Method for improving usability of short tobacco stem

A usability and tobacco stem technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of large loss of tobacco stem aroma components, complicated processing technology, and high processing intensity, so as to facilitate uniform blending, improve sensory quality, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

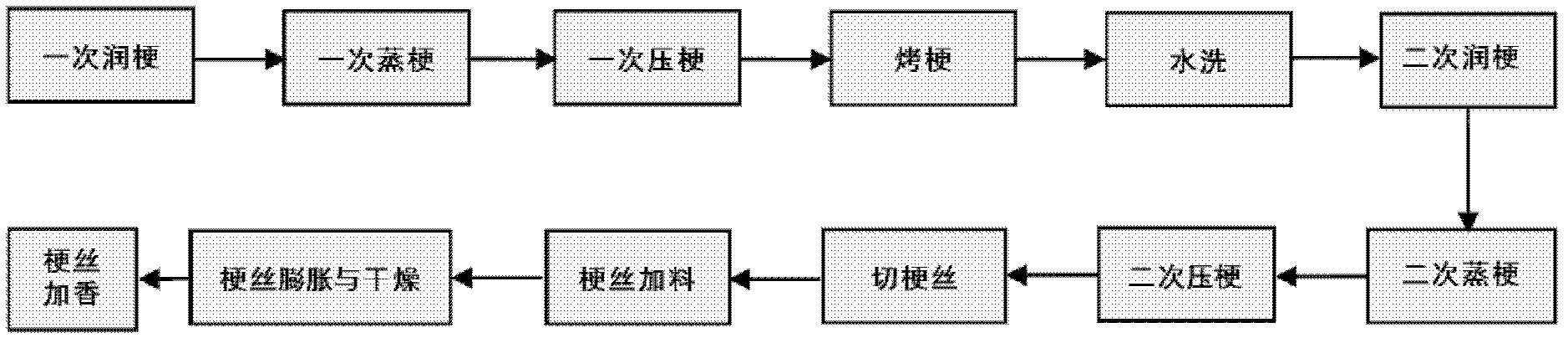

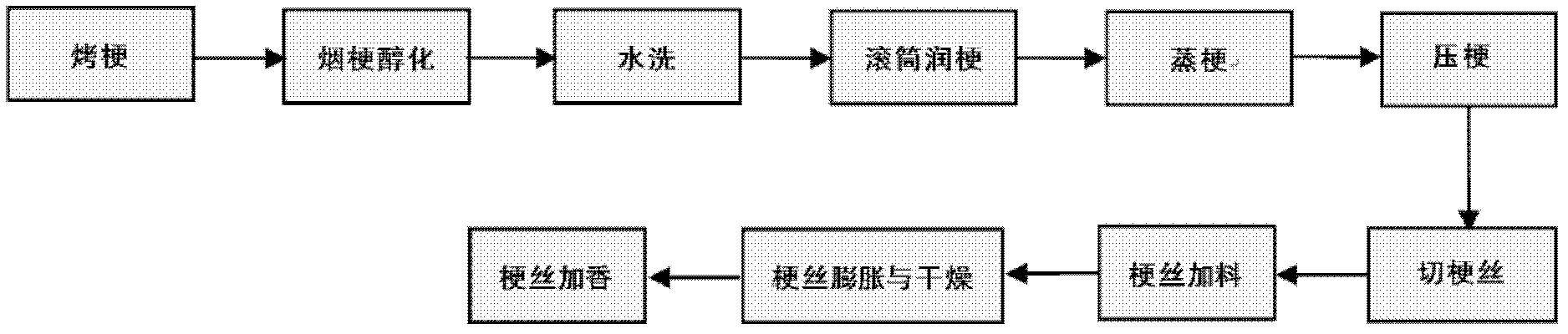

[0024] Compared figure 1 and figure 2 It can be seen that compared with the existing processing technology for large-scale production of long tobacco stems, the process improvement of the present invention is mainly reflected in the stem pressing treatment before roasting the stems, and the thinning and thin cutting treatment of shredded stems. The realization method of this technology comprises the following realization steps:

[0025] 1. The unroasted short tobacco stems after threshing are subjected to a drum moistening treatment. The temperature of the back room for moistening the stems is 80-85°C, the temperature of the short exit tobacco stems is 65-75°C, and the moisture content of the short exit tobacco stems is 25-30°C. %.

[0026] 2. Store the short tobacco stems after moistening for more than 1 hour, and then steam the stems once. The expansion steam flow rate is 650kg / h.

[0027] 3. Squeeze the short tobacco stems after the first steaming, and the gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com