Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Good penetration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

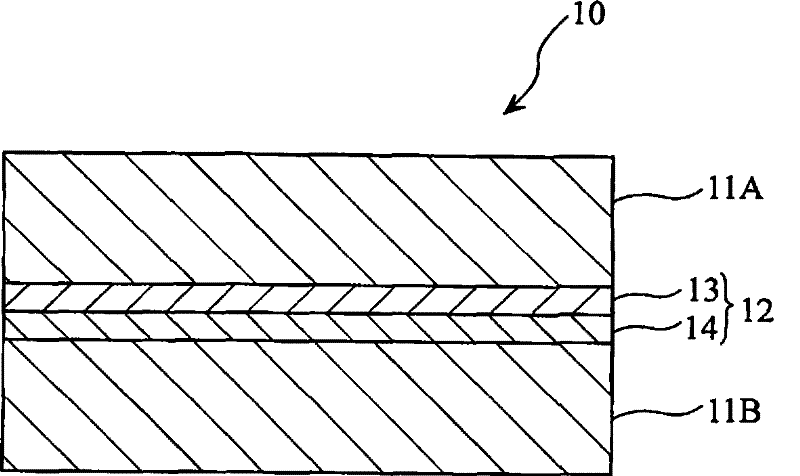

Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

InactiveCN101410341AHigh transparencyGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsWeather resistanceUv absorber

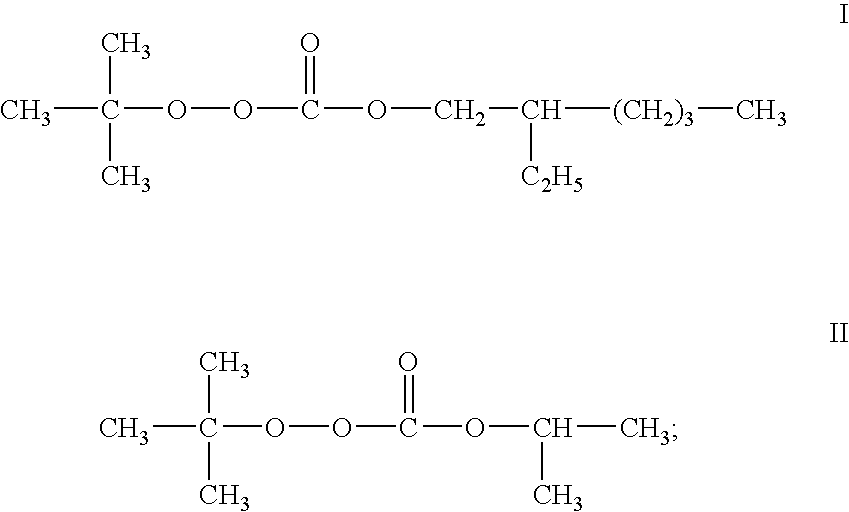

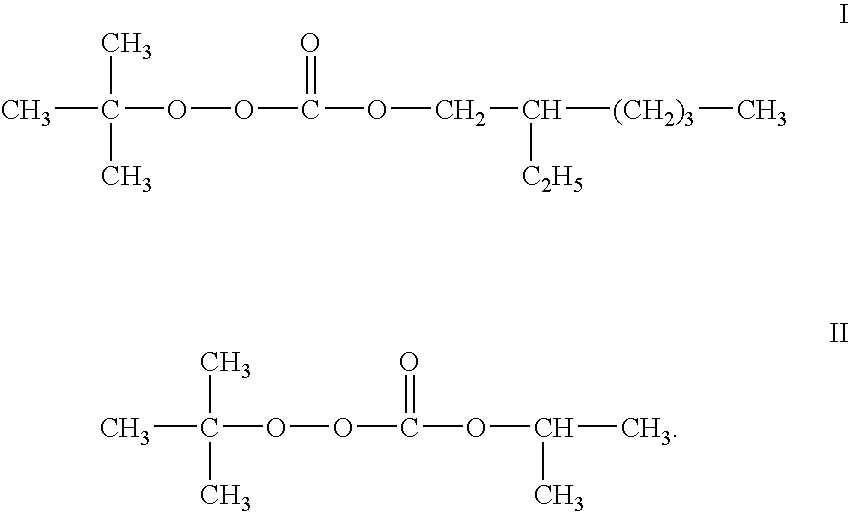

The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation. An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

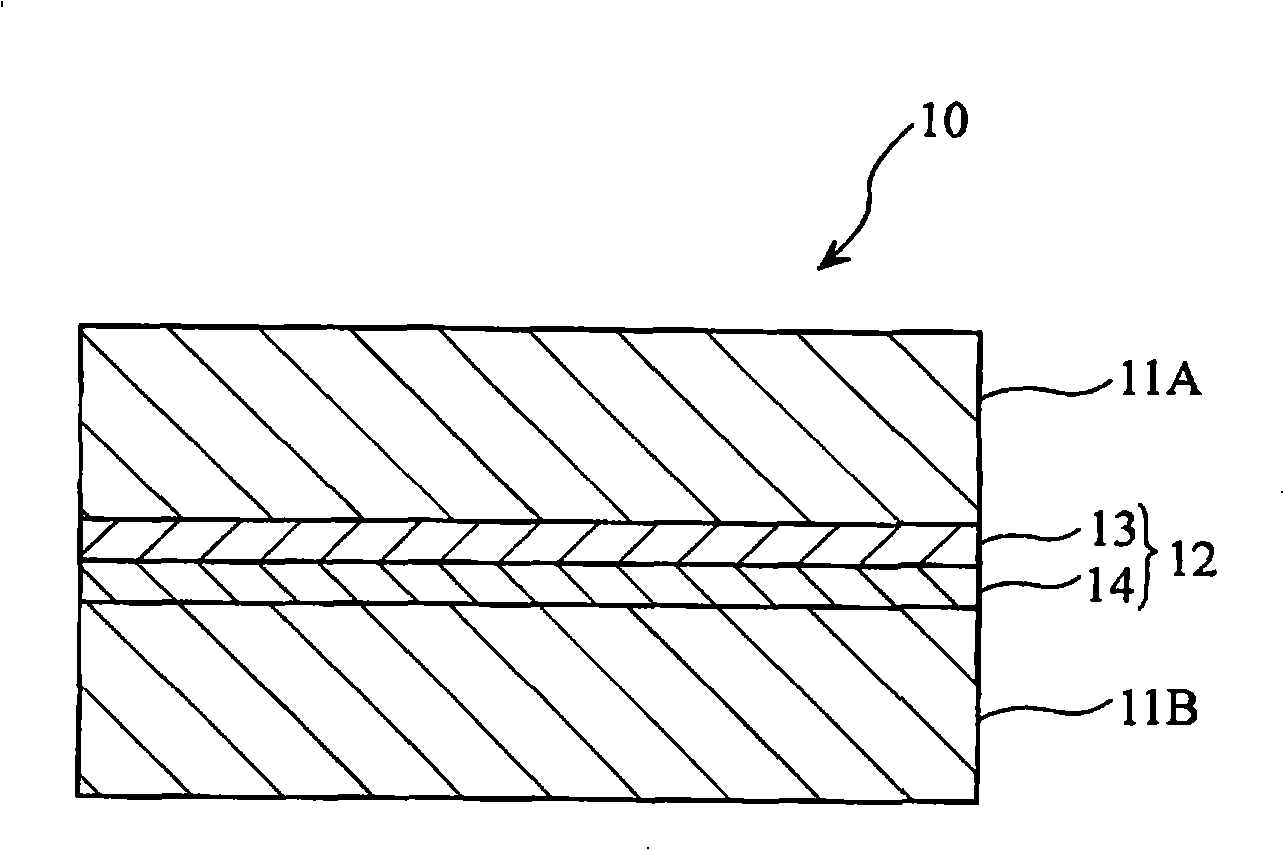

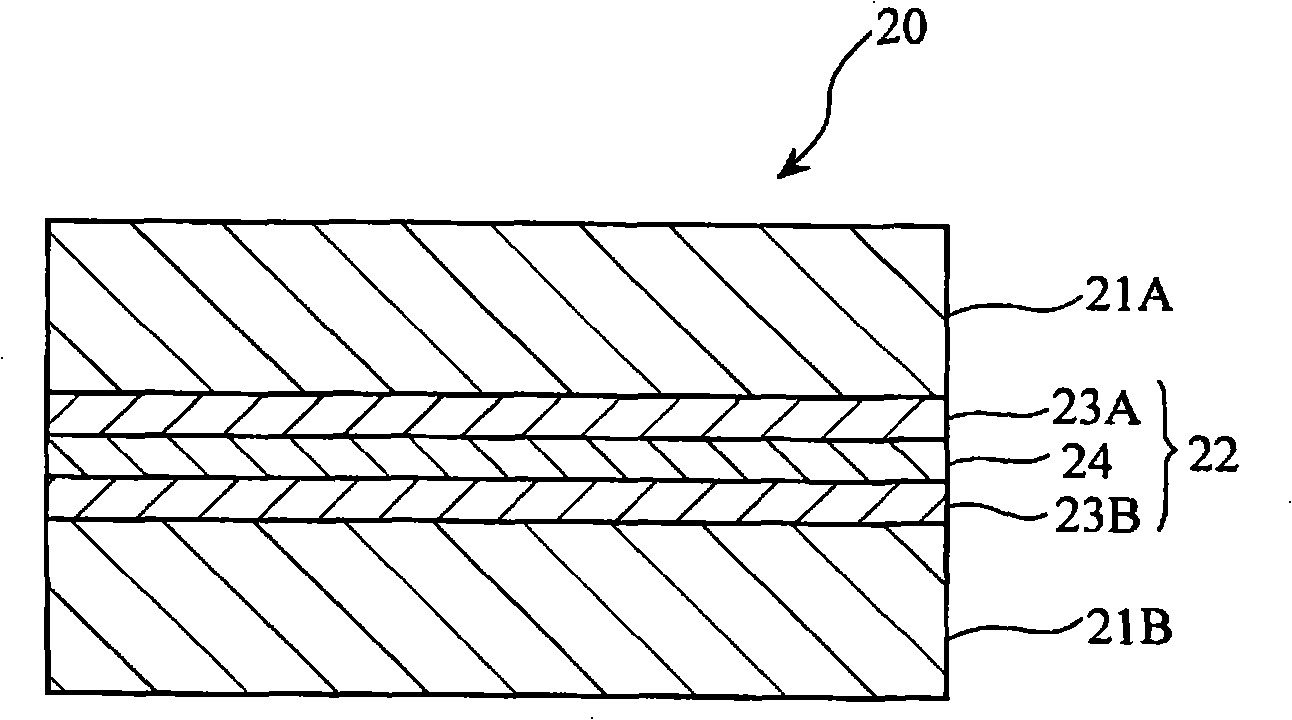

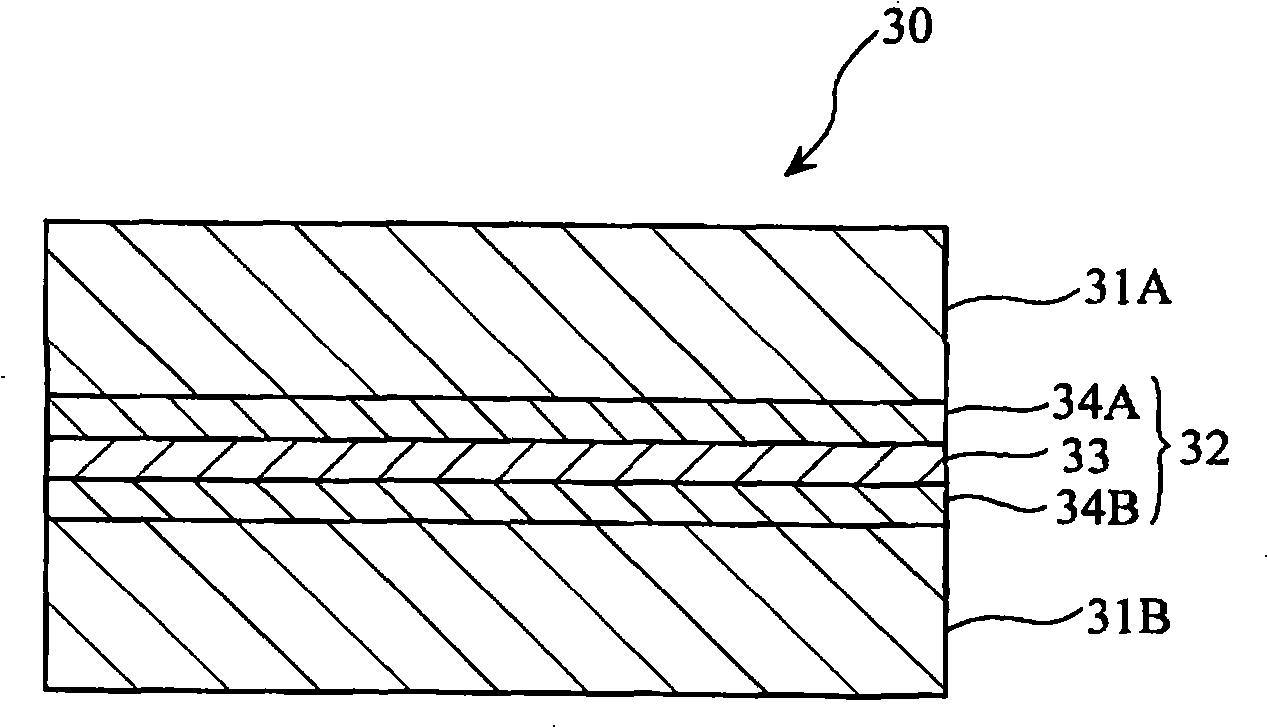

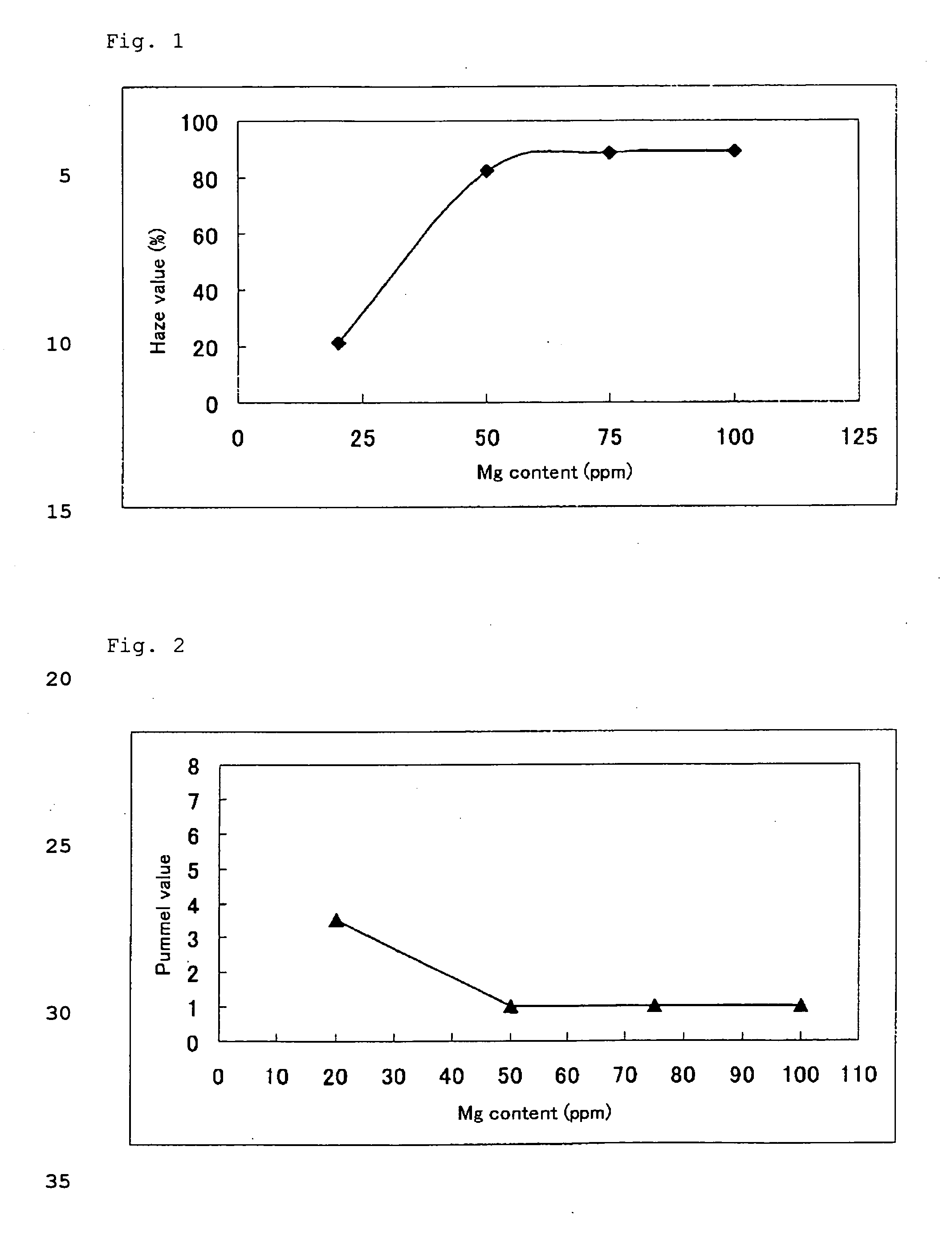

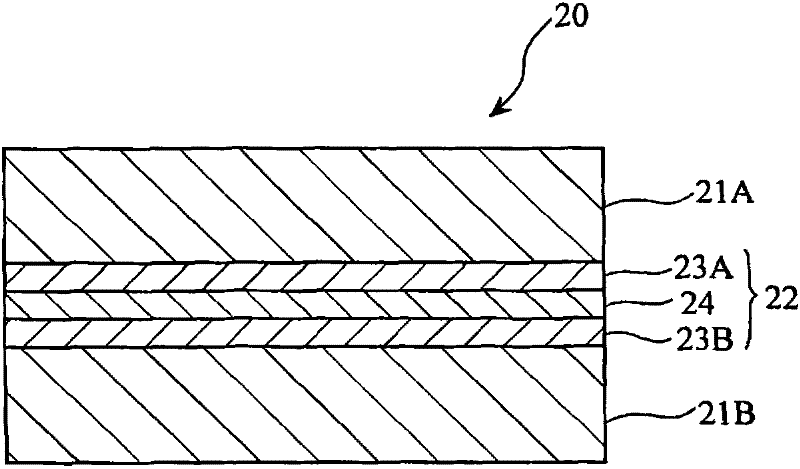

Interlayer film for laminated glass and laminated glass

InactiveUS20070178314A1Good penetration resistanceInhibition formationWindowsAntiglare equipmentMetal coatingTemporal change

It is an object of the present invention to provide an interlayer film for a laminated glass which can prevent the formation of a colored spot in a metal coating on a glass surface due to remaining alkali metal, has excellent penetration resistance and hardly causes temporal changes in the interlayer film's adhesion to glass and buildup (colored streaks of an interlayer film for a laminated glass), and a laminated glass. The present invention is directed to an interlayer film for a laminated glass, which contains a matrix resin, a liquid plasticizer, acetyl acetone, alkali metal and at least one kind of metal selected from the group consisting of magnesium and alkaline earth metal, the content of the alkali metal being 20 to 120 ppm, the content of at least one kind of metal selected from the group consisting of magnesium and alkaline earth metal being 15 ppm or more and less than 60 ppm, and the content of the acetyl acetone being 0.008 parts by weight or more with respect to 100 parts by weight of the matrix resin.

