Antibacterial cotton clothes fabric and preparation method thereof

An antibacterial fabric, cotton-padded technology, applied in chemical instruments and methods, fabric surface trimming, textile material treatment, etc., can solve the problems of gentle washing, fear of insect bites, like fading, etc., to achieve soft hand feel and avoid discomfort. Sensation, the effect of improving drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

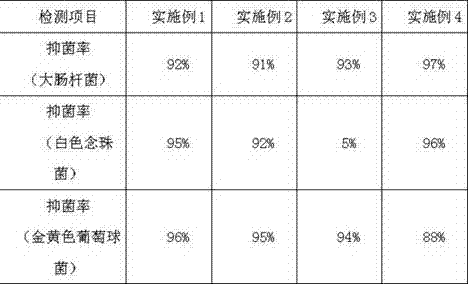

Examples

Embodiment 1

[0028] An antibacterial fabric for cotton clothes is formed by laminating two layers of blended yarn fabrics through an antibacterial coating coated on the surface of the blended yarn fabrics.

[0029] The blended yarn fabric is made of cotton fiber, hemp fiber, nylon fiber and viscose fiber blended, wherein the weight fraction ratio of superfine polyester fiber is 45%, the weight fraction ratio of cotton fiber is 15%, milk fiber The weight fraction ratio of cupro ammonia fiber is 25%, and the weight fraction ratio of cupro ammonia fiber is 15%.

[0030] The antibacterial coating is formed by coating the blended yarn fabric with an antibacterial coating agent and drying. The antibacterial coating agent includes the following components by weight fraction: tea extract, loquat leaf extract, aloe extract, Pomegranate Peel Extract

[0031] Tea Extract 10%

[0032] Loquat Leaf Extract 15%

[0033] Aloe Vera Extract 25%

[0034] Pomegranate Peel Extract 5%

[0035] The solid co...

Embodiment 2

[0047] An antibacterial fabric for cotton clothes is formed by laminating two layers of blended yarn fabrics through an antibacterial coating coated on the surface of the blended yarn fabrics.

[0048] The blended yarn fabric is made by blending cotton fiber, hemp fiber, nylon fiber and viscose fiber, wherein the weight fraction ratio of cotton fiber is 35-45%, and the weight fraction ratio of hemp fiber is 10-25%, The weight fraction ratio of hemp fiber is 35-45%, and the weight fraction ratio of viscose fiber is 10-25%.

[0049] The antibacterial coating is formed by coating the antibacterial coating agent on the blended yarn fabric and drying.

[0050] The antibacterial coating agent comprises the following components in weight fraction ratio:

[0051] Tea Extract 10%

[0052] Loquat Leaf Extract 15%

[0053] Aloe Vera Extract 25%

[0054] Pomegranate Peel Extract 5%

[0055] The solid content of described antibacterial coating agent is 30%, and viscosity is 1600.

[...

Embodiment 3

[0067] An antibacterial fabric for cotton clothes is formed by laminating two layers of blended yarn fabrics through an antibacterial coating coated on the surface of the blended yarn fabrics.

[0068] The blended yarn fabric is made of cotton fiber, hemp fiber, nylon fiber and viscose fiber blended, wherein the weight fraction ratio of superfine polyester fiber is 50%, the weight fraction ratio of cotton fiber is 15%, milk fiber The weight fraction ratio of cupro ammonia fiber is 25%, and the weight fraction ratio of cupro ammonia fiber is 10%.

[0069] The antibacterial coating is formed by coating the blended yarn fabric with an antibacterial coating agent, and the antibacterial coating agent includes the following components by weight fraction:

[0070] Tea Extract 10%

[0071] Loquat Leaf Extract 15%

[0072] Aloe Vera Extract 25%

[0073] Pomegranate Peel Extract 5%

[0074] The solid content of the antibacterial coating agent is 35.5%, and the viscosity is 1500.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com