Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2224 results about "Acrylic fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic fibers are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of -100,000, about 1900 monomer units. For a fiber to be called "acrylic" in the US, the polymer must contain at least 85% acrylonitrile monomer. Typical comonomers are vinyl acetate or methyl acrylate. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. It was first developed in the mid-1940s but was not produced in large quantities until the 1950s. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. It is manufactured as a filament, then cut into short staple lengths similar to wool hairs, and spun into yarn.

Flame-resistant fiber blend, yarn, and fabric, and method for making same

InactiveUS20060292953A1Improve flame retardant performanceReduce weightWarp knittingWoven fabricsYarnAramid

A fiber blend, a yarn spun from the fiber blend, and a fabric made from the yarn, wherein the fiber blend comprises: (a) about 40 wt.% to about 65 wt.% modacrylic fibers containing antimony, or FR acrylic fibers; (b) about 10 wt.% to about 50 wt.% cotton fibers or FR cotton fibers; (c) up to about 25 wt.% nylon fibers; and (d) greater than about 3 wt.% and less than 10 wt.% para-aramid fibers. The fabric is over 90 percent dyeable and is capable of achieving ASTM F1506 certification with an Arc Thermal Performance Value greater than 8.0 cal / cm2. The fabric is woven or knitted, and has a weight of about 4.0 oz. / yd.2 to about 10.5 oz. / yd.2. The fabric is suitable for garments worn during activities in which there is potential for exposure to flame and / or electrical arc.

