Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve stacking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

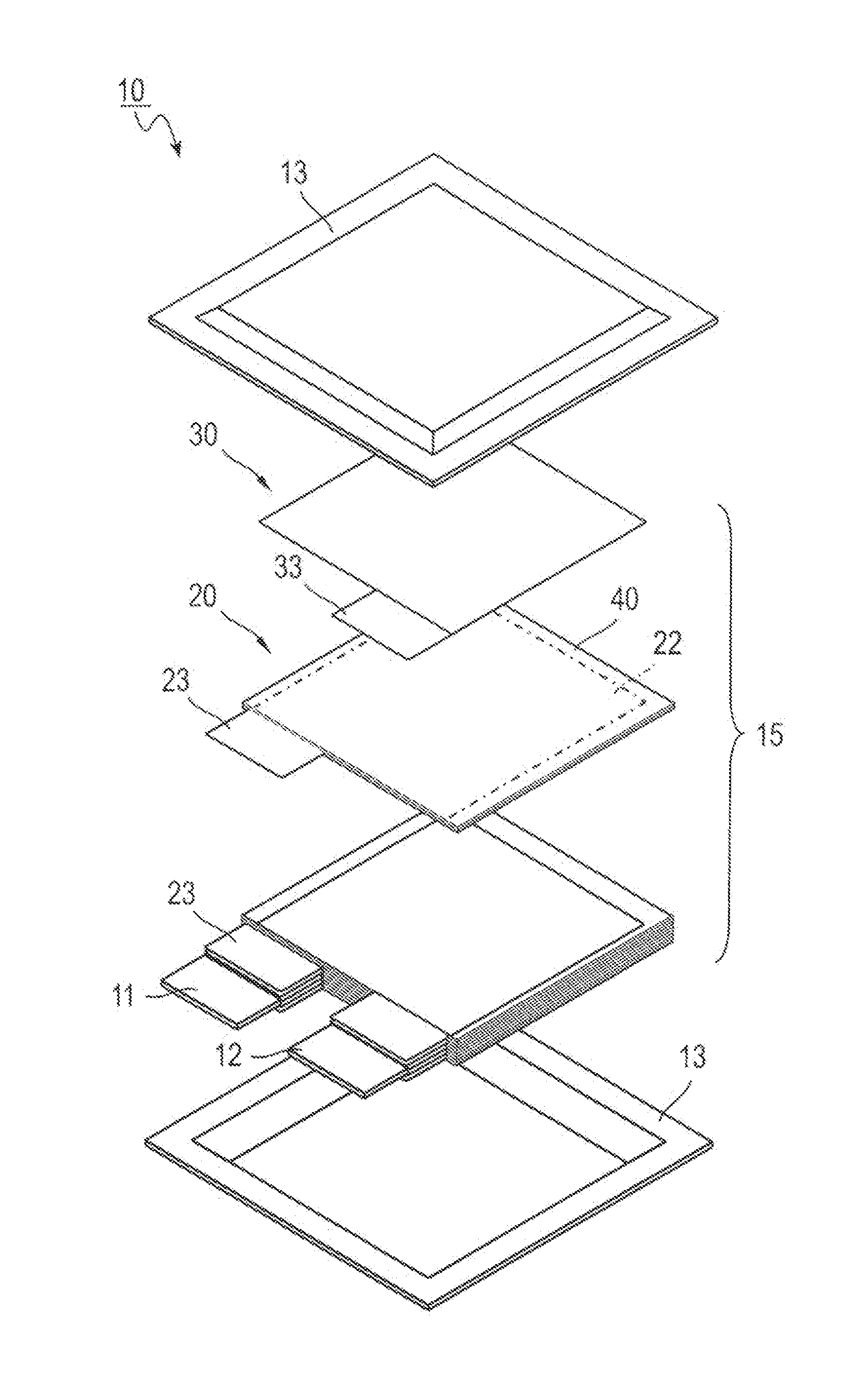

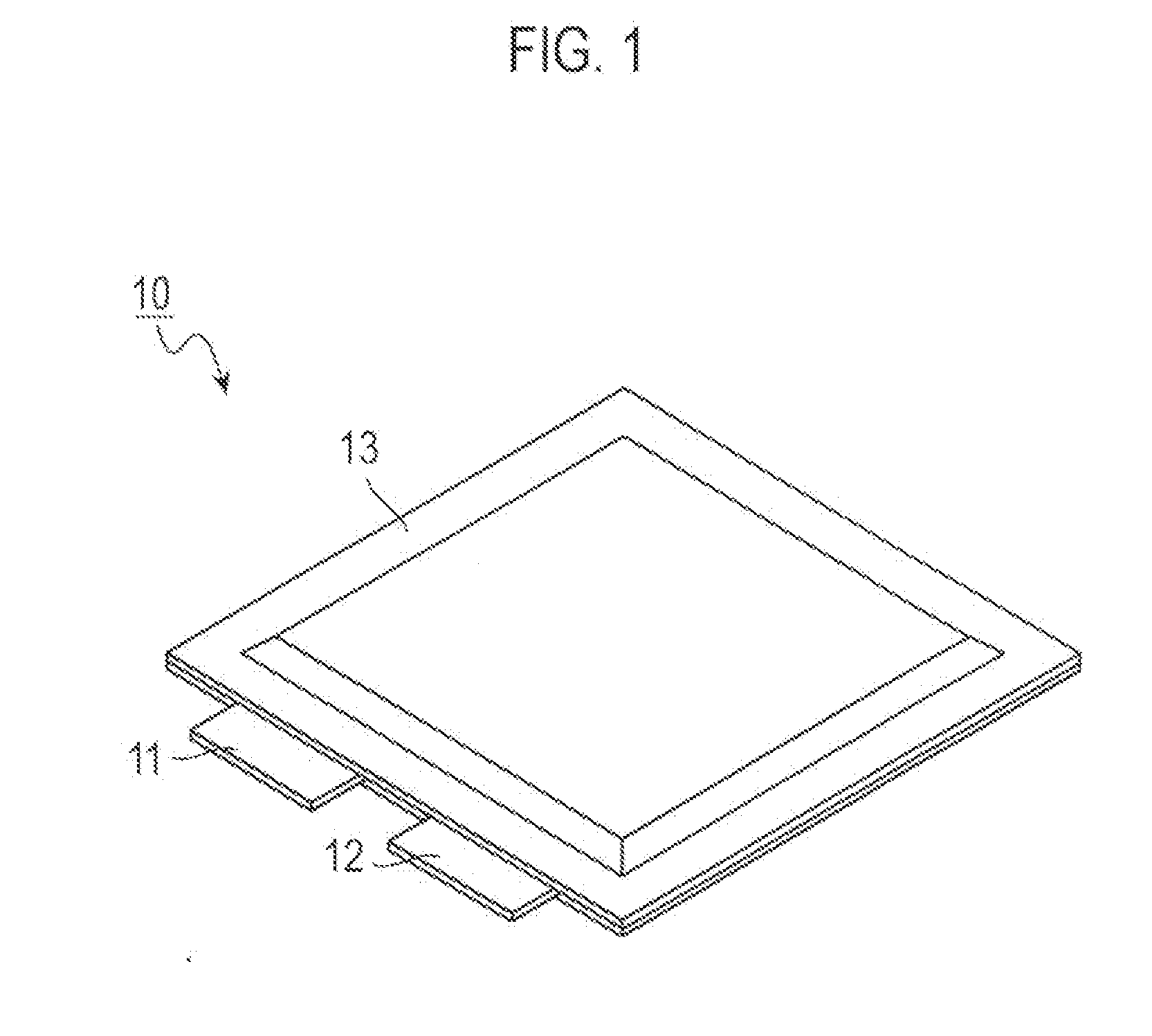

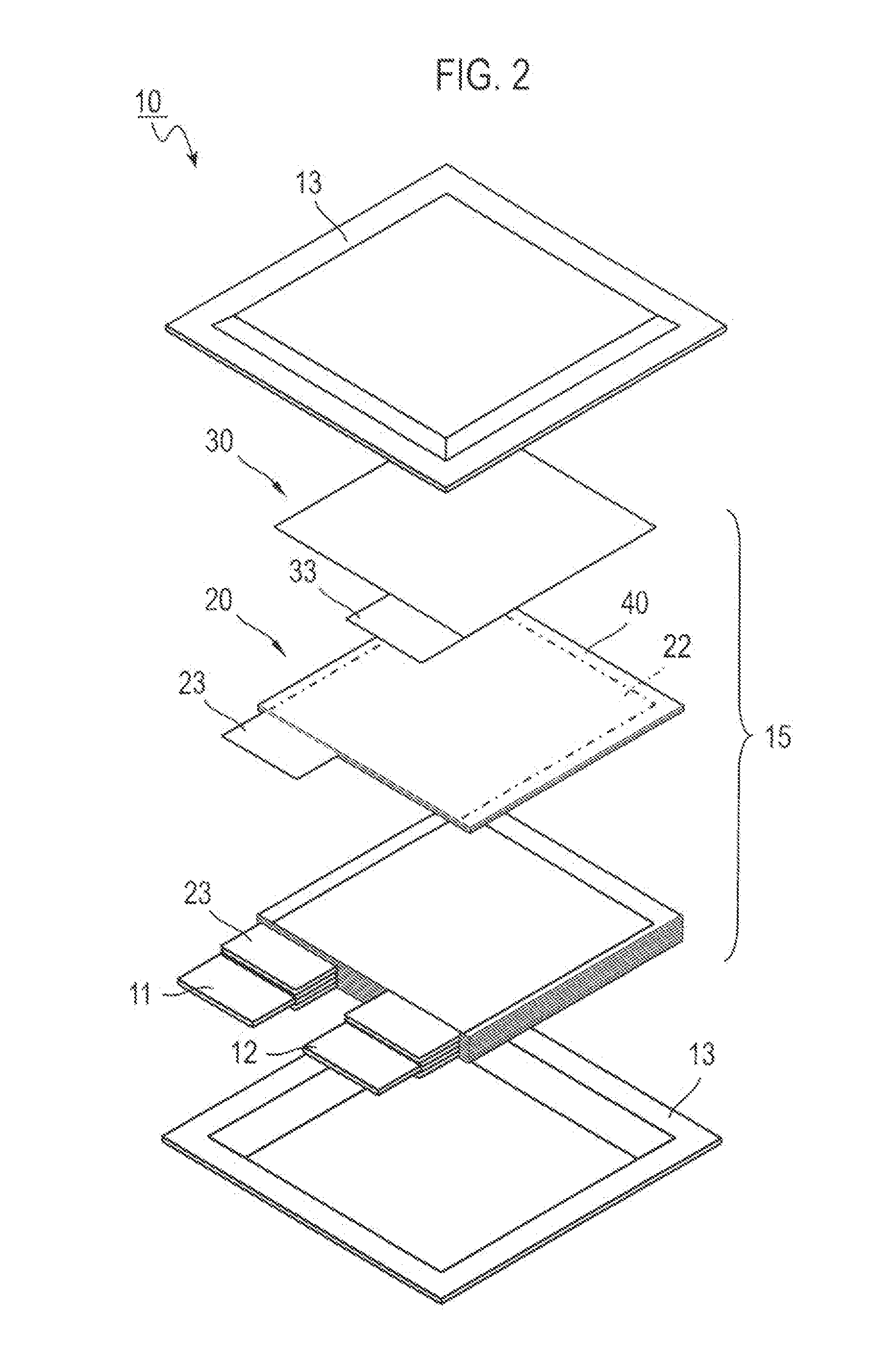

Electronic component and manufacturing method thereof

InactiveUS20090166431A1Improve sealingImprove reliabilityPrinted circuit aspectsSolid-state devicesSemiconductor chipInterposer

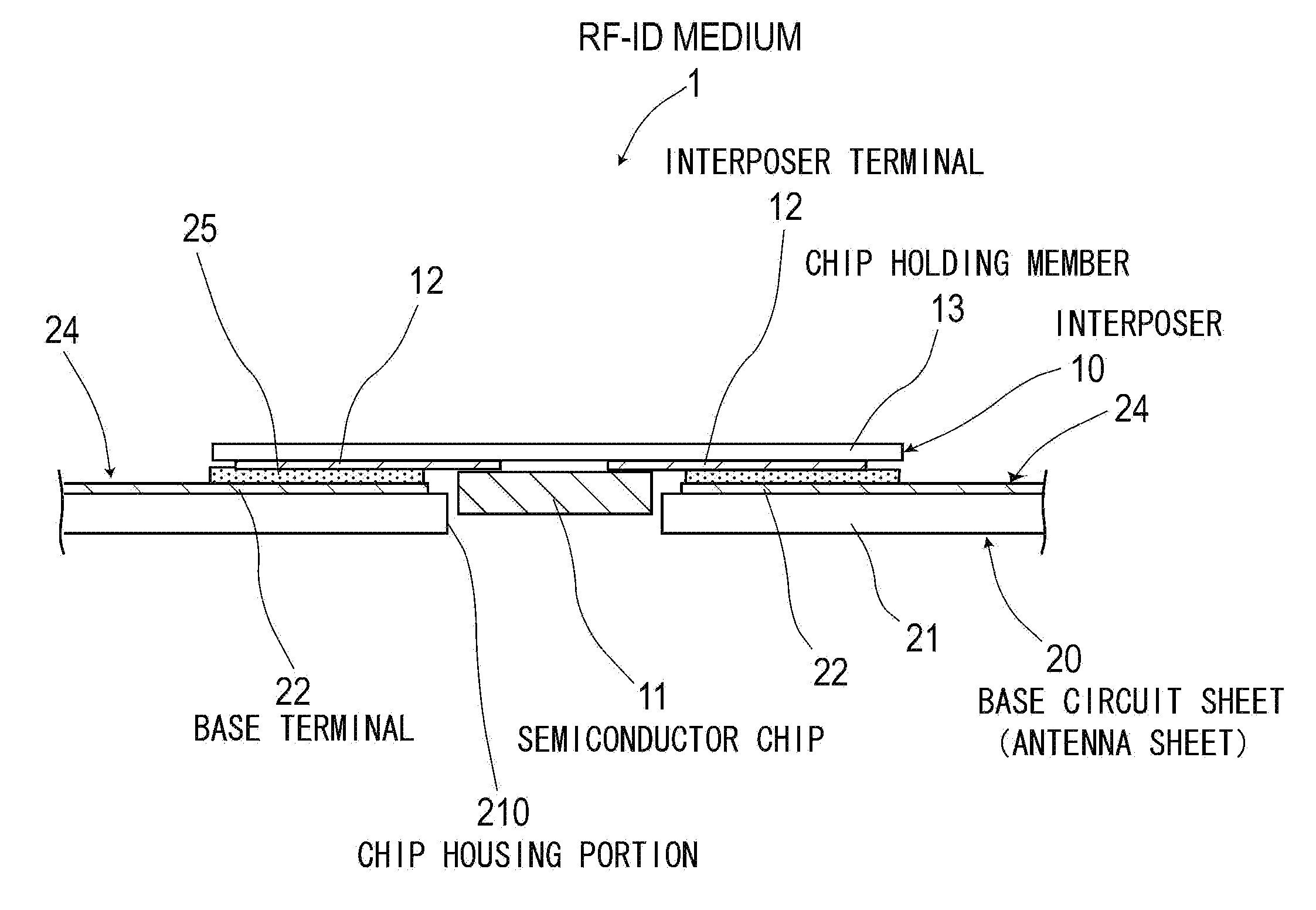

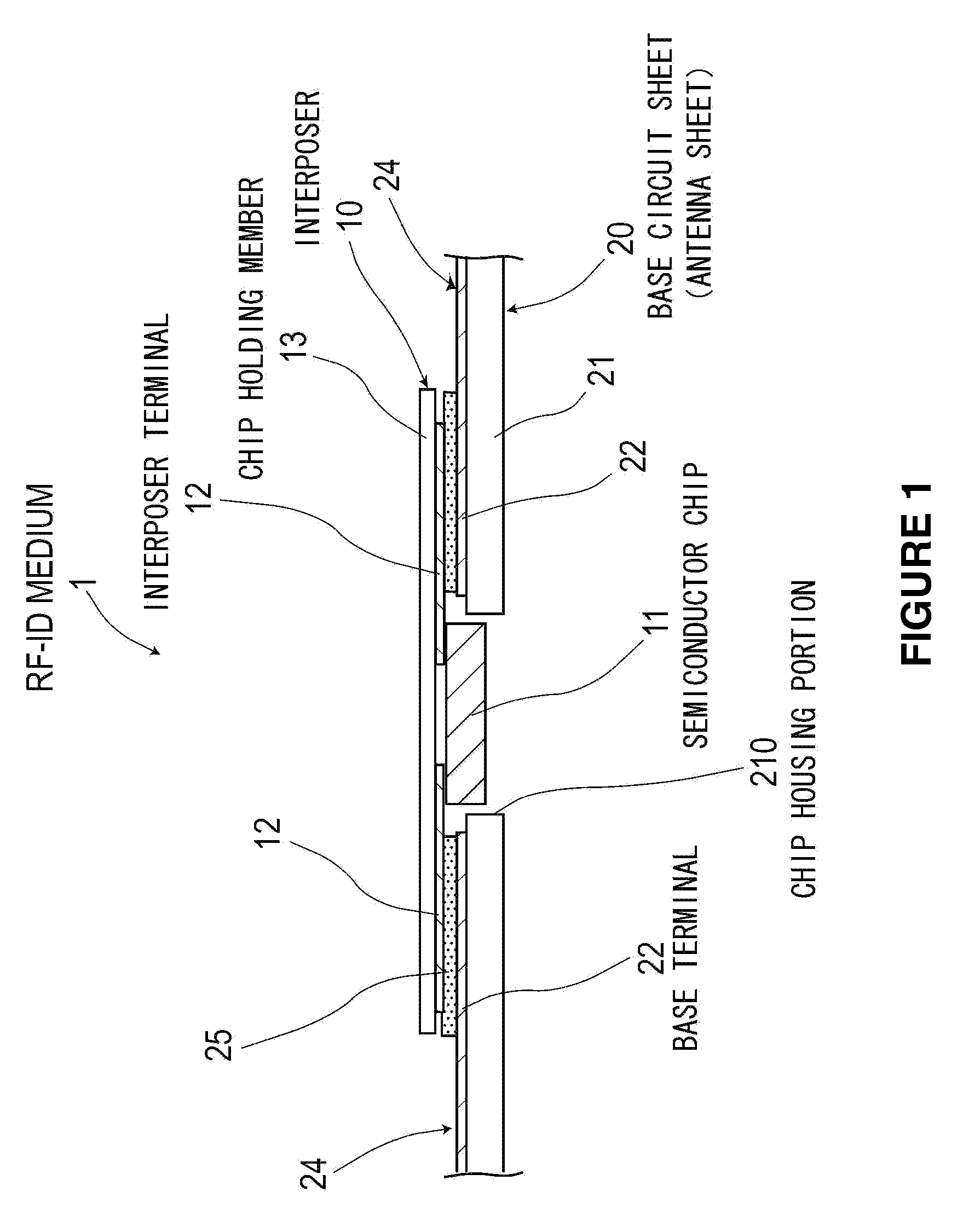

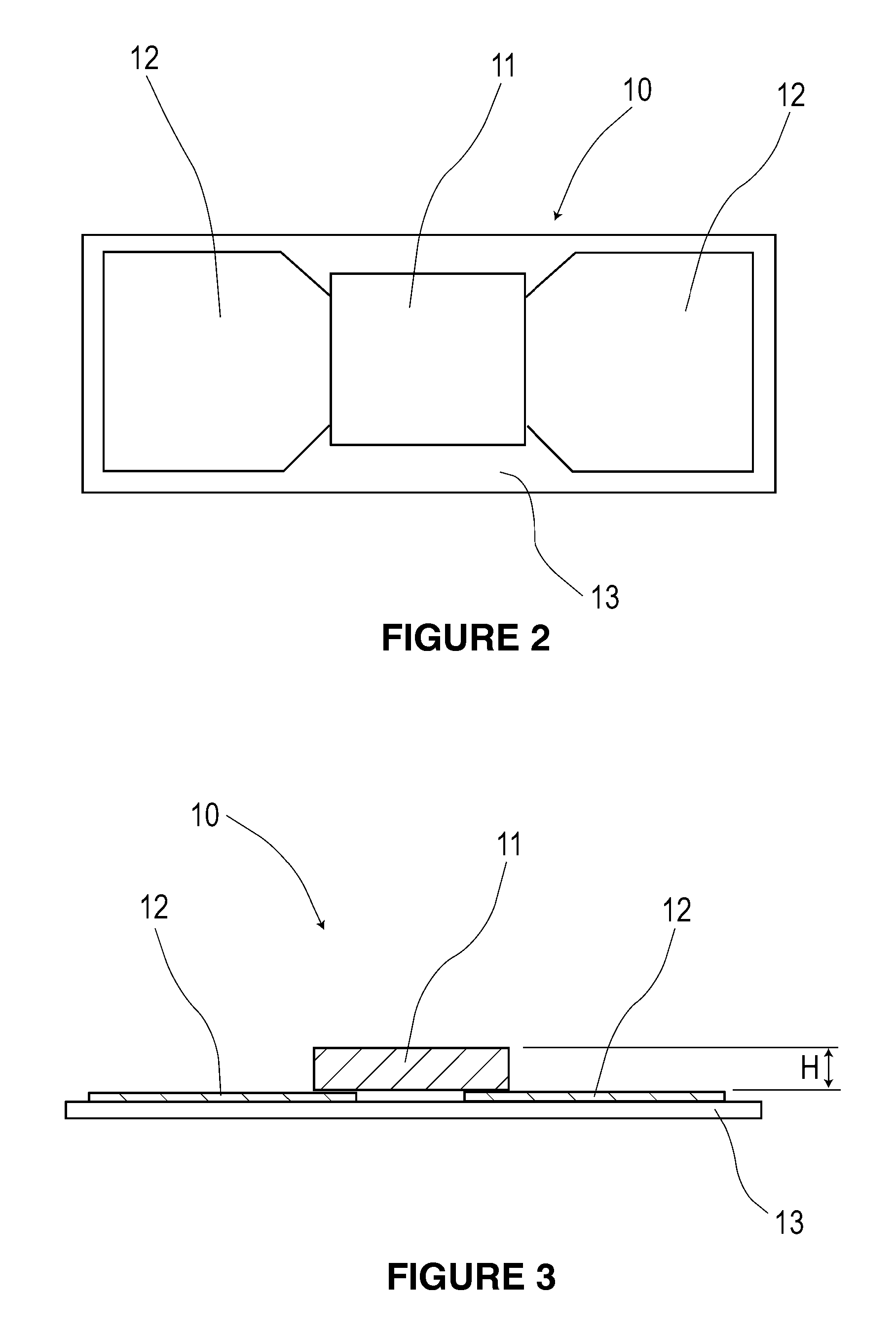

The invention relates to an RFID medium 1 in which an interposer 10 having a semiconductor chip 11 mounted on a sheet-like chip holding member 13 is bonded to a sheet-like base circuit sheet 20. The interposer 10 has the IC chip 11 mounted on a substantially planar surface of the chip holding member 13, and an interposer terminal that is electrically extended from a terminal of the IC chip 11. The base circuit sheet 20 has a base terminal 22 electrically connected to the interposer terminal 12, and has a through chip housing portion 210 for housing the semiconductor chip 11 on the interposer 10.

