Ultra-light foamed TPR material synthesized of modified thermoplastic rubber and preparation method thereof

A technology of thermoplastic rubber and thermoplastic styrene-butadiene, which is applied in the field of modified ultra-light foamed TPR material and its preparation, and rubber materials. It can solve the problems of high cost, non-recyclable, and failure to meet low-temperature resistance standards, and achieve low cost. , reduce energy consumption, and solve the effect of strength problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

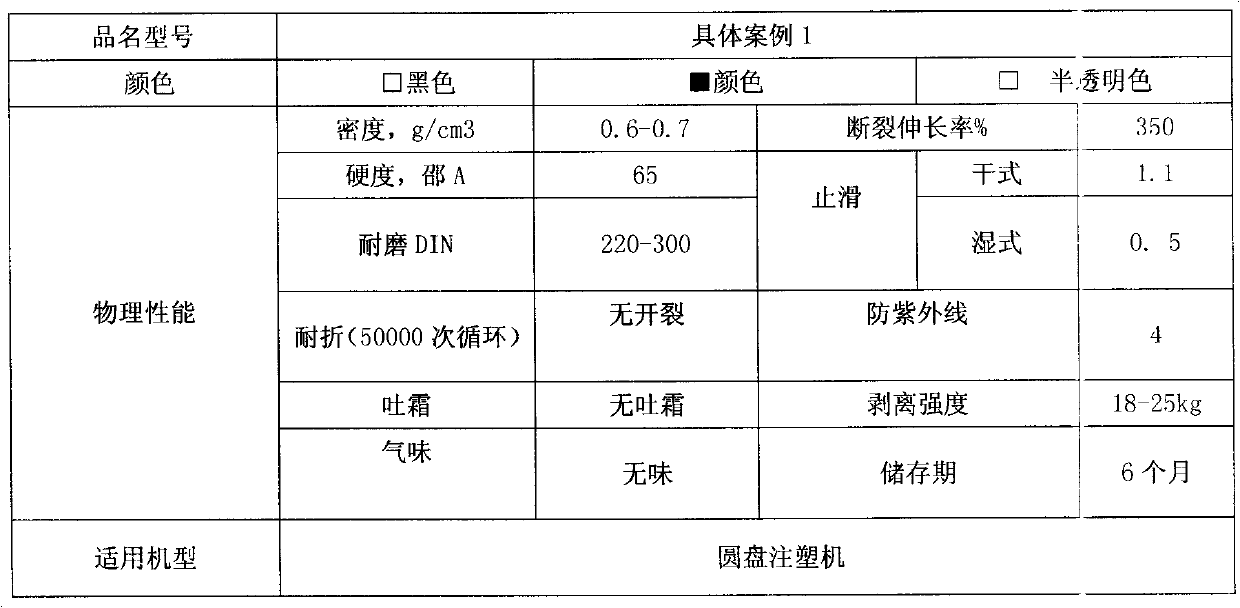

Embodiment 1

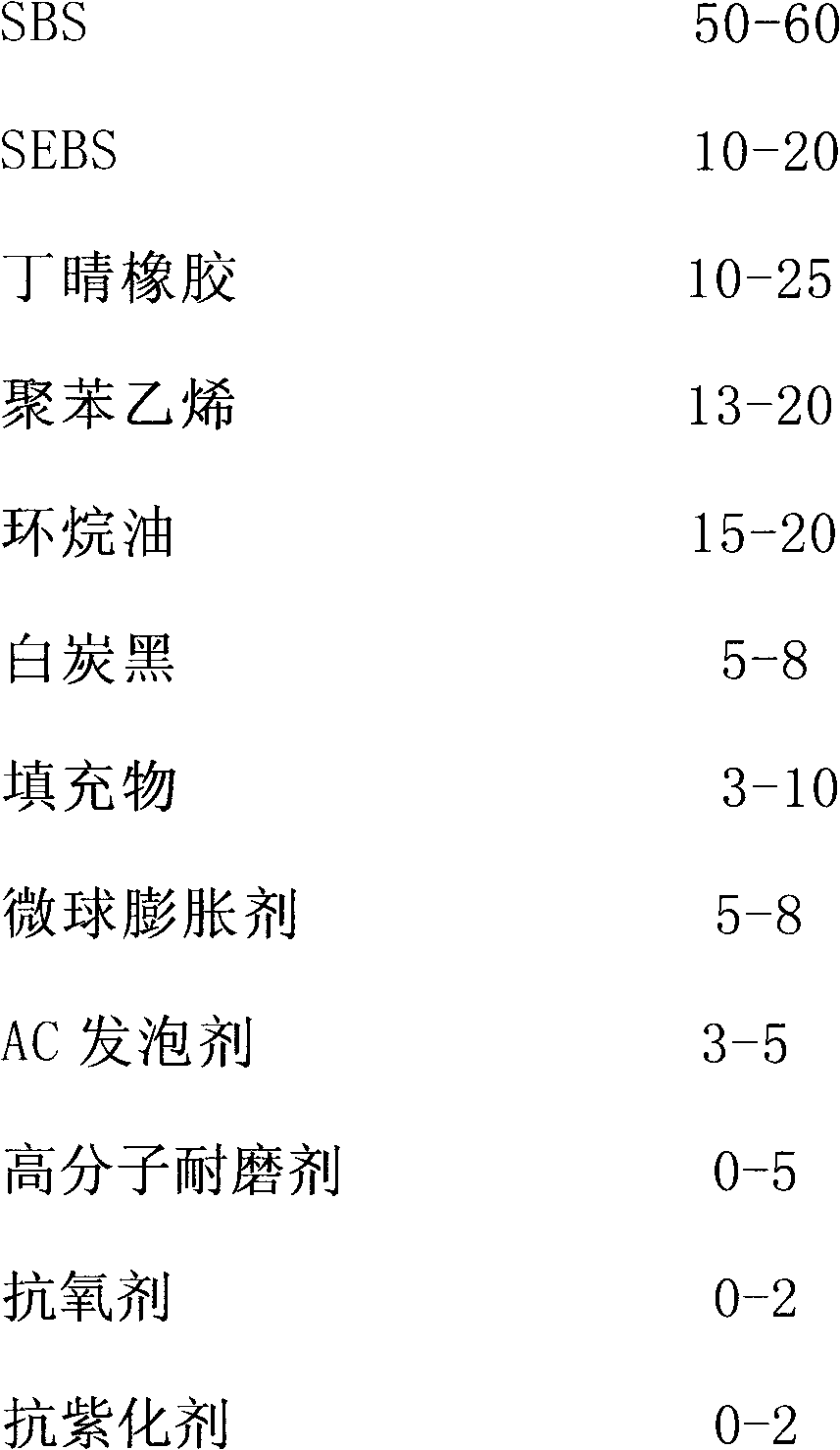

[0022] The material composition and proportioning of the present embodiment are as follows:

[0023] SBS (4452 of Yanshan Petrochemical): 50 parts, SEBS (602 of Yueyang Petrochemical): 10 parts, nitrile rubber (8561-Z): 10 parts, polystyrene: 13 parts, naphthenic oil: 15 parts, white carbon Black: 5 parts, calcium carbonate: 4 parts, microsphere low-temperature foaming agent (Matsumoto Japan): 5 parts, azodicarbonamide: 3 parts, polymer wear-resistant agent: 2 parts, antioxidant: 0.5 parts, Anti-purple agent: 0.5 part.

[0024] The preparation method steps of the present embodiment are as follows:

[0025] Fill 50 parts of SBS (4452 of Yanshan Petrochemical) and 10 parts of SEBS (602 of Yueyang Petrochemical) with 15 parts of naphthenic oil and stir for 70 minutes, then cut 10 parts of NBR into small pieces and stir for 35 minutes at the same time. Mix evenly, and then add other raw materials except azodicarbonamide according to the above ratio and stir, let the nitrile rubb...