Owner:SPRINGFIELD

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

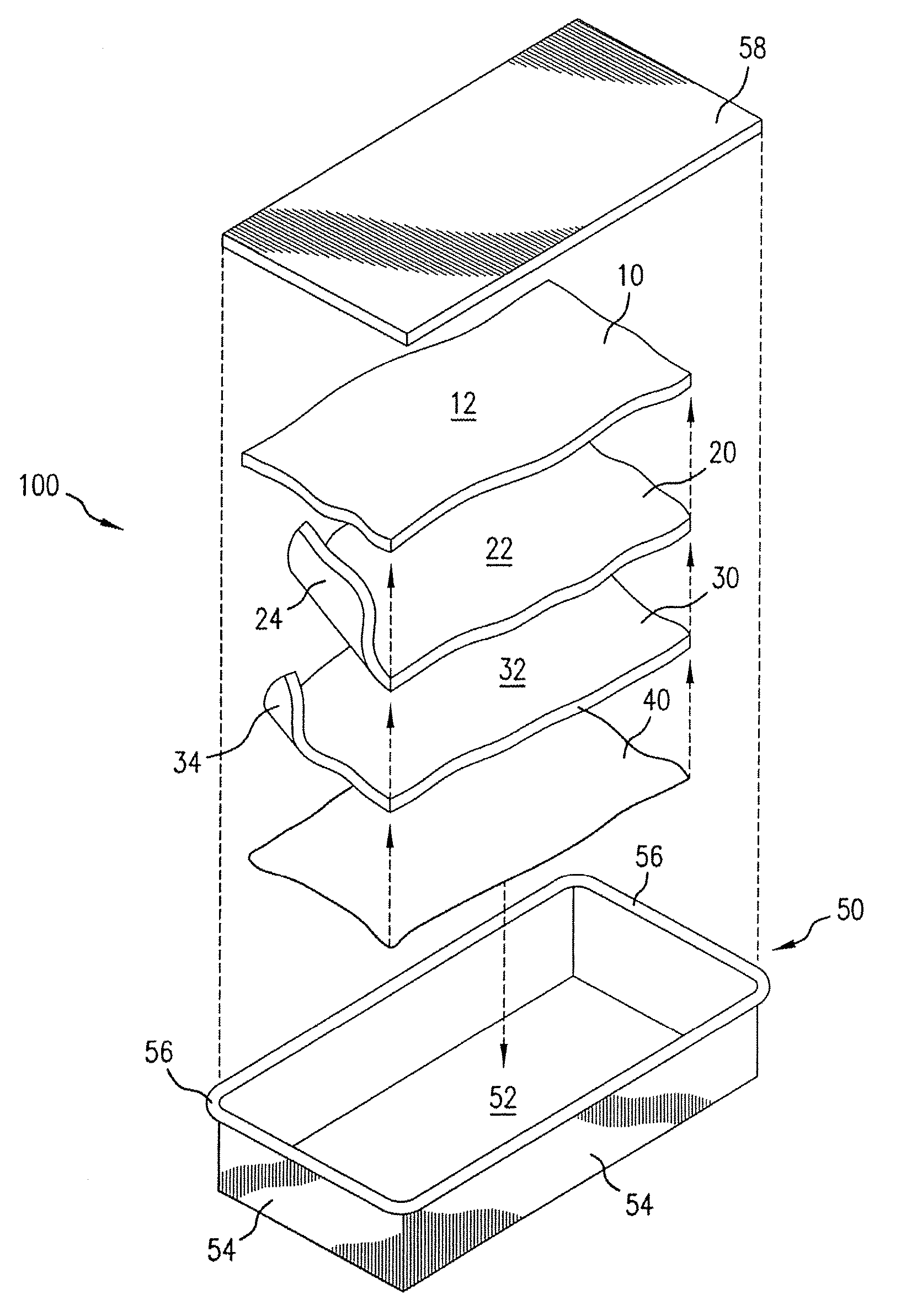

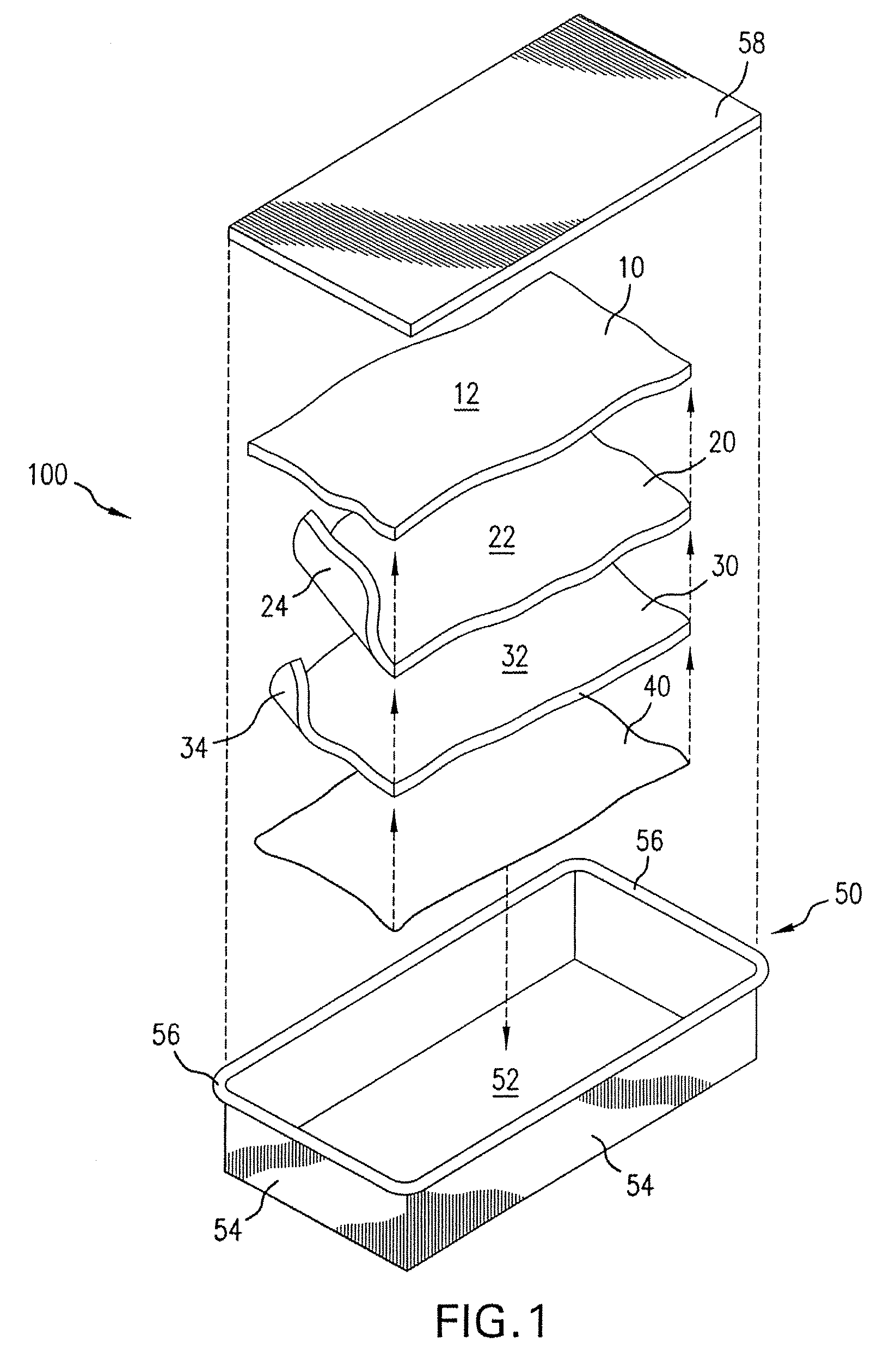

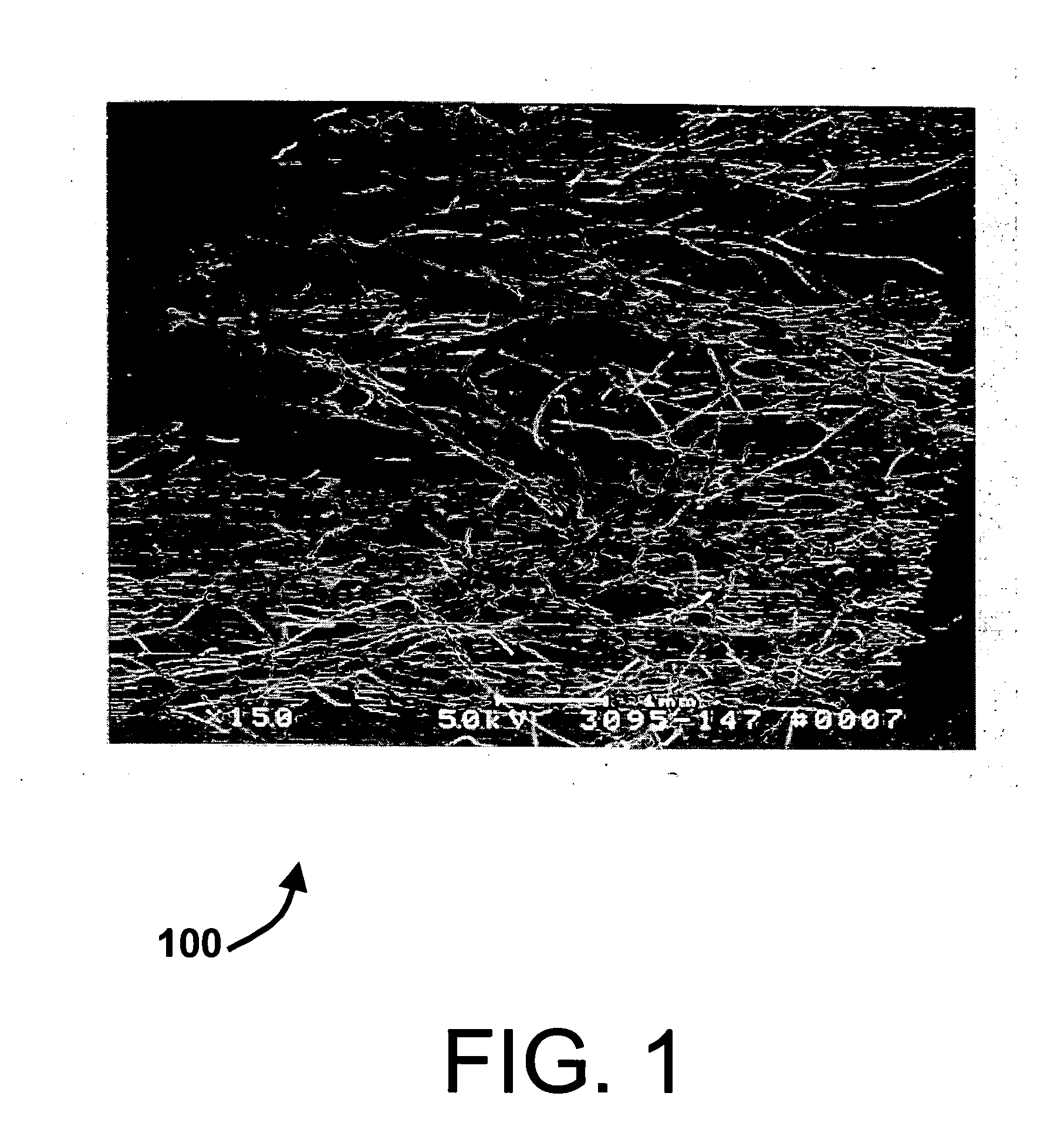

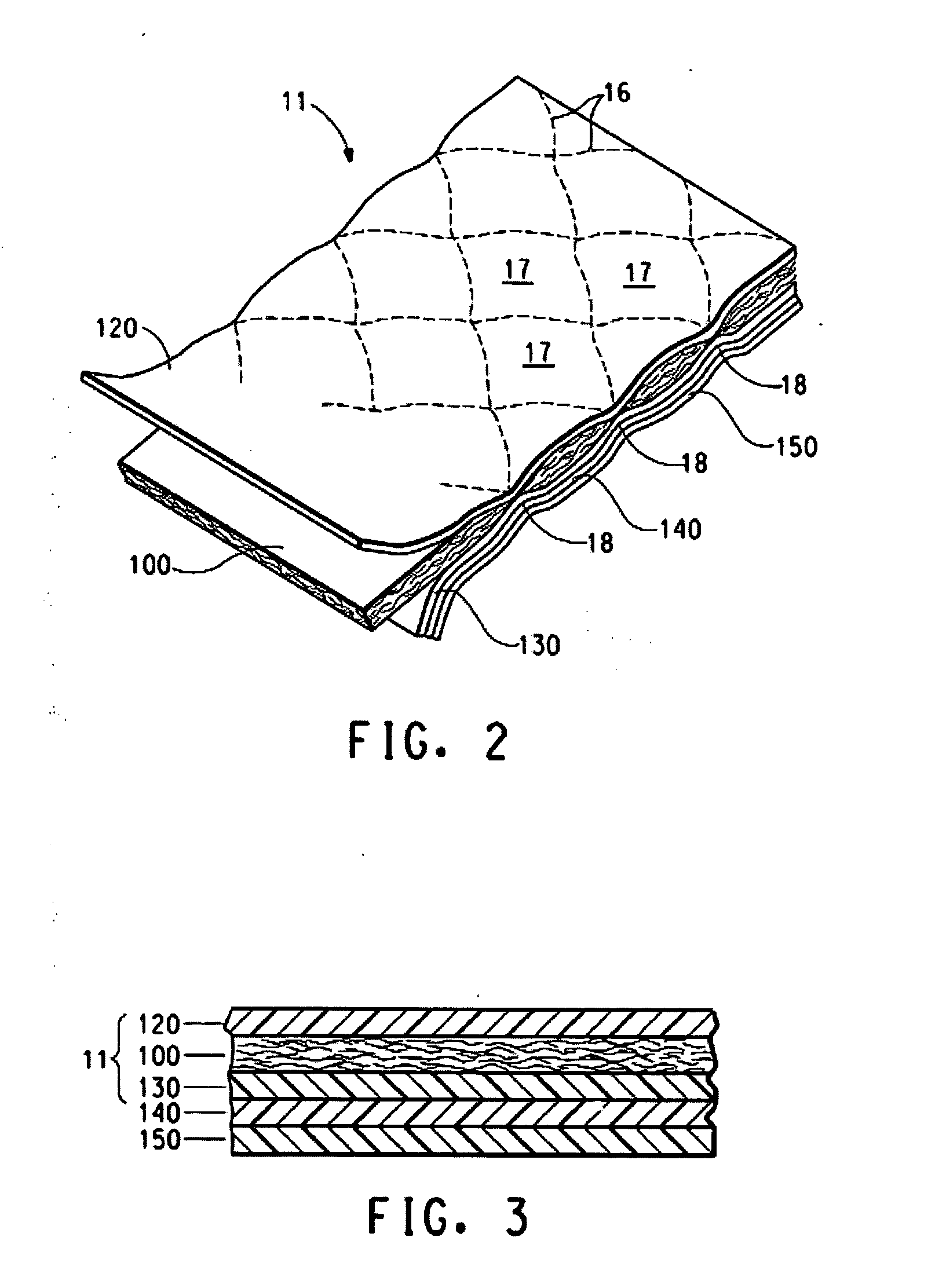

Tacky allergen trap and filter medium, and method for containing allergens

InactiveUS20080022645A1Reduce flammabilityMembrane filtersLoose filtering material filtersPolyesterPolymer science

The present invention provides a specific filtration media which includes a substrate having cellulose fibers, bicomponent fibers, adhesion fibers, binder, and pressure sensitive adhesive. Also contemplated are fire retardant filtration media containing bicomponent fibers and polyester fibers or acrylic fibers, and optionally cellulose fibers. The cellulose fibers of the invention are pretreated with flame retardant, providing a beneficial material for filtration purposes.