Owner:HARRIS CORP

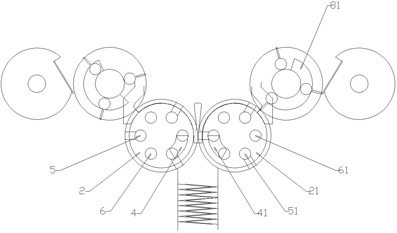

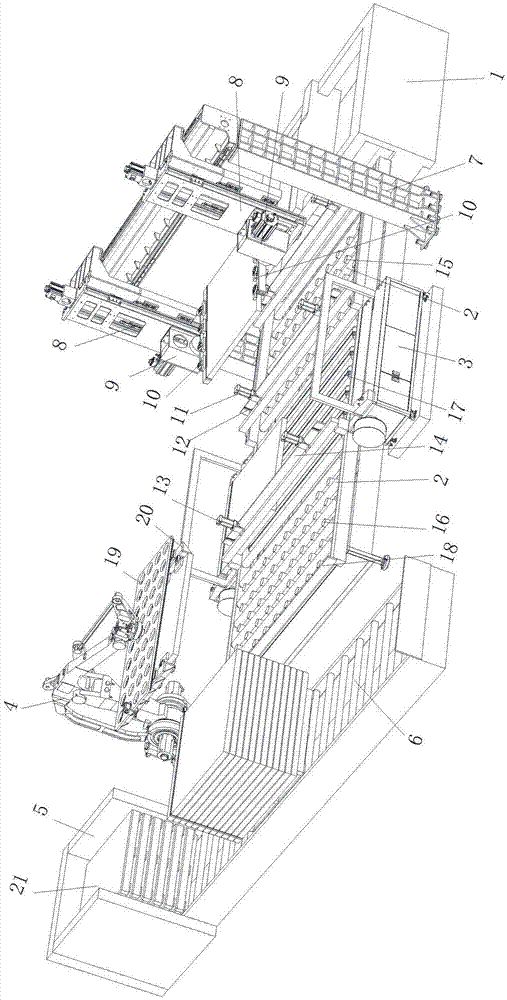

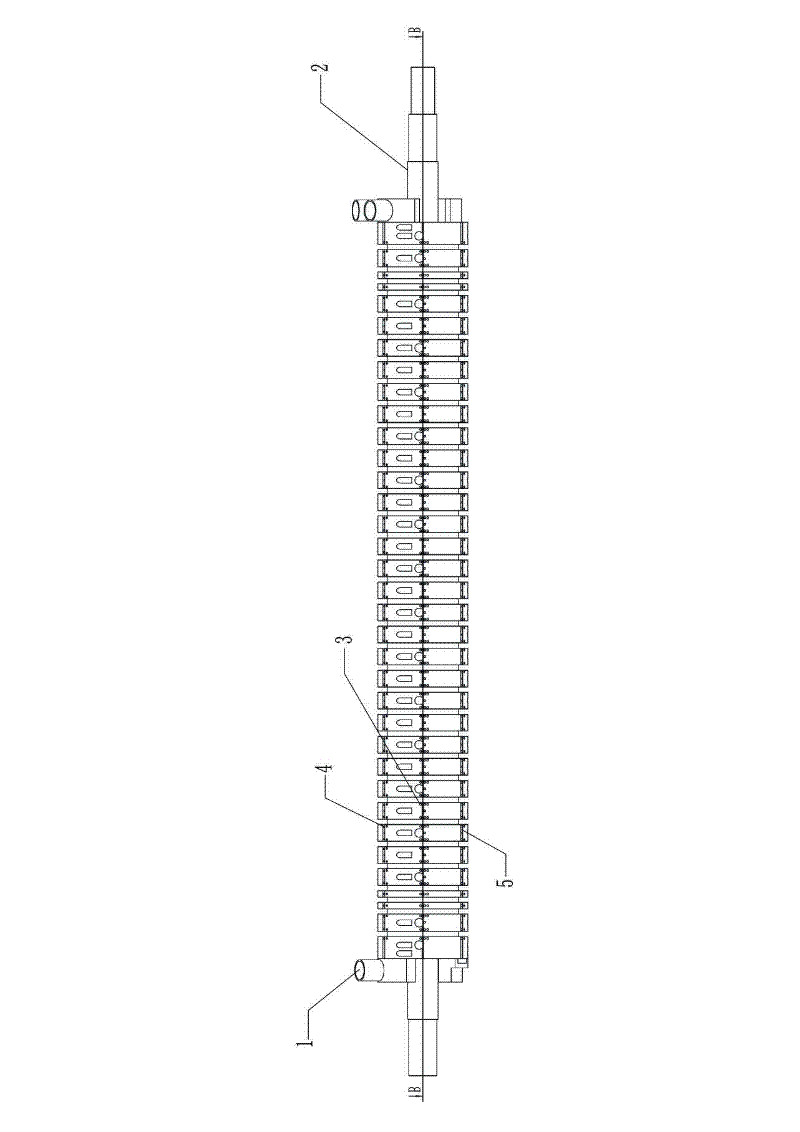

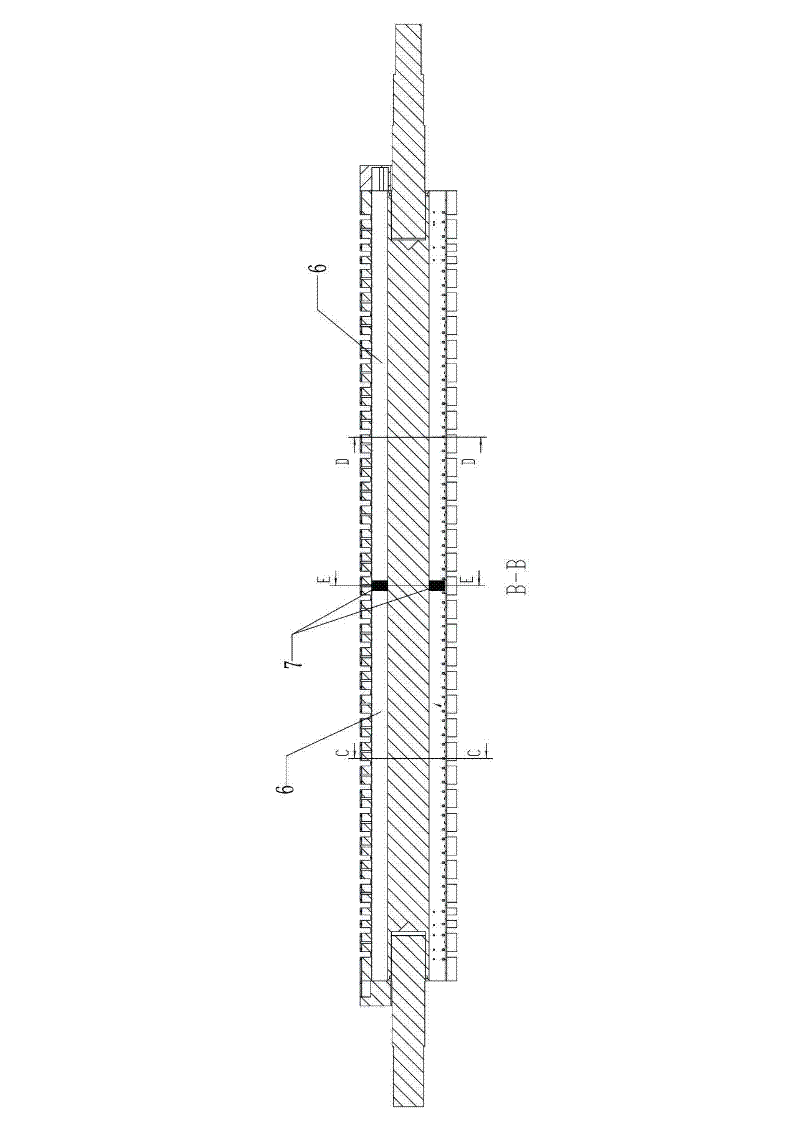

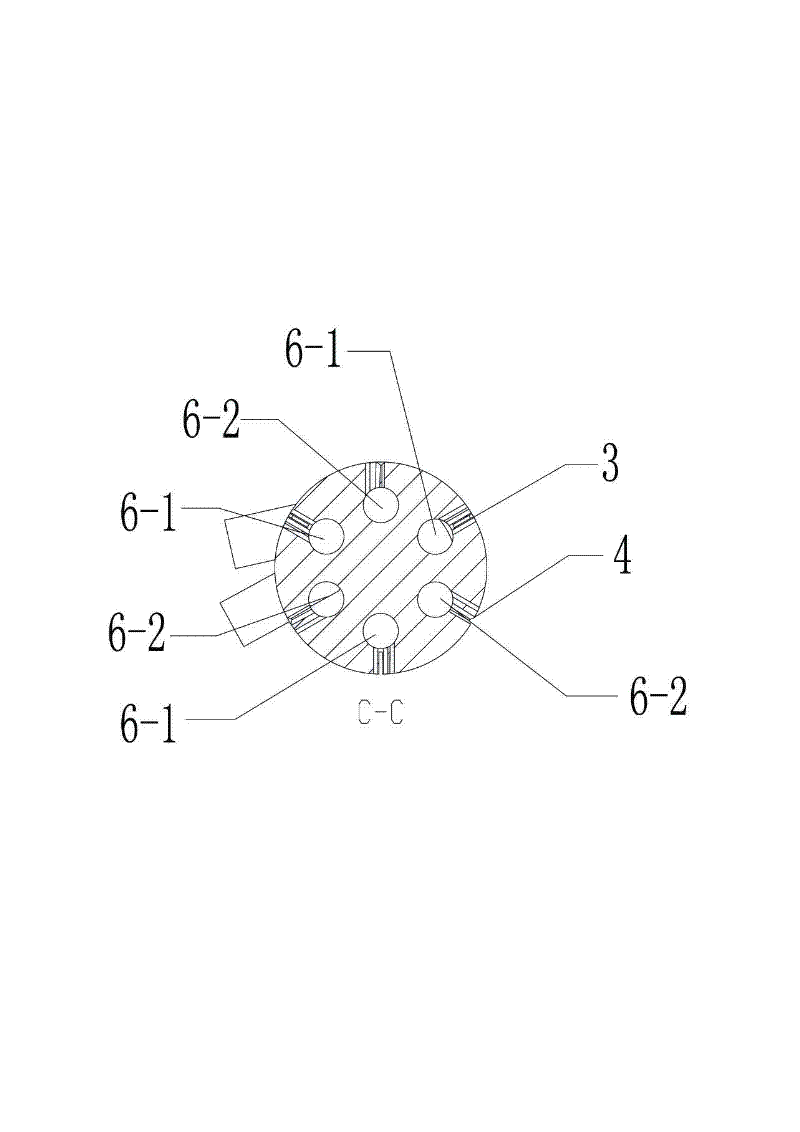

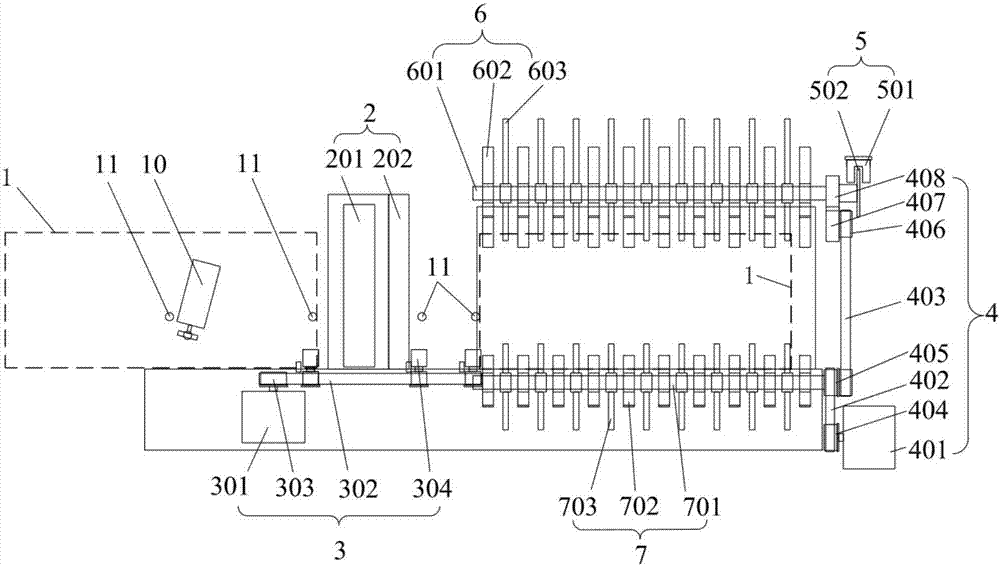

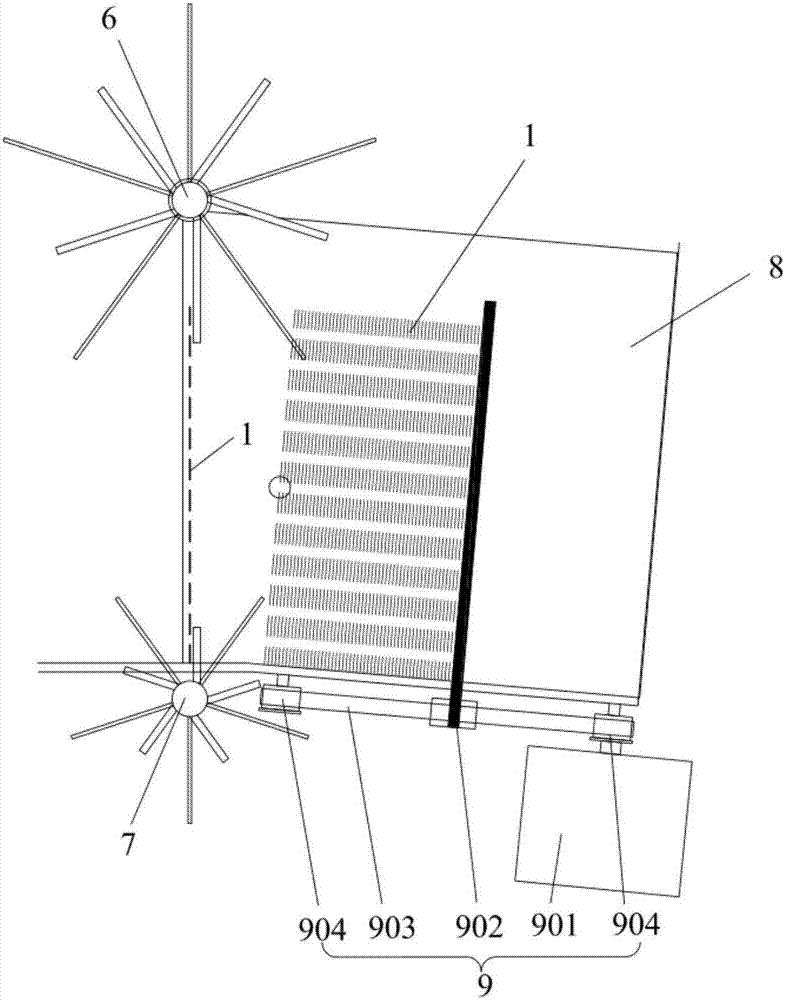

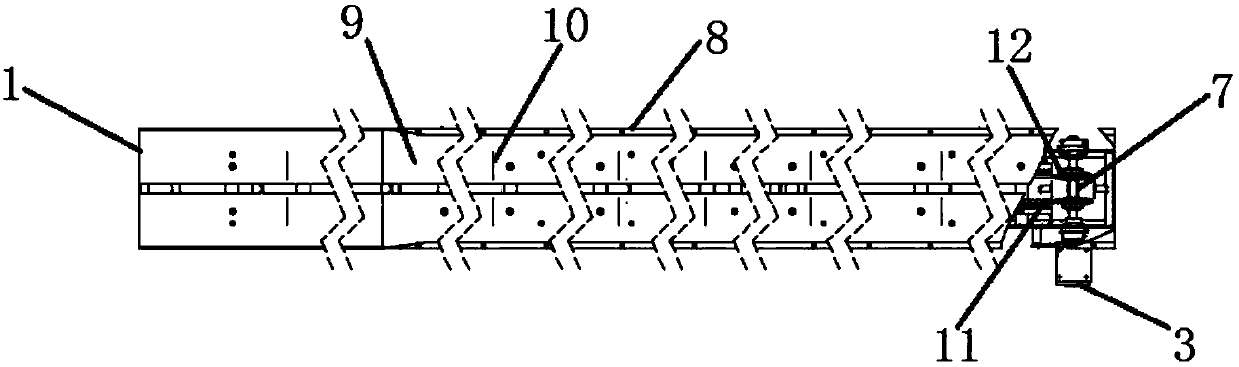

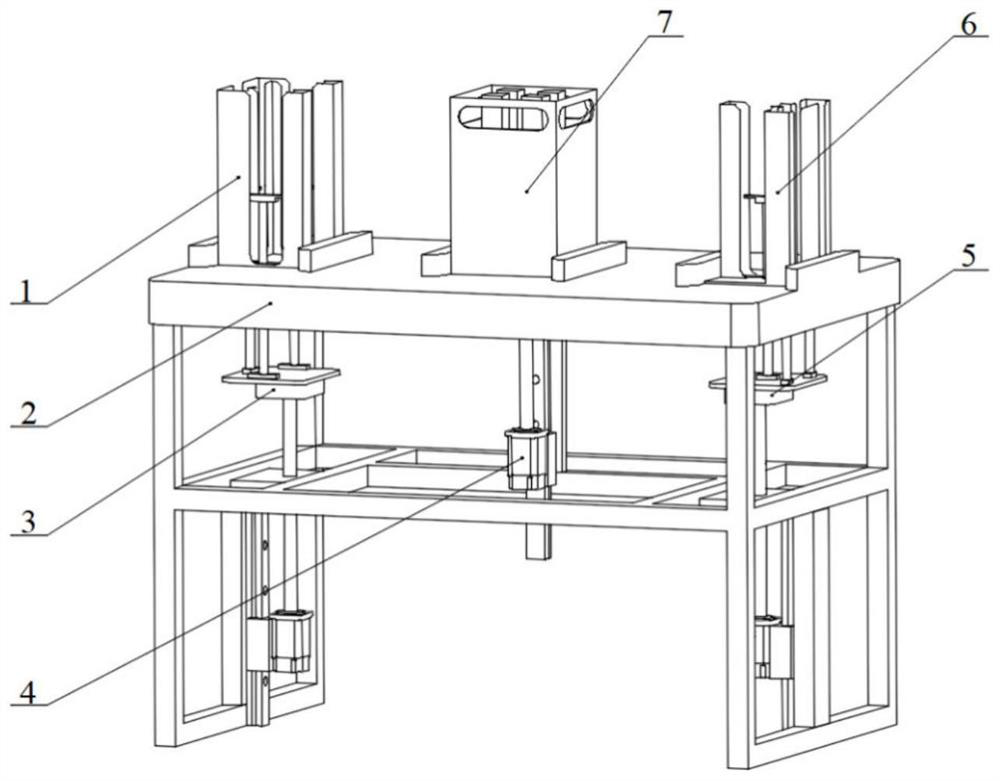

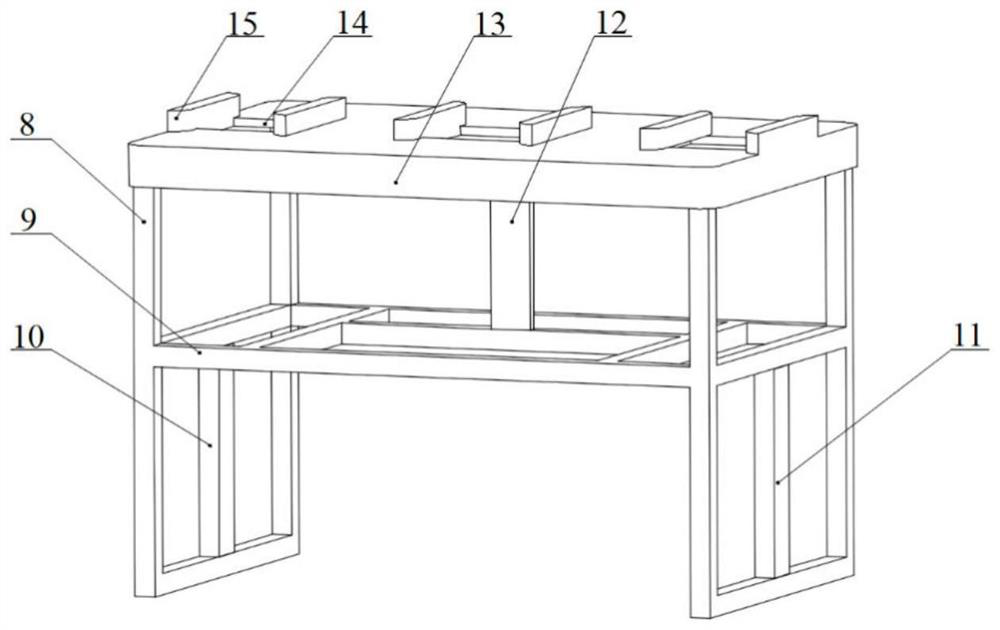

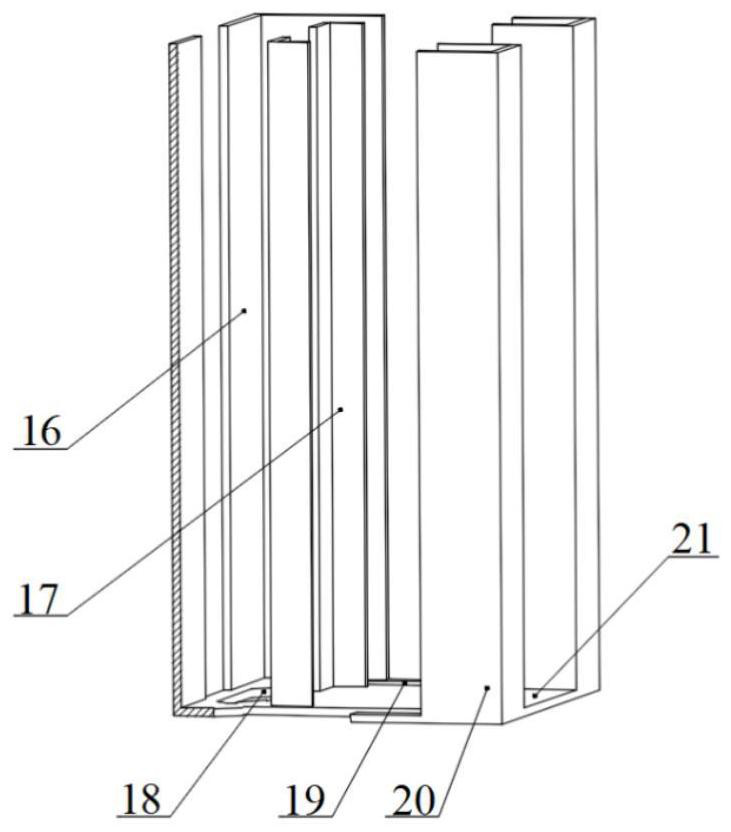

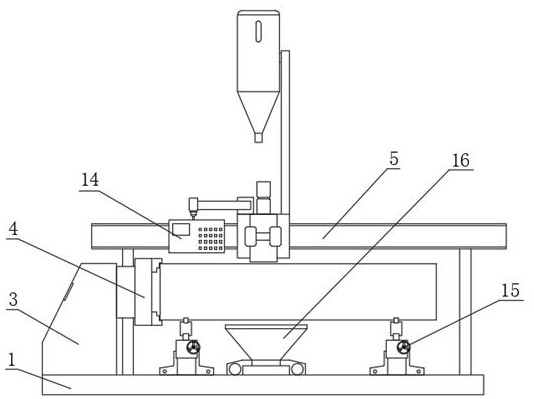

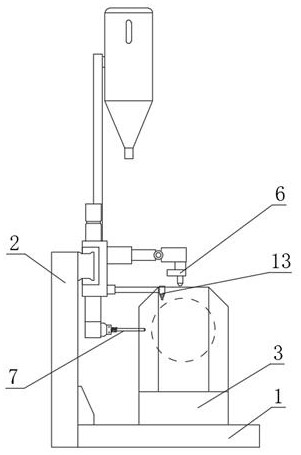

Automatic external laminating method and automatic external laminating device of motor stator core

ActiveCN106849533AImprove stacking accuracyEfficient separationManufacturing stator/rotor bodiesPunchingEngineering

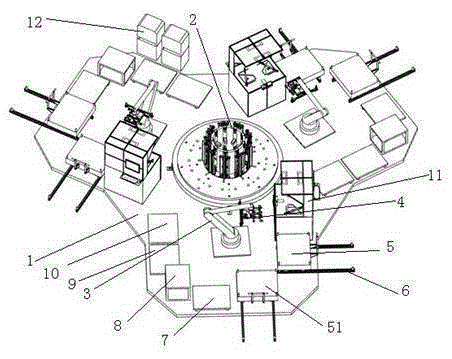

The invention discloses an automatic external laminating method and an automatic external laminating device of a motor stator core. The device comprises a working table (1), robots (3), centering tables (11), a laminating location table (2) and punching sheet material discs (5), wherein the laminating location table (2) is arranged in the center of the working table (1); the working table (1) is equally divided into three parts; each part is provided with one robot (3); tail end suction discs (4) are arranged at the ends of the robots (3); and the centering tables (11), the punching sheet material discs (5), iron sheet material discs (7), waste material discs (8), ventilation slot plate material discs (9) and compensating sheet material discs (10) are arranged around the robots (3). According to the method and the device, laminating of the core is accomplished by mechanical, automatic and standard movement, so that an error caused by a human factor is effectively reduced; a dust-free requirement of a laminating environment can be ensured; and the laminating efficiency can be improved.

Owner:DONGFANG ELECTRIC MACHINERY

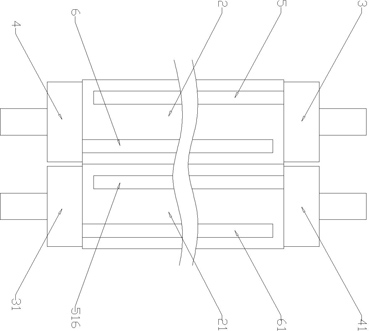

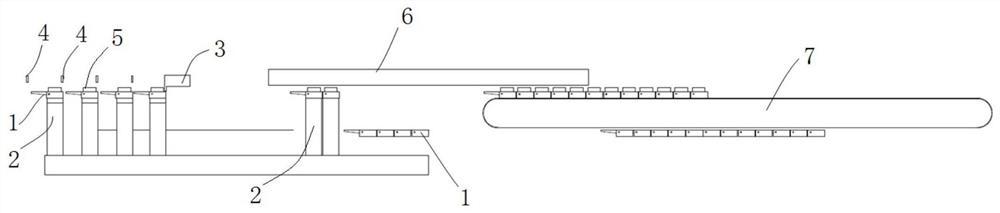

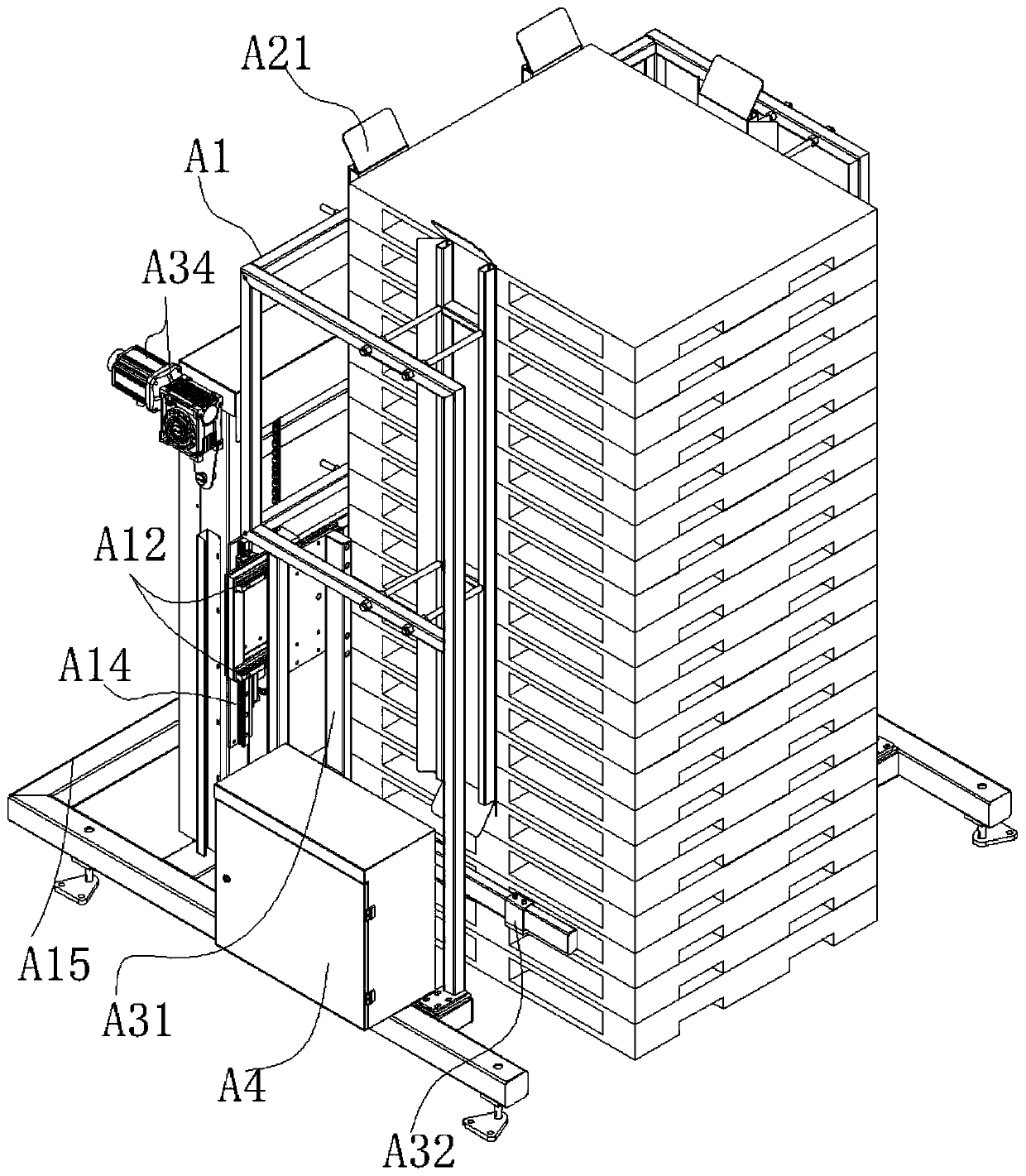

Stacking device and stacking method

ActiveUS20140026398A1Improve stacking accuracyImprove accuracyLamination plant layoutLamination ancillary operationsElectrical polarityEngineering

A first holding unit (114) reciprocates between a first table (121) and a stacking table (141) and a second holding unit (115) reciprocates between the stacking table (141) and a second table (141). When the first holding unit (114) holds a separator-electrode assembly (20) whose horizontal position has been adjusted on the first table (121), the second holding unit (115) releases a second electrode (30) over the stacking table (141). When the first holding unit (114) releases the separator-electrode assembly (20) over the stacking table (141), the second holding unit (115) holds the second electrode (30) whose horizontal position has been adjusted on the second table (131). The present invention provides a stacking device and a stacking method which are capable of stacking the separator-electrode assembly including a first electrode sandwiched by separators and the second electrode having a different polarity from the first electrode efficiently with high accuracy.