Owner:SEKISUI CHEM CO LTD

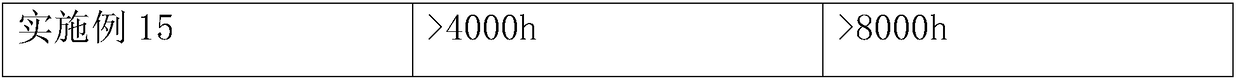

Epoxy rust graphene anticorrosive coating as well as preparation method and application thereof

ActiveCN108285718AWays and times of defermentGood penetration resistanceAnti-corrosive paintsEpoxy resin coatingsLong actingSolvent

The invention relates to the field of anticorrosive coatings, in particular to an epoxy rust graphene anticorrosive coating and a preparation method thereof. The epoxy rust graphene anticorrosive coating is prepared from the following components in percentage by weight: 0.1 to 5 percent of graphene, 30 to 60 percent of epoxy resin, 20 to 40 percent of an active pigment, 10 to 30 percent of a pigment filler, 0.1 to 10 percent of a dispersant, 0.1 to 5 percent of a coating additive and 8 to 30 percent of a solvent. According to the coating provided by the invention, all the components achieve asynergetic enhancement effect; the obtained coating is tightly combined with a rust layer and is excellent in anticorrosive property; rust spray coating, long-acting corrosion prevention and a primer-topcoat type are realized. According to the corresponding preparation method, all the components work synergistically, and the coating with uniformly dispersed graphene powder is obtained. The methodis simple, convenient and feasible in preparation, and the prepared coating is excellent in performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Intermediate film for laminated glass and laminated glass

ActiveUS20100233493A1Promote mutual integrationGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsPolyvinyl alcoholPlasticizer

The present invention provides an interlayer for a laminated glass, which contains a polyvinyl acetal resin, and can be easily bonded to a glass sheet to form a highly transparent laminated glass. And the present invention provides a laminated glass using the interlayer.The interlayer for a laminated glass contains 100 phr of a polyvinyl acetal resin and 42 to 60 phr of a plasticizer, wherein the plasticizer is unsaturated fatty acid alkyl ester having 16 to 20 carbon atoms.

Owner:SEKISUI CHEM CO LTD

Composite bulletproof armor plate and preparation method thereof

ActiveCN109855473AHigh compressive strengthIncrease elasticitySynthetic resin layered productsLaminationInterference fitCeramic composite

The invention discloses a composite bulletproof armor plate and a preparation method thereof. The composite bulletproof armor plate comprises a protective cover plate, ceramic plates, metal restraining plates, a fiber metal laminated plate and a porous metal sandwich plate; and the ceramic plates and the metal restraining plates are assembled and connected in an interference fit mode, the ceramicplates are supported through the fiber metal laminated plate and the porous metal sandwich plate, and the bullet resistance of a bulletproof armor plate is improved. The preparation technology is simple, the cost is low, compared with a traditional ceramic composite armor plate, the composite bulletproof armor plate is higher in impact resistance at a time and has the multi-time impact resistance,and the composite bulletproof armor plate has the wide application prospects in the bulletproof fields of armed helicopters, armored cars, vessels and the like.

Owner:XI AN JIAOTONG UNIV

PVC battery separation plate production method and PVC battery separation plate

The present invention discloses a PVC battery separation plate production method and a PVC battery separation plate, wherein the method and the separation plate are used in the battery separation plate fields of the fields of lead-acid storage batteries and lead-acid gel storage batteries. According to the present invention, with the mixing and the extraction of the solvent and the combination of various process steps, the battery separation plate has high porosity zone and small and ideal pore size distribution; and with the matrix of the PVC polyvinyl chloride resin, the PVC polyvinyl chloride resin has characteristics of good penetration resistance, good resilience, good compressive strength, and good toughness.

Owner:ZHAOYUAN HAISI MICROPORE DIAPHRAGM CO LTD

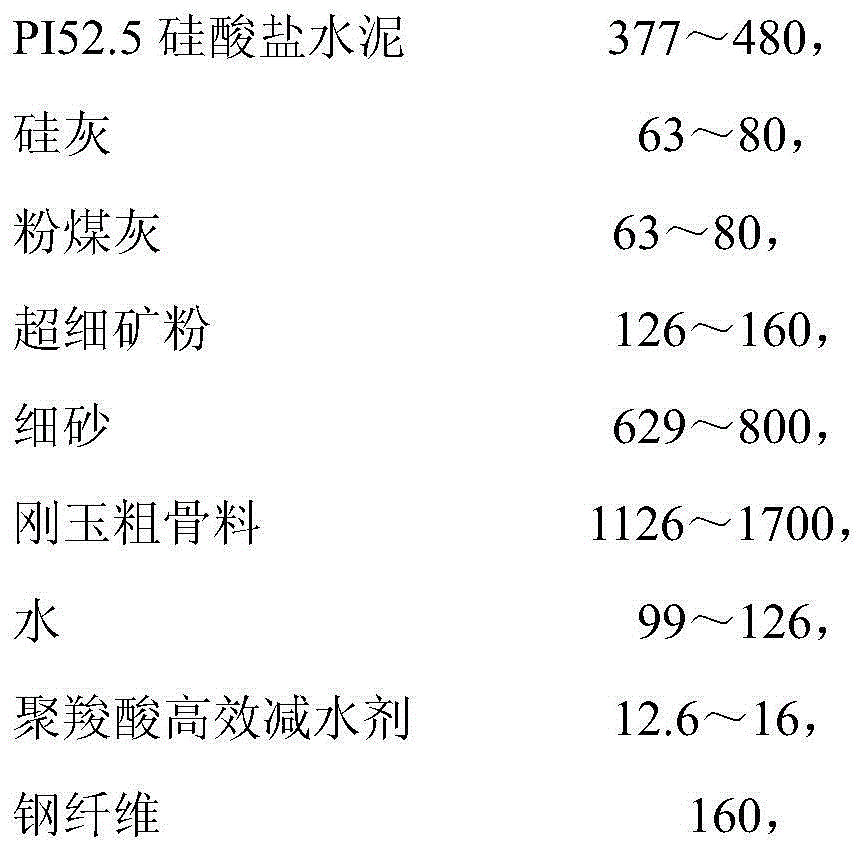

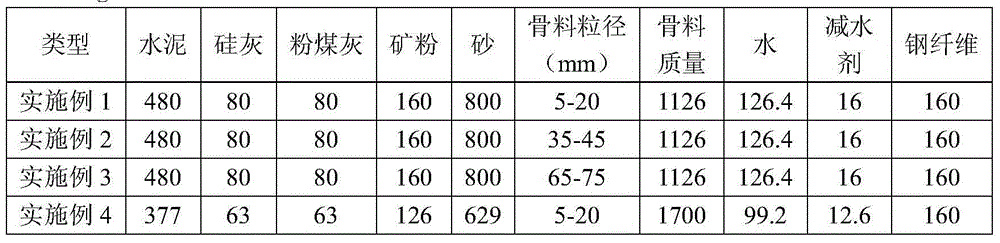

Penetration-resistant ultra-high performance concrete

The invention discloses a penetration-resistant ultra-high performance concrete. Each cubic meter of the finished product--concrete comprises the following components by weight: 377 to 480 of PI52.5 Portland cement, 63 to 80 of silica fume, 63 to 80 of fly ash, 126 to 160 of ultrafine ore powder, 629 to 800 of fine sand, 1126 to 1700 of crude corundum aggregate, 99 to 126 of water, 12.6 to 16 of polycarboxylate superplasticizer and 160 of steel fiber, wherein the unit of weight is kg. The concrete provided by the invention has good compression resistance, bending resistance and tensile strength and excellent penetration-resistance.

Owner:PLA UNIV OF SCI & TECH

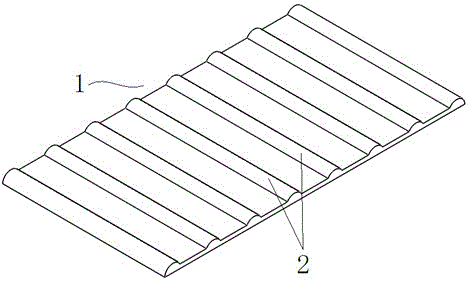

Reflective film for orchards

InactiveCN106313843AImprove toughnessImprove root puncture resistanceAgricultural articlesCultivating equipmentsGlass fiberPuncture resistance

The invention provides a reflective film for orchards. The reflective film for the orchards comprises a base material layer, wherein a tough waterproof layer is arranged on the upper surface of the base material layer; a tough reinforcing layer is arranged on the lower surface of the base material layer; a reflective layer is arranged on the upper surface of the tough waterproof layer; a surface protecting layer is arranged on the lower surface of the tough reinforcing layer; the base material layer is a glass fiber felt layer; the tough waterproof layer is a grapheme-modified polyurethane coating layer; the tough reinforcing layer is made of a graphene / natural rubber nanocomposite material; the reflective layer is an aluminum-plated reflective layer; the surface protecting layer is a PE film. The reflective film can be cut into different shapes according to actual situations of the orchards. The toughness and the root puncture resistance of the reflective film are greatly improved, so that the reflective film can be repeatedly used for several times, the utilization rate of the reflective film is improved, and thus the reflective film has a relatively high application value.

Owner:滁州嘉实农业科技有限公司

RH gunning mix and preparation method thereof

The invention relates to an RH gunning mix and a preparation method of the RH gunning mix, and belongs to the field of external refining of metallurgical production. According to the technical aim, the invention provides the RH gunning mix and the preparation method of the RH gunning mix. The RH gunning mix is composed of, by weight, 40-45 parts of fused magnesite coarse particles, 10-15 parts of fused magnesite fine particles, 20-30 parts of fused magnesite fine powder, 2-5 parts of nanometer zirconium dioxide, 2-6 parts of nanometer titania, 1-3 parts of calcium aluminate cement, 2-4 parts of silica powder, 2-3 parts of alpha-A12O32 and 0.05-0.1 part of carboxymethylcellulose. The RH gunning mix not only is superior in performance, but also achieves the chromium-free performance and completely meets the specified environmental index and use requirement.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

InactiveCN101410341BHigh transparencyGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsWeather resistanceUv absorber

Owner:BRIDGESTONE CORP

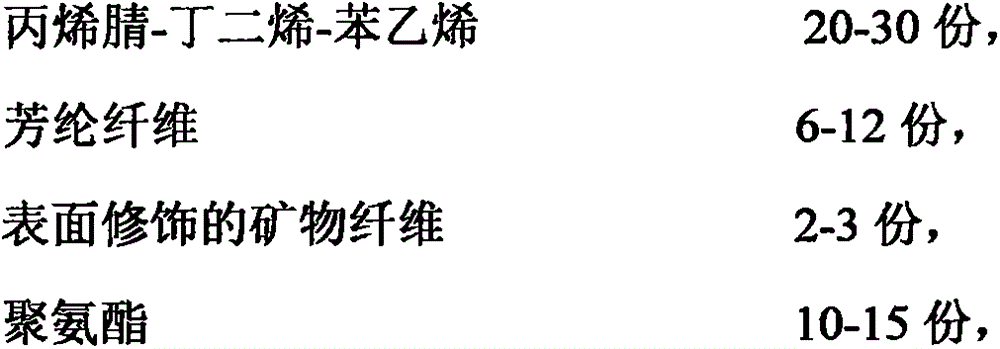

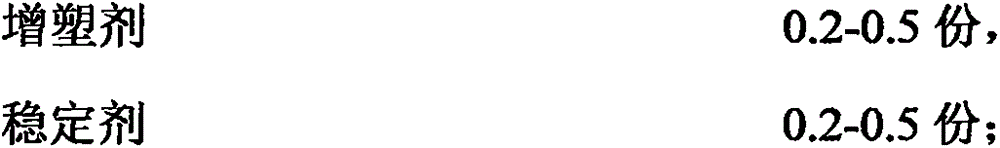

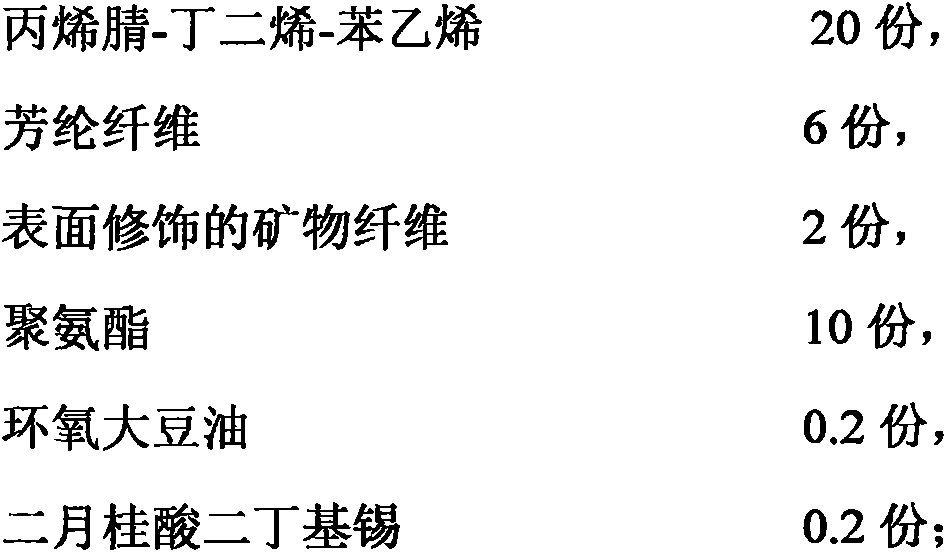

Packaging winding film

ActiveCN106398092ASimple preparation processRaw materials are easy to getFlexible coversWrappersPolymer sciencePlasticizer

The invention discloses a packaging winding film, which is prepared from acrylonitrile-butadiene-styrene, aramid fiber, surface modified mineral fiber, polyurethane, a plasticizer and a stabilizer as the raw materials. Specifically, the surface modified mineral fiber is prepared by adding TES into chloroform with suspending mineral fiber, and conducting shocking, standing, washing and drying. The packaging winding film is prepared by mechanical mixing, double-screw high temperature extrusion, and film casting by virtue of a melt casting machine. The packaging winding film provided by the invention has the advantages of simple preparation process, low cost, excellent tensile performance and penetration resistance, and excellent self-adhesion.

Owner:NINGBO HONGYAN PACKING MATERIAL

Heat strengthening laminated glass

ActiveCN103273702AGood penetration resistanceExtended service lifeGlass/slag layered productsEdge regionFirst glasses

The present invention relates to a laminated glass, particularly to a heat strengthening laminated glass with a suitable middle region mechanical strength and a high edge region mechanical strength, wherein the heat strengthening laminated glass comprises a first glass plate, a second glass plate and an intermediate film, at least one of the first glass plate and the second glass plate is a heat strengthening glass plate, the heat strengthening laminated glass comprises a middle region and an edge region, and the edge region comprises an edge compressive stress region and an edge tensile stress region, wherein the maximum edge compressive stress of the edge compressive stress region is more than 18 MPa, the maximum edge tensile stress of the edge tensile stress region is less than or equal to 7 MPa, and surface stress of the heat strengthening laminated glass is more than 6 MPa and is less than 14.8 MPa. The heat strengthening laminated glass has the following advantages that: penetration resistance is good, safety performances and regulatory requirements of vehicle parts are met, and damage on the glass periphery during an installation and use process can be avoided.

