Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2495 results about "Flanging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flanging /ˈflændʒɪŋ/ is an audio effect produced by mixing two identical signals together, one signal delayed by a small and gradually changing period, usually smaller than 20 milliseconds. This produces a swept comb filter effect: peaks and notches are produced in the resulting frequency spectrum, related to each other in a linear harmonic series. Varying the time delay causes these to sweep up and down the frequency spectrum. A flanger is an effects unit that creates this effect.

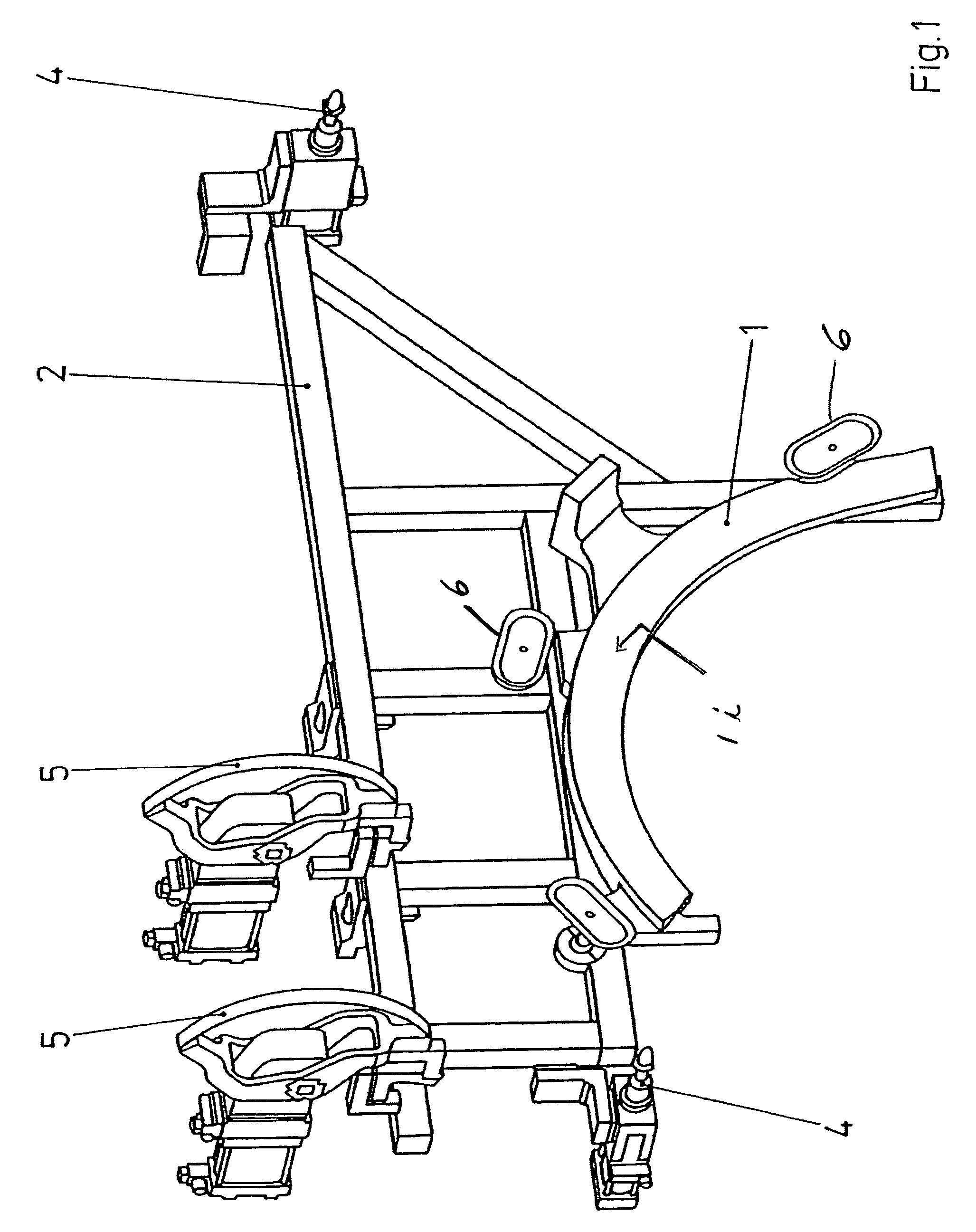

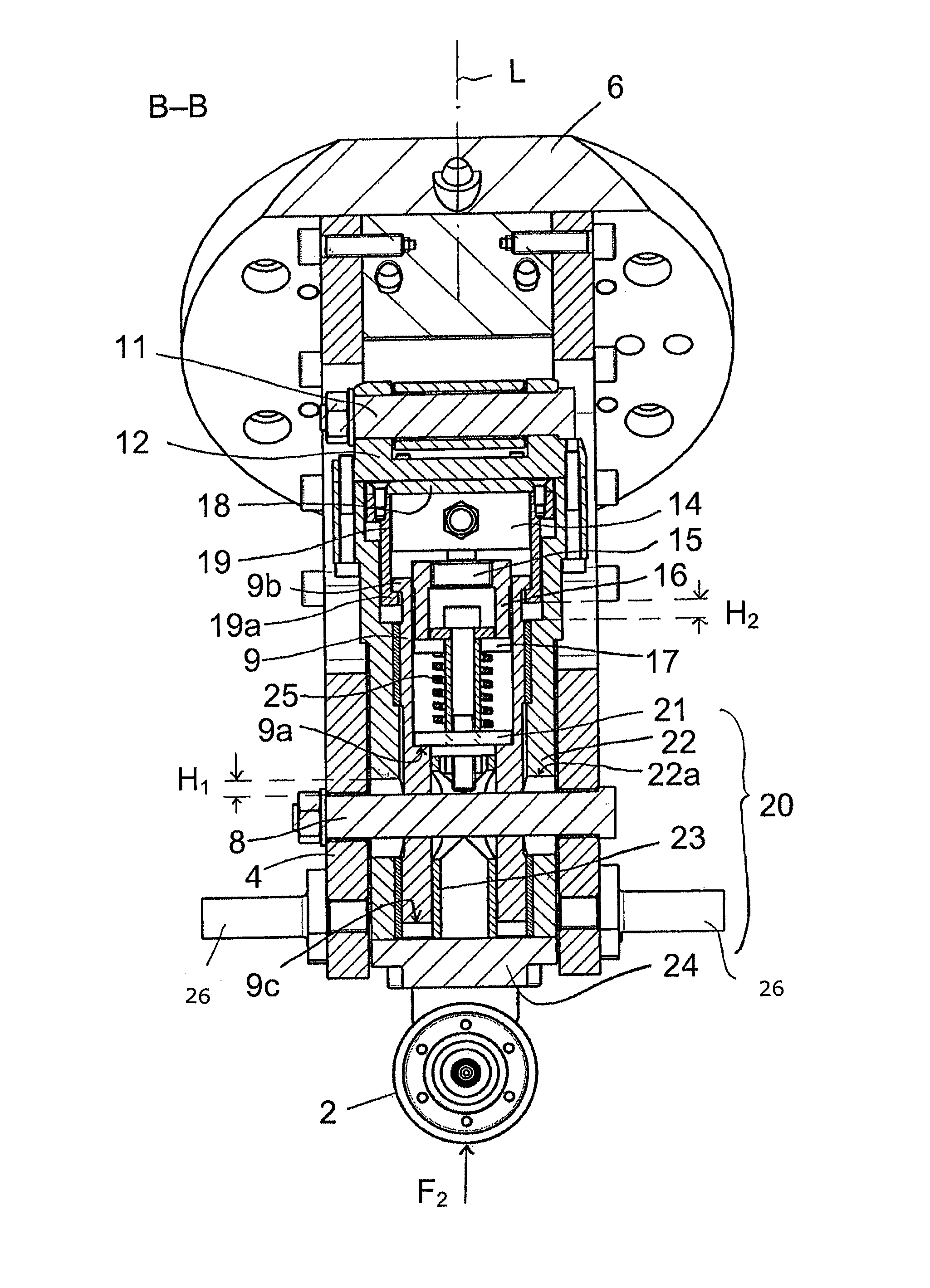

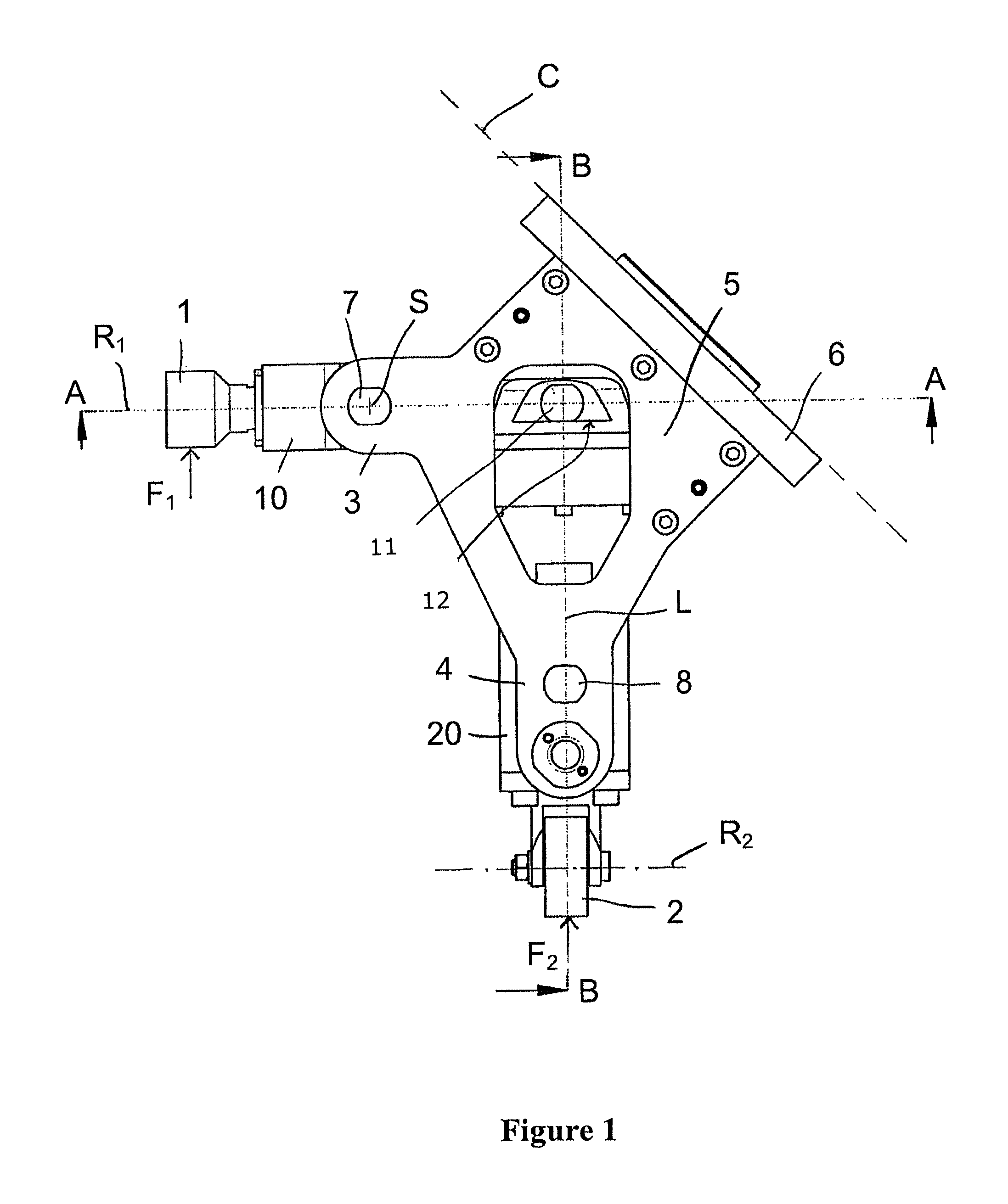

Flanging device and flanging method with component protection

ActiveUS7500373B2Adapt quicklyVehicle design optimisationMetal working apparatusCounter pressureEngineering

