Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

450results about "Lamination plant layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

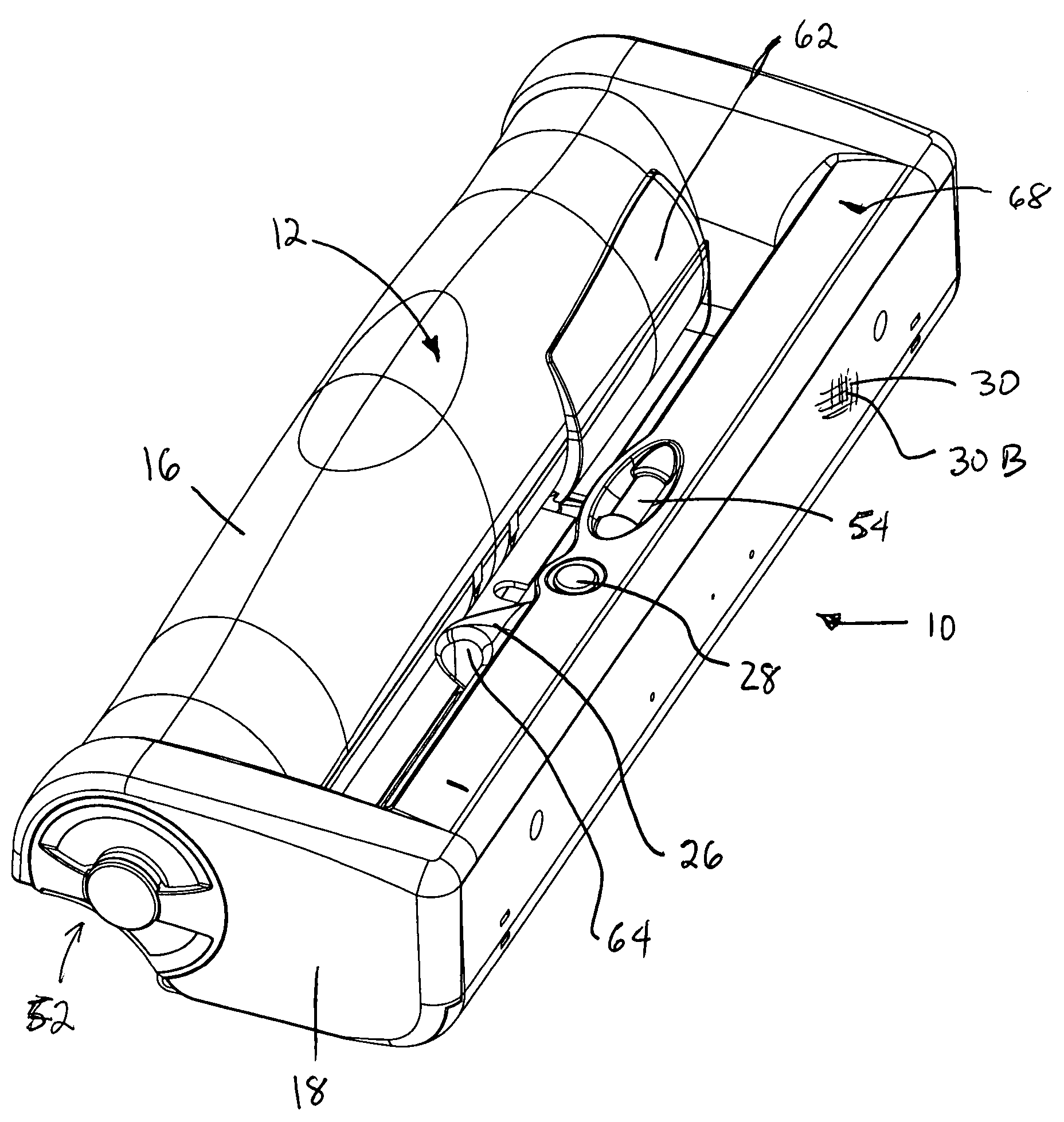

Method of transferring a micro device

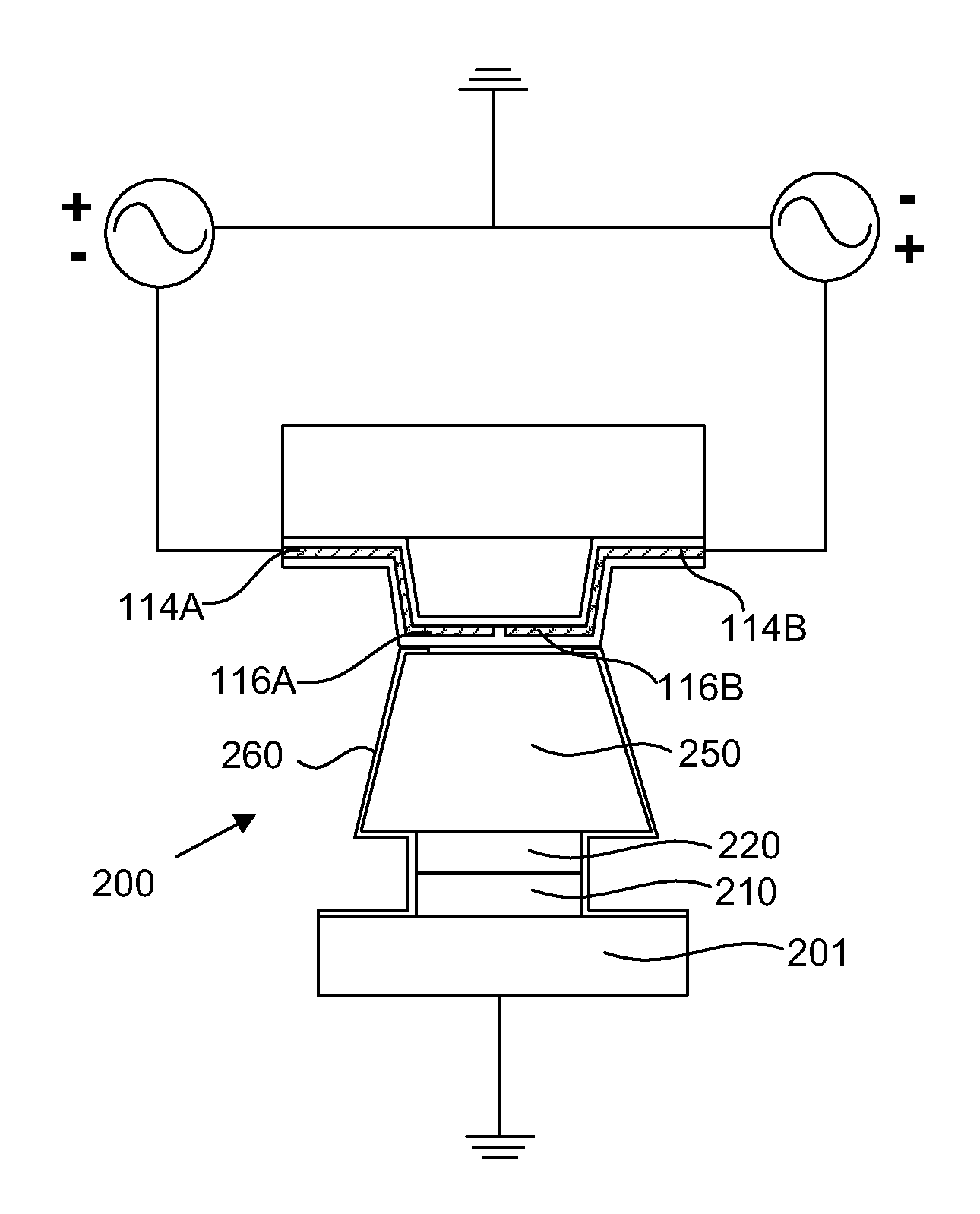

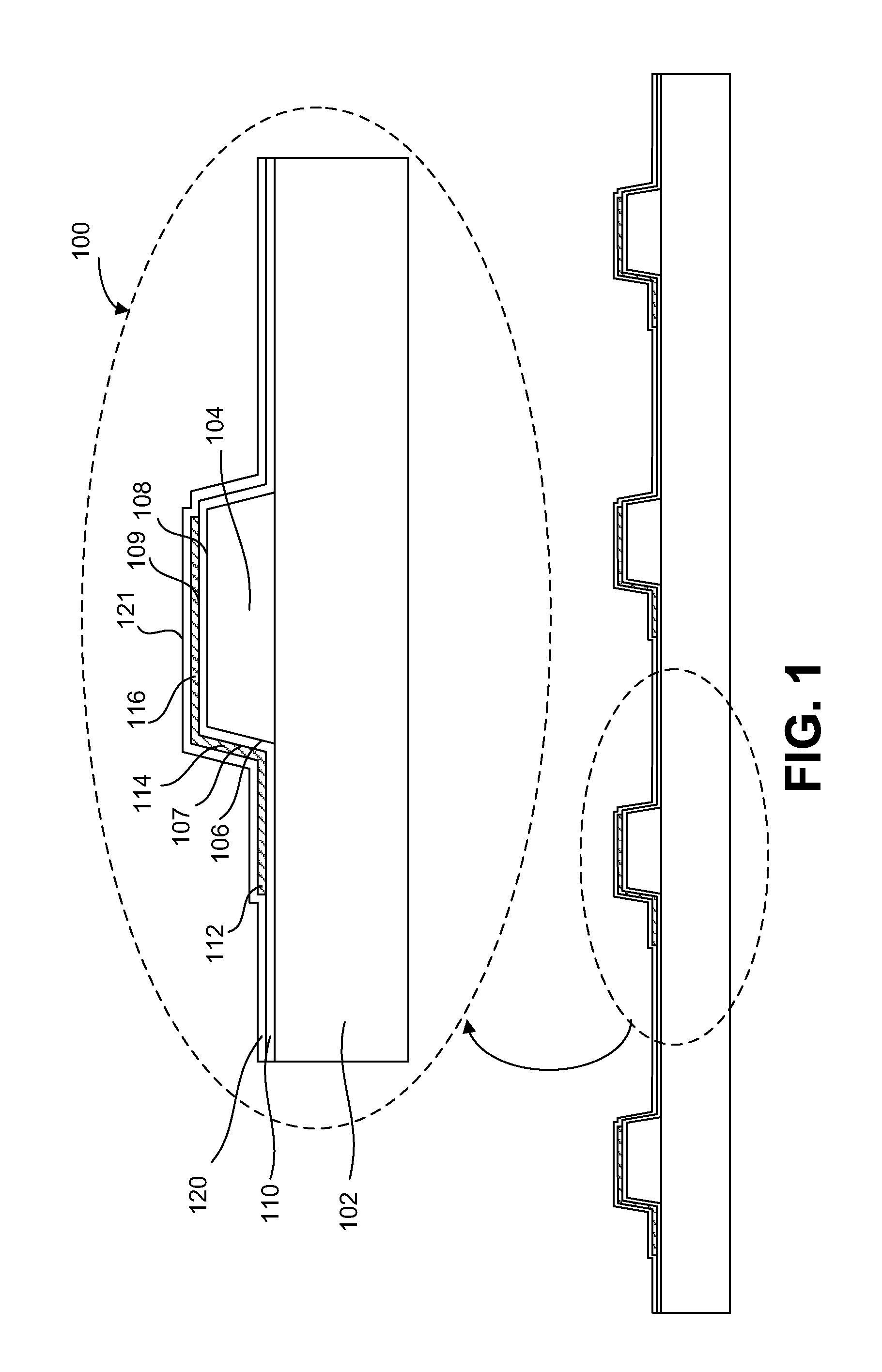

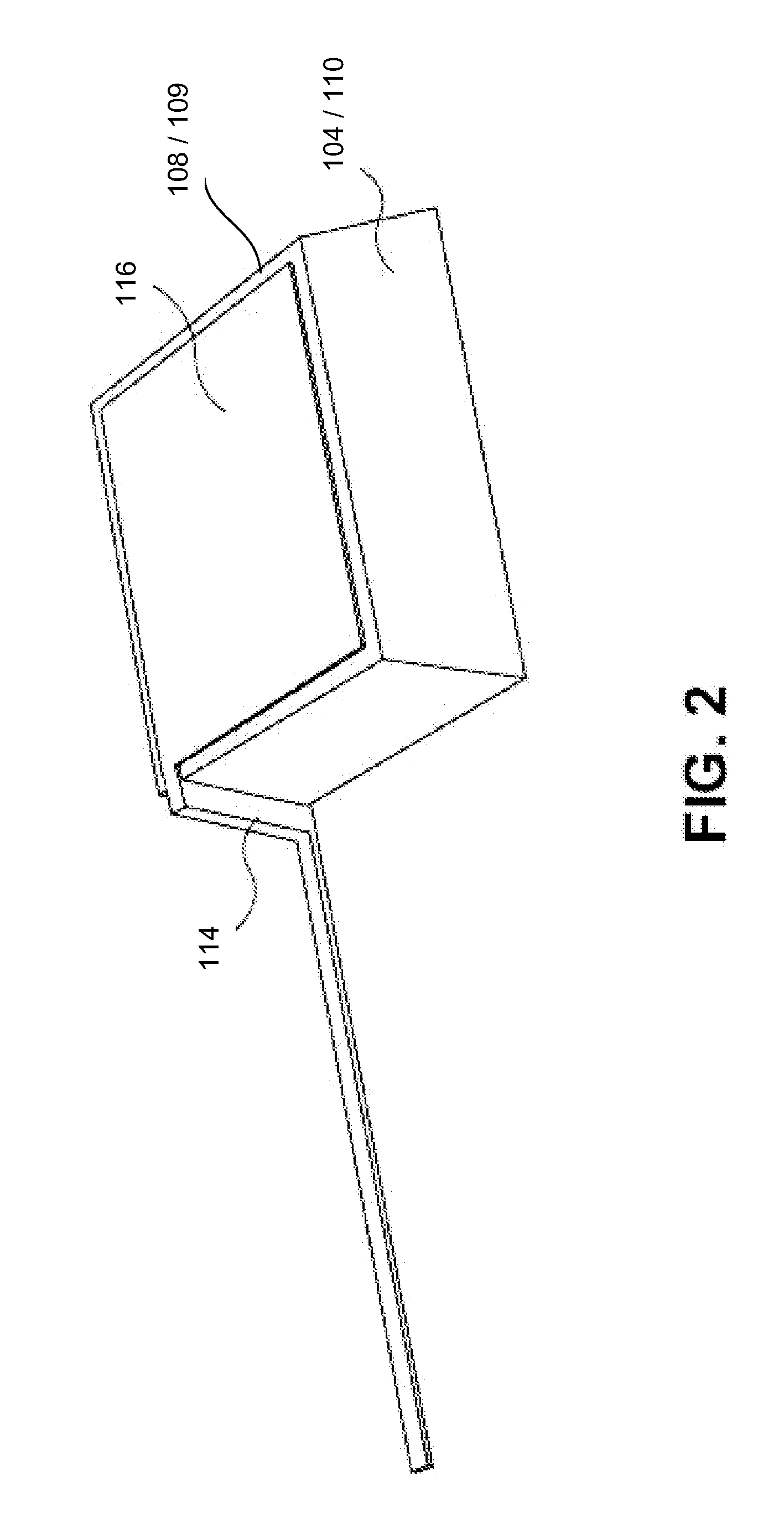

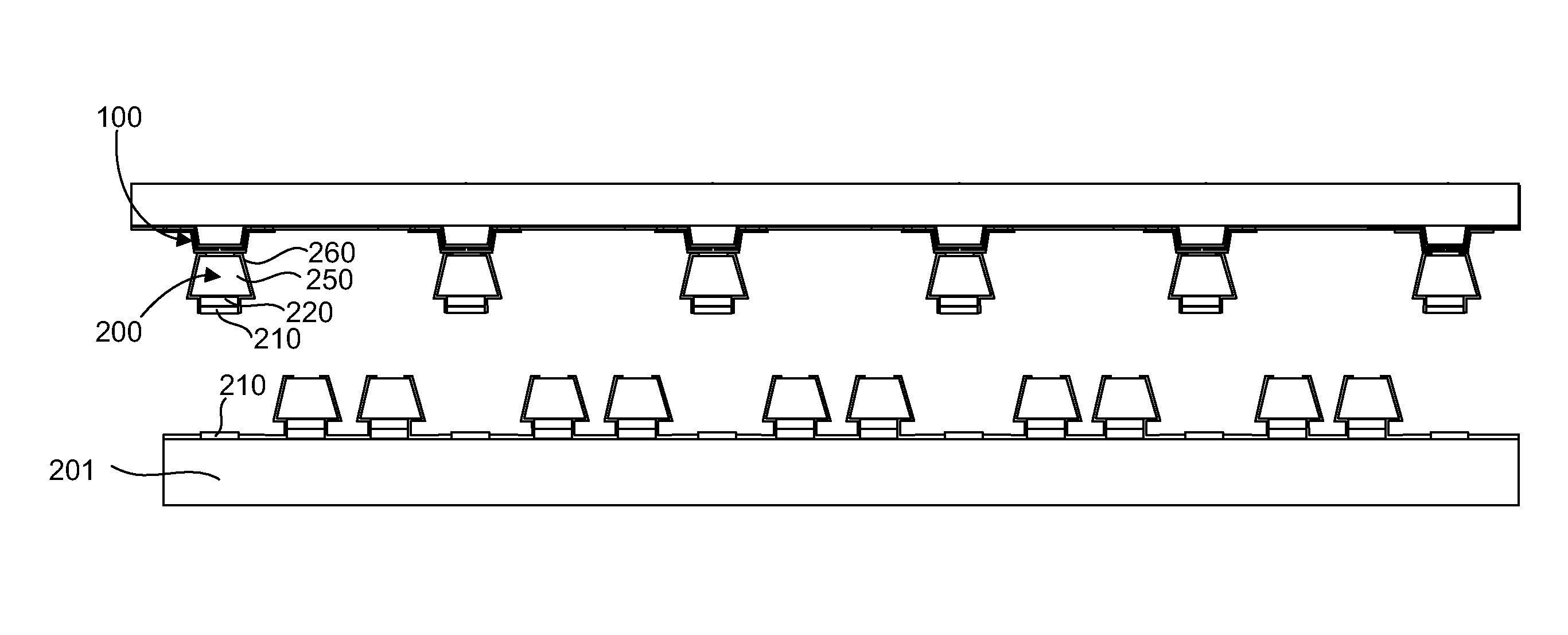

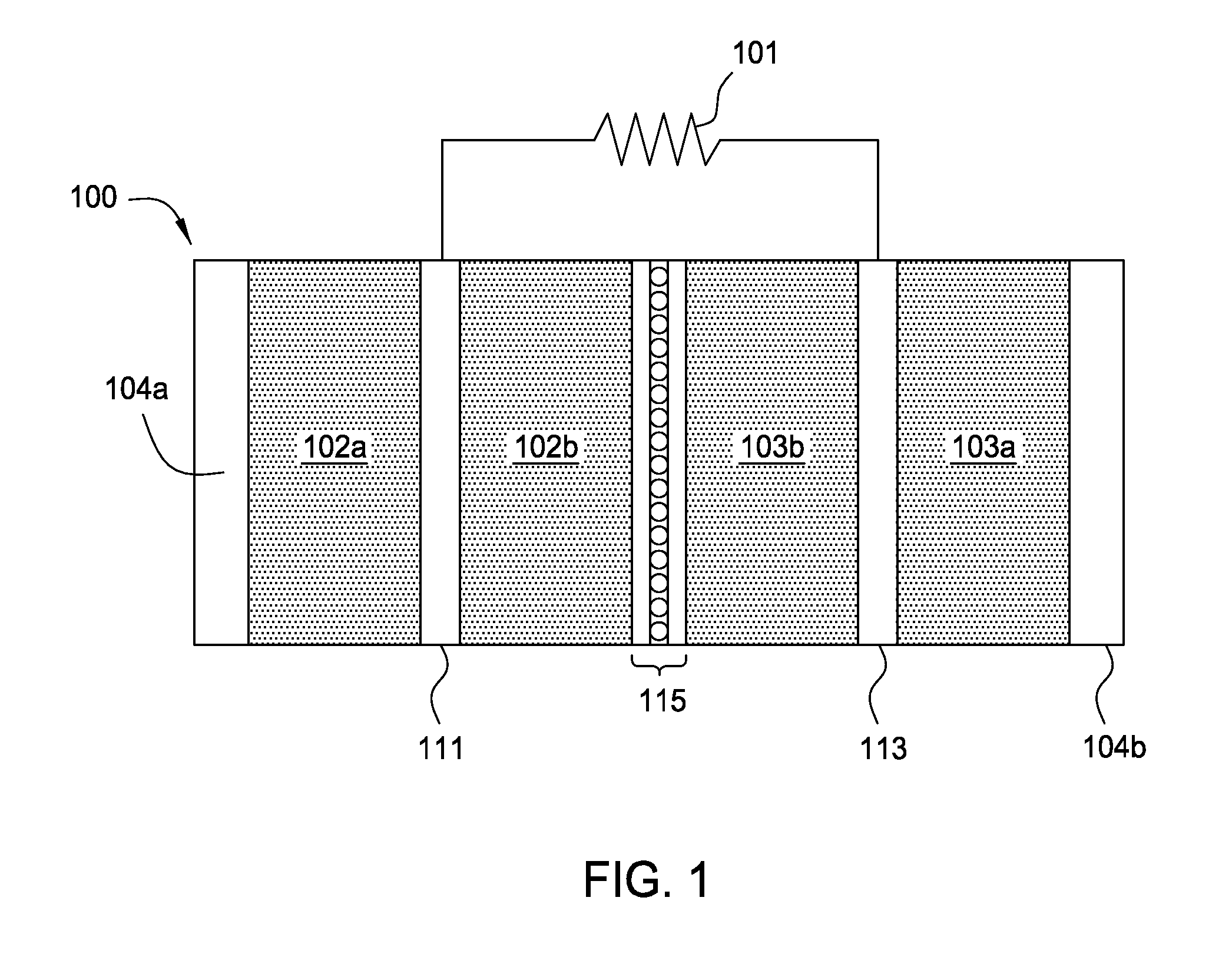

A micro device transfer head and head array are disclosed. In an embodiment, the micro device transfer head includes a base substrate, a mesa structure with sidewalls, an electrode formed over the mesa structure, and a dielectric layer covering the electrode. A voltage can be applied to the micro device transfer head and head array to pick up a micro device from a carrier substrate and release the micro device onto a receiving substrate.

Owner:APPLE INC

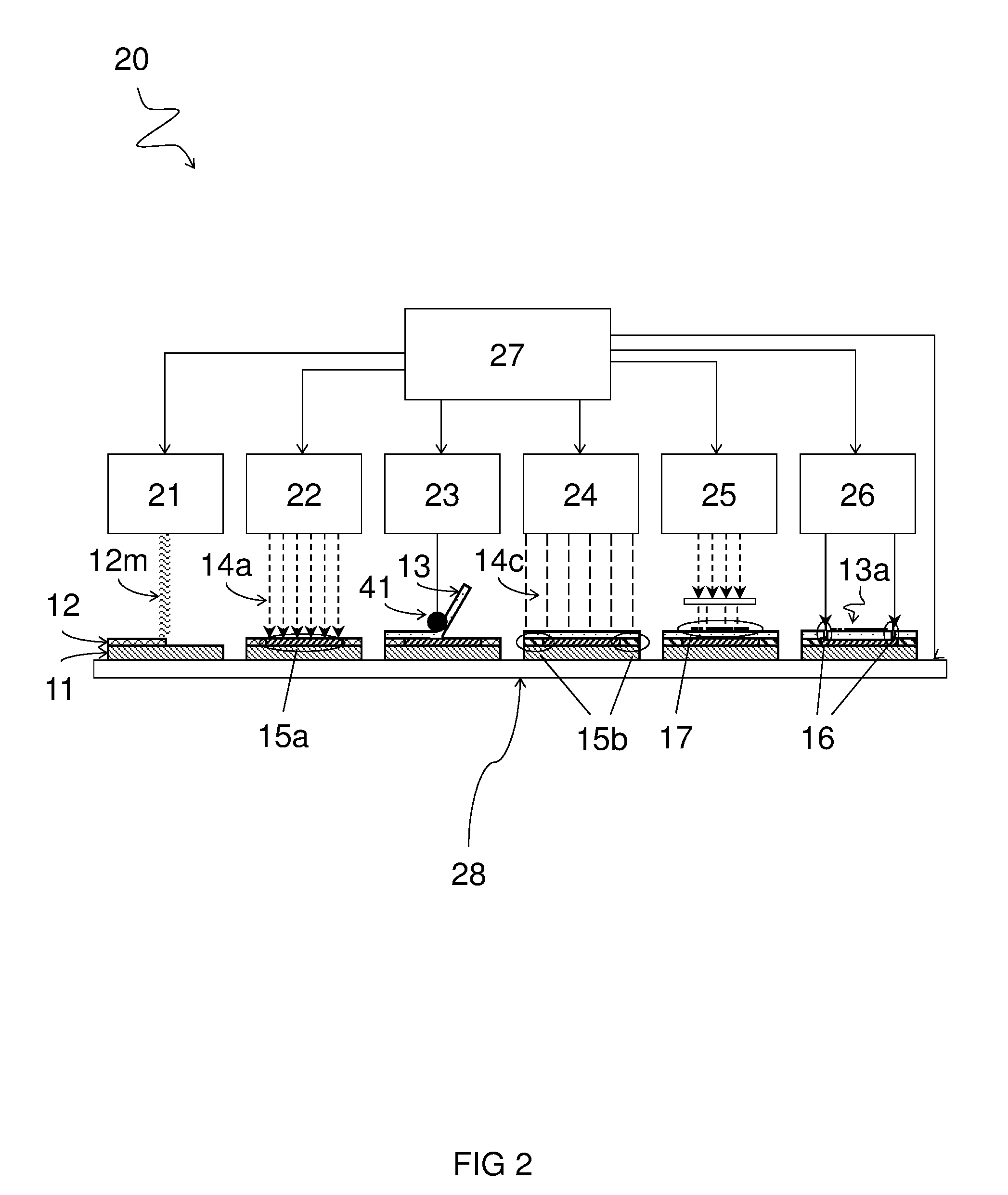

Micro device transfer head heater assembly and method of transferring a micro device

A method of transferring a micro device and an array of micro devices are disclosed. A carrier substrate carrying a micro device connected to a bonding layer is heated to a temperature below a liquidus temperature of the bonding layer, and a transfer head is heated to a temperature above the liquidus temperature of the bonding layer. Upon contacting the micro device with the transfer head, the heat from the transfer head transfers into the bonding layer to at least partially melt the bonding layer. A voltage applied to the transfer head creates a grip force which picks up the micro device from the carrier substrate.