Owner:FUYAO GLASS IND GROUP CO LTD

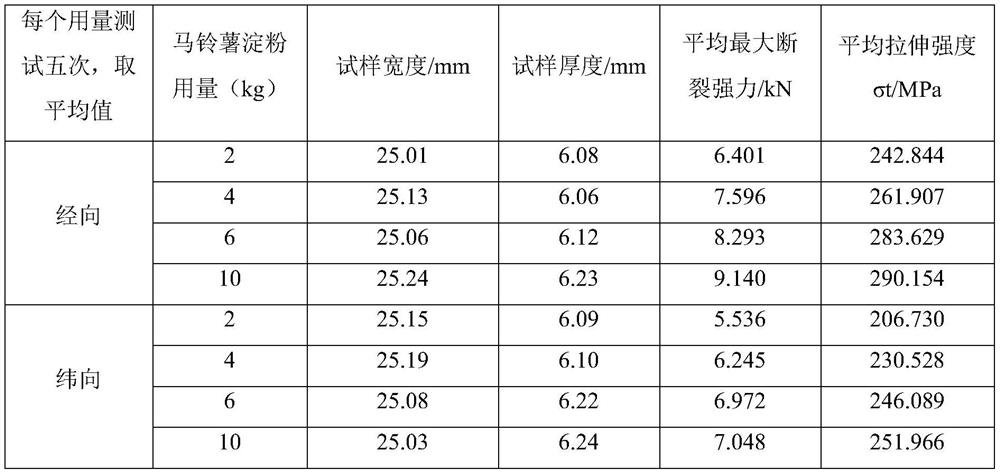

Flexible reinforced composite material and preparation method thereof

ActiveCN111501345AGood flexibilityLarge coverage areaCarbon fibresSynthetic resin layered productsElastomerReinforced concrete

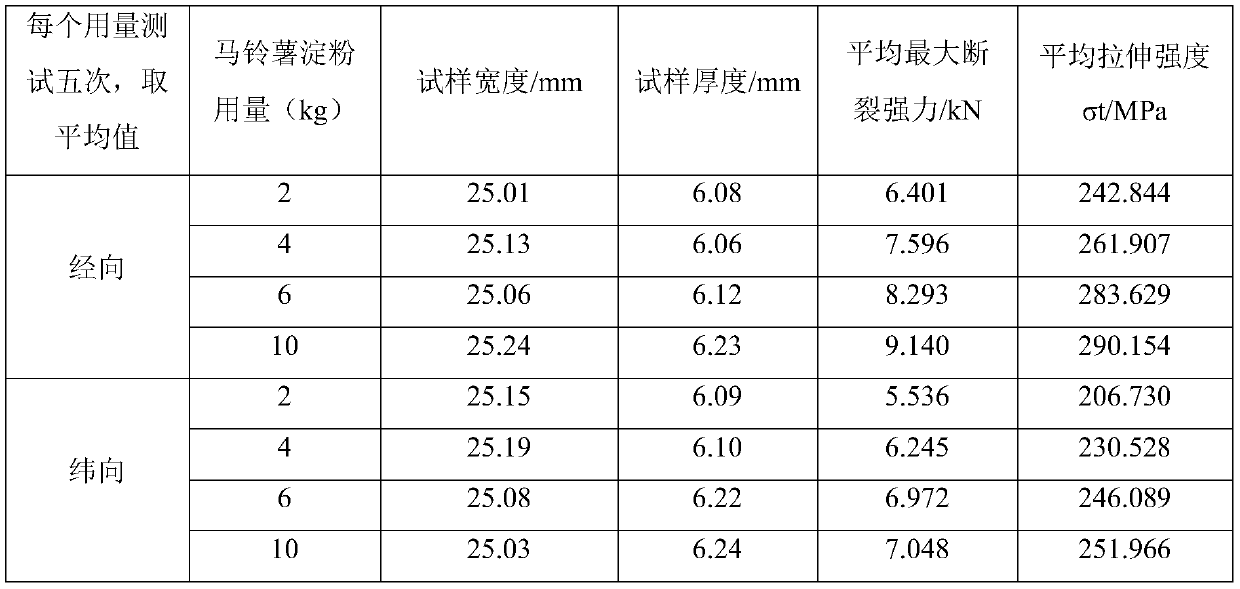

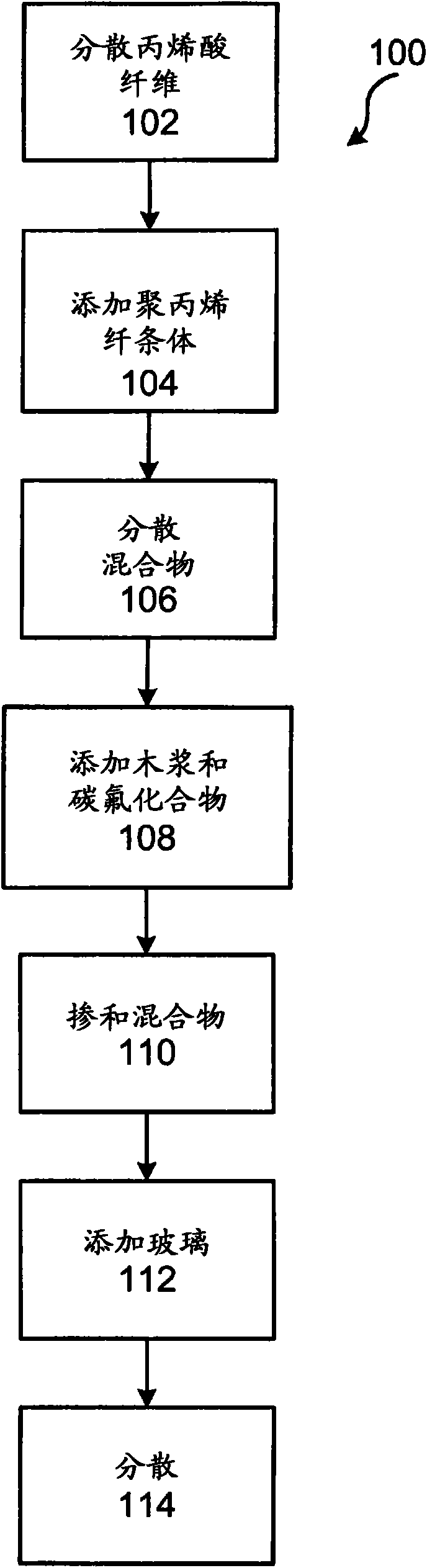

The invention discloses a flexible reinforced composite material and a preparation method thereof, and belongs to the technical field of protection engineering. The preparation method of the flexiblereinforced composite material comprises the following steps of impregnating a woven fabric in a slurry padding solution, and drying to obtain a pretreated woven fabric; and then spraying a polyurea coating on the surface of the pretreated woven fabric by using a polyurea elastomer spraying technology to obtain the flexible reinforced composite material, wherein the slurry padding liquid comprisesthe following components including potato starch, corn native starch and waterborne polyurethane. The flexible reinforced composite material prepared by the method can reinforce reinforced concrete materials, has the advantages of flexibility, large-area curved surface coverage, light weight, convenience in storage and transportation, wide application range, quick reinforcement and repair, good anti-explosion and anti-penetration performance and the like, and is more suitable for anti-explosion reinforcement of special structures such as arch bridges.

Owner:JIANGNAN UNIV

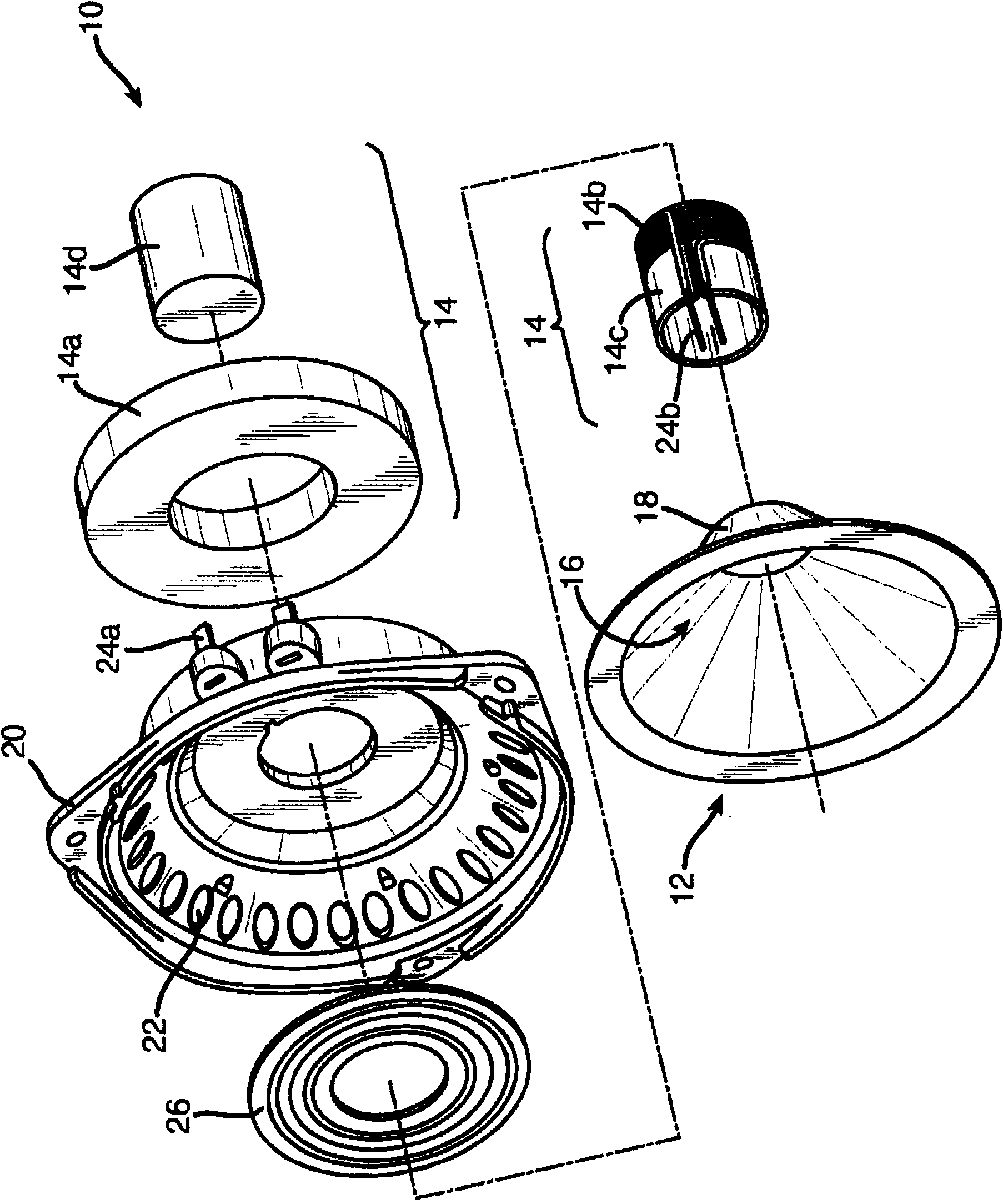

Waterproofing loudspeaker cones

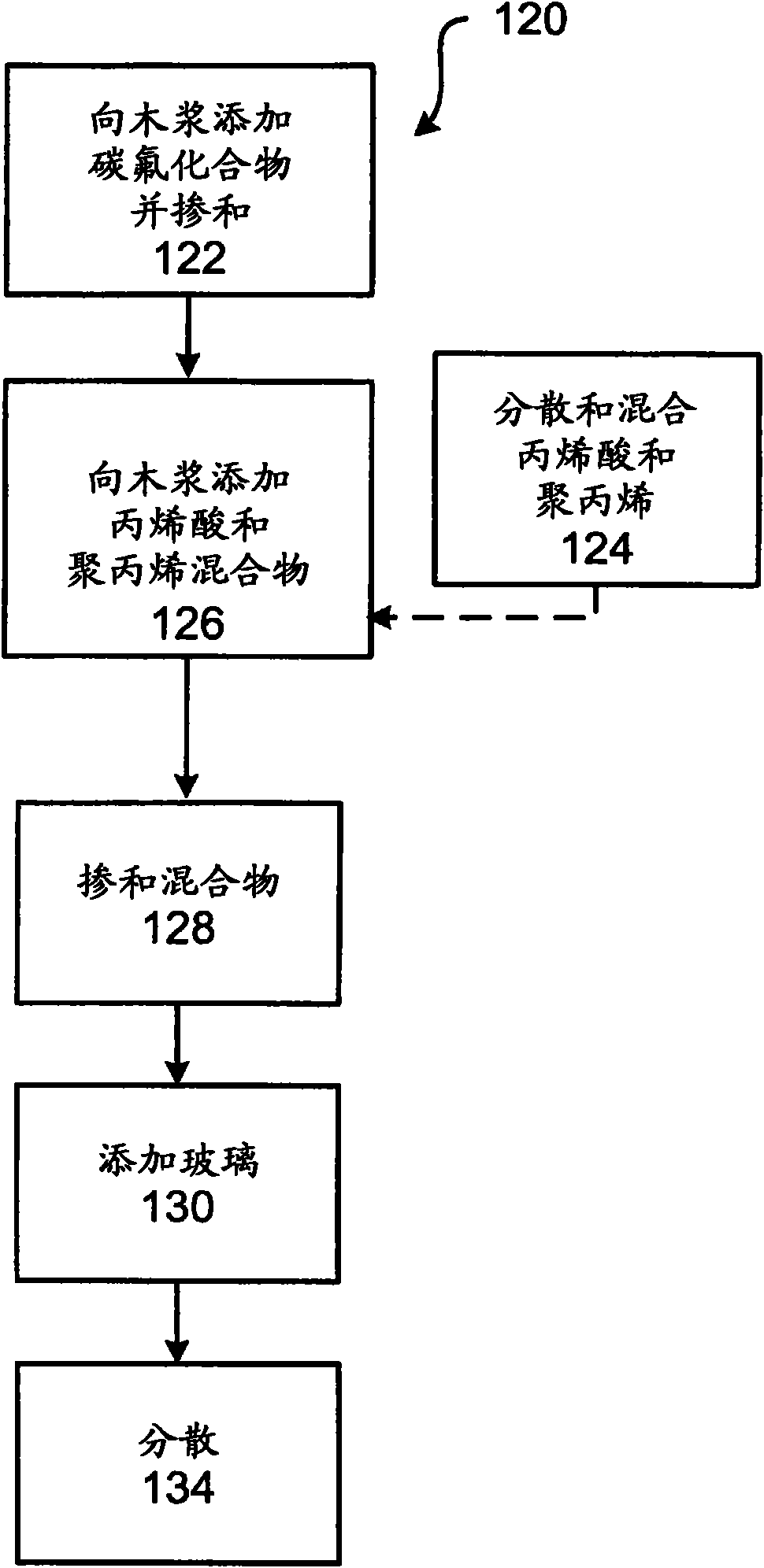

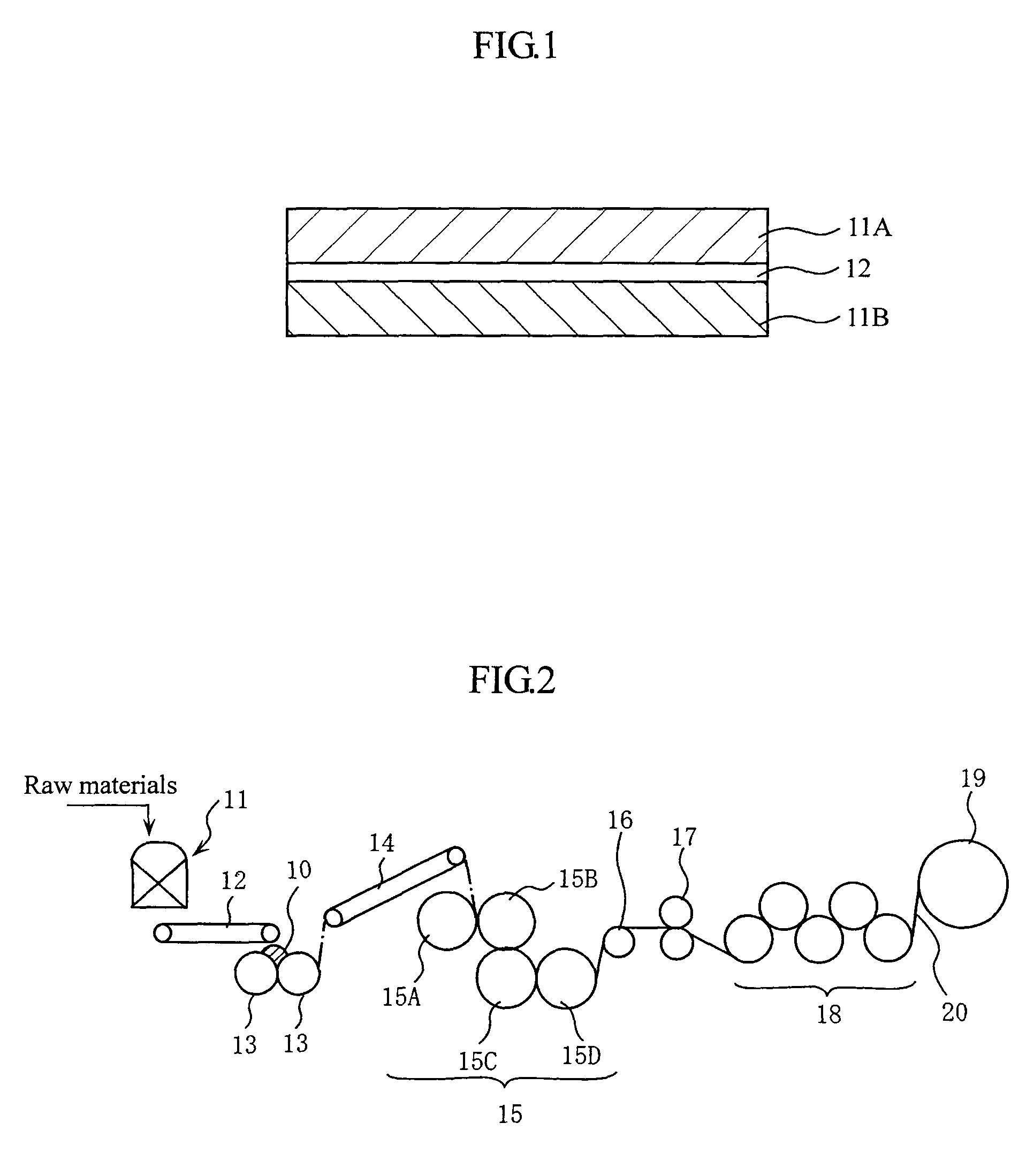

ActiveCN101978706AReduce wet rub defectsGood penetration resistanceFibre diaphragmsPolymeric diaphragmsGlass fiberWater resistant

A water-resistant composite paper, suitable for use as a loudspeaker component, is made from a composition including wood pulp, hydrophobic fibers, stiffening fibers that retain stiffness when wet, and fluorocarbon. In some examples, fibrillated acrylic fibers and glass fibers are used.

Owner:BOSE CORP

Sheet-shaped adhesive and laminate prepared by using the same

InactiveUS7854990B2Excellent adhesion and penetration resistanceIncrease production capacityAdhesive processesSynthetic resin layered productsAdhesive cementAcetic acid

Owner:BRIDGESTONE CORP

Light-weight bullet-proof glass and preparation method thereof

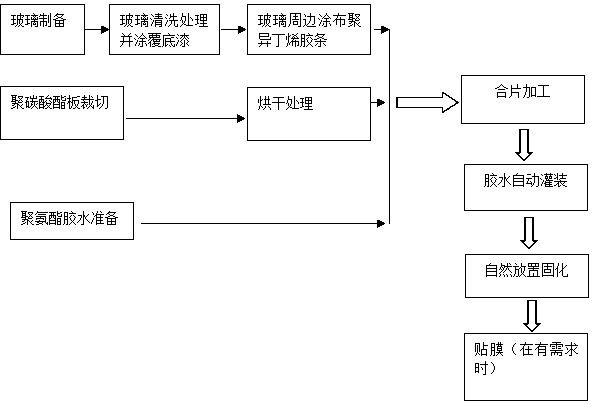

ActiveCN104369476AImprove impact resistanceReduce weightPolyureas/polyurethane adhesivesLaminationAlcoholTransmittance

The invention discloses light-weight bullet-proof glass and further provides a preparation method of the light-weight bullet-proof glass. Glass and a polycarbonate plate are glued by polyurethane glue, wherein the polyurethane glue is double-component polyurethane glue and comprises a component A, namely a polyhydric alcohol polymer, and a component B, namely isocyanate; and the volume ratio of the component A to the component B is 100 to (65-75). According to the bullet-proof glass, the double-component polyurethane glue is used for gluing the glass and the polycarbonate plate; and the defects that traditional bullet-proof glass is thick, the light transmittance is low and the like are overcome by using the flexibility and the penetration resistance of the cured polyurethane glue, and the flexibility of the polycarbonate plate, as well as the appearance cleaner than the glass and the light transmittance higher than that of the glass. The light-weight bullet-proof glass has the characteristics of light weight, small thickness, high light transmittance and the like.

