Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Increase drape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

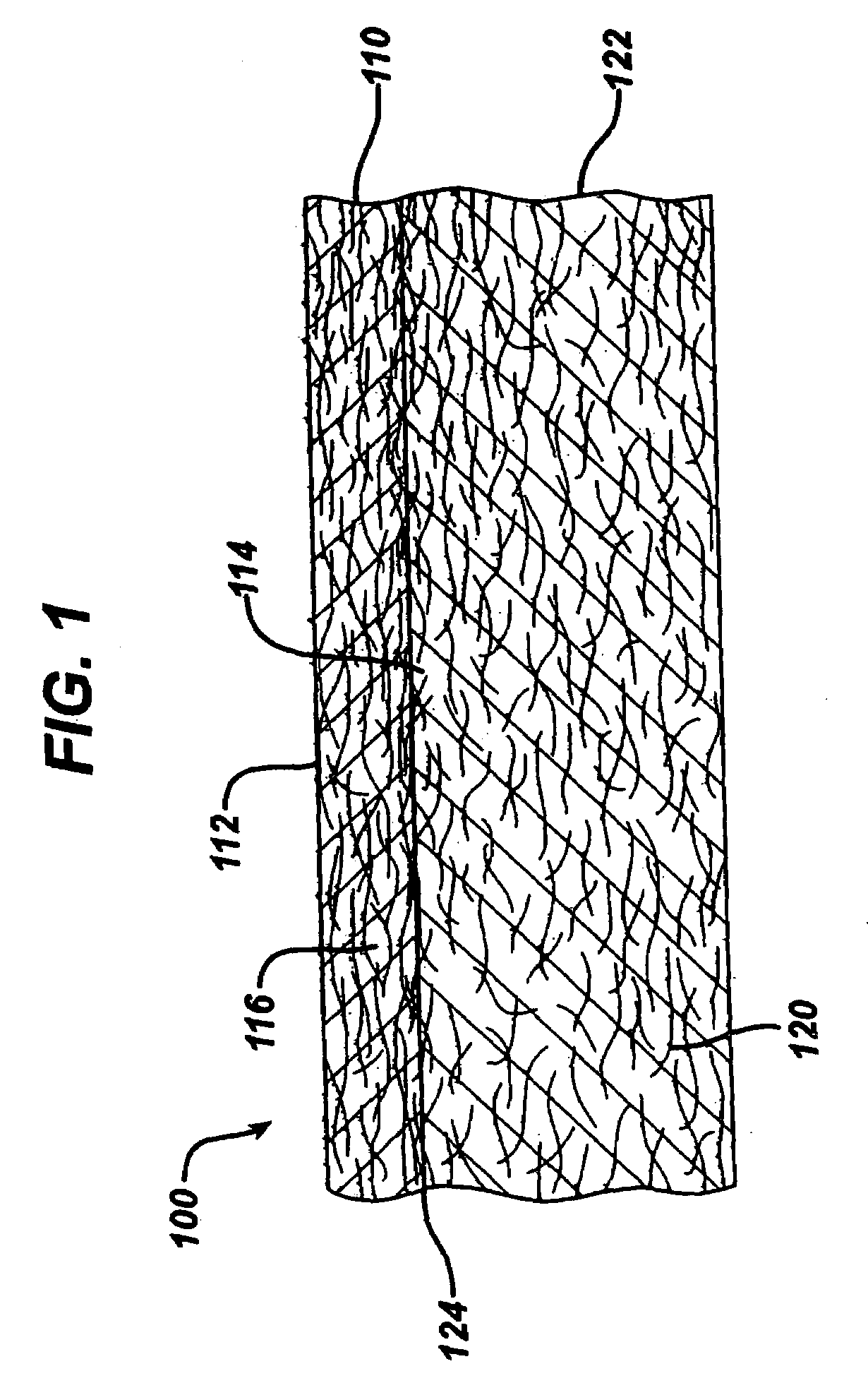

Low-density, non-woven structures and methods of making the same

InactiveUS20070123131A1Low-density propertyIncrease drapeSynthetic resin layered productsAbsorbent padsFiberPersonal care

Provided are fibrous, non-woven structures having a drapeability of greater than about 4 gsm / g and a density less than about 0.08g / cc, personal care articles comprising such structures, and methods of making such structures.

Owner:MCNEIL PPC INC

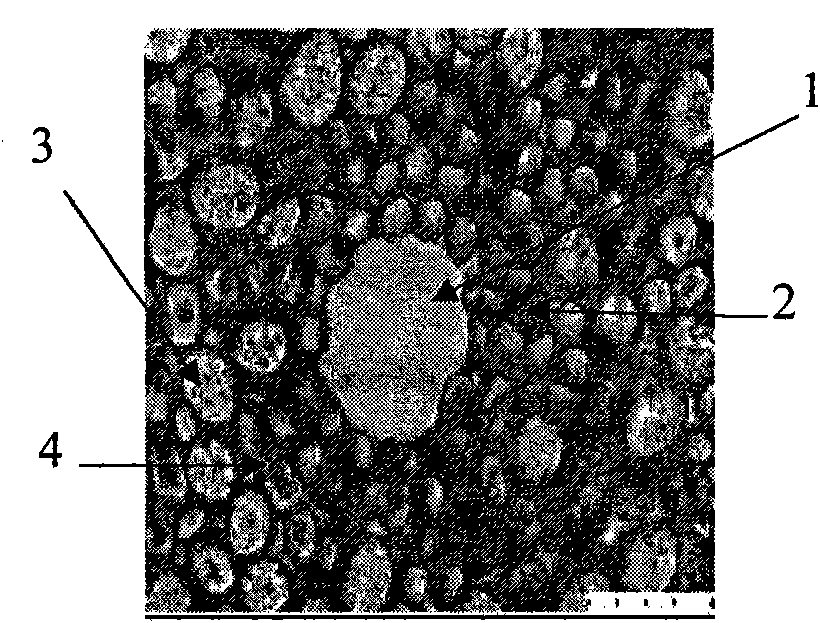

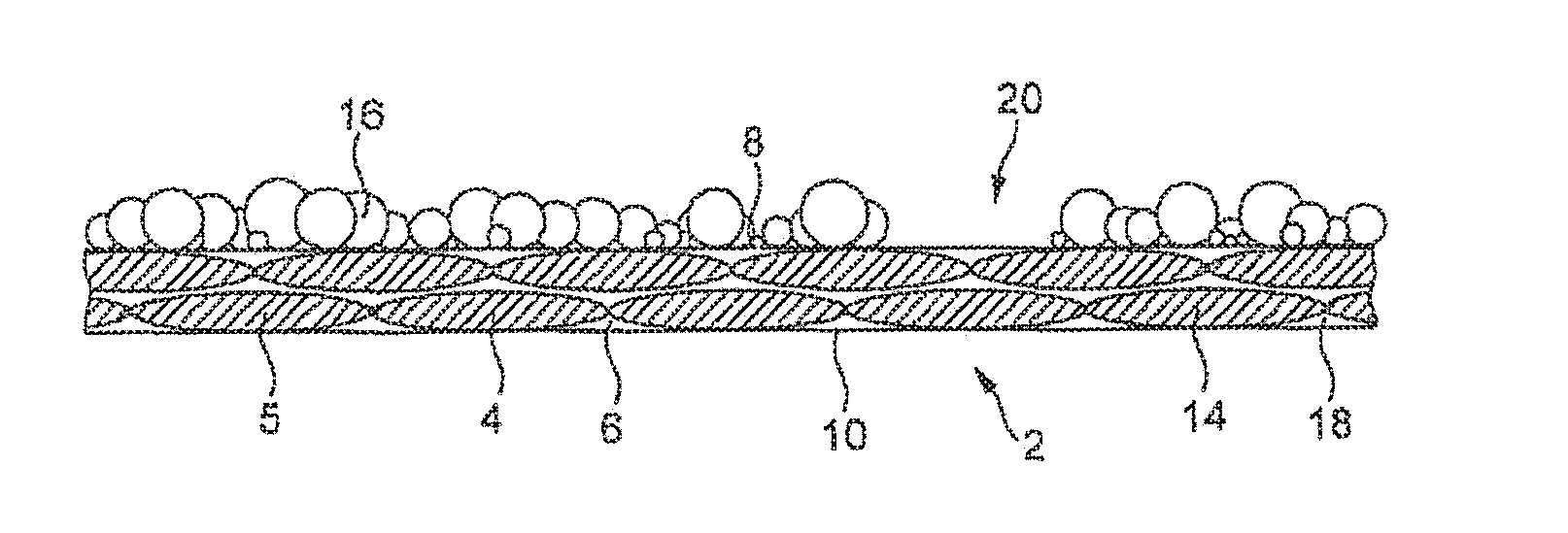

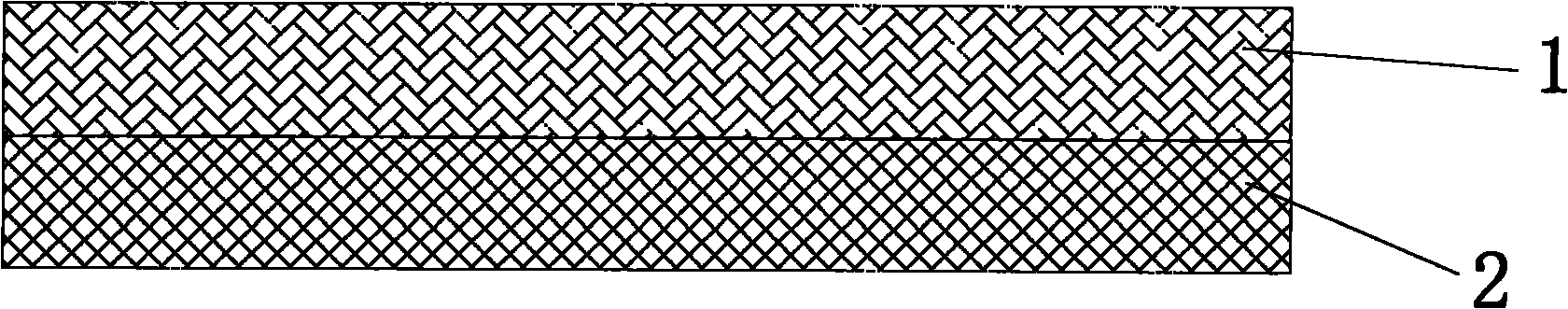

Prepreg for manufacturing composite materials

ActiveUS20140374018A1Improve particle dispersionImprove fracture toughnessLiquid surface applicatorsLamination ancillary operationsPowder coatingPre-preg