Owner:FFT PRODIONSSYST

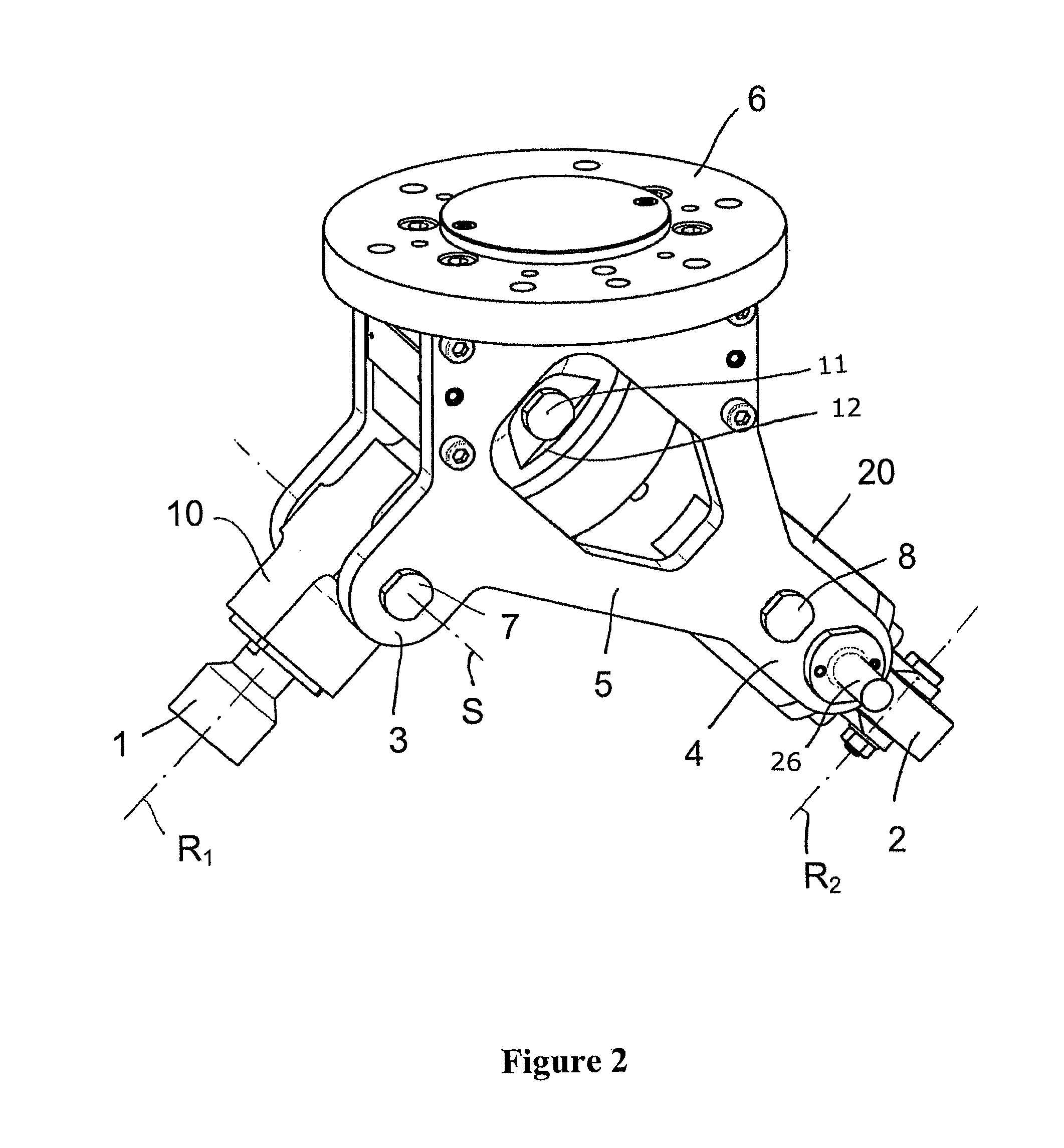

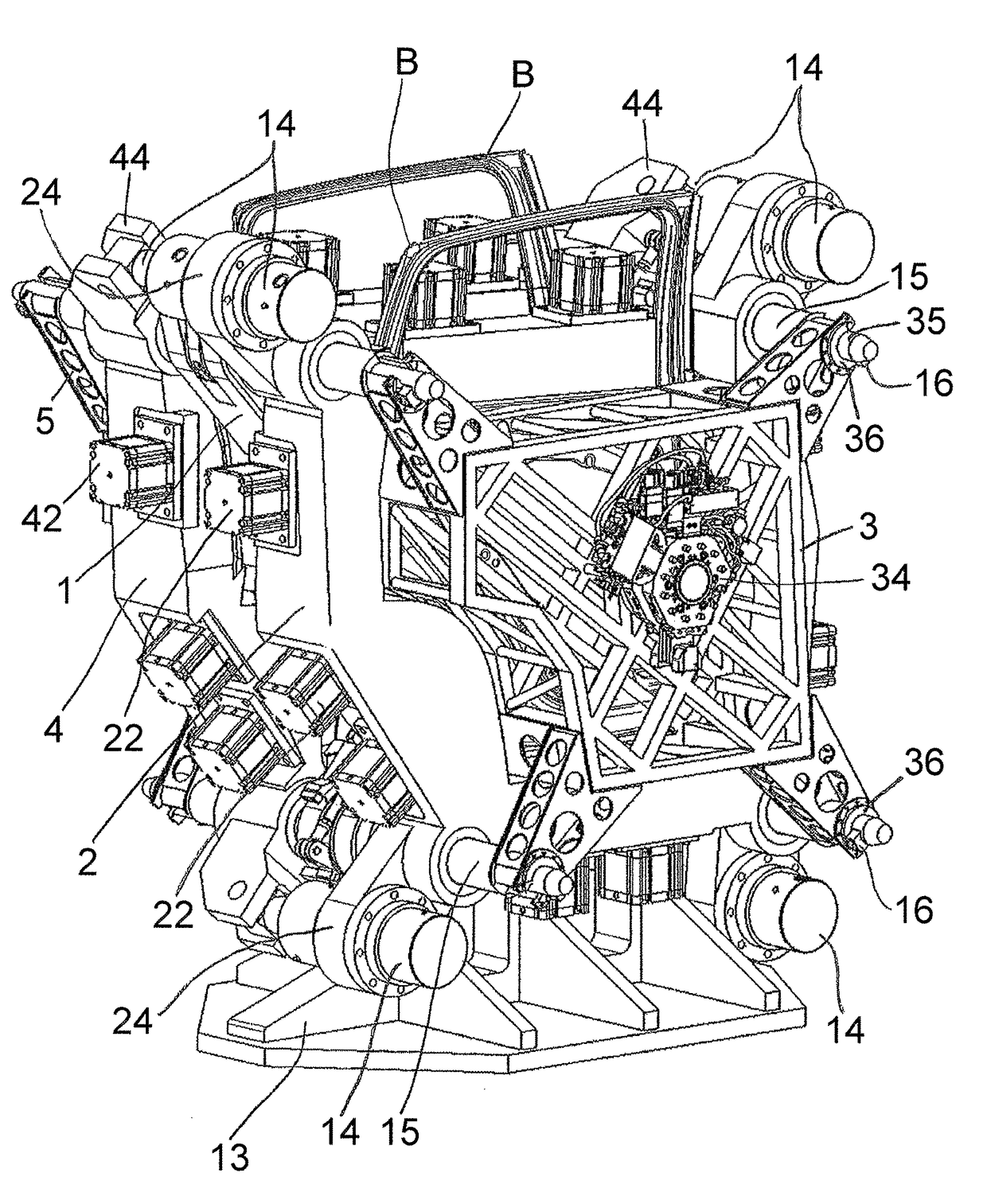

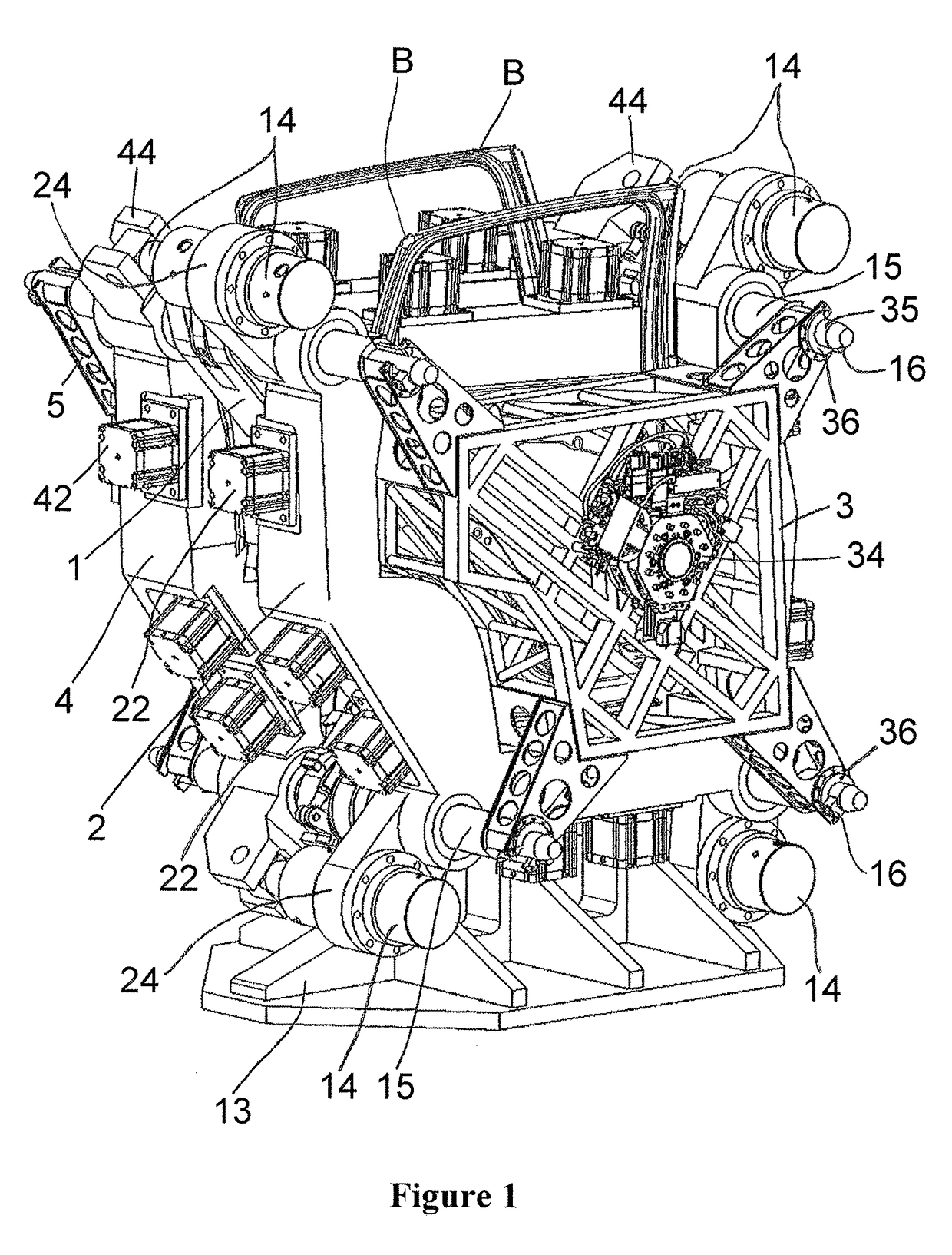

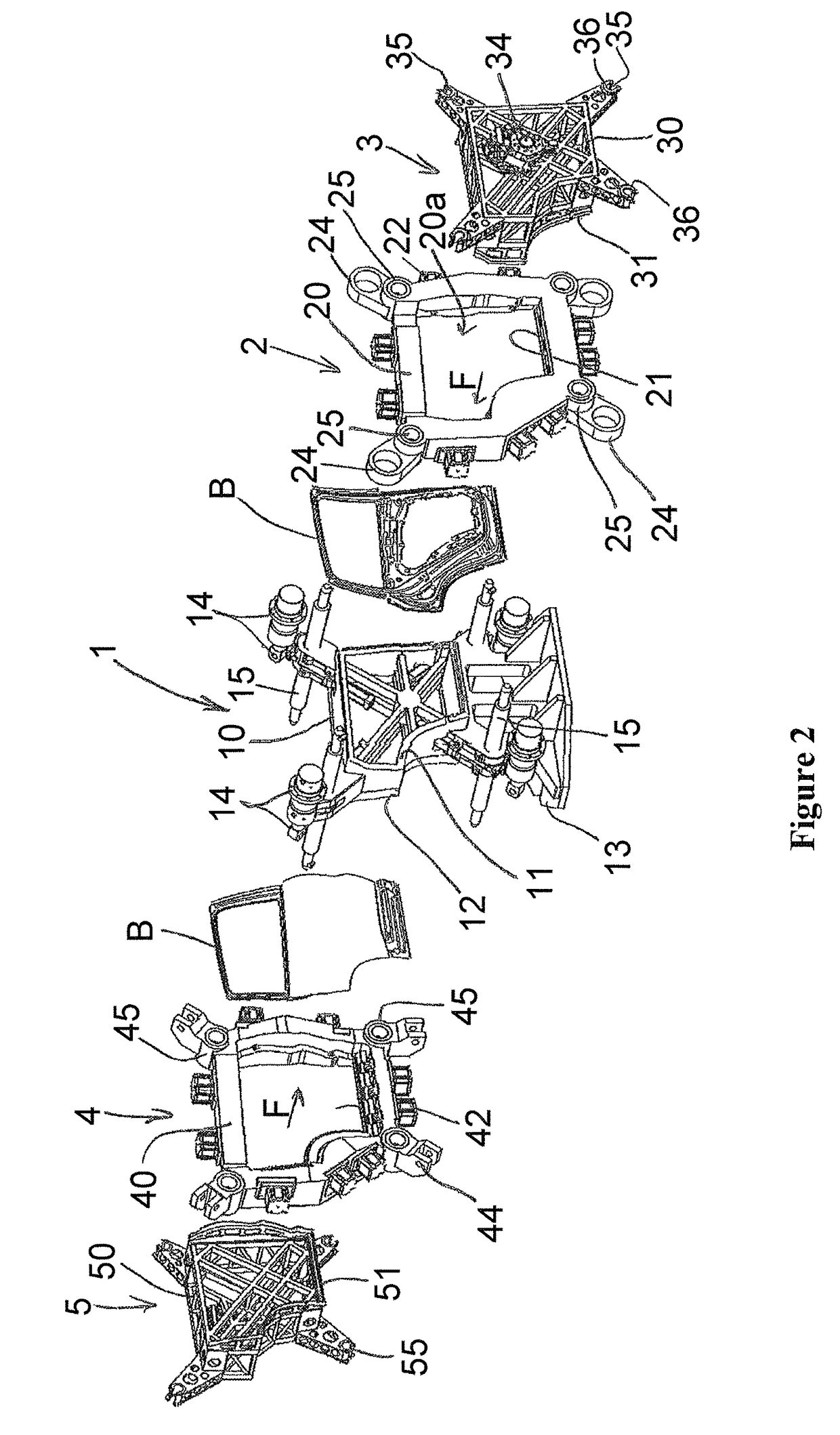

Edge curling tool

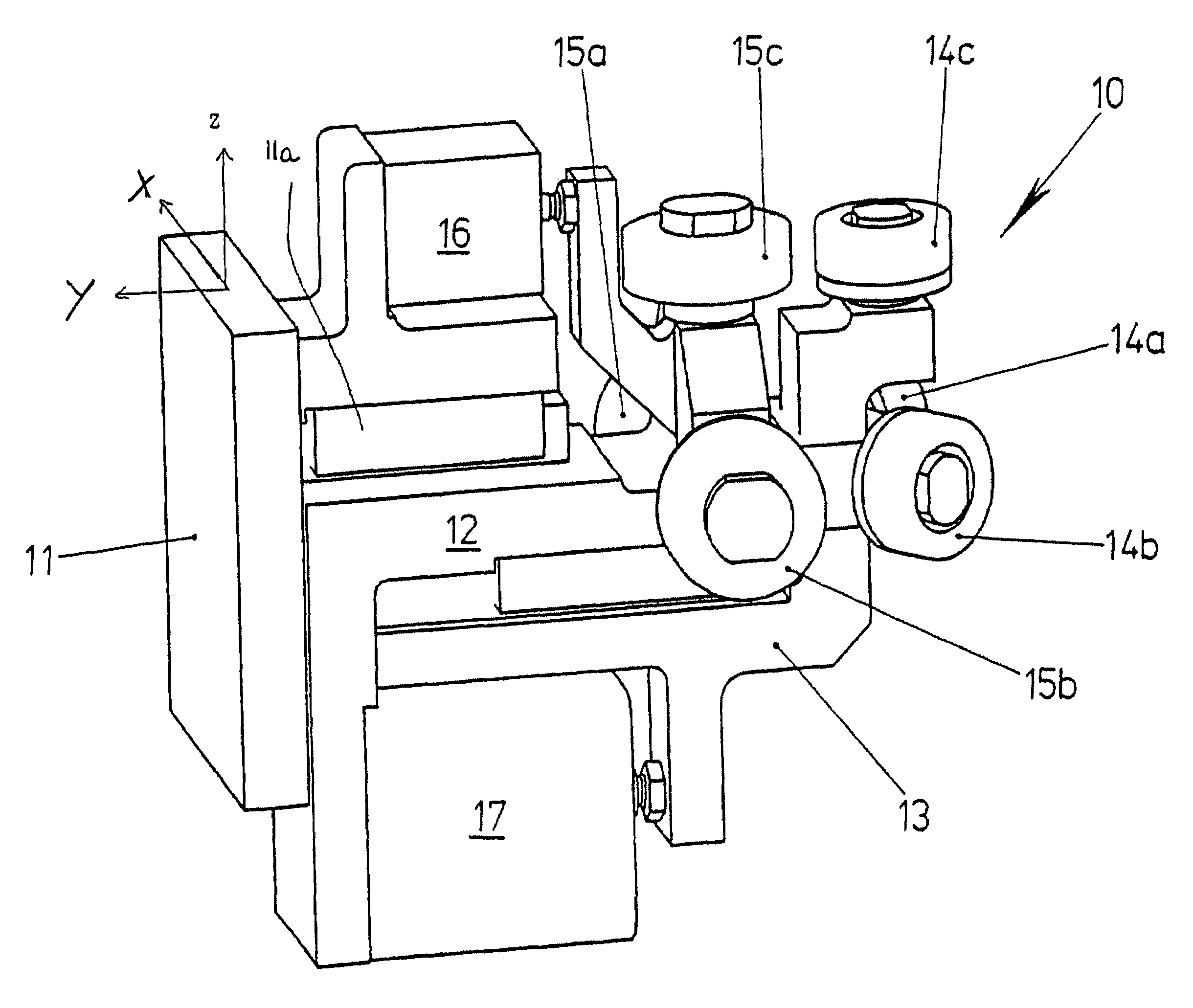

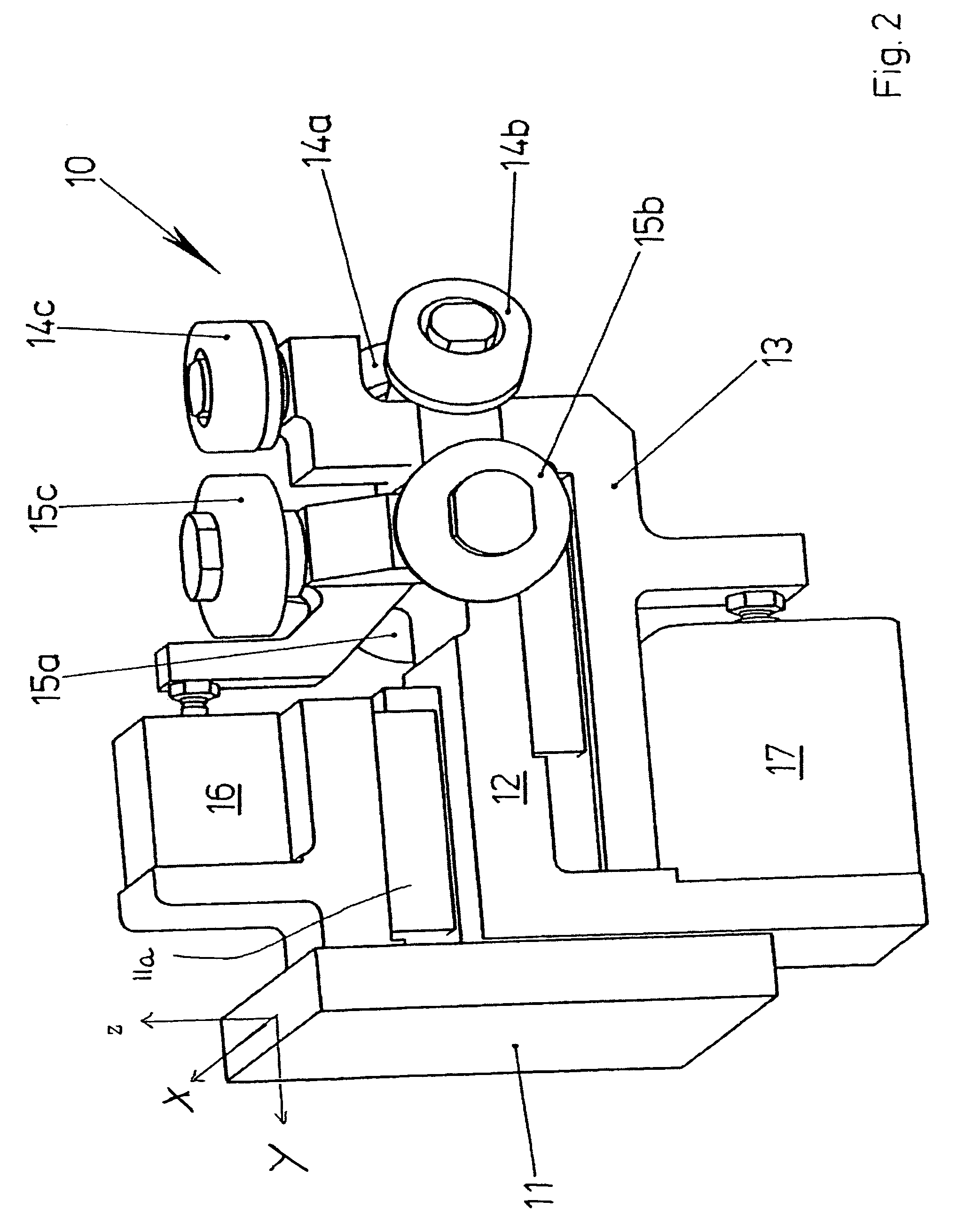

A roll-flanging tool, including a bearing structure having a connector, by which the tool can be connected via a connection plane to an actuator which can be moved spatially. A first arm and a second arm are spread apart from each other and connected to each other in a connection portion which includes the connector. A first flanging roller is mounted on an end of the first arm which faces away from the connection plane, such that it can be rotated about a first rotational axis which extends along the first arm and pierces the connection plane. A second flanging roller is mounted on an end of the second arm which faces away from the connection plane, such that it can be rotated about a second rotational axis. The first rotational axis intersects or crosses a perpendicular dropped onto the second rotational axis, in or on the roll-flanging tool.

Owner:FFT PRODIONSSYST

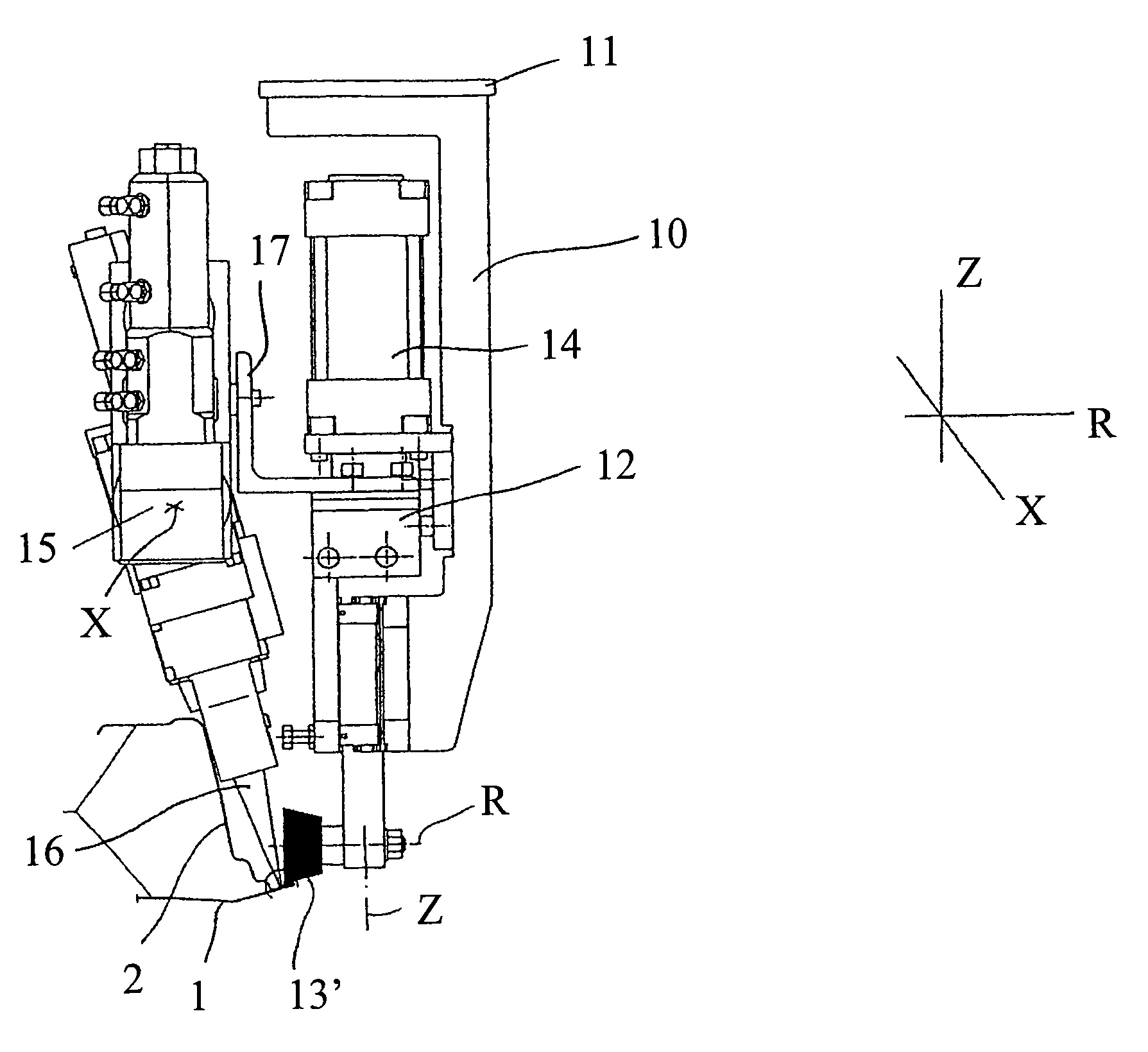

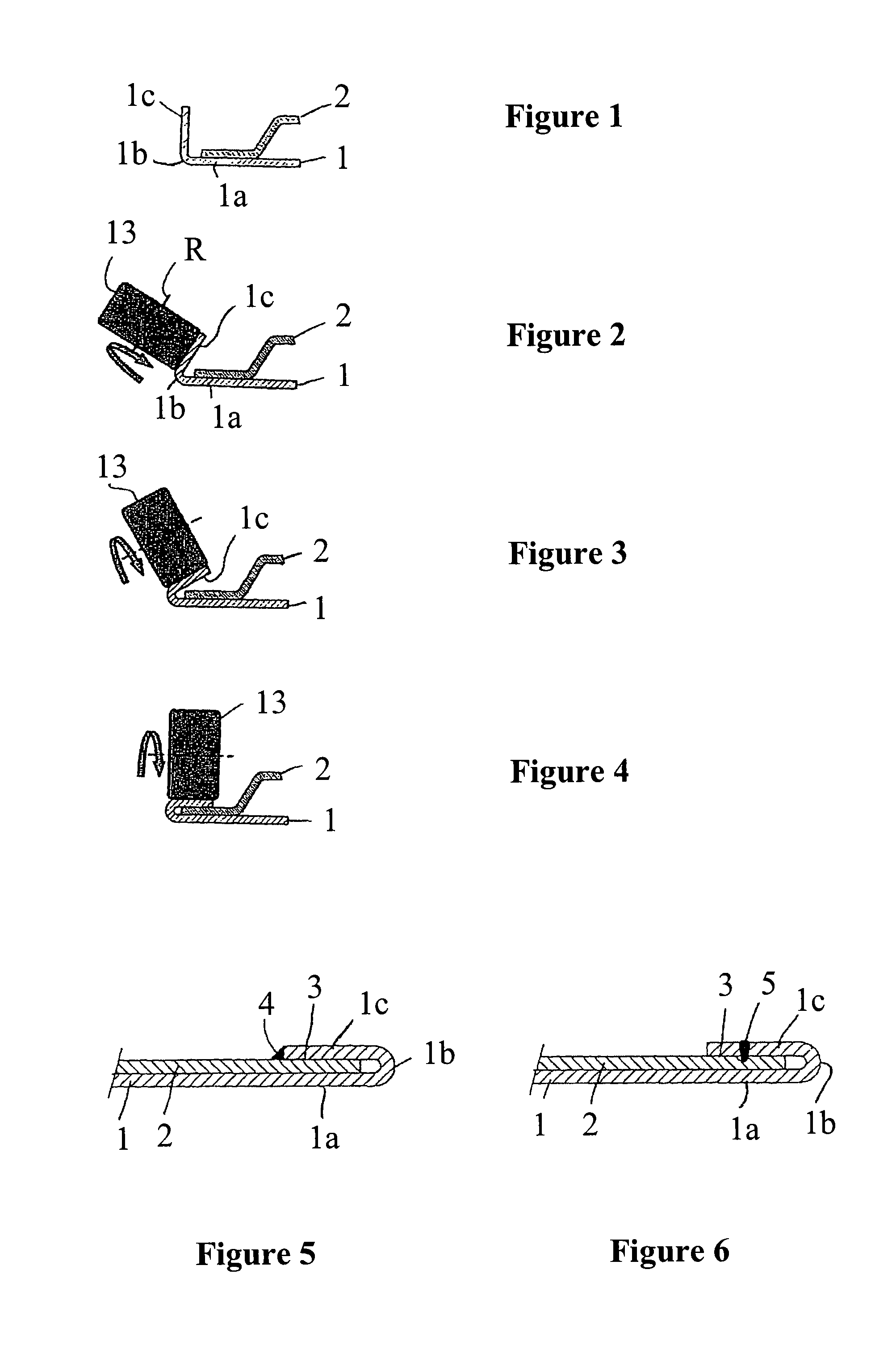

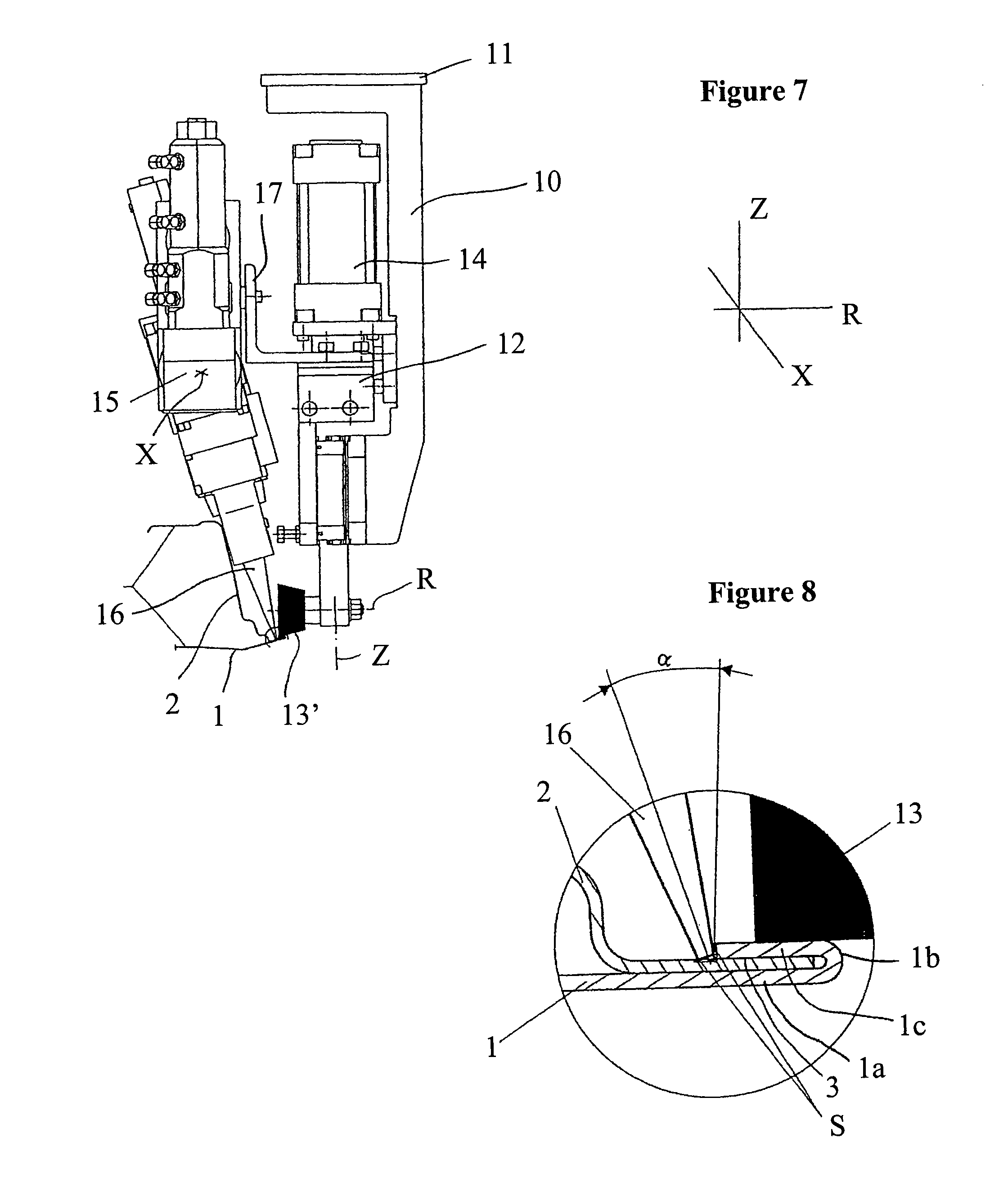

Sheet-metal composite, method for joining sheets and joining device

A metal sheet composite comprising an outer metal sheet having a flange which is folded over around a flanging edge; an inner metal sheet which forms a joint with the flange; and a welding or soldering seam which is produced on or in the joint and fixedly connects the metal sheets to each other. A method for joining metal sheets and a device for flanging and welding or soldering are also disclosed. The device includes: a tool head; a flanging member, arranged on the tool head, for roll-flanging or slide-flanging; and a welding or soldering tool arranged on the tool head, wherein the flanging member and the welding or soldering tool are arranged such that the flanging member forms a pressing means for a welding or soldering process which can be performed using the welding or soldering tool.