Owner:大连天然华鹰特种玻璃股份有限公司

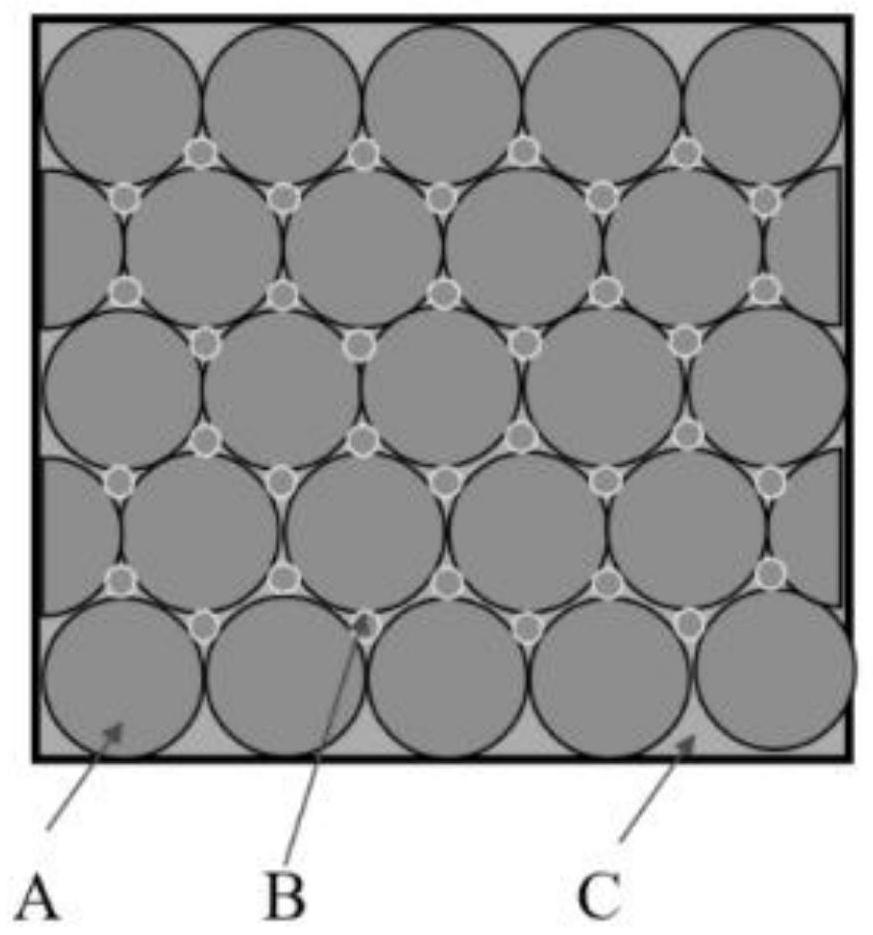

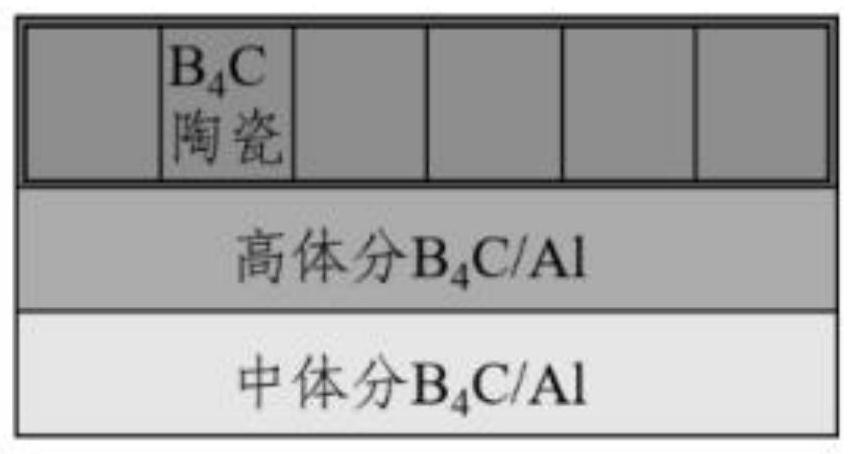

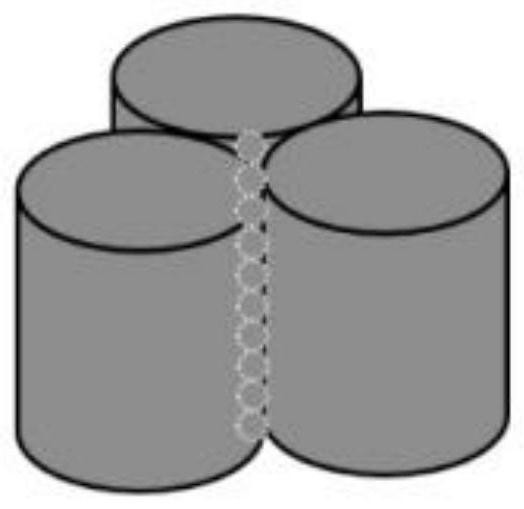

Gradient aluminum-based composite material for resisting 30 mm armor-piercing bullet and preparation method of gradient aluminum-based composite material

ActiveCN113234967AExtended failure timeReduce gapArmoured vehiclesArmour platesArmor-piercing shellCeramic composite

The invention relates to a gradient aluminum-based composite material for resisting a 30 mm armor-piercing bullet and a preparation method of the gradient aluminum-based composite material, and aims to solve the problems that a traditional ceramic composite armor structure is large in surface density and thickness and poor in frequent elasticity resistance are solved. The gradient aluminum-based composite material is of a three-layer gradient structure; the outer layer is made of an aluminum-based composite material which is reinforced by ceramic columns, ceramic balls and B4C ceramic powder which are densely arranged together; the middle layer is a high-volume-fraction B4C / Al composite material; and the inner layer is a medium-volume-fraction B4C / Al composite material. The method comprises the following steps: 1, densely arranging the ceramic columns; 2, filling gaps of the columns with the ceramic balls; 3, filling gaps with the B4C powder; 4, paving preform powder layer by layer; 5, carrying out compacting and cold-pressing to prepare a preform; and 6, melting molten aluminum, pressing the molten aluminum into the remaining gaps of the preform through pressure infiltration, and conducting pressure maintaining and demolding. Thea gradient aluminum-based composite material is used for the armor structure for resisting the 30 mm armor-piercing bullet.

Owner:HARBIN INST OF TECH

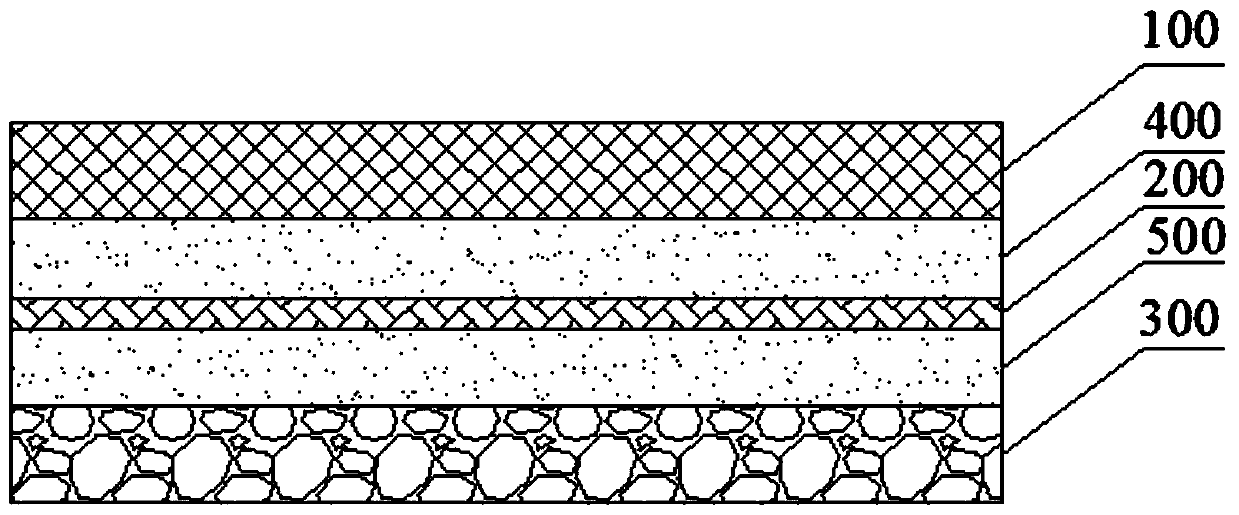

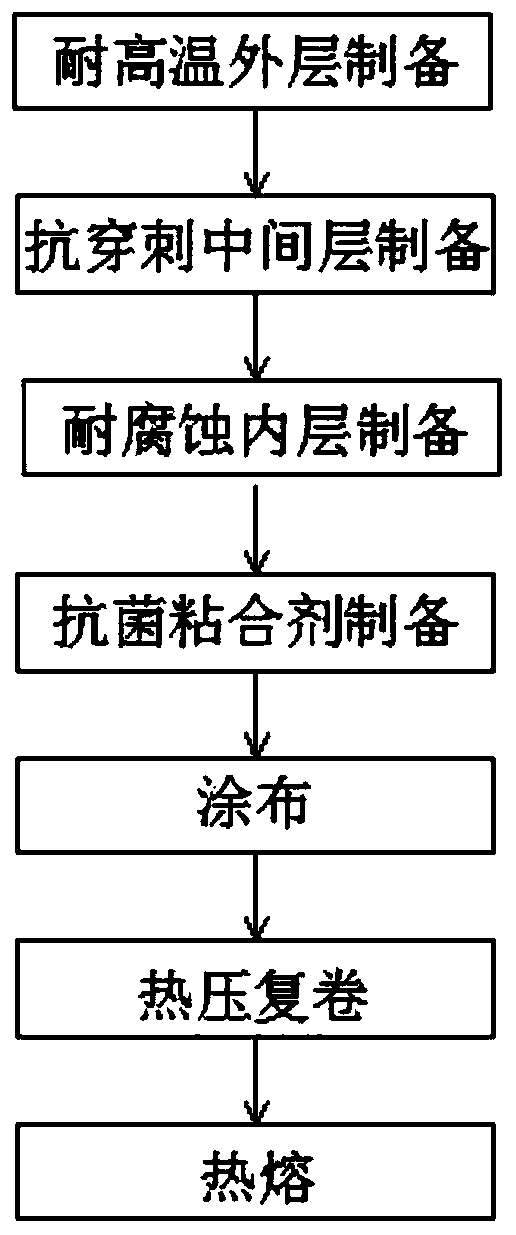

Vacuum compression bag with antibacterial function and production process thereof

ActiveCN110254933APromote absorptionImprove barrier propertiesNon-macromolecular adhesive additivesBio-packagingEscherichia coliStaphylococcus aureus

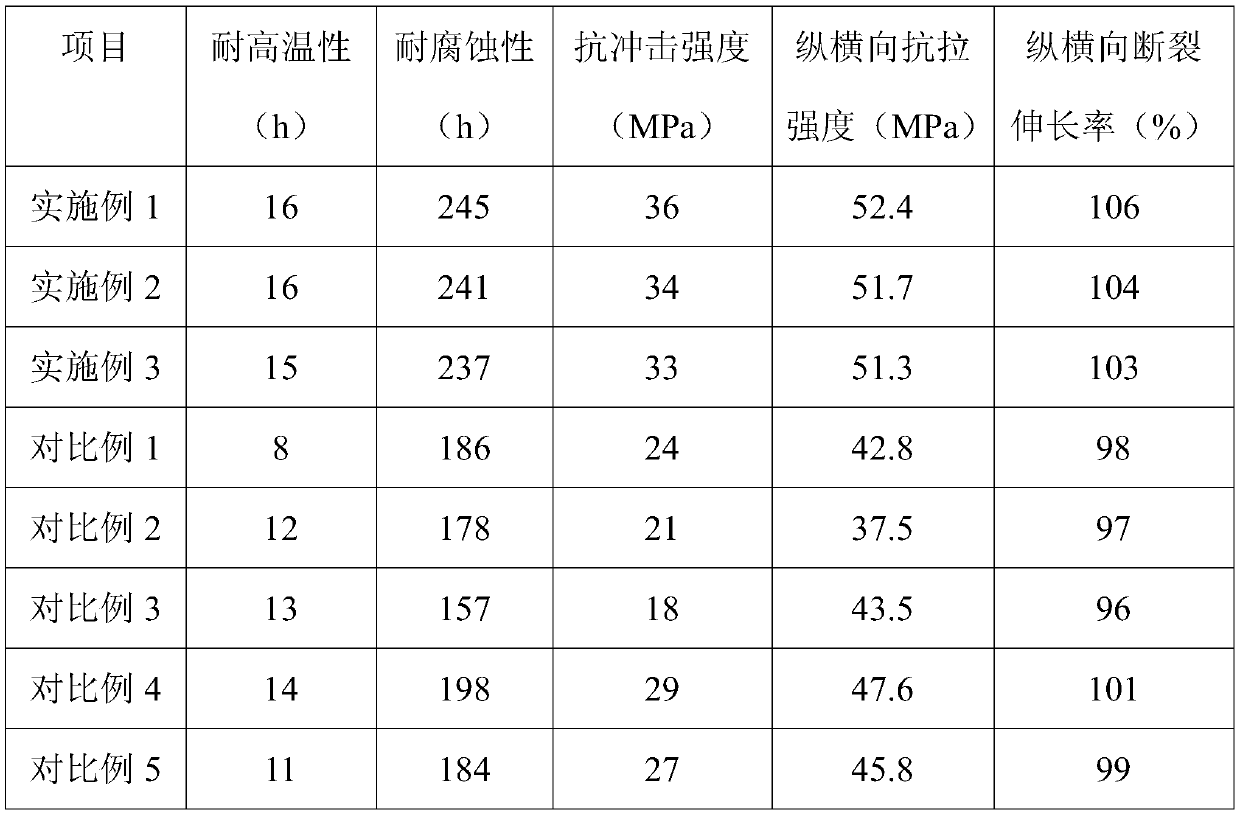

The invention discloses a vacuum compression bag with an antibacterial function and a production process thereof, and relates to the field of packaging materials. The vacuum compression bag is formed by a high-temperature-resistant outer layer, a first antibacterial adhesive layer, an impact-resistant intermediate layer, a second antibacterial adhesive layer and a corrosion-resistant inner layer from outside to inside through hot pressing. The production process comprises the seven procedures of preparation of the high-temperature-resistant outer layer, preparation of the impact-resistant intermediate layer, preparation of the corrosion-resistant inner layer, preparation of an antibacterial adhesive, coating, hot-pressing and rewinding and hot melting. Compared with the prior art, the vacuum compression bag has excellent antibacterial property, corrosion resistance, impact resistance, breakdown resistance and high temperature resistance, and is suitable for vacuum storage of materials in a high-temperature corrosion environment, the impact strength reaches 36 MPa, the tensile strength reaches 52.4 MPa, the elongation at break reaches 106%, and the antibacterial rate to escherichia coli, staphylococcus aureus and candida albicans reaches 99.7%, 98.3% and 95.7% correspondingly.

Owner:YUYAO HUAYIN PACKING MATERIAL CO LTD

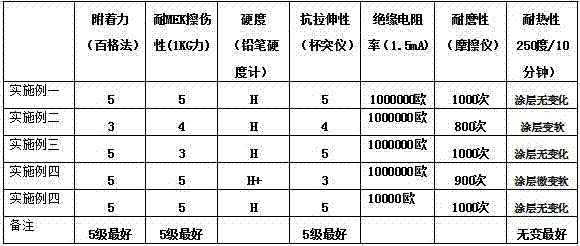

Capacitor aluminum shell coating and production and coating method thereof

ActiveCN106893459AGood penetration resistanceExcellent softening resistanceEpoxy resin coatingsPolyester coatingsSolventChemistry

The invention discloses capacitor aluminum shell coating and a production and coating method thereof. The coating is composed of a composition A and a composition B; the composition A is prepared from 40-50 parts of polyester resin, 10-15 parts of epoxy resin, 10-20 parts of S100# solvent oil, 10-20 parts of PMA (polymethyl acrylate), 1-2 parts of a dispersing agent, 1-2 parts of organic organo-siloxane debubbling and leveling agent, 0.3-0.5 part of acid catalysts, 3-5 parts of insulation carbon black and 5-8 parts of mica powder; the composition B is prepared from 15-20 parts of permethylated amino resin, 5-6 parts of polymethylene amino resin, 15-30 parts of n-butyl acetate and 3-5 parts of butoxy cellosolve. The production method includes: respectively producing the composition A and the composition B, and well mixing to obtain the coating. The coating method includes: subjecting an aluminum substrate to alkaline washing, uniformly coating the surface of the aluminum oxide substrate with the capacitor aluminum shell coating at the room temperature, and curing.