A prepreg for manufacturing a fibre-reinforced composite material, the prepreg comprising a body comprising a layer of fibrous reinforcement impregnated with a matrix resin material, and a powder coating layer of resin material on at least one major surface of the body and adhered to the matrix resin material

Owner:GURIT (UK) LTD

Low-density, non-woven structures and methods of making the same

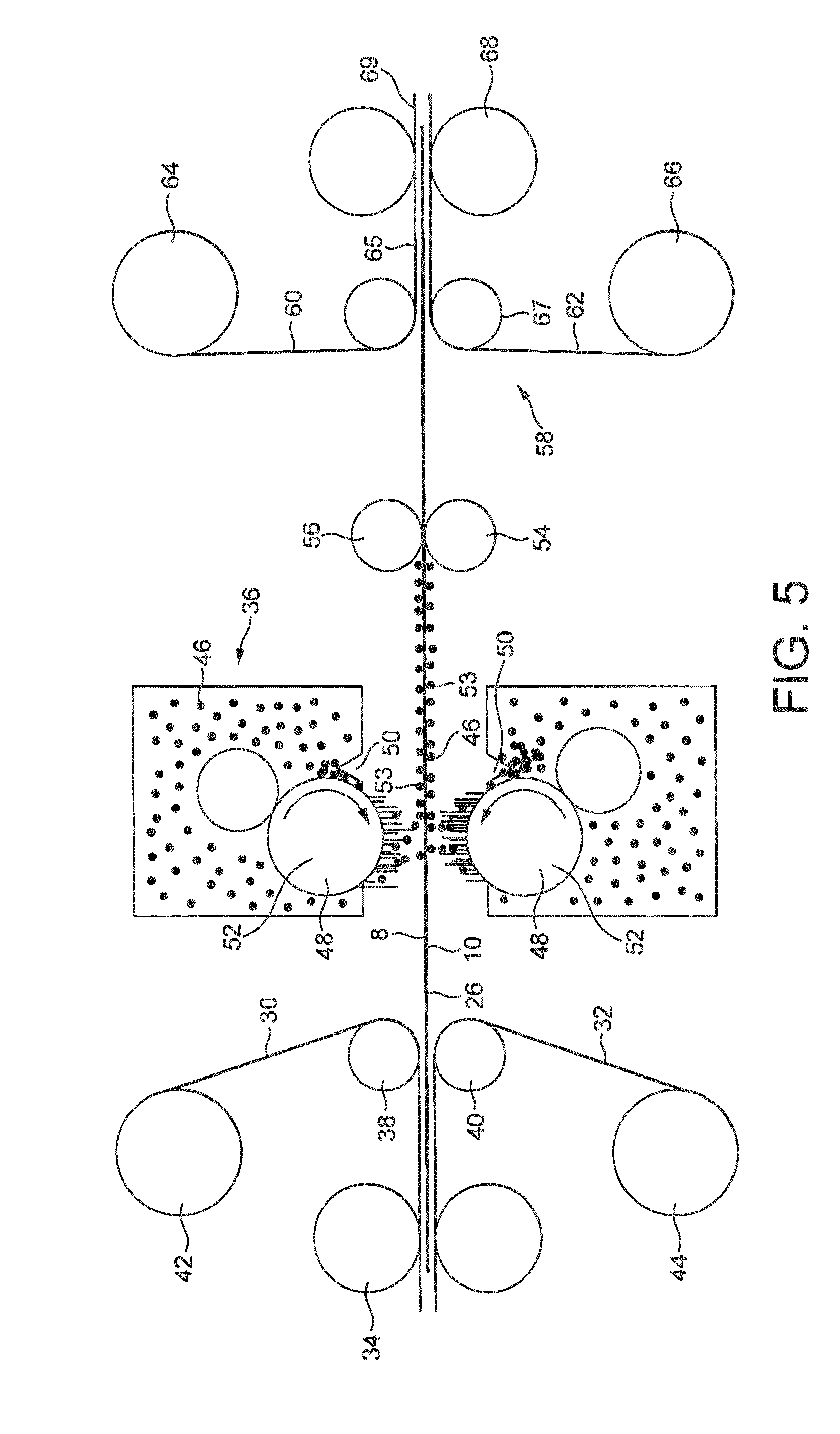

ActiveUS20070017075A1Low-density propertyIncrease drapePattern makingSynthetic resin layered productsPersonal careFiber

Provided are fibrous, non-woven structures having a drapeability of greater than about 4 gsm / g and a density less than about 0.08 g / cc, personal care articles comprising such structures, and methods of making such structures including methods comprising: stabilizing a thin layer of non-woven fibers into a stabilized web; supporting the stabilized web on an elastomeric support member; moving the support member and stabilized web thereon in a machine direction; and contacting the supported stabilized web with a stream of liquid.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

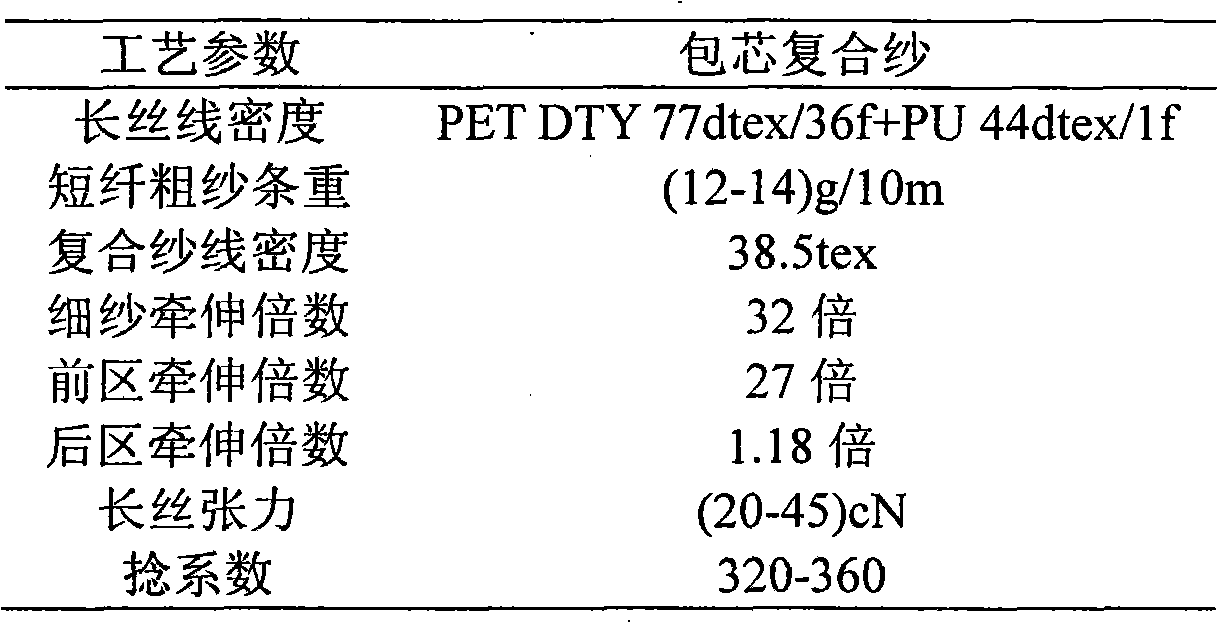

Three-component composite yarn and yarn forming method thereof

The invention provides three-component composite yarn which is formed by combined machining of 5%-30% of inner-layer core yarn and 70%-95% of outer-layer chopped fiber based on weight ratio via a ring spinning frame, wherein, the inner-layer core yarn of the composite yarn is formed by air texturing and machining of polyester filament yarn or polyamide filament yarn and polyurethane. The composite yarn of the invention has double modulus of elasticity and can improve generality of materials on garment after being made into fabrics, thus meeting the requirement for the modulus of elasticity in case of small deformation as well as the requirements for the modulus of elasticity and shape recovery ratio in case of large deformation, and improving close-fitting property, shape retention property and comfort while wearing clothes.

