Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2240 results about "Polyamide fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide Fiber. a synthetic fiber produced from melts or solutions of polyamides. Polyamide fibers are usually produced from linear aliphatic polyamides, most often polycaproamide and polyhexamethylene adipamide, with molecular weights varying from 15,000 to 30,000.

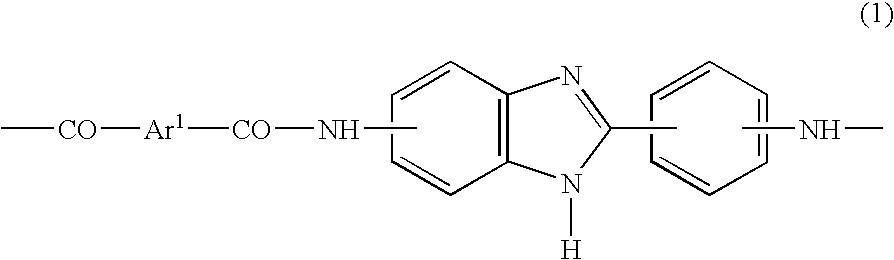

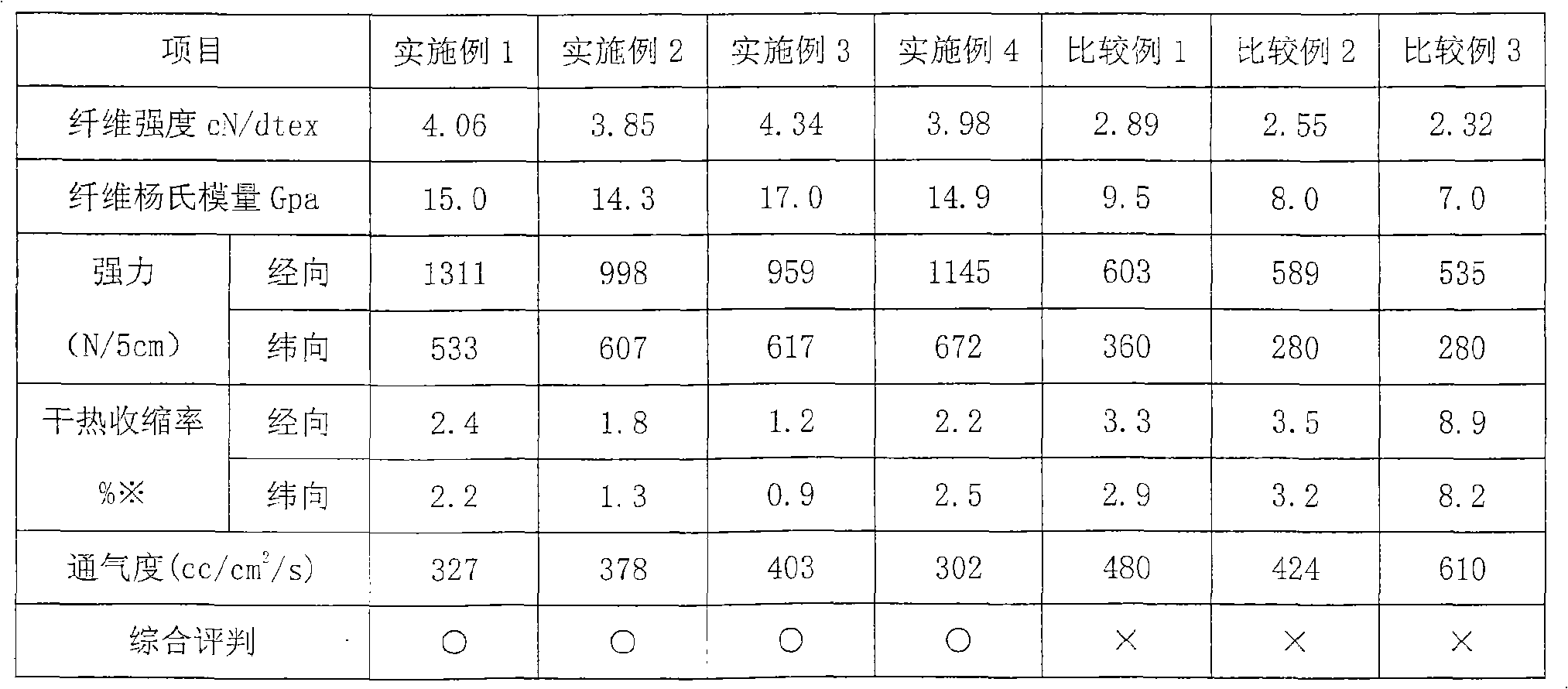

Heterocycle-containing aromatic polyamide fiber, method for producing the same, cloth constituted by the fiber, and fiber-reinforced composite material reinforced with the fiber

InactiveUS20100029159A1Improve balanceHigh strength holding ratioArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentAramidesFiber-reinforced composite

The heterocycle-containing aromatic polyamide fibers of the invention are excellent in balance among mechanical characteristics, particularly balance among tensile strength, initial modulus and strength in the direction perpendicular to the fiber axis, exhibit a high strength holding ratio under heat and humidity, and are excellent in flame retardancy, bulletproofness and cutting resistance, as compared to conventional aromatic polyamide fibers, and therefore can be favorably used in fields with severe mechanical characteristics and have stability to environmental variation. Accordingly, the heterocycle-containing aromatic polyamide fibers of the invention can be favorably used, for example, in fields including protective equipment, such as a helmet, a bulletproof vest and the like, a chassis for an automobile, a ship and the like, an electric insulating material, such as a printed circuit board and the like, and other various fields.