Owner:江门市德佑金属材料实业有限公司

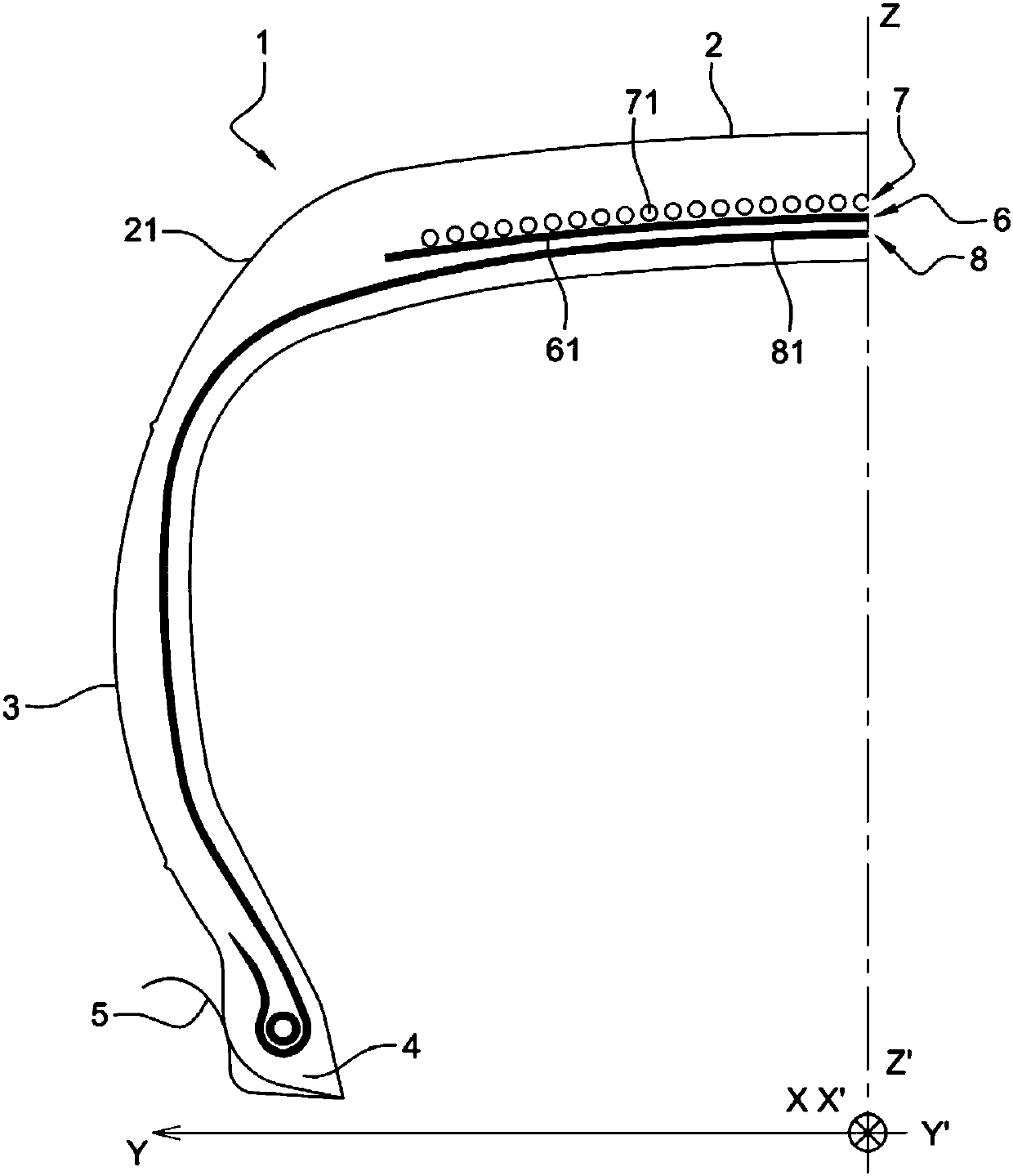

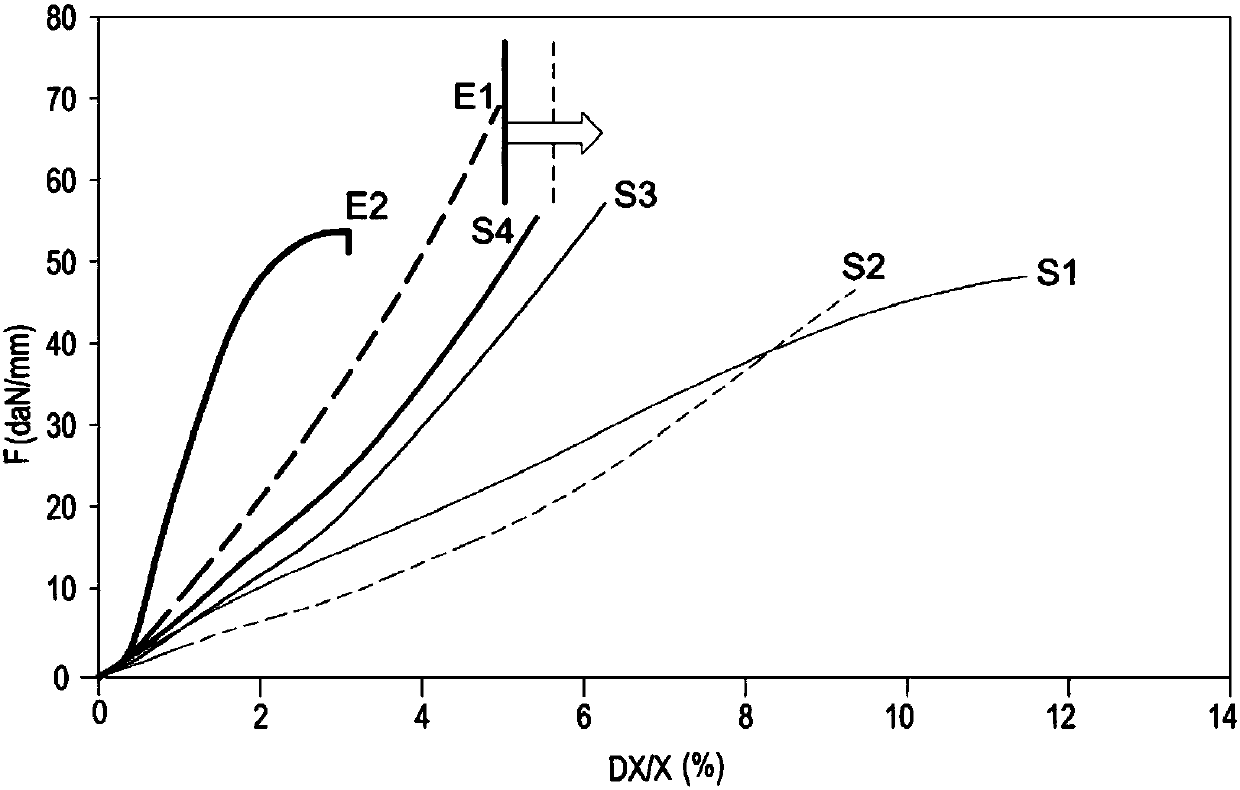

Tyre reinforcement

ActiveCN107592841AReduce variationControl Deformation ProfilePneumatic tyre reinforcementsBreaking strengthHooping

The invention relates to the reinforcement that reinforces a passenger vehicle tyre. It targets good resistance to penetration and perforation of its crown by foreign objects, with a reinforcing architecture that is simple and lightweight. According to the invention, the hooping layer (71) has a breaking strength per mm of axial width of the hooping layer FR at least equal to 35 daN / mm, an elongation at break AR at least equal to 5% and a secant extension modulus MA at least equal to 250 daN / mm, for an applied force F equal to 15% of the rupture strength FR of the said hooping layer (71). Theworking reinforcement (6) comprises a single working layer (61) of which the working reinforcements form, with the circumferential direction (YY'), an angle AT at least equal to 30 degrees and at mostequal to 50 degrees. The carcass reinforcements of the at least one carcass layer (81) form, with the circumferential direction (YY') and in the equatorial plane (XZ), an angle Ac2 at least equal to55 degrees and at most equal to 80 degrees and having an orientation that is the opposite of that of the angle AT of the working reinforcers, so that the carcass reinforcers and the working reinforcers constitute a triangulation system.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

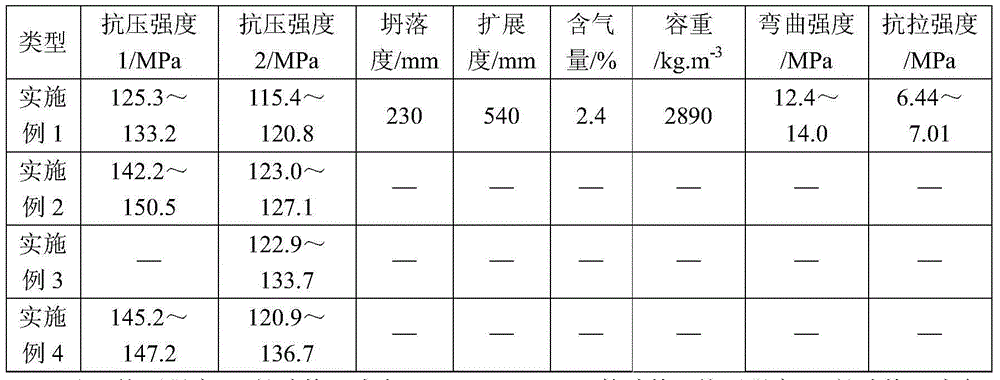

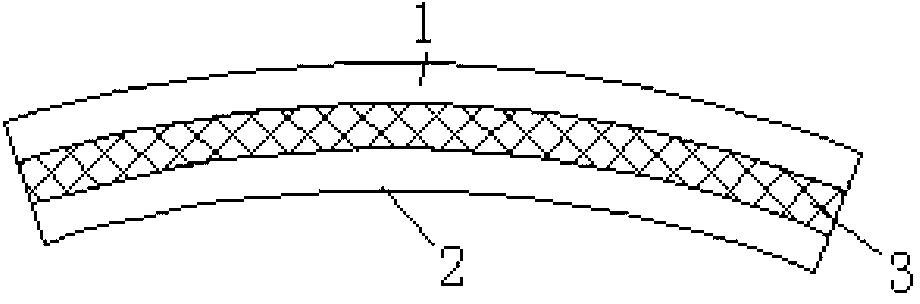

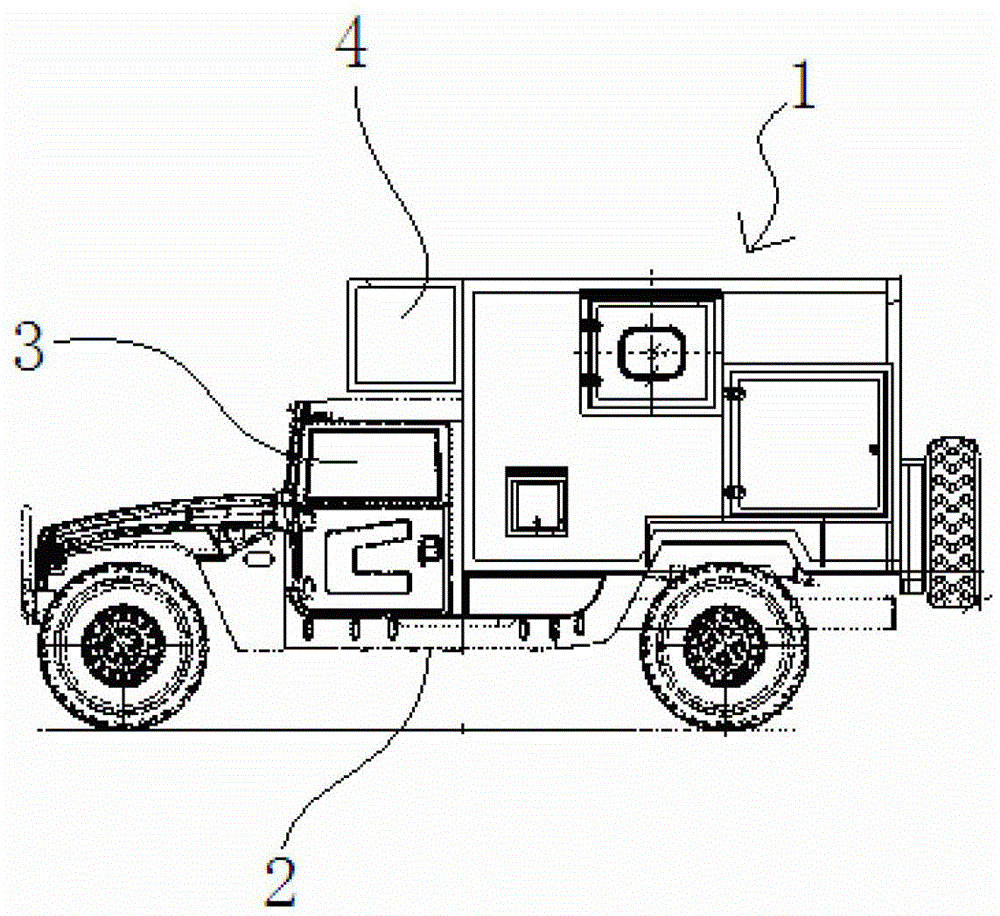

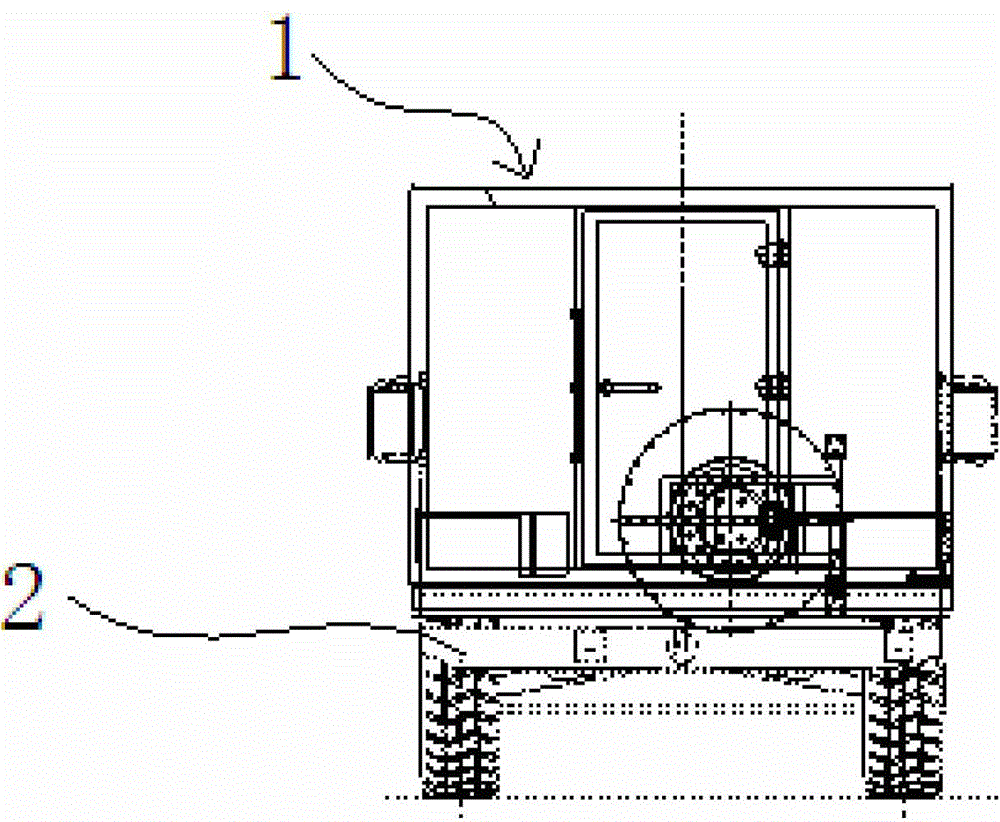

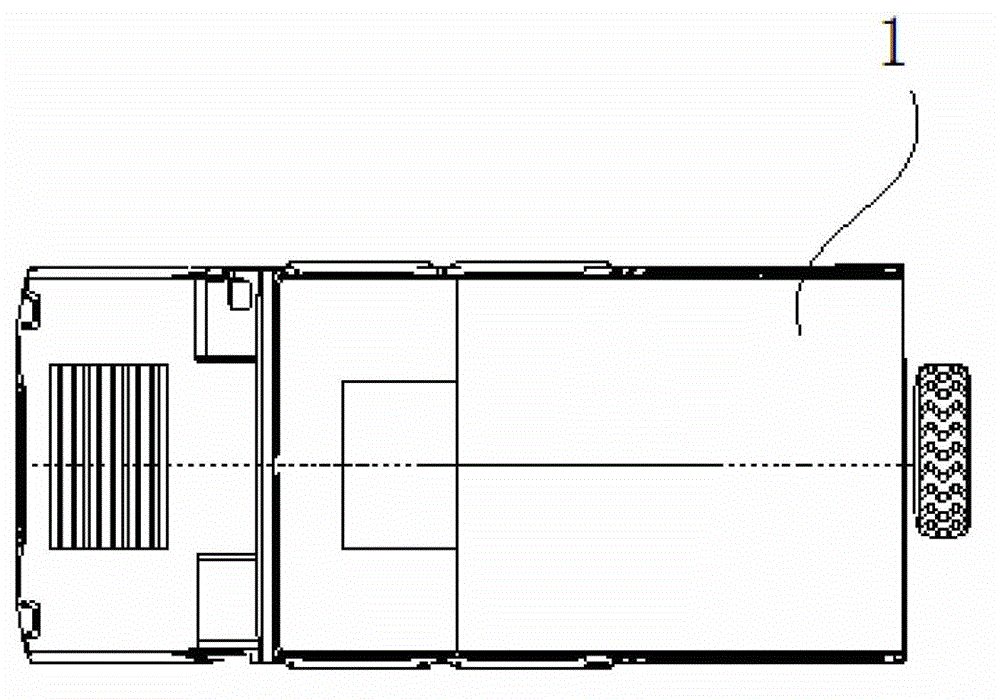

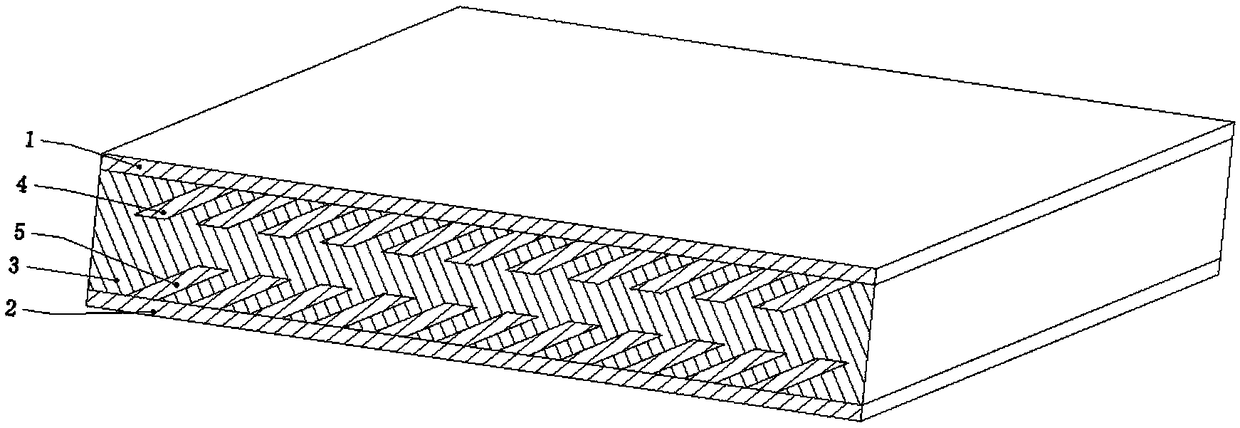

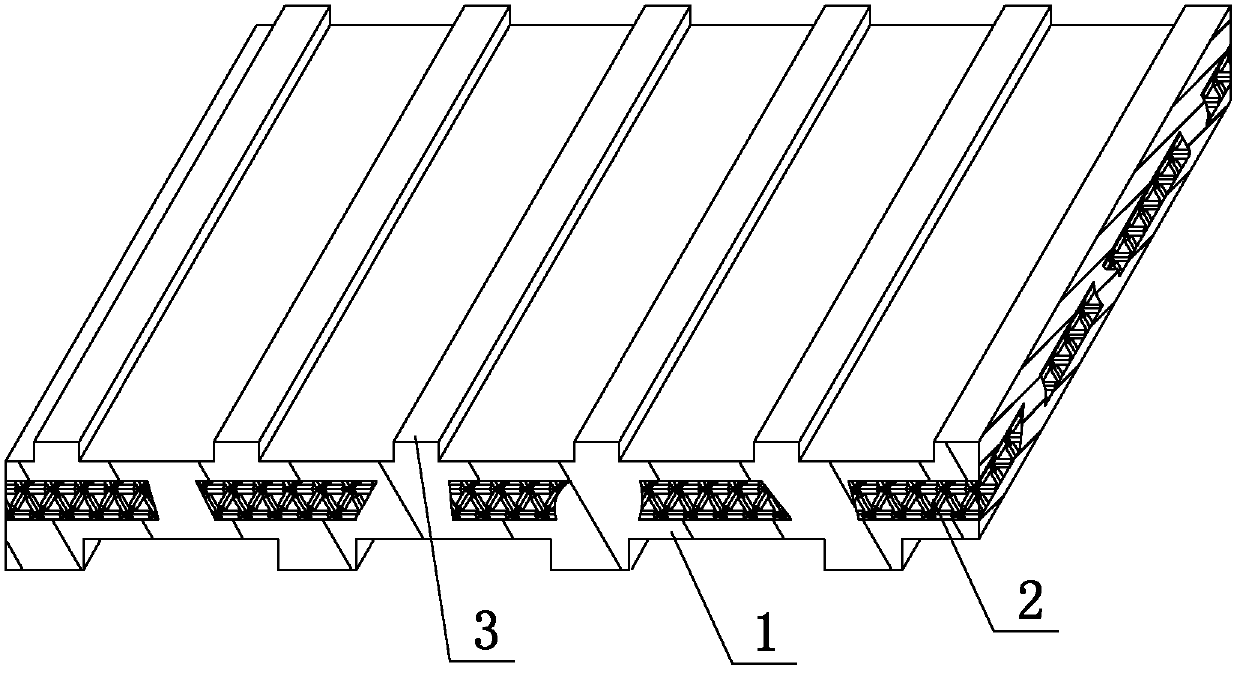

Square cabin with penetration-preventing wallboards

InactiveCN102877669APrevent penetrationGood penetration resistanceProtective buildings/sheltersSmall buildingsFiberThermal insulation