Owner:JIAXING UNIV

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

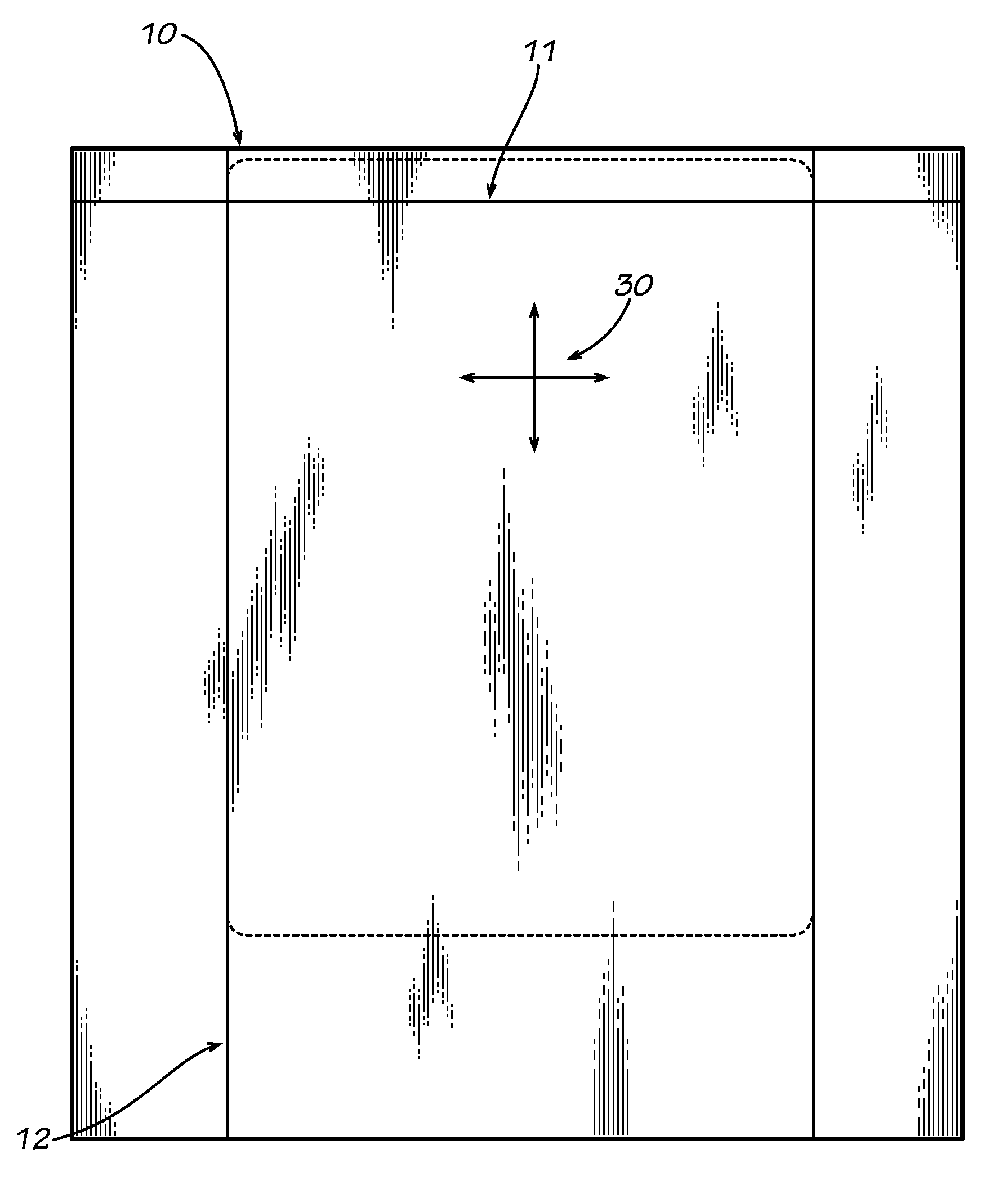

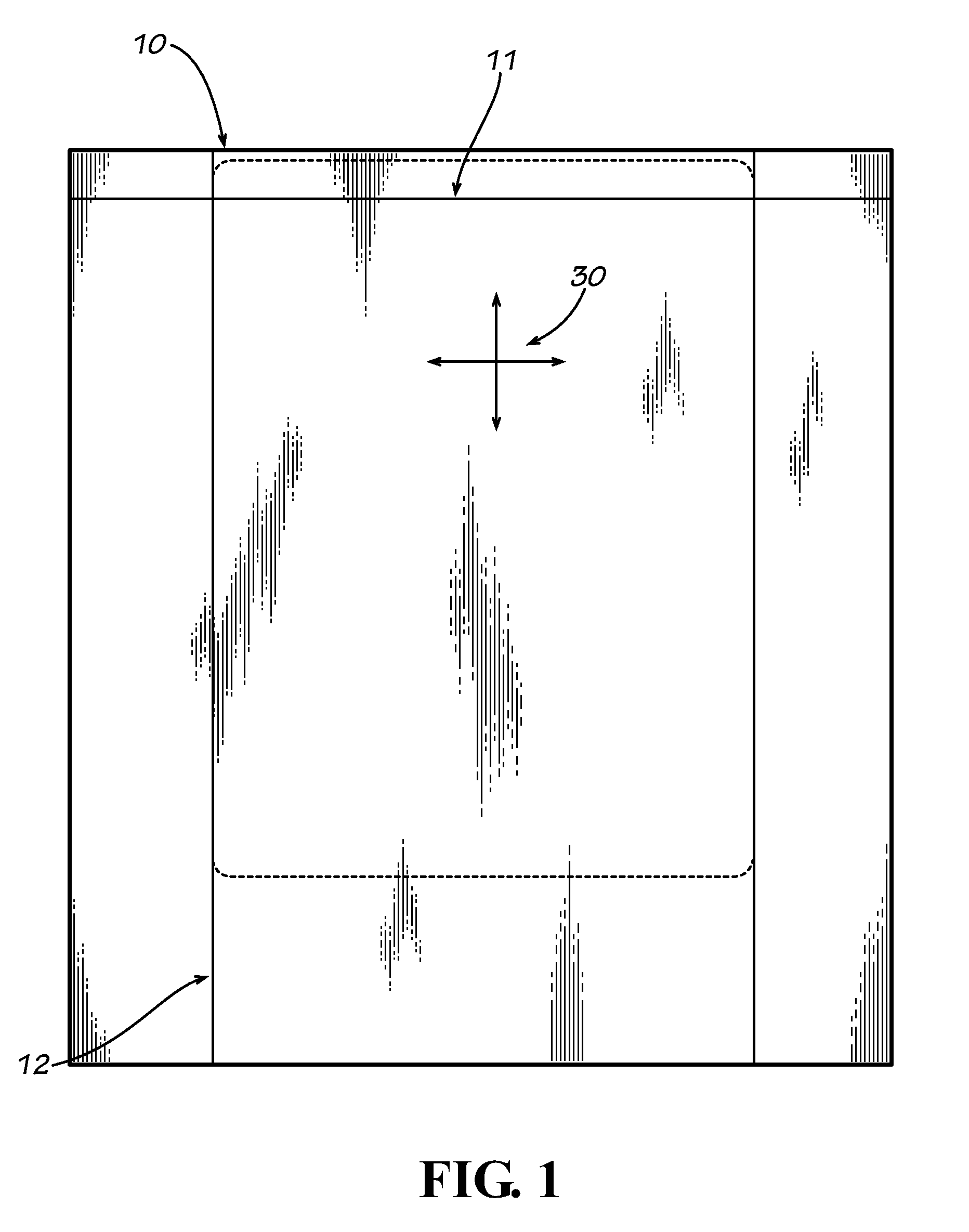

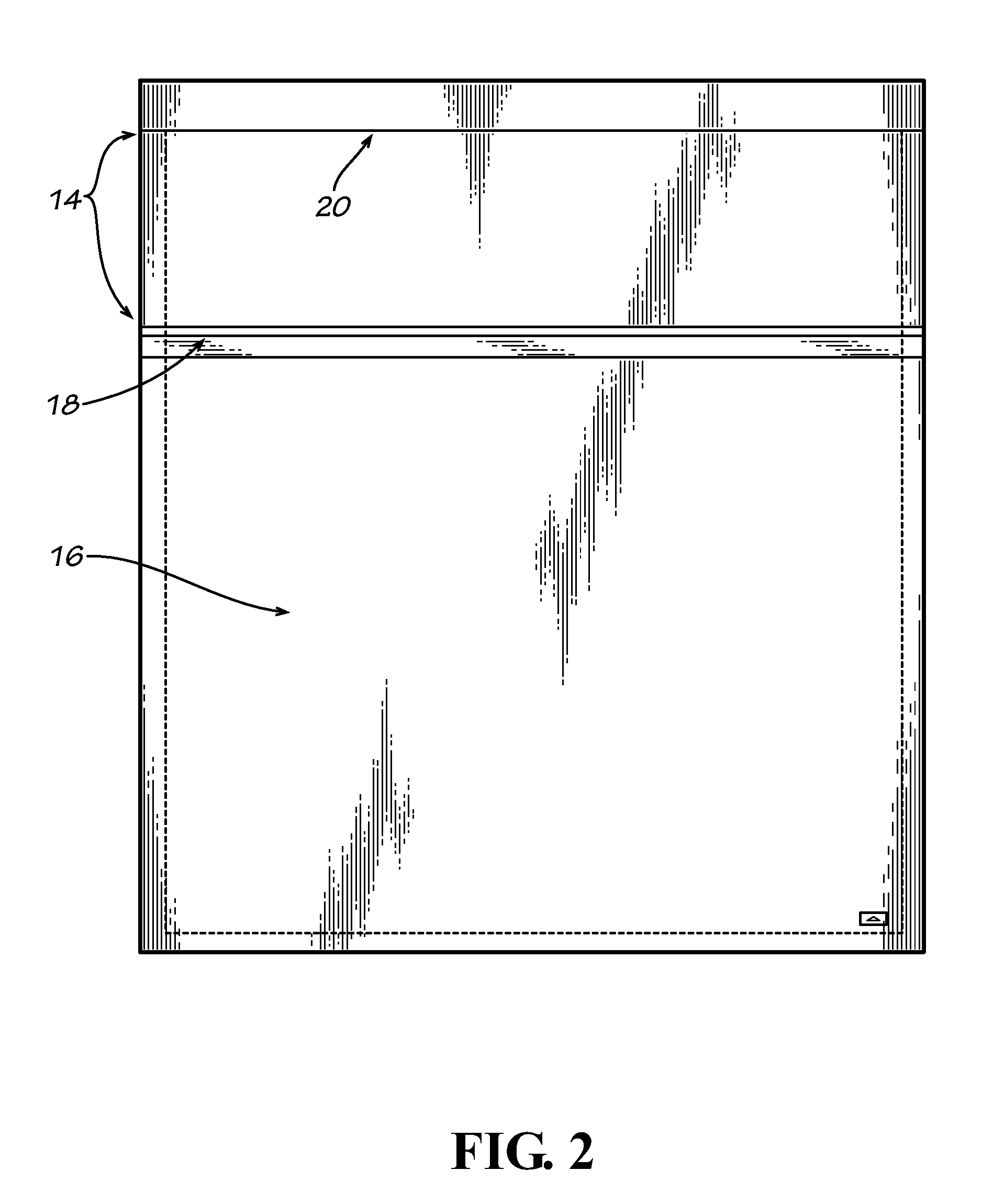

Fabric System

ActiveUS20110000020A1Improve heat transfer performanceCool to the touchLeather sewingBlanketEngineeringMoisture

Bedding material including a first fabric section manufactured from performance fabric and having a first and second side; and, a second fabric section attached to the first side of the first fabric section. Additionally, a third fabric section can be attached to the second side of the first fabric section. The first fabric section can be attached to the second fabric section through a flatlock stitch. The first fabric section can include a first zone and a second zone wherein the first zone contains different performance properties from the second zone and the first zone can have thermal or moisture wicking properties.