Owner:TEIJIN TECHNO PRODUCTS LTD

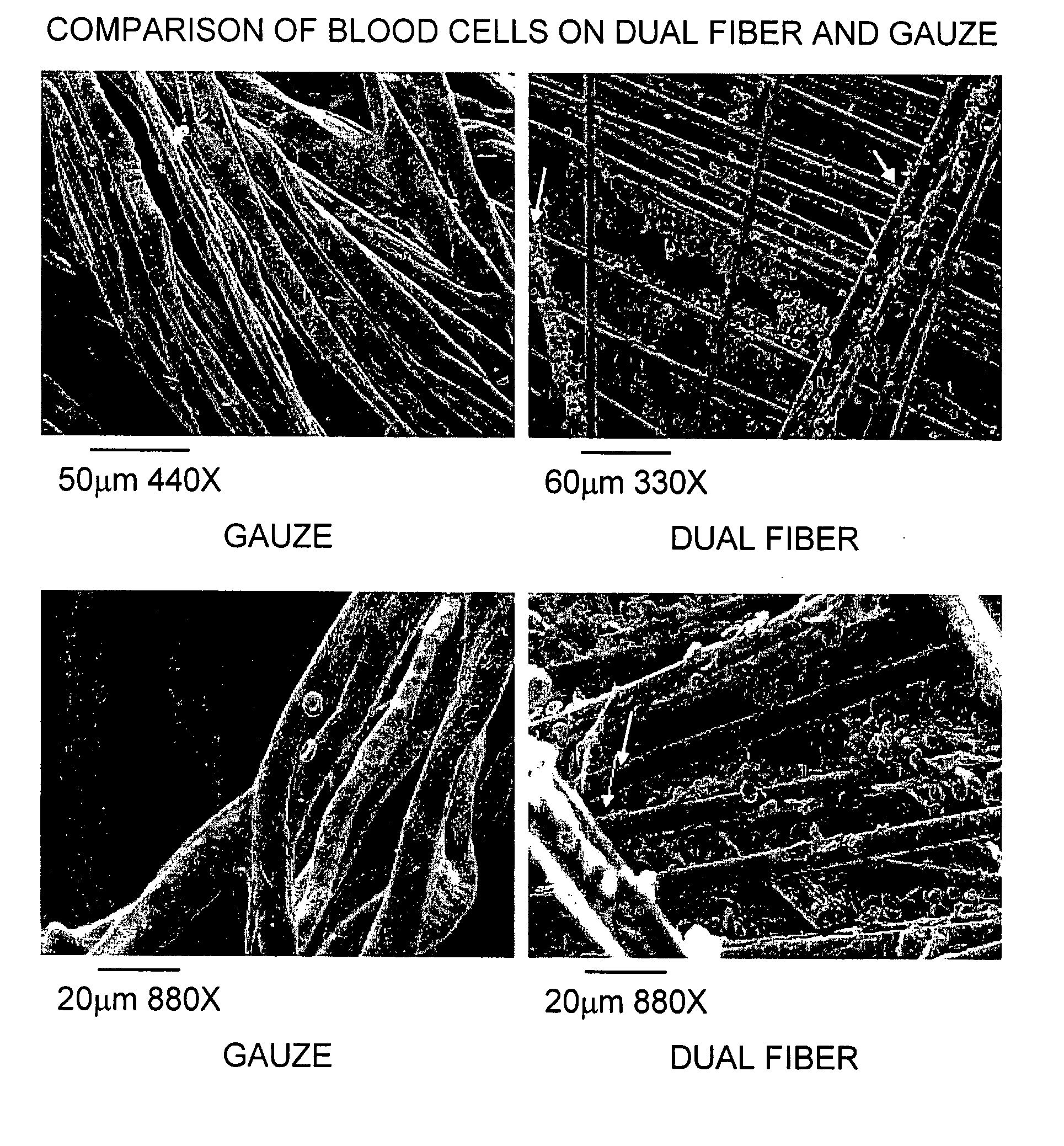

Hemostatic textile

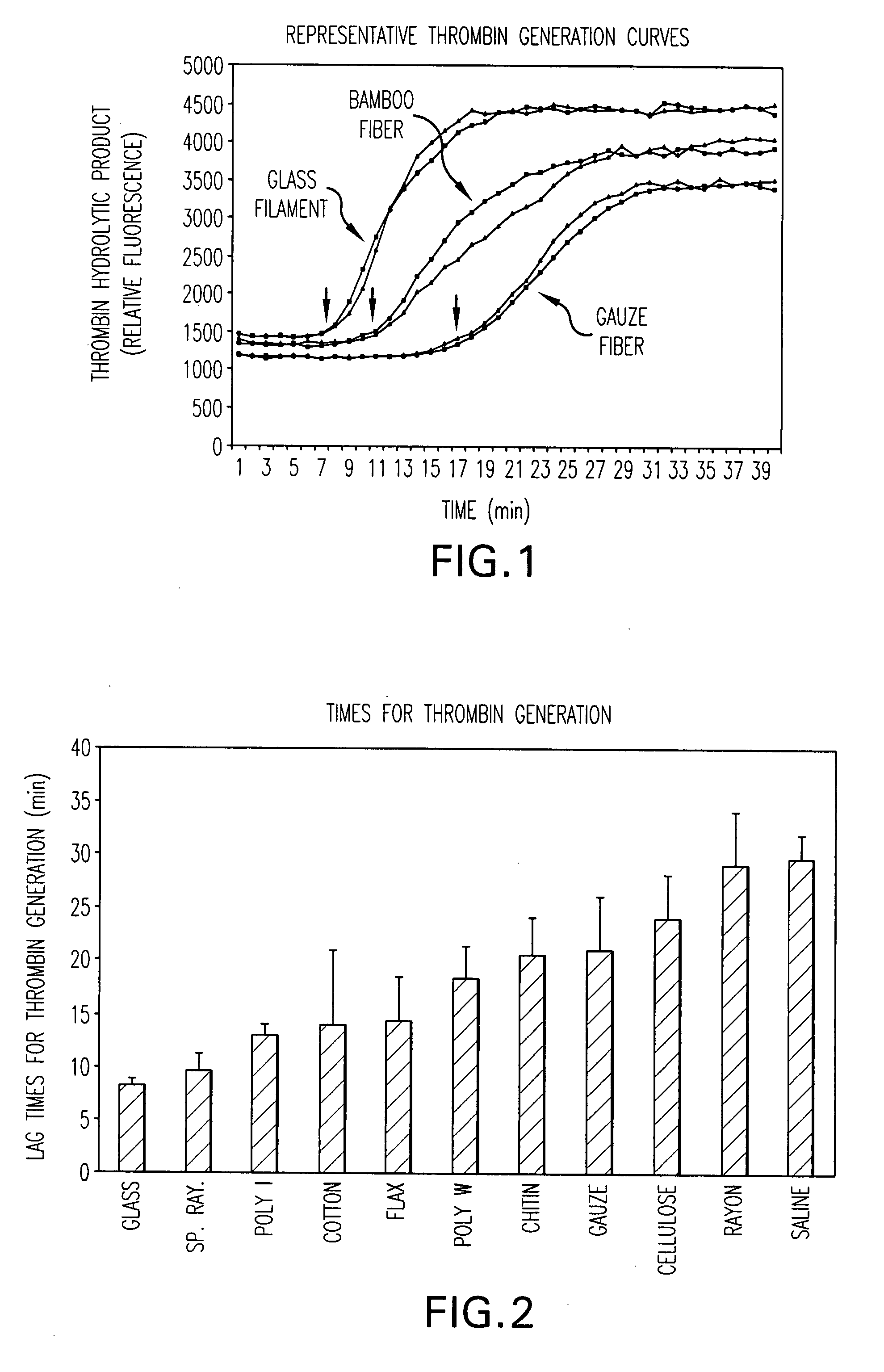

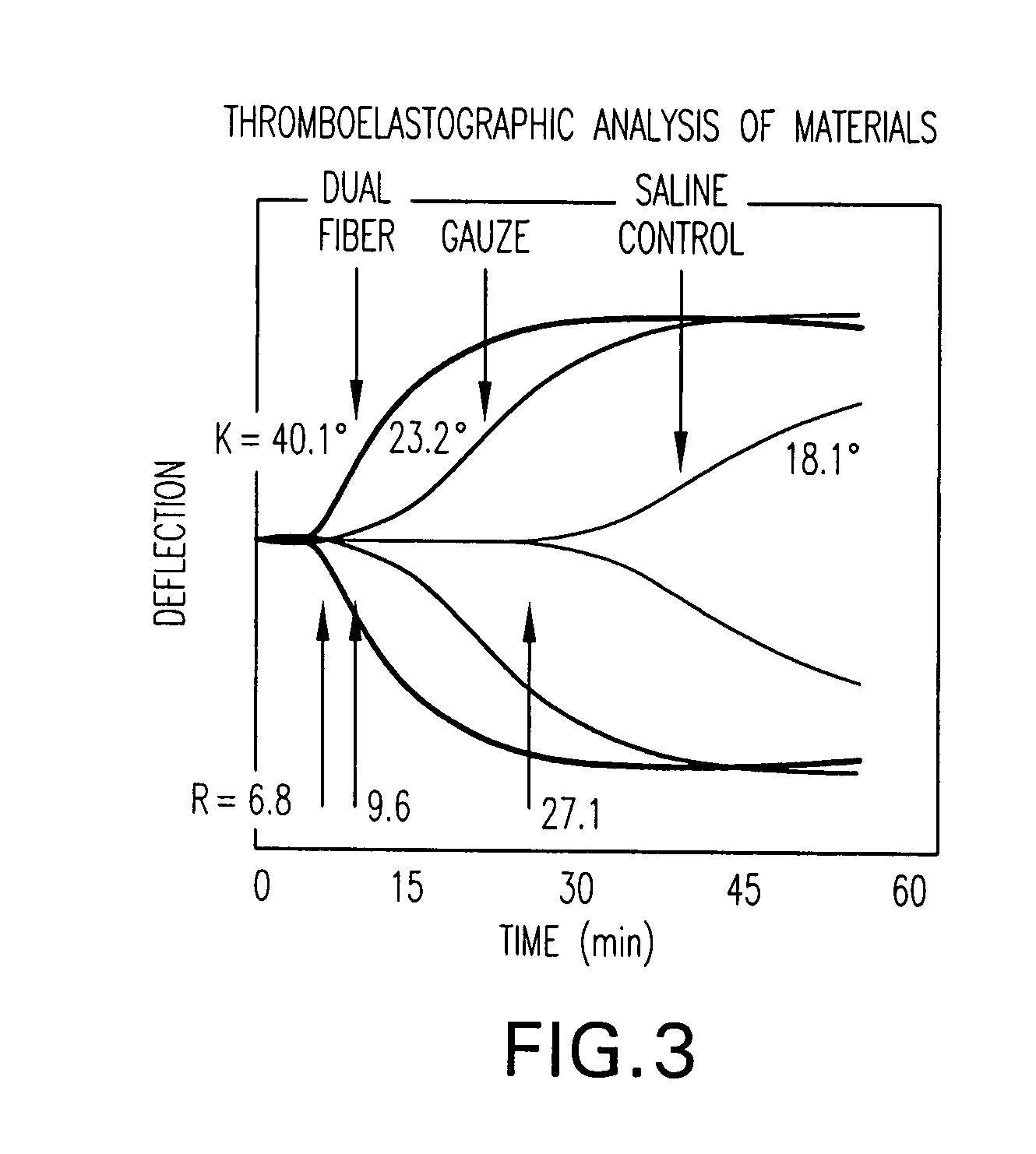

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Flame-resistant fiber blend, yarn, and fabric, and method for making same

InactiveUS20060292953A1Improve flame retardant performanceReduce weightWarp knittingWoven fabricsYarnAramid

A fiber blend, a yarn spun from the fiber blend, and a fabric made from the yarn, wherein the fiber blend comprises: (a) about 40 wt.% to about 65 wt.% modacrylic fibers containing antimony, or FR acrylic fibers; (b) about 10 wt.% to about 50 wt.% cotton fibers or FR cotton fibers; (c) up to about 25 wt.% nylon fibers; and (d) greater than about 3 wt.% and less than 10 wt.% para-aramid fibers. The fabric is over 90 percent dyeable and is capable of achieving ASTM F1506 certification with an Arc Thermal Performance Value greater than 8.0 cal / cm2. The fabric is woven or knitted, and has a weight of about 4.0 oz. / yd.2 to about 10.5 oz. / yd.2. The fabric is suitable for garments worn during activities in which there is potential for exposure to flame and / or electrical arc.