The invention discloses a square cabin with penetration-preventing wallboards, and belongs to the technical field of square cabins. The square cabin with the penetration-preventing wallboards comprises a square cabin body consisting of a front wallboard, a back wallboard, a left wallboard, a right wallboard, an upper wallboard and a lower wallboard. The square cabin with the penetration-preventing wallboards is characterized in that the wallboards comprise penetration-preventing outer layers, penetration-preventing middle layers and inner masks in sequence from exterior to interior; the penetration-preventing outer layers are high-strength fiber fabric composite boards; the penetration-preventing middle layers are high-strength fiber and staple fiber reinforced foam boards; skeletons are also arranged in the penetration-preventing middle layers at intervals; and thermal insulation bridges are arranged between the skeletons and the inner masks. The square cabin with the penetration-preventing wallboards has the advantages that the square cabin with the penetration-preventing wallboards has quite good penetration prevention capability; the wallboards of the square cabin can be prevented from being penetrated by a blasting fragment or a light bullet; the square cabin can work in a severe environment; meanwhile, the design and the manufacture of the square cabin provided by the invention accord with relevant national standards; and the thermal insulation, the air tightness and the electromagnetic shielding all meet requirements.

Owner:衡阳泰豪通信车辆有限公司

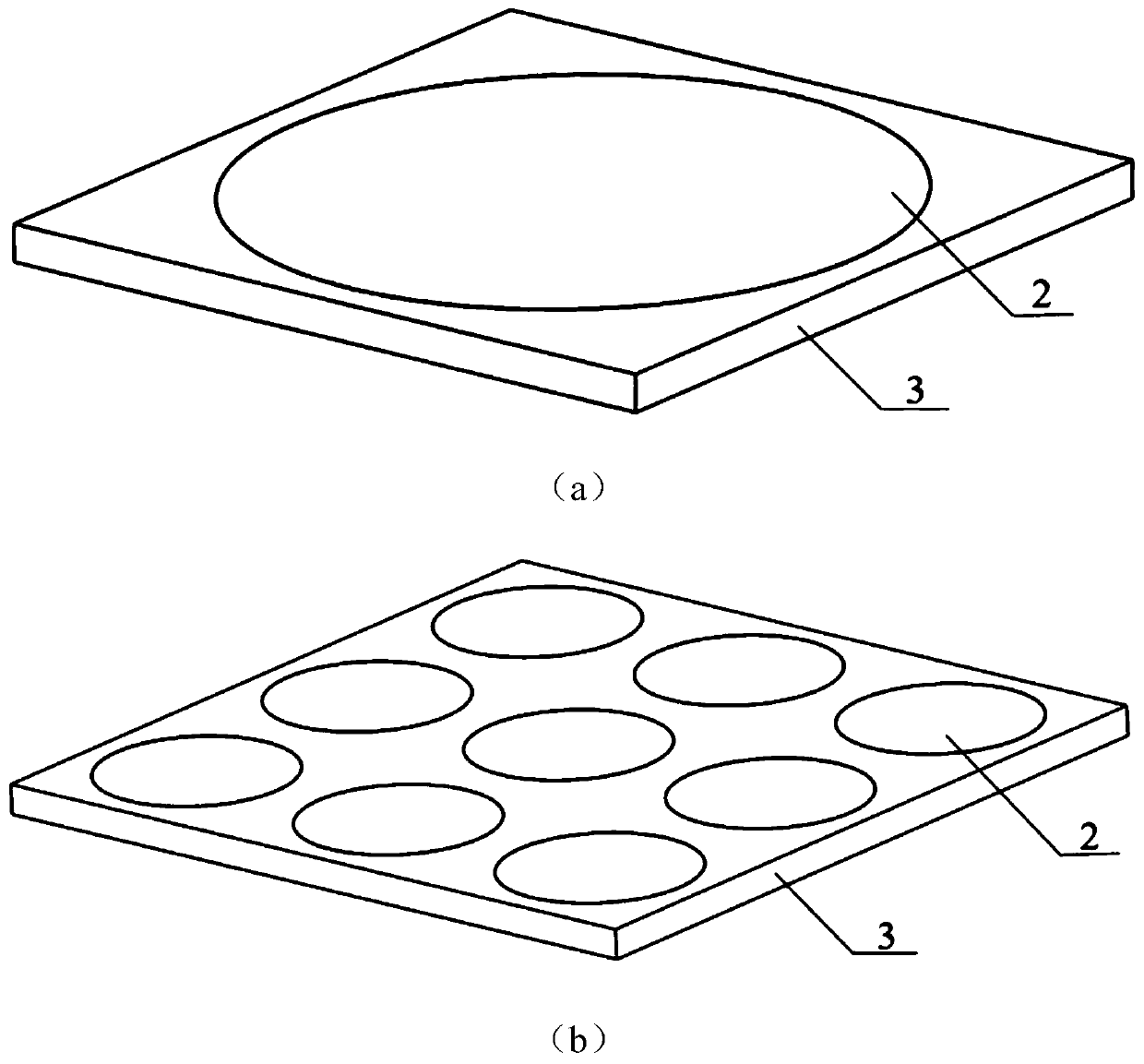

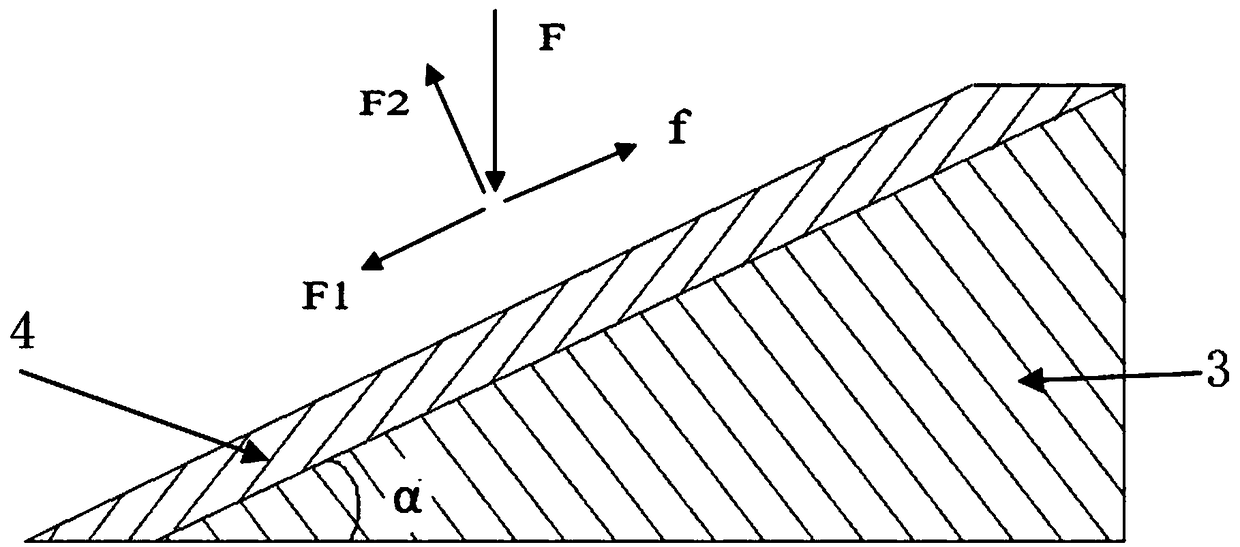

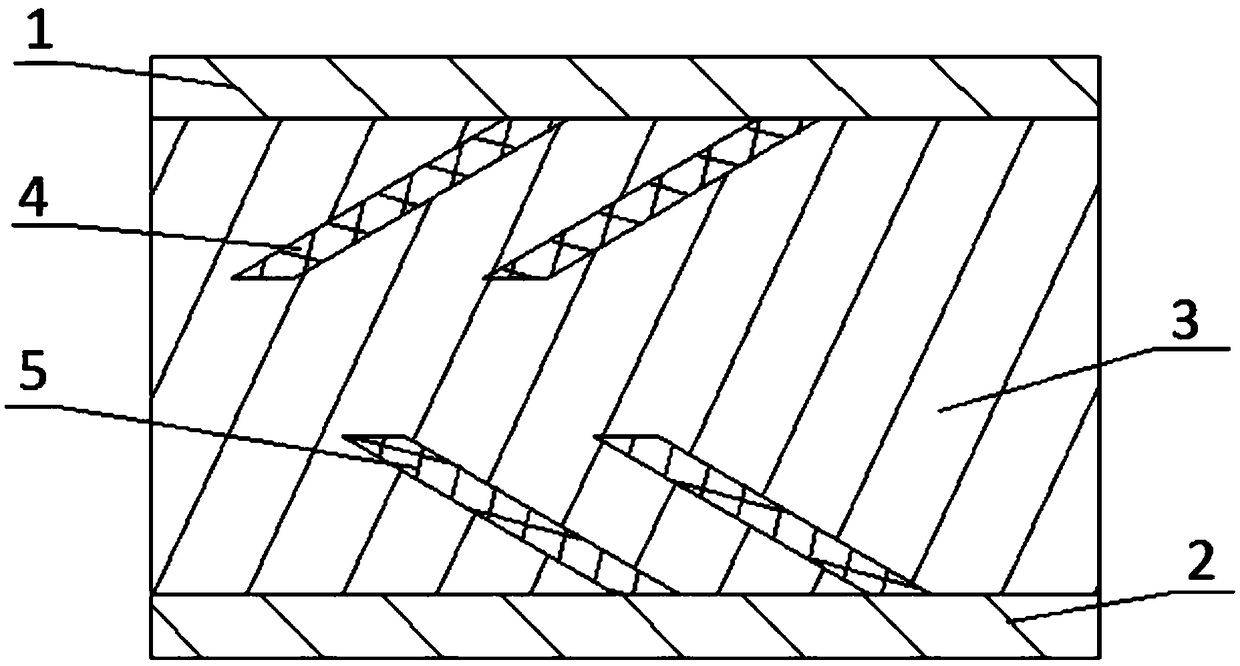

Unilateral anti-delamination sandwich plate with oblique rib plate and application, connection and preparation method thereof

InactiveCN108945290AReduce shockImprove protectionVessel designingHull panellingsEngineeringDelamination

The invention discloses an unilateral anti-delamination sandwich plate with an oblique rib plate, which comprises an upper panel, a lower panel and a core material filled between the upper and lower panels. The inner side of the upper panel is uniformly provided with a plurality of upper ribs arranged obliquely, and the inner side of the lower panel is uniformly provided with a plurality of lowerribs arranged obliquely. the oblique included angle between the lower rib plate and the lower panel is 15 to 45 degrees, the friction coefficient between the core material and the upper rib plate is [mu] ', and the oblique included angle between the upper rib plate and the upper panel is smaller than tan<-1> [mu] '. The invention overcomes the delamination phenomenon of the sandwich plate by changing the structure form of the traditional sandwich plate and obviously improves the anti-penetration performance of the sandwich plate, can improve the protective performance of the ship, can reduce the weight of the ship, and improves the comfort and safety of the ship. The invention has convenient processing method and lower cost, and will be widely applied in the fields of ship structure, building structure, armored vehicle, bulletproof structure and the like.

Owner:MARINE EQUIP & TECH INST JIANGSU UNIV OF SCI & TECH +1

Intermediate film for laminated glass and laminated glass

ActiveUS7985481B2Promote mutual integrationGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsPolyvinyl alcoholPlasticizer

The present invention provides an interlayer for a laminated glass, which contains a polyvinyl acetal resin, and can be easily bonded to a glass sheet to form a highly transparent laminated glass. And the present invention provides a laminated glass using the interlayer. The interlayer for a laminated glass contains 100 phr of a polyvinyl acetal resin and 42 to 60 phr of a plasticizer, wherein the plasticizer is unsaturated fatty acid alkyl ester having 16 to 20 carbon atoms.

