using a larger welding current, The welding piece is penetrated once, so that the molten pool is cooled and solidified on the weld liner forming groove, and the weld is formed at one time; the present invention uses a relatively large welding current, which means that the current intensity is above 120A.

[0024] The method of the present invention is especially suitable for the large-scale storage tank body used in the glass fiber production industry, which is generally formed by rolling and welding 8-20 mm carbon steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com