Owner:BUCKEYE TECH INC

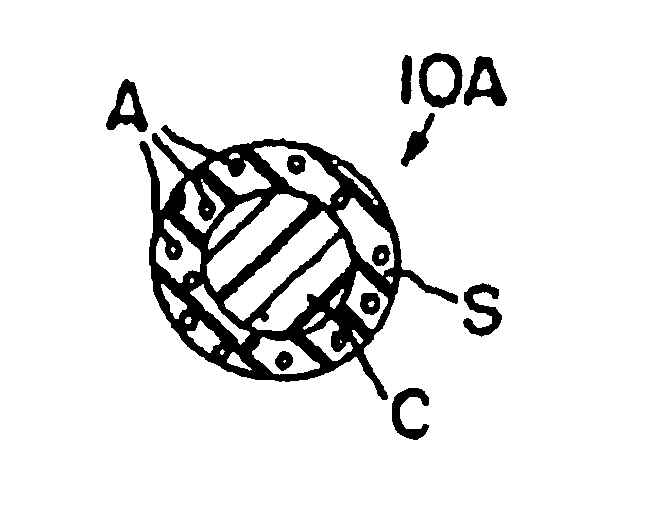

Anti-microbial fiber and fibrous products

InactiveUS6841244B2Resistant to washing off and wearing offLow costGarment special featuresDispersed particle filtrationPolyesterMicroorganism

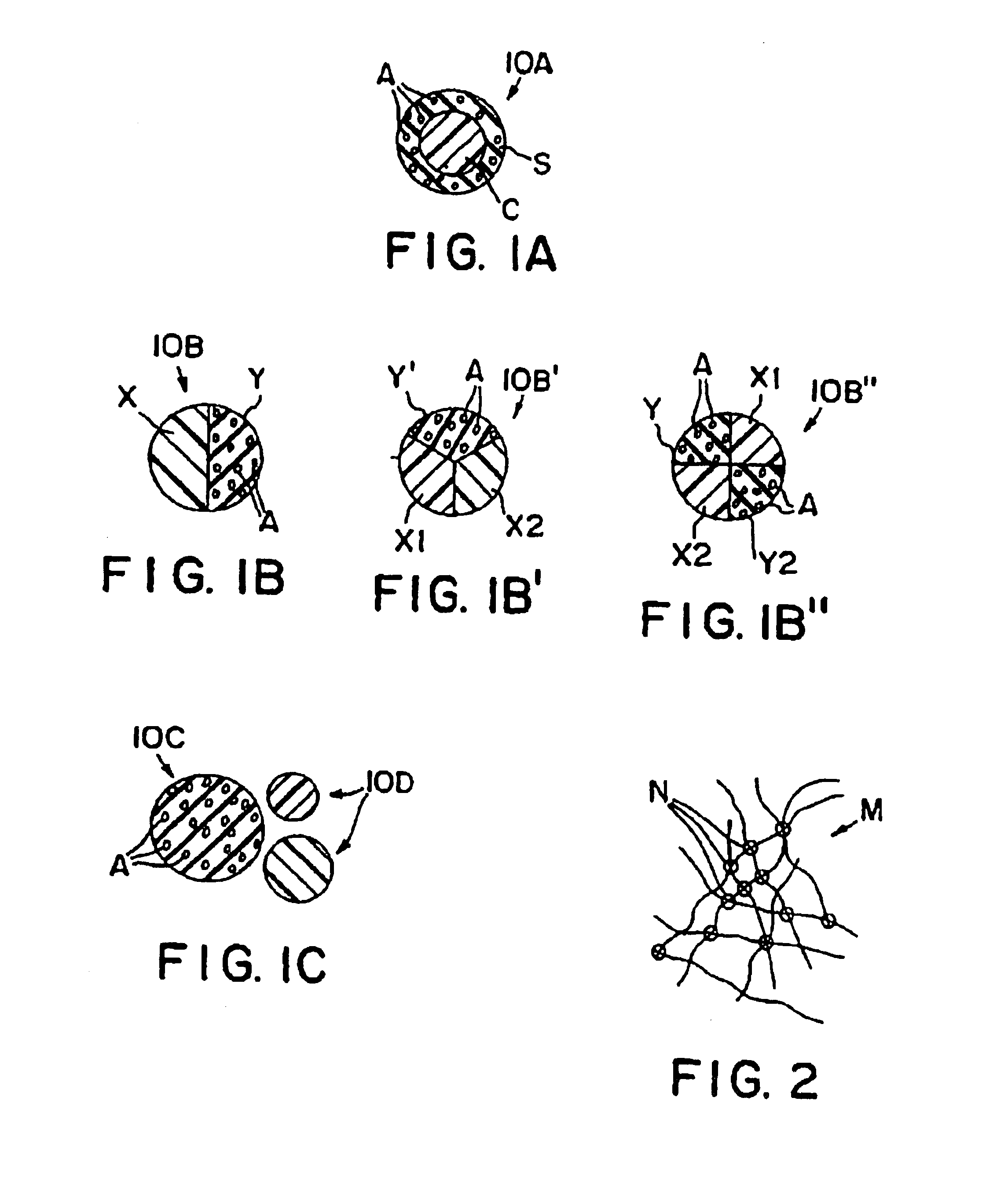

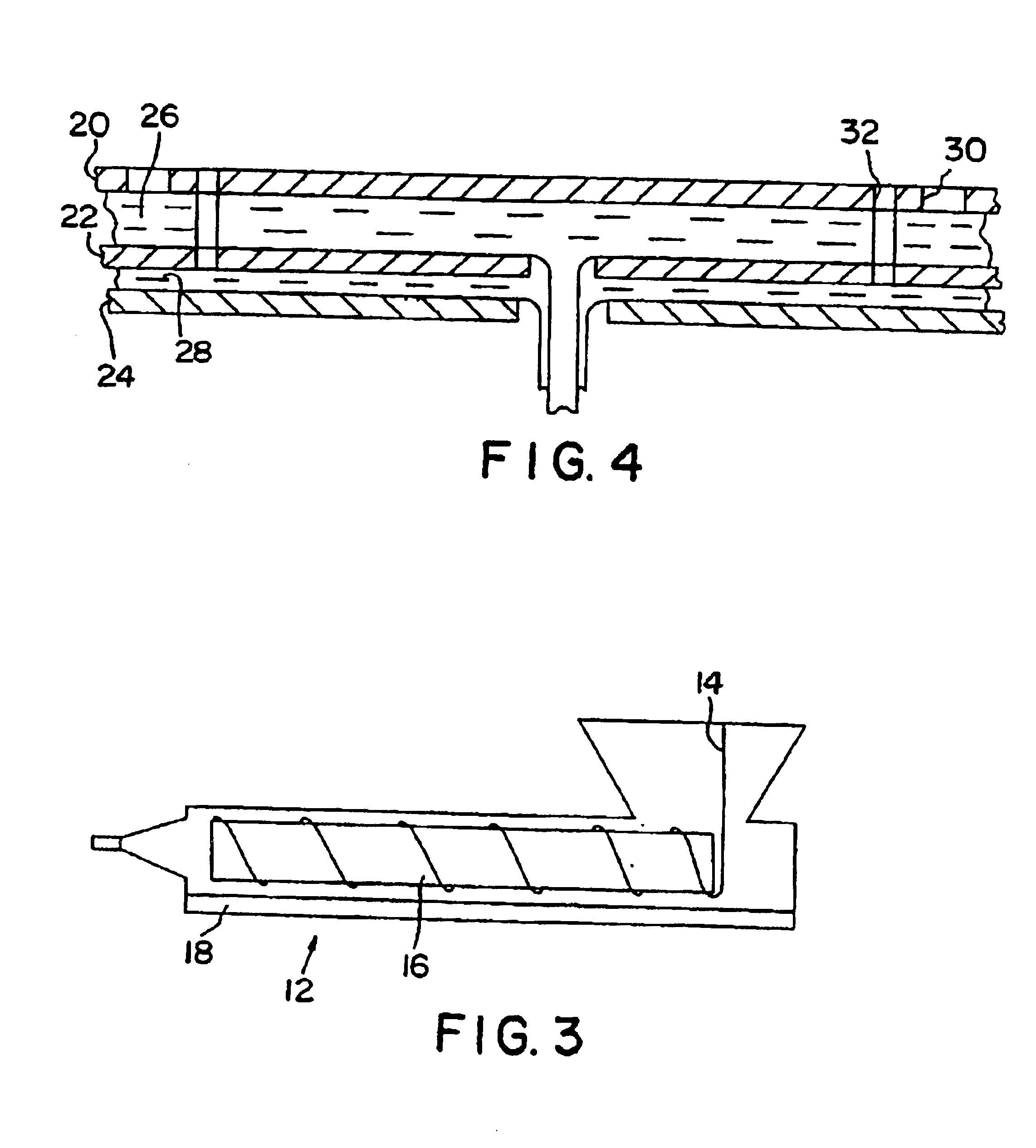

An anti-microbial and / or anti-fungal synthetic fiber that comprises various thermoplastic polymers and additives in a bi-component form in either a core-sheath or side-by-side configurations. The anti-microbial synthetic fibers comprise inorganic anti-microbial additives, distributed in certain areas to reduce the amount of the anti-microbial agents being used, and therefore the cost of such fibers. The fibers can incorporate anti-microbial additives so that they are not removed by repeating washing in boiling water and in dry clean cycles and become ineffective and conversely enhance access to the additives by washing or the like. The fibers comprise high tenacity polymers (e.g. PET) in one portion and hydrolysis resistance polymers (e.g. PCT) in another portion with the additives. The fibers can further be blended with non-anti-microbial fibers such as cotton, wool, polyester, acrylic, nylon etc. to provide anti-microbial finished fabrics. In one such embodiment, binder fibers are used which are mixed with other fibers.

Owner:FOSS PERFORMANCE MATERIALS LLC

Modacrylic/aramid fiber blends for arc and flame protection

A yarn, fabric and garment suitable for use in arc and flame protection contains modacrylic, p-aramid and m-aramid fibers.