Owner:KOPIN CORPORATION

Flanging press

ActiveUS9776234B2Firmly connectedStrong pressing forcePositioning apparatusMetal-working holdersEngineeringFlanging

Owner:FFT PRODIONSSYST

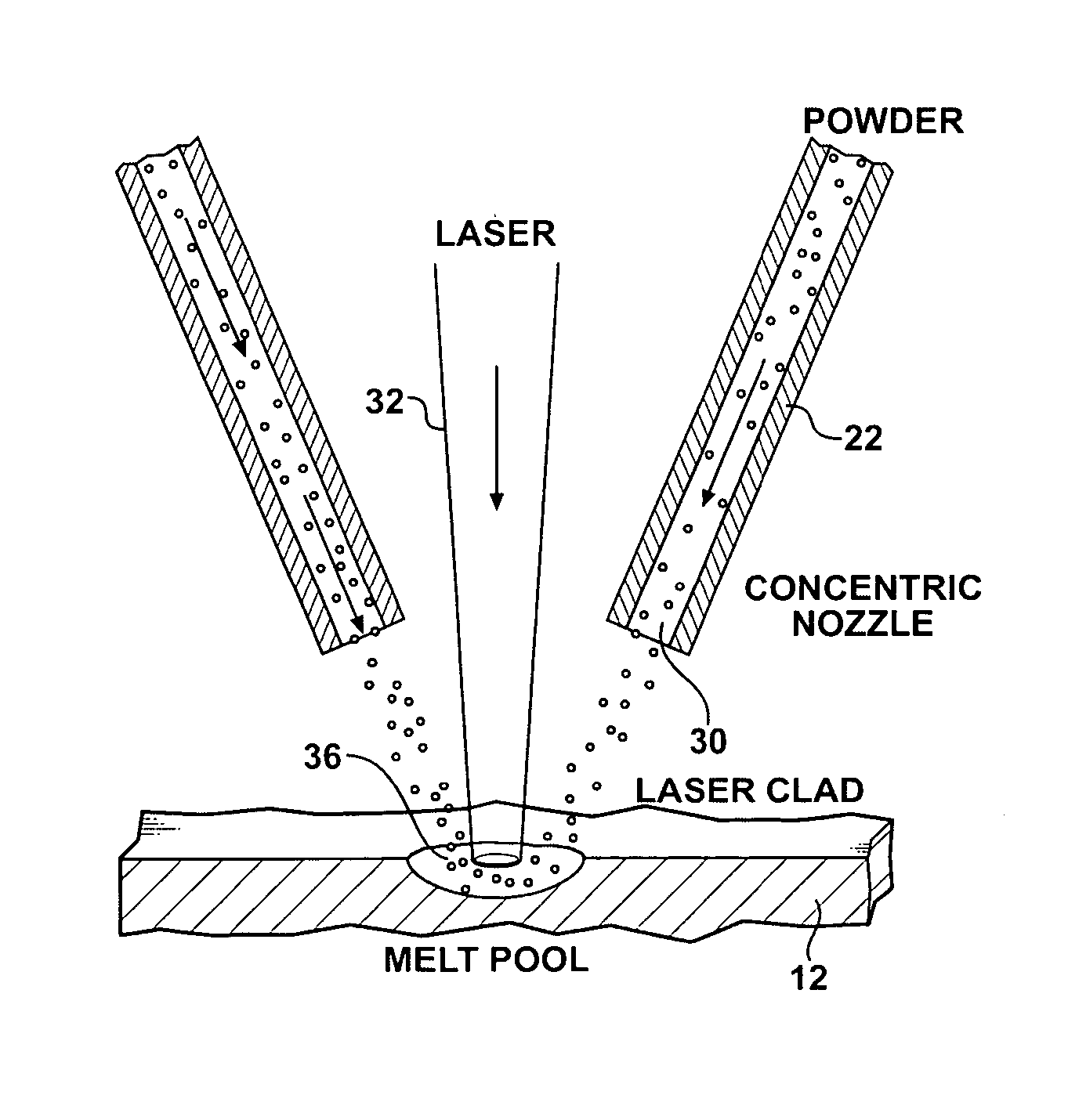

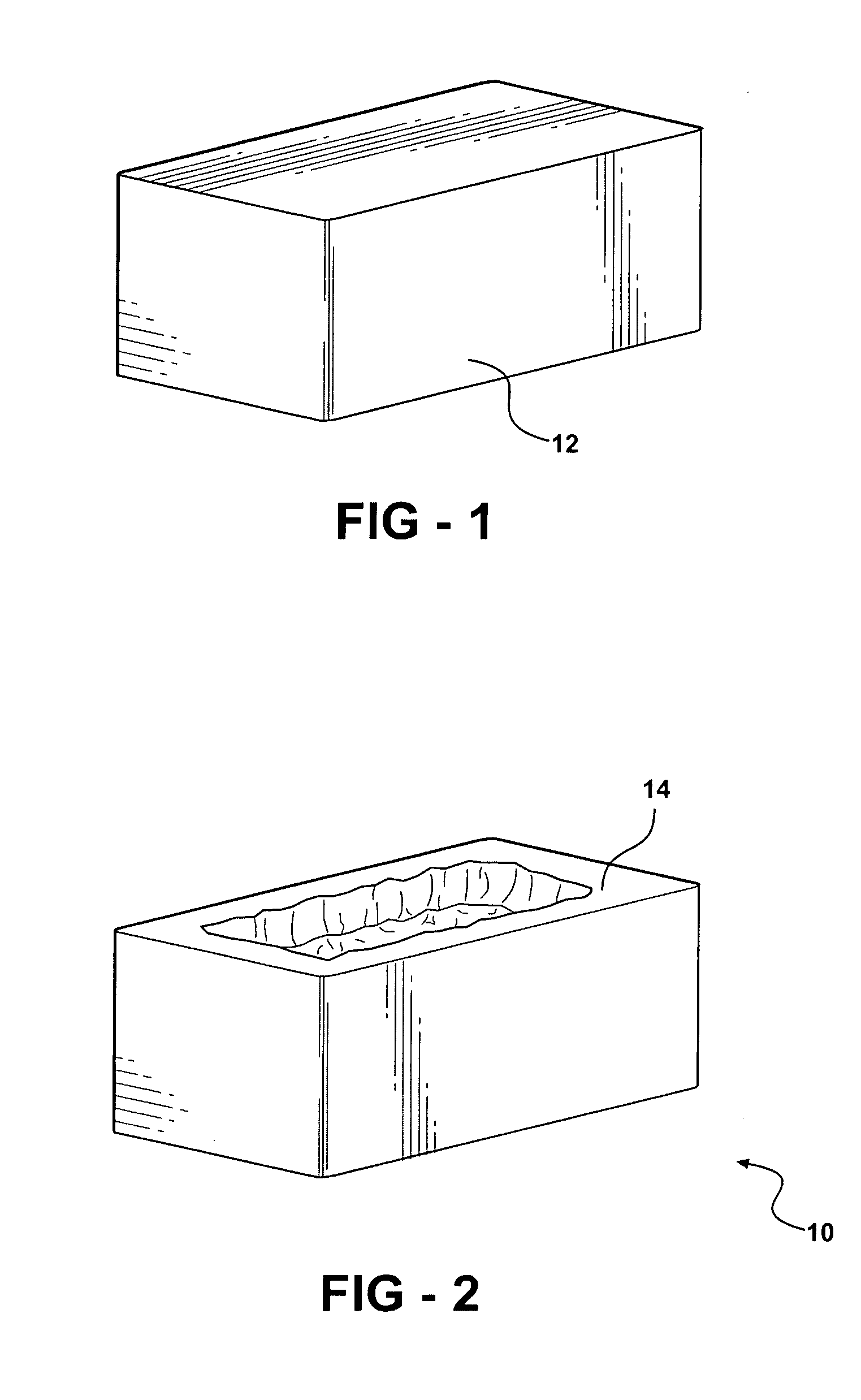

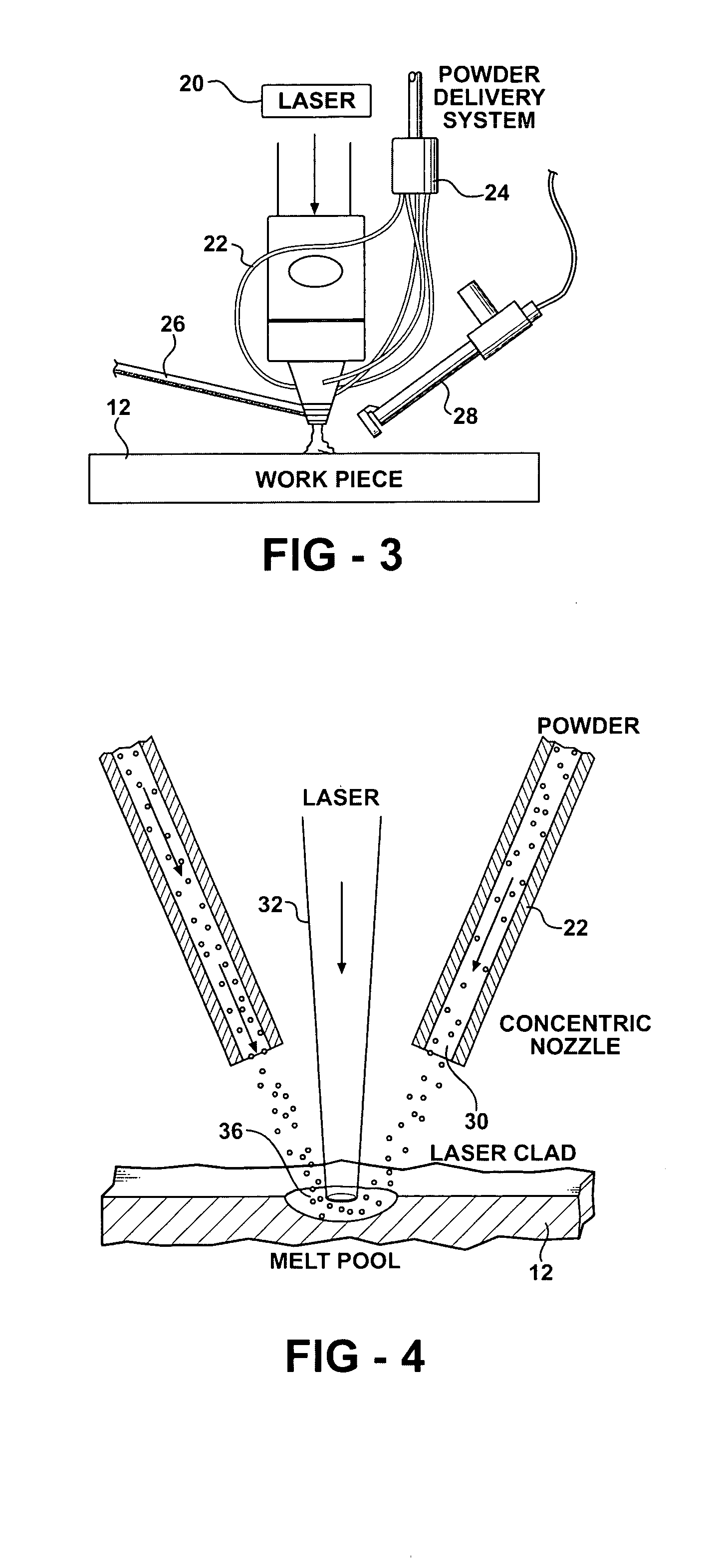

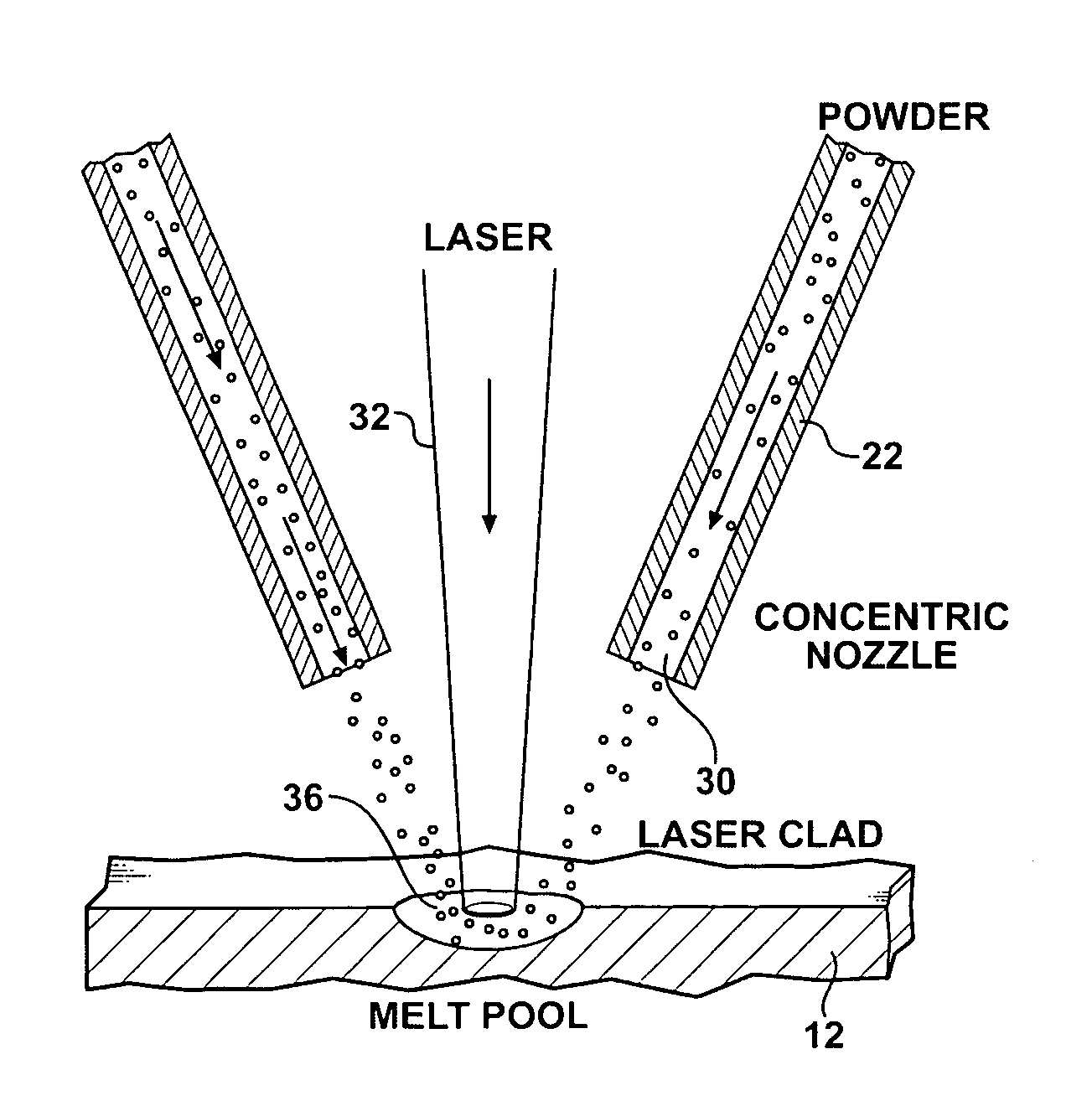

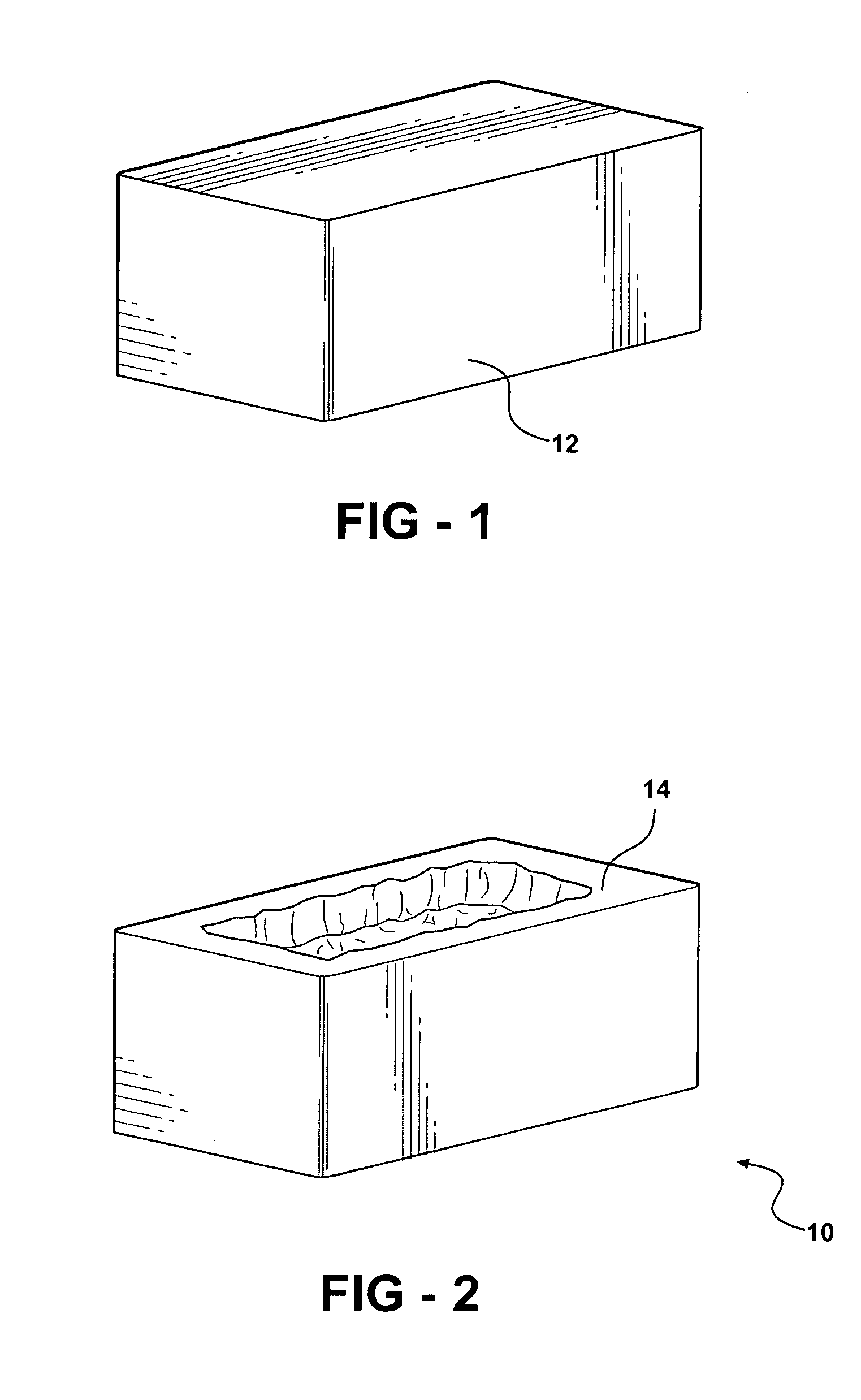

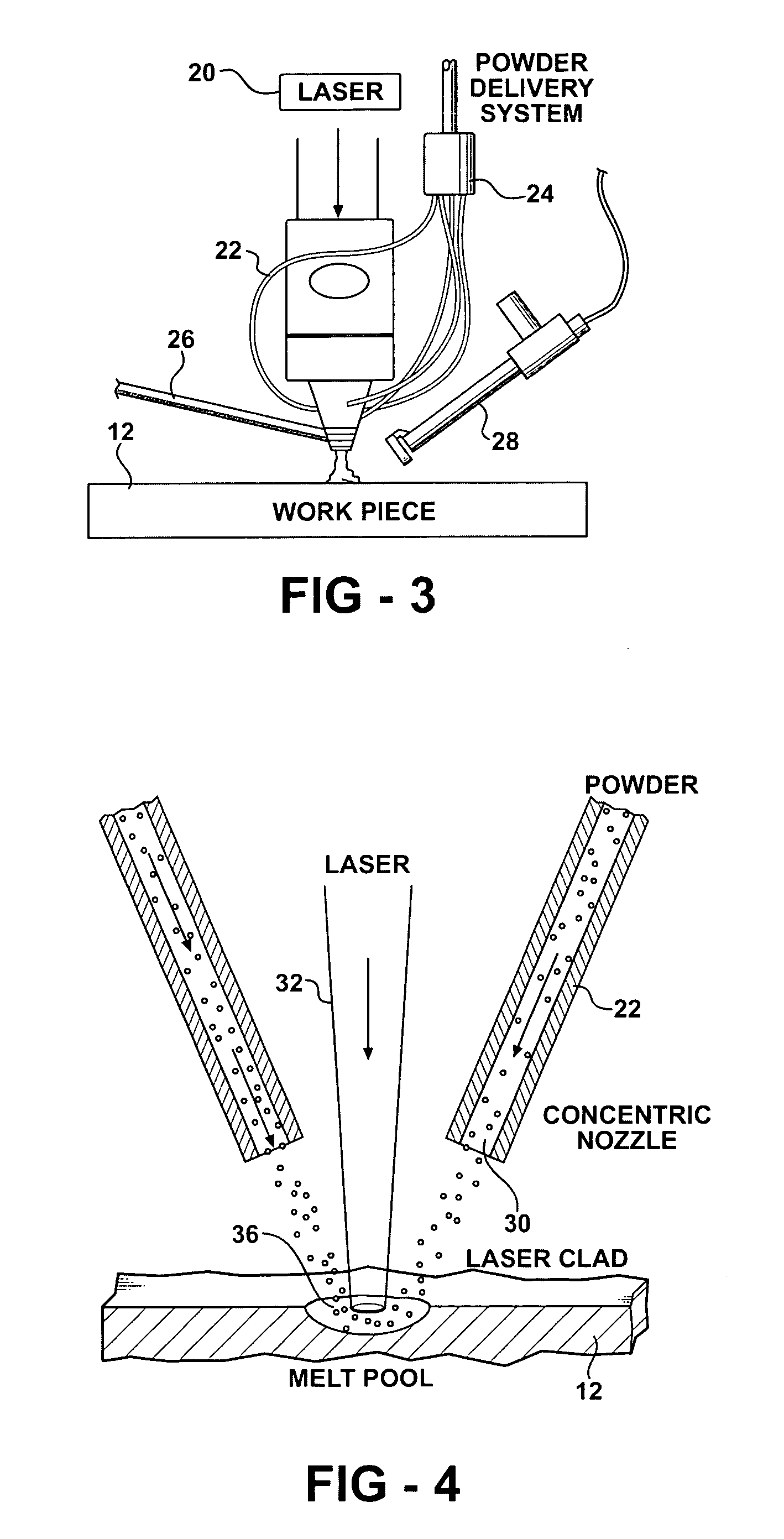

Method of fabricating composite tooling using closed-loop direct-metal deposition

ActiveUS20050038551A1Maximize performance service lifeAvoid lack of toughnessAdditive manufacturing apparatusRadiation applicationsWear resistantClosed loop

Manufacturing tools having a base and a working surface, such as trim steels, flange steels and die inserts, are formed by fabricating or casting a substrate out of a relatively ductile, low wear-resistant metal and forming the working surfaces such as cutting edges, flanging surfaces, die surfaces and die inserts by depositing layers of relatively hard, wear-resistant materials to the substrate by closed-loop direct-metal deposition or laser cladding. A multi-axis numerically controlled robot may be used to position and move a beam and deposition material over large substrates in forming such tooling.