Owner:SPRINGFIELD

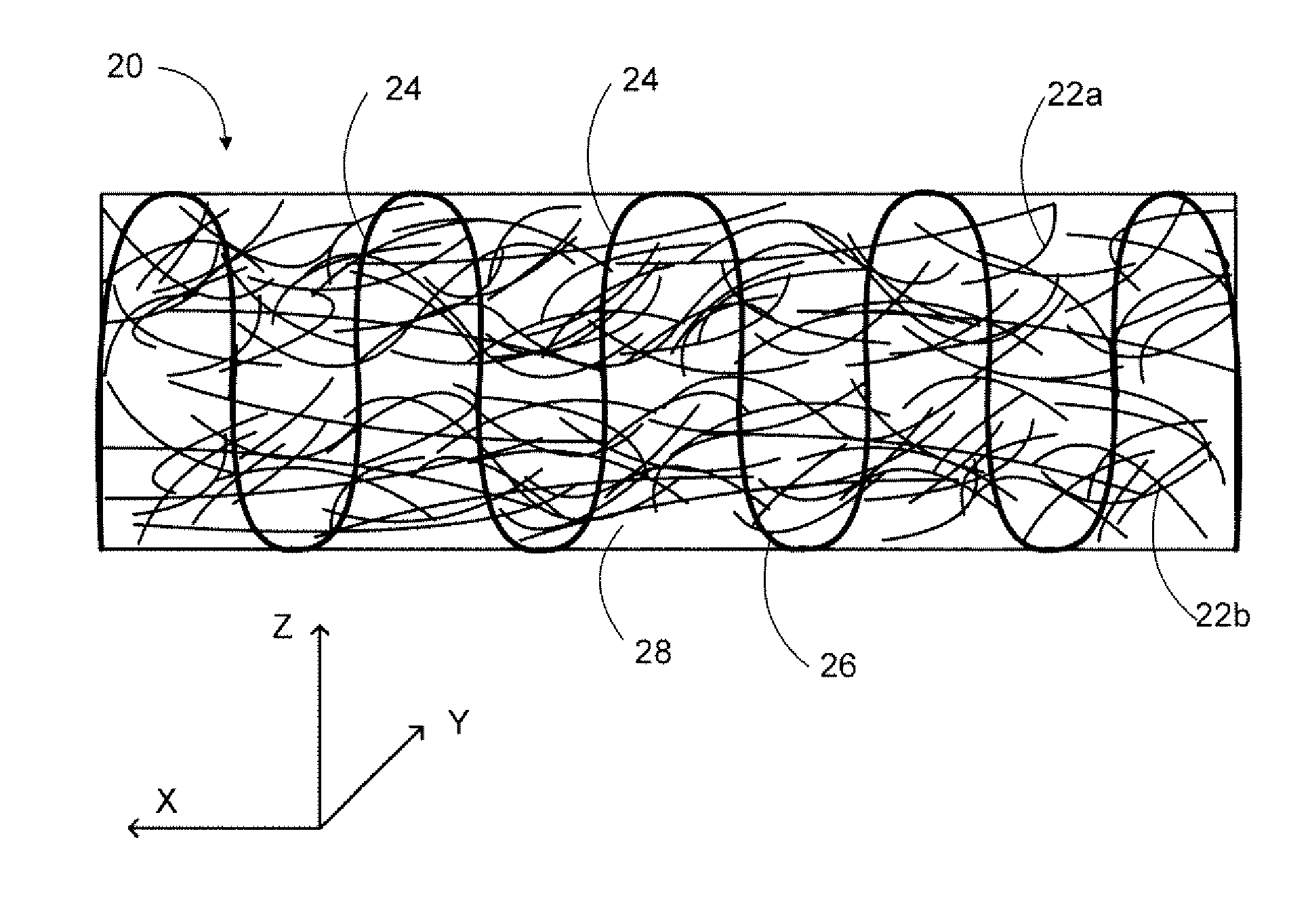

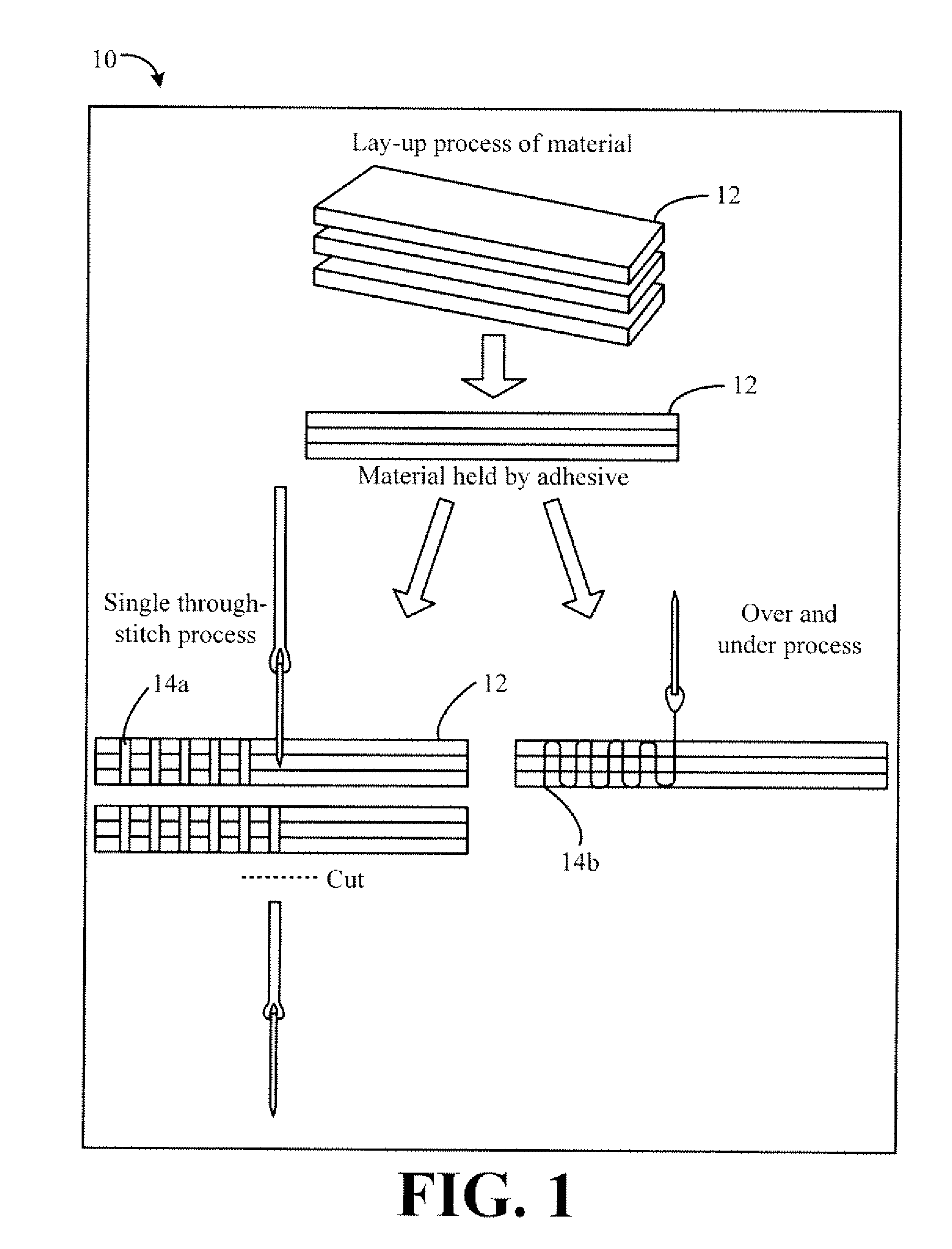

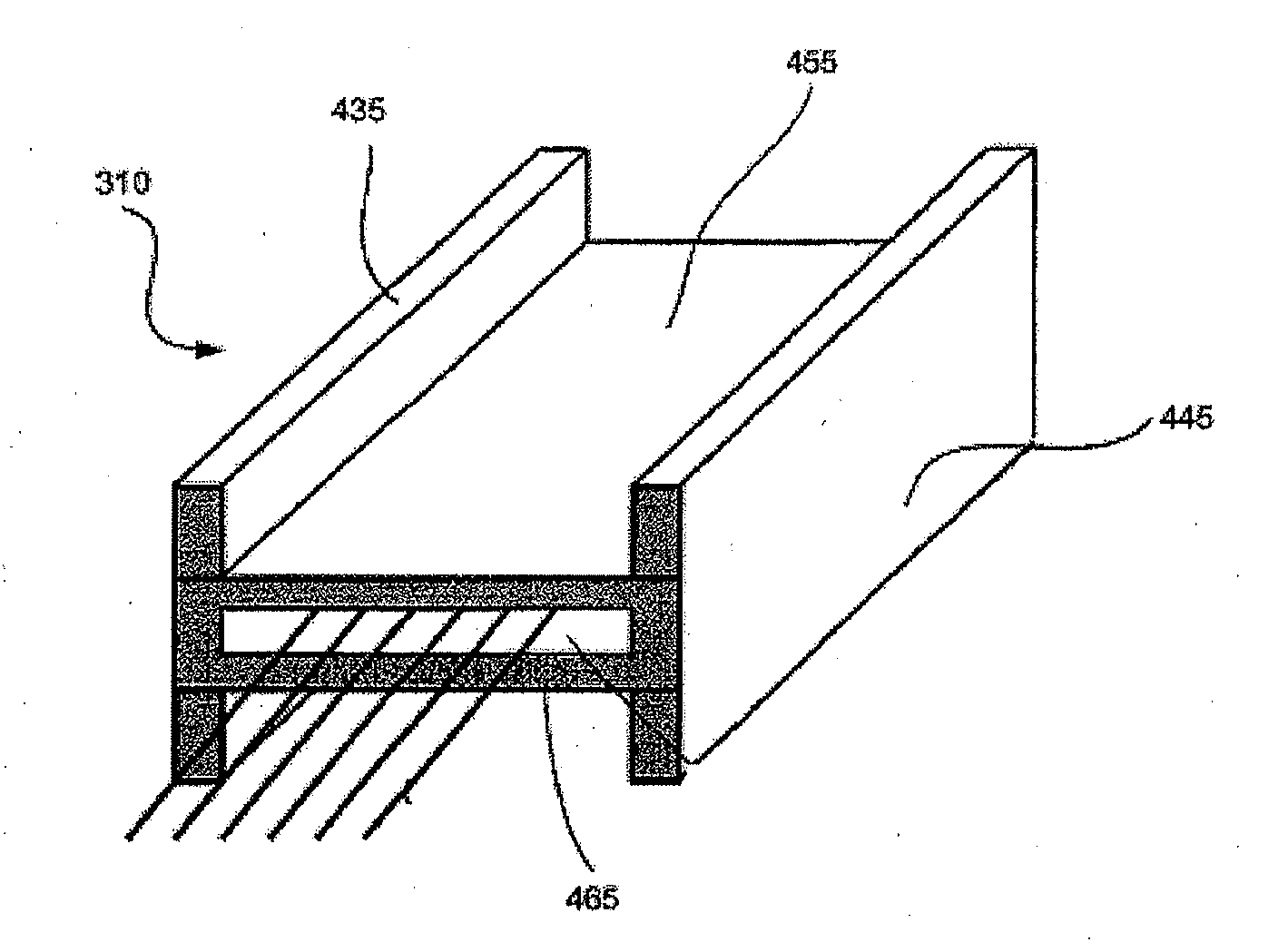

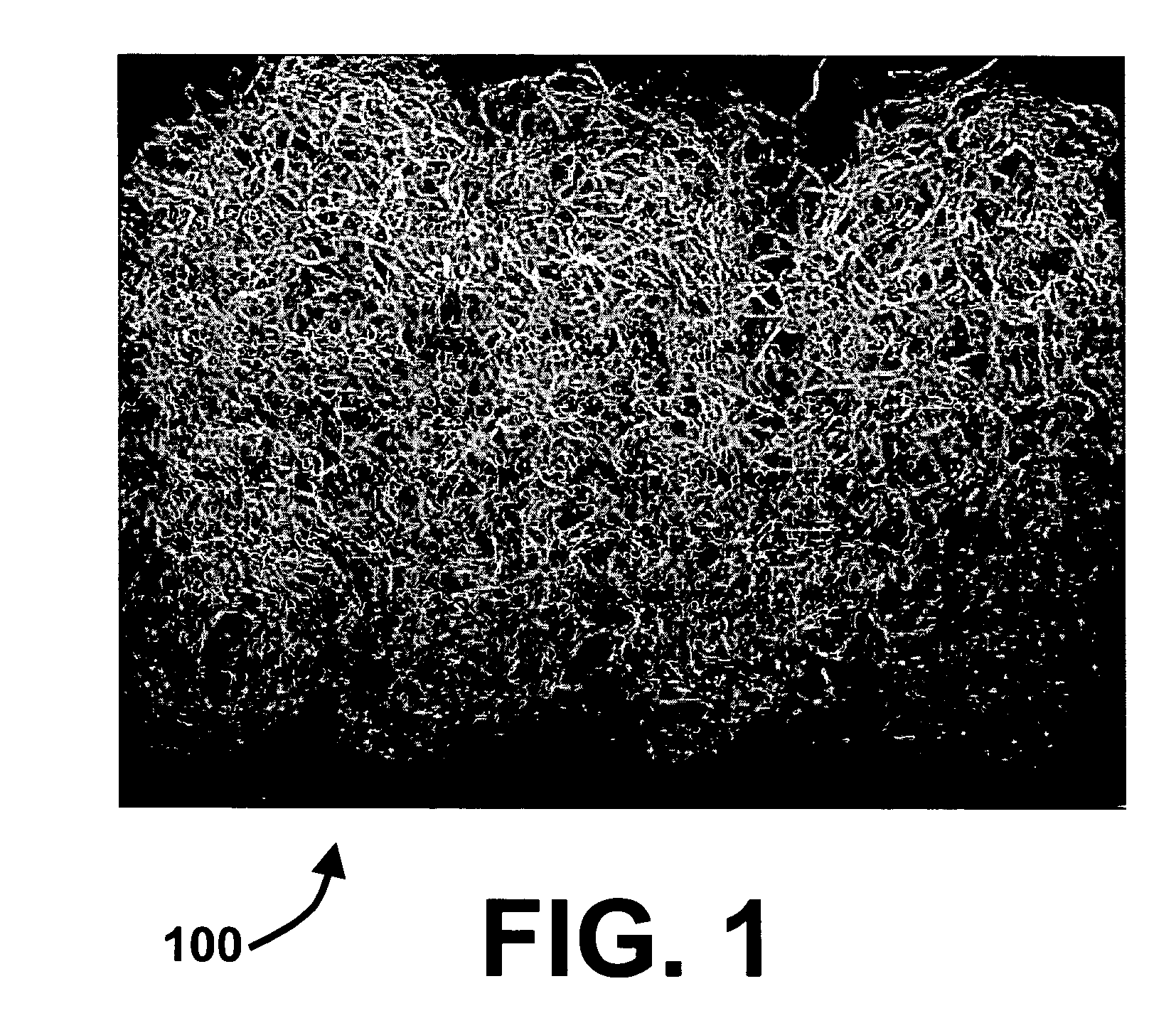

Composite material and method for increasing z-axis thermal conductivity of composite sheet material

InactiveUS20100021682A1Increases Z-axis thermal conductivityHand sewingLayered productsGlass fiberCarbon fibers

Methods are provided for making a composite material that includes (a) providing at least one sheet which includes woven or non-woven glass fibers, carbon fibers, aramid fibers, or nanoscale fibers; and (b) stitching a plurality of stitches of a thermally conductive fiber through the at least one sheet in a Z-axis direction to form paths of higher conductivity through the sheet of material to increase its thermal conductivity in the Z-axis.