Owner:DUPONT SAFETY & CONSTR INC

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS20060068664A1Optimal static dissipationBig contrastWarp knittingCircular knitting machinesPolyesterYarn

A fabric is provided for use in safety apparel, including a first yarn type comprising at least about 60 percent modacylic fibers and a second yarn type comprising an intimate blend of anti-static fibers and other fibers selected from the group of fibers consisting of polyester, nylon, rayon, modacrylic, cotton, wool, and combinations thereof. The fabric meets the American Society for Testing and Materials standard ASTM F-1506 for flame resistance, Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Flame-retardant nonwovens for panels

The present invention concerns a flame retardant (FR) nonwoven fabric useful in wall panels, especially for cubicles. The nonwoven fabric comprises from about 15 to 65 weight % of a low melt binder, and least one of FR rayon fiber, FR acrylic fiber, FR melamine fiber, or FR resin coated synthetic or natural fibers, and optional nonbonding fibers. The total amount of FR fibers and FR resin coated synthetic or natural fibers is about 30-85 wt. % of the fabric. The present invention also contemplates a wall panel constructed from the nonwoven fabric comprising FR rayon fibers, FR acrylic fibers, FR melamine fiber or a combination of these, and / or FR resin coated synthetic or natural fibers, with about 15 to about 65 weight % low melt binder. The wall panel from this construction passes the ASTM E 1354, 1999 tests. Preferably the nonwoven fabric has a batt weight of at least about 40 oz. / sq. yd. and preferably between about 40 oz. / sq. yd. and 60 oz. / sq. yd.

Owner:SYLVAN CHEM CO

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

Multifunctional aromatic type element fiber fabric protective clothing

ActiveCN103233287ASpinning solutions preparationArtifical filament manufactureAcute hyperglycaemiaSesamum orientale

The invention discloses multifunctional aromatic type element fiber fabric protective clothing. The multifunctional aromatic type element fiber fabric protective clothing comprises vitamin mineral substance nutrient element group, a free radical-scavenging anti-electromagnetic wave energy-accumulated heat-insulating material, natural antibiosis mite-proof traditional Chinese medicine fluid extract aroma nano microcapsule, and cotton, sesame, silk, wool, polypropylene fiber, nylon, acrylic fiber and a terylene viscose fiber spinning solution. The multifunctional aromatic type element fiber fabric protective clothing can entirely supplement and regulate the element balance of a human body, as well as the vitamin balance, release trace element negative ions, purify air, resist heavy metal elements and air, powerfully scavenge free radicals, enhance the immunity of the human body, and prevent electromagnetic wave pollution, is energy-accumulated, cold-proof and heat-insulating, as well as antimicrobial and mite-proof, can effectively prevent the infection of various pathogenic bacteria, influenza and skin pruritus, is anti-cancer, and resists hypertension, hyperlipidemia, hyperglycemia, cerebral thrombosis and the like, thus building the human body, and enabling the human body to emit natural and pleasant aroma.

Owner:中山巨邦科技集团有限公司

Acrylic shrinkable fiber and method for production thereof

InactiveUS20070098982A1Low heat resistanceCompatibilityYarnThin material handlingPolymer scienceSpinning

An object of the present invention is to provide a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing. By spinning an incompatible spinning solution, the above object can be achieved, and a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing can be provided.