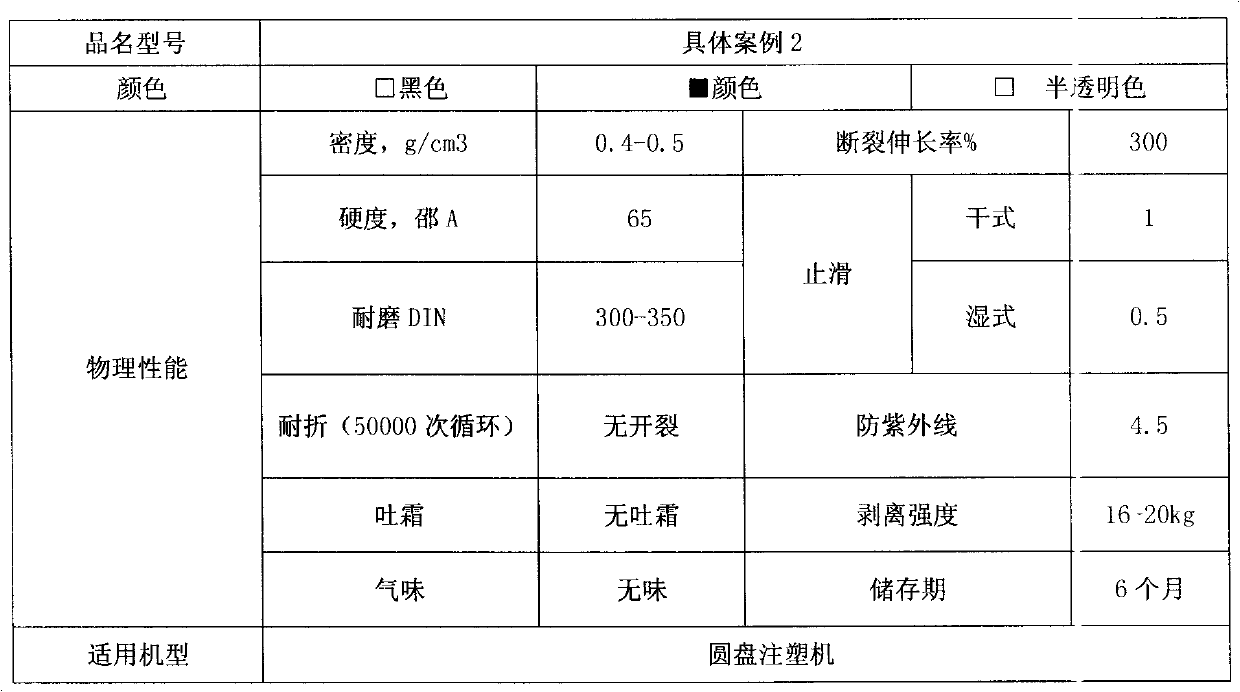

Embodiment 2

[0029] The material composition and proportioning of the present embodiment are as follows:

[0030] SBS (F675 of Maoming Petrochemical): 55 parts, SEBS (503 of Yueyang Petrochemical): 15 parts, nitrile rubber (8561-Z): 16 parts, polystyrene: 15 parts, naphthenic oil: 17 parts, white carbon Black: 7 parts, calcium carbonate: 5 parts, microsphere low-temperature foaming agent (Matsumoto Japan): 7 parts, azodicarbonamide: 4 parts, polymer wear-resistant agent: 4 parts, antioxidant: 1 part, Anti-purple agent: 1 part.

[0031] The preparation method steps of the present embodiment are as follows:

[0032] Fill 55 parts of SBS (F675 of Maoming Petrochemical) and 15 parts of SEBS (503 of Yueyang Petrochemical) with 17 parts of naphthenic oil and stir for 80 minutes, then cut 16 parts of NBR into small pieces and stir for 50 minutes at the same time. Mix evenly, and then add other raw materials except azodicarbonamide according to the above ratio and stir, let the nitrile rubber bl...

Embodiment 3

[0036] The material composition and proportioning of the present embodiment are as follows:

[0037] SBS (F475 of Maoming Petrochemical): 60 parts, SEBS (602 of Yueyang Petrochemical): 10 parts, nitrile rubber (8561-Z): 12 parts, polystyrene: 20 parts, naphthenic oil: 20 parts, white carbon Black: 5 parts, calcium carbonate: 3 parts, microsphere low-temperature foaming agent (Matsumoto Japan): 5 parts, azodicarbonamide: 5 parts, polymer wear-resistant agent: 2 parts, antioxidant: 2 parts, Anti-purple agent: 2 parts.

[0038] The preparation method steps of the present embodiment are as follows:

[0039] Fill 60 parts of SBS (F475 of Maoming Petrochemical) and 10 parts of SEBS (602 of Yueyang Petrochemical) with 20 parts of naphthenic oil and stir for 90 minutes, then cut 12 parts of nitrile rubber (8561-Z) into small pieces and put them in at the same time Stir for 60 minutes, fully mix evenly, and then add other raw materials except azodicarbonamide according to the above r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com