Owner:ENVISION AESC JAPAN LTD

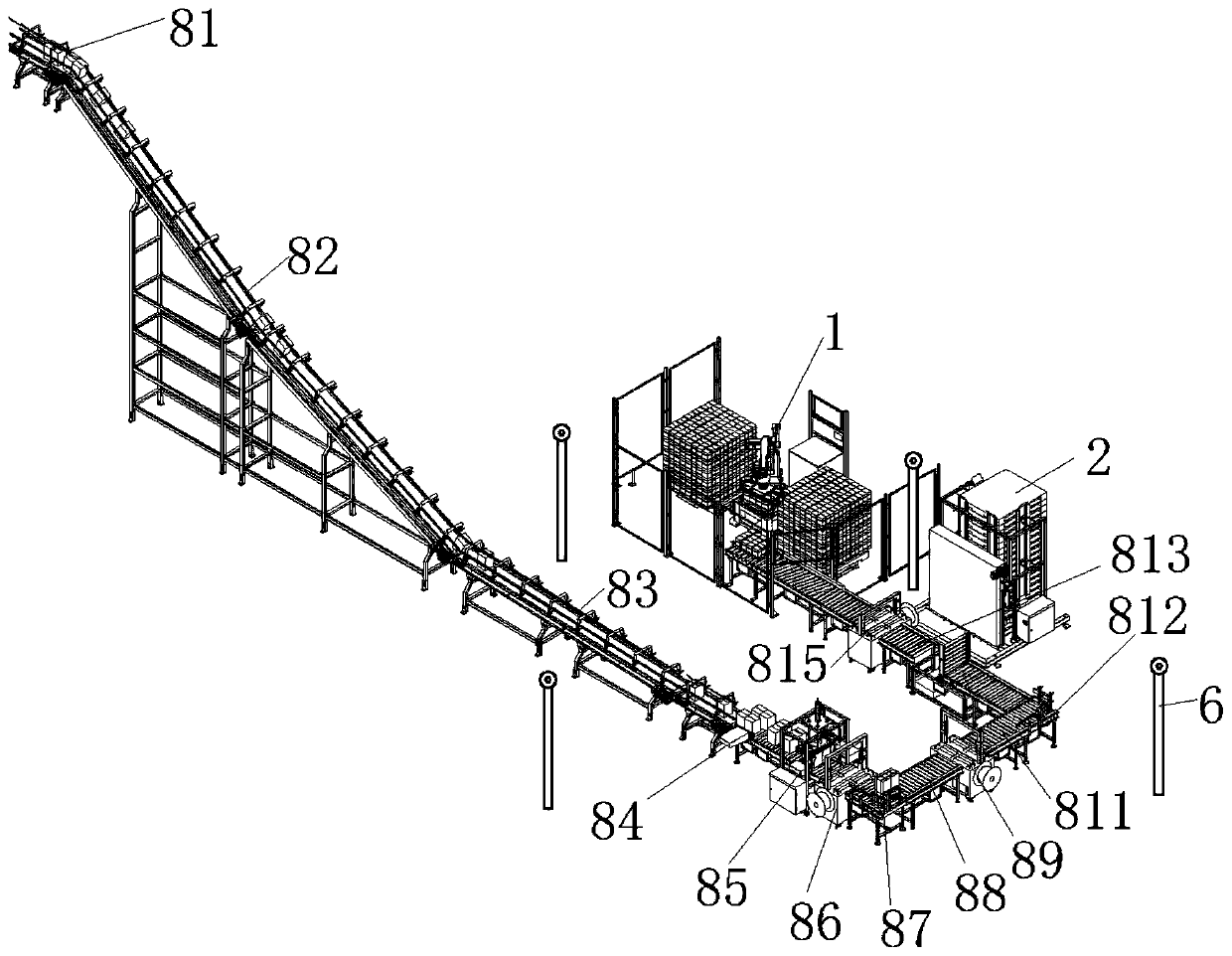

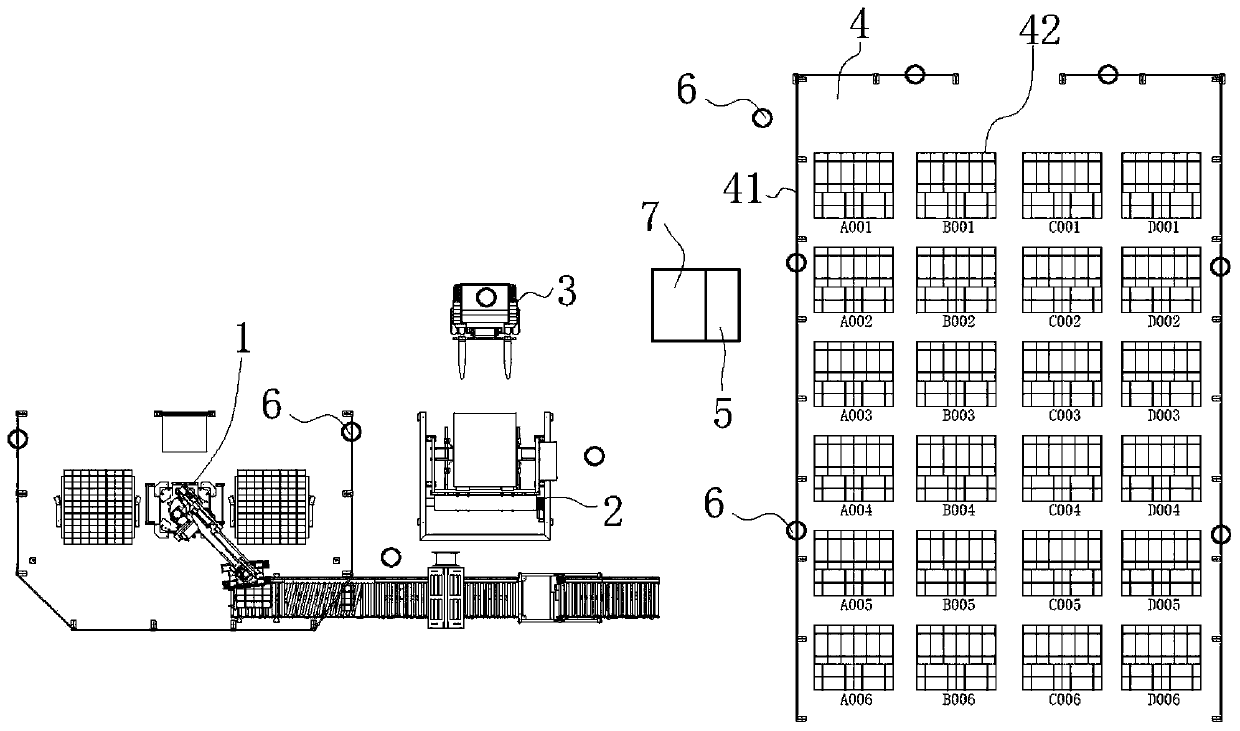

Intelligent unmanned assembly line for tea packaging

PendingCN111071546AEasy to operateEasy to useBundling machine detailsStorage devicesPalletizerWorkspace

The invention provides an intelligent unmanned assembly line for tea packaging, which belongs to the technical field of storage, and aims to solve the problems that an existing tea packaging, storingand sorting process wastes labor power, is low in sorting and storing efficiency and is great in occupied space. The intelligent unmanned assembly line for tea packaging comprises a stacking device, apallet device, a computer and a conveying assembly line, wherein the stacking device comprises a stacking robot, a conveying mechanism, a second control device and safety optical gratings, the multiple safety optical gratings define a working area; the pallet device is equipped with a baffle plate mechanism, a lifting mechanism and a first control device; the conveying assembly line is provided with a second-floor conveyor line, a slope conveyor line, a first-floor conveyor line, a box pusher, a box stacker, a first packaging machine, a first steering device, a first roller conveying device,a second packaging machine, a second roller conveying device, a second steering device, a box turnover machine, a third roller conveying device and a third packaging machine. The intelligent unmannedassembly line has the advantages of saving labor power, saving space, and improving sorting and storing efficiency.

Owner:浙江思密达智能装备有限公司

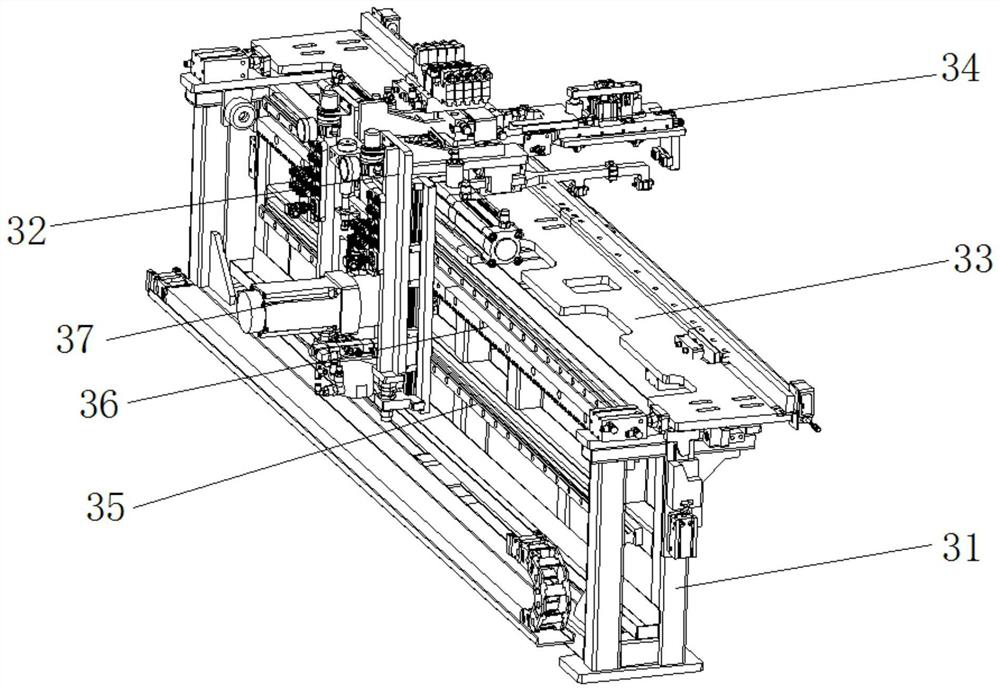

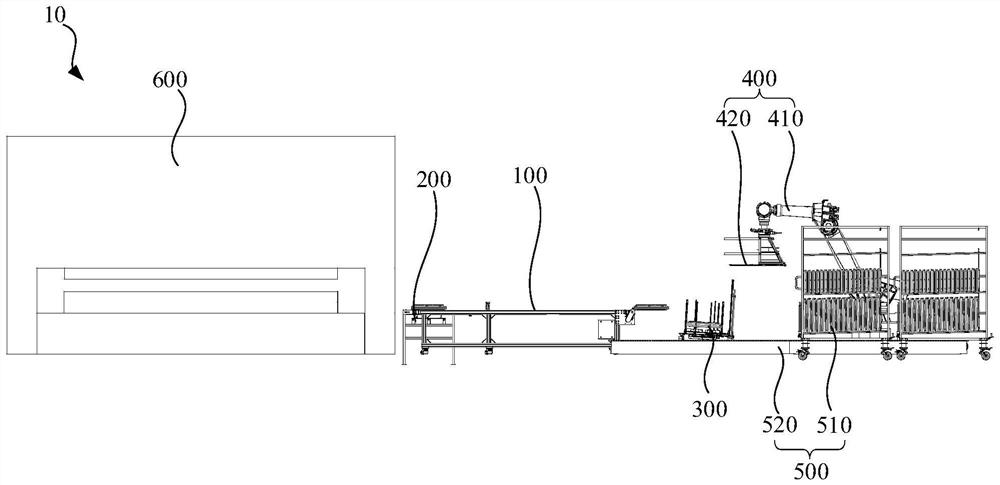

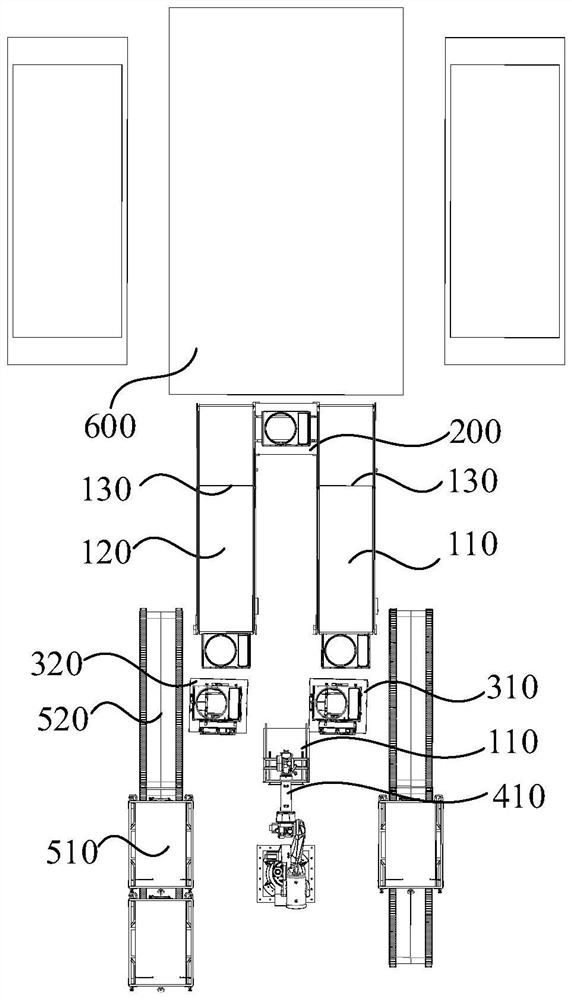

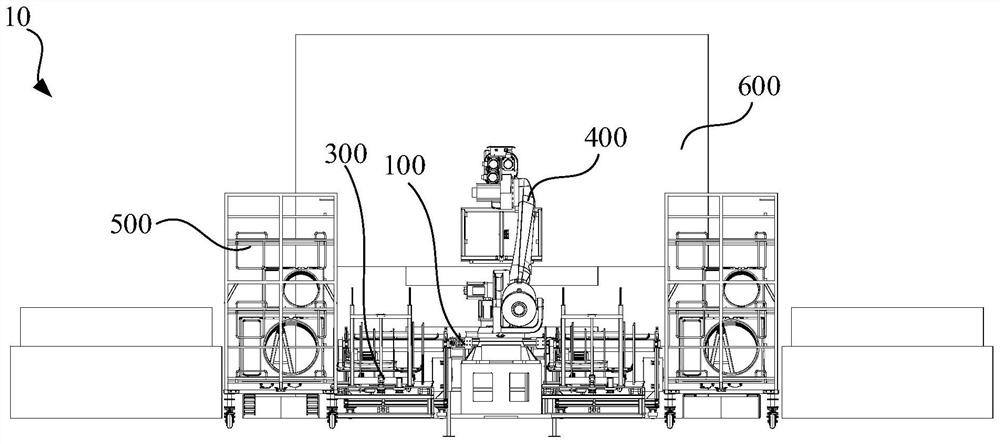

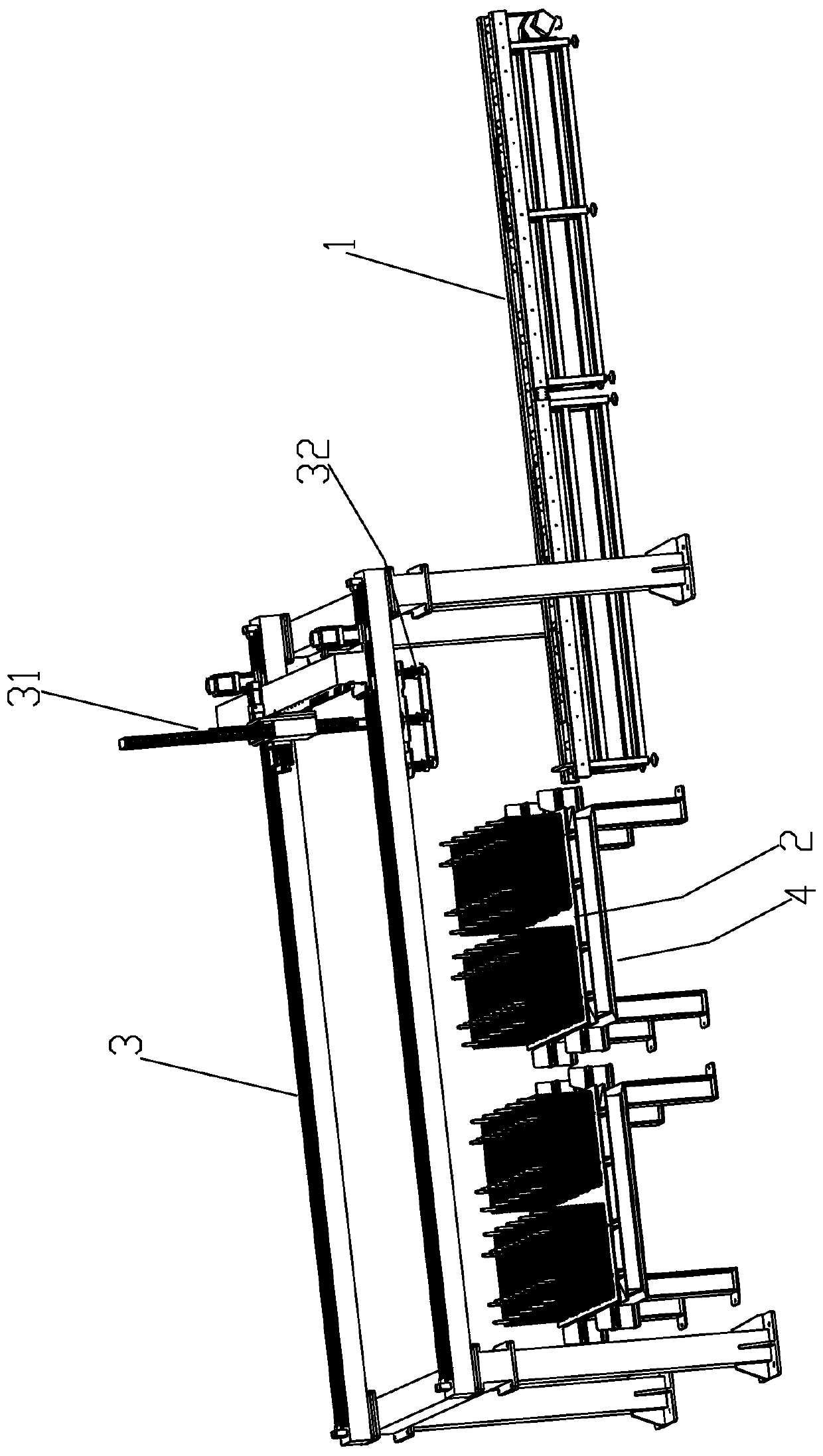

Automatic laminating production line for transformer iron cores

PendingCN112382502AOvercoming the problem of low stacking accuracyIncrease productivityTransformers/inductances detailsInductances/transformers/magnets manufactureProduction lineTransformer

The invention relates to the technical field of automatic equipment for transformer production, and particularly relates to an automatic laminating production line for transformer iron cores. The automatic laminating production line comprises an automatic transformer iron core laminating table and a sheet feeding device, wherein a column sheet fine positioning device and a yoke sheet fine positioning device are arranged on the two sides of the automatic transformer iron core laminating table respectively, the column sheet fine positioning device is connected with a column sheet conveying device, the yoke sheet fine positioning device is connected with a yoke sheet conveying device, feeding bins for storing corresponding silicon steel sheets are respectively arranged at the starting ends ofthe column sheet conveying device and the yoke sheet conveying device; and a column sheet stacking manipulator and a yoke sheet stacking manipulator can respectively transfer each core column siliconsteel sheet and upper and lower yoke silicon steel sheets subjected to fine positioning to the automatic laminating table, so that automatic lamination of the iron cores is realized. According to theproduction line, the production efficiency is remarkably improved, the lamination cost is reduced, the attractive appearance of the iron core and the quality stability of the transformer are guaranteed, and the product quality can be guaranteed.

Owner:ZHEJIANG JIANGSHAN TRANSFORMER CO LTD

Stacking device, loading machine and loading method

PendingCN111824798AEasy to stackEasy accessControl devices for conveyorsStacking articlesEngineeringMachine

The invention discloses a stacking device, a loading machine and a loading method, and relates to the technical field of loading. The stacking device comprises a stacking platform, a toggle mechanism,a push-out mechanism and a stacking width measuring mechanism in communication with the toggle mechanism. The stacking platform is used for receiving and carrying goods. The stacking width measuringmechanism can measure the distances between the two ends of the stacking platform in the first direction and the left and right side walls of a carriage respectively, and generating transverse position data. The toggle mechanism is arranged in the middle of the stacking platform, and can toggle the goods in the first direction or in the second direction opposite to the first direction according tothe transverse position data and preset stacking data, so that the two ends of the goods arranged in a row abut against the left side wall and the right side wall of the carriage. The push-out mechanism can push the goods out of the stacking platform in the third direction to stack the goods in a stacking position, wherein an included angle is formed between the first direction and the third direction. The stacking device, the loading machine and the loading method have the characteristics that the space utilization rate of the carriage is high, and the goods are not easy to extrude.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

