Stamping die for forming punching scrap and peripheral flanging simultaneously

A stamping die and flanging technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to achieve simultaneous forming, low raw material utilization, and low parts manufacturing accuracy, and achieve high material utilization, The effect of improving market competitiveness and improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

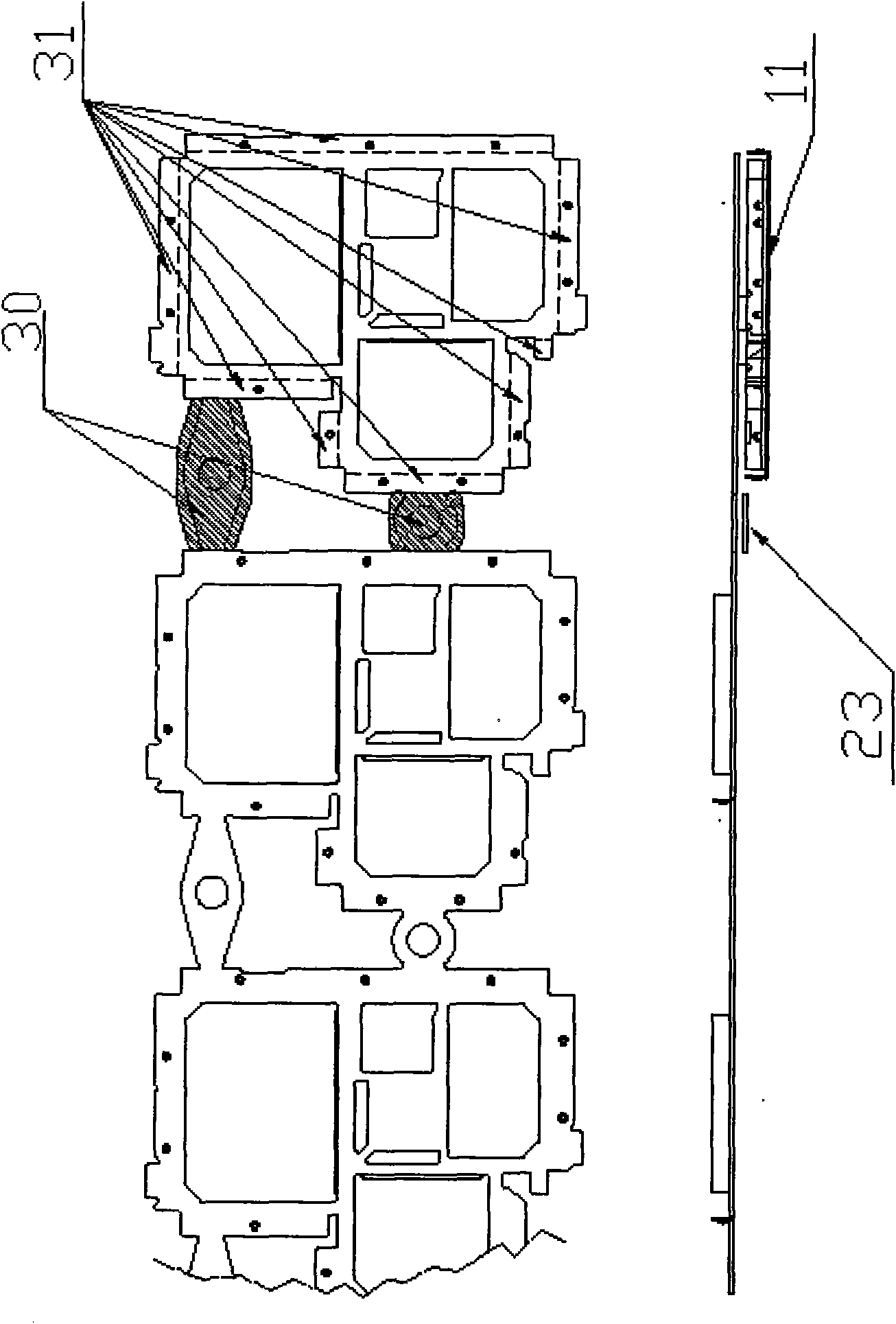

[0030] figure 1 It is a part layout drawing of the production product described in the present invention.

