Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Silky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

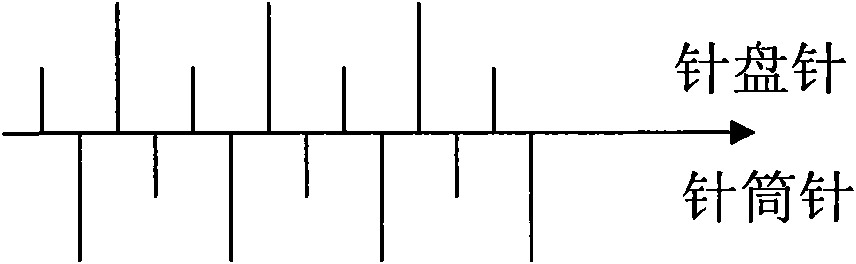

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

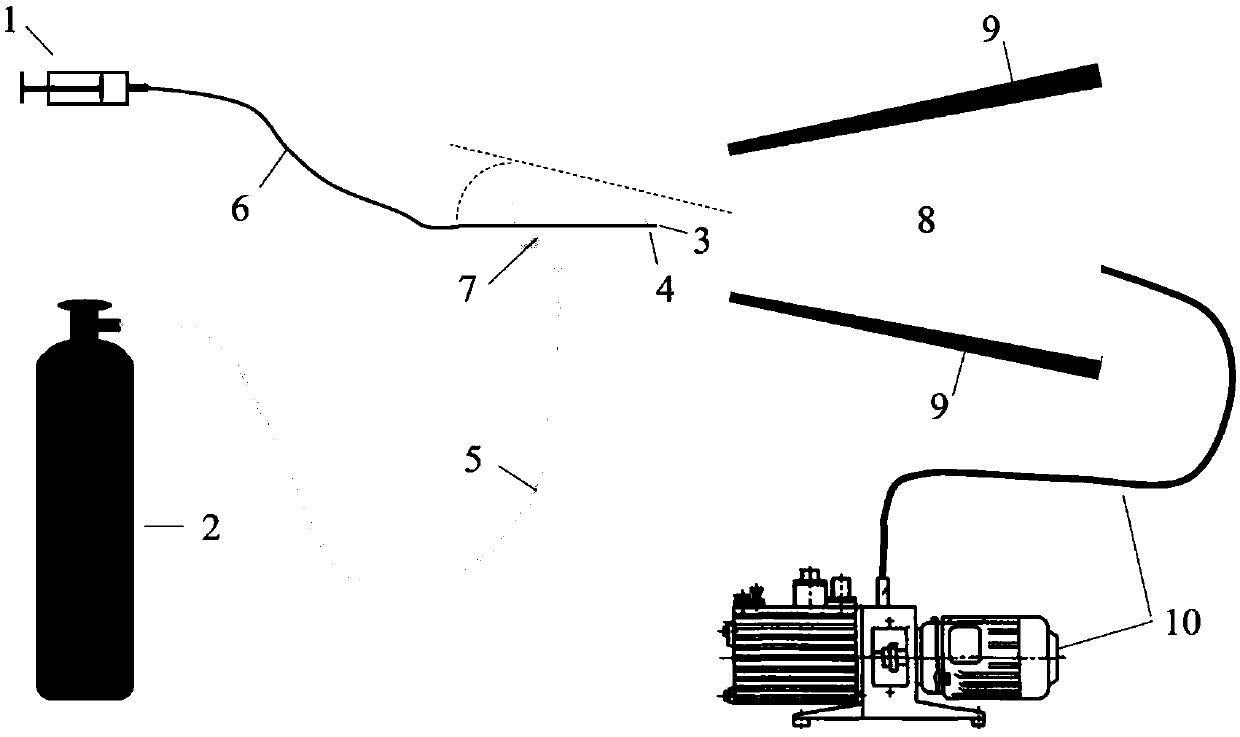

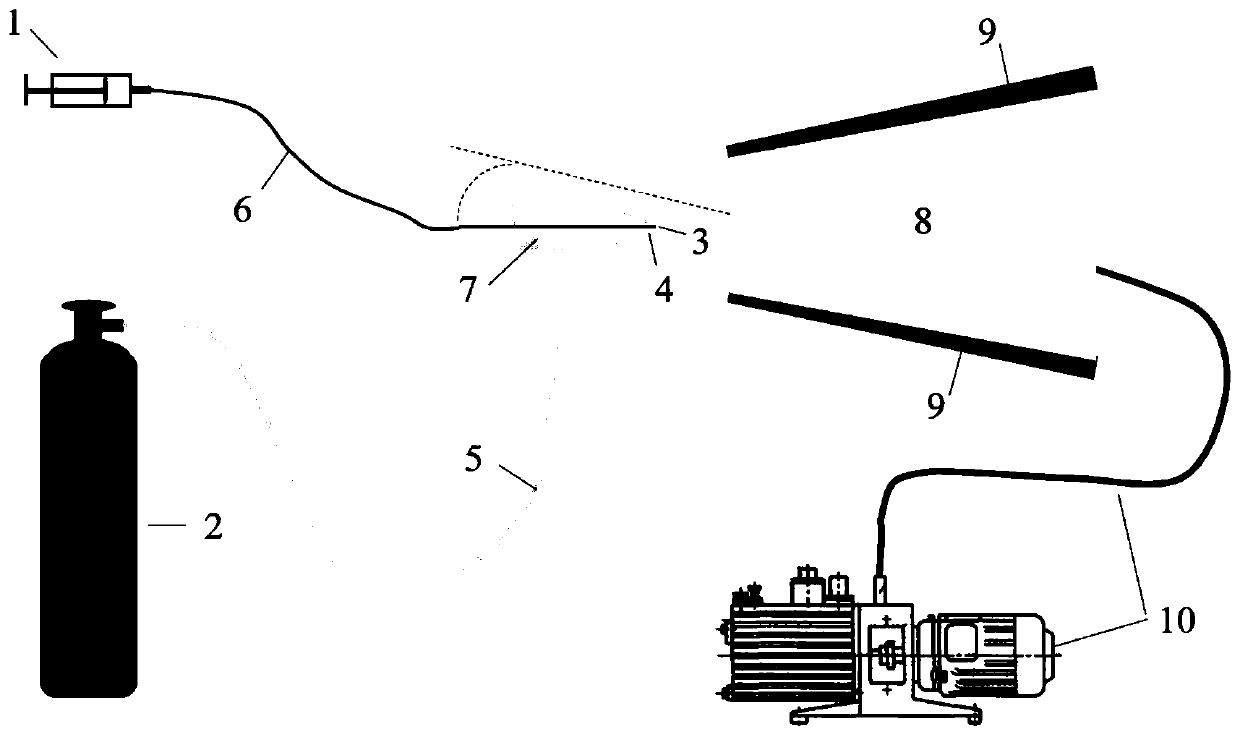

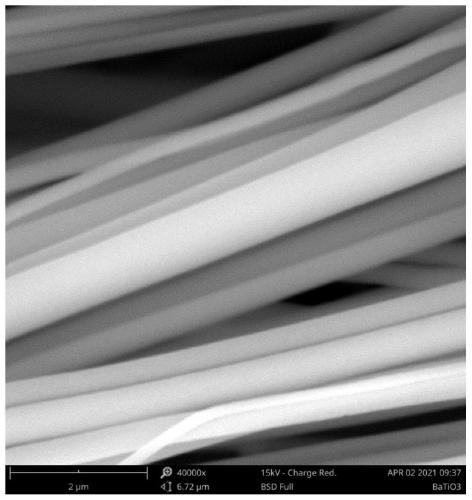

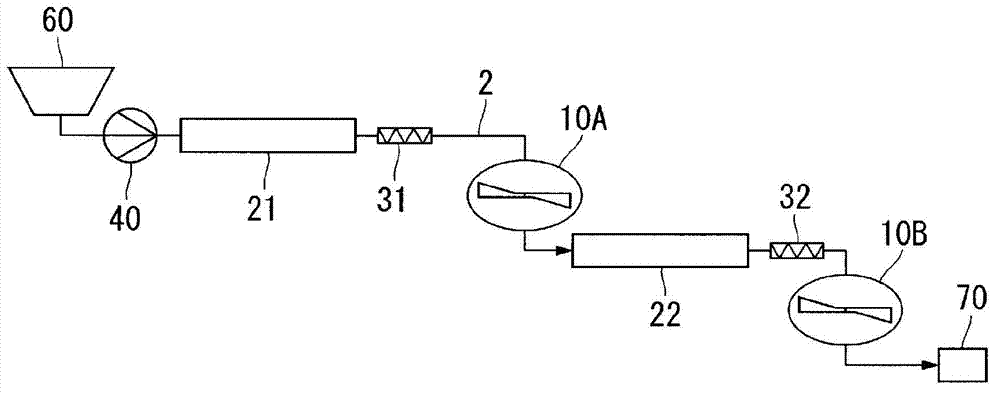

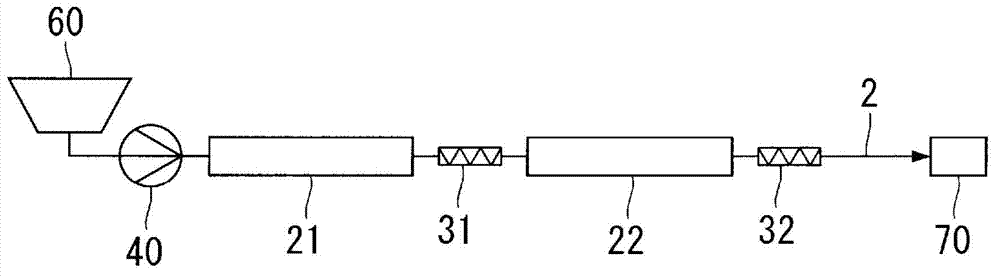

Device and method for preparing directionally arranged fiber by solution blow-spinning technology

ActiveCN109537073AEase of mass productionFacilitate single batch preparationNew-spun product collectionNon-woven fabricsFiberSpin system

The invention discloses a device and a method for preparing directionally arranged fiber by a solution blow-spinning technology. The device comprises a solution blow-spinning system and a system for collecting fiber directionally arranged by airflow; the solution blow-spinning system comprises a spinning solution, an airflow control system and a blow-spinning device; the blow-spinning device, a spinning solution and the airflow control system are connected; a spinning collection system comprises a paving collection net; the paving collection net is connected with a negative pressure device; and the solution blow-spinning system collects directionally arranged nanometer fiber on the paving collection net by adjusting the angle of the spinning air flow and the paving collection net and by taking high-speed airflow as a directional driving force. The device and the method are relatively simple to operate, have many adjustable parameters and are high in precision; and the fiber obtained through preparation is high in arrangement degree, large in preparation quantity and high in uniformity.

Owner:XI AN JIAOTONG UNIV

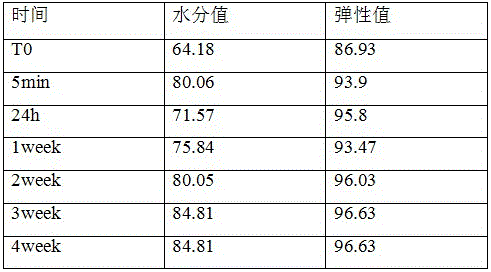

Moisturizing microcrystalline lotion and preparation method thereof

InactiveCN106176325AImprove moisture retentionSoothes the skinCosmetic preparationsToilet preparationsMoisture retentionChemistry