Owner:APPLE INC

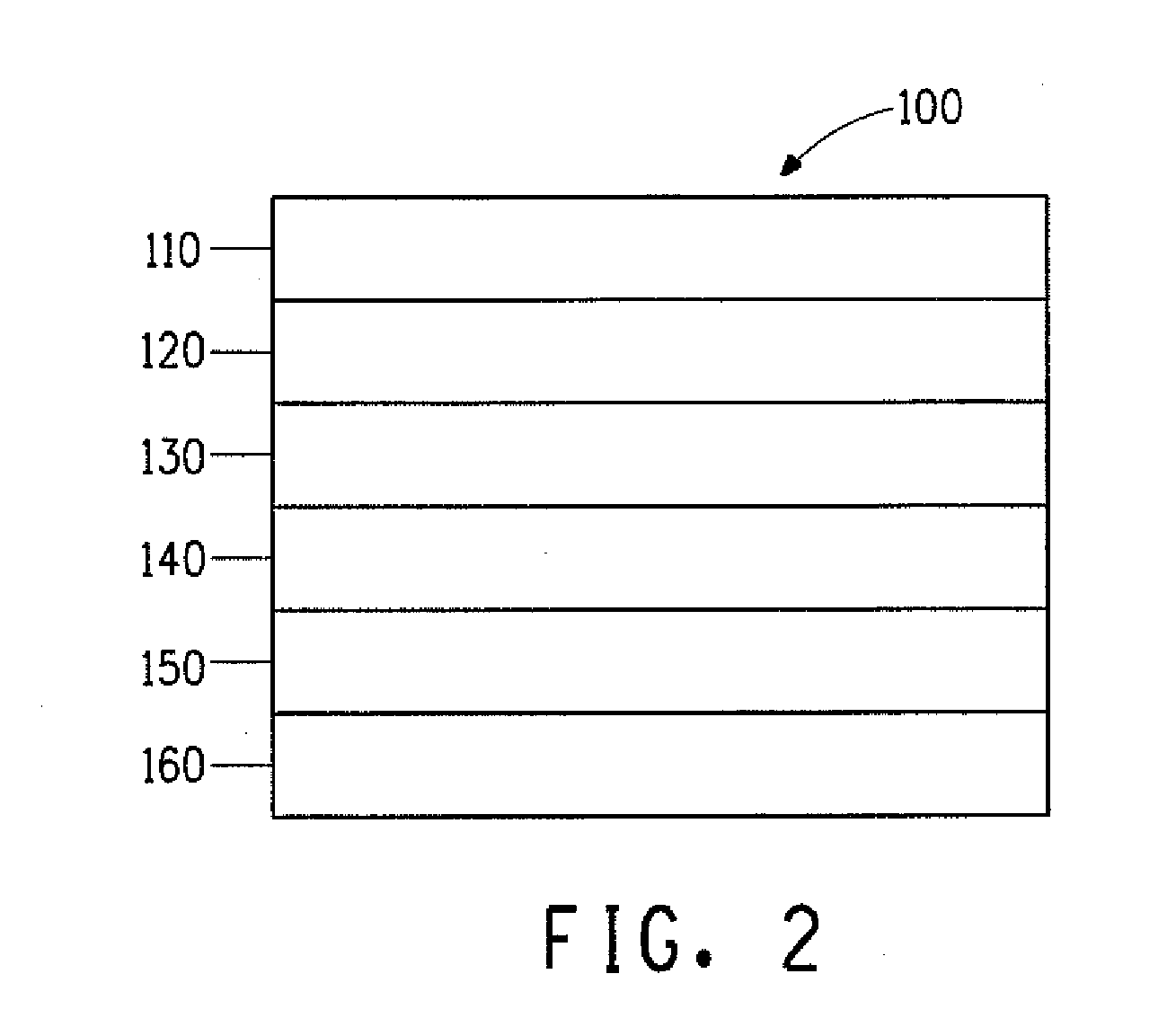

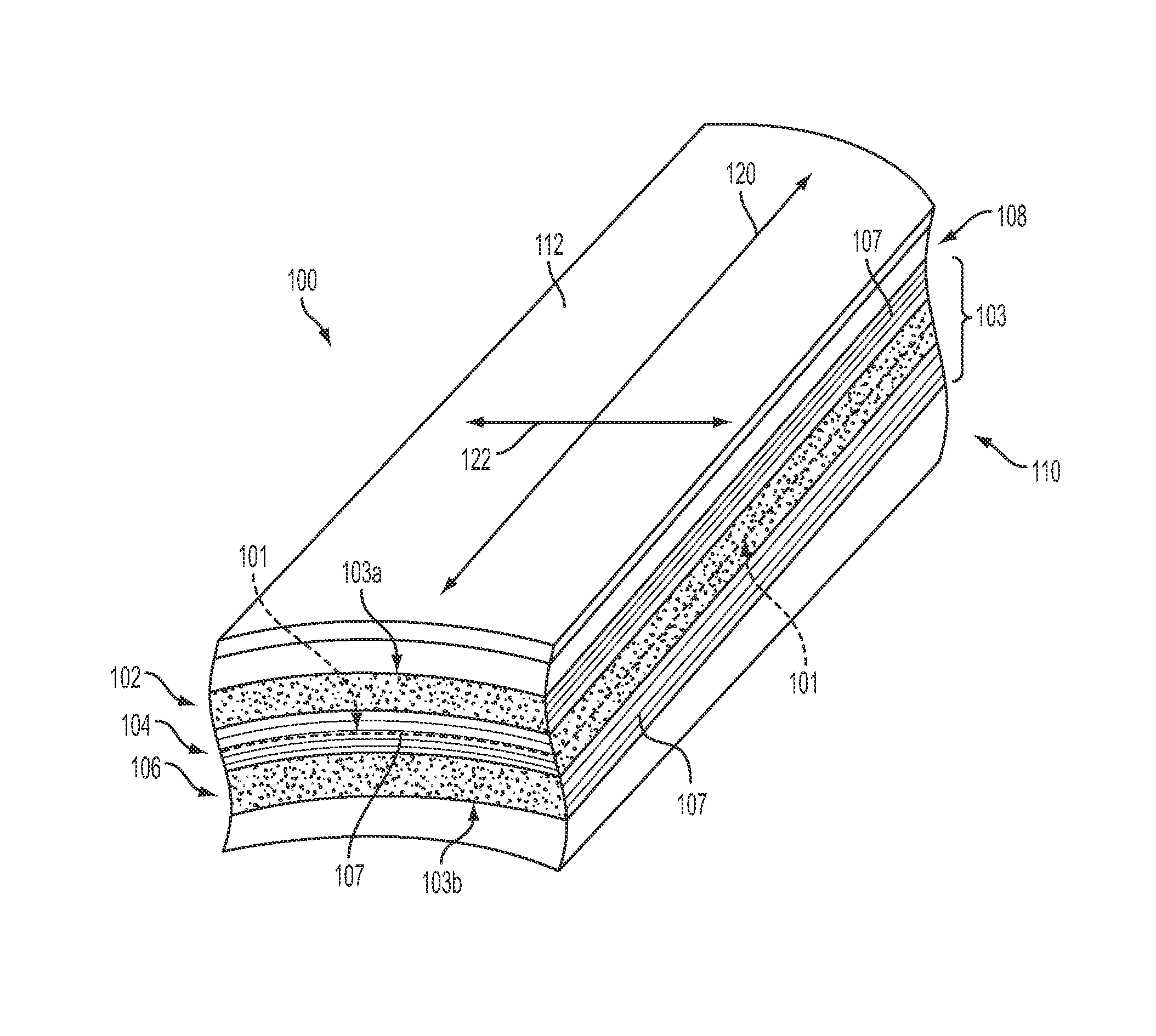

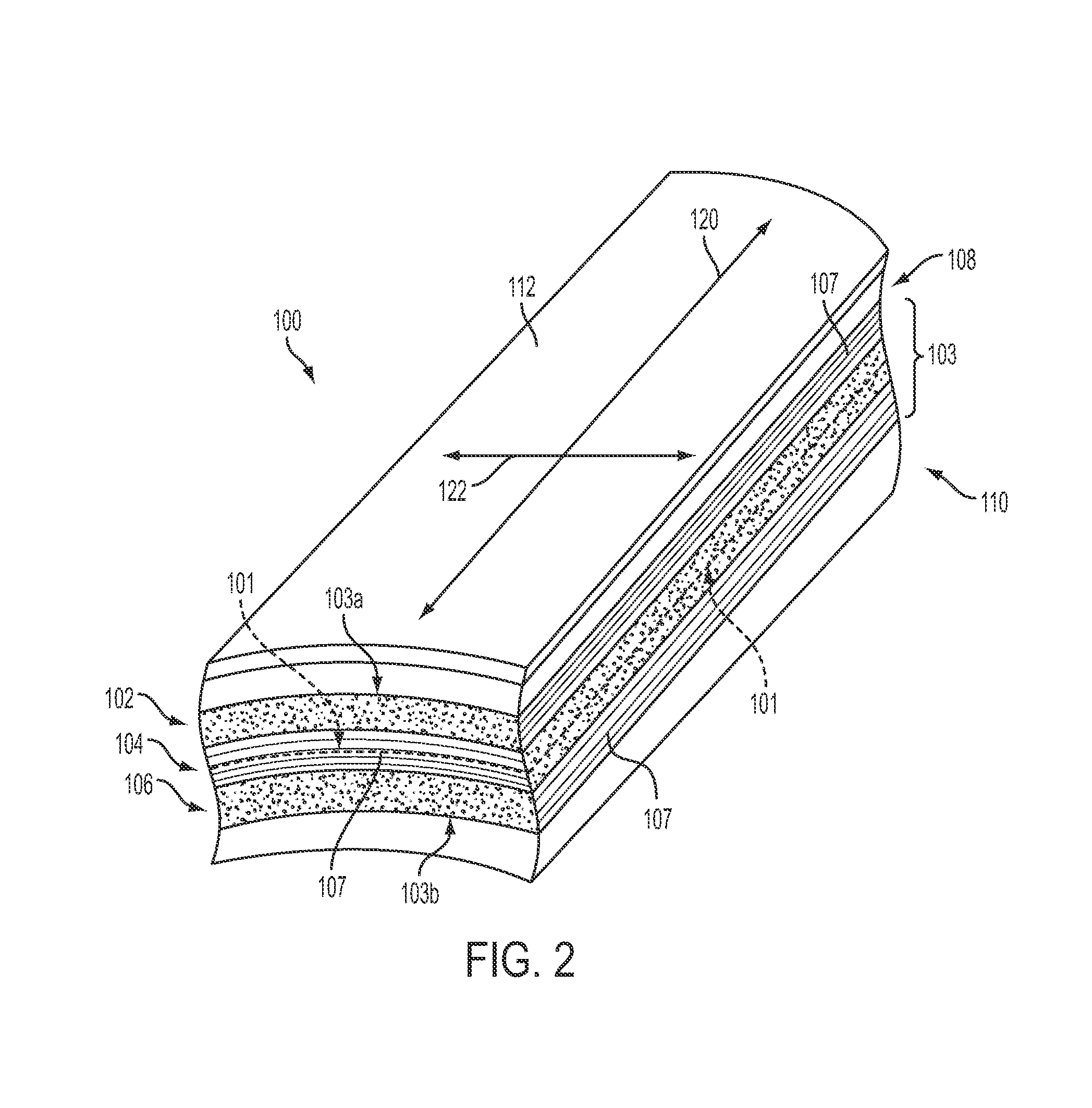

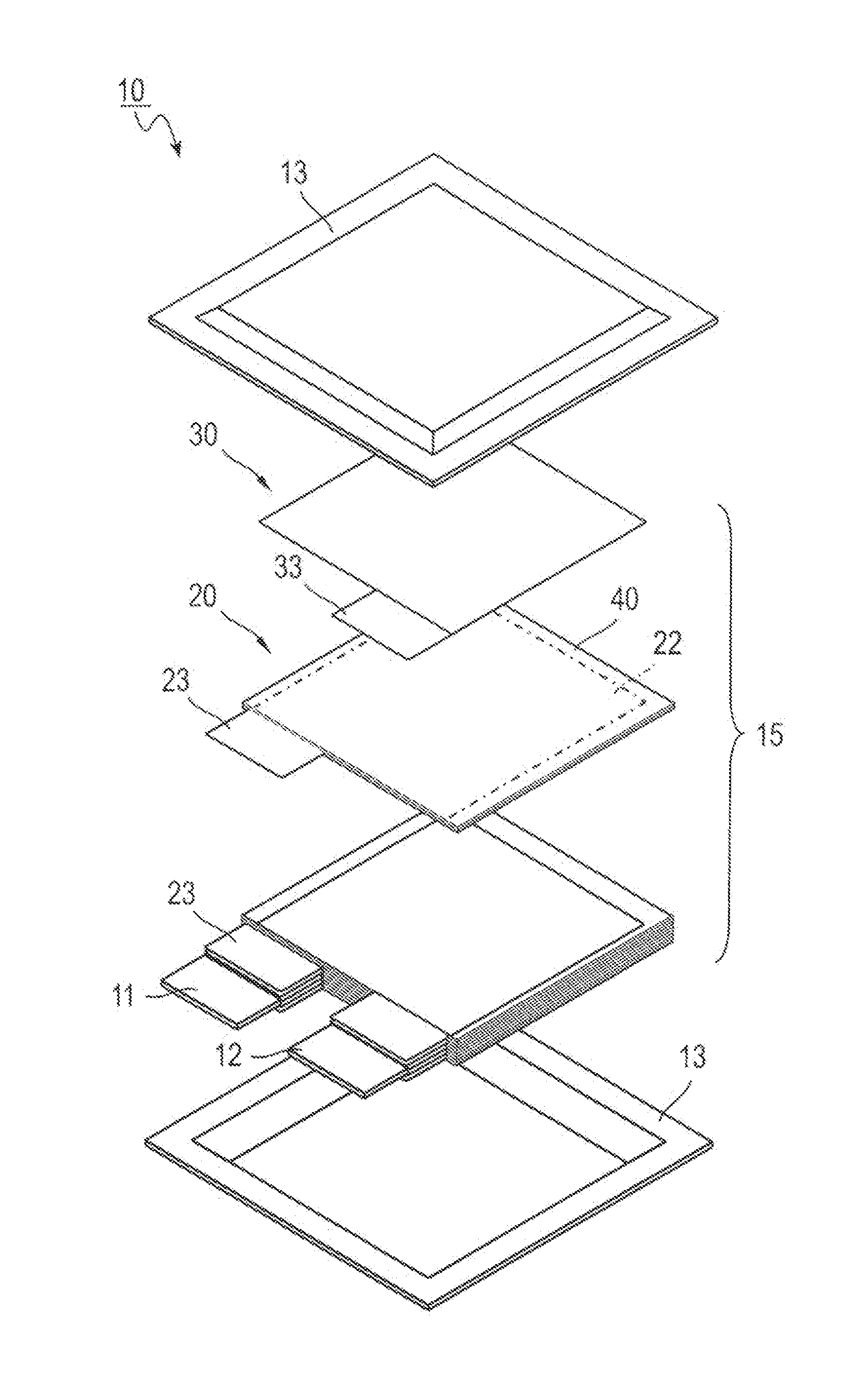

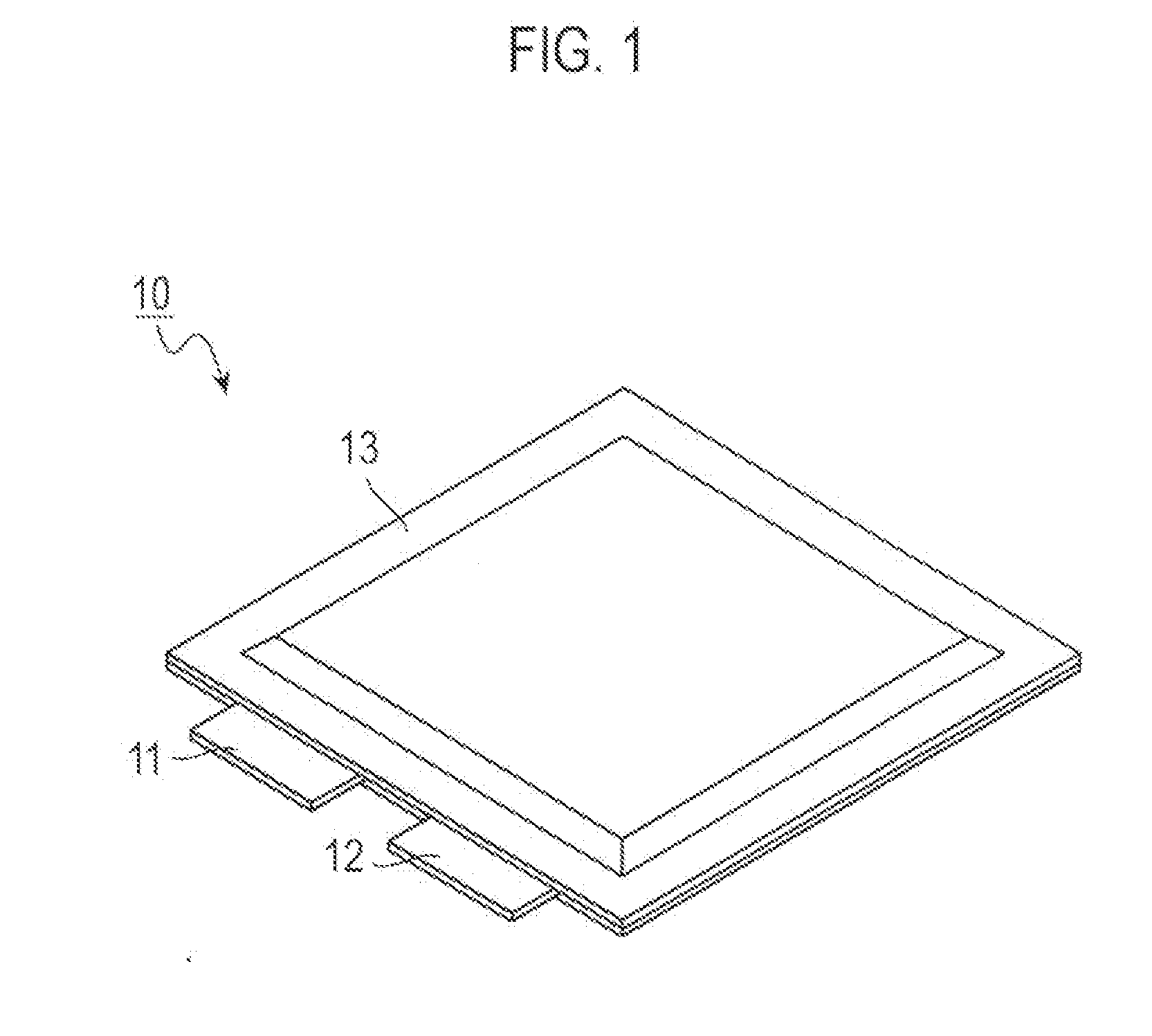

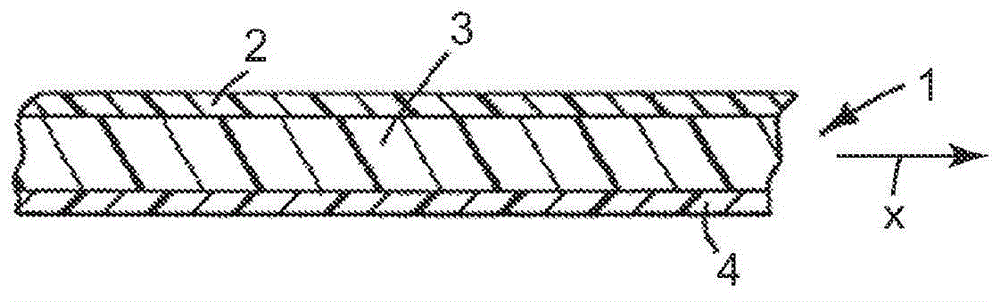

Integrated composite separator for lithium-ion batteries

Embodiments of the present invention relate generally to lithium-ion batteries, and more specifically, to batteries having integrated separators and methods of fabricating such batteries. In one embodiment, a lithium-ion battery having an electrode structure is provided. The lithium-ion battery comprises an anode stack, a cathode stack, and an integrated separator formed between the anode stack and the cathode stack. The anode stack comprises an anodic current collector and an anode structure formed over a first surface of the anodic current collector. The cathode stack comprises a cathodic current collector and a cathode structure formed over a first surface of the cathodic current collector. The integrated separator comprises a first ceramic layer, a second ceramic layer, and a polymer material layer deposited between the first ceramic layer and the second ceramic layer.

Owner:APPLIED MATERIALS INC

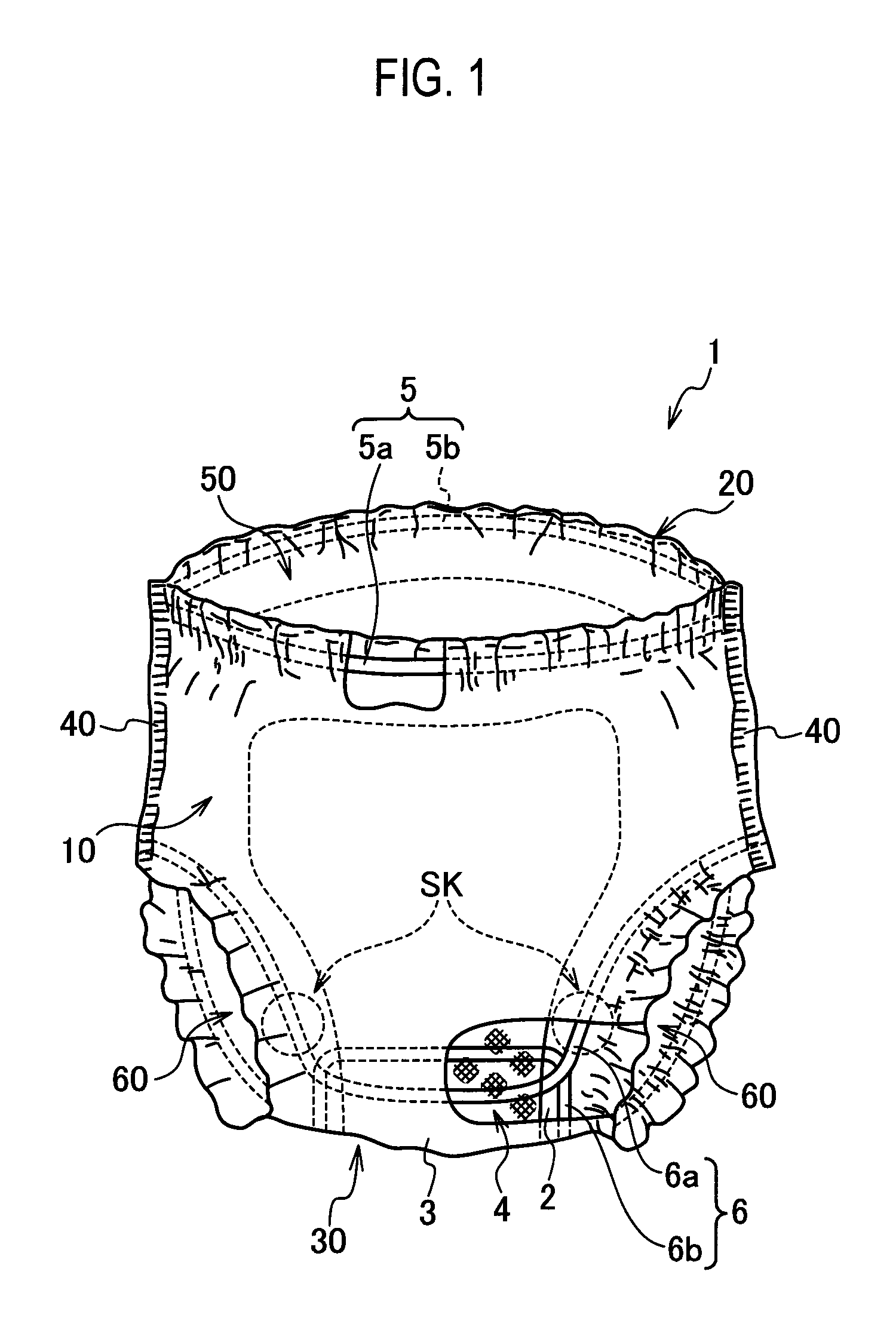

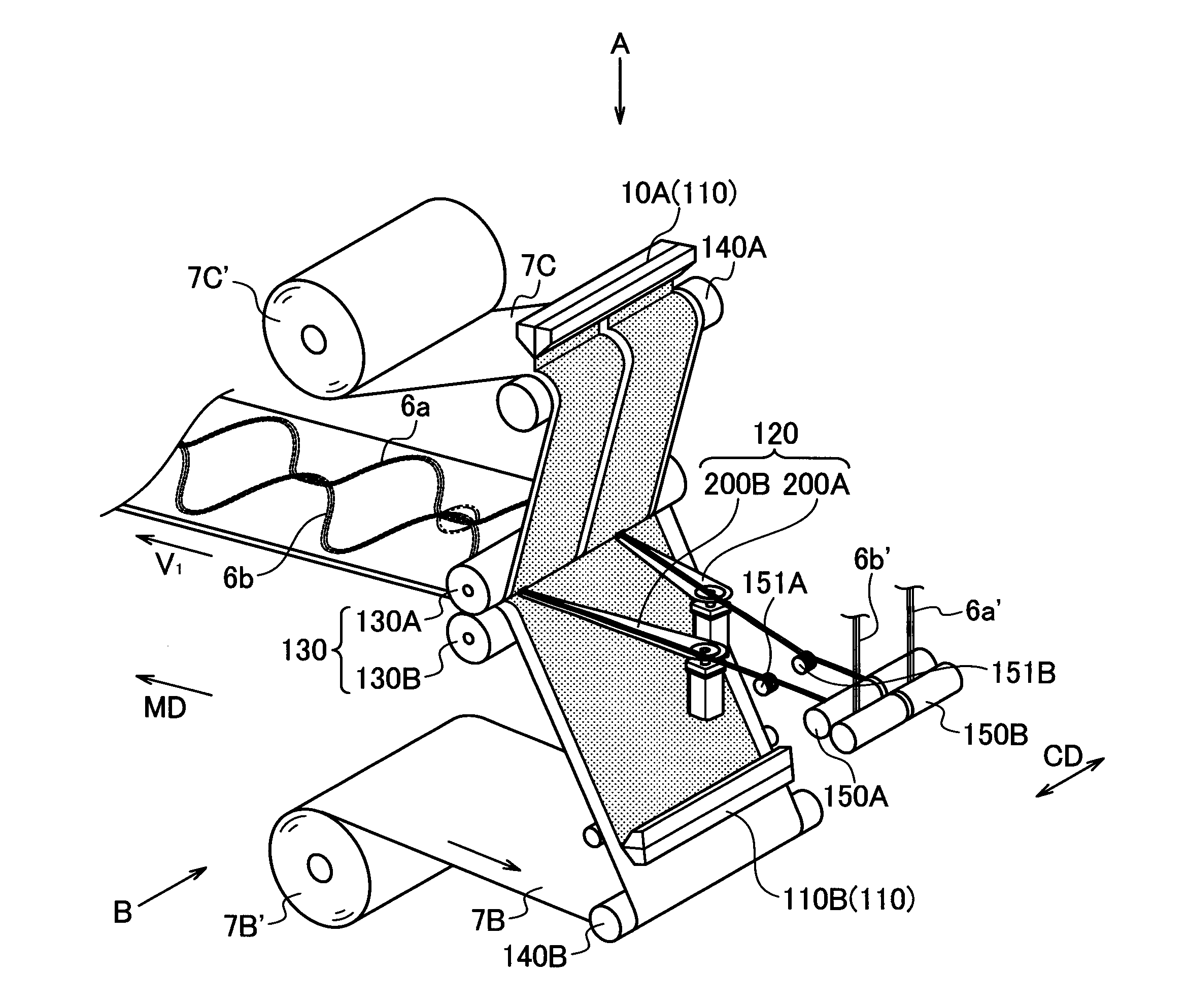

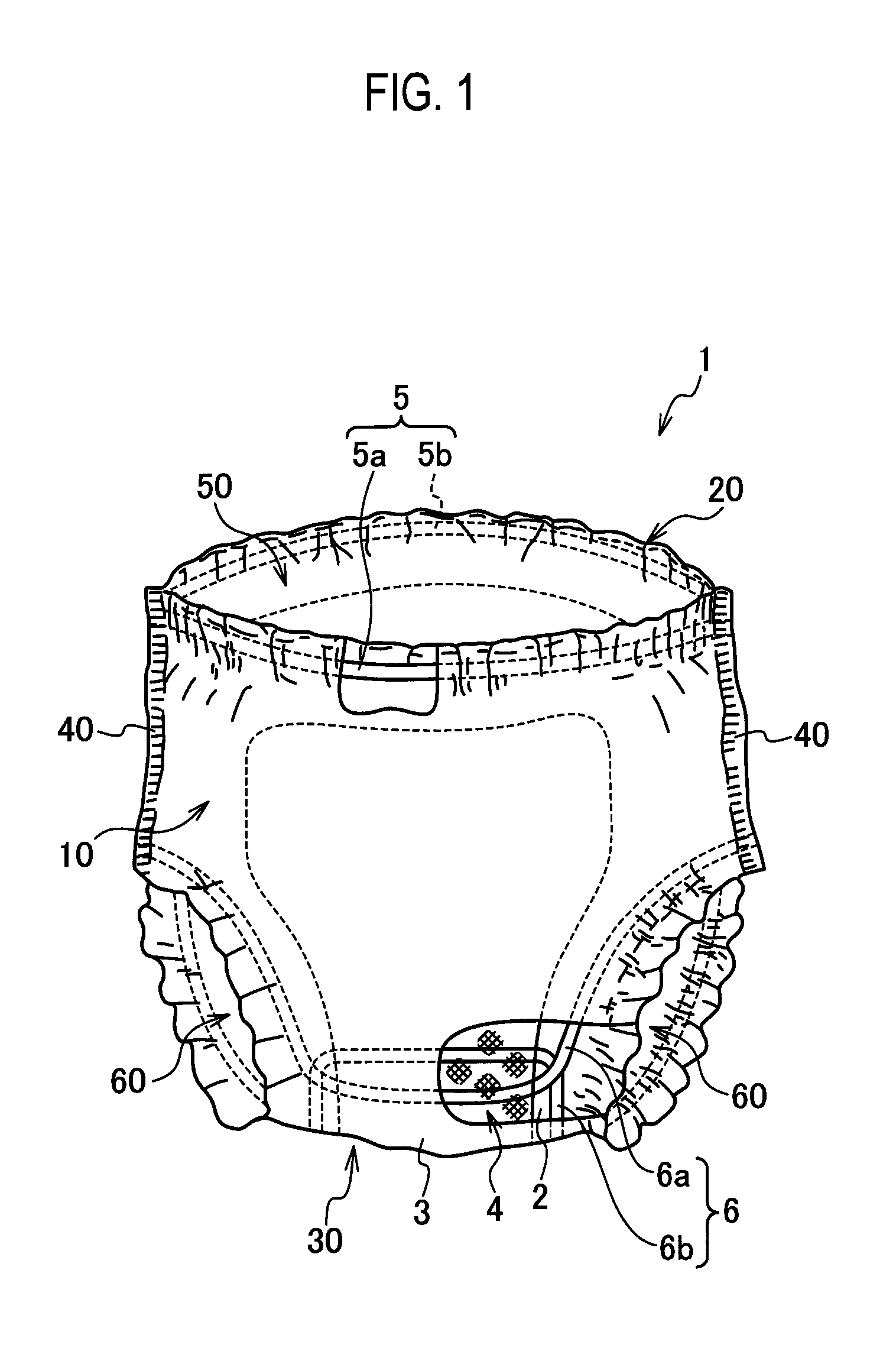

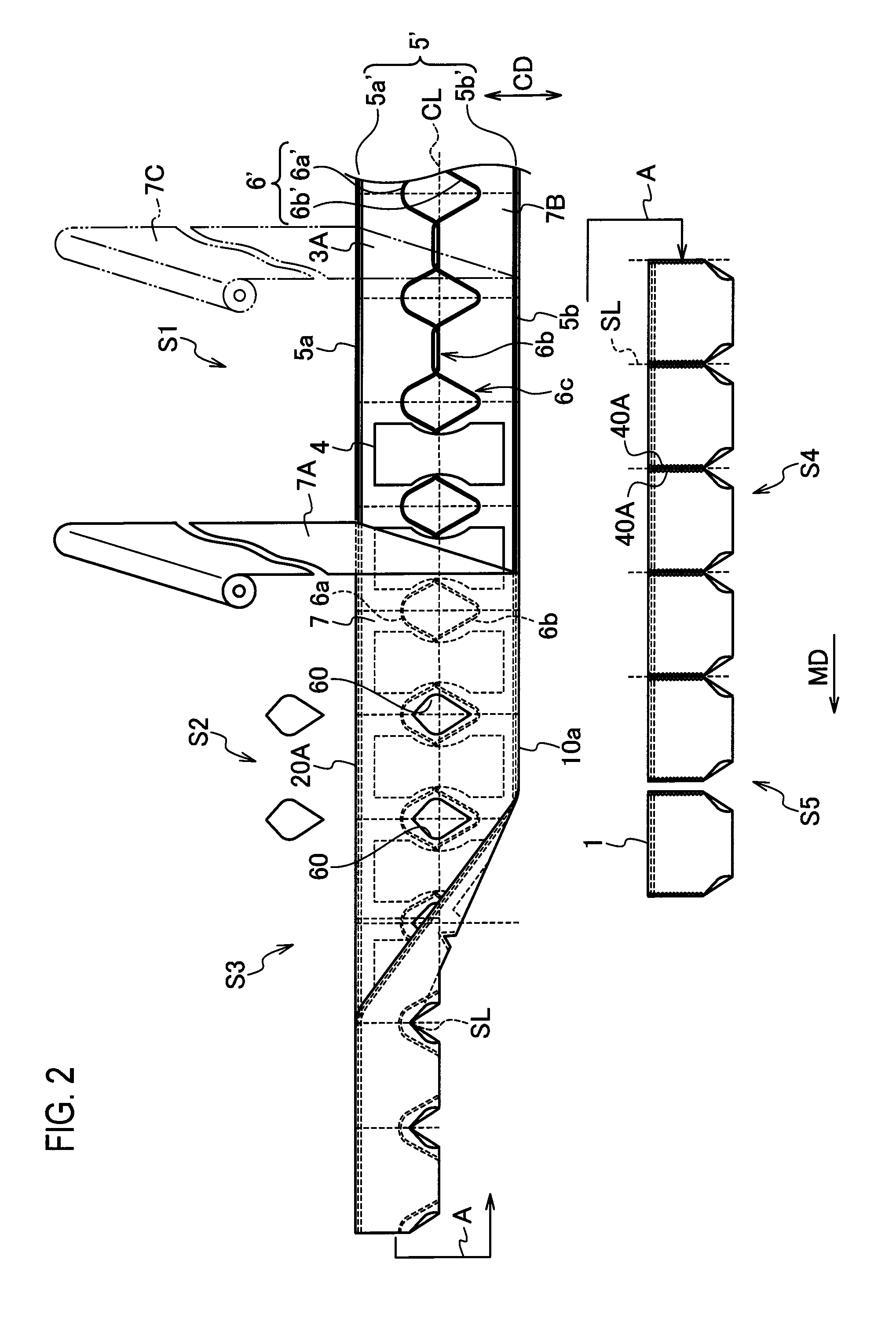

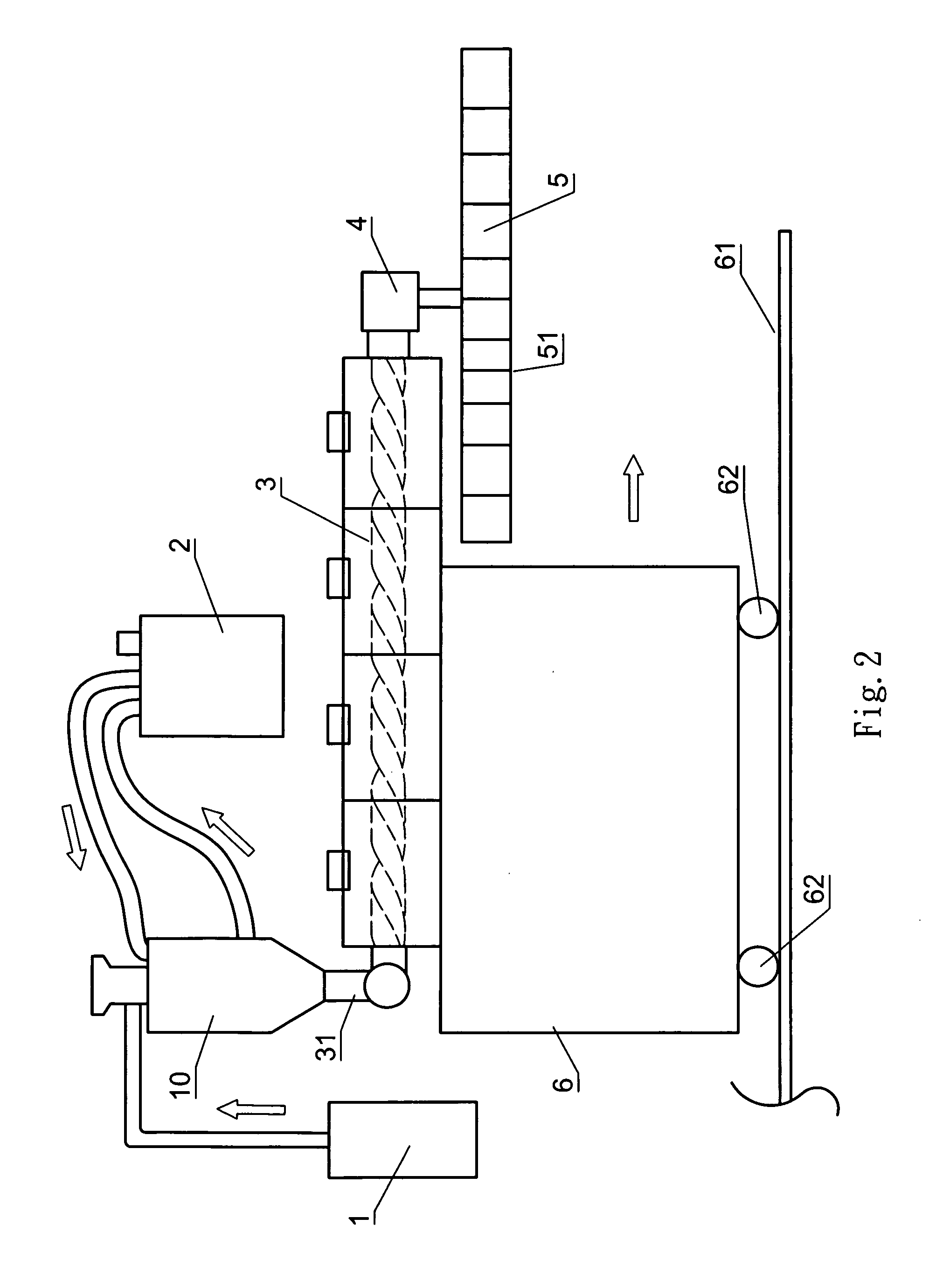

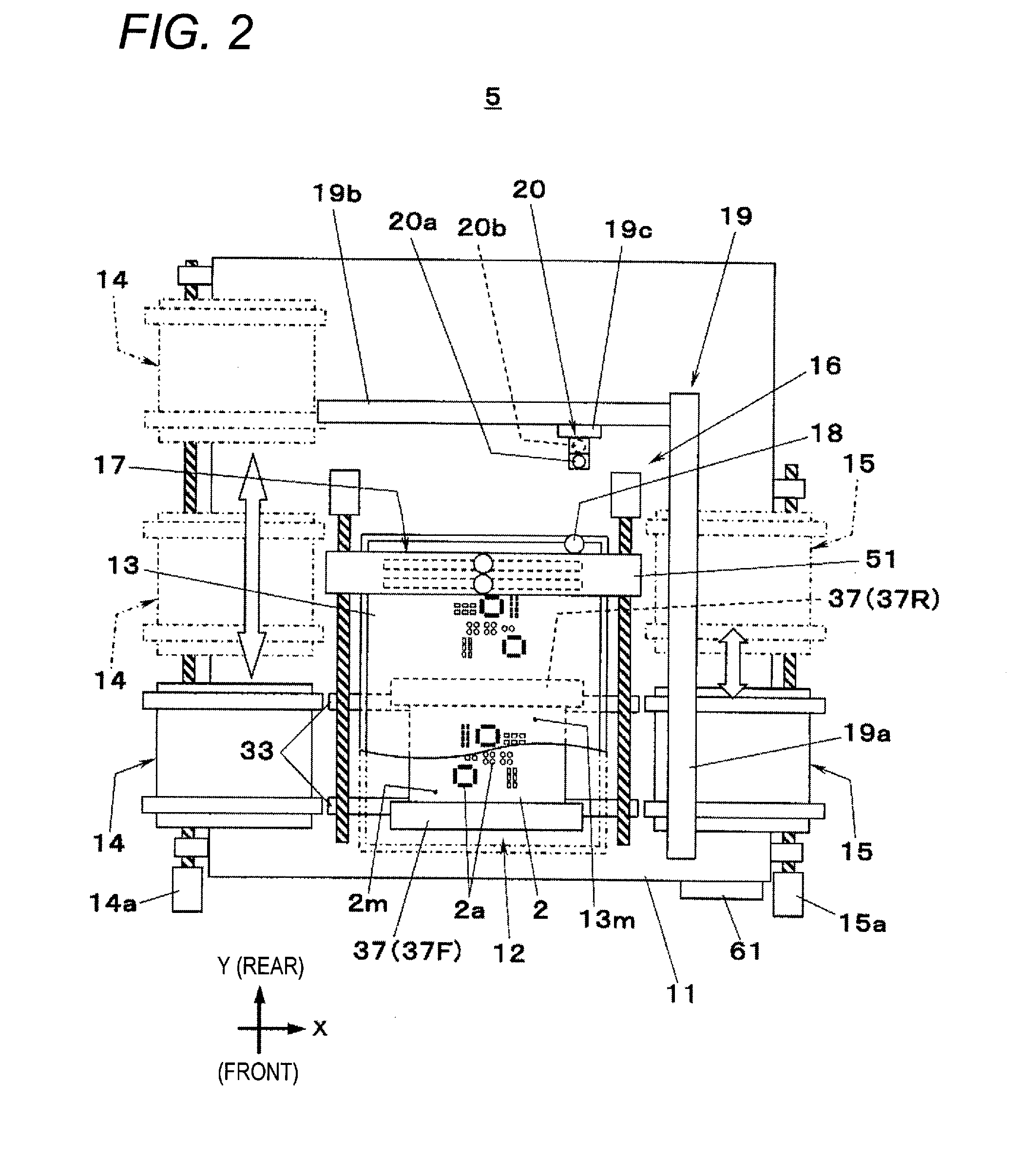

Manufacturing apparatus of absorbent article and manufacturing method of absorbent article

InactiveUS20100078119A1Convenient ArrangementLamination plant layoutLamination ancillary operationsManufactured apparatusExtremity Part

