Epoxy rust graphene anticorrosive coating as well as preparation method and application thereof

A technology of anti-corrosion coatings and graphene, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as environmental pollution, poor anti-corrosion performance, toxic pigments, etc., to delay the way and time, improve anti-corrosion performance, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

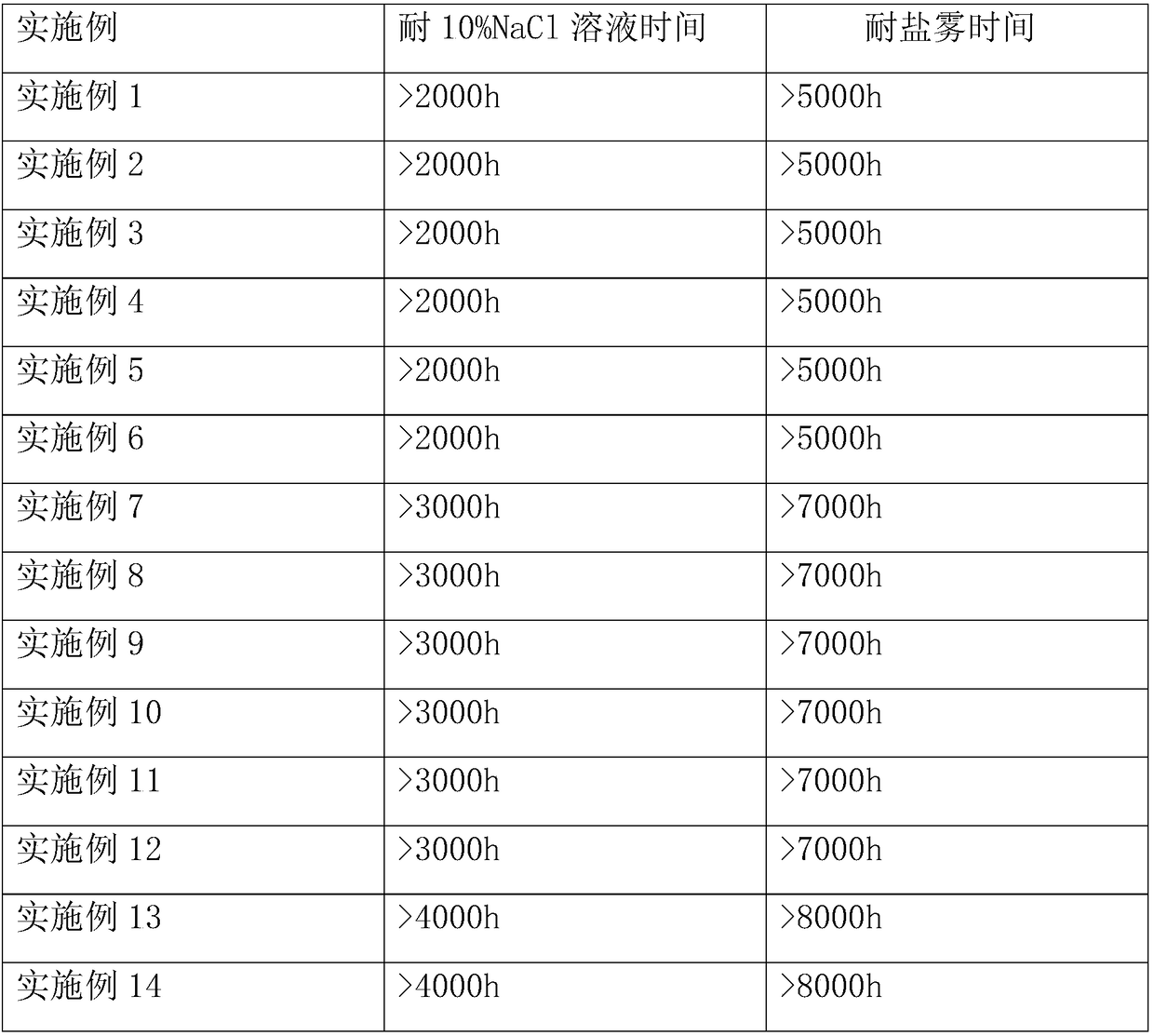

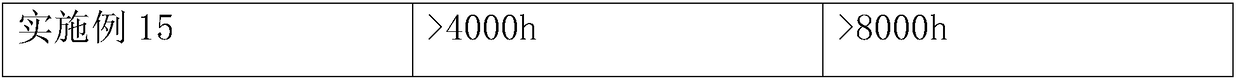

Examples

Embodiment 1

[0062] (1) Weigh the conductive and thermally conductive graphene powder (model: SE1231) produced by Changzhou Sixth Element Materials Technology Co., Ltd. (D50 is 9 μm), add dispersant and solvent, mix well and then grind, and then grind Ultrasonic dispersion to obtain a graphene dispersion;

[0063] (2) Add bisphenol A epoxy resin E51, active pigments, pigments and fillers, and coating additives to the graphene dispersion, stir and grind, and obtain component A after grinding.

[0064] Among them, the solvent is 200# solvent oil, the dispersant is silane coupling agent KH550, the pigment and filler are talcum powder and barium sulfate, the coating additives are defoamer Deqian 6800, the leveling agent Deqian 8629, and the thixotropic agent is organic Bentonite, active pigments are zinc phosphate, aluminum tripolyphosphate.

[0065] Wherein the weight percentage content of each substance in component A is: graphene 2%, bisphenol A type epoxy resin E5140%, zinc phosphate 15%,...

Embodiment 2

[0068] (1) Weigh the conductive and thermally conductive graphene powder (Model: SE1231) produced by Changzhou Sixth Element Materials Technology Co., Ltd. (D50 is 8μm), add dispersant and solvent, stir well and then grind, and then grind Ultrasonic dispersion to obtain a graphene dispersion;

[0069] (2) Add bisphenol A epoxy resin E44, active pigments, pigments and fillers, and coating additives to the graphene dispersion, stir and grind, and obtain component A after grinding.

[0070] Among them, the solvent is 200# solvent oil, the dispersant is silane coupling agent KH550, the pigment and filler are talcum powder and barium sulfate, the coating additives are defoamer Deqian 6800, leveling agent Deqian 8629, and the active pigments are zinc phosphate, Aluminum tripolyphosphate.

[0071] Among them, the weight percentage of each substance in component A is: graphene 1%, bisphenol A epoxy resin E44 40%, zinc phosphate 15%, aluminum tripolyphosphate 10%, talcum powder 5%, ba...

Embodiment 3

[0074] (1) Weigh the conductive and thermally conductive graphene powder (Model: SE1231) produced by Changzhou Sixth Element Materials Technology Co., Ltd. (D50 is 3 μm), add dispersant and solvent, stir well and then grind, and then grind Ultrasonic dispersion to obtain a graphene dispersion;

[0075] (2) Add epoxy resin solution, active pigments, pigments and fillers, and coating additives to the graphene dispersion, stir and grind, and obtain component A after grinding.

[0076] The solvent is xylene and n-butanol, the epoxy resin solution is epoxy resin E20 soluble in solvent, the dispersant is silane coupling agent KH550, the coating additives are defoamer Deqian 6800 and leveling agent Deqian 8629 , The active pigments are zinc phosphate and aluminum tripolyphosphate.

[0077] Among them, the weight percentage of each substance in component A is: graphene 5%, epoxy resin E20 30%, zinc phosphate 10%, aluminum tripolyphosphate 10%, talcum powder 5%, barium sulfate 10%, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com