Supporting device, stator including same, and method for assembling stator core

A technology for supporting devices and stator cores, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, and electric components. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

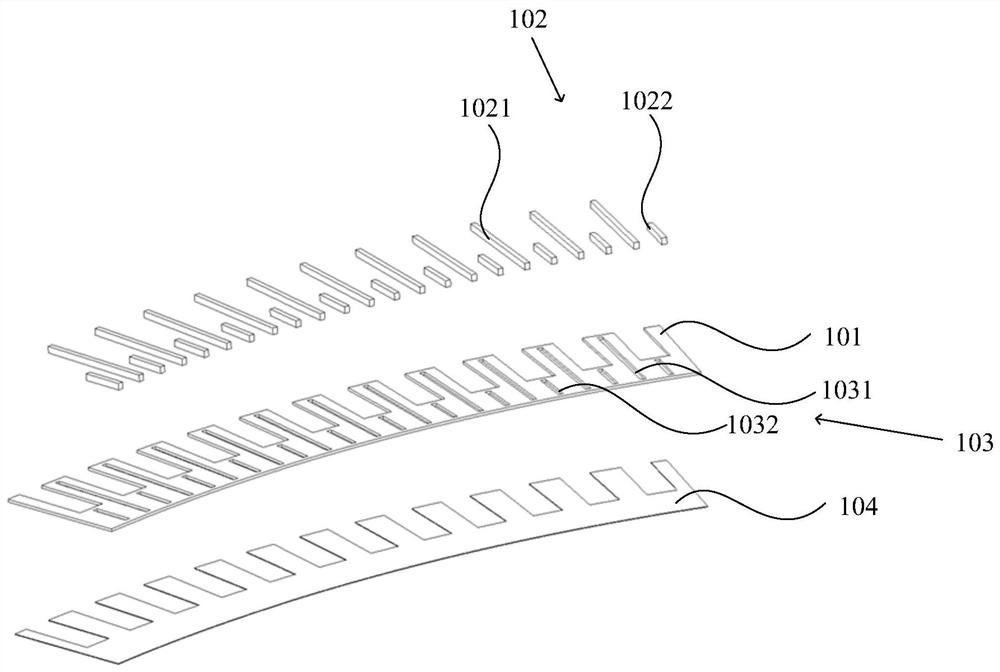

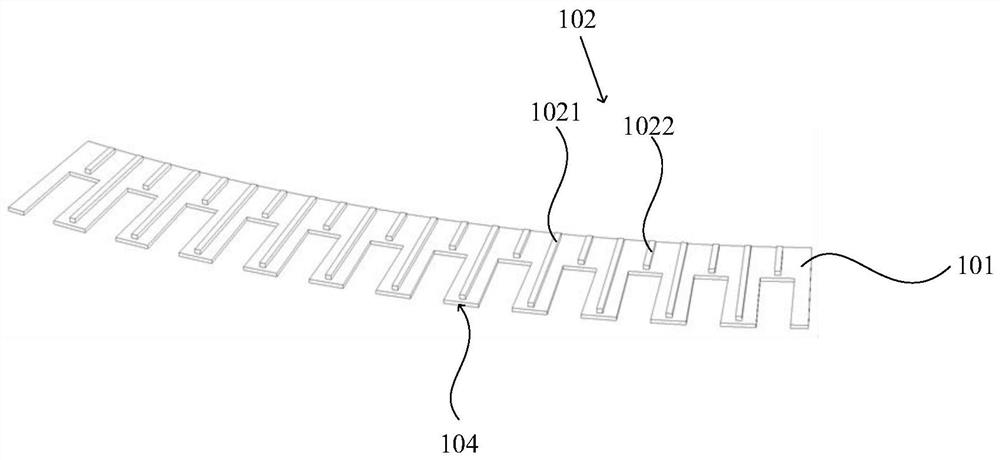

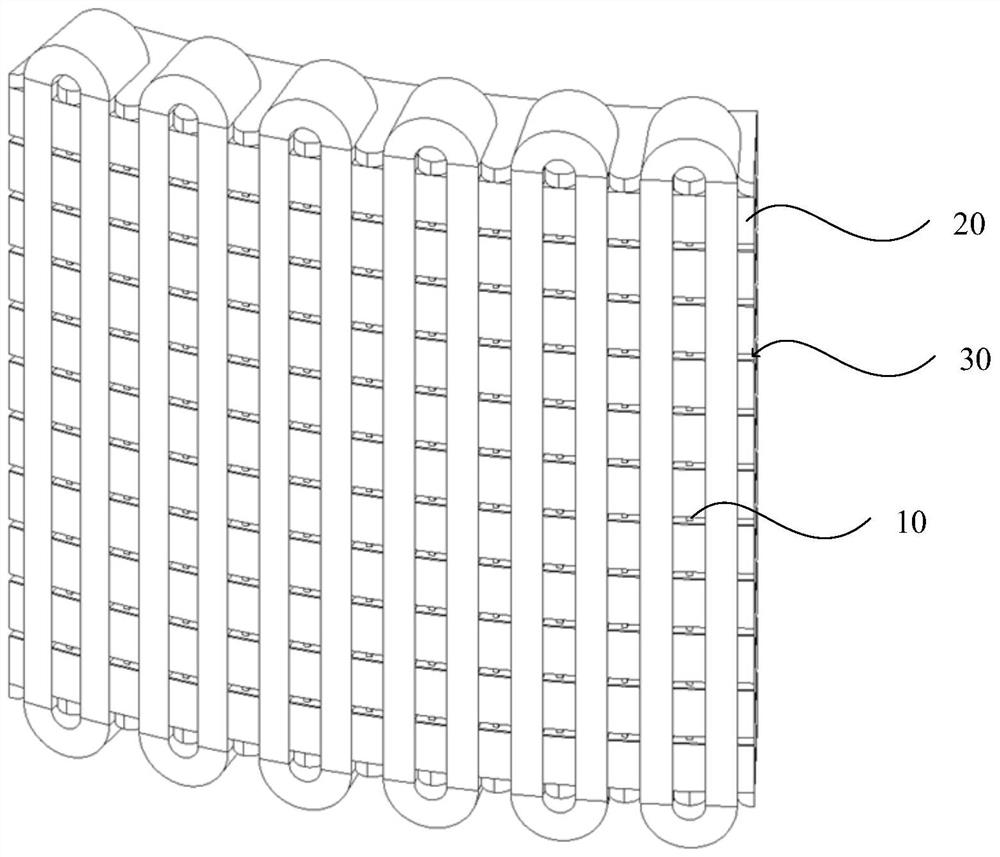

[0078] The present invention provides a support device for supporting the radial ventilation slots of the stator, such as Figure 1-2 As shown, the supporting device 10 includes a positioning component 101 and a plurality of supporting ribs 102 .

[0079] A plurality of supporting ribs 102 are arranged at intervals along the circumferential direction of the stator, and one end of the plurality of supporting ribs 102 along the axial direction of the stator is provided with a positioning assembly 101, and the positioning assembly 101 is provided with a plurality of accommodations for accommodating the supporting ribs 102. Groove 103. In other alternative embodiments, the positioning assembly 101 is not limited to be arranged at one end of the plurality of support ribs 102, and the positioning assembly 101 can be provided at both ends of the plurality of support ribs 102 along the axial direction of the stator, which can play a role The positioning effect of the accommodating gr...

Embodiment 2

[0101] The structure of this embodiment is basically the same as that of Embodiment 1, except that the number of positioning components 101 is different, the structure of positioning components 101 is different, the structure of supporting ribs 102 is different, and the number of substrates 104 is different. The same reference numerals in Example 1 refer to the same elements.

