Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200 results about "Superfinishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superfinishing, also known as micromachining, microfinishing, and short-stroke honing, is a metalworking process that improves surface finish and workpiece geometry. This is achieved by removing just the thin amorphous surface layer left by the last process with an abrasive stone or tape; this layer is usually about 1 μm in magnitude. Superfinishing, unlike polishing which produces a mirror finish, creates a cross-hatch pattern on the workpiece.

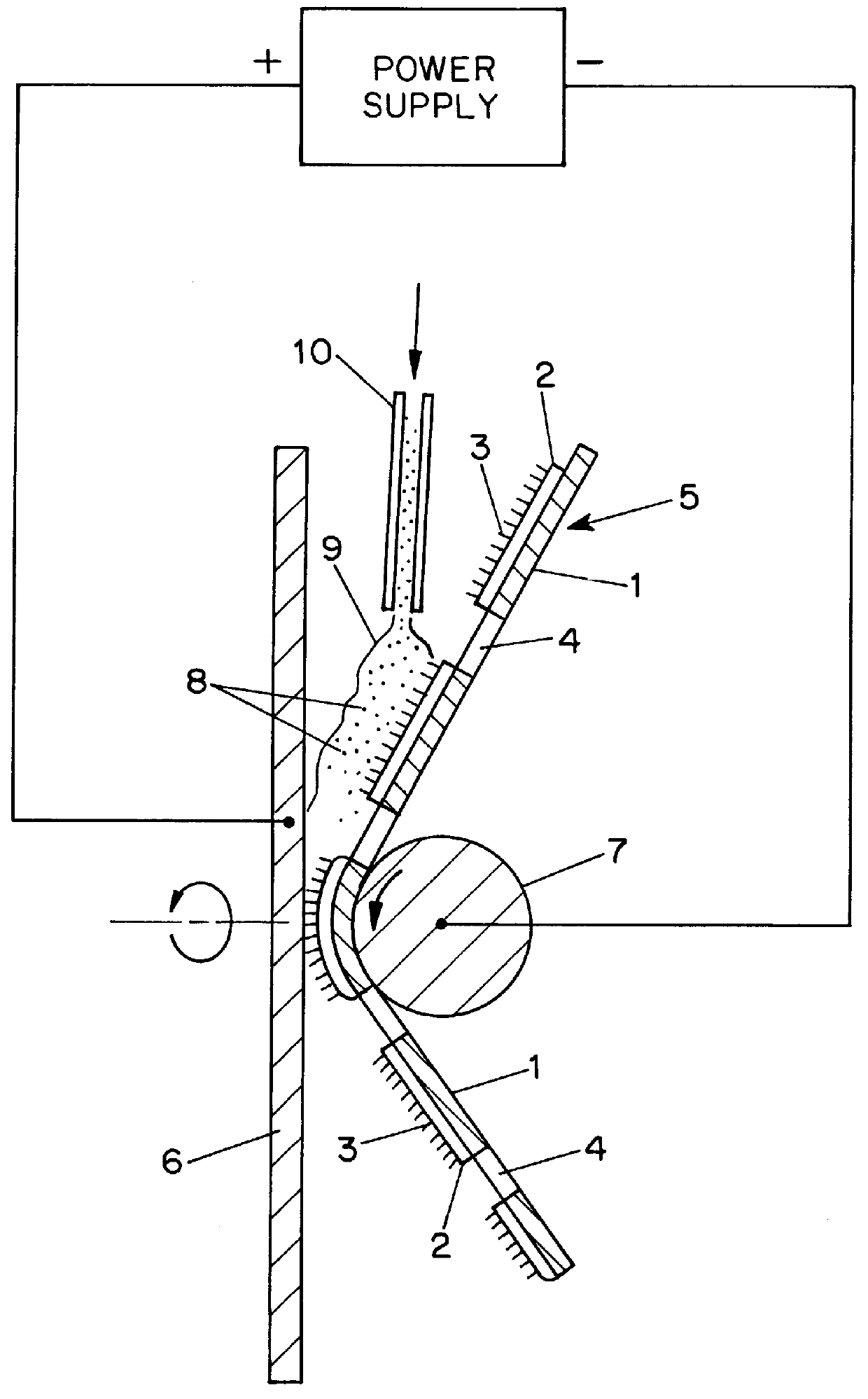

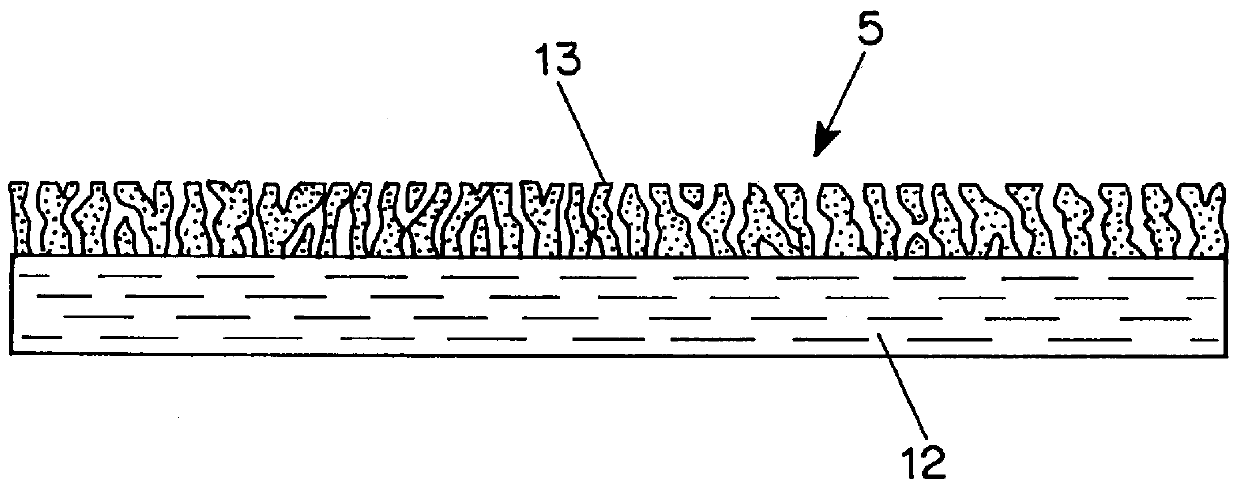

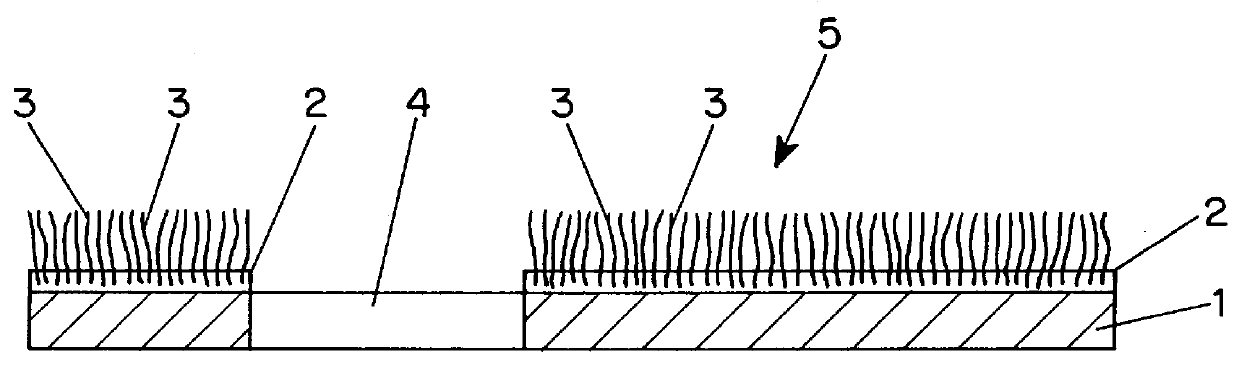

Combination electrolytic polishing and abrasive super-finishing method

InactiveUS6074284AHigh surface finishEfficient supplyBelt grinding machinesAbrasion apparatusFiberElectrolytic agent

An abrasive super-finishing method for workpieces, such as metallic thin-film magnetic discs, employs a polishing / texturing material having a backing, such as synthetic resin film or woven material or non-woven cloth, and a layer which can hold abrasive grains on the backing, such as flocked fibre or a porous polymer foam, on one surface of the backing. An electrolytic solution in which abrasive grains are suspended is supplied to the polishing / texturing material to conduct polishing or texturing of the workpiece surfaces. The workpiece is connected to an anode and a pressure roller or a cathode bar is connected to a cathode. A voltage is applied between the workpiece and the pressure roller or cathode bar to conduct simultaneously electrolytic polishing and abrasive polishing / texturing.