The invention relates to the technical field of skin care products, in particular to a moisturizing microcrystalline lotion and a preparation method thereof, comprising the following raw materials in parts by weight: water, humectant, sea grape extract, pH regulator, moisturizing soothing agent, suspending agent, moisturizing Skin agent, preservative, essence, Turkic rose flower oil, rose flower water, water, humectant, pH regulator, moisturizing soothing agent and suspending agent are mixed evenly, heated and dissolved, stirred evenly, and then homogenized at 350-380MPa, Cool down to 40-50°C, add sea grape extract, essence, and preservative according to the above ratio, stir for 5 minutes, filter and defoam, finally add emollient, stir for 0.5-1min, and control the particle size of oil beads at 1- Moisturizing Micro-Crystal Lotion with 1‑2mm diameter oil droplets suspended in the transparent water agent can be obtained within 2mm. It contains uniform oil bead molecules in the water-based system, which has good moisturizing effect, outstanding water-locking effect, and excellent long-lasting moisturizing performance .

Owner:GLOBAL COSMETICS HONG KONG CO LTD

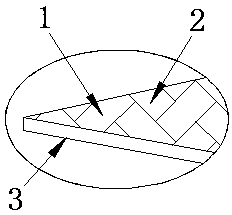

Synthetic leather for touch screen gloves and preparation method thereof

The invention belongs to the field of the preparation of synthetic leather and particularly relates to synthetic leather for touch screen gloves. The synthetic leather comprises a base (1), a face layer (2) and a face layer (3) from bottom to top, wherein the base (1) is a washer wrinkle fabric, the face layer (2) is prepared from, by weight, 30 parts of PC-8030 elastic resin, 70 parts of PC-8010 elastic resin, 100 parts of N,N-dimethyl formamide, 3 parts of touch-screen powder and 5 parts of toner, and the face layer (3) is prepared from, by weight, 100 parts of PC-8010 elastic resin, 100 parts of N,N-dimethyl formamide, 4 parts of touch-screen powder and 6 parts of toner. In addition, the formula of the touch-screen powder is improved, and the touch-screen powder has the silky feeling, flow-leveling abrasion-resisting and anti-sticking effects. After the touch-screen powder is added in the synthetic leather, the synthetic leather for the touch screen gloves has the advantages of being soft and flexible, is flexible in touch and does not scratch touch screens.