Owner:SHEEX

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

Organosilicon emulsion used for hand feel finishing of wool and blended yarn thereof and preparation method and application thereof

The invention provides an organosilicon emulsion used for the hand feel finishing of wool and blended yarn thereof, which comprises 40 to 60% of amino silicon oil emulsion, 30 to 50% of hydroxy silicon oil emulsion and 10% of hydrogen-containing silicone oil emulsion. A preparation method comprises the steps of preparing the amino silicone oil emulsion, the hydroxy silicon oil emulsion and the hydrogen-containing silicone oil emulsion, and then mixing according to the proportion of 40-60%, 30-50% and 10%. The application comprises putting the wool or the blended yarn thereof into the organosilicone emulsion, soaking at the temperature of 40-45 DEG C for 30-60 minutes and drying at the temperature of 85-100 DEG C after dehydration. The effect of the comprehensive hand feeling of smoothness without grease, softness, overhang feel, slip and bulkiness is achieved.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Prepreg for manufacturing composite materials

InactiveUS20160159998A1Good removal effectReduce porositySynthetic resin layered productsPretreated surfacesFiber-reinforced compositePowder coating

A prepreg for manufacturing a fibre-reinforced composite material, the prepreg including a body having a layer of fibrous reinforcement impregnated with a matrix resin material, and a powder coating layer of resin material on at least one major surface of the body and at least partly fused to the matrix resin material

Owner:GURIT (UK) LTD

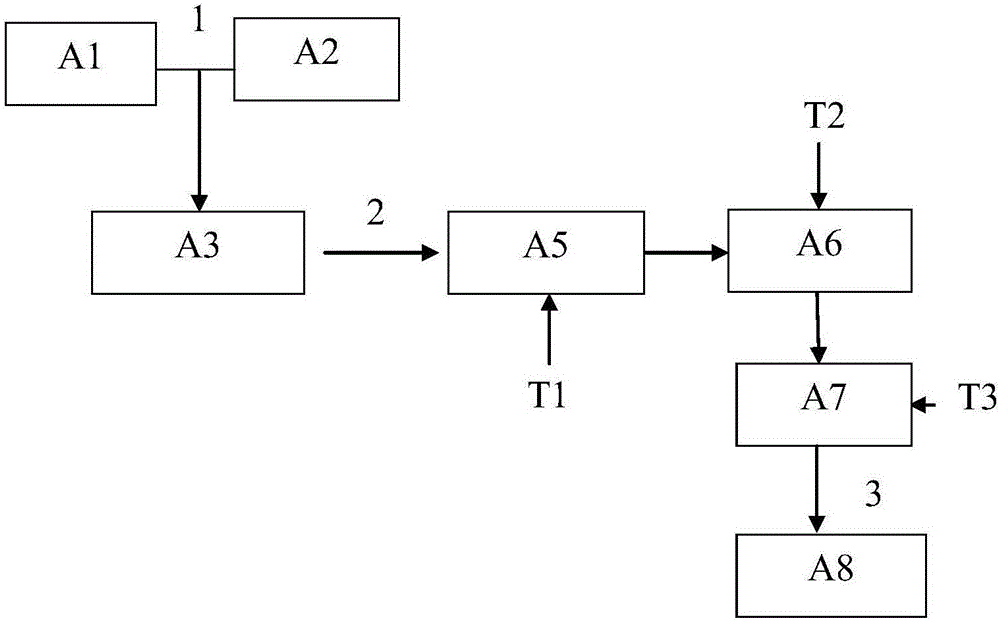

Production method of full-dull polyester fiber

InactiveCN103451768AAbsolute Addition ReductionIncrease drapeFilament/thread formingMonocomponent polyesters artificial filamentPolyesterMaterials science

The invention provides a production method of a full-dull polyester fiber. According to the production method, common semi-dull polyester chips are taken as a main producing material, and melt spinning is performed by adding full-dull master batch so as to produce the full-dull polyester fiber. A composite spinning component is used in the melt spinning process, correspondingly, the material chips are divided into two or more components, the full-dull master batch is added into one component in the feeding process, and the content of titanium dioxide particles accounts for 1wt%-5wt% of the total weight parts of the fiber.

Owner:SUZHOU LONGJIE SPECIAL FIBER

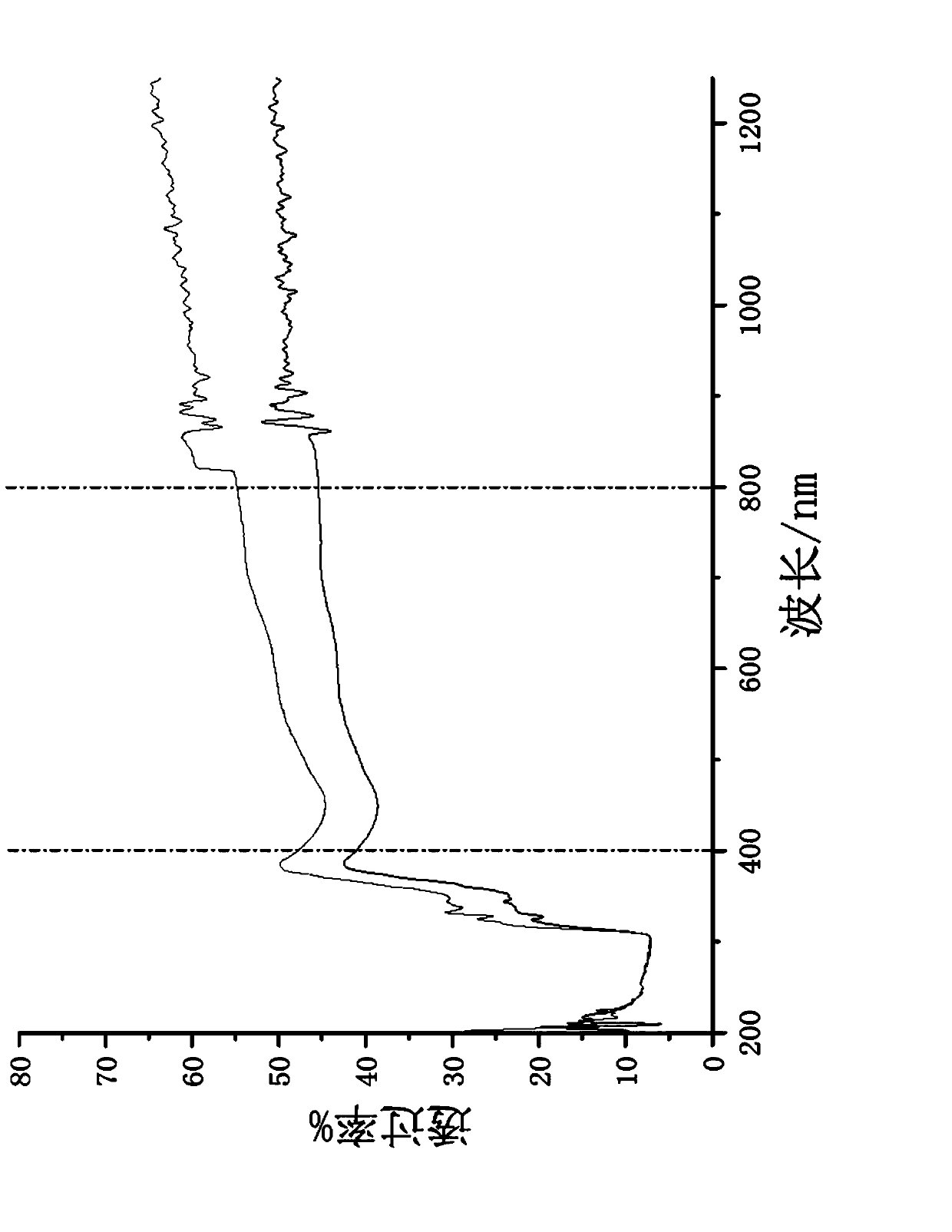

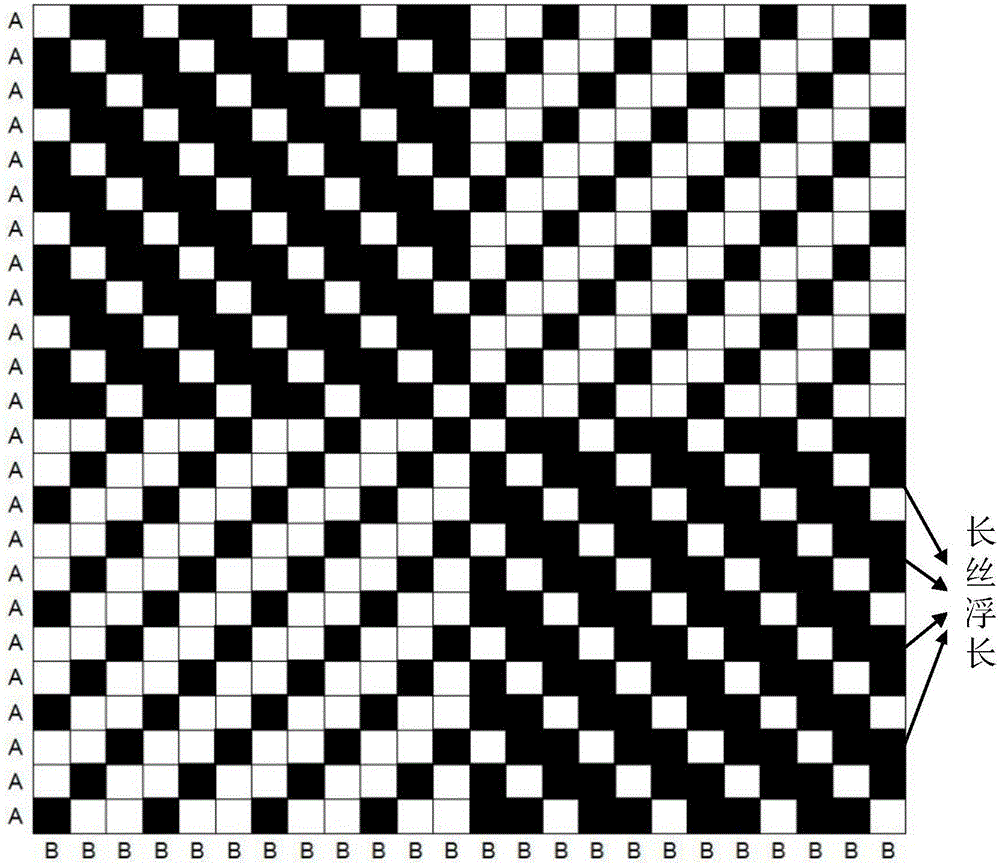

Method for processing low-ultraviolet high-transmittance window screen fabric

ActiveCN104195709ARaise the proportionImprove drapabilityInsect protectionHeating/cooling textile fabricsEnvironmentally friendlyWindow screen