Owner:UNIQUE TECH INT PTE

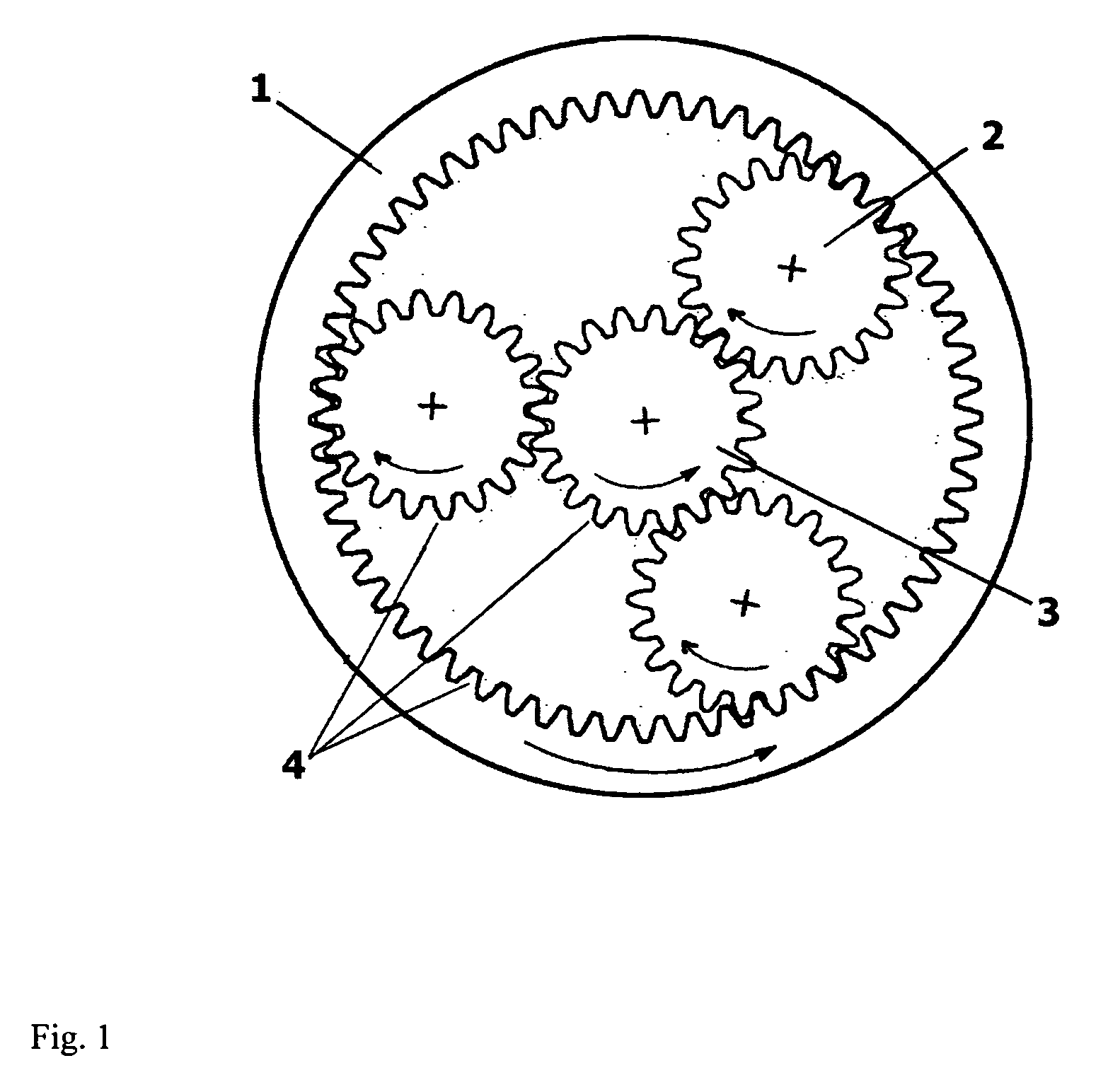

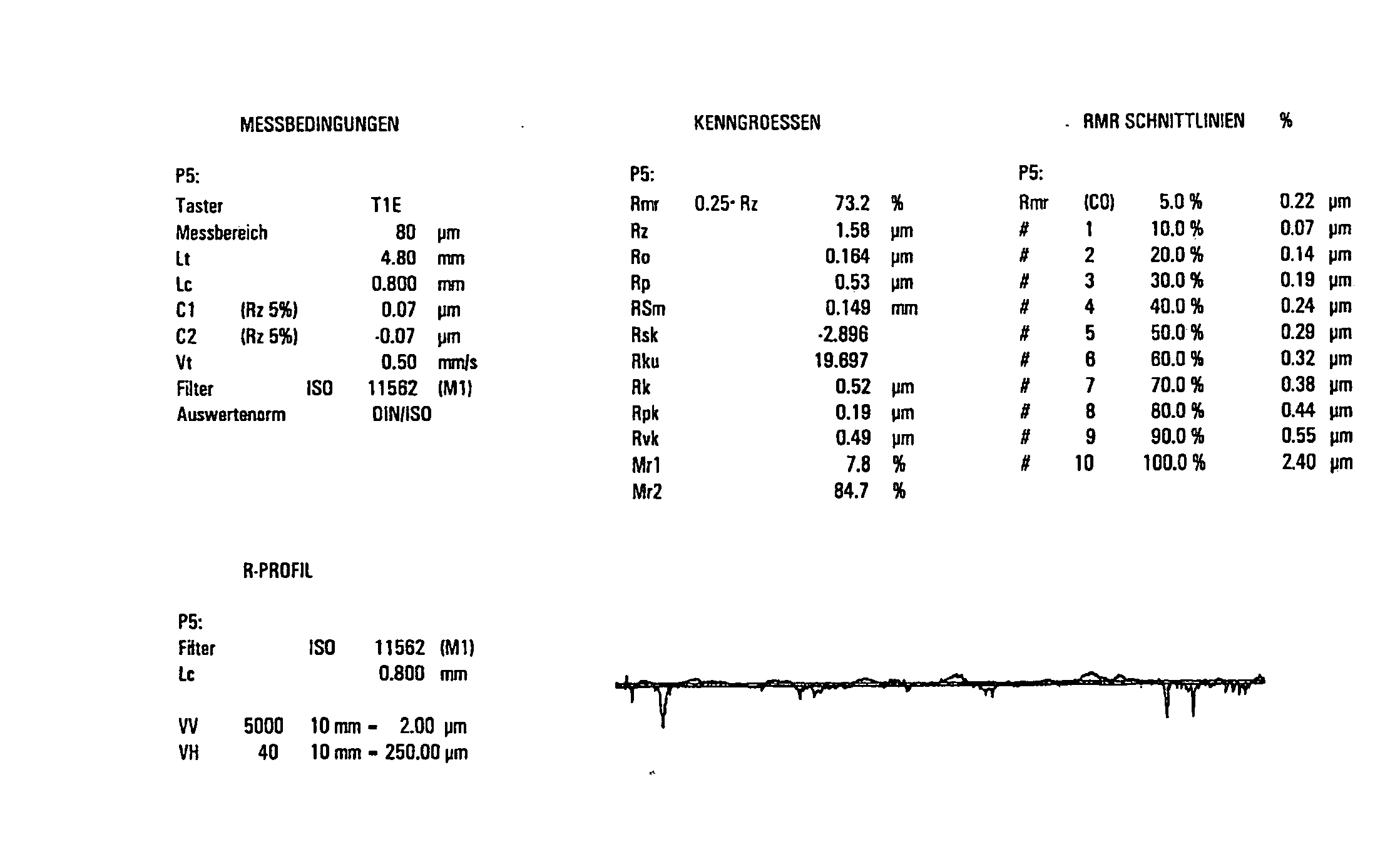

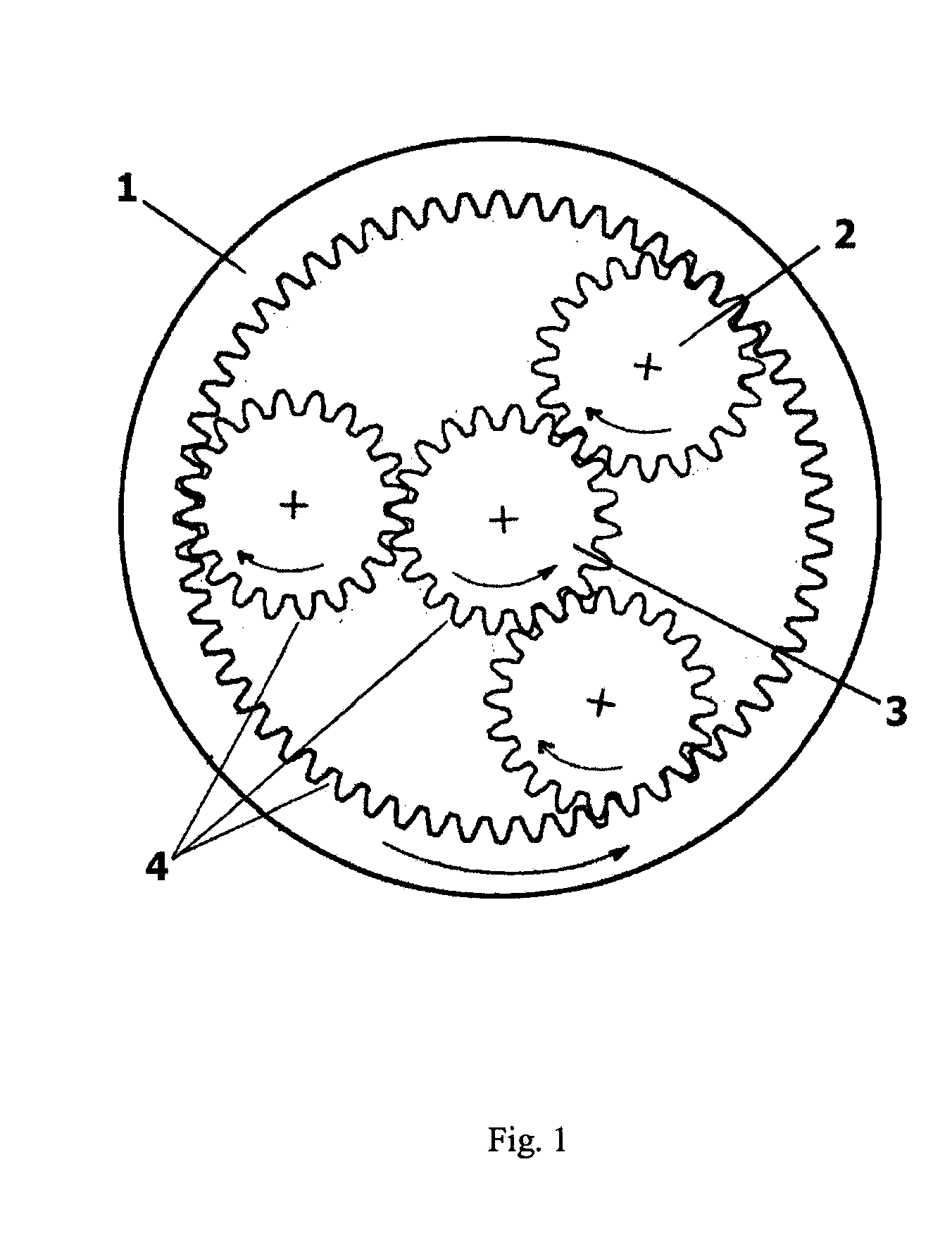

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

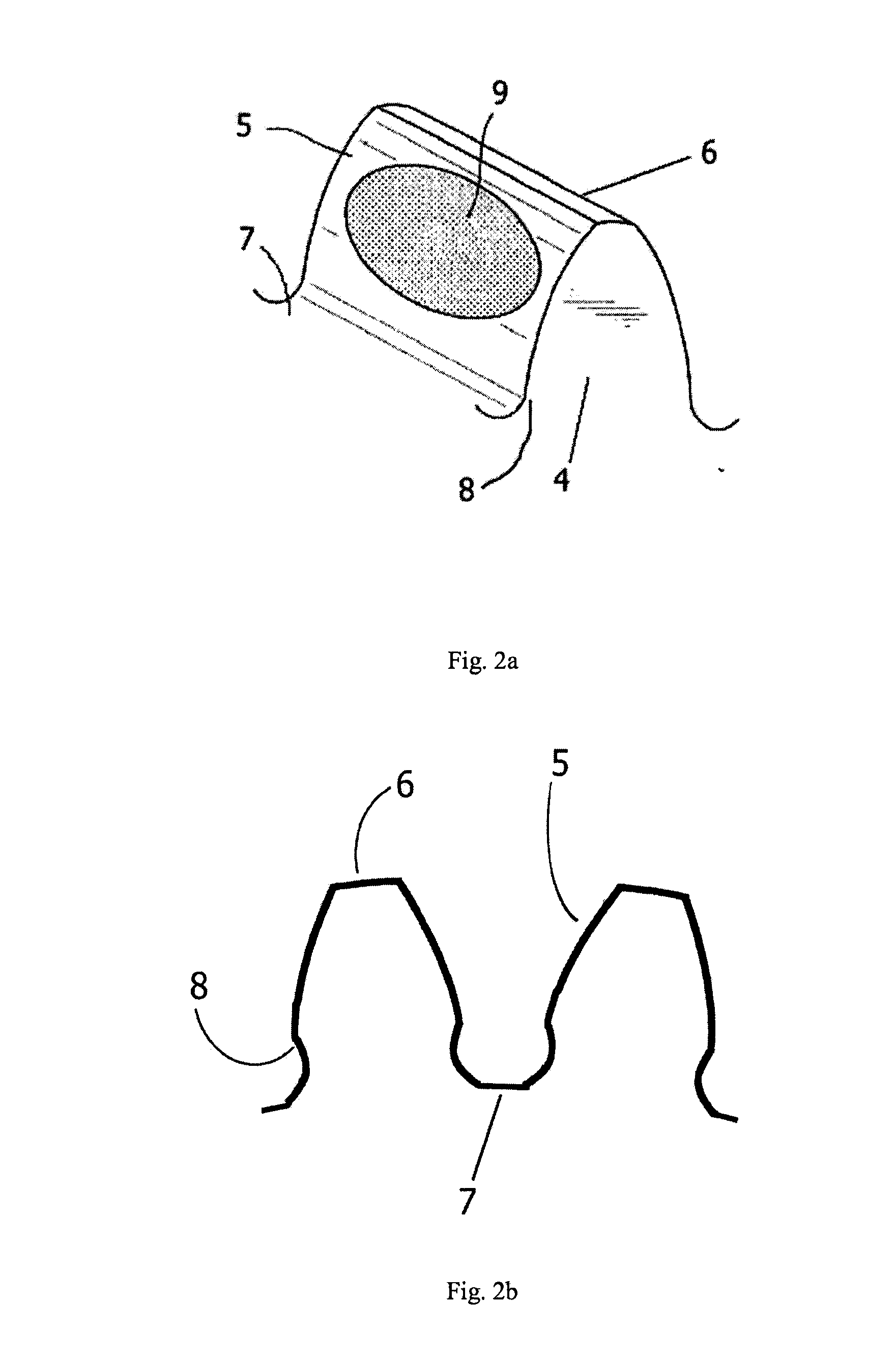

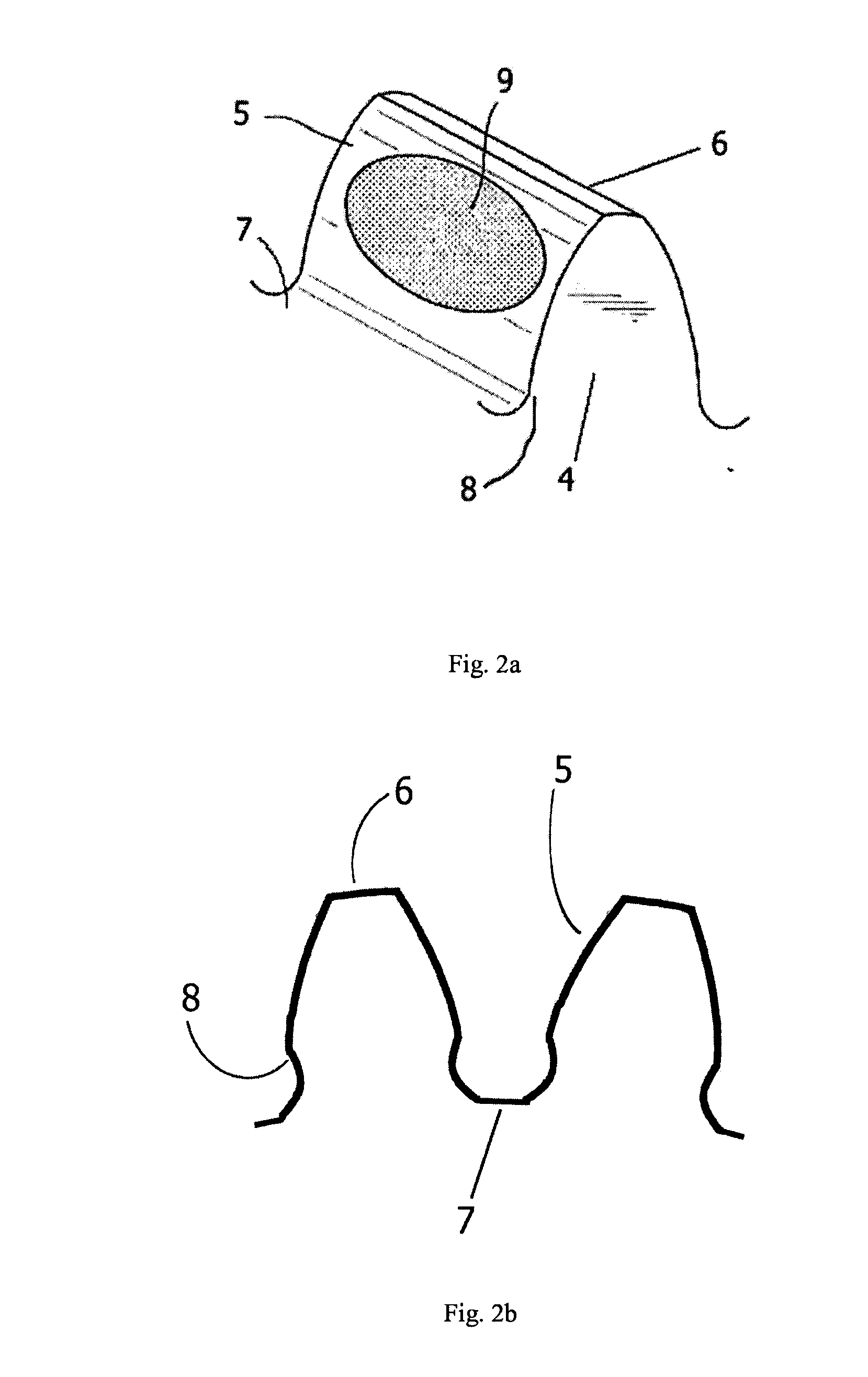

Cutting tool for high-quality high-efficiency machining and cutting method using the same