Owner:KANEKA CORP

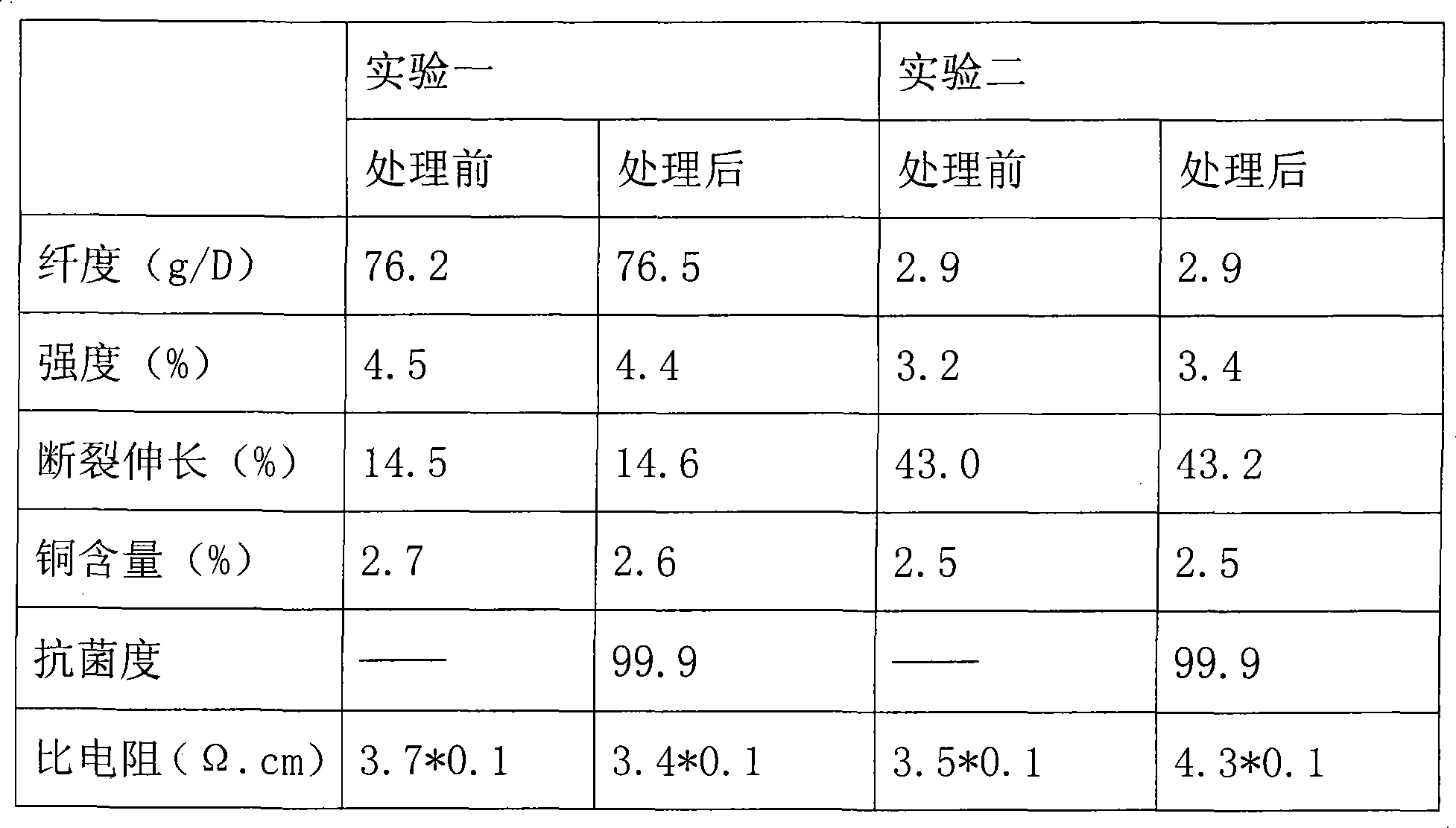

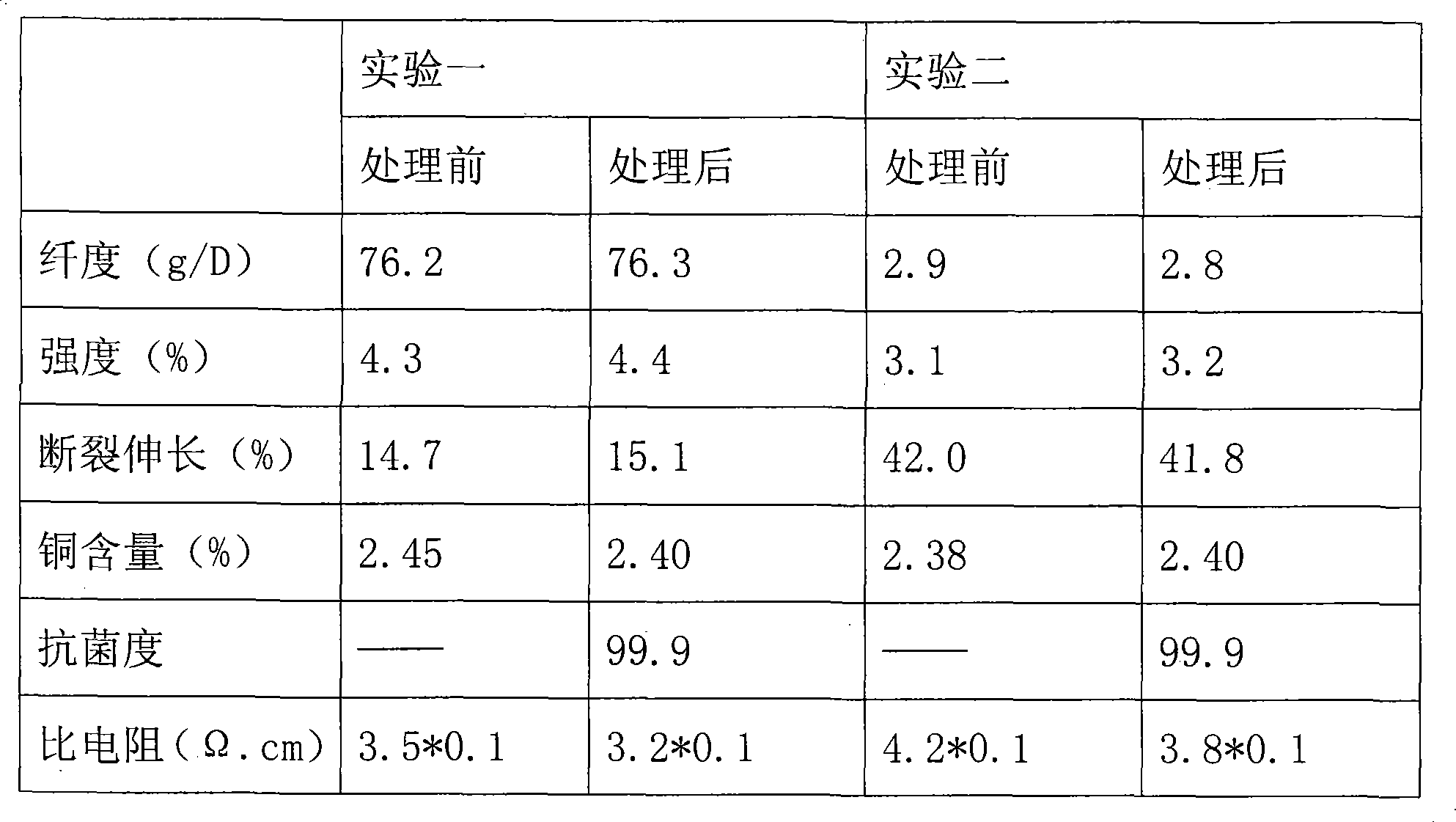

Process for manufacturing antimicrobial conductive acrylic fibre fibre

The invention belongs to a manufacture method of an antibacterial conductive acrylic fiber, which is characterized by being composed of the following steps: (1) arranging the acrylic fiber into a reaction vessel, then pouring a solvent into the reaction vessel, dissolving copper salt containing Cu<2+> into the solvent, adjusting the pH valve of the solution to be between 1.5 to 3.0, then adding a reducer and heating, maintaining the temperature of the solution to be between 90 to 100 DEG C, carrying out reduction on the Cu<2+> by utilizing the reducer to generate Cu<+> and lead the Cu<+> to be absorbed on the acrylic fiber; (2) adjusting the pH value of the solution to be between 1.5 to 3.0 and then maintaining the temperature of the solution to be between 40 to 120 DEG C, adding salt containing sulfur atoms and leading a great amount of Cu<+> to be oxidized to generate the Cu<2+> after the reaction time lasts 2 to 4 hours; thereby generating a sulfide of copper that is not easy to be dissolved in the solvent to lead the sulfide of copper to be sufficiently and uniformly dispersed on the surface of the whole fiber. The copper sulphide in the acrylic fiber manufactured by utilizing the method is dispersed on the surface of the whole fiber. The self physical and chemical characteristics of the copper sulphide lead the fiber to have excellent antibacterial property and conductibility; the copper sulphide on the fiber surface is not easy to fall off and has excellent anti-washing property.

Owner:金素娟

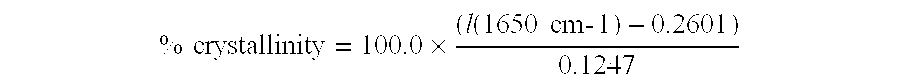

Carbon fibers, acrylic fibers, and production processes thereof

InactiveUS6103211AMonocomponent synthetic polymer artificial filamentThin material handlingCarbon fibersTurbine

PCT No. PCT / JP97 / 01716 Sec. 371 Date Jan. 20, 1998 Sec. 102(e) Date Jan. 20, 1998 PCT Filed May 22, 1997 PCT Pub. No. WO97 / 45576 PCT Pub. Date Dec. 4, 1997The object of the present invention is to provide carbon fibers with high tensile strength as a resin impregnated strand even if the single filaments constituting the carbon fibers are thick. The carbon fibers of the present invention consisting of a plurality of single filaments are characterized by satisfying the following relation: sigma > / =11.1-0.75dwhere sigma is the tensile strength of the carbon fibers as a resin impregnated strand (in GPa) and d is the average diameter of the single filaments (in mu m). The carbon fibers can be preferably used as a material for forming energy-related apparatuses such as CNG tanks, fly wheels, wind mills and turbine blades, a material for reinforcing structural members of roads, bridge piers, etc., and also a material for forming or reinforcing architectural members such as timber and curtain walls.

Owner:TORAY IND INC

Production technology of flexible silk azelon laschel blanket

ActiveCN102912552ABright colorSoft and delicateWarp knittingHeating/cooling textile fabricsTextile printerEngineering

The invention relates to a production technology of a flexible silk azelon laschel blanket. The production technology comprises the following steps of: chaining, beaming, knitting, bleaching, sizing, dyeing, soaping, mellowing, drying and postprocessing and the like. The production technology of the flexible silk azelon laschel blanket provided by the invention optimizes a spinning technology, and techniques of weaving, front finishing, textile printing (dyeing) and after finishing according to characteristics of flexible silk azelon and acrylic fibers, so that a functional blanket meeting new requirements that consumers pursue comfort and heath and the like is produced. The flexible silk azelon laschel blanket provided by the invention is bright in color, soft, fine and smooth in hand feeling, and mothproof and mildewproof, and simultaneously has health-care functions of far infrared emission and anions and the like.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

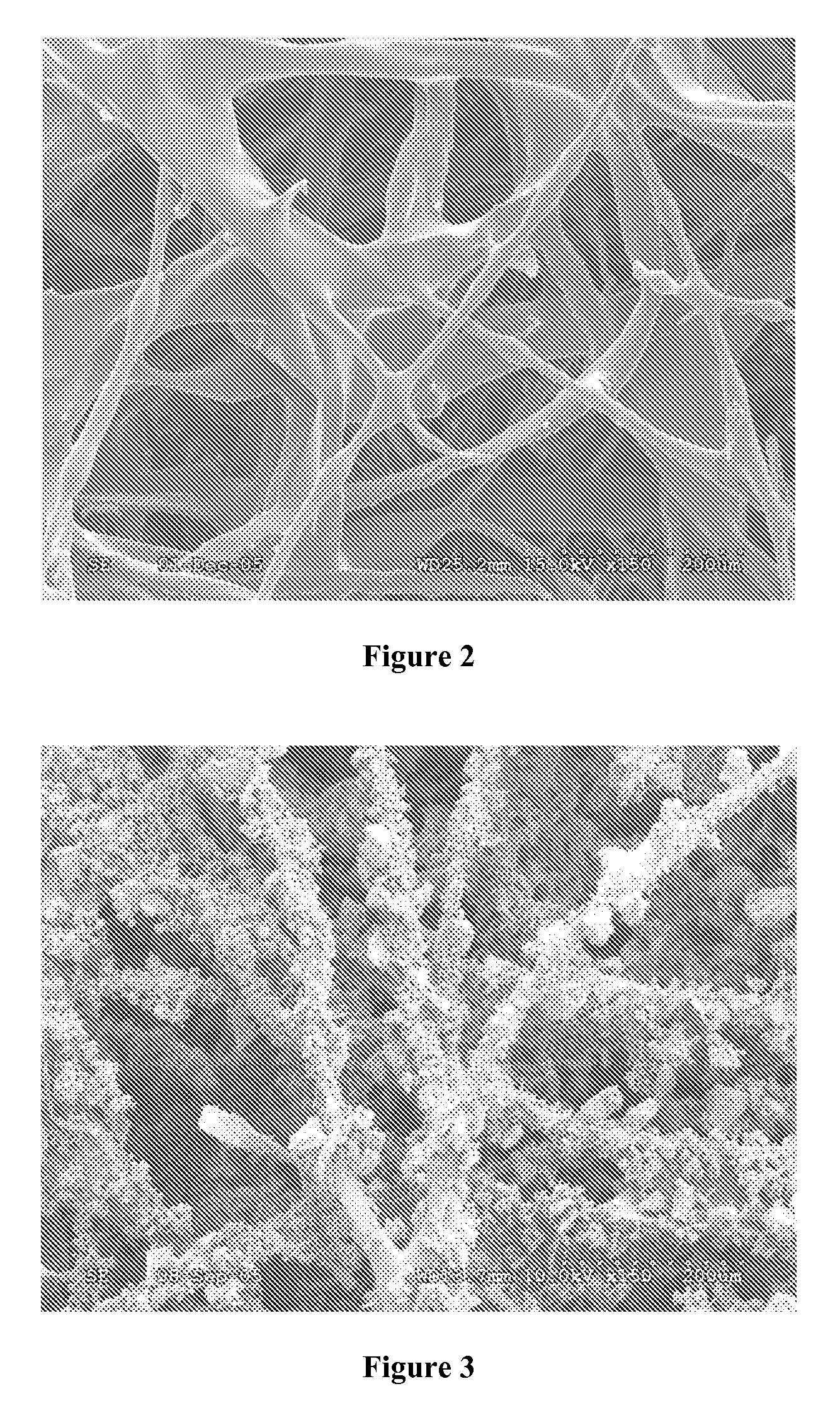

Titanium white for dry acrylic spinning delustering its preparing method

InactiveCN1858309ADry spinning methodsPigment treatment with organosilicon compoundsWeather resistanceWhite powder

The present invention discloses a kind of titanium white powder for extinction in dry spinning acrylic fiber and its preparation process. The titanium white powder is prepared with anatase type titanium white as material and through pulping, sanding milling, grading, purifying and other steps to eliminate coarse grains and impurity ions, coating with compact Al2O3 to obtain high weather resistance, water washing and coating with organic material. It has excellent dispersivity in spinning solution for dry spinning acrylic fiber and is used for extinction. It can result in excellent filtering performance and spinnability, low end breakage, high tow strength, high whiteness and high dyeability.