Vision-based automatic stacking system and method

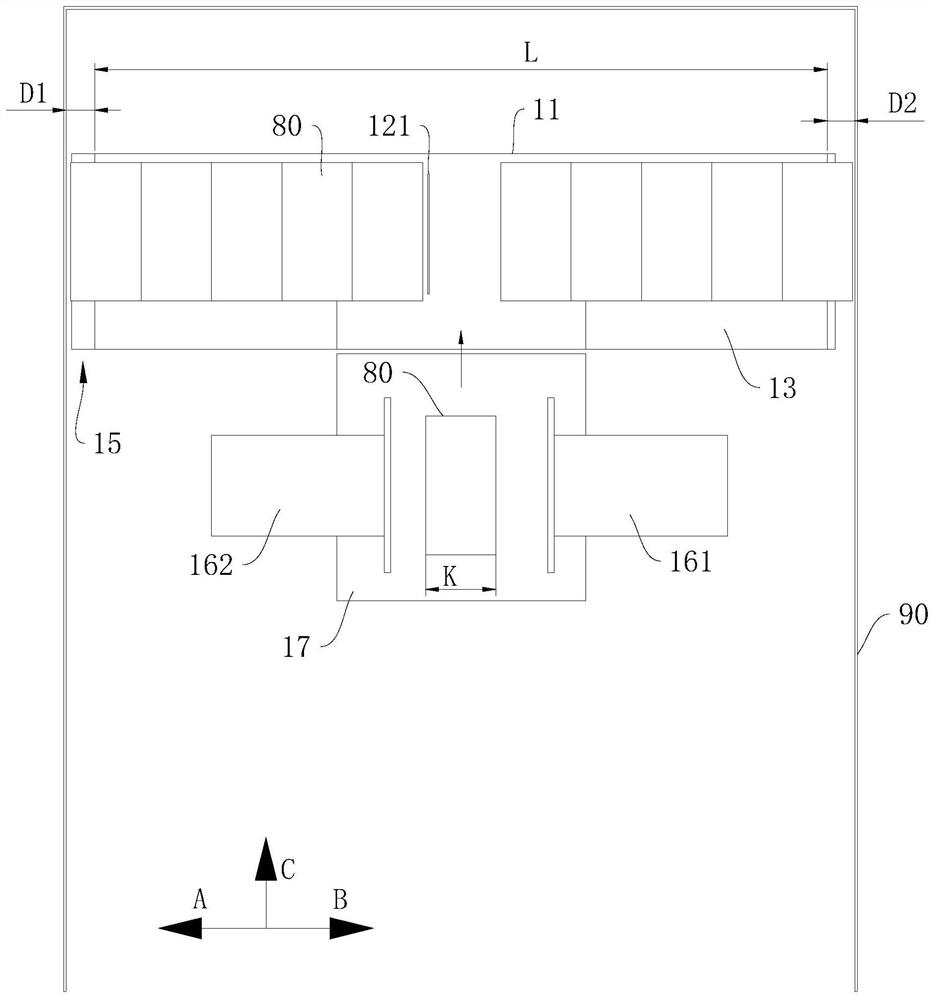

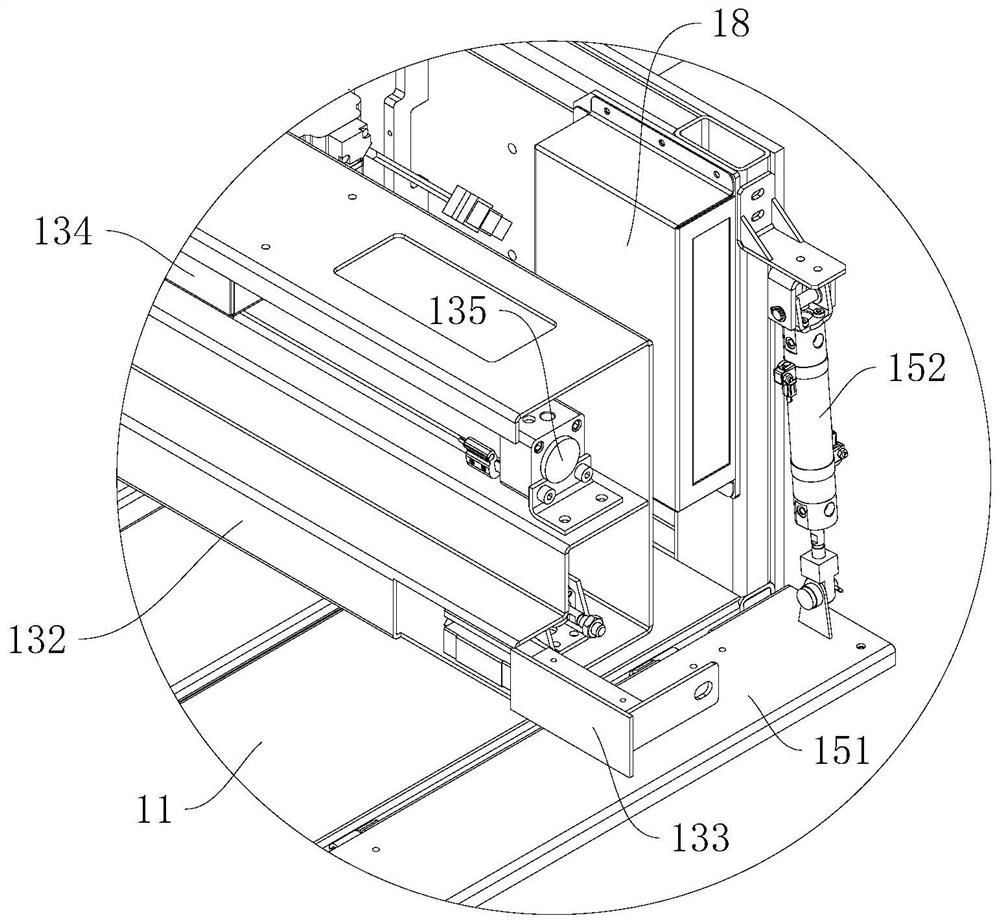

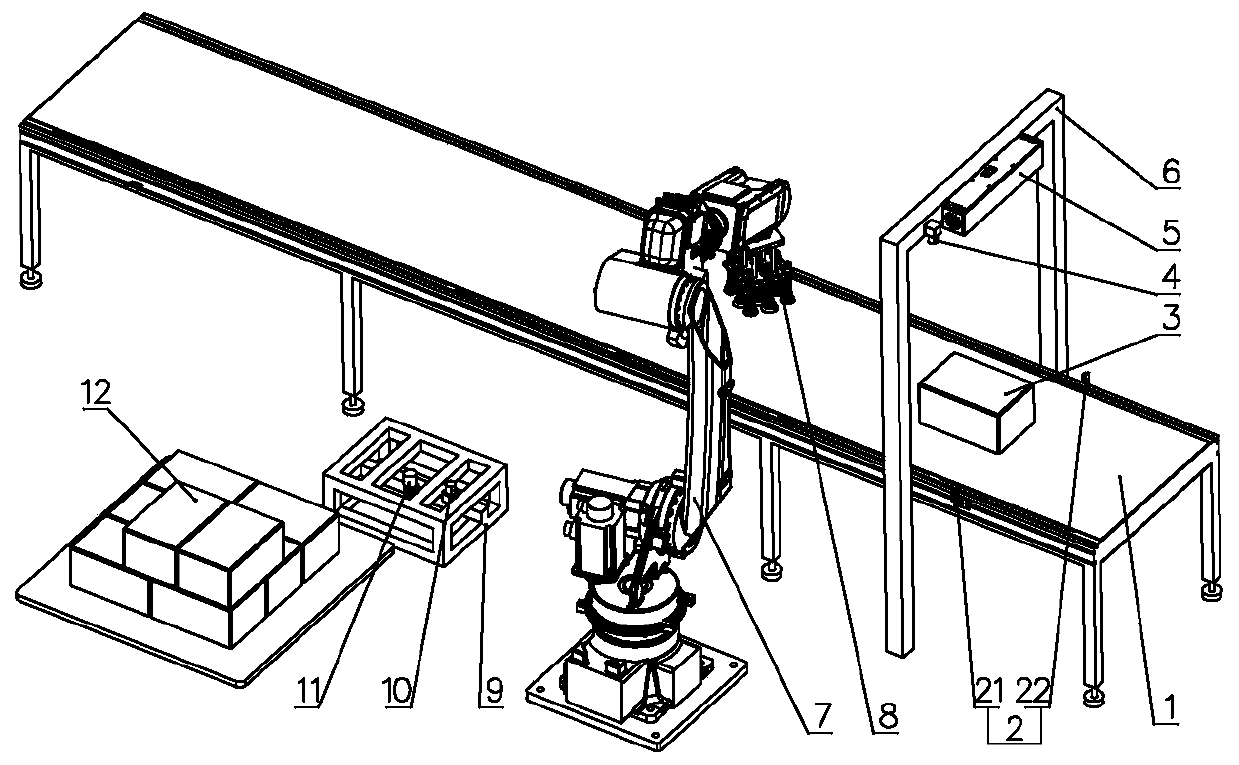

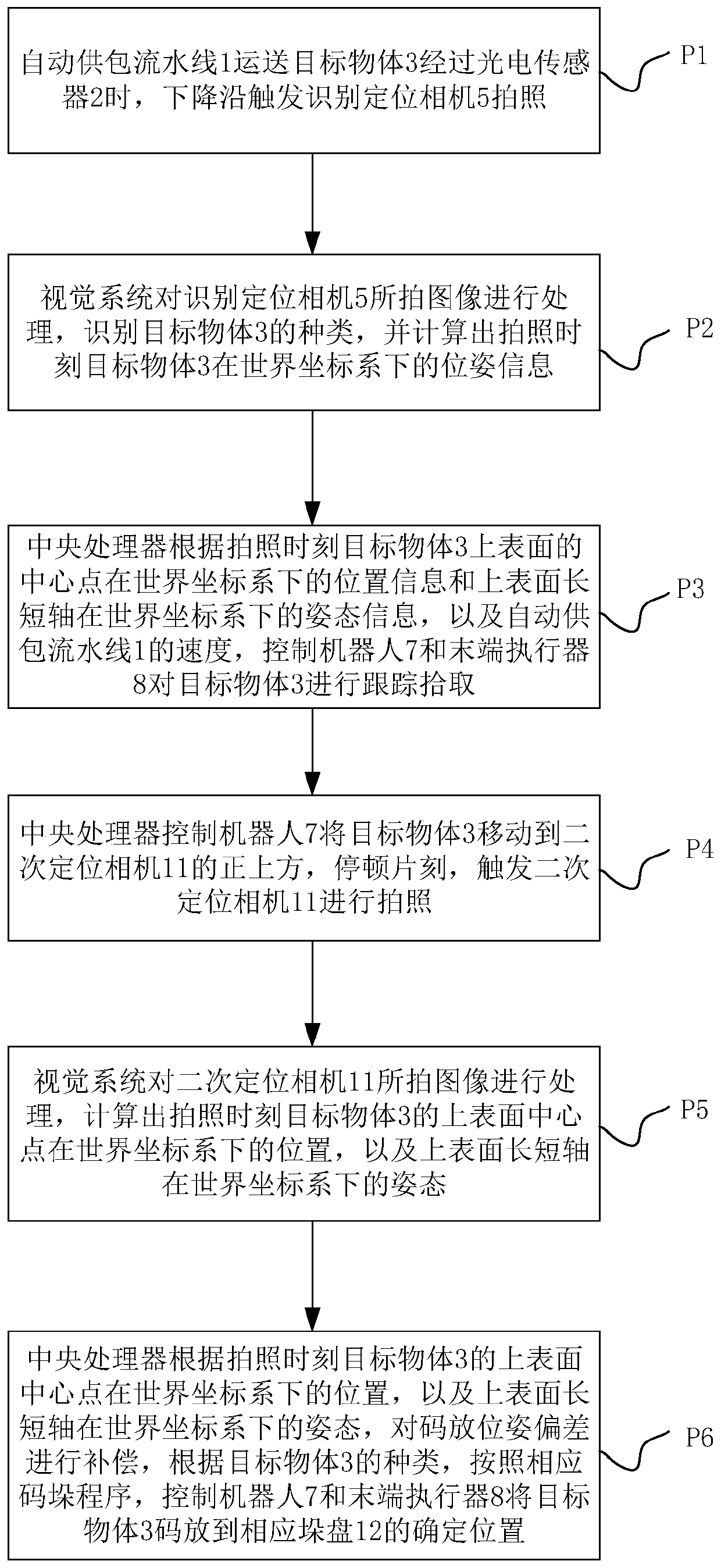

InactiveCN110342267AAdaptableHigh pick-up success rateConveyorsStacking articlesFixed frameVision based

The invention discloses a vision-based automatic stacking system and method. The vision-based automatic stacking system comprises an automatic package supplying assembly line, a photoelectric sensor,target objects, a support, a stacking subsystem, a vision system and a secondary positioning subsystem, wherein the secondary positioning subsystem comprises a secondary positioning light source and asecondary positioning camera; the stacking subsystem comprises a robot, an end effector, a fixing frame, a stacking disc and a secondary positioning subsystem; and the vision system comprises an identification positioning light source, an identification positioning camera and a secondary positioning subsystem. The vision-based automatic stacking system and method do not need an auxiliary positioning mechanism, and are high in adaptability to target objects with different sizes and specifications; the picking success rate is high, and the stacking precision is high; the target objects are at one automatic package supplying and stacking assembly line, and meanwhile, multiple categories of target objects can be identified, positioned, tracked and picked up, classified and stacked; and the automation degree is high, and the intelligent level is high.

Owner:杭州灵西机器人智能科技有限公司

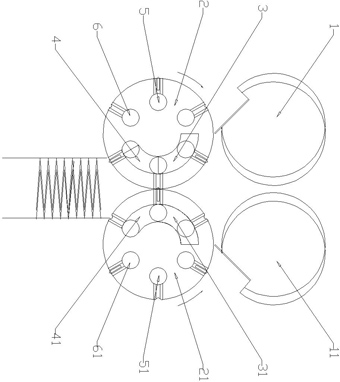

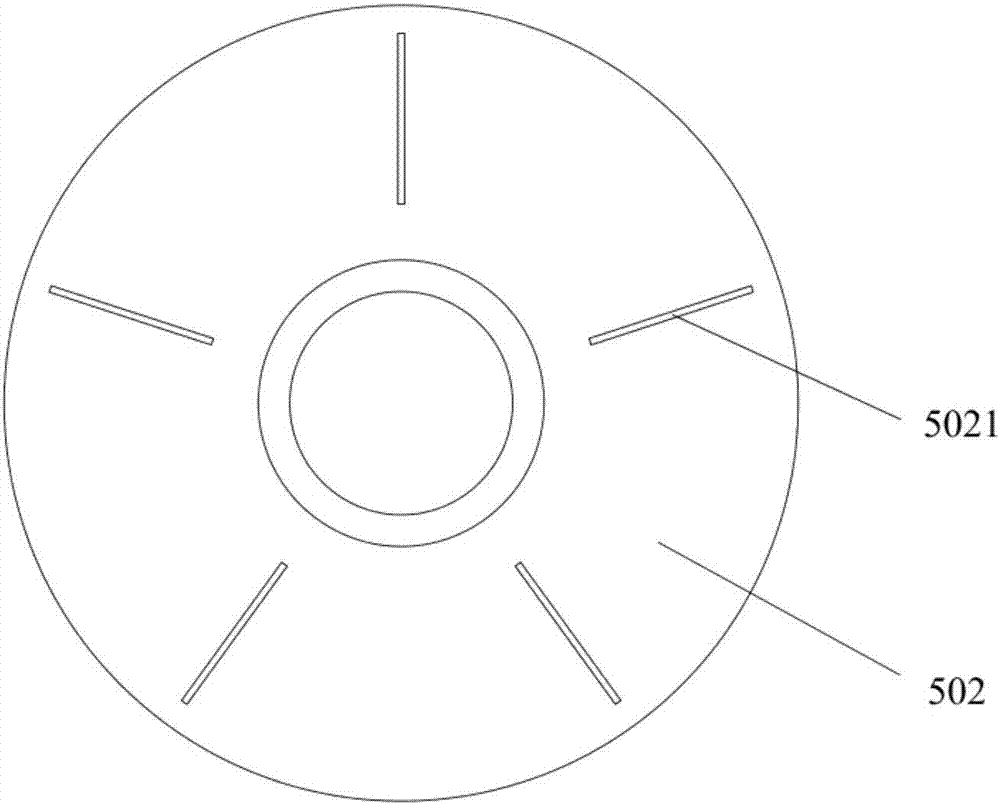

Air suction/exhaust method and structure of V-shaped box type facial tissue folding machine

InactiveCN102060208ASimple compositionInhale evenlyFolding thin materialsSuction controlFacial tissue

The invention discloses an air suction / exhaust method and structure of a V-shaped box facial tissue folding machine. The two ends of each tissue folding roller with a cutter on the roller surface are provided with air suction control ports in mutual communication respectively; air suction is performed at the air suction control ports at the two ends at the same time to form a negative pressure and absorb the facial tissue; and thus the processes of tissue feeding, cutting and folding are realized on the same tissue folding roller. The structure disclosed by the invention comprises two parallel tissue folding rollers and two cutter shafts; the roller surface of each tissue folding roller is axially provided with a cutter corresponding to the cutter shaft; each side of each tissue folding roller is provided with a tissue feeding air suction control port, a tissue folding air suction port and a corresponding air valve; the tissue feeding air suction control port and the tissue folding air suction control port are mutually communicated through an air suction channel; and air suction holes are correspondingly communicated with the corresponding air suction channel to form a structure realizing respective and synchronous air suction of the tissue feeding air suction control port and the tissue folding air suction control port on the two sides of the tissue folding roller. The invention has the advantages of high efficiency, high tissue folding precision, low energy consumption and low production and operation cost.

Owner:吴兆广

Full-automatic paperboard stacking equipment and paperboard stacking method

PendingCN107879120AImprove stacking accuracyImprove stack qualityOverturning articlesStacking articlesPaperboardPalletizer

The invention discloses full-automatic paperboard stacking equipment. The full-automatic paperboard stacking equipment is characterized by comprising a paperboard machine, a laminating mechanism, a binding mechanism, a stacking mechanism and a conveying mechanism which are sequentially connected from back to front, wherein the laminating mechanism, the binding mechanism and the stacking mechanismare sequentially connected through a conveying line, the laminating mechanism comprises a laminating mechanical arm, a first positioning device and a first jacking device, the binding mechanism comprises a binding machine, a second positioning device and a lifting conveying device, the stacking mechanism comprises a second jacking device and a stacking mechanical arm, and the conveying mechanism comprises a pallet machine and a pallet conveying line. The invention further discloses a stacking method for the paperboard stacking equipment.

Owner:DONGGUAN ALFA AUTOMATION TECH CO LTD

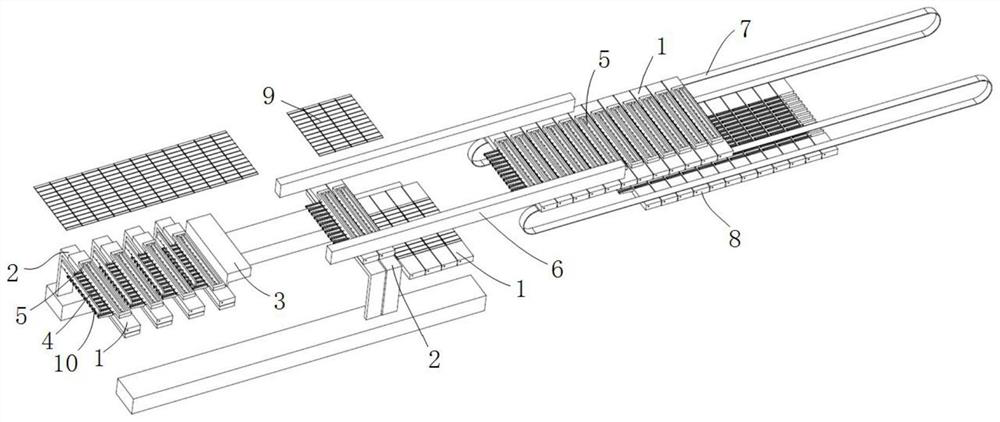

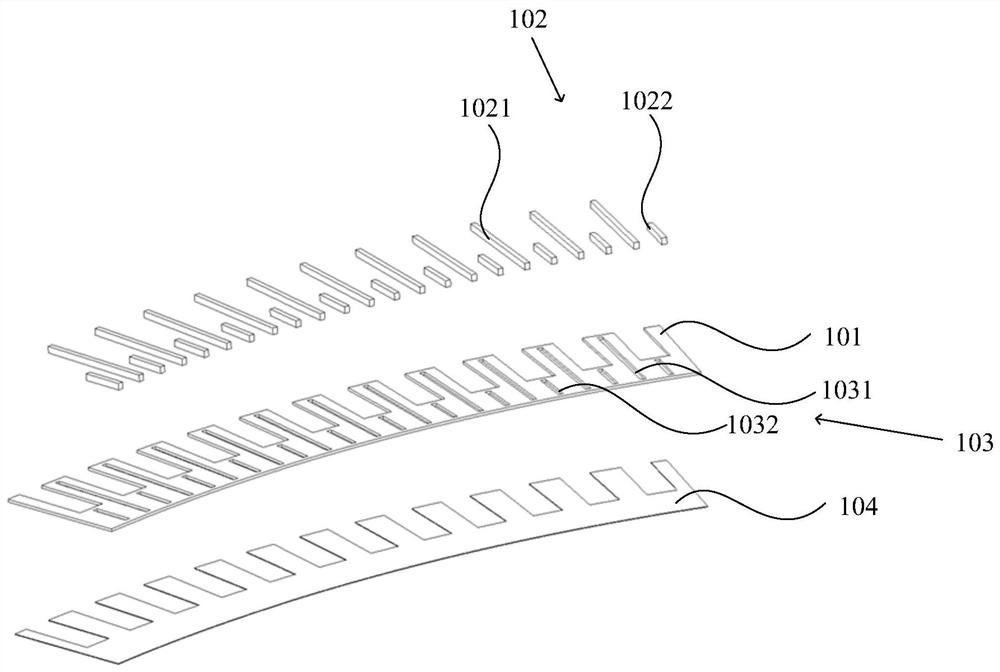

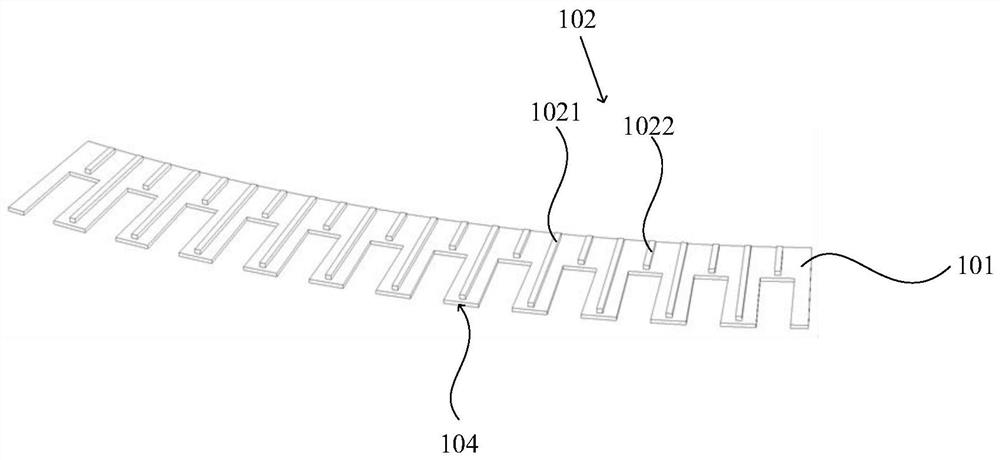

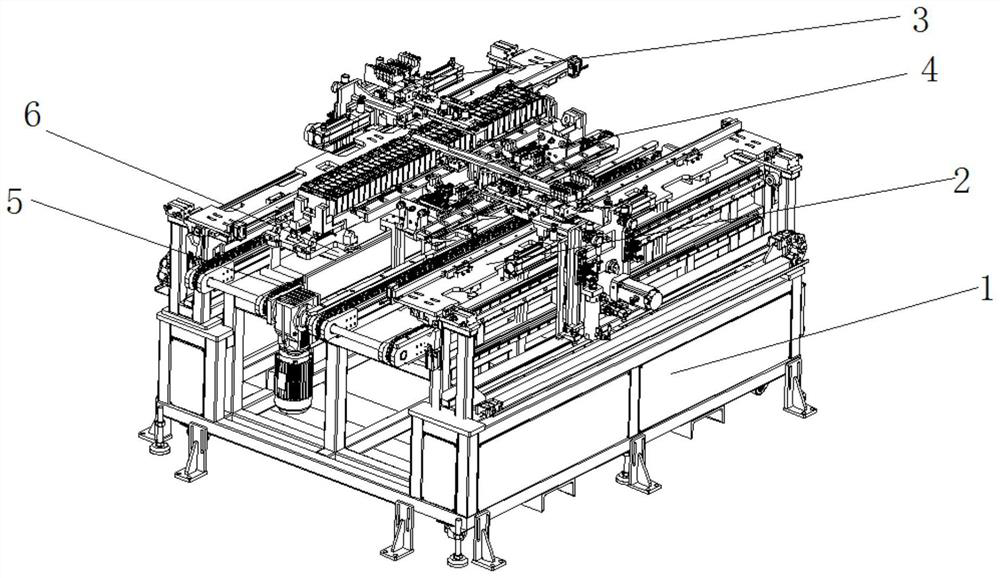

Battery string production equipment and battery string production method

PendingCN113193075AImprove product qualityImprove stacking accuracyFinal product manufacturePhotovoltaic energy generationElectrical batteryMechanical engineering

The invention discloses battery string production equipment and a battery string production method. The battery string production equipment comprises a battery piece supply device, a welding strip supply device, bearing components, a carrying device, a welding conveying device and a welding device. A plurality of bearing components are arranged. The battery piece providing device is used for placing battery pieces on battery piece bearing parts of the bearing components. The welding strip providing device places the rear half sections of welding strips into strip-shaped grooves of the welding strip bearing parts of the bearing components, and stacks the front half sections of the welding strips on the battery pieces borne by the battery piece bearing parts. The carrying device carries the bearing components bearing the battery pieces and the welding strips to the welding conveying device, and a first supporting part of the next bearing component on the welding conveying device and a second supporting part of the previous bearing component on the welding conveying device are connected in a staggered and inserted mode. The welding device is used for welding the battery pieces and the welding strips, which are conveyed by the welding conveying device to a welding station, on the bearing components. According to the technical scheme, the stacking precision of the battery pieces and the welding strips can be improved.

Owner:WUXI AUTOWELL TECH

Paper folding roll structure for folding machine for boxed extraction type paper towels

InactiveCN102502327ASolve the problem of large airflow fluctuationsReduce energy costsFolding thin materialsProduction linePaper towel

The invention provides a paper folding roll structure for a folding machine for boxed extraction type paper towels, which comprises a paper folding roll body. Suction control openings are arranged on both ends of the paper folding roll body, a plurality of paper conveying and folding suction holes which are axially arrayed are disposed on the surface of the paper folding roll body, the paper conveying and folding suction holes are communicated with airflow channels in the paper folding roll body, and a spacing part is arranged in the middle of each airflow channel and divides the airflow channel penetrating through the inside of the paper folding roll into two sections. During operation, periodic communicating air suction of each section of airflow channels and each of respective suction control openings of the airflow channels is realized. The problem that fluctuation of airflow inside an existing paper folding roll is high can be effectively solved, accordingly, the paper folding roll structure is higher in efficiency and paper folding precision while energy consumption and running cost are reduced, paper conveying and folding speed is faster, actual production requirements can be met completely, the paper folding roll structure and body paper production equipment can be easily combined to form a production line, and automatic operation is realized.

Owner:陆德昌

Device for bill identification and storage

PendingCN107170150AImprove stacking accuracyPrevent damage to notes of valueComplete banking machinesPaper-money testing devicesComputer science

The invention discloses a device for bill identification and storage and belongs to the technical field of financial equipment. The device for bill identification and storage comprises a control assembly, an identification part and a storage part. The identification mechanism is used for identifying the authenticity of information carried in value bills. The control assembly controls the movement direction of a first drive mechanism according to the authenticity of the value bills, conveys the true value bills to the storage part and retreats the false value bills from the identification part. A bill stacking mechanism can stack the value bills in a storage box one by one, the position of the bill stacking mechanism is limited through a limiting mechanism in the bill stacking process, the control assembly controls movement of a second drive mechanism according to acquired position information, the bill stacking precision can be improved, and the phenomenon that the value bills are damaged due to the fact that errors are generated in the bill stacking process is avoided.