Owner:福鼎市永大合成革有限公司

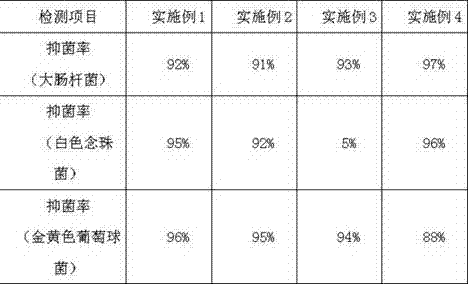

Anti-bacterial underwear fabric and preparation method thereof

InactiveCN107650448AHigh strengthSoft touchStarch dervative coatingsAntifouling/underwater paintsYarnEnvironmental resistance

The invention discloses an antibacterial fabric for underwear, which is formed by laminating two layers of blended yarn fabrics with an antibacterial coating coated on the surface of the blended yarn fabrics. It adopts cotton fiber, hemp fiber, nylon fiber and viscose fiber to make blended yarn fabric, which has good applicability. At the same time, the invention creatively adopts the pressure-sensitive adhesive bonding technology to bond the two layers of blended yarns together with a natural antibacterial coating, which inhibits the growth of bacteria in cotton clothes and has good environmental protection, antibacterial and deodorizing effects.

Owner:TIANCHANG EARTHQUAKE OFFICE

Double-layered composite skincare fiber shell fabric

The invention discloses a double-layered composite skincare fiber shell fabric. The double-layered composite skincare fiber shell fabric comprises two fiber shell fabric layers which are of netty structures interwoven by warps and wefts, wherein the warps of the first composite fiber shell fabric layer are bamboo fibers and the wefts are Tancel fibers; the warps of the second composite fiber shell fabric layer are milk fibers and the wefts are pearl fibers. The shell fabric disclosed by the invention is compounded by a two-layer structure and has the characteristics of smoothness, ventilation, lightness and thinness, flexibility, comfort, and elasticity, and is fitted and skincare.

Owner:南安市荣兴专利技术转移中心有限公司

All-cotton jacquard poplin yarn-dyed fabric and production process thereof

The invention provides an all-cotton jacquard poplin yarn-dyed fabric, which is formed by interweaving earth axis warps, bubble axis warps and wefts. The fabric comprises a 1 / 1 plain weave and a jacquard weave, wherein the earth axis warps of the fabric use medium blue 80S CPT and beige 80S CPT as raw materials in the weight ratio of (210-220):(30-35); the bubble axis warps use beige 80S CPT as a raw material; and the wefts use medium blue 80S CPT and beige 80S CPT as raw materials in the weight ratio of (195-200):(50-60). The invention has the advantages that: (1) the fabric has a compact structure, a smooth cloth cover, a light texture, clear particles, bright luster, smooth handfeel, silk-like feel, reasonable color designs and attractive and elegant colors; and (2) a production process of the all-cotton jacquard poplin yarn-dyed fabric is simple, efficient and mature.

Owner:HAIAN LIANFA ZHANGSHI YARN DYED

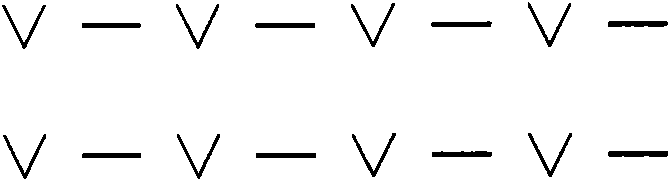

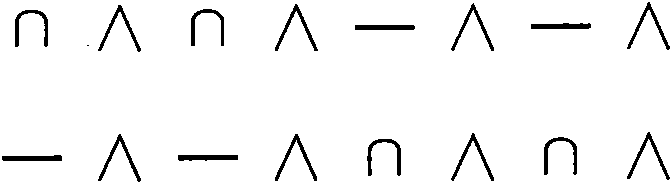

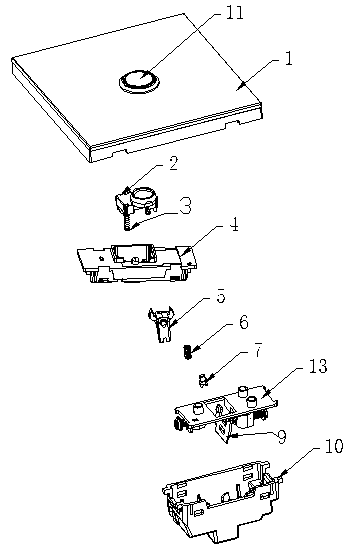

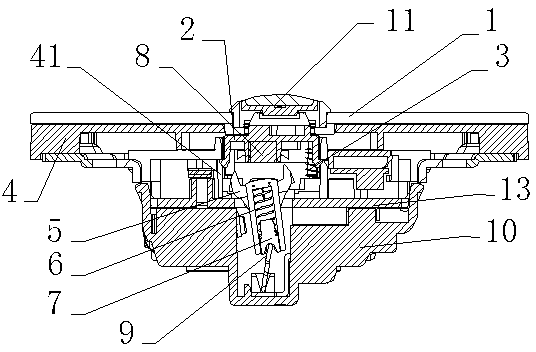

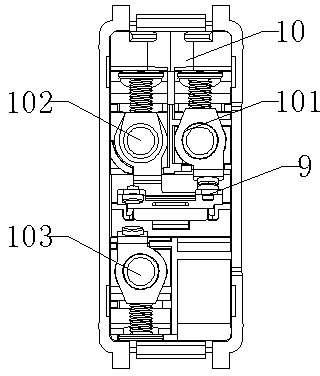

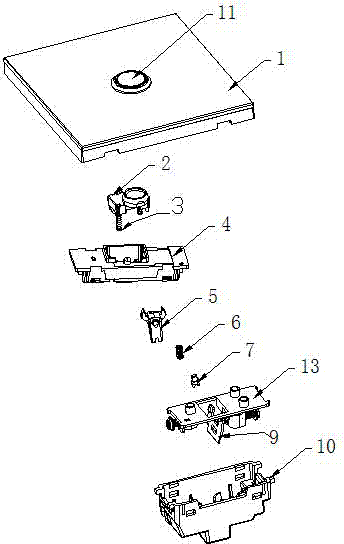

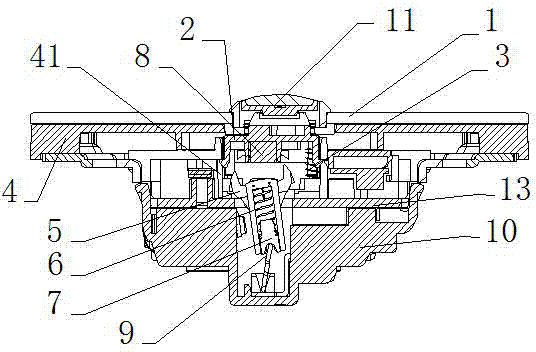

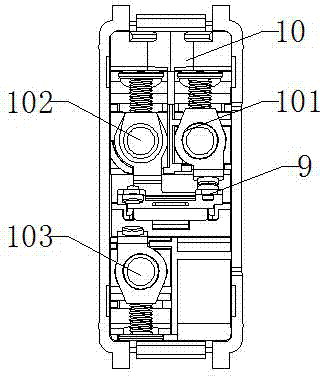

Power supply control switch

ActiveCN103258680AEasy to installReduce difficultyTumbler/rocker switch detailsExternal pressureControl switch

The invention relates to a power supply control switch which comprises a panel, a switch system and a back seat, wherein a button transmitting external pressure is arranged on the panel, the switch system is installed between the back seat and the panel, and a conductive edge column I, a conductive edge column II and a conductive supporting frame are installed at the bottom of the back seat. The power supply control switch is characterized in that the switch system is of a self-reset reciprocating type switch structure and comprises a press block component, a balance component, a seesaw, neutrons and a springboard. The provided power supply control switch aims to have the technical advantages that service life is long, transmission of the parts of the switch system is stable in a moving process, control over a power supply by the switch system is high in stability, connecting among all the parts is achieved by fully adoption of button placement matching among the parts, producing and installing efficiency is improved, and the power supply control switch is convenient to assemble and disassemble in a using process and is in line with the design concept of modern industrial production.

