Special tool for coating face gluing layer on stretching net of surface mount technology (SMT) laser template

A special tool and laser template technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of large consumption of masking tape, different width of the surface adhesive layer, labor and time-consuming masking tape, etc. Achieve the effect of anti-mesh degumming, uniform and consistent thickness, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment further illustrate the present invention.

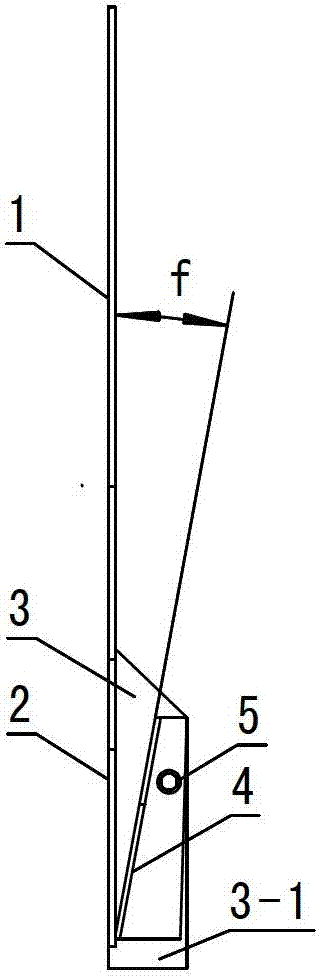

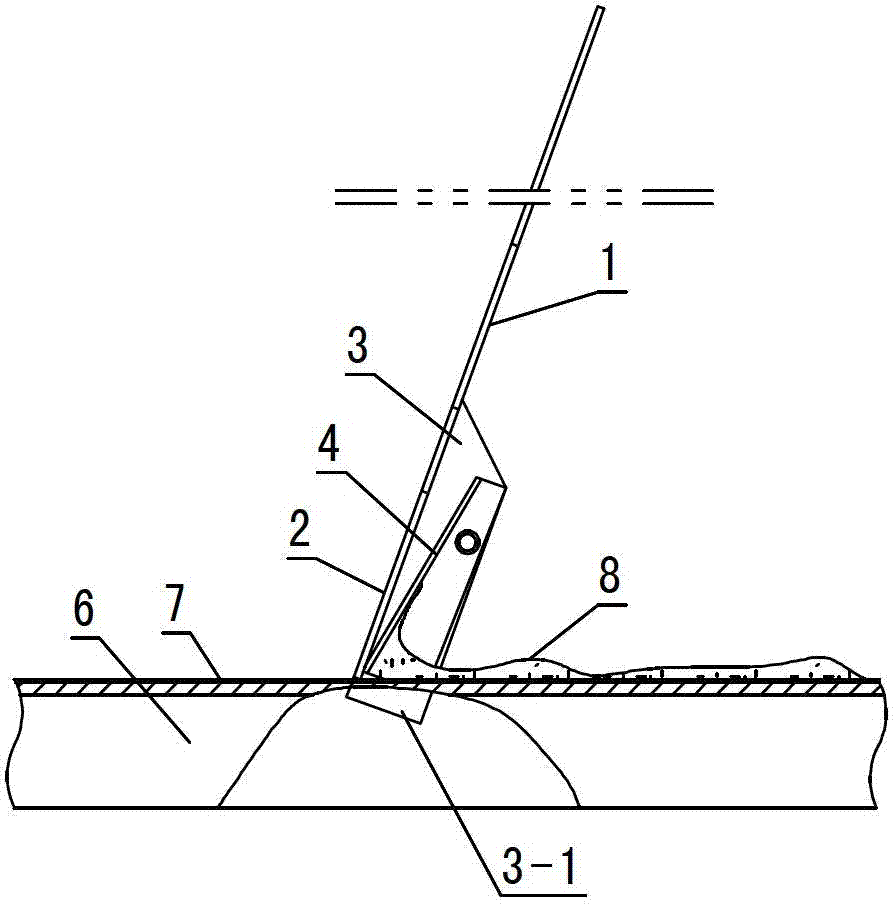

[0016] Such as figure 1 , 2 In the shown embodiment, the main body of this special tool is composed of a handle 1 and a scraper 2 connected to the bottom end of the handle. One side of the scraper 2 is provided with a baffle 3 perpendicular to the scraper. The width of the bottom end 2-1 of the scraper is equal to that of the rubber layer width.

[0017] The baffle 3 is provided with a protrusion 3-1 relative to the bottom end 2-1 of the scraper.

[0018] The baffle plate 3 is provided with a glue return plate 4 with a width of 1 / 4 to 1 / 3 of the width of the bottom end of the scraper 2-1 on the side corresponding to the scraper 2, and the bottom end of the glue return plate is connected to the bottom end of the scraper. There is an angle f of 15--30° between the glue return plate and the scraper surface.

[0019] The glue return plate 4 of the embodiment is provided with a flange 4-1 jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com