The invention discloses a method for processing low-ultraviolet high-transmittance window screen fabric. Polyester filament yarn with TiO2 is mainly adopted as main raw materials in the window screen fabric, and the window screen fabric is formed by weaving twill weave and self-designed crepe weave according to different rationcombinations and dyed yarn matching through damp and hot shaping. According to the fabric, on the premise of lowering the ultraviolet transmittance, the high visible light transmittance is achieved at the same time, the front face and the back face have different visible light transmittances, and the hidden function and the peep prevention function are achieved. The window screen fabric is not dyed and coated, color and style design of the fabric is completed by adopting the natural color and dyed yarn in different ration matching modes, and the fabric is environmentally friendly. The method has novelty and originality and has better applicability and adaptability. According to the window screen fabric manufactured through the processing method, on the premise of guaranteeing the good light transmittance, the ultraviolet transmittance is lowered, and finally the functions of meeting normal indoor lighting and lowering ultraviolet transmittance are achieved.

Owner:ZHEJIANG MAYAFABRIC CO LTD

Antibacterial blended yarn and preparation method thereof

The invention discloses an antibacterial blended yarn, which is blended and woven by using wool, rabbit hairs, bamboo fibers, ultrafine polyester fibers, paper mulberry fibers and milk fibers, wherein the weight percentage of wool is 40-55 percent, the weight percentage of rabbit hairs is 3-8 percent, the weight percentage of ultrafine polyester fibers is 15-25 percent, the weight percentage of bamboo fibers is 5-10 percent, the weight percentage of paper mulberry fibers is 5-10 percent and the weight percentage of milk fibers is 10-25 percent. The antibacterial blended yarn reaches good moisture absorbing and guide, mold resistance, worm-eating resistance and antibacterial and bacteriostatic performance through proportioning of various fibers and a corresponding preparation method.

Owner:浙江龙一毛纺科技有限公司

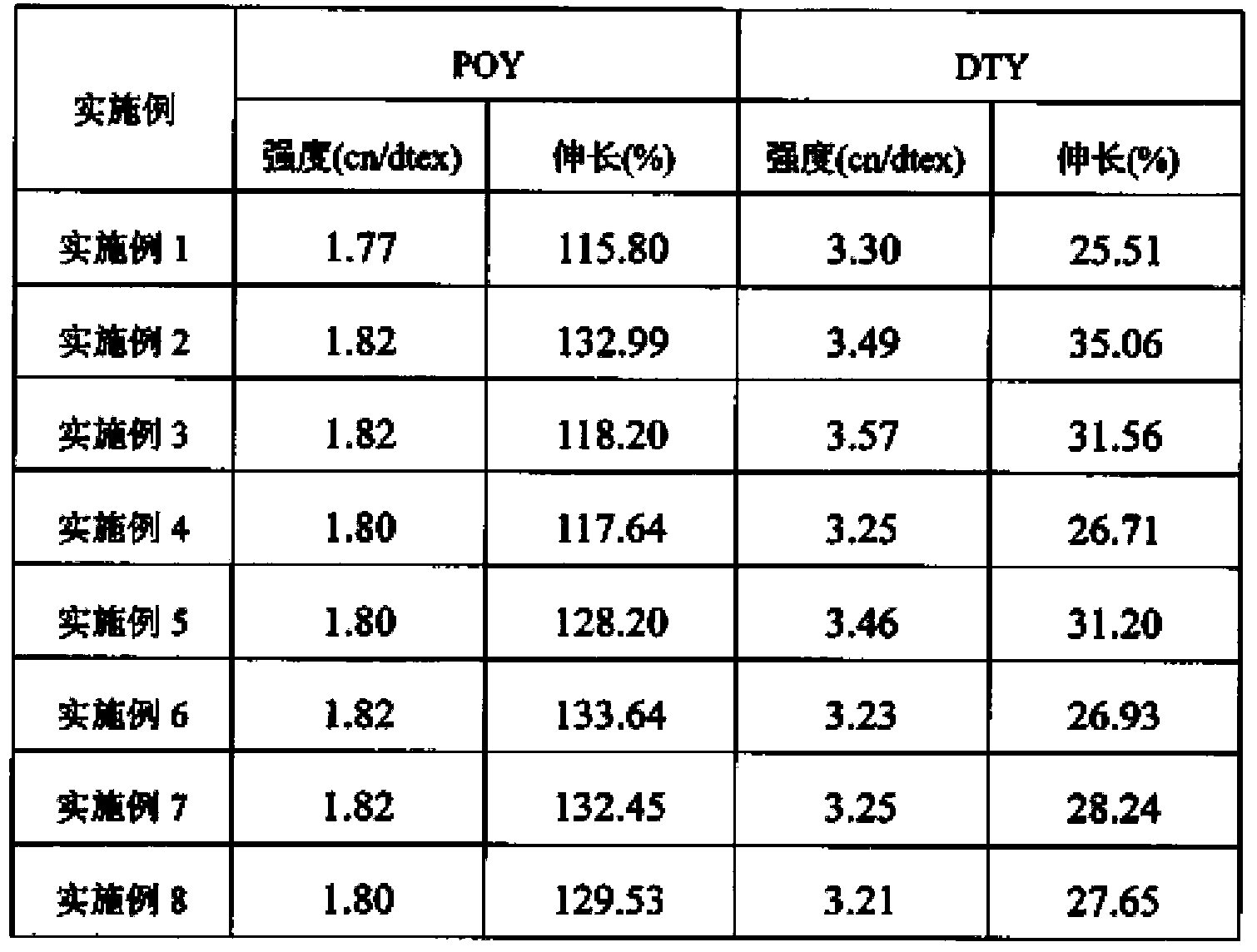

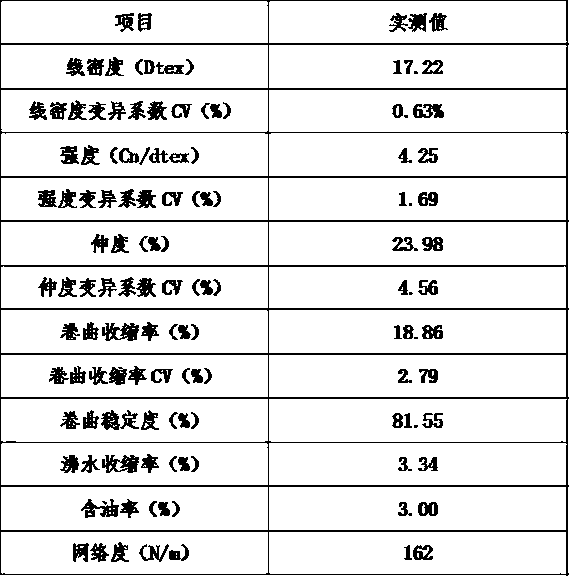

Method for preparing ultra-fine denier skin-affinity polyester filaments

The invention discloses a method for preparing ultra-fine denier skin-affinity polyester filaments. The method comprises the steps of POY precursors, pre-interlace, first feeding roller, first deformation heat box, cooling plate, false twister, second feeding roller, intermediate interlace, second heat box, third feeding roller, oiling roller, DTY winding shaping and spinning cake inspection, wherein the intermediate interlace procedure can be removed, the temperature of the first deformation heat box is 165 DEG C-175 DEG C, the temperature of the second heat box is 130 DEG C-140 DEG C, the draft ratio is 1.58-1.68, the false twist ratio is 1.66-1.80, and the interlace air pressure is 0.03-0.15 MPA. The method has the advantages of being simple and easy to operate, fabric prepared by polyester filaments prepared by means of the method has the advantages of being more flexible, good in comfort performance and strong in visual and tactile feeling.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Comfortable anti-flaming fabric and manufacturing method thereof

InactiveCN106592064AFlame retardant permanentComfortable foreverHeat resistant fibresHeating/cooling textile fabricsEngineeringFire resistance

The invention discloses a comfortable anti-flaming fabric. The comfortable anti-flaming fabric is characterized by being formed by vertically interweaving first yarns and second yarns, wherein the first yarns are made from staple fibers with anti-flaming property; the second yarns are made from anti-flaming filament yarns; after the fabric is padded, a firm fibroin sericin film is formed on the surface. The comfortable anti-flaming fabric has the advantage that the fire resistance and the comfort property are effectively combined so that the fabric has permanent flame retardance, wet-absorbing and breathable properties, skin-friendly and smooth properties, anti-pilling property, shrink-proof and anti-wrinkle properties, and the like.

Owner:北京邦维普泰防护纺织有限公司

Fabric System

Bedding material including a first fabric section manufactured from performance fabric and having a first and second side; and, a second fabric section attached to the first side of the first fabric section. Additionally, a third fabric section can be attached to the second side of the first fabric section. The first fabric section can be attached to the second fabric section through a flatlock stitch. The first fabric section can include a first zone and a second zone wherein the first zone contains different performance properties from the second zone and the first zone can have thermal or moisture wicking properties.