Owner:FLORIDA STATE UNIV RES FOUND INC

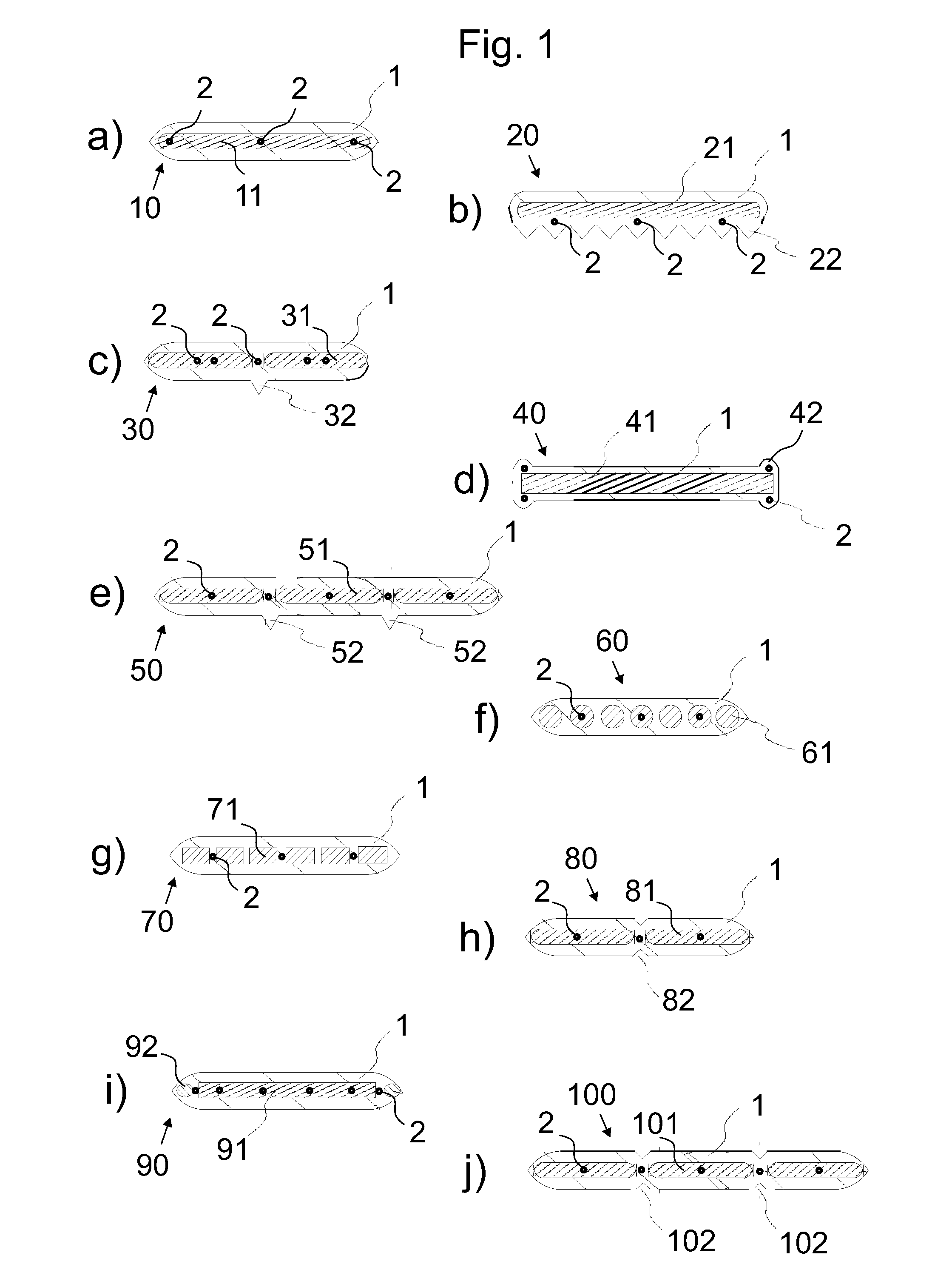

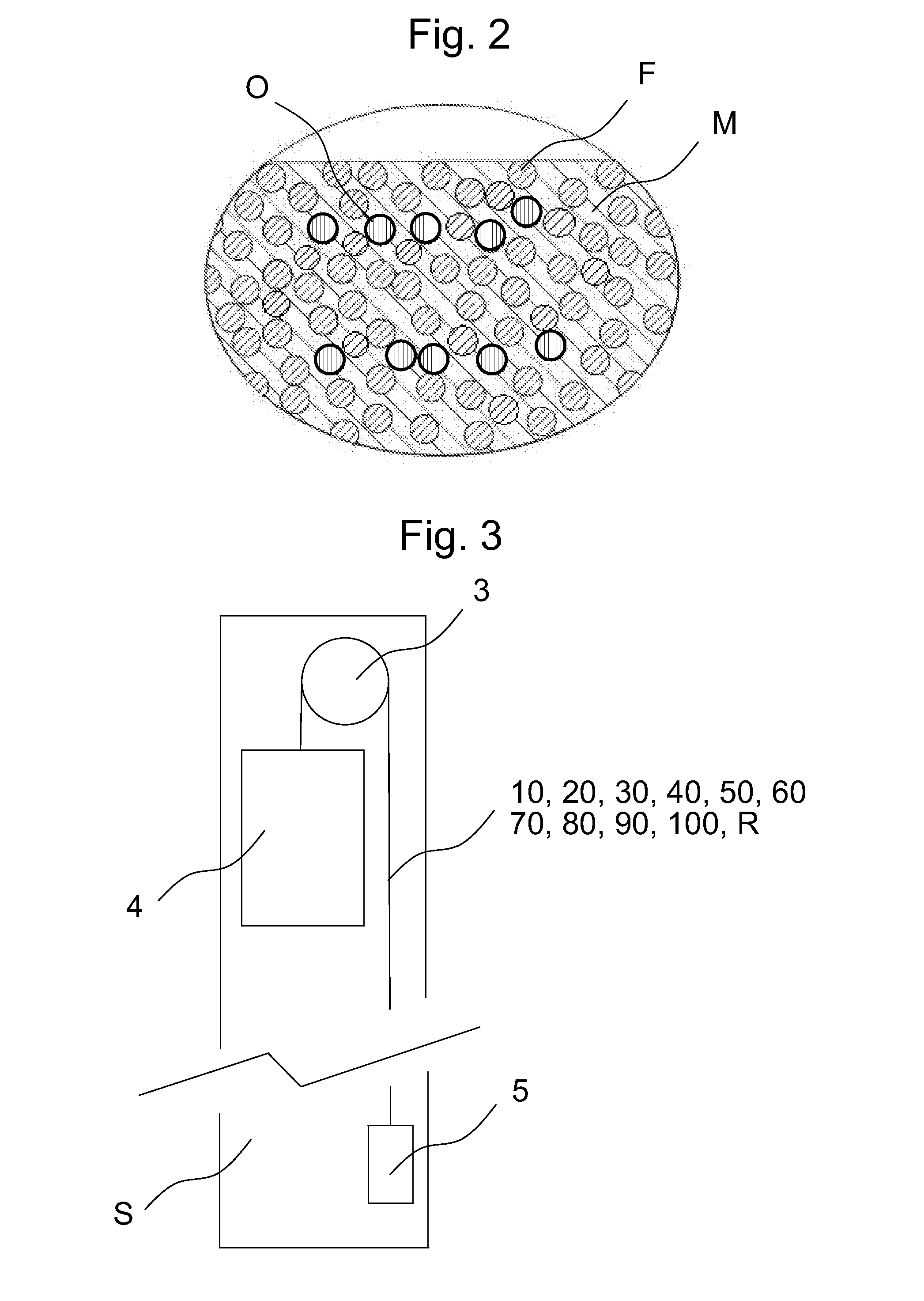

Rope of a lifting device, a rope arrangement, an elevator and a condition monitoring method for the rope of a lifting device

ActiveUS20140305744A1Solve the lack of mechanical propertiesConvenient condition monitoringElevatorsBuilding liftsGlass fiberCarbon fibers

In a rope of a lifting device, particularly of a passenger transport elevator and / or freight transport elevator, the width of which rope is greater than the thickness in the transverse direction of the rope, which rope includes a load-bearing part in the longitudinal direction of the rope, which load-bearing part includes carbon-fiber reinforced, aramid-fiber reinforced and / or glass-fiber reinforced composite material in a polymer matrix, and which rope includes one or more optical fibers and / or fiber bundles in connection with the load-bearing part and the optical fiber and / or fiber bundle is laminated inside the load-bearing part and / or the optical fiber and / or fiber bundle is glued onto the surface of the load-bearing part and / or and that the optical fiber and / or fiber bundle is embedded or glued into the polymer envelope surrounding the load-bearing part, as well as to a condition monitoring method for the rope of a lifting device.

Owner:KONE CORP

Polyamide moulding composition and use thereof

ActiveUS20140066560A1Good mechanical propertyHigh rigidityAnti-corrosive paintsChemistryHigh intensity

Owner:EMS PATENT AG

High-tenacity crack-control impervious fiber concrete

ActiveCN101665342AEvenly dispersedFully exerted tensile strengthSolid waste managementSlagPolyvinyl alcohol

The invention relates to a fiber concrete material belonging to the field of building materials. The fiber concrete material mainly contains cement, active mineral blending materials, aggregates, fibers and water and is characterized in that the active mineral blending materials adopt coal ash, siliceous dust, pelletization blast furnace slag and metakaolin; the fibers adopt polyvinyl alcohol fibers, polyethylene fibers and aromatic polyamide fibers; the maximum particle size of the aggregates is smaller than or equal to 0.5mm, and the ratio of the weight of the aggregates to the total weightof the cement and the active mineral blending materials is 1-70 percent; and the blending volume of the fibers accounts for 1.5-2.5 percent of the total volume of fiber concrete. The fiber concrete material has the advantages of high tenacity, higher deformation capability, tensile strength and bending strength, limit tension strain of 1.8-7.5 percent, tensile strength of 4-10MPa and bending strength of 10-20MPa, can control the width of a crack lower than 0.1mm, effectively enhance the integrity and the shock resistance of a structure and ensure the permeability resistance and the durabilityof the structure.

Owner:徐世烺

Modacrylic/aramid fiber blends for arc and flame protection and reduced shrinkage

ActiveUS7348059B2Resistance to break open and abrasionReduce Shrinkage ProblemsSynthetic resin layered productsNatural mineral layered productsYarnPolymer science

Owner:DUPONT SAFETY & CONSTR INC

Method for preparing aramid composite diaphragm

ActiveCN103242556AImprove breathabilityImprove mechanical propertiesCell component detailsCoatingsLithium-ion batteryAramid

The invention discloses a method for preparing an aramid composite diaphragm. The method comprises the following steps of: (1) uniformly mixing aramid fibers, a solvent, a cosolvent and a pore forming agent so as to prepare membrane forming liquid; (2) coating the membrane forming liquid on a diaphragm of a lithium-ion battery so as to obtain a wet diaphragm; and (3) drying the wet diaphragm so as to obtain the aramid composite diaphragm; or firstly baking the wet diaphragm, soaking the wet diaphragm in water and then drying so as to obtain the aramid composite diaphragm. According to the method, the diaphragm is prepared through mixing and coating the aramid fibers and the pore forming agent; the prepared diaphragm has the characteristics of good air permeability, good mechanical properties and strong high-temperature resistance; and the method is simple and convenient, and the preparation cost is saved.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

Cellulosic/polyamide composite

InactiveUS20070163217A1Prevent peelingCombination devicesSynthetic resin layered productsElectrospinningCellulose fiber

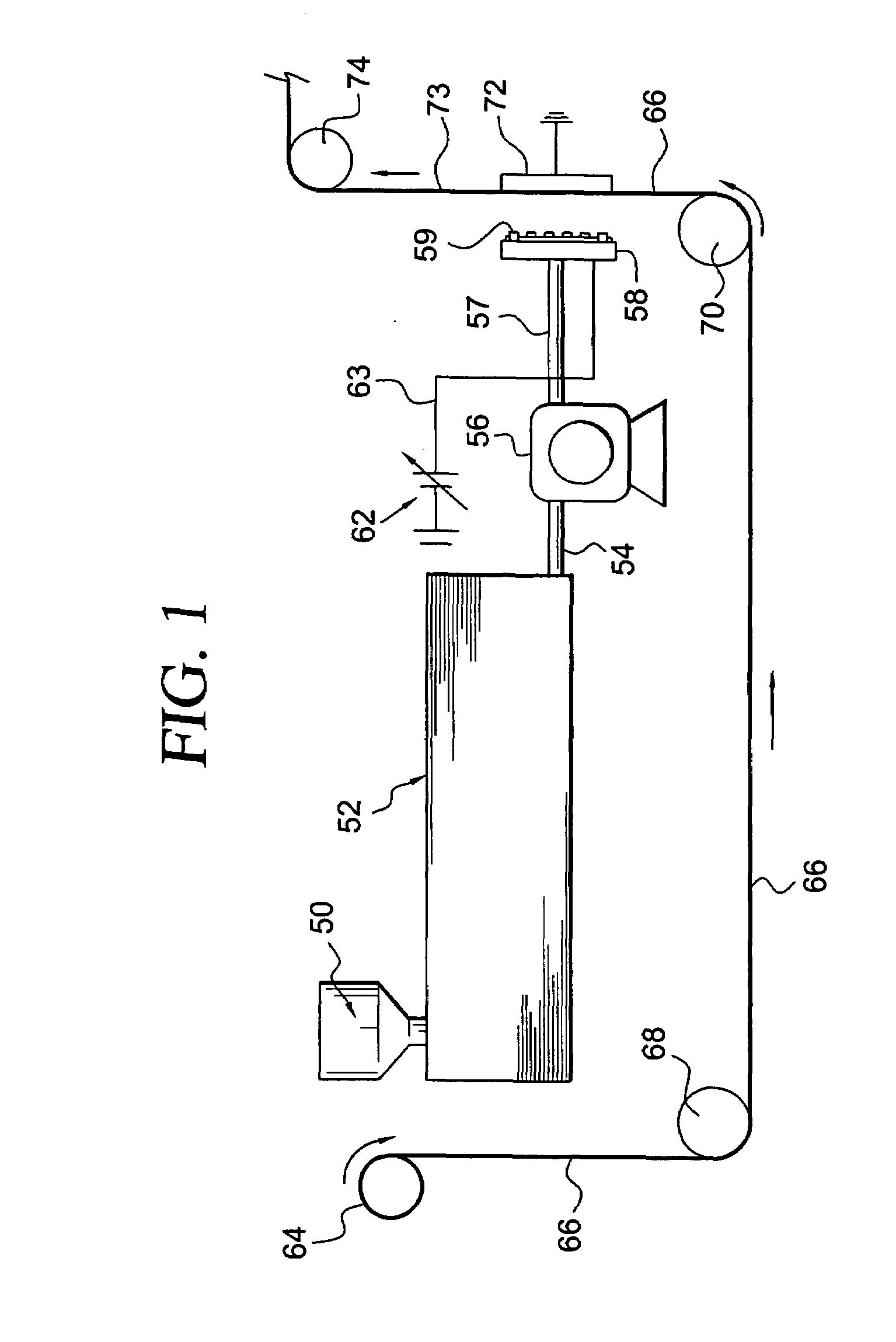

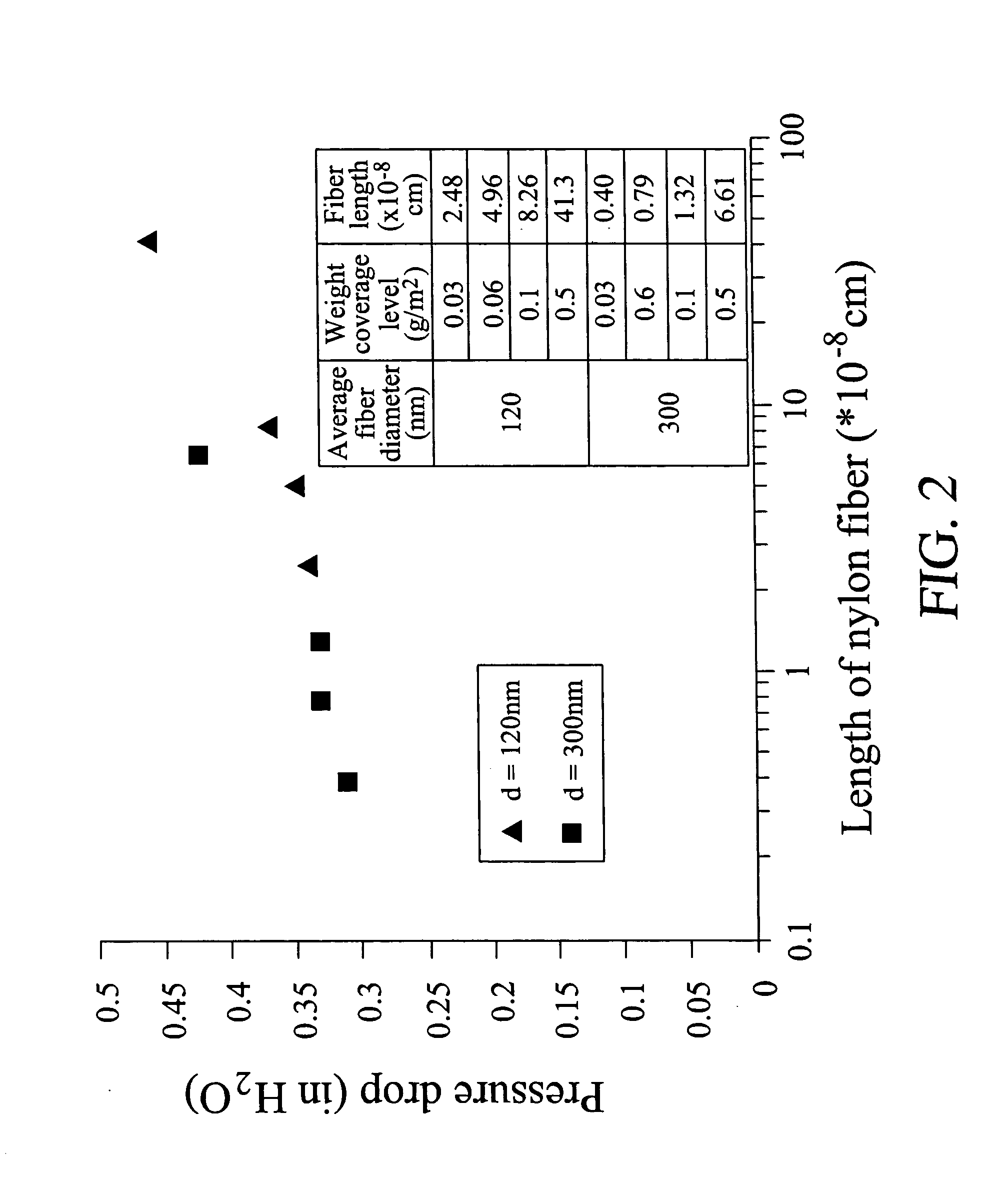

Composite of polyamide layer solvent bonded to cellulosic substrate is formed by solution electrospinning deposit of polyamide on cellulosic substrate with the solution subjected to electrospinning containing as solvent for polyamide one that swells cellulosic fibers on contact therewith and / or by depositing very long polyamide fibers of low average diameter.