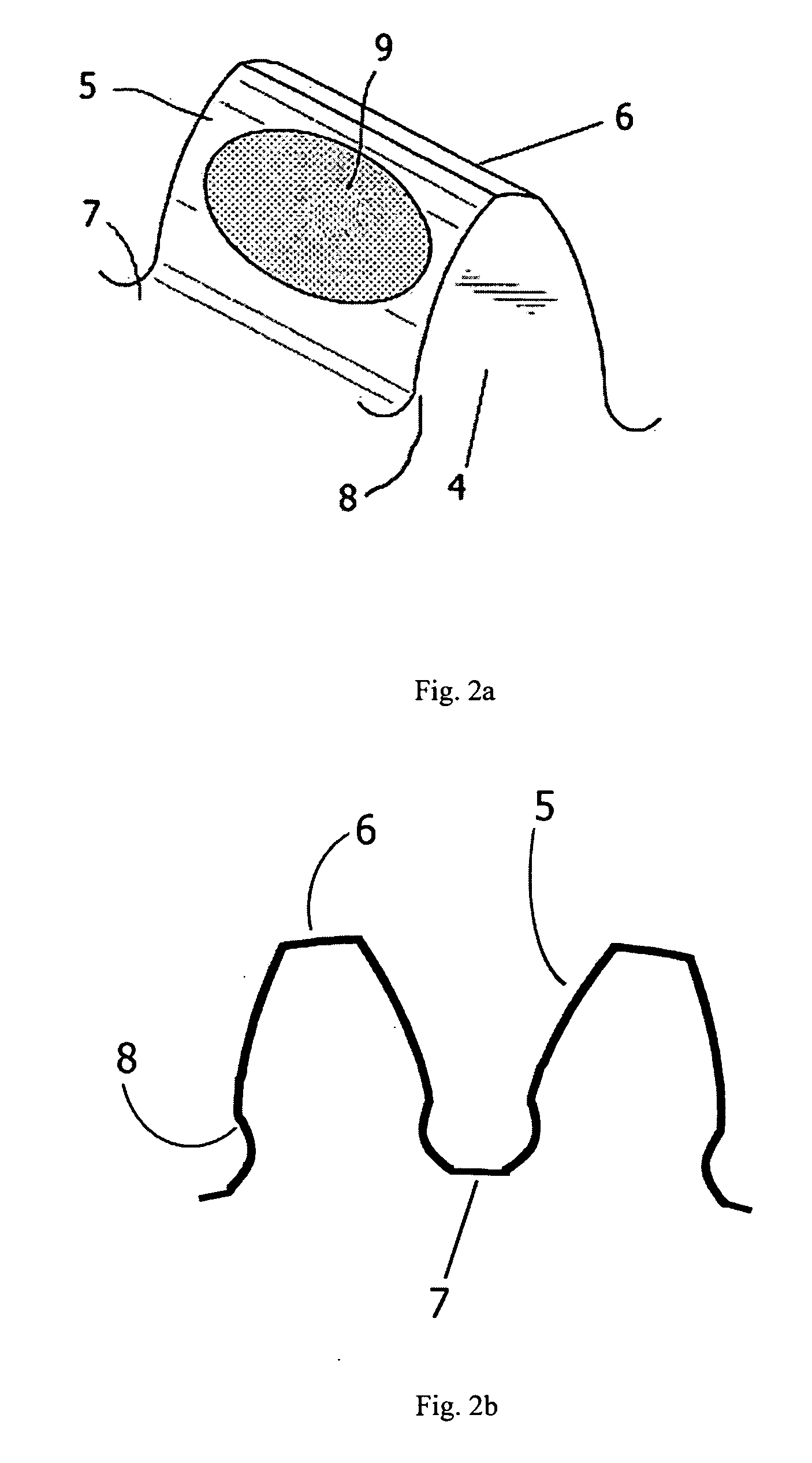

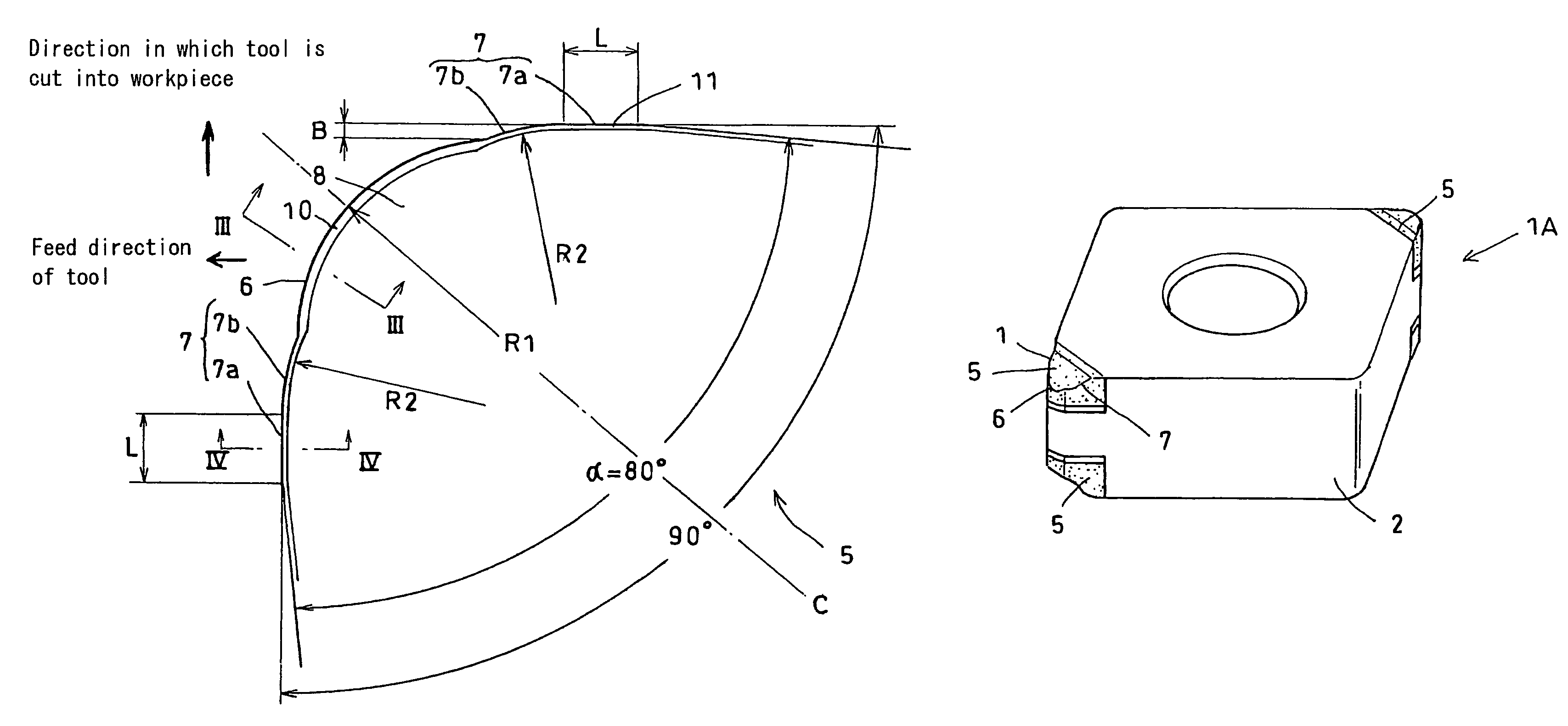

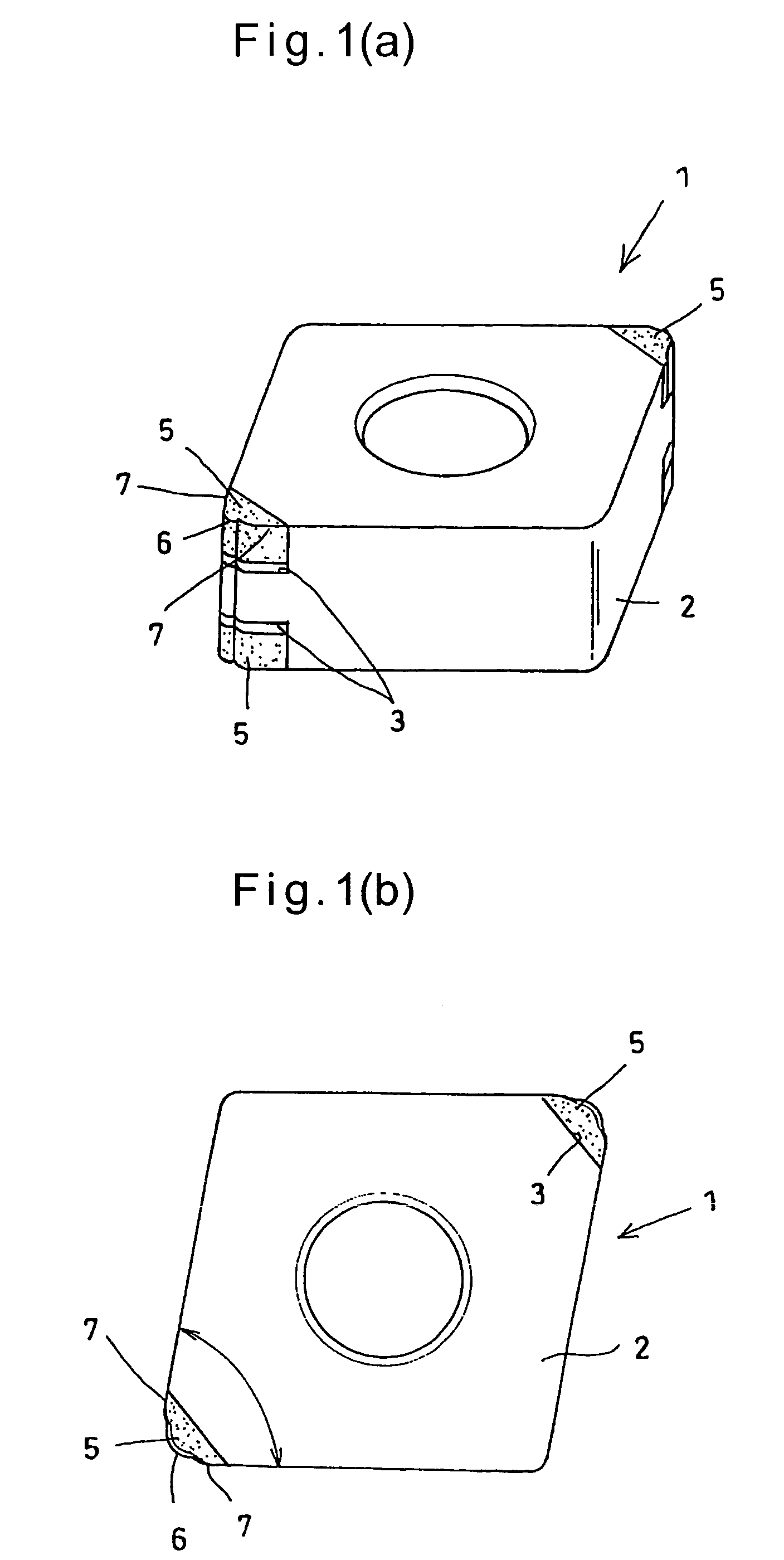

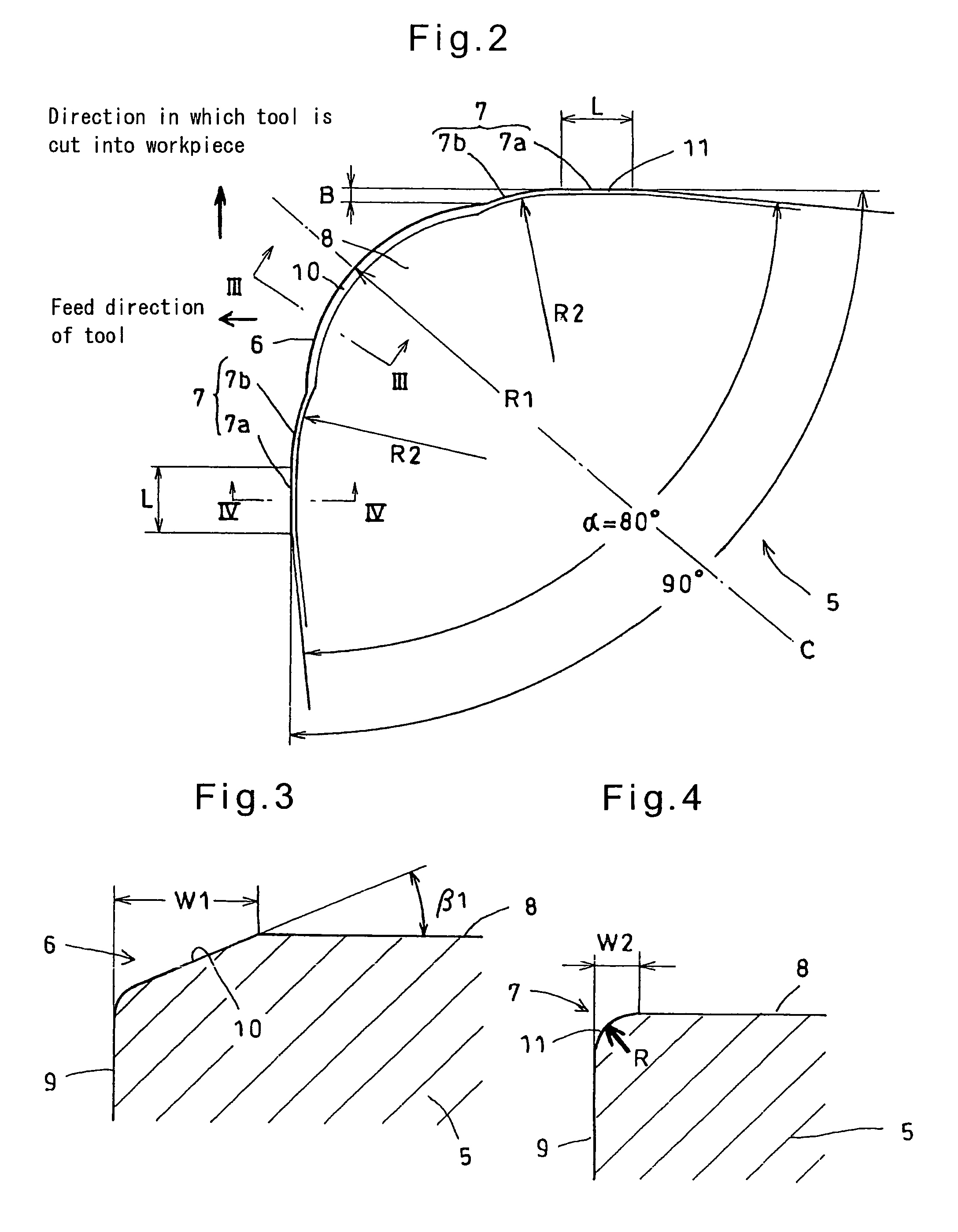

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

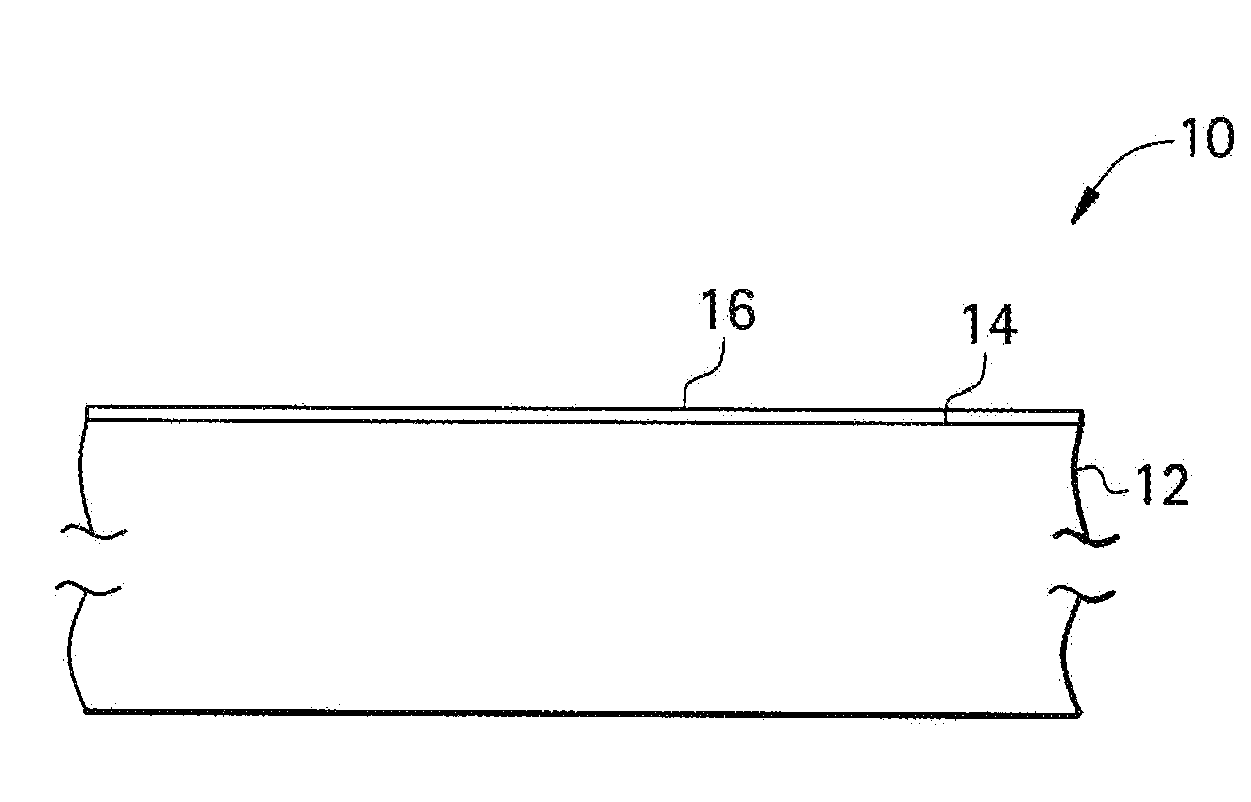

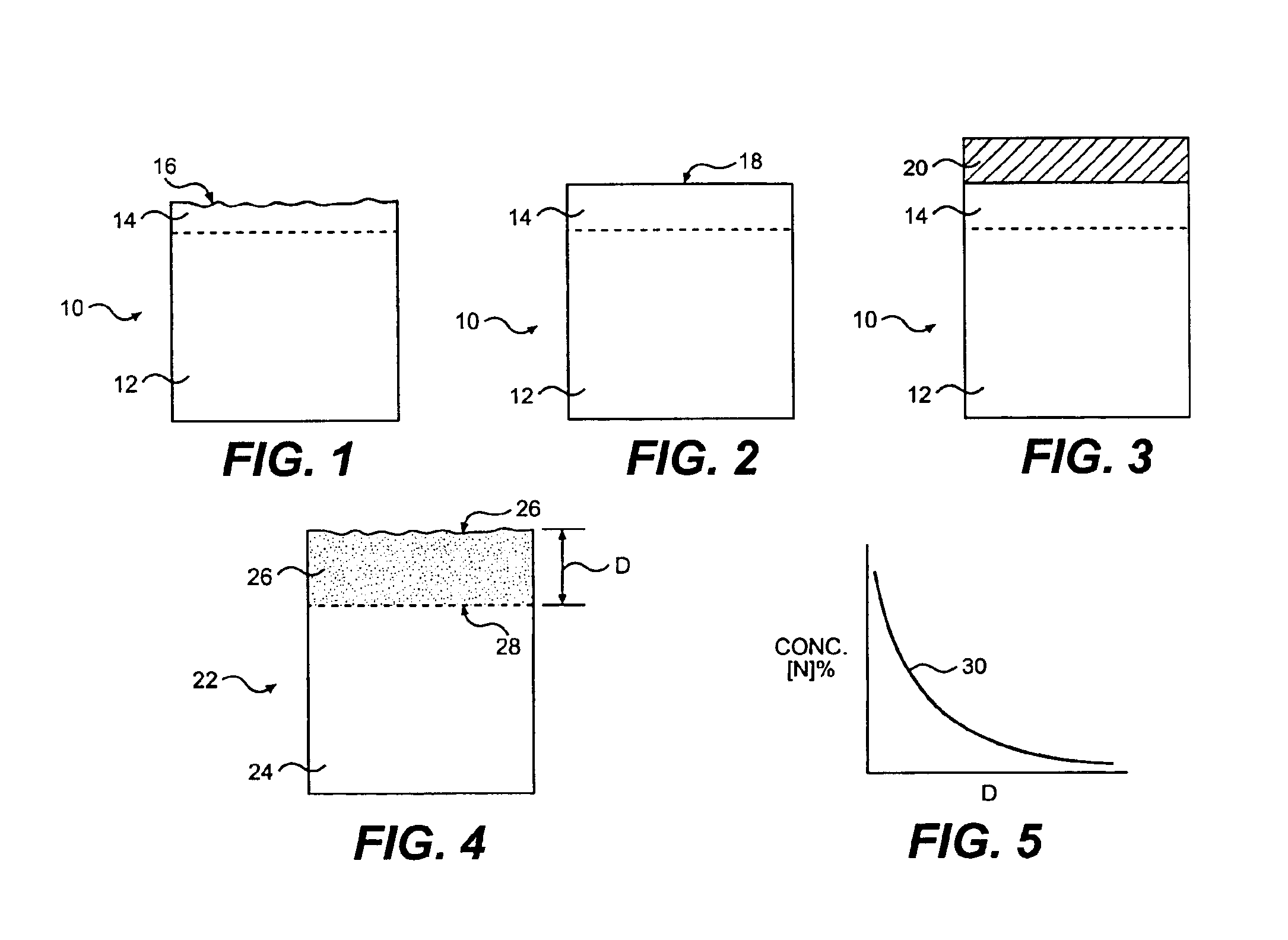

Surface Treatments for Turbine Components to Reduce Particle Accumulation During Use Thereof

InactiveUS20100086397A1Preventing micropittingEasy to understandPropellersVacuum evaporation coatingElectron beam physical vapor depositionSputtering

A turbine engine component includes at least one treated surface wherein the treated surface has a surface roughness (Ra) of less than 12 microinches; and a hard coating disposed on the superfinished surface, wherein the hard coating is a nitride and / or a carbide material at a thickness of less than 50 microns formed using electron beam physical vapor deposition, cathodic arc evaporation, or magnetron sputtering. disclosed are methods for substantially preventing micropitting on a surface of a turbine engine component.

Owner:GENERAL ELECTRIC CO

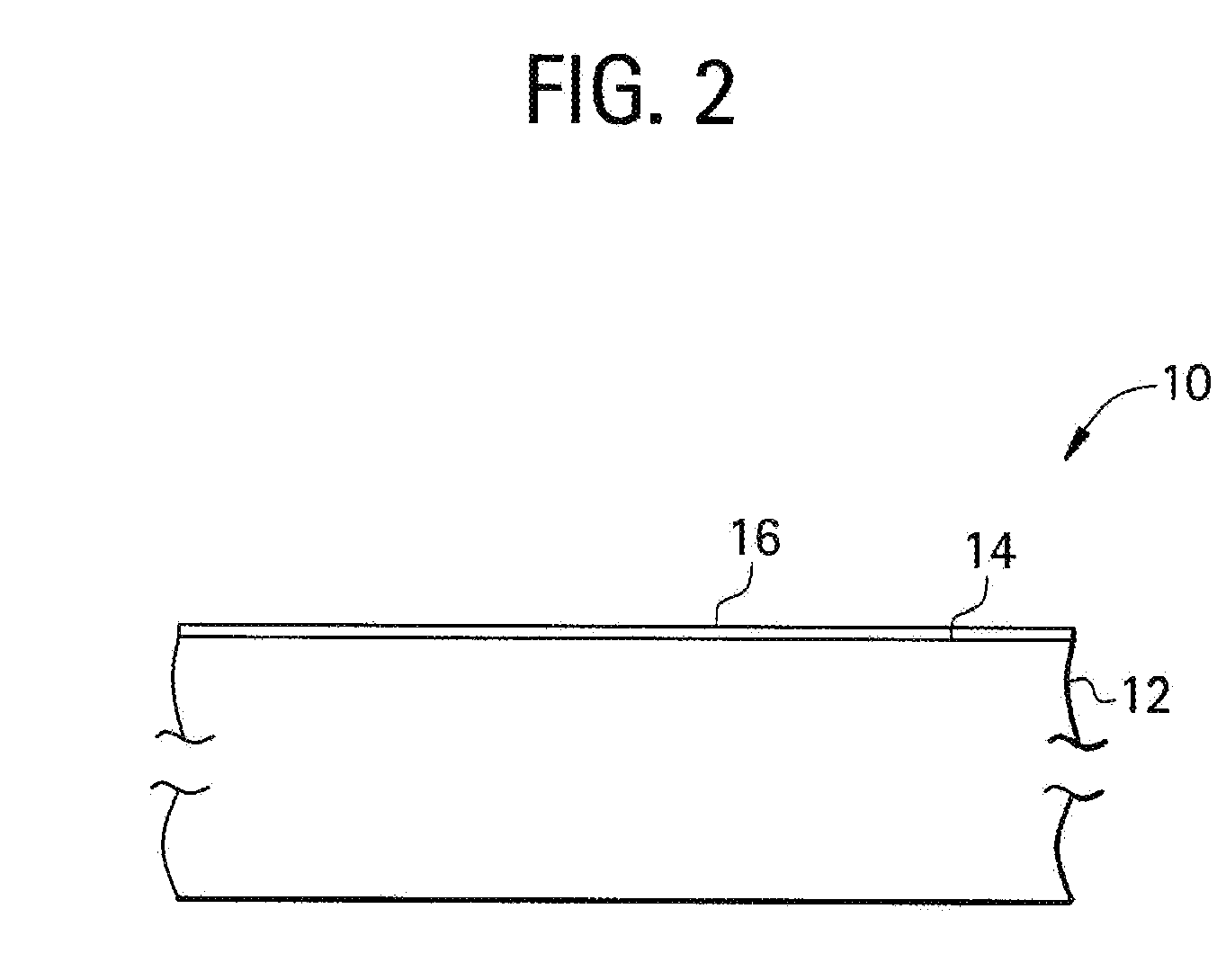

Surface process involving isotropic superfinishing

ActiveUS6881498B1Poor adhesionWear resistance be provideSoldering apparatusVacuum evaporation coatingSurface finishingHardness

A surface processing method and power transmission component includes refining a surface region of a metal from a first roughness to a second roughness less than the first roughness. A solid lubricous coating or a hard coating is then deposited on the surface region. The metal has a surface hardness above 50 Rc to reduce the risk that the metal will deform under the coating and leave the coating unsupported. The surface region of the metal may be transformed into a nitrogen-containing compound or solid solution surface region before the surface refining step and deposition of the coating.

Owner:SIKORSKY AIRCRAFT

Manufacturing method of precise tapered roller specially for high speed train unit

InactiveCN103710509AAvoid bumpingEffectively control batch diameter variationBearing componentsCold treatmentTempering

The invention discloses a manufacturing method of a precise tapered roller specially for a high speed train unit. The manufacturing method comprises the processes of high-speed multistation cold-forging molding, hot acid pickling, stress-relieving annealing, pre-cleaning, quenching treatment, low-temperature cold treatment, first tempering, grinding, magnetic powder inspection, superfinishing, cleaning, finished product appearance inspection, size sorting, spot checking for surface quality, oiling, counting and packaging. The high-speed multistation cold-forging molding process is adopted to realize direct heat treatment on a forged piece, the incomplete quenching process is adopted to carry out hot quenching treatment under the protection of controllable atmosphere, low-temperature cold treatment is carried out immediately after quenching treatment, after the temperature of a steel ball after cold treatment is restored to be at room temperature, the first tempering treatment is carried out, a ball grinding cardinal plane during grinding is in a non-magnetic mode, and all related processes of grinding processing after quenching can be carried out one time. By adopting the manufacturing method, the service life of a roller can be prolonged, the material consumption and the production cost are reduced, the quality of a roller blank is improved, the processing flows of the roller are reduced and the production efficiency is improved.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Method for superfinishing of metal part with thin-wall large curved surface

ActiveCN103600284AHigh precisionIncrease productivityPolishing machinesGrinding feed controlNumerical controlSurface roughness

The invention discloses a method for superfinishing of a metal part with a thin-wall large curved surface. The method comprises the steps of numerical control processing, preliminary detection, primary polishing, primary detection, secondary polishing and secondary detection and the like. The part does not need to be clamped in the superfinishing process, and deformation caused by the clamping is avoided; and simultaneously due to the fact that the part is not subjected to cutter cutting, curved surface deformation caused by stress in the processing is avoided. Superfinishing is performed on the metal part with the thin-wall large curved surface through the processing steps of polishing and detection and the like, and the requirement of the surface profile within 0.015 and the requirement of surface roughness of below Ra0.2 are met.

Owner:HEBEI HUABEI DIESEL ENGINE

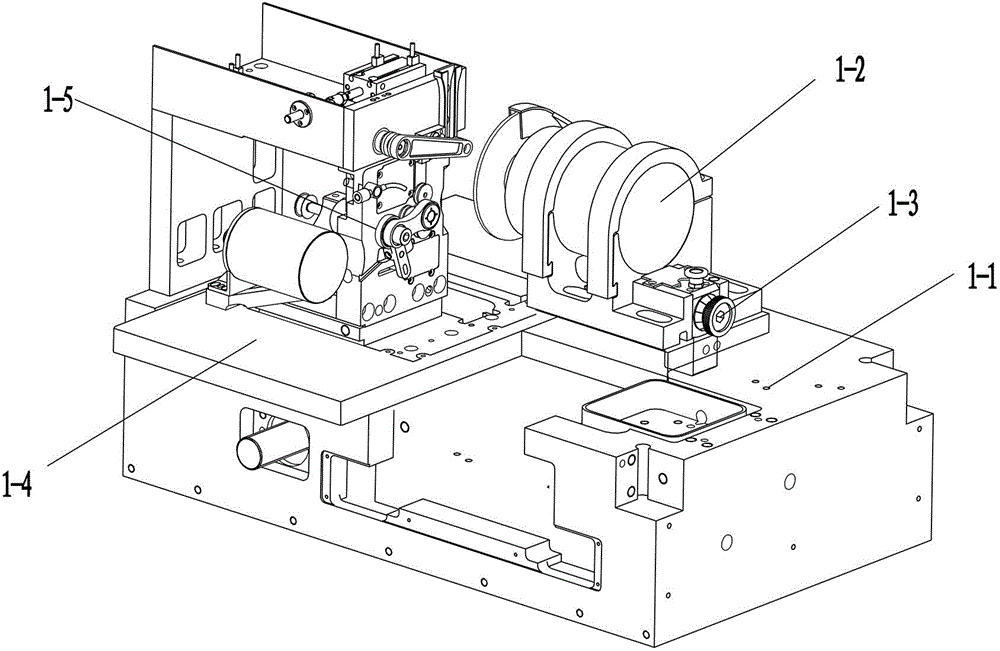

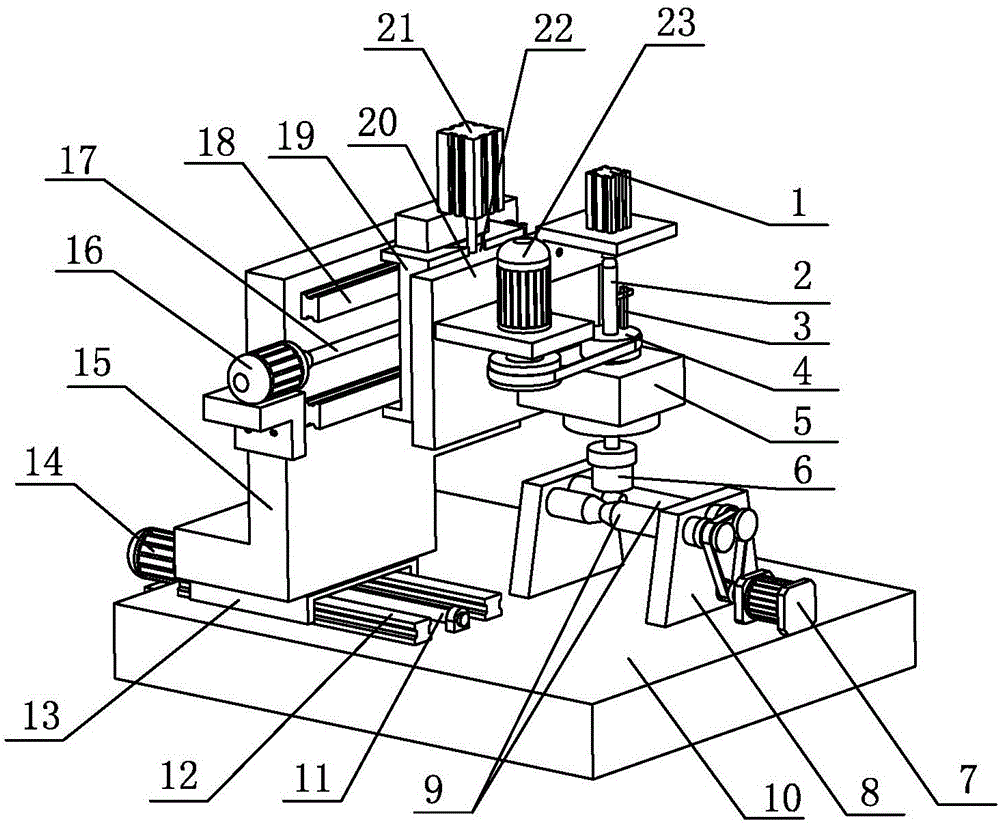

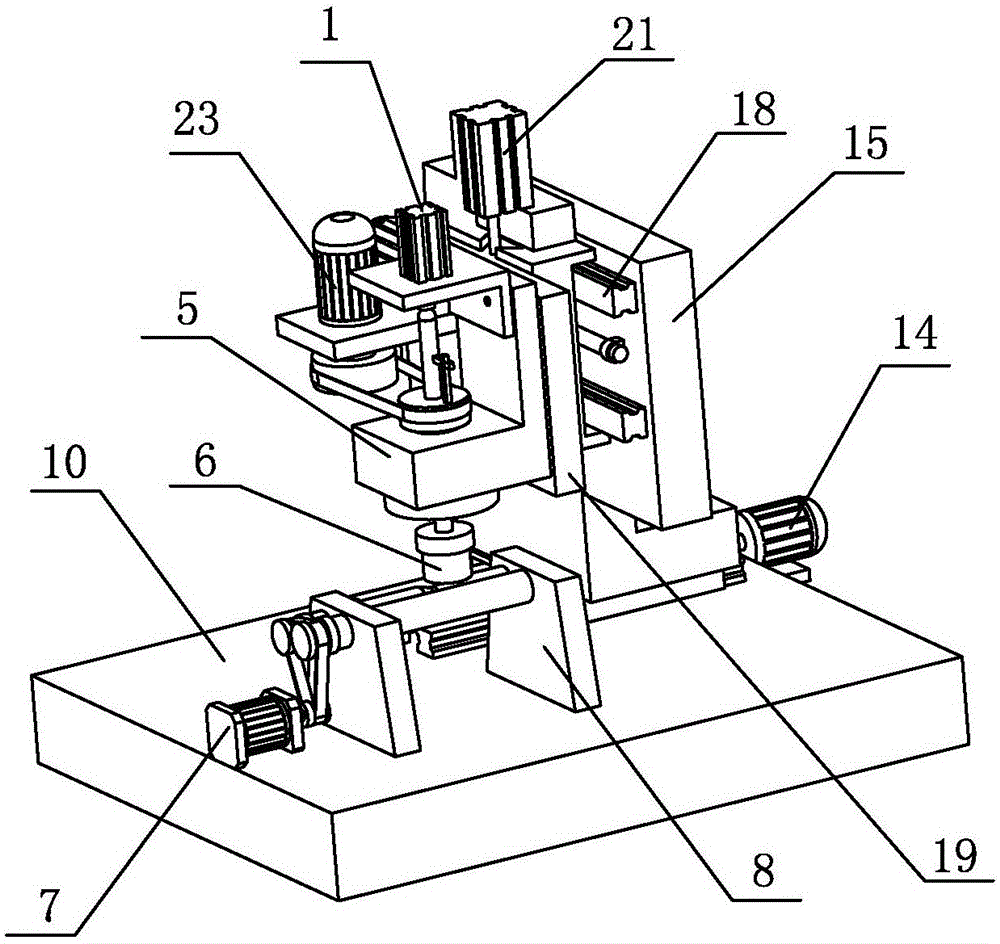

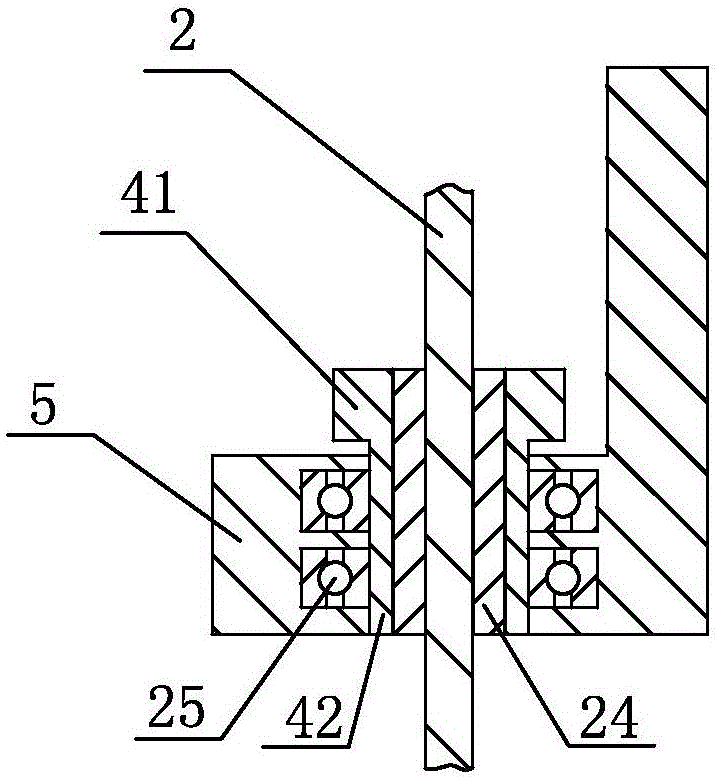

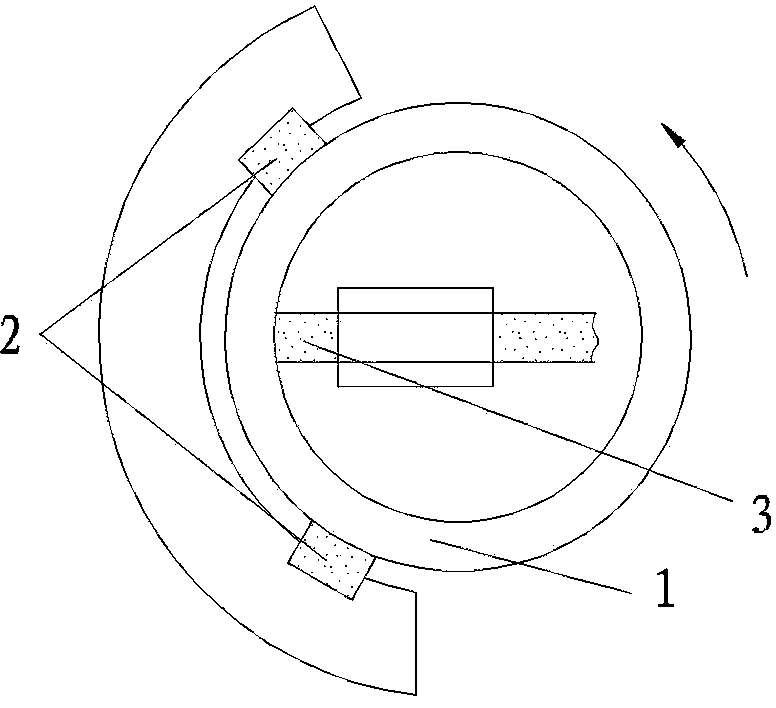

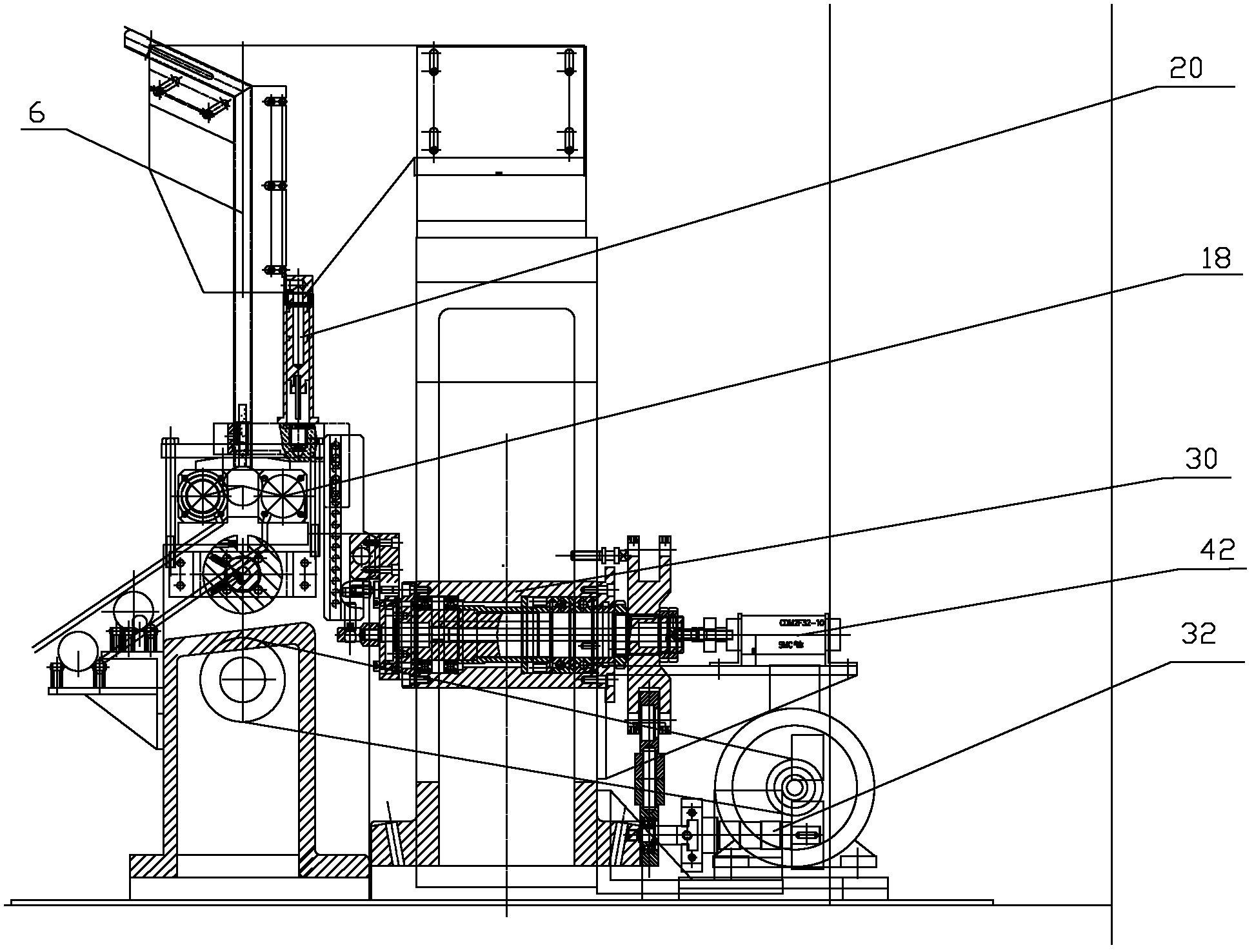

Outer-ring superfinishing machine for four-point contact bearings

InactiveCN104149018AEasy to replaceImprove machining accuracyGrinding feedersSuperfinishing machinesMachine partsSuperfinishing