Owner:EAST CHINA UNIV OF SCI & TECH

Flame-retardant and fireproof fabric, and processing technology and textile thereof

ActiveCN103352293AImprove flame retardant performanceHigh metabolismWeft knittingFibre treatmentPolyesterPolymer science

The invention relates to flame-retardant and fireproof fabric, and a processing technology and textile thereof. Warp yarns adopt wool tops formed by blending flame-retardant acrylic, flame viscose, fine-denier polyester and aramid fiber 1313 fiber; weft yarns adopt wool tops formed by blending alginate fiber, polyphenylene sulfide, polysulfonamide and phenolic fiber; then the warp yarns and the weft yarns form the flame-retardant and fireproof fabric through steps of dyeing, fixation, rinsing, sizing, weaving, desizing, rinsing, drying, baking, full decatizing and the like. The fabric has the characteristics of simple processing technology, good flame-retardant effect and the like, and can be applied to apparel, home textile, sports goods, medical care and fireproof fabric.

Owner:SHANGHAI ZANRAY IND

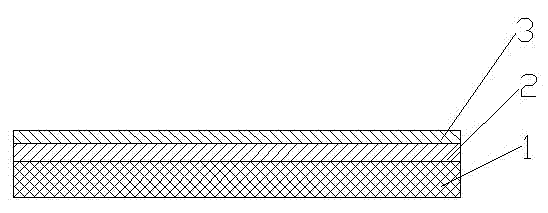

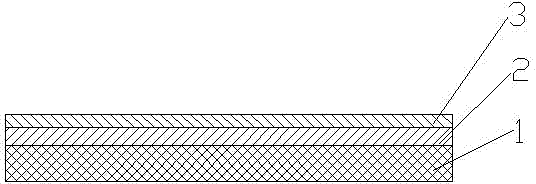

Anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing

InactiveCN102499501AFeel goodHigh strengthWoven fabricsProtective garmentThermal insulationTemperature resistance

The invention discloses an anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing. The composite fabric comprises base fabric, wherein a metal aluminium foil layer is arranged on the outer surface of the base fabric; a coating layer is arranged on the metal aluminium foil layer; the base fabric is formed by interweaving of warps and wefts; the warps and the wefts are covering yarns; the covering yarns comprise core yarns and covering fiber; the core yarns are glass fiber filaments or chemical fiber filaments; the covering fiber comprises one or more of flame-retarding acrylic fiber, flame-retarding viscose, aramid fiber, flame-retarding cotton, PBI (polybenzimidazole) fiber and lenzing fiber. With the adoption of the method, the anti-corrosion high-temperature-resistance thermal-insulation composite fabric has good handfeel, high strength, wear resistance, corrosion resistance, high temperature resistance, good thermal-insulation performance and long service life; the surfaces of the yarns of the base fabric do not contain glass fiber, therefore, the health of people wearing the protective clothing is furthest protected.

Owner:SUZHOU CHUANGYU WEAVING

Acrylonitrile copolymer, preparation and use thereof

InactiveCN101323656AReduce pollutionLow costMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceNitrogen

The invention relates to an acrylonitrile copolymer and a preparation method and an application thereof, wherein, the mole ratio of an acrylonitrile on a molecular chain of the acrylonitrile copolymer to a second monomeric unit is 2:1 to 19:1; the formula of the acrylonitrile copolymer is that: 70.0 mol percent to 90.0 mol percent of the acrylonitrile monomer, 10.0 mol percent to 30.0 mol percent of the second monomeric unit, an evocating agent and a chain-transferring control agent respectively taking up 0.1 mol percent to 16.2mol percent and 0.05 mol percent to 5.0mol percent of the total quantity of monomers. The preparation method adopts the formula of the acrylonitrile copolymer and the following technique: a proper amount of deionized water is put in a reaction vessel and cleaned with nitrogen for 5 minutes to 400 minutes at a temperature of 0 DEG C to 70 DEG C; the evocating agent and the chain-transferring control agent are added in one time; the acrylonitrile monomer and the second monomer are put into a blending container, evenly blended and the dropped slowly into the reaction vessel; and then all reactants continue to be stirred for 20minutes to 40 minutes and the product is obtained after being filtered, cleaned with the deionized water for three times and dried in vacuum. The acrylonitrile copolymer of the invention can be produced into acrylic fiber or film with good performance through a fusion processing method.

Owner:TIANJIN POLYTECHNIC UNIV

Graphene/polyvinyl alcohol modified nonwoven fabric production method

ActiveCN105002736AImprove hydrophilicityImprove antibacterial propertiesFibre typesPolymer sciencePolyvinyl alcohol

The invention relates to a graphene / polyvinyl alcohol modified nonwoven fabric production method, and belongs to the technical field of textile chemistry. The method comprises the following steps: dipping a nonwoven fabric in a graphene oxide / polyvinyl alcohol composite modification solution, drying the nonwoven fabric, and reducing graphene oxide to make the surface of the nonwoven fabric covered with a layer of reduced graphene oxide in order to obtain a nonwoven fabric product with excellent hydrophilic, antibiotic, antistatic and adsorptive functions. The method is suitable for modifying polypropylene fibers, terylene, polyamide, acrylic fibers, polyethylene fibers, polyvinyl chloride fibers, polytetrafluoroethylene, polyphenylene sulfide and other nonwoven fibers, and the nonwoven fabric product obtained in the invention can be used in fields of clothes, home textiles, medical health care, air purification, sewage treatment and military matters. The preparation method has the advantages of simplicity, low cost, wide application range and high application values.