Owner:CORNELL RES FOUNDATION INC +1

Lightweight soft body-armor product

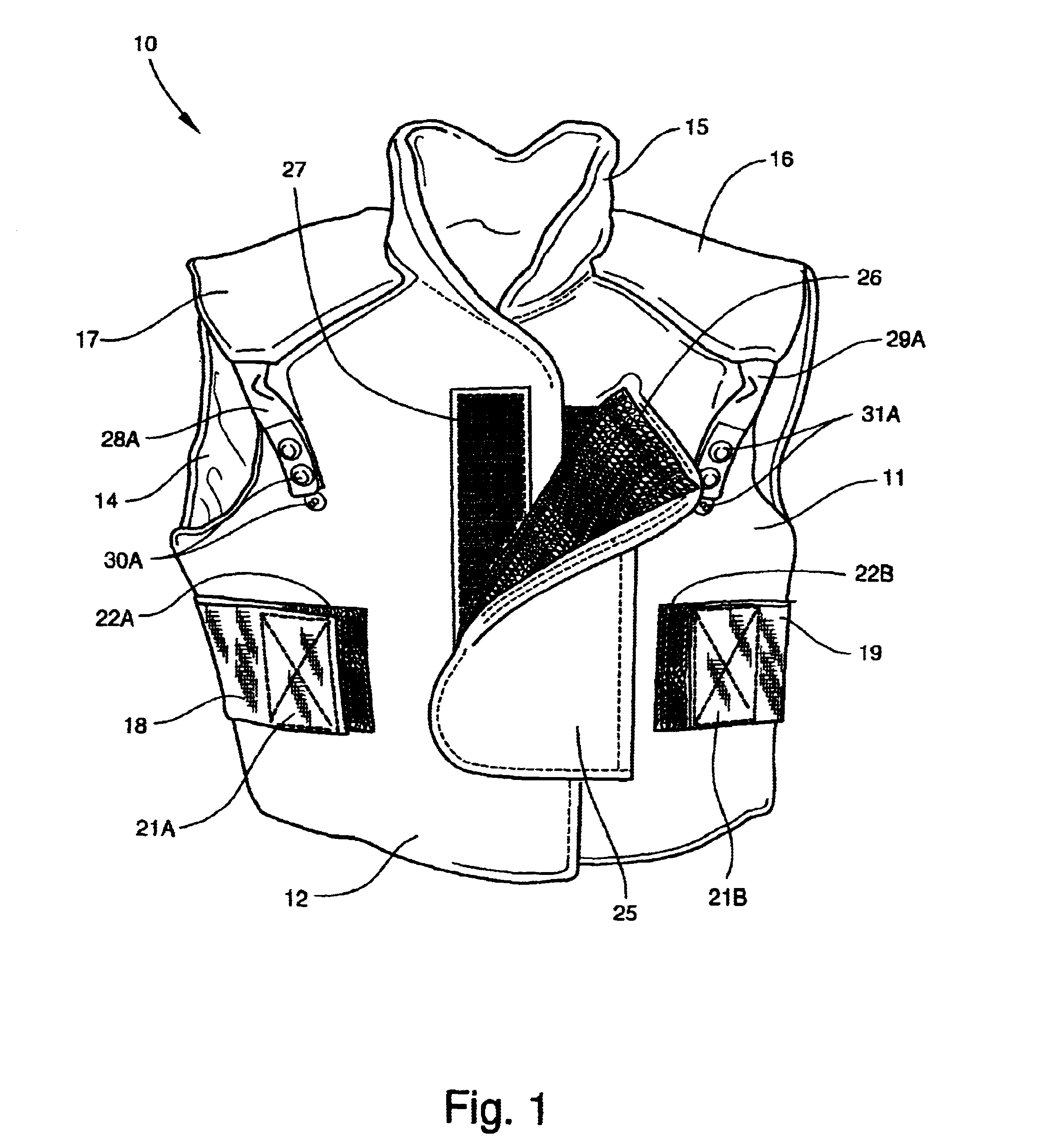

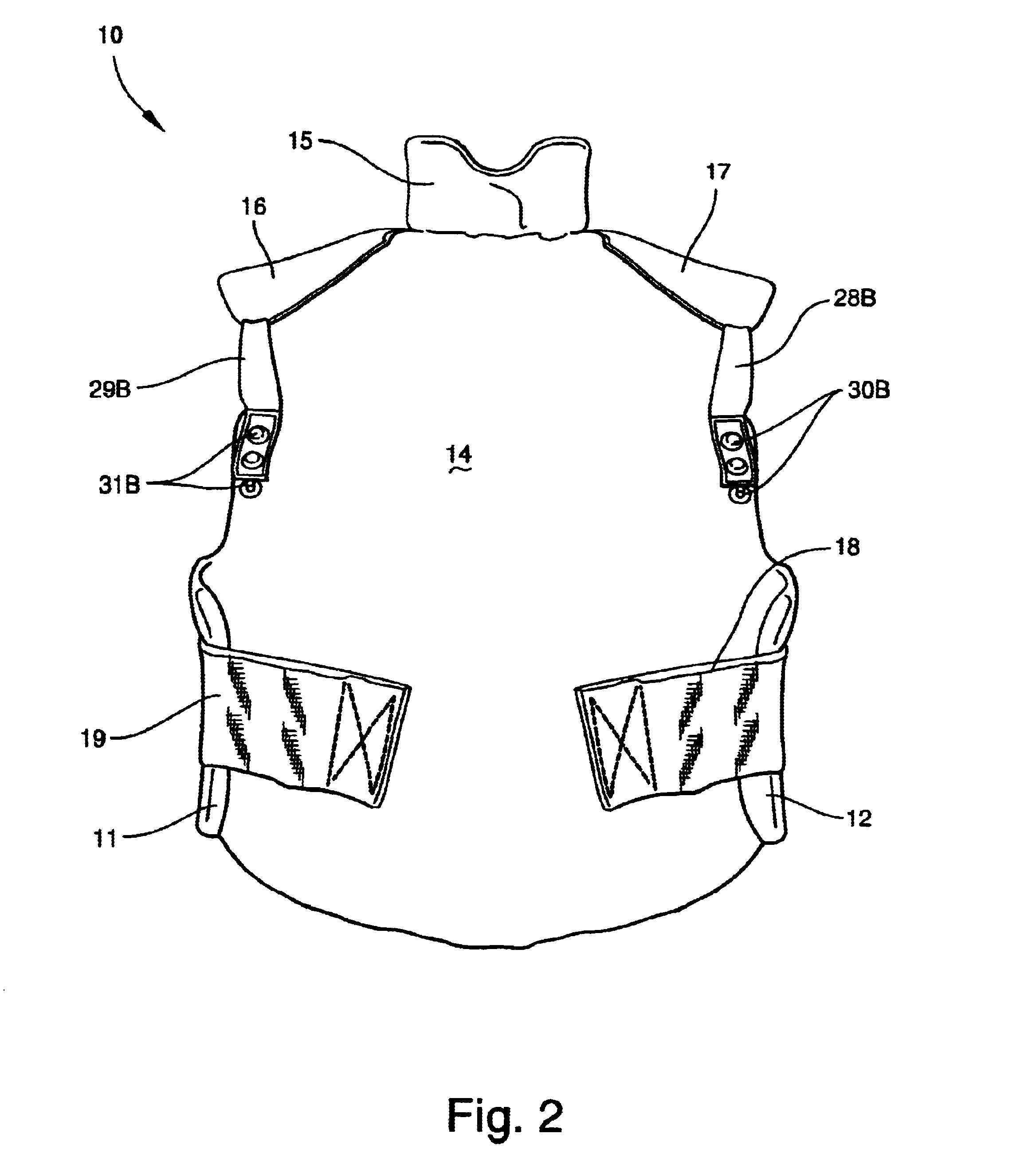

InactiveUS6651543B2Improve the immunityReduce weightPersonal protection gearArmour platesYarnFoot per second

A ballistic panel is provided for being incorporated into a lightweight soft body-armor product adapted for covering an area of the body. The ballistic panel includes an assembly of woven fabric plies with warp and fill yarns formed of bundled aramid fibers. The plies have a collective areal density of no greater than 1.30 pounds per square foot, and a V50 ballistic limit of no less than 1925 feet per second using a .22 caliber, 17 grain FSP at 0 degrees obliquity.

Owner:ARMORWORKS ENTERPRISES

Method for dip-dyeing polyamide/cotton (viscose) fabrics with acid or neutral and reactive dyes in one-bath way

The invention discloses a method for dyeing polyamide / cotton (viscose) fabrics with acid (neutral) and reactive dyes in a one-bath way. The method comprises the following steps of: adding alkali in reactive dyes till pH value is 11-11.5 and dyeing cotton fibers with the reactive dyes at the low temperature of 60-65 DEG C or two temperature ranges of 60-65 DEG C and 80-85 DEG C; and then adding acid until the pH value is 5-6, and raising the temperature to 95-98 DEG C and dyeing the polyamide fibers with the acid (neutral) dyes; and meanwhile, fixing the colour of the acid (neutral) dyes in the reactive dye soaping process. According to the invention, as the one-bath two-step dyeing technology is used for replacing the traditional two-bath process, the dyeing time is shortened, the yield is increased and the consumption of energy and water and the alkali usage are reduced, thus lowering the production cost and protecting the environment; when the acid (neutral) dyes are used for dyeing, the dye liquid is a buffer system formed by sodium acetate and acetic acid and can improve the dye reproducibility (dyeing right first time) and reduce rehandling. The method has very obvious practical value.

Owner:ZHEJIANG SCI-TECH UNIV

Cellulosic and para-aramid pulp and processes of making same

InactiveUS20050284595A1Non-fibrous pulp additionNatural cellulose pulp/paperFibrilPulp and paper industry

The present invention relates to cellulosic and para-aramid pulp for use as reinforcement material in products such as seals and friction materials. The pulp comprises (a) irregularly shaped, cellulosic fibrous structures, (b) irregularly shaped, para-aramid fibrous structures, and (c) water, whereby cellulosic fibrils and / or stalks are substantially entangled with para-aramid fibrils and / or stalks. The invention further relates to processes for making such cellulosic and aramid pulp.