Owner:UNI CHARM CORP

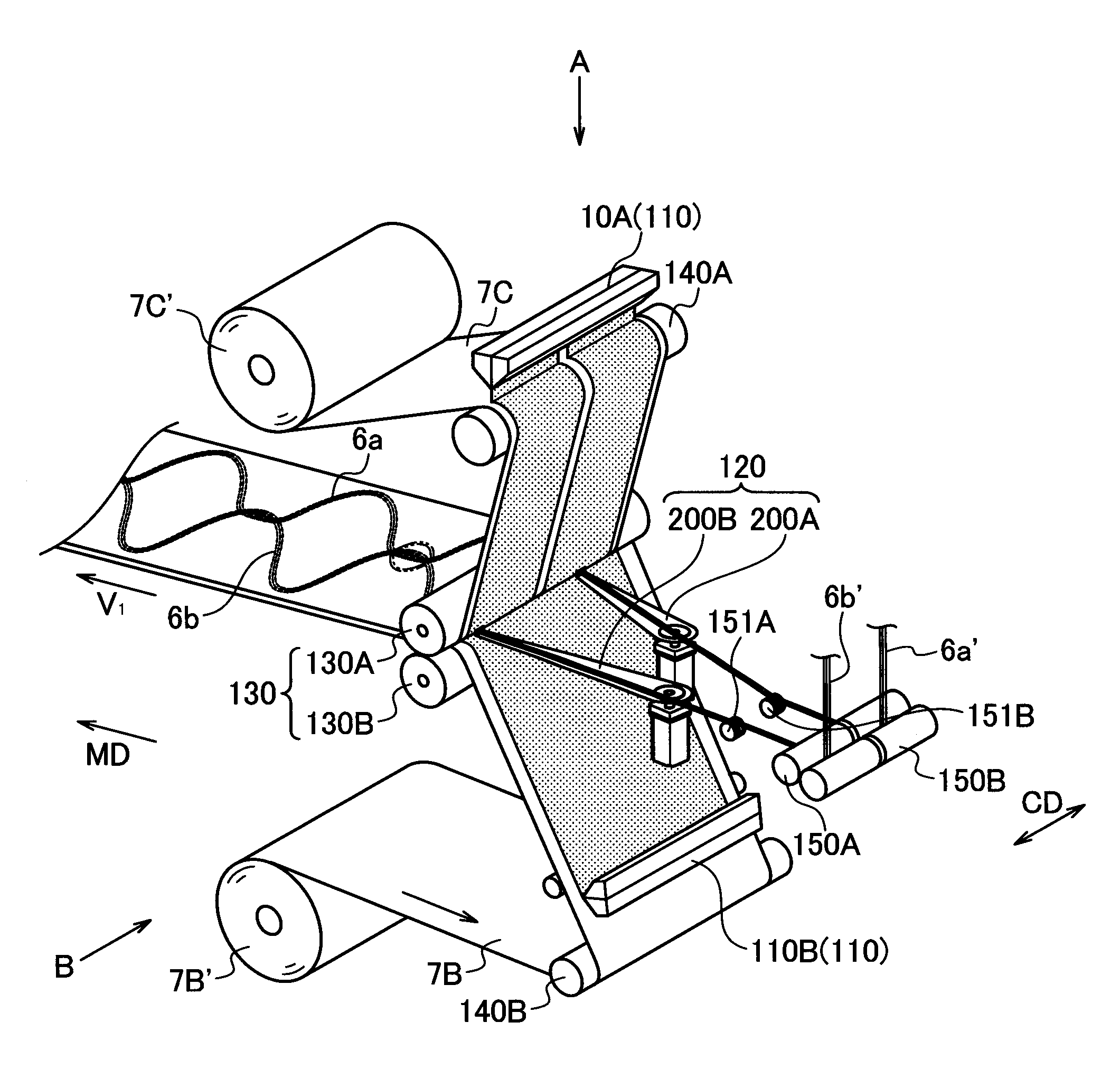

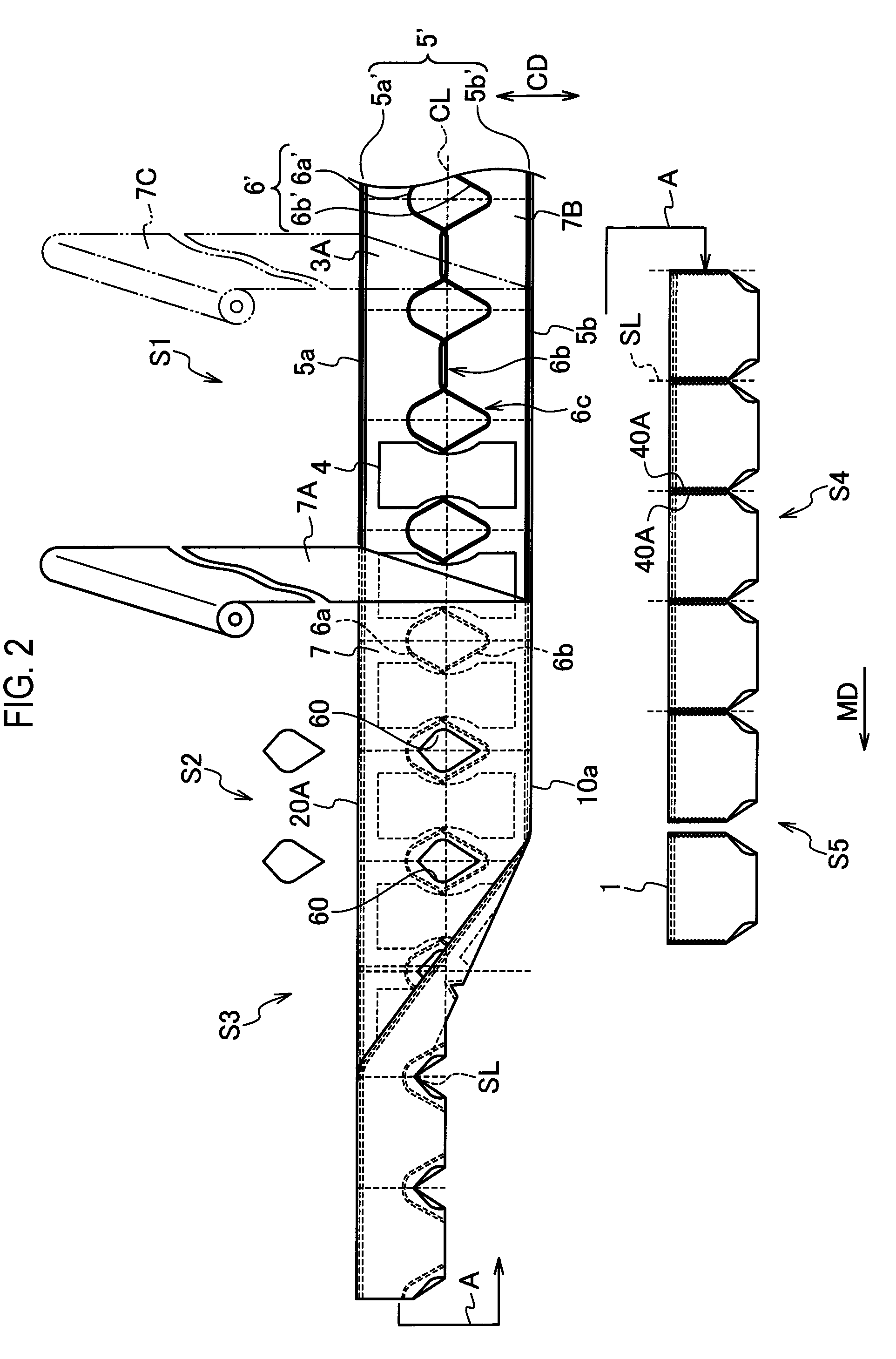

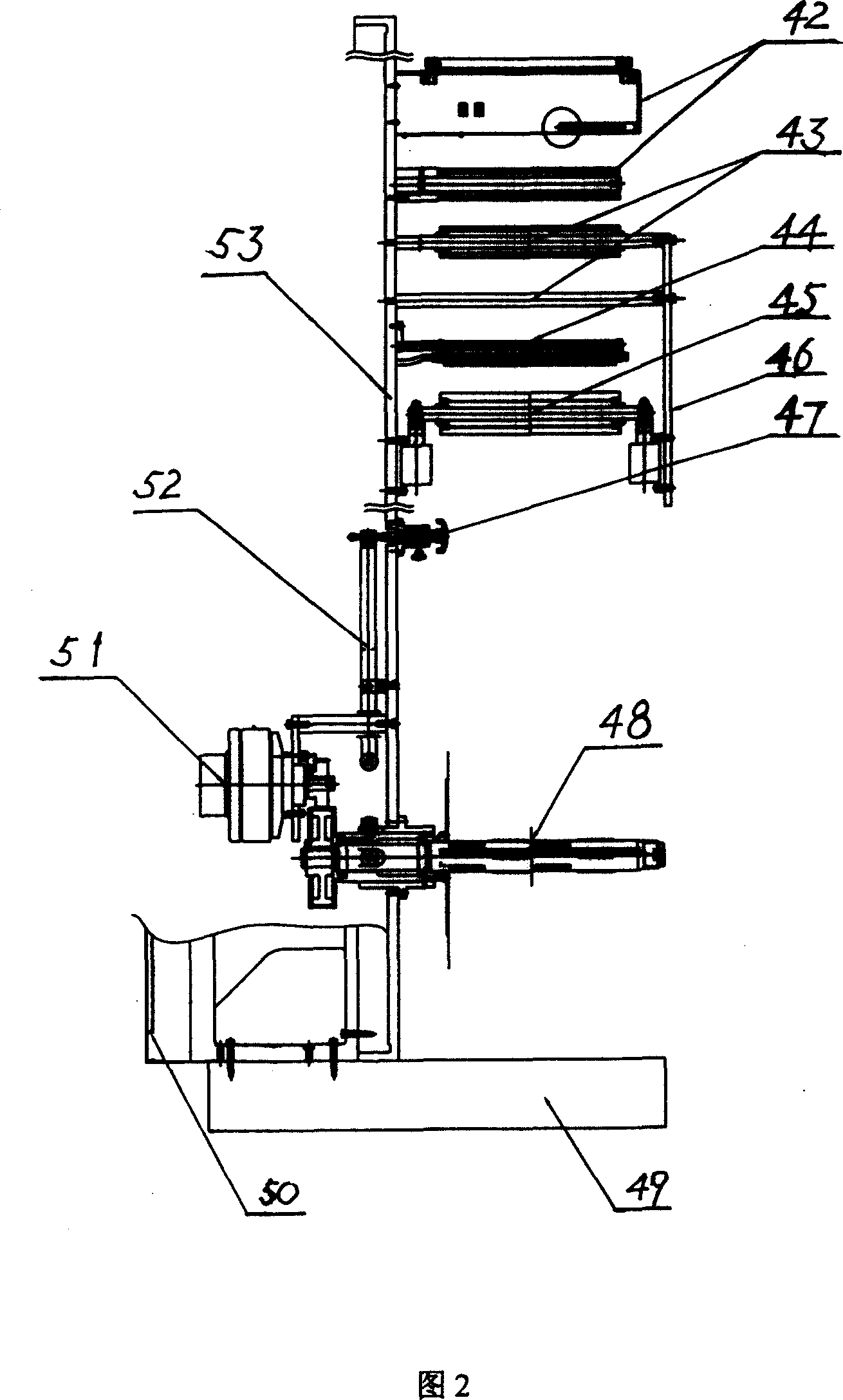

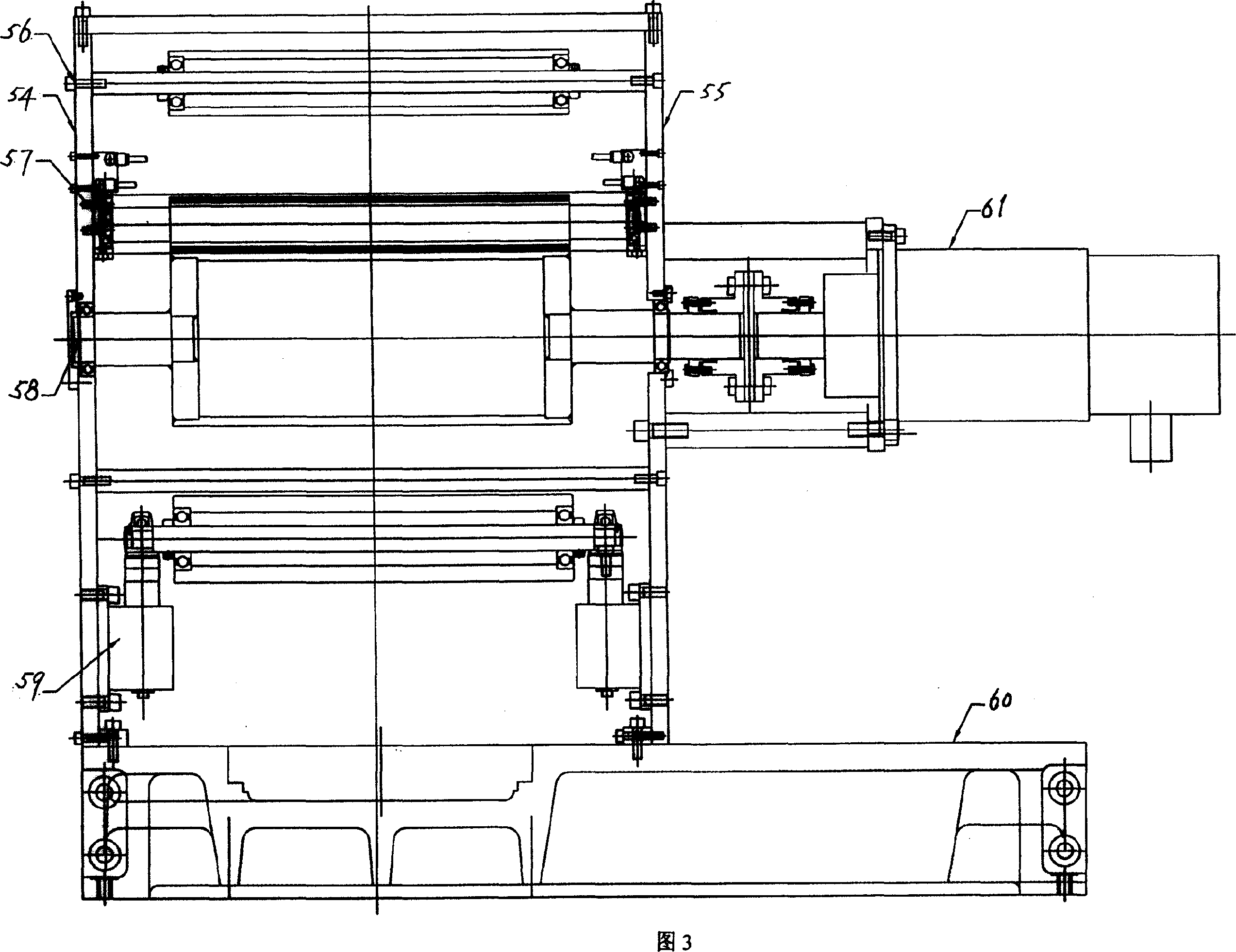

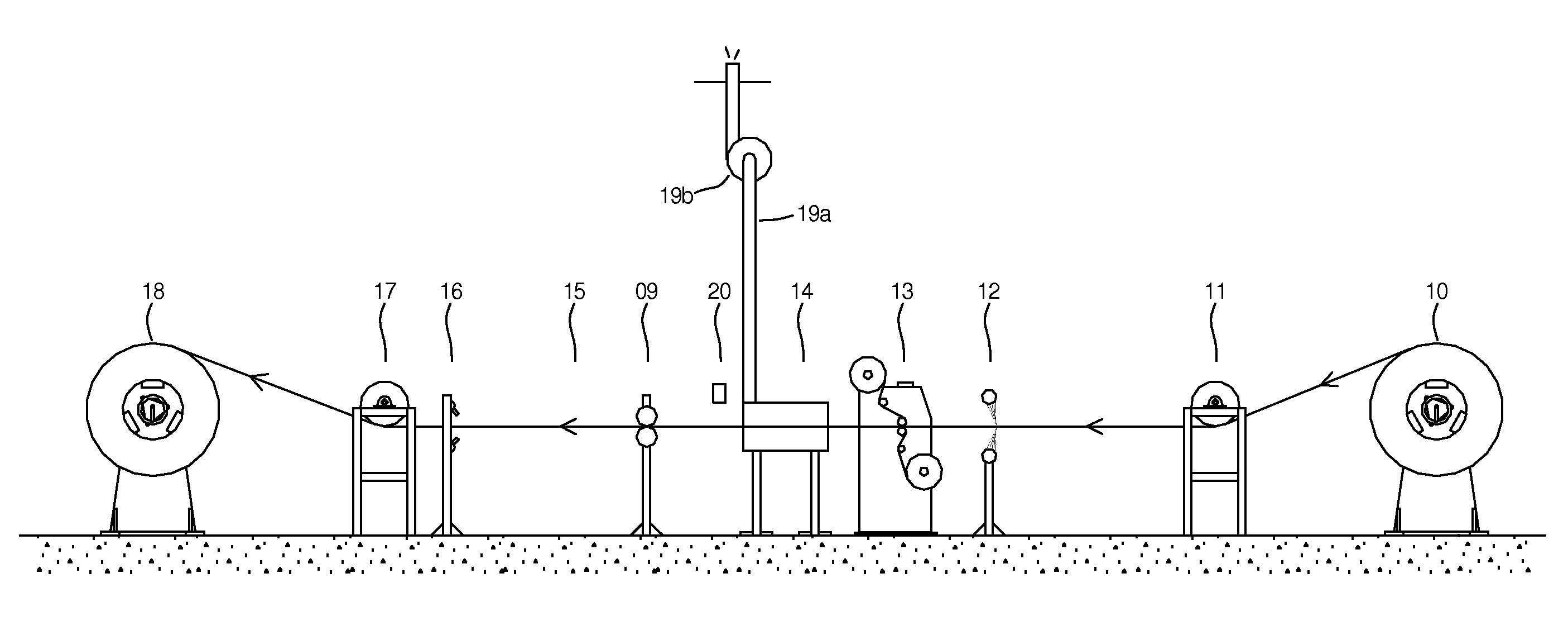

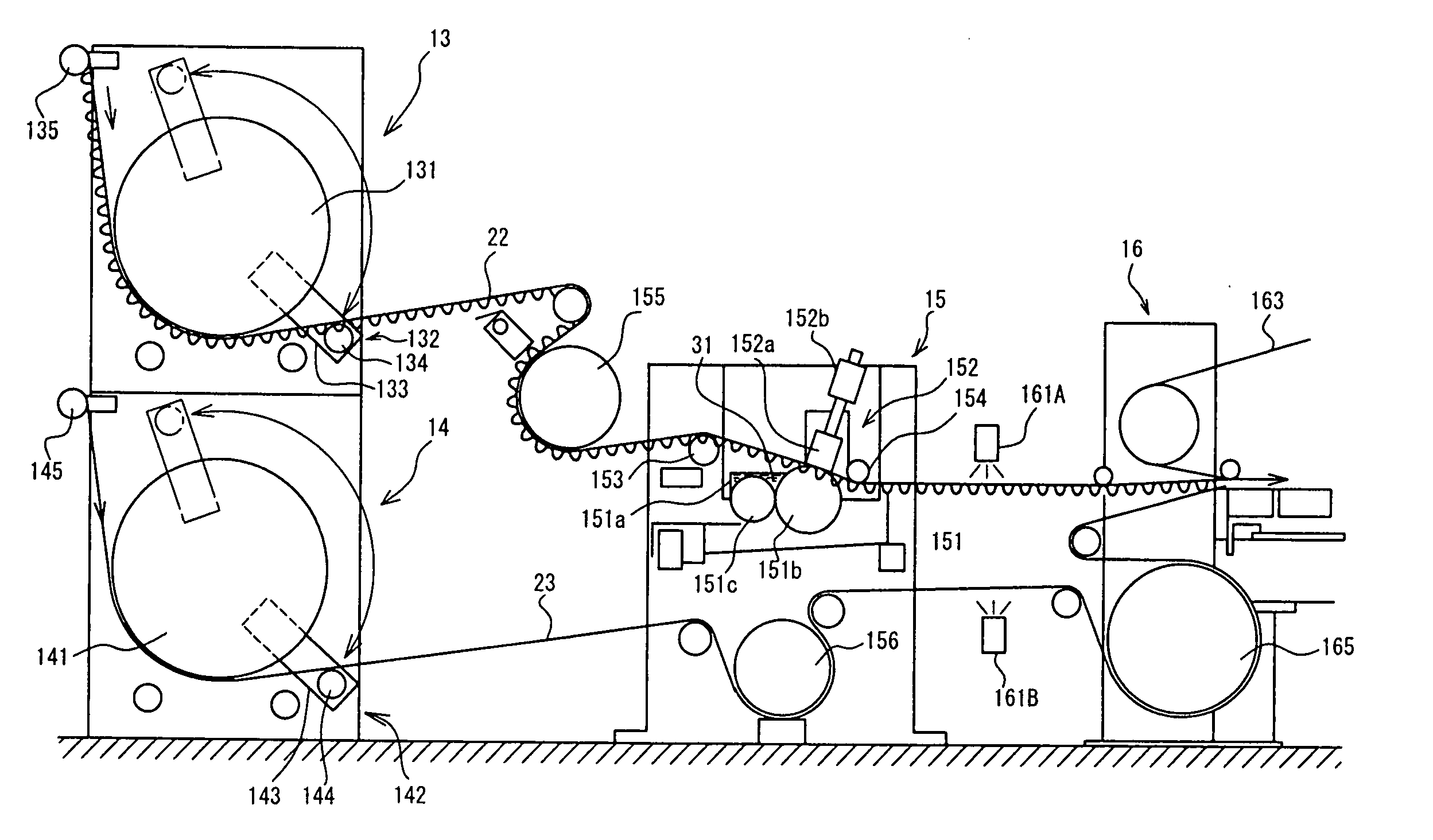

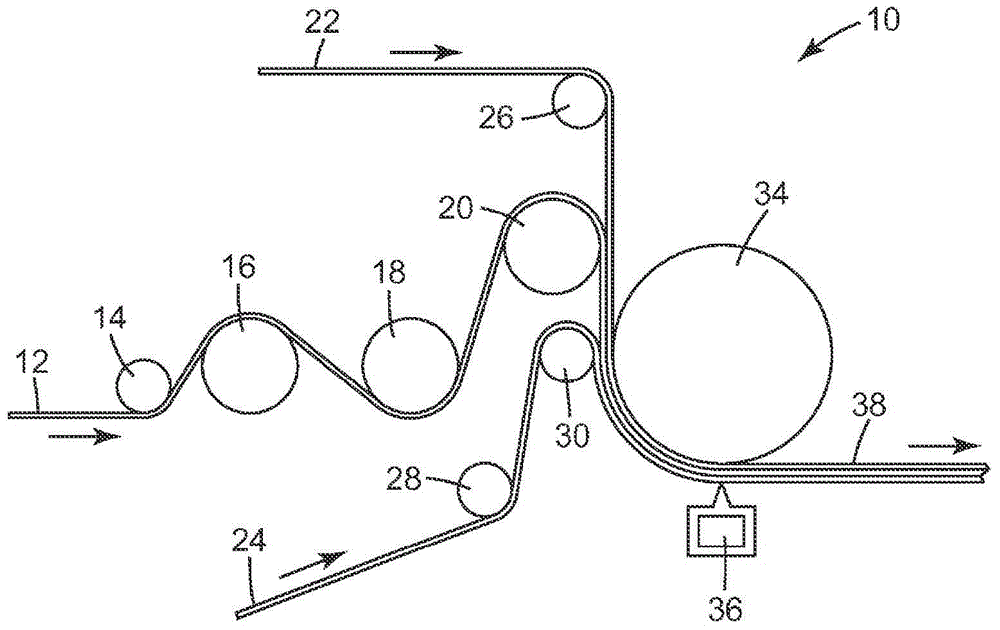

Manufacturing method of absorbent article and manufacturing apparatus of absorbent article

ActiveUS20100078127A1Increase ratingsReduce harmLamination plant layoutAdhesive processesRotational axisReduction drive

The present invention provides a method includes the steps of: conveying in a conveyance direction MD a second web in which components forming one part of an absorbent article are sequentially arranged; swinging an elastic member in a cross direction CD at a predetermined cycle by using a swing guide mechanism for guiding the elastic member; and pressing, between one pair of press rollers, the second web on which the elastic member is arranged. The swing guide mechanism has a motor with a rotational shaft, an arm member for guiding the elastic member to a predetermined position on the second web in the cross direction, and a speed reducer provided between the rotational shaft and a base of the arm member to make a rotational speed of the arm member slower than a rotational speed of the rotational shaft.