Owner:HUNAN SIASE ELECTRIC INDAL

Cuqing fiber and bamboo fiber blended yarn product and spinning method thereof

InactiveCN105926096ALittle strengthFeel goodFibre cleaning and opening machine combinationsCarding machinesYarnEngineering

The invention discloses a Cuqing fiber and bamboo fiber blended yarn product and a spinning method thereof. The mass ratio of Cuqing fibers to bamboo fibers in the blended yarn product is 3:7-1:1. The spinning method of the Cuqing fiber and bamboo fiber blended yarn product adopts sliver blending and multi-sliver mixed compact siro spinning and comprises the following processes: an opening and cleaning process, a cotton carding process, a drawing process, a roving process, a spinning process and a spooling process. The Cuqing fibers have high strength, good elasticity and high cost; the bamboo fibers feel soft and are bright in color, low in strength and high in moisture regain; the two fibers with different properties complement each other's advantages after blended, so that the blended yarn product feels soft, has silk sense, keeps unique natural bacteria resistance and bacteriostasis performance and has functions of skin affinity and protection, health preservation and heat preservation.

Owner:SHANDONG YANGGU SHUNDA TEXTILE

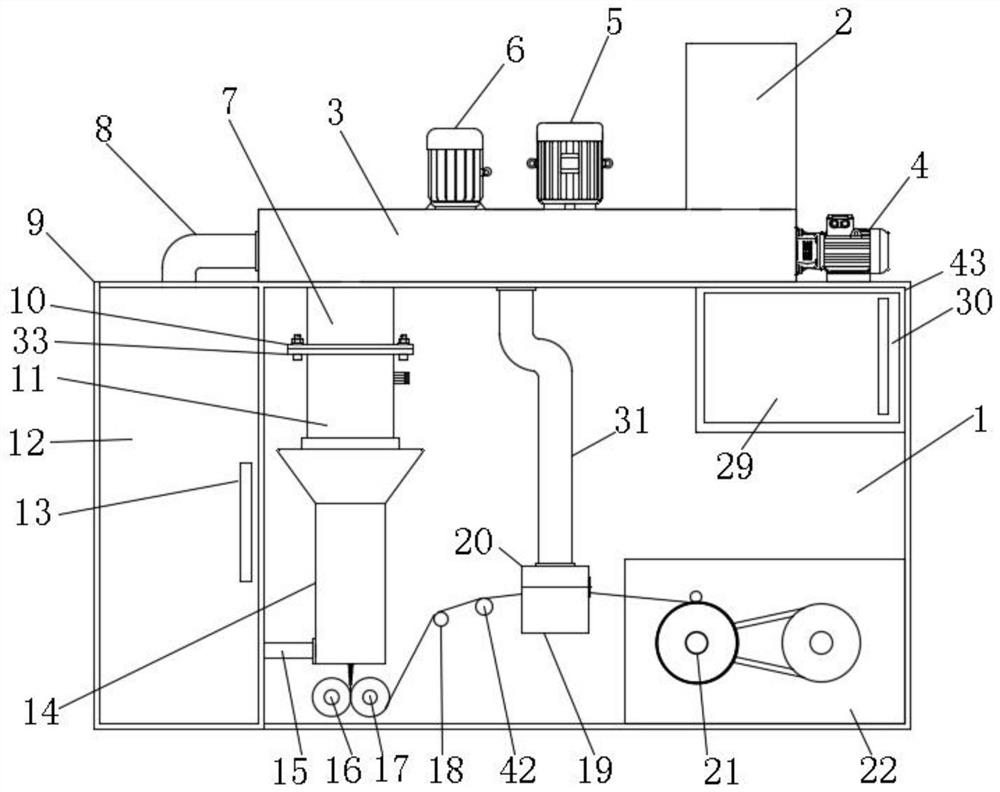

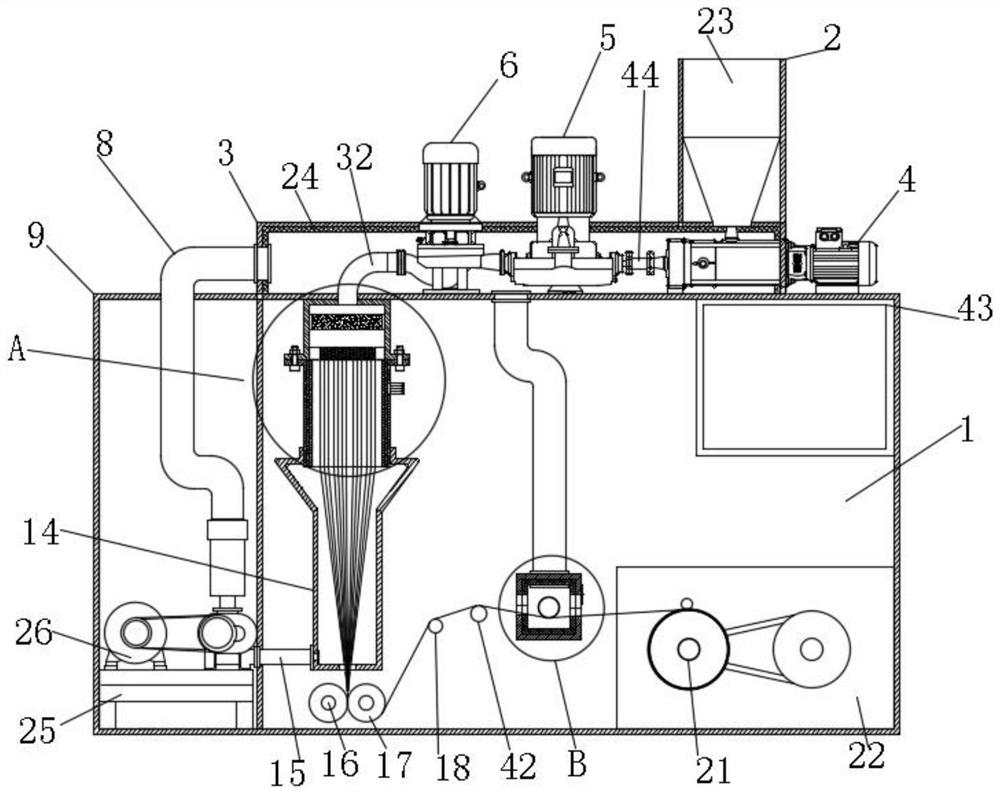

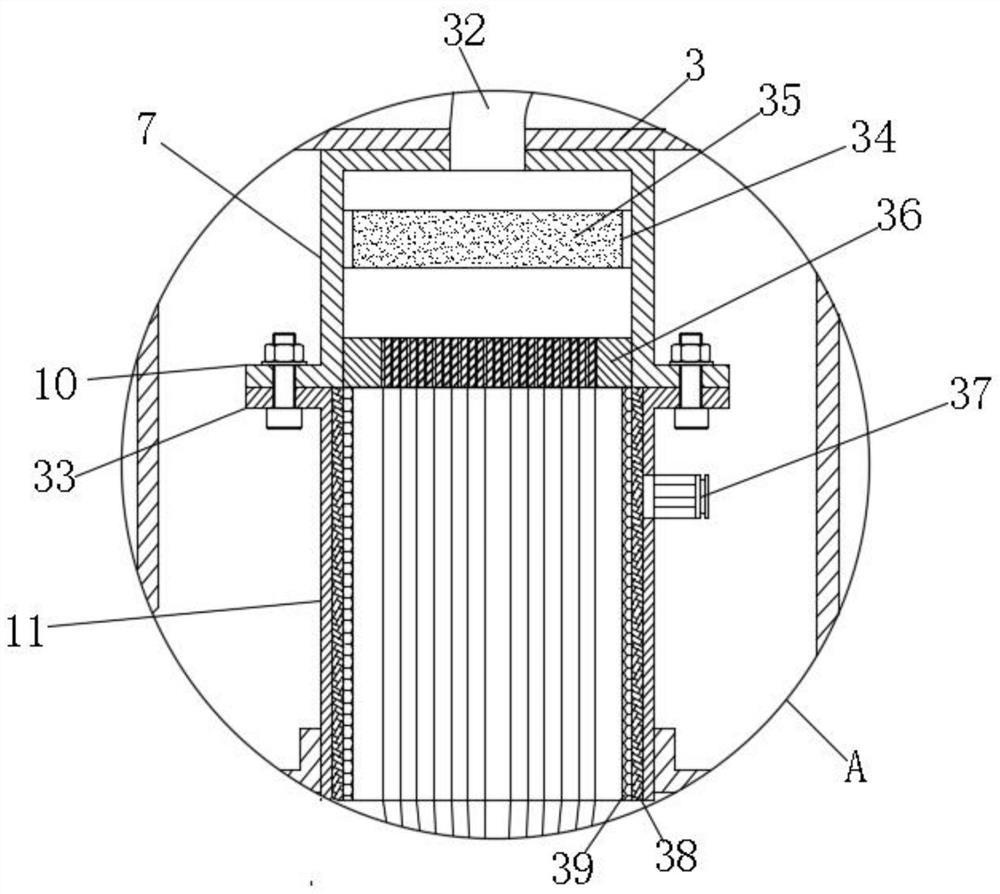

Spinning equipment and spinning process for high-strength low-shrinkage composite fibers

PendingCN112981568AImprove cooling effectReduce heat lossSpinning head liquid feederMelt spinning methodsHeat conservationMaterial supply

The invention provides spinning equipment and a spinning process for high-strength low-shrinkage composite fibers, and relates to the field of fiber spinning. The spinning equipment for the high-strength low-shrinkage composite fibers includes a machine box, wherein a material supply box is fixedly connected with the upper surface of the machine box, a material melting box is fixedly connected with the upper surface of the material supply box, and a spinning box is fixedly connected with the upper wall of the inner side of the machine box. According to the spinning equipment, cooling air is collecting through a hot air collection hood and taken away by an air blower, so that the cooling effect is improved; the high-temperature cooling air is blown into the material supply box through the air blower, so that heat loss is reduced; the hot air is blown into a heat setting box through the air blower, so that energy consumption needed by heating of a heat setting roller is reduced, and meanwhile the heat preservation effect is good through the heat setting cover and a second heat preservation layer; spinneret orifices are radially and annularly distributed in the spinneret plate in the mode that the spinneret orifices are gradually diffused outwards from a circle center, a ventilation channel is formed between every two sets of filaments, and the cooling air can penetrate through tows more easily for cooling.