Owner:EI DU PONT DE NEMOURS & CO

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

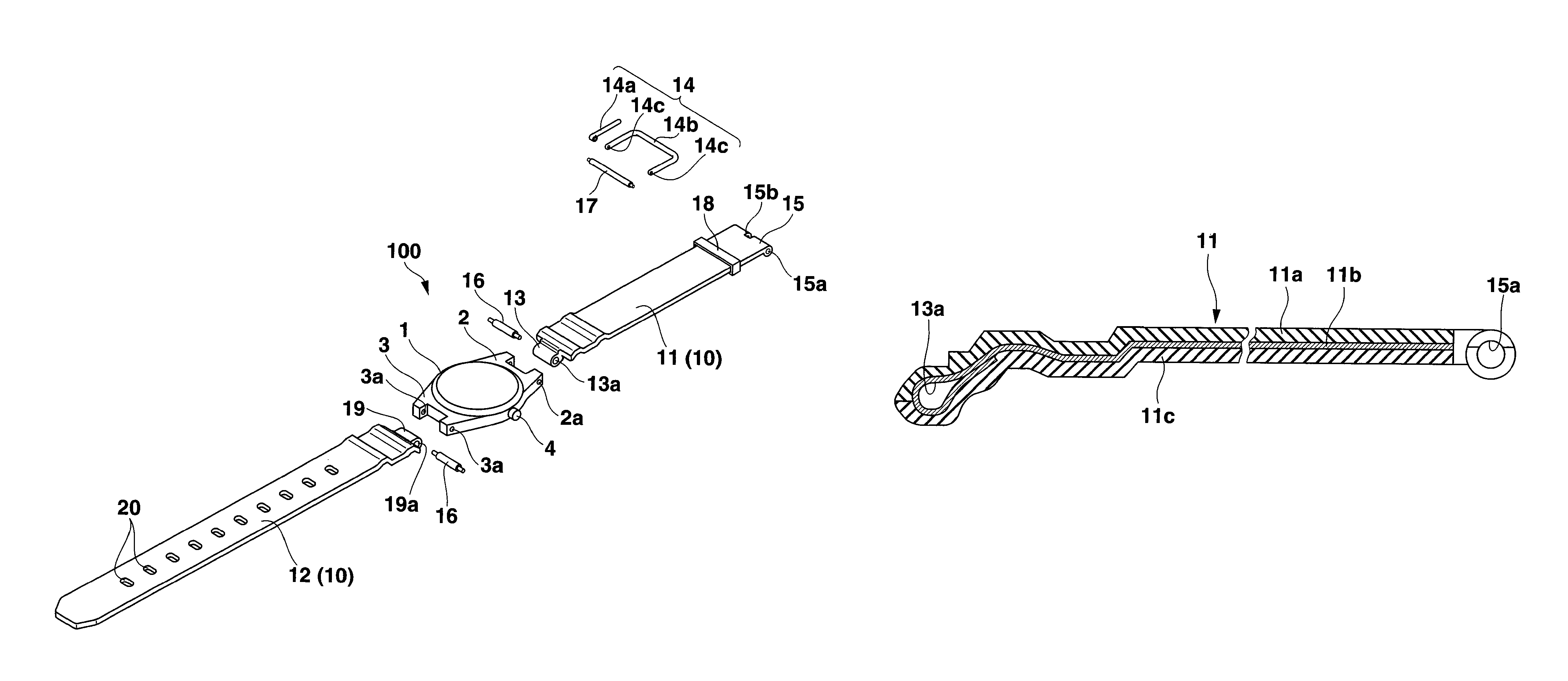

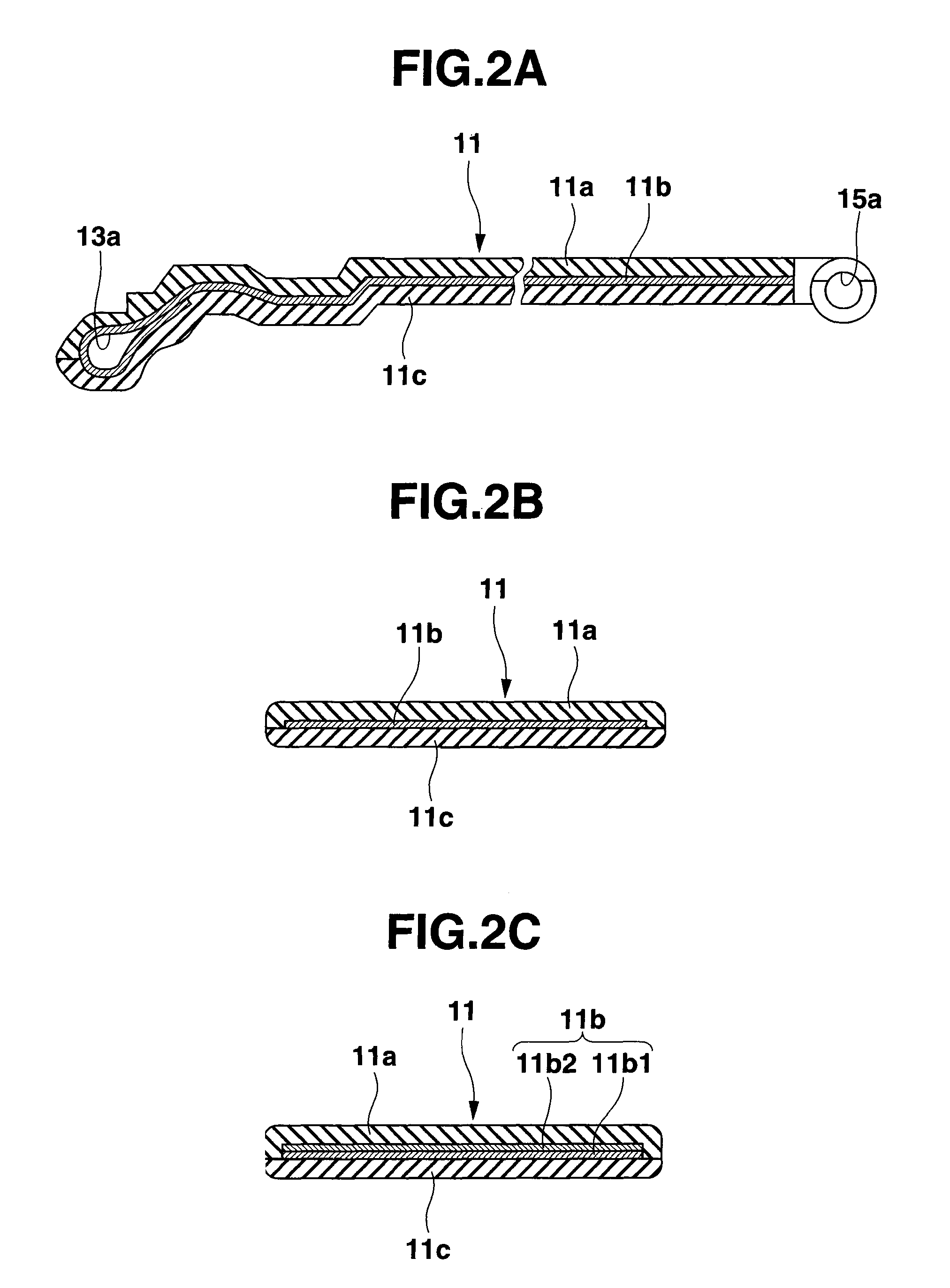

Band, wristwatch with the band and method of making the band

ActiveUS8613544B2High strengthEasy to liftSynthetic resin layered productsBraceletsPolymer scienceFiber bundle

A band, a wristwatch with the band and a method of making the band are described. The band includes a strip-like body with a series of holes provided therein along a length thereof for adjusting an effective length thereof. The body includes a band-shaped support layer of woven or knit fabric of bundles of one or more kinds of fibers, the fibers being selected from a group including carbon fibers, glass fibers, aramid fibers and boron fibers. The body also includes a first resin layer adhering closely to one surface of the support layer, and a second resin layer adhering closely to the other surface of the support layer. The fibers of the support layer extend at a predetermined angle to longitudinal and transverse directions of the body.