Owner:UNI CHARM CORP

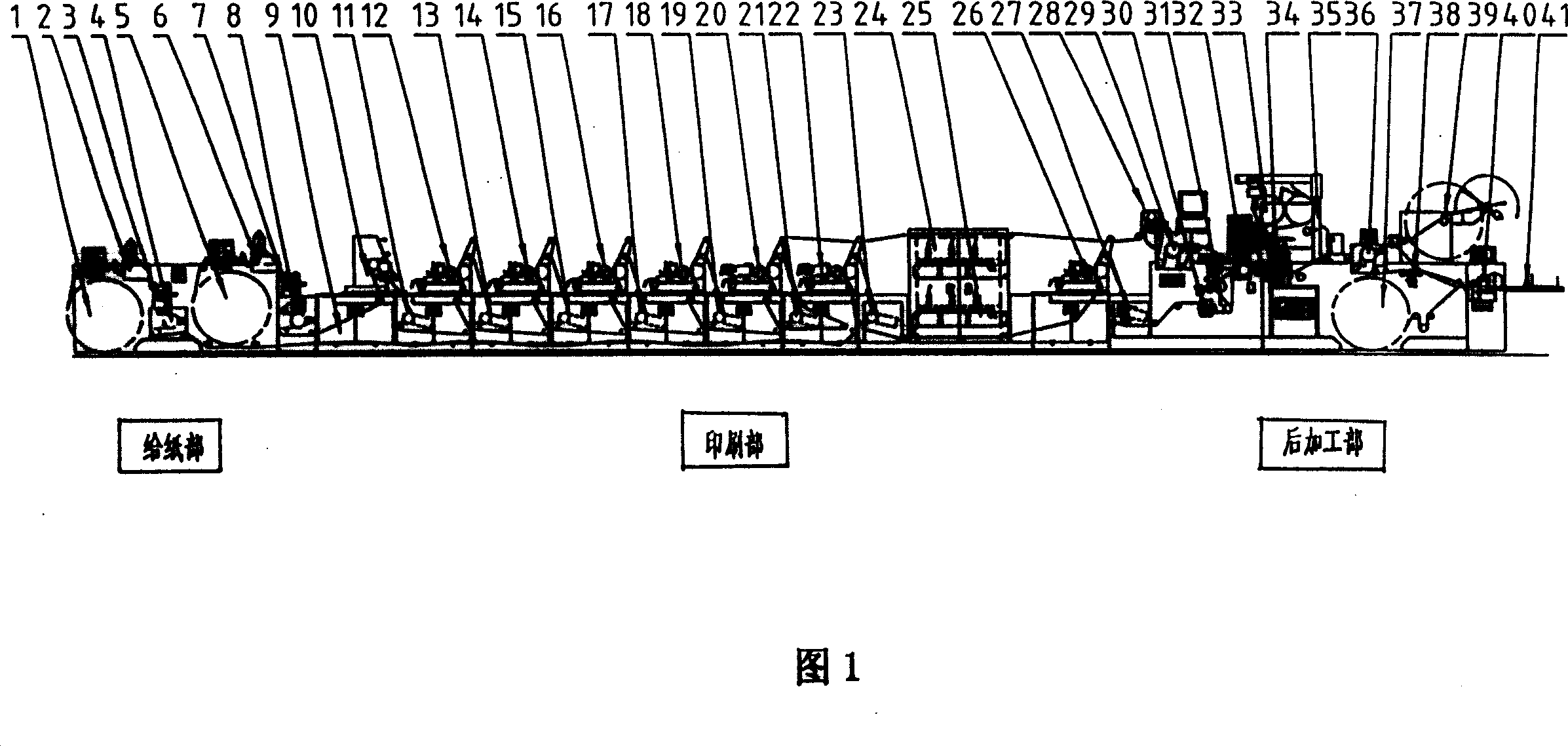

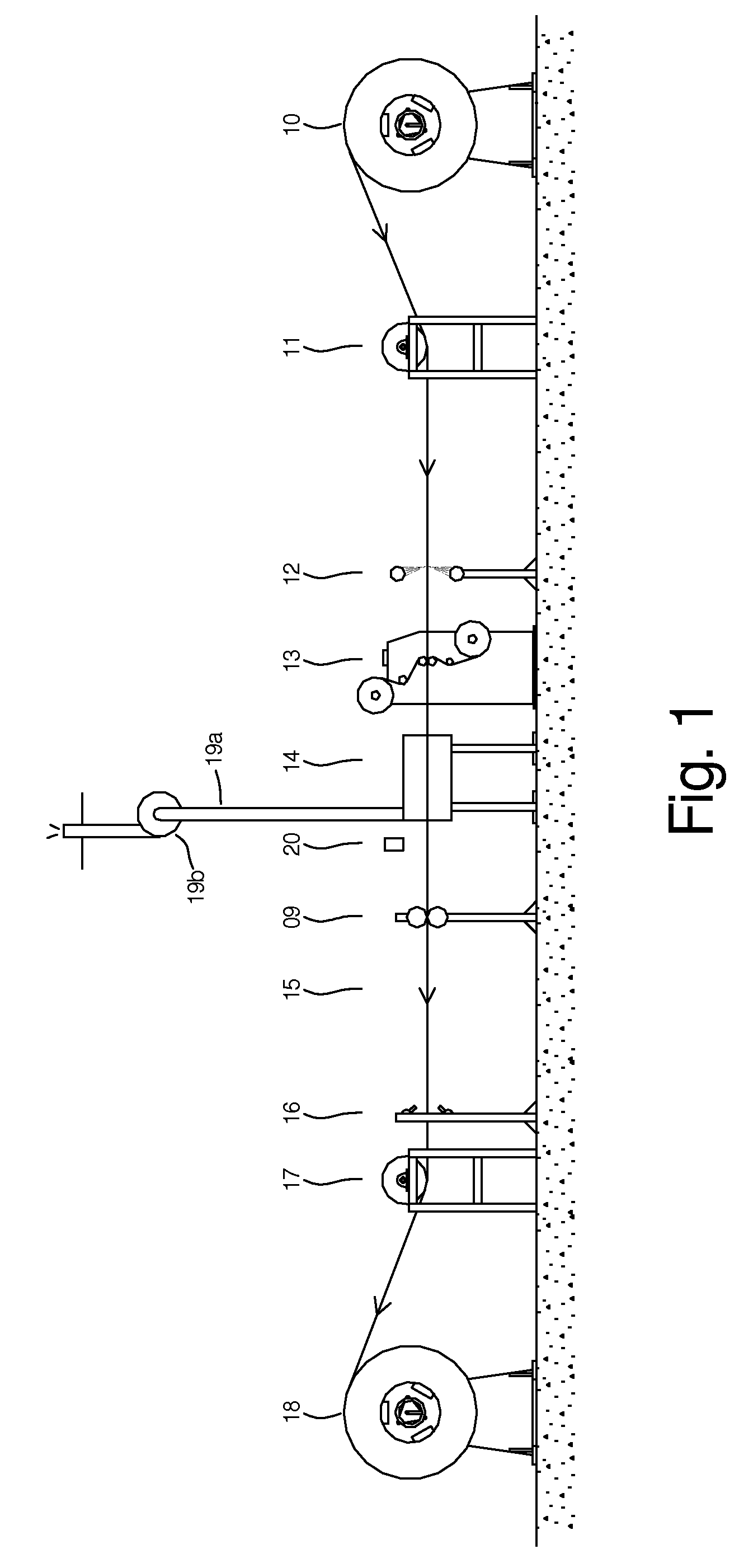

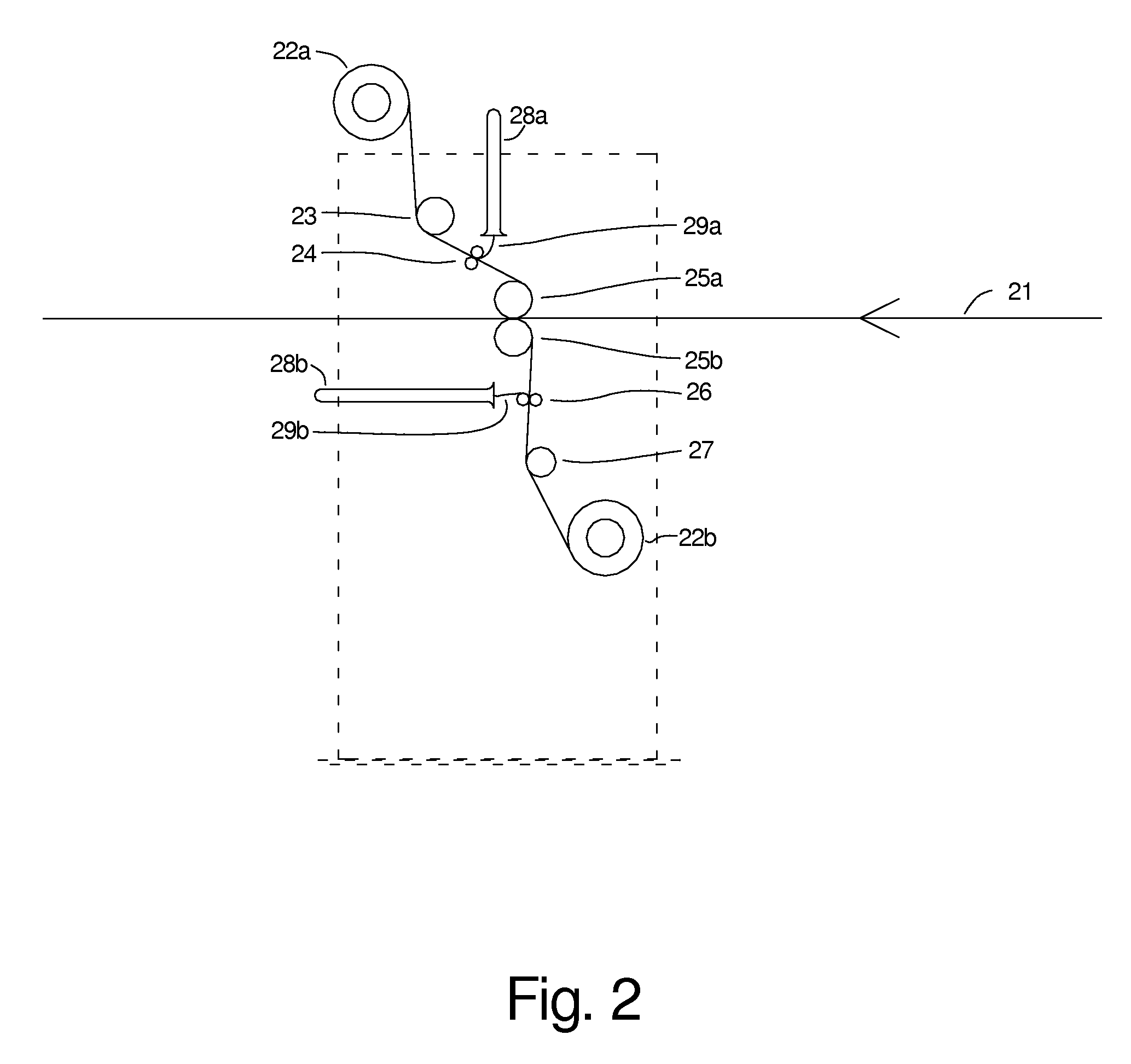

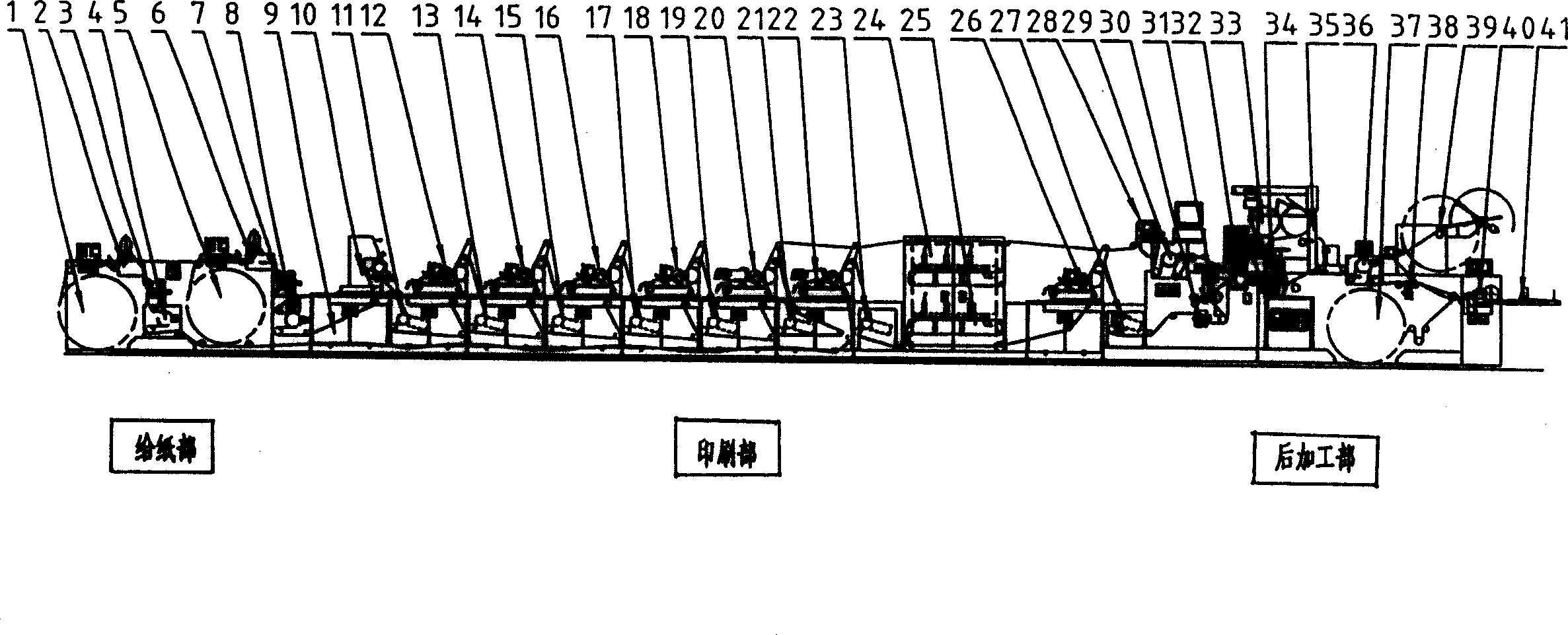

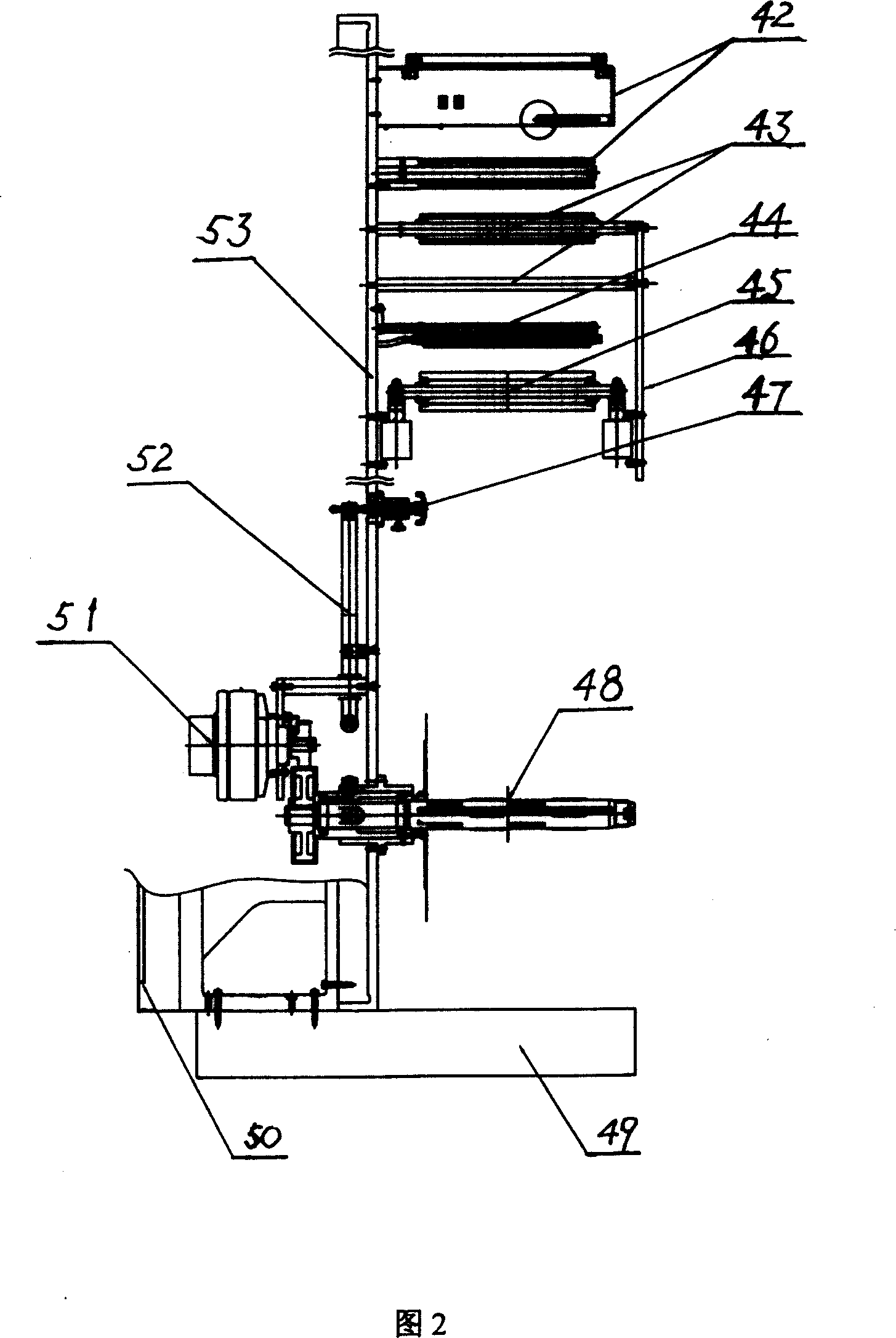

Production method for two-monolayer paper supporting to print and process into stickers

InactiveCN101054010ARealize printingSimultaneous printingLamination plant layoutStampsPulp and paper industryPlastic film

The invention relates to a method which feeds single layer paper or double layer paper to respectively print and then processes the paper into non-drying glue label. The method is characterized in that: the label is made of single layer or double layer web and film and is printed, gelatinized, hinged, post-processed on same non-drying glue rotary printing. The method includes following steps: the single layer or double layer web and film are respectively arranged on two paper feeding portions of the non-drying glue rotary printing; printing color class is selected, and the single layer or double layer web and film respectively penetrate corresponding printing station and following stations such as gelatinization, joint, mould cutting and so on; the surfaces of the single layer or double layer web and film is printed simultaneously; the single layer or double layer web and film, whose surface has been coated by hot melting glue, arranged on the lower paper feeding portion joints with the back side of the film arranged on the upper paper feeding portion; and a transparent plastic film is coated on the surface of the joint non-drying glue paper, and the mould cutting device cuts the part needing to be cut and reserves base paper.

Owner:SHANGHAI XINMIN TAIYO KIKAI

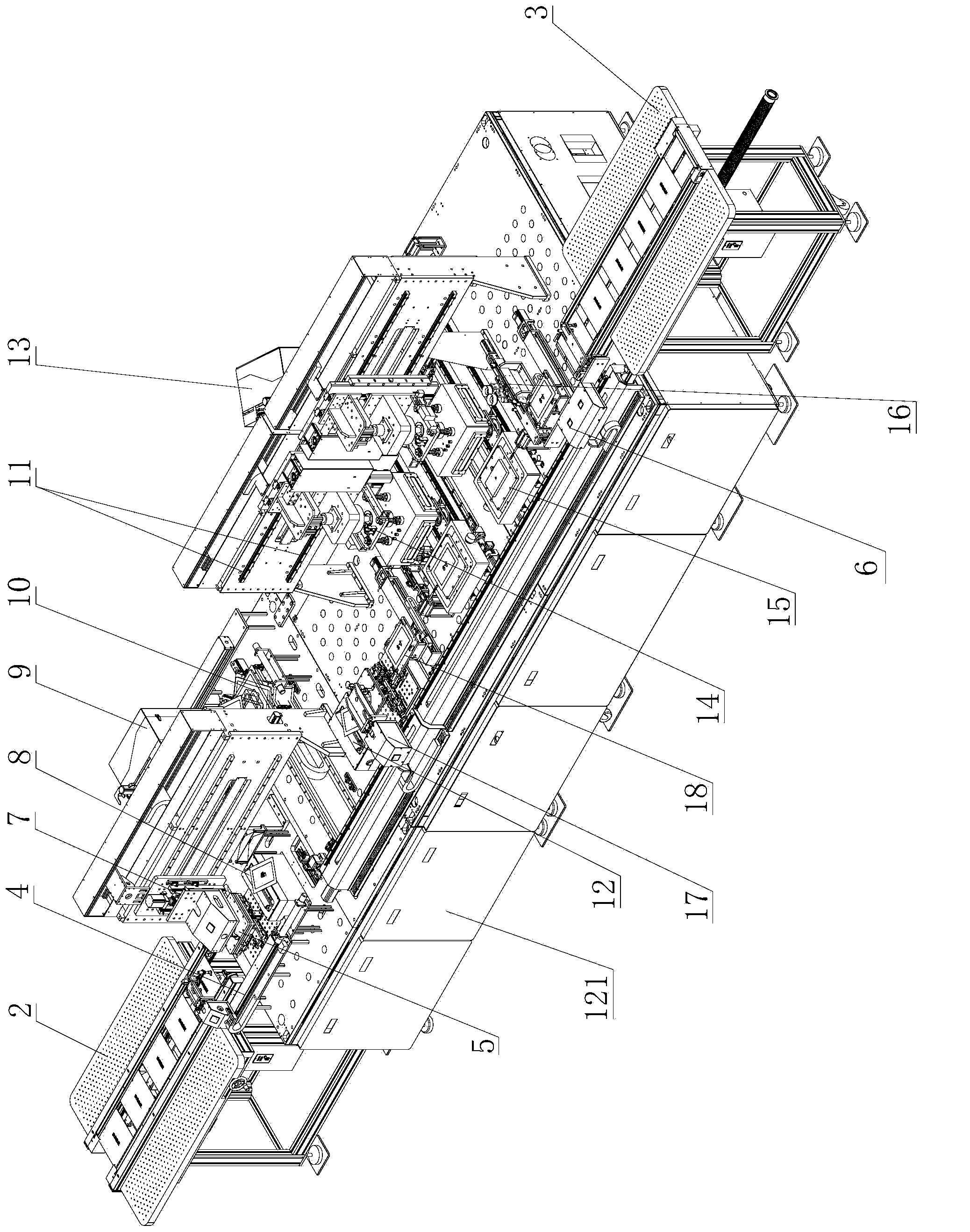

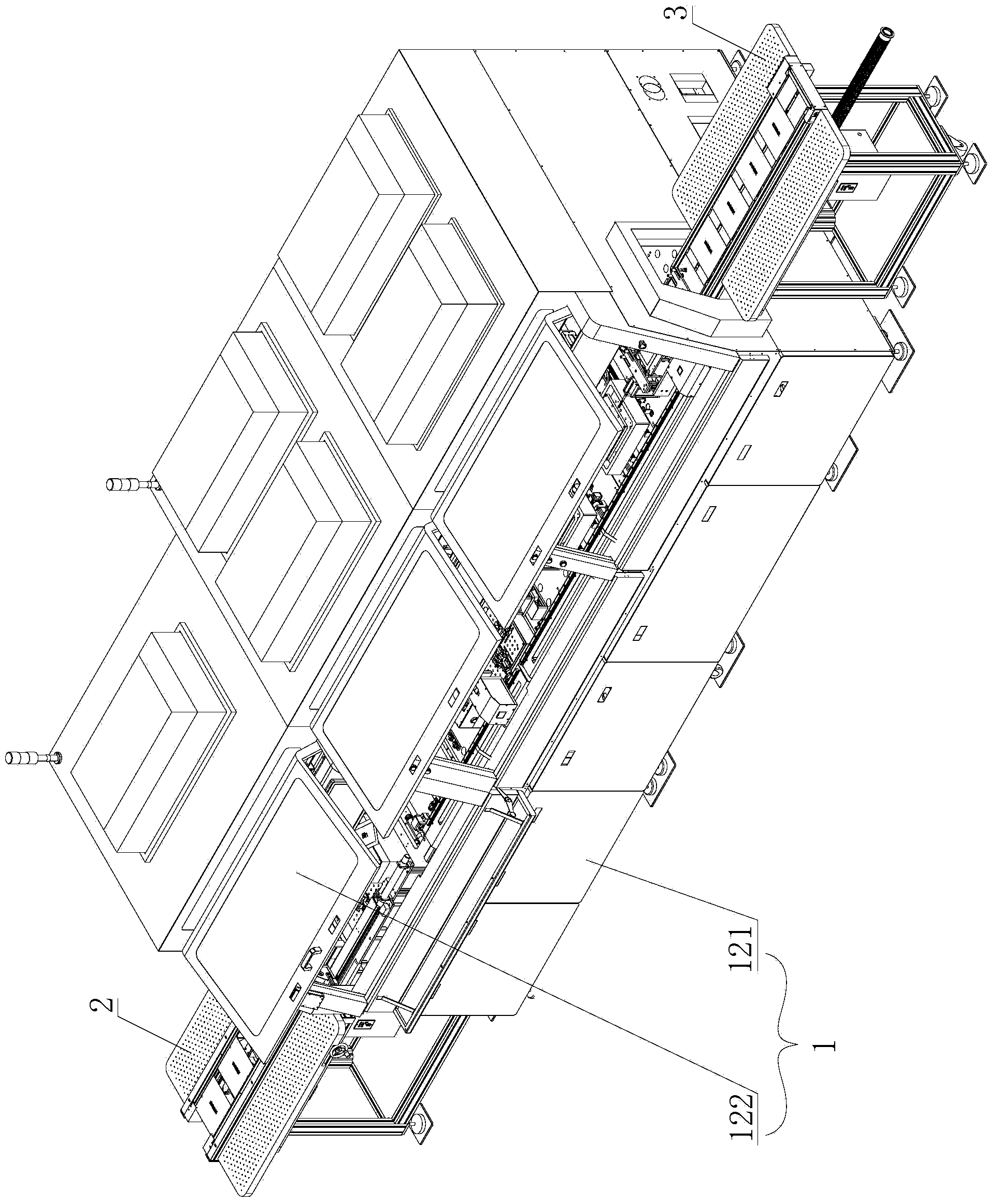

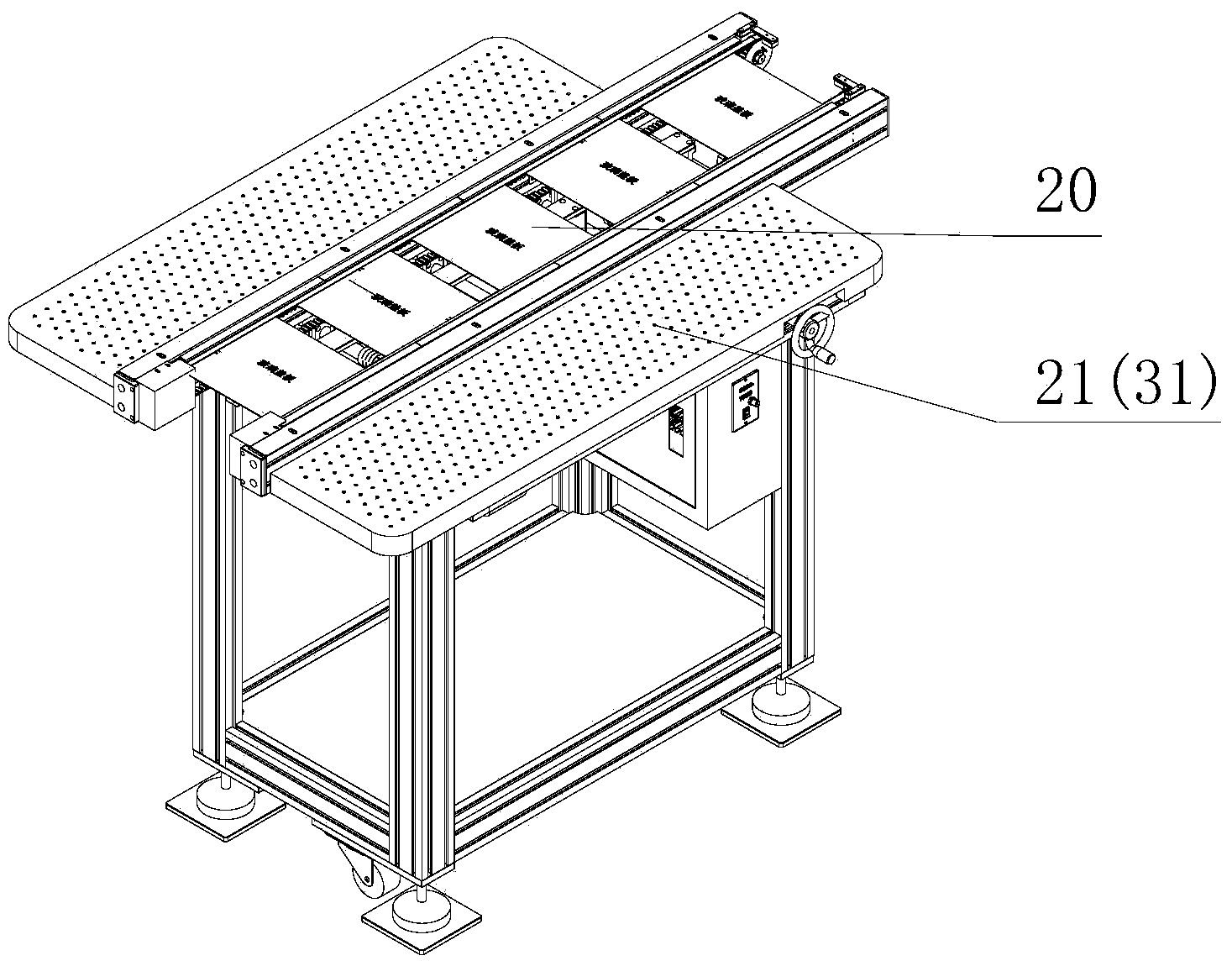

Full-automatic fitting assembling intelligent production line

ActiveCN104015454AEasy to operateHigh degree of automationLamination plant layoutLaminationProduction lineGlass cover

The invention relates to the technical field of production lines, and discloses a full-automatic fitting assembling intelligent production line. The full-automatic fitting assembling intelligent production line comprises a frame, and a material loading system and a feeding system arranged at two sides of the frame; the frame is provided with a material-loading manipulator, an automatic correction system, a first fitting system capable of fitting a glass cover plate with an optically clear adhesive, and a second fitting system capable of fitting the film-pasted glass cover plate with an LCD display module; and the full-automatic fitting assembling intelligent production line also comprises a material conveying system and an electric control system. According to the production line, the material-loading system and the feeding system are employed, and the two fitting systems help to realize fitting of the cover plate with the optically clear adhesive and fitting of the cover plate with the LCD display module. The production line has the advantages of being simple and convenient in operation, high in automation degree and reduced in manual operation.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

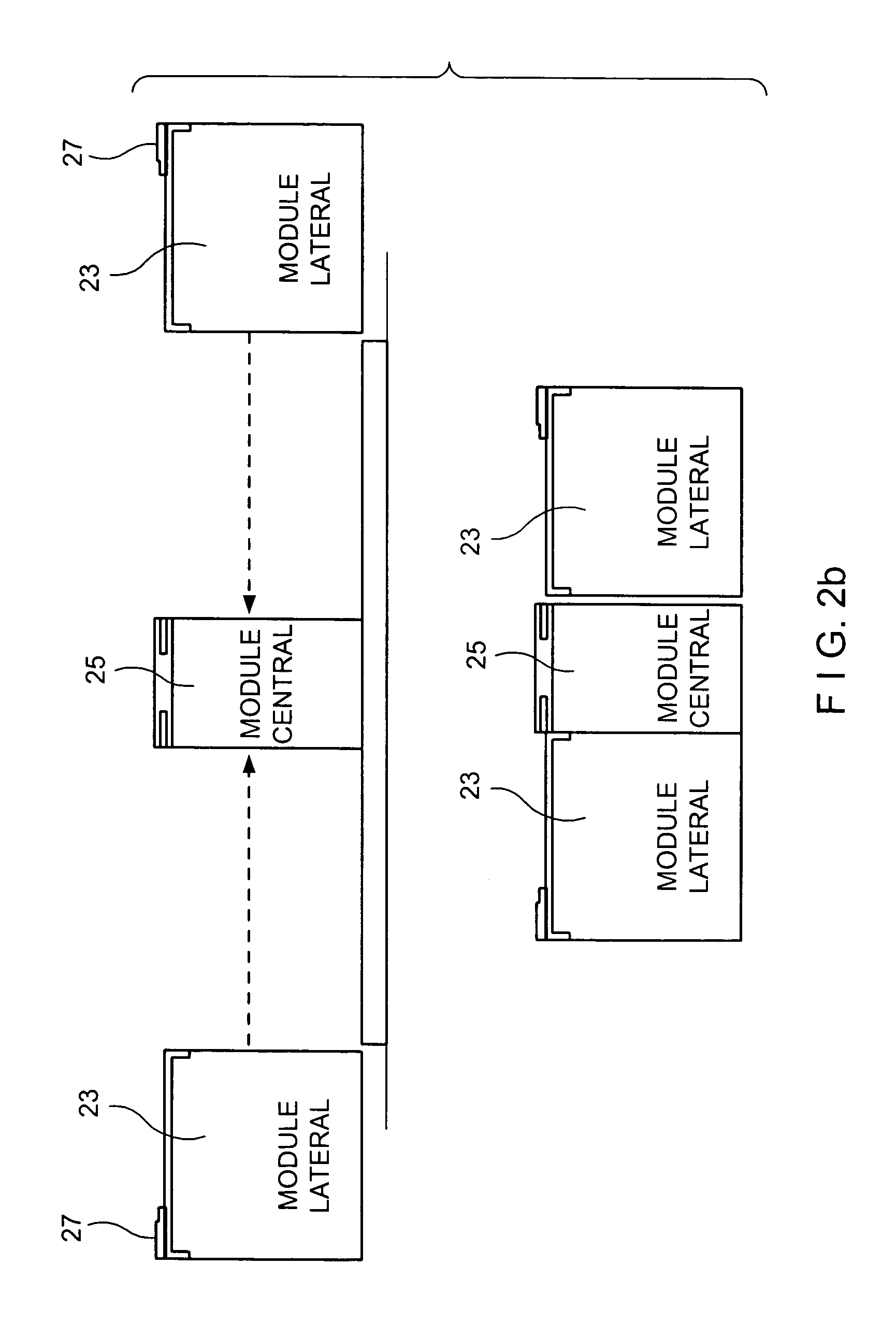

Flexible manufacturing system

A flexible manufacturing system having a feature section including at least one module, at least one operational unit mounted to the module and a local controller operatively connected to the operational unit. The local controller is adapted to receive a reference signal and to control the operation of the operational unit based upon the reference signal.

Owner:THE PROCTER & GAMBLE COMPANY

Fabric handling apparatus

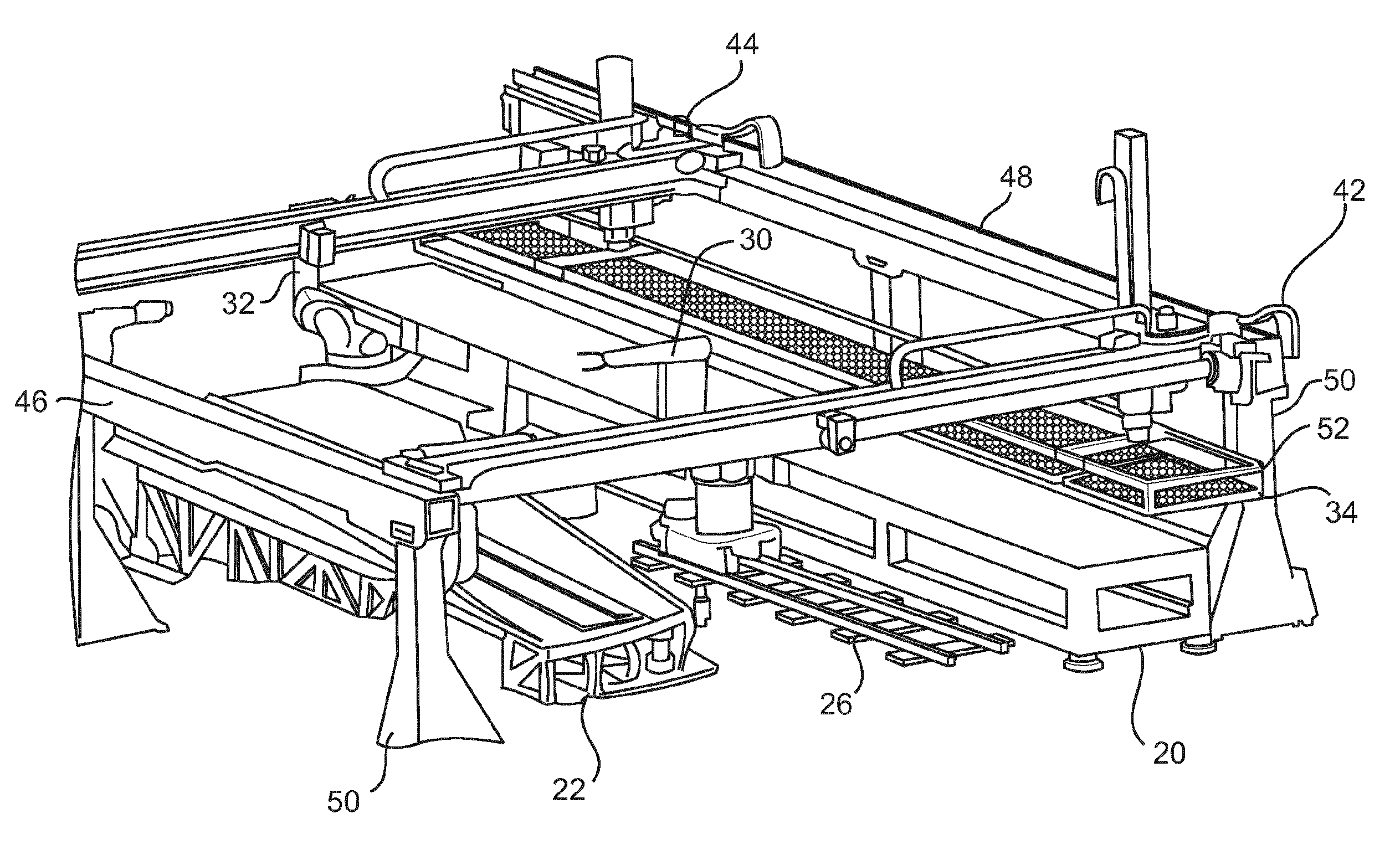

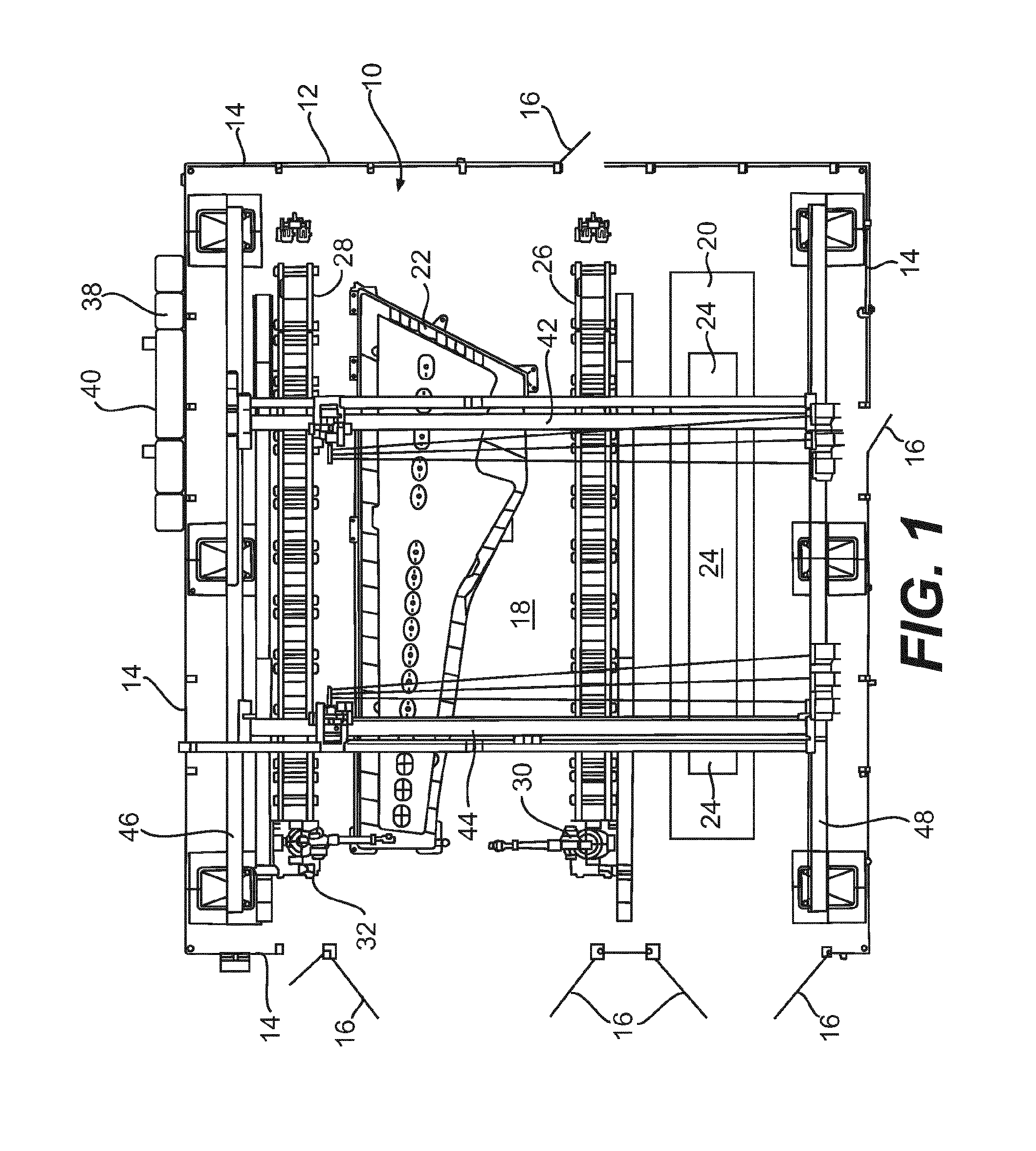

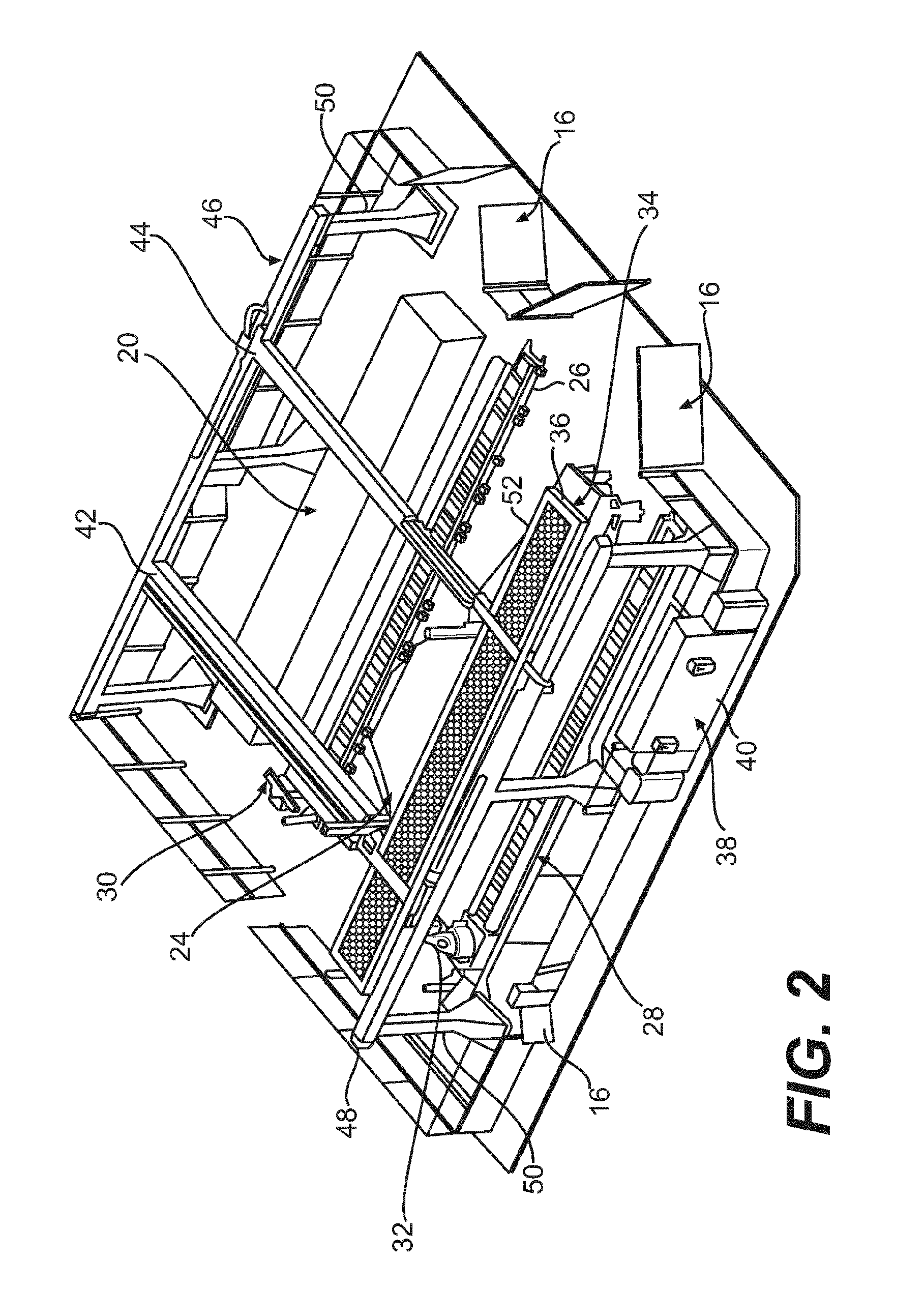

ActiveUS20150314583A1Constant positional relationshipProgramme-controlled manipulatorGripping headsEngineeringAttractor

A fabric handling apparatus includes a layup table, a mold disposed adjacent to the layup table, and a fabric handling array suspended above the layup table and the mold. The fabric handling array is adapted to transfer at least one fabric shape from the layup table to the mold. The fabric handling array includes a plurality of attractors in an attractor array. An orientation of the fabric handling array is alterable with respect to at least one of the layup table and the mold so that the at least one fabric shape is positionable on the mold in a predetermined orientation.