Owner:MAZUMDER JYOTI +1

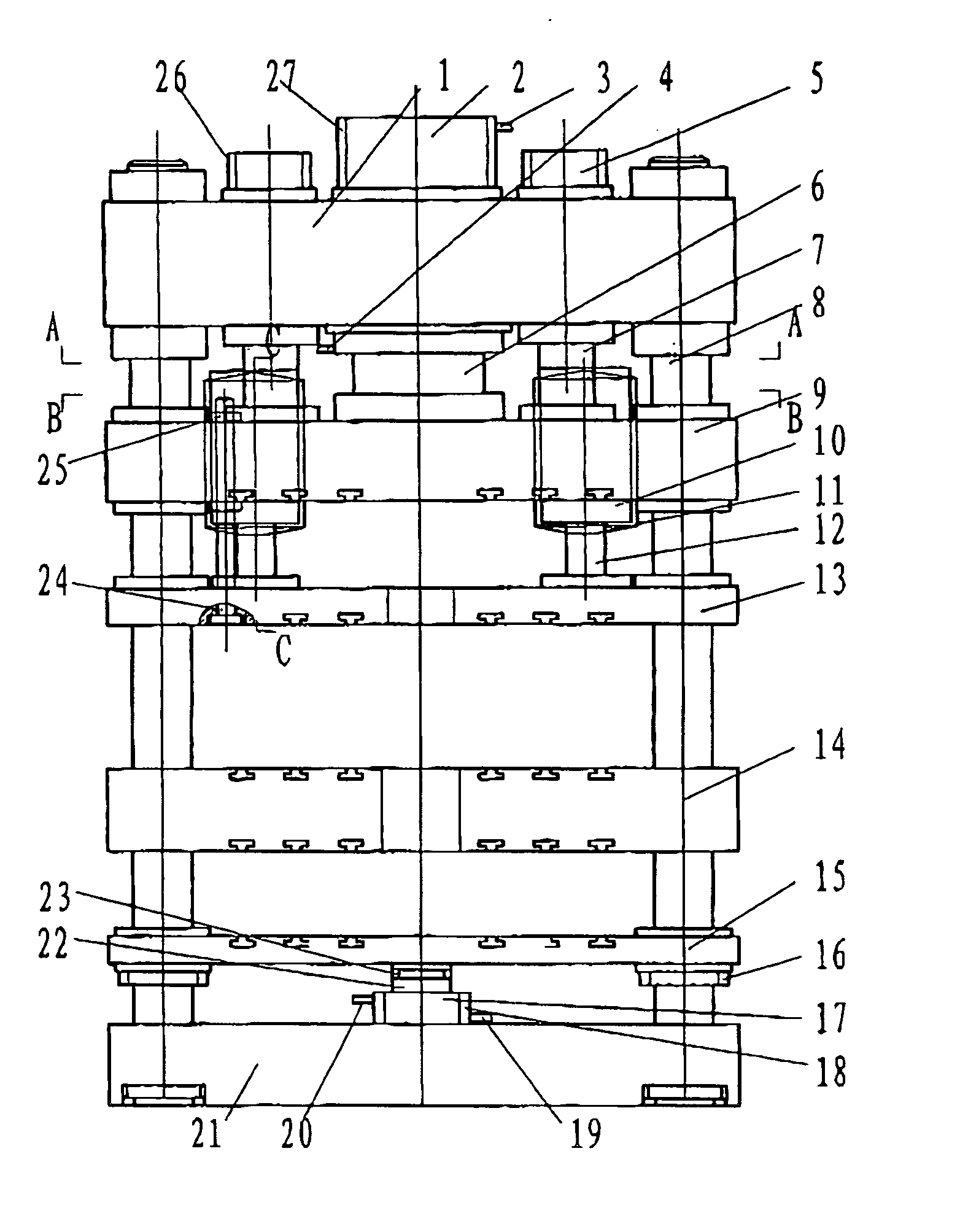

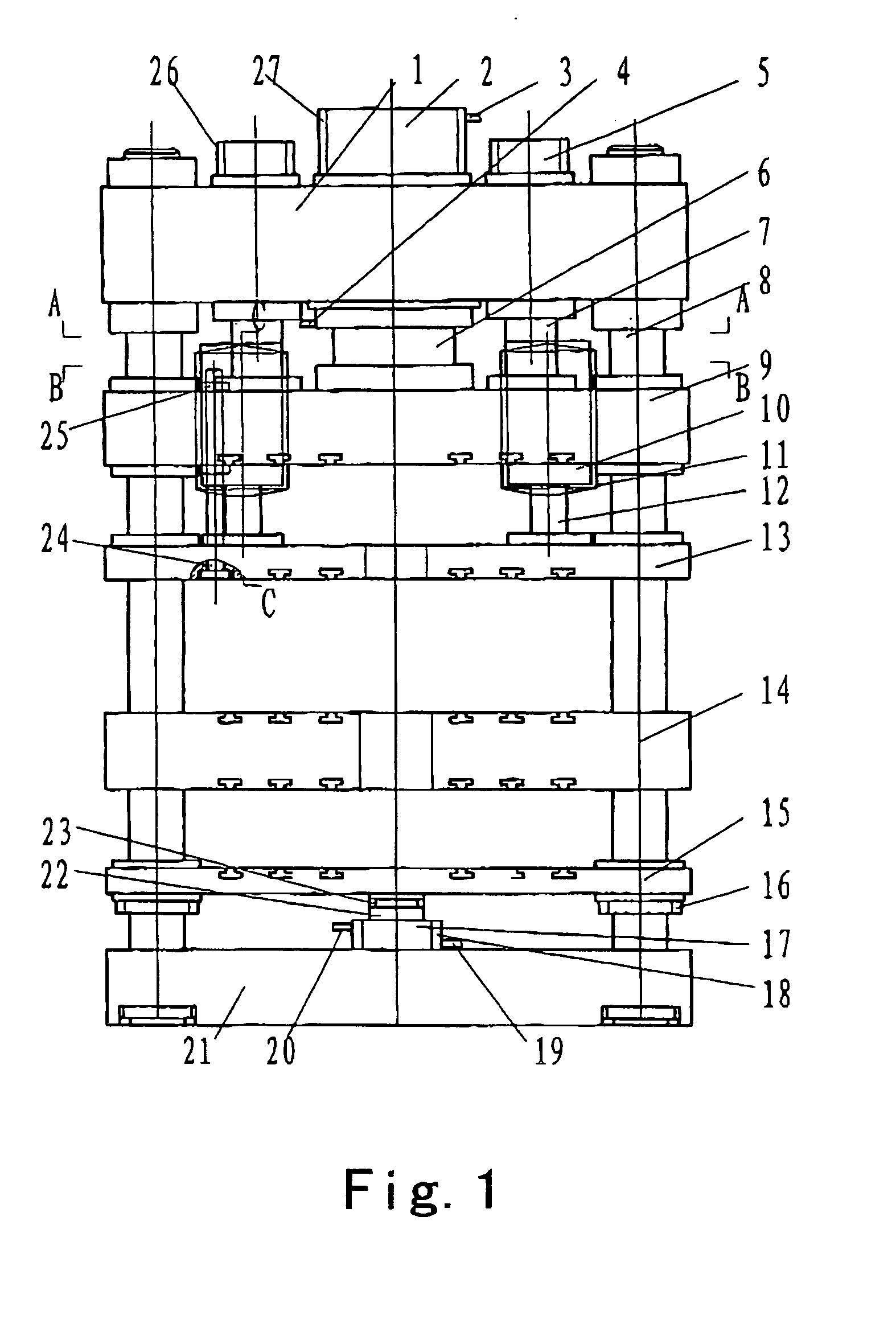

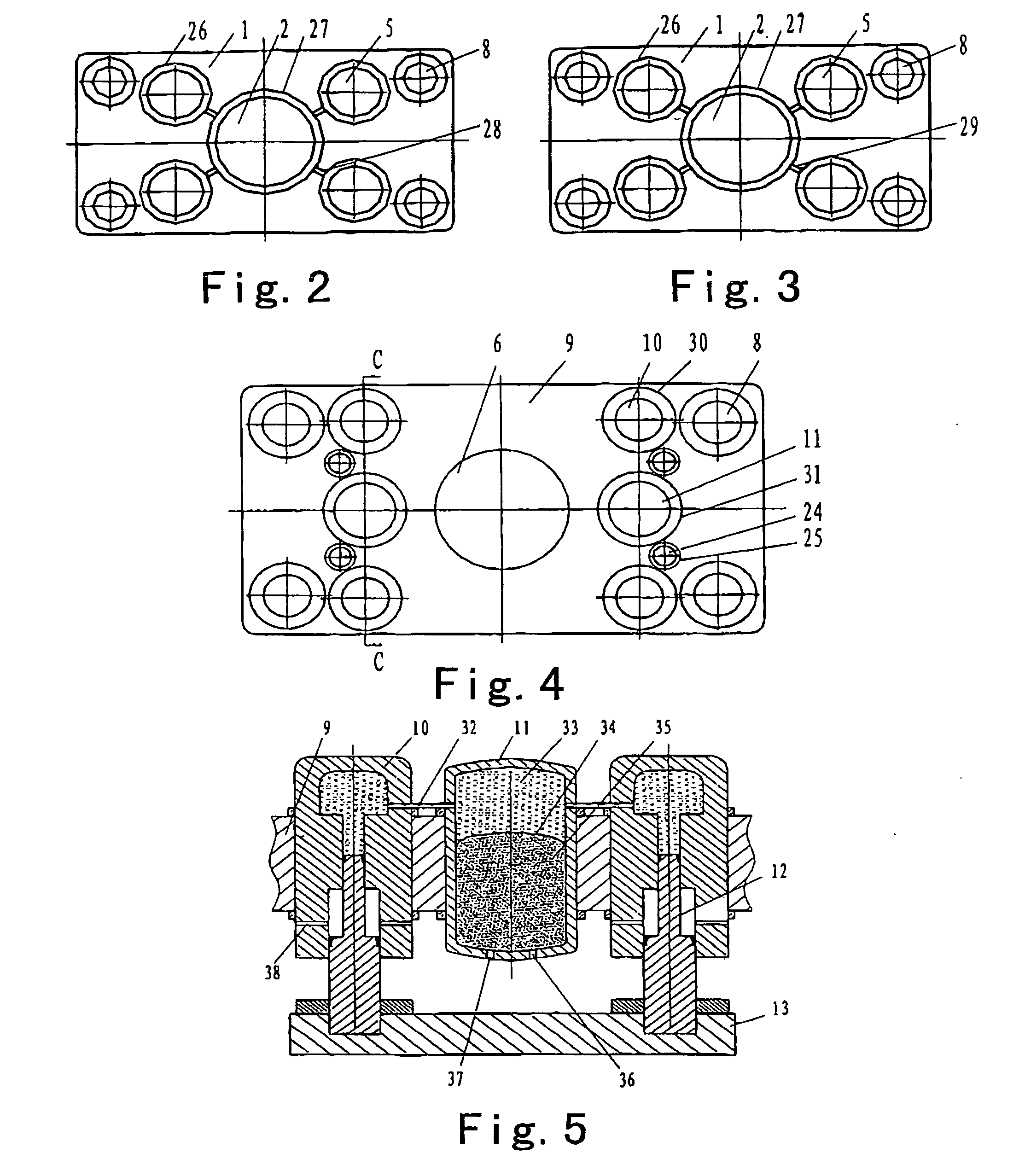

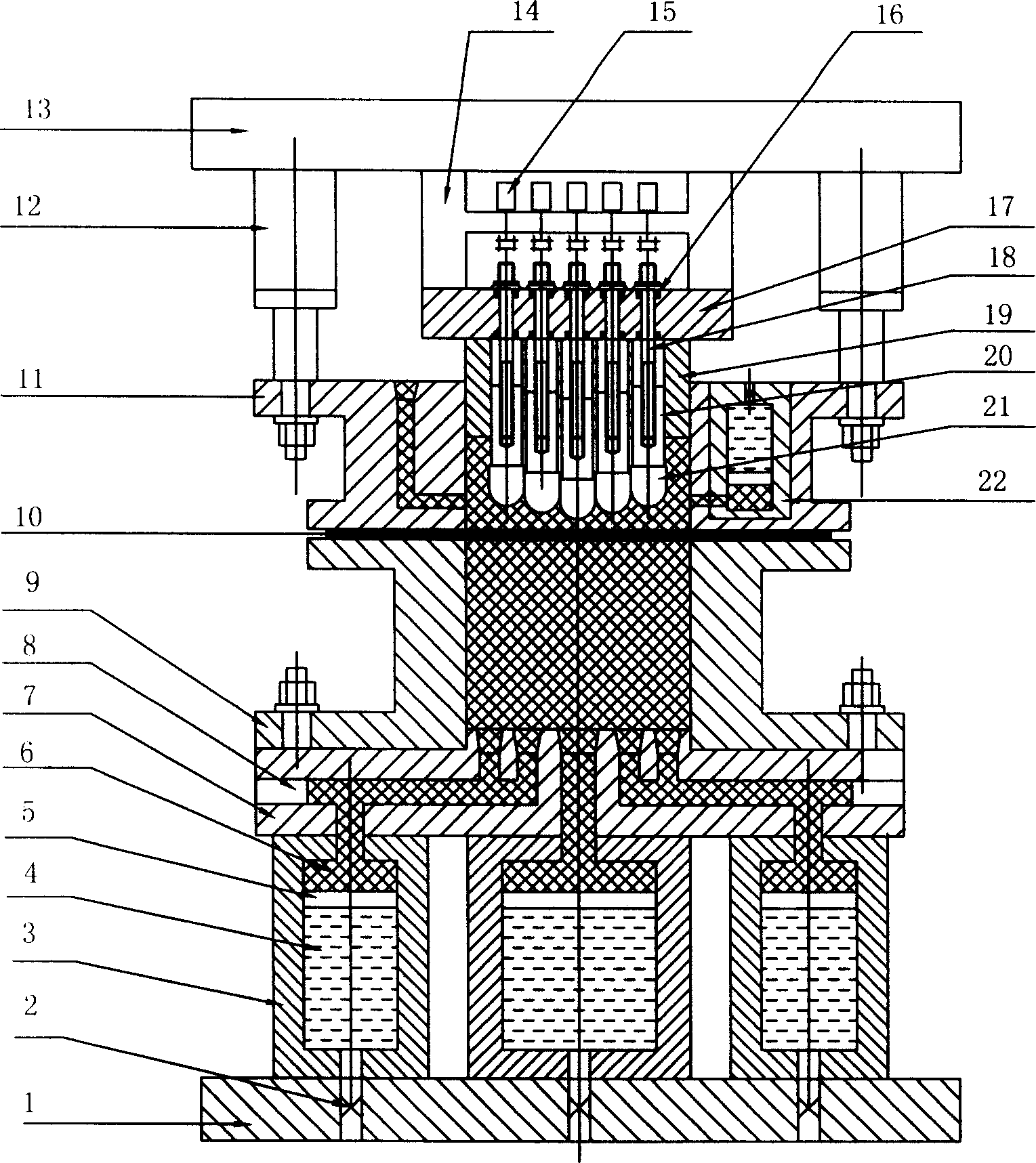

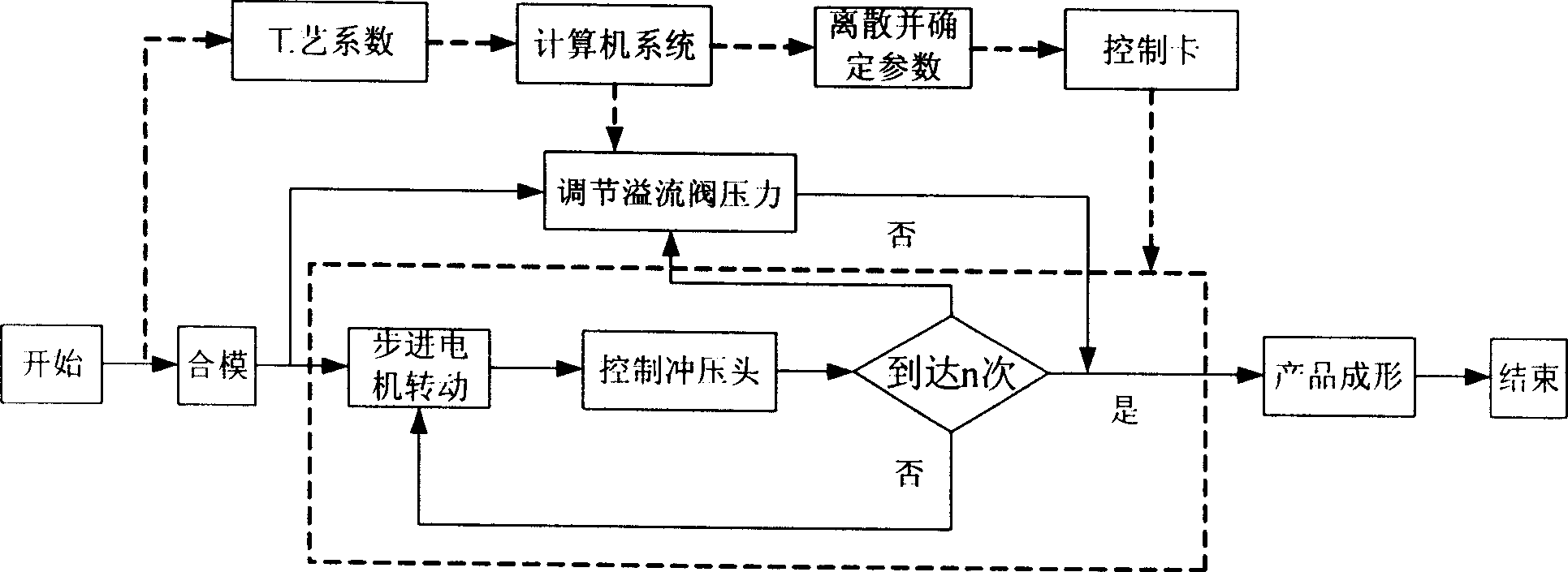

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

High-strength steel sheets and processes for production of the same

InactiveUS20090277547A1Improve stamping formabilityHigh strengthFurnace typesHeat treatment furnacesFlangingEquivalent weight

A high strength steel sheet with both excellent elongation and stretch-flanging performance is provided.The high strength steel sheet of the present invention comprises, in percent by mass, C: 0.05 to 0.3%, Si: 0.01 to 3.0%, Mn: 0.5 to 3.0%, Al: 0.01 to 0.1%, and Fe and inevitable impurities as the remainder, and has a structure mainly composed of tempered martensite and annealed bainite. The space factor of the tempered martensite is 50 to 95%, the space factor of the annealed bainite is 5 to 30%, and the mean grain size of the tempered martensite is 10 μm or smaller in terms of the equivalent of a circle diameter. The steel sheet has a tensile strength of 590 MPa or higher.The high strength steel sheet of the present invention has a space factor of the martensite phase which is a main component of the metal structure is 80% or higher; the mean grain size of the martensite phase is 10 μm or smaller in terms of the equivalent of a circle diameter; in the martensite phase, the space factor of the martensite phase having a grain size of 10 μm or larger in terms of the equivalent of a circle diameter is 15% or lower; and the space factor of the retained austenite phase in the metal structure is 3% or lower.The high strength steel sheet of the present invention is a dual phase steel sheet mainly composed of a ferrite phase and martensite, and the space factor of the ferrite phase is 5 to 30%, and the space factor of the martensite phase is 50 to 95%. Moreover, the ferrite phase is annealed martensite.

Owner:KOBE STEEL LTD

Method of fabricating composite tooling using closed-loop direct-metal deposition

InactiveUS7139633B2Maximize performance service lifeAvoid lack of toughnessAdditive manufacturing apparatusRadiation applicationsWear resistantClosed loop

Manufacturing tools having a base and a working surface, such as trim steels, flange steels and die inserts, are formed by fabricating or casting a substrate out of a relatively ductile, low wear-resistant metal and forming the working surfaces such as cutting edges, flanging surfaces, die surfaces and die inserts by depositing layers of relatively hard, wear-resistant materials to the substrate by closed-loop direct-metal deposition or laser cladding. A multi-axis numerically controlled robot may be used to position and move a beam and deposition material over large substrates in forming such tooling.

Owner:MAZUMDER JYOTI +1

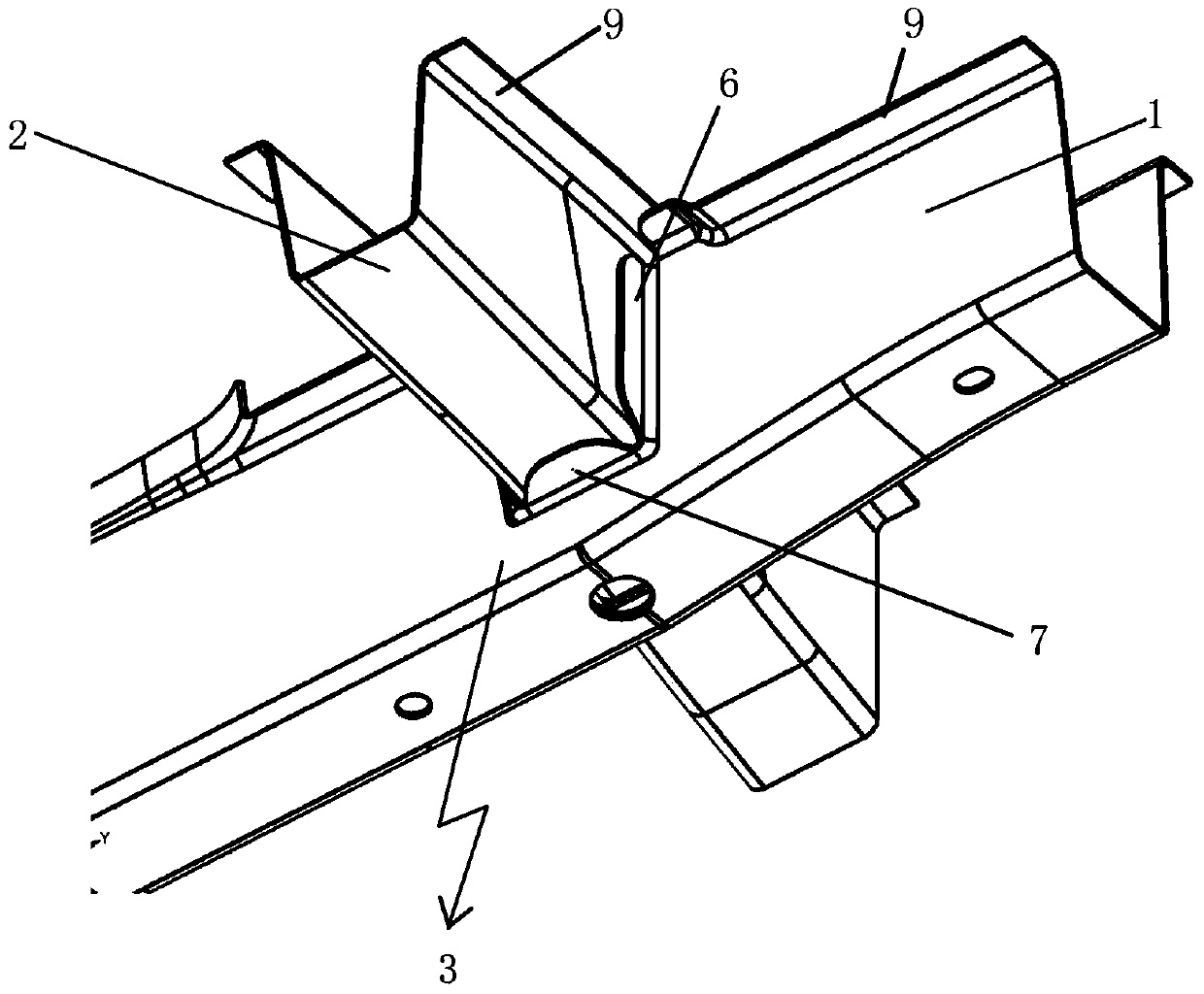

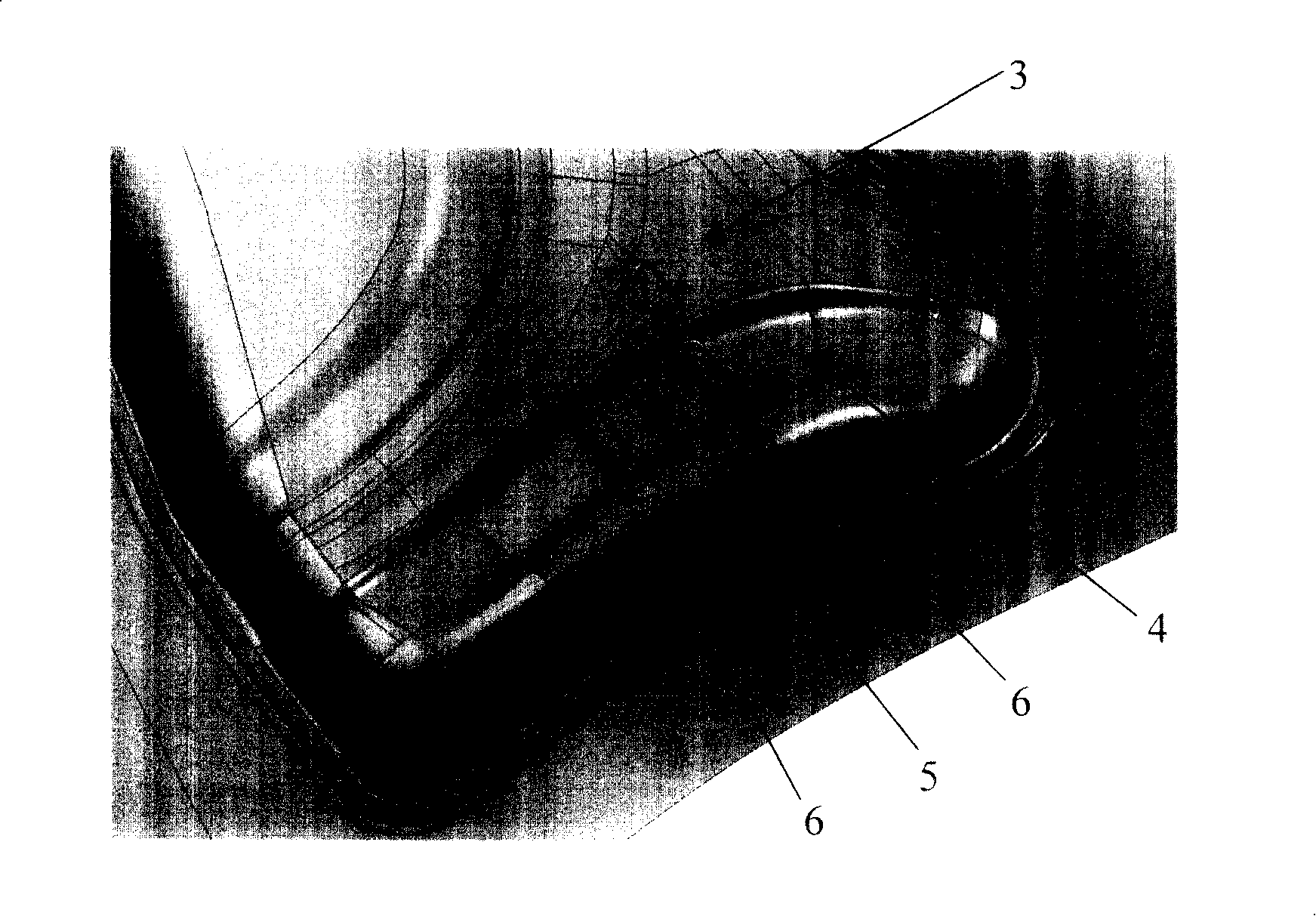

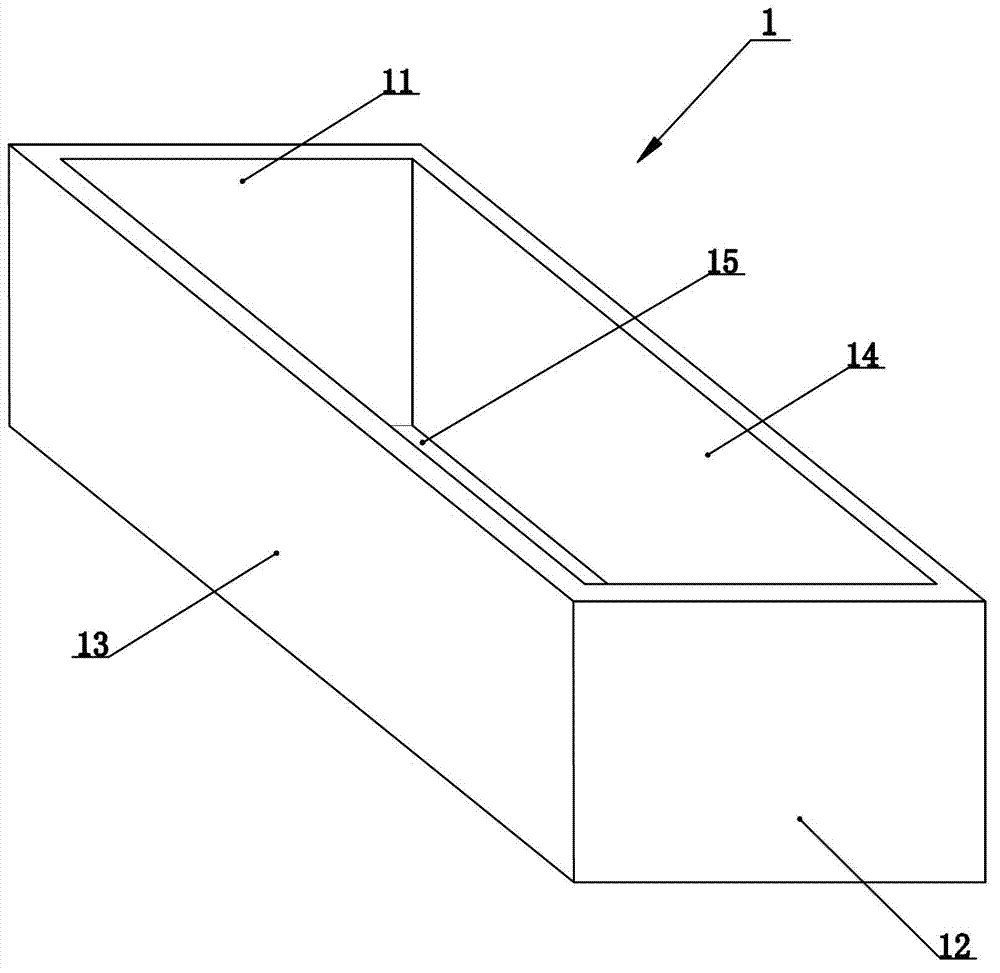

Beam and longitudinal beam connecting assembly

The invention discloses a beam and longitudinal beam connecting assembly which comprises a beam, a longitudinal beam and a connecting piece for connecting the beam and the longitudinal beam. The corresponding positions on two opposite arms of the beam are provided with abutting openings; the connecting piece is a hollow blocky body; the middle parts of two side walls of the connecting piece are provided with connecting openings; the abutting openings on the beams correspond to the connecting openings of the connecting piece on the aspects of position, shape and size; the positions of the connecting openings on the side walls of the connecting piece are provided with outward turnover walls; the beam is connected with the connecting piece; the longitudinal beam is connected with the connecting piece; the connecting piece is embedded into the abutting openings of the beam; the longitudinal beam is embedded into the connecting openings of the connecting piece. The beam and longitudinal beam connecting assembly disclosed by the invention has a simple structure and solves the problem of difficulty in forming a U-shaped flanging of the beam; development of a die is simplified; quality of the beam and the longitudinal beam is controlled; the phenomena of wrinkling and cracking of a metal plate of a part are eliminated; local strength of a vehicle body and riding safety are improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