Owner:CASIO COMPUTER CO LTD

Para-aramid pulp including meta-aramid fibrids and processes of making same

Owner:DUPONT SAFETY & CONSTR INC

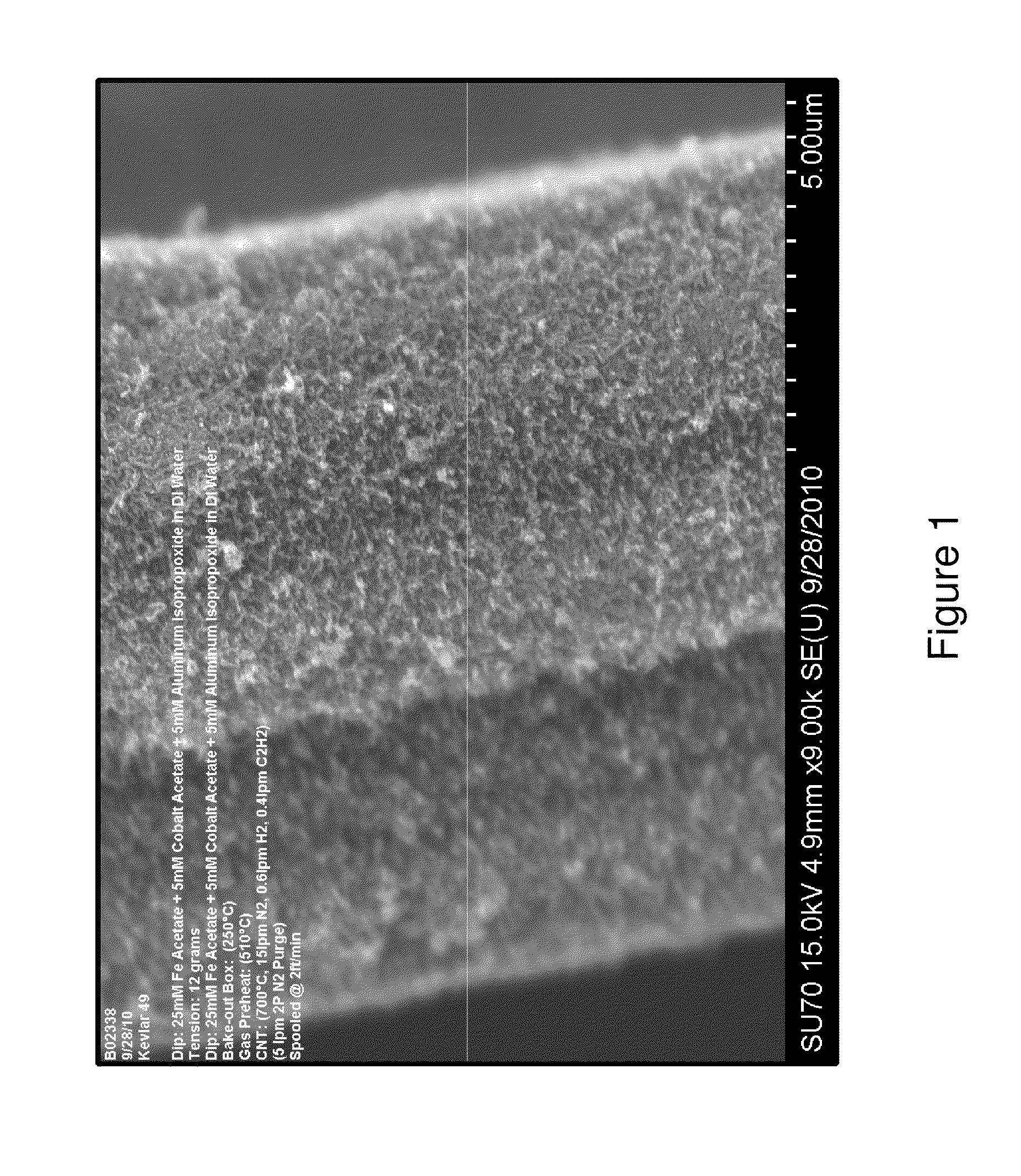

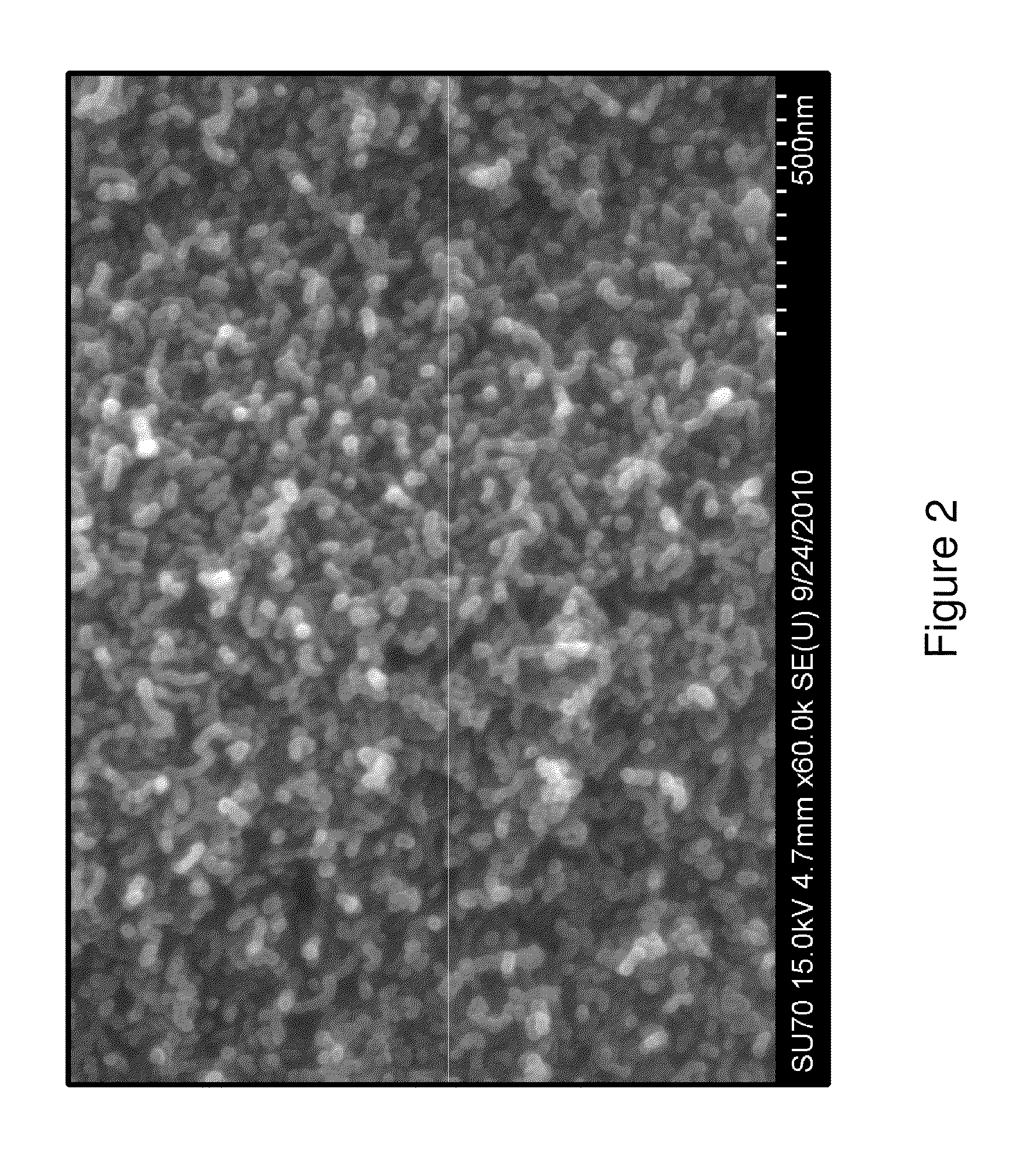

Cnt-infused aramid fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused aramid fiber material that includes an aramid fiber material of spoolable dimensions, a barrier coating conformally disposed about the aramid fiber material, and carbon nanotubes (CNTs) infused to the aramid fiber material. The infused CNTs are uniform in length and uniform in density. A continuous CNT infusion process includes:(a) disposing a barrier coating and a carbon nanotube (CNT)-forming catalyst on a surface of an aramid fiber material of spoolable dimensions; and (b) synthesizing carbon nanotubes on the aramid fiber material, thereby forming a carbon nanotube-infused aramid fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

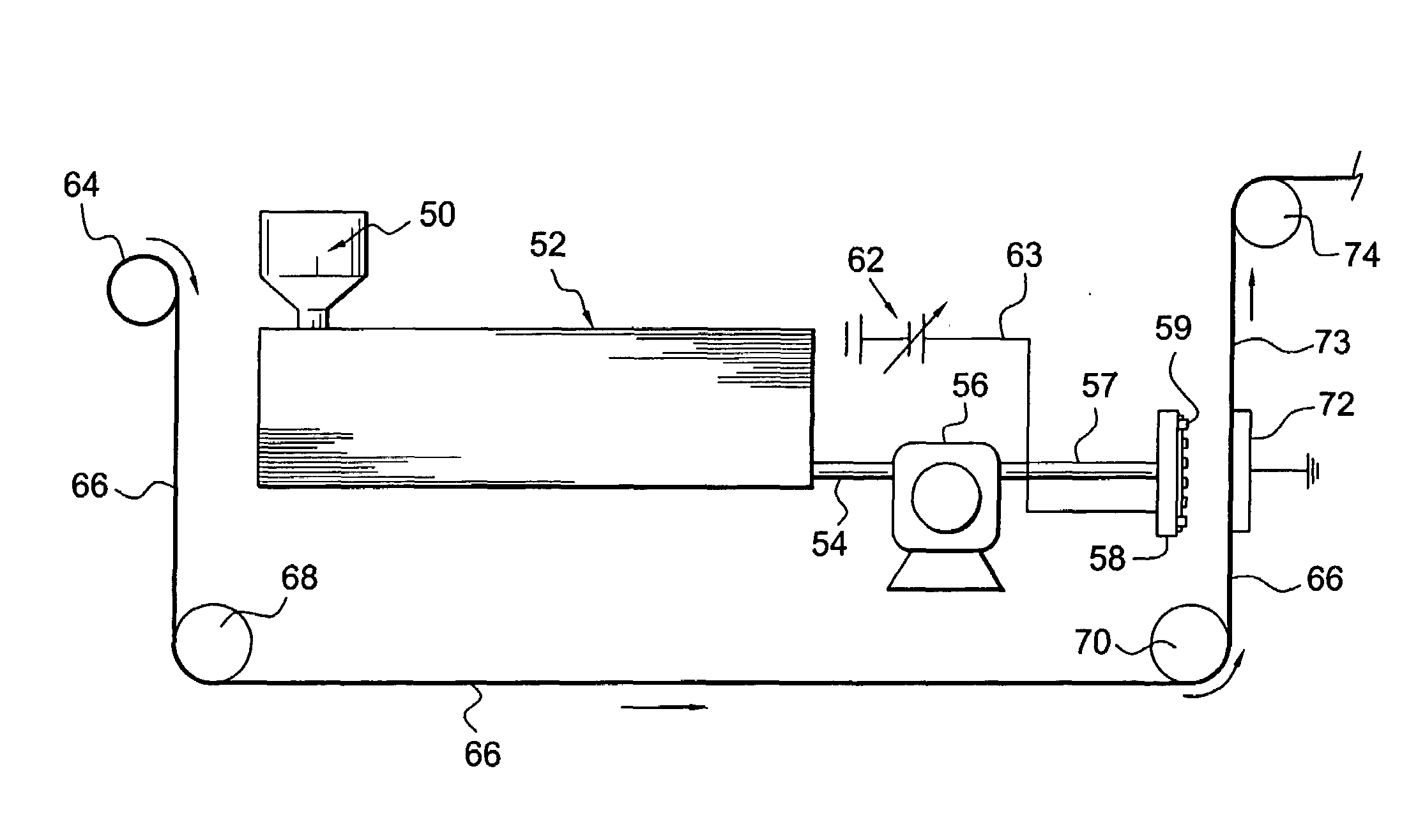

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

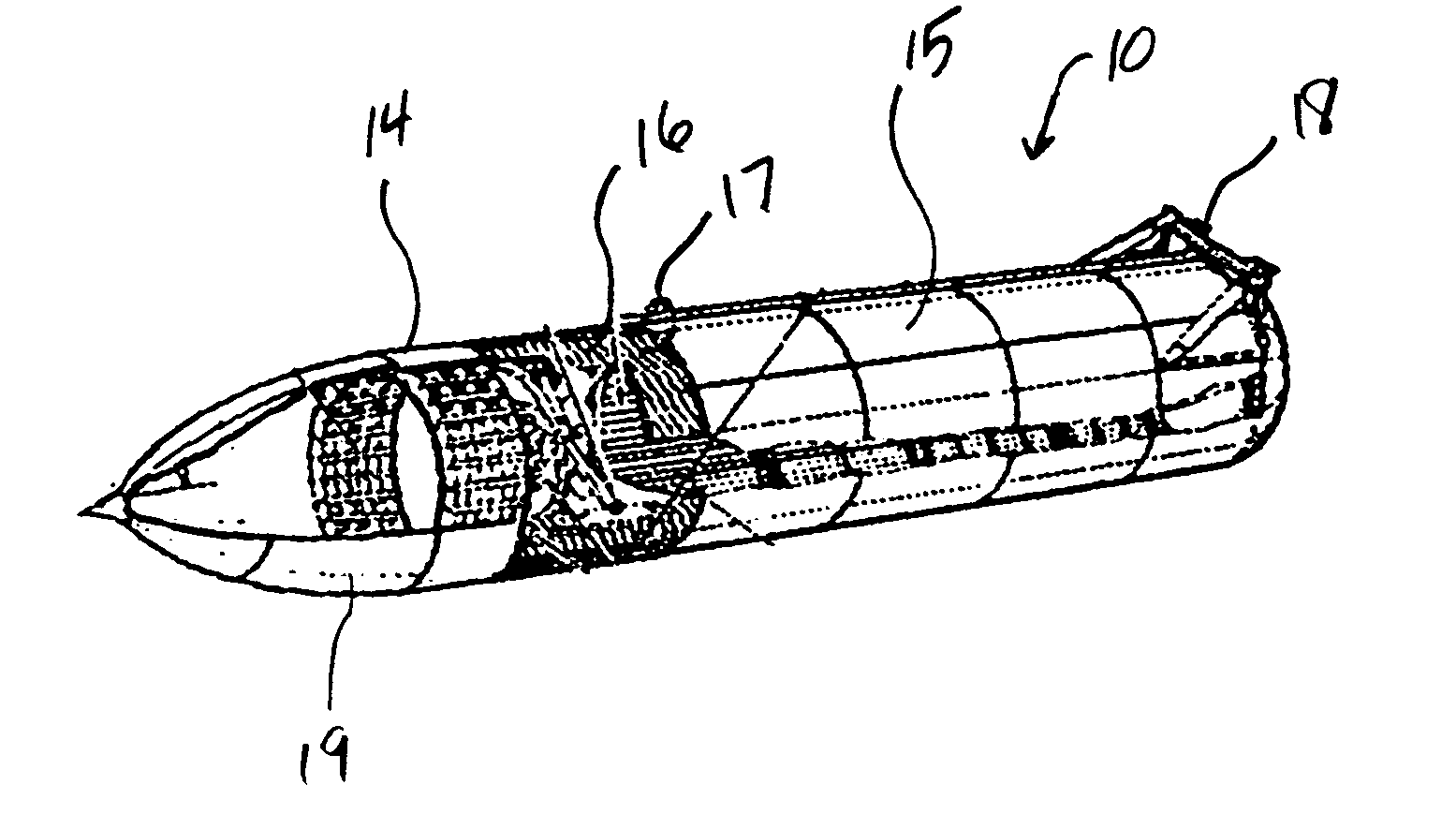

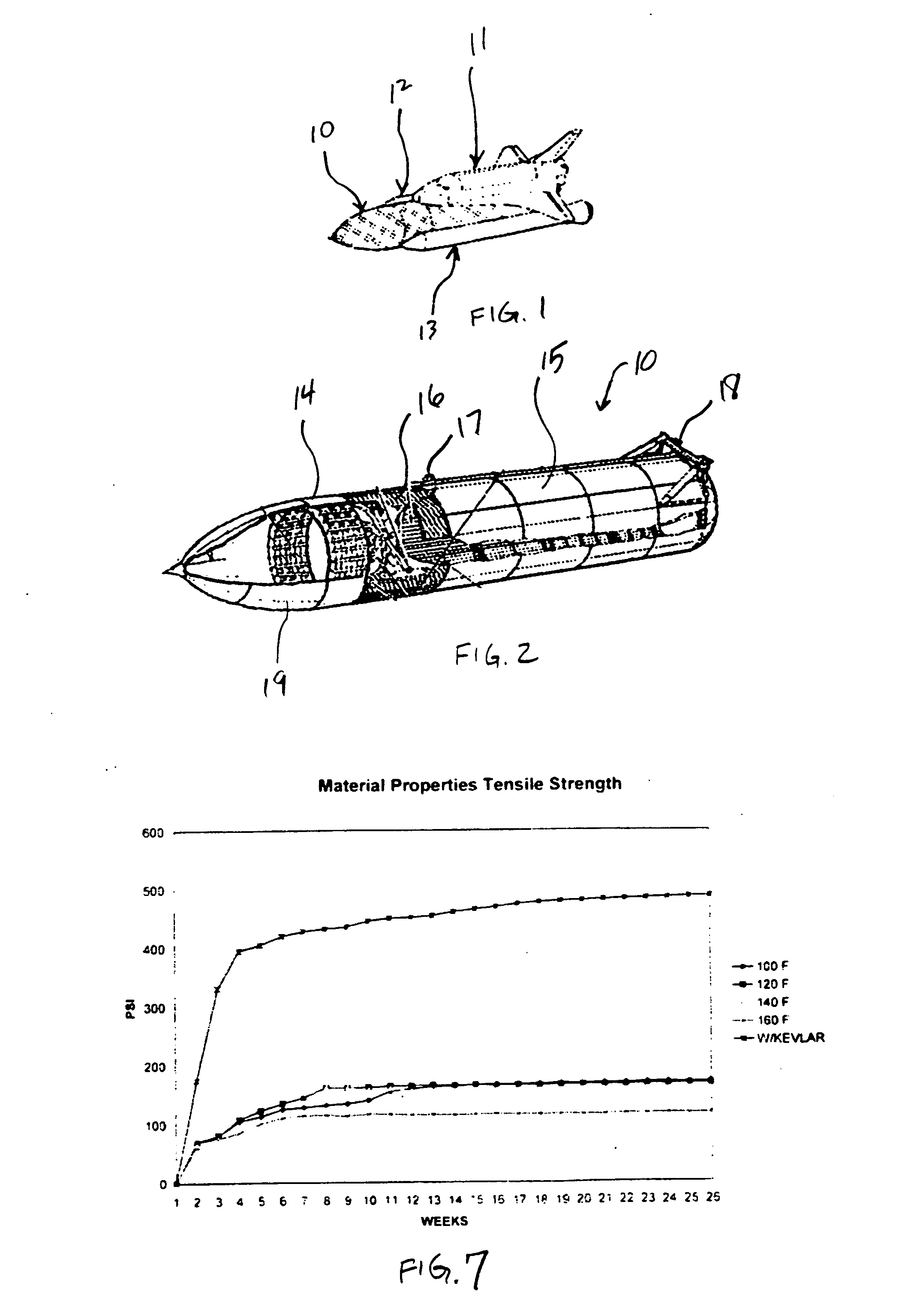

Reinforced foam covering for cryogenic fuel tanks

InactiveUS20050001100A1High strengthMaterial nanotechnologyCosmonautic vehiclesFuel tankCarbon nanotube

A cryogenic fuel tank adapted for attachment to an aerospace vehicle includes an exterior layer of reinforced composite insulating foam. The insulating foam is reinforced with an aramid fiber mesh or a closed cell foam may be reinforced with one or more of carbon nanotubes, graphite whiskers, silicon carbide fibers or graphite fibers. The improved composite insulating structure disclosed herein provides a remedy for insulating material breaking off the large external fuel tank attached to the space shuttle during launch and ascent into space.