Owner:WUXI LANMA MACHINERY MFR

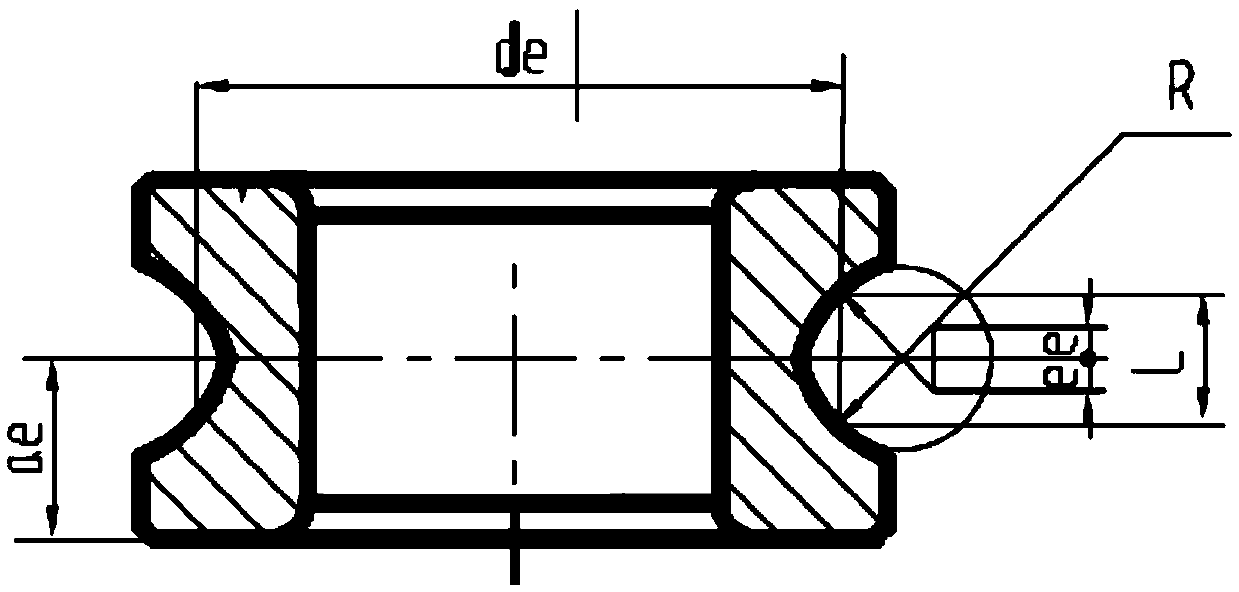

Production method of precise tapered roller

InactiveCN103821828AHigh precisionRaise the potentialBearing componentsGround rollerSurface roughness

The invention discloses a production method of a precise tapered roller. The method comprises the following steps: 1, preprocessing: carrying out cold heading processing of light tensioned steel wires to form a roller blank; 2, soft buffing processing: carrying out soft buffing of the external diameter of the roller blank, carrying out two-step grinding processing on two centerless grinders, and carrying out soft buffing of the end surfaces of the roller blank; 3, heat treatment and hard grinding: carrying out hard grinding of the external diameter of the surface processed roller on a centerless grinder; 4, base surface: carrying out spherical base surface processing of the fine ground roller on a spherical base grinder; 5, fine finishing: carrying out final grinding of the external diameter on the centerless grinder; and 6, superfinishing: carrying out superfine crown processing of the fine finished roller to obtain the finished tapered roller. A detection result shows that all indexes of the tapered roller obtained in the invention can stably reach national standard (GB / T25767-2010) II level standards, and the rolling surface roughness, the spherical base surface jumping SDW and the circularity of the tapered roller can reach national standard I level standards, and the bus of the external diameter of the roller has a crown form.

Owner:SHANDONG DONGE STEEL BALL GRP

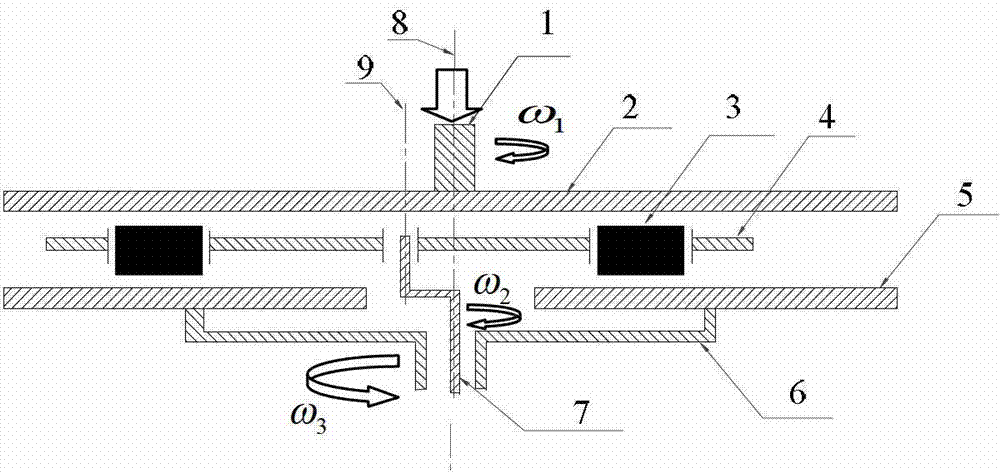

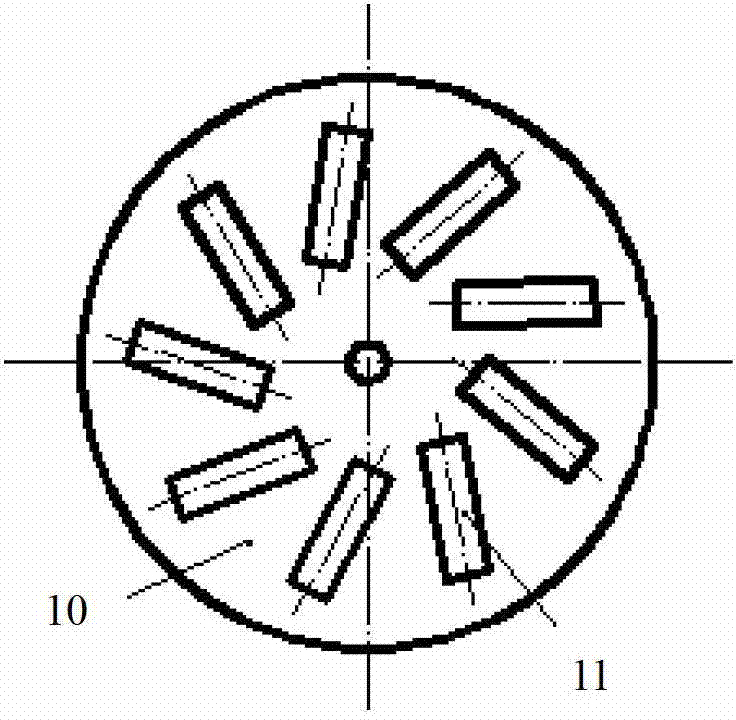

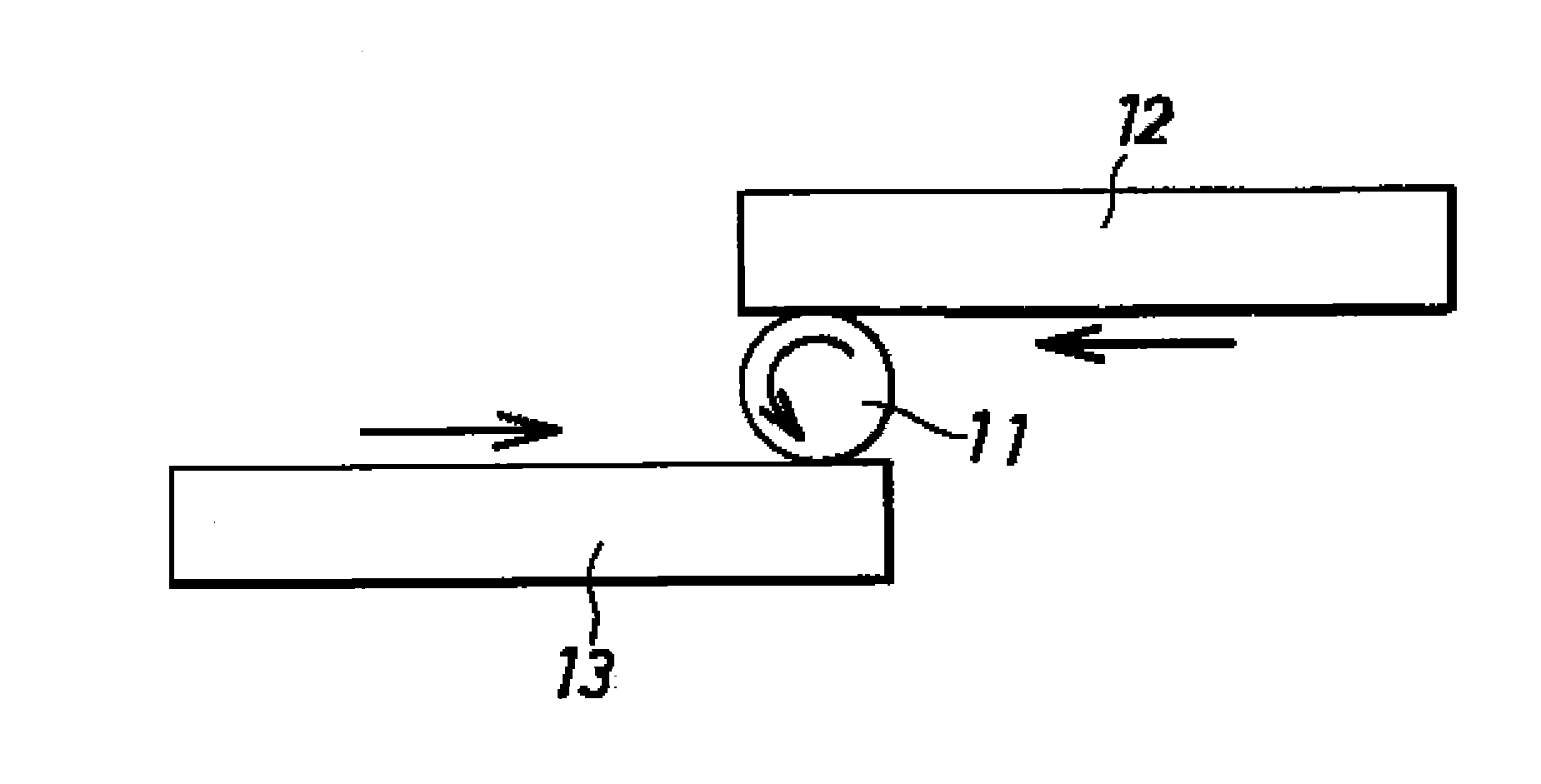

Superfinishing method for outer circle of high-precision cylindrical part

ActiveCN103537981AReduce dependencyReduce manufacturing costLapping machinesWork carriersOffset distanceSuperfinishing

Provided is a superfinishing method for the outer circle of a high-precision cylindrical part. A machining device for achieving the superfinishing method comprises an upper grinding disc, a holder and a lower grinding disc, wherein the holder is located between the upper grinding disc and the lower grinding disc, the rotating shaft of the upper grinding disc and the rotating shaft of the lower grinding disc are coaxially arranged, a certain offset distance exists between the axial line of holder and the upper grinding disc and between the axial line of the holder and the lower grinding disc, and the holder is connected with a holder driving crank shaft. The upper grinding disc, the lower grinding disc, the holder and the holder driving crank shaft can all independently rotate according to the respective speeds. A cylindrical part to be machined is arranged on a working position of the holder, the center of the holder carries out obit motion around the rotating shaft of the upper grinding disc and the rotating shaft of the lower grinding disc under the driving of the holder driving crank shaft, and meanwhile the holder maintains spin notion around the center of the holder. The cylindrical part carries out complex space rolling and rotational motion under the driving of the holder, the upper grinding disc and the lower grinding disc. Machining load is applied to the cylindrical part through the upper grinding disc. Superfinishing is carried out on the outer circle of the cylindrical part by matching the plane of the upper grinding disc and the plane of the lower grinding disc with grinding materials. According to the superfinishing method for the outer circle of the high-precision cylindrical part, evenness and machining uniformity are good.

Owner:ZHEJIANG UNIV OF TECH

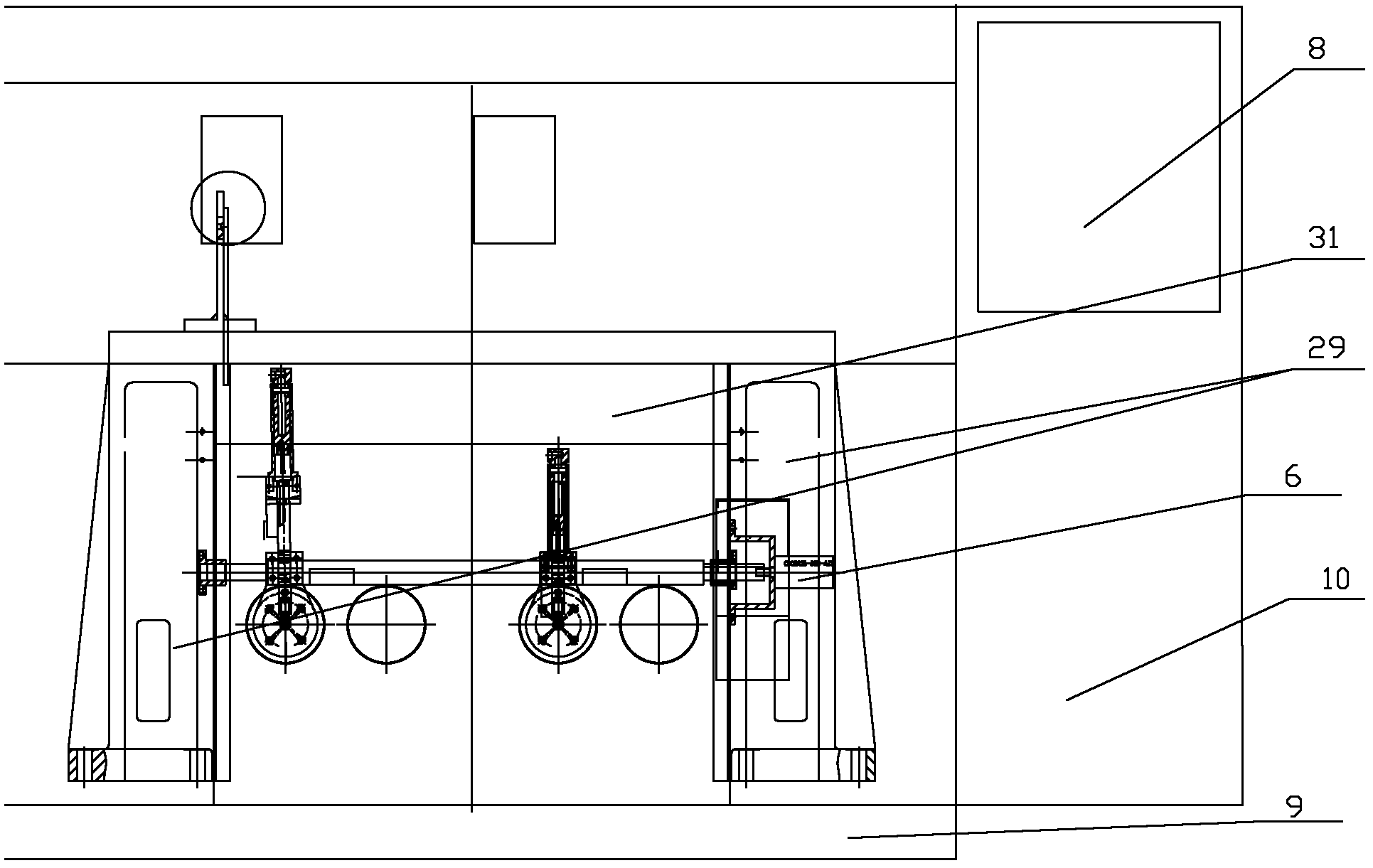

Inner ring groove grinding and ultra-fine-processing integral machine for fully automatic bearing ring

ActiveCN105751037ASimple structureImprove inner ring processing efficiencyGrinding feed controlGrinding machinesSuperfinishingEngineering

The invention discloses an inner ring groove grinding and ultra-fine-processing integral machine for a fully automatic bearing ring. The inner ring groove grinding and ultra-fine-processing integral machine comprises a machine tool, wherein a grinding device, a groove grinding detection device and an ultra-fine-processing device are arranged on the machine tool. The problem of low efficiency of the existing inner ring groove forming is solved. The grinding device, the groove grinding detection device and the ultra-fine-processing device are installed together; the inner ring processing efficiency of the bearing ring is improved; meanwhile, the processing precision stability is high. A grinding wheel trimmer is added, so that the service life of the grinding and ultra-fine-processing integral machine is higher, and the precision is higher.

Owner:NINGBO MINGRUN MACHINERY MFG

Grinding and finish lapping process for bearing ring whole peach type channel

ActiveCN105364639ASolve problems that cannot be refinedSolve the problem of inaccurate detection and affecting product qualityNumerical controlSuperfinishing

The invention relates to a grinding and finish lapping process for a bearing ring whole peach type channel. The defect of existing grinding and superfinishing of the whole peach type channel is overcome. The process comprises the steps that firstly, high-precision numerical control inner circle grinding equipment is selected, and a bearing ring channel is ground to be in a peach type; secondly, the shape of the whole peach type channel is detected; thirdly, the whole peach type channel is subjected to rough lapping; and fourthly, the whole peach type channel is subjected to finish lapping. According to the process, the detection accuracy is greatly improved, the using property and the surface quality of a bearing are also improved. The grinding and finish lapping process is used for the field of bearing ring grinding and finish lapping.