Owner:SHENZHEN YIHUA COMP +2

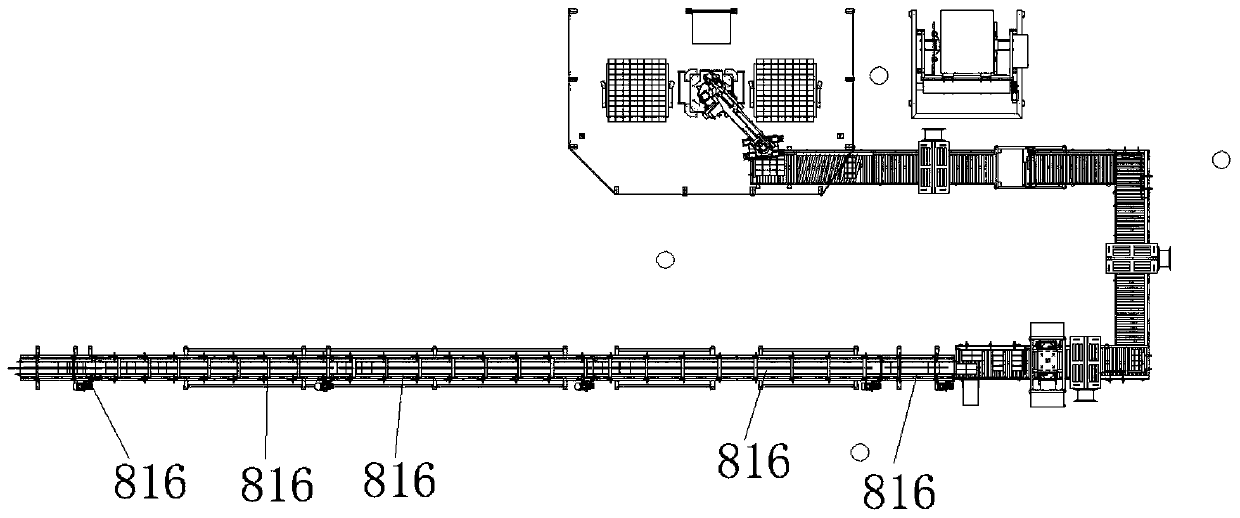

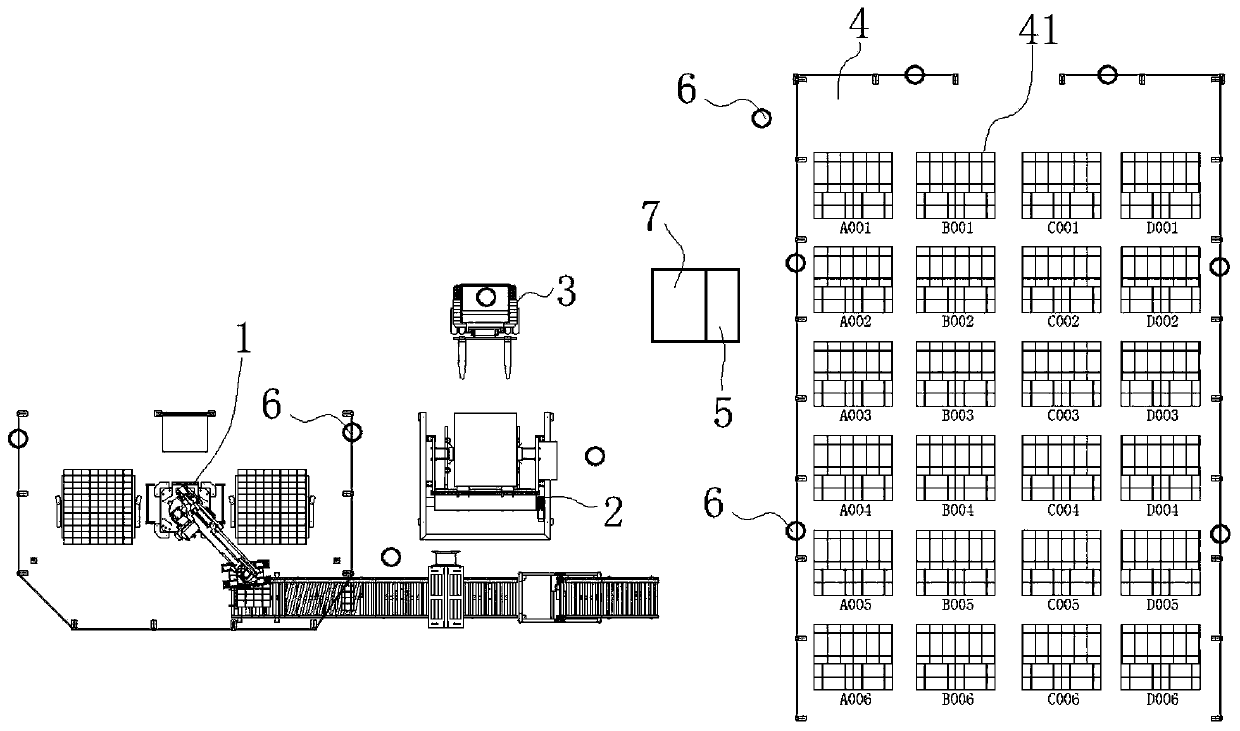

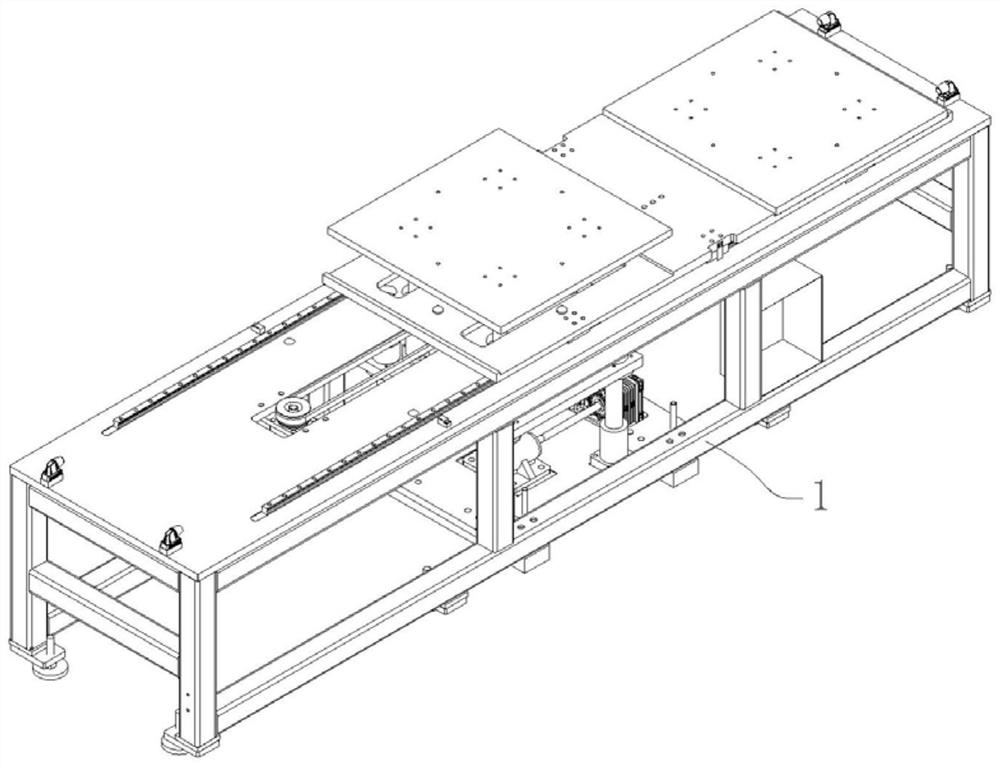

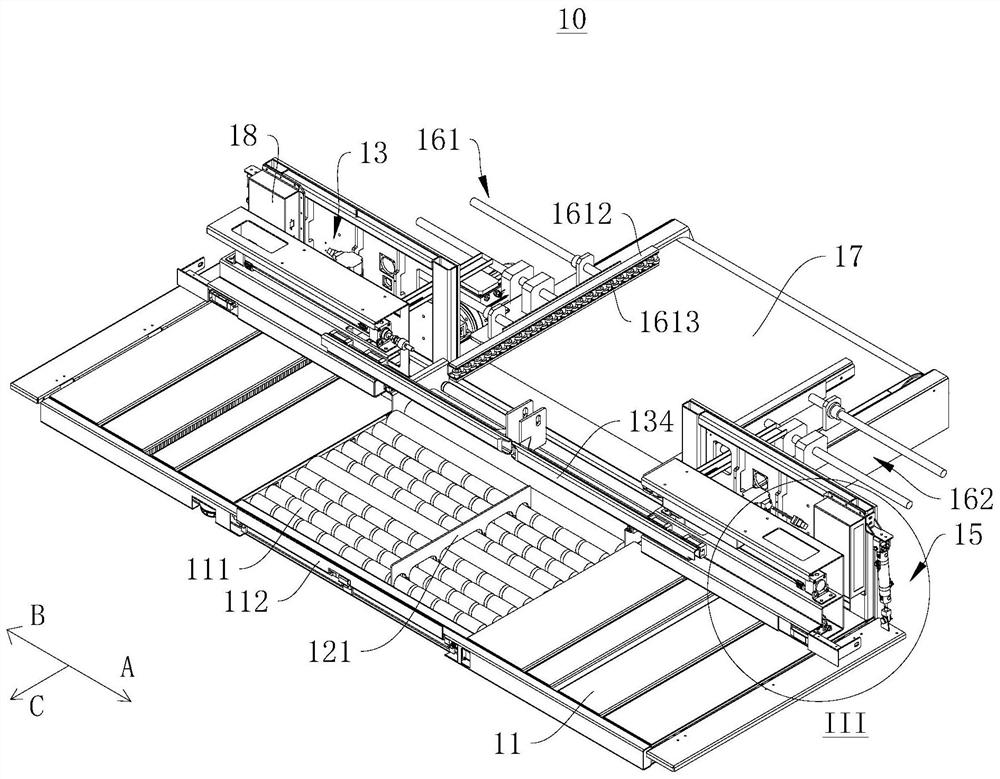

Intelligent AGV tray supplying and warehousing system

The invention provides an intelligent AGV tray supplying and warehousing system and belongs to the technical field of warehousing. According to the intelligent AGV tray supplying and warehousing system, the problems that a manual manner is adopted in an existing warehousing and sorting process, the labor force is wasted, and the sorting and warehousing efficiency is low are solved. The intelligentAGV tray supplying and warehousing system comprises a stacking mechanism, a tray mechanism, an AGC, a computer, a camera device and a warehouse area. The stacking mechanism comprises a stacking robot, a conveying mechanism, a second control device and safety gratings. The multiple safety gratings form a working area. The tray mechanism comprises a rack, and a baffle mechanism, a lifting mechanismand a first control device are installed on the rack. The warehouse area is provided with an outer wall defined by the multiple safety gratings, and multiple storage locations evenly arranged. The computer is in communication connection with the stacking mechanism, the tray mechanism, the AGV, the camera device and the safety gratings of the warehouse area. An AGV charging seat is further arranged beside the warehouse area. The intelligent AGV tray supplying and warehousing system has the beneficial effects that the labor is saved, and the sorting and warehousing efficiency is improved.

Owner:浙江思密达智能装备有限公司

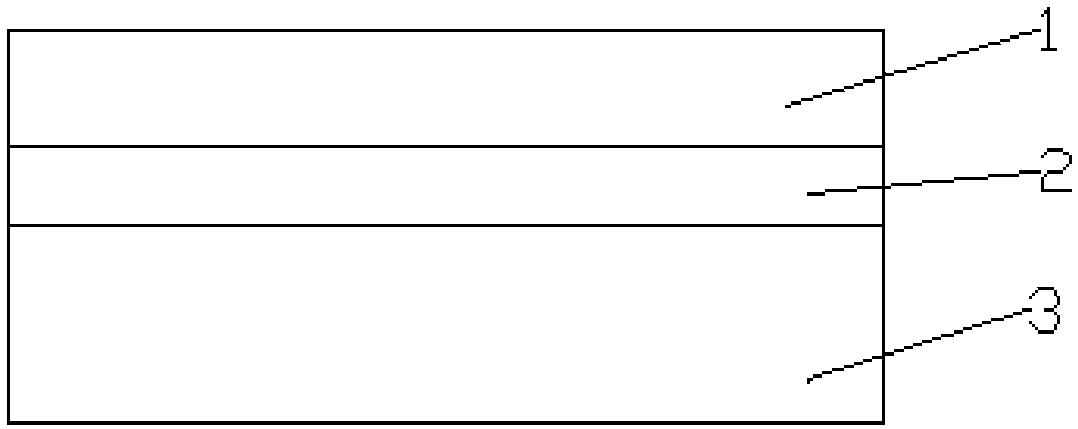

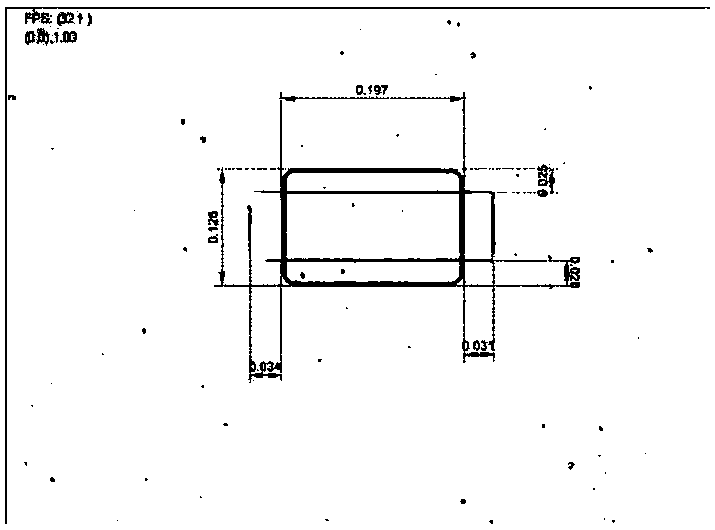

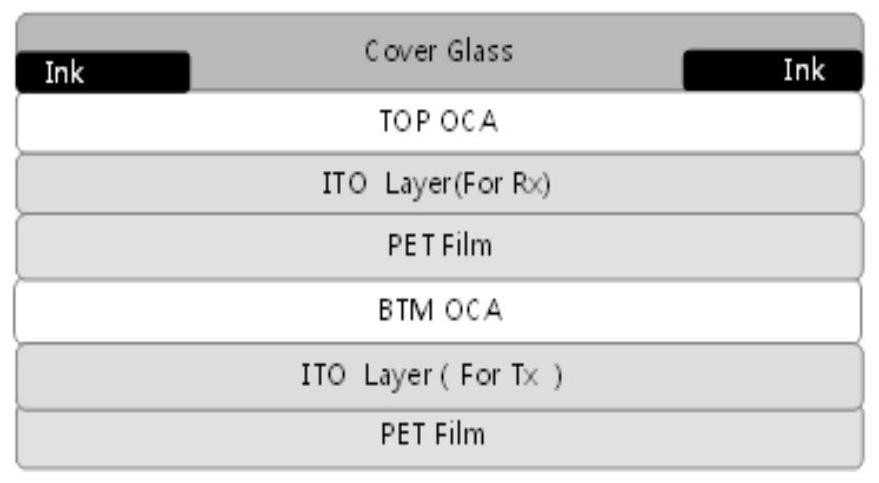

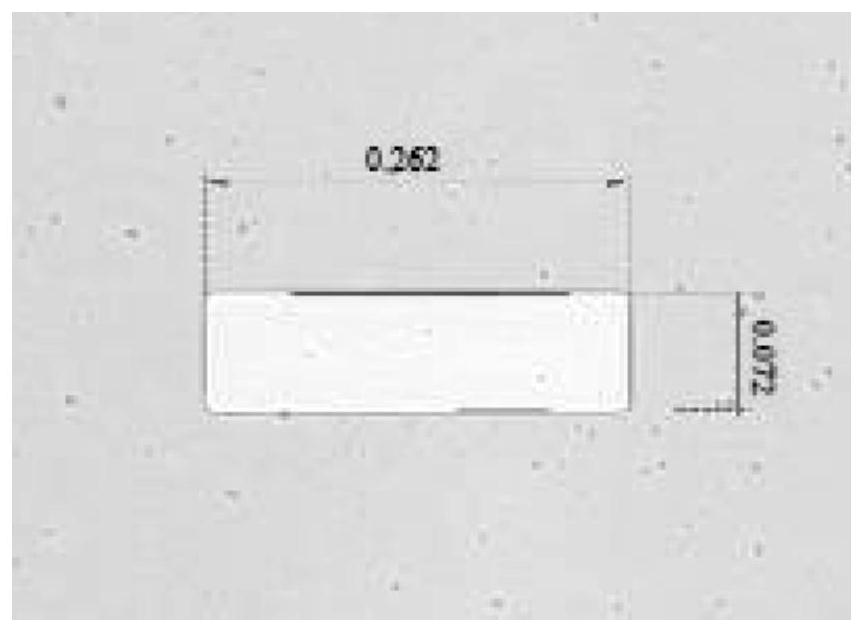

Manufacturing method of thin film touch sensor and thin film touch sensor

ActiveCN109992138ASolve the problem of difficult sheet productionAvoid deformationInput/output processes for data processingCooking & bakingTouch Senses

The invention relates to the field of touch screens, and particularly provides a manufacturing method of a thin film touch sensor and the thin film touch sensor. The manufacturing method of the thin film touch sensor comprises the following steps that (a) a rigid carrier plate attached with a thin film base material is baked, and the baking temperature is 120-150 DEG C; baking time is 30-60 min; (b) a multi-layer touch circuit is manufactured, and the standing time after soft baking is 2-10 min, the temperature of the exposure table top is 25-35 DEG C; and (c) separating the thin film substrate on which the multi-layer touch circuit is completed from the rigid support plate to obtain the thin film touch sensor. The method can effectively solve the problems of line stacking deviation and low exposure alignment efficiency when a touch sensing layer is manufactured on one thin film, exposure alignment is accurate and high in efficiency, the line stacking deviation is small, the product yield is high, and in addition, a thin film touch sensor can be produced in a sheet mode.

Owner:LENS TECH CHANGSHA

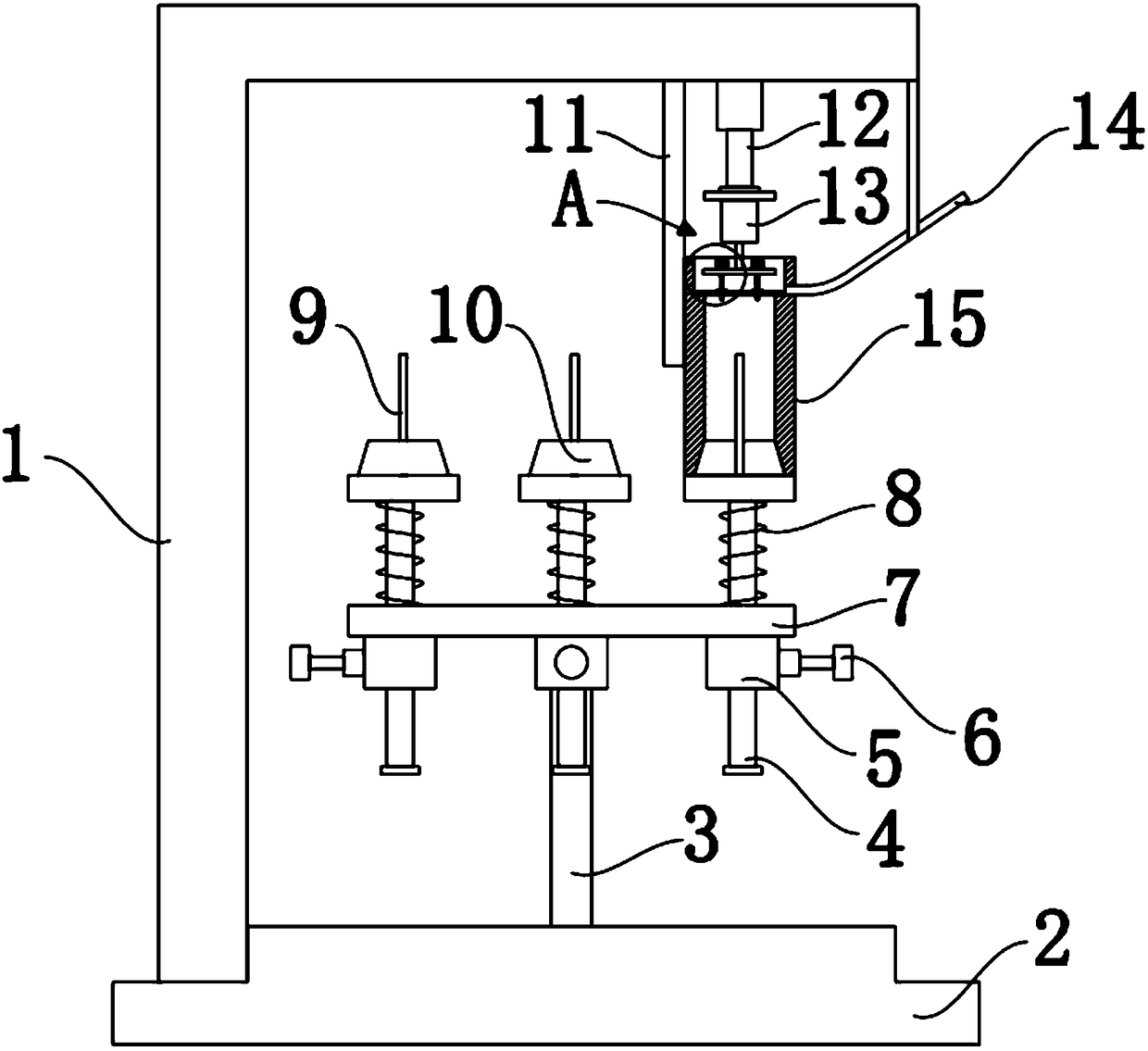

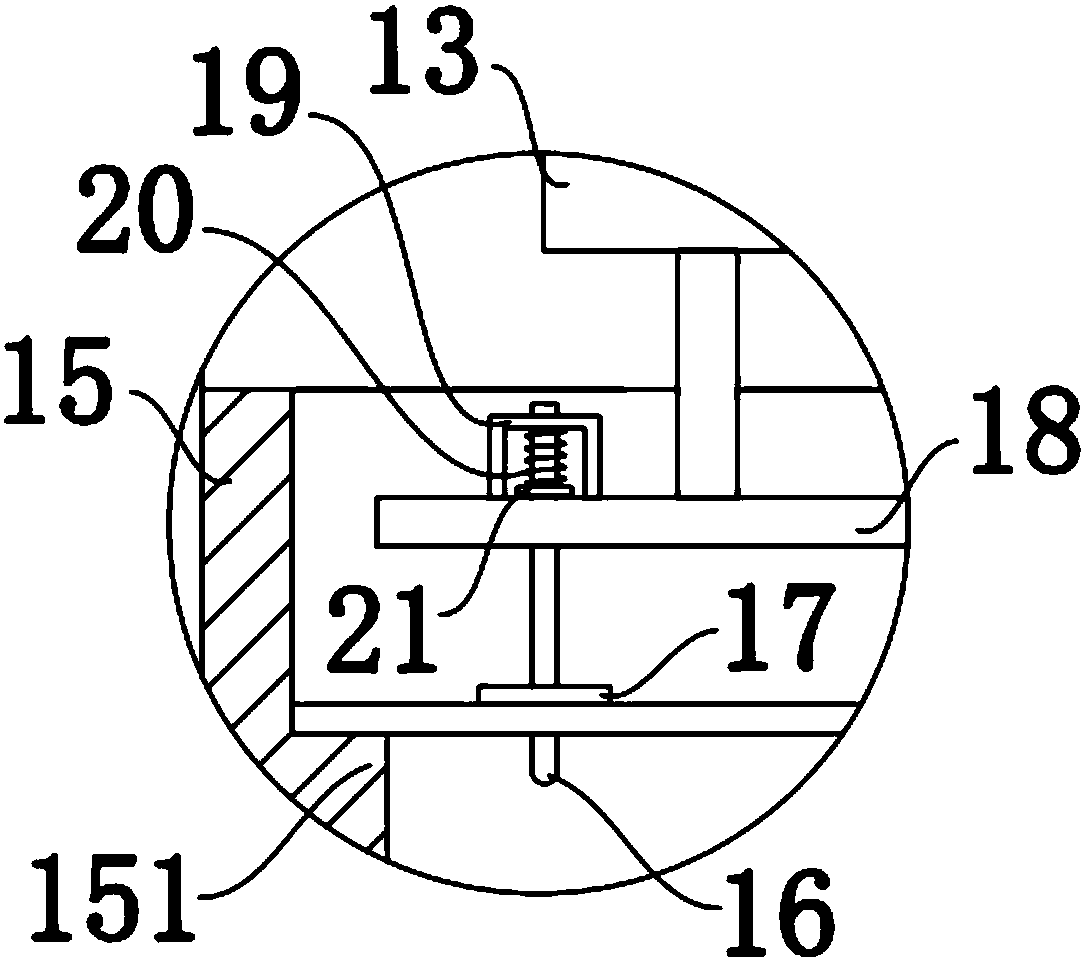

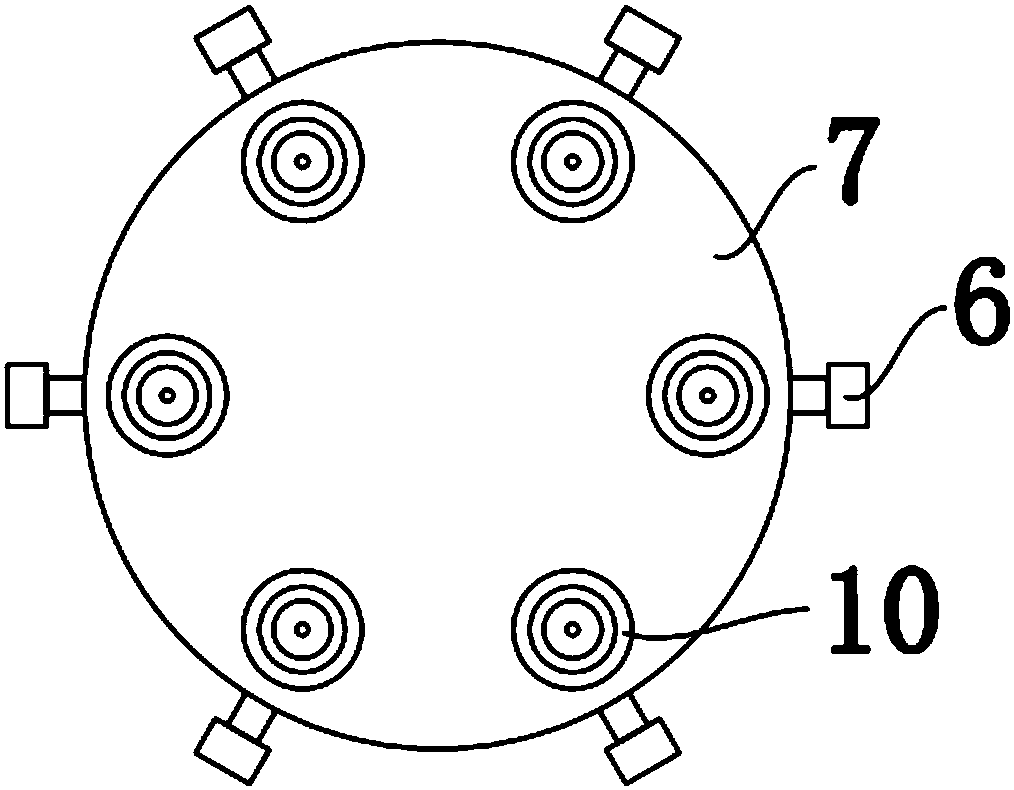

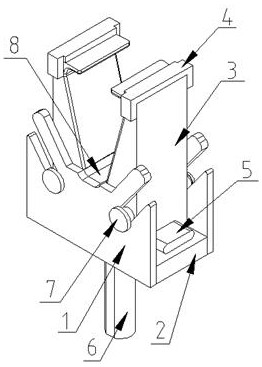

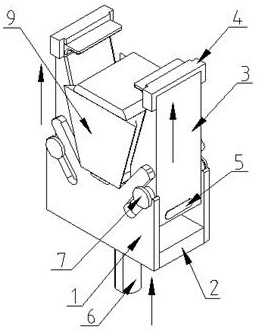

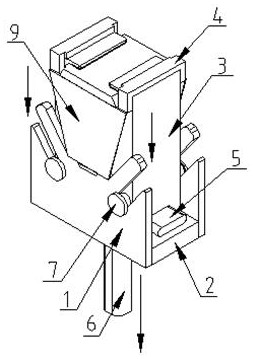

Stacking equipment for motor rotor cores

ActiveCN108599477AImprove stacking efficiencyHigh stacking accuracyManufacturing stator/rotor bodiesEngineeringHydraulic cylinder

The invention discloses stacking equipment for motor rotor cores. The equipment comprises a tray and a bushing, wherein the center of the tray is rotationally connected to a base through a support shaft, sliding sleeves are welded and fixed on the lower surface of the tray, ejector rods are glidingly connected in the sliding sleeves, and rotor rotating shafts are installed at the centers of support platforms; a motor is connected to a support arm through a hydraulic cylinder, an output shaft of the motor extends into the upper end of the bushing and is provided with a support plate, and guidepins are movably connected with two ends of the support plate. The guide pins on the support plate are driven by the motor to rotate, positions of silicon steel sheets can be adjusted, the silicon steel sheets are automatically installed on rotor rotating shafts in the same posture, and accordingly, stacking efficiency of the rotor cores is improved, and stacking precision is high; after the coreson the rotor rotating shafts are stacked, the tray is rotated, unloaded support platforms are replaced in the bushing, the rotor rotating shafts loaded with the cores are then replaced, and next corestacking is started. The equipment has the advantages of short downtime and high continuity during stacking.