Owner:SEKISUI CHEM CO LTD

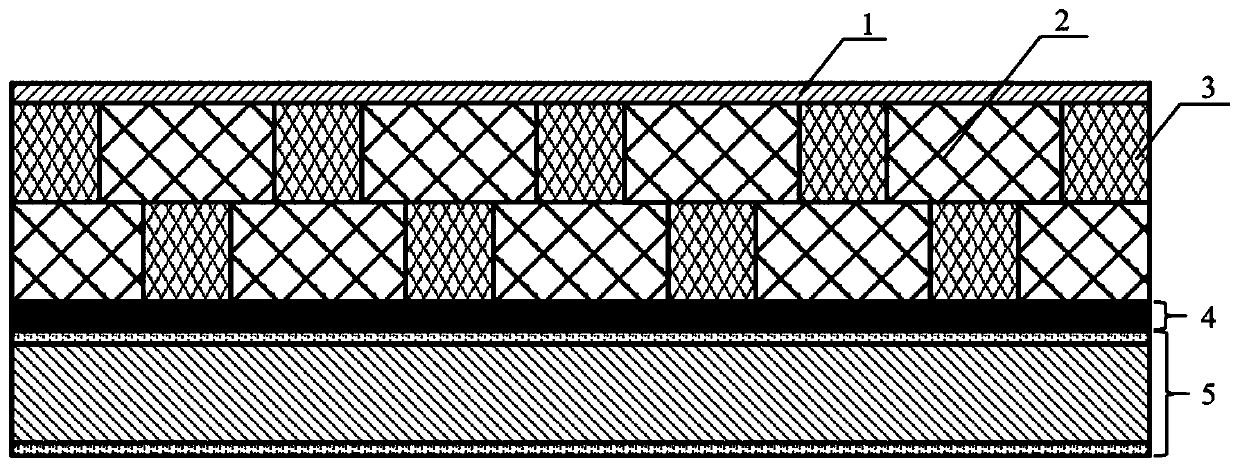

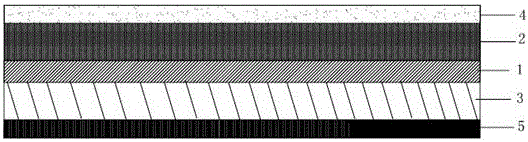

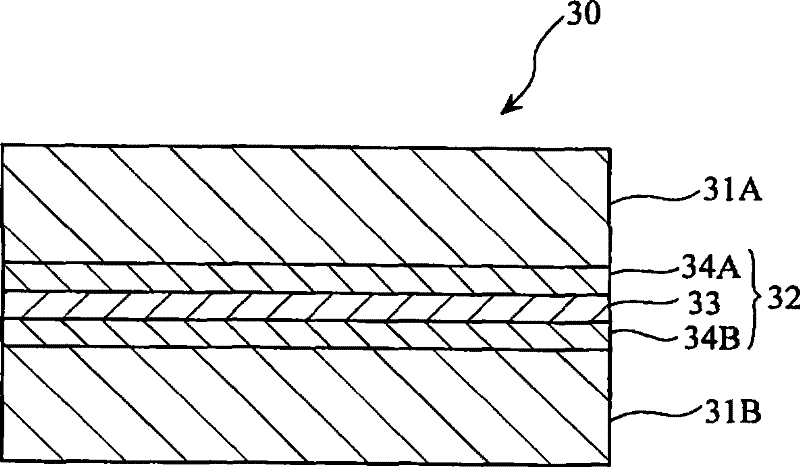

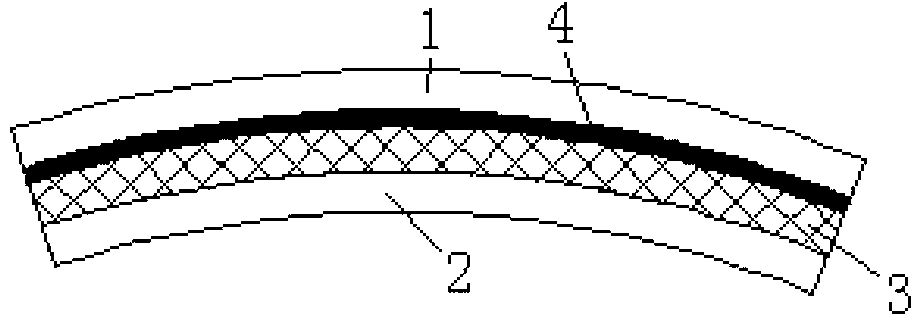

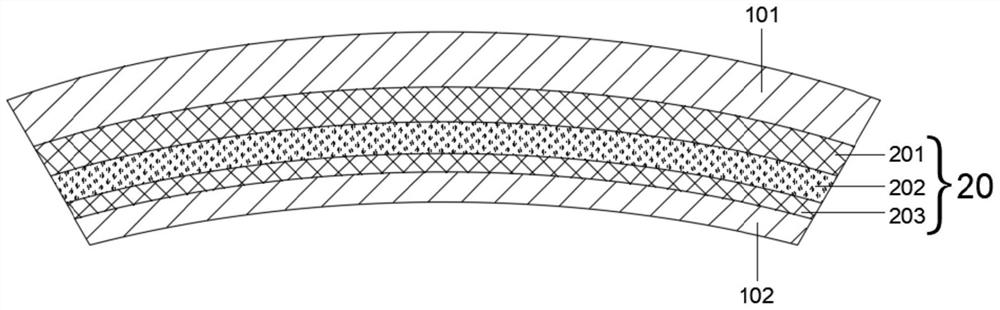

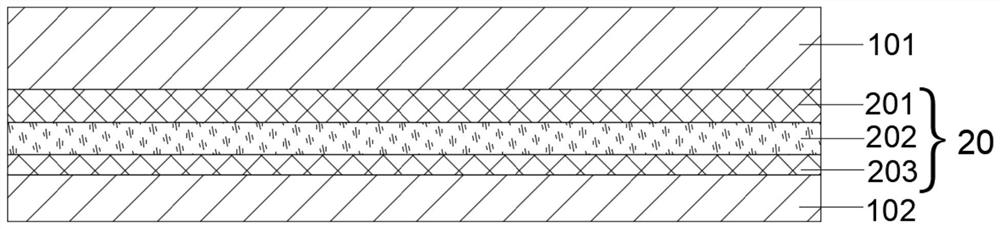

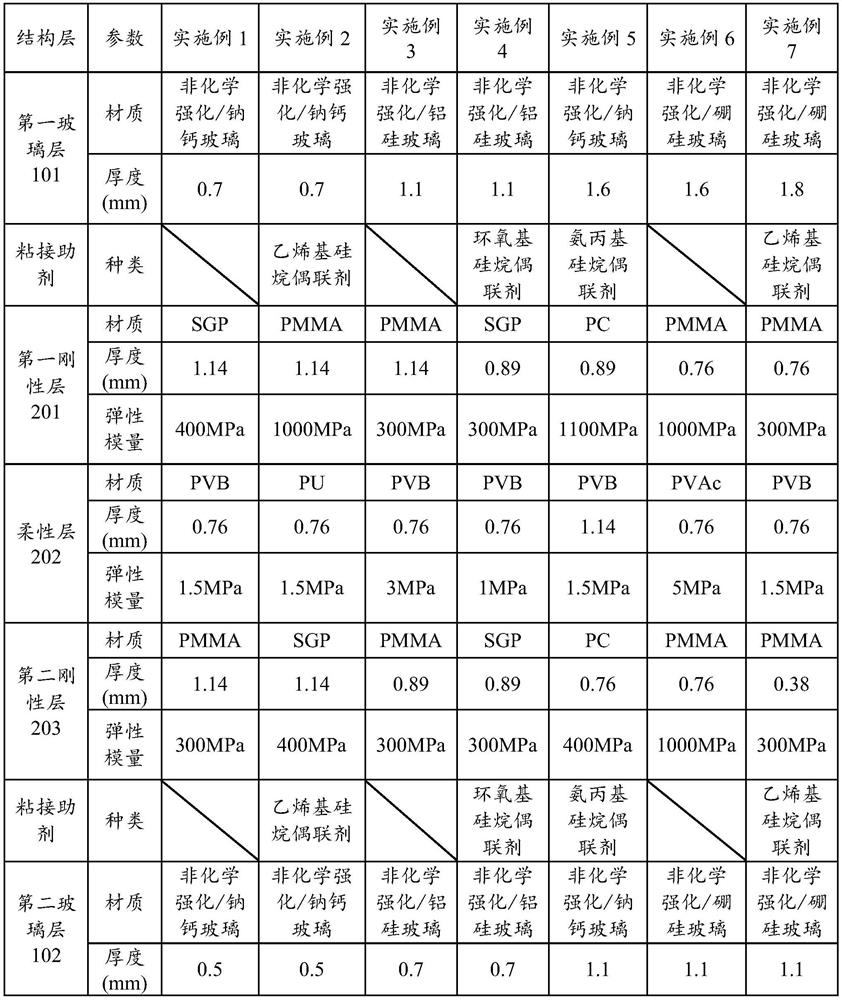

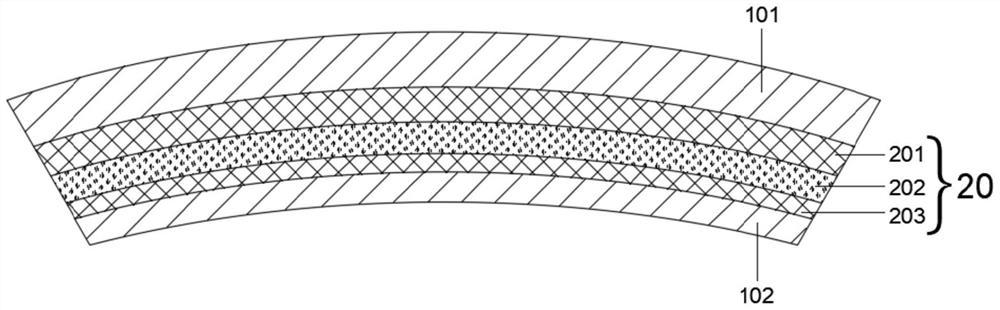

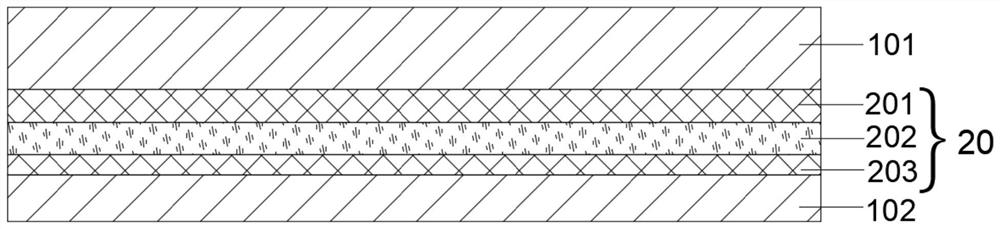

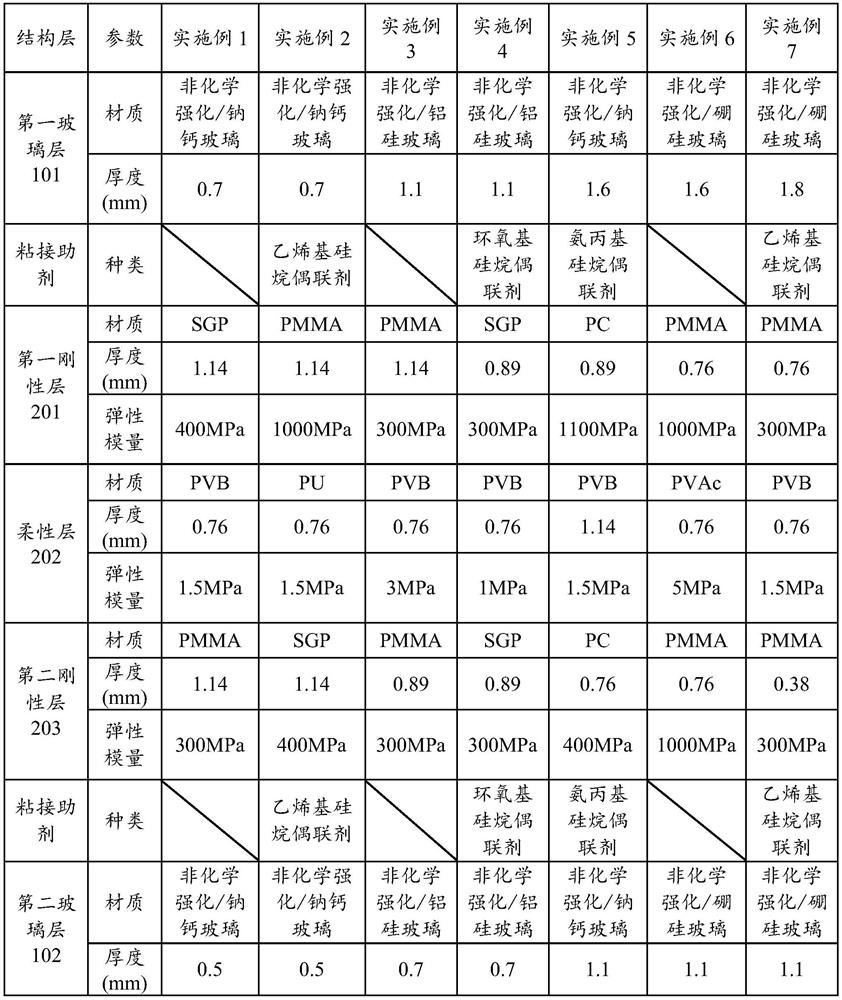

Laminated glass for vehicle window and preparation method thereof

ActiveCN112721355ASimple and fast operationSuitable for industrial mass productionWindowsWindscreensImpact resistanceChemically strengthened glass

The invention provides laminated glass for a vehicle window. The laminated glass comprises a first glass layer, a second glass layer and a composite middle layer arranged between the first glass layer and the second glass layer. The first glass layer and the second glass layer are non-chemically strengthened glass; the thickness of the first glass layer and the thickness of the second glass layer are both smaller than or equal to 2.1 mm. The composite middle layer comprises a first rigid layer, a flexible layer and a second rigid layer which are stacked in sequence; the first rigid layer is located between the first glass layer and the flexible layer; the second rigid layer is positioned between the flexible layer and the second glass layer; the elastic modulus of the first rigid layer and the second rigid layer is greater than or equal to 300Mpa; and the elastic modulus of the flexible layer is less than or equal to 10Mpa. The laminated glass has good impact resistance and penetration resistance, the thickness of glass in the laminated glass is small, and the weight of the laminated glass can be greatly reduced. The invention further provides a preparation method of the laminated glass for the vehicle window.

Owner:FUYAO GLASS IND GROUP CO LTD

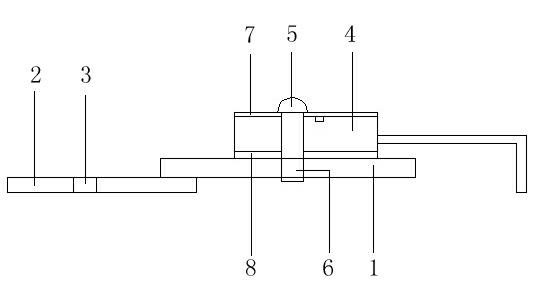

Assembled radiating fin with transistor

InactiveCN102306638ASimple structureGood penetration resistanceSemiconductor/solid-state device detailsSolid-state devicesPhysicsHeat sink

The invention discloses an assembled radiating fin with a transistor. The radiating fin comprises a radiating fin main body and a transistor. The radiating fin is characterized in that: the radiating fin main body is composed of a heat radiation surface and a clinging surface; the heat radiation surface is superposed on the clinging surface in transplacement and is provided with a screw hole that is used for fixing the transistor; the transistor is fixed above the heat radiation surface; the clinging surface is provided with a fixed screw hole and a surface of the transistor is provided with an insulating silica gel protective layer. According to the invention, the assembled radiating fin is mainly used for auxiliary heat radiation for a circuit board; and the assembled radiating fin has advantages of simple structure, good anti-breakthrough performance and good heat radiation effect for a transistor.

Owner:KUNSHAN JINTAI ELECTRONICS EQUIP

A kind of laminated glass for vehicle window and preparation method thereof

ActiveCN112721355BSimple and fast operationSuitable for industrial mass productionWindowsWindscreensImpact resistanceChemically strengthened glass

The application provides a laminated glass for vehicle windows, comprising a first glass layer, a second glass layer and a composite interlayer arranged between the first glass layer and the second glass layer; the first glass layer and the second glass layer It is non-chemically strengthened glass; the thickness of the first glass layer and the second glass layer are both less than or equal to 2.1mm; the composite intermediate layer includes the first rigid layer, flexible layer and second rigid layer stacked in sequence; the first rigid layer is located at the second Between the first glass layer and the flexible layer; the second rigid layer is located between the flexible layer and the second glass layer; the elastic modulus of the first rigid layer and the second rigid layer ≥ 300Mpa; the elastic modulus of the flexible layer ≤ 10Mpa. The laminated glass has good impact resistance and penetration resistance, and the thickness of the glass in the laminated glass is small, which can greatly reduce the weight of the laminated glass. The present application also provides a method for preparing laminated glass for vehicle windows.

Owner:FUYAO GLASS IND GROUP CO LTD

A kind of flexible reinforced composite material and preparation method thereof

ActiveCN111501345BImprove antiknockImprove penetration resistanceCarbon fibresSynthetic resin layered productsElastomerReinforced concrete

The invention discloses a flexible reinforced composite material and a preparation method thereof, belonging to the technical field of protective engineering. The preparation method of the flexible reinforced composite material of the present invention comprises the following steps: immersing and drying the woven fabric in the slurry padding liquid to obtain the pretreated woven fabric; then spraying polyurea elastomer technology on the pretreated machine The surface of the fabric is sprayed with a polyurea coating to obtain a flexible and reinforced composite material; wherein the components of the slurry padding liquid include potato starch, corn starch, and water-based polyurethane. The flexible reinforced composite material prepared by the present invention can reinforce reinforced concrete materials, and has the advantages of flexibility, large-area curved surface coverage, light weight, convenient storage and transportation, wide application range, rapid reinforcement and repair, good explosion resistance and penetration resistance, etc. , more suitable for anti-blast reinforcement of special structures such as arch bridges.