Owner:SHORT BROTHERS

Laminating polyester onto metal substrate

InactiveUS7942991B1Cheap methodSuitable propertyLamination plant layoutAdhesive processesPolyesterPolymer science

Owner:POLYTECH AMERICA LLC

Label wheel rotary printing machine

InactiveCN101054011AImprove matchDry in timeLamination plant layoutStampsPlastics industryEngineering

The invention relates to a label rotary printing which is characterized by that: it is mainly comprised by paper feeding device, printing section, post-process portion, and can be linked with relief printing, flexographic printing, offset printing, and can be further linked with code spray, silicon oil coating, hot melting glue coating to make multi-layer anti-counterfeiting label, and two paper feeding portions can simultaneously print two rolls of stocks, and coats hot melting glue between the two rolls of stocks, and compounds them to obtain the non-drying glue label, and the invention is applicable in plastic industry for plastic film printing, and can be also used in printing commercial table and printing non-carbon impact paper; because the invention has five flexo printing color classes, it can be regarded as a pure five-color rotary flexo printing used in commercial packing printing field. The advantage of the invention is that: the invention can print single roll of stock as well as two rolls of stocks and can compound the two rolls of stocks, multi-layer non-drying glue label can be processed by multiple printings and ink jet printing on same device.

Owner:SHANGHAI XINMIN TAIYO KIKAI

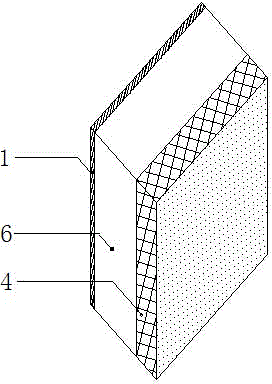

Nano-plate plane glue distributing device and method

InactiveCN101085563AConsistent thicknessImprove efficiencyLamination plant layoutLamination ancillary operationsFiberglass meshGlass fiber

The invention relates to the nanometer plate surface glue equipment and the cloth glue that comprises the working platform, cloth hopper distributing nanometer fluid on the compound extractor, vibrating device connected with the cloth hopper, cloth applying device setting the glass fiber net on the nanometer glue band, and the scraping device and compression device. The compound extraction band moving horizontally on the working platform and forming nanometer band, setting glass fiber net cloth with tension on the nanometer band, compressing the glass fiber net cloth and the nanometer band into nanometer compound band, compressing the compound band tightly. It is heat and sound insulation, radiation resistant, and improved in product feature and reduced in production cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Method for continuously producing expanded thermoformable materials

InactiveUS6322651B1Save energyPaper/cardboard articlesAdhesive articlesEngineeringMechanical engineering

A method for continuously producing expanded thermoformable materials comprising the steps of: conveying a thermoformable assembly by means of a conveyor through a plurality of heating zones, whereby the thermoformable assembly is heated to a temperature at which the thermoformable material adhesively bonds to the first and second mold plates; disposing the thermoformable assembly between an upper press plate and a lower press plate, and heating the thermoformable material to a temperature in the range between about 50° to 300°C. while moving the upper and lower press plates so as to effect an expansion of the cross-section of the thermoformable material; and conveying the expanded thermoformable material through a cooling zone, wherein the expanded thermoformable material is cooled to a temperature sufficient for maintaining its structural integrity.

Owner:PANTERRA ENGINEERED PLASTICS +1

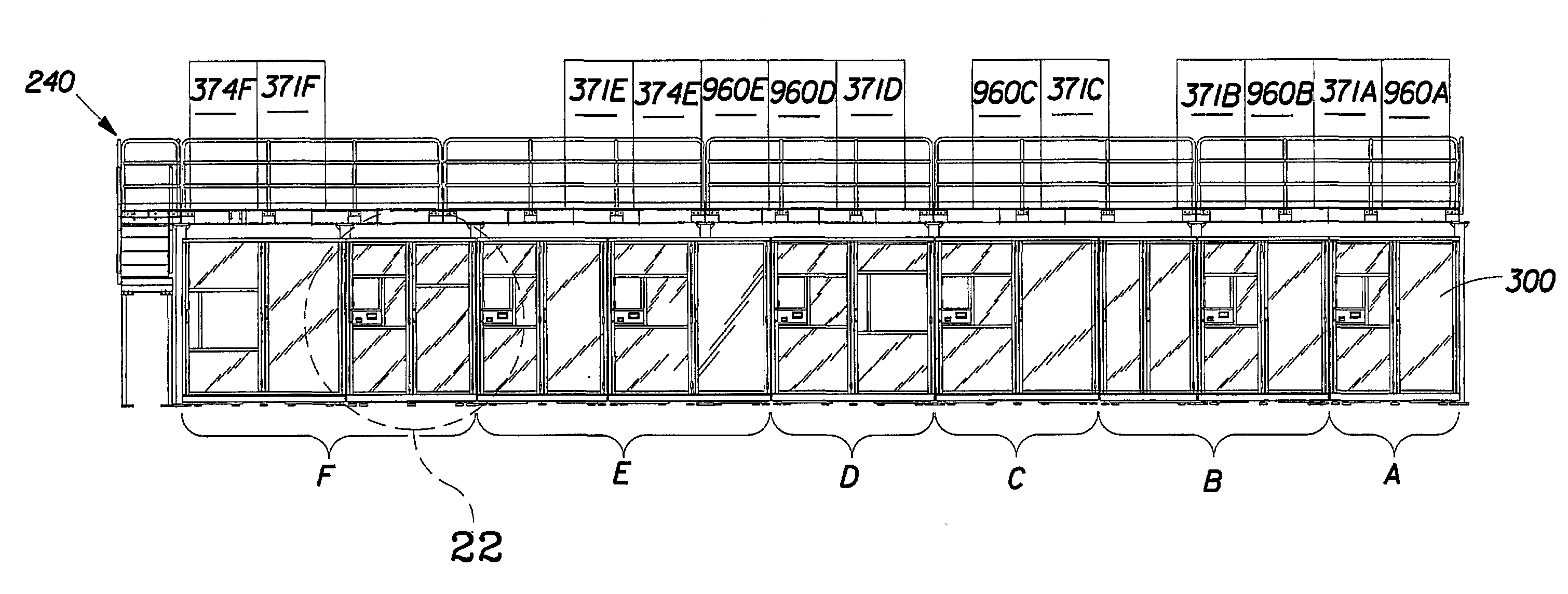

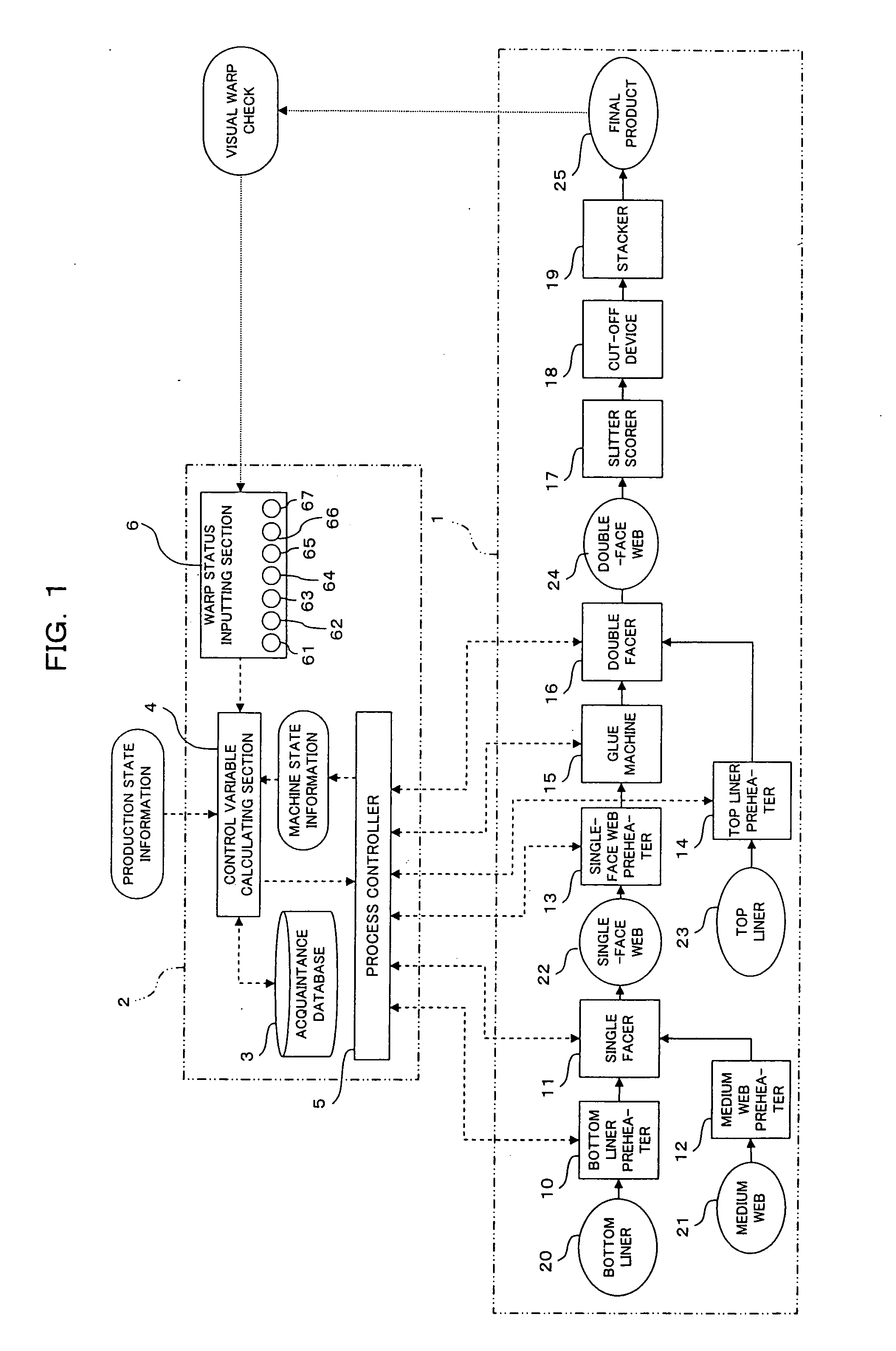

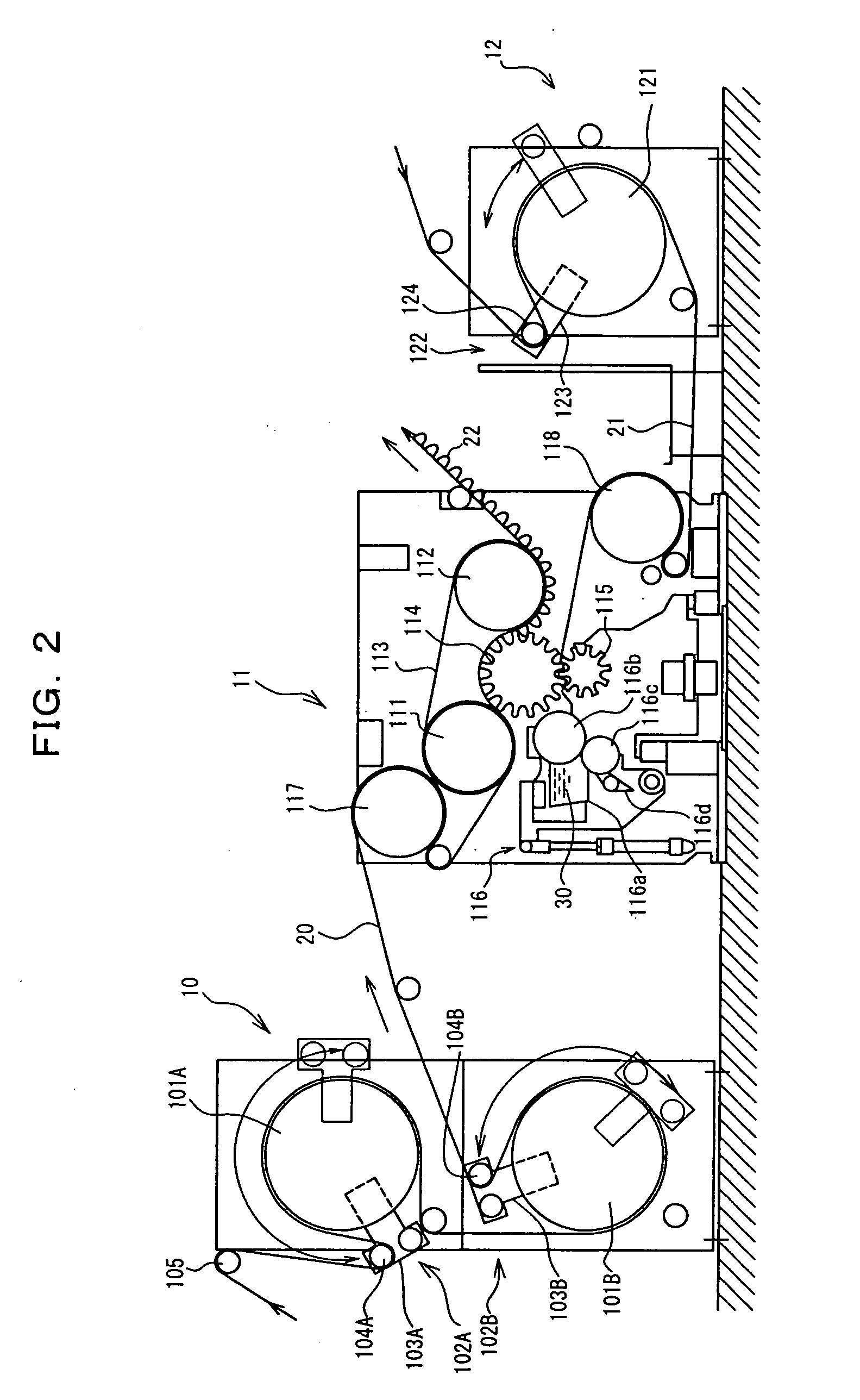

Production system for corrugated carboard sheet

InactiveUS20050284579A1Accurate correctionLamination plant layoutMechanical working/deformationCardboardEngineering

A system for fabricating a corrugated board sheet fabricated includes warp status information obtaining means (6, 6A-6H, 7, 7A, 7B, 8, 8A-8H, 240a, 240b, 241a, 241b) for obtaining warp status information concerning status of the warp of the corrugated board sheet fabricated by a corrugated-board fabrication machine (1); running-state information obtaining means (5, 5A-5H) for obtaining running state information concerning a running state of the corrugated-board fabrication machine (1); control variable calculating means (4, 4A-4H) for calculating a control variable of a particular control factor that affects the warp of the corrugated board sheet and that is one among control factors used to control the corrugated-board fabrication machine (1) based on the warp status information of the corrugated board sheet and the running state information of the corrugated-board fabrication machine (1); and control means (5, 5A-5H) for controlling the particular control factor using the control variable calculated by the control variable calculating means (4, 4A-4H).

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

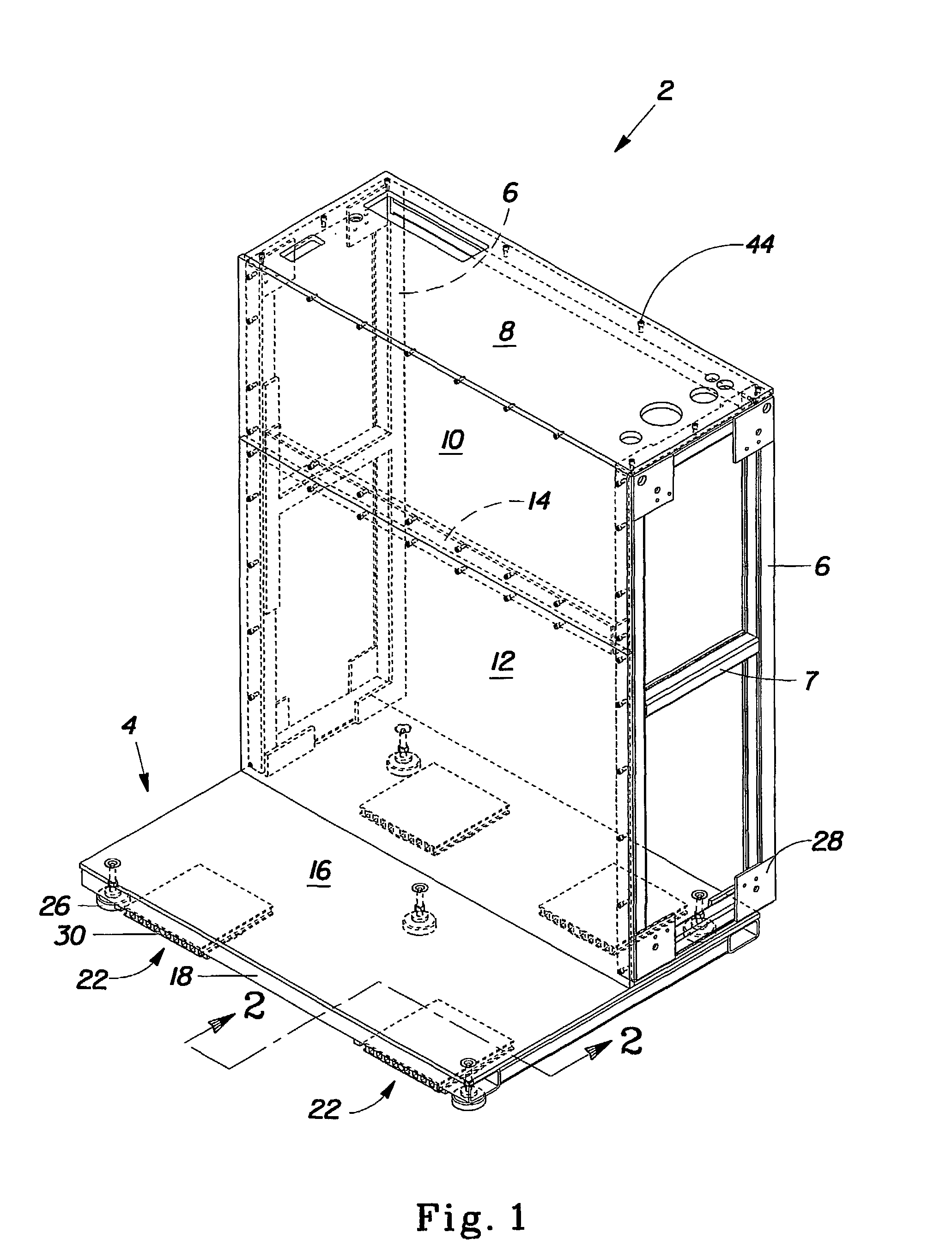

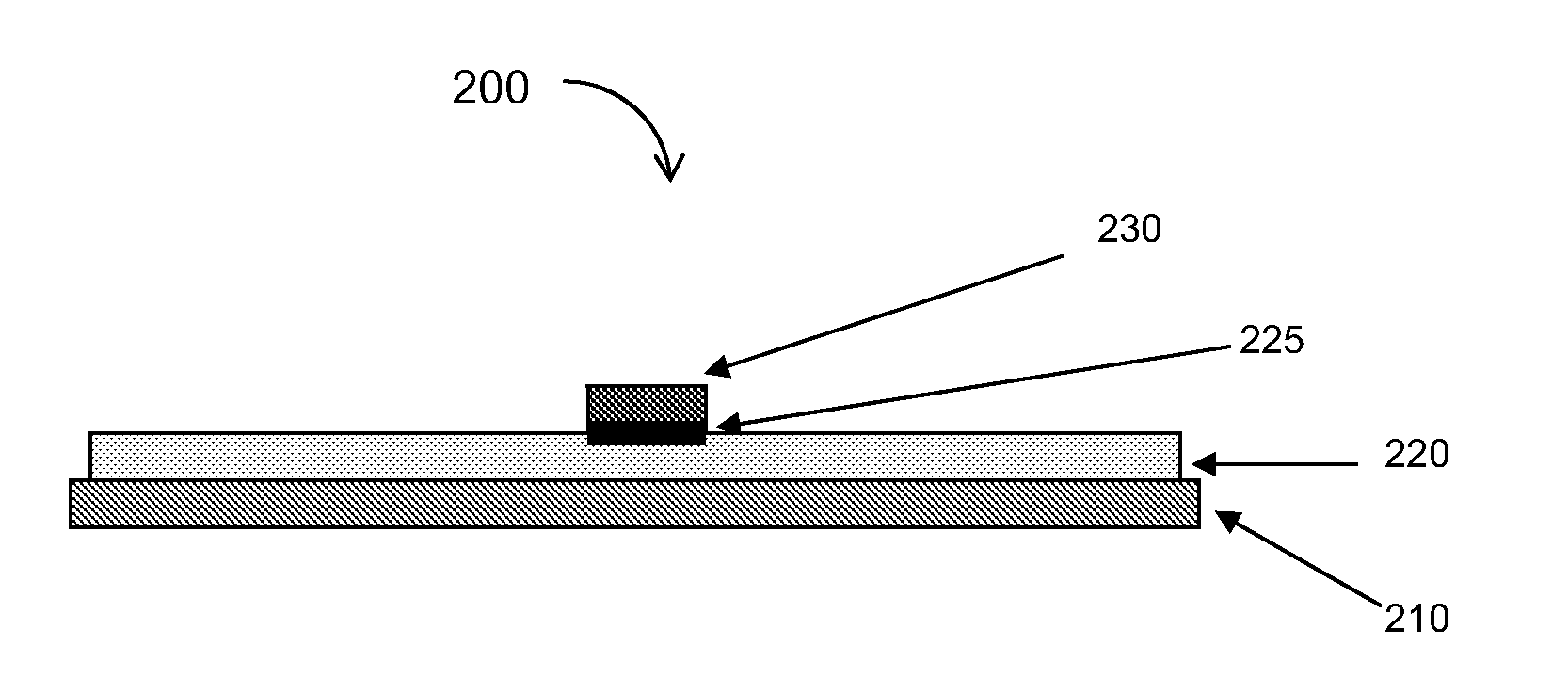

Releasable substrate on a carrier

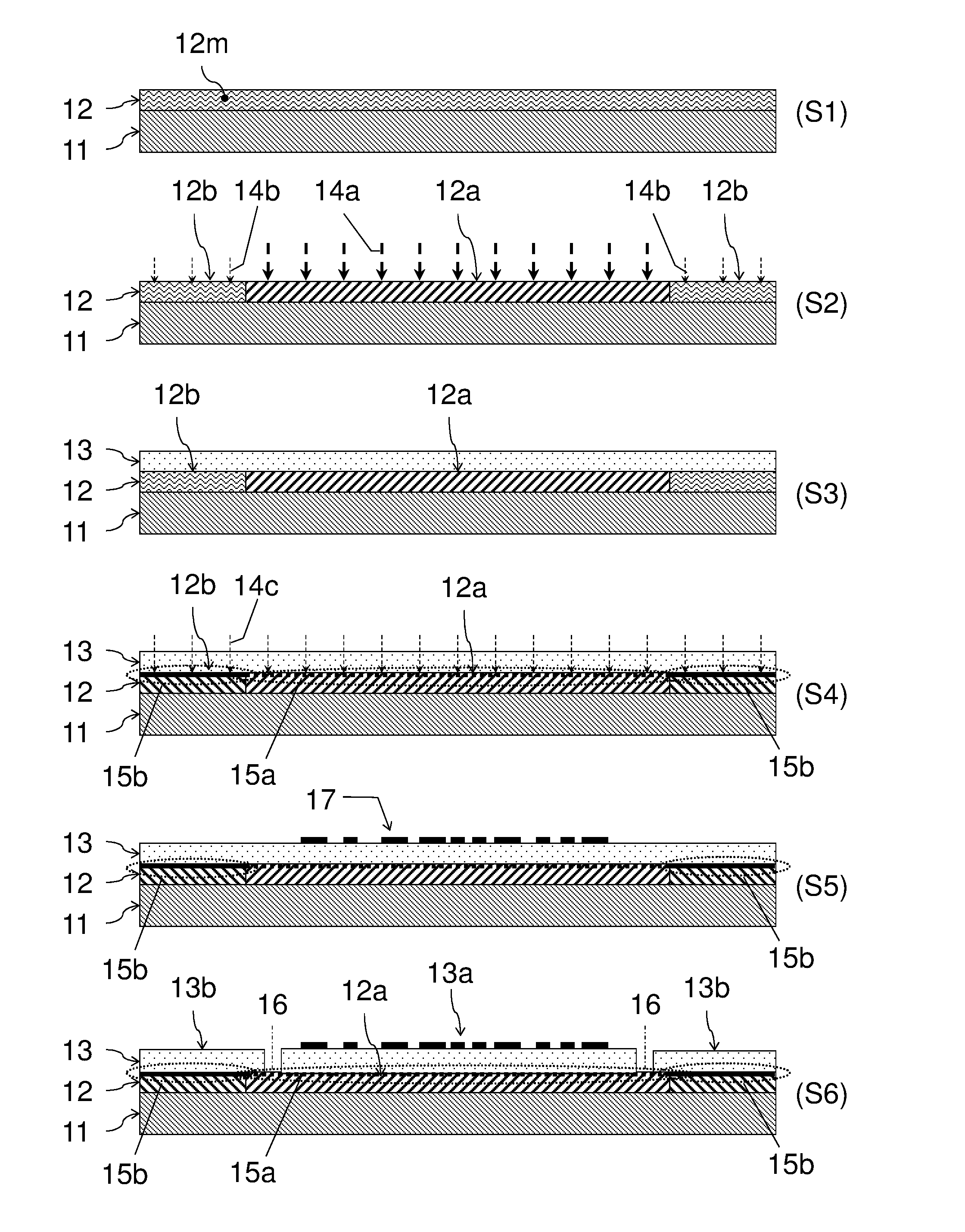

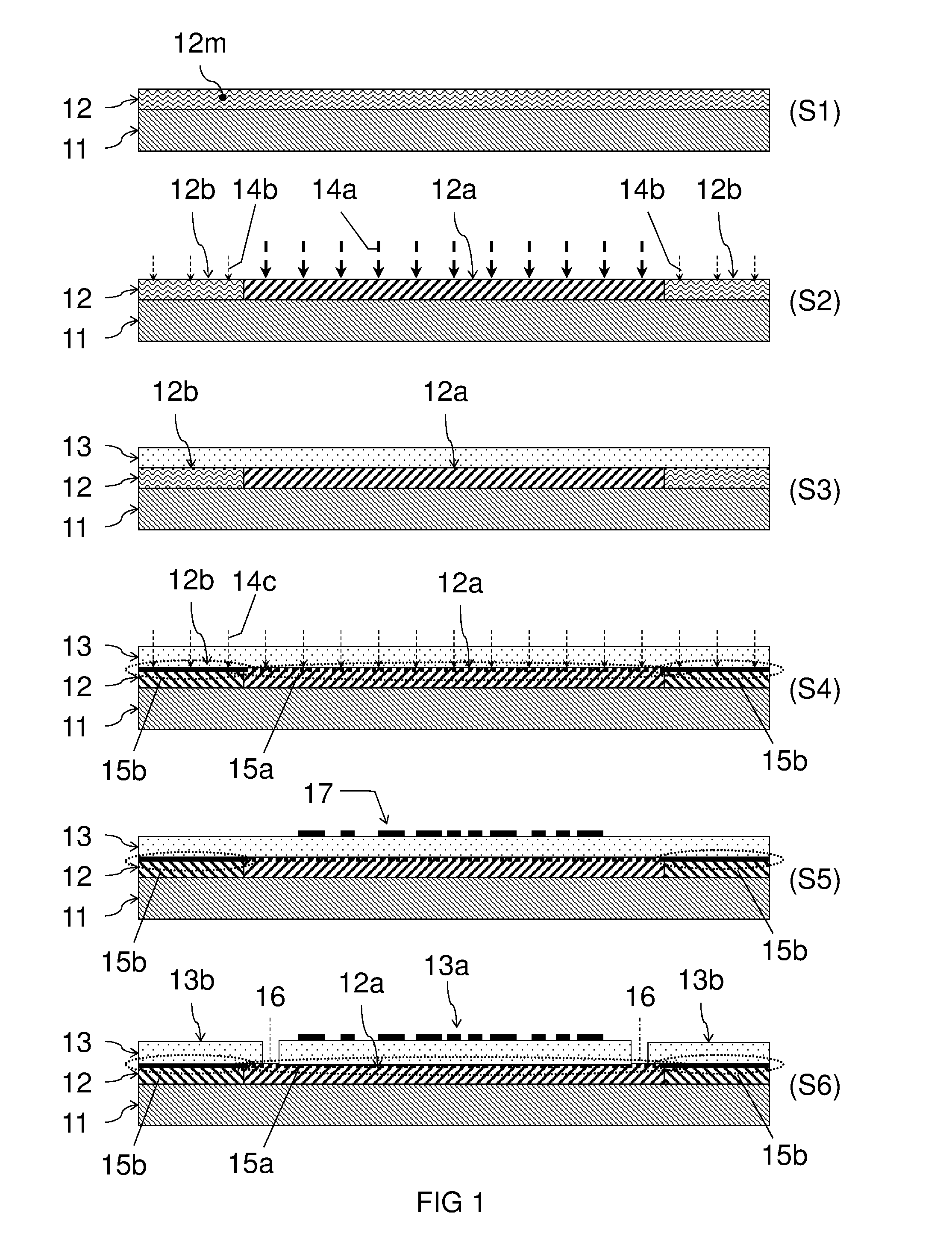

ActiveUS20150231858A1Easy to disassembleProcess condition is harshLamination plant layoutLamination ancillary operationsAdhesion forceAdhesive

A method and system provide a releasable substrate on a carrier. The method includes providing the carrier with a bonding layer of radiation curable adhesive; selectively irradiating a first area subsection of the bonding layer with a first radiation for selectively at least partially curing the first area subsection; bringing a substrate in contact with the first area subsection and a second area subsection of the bonding layer; and curing the second area subsection in contact with the substrate for forming an adhesion area between the second area subsection and the substrate. The first area subsection forms a release area with an adhesion force between the bonding layer and the substrate lower in the release area than in the adhesion area as a result of the first area subsection being more cured than the second area subsection prior to being in contact with the substrate.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

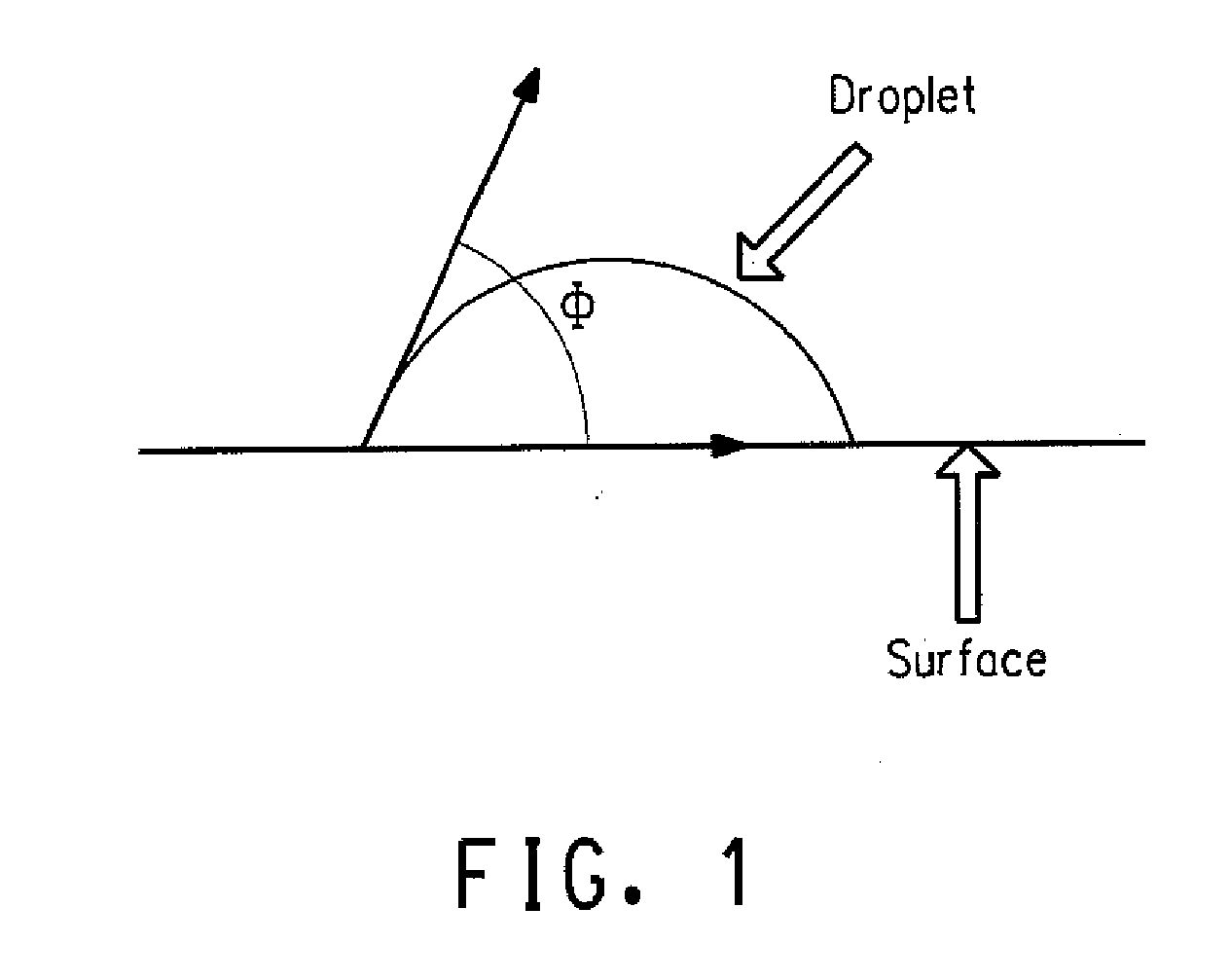

Process and materials for making contained layers and devices made with same

ActiveUS20110017980A1Efficient removalLamination plant layoutLamination ancillary operationsPhysicsRadiation

There is provided a process for forming a contained second layer over a first layer, including the steps:forming the first layer having a first surface energy;treating the first layer with a priming layer;exposing the priming layer patternwise with radiation resulting in exposed areas and unexposed areas;developing the priming layer to effectively remove the priming layer from either the exposed areas or the unexposed areas resulting in a first layer having a pattern of priming layer, wherein the pattern of priming layer has a second surface energy that is higher than the first surface energy; andforming the second layer by liquid depositions on the pattern of priming layer on the first layer.There is also provided an organic electronic device made by the process.

