Process for manufacturing antimicrobial conductive acrylic fibre fibre

A technology of acrylic fiber and manufacturing method, which is applied in the field of manufacturing antibacterial conductive acrylic fiber, and can solve problems such as fiber shedding and unsatisfactory use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

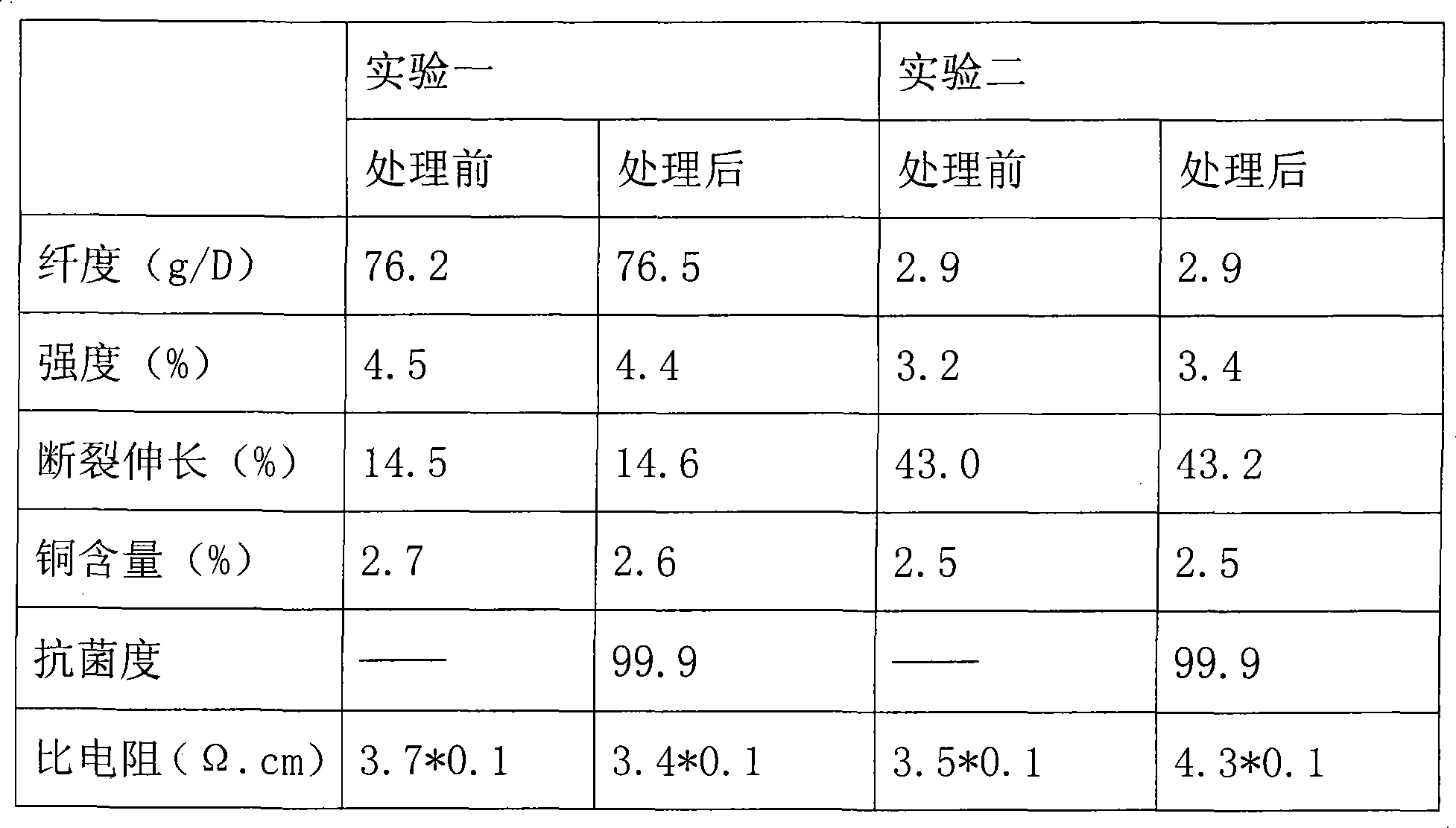

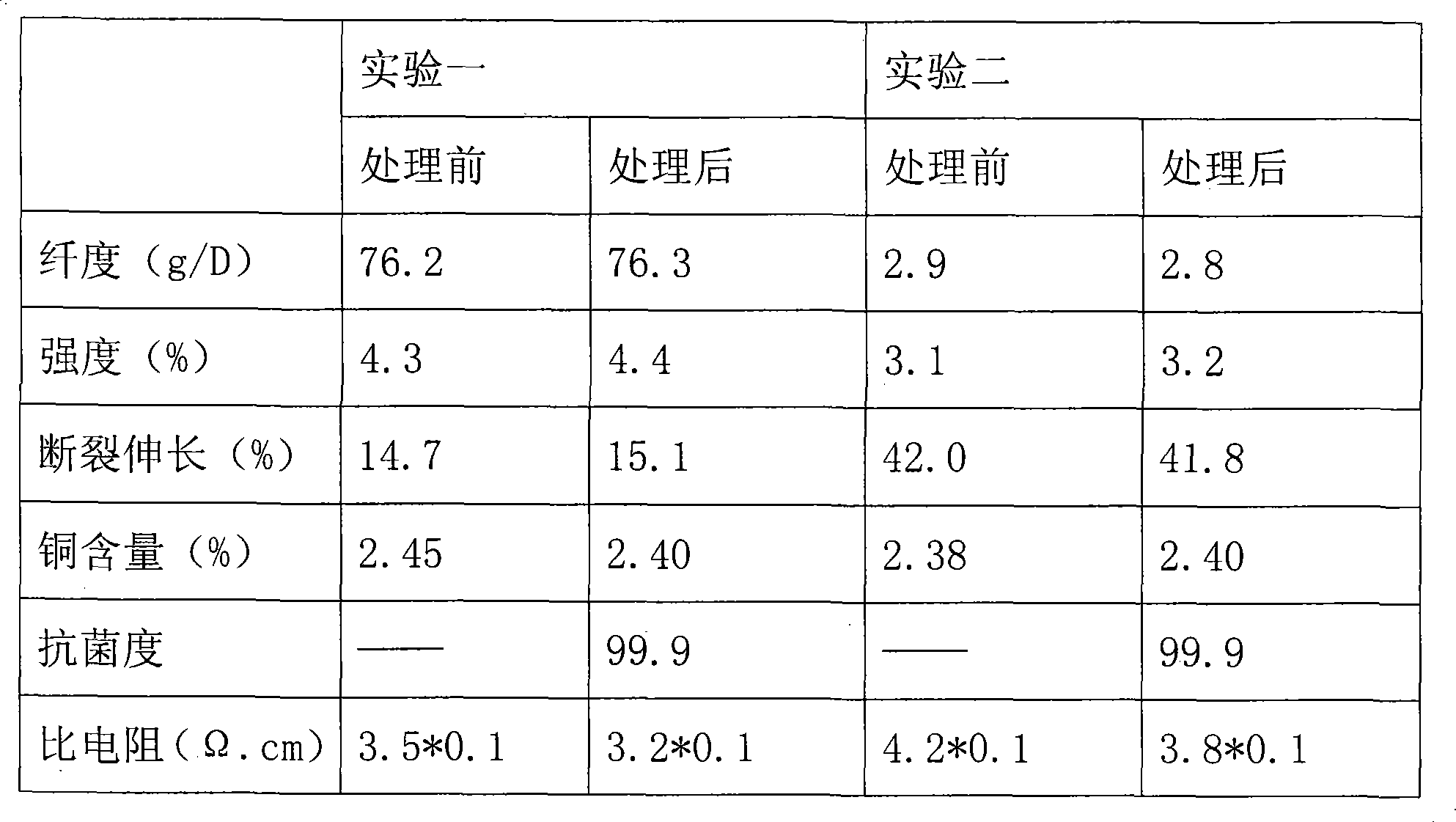

Examples

Embodiment

[0025] Adsorption of copper sulfide on acrylic-based fibers containing more than 50% acrylonitrile.

[0026] Get the acrylic fiber 100g that contains more than 50% acrylonitrile, put into by copper sulfate (Cu 2 SO 4 ), sodium sulfite (Na 2 SO 3 ), sodium chlorate (NaClO 3 ) and citric acid (C 6 h 5 o 7 ) in 20g--30g of the mixed solution, wherein the concentration of the reducing agent in the mixed solution is 20%-90%, the concentration of copper sulfate is 100%, the pH value is 2-5, and the reaction temperature is adjusted at 50°C - Between 80°C, the reaction time is 2 hours - 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com