Ice-cold fiber knitted fabric and manufacturing method thereof

A technology of cool fibers and knitted fabrics, applied in knitting, weft knitting, warp knitting and other directions, can solve the problem of sweat not being discharged in time, unable to meet health requirements, etc., achieve pure plump dyeing effect, reduce gram weight, and dissipate heat quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] best practice

[0025] 1. The manufacture of cold fiber knitted fabrics includes the following processes:

[0026] 1. Weaving

[0027] 1.1 Raw material selection and fabric structure design

[0028] It is interwoven with cool fiber (nylon 70D / 48F) developed by Taiwan Julong Company and combed cotton yarn 18.2Tex (32S). The layer has a mesh structure to obtain cool, silky and breathable effects; the outer layer is made of pure cotton to facilitate the dissipation of sweat, and the outer layer adopts a plain stitch structure, and the coils are arranged closely, which helps to block The damage of ultraviolet rays to human skin.

[0029] 1.2 Equipment selection

[0030] Model: TERROT double-sided circular knitting machine

[0031] 1.3 Process

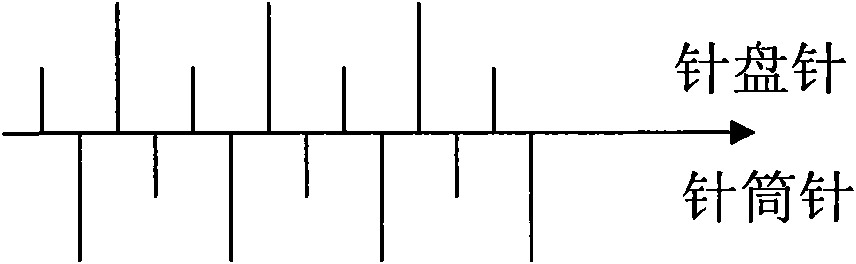

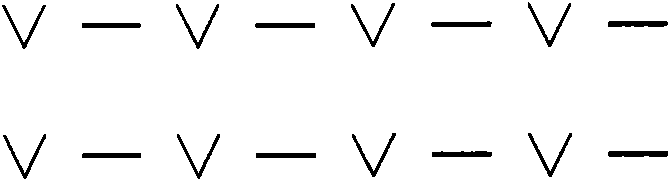

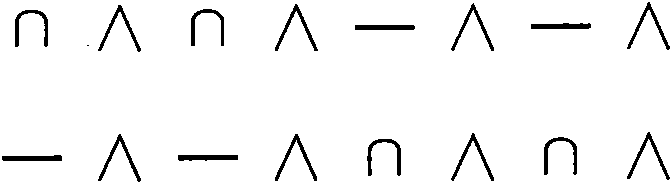

[0032] When knitting on a large double-sided knitting machine, the knitting needles, dial triangles, and cylinder triangles are arranged as shown in figure 1 , figure 2 , image 3 . The yarn configuration is as follows: od...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com