Owner:AVIC HARBIN BEARING

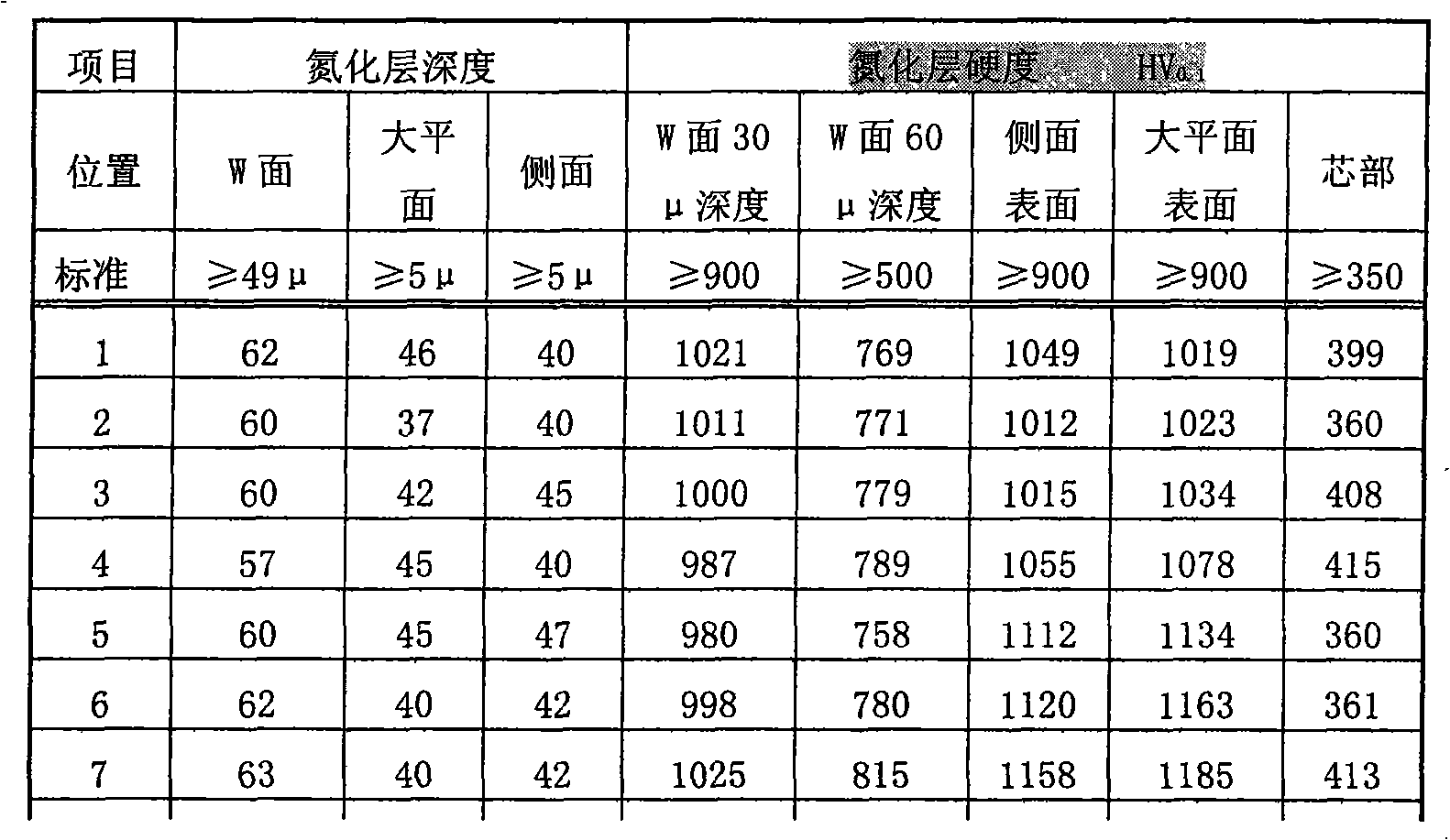

Method for manufacturing special sliders for rotary compressors by adopting 9Cr18 or 9Cr18Mo stainless steel

InactiveCN101905420ASave cryogenic treatmentSave energyOther manufacturing equipments/toolsAfter treatmentMartensitic stainless steel

The invention relates to a method for manufacturing special sliders for rotary compressors by adopting 9Cr18 or 9Cr18Mo stainless steel, which is characterized by comprising the following steps of selection of proper profile materials, blanking, rough machining, vacuum hardening and tempering, fine machining, rolled polishing, cleaning, liquid tufftriding salt bath treatment, rolled polishing, thickness and width superfine machining and cleaning to form finished products. In the whole process, three different machining modes of rough machining, fine machining and superfine machining are adopted, and the steps of vacuum hardening and tempering and liquid tufftriding salt bath treatment are respectively carried out in the three machining modes. The method has the advantages that as the special sliders for rotary compressors are manufactured by adopting martensite stainless steel 9Cr18 or 9Cr18Mo and the like and the martensite stainless steel has high content of Cr and good nitriding performance, the martensite stainless steel can be nitrided at lower temperature, thereby ensuring the less deformation of the sliders and being beneficial to precise machining after treatment.

Owner:浙江百达精工股份有限公司

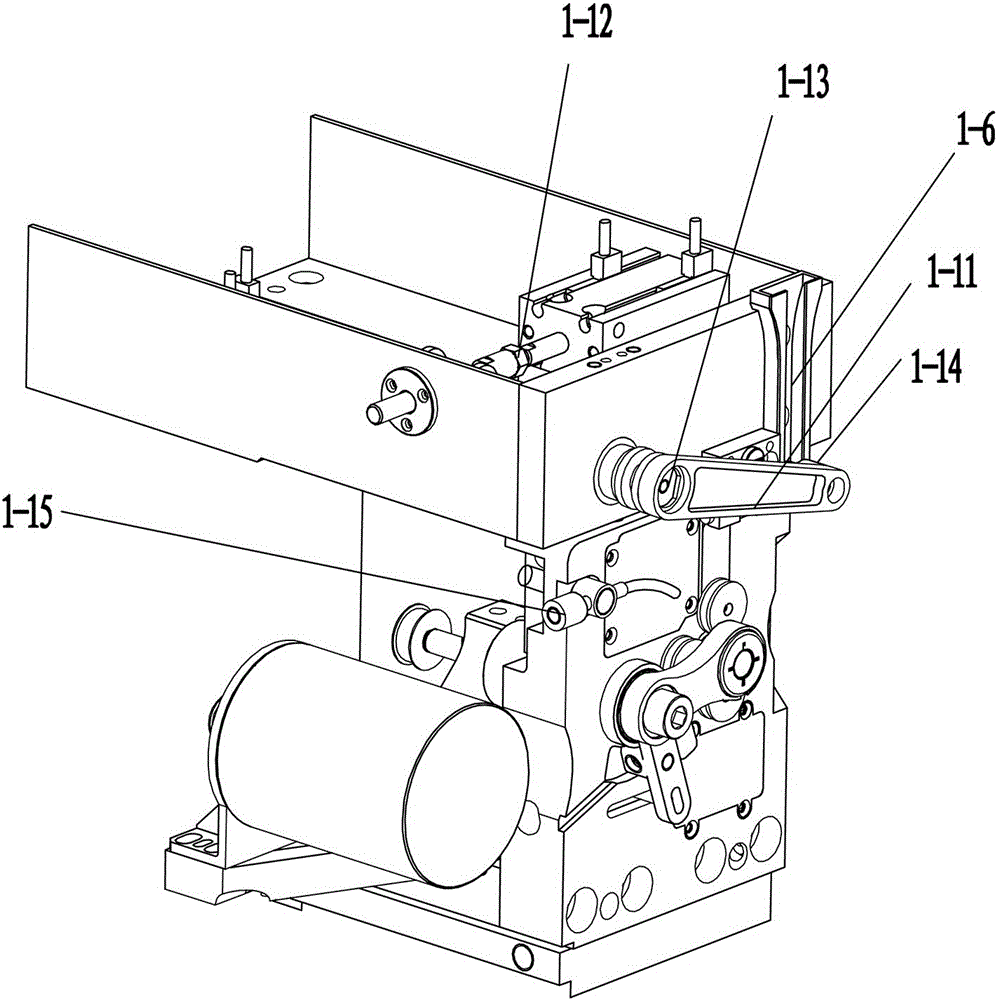

Bearing roller spherical surface superfinishing mechanism

ActiveCN106695530AEasy to processIncreased Superfine AccuracySuperfinishing machinesGrinding work supportsControl systemEngineering

The invention relates to a bearing roller spherical surface superfinishing mechanism, and belongs to the technical field of bearing roller superfinishing. The bearing roller spherical surface superfinishing mechanism comprises a lathe bed, a workpiece supporting mechanism, a workpiece driving device, a cutter device and a control system, wherein the workpiece supporting mechanism, the workpiece driving device, the cutter device and the control system are arranged on the lathe bed. The cutter device comprises an installation support, an oil stone, an oil stone driving mechanism and a Z-axis feeding mechanism; the working end of the oil stone is in a cylindrical shape; the inner diameter of the oil stone is larger than the chord length of the arc shape of a spherical roller to be machined; the oil stone is driven by a servo motor of the oil stone driving mechanism to rotate by adopting an oil stone central axis as a center; the workpiece supporting mechanism is arranged under the oil stone, and comprises a support and two horizontal cylindrical support rollers supported on a central axis of the support and parallel to each other; a workpiece supporting part is formed between the cylindrical surfaces of the two supporting rollers; the two supporting rollers are driven by the workpiece driving device to rotate towards the same direction at the same speed; and each mechanism is controlled by the control system. The bearing roller spherical surface superfinishing mechanism provided by the invention overcomes the defects of low machining efficiency and low machining accuracy during existing workpiece spherical surface superfinishing.

Owner:XINCHANG COUNTY CHENGBEN ROLLER BEARING

Method of manufacturing bearing ring of rolling bearing

InactiveUS20130326880A1Low costBall bearingsMetal-working apparatusRolling-element bearingEngineering

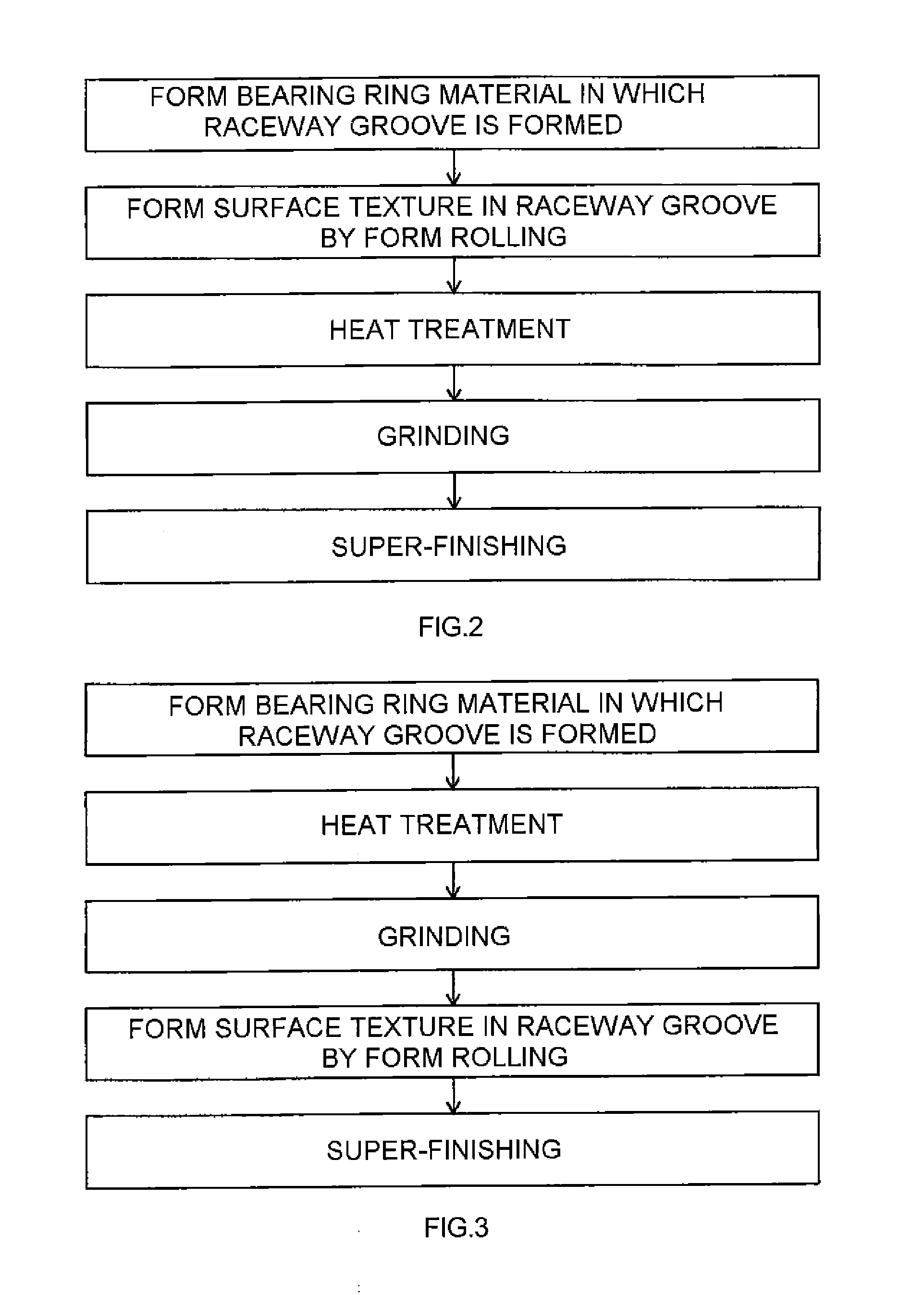

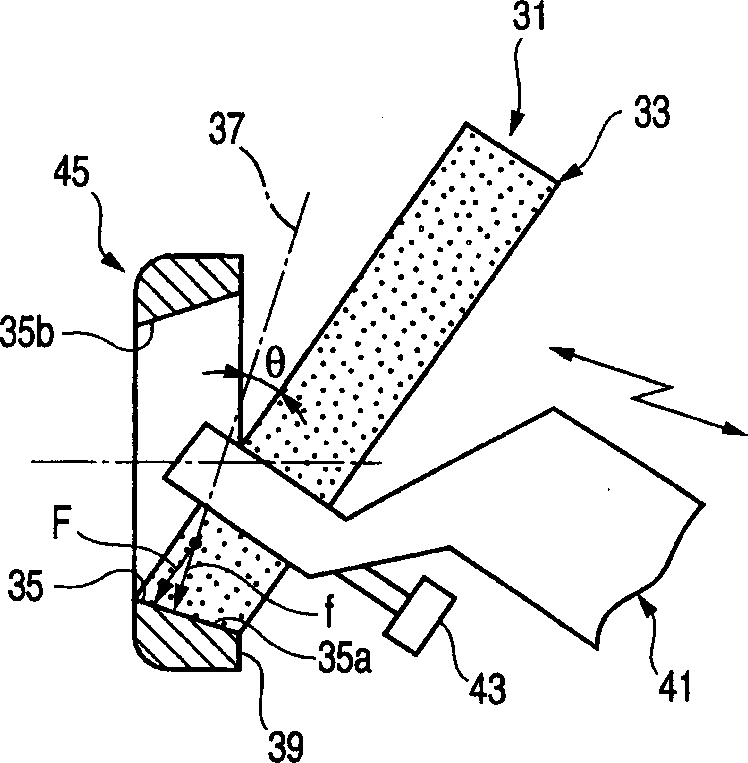

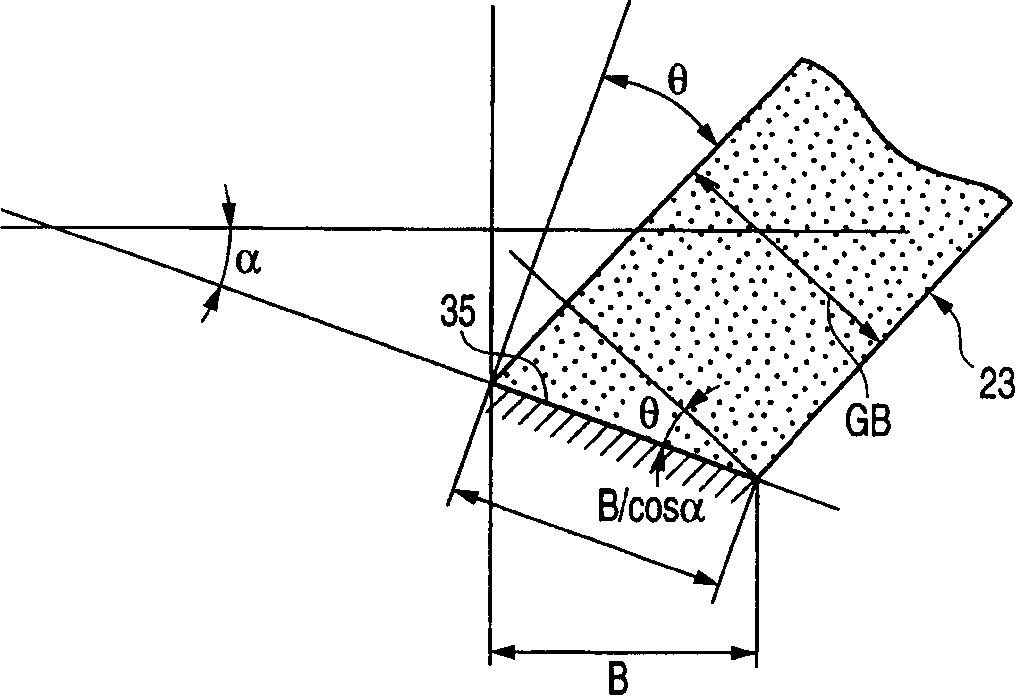

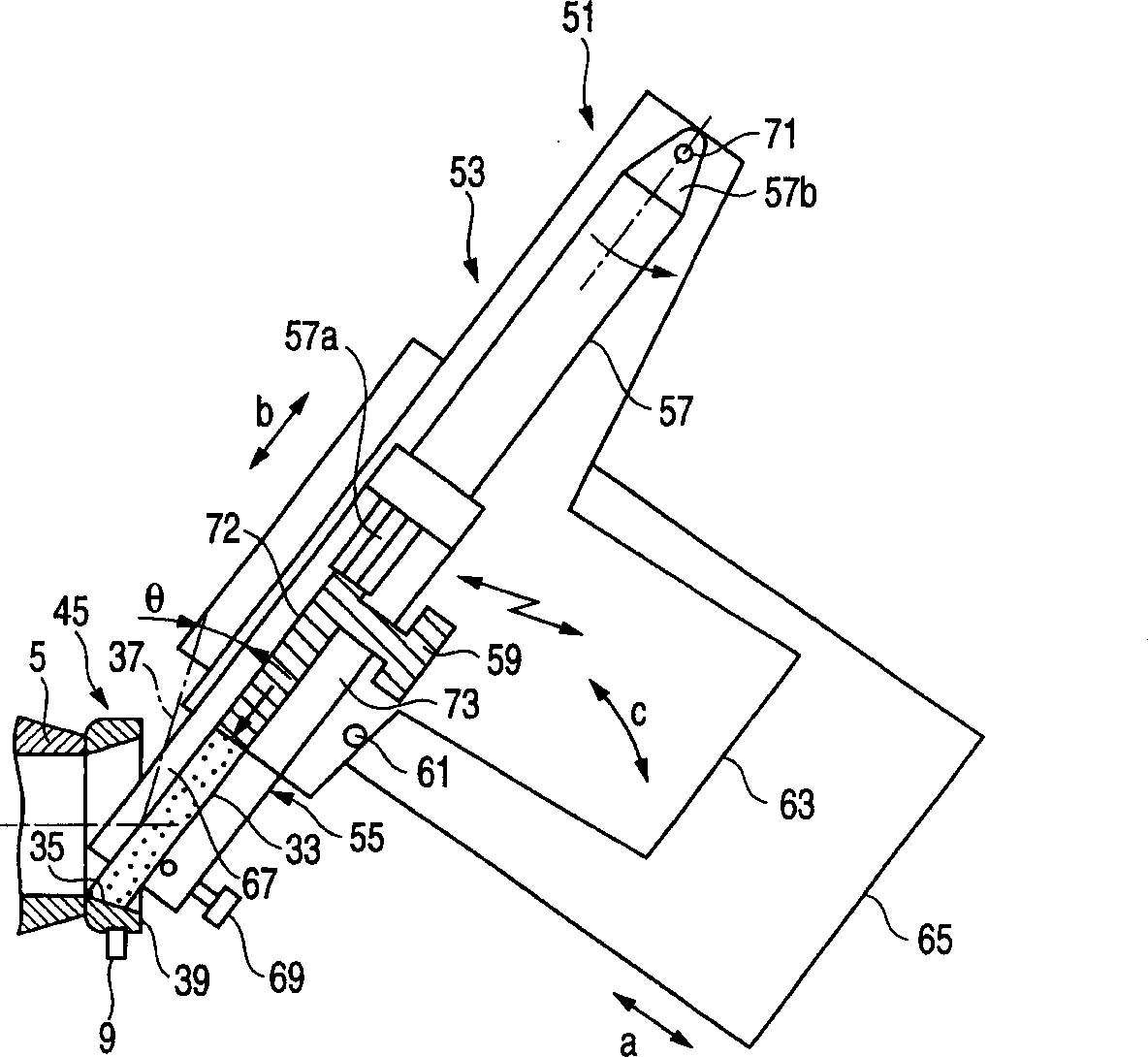

A method of manufacturing a bearing ring of a rolling bearing includes a process of forming a bearing ring material in which a raceway groove is formed, a process of performing form rolling so as to form surface textures in axially opposite end portions of the raceway groove, a heat treatment process, a grinding process, and a super-finishing process.

Owner:JTEKT CORP

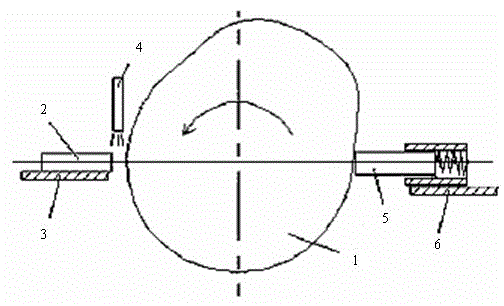

Method for working ultrafine conical rolling bearing

A superfinishing method for a tapered roller bearing, comprising the steps of: rotating the outer ring of the tapered roller bearing around the central axis of the tapered roller bearing; inserting a right-angled superfinishing stone from the front of the outer ring; and The front end face of the superfinishing stone is in sliding contact with the surface of the conical race formed on the inner peripheral surface of the outer ring, and thereby superfinishes the race surface. The super-finishing stones are inclined to the outside in front of the outer ring corresponding to the vertical line of the race surface.

Owner:NSK LTD

Superfinishing of high density carbides

A method for superfinishing a high density carbide steel component using chemically accelerated finishing is provided. The high density carbide steel component is vibrated in a vessel containing a plurality of media, with active chemistry being added to the vessel at a low flow rate. An active chemistry composition is also provided, consisting of one or more conversion coating agents having preferably a phosphate radical, and one or more chelating agents preferably including citric acid.