Owner:上海发腾航空科技股份有限公司

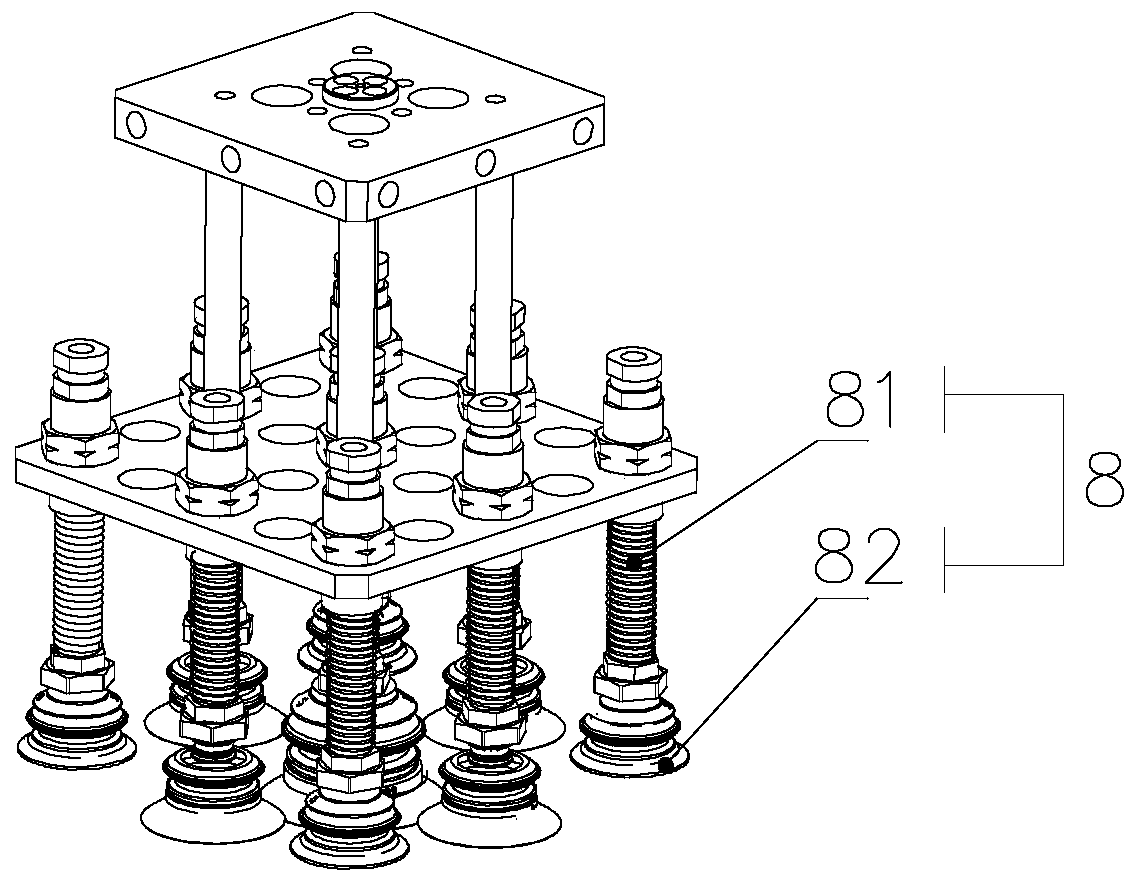

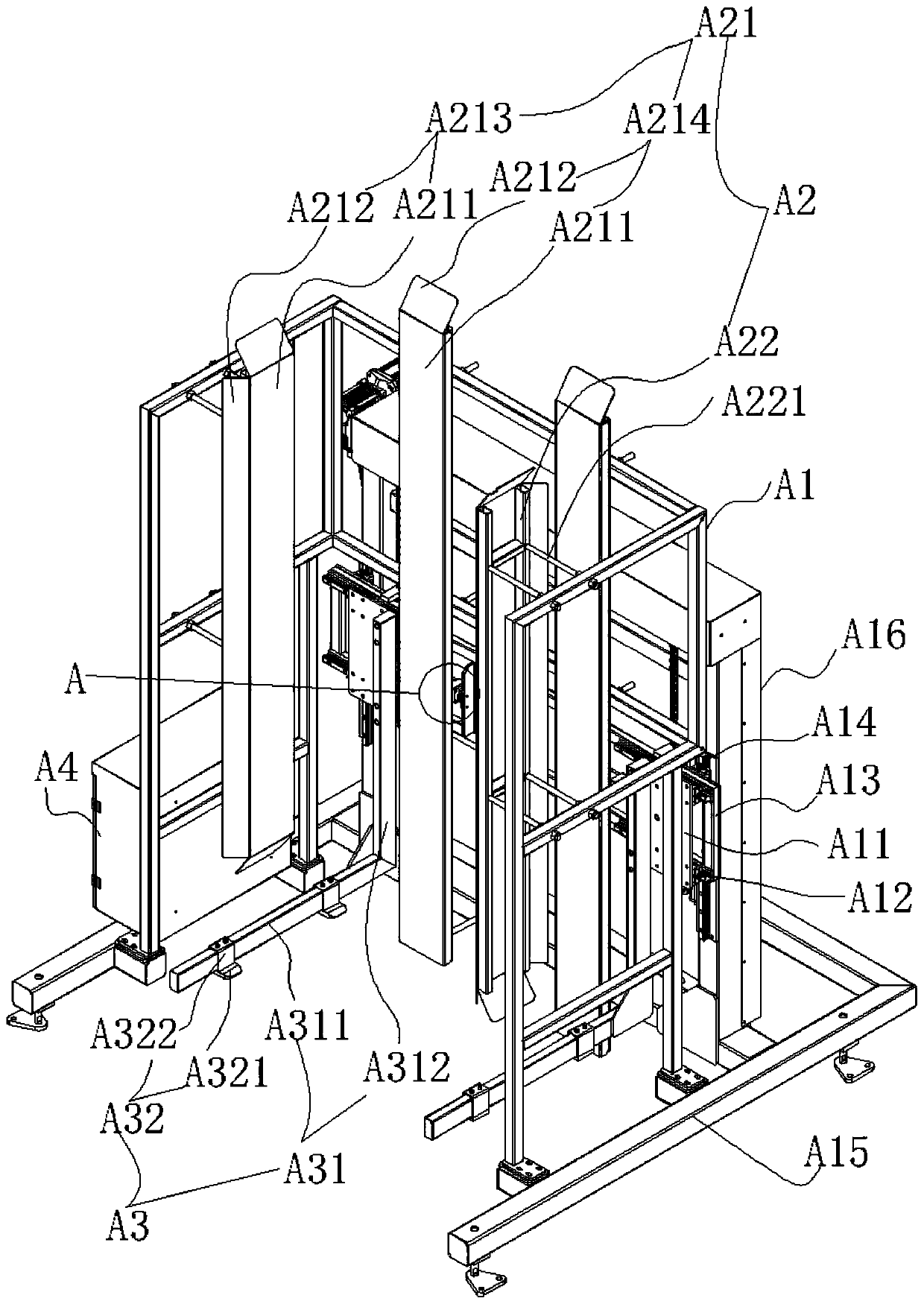

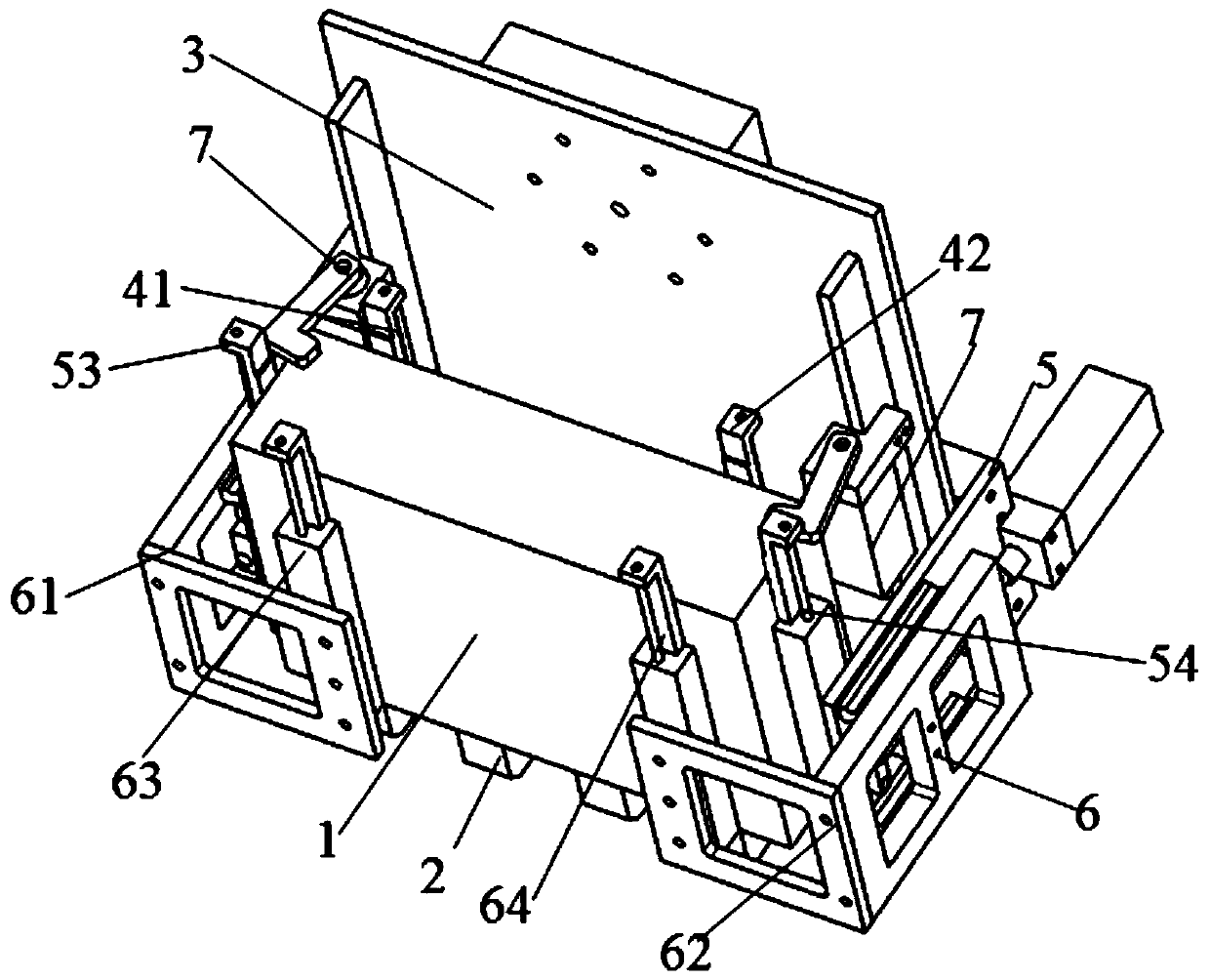

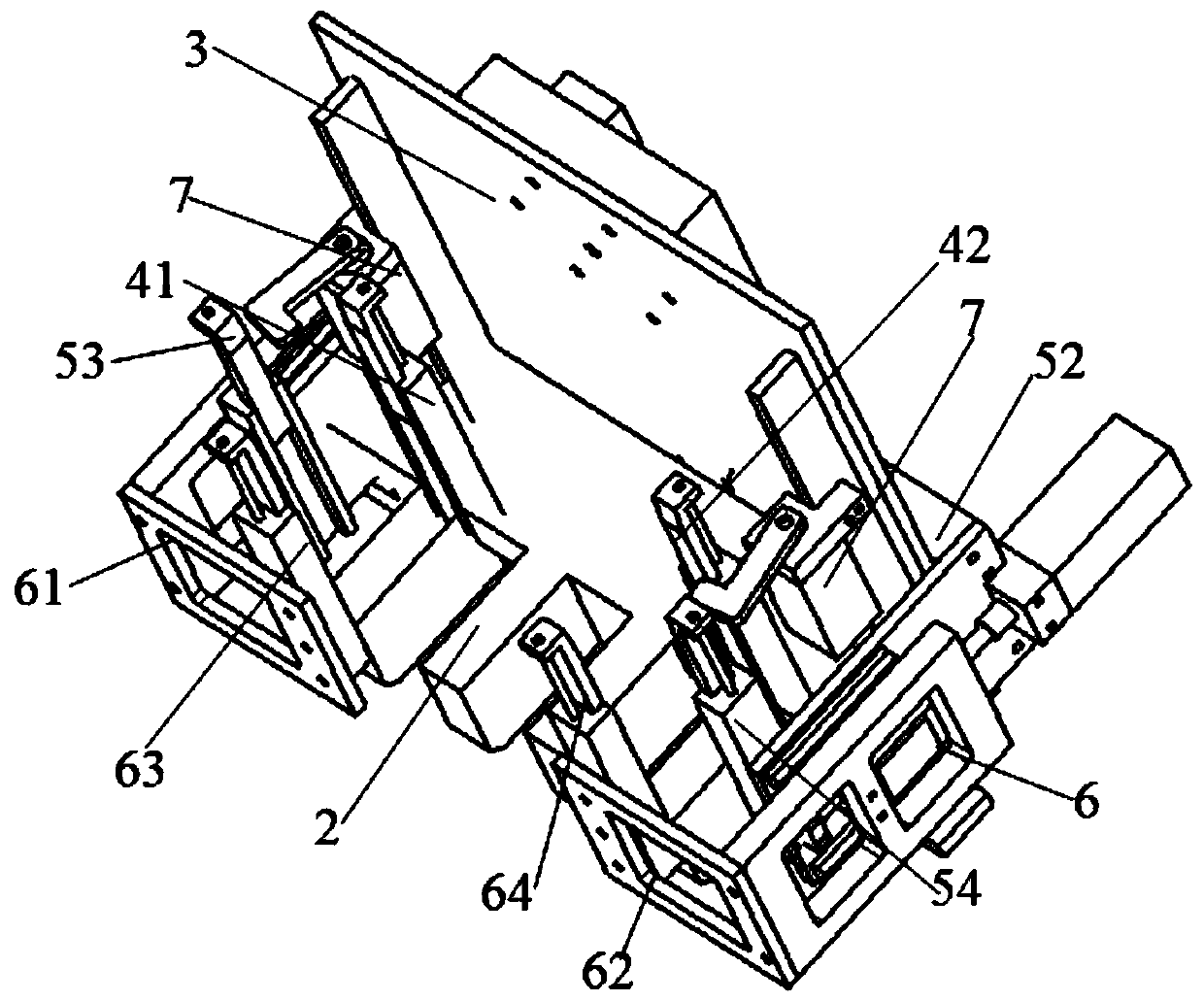

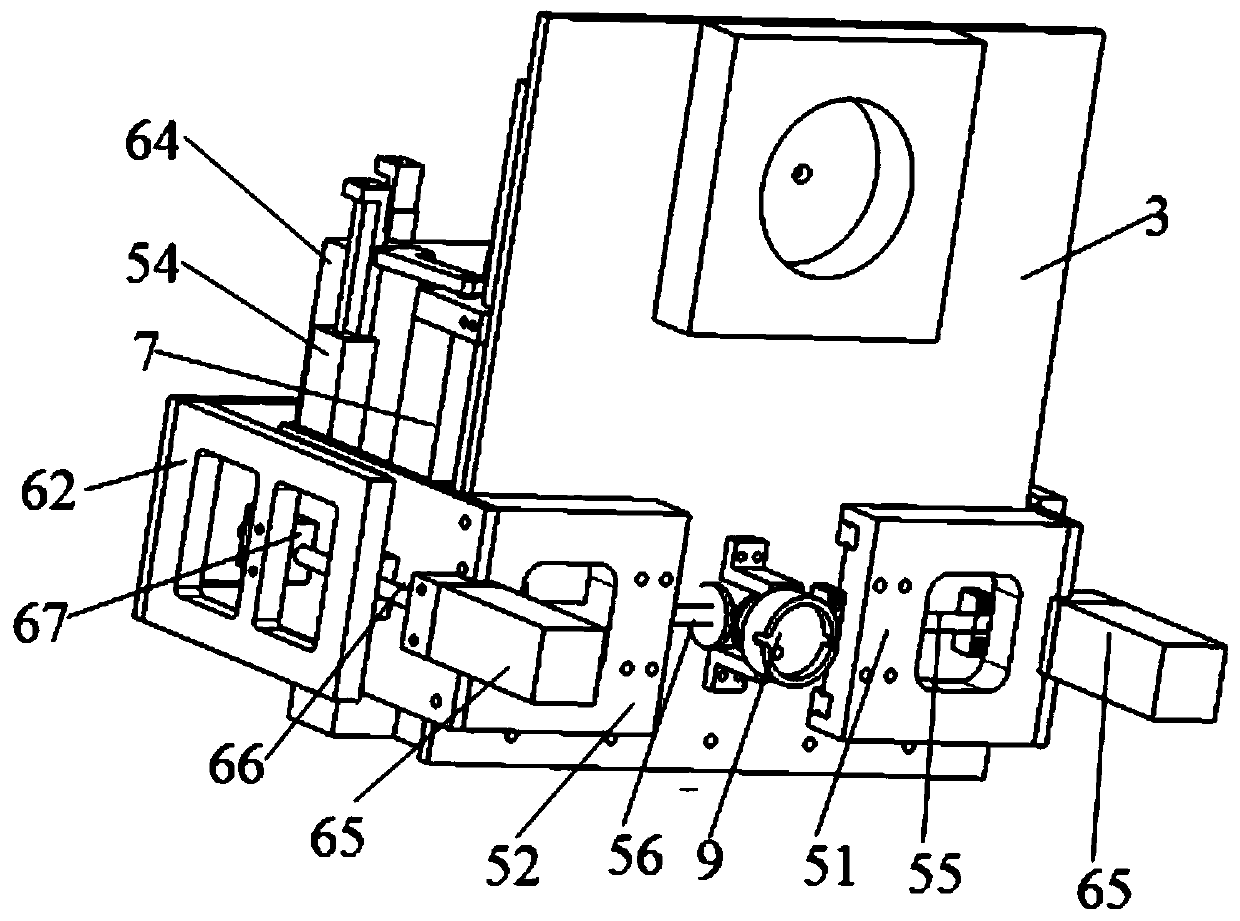

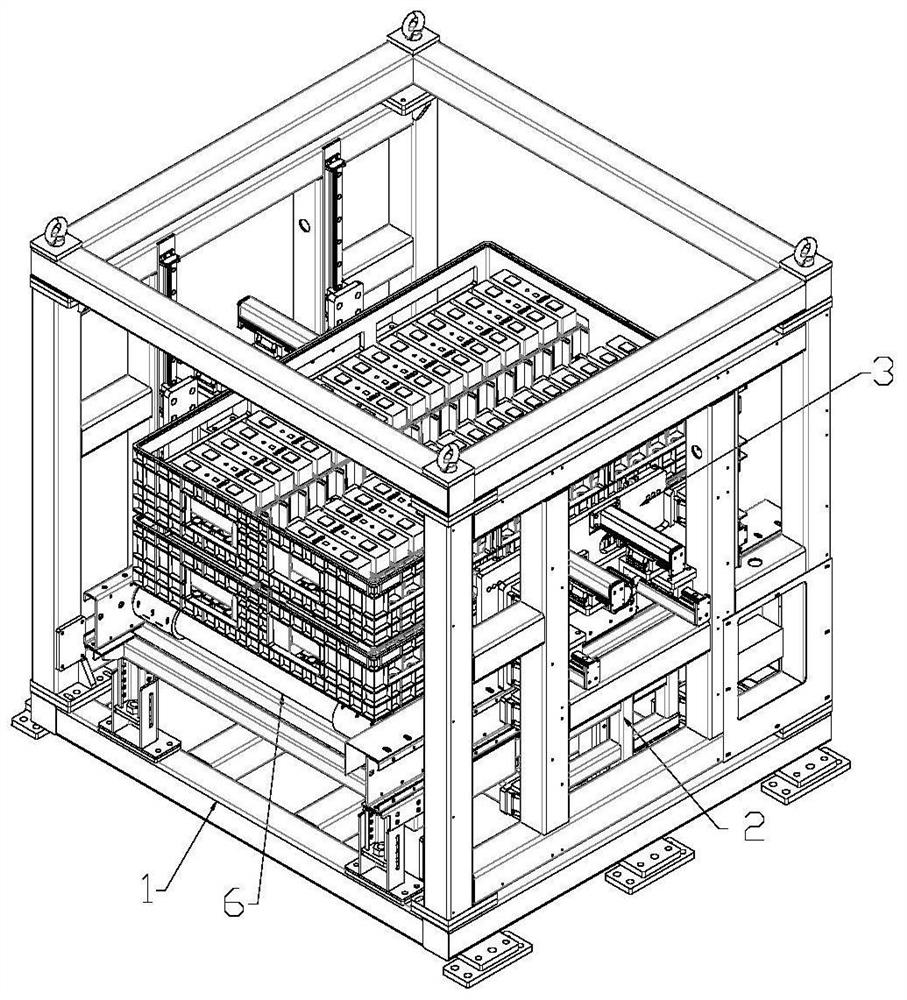

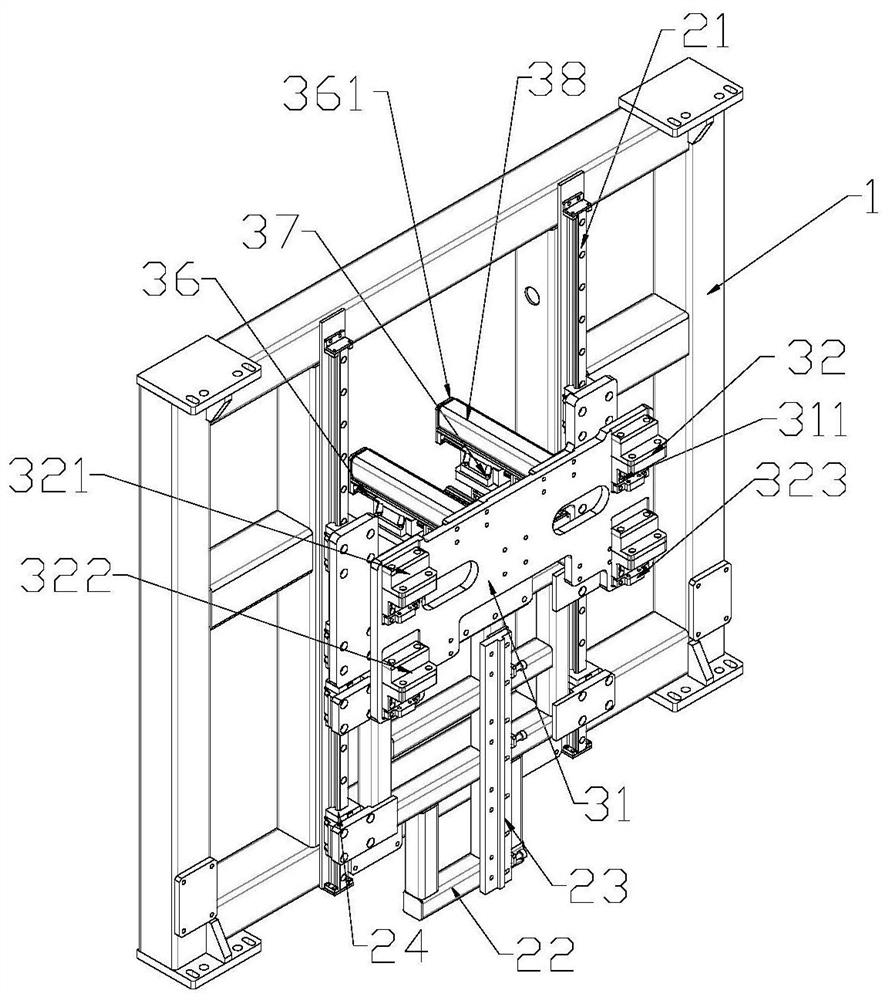

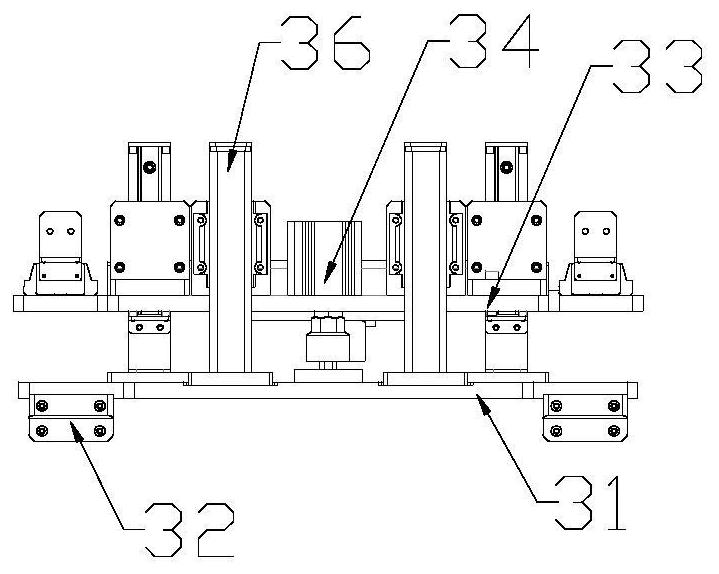

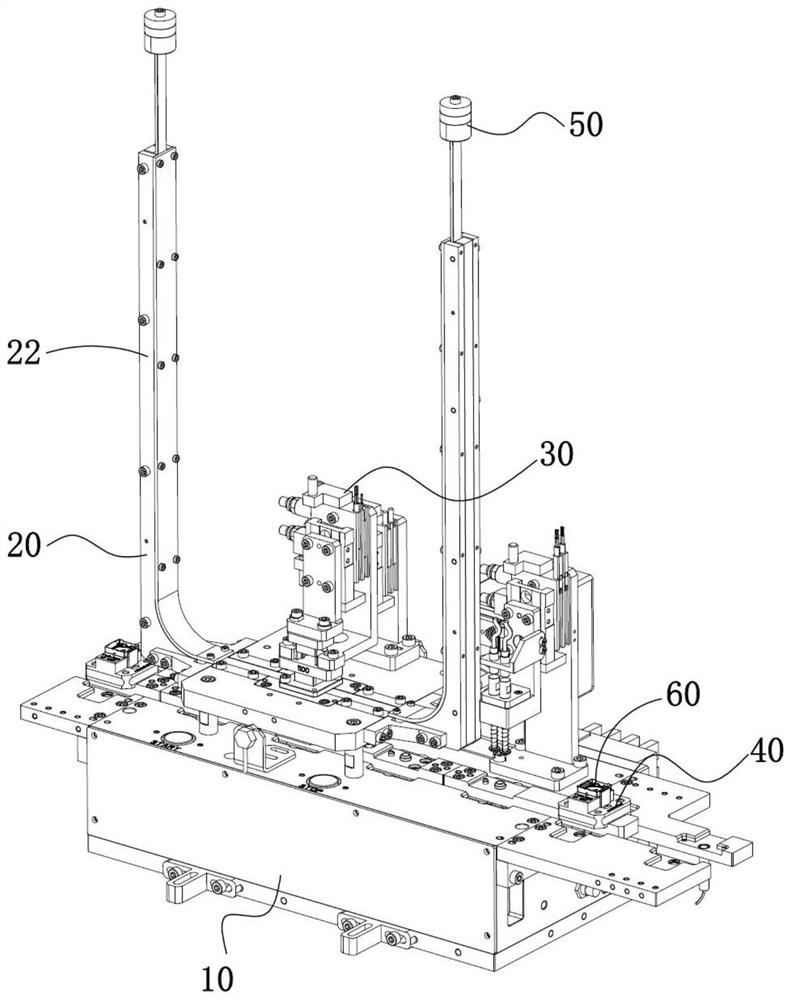

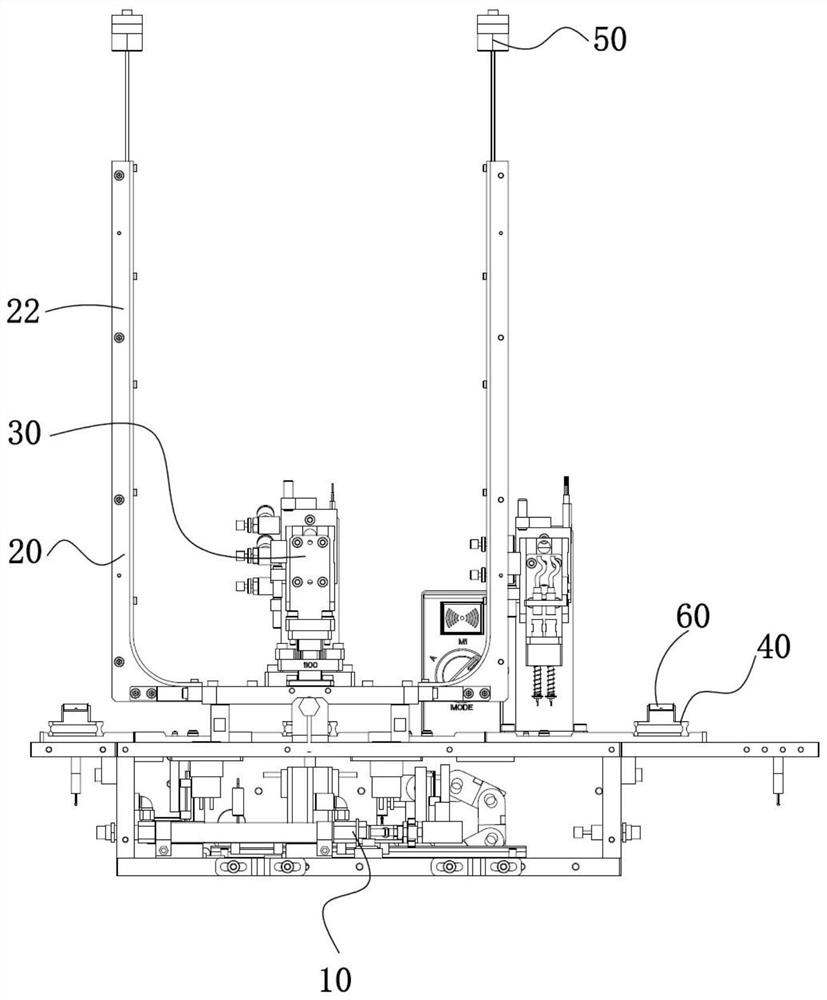

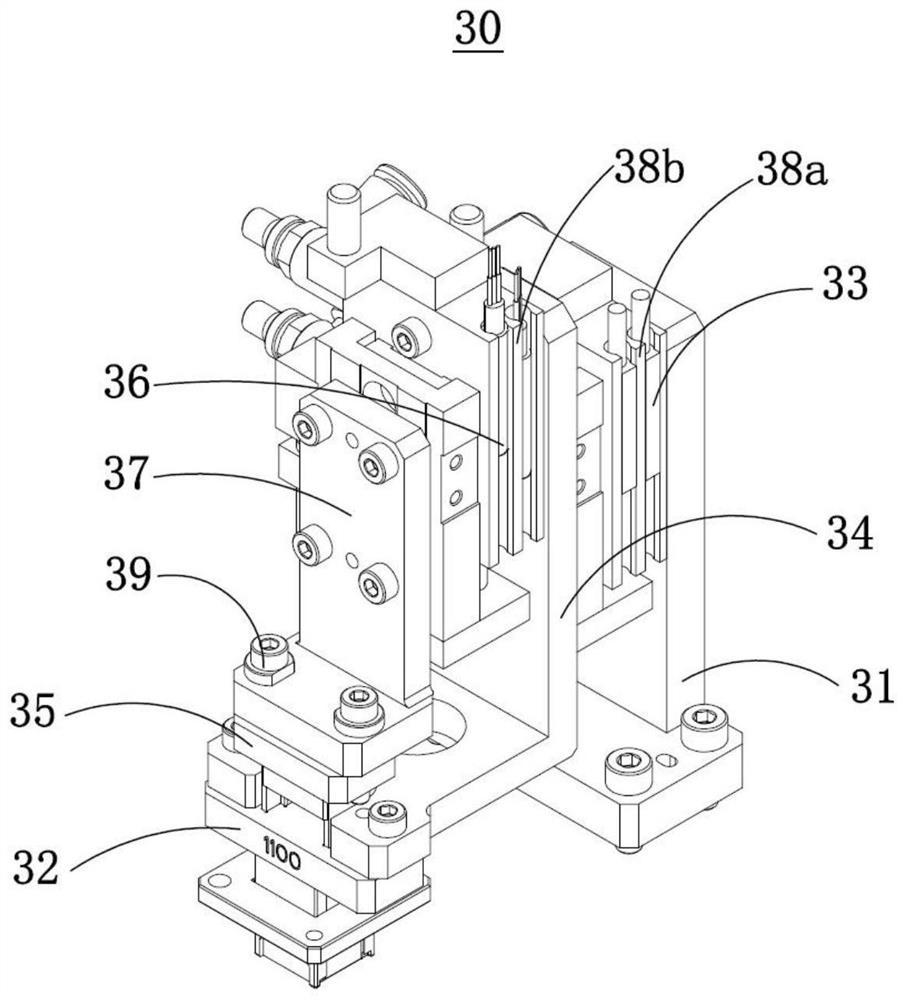

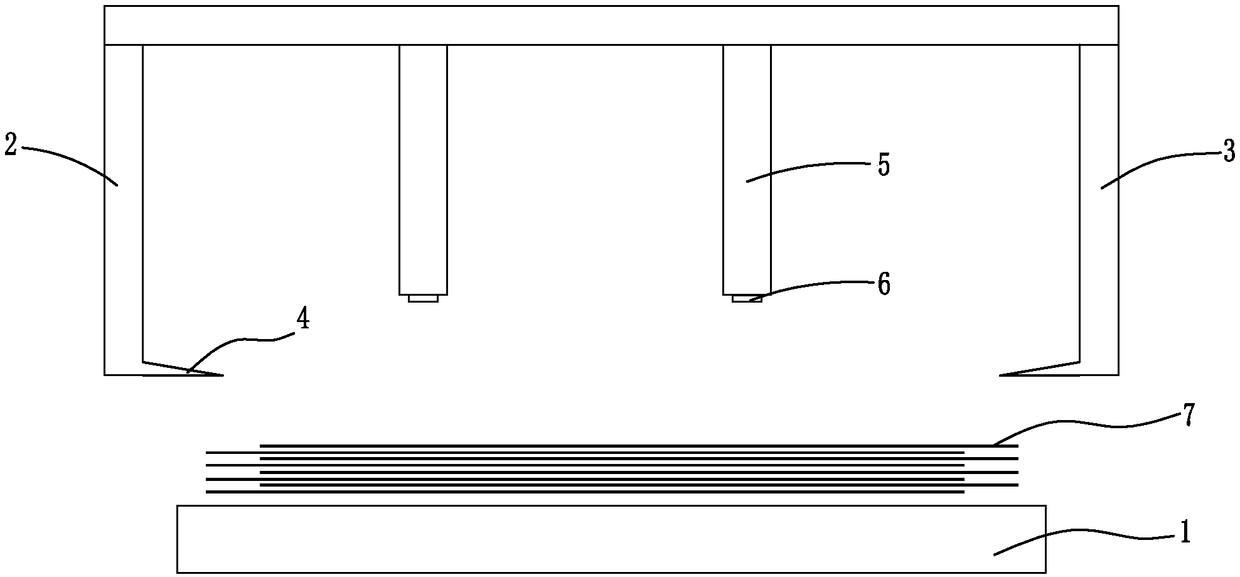

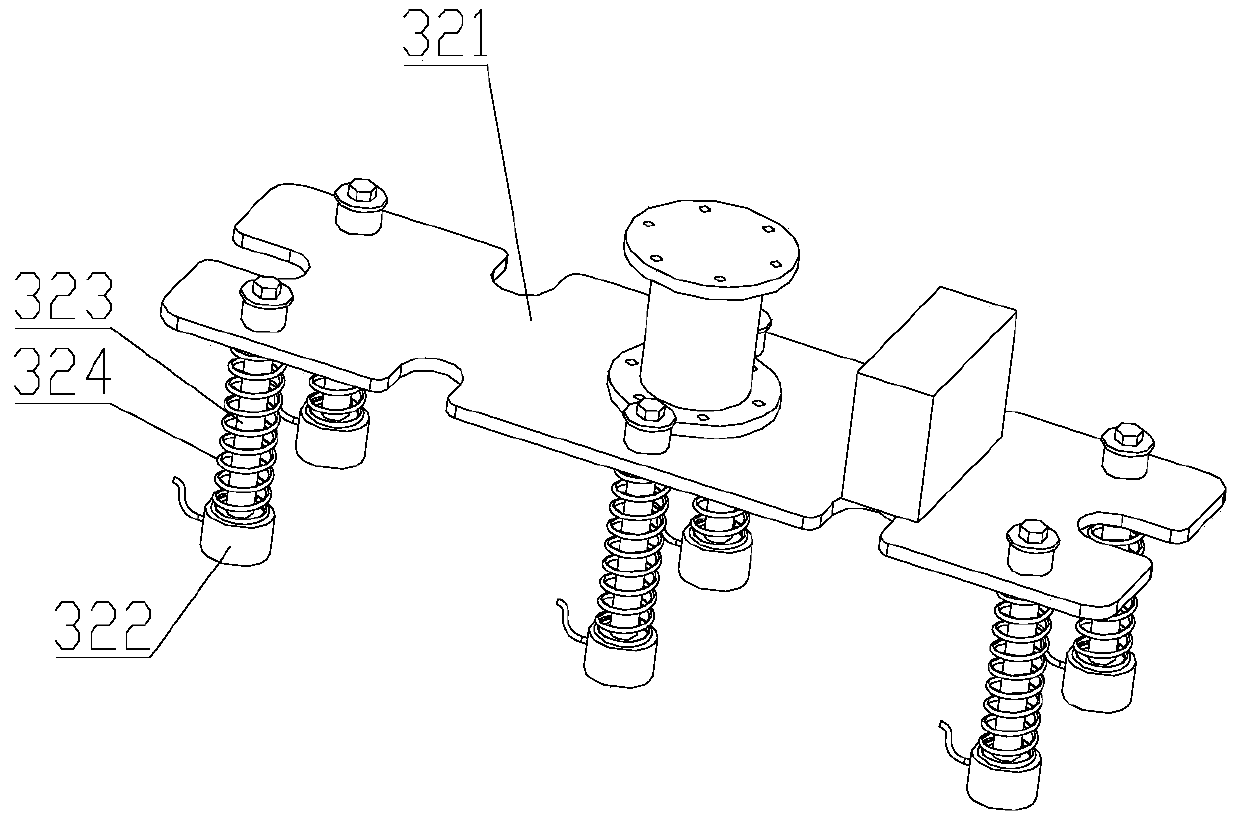

Holding tool device for automatically stacking fuel cell stacks

ActiveCN111403787AImprove stacking accuracySimple structureFuel cellsStructural engineeringElectrical and Electronics engineering

The invention discloses a holding tool device for automatically stacking fuel cell stacks. The device is characterized in that the device comprises a bottom plate which is used for placing an electricpile and a back plate which is fixedly connected to the bottom plate; the bottom plate is provided with a plurality of fixed base columns which are transversely arranged at intervals in front of theback plate; the back plate is provided with a first guide mechanism which can be transversely opened and closed and is matched with the two transverse sides of the galvanic pile for limiting; the first guide mechanism is provided with a second guide mechanism capable of longitudinally moving in front of the fixed base column, the second guide mechanism, the fixed base column and the two longitudinal sides of the electric pile are matched for limiting, and the bottom plate is further provided with a pressing mechanism capable of vertically pressing the electric pile. The transverse size of theelectric pile is controlled and kept through automatic opening and closing of the first guide mechanism, then the longitudinal size between the electric pile and the fixed base column is controlled through movement of the second guide mechanism, the electric pile is vertically pre-pressed and limited through the pressing mechanism after stacking is completed, and the electric pile can be stably transferred to a pressing station.

Owner:DONGFENG MOTOR CORP HUBEI

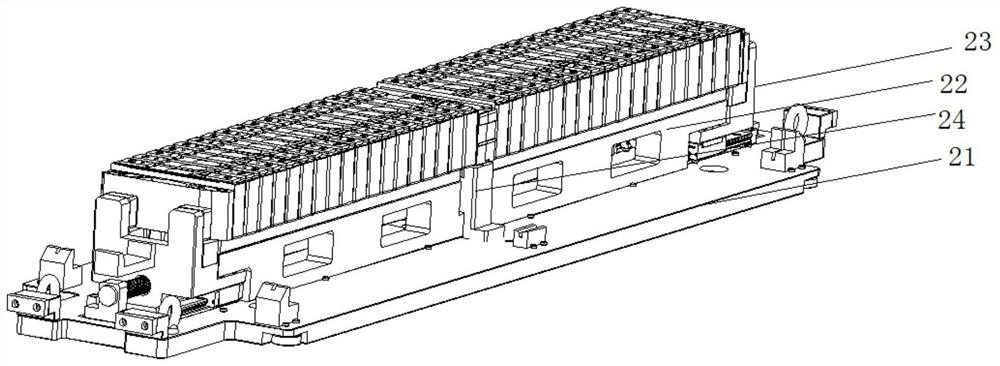

New energy battery tray stacking device

PendingCN113998473AReduce positional deviationImprove stacking accuracyConveyorsStacking articlesNew energyBattery cell

The invention discloses a new energy battery tray stacking device. The device comprises a support, lifting mechanisms are arranged on the two sides of the upper surface of the bottom of the support, clamping mechanisms are installed on the inner sides of the lifting mechanisms, each clamping mechanism comprises a clamping plate, the clamping plates are arranged on the inner sides of the clamping mechanisms and move front and back along with the clamping mechanisms, two sets of supporting plates which are arranged up and down are installed on the end faces of the inner sides of the clamping plates, and the supporting plates comprise the first supporting plates on the upper side and the second supporting plates on the lower side. The problem that when a stacking machine stacks multiple layers of battery trays, the battery trays are prone to damaging in the prior art is solved. Two rows of supporting plates are arranged, and the upper row of supporting plates and the lower row of supporting plates are used for supporting for several times or at the same time, so that the position deviation of the battery trays is reduced, the stacking precision is improved, the stacking precision between the battery trays can be controlled within 5 mm, and the single row of supporting plates only bear the weight of a single layer of battery trays, and the battery trays are not prone to damaging.

