Nano-plate plane glue distributing device and method

An adhesive method and nanotechnology, which are applied in chemical instruments and methods, devices for coating liquid on surfaces, and surface pretreatment, etc., can solve the problems of uneven product thickness, high product cost, and low production efficiency. Efficiency and quality improvement, good surface flatness, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

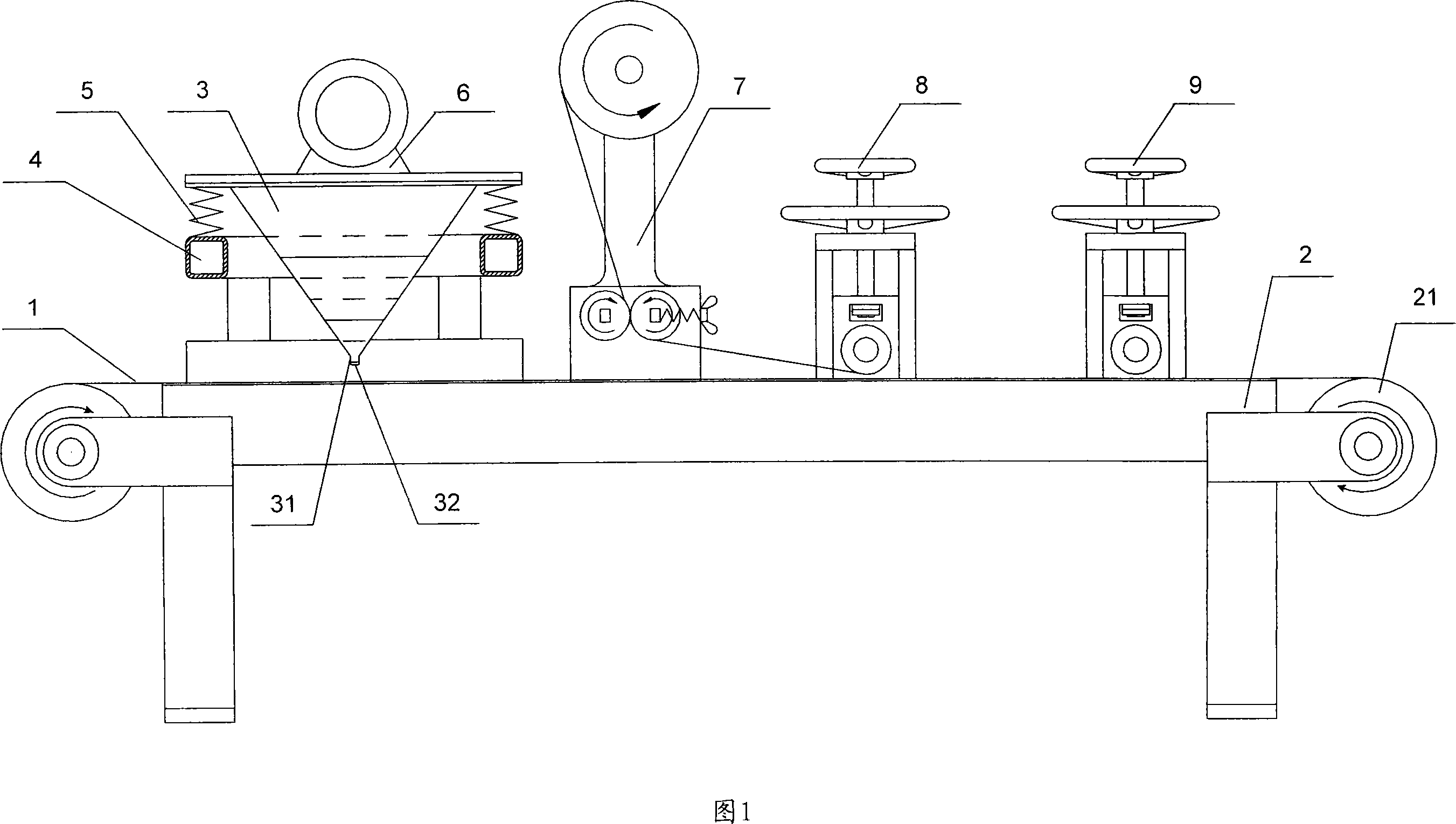

[0079] Fig. 1 is a schematic structural view of the nano-sheet planar glue-distributing equipment of the present invention. As shown in Figure 1, the main structure of the flat glue distribution equipment for nano-sheets includes a workbench 2, a distribution hopper 3, a support frame 4, a vibration device 6, an application device 7, a scraping device 8 and a pressing device 9, and the workbench 2 It is a machined flat work surface to ensure consistent thickness of nano-sheet products; at least two transmission rollers 21 are arranged on the work table 2, which are used to drive the composite traction belt 1 to be transported horizontally on the horizontal work table 2; The distributing hopper 3 of shaped nano-semifluid is located above the workbench 2, and is used to lay the nano-semifluid on the composite traction belt and form a nano-tape. 32. The material opening gate 32 is used to open and close the material opening 31, and the opening size of the material opening 31 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com