Owner:FLORIDA INT UNIV BOARD OF TRUSTEES

Anti-static polytetrafluoroethylene filter bag and preparation method thereof

InactiveCN103191602AHigh temperature resistantCorrosion resistantDispersed particle filtrationSynthetic resin layered productsChemical industryEngineering

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Owner:南京际华三五二一环保科技有限公司

Reinforcing fabric for non-woven fabric heat-resisting filter material and application thereof

The invention discloses reinforcing fabric for a non-woven fabric heat-resisting filter material. Fibers for forming the reinforcing fabric at least contain meta-aromatic polyamide fibers. The reinforcing fabric has high strength and good size stability. The invention provides the reinforcing fabric used for the high-strength non-woven fabric heat-resisting filter material so as to prolong the service life of the filter material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Fire blocker fiber composition, high loft web structures, and articles made therefrom

The present invention is directed to a fiber composition useful for fire blocking; a high loft web structure made from such fiber composition and a process for making such web structure; and a fire blocked article such as a mattress or furniture incorporating such high loft web structure and a method for fireblocking said articles; the fiber composition comprising (a) 1 to 20 parts by weight p-aramid fibers, (b) 20 to 60 parts by weight regenerated cellulose fibers containing silicic acid, and (c) 10 to 60 parts by weight polyester fibers, (d) up to 20 parts by weight binder material wherein the total of (a), (b), (c) and (d) is on a basis of 100 parts by weight.

Owner:EI DU PONT DE NEMOURS & CO +1

Continuous pad dyeing method of polyamide fibers and blended fabrics thereof

InactiveCN101446048ADeep color yieldGuaranteed color yieldDyeing processLiquid/gas/vapor textile treatmentAfter treatmentPre treatment

The invention provides a continuous pad dyeing method of polyamide fibers and blended fabrics thereof, and the method comprises: the polyamide fibers or the blended fabrics thereof are dyed after pre-treatment, and the dyeing is the single pad dyeing of acid dyes or the sequential pad dyeing of the acid dyes and active dyes. The pad dyeing of the acid dyes has steps as follows: the polyamide fibers or the blended fabrics thereof after treatment are immersed in dyeing liquid, the acid dyes are hot rolled at 60-85 DEG C, color fixing liquid is padded after drying, the color fixing liquid is further padded after steaming and washing, and then washing and drying are carried out. The continuous pad dyeing method has the beneficial effects that the continuous pad dyeing method selects the hot rolling to lead the color yield of the polyamide fibers to be deeper and combines the dual-color-fixing process to ensure the color yield and the color fastness of the fabrics, thereby leading the fabrics to have good using value and meeting the needs of medium and high-grade fabrics.

Owner:SHANGYU XINSHENG CHEM IND

Use of fibers in a care composition or a make-up composition to make the skin matte

InactiveUS20020028222A1Avoid injurySatisfied with the resultCosmetic preparationsBiocideFine lineSkin complexion

The present application relates to the use of fibers in a skincare composition or a make-up composition for the skin, to make the complexion matte, smooth and / or uniform, and / or to fade out skin relief defects. The fibers are in particular polyamide fibers having a length of from 1 mum to 10 mm and a shape factor of from 5 to 150. The composition used gives the skin a covering index of greater than 0.1 and preferably greater than 0.13. The invention also relates to a cosmetic treatment process for fading the complexion matte, smooth and / or uniform, and / or for fading out microreliefs, wrinkles, fine lines and pores in the skin, comprising the application to the skin of fibers in a cosmetic composition.

Owner:LOREAL SA

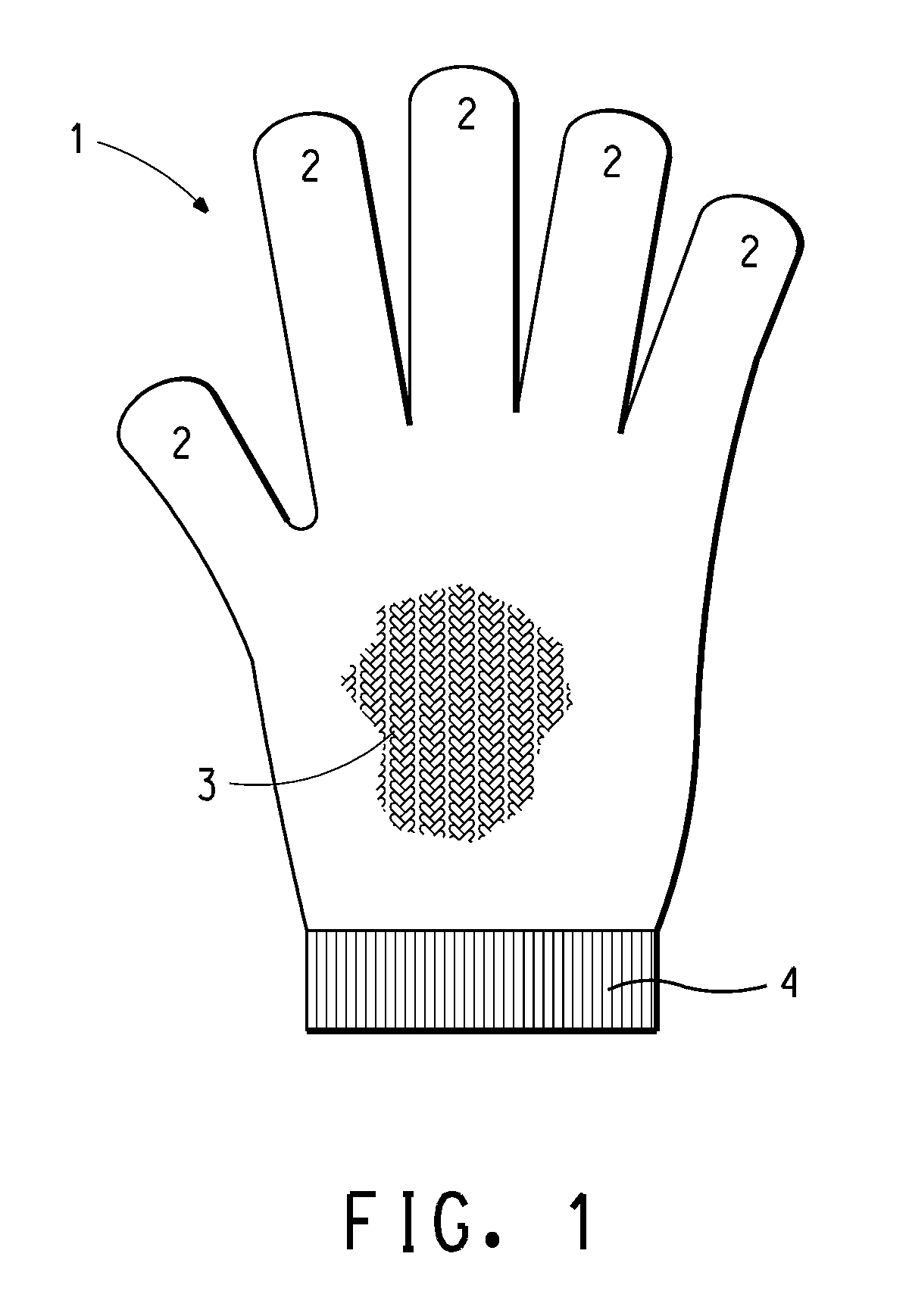

Cut-resistant gloves containing fiberglass and para-aramid

A cut-resistant knit glove comprising cut-resistant composite yarn, companion yarn and lining yarn. The cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core. The companion yarn comprising para-aramid. The lining yarn comprises either (i) composite yarn having an elastomeric yarn core and at least one second wrapping yarn helically wrapped around the yarn core or (ii) yarn comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof. The cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

Modacrylic/aramid fiber blends for arc and flame protection and reduced shrinkage

ActiveUS20050287364A1Resistance to break open and abrasionReduce Shrinkage ProblemsSynthetic resin layered productsNatural mineral layered productsYarnPolymer science

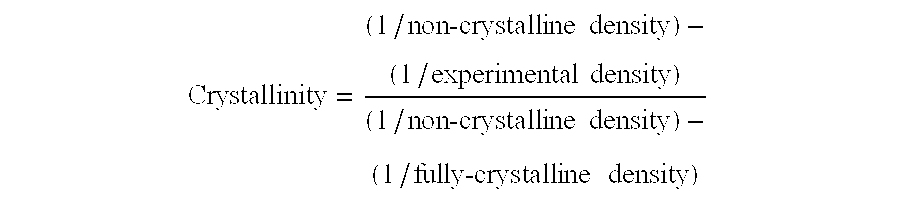

A yarn, fabric and garment suitable for use in arc and flame protection contains modacrylic, p-aramid and m-aramid fibers wherein the m-aramid fibers have a degree of crystallinity of at least 20%.

Owner:DUPONT SAFETY & CONSTR INC

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Anion fiber weaving

InactiveCN101187086AImprove securityImprove weaving efficiencyFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer scienceCopolymer

The invention provides a novel weaving idea of a negative ion fiber fabric and process, which takes polyester fibers such as polyester as a vector to spin, wherein 2-6 percent of nano negative ion power, 15-45 percent of compound negative ion power which is crashed, 0.5-2.6 percent of coupling agent such as JH-S69 type silane coupling agent, 0.3-1.8 percent of dispersant such as low molecular weight polyethylene wax and ethylene copolymer are uniformly mixed and blended into the polyester fibers to be kneaded, granulated and dried, and then being extruded to spin into a skin-core structure with the polyester fibers or polyamide fiber according to the rate of 40:60-60:40 through a twin-screw, after being stretched for 1.5-2.6 times, the skin-core structure is spun, and the function release amount is happened at 5000-30000 ind / cubic centimeter. The negative ion fiber fabric has lasting negative air ions and strong far infrared launching functions and has excellent antibacterial bactericidal functions, the processing technology is simple, the weaving effect is high, and the production value of products is increased.

Owner:SHENGHONG GRP CO LTD

Negative ion polyamide fibre and manufacturing method therefor

InactiveCN101109114AImprove mechanical propertiesGood conditionFilament/thread formingArtifical filament manufactureEndocrine systemNormal state

The invention provides an anion polyamide fiber and a preparing method for the fiber, and provides a polyamide fiber that can release anions and the making way for the fiber, which comprises the making of the anion mother particles and anion polyamide fiber. Wherein, sodium powder, toturmaline, verdelite, and opal powder particles are taken as anion generating agent, after surface treatment, they are molten with polyamide chips in proper proportion to make anion mother particles. Then they are mixed with polyamide raw materials by a mixer in proper proportion, and are spun into anion fibers by hi-speed spinning on a chinlon spinning machine. The invention is of a simple process, easy to implement, fills the blank in the field both at home and abroad. According to practice, the concentration of anions surrounding a person wearing a garment made of the fibers from the invention is obviously increased. A clothing of the fibers from the invention can fully neutralize and balance the anions for the free radicals generated during the metabolism of a body, maintain the immunity function and normal state of the incretion system of a body, and is beneficial for health.

Owner:LIAONING YINZHU CHEMTEX GROUP

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com