A kind of production method of pickling-reducing steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

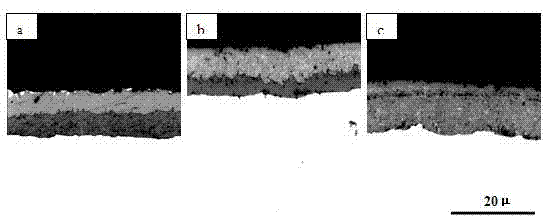

Image

Examples

Embodiment 1

[0039] Example 1: Purified molten steel is obtained by smelting, and then continuously cast into a slab through a continuous casting machine, and its composition weight percentage is: C: 0.045%, Si: ≤0.023%, Mn: 0.21%, P: ≤0.015 %, S: ≤0.004%, Als: 0.02%.

[0040] Heat the slab to 1190°C, keep it warm for 30 minutes, then turn on all the high-pressure water for descaling, and the pressure is 19Mpa; the slab after descaling is subjected to rough rolling for 3+3 times, the rough rolling start temperature is 1170°C, and the final rolling temperature The temperature is 1020°C, ensuring that the pressure of the secondary descaling water is not less than 18Mpa; after exiting the rough rolling mill, the insulation cover is fully opened, the temperature at the entrance of the finish rolling is set at 990°C, and the cooling water between the stands is opened for 3-4 groups. The temperature setting value of the finish rolling exit is 880°C, and the thickness range is 4.5-3.5mm. The fini...

Embodiment 2

[0041] Example 2: Purified molten steel is obtained by smelting, and then continuously cast into a slab through a continuous casting machine, and its composition weight percentage is: C: 0.033%, Si: 0.015%, Mn: 0.22%, P: ≤ 0.0104% , S: ≤0.0156%, Als: 0.0189%.

[0042] Heat the slab to 1180°C, keep it warm for 40 minutes, and then turn on all the descaling high-pressure water at a pressure of 20bar; the slab after descaling is subjected to rough rolling for 3+3 times, the rough rolling start temperature is 1170°C, and the final rolling temperature The temperature is 1010°C, ensuring that the pressure of the secondary descaling water is not less than 19Mpa; after exiting the rough rolling mill, the heat preservation cover is fully opened, the temperature setting value of the finish rolling entrance is 990°C, and the cooling water between the stands is opened for 3-4 groups. The temperature setting value of the finish rolling exit is 874 °C, the temperature setting value of the f...

Embodiment 3

[0043] Example 3: Purified molten steel is obtained by smelting, and then continuously cast into a slab through a continuous casting machine. The composition weight percentages are: C: 0.032%, Si: ≤0.011%, Mn: 0.177%, P: 0.0087%, S: 0.010%, Als: 0.0209%.

[0044] Heat the slab to 1200°C, keep it warm for 20 minutes, and then turn on all the descaling high-pressure water at a pressure of 20 Mpa; the slab after descaling is subjected to rough rolling for 3+5 times, the rough rolling start temperature is 1180°C, and the final rolling The temperature is 1020°C, ensuring that the pressure of the secondary descaling water is not less than 20Mpa; after exiting the rough rolling mill, all the heat preservation covers are opened, the temperature setting value of the finish rolling entrance is 1100°C, and the cooling water between the stands is opened for 3-4 groups. The temperature setting value of the finish rolling exit is 890°C, and the thickness range is 3.0-2.5 mm. The finish roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com