Owner:JIANGNAN UNIV

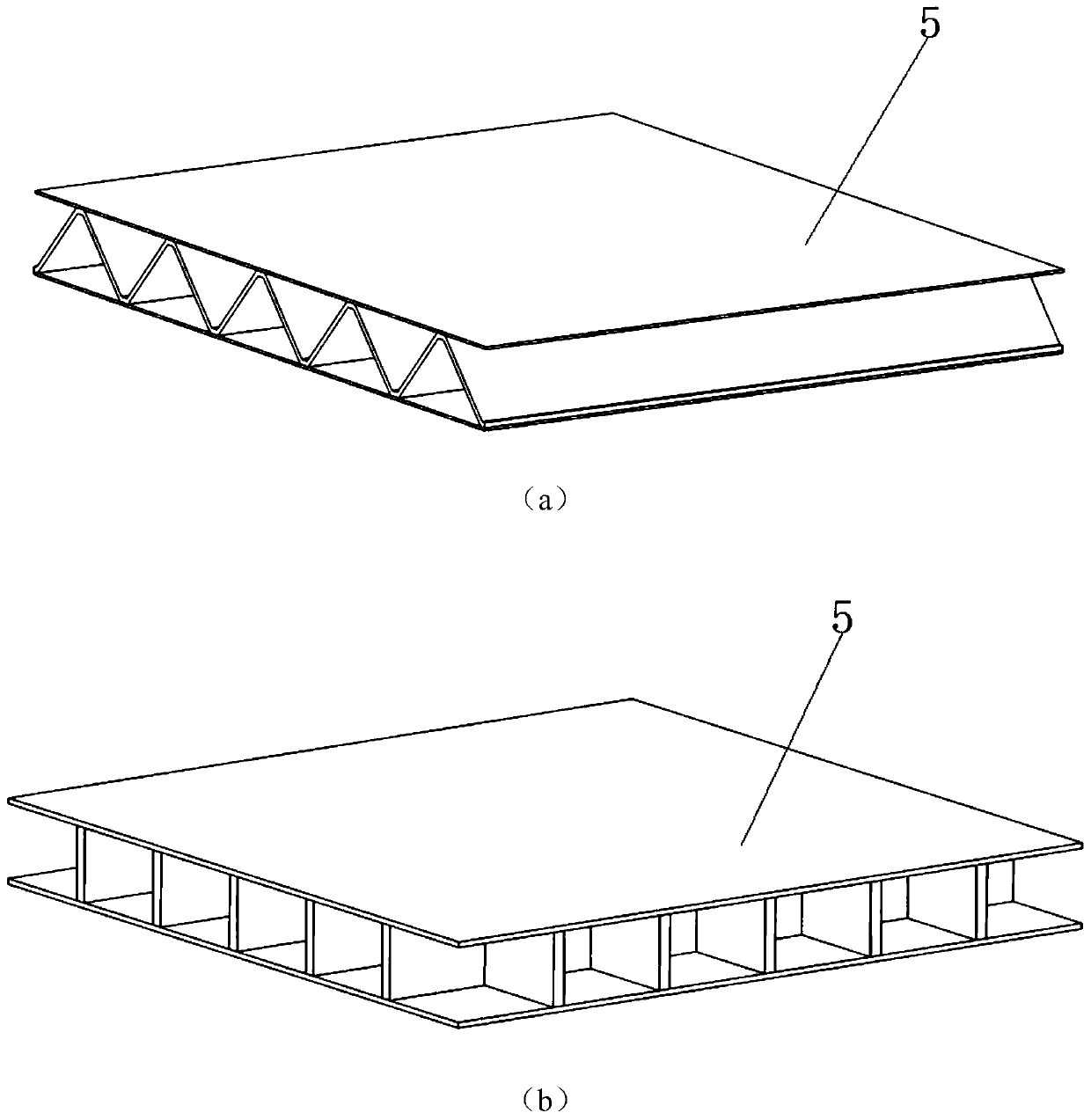

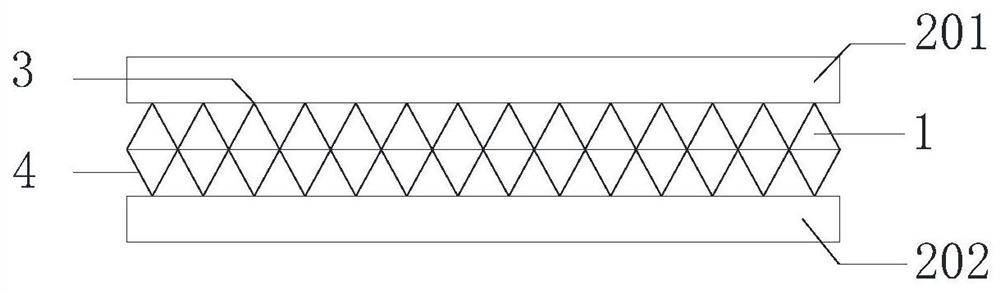

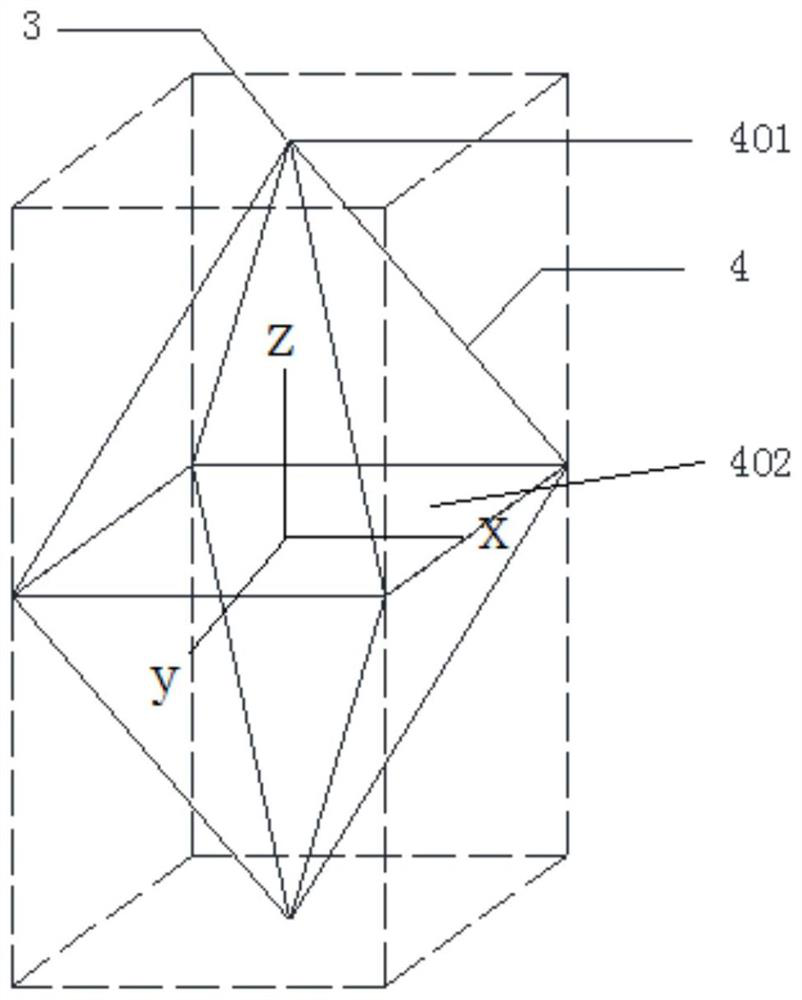

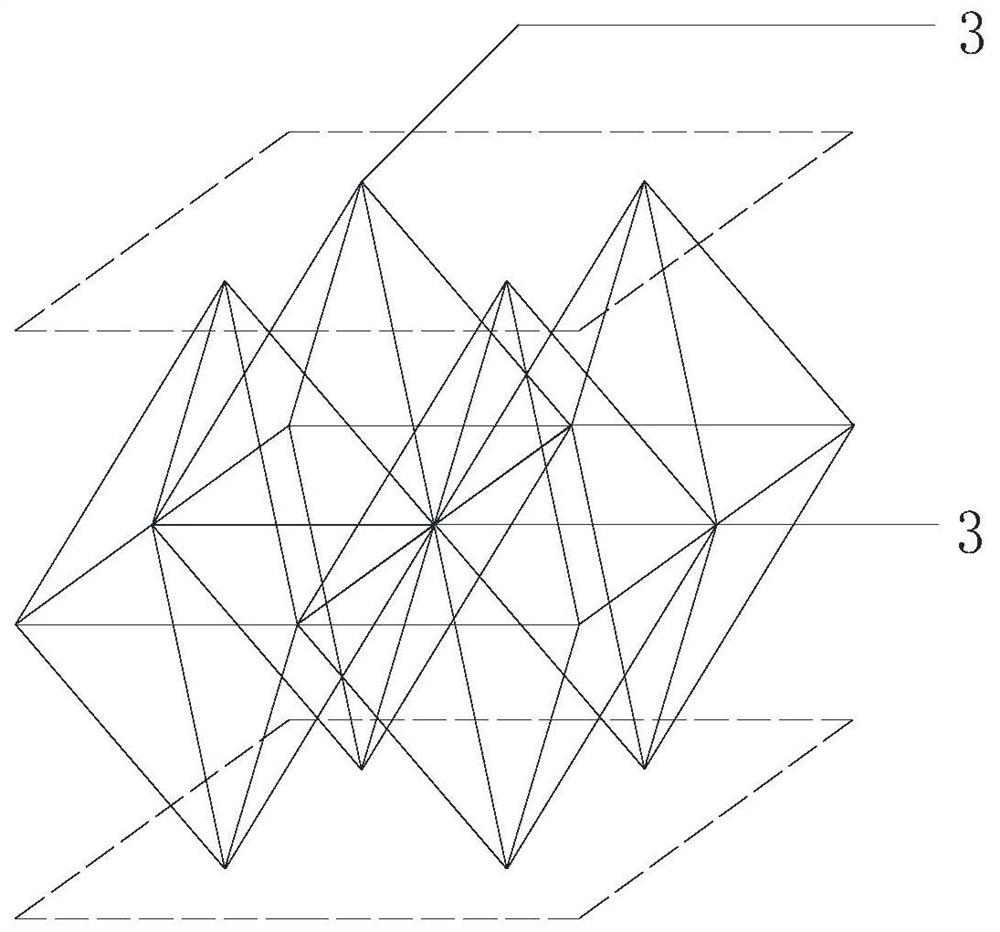

Lightweight FRP-octahedral lattice combined protection structure and design method thereof

PendingCN113415052AGood penetration resistanceWith fire performanceDefence devicesGeometric CADEnergy absorptionFinite element analysis software

The invention relates to a lightweight FRP-octahedral lattice combined protection structure and a design method thereof. The protection structure comprises an FRP surface layer, the FRP surface layer comprises an FRP upper panel and an FRP lower panel, and an octahedral lattice core layer is clamped between the FRP upper panel and the FRP lower panel; the interior of the lattice core layer is hollow and has a good deformation energy absorption effect, the octahedral lattice structure is dominated by tensile deformation, the deformation bearing capacity is larger, the energy absorption effect is better, the octahedral lattice structure is provided with three symmetric planes perpendicular to one another and has the characteristic of three-dimensional isotropy, and by designing an orthogonal test and by means of finite element analysis software, the FRP-octahedral lattice combined protection structure can be optimally designed, the structure mass is reduced on the basis of meeting the protection grade, and the advantage of light weight is fully exerted; the defects that a traditional protection system is heavy and large in size can be overcome, transportation and construction are convenient, the protection performance is improved, and good application prospects are achieved in the aspects of military protection and civil buildings.

Owner:SOUTHEAST UNIV

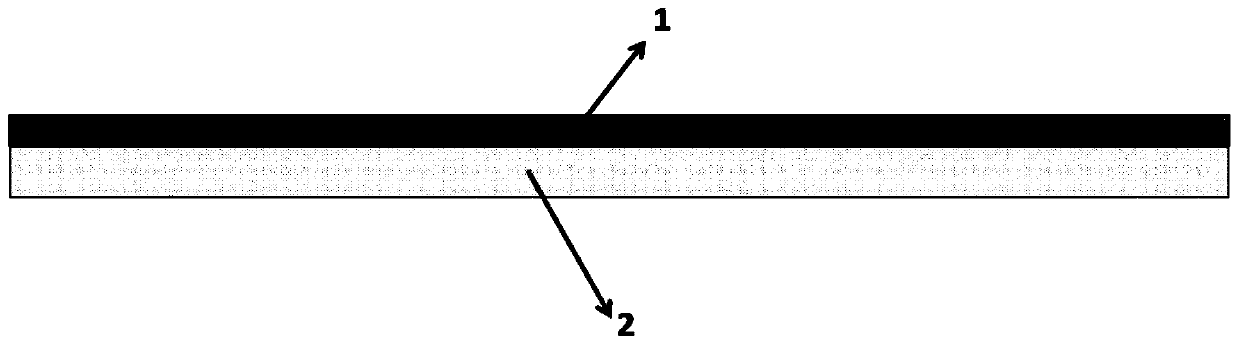

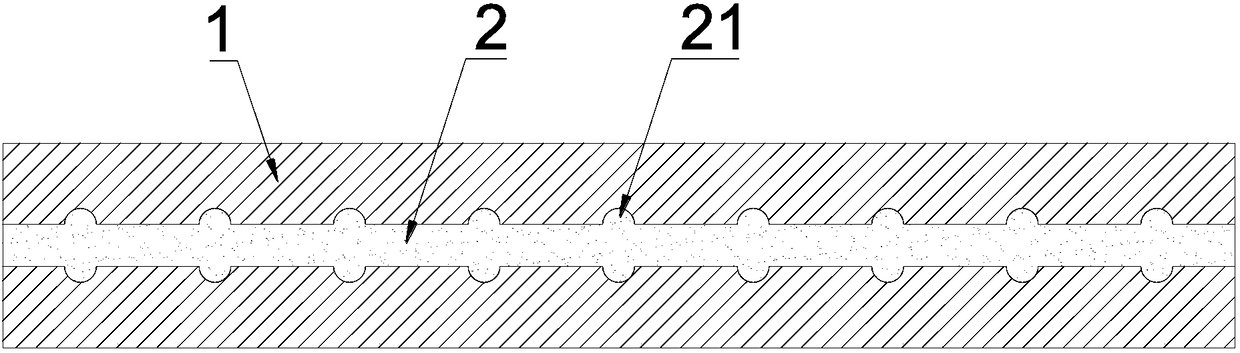

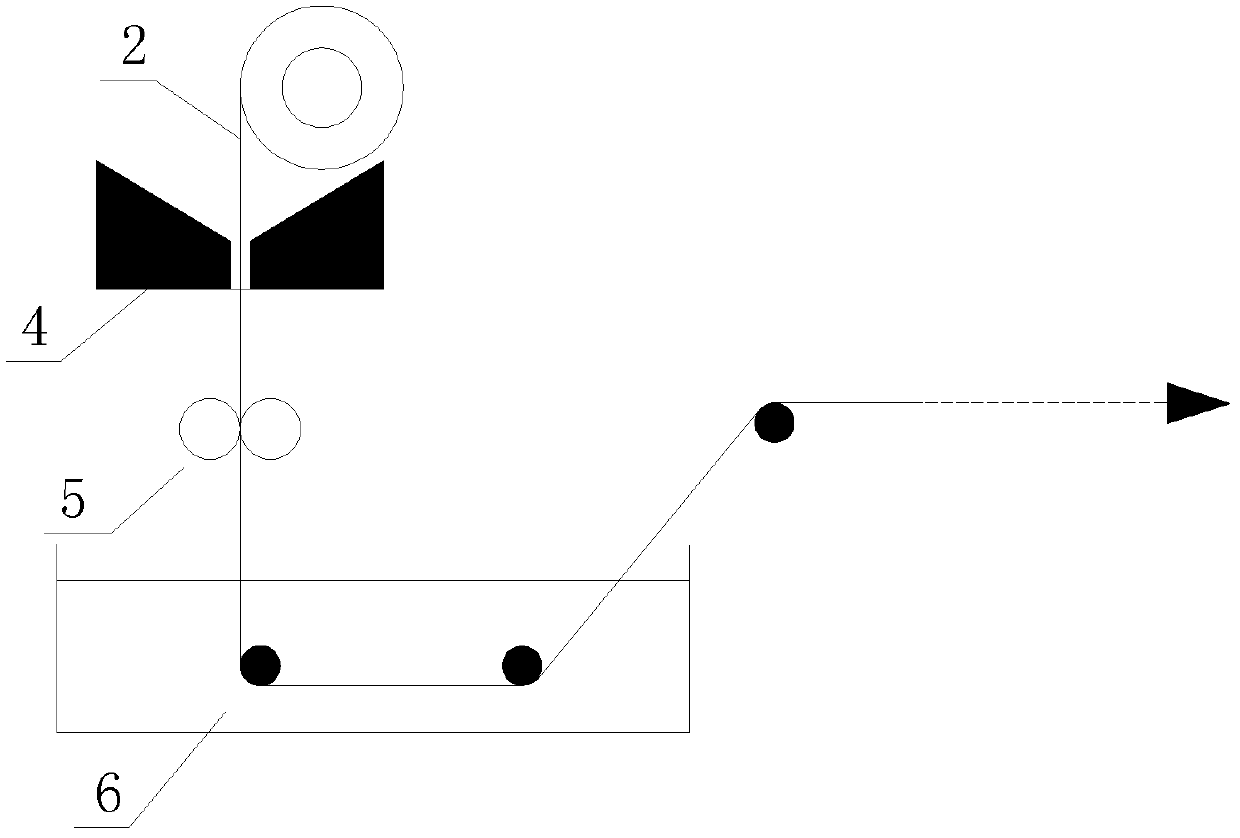

Ultra-low temperature anti-penetration PVB interlayer film

InactiveCN108582921APromote technological progressGood penetration resistanceProtective equipmentSynthetic resin layered productsFiberPlasticizer

The invention discloses a ultra-low temperature anti-penetration PVB interlayer film. The interlayer film comprises an interlayer film body, wherein the interlayer film body is made from high-viscosity PVB resin, a fiber reinforced layer is compounded in the interlayer film body, and a plurality of bulges are formed on the upper surface and lower surface of the fiber reinforced layer; and a compound plasticizer which is triethylene glycol diisooctanoate is compounded in the interlayer film body. Compared with a conventional product, the interlayer film has the characteristic of better anti-penetration performance, can be applied to manufacture of interlayer safety glass and meet high-level safety requirements for strong penetration resistance, and can be widely applied to the fields of front and rear windshields of an automobile, bulletproof glass and the like, so that technological progress of a domestic PVB interlayer film is facilitated, the international competitiveness of the domestic PVB interlayer film is improved, and a positive promoting effect on the competitiveness and brand building of enterprises is achieved.

Owner:JIANGSU AOTIANLI NEW MATERIAL CO LTD

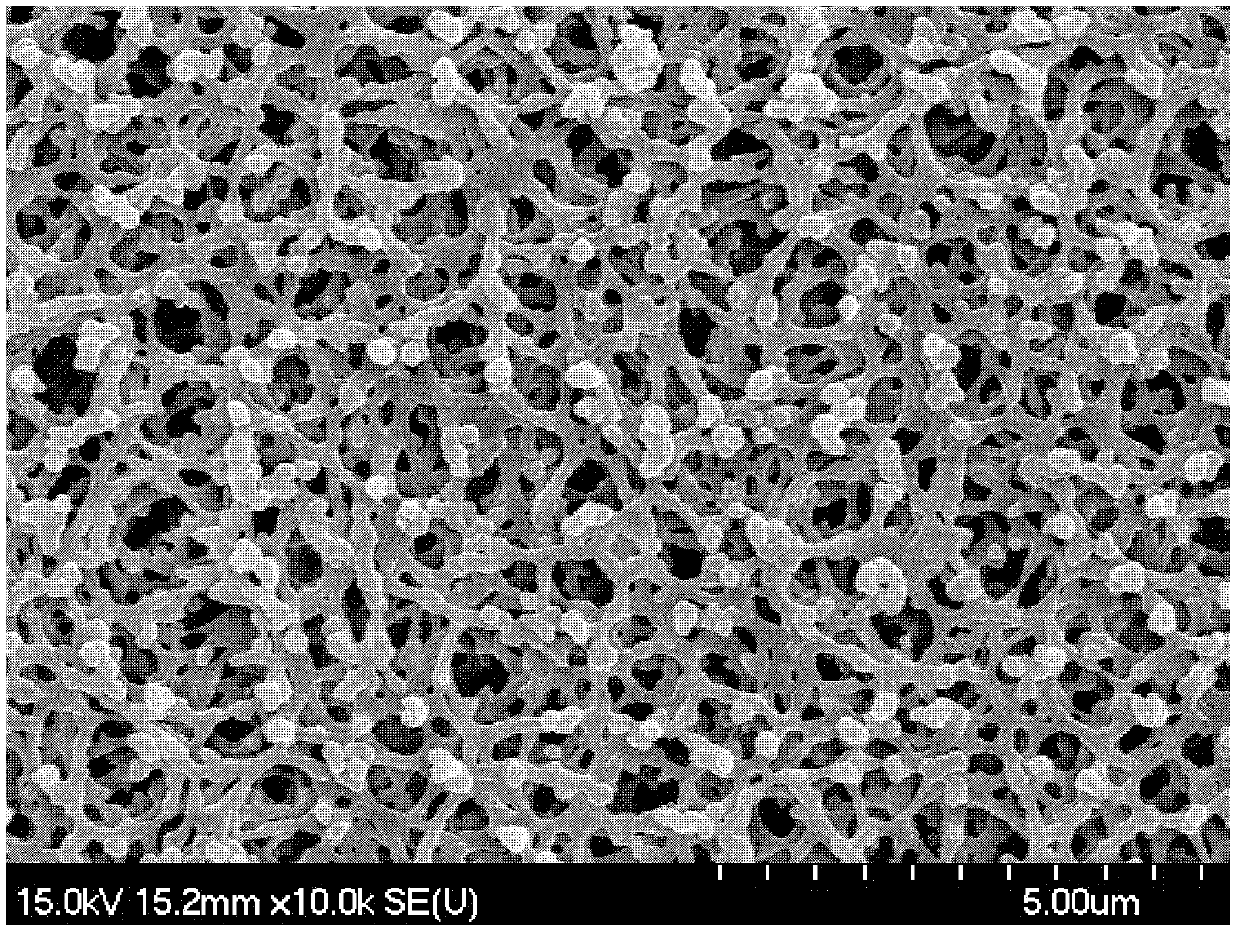

Siloxane-containing vinyl chloride copolymer, preparation method of the siloxane-containing vinyl chloride copolymer, battery division plate prepared from the siloxane-containing vinyl chloride copolymer, and manufacturing method of the battery division plate

ActiveCN102898573BControl macroscopic propertiesHigh strengthSynthetic resin layered productsCell component detailsPolymer scienceNonwoven fabric

The invention discloses a siloxane-containing vinyl chloride copolymer, a preparation method of the siloxane-containing vinyl chloride copolymer, a battery division plate prepared from the siloxane-containing vinyl chloride copolymer, and a manufacturing method of the battery division plate. The siloxane-containing vinyl chloride copolymer has molecular weight of 20000 to 50000 and is shown in the structural formula (1). The battery division plate comprises a porous non-woven fabric. Two copolymer film layers are respectively coated on surfaces of two sides of the porous non-woven fabric. Apertures are uniformly and densely arranged on the surfaces of the copolymer film layers and an average diameter of the apertures is in a range of 0.1 to 10 microns. The copolymer film layers comprise the siloxane-containing vinyl chloride copolymer or mainly comprise the siloxane-containing vinyl chloride copolymer. The battery division plate prepared from the siloxane-containing vinyl chloride copolymer has good strength and hydrophily. The battery division plate has good wettability, high acid adsorption capacity, good flexibility, good foldability, large mechanical strength and good penetration resistance, is suitable for tightening assembling, and can effectively improve use performances of a storage battery.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com