Owner:REM TECHNOLOGY INC

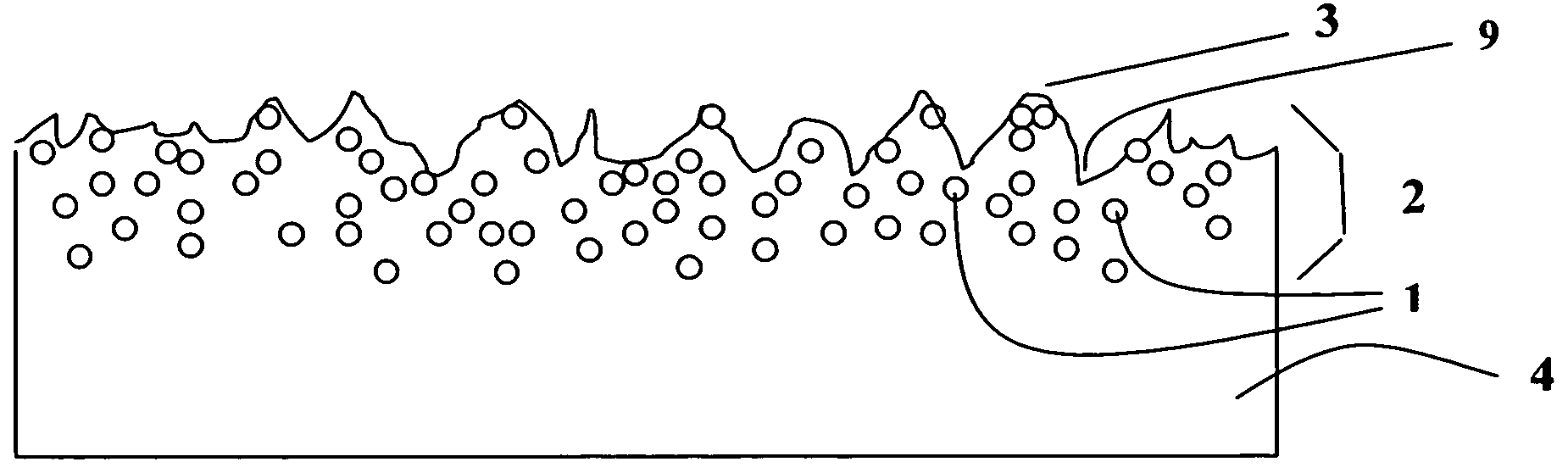

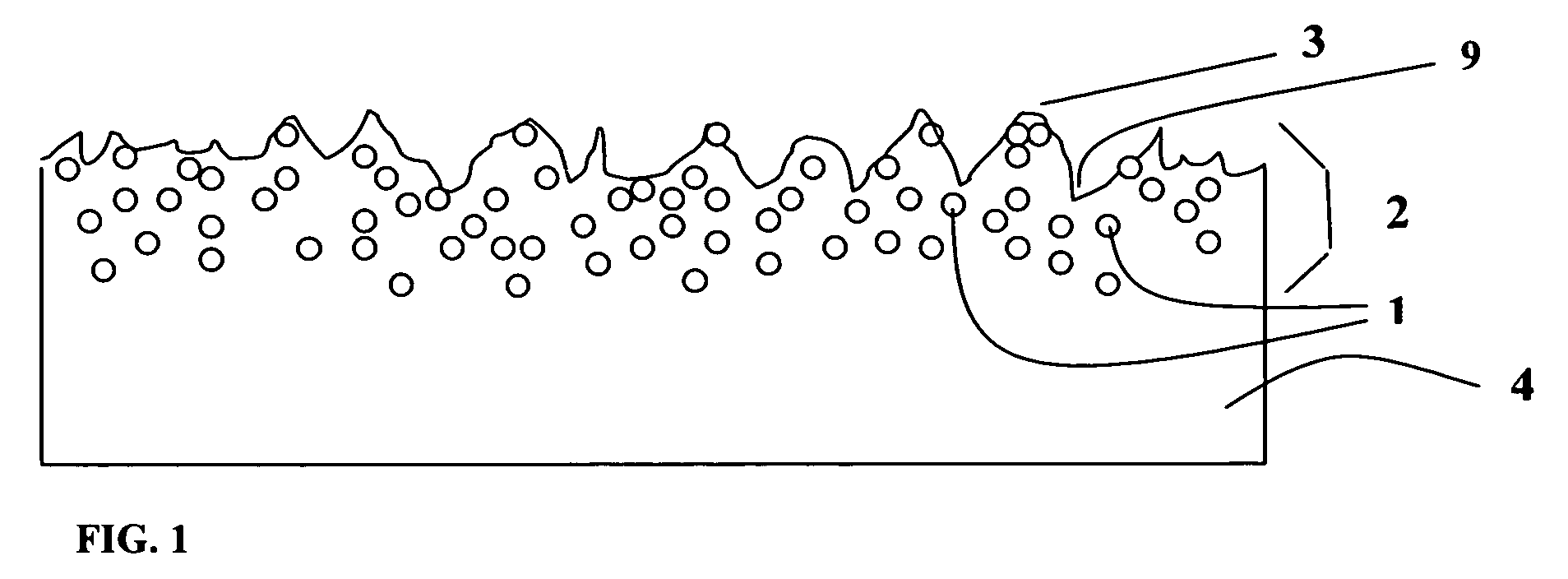

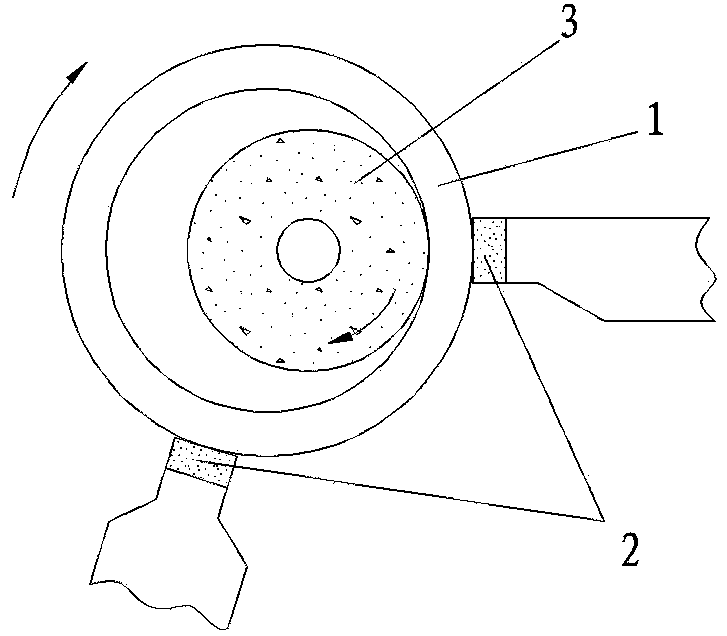

Magnalium alloy automobile covering piece outer plate forming and manufacturing method

ActiveCN109590689AHigh precisionConform to the mechanical curveAircraft componentsNumerical controlSuperfinishing

The invention provides a magnalium alloy automobile covering piece outer plate forming and manufacturing method which comprises the following steps of die numerical control machining, die surface superfinishing, micro-distortion heat treatment, protective surface refining, circular bead streamline transition, draw bead optimizing, deburring die cutting edge passivating, flanging die retainer coreenlarging, and reverse-drawing debugging. The magnalium alloy automobile covering piece outer plate forming and manufacturing method provided by the invention has the advantages that a die has high precision, conforms to the dynamics curve and is smooth in stressing, so that the problems of surface stickiness of a magnalium alloy panel and easiness in scratching the surface are solved, and the product defects such as springback cracking and the like caused by a large number of material performance problems are overcome; and a springback effect of the materials are controlled, and experimentaldata is summarized, so that a magnalium alloy automobile covering piece outer plate is controllably formed, and the problems that the springback cannot be controlled, re-forming cannot be realized, and the product qualification rate is low are solved.

Owner:HEBI TIANQI MOTOR DIES

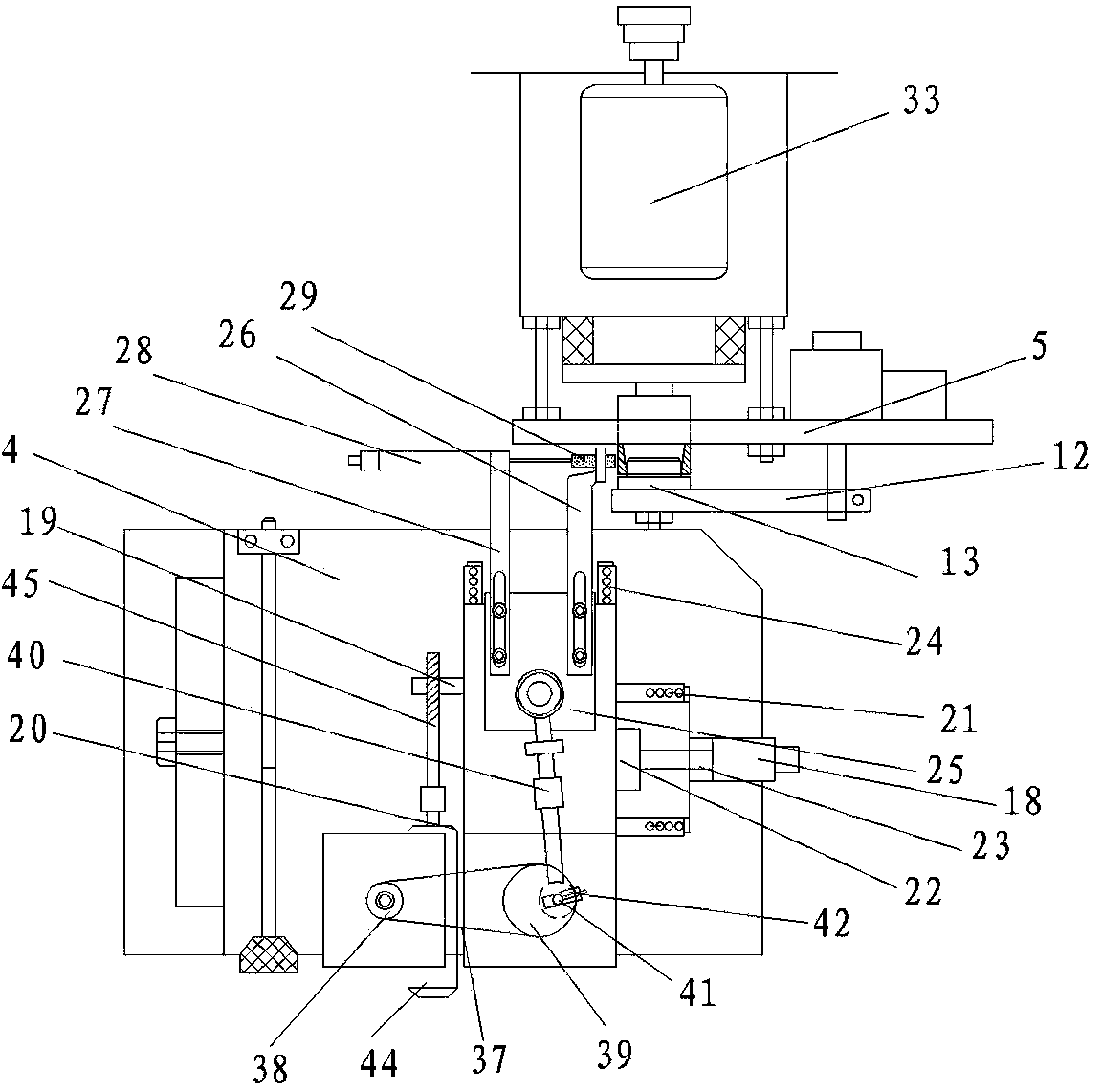

Bearing outer-circle superfinishing machine

ActiveCN103659568AHigh precisionReduce scrap rateGrinding feedersSuperfinishing machinesMicrometerSoft materials

The invention discloses a bearing outer-circle superfinishing machine which comprises a base. A vertical plate is arranged on the base, a polishing mechanism is further arranged on the base, and a feeding mechanism is arranged on the vertical plate. The bearing outer-circle superfinishing machine has the advantages that a bearing is located through an electromagnetic pole tip and a soft material conveying ring sleeve, an outer circle of the bearing is grinded through self-compensating oilstone, accuracy is high, supporting marks can be eliminated with a 5-8-micrometer outer-diameter allowance of the outer circle of the bearing, and the rejection rate is quite low.

Owner:HUANCHI BEARING GROUP

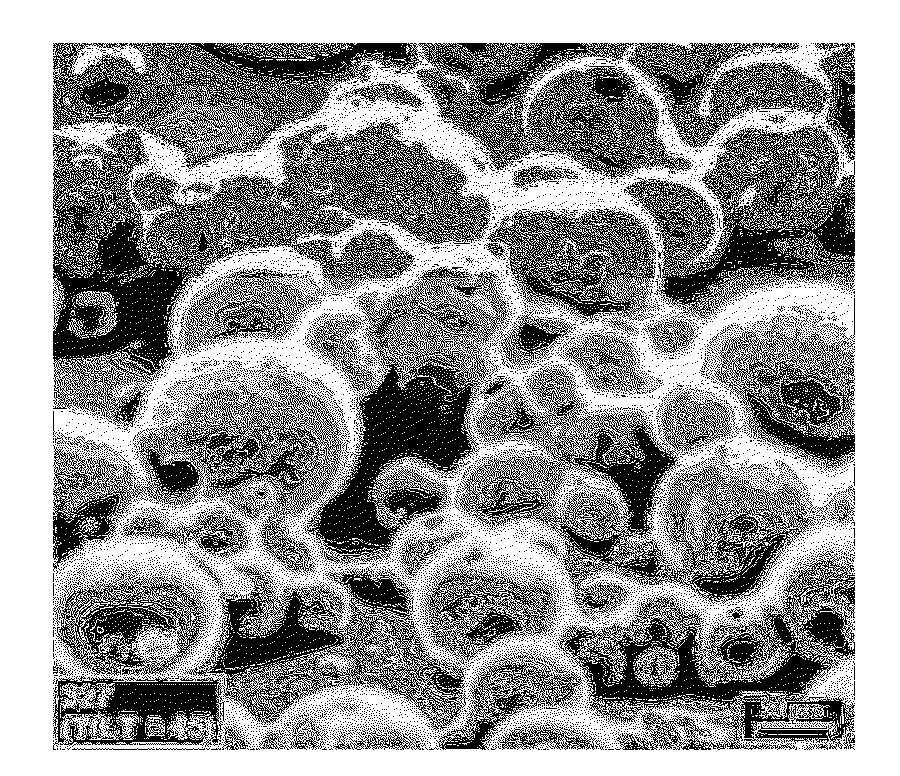

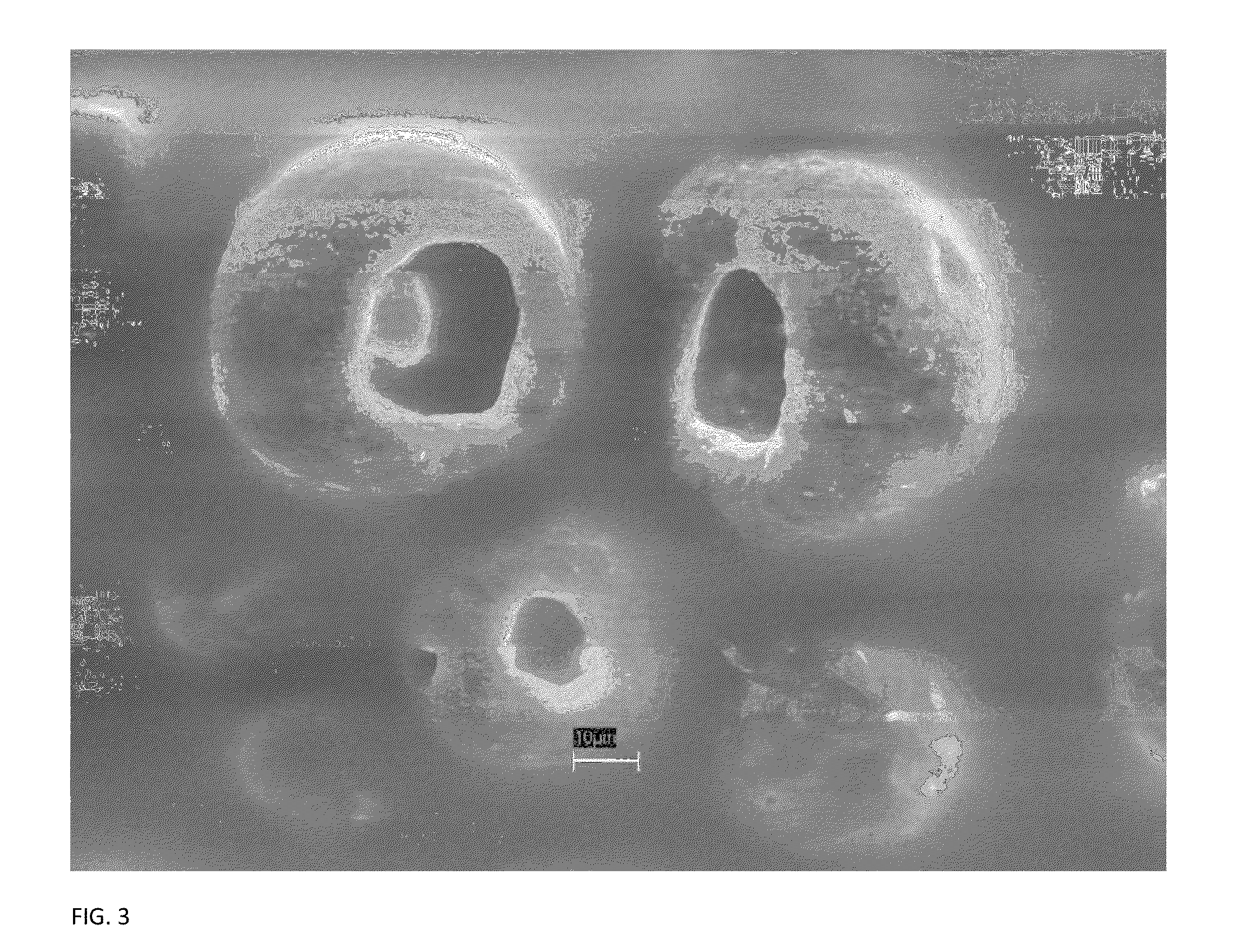

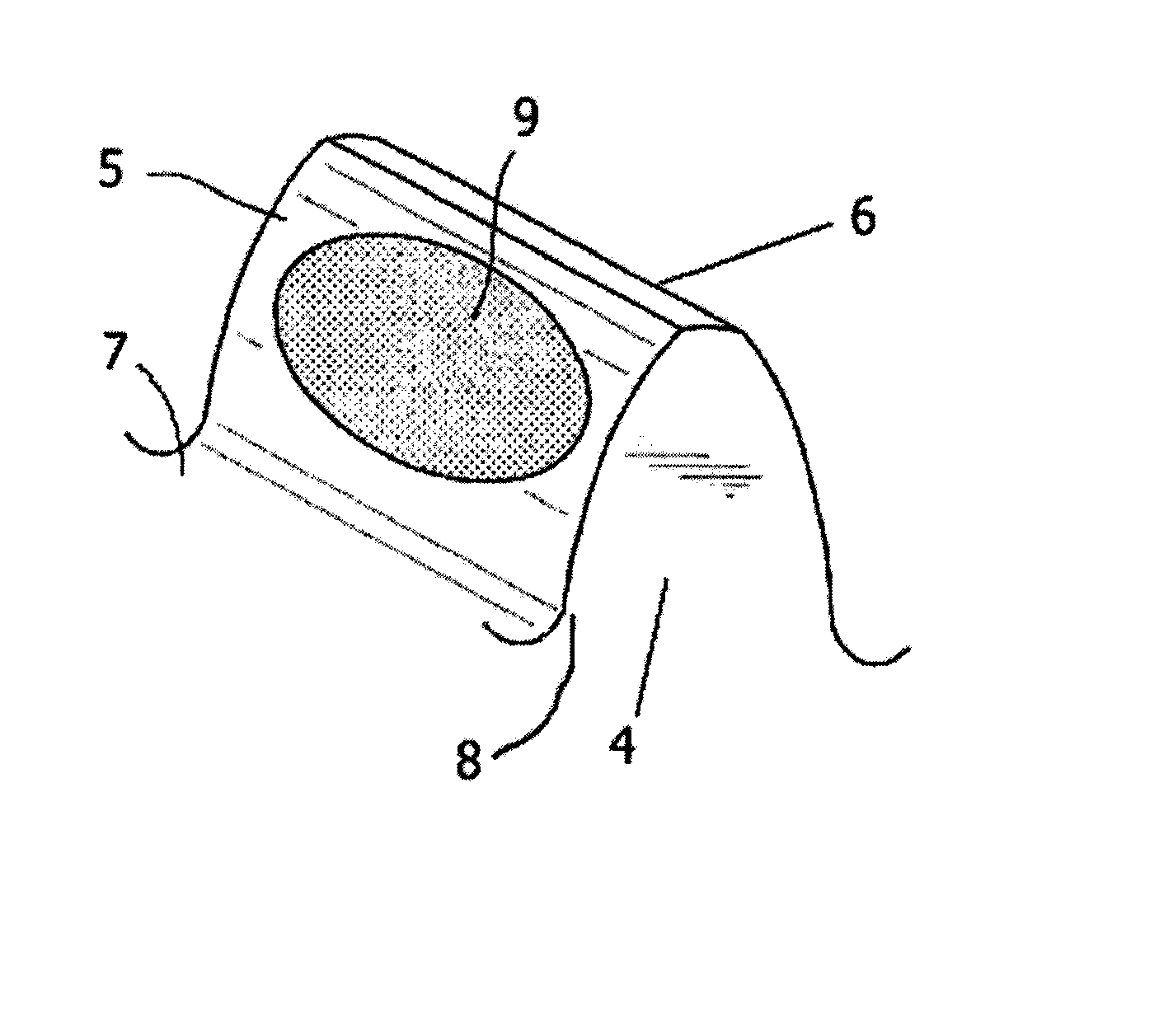

Abrasive products and methods for finishing hard surfaces

A coated abrasive product includes green, unfired abrasive aggregates having a generally spheroidal or toroidal shape, the aggregates formed from a composition comprising abrasive grit particles and a nanoparticle binder, wherein the abrasive aggregates are dispersed within a polymer resin coating, and wherein the coated abrasive product is capable of superfinishing a metal surface having an initial Ra in the range of about 1.5 micro inches to about 12.5 micro inches prior to application of the coated abrasive product and after application the surface has an Ra of less than 1.0 micro inch.