[0102] Such as Figure 4-6 As shown, along the axial direction of the stator, positioning components 101 are provided at both ends of a plurality of first supporting ribs 1021 and a plurality of second supporting ribs 1022, wherein one positioning component 101 is a first positioning component 1011, and the other positioning component Component 101 is a second positioning component 1012 . The two positioning components 101 can better limit the movement of the first support rib 1021 and the second support rib 1022 along the circumferential and radial directions of the stator, improve the stacking accura...

Embodiment 3

[0109] The structure of this embodiment is basically the same as that of Embodiment 2, the difference being that the structure of the positioning assembly 101 is different, and the same reference numerals in this embodiment and Embodiment 2 refer to the same elements.

[0110] Such as Figure 7-8 As shown, a first accommodating groove 1031 and a second accommodating groove 1032 adjacent to it are a set of accommodating grooves, and two adjacent accommodating groove groups are sequentially arranged on the first positioning assembly 1011 and the second positioning assembly 1012 Arranged alternately, it can reduce the number of accommodation grooves 103 while playing a better role of the accommodation grooves 103 in limiting the first support rib 1021 and the second support rib 1022, saving the man-hours required for forming the accommodation groove 103 . The first support rib 1021 is accommodated in the first accommodation groove 1031 , and the second support rib 1022 is accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com