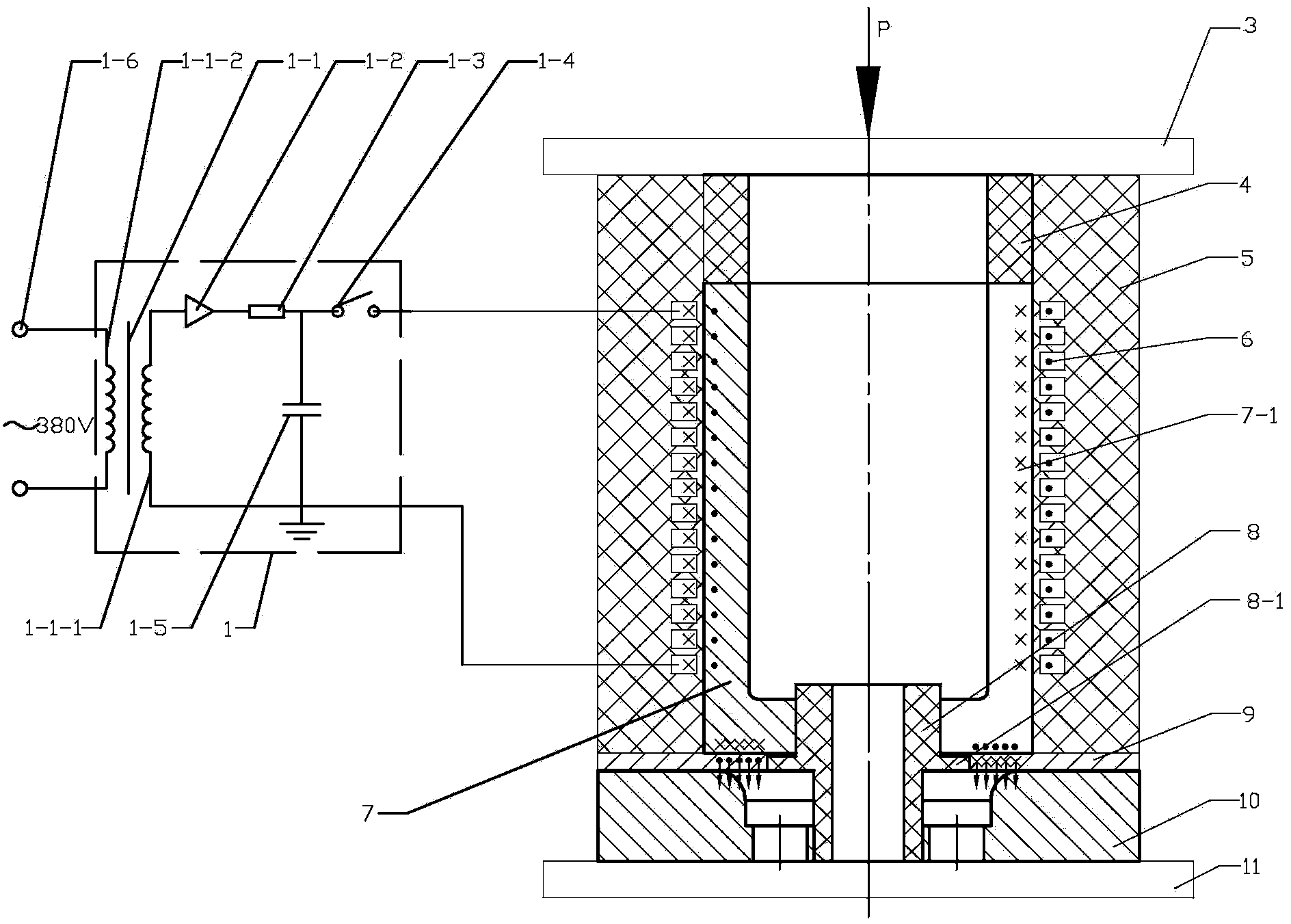

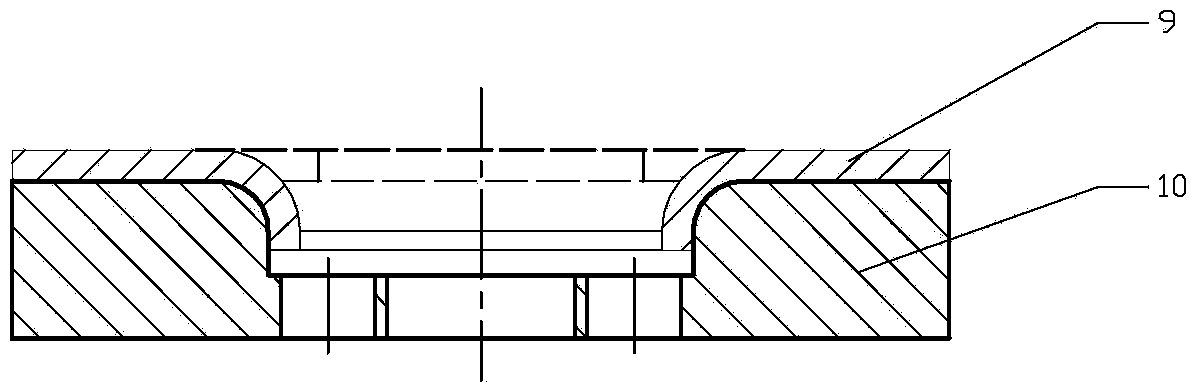

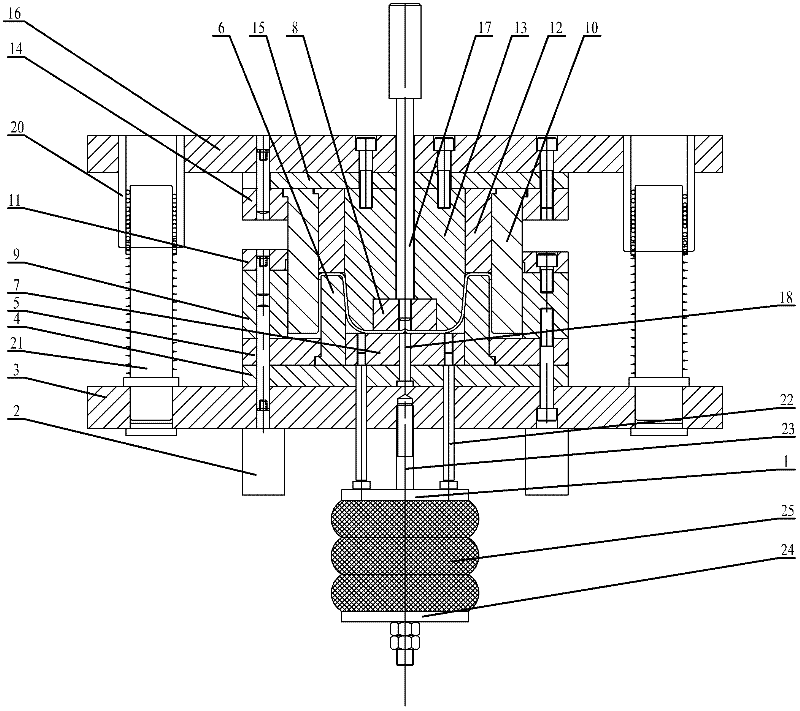

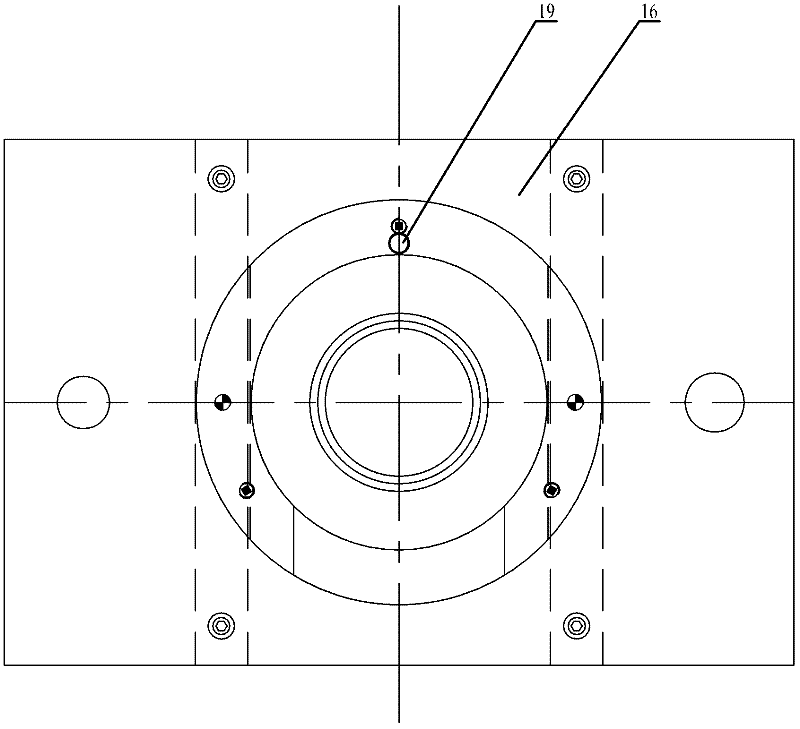

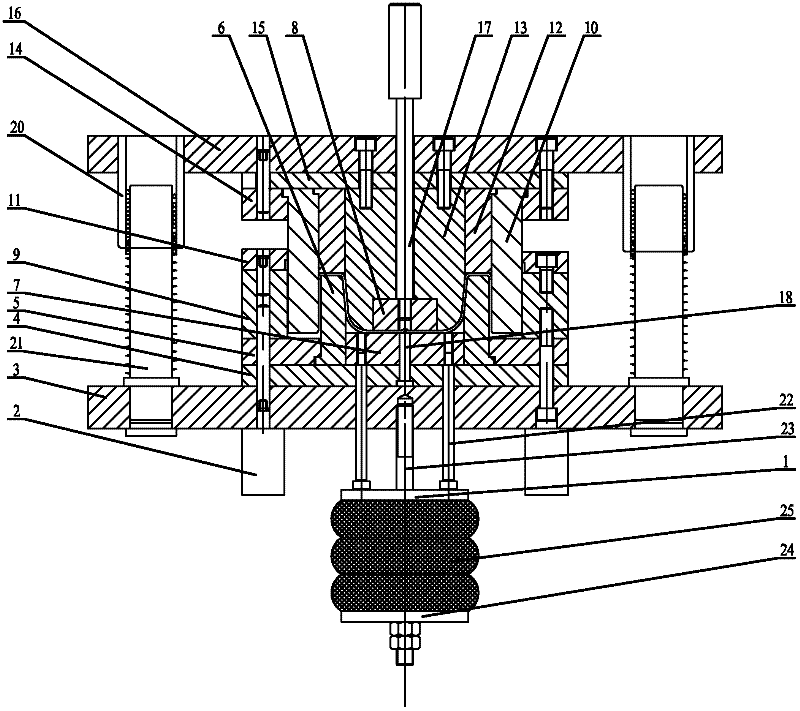

Device and method for forming small-diameter flanging holes in aluminum alloy plate through magnetic pulses

ActiveCN103861930AImprove the strength of its own structureImprove structural strengthPulse controlAlloy

The invention discloses a device and method for forming small-diameter flanging holes in an aluminum alloy plate through magnetic pulses, and belongs to the field of metal plate part plastic forming and manufacture. The device and method solve the problems that when the flanging holes are formed in the aluminum alloy plate through an existing magnetic pulse forming technology, the service life of a coil is short, damage easily happens to the machined workpiece, a plurality of flanging and forming procedures exist when a steel die is adopted, and the forming quality is not stable. A coil wire turn is packaged in a coil framework, a flanging female die is fixed to a bottom plate, the upper section of a positioning ring and the lower section of the positioning ring are arranged in a columnar magnetic trap and the flanging female die, a magnetic trap limiting ring is arranged on the upper end face of the columnar magnetic trap, the solenoid coil is arranged on the outer side wall of the columnar magnetic trap and the outer side wall of the magnetic trap limiting ring in a sleeved mode, and a longitudinal seam is formed in the side wall of the columnar magnetic trap. An upper pressing plate is arranged on the upper end face of the magnetic trap limiting ring and the upper end face of the coil framework. The aluminum alloy plate is arranged between the flanging female die and the coil framework, and two output ends of a magnetic pulse control circuit are connected with two wiring terminals of the coil wire turn. The device and method are used for forming the small-diameter flanging holes in the aluminum alloy plate through magnetic pulses.

Owner:HARBIN INST OF TECH

Circumcision stitching instrument

InactiveCN102920494AReduce workloadFacilitates postoperative careExcision instrumentsSurgical staplesPost operativeEngineering

The invention discloses a circumcision stitching instrument which is characterized in that the left end of a fixed lance handle is a cylindrical cavity; the right side of the fixed lance handle is connected to a pistol trigger; the pistol trigger is connected with an insurance; a post rod, a cutter blade and a long rod target base are sequentially arranged in the cylindrical cavity of the fixed lance handle from outside to inside; cartridge clips are circularly arranged in the fixed lance handle abutted against the left end of the post rod and are all provided with bullets; the right end of the post rod is connected to the pistol trigger; the cutter blade is of a cylindrical structure coaxial with the long rod target base; the left end of the long rod target base is a semi-circular recessed cavity; a target base baffle ring of a flanging structure is arranged at the edge of the left end of the long rod target base; the right end of the long rod target base is connected with a locking nut; and the position of the target base baffle ring corresponds to those of the bullets. The circumcision stitching instrument enables the circumcision to be convenient, rapid, safe and labor saving, has the advantages of regular operative incision, less bleeding and pain, convenient post-operative nursing and stitch and loop removal free, and maximally reduces the doctor workload.

Owner:JIANG XI YUAN SHENG LANG HE MEDICAL EQUIP

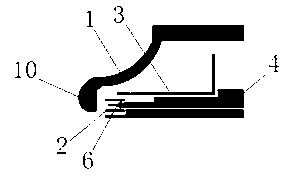

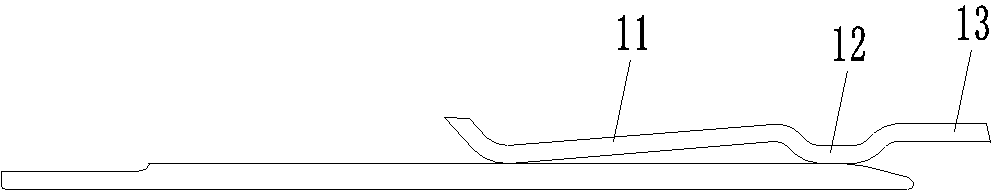

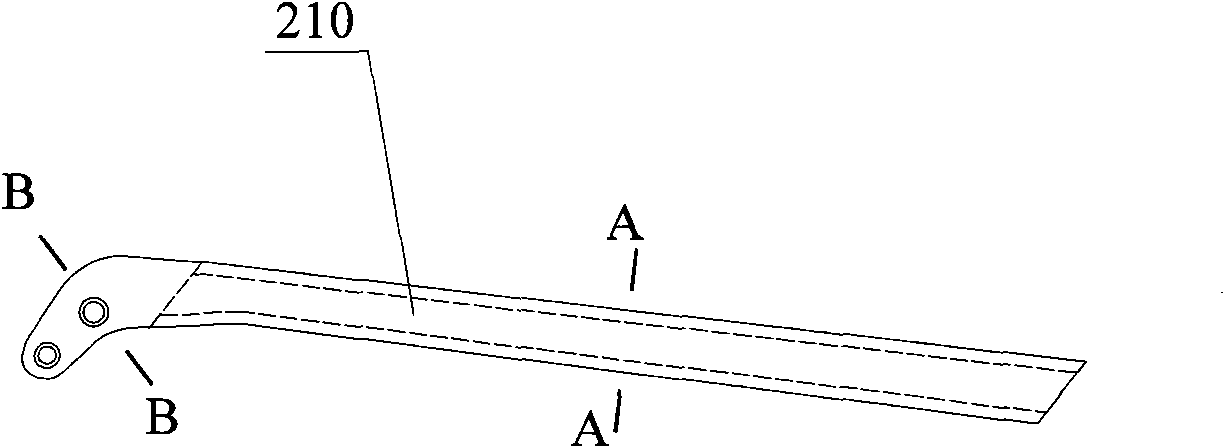

Bent contact member, jack module and electrical connector

ActiveCN104167620ALow insertion lossShorten the cantilever lengthCoupling contact membersFlangingEngineering

The invention relates to the field of electrical connectors, and especially relates to a bent contact member, a jack module and an electrical connector. The front end of the bent contact member is used as a plugging end. The bent contact member comprises a plugging part and a horizontal mounting part disposed behind the plugging part. The front end of the plugging part is provided with a flanging formed through upward bending. The lower side of the bend of the flanging forms a front contact part used for contacting a matching contact member. A concave part which is concave downward relative to the plugging part is arranged between the plugging part and the mounting part. The concave part forms a rear contact part of the contact member. The plugging part gradually slopes downward from back to front from the joint of the plugging part and the concave part. Before use, the front and rear contact parts can be respectively in contact with the root and the end of the matching contact member, so that the formation of a cantilever structure on the matching contact member is avoided or the length of the cantilever of the matching contact member is shortened at least, thereby reducing the insertion loss of a differential connector. In conclusion, the bent contact member can reduce the insertion loss between a plug and a socket of a differential connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