Owner:CHANGZHOU CHUANGSHENG INTELLIGENT EQUIP

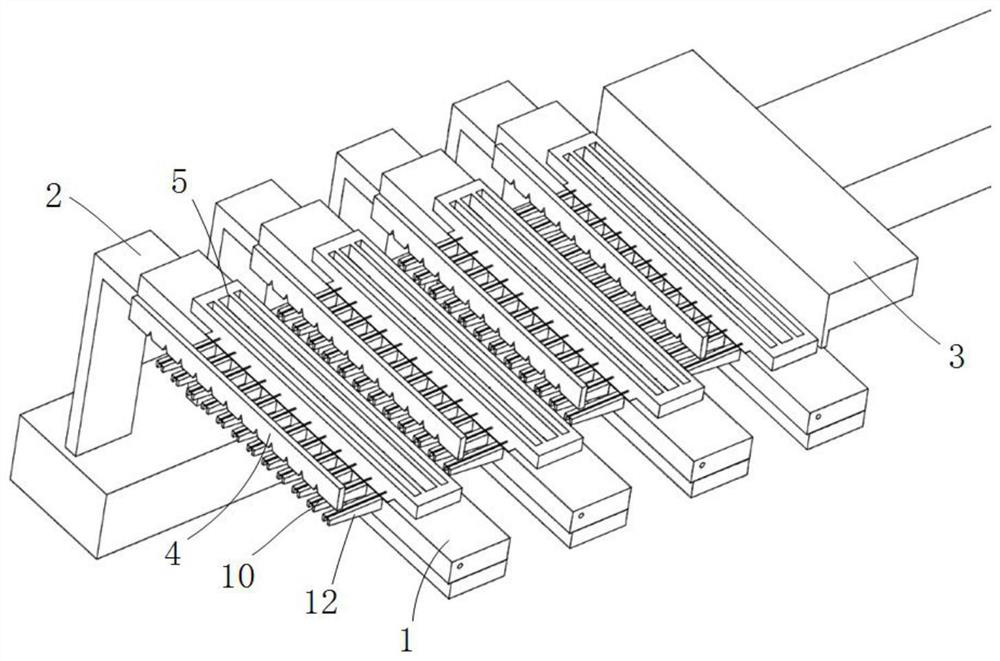

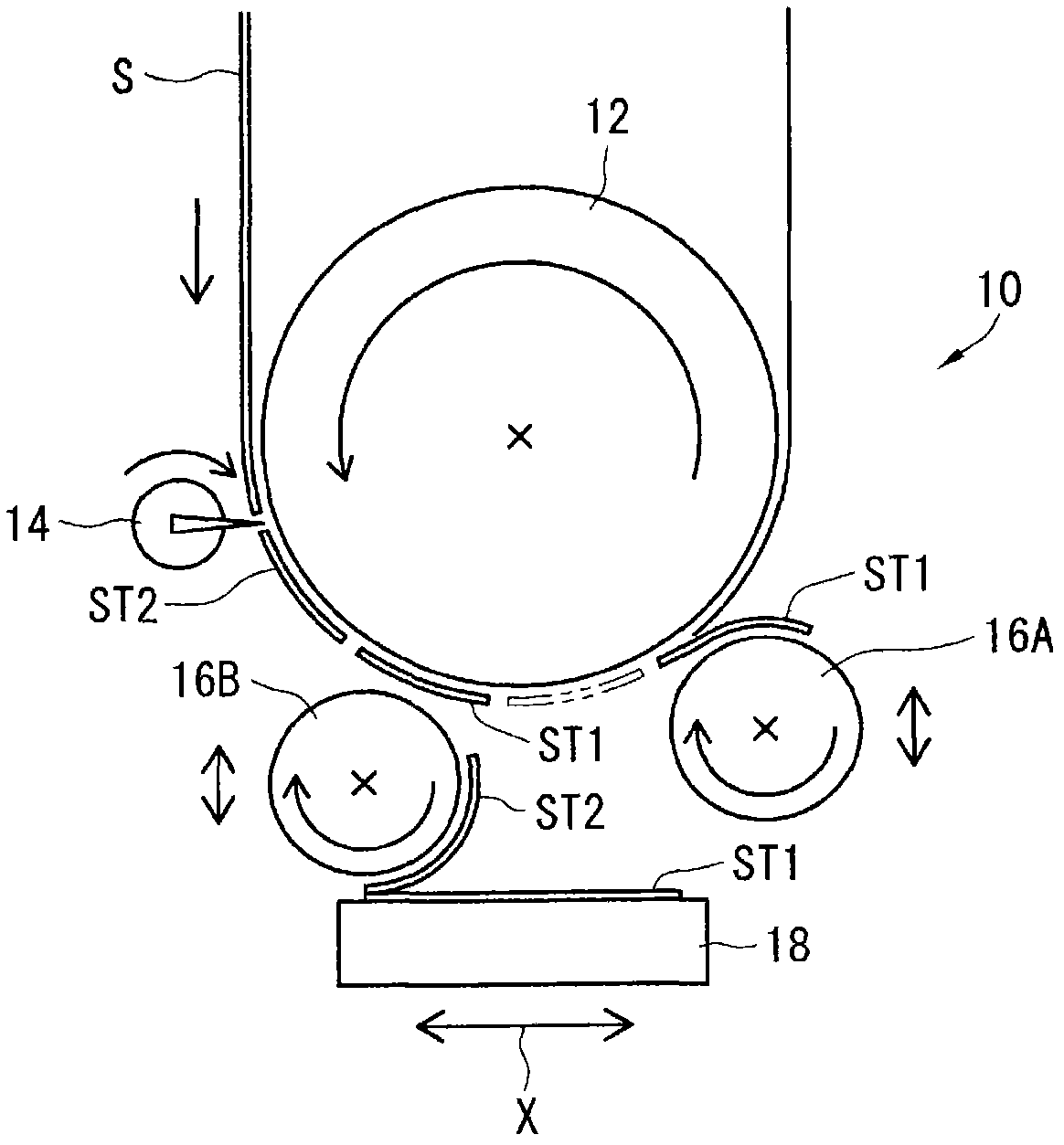

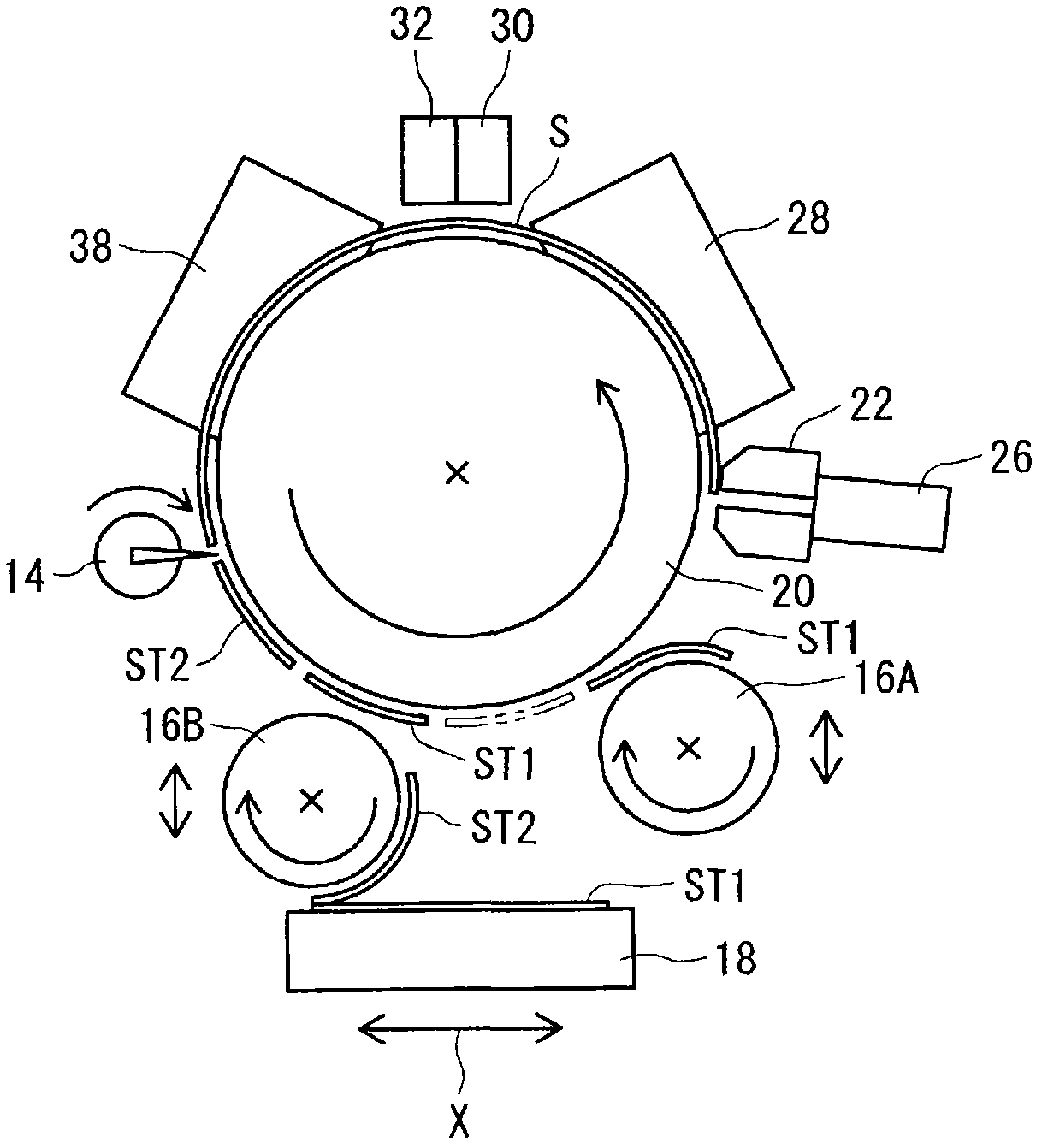

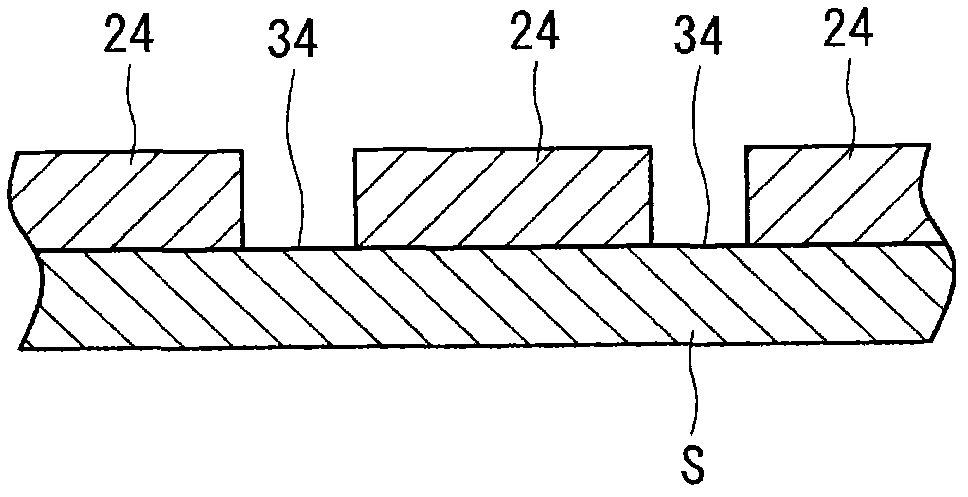

Apparatus and method for manufacturing laminated electronic component

ActiveCN102315023AAvoid damageReduce deformationFixed capacitor dielectricStacked capacitorsMiniaturizationElectronic component

A laminated type electronic component manufacturing device which is enabled to reduce the size of facilities, lower the cost and manufacture high-quality laminated type electronic components with high efficiency is provided. A manufacturing method thereof is also provided. The manufacturing device comprises a sheet material conveying component for continuously conveying the ceramic sheet materials towards a preset direction; a sheet material cutting component for cutting ceramic sheet materials into a preset length; a sheet material laminating component for laminating the cut ceramic sheet materials with a preset length; and a plurality of sheet material transfer printing component which makes the cut ceramic sheet materials peeled from the sheet material conveying component and transfer printing the cut ceramic sheet material on the sheet material laminating component. One sheet transfer printing component and another sheet material transfer printing component make the cut ceramic sheet material alternately transfer printed and laminated.

Owner:MURATA MFG CO LTD

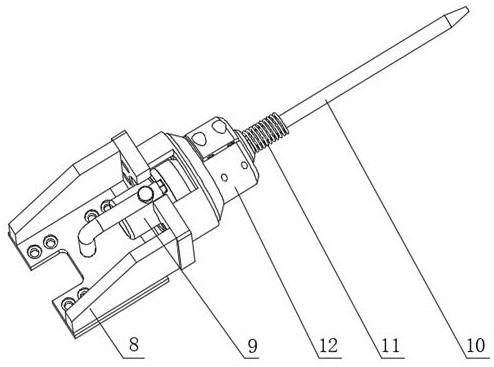

Device for mounting motor magnets of camera

ActiveCN111934501AImprove stacking accuracyLower acquisition costsMagnetsManufacturing stator/rotor bodiesMachineBilateral symmetry

The invention discloses a device for mounting motor magnets of a camera. The device comprises a machine table, a magnet feeding mechanism, a magnet mounting mechanism and a clamp conveying mechanism,wherein the magnet feeding mechanism comprises a feeding bottom plate and two feeding slideways, the feeding bottom plate is fixed to the machine table, the two feeding slideways are arranged at the two ends of the feeding bottom plate in a bilateral symmetry mode respectively, the feeding slideways are used for containing two rows of strip-shaped magnets arranged side by side, and a through holeis formed in the center of the feeding bottom plate; the magnet mounting mechanism comprises a fixing support, a punching core, a punching core air cylinder, a punching core support, a punching claw,a punching claw air cylinder and a punching claw support, the punching claw is arranged on the peripheral side of the punching core in a sleeving mode, and the size of the punching claw is matched with that of the through hole so as to enable the punching claw to penetrate through the through hole. According to the device for mounting the motor magnets of the camera provided by the invention, theupper and lower layers of magnets can be mounted at the same time, equivalently, the work of two existing devices is completed at a time, the equipment acquisition cost is reduced, and the labor costis saved; and the stacking precision of the two layers of magnets is high, and the product quality is improved.

