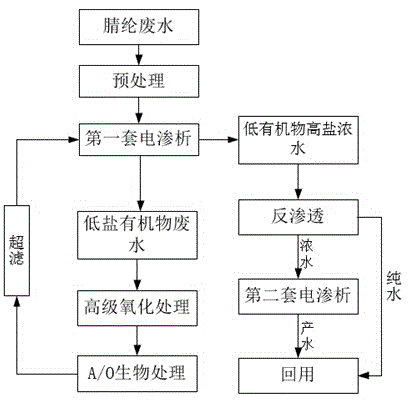

Treatment process for acrylic fiber waste water

A waste water treatment, waste water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc., to achieve the effect of reducing costs and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The acrylic fiber wastewater produced by an acrylic fiber production plant has a COD of 2000mg / L, a BOD / COD of 0.1, a TDS of 20000 mg / L, and a water volume of 100m 3 / h. First, after coagulation sedimentation, multi-media filtration pretreatment, and then ultrafiltration treatment, it enters the first electrodialysis device. pretreated acrylic waste water), the water volume is 100 m 3 / h, the water in the concentrated water chamber is the wastewater after the subsequent A / O biological treatment reaches the standard, and the water volume is 100 m 3 / h, replace it with production water at the first start-up, and use the subsequent A / O biological treatment to meet the standard wastewater after the entire process linkage is normal. The first set of electrodialysis fresh water effluent is organic wastewater with low salt content, with a water volume of 100 m 3 / h, the effluent of concentrated brine is high-salt wastewater with low concentration of organic matter, an...

Embodiment 2

[0030] The acrylic fiber wastewater produced by an acrylic fiber production plant has a COD of 3000mg / L, a BOD / COD of 0.1, a TDS of 10000 mg / L, and a water volume of 200m 3 / h. First, after coagulation sedimentation, multi-media filtration pretreatment, and then ultrafiltration treatment, it enters the first electrodialysis device. Acrylic waste water after filtration pretreatment), the water volume is 200 m 3 / h, the water in the concentrated water chamber is the wastewater after the subsequent A / O biological treatment reaches the standard, and the water volume is 200 m 3 / h, replace it with production water at the first start-up, and use the subsequent A / O biological treatment to meet the standard wastewater after the entire process linkage is normal. The first set of electrodialysis fresh water effluent is organic wastewater with low salt content, with a water volume of 200 m 3 / h, the effluent of concentrated brine is high-salt wastewater with low concentration of organi...

Embodiment 3

[0032] The acrylic fiber wastewater produced by an acrylic fiber production plant has a COD of 4000mg / L, a BOD / COD of 0.1, a TDS of 10000 mg / L, and a water volume of 100m 3 / h. First, after coagulation sedimentation, multi-media filtration pretreatment, and then ultrafiltration treatment, it enters the first electrodialysis device. Acrylic waste water after filtration pretreatment), the water volume is 100 m 3 / h, the water in the concentrated water chamber is the wastewater after the subsequent A / O biological treatment reaches the standard, and the water volume is 100 m 3 / h, replace it with production water at the first start-up, and use the subsequent A / O biological treatment to meet the standard wastewater after the entire process linkage is normal. The first set of electrodialysis fresh water effluent is organic wastewater with low salt content, with a water volume of 100 m 3 / h, the effluent of concentrated brine is high-salt wastewater with low concentration of organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com