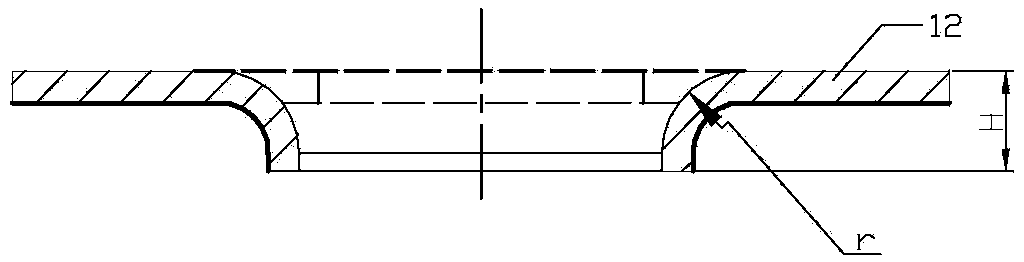

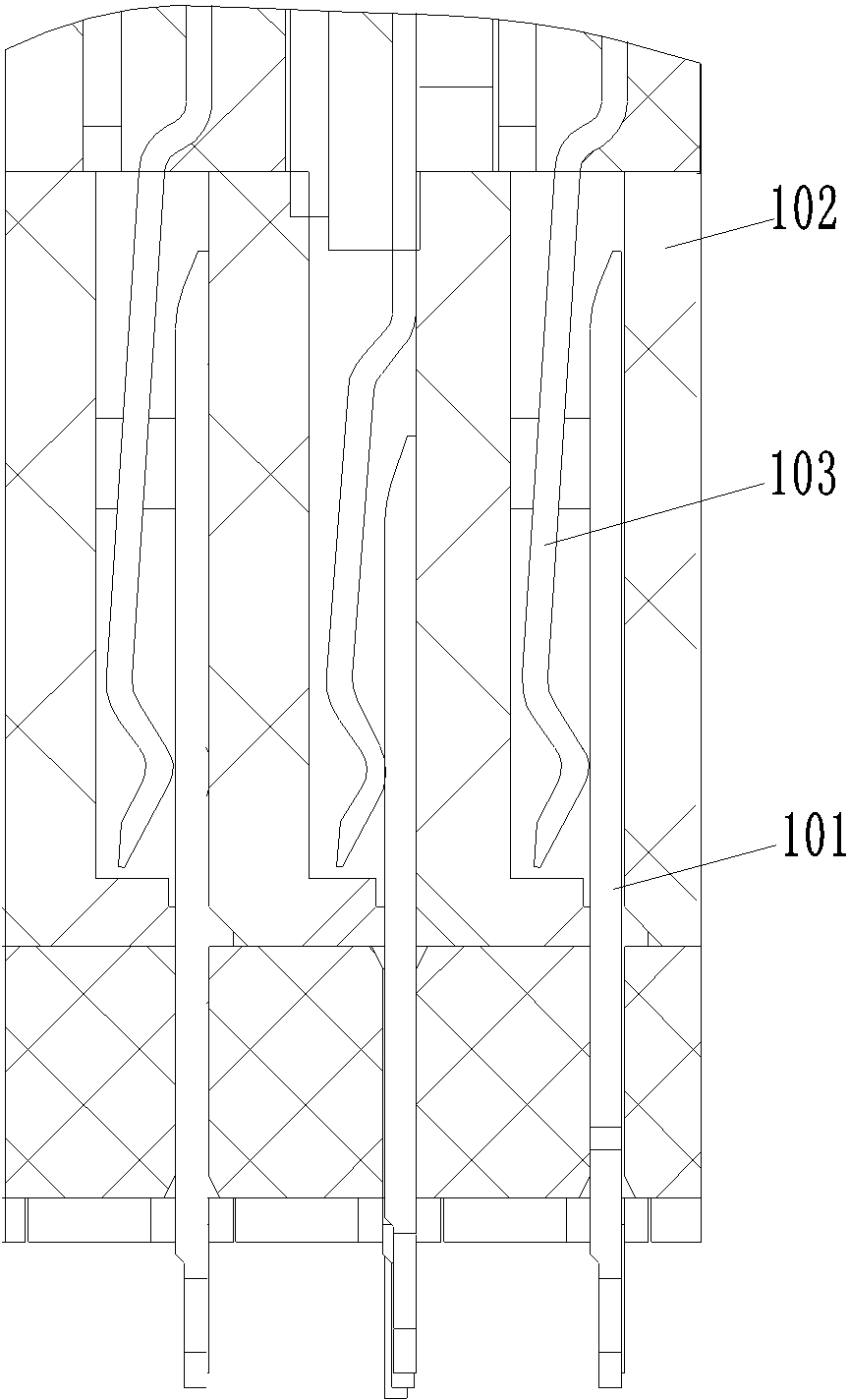

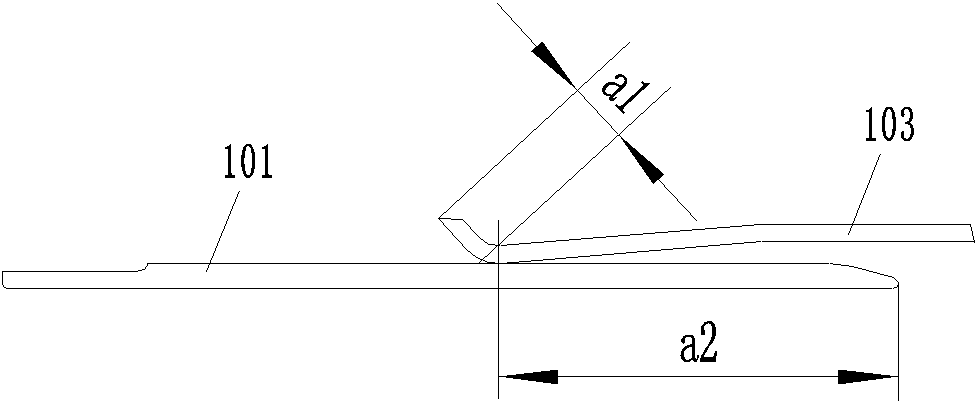

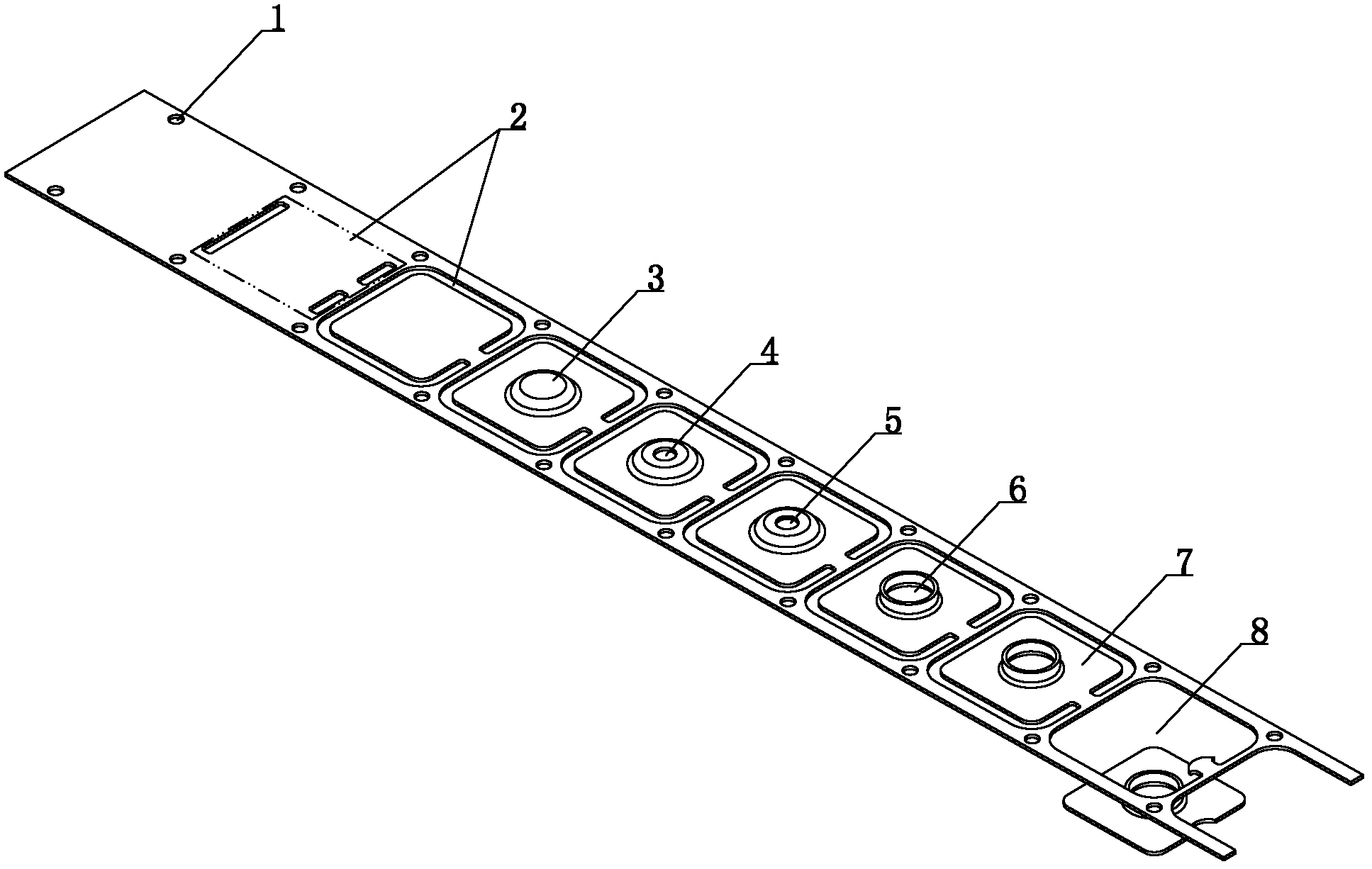

Molding process of progressive die of high temperature alloy sheet metal component with high flanging hole

The invention relates to a molding process of a progressive die of a high temperature alloy sheet metal component with a high flanging hole is disclosed, comprising the steps of: punching a positioning hole; compressing; stretching; punching a small hole; preparing a chamfer; flanging; correcting; and cutting and forming. Compared with prior art, the invention adopts the molding process of the progressive die for continuously production to improve the work efficiency by times. The positioning hole is machined at the position close to the side edge on a strip to form a uniform positioning standard, thereby improving the positioning precision and ensuring the quality and consistency of products. In prior art, work finished by a plurality of devices is finished by one punching device, thereby saving the devices and labor occupied, reducing the production cost and meeting the requirements of batch production.

Owner:天津市津兆机电开发有限公司

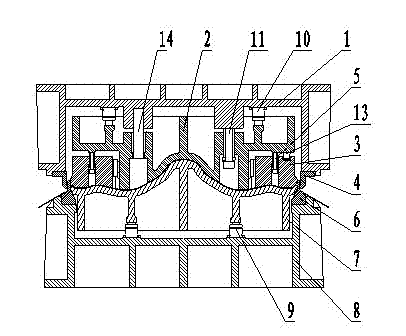

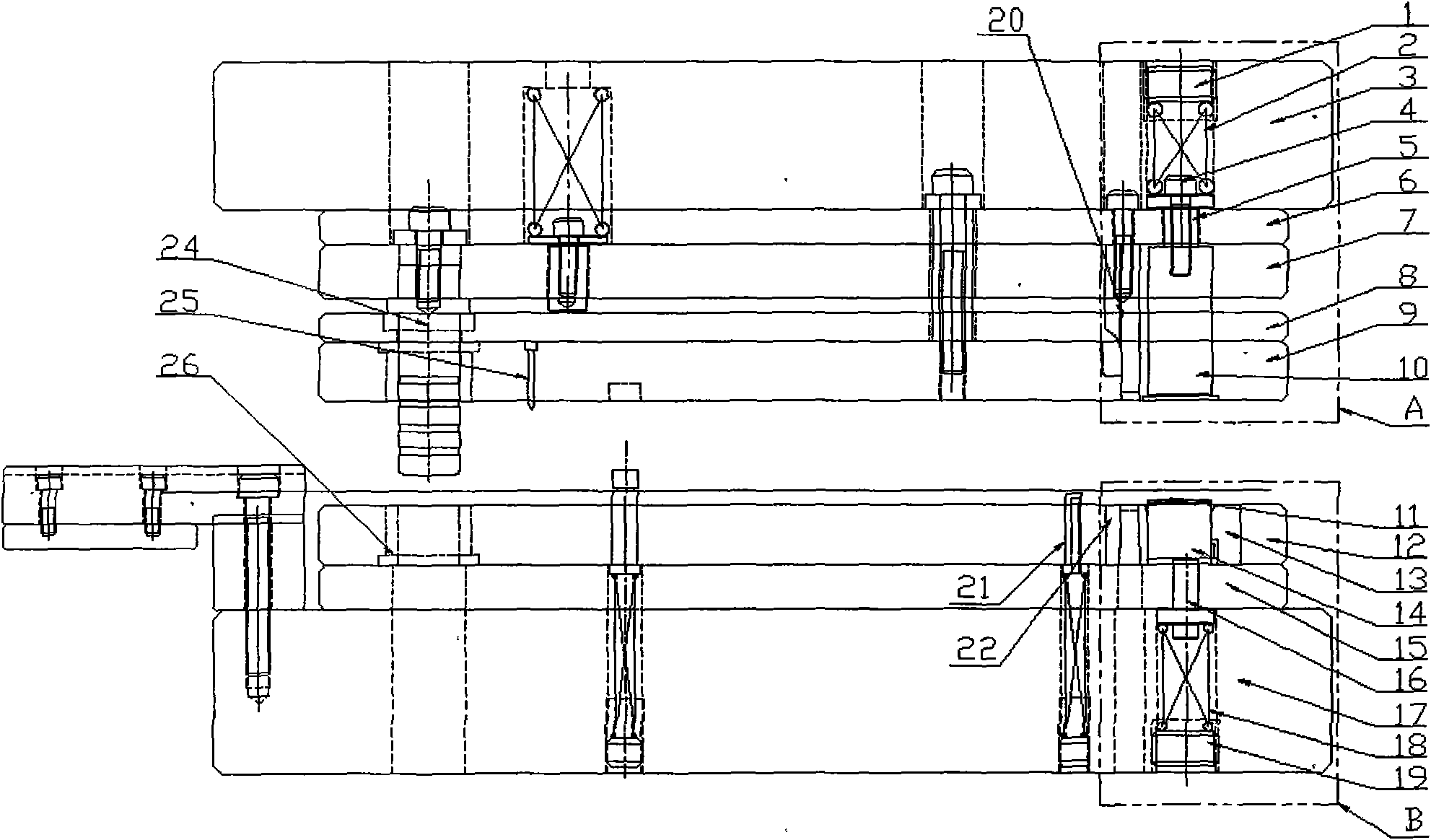

Trimming and flanging composite stamping die

ActiveCN102513445AReduce manufacturing costReduce duplicationShaping toolsFlangingSymmetric structure

The invention discloses a trimming and flanging composite stamping die used for finishing one-step stamping for trimming and flanging processing of a workpiece. The trimming and flanging composite stamping die comprises a combination segmental blade, a pressing mechanism, a supporting mechanism, an upper die base and a lower die base and is characterized in that a trimming die and a flanging die which share the same pressing mechanism and supporting mechanism are combined together; the whole die is of a bilaterally-symmetric structure; trimming segmental blades are distributed at two sides of the die; and the pressing mechanism and the supporting mechanism are arranged between the upper die base and the lower die base. According to the invention, workpiece trimming and flanging operations are independently finished by using one die, accumulation of die locating deviation and workpiece processing errors caused by two processes in the past is avoided, the repeated installing and debugging steps in the original processing method are reduced, the production cost is greatly reduced, the production efficiency is remarkably increased, and meanwhile, the consistency of products is also ensured.

Owner:HYCET ENGINE SYST JIANGSU CO LTD

Method of preparing lining for cars

InactiveCN101209472ASolve concentrated stressSolve crackingMetal-working apparatusStress concentrationPunching

The invention relates to a manufacturing method of a vehicle bushing, comprising the following steps that: (1) blanking: a blanking die and a hydraulic device are used for blanking a steel plate EC, and a round material A is obtained; (2) drawing: the round material obtained by the step (1) is drawn by five times by drawing dies with different drawing ratio and the hydraulic device, and a cylindrical piece B with a flange edge is obtained; (3) punching: a cylinder bottom of the cylindrical piece B with a flange edge obtained by the step (2) is punched and cut by a punching die and the hydraulic device, and a part C is obtained; (4) shaping and trimming: the part C obtained by the step (3) is shaped by a shaping and trimming die, and the flange edge is punched and cut into the bushing with the dimension consistent with the demand. The invention solves the problems of a flanging technique that stress concentration and crack are existed at corners, thus improving the percent of pass and prolonging the service life of the parts.

Owner:上海德真工贸有限公司

Method for forming part with hole

The invention relates to a molding method of a part with a hole, comprising the following steps that: (a) a panel material is drawn and molded, the drawn and molded part comprises a body and a binding edge connected with the body, and the binding edge comprises a punching area and storing bars located around the punching area; (b) the punching area is punched; (c) the binding edge is flanged and shaped. As the storing bars are formed around the punching area through drawing and molding in the molding method of the part with a hole provided by the invention, the storing bar can balance the flowing of the material during the flanging and shaping process after punching the punching area, so as to compensate the needed material; therefore, the holes punched earlier do not deform, thus enhancing the molding quality of the parts and reducing the defective ratio.

Owner:BYD CO LTD

Stamping method for using high-strength steel plate to manufacture automobile rear bumper steel girder

The invention proposes a punching method for adopting high intensity steel plates to manufacture the girder of the back bumper of a car. The invention adopts a cold punching shaping method which includes four steps of blanking and piercing, shaping and drawing, side rolling and hole flanging as well as punching; the punching technique is designed into the mode which is primary in shaping and secondary in drawing for avoiding the defects that the traditional drawing needs a large pressure-pad-force and a larger technique complementing surface and organically integrates the traditional single drawing with single shaping to lead the bumper to mainly obtain an approximate shape by shaping and needing no technique complementing surface during the shaping; thereby the conventional trimming die is reduced; the shape is solidified by the drawing at the chamfer angle positions of the part and a part of the side surface to reduce rebounding to ensure precision; thereby the operating factors of the part material is improved to the largest extent, the cost is reduced and the manufacture and debug periods of the die is decreased.

Owner:CHANGAN FORD AUTOMOBILE CO LTD

Bonding and forming device for inner box of paper box and surface paper

The invention relates to a bonding and forming device for an inner box of a paper box and surface paper. The bonding and forming device comprises a stand, a lifting platform, a paper box inner support member, a flanging pressing plate, an ejector pin, a left hairbrush, a right hairbrush, a first pushing part, a front hairbrush, a rear hairbrush and a second pushing part and also comprises a driving device, a first control device a second control device, a third control device, a fourth control device and a fifth control device, wherein the driving device is used for driving the ejector pin to rise or fall; the first control device is used for controlling the paper box inner support member to rise or fall; the second control device is used for controlling the left hairbrush and the right hairbrush to stretch; the third control device is used for controlling the first pushing part to stretch; the fourth control device is used for controlling the front hairbrush and the rear hairbrush to stretch; the fifth control device is used for controlling the second pushing part to stretch; an inhibiting device is arranged between the first control device and the driving device; and the paper box inner support member and the flanging pressing plate are respectively provided with a through hole for the ejector pin to pass through. By adopting the technical scheme, according to the bonding and forming device for the inner box of the paper box and the surface paper, provided by the invention, the inner box and other surfaces of the surface paper can be automatically bonded to be formed after a bottom plate of the inner box and the bottom surface of the surface paper are bonded. The degree of automation is high and the production efficiency is high.

Owner:瑞安市华科包装机械有限公司

Metal barrel flanging device

The invention discloses metal cylinder flanging equipment, comprising a working platform; the working platform is provided with a cylinder locating component, an arc flanging component and a driver; the cylinder locating component comprises a rotating shaft, a cylinder circle-expanding mold, a swaging tray and a locking device; the rotating shaft is connected with the driver in a transmission way and fixed with the cylinder circle-expanding mold; the swaging tray is arranged above the cylinder circle-expanding mold and provided with the locking device; the arc flanging component comprises a rotating flanging mold which is vertically fixed on the working platform and the section of the flanging mold is round and the two longitudinal sidelines of the mold are hyperbola. In the proposal, the location of a cylinder fixes a metal cylinder and drives the metal cylinder to rotate at the same time; when the metal cylinder rotates, the inside toward the end opening is in contact with the flanging mold and the arc extension of the metal cylinder edge is realized. Therefore, the labor intensity of workers is reduced, and the productivity, the product precision and the yield are promoted.

Owner:SHANGYU MINGXIN FANS

Joint arm of cloth arm bracket and manufacturing method thereof as well as concrete conveying machine

The invention discloses a joint arm of a cloth arm bracket and a manufacturing method thereof and also relates to a concrete conveying machine provided with the joint arm. The joint arm of the cloth arm bracket comprises a transverse plate and a vertical plate, wherein in the longitudinal direction, the transverse plate and the vertical plate extend along the same direction; in the transverse section, the transverse plate extends horizontally, and the vertical plate extends vertically; the side of the vertical plate has flanging, and the side of the vertical plate and the horizontal flanging are fixed with the transverse plate; and the transverse plate and the vertical plate are respectively provided with a composite material layer which comprises resin and fiber. The joint arm can maintain less weight while ensuring higher strength and fatigue resistance, and also can reduce the adverse effect for the joint arm caused by welding; furthermore, the joint arm provided by the invention also has damping performance and corrosion resistance, thus prolonging the service life of the joint arm.

Owner:SANY HEAVY IND CO LTD (CN)

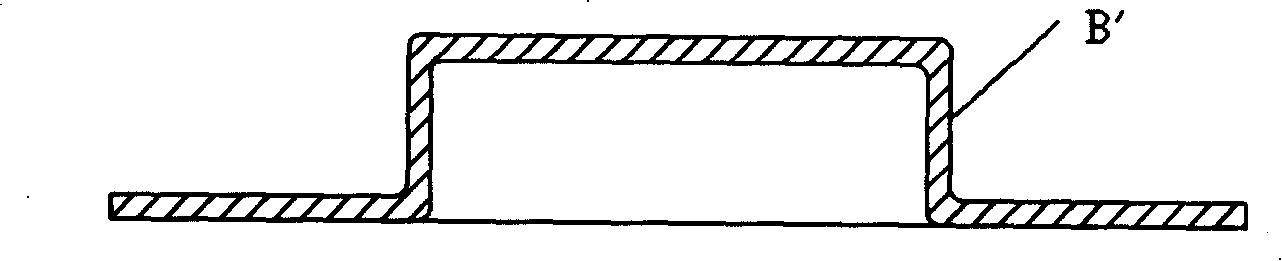

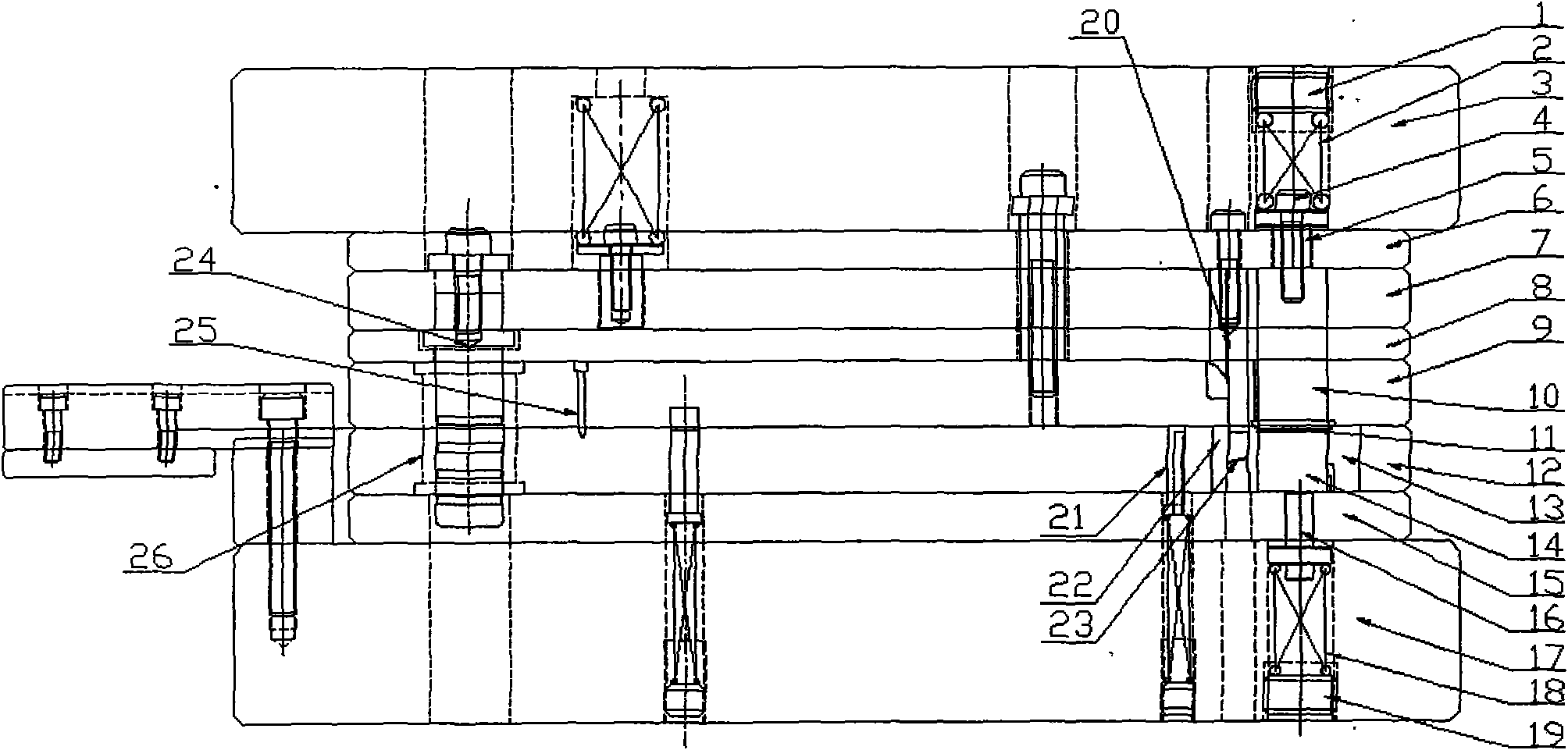

Composite flanging mechanism of stamping die

ActiveCN102513444ASolve the problem of collisionReduce manufacturing costShaping toolsEngineeringFlanging

The invention discloses a composite flanging mechanism of a stamping die. The mechanism is used for implementing one-time stamping forming of 'transverse U' shaped flanges of workpieces. The mechanism comprises a vertical flanging part, a side flanging part, a pressing device, an upper die holder and a lower die holder. The mechanism is characterized in that: a vertical flanging die and a side flanging die are combined together and share a set of pressing device, and the vertical flanging part is arranged between the pressing device and the side flanging part. Stamping forming of a 'transverse U' shaped flange structure is independently finished by one set of die, so that the manufacturing cost of a product is effectively reduced; and repeated installation and operation steps in the conventional machining method are reduced, so that the production efficiency is remarkably improved.