Owner:LG CHEM LTD

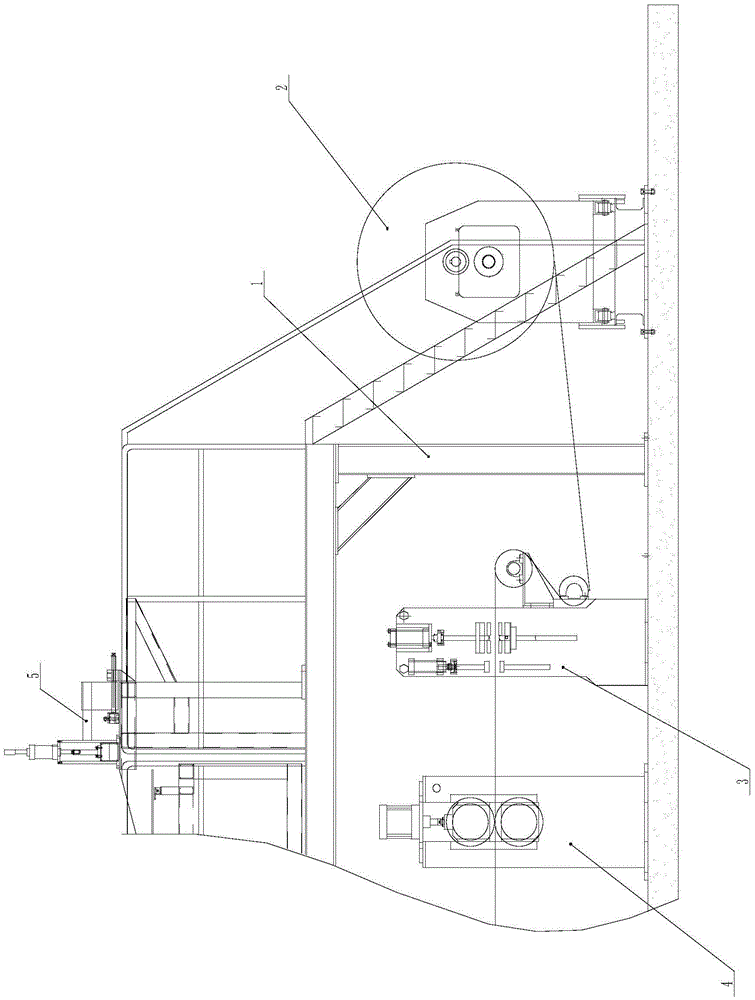

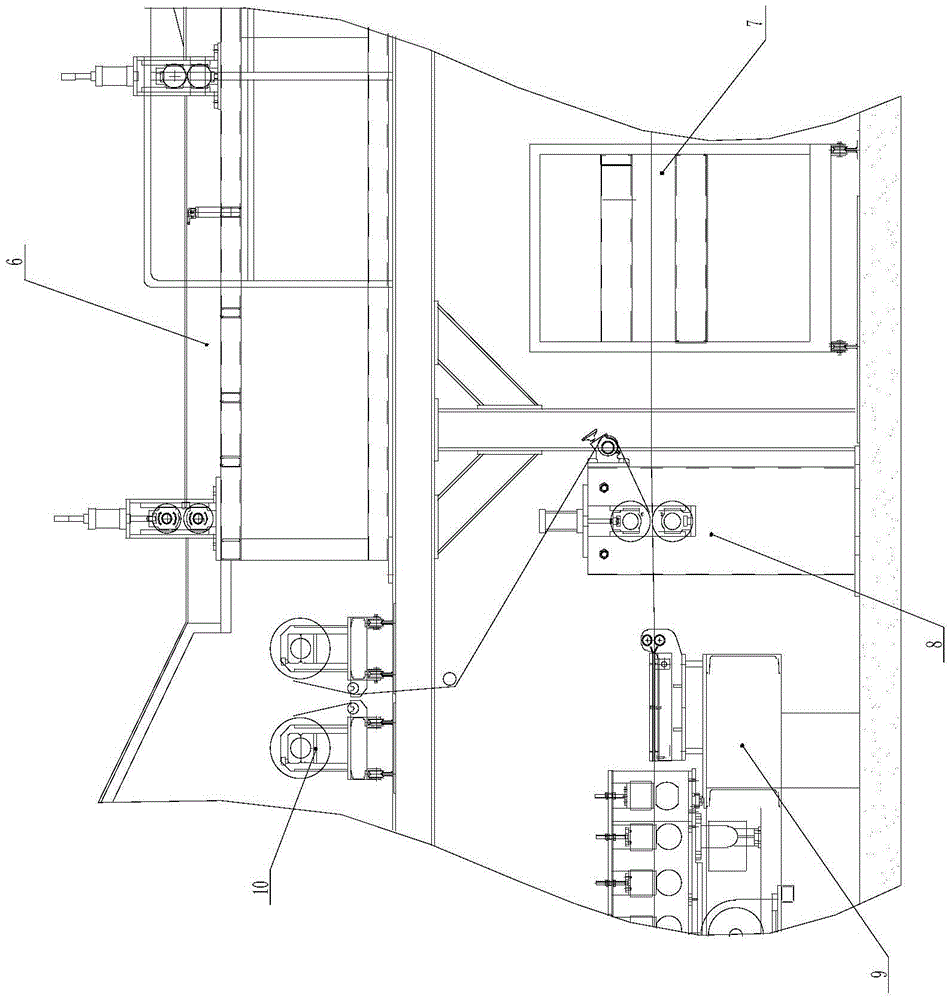

Apparatus for automatically punching and bonding MEA materials for fuel cell

The present invention provides an apparatus for automatically punching and bonding MEA materials for a fuel cell, which can automatically and continuously perform a punching process and a bonding process for the MEA materials by improving a conventional method in which a 5-layer MEA material is manually manufactured. Accordingly, it is possible to reduce the time required to manufacture the 5-layer MEA, provide a reduction in manpower and an efficient production, enable mass production, and improve the quality of the finished 5-layer MEA material.

Owner:HYUNDAI MOTOR CO LTD

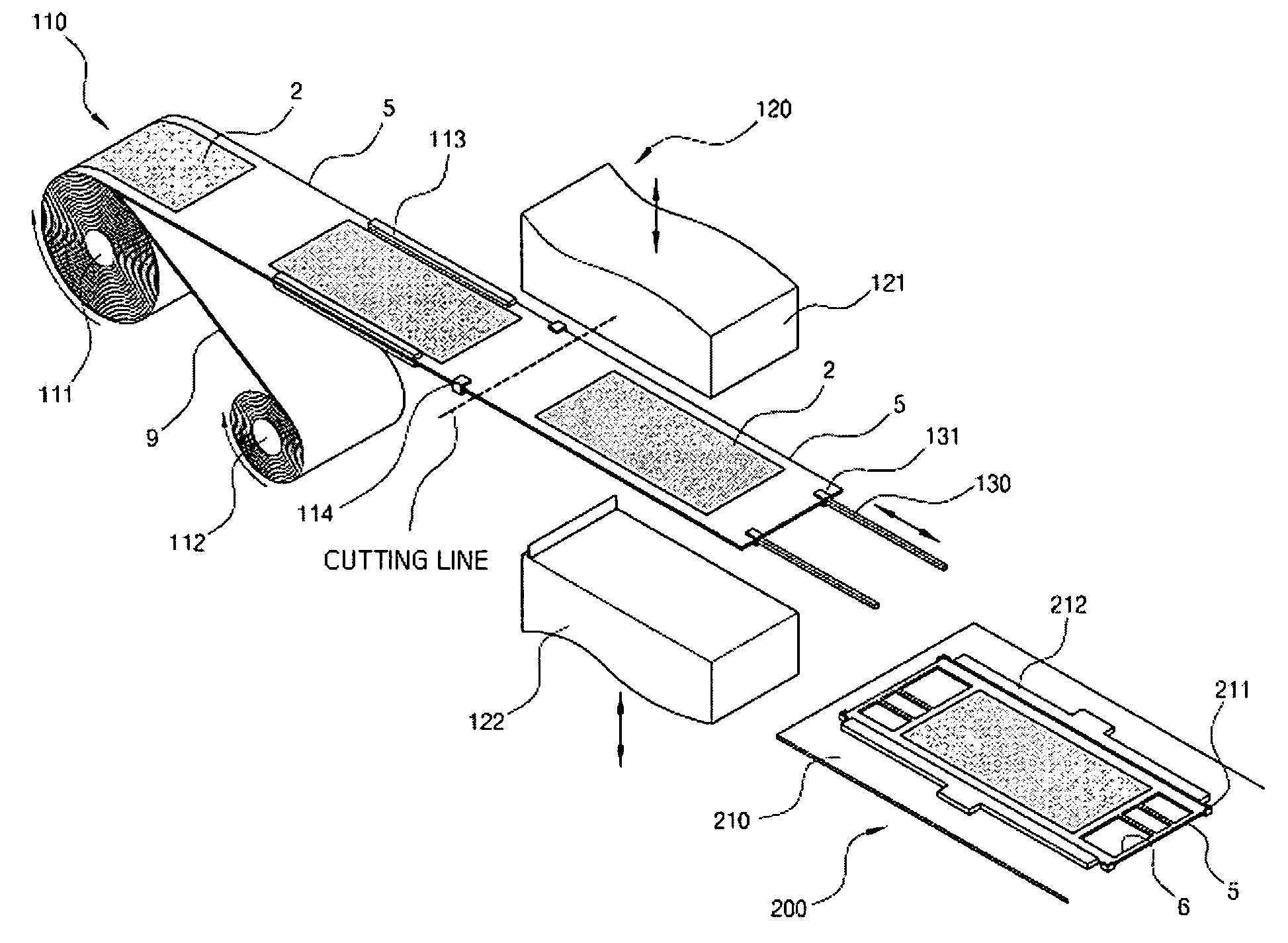

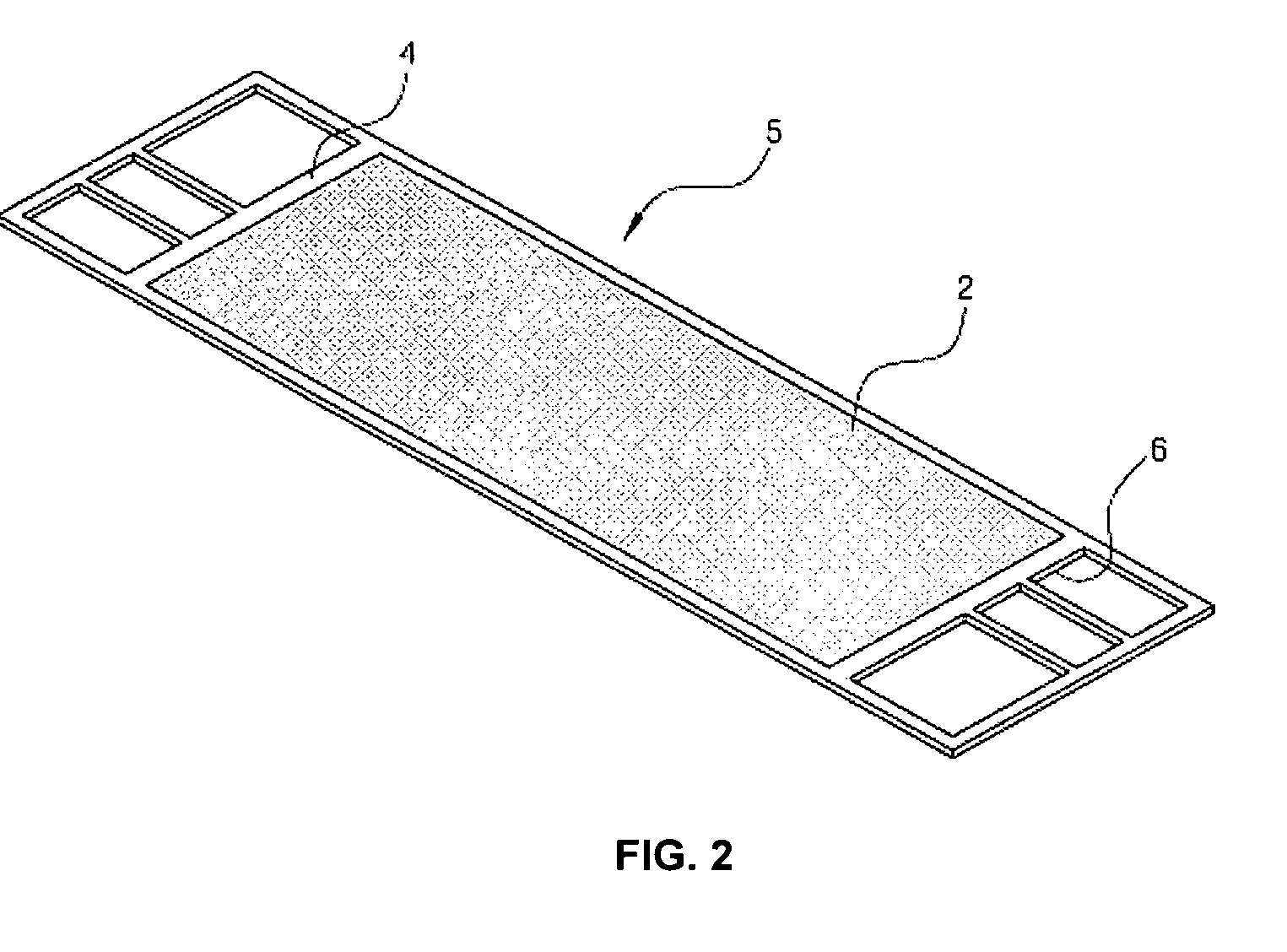

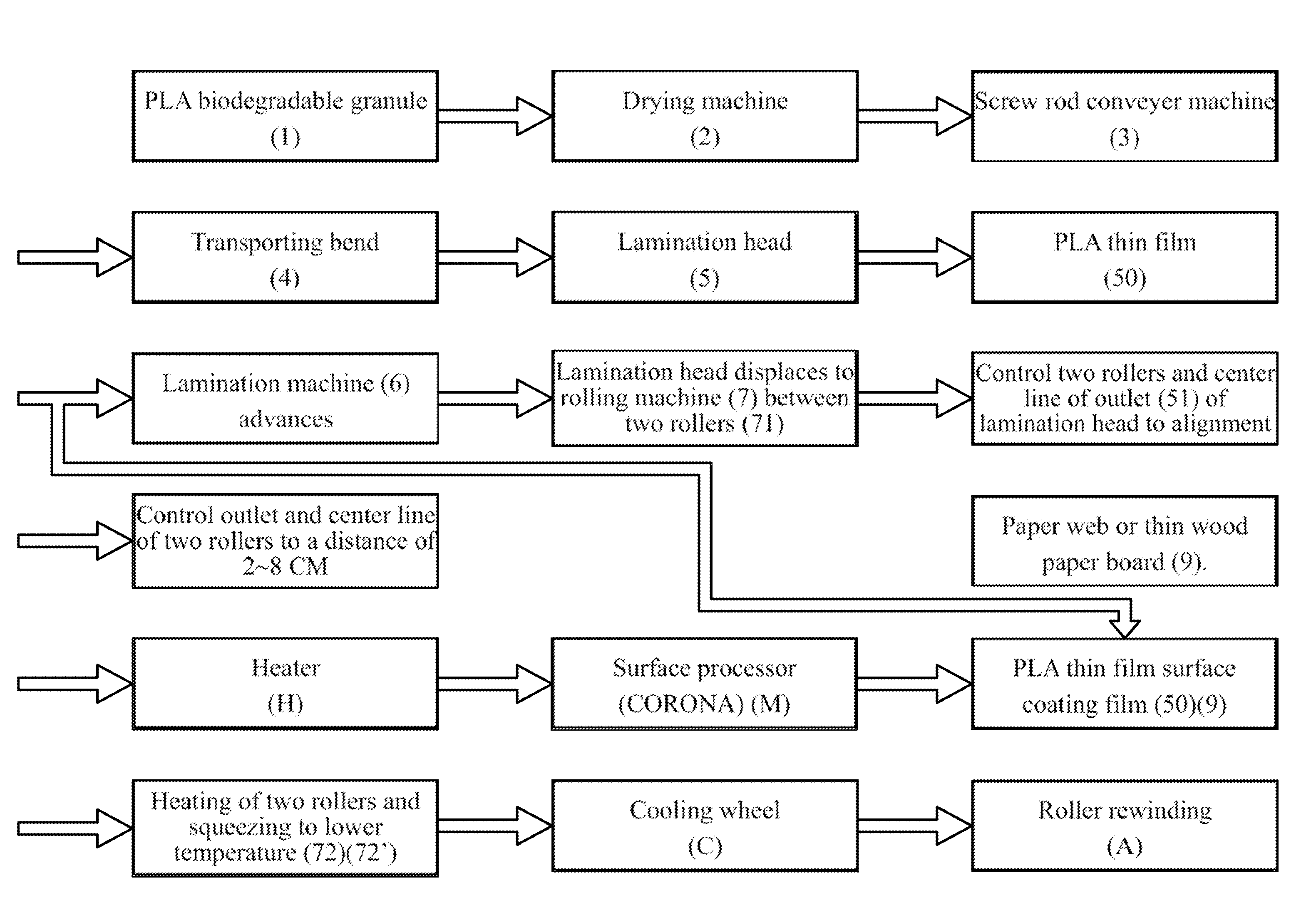

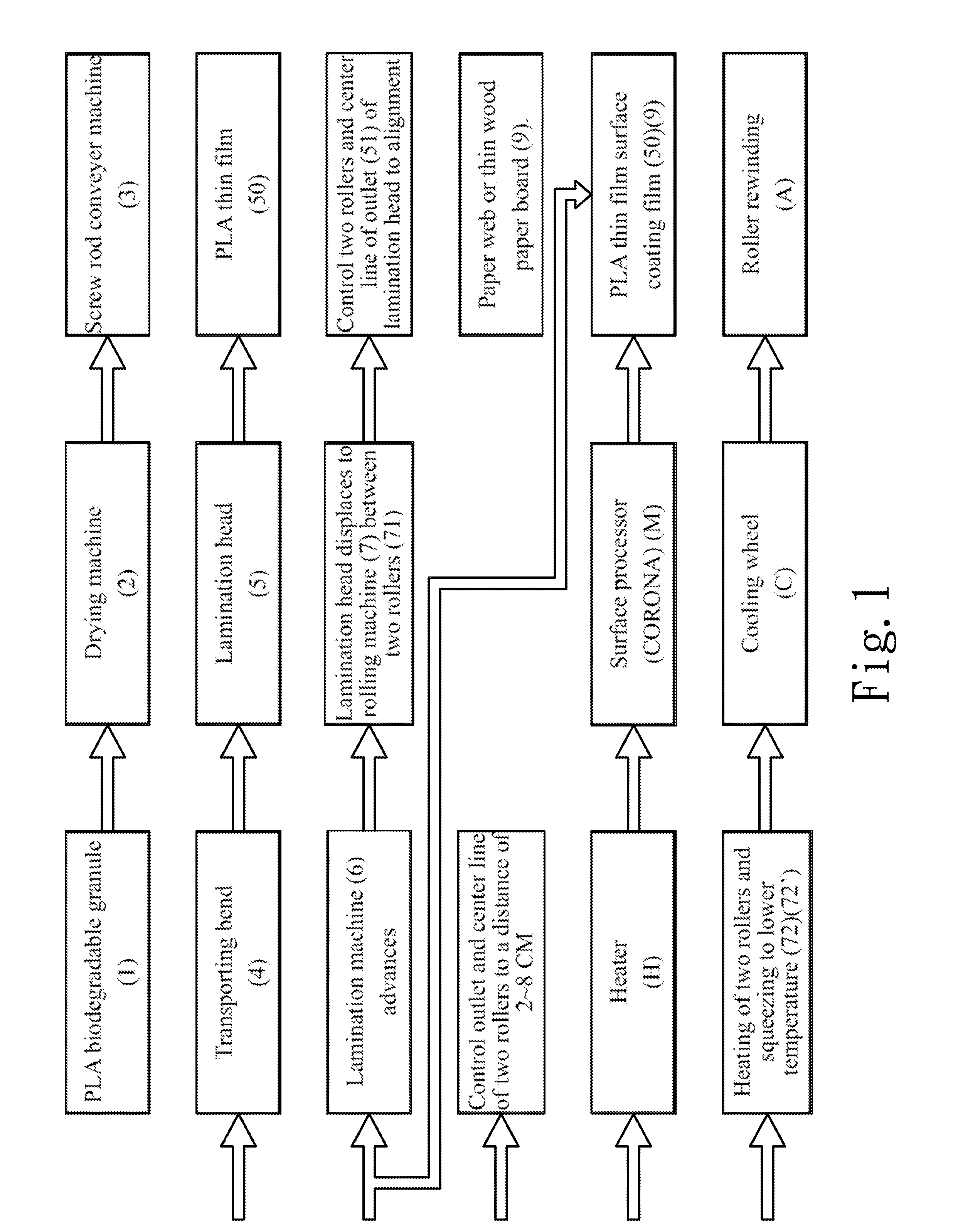

Preparation of film coating of PLA biodegradable materials and its setup

InactiveUS20110174434A1Easy laminationEasy to dropLamination plant layoutMechanical working/deformationNatural degradationPulp and paper industry

A manufacturing method of coating film PLA biodegradable material and its setup using PLA biodegradable granule through drying machine to process water content before heating granule to molten on one hand and entering lamination head on the other hand through conveyer and squeezing out a thin film, then pushes lamination machine to fixed location and position lamination head between two rollers, than through lateral cylinder to control its displacement so that lamination head locates at center of two rollers, same time control rolling machine so that lamination point ascends to proper distance from outlet; while paper web or thin wood paper board surface heating through heater and enlarging pores, then using surface treatment so that pores are further enlarged to facilitate PLA thin film easy to coat film for providing fast lamination and increase yield and producing all kinds of paper containers and achieve natural degradation.

Owner:HOME ROUND PAPER

Continuous and automatic production line for aluminum honeycomb composite boards and continuous production process

InactiveCN105538870AFit tightlyReduce manual involvementLamination plant layoutLaminationProduction lineAluminum honeycomb

The invention discloses a continuous and automatic production line for aluminum honeycomb composite boards. The continuous and automatic production line comprises a rack, an aluminum honeycomb core layer forming unit, an upper-layer board forming unit, a lower-layer board forming unit and a composite forming unit. The aluminum honeycomb core layer forming unit achieves automation of splicing, stretching and unfolding aluminum honeycomb core strips into aluminum honeycomb core layers and coating the aluminum honeycomb core layers with polymeric membranes in advance, the upper-layer board forming unit and the lower-layer board forming unit are used for unreeling upper-layer boards and lower-layer boards and coating the upper-layer boards and the lower-layer boards with polymeric membranes in advance respectively, and finally the three layers are compounded on the composite forming unit. The aluminum honeycomb composite boards can be continuously produced through the continuous production line, capacity is improved, the quality of the formed aluminum honeycomb composite boards is consistent, and the thickness is uniform.

Owner:张家港市弘扬机械设备有限公司

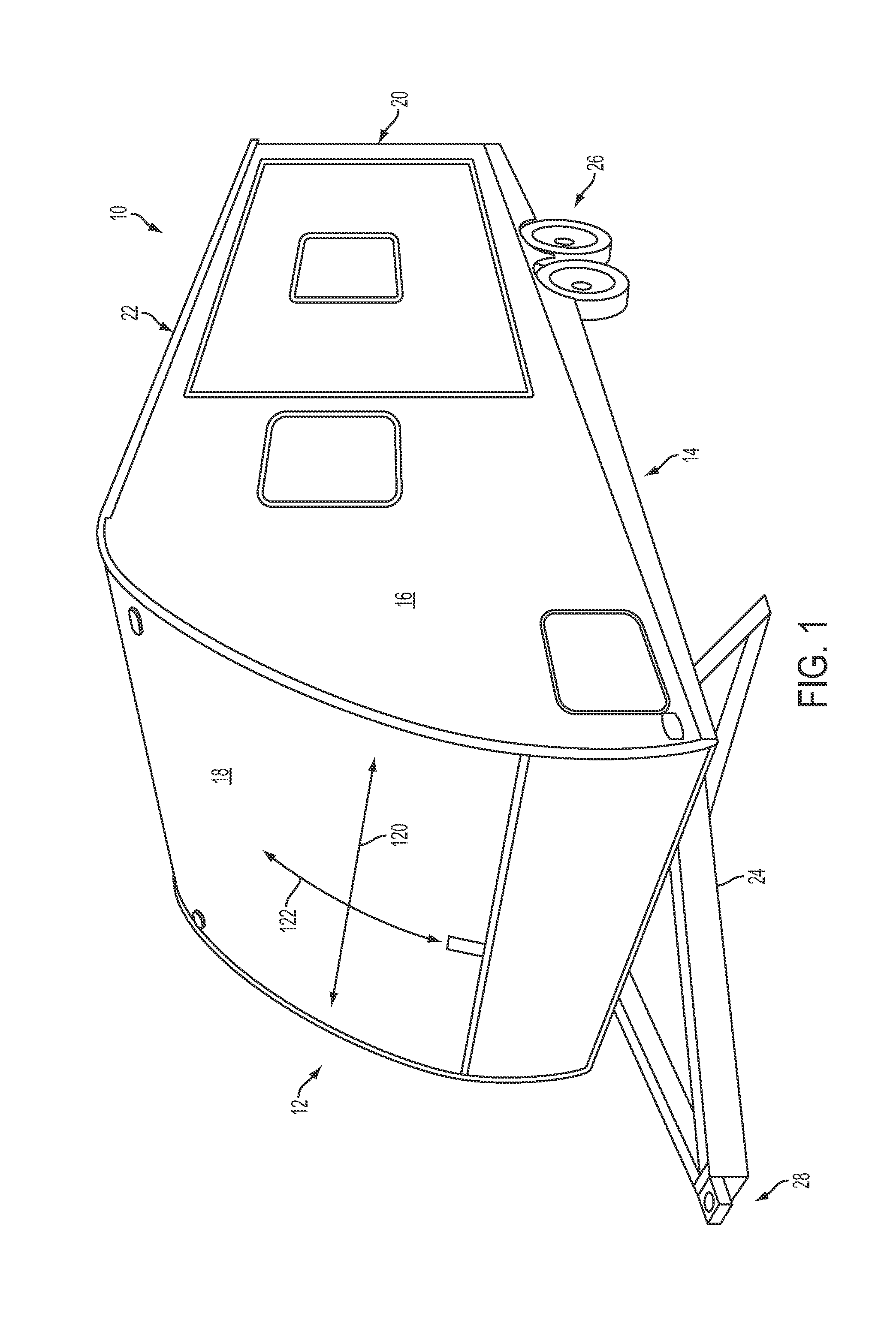

Composite panel

A composite wall panel for use in vehicles having a floor structure and a front wall, the composite wall panel including a first polymer resin layer having a plurality of unidirectional fibers embedded therein that are substantially parallel to a first axis, and a second polymer resin layer having a plurality of unidirectional fibers embedded therein that are substantially parallel to a second axis, the second polymer resin layer being bonded to the first polymer resin layer so that the second axis is substantially perpendicular to the first axis. The composite wall panel is disposed so that the first axis is substantially parallel to the floor structure, and the rigidity of the composite wall panel is greater along the first axis than the second axis.

Owner:IMPACT GUARD LLC

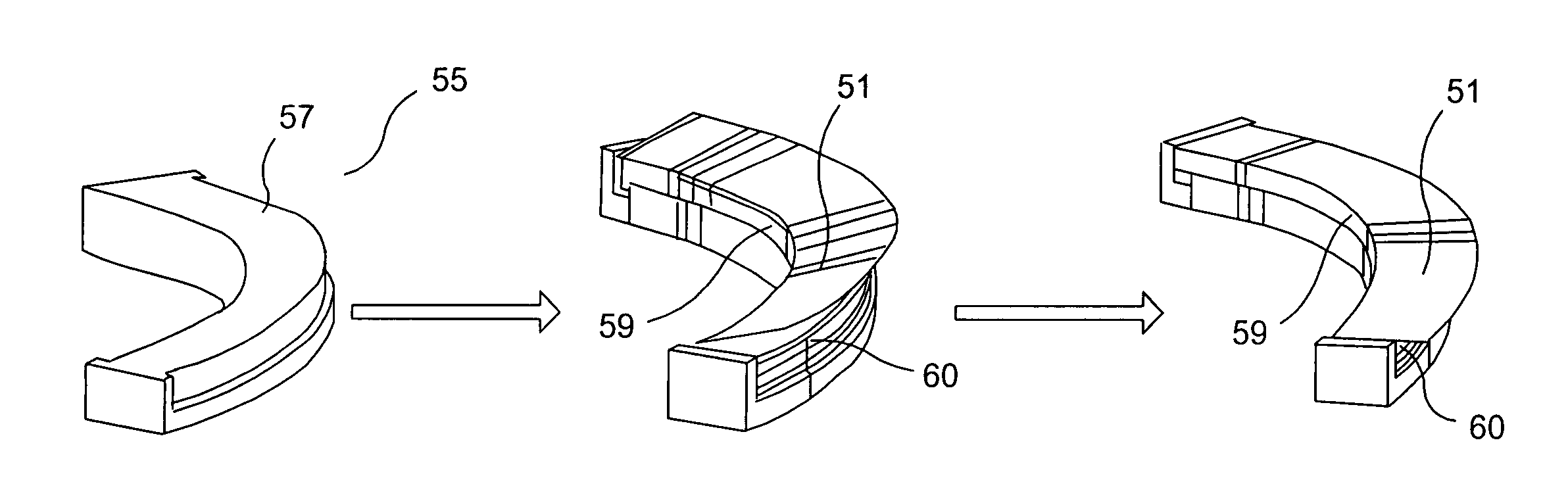

Process and tools for manufacturing composite ring frames

ActiveUS7544261B1Easy to manufactureEasy to controlLamination plant layoutMechanical working/deformationEngineeringElastic membrane

The present invention relates to a process for manufacturing composite ring frames for aeronautical fuselages by means of the application of the RTM technology to two preforms with C- and L-shaped sections manufactured using two tools (21, 55) in the following steps: providing the material; hot-forming planar rectangular laminates (41); hot-forming laminates of right angle section (51) on one part of right angle section of the first tool (21), placing an elastic membrane (55) and applying a temperature and vacuum cycle; hot-forming the preforms into a C shape (11) and L shape (13) on a second curved tool (55) by deforming said laminates of right angle section (51) thereon, and applying a temperature and vacuum cycle. The invention also relates to said tools (21, 55).