[0031] Such as figure 1 As shown: the edge material 30 in the shaded part needs to be punched off, and the cut part is still a semi-finished product, and part of the material of the semi-finished product 31 still needs to be bent upwards along the dotted line to become a finished product. These two steps are completed at the same time .

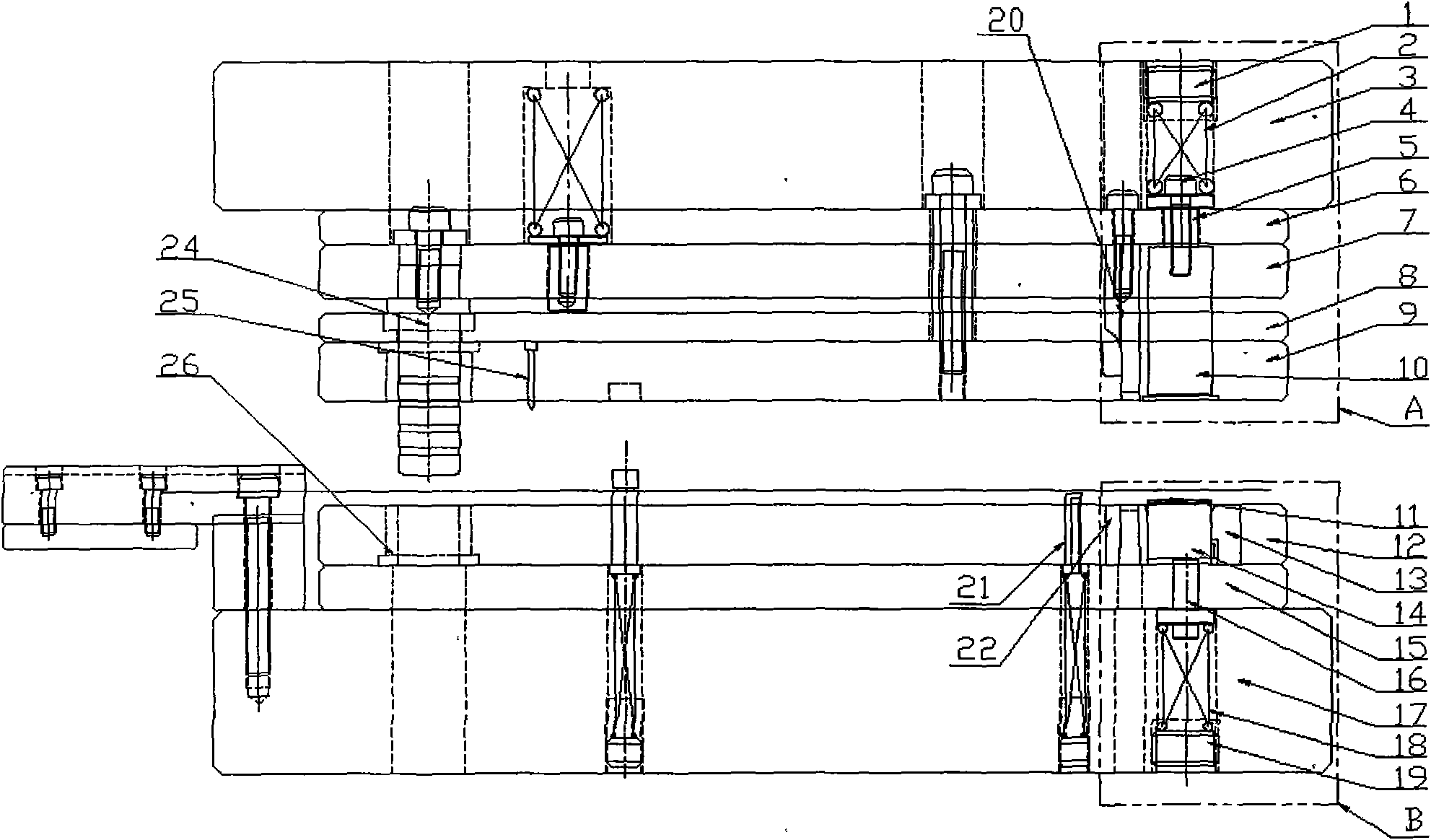

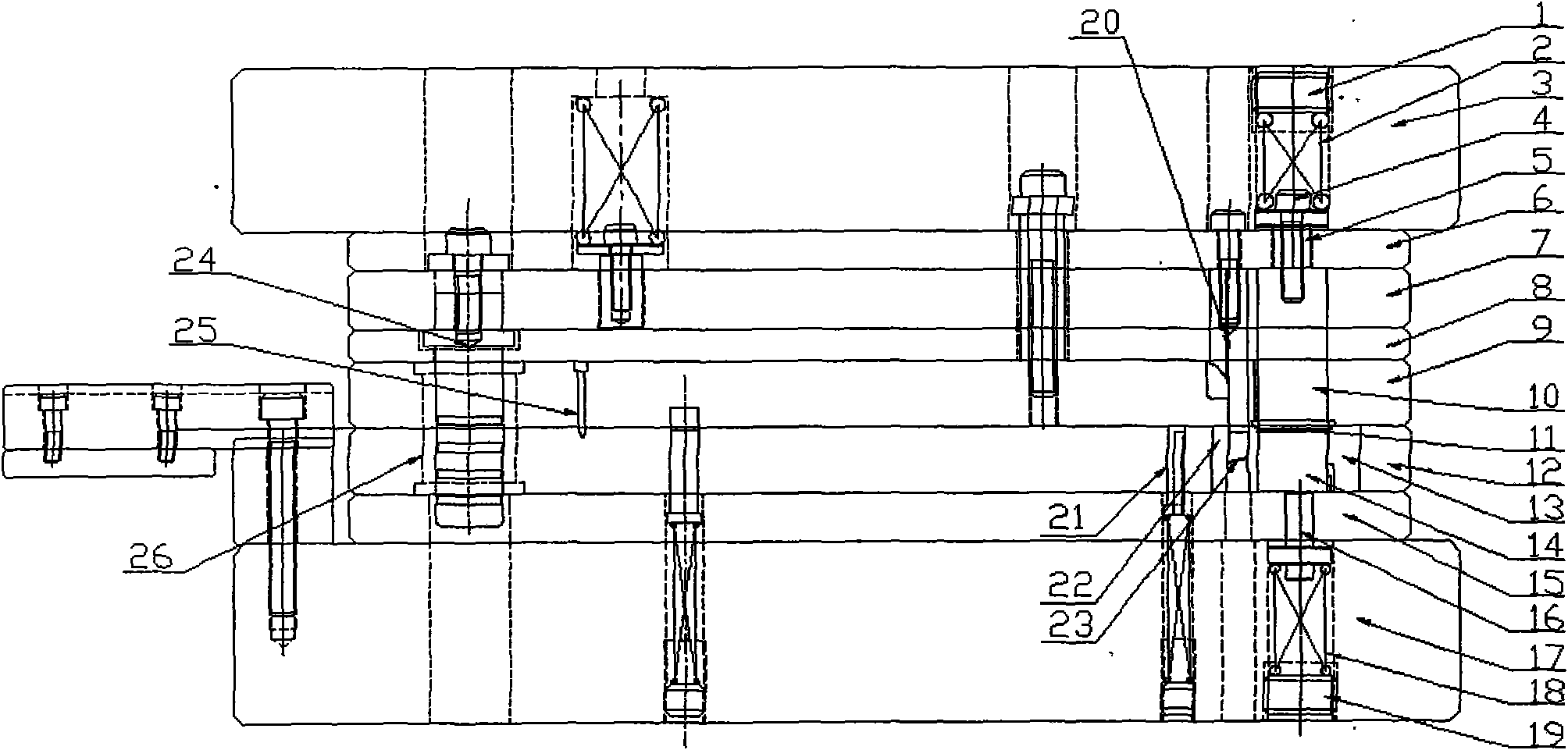

[0032] figure 2 It is an opening state diagram of an embodiment of the present invention; image 3 It is a closed state diagram of an embodiment of the present invention; Figure 4 for figure 2 Enlarged view of Part A of ; Figure 5 for figure 2 Enlarged view of Part B.

[0033] Such as Figure 2 to Figure 5 Shown: a stamping die for synchronous forming of the punching edge and the surrounding flanging, including an upper die and a lower die, wherein the upper die includes an upper die base 3, an upper backing plate 6, a pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com