Owner:SAINT GOBAIN ABRASIVES INC +1

Superfinishing grindstone

InactiveUS6887288B2Easy to disassembleEdge grinding machinesPigmenting treatmentHardnessSuperfinishing

Owner:MINEBEA CO LTD

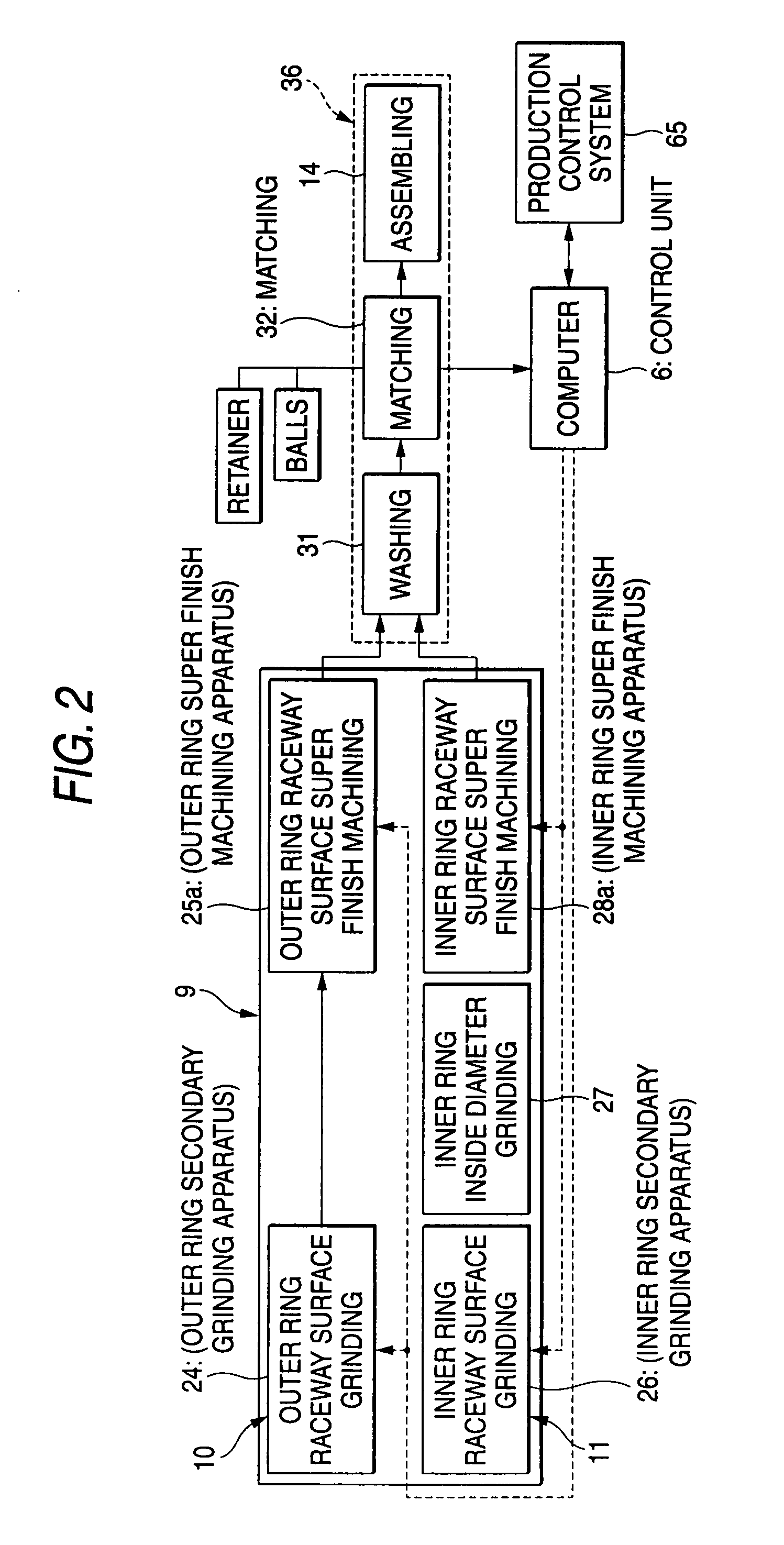

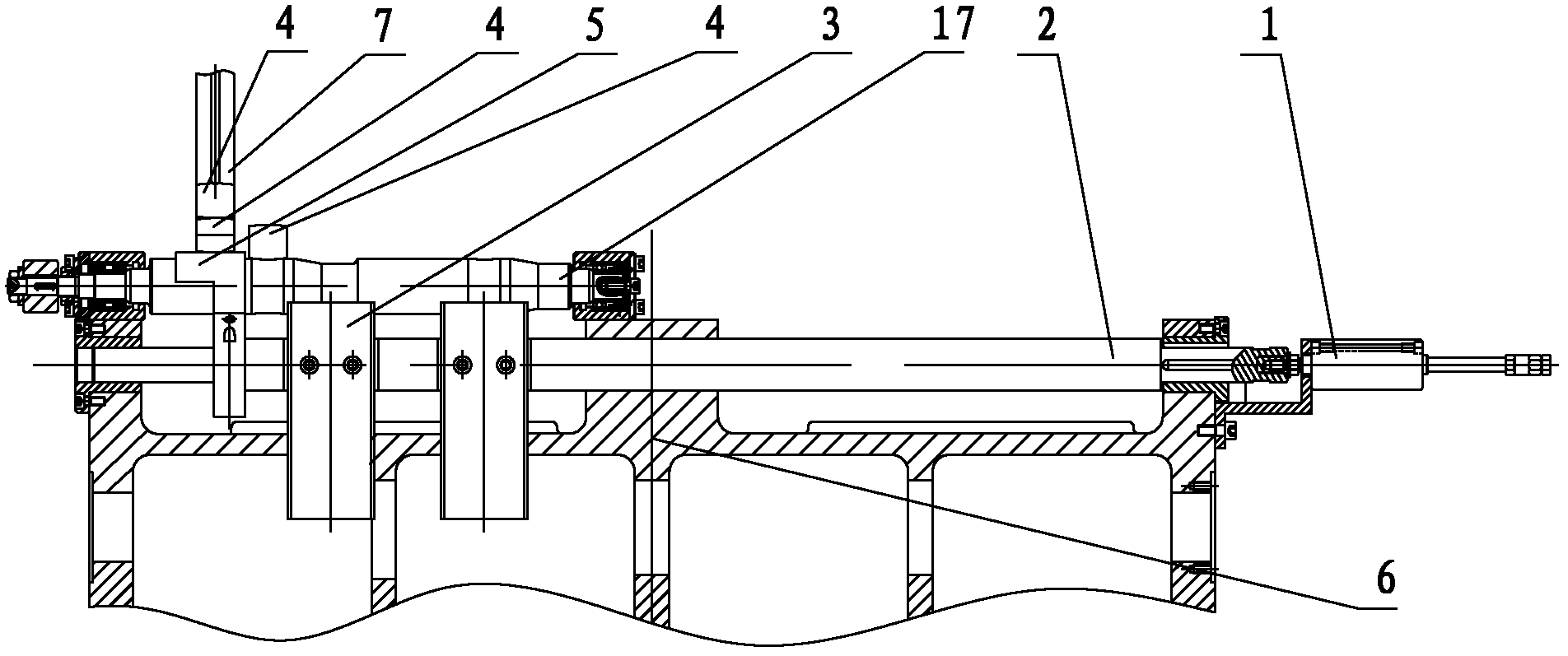

Manufacturing facility and super finishing apparatus for ball bearing

InactiveCN101060957AHigh dimensional accuracyHigh shape accuracyBall bearingsGrinding feed controlBall bearingControl signal

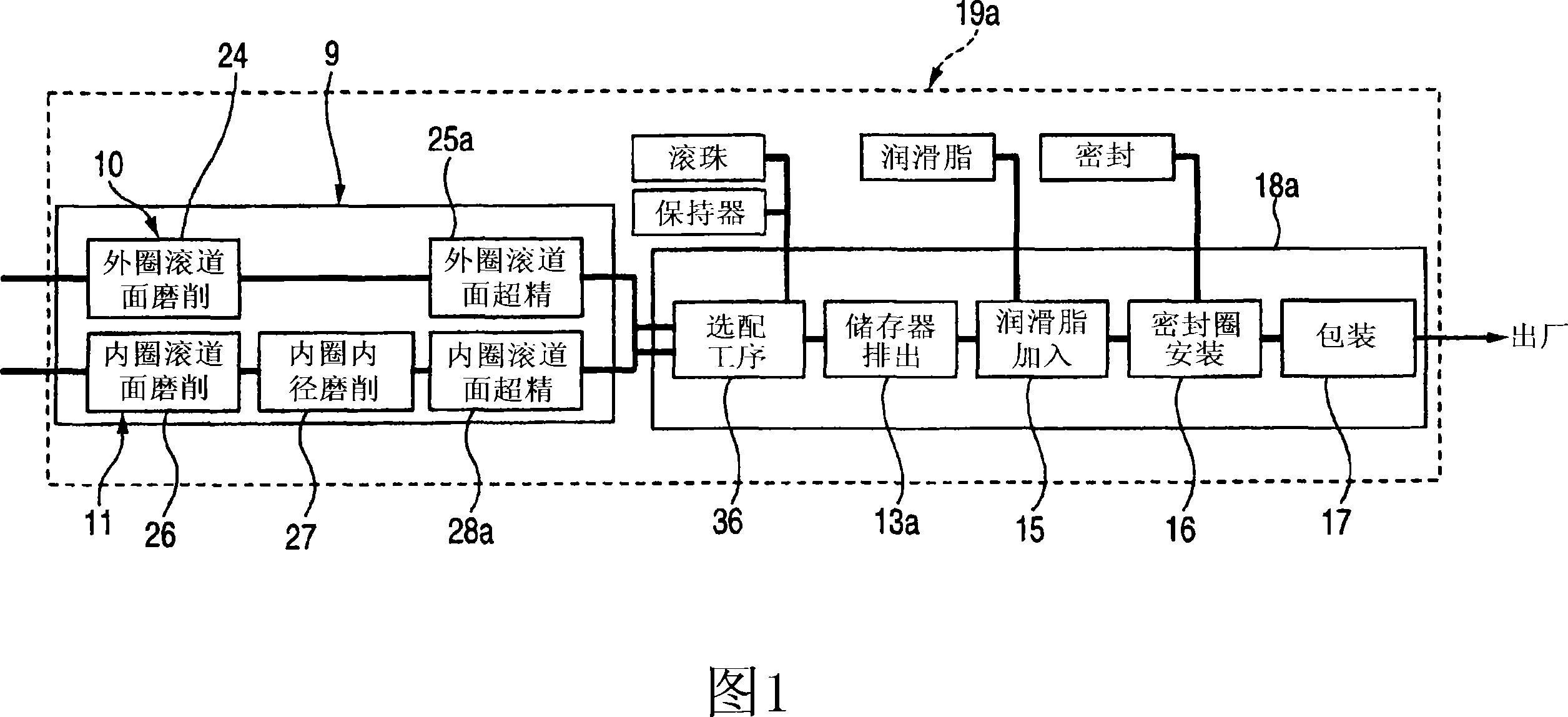

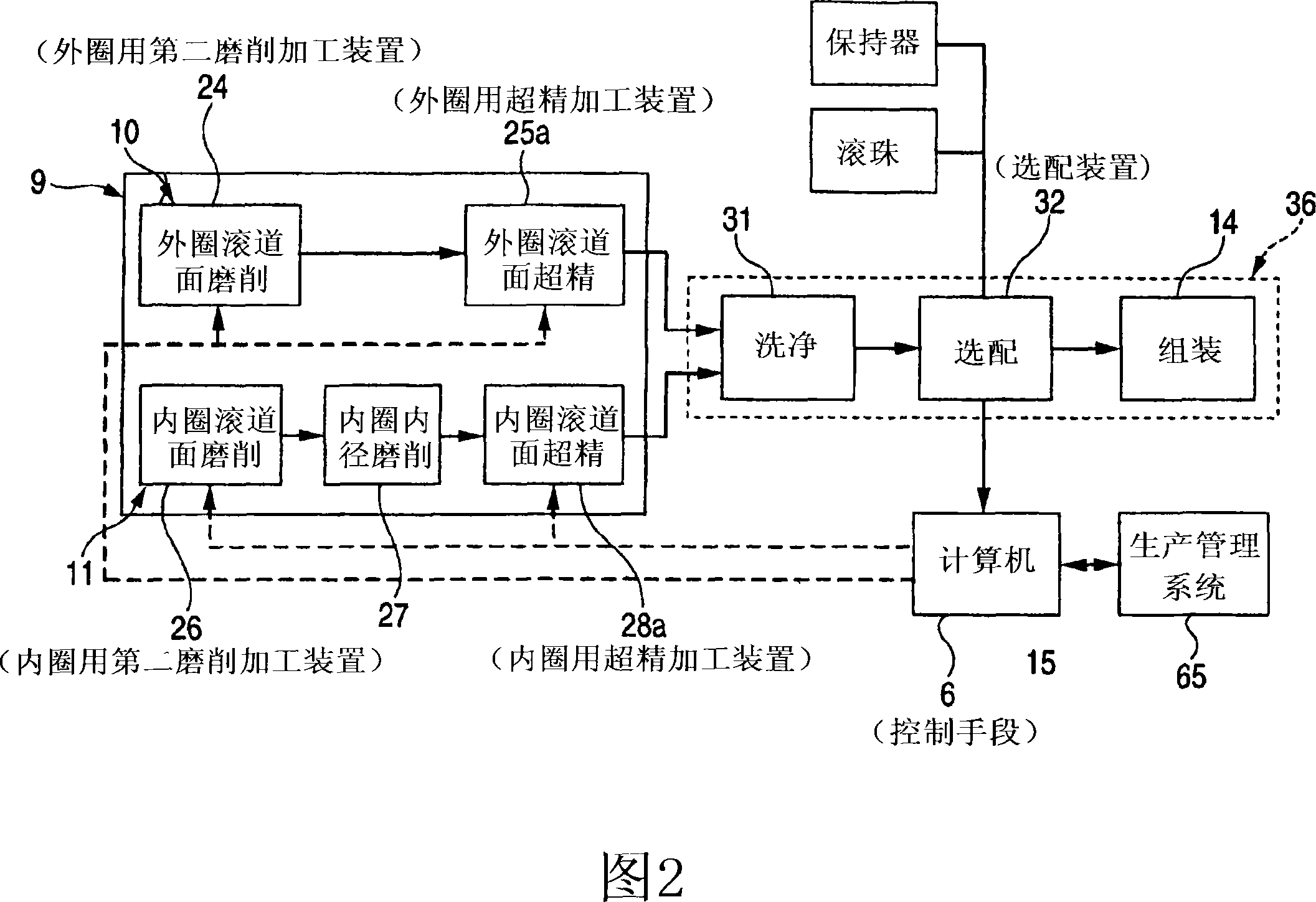

The invention has a structure: a control device 6 composed of a computer is connected with a detection part of a matching device 32, thus sending detection signals that represent measured values of the diameter of the raceway of an outer ring and the raceway of an inner ring; the control device 6 is further connected with a second grinding process device 24 in the outer ring, a superfinishing device 25a in the outer ring, a second grinding process device 26 in the inner ring and a superfinishing device 28a in the inner ring, so as to be convenient for receiving control signals; according to the measured values of the diameter of the raceway of the outer ring and the raceway of the inner ring that are measured by the detection part, the control device 6 provides change values to diameter-processing target values which are respectively set for the grinding process device 24 (or 26) and the superfinishing device 25a (or 28a) that are used for processing roll surfaces of at least one roll wheel in the outer ring and the inner ring.

Owner:NSK LTD

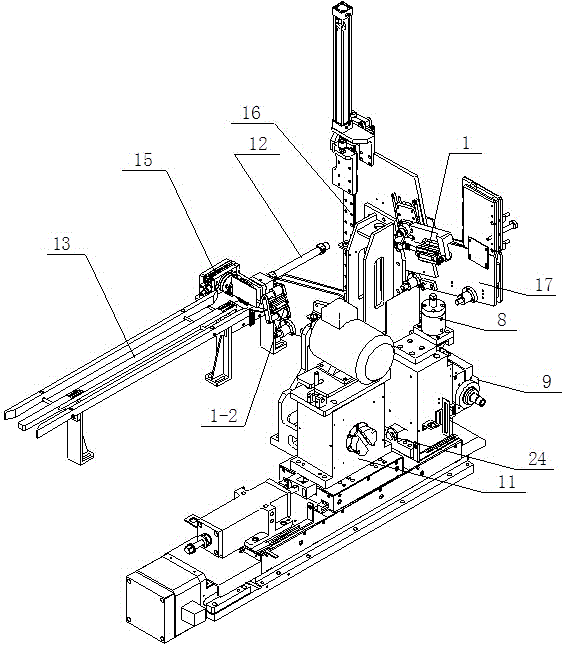

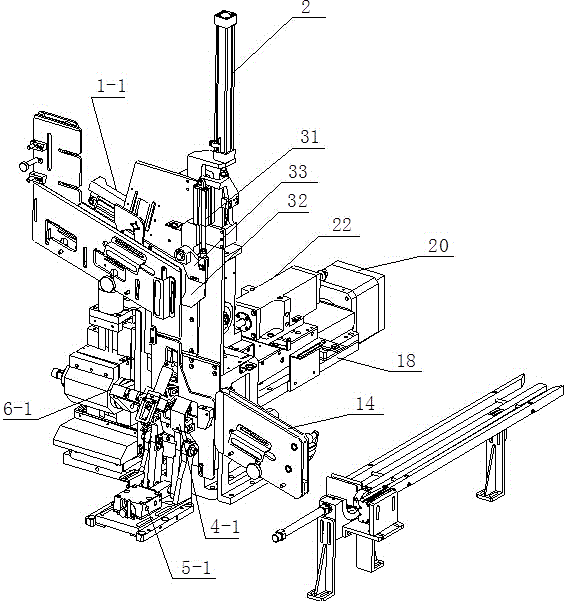

Conical/cylindrical linear rollaway nest superfinishing equipment

ActiveCN104690619APrecise displacement controlSimple structureGrinding machinesSuperfinishing machinesEngineeringSuperfinishing

The invention discloses conical / cylindrical linear rollaway nest superfinishing equipment. The conical / cylindrical linear rollaway nest superfinishing equipment comprises an operating table and a material feeding and discharging conveying mechanism arranged on the operating table, wherein a big reciprocating and small vibrating mechanism, a rollaway nest superfinishing swinging head and a flange superfinishing swinging head are further arranged on the operating table; a feeding opening is formed in the middle of the material feeding and discharging conveying mechanism; a main shaft is arranged on the back side of the feeding opening; an inner hole centering component is arranged at the upper end of the main shaft; the big reciprocating and small vibrating mechanism comprises a big reciprocating mechanism and a small vibrating mechanism; the big reciprocating mechanism and the small vibrating mechanism are connected through a first connecting plate; a first skipping component is arranged on the back side of the rollaway nest superfinishing swinging head; a second skipping component is arranged on the back side of the flange superfinishing swinging head; both the rollaway nest superfinishing swinging head and the flange superfinishing swinging head are driven by the big reciprocating and small vibrating mechanism for superfinishing. The conical / cylindrical linear rollaway nest superfinishing equipment performs rollaway nest superfinishing and flange superfinishing at the same time, is simplex in rollaway nest superfinishing vibration and stable and reliable in working conveying, and can meet superfinishing requirements of a high-precision workpiece.

Owner:WUXI LANMA MACHINERY MFR

Superfinishing Large Planetary Gear Systems

InactiveUS20080108470A1Reduces and eliminates lubricant debrisEdge grinding machinesPolishing machinesEngineeringSuperfinishing

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:REM TECHNOLOGY INC

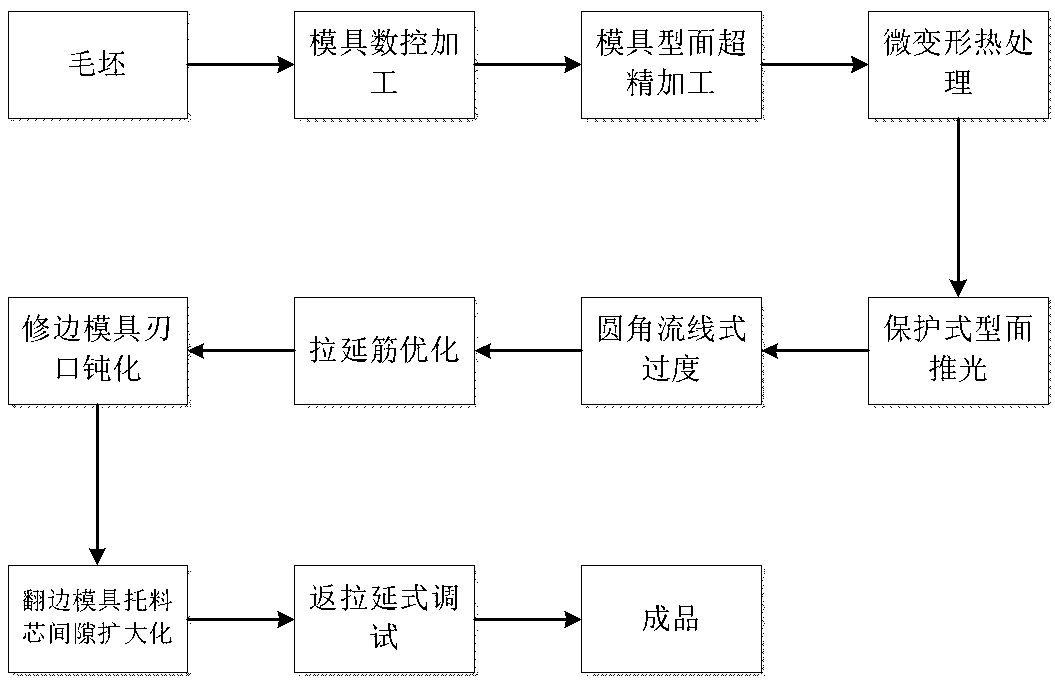

Method for extremely fine grinding and finishing surface of cam of internal combustion engine camshaft through electrochemical composite oilstone with reverse pulses

The invention provides a method for extremely fine grinding and finishing the surface of a cam of an internal combustion engine camshaft through electrochemical composite oilstone with reverse pulses. The method has the following advantages that firstly, the surface of the cam can be directly finished to Ra0.1 micrometer or lower through one step after being coarsely ground, so that mirror finishing is achieved; secondly, compared with grinding at the same roughness level, the productivity can be improved by three times to five times or more, and finishing efficiency is quite high; thirdly, in the finishing process, no grinding force or grinding heat is generated, so that the surface layer is free of metallographic structure changes, work hardening and stress condition changes, and the finished surface layer is high in quality; fourthly, passive film on the metal surface is mainly removed through the oilstone, and therefore loss of the oilstone is much smaller than loss caused by ultra-fine machining; fifthly, sediments and microscopic peaks on the surface of an electrode are dissolved through the reverse pulses, the electrode is finished, and the shape of the electrode is kept; sixthly, the process device is simple and is convenient to operate and maintain.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Ball bearing manufacturing facility and super finish machining apparatus

InactiveUS20090165274A1Increase in defect-freeAdd partsBall bearingsGrinding feed controlBall bearingControl signal

A detection unit of a matching apparatus 32 is connected to a control unit 6 of a computer so that a detection signal indicating measured values of diameters of outer and inner ring raceways can be sent thereinto. An outer ring secondary grinding apparatus 24, an cuter ring super finish machining apparatus 25a, an inner ring secondary grinding apparatus 26 and an inner ring super finish machining apparatus 28a are connected to the control unit 6 so that control signals can be received. The control unit 6 imparts shift amounts to diameter machining target values which are set, respectively, in the grinding apparatus 24, 26 and the super finish machining apparatus 25a, 28a for machining a raceway surface of at least one bearing ring of outer and inner rings, based on measured values of diameters of the outer and inner ring raceways which were measured by the detection unit.