Owner:WUHAN TEXTILE UNIV

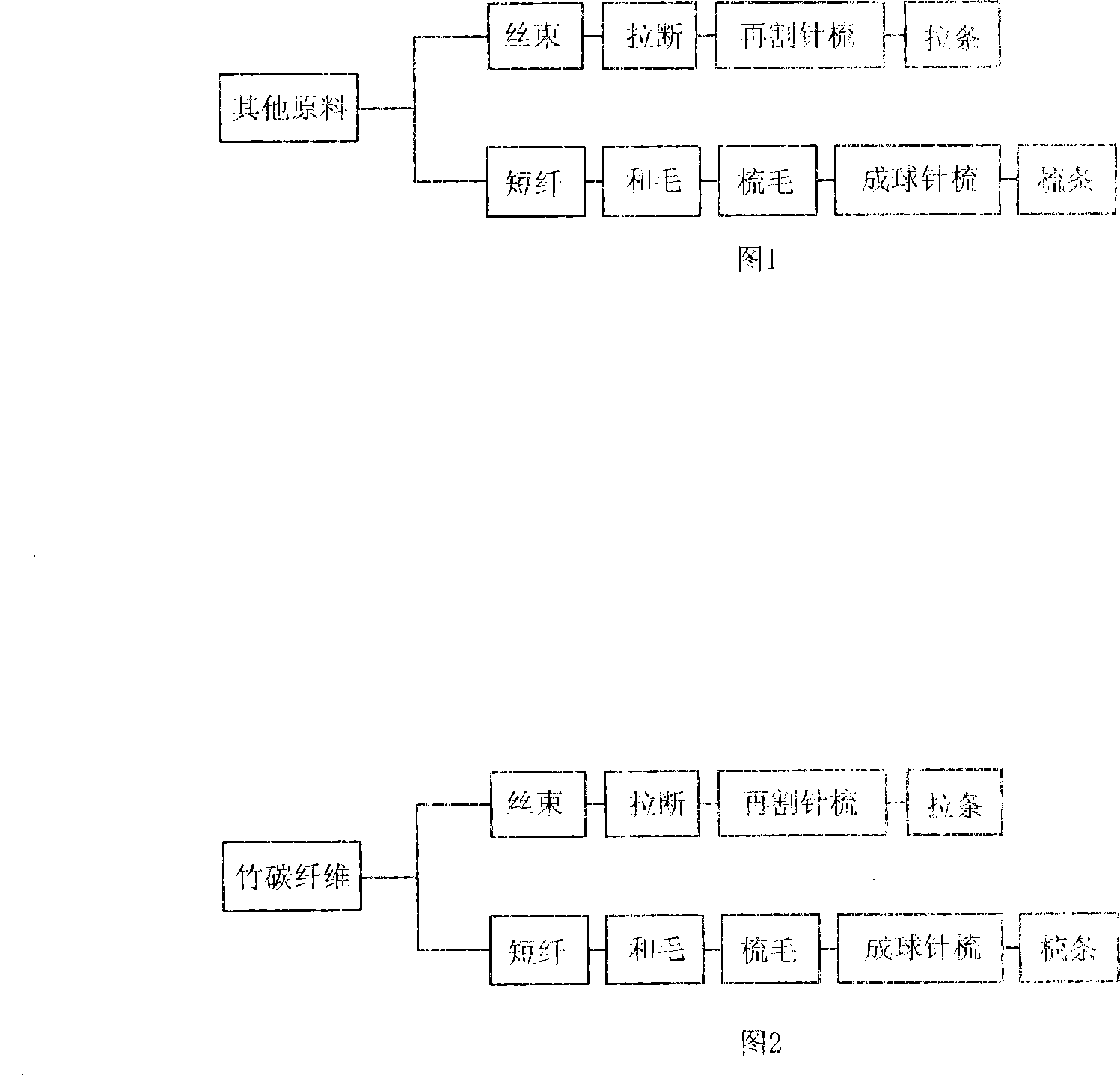

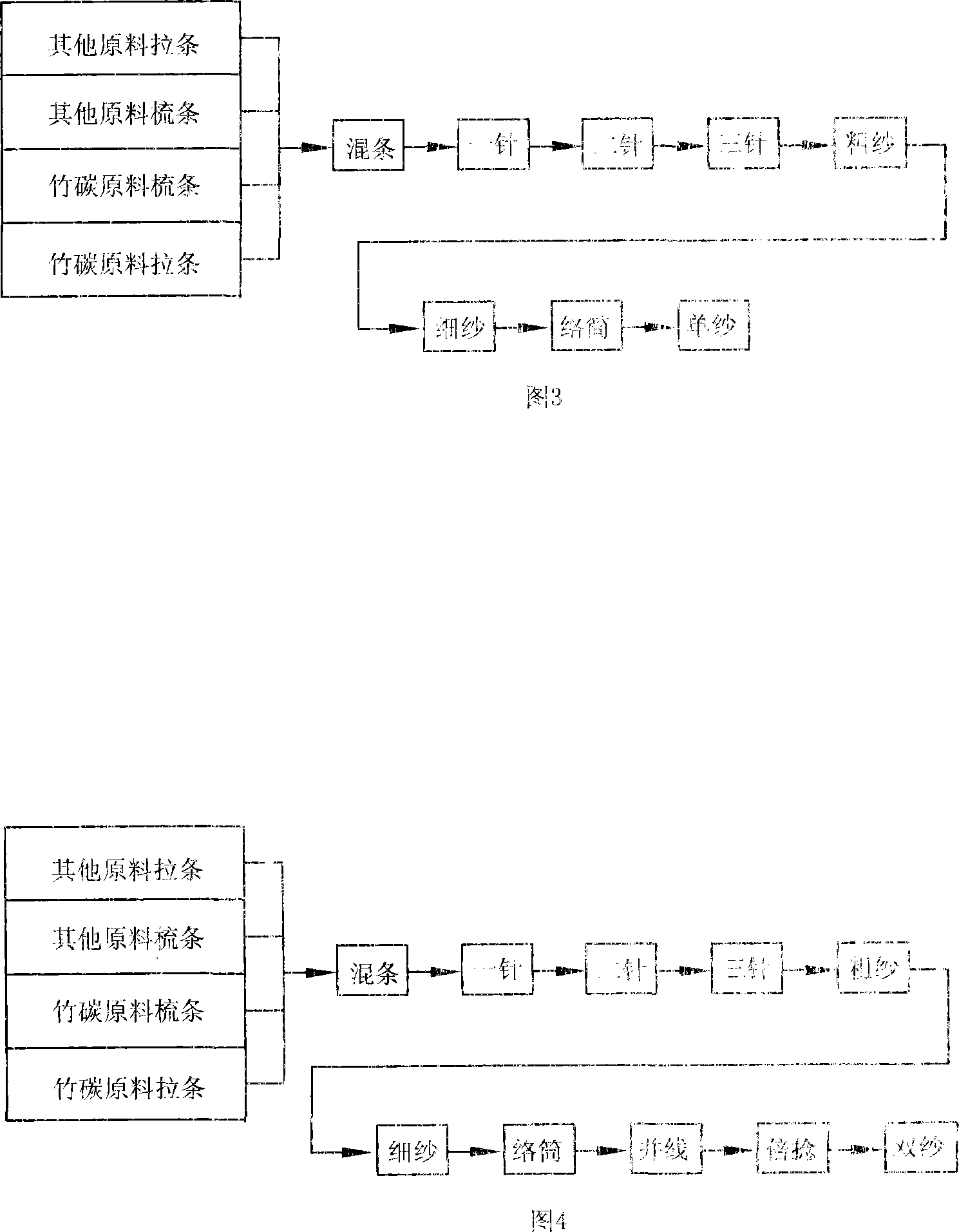

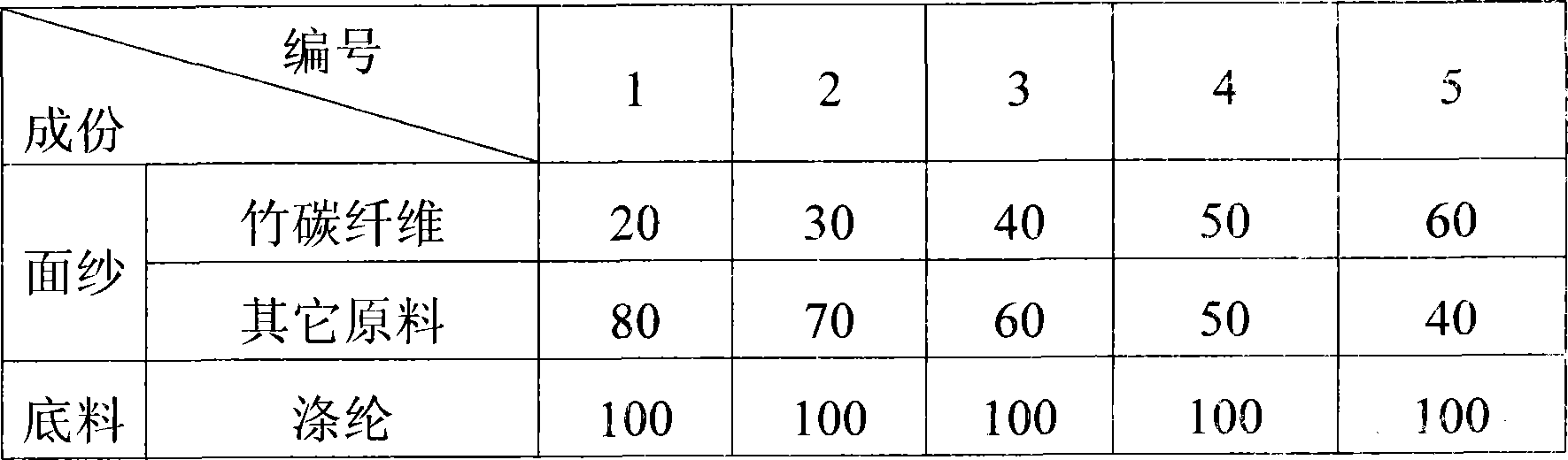

Bamboo carbon fiber blanket material and finished products thereof

The invention relates to woven bamboo charcoal fabric series woollen blankets using bamboo charcoal fabric and other components as raw materials. The material comprises following components by weight percentage: face yarns : bamboo charcoal fabric : 20%; other raw materials: 80%; bottom material: 100; wherein the other raw materials of the face yarn are one or several types selected from cotton, wool, real silk, chinlon, polypropylene, acrylic fibre, dacron and fabric; the bottom material is dacron; the material compatibility of the invented bamboo charcoal fabric woollen blanket is reasonable, and the invented bamboo charcoal fabric woollen blanket is provided with good weaving performance and moderate price, and accords with market demand; strong ultraviolet resistant ability and adsorption decomposition capacity of bamboo charcoal fibrous are utilized sufficiently; bamboo charcoal fabric raschel woollen blankets, acrylic bamboo charcoal fabric woollen blankets and coral fur bamboo charcoal fabric woollen blankets made by above materials are enriched of metallic elements such as potassium, magnesium, calcium, aluminum, zirconium, manganese and other carbides, have strong far-infrared ray emitting and negative ion emitting functions; and have strong moisture-guiding, moisture absorption, drying, deodor and bacteria inhibition functions.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Tacky allergen trap and filter medium, and method for containing allergens

The present invention provides a specific filtration media which includes a substrate having cellulose fibers, bicomponent fibers, adhesion fibers, binder, and pressure sensitive adhesive. Also contemplated are fire retardant filtration media containing bicomponent fibers and polyester fibers or acrylic fibers, and optionally cellulose fibers. The cellulose fibers of the invention are pretreated with flame retardant, providing a beneficial material for filtration purposes.