Owner:SHEEX

Manufacturing method of anti-microbial satin fabric

ActiveCN105862225AGood hygroscopicityStrong moisture wickingSucessive textile treatmentsLiquid/gas/vapor removalPolyesterFiber

The invention discloses a preparation method of an anti-microbial satin fabric. The fabric is manufactured from superfine polyester fiber, thereby having better hygroscopicity, moisture absorption and sweat releasing performance, gas permeability and drapability compared with a conventional imitation silk fabric. Appropriate twisting is adopted, the polyester fiber produces the diffuse reflection phenomenon for light, the gloss is approximate to gloss of real silk, and drapability of the fabric is increased; cattail fiber is added for blending, and the anti-microbial performance of the fabric is increased; the cattail fiber is pretreated, so that it is ensured that anti-microbial effective ingredients are not damaged to the greatest degree.

Owner:江西求学纺织科技有限公司

Double-face isomeric novel curtain textile and production process

InactiveCN101724973AIncrease the proportionStrong reflexesWarp knittingCurtainsOptical propertyUser privacy

The invention discloses a functional home textile product and a spinning process thereof, in particular a double-face isomeric single-layer curtain textile capable of transmitting light, resisting ultraviolet rays and preventing snooping. A special organization structure and parameters are designed by utilizing the good optical properties of profiled cross sections and extinction polyester filament yarns, and different raw materials are covered on the front face and the back face of the textile respectively in the forms of coils and drawn tows so as to ensure that the front face and the back face of the curtain obtain optical property differences; and then different structural characteristics are combined so as to finally have the effects of achieve the functions of indoor normal lighting, ultraviolet rays resistance and user privacy protection.

Owner:陈慰来 +1

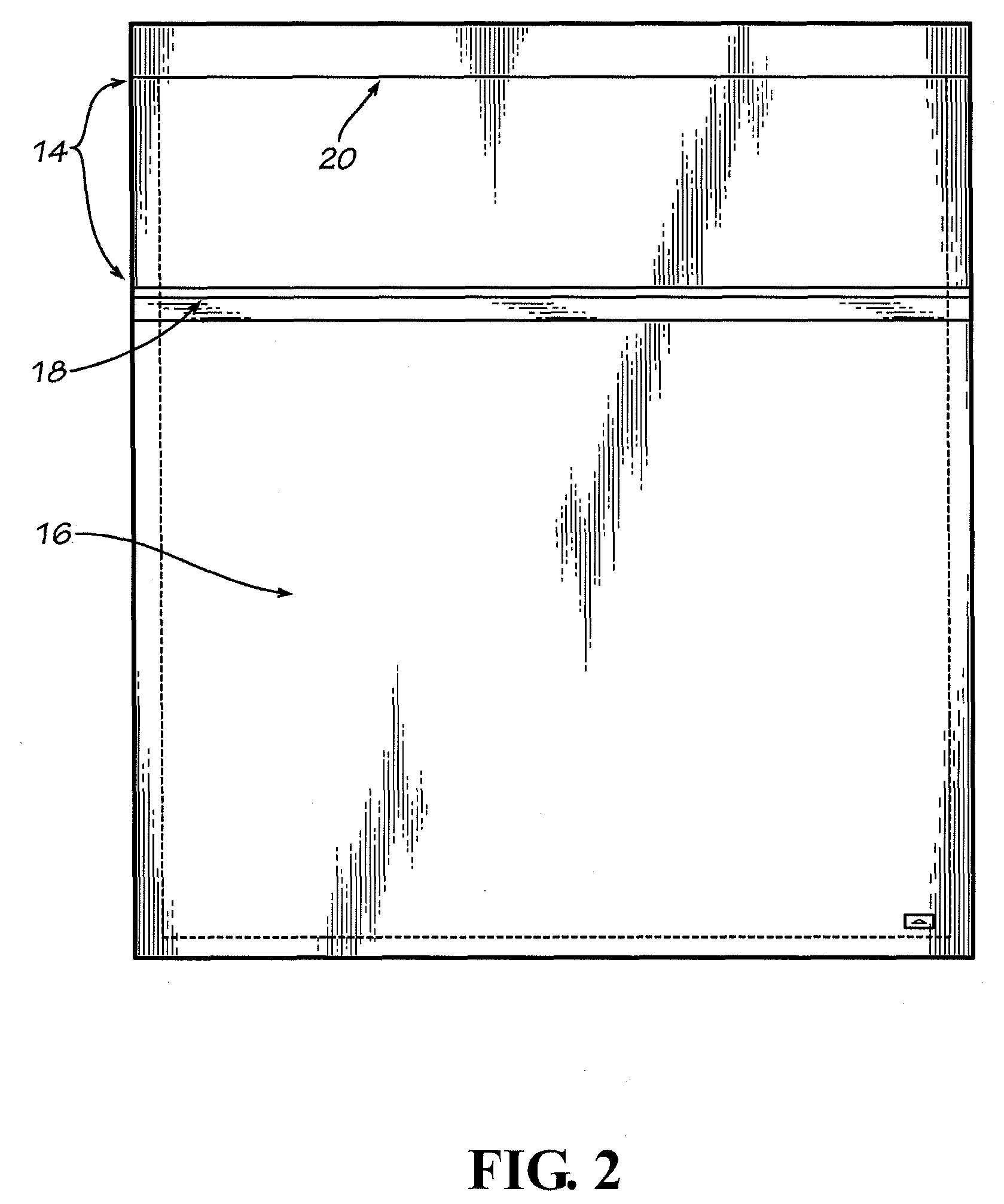

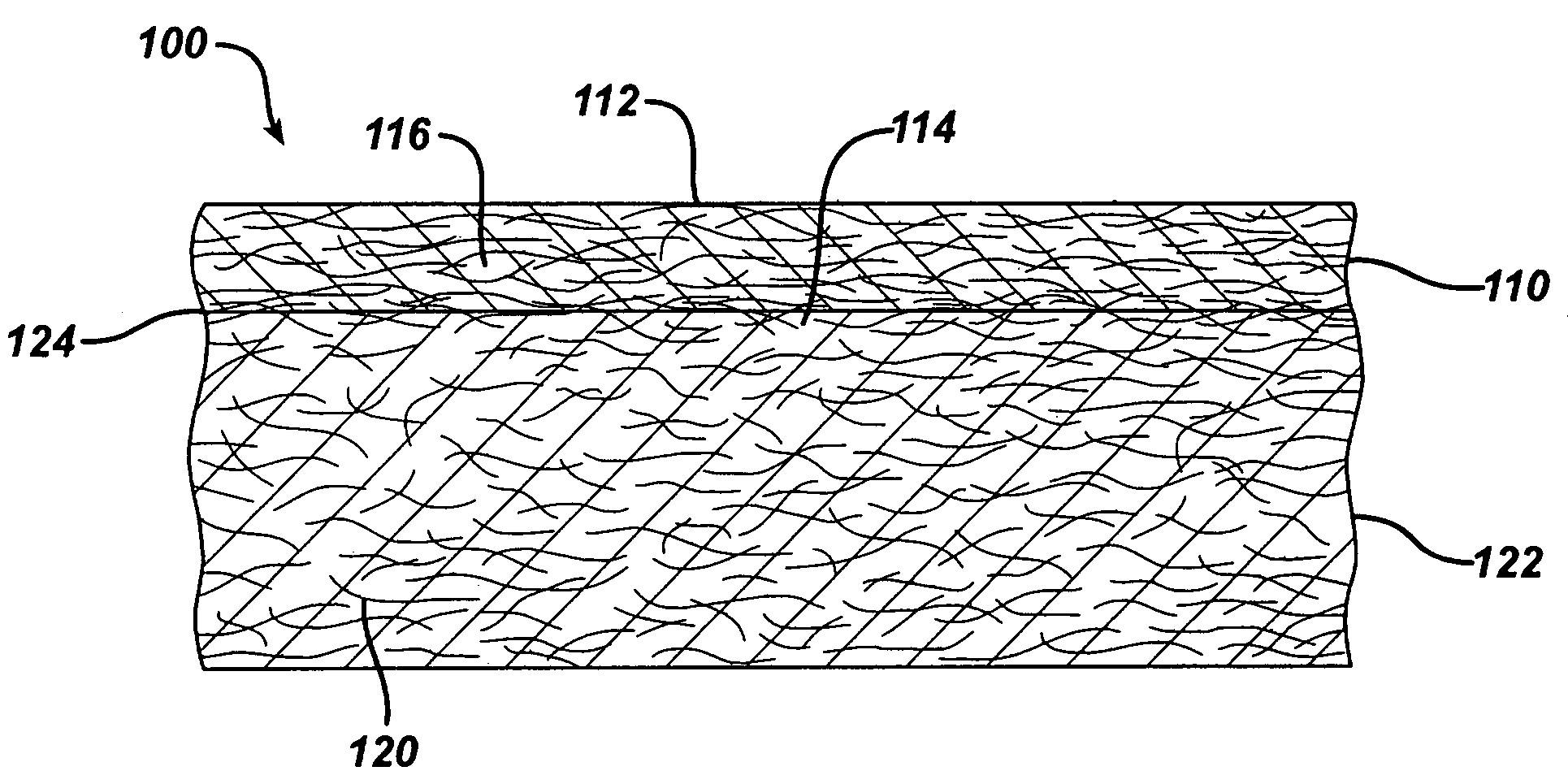

Non-woven structures and methods of making the same

InactiveUS20080000057A1High laminate strengthHigh drapeabilityPattern makingNeedling machinesFibrous layerMaterials science

Provided are layered non-woven structures comprising a fibrous, water-permeable anchoring layer and a fibrous layer having fibers entangled about the anchoring layer, including patterned and non-patterned structures. Also provided are personal care products comprising the present structures and methods of making the structures.