Owner:NSK LTD

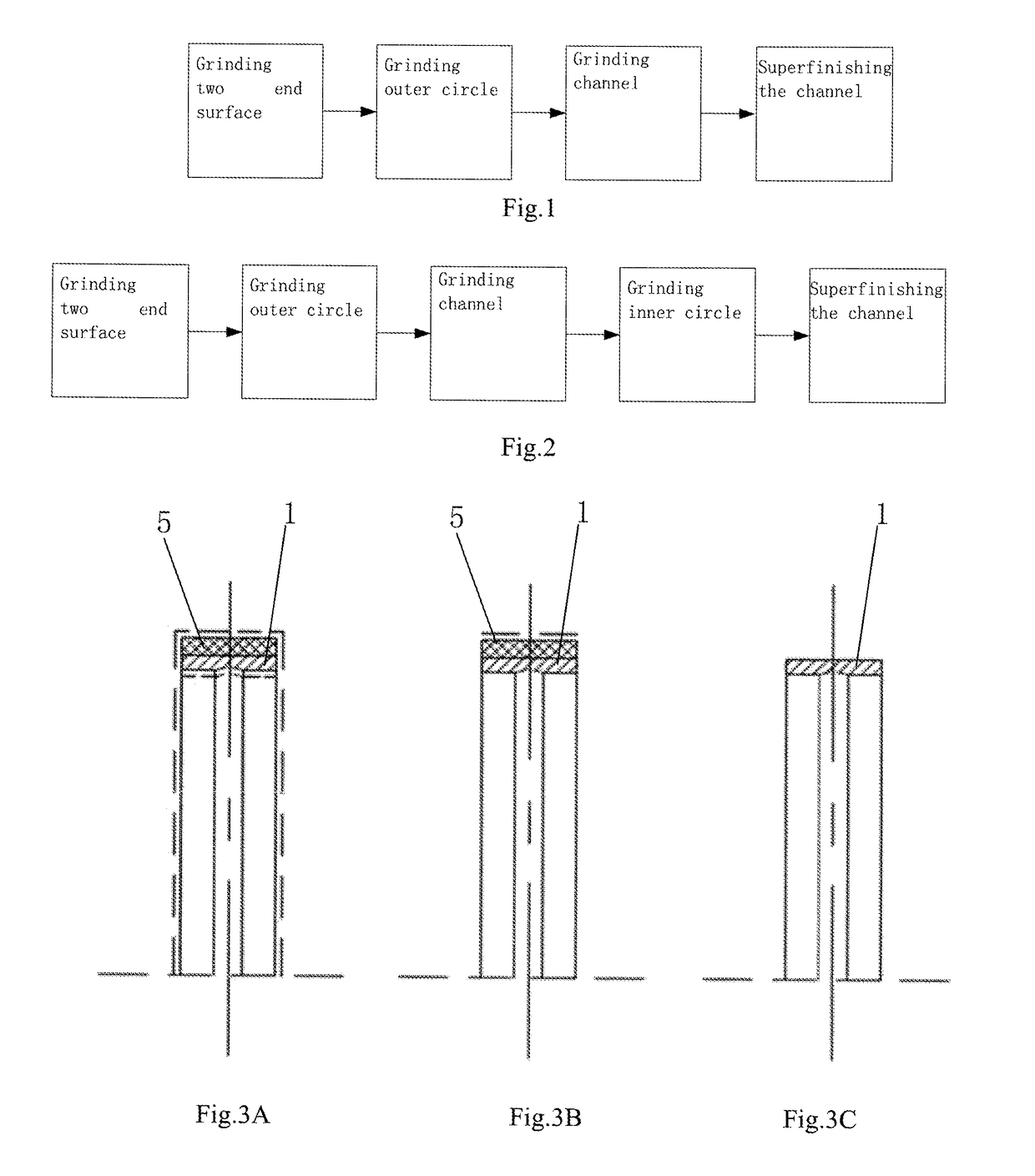

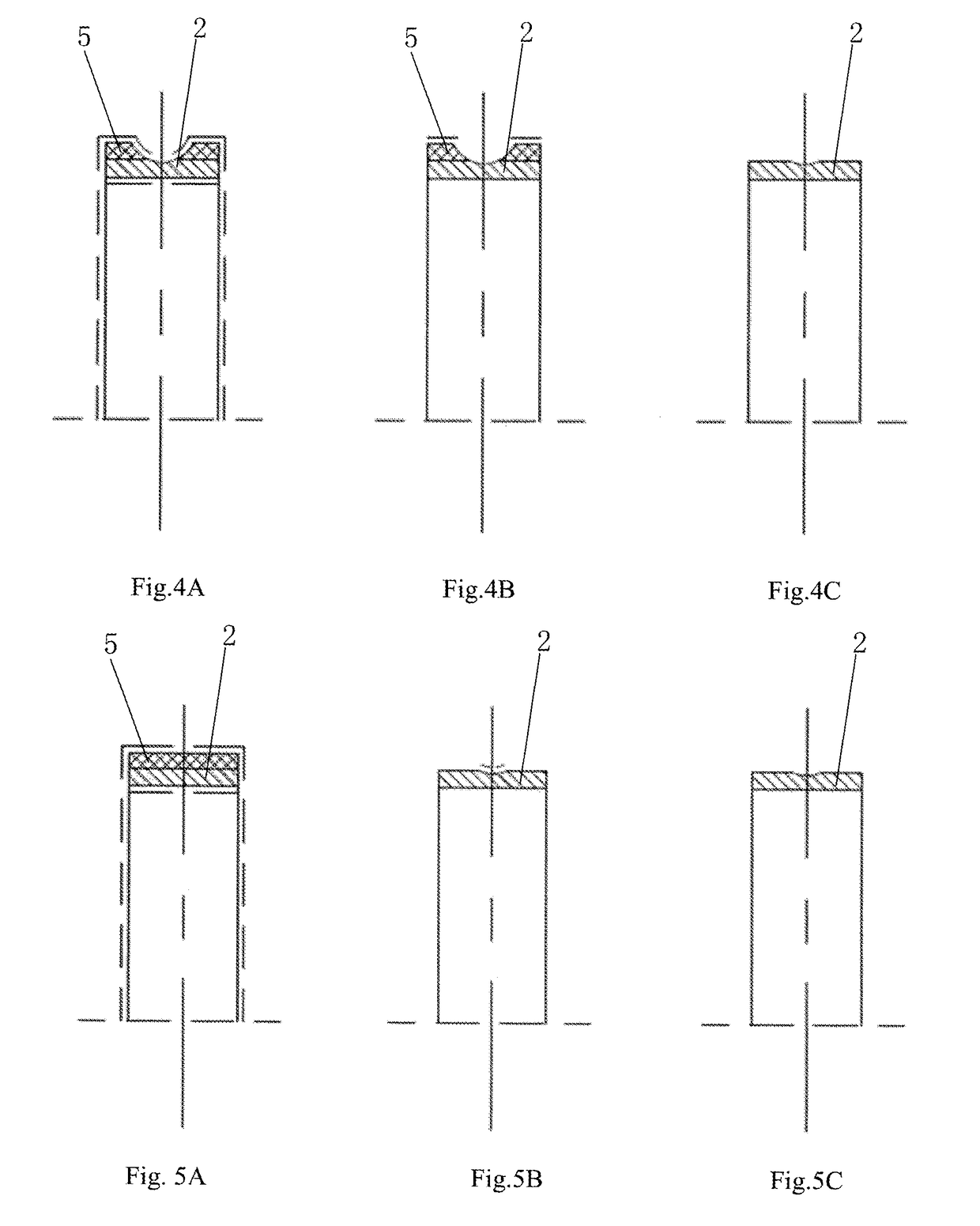

Manufacturing method of thin-wall bearing and method for machining thin-wall inner ring/outer ring of the thin-wall bearing as well as precise flexible bearing

ActiveUS20180328409A1Low efficiencyLow costBall bearingsBearing componentsBall bearingSuperfinishing

The invention provides a manufacturing method for thin-wall bearing and a method for machining a thin-wall inner ring / outer ring as well as a precision flexible bearing. The method for machining the thin-wall inner ring / outer ring comprises the following steps of: S0. providing a thin-wall ring with machining allowance left; S1: reinforcing along the radial direction and / or axial direction of the thin-wall ring; S2: carrying out quenching-tempering heat treatment on the reinforcing ring obtained by reinforcement in the S1; S3: carrying out corresponding grinding, hard cutting and super finishing on the reinforcing ring after receiving heat treatment, which includes removal of the machining allowance and a reinforcing part obtained by reinforcement in the S1, thereby obtaining finished thin-wall ring product. The thin-wall ring reinforced machining method substantially reduces and even avoids deformation of the thin-wall ring in all manufacturing links, thereby obtaining very high machining precision. The precision thin-wall bearing and the precision flexible bearing can be manufactured by fitting of the precision thin-wall ring and a precision rolling body.

Owner:SHANGHAI F&S BEARING TECH

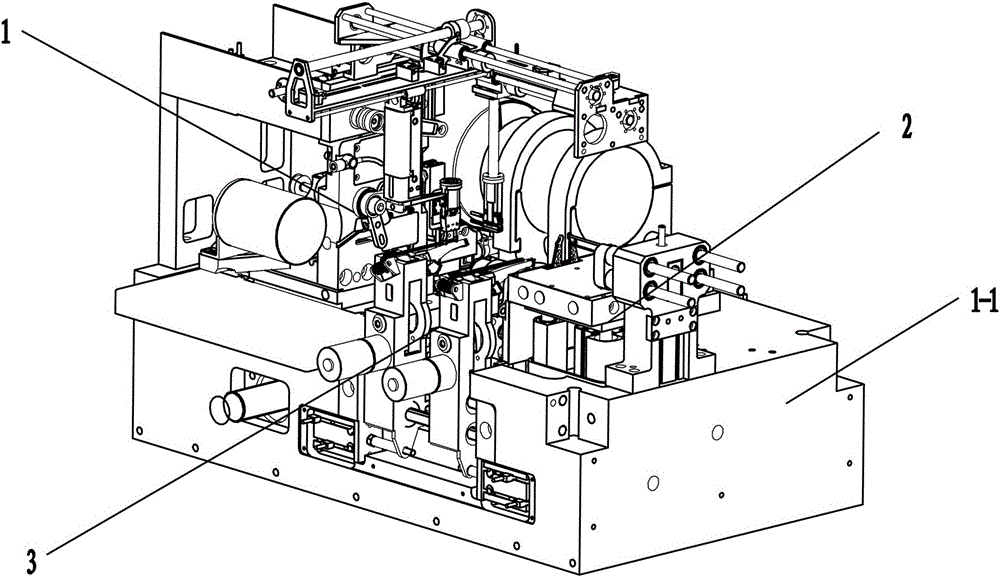

Outer-diameter superfinishing machine tool for spherical roller

ActiveCN102303279AOptimizing the ultra-finishing processImprove surface qualitySuperfinishing machinesLow noiseElectrical control

The invention discloses an outer-diameter superfinishing machine tool for a spherical roller. The machine tool comprises a bed body, an electric control cabinet and a cooling mechanism, as well as a loading / unloading mechanism, a workpiece transmission mechanism, a swinging mechanism and a superfinishing mechanism, wherein the bed body is provided with an upright; a box body is mounted on the upright; the workpiece transmission mechanism is mounted on the front portion of the bed body; an upright and a box body are mounted on the rear portion of the workpiece transmission mechanism; the swinging mechanism comprises a swinging main shaft and an oil stone plunge cylinder; the swinging main shaft is mounted on the front end of the swinging main shaft; the oil stone plunge cylinder is mounted on the rear portion of the swinging main shaft; the loading / unloading mechanism comprises a loading path and an unloading path; the loading path is mounted on the upper portion of the box body, while the unloading path is mounted on the lower portion of the workpiece transmission mechanism; all the mechanisms are arranged in a totally enclosed housing; and the electric control cabinet is arranged on the right side of the housing. The machine tool has the advantages of low roughness degree value, low roundness, long service life and low noise, etc.

Owner:WUXI RUIDING MACHINE TOOLS

Superfinishing Large Planetary Gear Systems

ActiveUS20080104842A1Reduces and eliminates lubricant debrisEdge grinding machinesPolishing machinesGear wheelEngineering

Owner:REM TECHNOLOGY INC +1

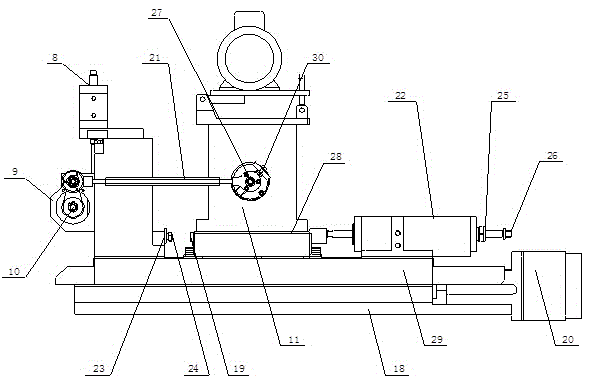

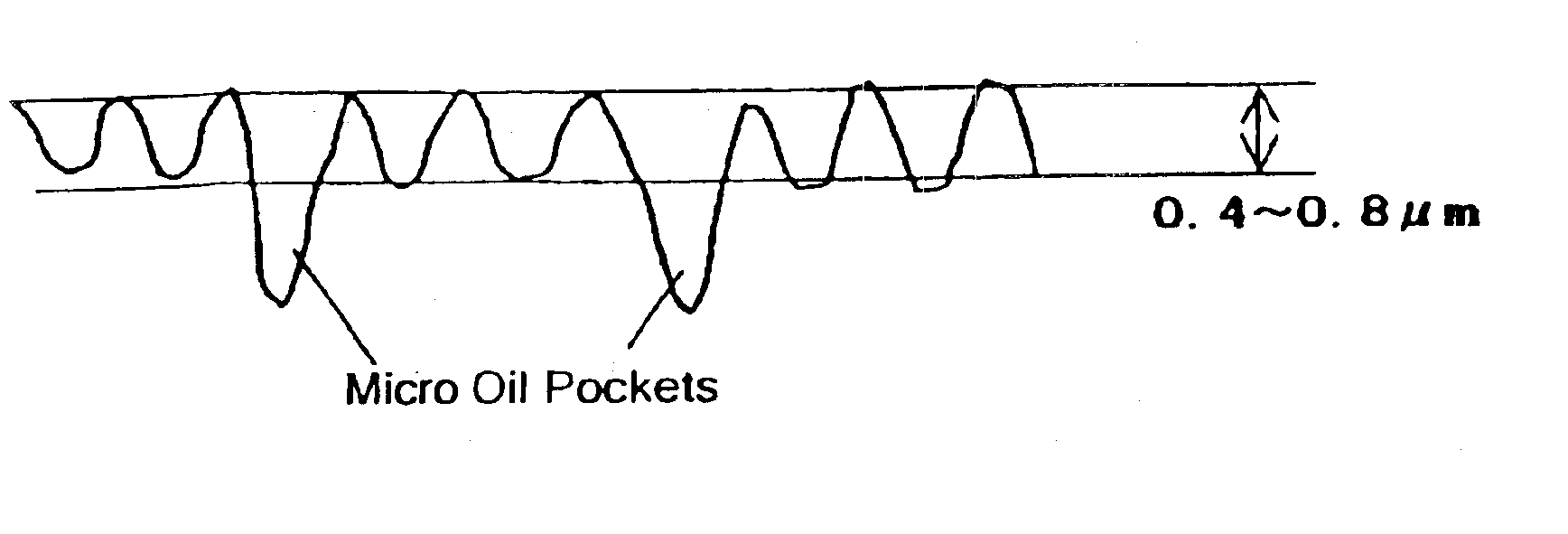

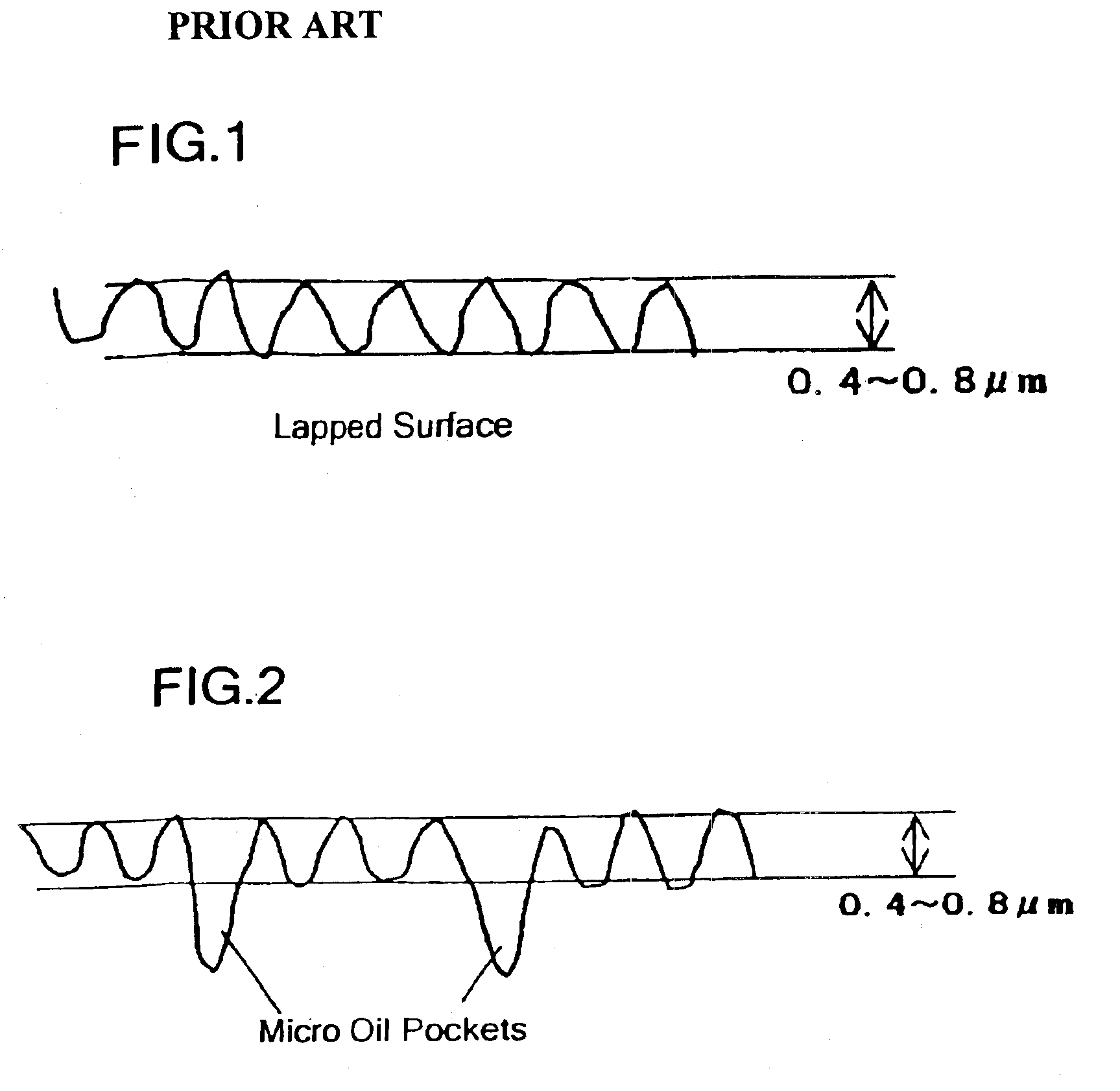

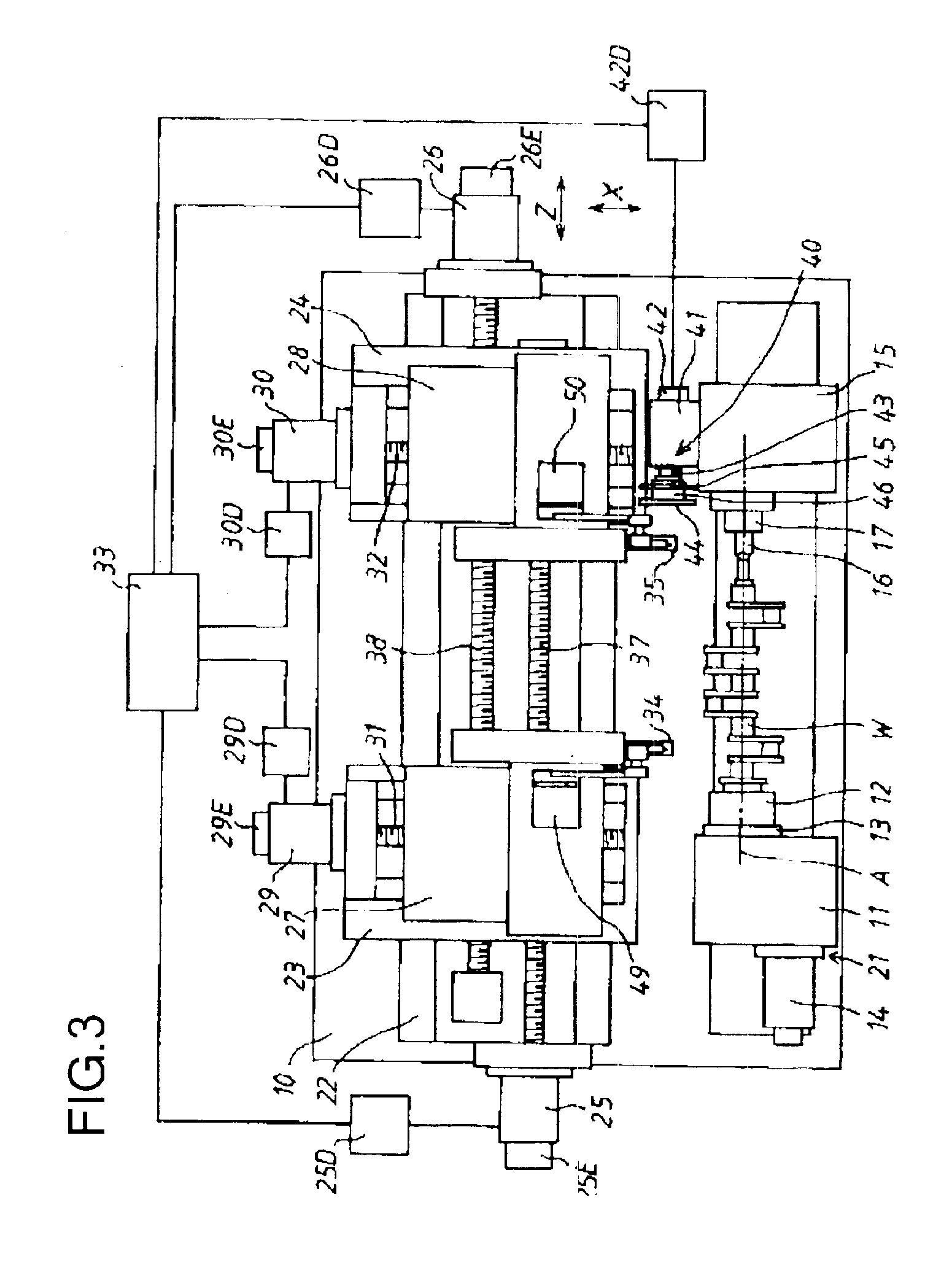

Method and apparatus for grinding workpiece surfaces to super-finish surface with micro oil pockets

InactiveUS6852015B2High quality of surface roughnessLong useful lifeEdge grinding machinesRevolution surface grinding machinesSurface roughnessSuperfinishing

A grinding machine rotatably carrying a finish grinding wheel and a super-finish grinding wheel respectively on first and second wheel heads practices a method of grinding workpiece surfaces to super-finish surfaces with micro oil pockets. A surface of a workpiece rotatably carried on the machine is first ground with the finish grinding wheel to a predetermined diameter under the control of a sizing device. The workpiece surface is then ground with the super-finish grinding wheel to a target diameter under the control of a sizing device. The super-finish grinding is performed to the extent that peaks of a section curve representing the roughness of the workpiece surface attained by the finish grinding are removed but bottoms of the surface curve are left to a depth when the target diameter is reached, so that the bottoms so left of the roughness constitute the micro oil pockets.

Owner:TOYODA MASCH WORKS LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com