Owner:ZHEJIANG HENGYOU CHEM FIBER CO LTD

High elastic thermal fabric and processing technology thereof

InactiveCN108754769AIncrease elasticityImprove wear resistanceWoven fabricsYarnPolyesterCuprammonium rayon

The invention discloses high elastic thermal fabric interwoven together by warp and weft. The high elastic thermal fabric is characterized in that the warp is made of cuprammonium rayon, polyacrylonitrile fiber and polyester fiber which conduct blended weaving; the weft is made of polyacrylonitrile fiber and cuprammonium rayon which conduct blended weaving; the blending ratio of the cuprammonium rayon, polyacrylonitrile fiber and polyester fiber in the warp is 2: 3: 1; the blending ratio of the polyacrylonitrile fiber and cuprammonium rayon in the weft is 2: 1. The disclosed high elastic thermal fabric has the advantages of having soft touch, high elasticity, silk feeling, strong moisture absorption and dehumidification, high wear resistance, refreshing anti-static property and high warmthretention.

Owner:NANTONG ZHONGRUN TEXTILE PRINTING & DYEING CO LTD

Antibacterial cotton clothes fabric and preparation method thereof

InactiveCN107877949AHigh strengthSoft touchBiochemical fibre treatmentSynthetic resin layered productsYarnPolymer science

The invention discloses an antibacterial cotton clothes fabric which is prepared by laminating two layers of blended yarn fabrics by virtue of an antibacterial coating applied to the surface of the blended yarn fabrics. The blended yarn fabrics are made from cotton fibers, jute fibers, polyamide fibers and viscose acetal fibers, and have excellent applicability. Meanwhile, the two layers of blended yarns are adhered together by creatively adopting the natural antibacterial coating for a technology for adhering pressure-sensitive adhesives, bacteria breeding of cotton clothes is inhibited, andexcellent environment-friendly, antibacterial and odor resistance effects are achieved.

Owner:TIANCHANG EARTHQUAKE OFFICE

All-cotton poplin shell fabric

The invention provides all-cotton poplin shell fabric. The all-cotton poplin shell fabric is made of warp and weft in an interweaving mode. The all-cotton poplin shell fabric is of a 1 / 1 plain weave structure. 40S extra-white JKC, 40S blue JKC, 40S red JKC and 40S bright blue CPT are selected and used as raw materials of both the warp and the weft. The all-cotton poplin shell fabric has the advantages of being compact and tight in structure, smooth and clean in cloth cover, light and thin in texture, clear in particle, bright and smooth in gloss, smooth to touch, silk-like, reasonable in color design, and elegant in color, and plain, neat and refined in color.