Owner:MCNEIL PPC INC

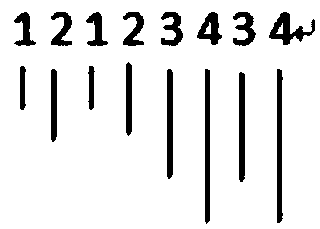

Polyester spandex super-quick-drying knitted fabric and processing method thereof

ActiveCN109056171AAchieve the effect of moisture absorption and quick dryingSoftSolvent-treatmentWeft knittingFiberPolyester

The invention discloses a polyester spandex super-quick-drying knitted fabric and a processing method thereof. The fabric is woven through a special weaving method with complete-extinction super-fine-denier polyester fibers with the filament number of 1.1-1.7 D and spandex fibers as the raw materials, and the close-fitting surface of the fabric is provided with dotted jacquard protrusions capableof guiding moisture in one direction. The processing method includes the steps of conducting weaving through a four-track single-side knitting machine, wherein four needles 1, 2, 3 and 4 are adopted;forming one loop through fourteen paths; conducting post-processing through polyester keratase. By means of the special weaving structure, the close-fitting surface has a small protrusion jacquard effect, the contact area of the close-fitting surface and a human body is reduced, and the movable friction coefficient is reduced; the dotted protrusion jacquard part making contact with skin has a one-way moisture guide function, and the water expanding capacity is improved. The complete-extinction super-fine-denier polyester fibers are selected as the raw material, the surface area of the fibers is increased, subsequent fibers have a certain anti-UV effect, and the knitted fabric has the advantages of being soft in color and luster, good in deep dyeing performance, high in textile drapability,strong in shielding performance and the like.

Owner:SHANGHAI JIALE

Blended yarn

The present invention is one kind of blended yarn of bamboo fiber and chemical fiber, and solves the problem of insufficiency of natural textile material. Fabric of the blended yarn has the features of bacteriostasis, fast moisture absorption, coolness and soft hand feeling, and the ultimate fabric has stiffness and draping and can meet the requirement as costume material.

Owner:上海日舒棉纺织厂

Production method for microfiber leather

InactiveCN106192441AGood flexibilityStrong sense of leatherFilament/thread formingLiquid/gas/vapor textile treatmentWater vapor permeabilityNonwoven fabric

The invention relates to a production method for microfiber leather. The production method comprises the following steps that firstly, composite fibers are spun; secondly, non-woven fabric is made; thirdly, the non-woven fabric is shaped; fourthly, a polyurethane resin working solution with high solid content and high viscosity is prepared; fifthly, a polyurethane resin working solution is smeared; sixthly, a polyurethane resin working solution with low solid content and low viscosity is prepared; seventhly, soaking and continuous rolling are carried out with the polyurethane resin working solution; eighthly, polyurethane is solidified; ninthly, methylbenzene decrement treatment is carried out. Compared with the prior art, the microfiber leather has the advantages of being good in hand touch and drape effect and high in air and water vapor permeability.

Owner:SHANDONG FRIENDSHIP MACHINERY

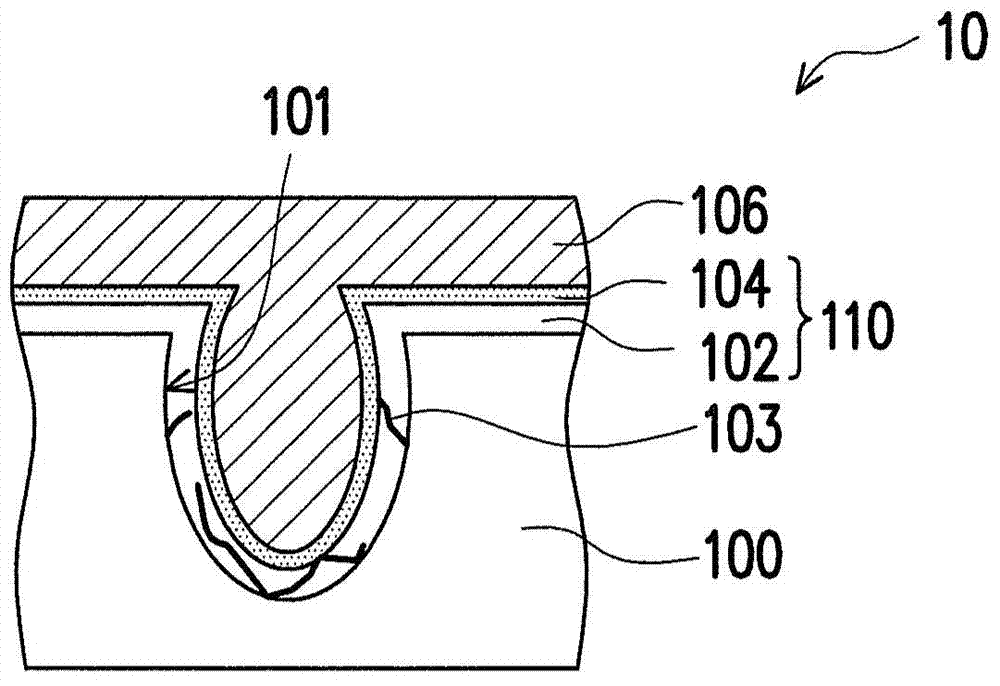

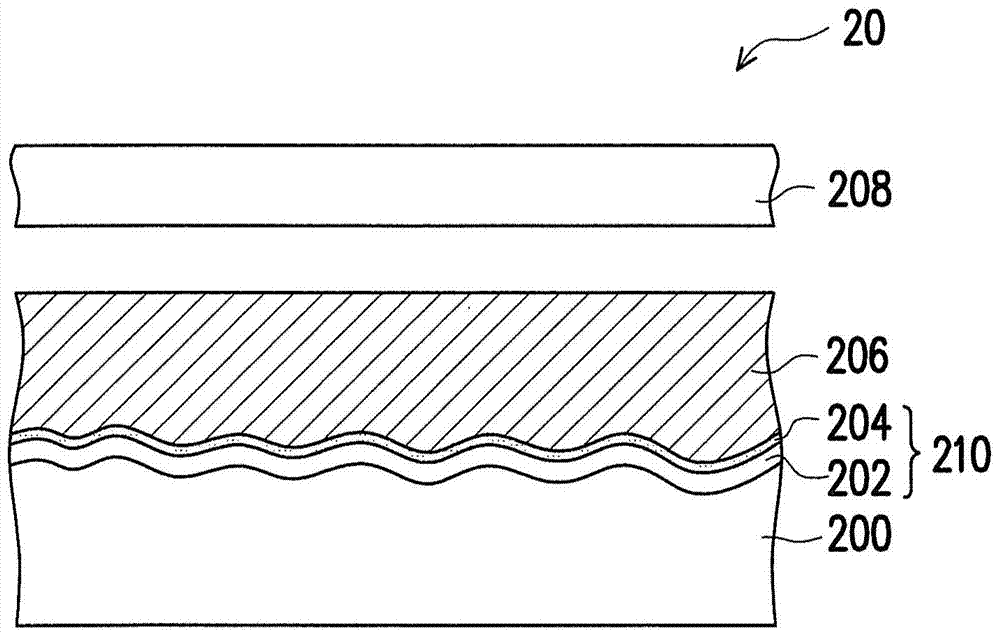

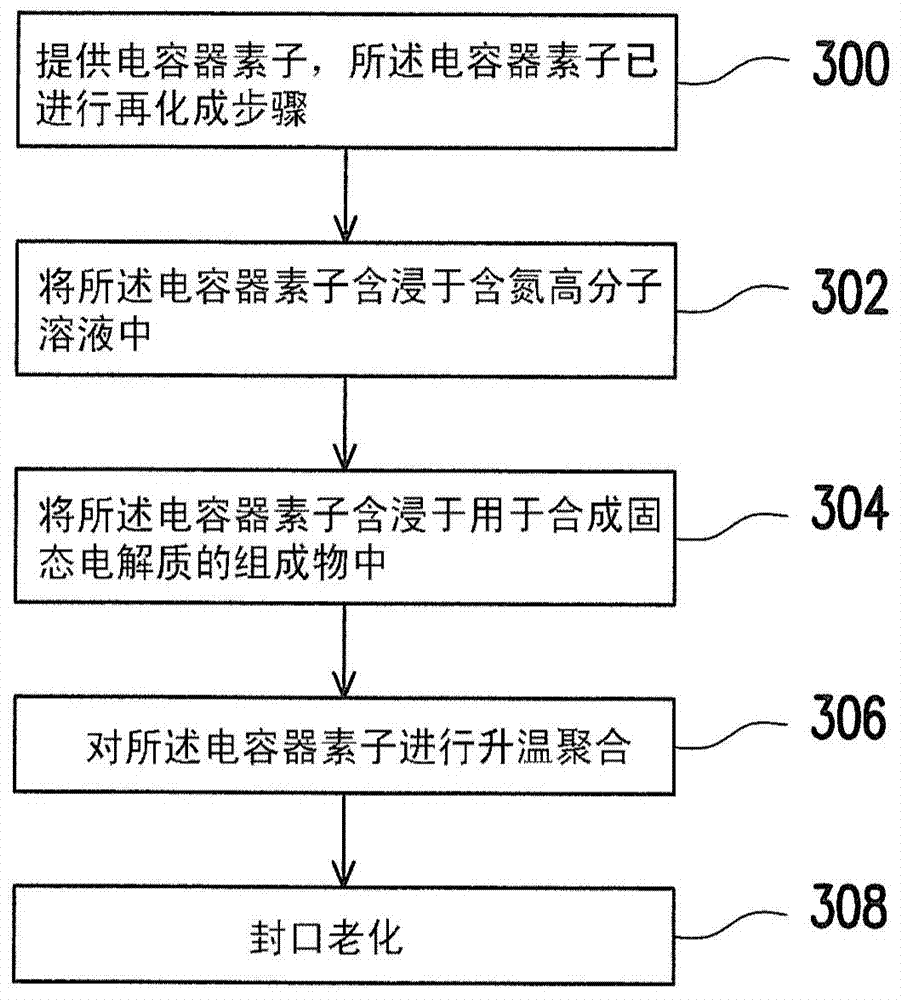

Composite electrode and electrolytic capacitor

ActiveCN104752061AImprove insulation performanceIncrease drapeFixed capacitor electrodesSolid electrolytic capacitorsElectrolysisComposite electrode

Provided is a composite electrode including a metal layer and a composite dielectric layer. The composite dielectric layer includes a metal oxide dielectric layer and a polymer dielectric layer. The composite dielectric layer overlays the metal layer. The polymer dielectric layer includes a nitrogen-containing polymer and overlays the metal oxide dielectric layer. An electrolytic capacitor is also provided. The electrolytic capacitor has a polymer dielectric layer made of a nitrogen-containing polymer, and such polymer dielectric layer is beneficial to increase the insulating property of the metal oxide dielectric layer and the coverage property of the conductive polymer. Thereby, the conventional leakage current can be significantly reduced and the yield can be improved.