Owner:HYCET ENGINE SYST JIANGSU CO LTD

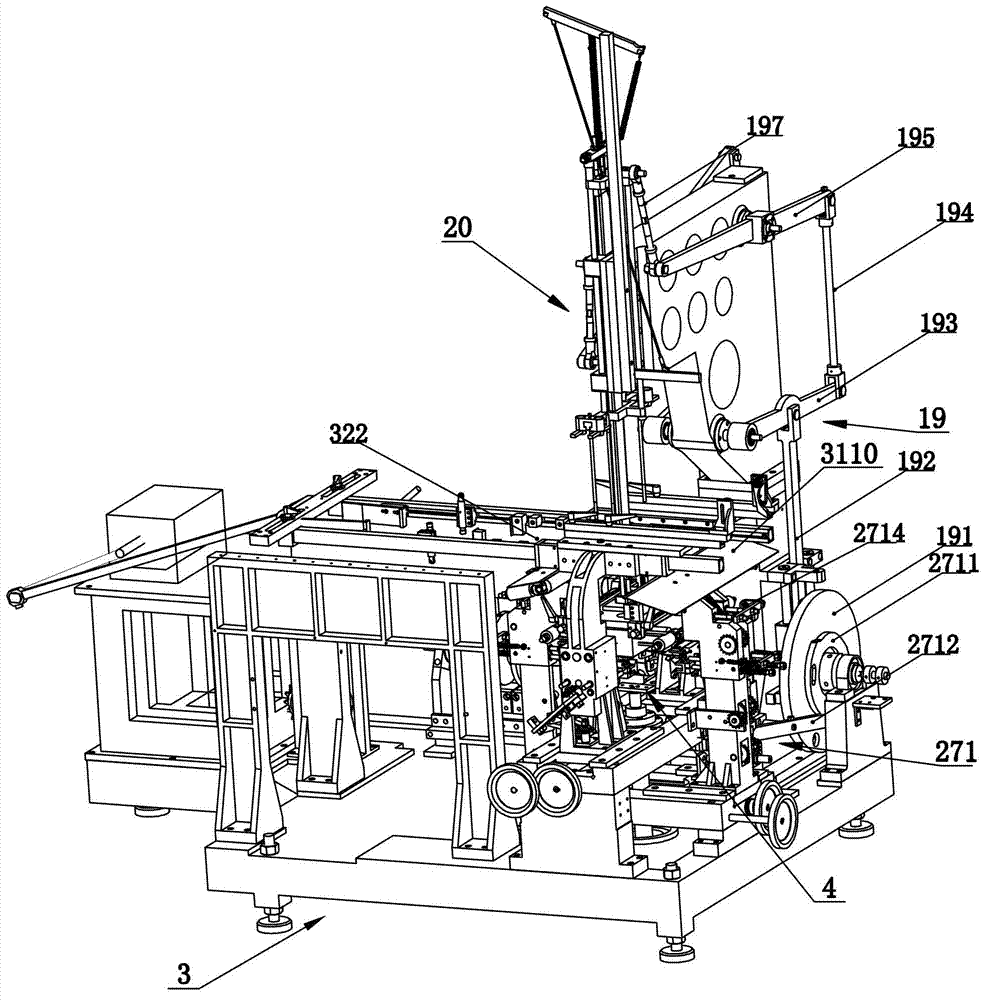

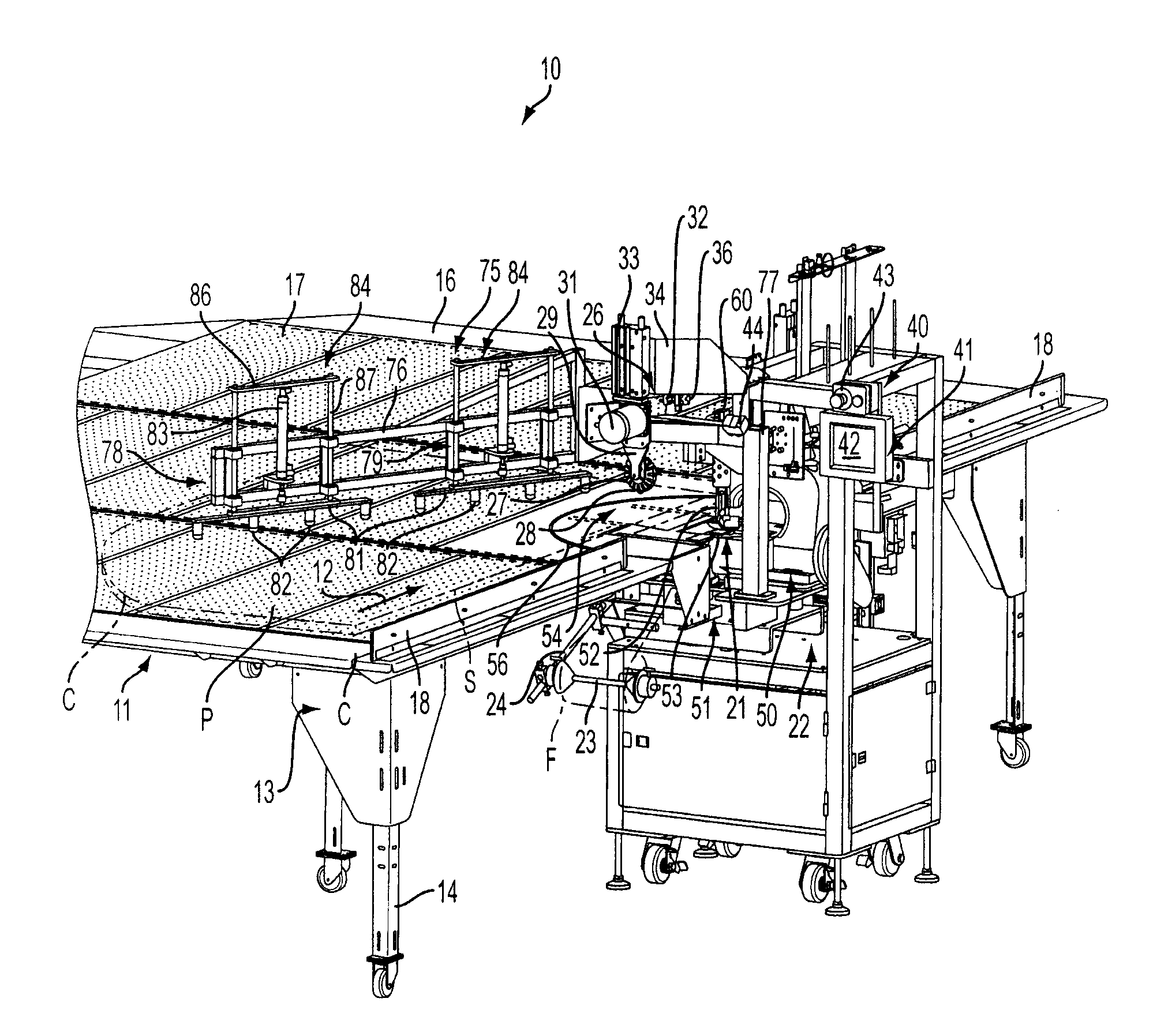

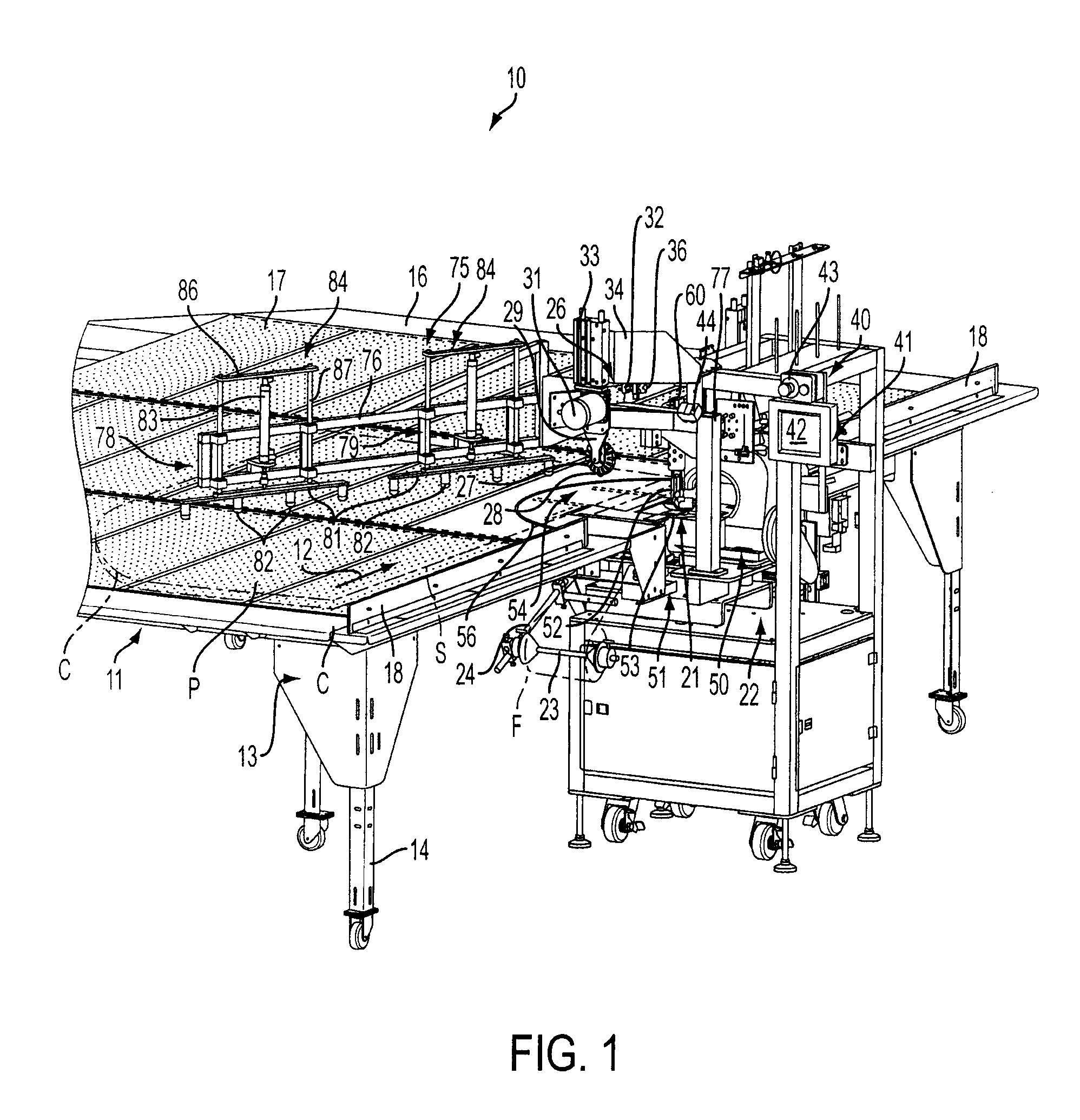

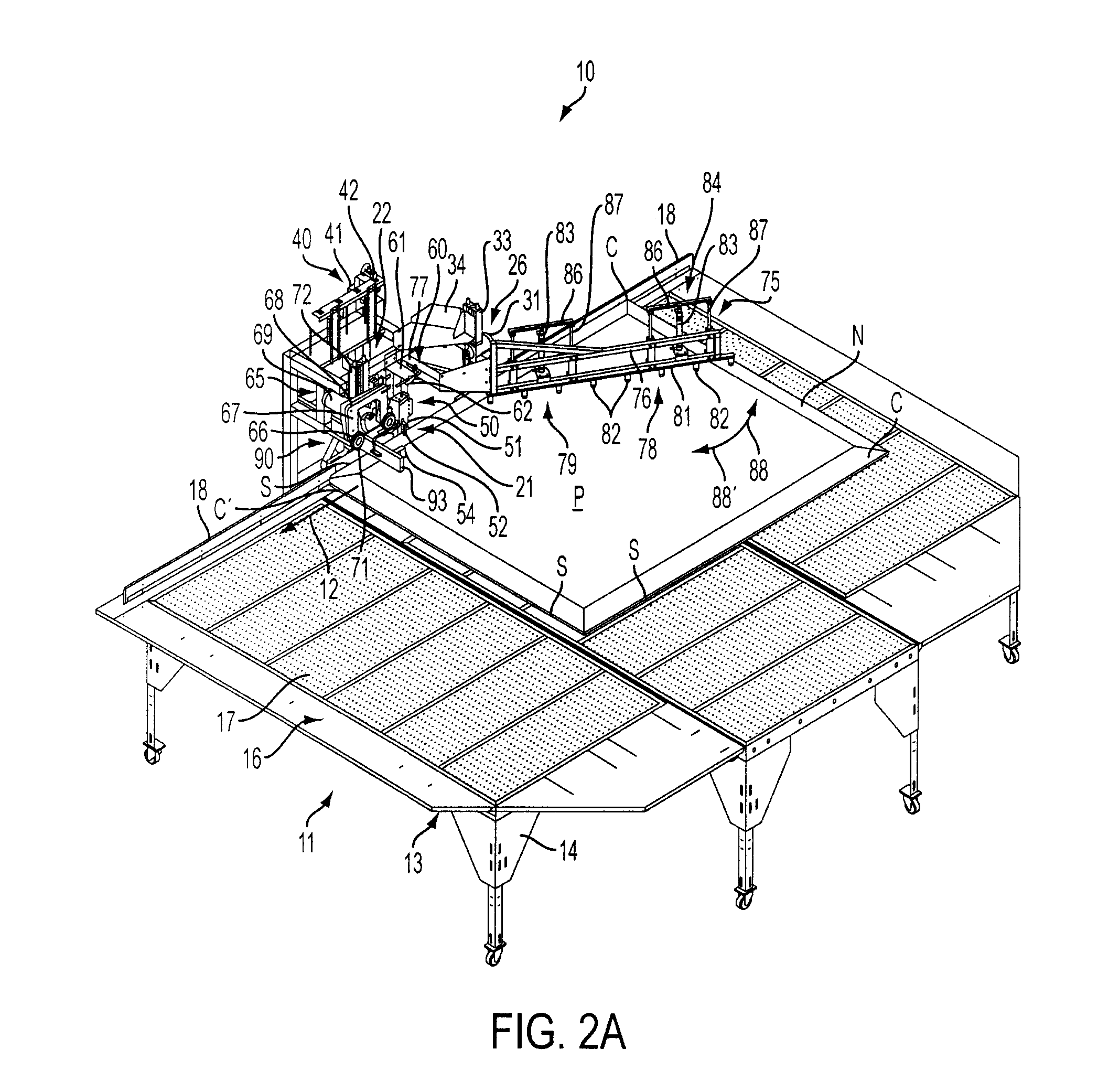

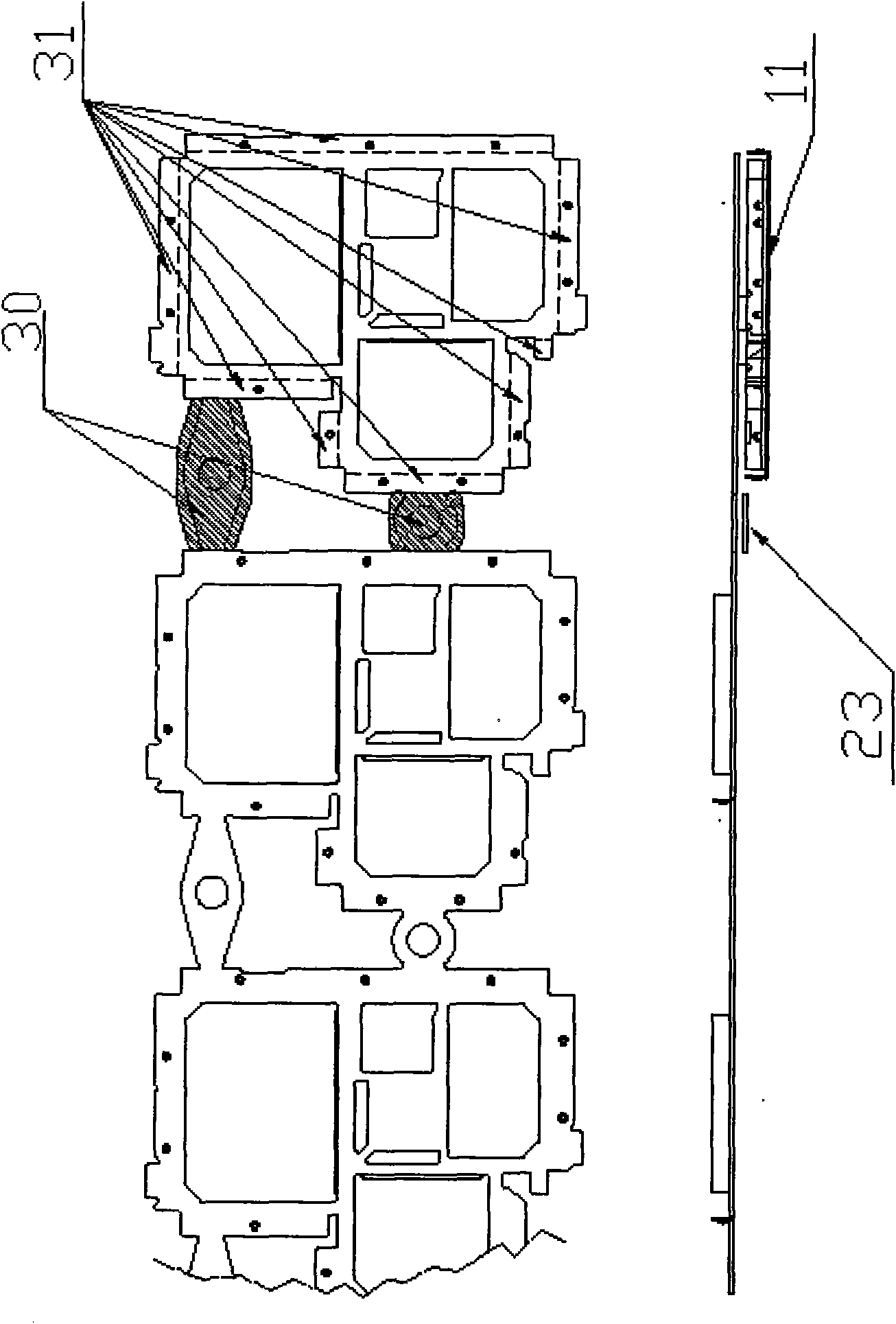

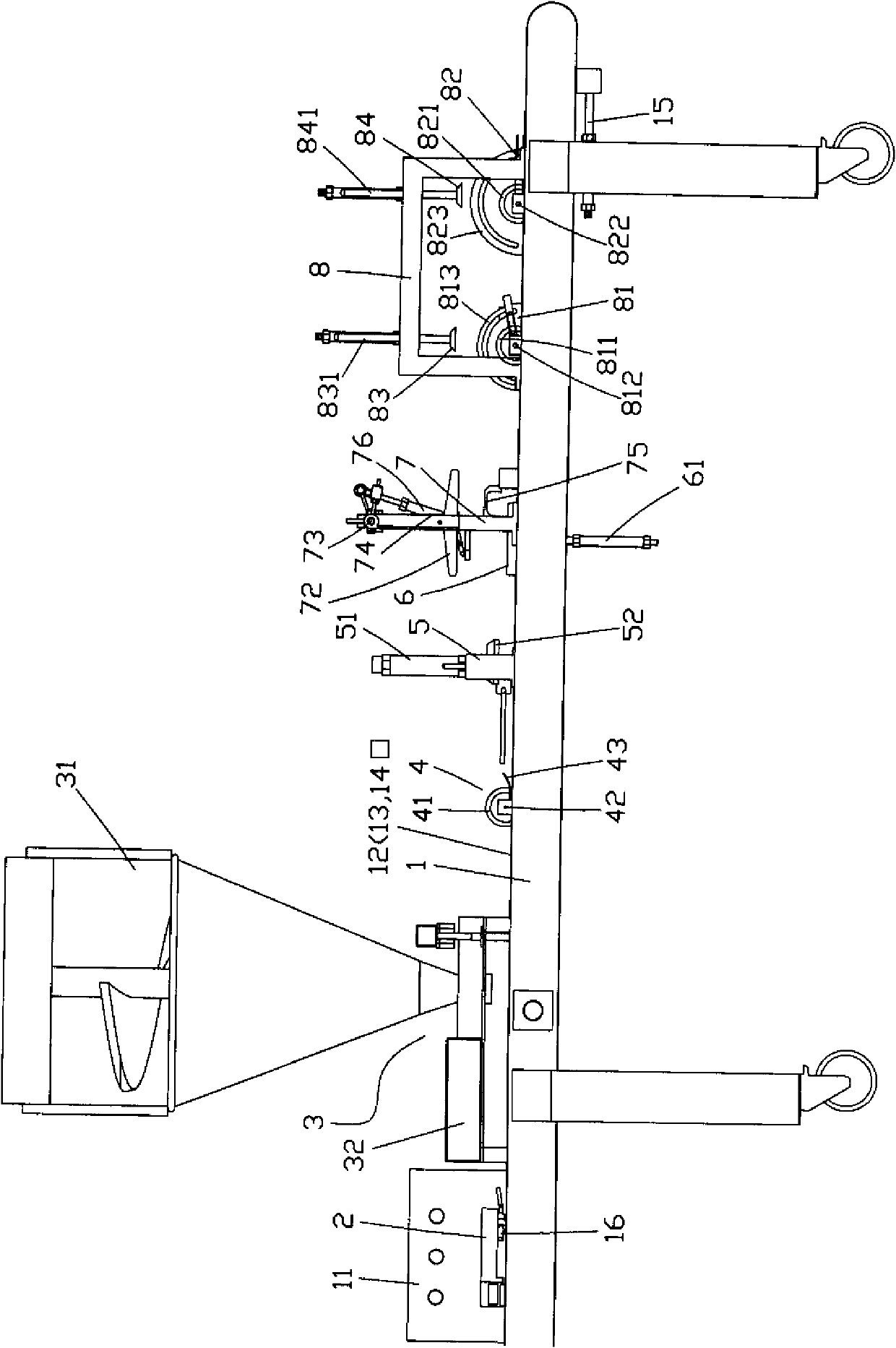

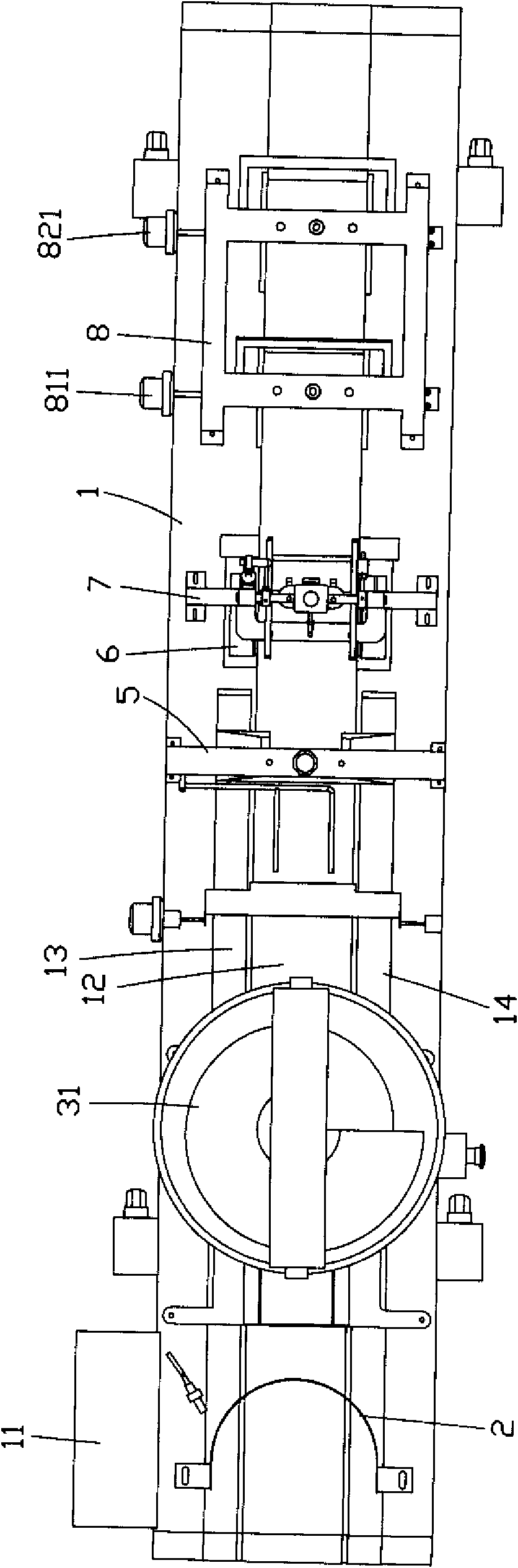

Automatic panel sewing and flanging system

ActiveUS7984681B1Less distortionMore accurate rounded or accurate cornersWork-feeding meansMattress sewingFlangingSewing machine

A system for automatically attaching a flanging material to the edges of a panel such as for a mattress, including a work table on which the panel is supported and a sewing assembly having a sewing machine located along a path of travel of the panel across the work table. The flanging material is fed from a supply of flanging material located adjacent the sewing assembly, and is attached to the side edges and about the corners of the panel by the sewing machine of the sewing assembly. A clamp mechanism engages and holds the panel as the sewing machine of the sewing assembly attaches the flanging material about the corners of the panel.

Owner:ATLANTA ATTACHMENT

Production line for aluminum alloy base plates of suspended ceilings

ActiveCN104999279AReduce manual operationsIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineFlanging

The invention provides a production line for aluminum alloy base plates of suspended ceilings. The production line solves the technical problems that since an existing production line is not provided with a slicing device, a forming device and a flanging device, manual slicing, manual forming and manual flanging are needed, and the production efficiency is low. The production line for the aluminum alloy base plates of the suspended ceilings comprises a full-automatic slicing machine, an edge and corner one-time forming device and a flanging device. The full-automatic slicing machine comprises a paying-off roll for carrying an aluminum alloy base plate strip, a slicing rack, a slicing knife, flattening rolls, a feed roll and conveying belts. A knife rest and a slicing air cylinder are arranged on the slicing rack. The slicing air cylinder is fixed to the upper end of the knife rest. The slicing knife is connected with a push rod of the slicing air cylinder. Under the action of the slicing air cylinder, the slicing knife moves up and down along the knife rest. The front end of the knife rest is provided with a horizontal feed plate. The rear end of the knife rest is provided with the conveying belts. A collection platform is arranged at one ends of the conveying belts. Vertical plates are fixed to the two sides of the feed plate. The two ends of each flattening roll and the two ends of the feed roll are connected to the vertical plates. The production line has the advantage of high production efficiency.

Owner:益龙建材(东莞)有限公司

One-piece forming die with multiple functions

The invention relates to a one-piece forming die with multiple functions, in particular to one-piece forming cup die for use in fields of blanking, stretching, raising, lettering, flanging and the like. In the technical scheme, the one-piece forming die with multiple functions comprises an upper die plate and a lower die plate, wherein a guide sleeve is fixed to the edge part of the upper die plate; a stretching male die is fixedly arranged on the middle part of the lower surface of the upper die plate; a punching block is arranged inside the bottom end part of the stretching male die; a flanging female die insert is sleeved outside the stretching male die; a blanking flanging female and male die is sleeved outside the flanging female die insert; an upper fixed plate is sleeved outside the blanking flanging female and male die; a punching rod is arranged in the stretching male die and the upper die plate in a sliding mode; and the bottom end part of the punching rod is connected with the punching block. By the one-piece forming die, products can be formed in one piece, so that the yield and quality of the products can be improved.

