Waterproofing loudspeaker cones

A loudspeaker and hydrophobic fiber technology, applied in sensors, ceramic material diaphragms, textiles, etc., to achieve the effects of reducing wet rubbing defects, good acoustic performance, and good penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

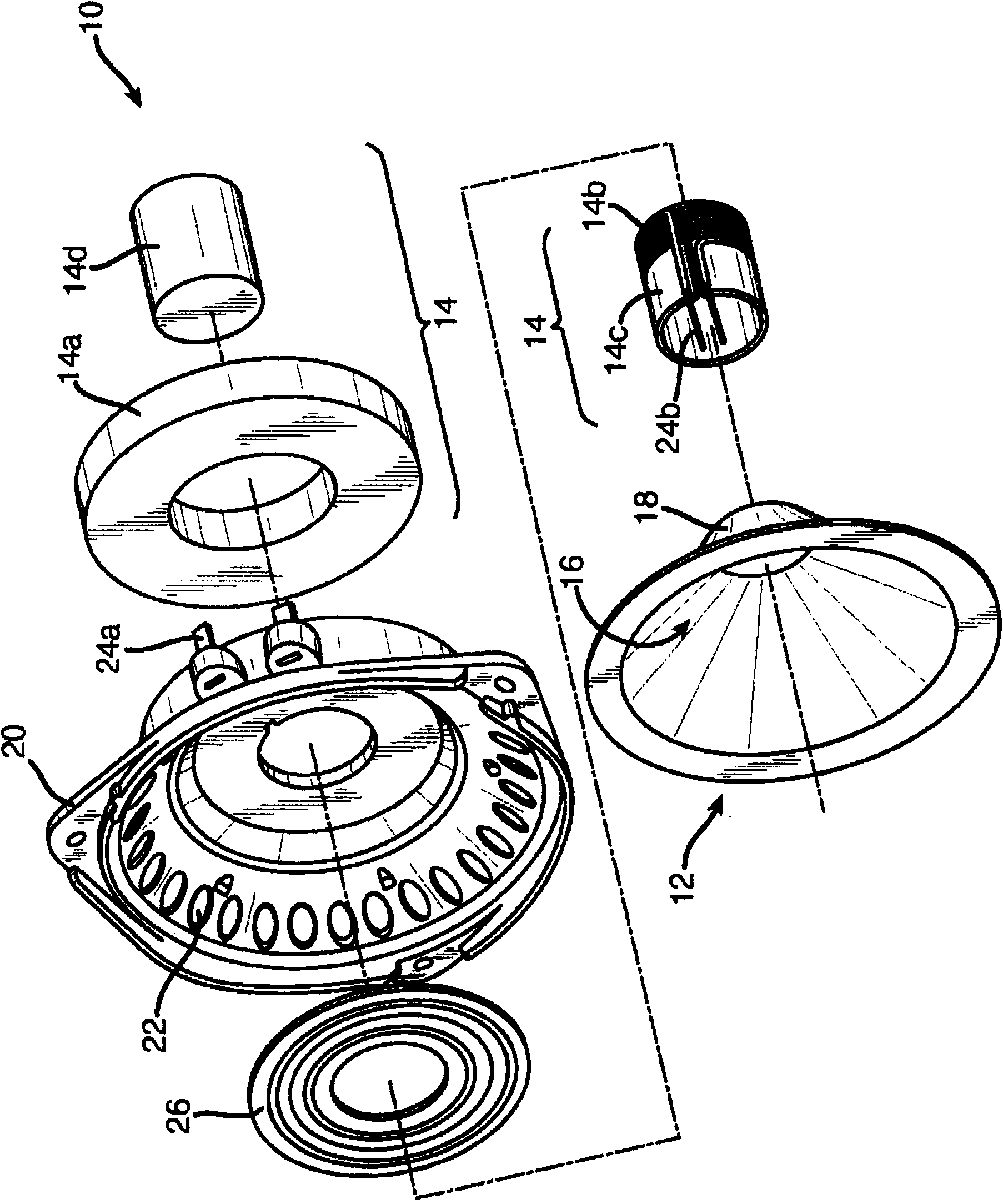

[0013] figure 1 The loudspeaker 10 shown in includes a cone 12 made of paper as described above. In the context of a loudspeaker that will be exposed to water, the basin is described as having a wet side 18 and a dry side 16 . It is desirable that other structures, such as a speaker enclosure (not shown), prevent moisture from reaching the dry side 16 of the basin 12 . figure 1 Middle motor 14 (in figure 1 In the example, including the magnet 14a, the voice coil 14b, the bobbin 14c and the pole 14d), the relationship with the dry side and the wet side of the basin 12 is for example only. Other arrangements are also possible, for example the inside of the basin 12 could be the wet side and the motor 14 could be located within the volume defined by the basin regardless of which side is dry and which is wet. figure 1 Other components of the example speaker include cage 20 having ventilation holes 22 , electrical connections 24 a and 24 b , and suspension 26 .

[0014] To impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com