Owner:JIANGSU DECENT TEXTILE

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896BAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

Owner:SHANGHAI WEILE TEXTILES CO LTD

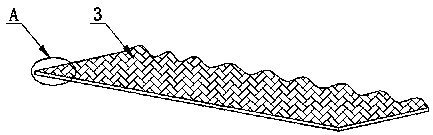

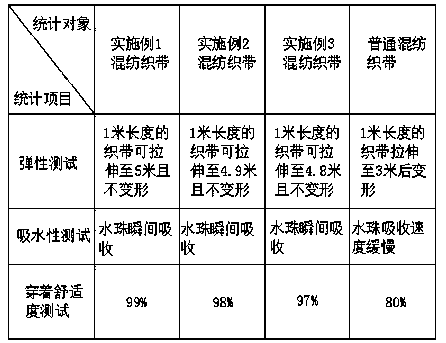

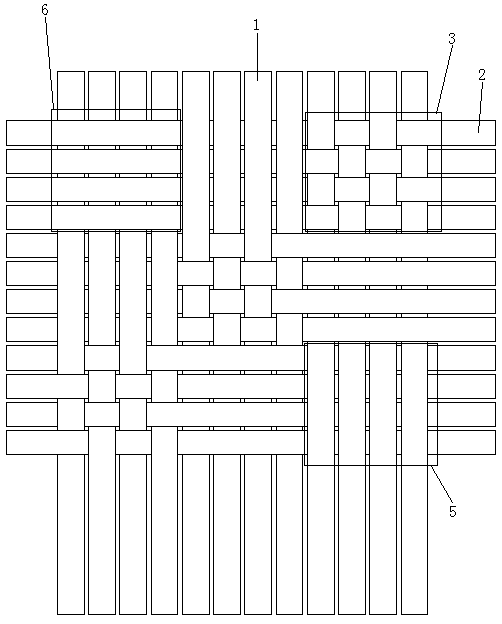

Unlikely-to-deform elastic blended woven tape

The invention discloses an unlikely-to-deform elastic blended woven tape which comprises warps and wefts, the warps and wefts are cross-woven by a textile machine to form the woven tape, and the warpsand wefts comprise the following raw materials in parts by weight: 20-30 parts of cotton fibers, 6-15 parts of bamboo fibers, 7-15 parts of polyester fibers, 6-8 parts of superfine fibers, 8-12 partsof synthetic fibers and 15-20 parts of copper ammonia fibers. The invention relates to the technical field of fabric textiles. According to the unlikely-to-deform elastic blended woven tape, the firmness and good elasticity of the woven tape are guaranteed by using the cotton fibers and the polyester fibers as base materials, and the elasticity and resilience of the woven tape are further improved by adding the synthetic fibers and the bamboo fibers, so that the woven tape is unlikely to deform; at the same time, the woven tape has natural antibacterial, bacteriostatic, acarus-killing, deodorant, anti-ultraviolet and radiation-protecting functions; by adding the copper ammonia fibers, the woven tape is soft in gloss, silky in touch and soft in hand feeling, and the production steps are simple, feasible, and easy to promote.

Owner:广东威信纺织有限公司

Non-woven fabric and preparation method thereof

ActiveCN112709003ASoft lusterSilkyTextile/flexible product manufactureNon-woven fabricsWoven fabricCombing

The invention discloses a non-woven fabric and a preparation method thereof. The preparation method comprises the following steps of (1) preparing materials, namely, uniformly mixing copper ammonia fibers, polylactic acid fibers and bamboo fibers to obtain mixed fibers; (2) oiling treatment, namely, spraying an oil preparation on the mixed fibers to obtain oiled mixed fibers; (3) performing common combing; (4) combing; (5) performing cross lapping, namely, carrying out cross lapping process treatment on the combed mixed fibers to obtain a mixed fiber web; (6) performing spunlace; (7) performing drying; (8) performing deoiling treatment, namely, performing deoiling treatment on the dried non-woven fabric by using a deoiling agent, and then performing water washing and drying to obtain the de-oiled non-woven fabric; and (9) winding, namely, winding the finished product of the de-oiled non-woven fabric. The prepared non-woven fabric is soft, breathable and antibacterial, and has good water absorption performance and mechanical properties.

Owner:JIANGSU AOKAI ENVIRONMENT TECH CO LTD

Jacquard poplin fabric

The invention provides a jacquard poplin fabric, which is formed by interweaving warp and weft yarns. The fabric has a jacquard structure, the warp yarns are made of 50S special primary color CPT and 50S additive white CPT, the weight ratio of the raw materials is 112:16, and the weft yarns are made of 50S additive white CPT. The all-cotton jacquard poplin fabric has the following technical effects: (1) the fabric has a compact structure, a light and thin texture, glittering and translucent burnish, smooth hand feeling and a silk sense; and (2) the color is reasonably designed, and is plain, neat and refined.

Owner:HAIAN LIANFA ZHANGSHI YARN DYED

Cotton poplin fabric

The invention provides cotton poplin fabric which is interweaved by warps and abbs. The fabric is in a 1 / 1 plain weava. Raw materials of the warps are selected from 60S medium white CPT, 60S red CPT, 60S wine CPT, 60S dark blue CPT, 60S vegetable green CPT, and 60S bright yellow CPT. The weight ratio of warpswarpss raw materials are 6:45.5:36.5:122:11:7.5. The raw materials of the abbs are selected from 60S red CPT, 60S wine red CPT, 60S dark blue CPT and 60S bright yellow CPT. The weight ratio of raw materials of the abbs are 21:38:112.5:7.5. The cotton poplin fabric has the advantages of being compact in structure, smooth and clean in the surface of cloth, light and thin in texture, distinct in particles, bright and smooth in gloss, slippery in handle, and silk-like in sense. In addition, the color design is reasonable, the color is abstract and elegant, and the colour and lustre is quiet and refined.

Owner:JIANGSU DECENT TEXTILE

A device and method for preparing aligned fibers using solution blow spinning technology

ActiveCN109537073BEase of mass productionFacilitate single batch preparationNew-spun product collectionNon-woven fabricsFiberSpinning

The invention discloses a device and a method for preparing directionally arranged fiber by a solution blow-spinning technology. The device comprises a solution blow-spinning system and a system for collecting fiber directionally arranged by airflow; the solution blow-spinning system comprises a spinning solution, an airflow control system and a blow-spinning device; the blow-spinning device, a spinning solution and the airflow control system are connected; a spinning collection system comprises a paving collection net; the paving collection net is connected with a negative pressure device; and the solution blow-spinning system collects directionally arranged nanometer fiber on the paving collection net by adjusting the angle of the spinning air flow and the paving collection net and by taking high-speed airflow as a directional driving force. The device and the method are relatively simple to operate, have many adjustable parameters and are high in precision; and the fiber obtained through preparation is high in arrangement degree, large in preparation quantity and high in uniformity.