Owner:无锡绿缘汽车零部件有限公司

Stamping die for forming punching scrap and peripheral flanging simultaneously

The invention discloses a stamping die for forming a punching scrap and a peripheral flanging simultaneously. The stamping die comprises an upper die and a lower die which are guided and fixed throughan inner guide pillar arranged on the upper die and an inner guide sleeve arranged on the lower die, wherein the upper die is provided with a punching terrace die and a bending terrace die; the punching terrace die is fixed on a terrace die fixed plate through an upper die screw; the bending terrace die is a movable member and is located in the terrace die fixed plate; the lower die is provided with a bending female die and a punching female die; and the punching terrace die and the bending terrace die of the upper die respectively correspond to the punching female die and the bending femaledie of the lower die. The invention reduces the procedure, personnel, stamping devices, containers of semi-finished products, sites and the like so that the use ratio of materials is higher. At the same time, the invention realizes the automatic production, increases the efficiency by nearly seven times, thereby improving the labor efficiency and the precision of products, reducing the unit priceof parts and improving the market competitiveness of products.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

Sheet material mold-free multi-point forming device based on viscous medium transfer force and method

The invention relates to a sheet multipoint molding device and relative method, based on adhesive medium force transmission. Wherein, the lower die cavity is formed by concave mould and the bottom plate of concave mould; the bottom of concave mould has the discharge hole of adhesive medium, which is connected to the cylinder via the channel inside the bottom plate; the fixing compress device is formed by the upper mould, motor, mounting element, convex mounting plate and the punch head connected to the flexible sheath; the flanging ring, convex mould fixing plate, flexible sheath and the punch head form the upper die chamber; the sheet compress device is formed by the upper edge of concave mould and the flanging ring. The invention uses adhesive medium with uniform force transmission, to reduce the producing period, the producing cost, avoid the surface crack caused by rigid mould, while the thickness is uniform.

Owner:重庆工学院

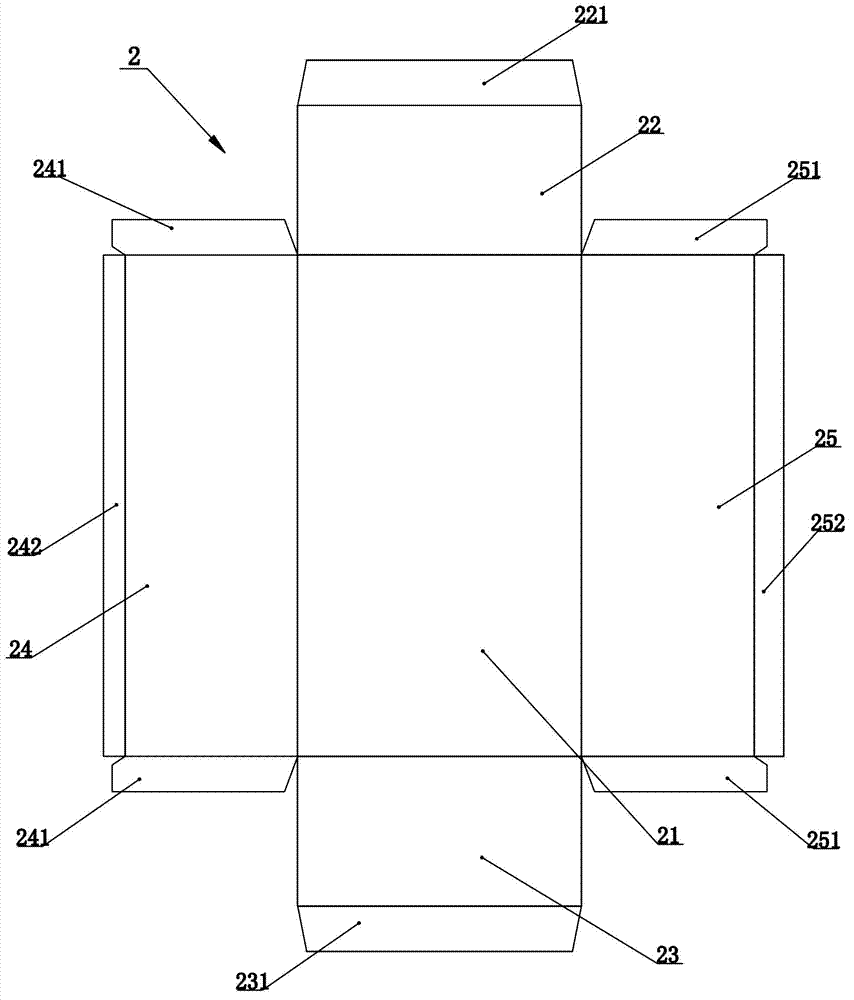

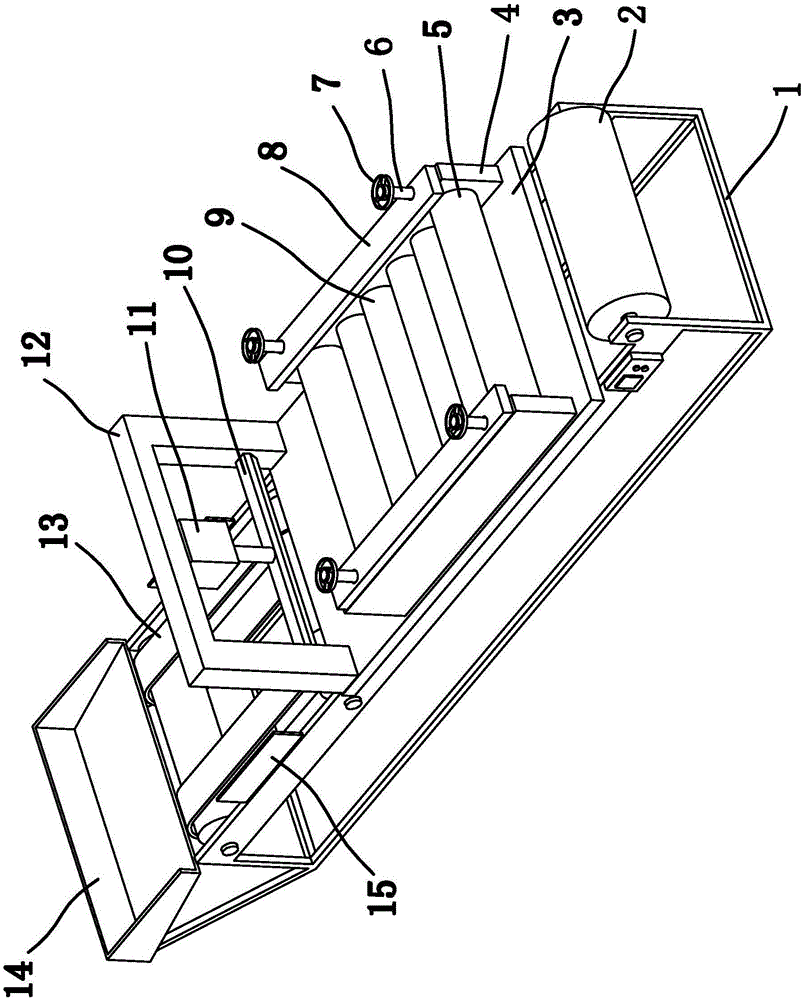

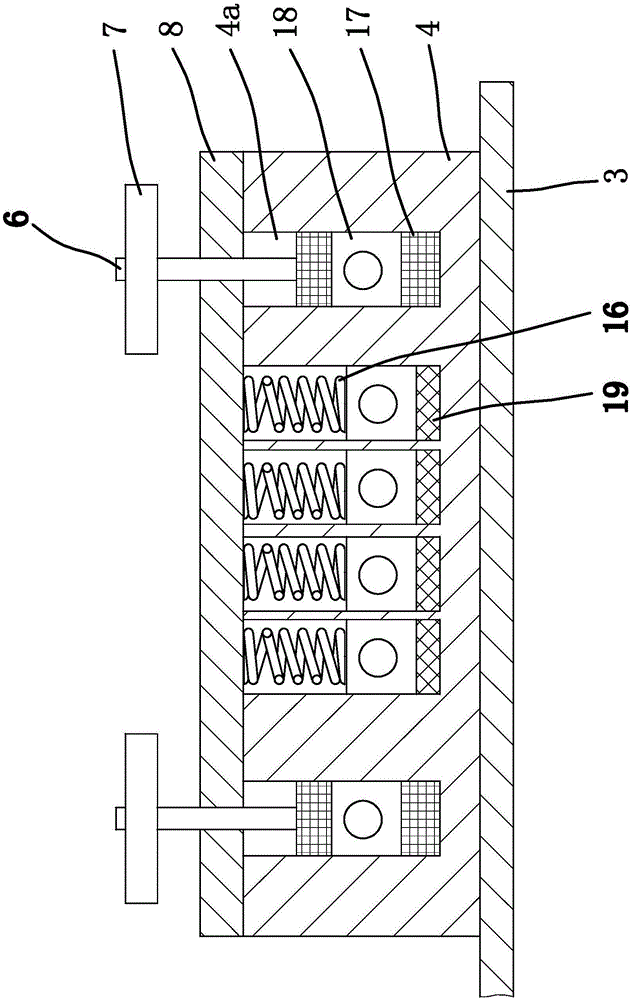

Dough sheet and stuffing food multiple-folding and rolling forming device

The invention provides a dough sheet and stuffing food multiple-folding and rolling forming device which comprises a machine table (1); a control box (11) and a conveying belt (12) are arranged on the machine table (1); the two sides of the conveying belt (12) are connected with shorter conveying belts (13and 14) in parallel; a dough sheet imbedding and positioning machine plate (2), a stuffing supply device (3), a dough sheet front edge flanging plate (4), a dough sheet two-side flanging plate (6), a dough sheet edge-pressing and compacting frame (7) and a continuous turnover and compaction frame (8) are mainly arranged above the conveying belt (12) in sequence, wherein the dough sheet imbedding and positioning machine plate (2) is arranged at the front end of the conveying belt (12) on the machine table (1); and the dough sheet edge-pressing and compacting frame (7) is arranged on the conveying belt (12) above the dough sheet two-side flanging plate (6). The dough sheet and stuffing food multiple-folding and rolling forming device can be widely applied to various occasions requiring use of the dough sheet and stuffing food multiple-folding and rolling forming device.

Owner:欧阳禹

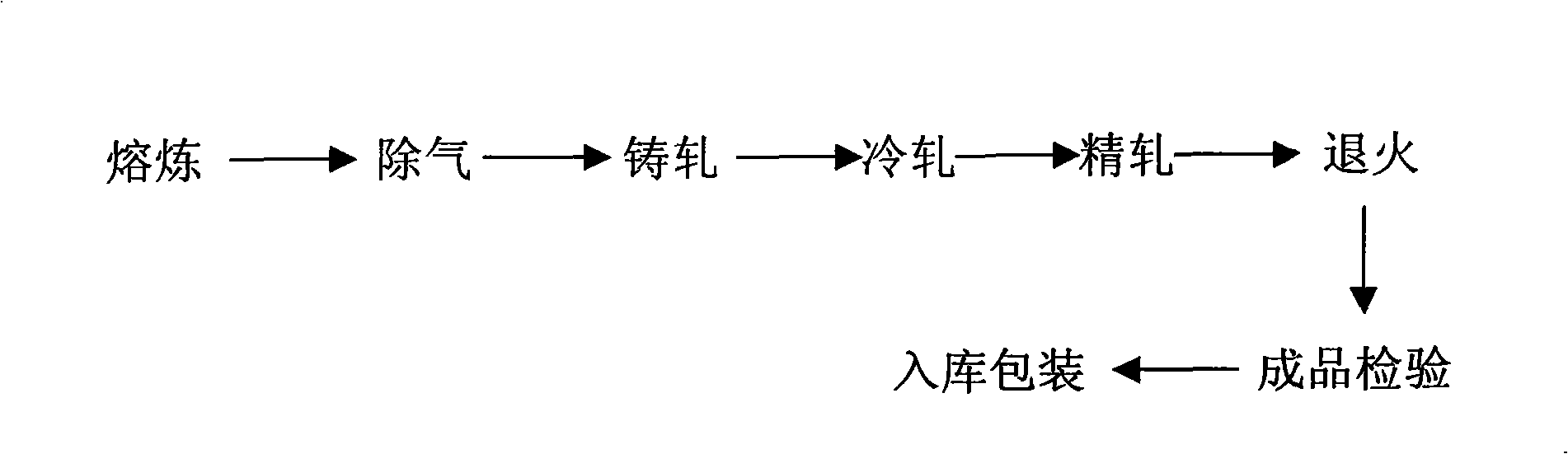

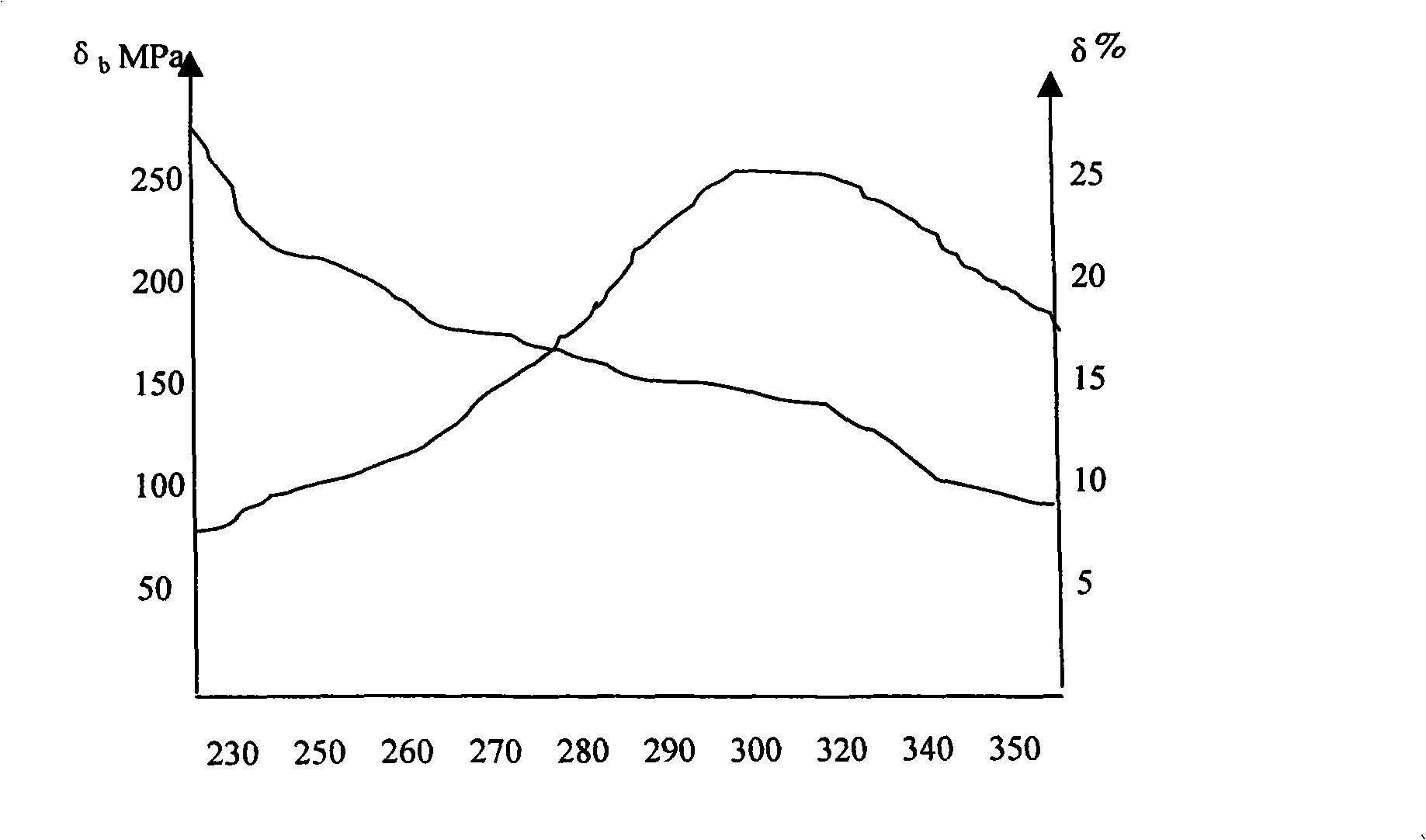

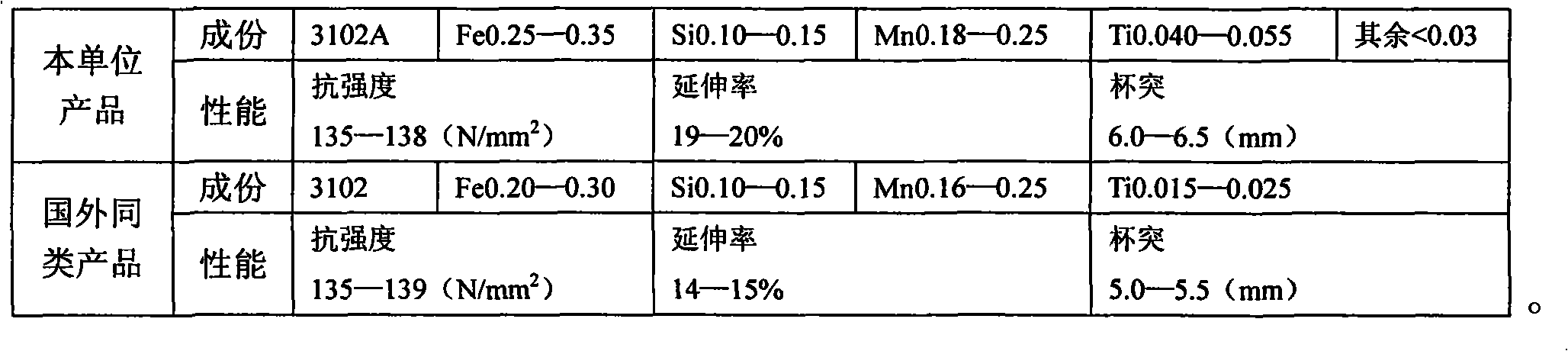

High performance air conditioning aluminum foil and method for preparing same

InactiveCN101307404AHigh strengthImprove plasticityRoll mill control devicesMetal rolling arrangementsFlangingAlloy

The invention relates to a high-performance air conditioner aluminum foil and a method for preparing the same. The aluminum foil mainly consists of the following alloying elements in percentage by weight: 0.28 to 0.33 percent of FeO, 0.1 to 0.15 percent of Si, 0.20 to 0.25 percent of Mn, 0.01 percent of Cu, 0.05 percent of Zn, 0.04 to 0.055 percent of Ti and the balance being Al and inevitable impurities. The preparation method mainly comprises the following: step one, melting, refining and heat preservation; step two, casting and rolling; step three, cold rolling and trimming cut; step four, precision rolling; step five, annealing at an annealing temperature of between 260 and 310 DEG C and heat preservation for 2 to 3 hours; step six, checkup and packaging. The high-performance air conditioner aluminum foil and the method can lessen the thickness of the air conditioner aluminum foil and ensure plasticity, height of the air conditioner aluminum foil and no flanging of longthrust.

Owner:江阴博威合金材料有限公司

Common mode manufacturing method for automobile covering part

The invention discloses a common mode manufacturing method for an automobile covering part. The method includes the steps of drawing, trimming deflashing punching, flanging shaping and shaping side cutting. The process technology is used for inner plate parts on the side periphery. At first, the basic shape of each part is drawn out by means of a square plate, then shape holes in the periphery and the middle of each part and transition holes needing to be machined at later procedures are punched, shaping is carried out on high required positions and small R angles, flanging is carried out on gluing supporting positions and periphery modeling, and finally positions with incomplete trimming deflashing on the periphery of former procedures are cut off, side trimming is conducted on a part of each part, process holes, positioning holes and installation holes are punched, and the two parts are separated and taken out of different positions to be stored. The process technology breaks through the thought that one kind of parts is produced through a pair of molds, the utilization rate of materials is improved, mold investment and material investment of the parts are reduced, investment of staff, equipment and production time in procedures of the later period is eliminated, and the method plays an active role in the overall energy conservation effect enhancement plan of enterprises.

Owner:HEFEI CHANGAN AUTOMOBILE

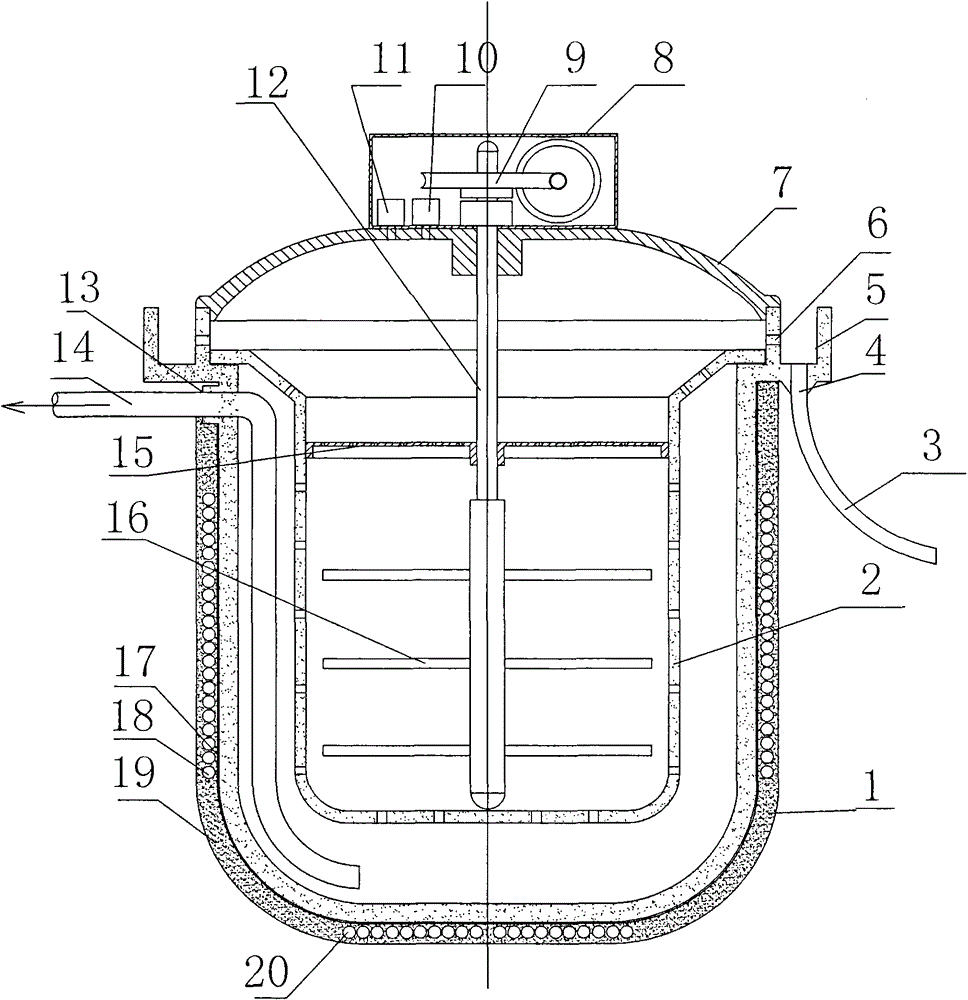

Environment-friendly and energy-saving intelligent composite medicine boiling marmite

The invention provides an environment-friendly and energy-saving intelligent composite medicine boiling marmite which is structurally composed of a marmite body, a colander, a pot cover, a speed reducer, a stirrer and a medicine outlet pipe. A steel plate outer cover is arranged on the outer wall of the marmite body, annular electromagnetic heaters are arranged on the periphery of the outer wall of the steel plate outer cover, disk-shaped electromagnetic heaters are arranged on the bottom of the steel plate outer cover, and the annular electromagnetic heaters and the disk-shaped electromagnetic heaters are embedded in a thermal insulating cover. An upper opening of the marmite body is provided with an annular medicine dreg collecting groove with an upward opening. Medicine dreg overflowing holes are formed in the inner side groove wall of the annular medicine dreg collecting groove, a medicine dreg drain hole is formed in the bottom of the annular medicine dreg collecting groove, the lower portion of the medicine dreg drain hole is connected with a medicine dreg flow guide pipe, a sub opening is formed in the edge of the pot cover to be connected with an upper opening of the inner side groove wall of the annular medicine dreg collecting groove, and a step is arranged below the inner side groove wall of the annular medicine dreg collecting groove. An upper opening of the colander is provided with an annular flanging which is connected with the step, the top of the pot cover is provided with a machine shell of the speed reducer, and an ultrasonic liquid level detecting instrument, a far infrared temperature measuring set and the speed reducer are fixed inside the machine shell of the speed reducer.

Owner:王华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com