Owner:AIRBUS OPERATIONS SL

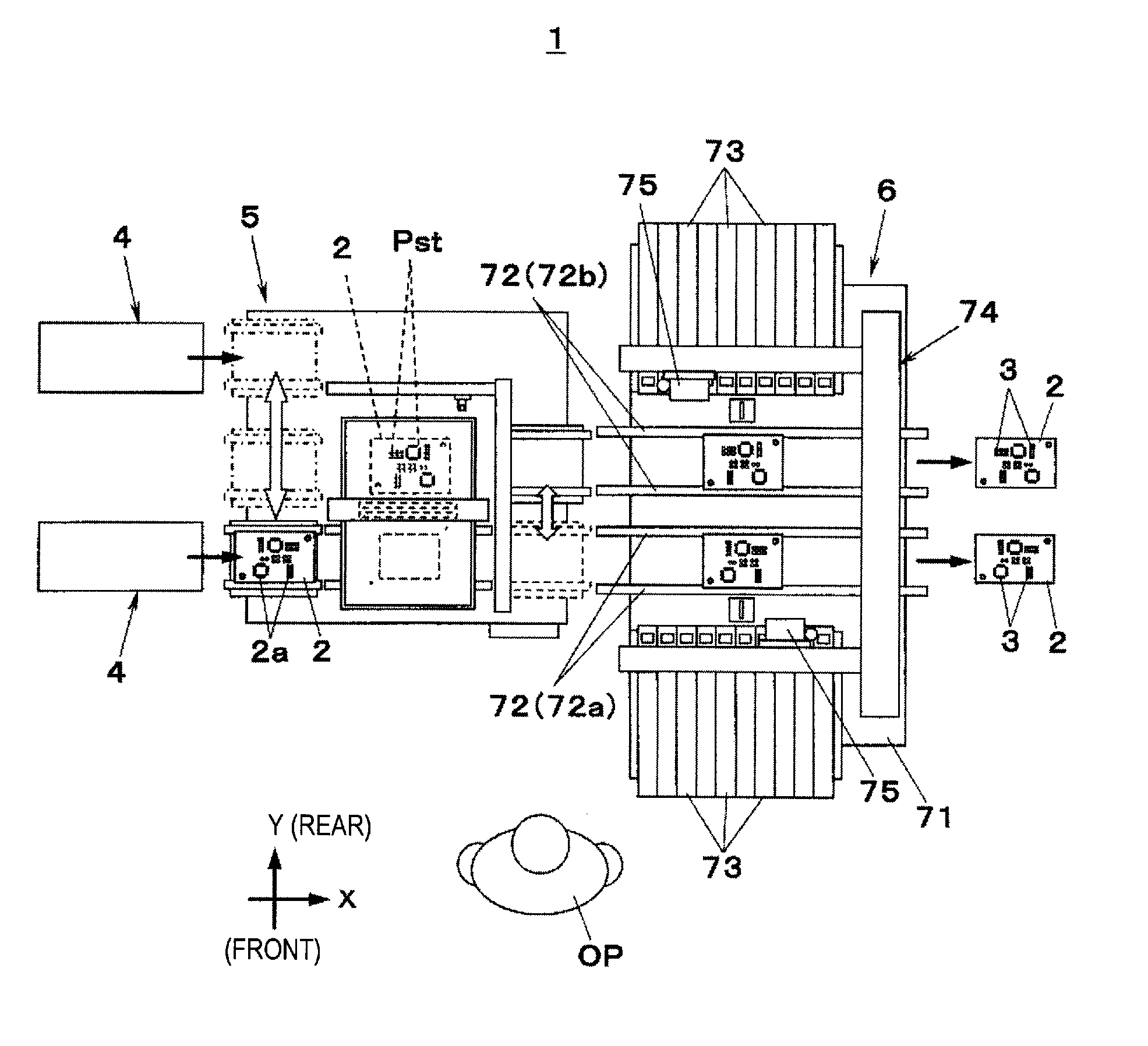

Screen printer and component mounting line

InactiveUS20150075721A1Simple configurationReduce the amount requiredInking apparatusLiquid surface applicatorsEngineeringSilk-screen printer

A screen printer includes: a mask having a first area formed with a first pattern and a second area formed with a second pattern; and a print head which forms a past printing on a board and is movable on the mask. When a paste print is formed using the first pattern, the print head moves from a start position located between the first area and the second area to the first area and then returns to the start position. When a paste print is formed using the second pattern, the print head moves from the start position to the second area and then returns to the start position.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

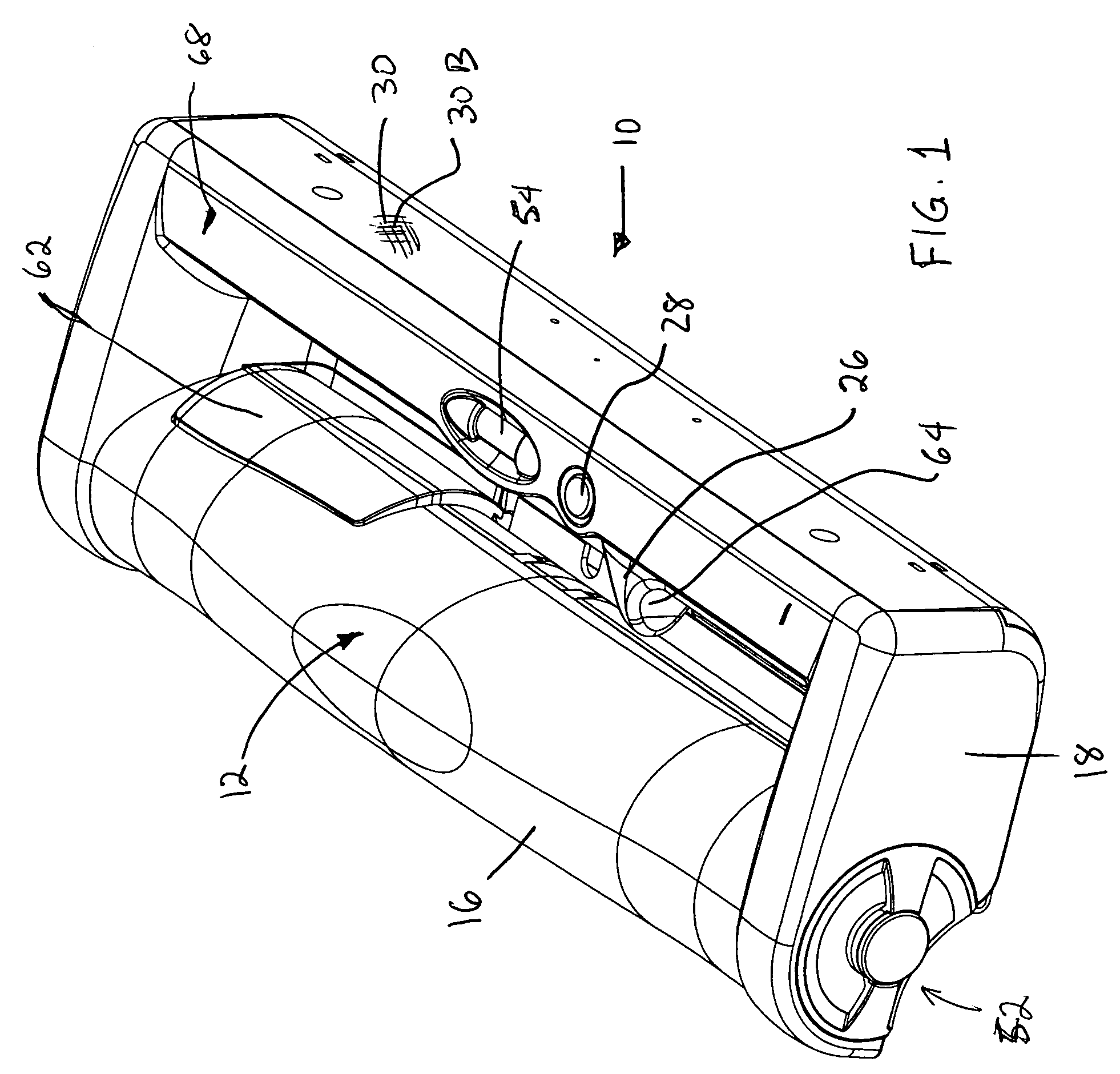

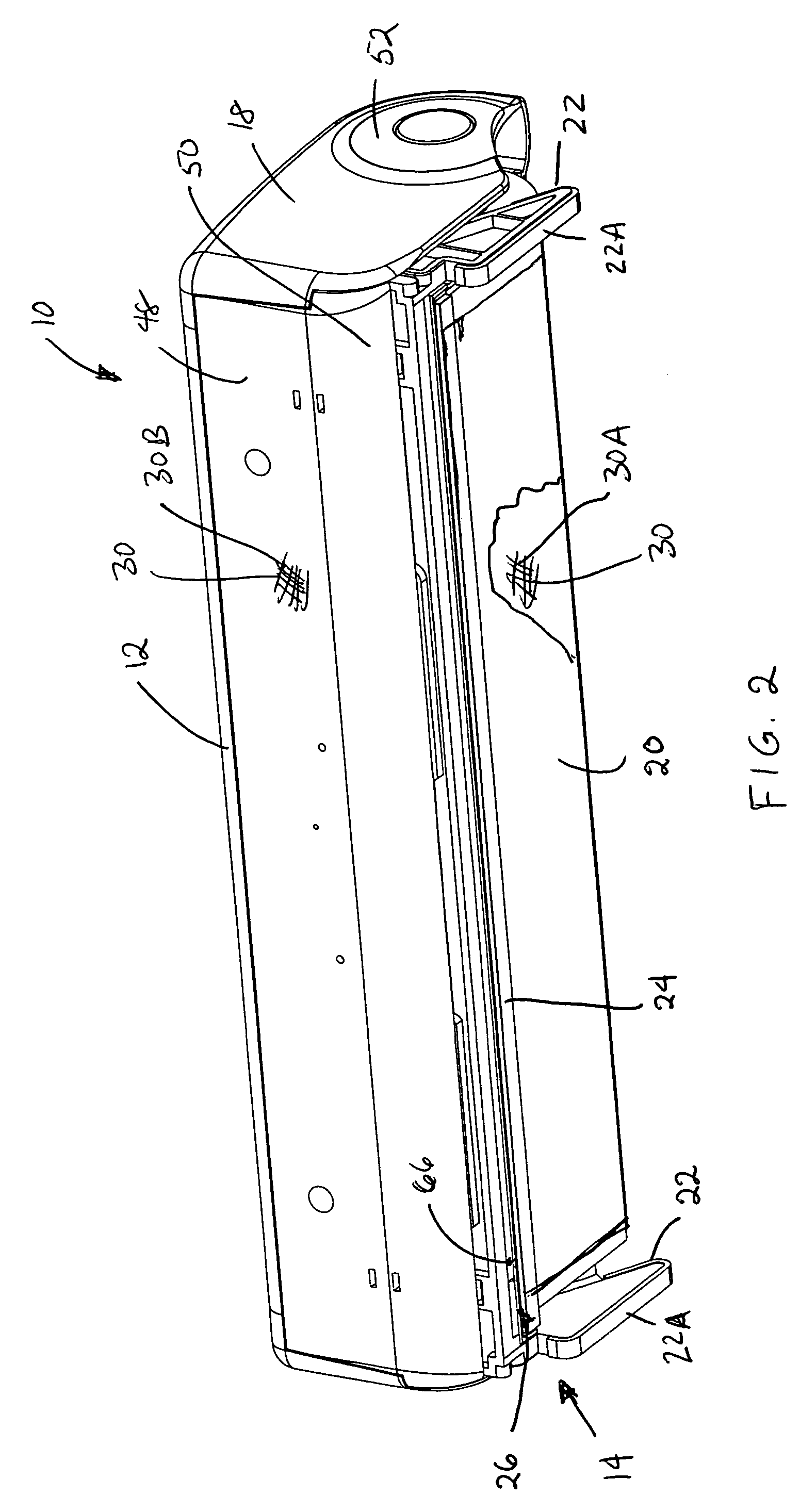

Applicator for and method of applying a sheet material to a substrate

A method and device for applying sheet material, such as wallpaper, to a substrate. The applicator is bi-positionable, having a first position where the sheet material is spaced apart from the substrate and a second position where the sheet material contacts the substrate. Additionally or alternatively, the applicator may be provided with a control bar. In the first position, the control bar contacts a portion of the sheet material such as its free end. This minimizes the chance of the sheet material prematurely contacting the substrate. In the second position, the sheet material is disengaged from the control bar for application to the substrate. The applicator and sheet material may be provided together in a kit.

Owner:PROCTER & GAMBLE CO

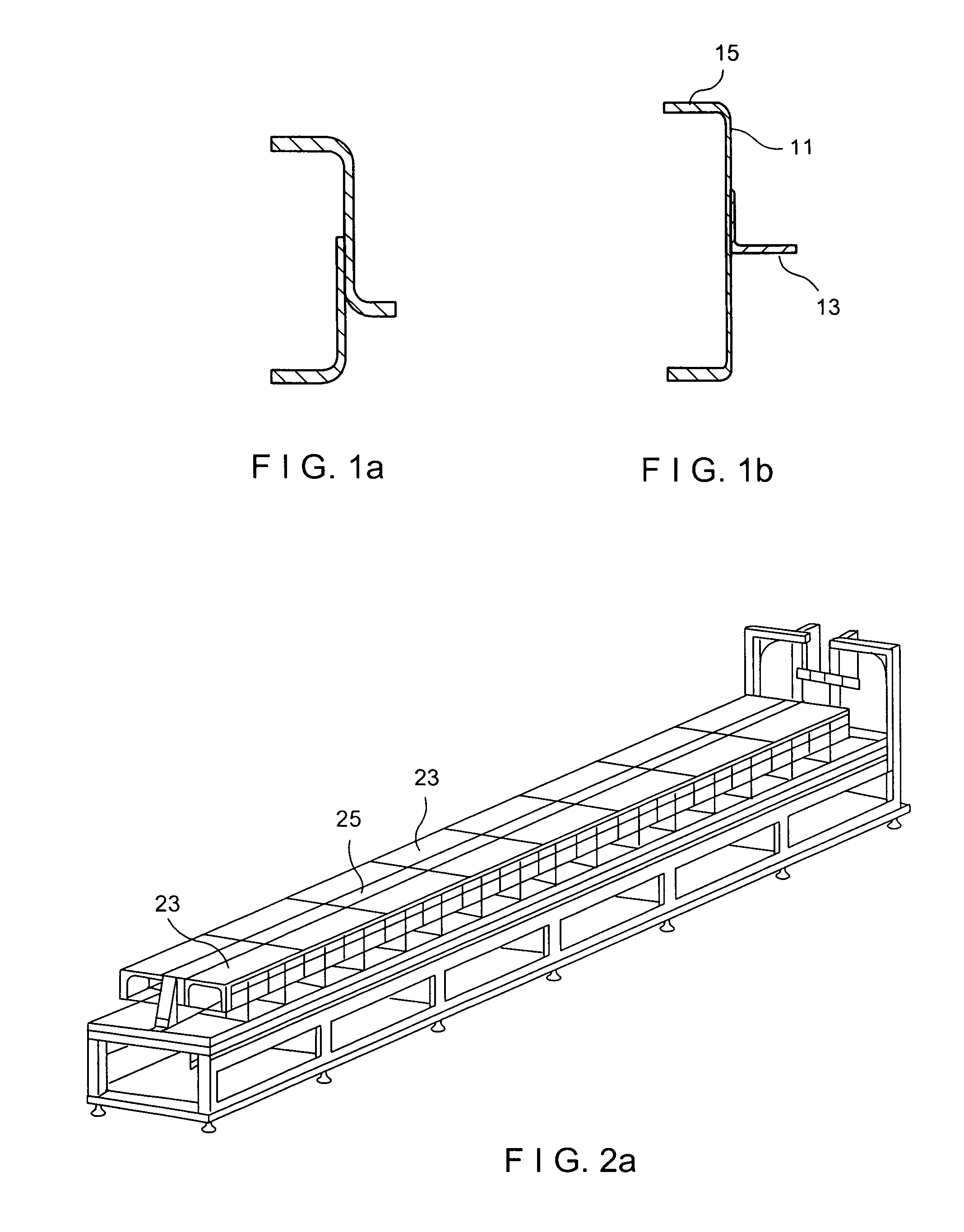

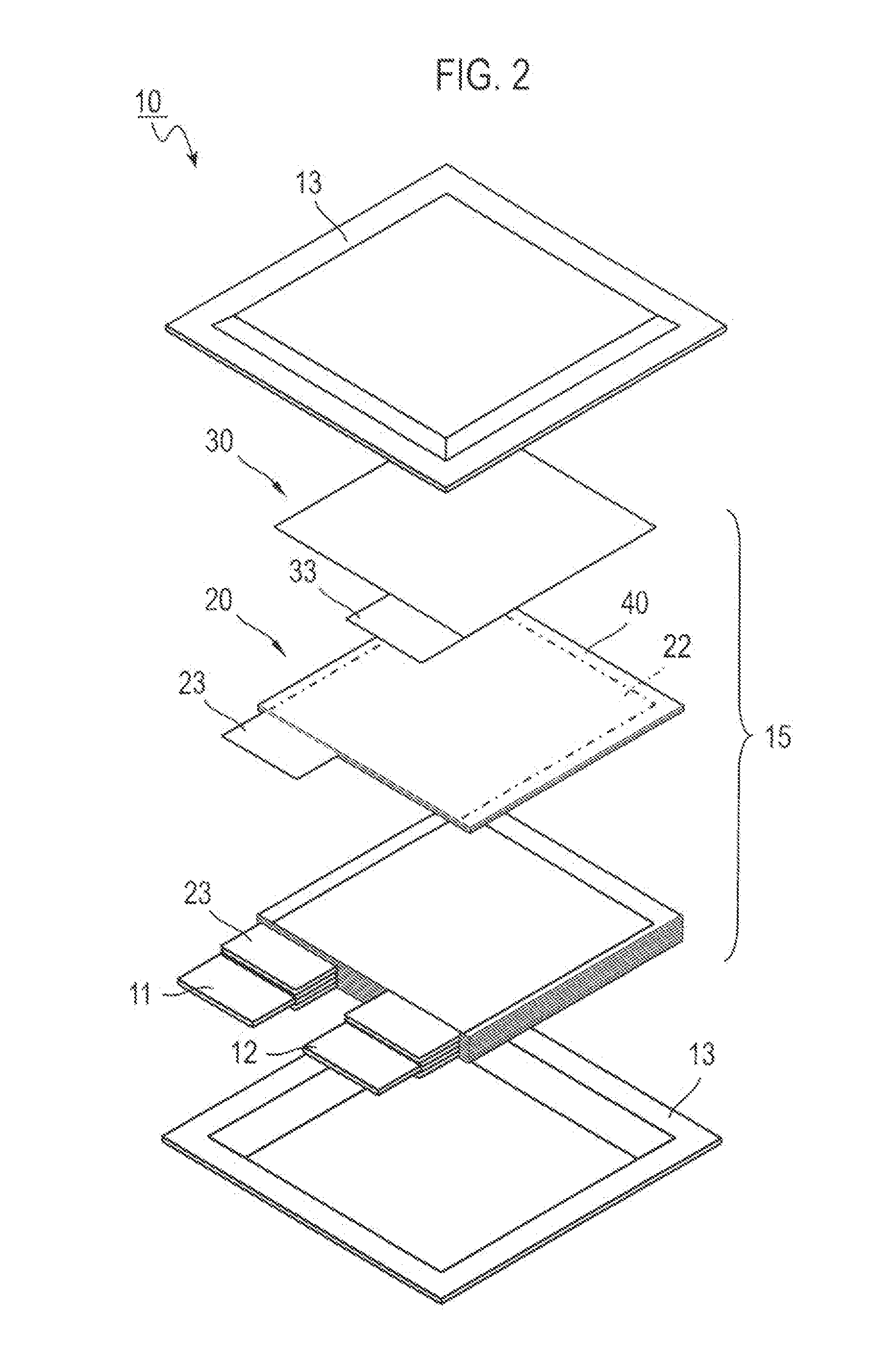

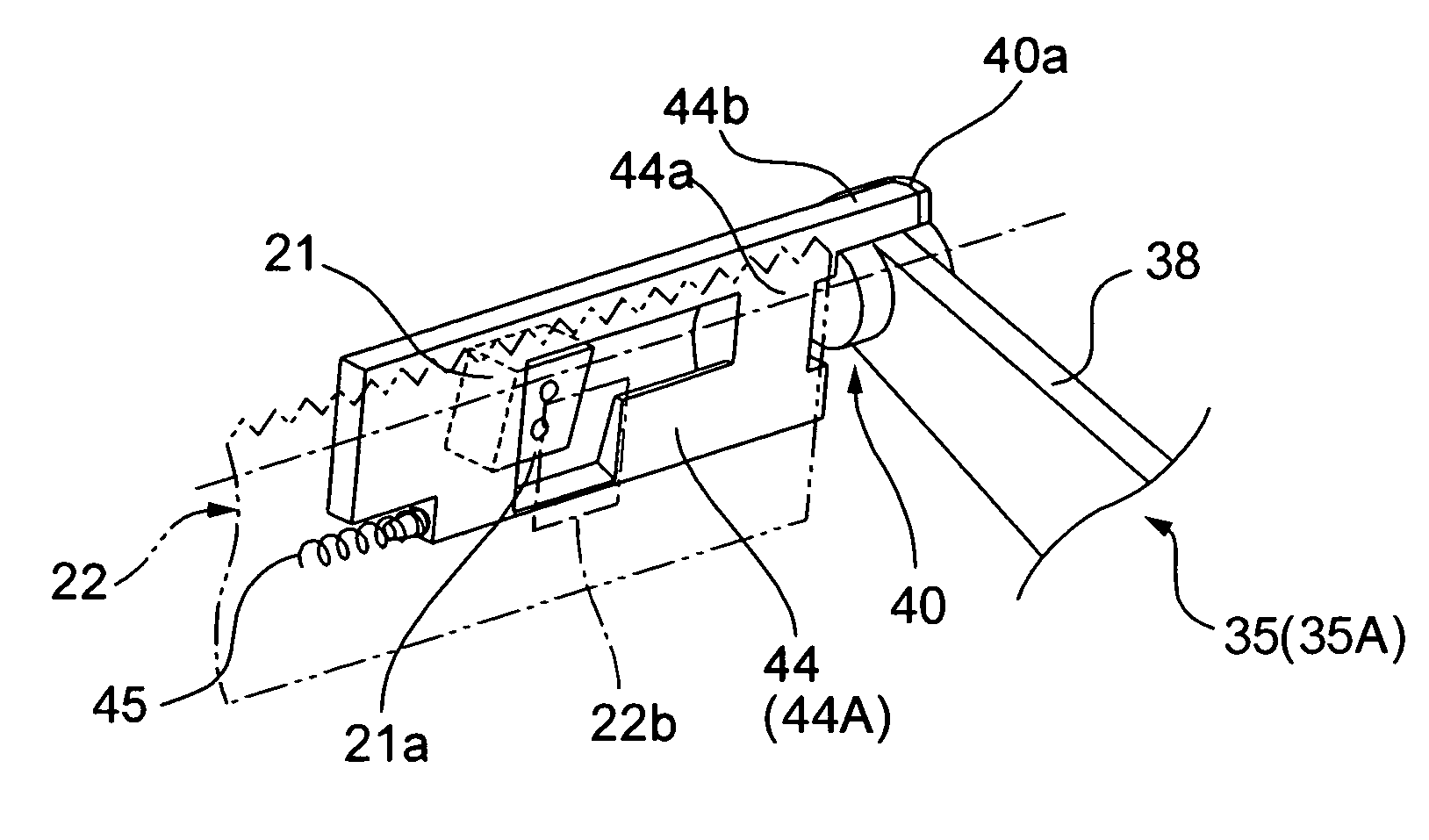

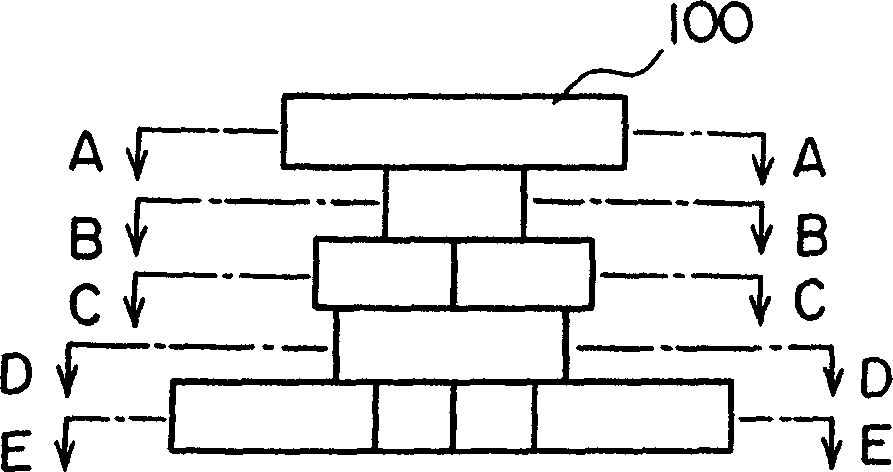

Stacking device and stacking method

ActiveUS20140026398A1Improve stacking accuracyImprove accuracyLamination plant layoutLamination ancillary operationsElectrical polarityEngineering

A first holding unit (114) reciprocates between a first table (121) and a stacking table (141) and a second holding unit (115) reciprocates between the stacking table (141) and a second table (141). When the first holding unit (114) holds a separator-electrode assembly (20) whose horizontal position has been adjusted on the first table (121), the second holding unit (115) releases a second electrode (30) over the stacking table (141). When the first holding unit (114) releases the separator-electrode assembly (20) over the stacking table (141), the second holding unit (115) holds the second electrode (30) whose horizontal position has been adjusted on the second table (131). The present invention provides a stacking device and a stacking method which are capable of stacking the separator-electrode assembly including a first electrode sandwiched by separators and the second electrode having a different polarity from the first electrode efficiently with high accuracy.

Owner:ENVISION AESC JAPAN LTD

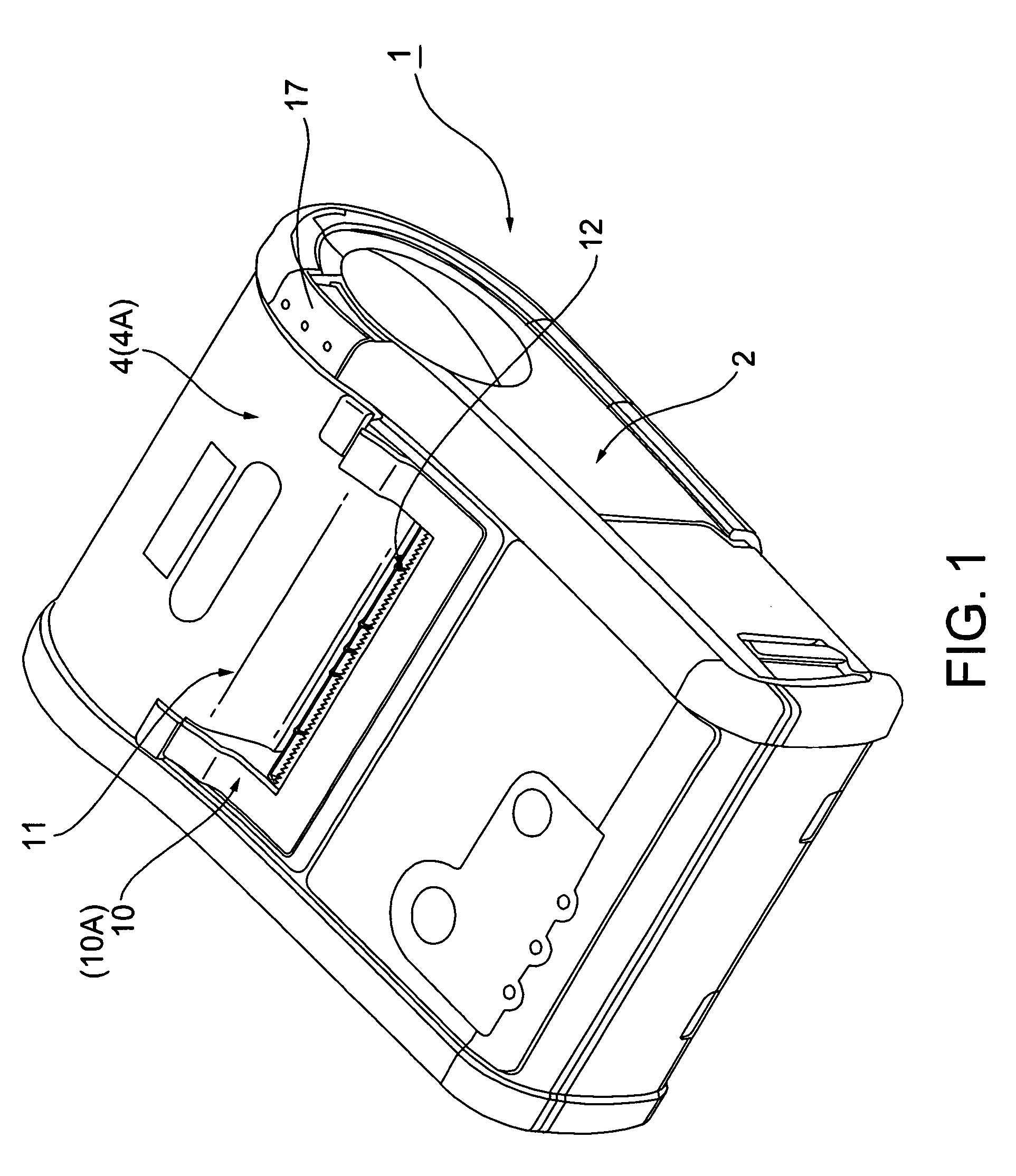

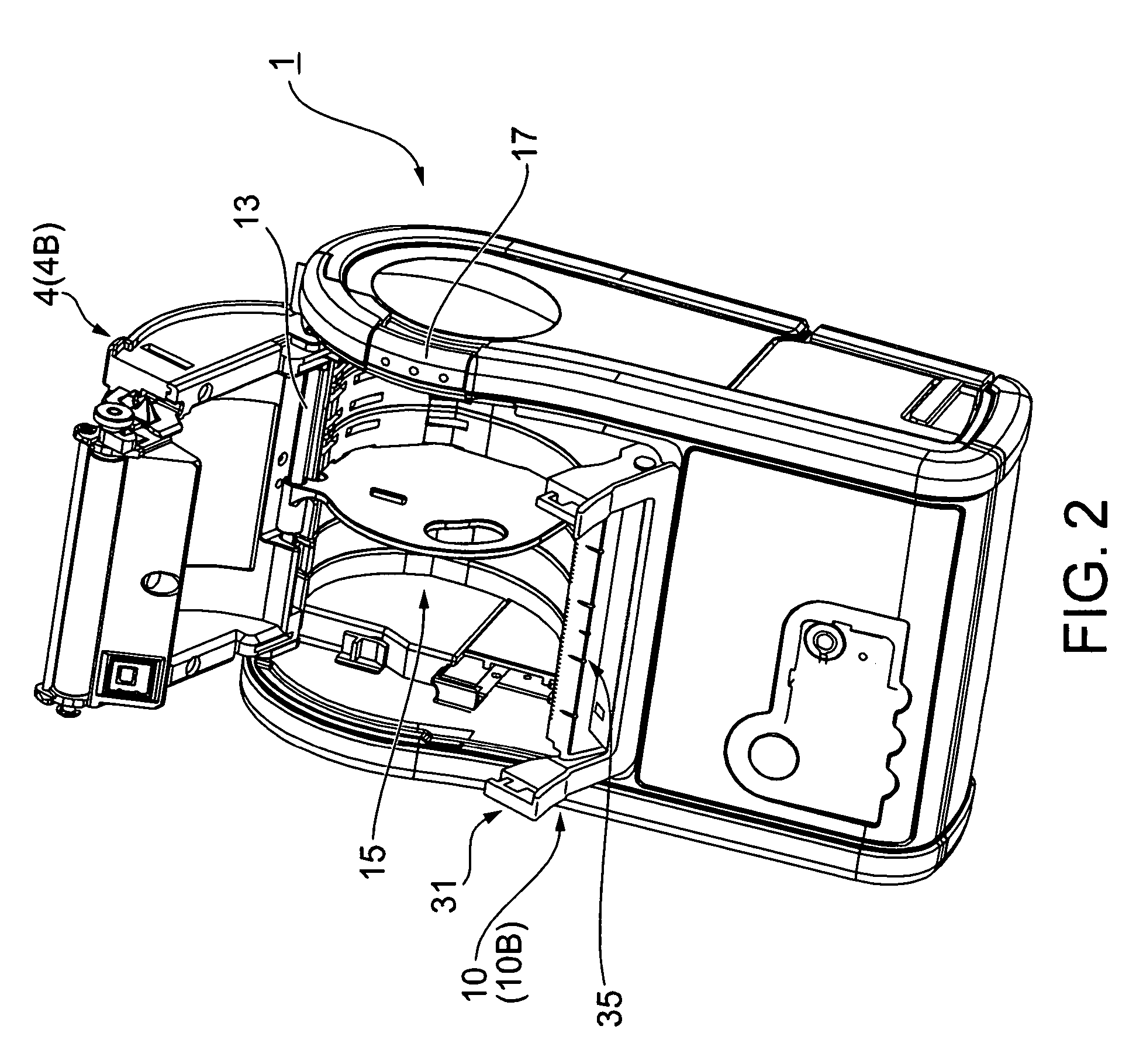

Printer

InactiveUS7578332B2Smooth bootLamination plant layoutLamination ancillary operationsMechanical engineeringPhotoelectric sensor

A printer with a peeler mechanism 1 for peeling labels from a web, the printer having a movable web pressure roller 24 which may be moved from a web pressure position 24A in which pressure is applied to a platen roller 20 to a retracted position 24B in which pressure is not applied. The printer also has a photosensor 21 and photoreceptor having an emitter / receptor surface 21a for detecting the presence and absence of labels peeled from the web. A window 22b in the label guide surface 22a becomes covered to shield the photosensor output for defining a no-label detection stateWhether the peeler mechanism is set to operate in the label peeling mode or is set to a retracted position defining a non-peeling continuous label dispensing mode of operation can be determined based on the output of the label detection photosensor 21, and the label dispensing mode can be set to the label peeling mode or continuous label dispensing mode based on this determination.