Owner:XI AN JIAOTONG UNIV

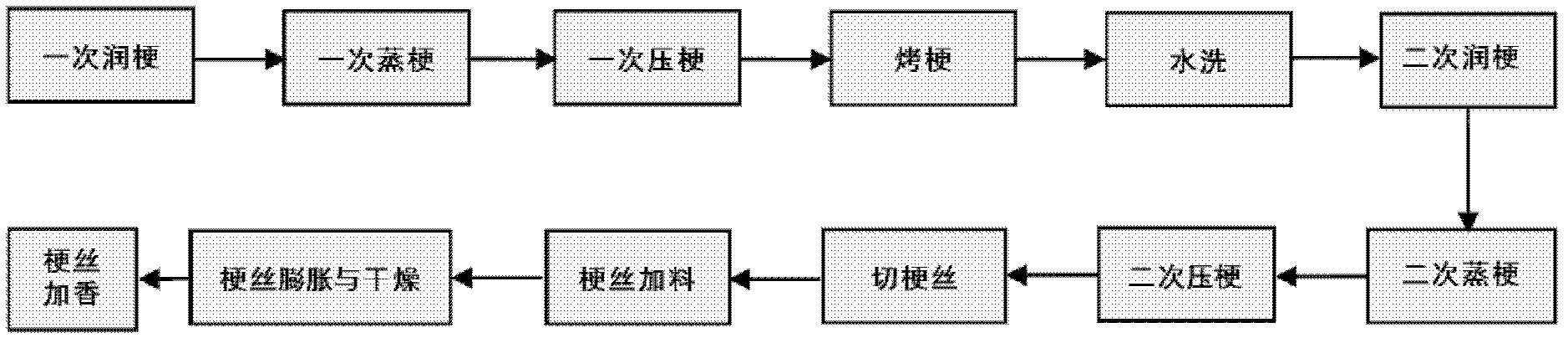

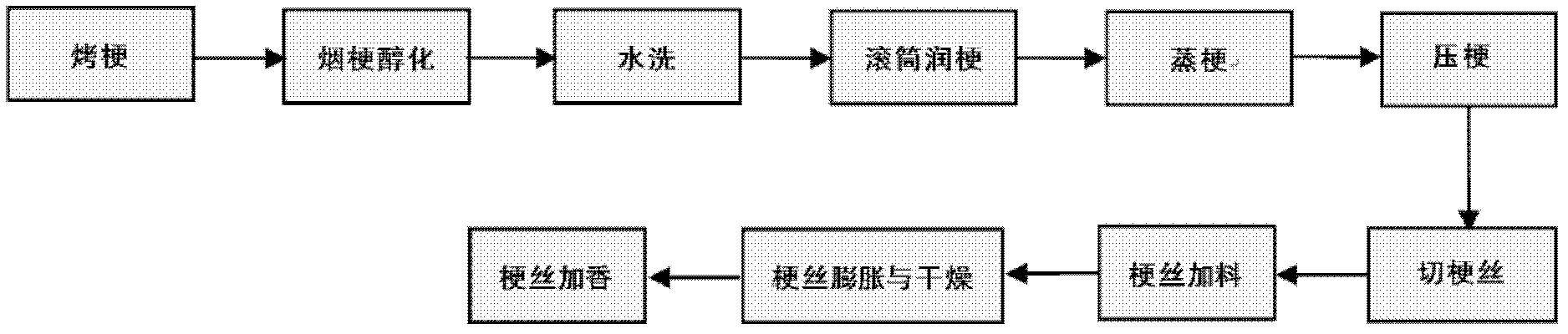

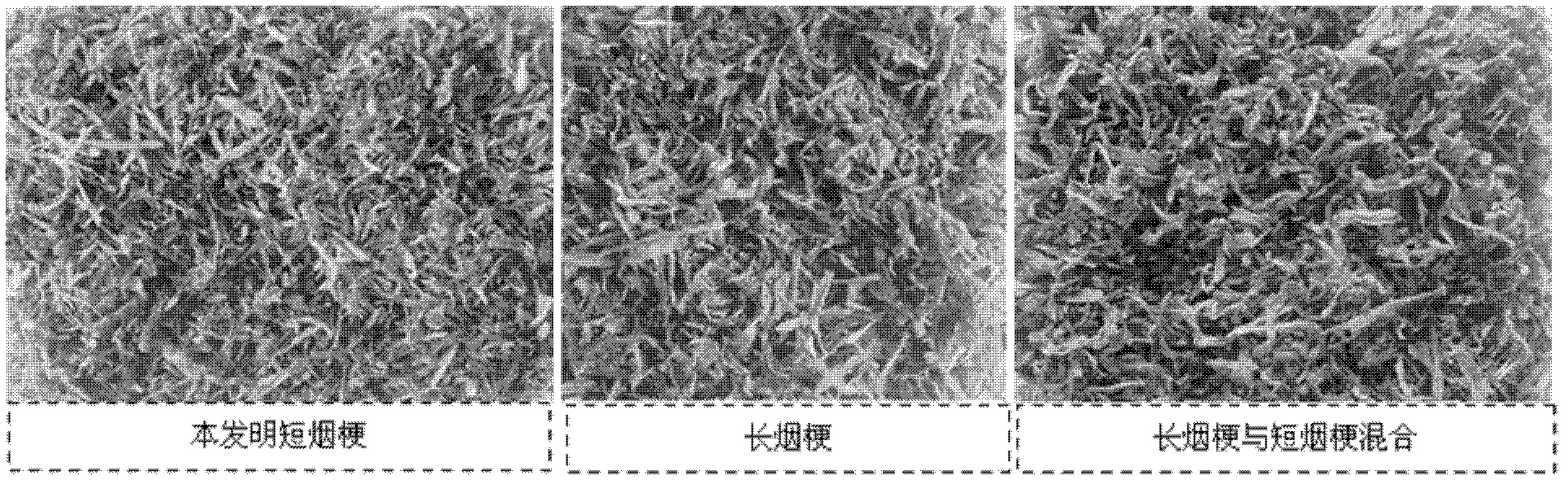

Method for improving usability of short tobacco stem

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

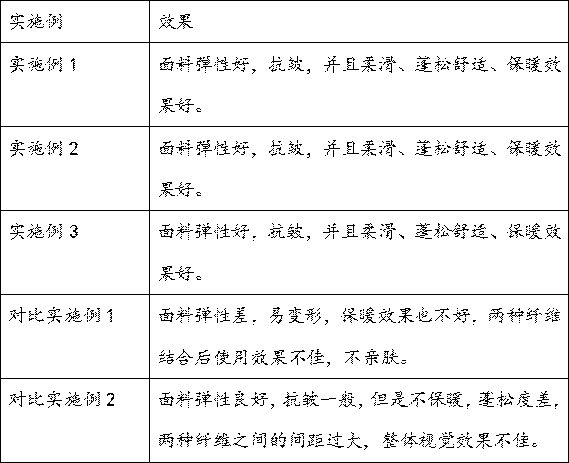

Lightweight long-staple cotton, hollow special-shaped polyester blended yarn jacquard warm knitted fabric

ActiveCN105780258BWith softness no.Good skin affinityWrinkle resistant fibresGrip property fibresPolyesterYarn

The invention relates to lightweight long-staple cotton and hollow special-shaped polyester blended yarn jacquard warm-keeping knitted fabric, which is made of long-staple cotton and hollow special-shaped polyester as raw materials, and the knitted fabric is made of organic silicon anti-wrinkle finishing agent and polyether modified amino The post-finishing technology of silicone oil softener; the post-finishing technical conditions are: 200-300 parts by weight of polyether modified amino silicone oil softener, 250-400 parts by weight of silicone anti-wrinkle finishing agent, soap oil of 1-3 parts by weight, 2-5 parts by weight of malic acid, 100-300 parts by weight of water, the excess rate is 75-85%, the speed of the shrinking machine is 7-11m / min, the light-weight long-staple cotton and hollow special-shaped polyester of the present invention The blended yarn jacquard warm-keeping knitted fabric can improve the defects of long-staple cotton and hollow special-shaped polyester, so that the final fabric has good elasticity, wrinkle resistance, and is silky, fluffy and comfortable, and has a good thermal effect.