Owner:湖南新视电子技术有限公司

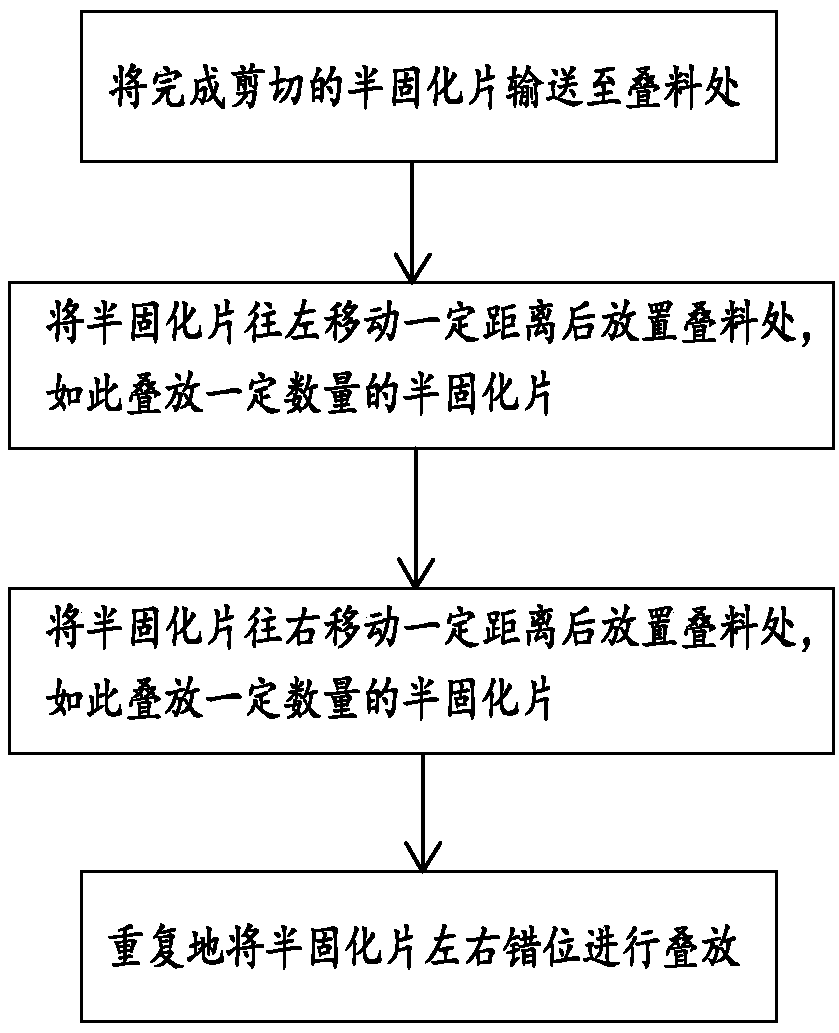

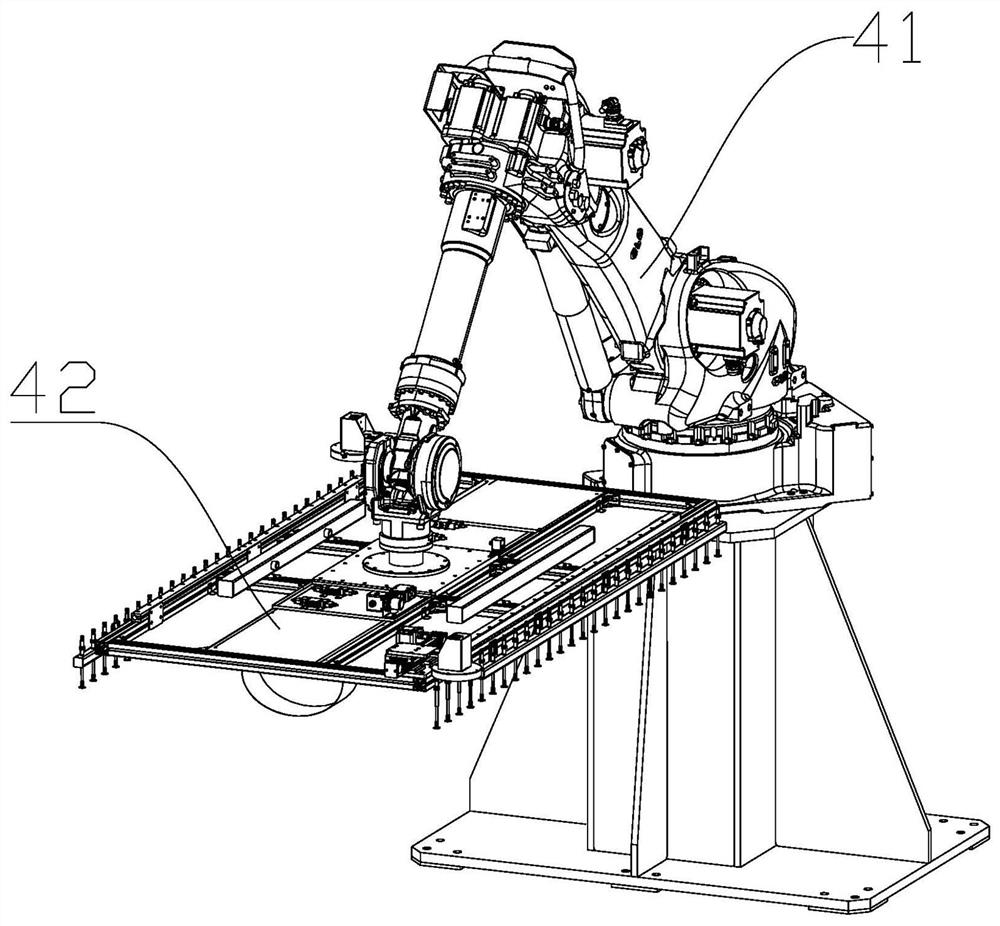

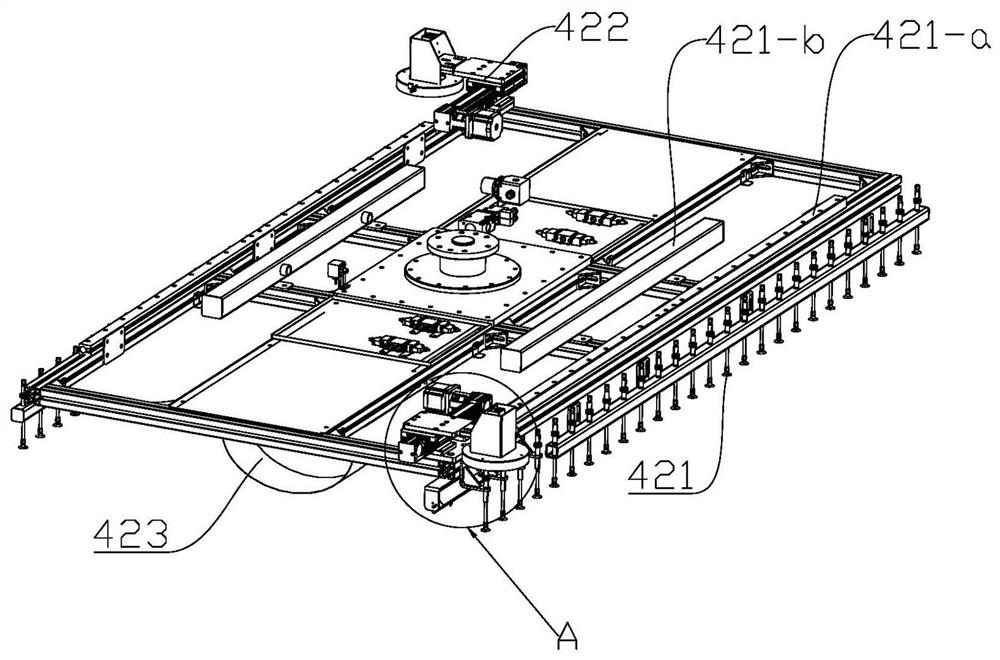

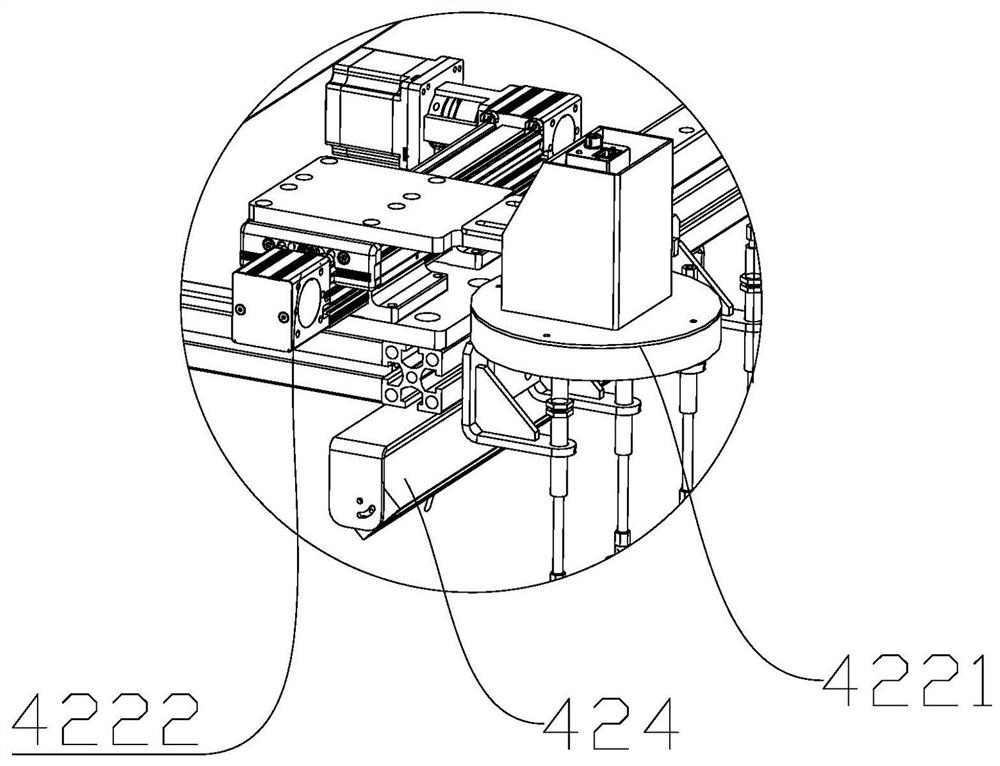

Prepreg stacking device and stacking method

PendingCN109178920AHigh stacking accuracyEfficient stacking methodConveyorsStacking articlesEngineeringConveyor belt

The invention discloses a prepreg stacking device and a stacking method. The prepreg stacking device comprises a machine frame, wherein the machine frame is provided with a conveyor belt for transporting prepregs, a stacking rack for stacking the prepregs, a left mechanical arm and a right mechanical arm; the left mechanical arm and the right mechanical arm are arranged on the machine frame in a left-right movement mode and located above the stacking rack; and the left mechanical arm is matched with the right mechanical arm to stack the prepregs conveyed by the conveyor belt on the stacking rack in a left-right staggered mode. Therefore, the stacking method is more efficient without manual staggered stacking, a certain number of prepregs can be used as a stack, and the stacks are staggered, so that fetching is more convenient, the time and labor cost is saved, and the production efficiency is improved effectively.

Owner:KAIPING PACIFIC INSULATION MATERIAL

PP manipulator hanging head and typesetting device using same

PendingCN114434482AImprove stacking accuracyEffect of stacking accuracyProgramme-controlled manipulatorGripping headsStructural engineeringPlastic film

The invention discloses a PP mechanical arm hanging head and a typesetting device using a mechanical arm, and relates to the technical field of plastic film transportation and stacking. The first feeding platform is arranged on one side of the storage table; the second feeding platform is arranged on the other side, opposite to the first feeding platform, of the storage table; according to any technical scheme, the manipulator for moving the PP film comprises a manipulator assembly and a suction cup frame arranged at the top end of the manipulator assembly, at least two rows of suction cups are arranged on the two sides of the suction cup frame, and the lower end faces of all the suction cups are located at the same height; at least two calibration devices which are arranged diagonally are arranged on the suction cup frame, and the calibration devices are used for calibrating the position of the suction cup frame for grabbing a diaphragm; a plurality of tensioning parts are arranged on the lower end face of the suction cup frame, and the tensioning parts are arranged on the lower end face of the suction cup frame and located between the two rows of suction cups. And the stacking precision of the PP films is improved in a mechanical stacking mode.

Owner:浙江安浦科技有限公司

A silicon steel sheet stacking device

ActiveCN110993304BPrevent rotationMeet production needsTransformers/inductances detailsInductances/transformers/magnets manufactureSlide plateSilicon

The invention discloses a device for stacking trapezoidal silicon steel sheets. The device includes a fixing piece whose end face is a U-shaped groove; two first fixing plates before and after the fixing piece are connected with a third fixing plate; both sides of the first fixing plate are provided with The guide groove, the shrinkage block is located in the U-shaped groove, the two shrinkage blocks are placed on the two sides of the third fixed plate, and are set on the sliding plate; the two sides of each shrinkage block are fixed with sliding pins, and the two sliding pins They are respectively located in the guide grooves of the first fixed plates on both sides; the second fixed plate at the bottom of the U-shaped groove is provided with a vertical through hole, and a connecting rod is arranged in the through hole, and the upper part of the connecting rod is fixedly connected with the sliding plate . The beneficial effect of the invention is to ensure accurate and rapid stacking of trapezoidal silicon steel sheets, meet the needs of mass production in factories, greatly improve stacking work efficiency, improve stacking accuracy, and also meet the stacking quality control of trapezoidal silicon steel sheets. The shrinkable block of the present invention shrinks and opens and closes depending on the integral function of each component, and has simple structure, convenient operation and high reliability.

Owner:铜陵市多元微分科技有限公司

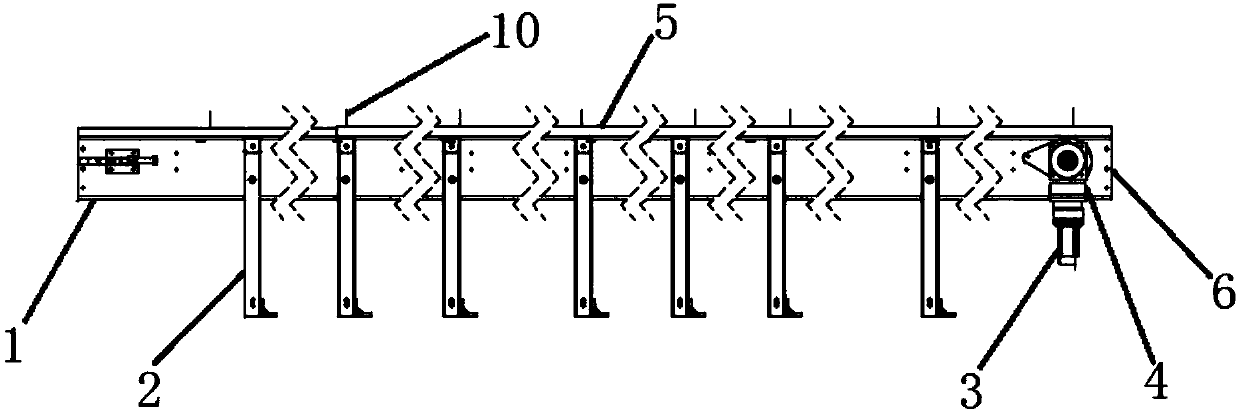

Double-chain conveyor with attaching plate

PendingCN107628406AStable positionImprove the accuracy of stackingConveyorsPackagingSprocketFuselage

The invention relates to a double-chain conveyor with an attaching plate. The conveyor comprises a machine head, a machine body and a machine tail which are sequentially connected, wherein supportinglegs are arranged at the two sides of the machine body; a servo motor and a pair of drive chain wheels which are in transmission connection with the servo motor are arranged in the machine tail; a pair of driven chain wheels is arranged in the machine head; a chain is wound between each drive chain wheel and the corresponding driven chain wheel; the attaching plate is arranged on the chains in thehorizontal direction; and a plurality of positioning baffle plates which are perpendicular to the attaching plate are uniformly arranged on the attaching plate. Compared with the prior art, the double-chain conveyor has the advantages that a chain rotating process and a plastic box moving process can be precisely controlled, and positioning precision is high; and moreover, spacing between every two positioning baffle plates and a distance between two guard bars are regulated, so that products of different specifications are conveyed and unloaded, and therefore, the double-chain conveyor is strong in universality, and can meet the yield needs of various kinds of food package production.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Pushing device for stacking silicon steel sheets of transformer iron core

PendingCN112309705ASimple structureEasy to processInductances/transformers/magnets manufactureTransformerStructural engineering

The invention relates to a pushing device for stacking silicon steel sheets of a transformer iron core. According to the technical scheme, a left silicon steel sheet box (1), a workpiece box (7) and aright silicon steel sheet box (6) are sequentially arranged on the upper plane of a rack (2) from left to right; a fixed part of a left pushing device (3) is fixed on the left side of the rack (2), and the upper end of the left pushing device (3) penetrates through a lower mounting frame (9) and is movably mounted in the left silicon steel sheet box (1); the fixed part of the right pushing device(5) is fixed on the right side of the rack (2), and the upper end of the right pushing device (5) penetrates through the lower mounting frame (9) and is movably mounted in the right silicon steel sheet box (6); and the fixed part of a workpiece pushing device (4) is fixed on the front side of a middle mounting plate (12), and the upper end of the workpiece pushing device (4) is movably arranged in the workpiece box (7). The device is simple in structure, easy to machine, low in cost, wide in application range and high in iron core silicon steel sheet pushing precision and efficiency.

Owner:WUHAN UNIV OF SCI & TECH

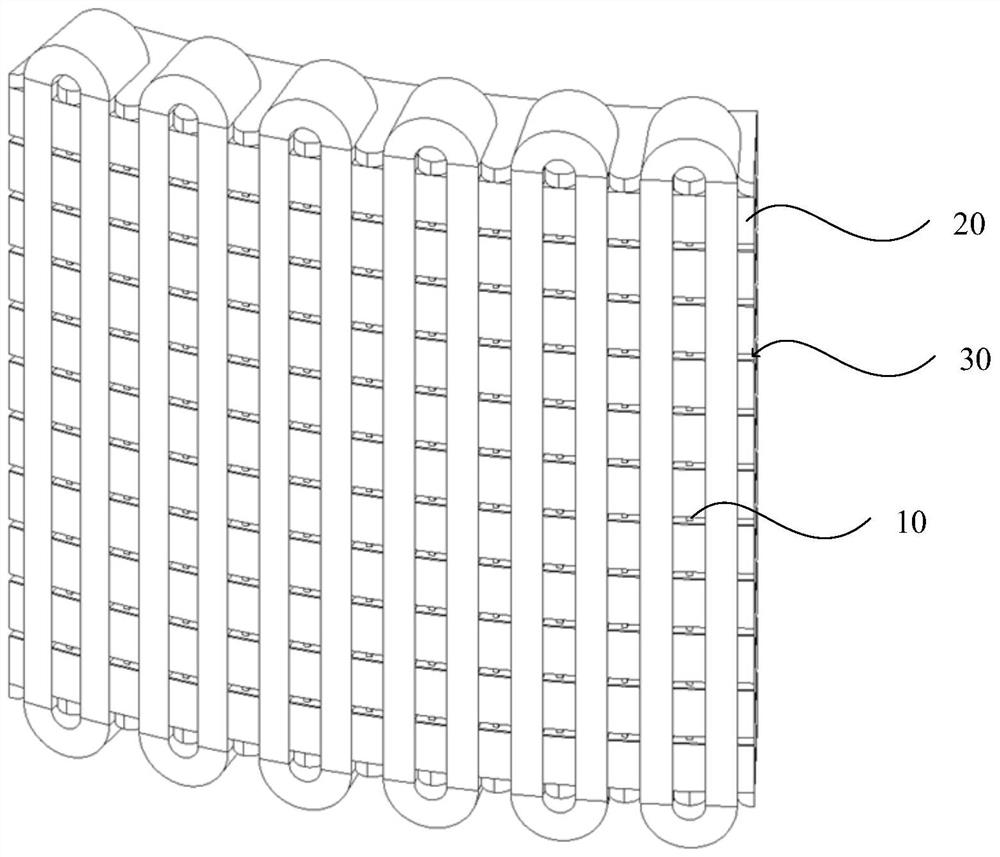

Supporting device, stator including same, and method for assembling stator core

ActiveCN110504803BSave man hoursImprove stacking accuracyMagnetic circuit stationary partsManufacturing stator/rotor bodiesStructural engineeringMechanical engineering

The invention discloses a support device, a stator including the same and an assembly method of the stator core, which are used to support radial ventilation slots of the stator. The support device includes a plurality of support ribs and a positioning component. A plurality of support ribs are arranged at intervals along the circumferential direction of the stator, at least one end of the plurality of support ribs along the axial direction of the stator is provided with a positioning assembly, and a plurality of accommodating grooves for accommodating the support ribs are provided on the positioning assembly, along the stator The axial direction of the accommodating groove is towards the supporting rib, the accommodating groove is used to accommodate one end of the corresponding supporting rib, and the other end of the corresponding supporting rib is located outside the accommodating groove, and the accommodating groove is used to limit the supporting rib Movement in the circumferential and radial directions of the stator. The invention restricts the movement of the support ribs along the circumferential direction and the radial direction of the stator by directly placing the support ribs in the accommodation groove of the positioning assembly, which saves a lot of man-hours required for welding the support ribs and the base plate in the prior art, The manufacturing cost is reduced, and the stacking accuracy of the stator core is improved.

Owner:ZHEJIANG UNIV +1

A welding and forging composite process and device for surface remanufacturing of metallurgical roller table

ActiveCN113478170BAchieve work (forging) hardeningAchieving the problem of uneven compositionRollsMetal rolling arrangementsIndustrial engineeringComposite process

The invention discloses a welding and forging composite process and device for remanufacturing the surface of a metallurgical roller table. When the weld bead cools to the preset temperature, the forging device starts to work to forge the weld bead area cooled to the preset temperature; finally, post-weld treatment and finishing are performed on the repaired roller table, that is, the surface of the roller table is realized remanufacturing. The welding torch and the forging device move at the same speed on the track, and the roller table is driven by the machine head to rotate around its axis, so that the welding material with a set thickness is fully welded in the form of a spiral on the circumferential surface of the roller table. The welding torch is located above the axis of the roller table and vertically downward, and the forging direction of the forging device is horizontally facing the axis of the roller table. The invention can effectively realize the finishing of the surface of the roller table and the homogenization of the structure and composition of the accumulated material, thereby improving the service life of the roller table.

Owner:CHONGQING UNIV +3

Self-adaptive centering stacking equipment

PendingCN114069015AImprove stacking accuracyGuaranteed coincidenceLarge-sized flat cells/batteriesFinal product manufactureStructural engineeringMechanical engineering

The invention relates to self-adaptive centering stacking equipment, and the equipment comprises a machine table, a stacking tray, a self-adaptive reference stacking mechanism and a centering positioning mechanism; the self-adaptive reference stacking mechanism comprises a self-adaptive reference adjusting assembly and a battery cell stacking assembly; the self-adaptive adjusting assembly comprises a reference plate and a reference plate driving source, the reference plate driving source drives the reference plate to abut against a reference positioning pin of the stacking tray, and a stacking reference surface is formed on one side of the stacking tray; the battery cell stacking assembly is used for pressing a battery cell on a stacking tray and a stacking reference surface in an abutting manner and can push the battery cell in the stacking tray; the centering positioning mechanism comprises a centering positioning plate capable of being inserted into the stacking tray and a pressing assembly, the centering positioning plate is pressed and fixed in the stacking tray through the pressing assembly, and the stacking arm pushes the battery cell to abut against the centering positioning plate. While the cell stacking precision is improved, the cell stacking device is suitable for cell stacking of a long module, and the stacking precision is not affected by change of a stacking platform.

Owner:BOZHON PRECISION IND TECH CO LTD

Manufacturing method of thin film touch sensor and thin film touch sensor

ActiveCN109992138BSolve the problem of difficult sheet productionAvoid deformationInput/output processes for data processingThin membraneEngineering

The invention relates to the field of touch screens, and specifically provides a method for manufacturing a thin-film touch sensor and the thin-film touch sensor. The manufacturing method of the thin film touch sensor comprises the following steps: (a) baking the rigid carrier plate covered with the film substrate, the baking temperature is 120-150°C, and the baking time is 30-60min; b) Make a multi-layer touch circuit, wherein, the rest time after soft baking is 2-10min, and the temperature of the exposure table is 25-35°C; (c) combine the film substrate of the multi-layer touch circuit with the rigid The board is separated to obtain the thin film touch sensor. This method can effectively solve the problems of circuit stack offset and low exposure alignment efficiency of each layer when making a touch sensing layer on a film. The exposure alignment is accurate, the efficiency is high, and the line stack offset is small, and the product is good. In addition, it can also produce thin film touch sensors in sheet form.

Owner:LENS TECH CHANGSHA

Stacking equipment and stacking storage method

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

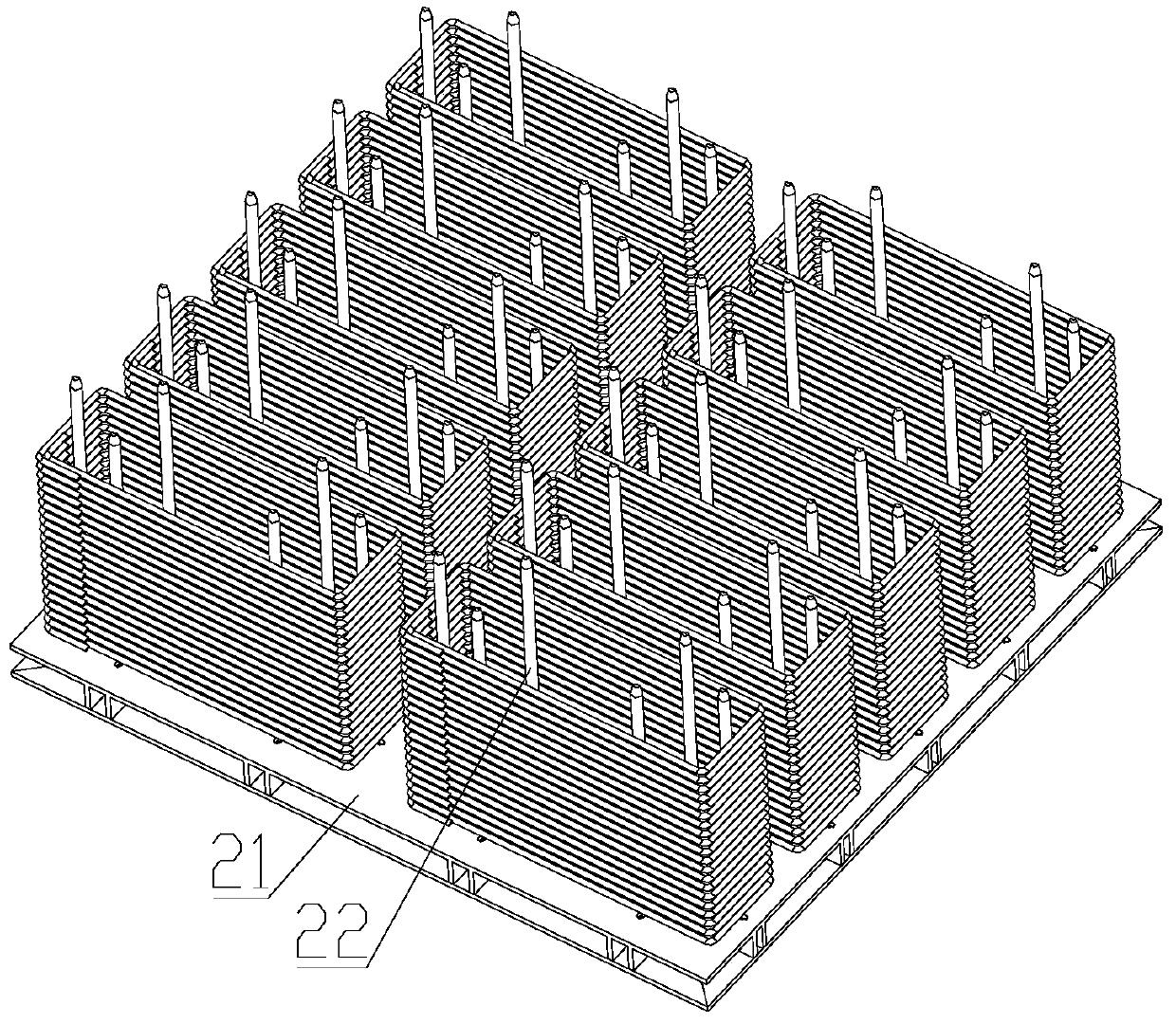

Automatic sleeper stirrup stacking equipment

PendingCN111392084ARealize automatic stackingImprove stacking accuracyStacking articlesIndividual articlesStirrupManual handling

The invention discloses automatic sleeper stirrup stacking equipment. The automatic sleeper stirrup stacking equipment comprises a conveying device for conveying sleeper stirrups. Transfer pallets arearranged at the tail end of the conveying device. The tail end of the conveying device is further provided with a stacking mechanism. The stacking mechanism is used for stacking the sleeper stirrupsconveyed by the conveying device on the transfer pallets. Each transfer pallet comprises a base plate, and a plurality of locating assemblies are arranged on the upper end face of the base plate. Eachlocating assembly comprises a plurality of locating columns arranged along the inner contours of the sleeper stirrups. In a stacked state, the sleeper stirrups are sleeved outside the locating assemblies formed by the locating columns. The automatic sleeper stirrup stacking equipment can achieve the automatic stacking effect of the sleeper stirrups and can effectively improve the stacking efficiency compared with a traditional manual operation mode. Moreover, through automatic sleeper stirrup stacking equipment controls the stacking accuracy of the transfer pallets through guide assemblies, can simplify an equipment control program and can also improve the sleeper stirrup stacking accuracy.

Owner:北京好运达智创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com