Owner:SEIKO EPSON CORP

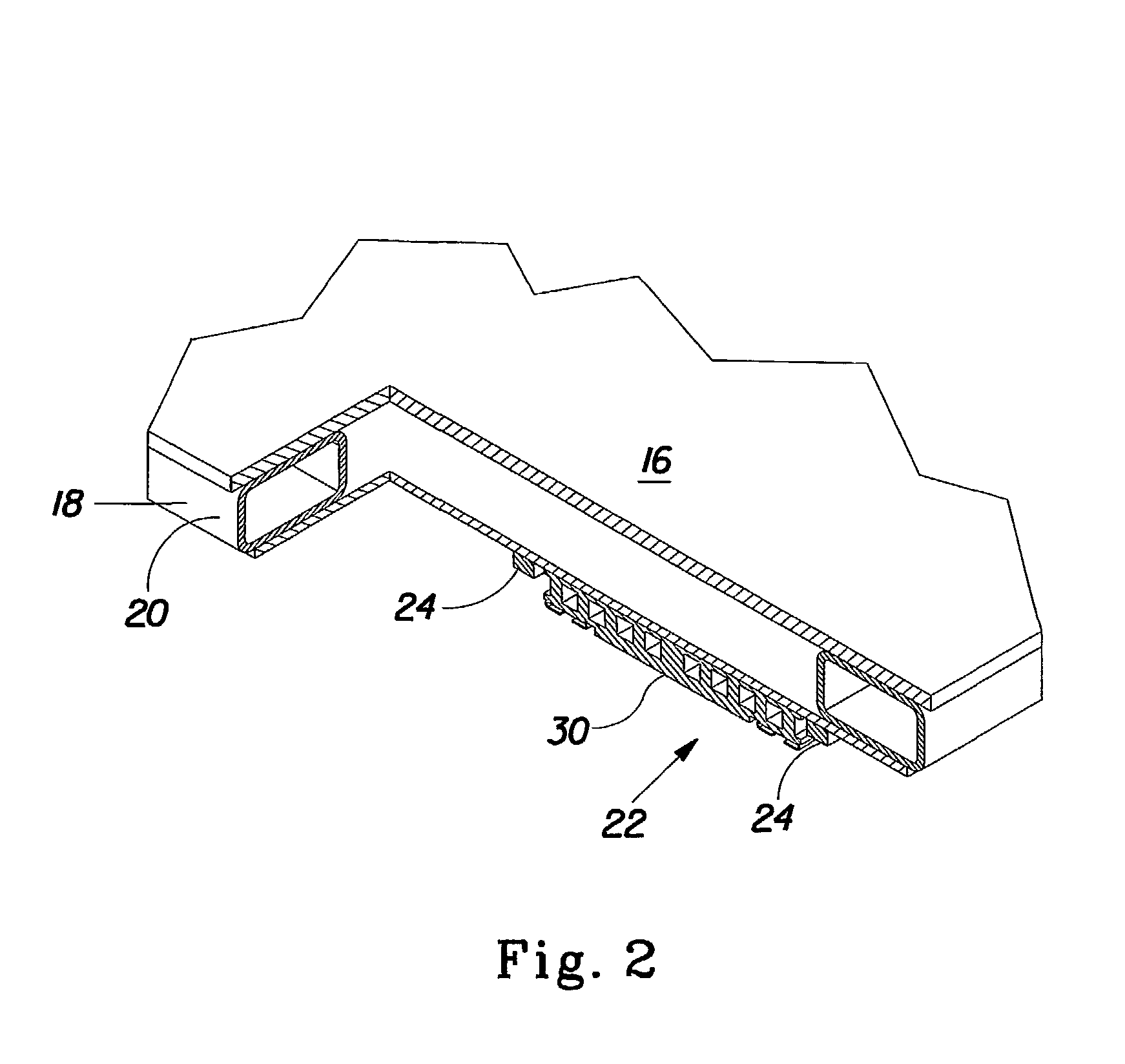

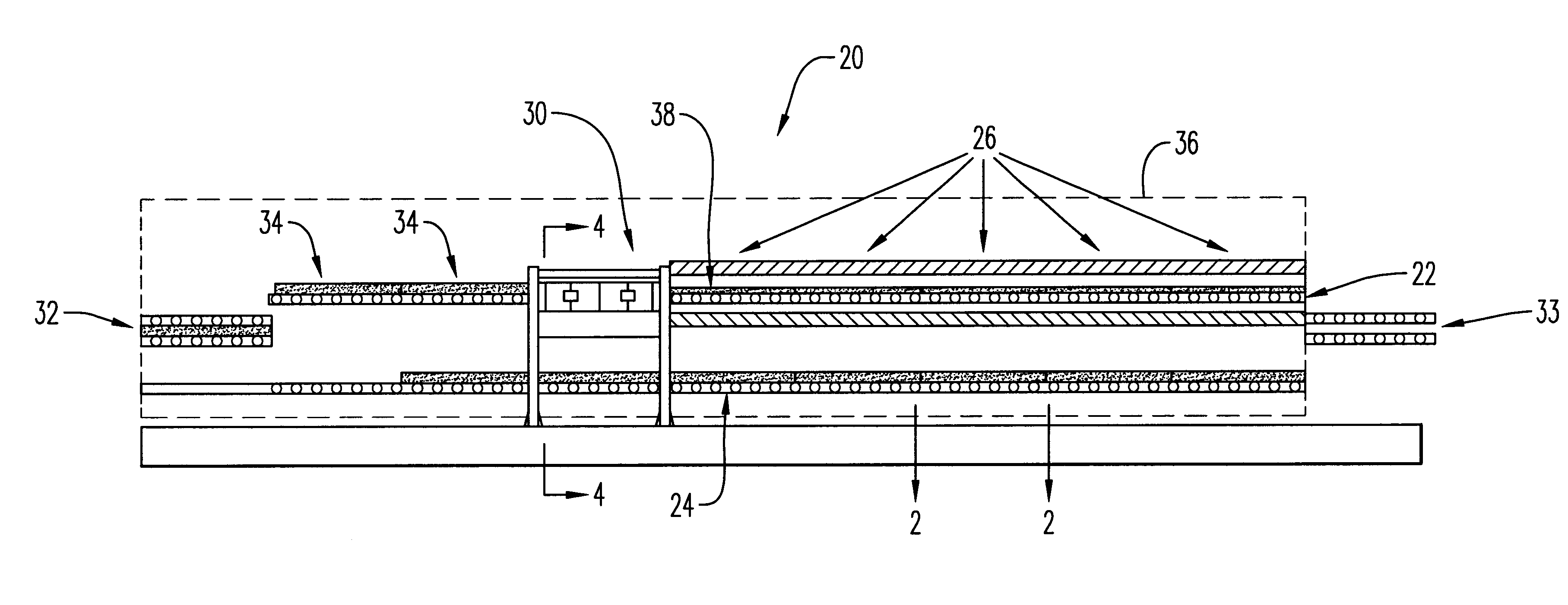

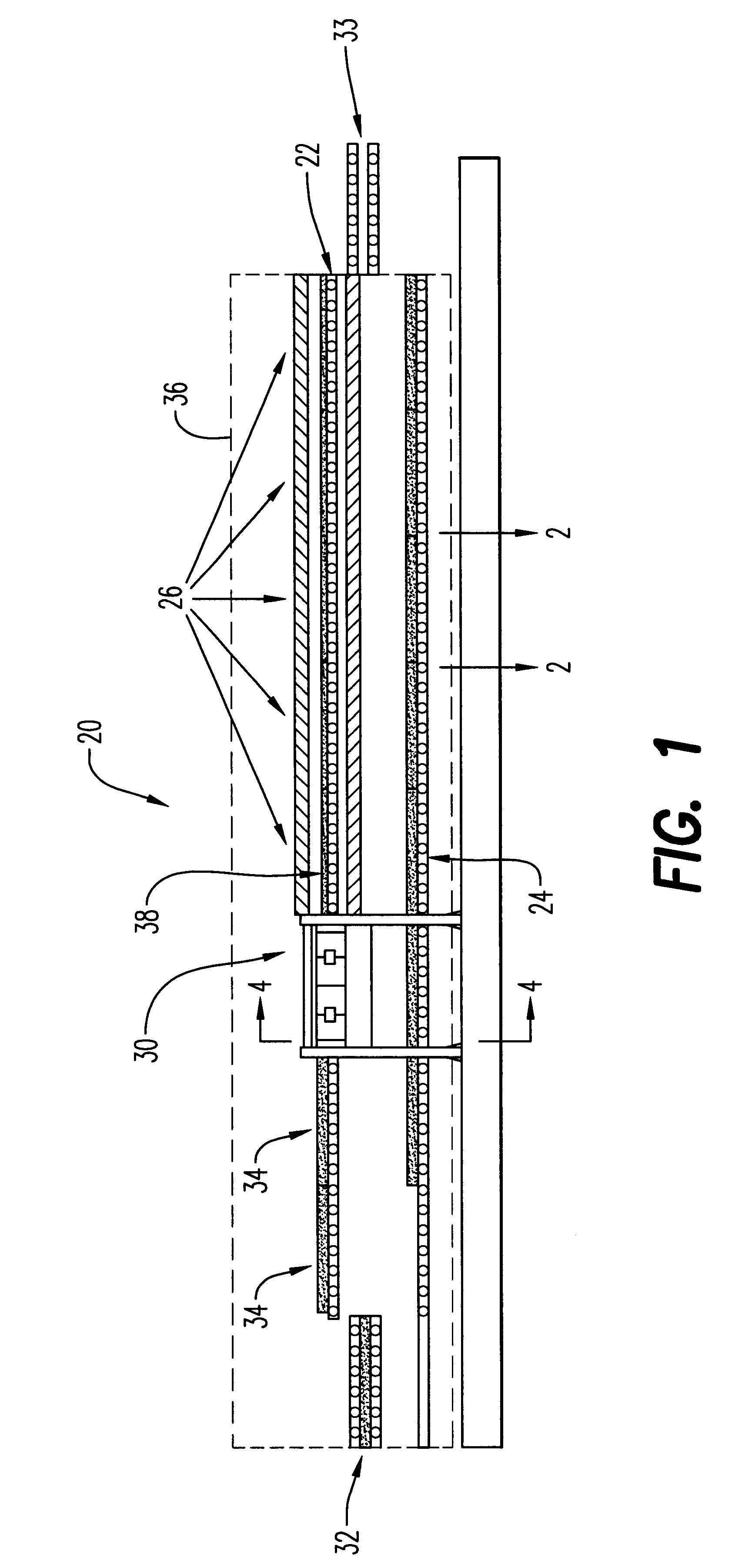

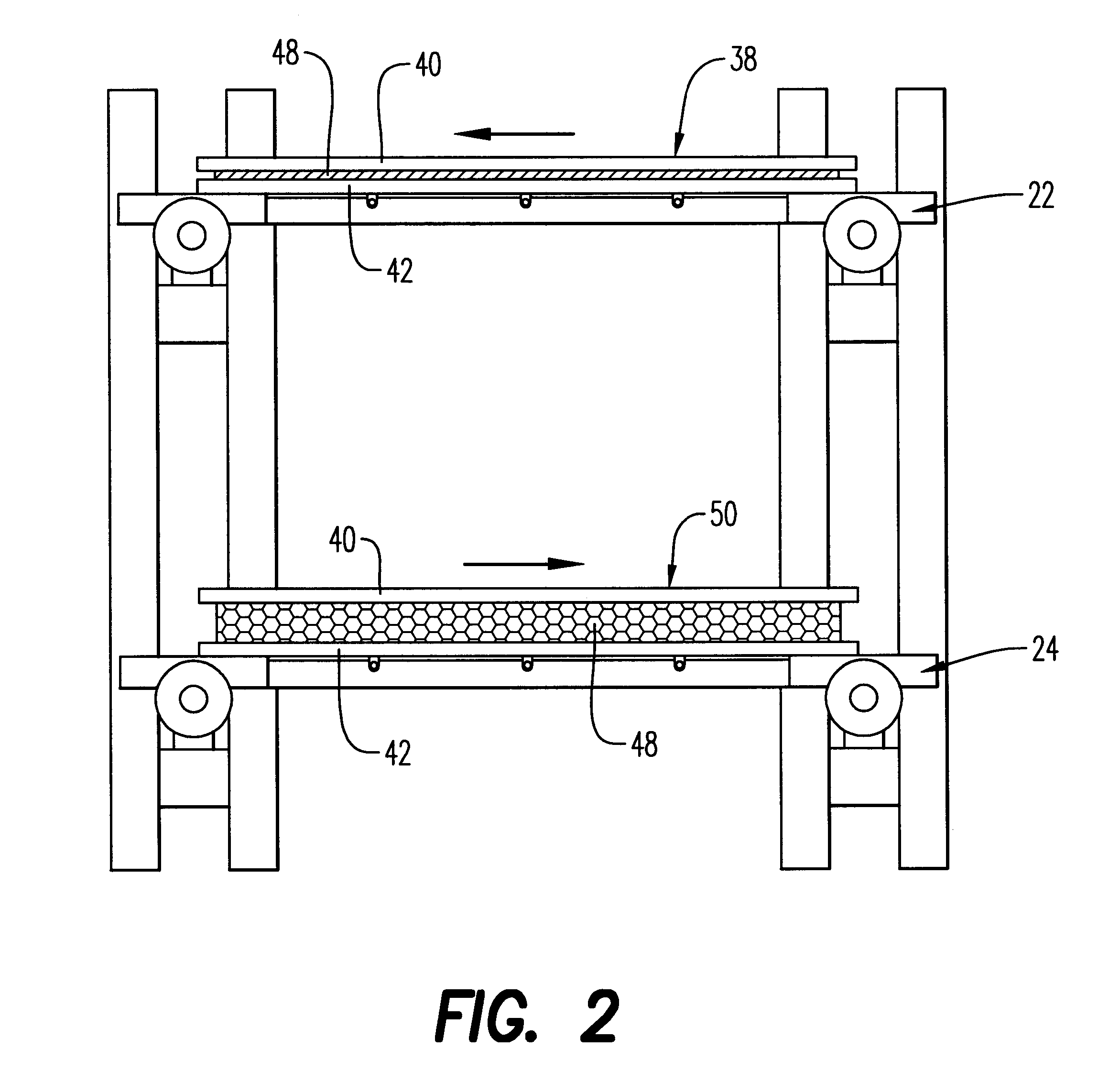

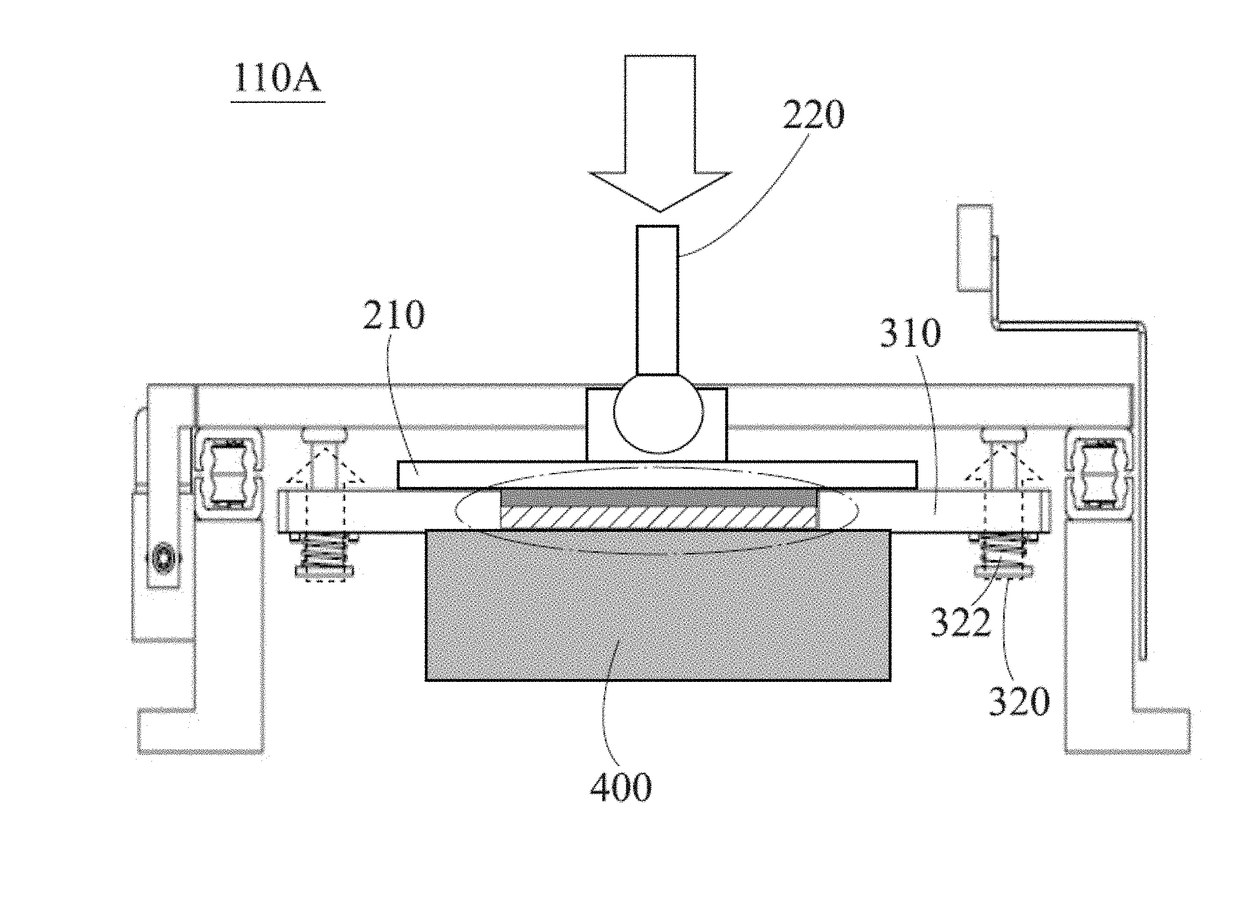

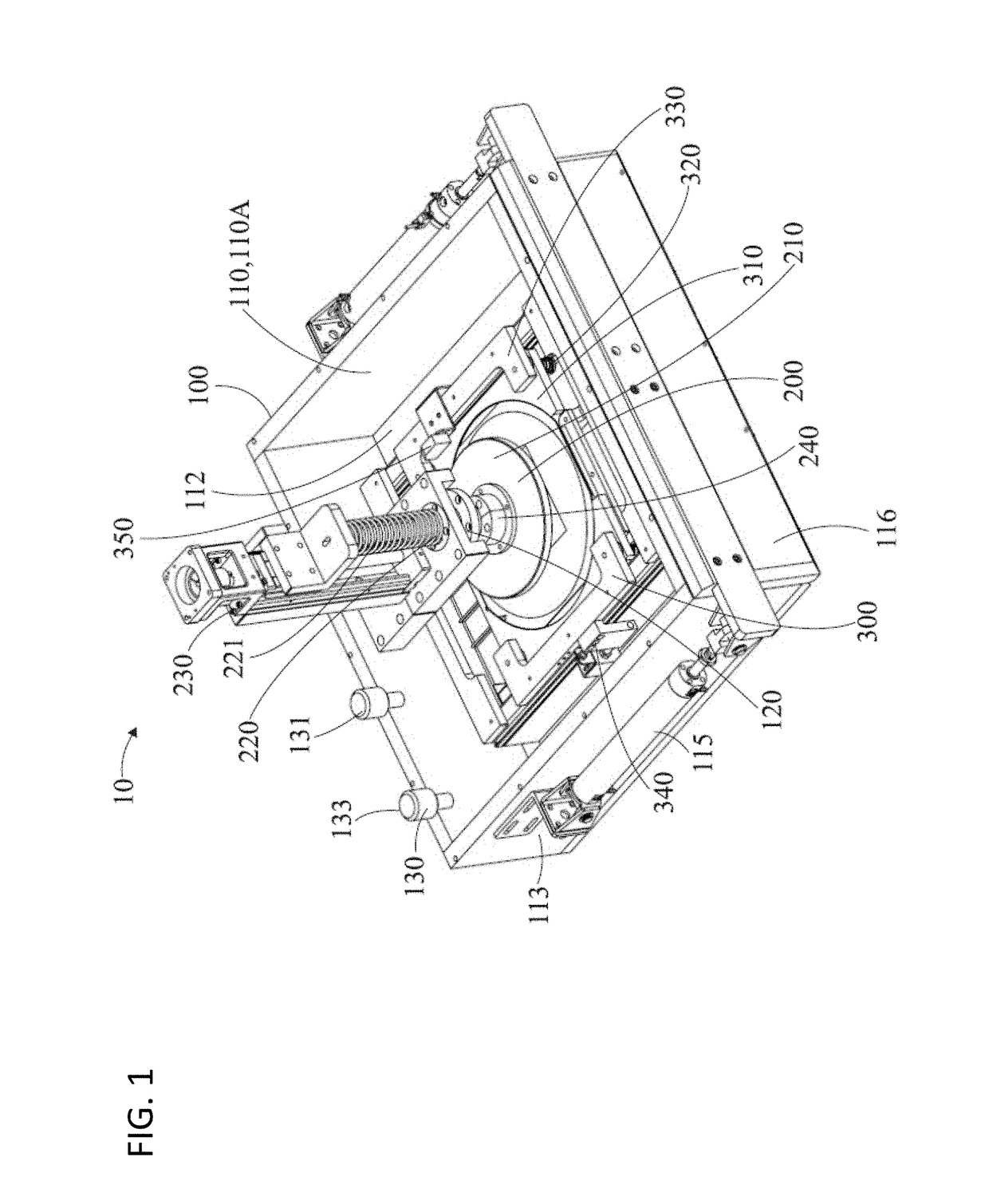

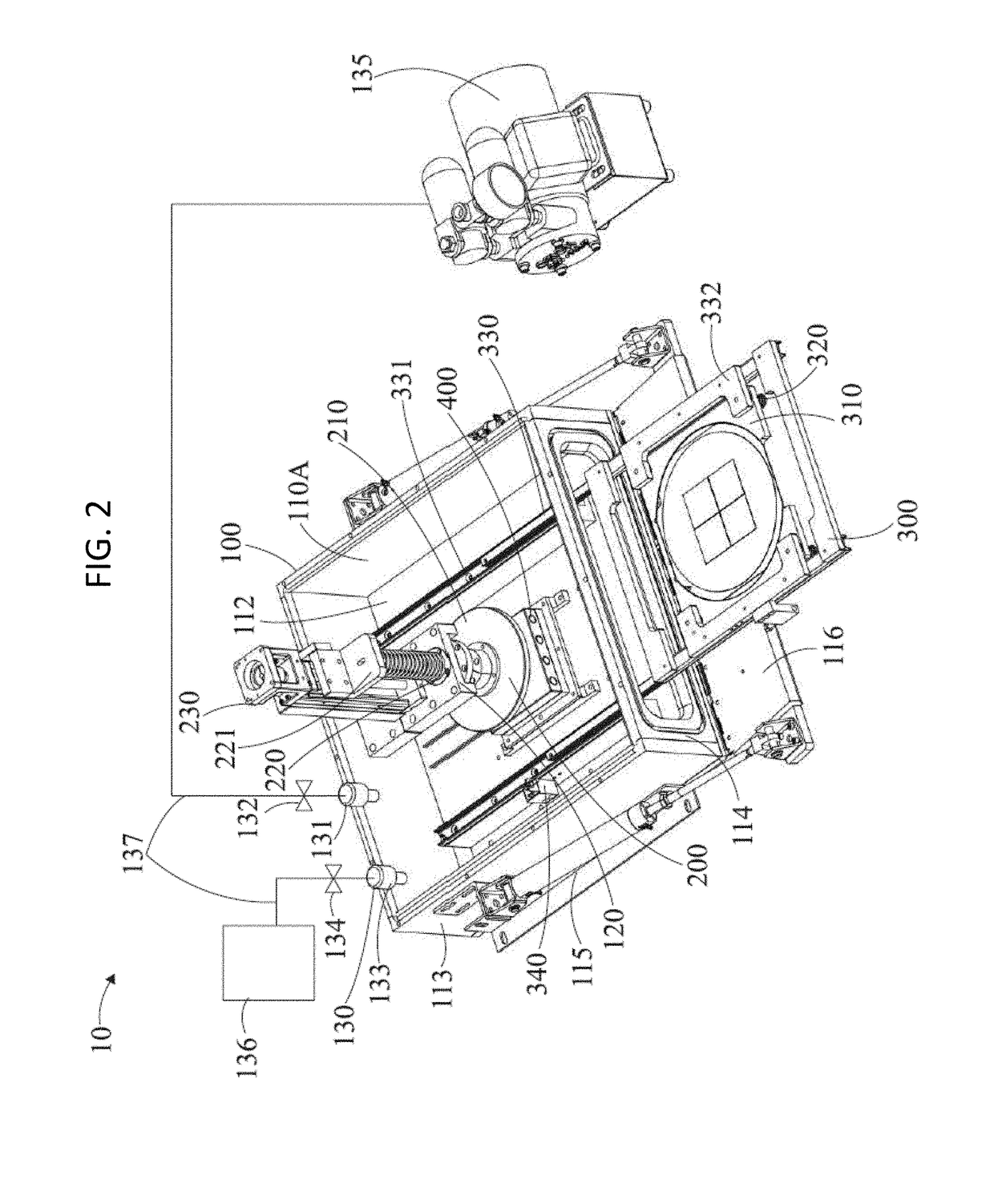

System and method for vacuum film lamination

ActiveUS20180201007A1Avoid and reduce lamination defectImprove production yieldLamination plant layoutLayered product treatmentSusceptorAdhesive glue

A vacuum system for film lamination, including a vacuum chamber module, a film-pressing module, a substrate susceptor module and a hot-plate heating module, is disclosed, wherein the film-pressing module includes a film-pressing platen, and the substrate susceptor module includes a substrate susceptor supported by a spring-loaded mechanism. During a film-lamination process, the film-pressing platen is actuated to move downwards to attach a laminating film onto a substrate, and the substrate susceptor is actuated to move downwards and finally rest on the hot-plate heating module. Therefore an adhesive glue disposed between the laminating film and the substrate can be thermally cured. After completing the film-lamination process, the film-pressing platen is actuated upwards so that the substrate susceptor also is actuated to move upwards to its initial position by a restoring force exerted by the spring-loaded mechanism. In such manner, the laminating film can be properly bonded to the substrate to avoid lamination defects such as air bubbles and to improve adhesion strength.

Owner:MAVEN OPTRONICS CO LTD

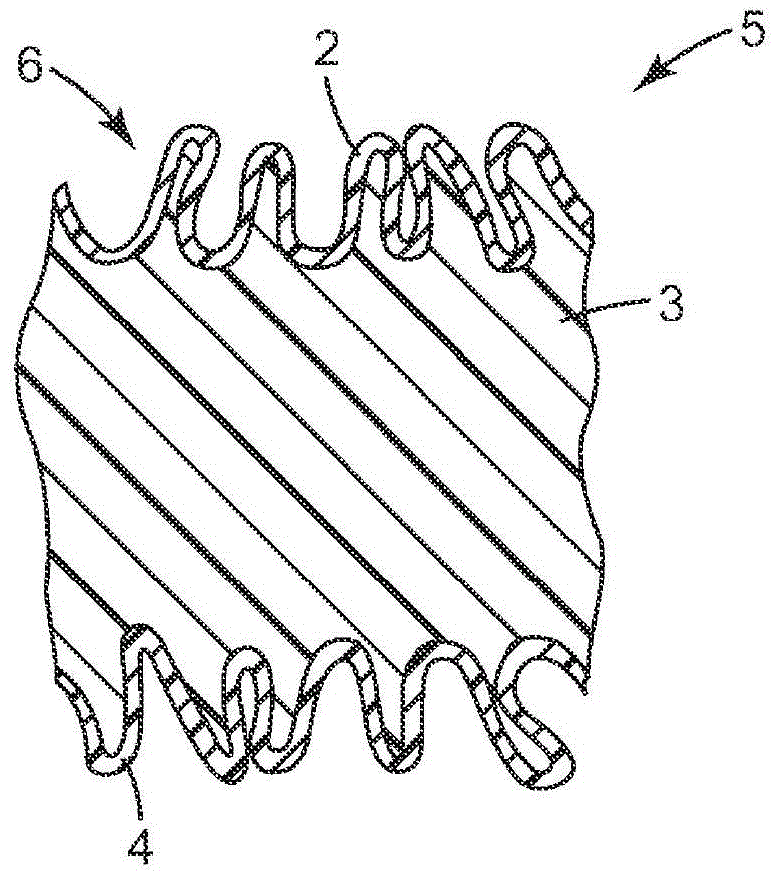

Method of making extensible web laminates

ActiveCN104540679AReduce neckingReduce width variationLamination plant layoutPersonal careElastomerPersonal care

A method of making extensible web laminates comprising a multilayer film and at least one web layer and the use of such extensible web laminates in personal care articles. The method generally includes activating the multilayer film in a first direction by stretching at least a portion of the multilayer film past the elastic deformation limit of the skin layers and recovering the skin layers with the elastomeric core layer to produce a multilayer film that is elastic in the first direction. The activated multilayer film is subsequently stretched beyond the deformation limit of the skin layers in a second direction substantially perpendicular to the first direction. At least one web layer is applied to the multilayer film while in the stretched state. The multilayer film is then recovered to produce an extensible web laminate.

Owner:3M INNOVATIVE PROPERTIES CO

Method and device for producing laminate

Owner:INST OF TECH PRECISION ELECTRICAL DISCHARGE WORKS

Inorganic veneer insulation decorative board and continuous production method thereof

ActiveCN104631738AImprove adhesionImprove product qualityLamination plant layoutCovering/liningsTemperature controlProduction line

The invention relates to an inorganic veneer insulation decorative board and a continuous production method thereof, and belongs to the technical field of building materials. The method comprises the steps that a continuous production line composed of a high / low pressure foaming machine system, a front conveying table, a rear conveying table, a dual-track laminating machine system, a coiled material uncoiling mechanism and a casting table is adopted, firstly, polyurethane insulation component materials are added into a charging bucket as needed to conduct temperature control, coiled materials are installed on the coiled material uncoiling mechanism, the inorganic decorative board is placed on the front conveying table for operation delivery, and the mixed component materials are distributed on the inorganic decorative board through a gun head of the high / low pressure foaming machine system; after the material distribution is finished, the inorganic decorative board is fed into the dual-track laminating machine system, forming and curing of the insulation component materials are completed in the dual-track laminating machine system, insulation layers, the inorganic decorative board and the coiled materials are combined and formed, and finished products are guided out through the rear conveying table. According to the inorganic veneer insulation decorative board and the continuous production method of the inorganic veneer insulation decorative board, a traditional technology is changed, continuous production of the polyurethane insulation decorative board is initiatively achieved on the polyurethane insulation board continuous production line, the technology is simple, the production efficiency is high, the product quality is stable, and the cost and energy consumption are greatly lowered.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

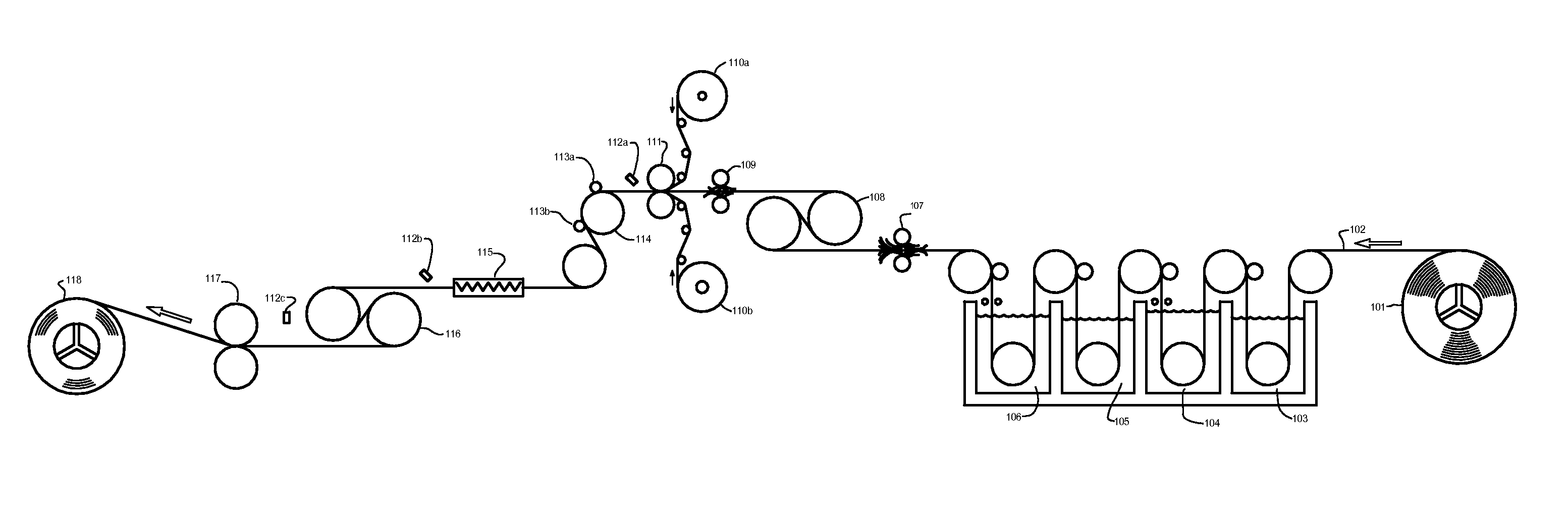

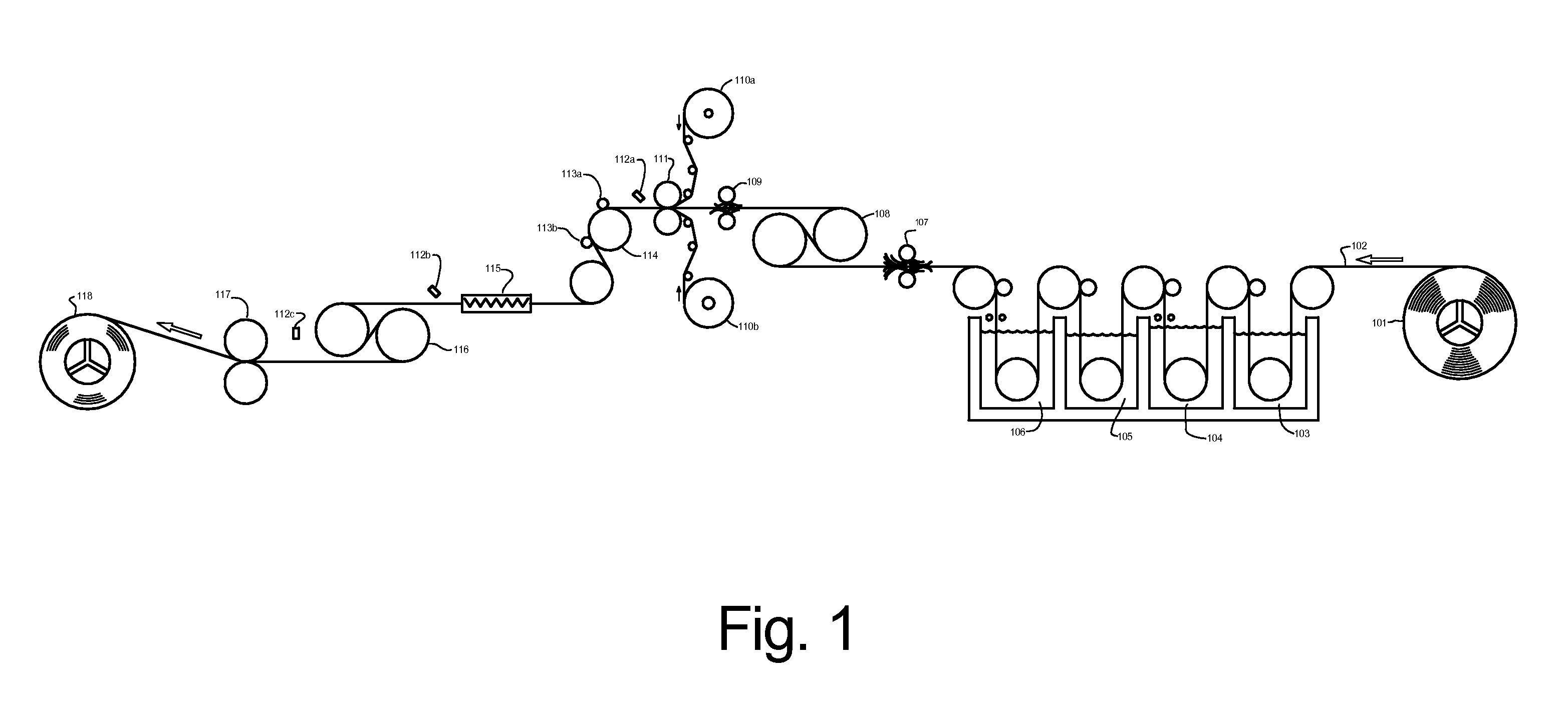

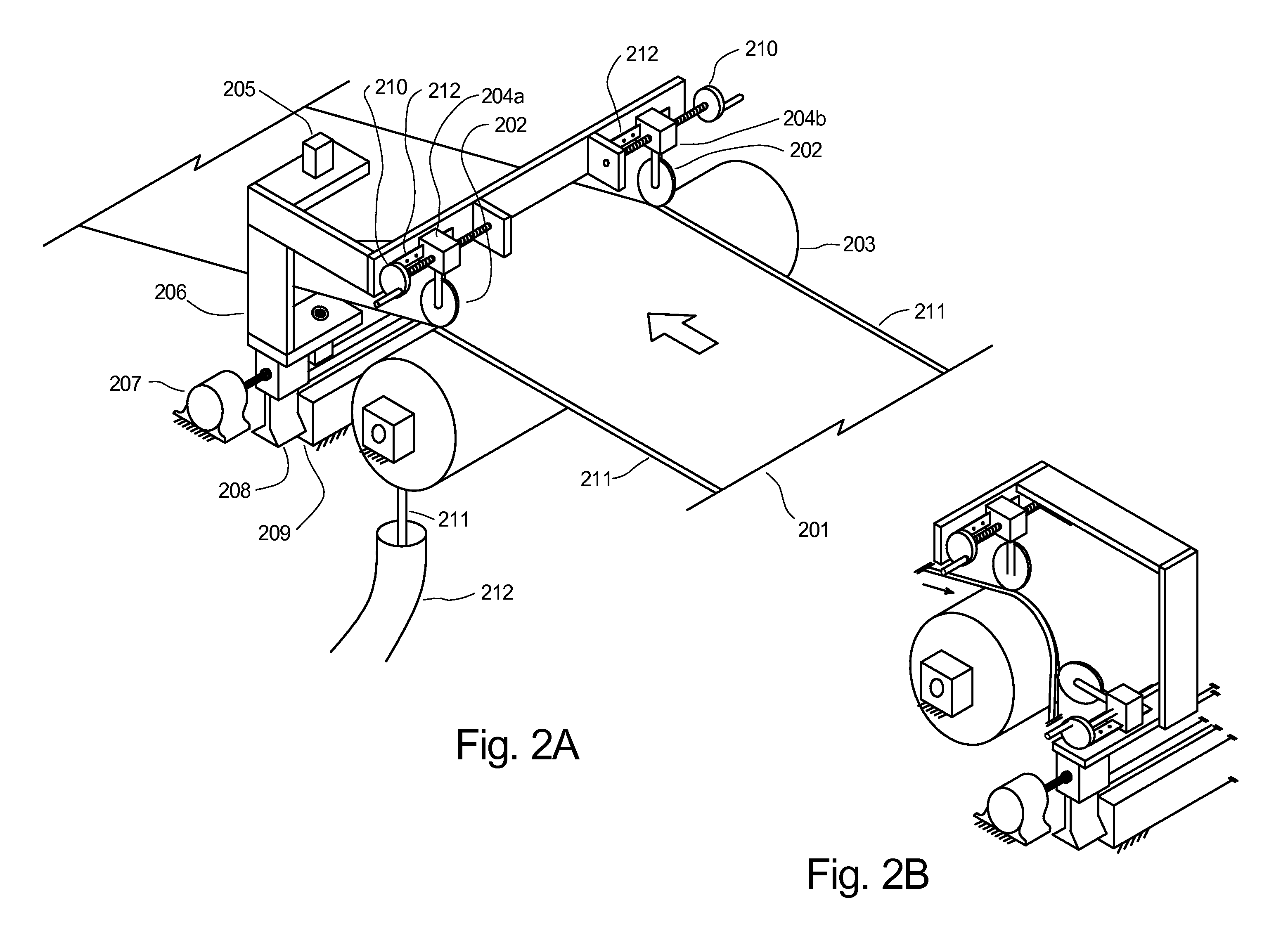

Operating methods for a batch commercial metal coil laminating line

ActiveUS7678213B1Low and competitive operational costOptimize laborLamination plant layoutAdhesive processesProduction lineControl system

Important features and improvements of a commercial coil batch laminating production line are disclosed for a successful, commercial, and economical operation. This invention addresses important processing sequences, operating parameters, control systems, designs, operating methods, and other novel features. This invention provides for a competitive cost structure meeting the needs of commercialization.

Owner:POLYTECH AMERICA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com