Owner:POLARGOOSE CLOTHING

Power supply control switch

ActiveCN103258680BLimited spatial freedomMaintain freedom of movementTumbler/rocker switch detailsControl switchNeutron

The invention relates to a power supply control switch which comprises a panel, a switch system and a back seat, wherein a button transmitting external pressure is arranged on the panel, the switch system is installed between the back seat and the panel, and a conductive edge column I, a conductive edge column II and a conductive supporting frame are installed at the bottom of the back seat. The power supply control switch is characterized in that the switch system is of a self-reset reciprocating type switch structure and comprises a press block component, a balance component, a seesaw, neutrons and a springboard. The provided power supply control switch aims to have the technical advantages that service life is long, transmission of the parts of the switch system is stable in a moving process, control over a power supply by the switch system is high in stability, connecting among all the parts is achieved by fully adoption of button placement matching among the parts, producing and installing efficiency is improved, and the power supply control switch is convenient to assemble and disassemble in a using process and is in line with the design concept of modern industrial production.

Owner:HUNAN SIASE ELECTRIC INDAL

Touch screen glove and preparation method thereof

The invention discloses a touch screen glove and a preparation method thereof. The touch screen glove is prepared from the following formula ingredients in parts by mass: 4 to 6 parts of nanometer microcrystal powder, 3 to 7 parts of pine soot powder, 6 to 10 parts of silicone oil, 10 to 20 parts of elastic resin, 3 to 7 parts of dimethyl formamide, 1 to 3 parts of toughening agents, 8 to 12 parts of starch, 6 to 8 parts of touch screen powder, 4 to 5 parts of octadecyl acrylate, 13 to 15 parts of silica gel, 1 to 3 parts of toner, 30 to 40 parts of natural resin and 1 to 3 parts of functional additives. The touch screen glove has the effects of silk smoothness, levelling property, abrasion resistance, adhesion resistance and the like; the ingredients are added into synthetic leather, so that the synthetic leather for the touch screen glove has the advantages of softness and toughness; the touch feeling is sensitive; the scratch damage to a touch screen is avoided.

Owner:QINZHOU UNIV

All-cotton poplin shell fabric

The invention provides all-cotton poplin shell fabric. The all-cotton poplin shell fabric is made of warp and weft in an interweaving mode. The all-cotton poplin shell fabric is of a 1 / 1 plain weave structure. 50S extra-white CPT, 50S navy blue CPT, 50S khaki CPT, 50S bright red CPT and 50S yellow CPT are selected and used as raw materials of both the warp and the weft. The all-cotton poplin shell fabric has the advantages of being compact and tight in structure, smooth and clean in cloth cover, light and thin in texture, clear in particle, bright and smooth in gloss, smooth to touch, silk-like, reasonable in color design, and elegant in color, and plain, neat and refined in color.

Owner:JIANGSU DECENT TEXTILE

Cotton easy-care poplin fabric

InactiveCN103122529ACompact structureSmooth surfaceSwivel-woven fabricsLappet-woven fabricsSilk clothWeft yarn

The invention provides cotton easy-care poplin fabric which is interweaved by warps and abbs. The fabric is in a 1 / 1 plain and jacquard structure. Raw materials of the warps are selected from 50S raw white CPT, and raw materials of the abbs are selected from 50S light blue CPT. The cotton easy-care poplin fabric has the advantages of being compact in structure, smooth and clean in the surface of cloth, light and thin in texture, smooth in handle, and silk-like in sense, reasonable in color design, quiet and refined in colour and lustre.

Owner:JIANGSU DECENT TEXTILE

Cheese-containing food and method for producing same

Disclosed is a method for producing a cheese-containing food, comprising a step (1) for heating a soft cheese-containing mixture, which contains 70-100 mass% of a soft cheese, with a Joule heater and a step (2) for stirring the heated soft cheese-containing mixture under shearing with a high-speed shear cooker, wherein a series of procedures including the steps (1) and (2) is carried out twice or more. According to this method, a cheese-containing food having sufficiently good qualities, such as smooth meltability in mouth and good flavor, can be produced by using a starting material having a high soft cheese content.

Owner:MORINAGA MILK IND CO LTD

All-cotton jacquard poplin fabric

Owner:HAIAN LIANFA ZHANGSHI YARN DYED

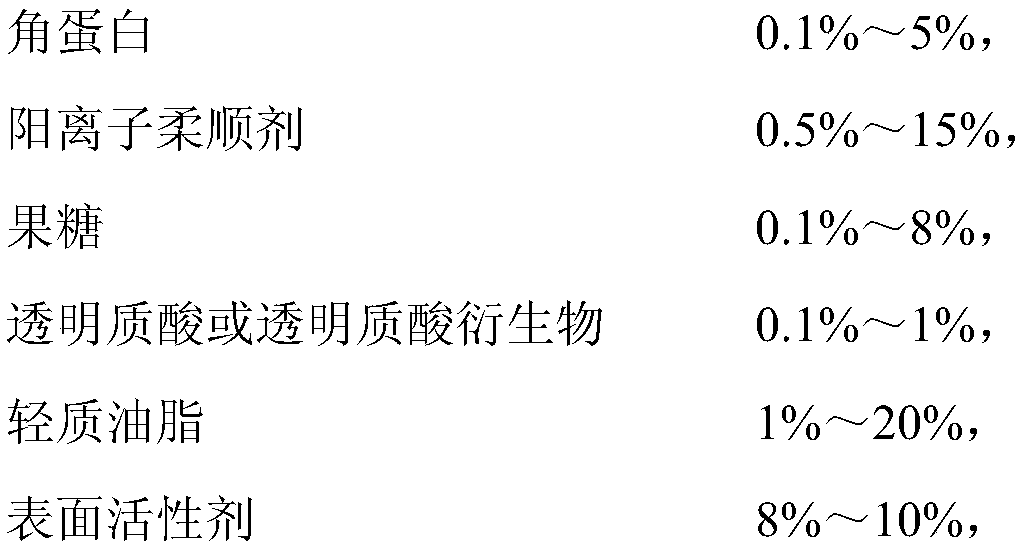

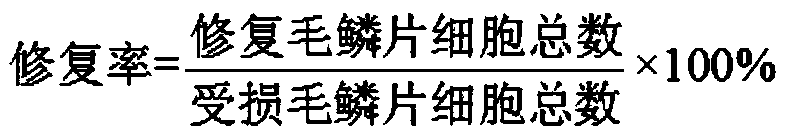

A conditioning and refreshing shampoo without silicone oil

ActiveCN105997567BGood conditioning effectSilkyCosmetic preparationsHair cosmeticsSilicone oilHyaluronic acid

Owner:广州好迪集团有限公司

All-cotton silk-like poplin shell fabric

InactiveCN103122522ACompact structureFlat surfaceSwivel-woven fabricsLappet-woven fabricsPolymer scienceSilk cloth

The invention provides all-cotton silk-like poplin shell fabric. The all-cotton silk-like poplin shell fabric is made of warp and weft in an interweaving mode. The all-cotton silk-like poplin shell fabric is of a 1 / 1 plain weave plus jacquard weave structure. 60S extra-white CPT and 60S primary color CPT are selected and used as raw materials of the warp. The 60S extra-white CPT is selected and used as raw materials of the weft. The all-cotton silk-like poplin shell fabric has the advantages of being compact and tight in structure, smooth and clean in cloth cover, light and thin in texture, smooth to touch, silk-like in hand feel, reasonable in color design, and plain, neat and elegant in color.

Owner:JIANGSU DECENT TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com