Owner:BUCKEYE TECH INC

Modacrylic/cotton/aramid fiber blends for arc and flame protection

Owner:EI DU PONT DE NEMOURS & CO

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS6946412B2High tensile strengthImprove energy absorptionCombination devicesPressurized chemical processVisibilityFiber

A fabric for use in safety apparel comprising a first set of yarns comprising modacrylic fibers, and a second set of yarns comprising anti-static fibers. The fabric meets the Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Ultra fine soft wool yern and its production method

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

Manufacture method of conductive fire-retardant acrylic fiber

InactiveCN104805684AMake up for the shortcomings of flammabilityPrevent static electricityFibre typesPolymer scienceFire retardant

The invention discloses a manufacture method of conductive fire-retardant acrylic fiber. The manufacture method comprises the following steps: (1) preparing a spinning solution; (2) performing spinning formation; (3) performing copper salt treatment; (4) adding acrylic fiber containing copper ions obtained in the step (3) into a mixed aqueous solution, and reacting in an airtight high-temperature reaction kettle at 120-140 DEG C for 4-5 hours to prepare the fire-retardant acrylic fiber; (5) taking out and cleaning the acrylic fiber obtained in the step (4), and putting the acrylic fiber at 70-90 DEG C for 2-3 hours in a constant-temperature manner. Through the manner and with the adoption of the manufacture method of conductive fire-retardant acrylic fiber, the acrylic fiber subjected to the antistatic treatment can prevent static electricity during application, ensures normal application of a user, has a fire-retardant function, and overcomes the flammable defect of cloth.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

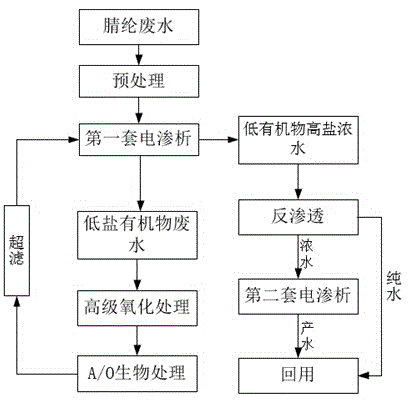

Treatment process for acrylic fiber waste water

ActiveCN104150722AEfficient degradationImprove processing efficiencyGeneral water supply conservationMultistage water/sewage treatmentSeparation technologyEnvironmental engineering

The invention discloses a treatment process for acrylic fiber waste water. The acrylic fiber waste water is pretreated and then is subjected to first-set electrodialysis separation to obtain organic waste water with low salt content and high-salinity concentrated water containing organic matters with low concentration; the organic waste water with the low salt content is subjected to advanced oxidation treatment to improve the biodegradability, and then is subjected to A / O biological treatment to reach the standard; the high-salinity concentrated water containing the organic matters with the low concentration is subjected to reverse osmosis desalination to obtain purified water and reverse osmosis concentrated water; the purified water is used for production; the reverse osmosis concentrated water is subjected to second-set electrodialysis concentration to produce water. According to the process method provided by the invention, on the basis of an advanced oxidation technology and a biological treatment technology, the degradation of refractory organics and macromolecule organic matters which are difficult to naturally settle is realized relatively fully and effectively by comprehensively utilizing a membrane separation technology; the degraded waste water is recycled; the obtained purified water can be used for production, so the resourceful treatment is really realized.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

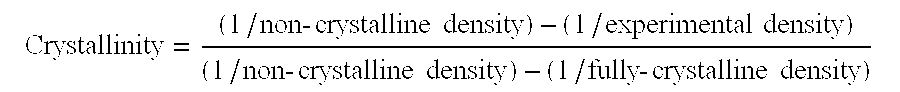

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Fire blocker fiber composition, high loft web structures, and articles made therefrom

The present invention is directed to a fiber composition useful for fire blocking; a high loft web structure made from such fiber composition and a process for making such web structure; and a fire blocked article such as a mattress or furniture incorporating such high loft web structure and a method for fireblocking said articles; the fiber composition comprising (a) 1 to 20 parts by weight p-aramid fiber, (b) 5 to 30 parts by weight regenerated cellulose fiber containing silicic acid, and (c) 10 to 40 parts by weight modacrylic fiber, (d) 10 to 60 parts by weight polyester fiber, (e) up to 20 parts by weight binder material wherein the total of (a), (b), (c), (d) and (e) is on a basis of 100 parts by weight.

Owner:EI DU PONT DE NEMOURS & CO

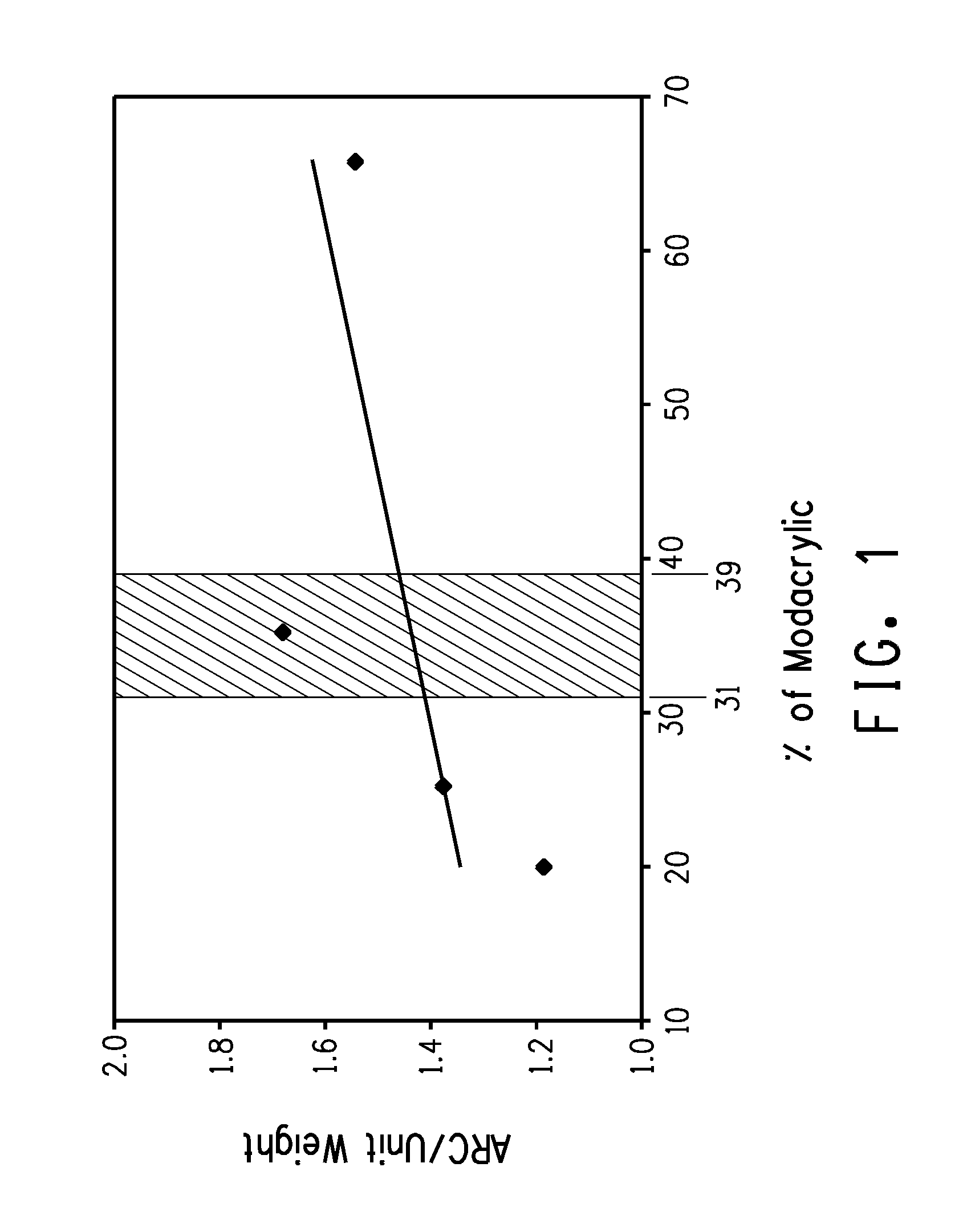

Crystallized meta-aramid blends for improved flash fire and superior arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection, consisting essentially of (a) 50 to 60 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%; (b) 31 to 39 weight percent modacrylic fiber; and (c) 5 to 15 weight percent para-aramid fiber; said percentages on the basis of components (a), (b), and (c). In some embodiments, 1 to 3 weight percent of the meta-aramid fiber is replaced with an antistatic fiber comprising carbon or metal with the proviso that at least 50 weight percent meta-aramid fiber is maintained. Garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Acrylic chelating fibre for removing heavy metal ion in water and preparation

InactiveCN101264438AExtensive and excellent complexing performance of heavy metal ionsEasy to makeOther chemical processesWater/sewage treatment by sorptionChloroacetic acidsChloroacetic acid

The invention discloses an acrylic chelating fiber for removing heavy metal ions in water and the preparation method, belonging to chelating fiber technology. The chelating fiber adopts acrylic fiber as matrix, and the matrix loads poly (carboxymethyl) amino functional group by means of covalent bond. The preparation method of the acrylic chelating fiber comprises the following steps: enabling amination reaction of the acrylic fiber and polyamine or polyamine water solution; enabling carboxy methylation reaction with the alkali-bearing chloroacetic acid water solution after washing and drying, so as to obtain the acrylic chelating fiber with poly (carboxymethyl) amino functional group. The acrylic chelating fiber has the advantages of wide and excellent performance for complexing heavy metal ions, high complex capacity and high complex speed of metal ion, simple preparation and low cost.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com