Owner:IND TECH RES INST

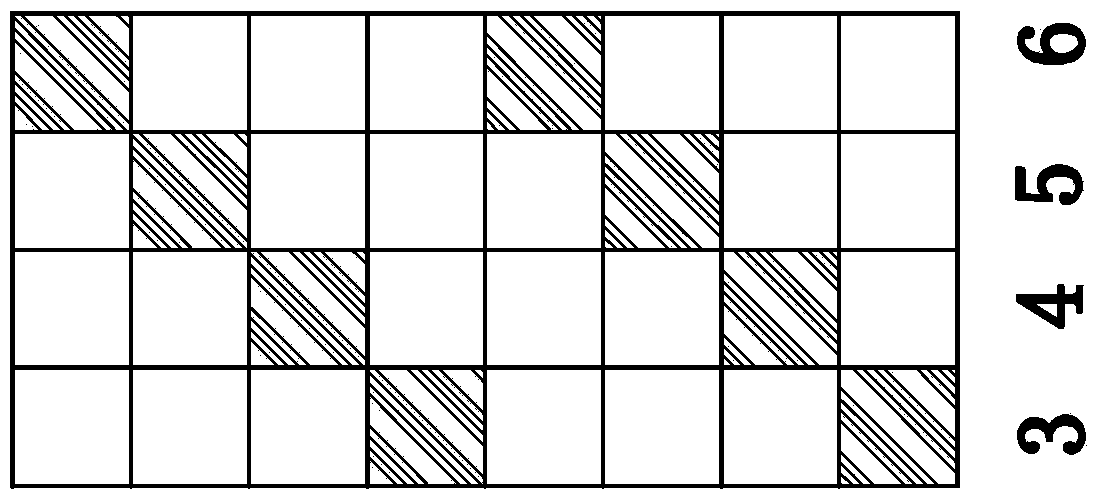

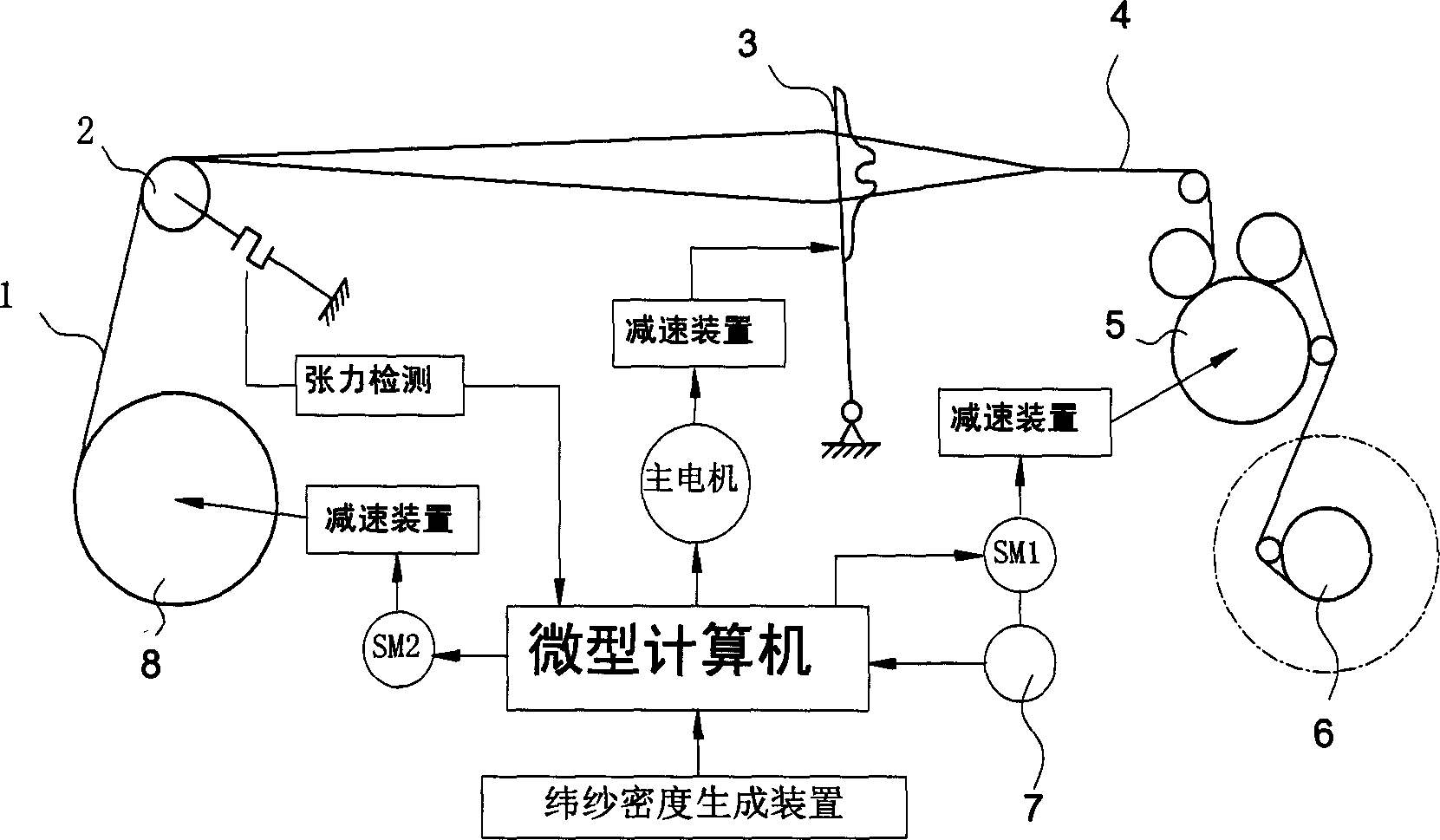

Spacing weft fabric and its weaving method

InactiveCN1776052AImprove applicabilityIncrease added valueWoven fabricsEngineeringMechanical engineering

This invention discloses weft density changeable fabric whose weft yarn distribution density along grain straight direction is changed according to preset rule which uses a garment piece length as unit. During weaving, the loom with electronic rolling-up device utilizes weft yarn density generator to convert the preset weft density into current angle motion of roller for controlling electronic rolling-up device to obtain the preset weft yarn density change. According to said invention, some dress having special demand can be made.

Owner:SUZHOU UNIV

Method for conducting flame-retardant finishing on polyester fabric by means of grafted primary amine type phosphorus-containing flame retardant

ActiveCN106592219AImprove flame retardant performanceAvoid feeling downBiochemical fibre treatmentHeat resistant fibresPolyesterFiber

The invention discloses a method for conducting flame-retardant finishing on a polyester fabric by means of a grafted primary amine type phosphorus-containing flame retardant, belongs to the technical field of textile dyeing and finishing, and aims at overcoming the defect that in traditional polyester fabric flame-retardant finishing, the washability is low, or in high-temperature baking, the handfeel and the whiteness of the fabric are prone to be reduced. According to the method, the polyester fabric is pretreated with ester bond hydrolase, and then hydroxyl groups are generated on the surface of the polyester fabric; the hydroxyl groups are made to be converted into aldehyde groups by combining tetramethylpiperidine nitric oxide (TEMPO) and laccase oxidization, flame-retardant finishing processing is conducted on the aldehyde groups and the amino group-containing primary amine type phosphorus-containing flame retardant on this basis, and then flame-retardant finishing of the polyester is achieved. The method comprises the technological processes of polyester pretreating, polyester oxidization pretreating, primary amine type phosphorus-containing flame retardant grafting, washing and treating after drying. The polyester fabric treated through the method has the advantages that the flame retardance can be improved, and the drapability is improved. Compared with a traditional high-temperature baking technology, the flame-retardant finishing method is good in effect and low in energy consumption.

Owner:江苏大同宝富纺织科技有限公司

Non-woven structures and methods of making the same

InactiveUS20080003908A1High laminate strengthLow density propertyAbsorbent padsWoven fabricsPersonal careMaterials science

Provided are layered non-woven structures comprising a fibrous, water-permeable anchoring layer and a fibrous layer having fibers entangled about the anchoring layer, including patterned and non-patterned structures. Also provided are personal care

Owner:MCNEIL PPC INC

Preparation method of super-soft and super-fine polyester filament yarn

The invention discloses a preparation method of a super-soft and super-fine polyester filament yarn. The preparation method comprises the following steps: preparation of POY protofilaments, pre-interlacing, processing with a first thread feeding roller, processing with a first deformation heat box, processing with a cooling plate, processing with a false twister, processing with a second thread feeding roller, medium interlacing, processing with a second heat box, processing with a third thread feeding roller, processing with a finish application roller, winding formation of DTYs and inspection of a spinning cake. In the preparation method, the process of pre-interlacing is added between the preparation of the POY protofilaments and the step of processing with the first thread feeding roller, so that the cohesive property and the draping property of fibers can be effectively improved, the processed polyester filament yarn is upright in strands and good in bundling and is favorable fornaps of subsequently woven fabric to be upright, and the super-soft and super-fine style is met; the temperature of the second heat box is controlled to 160-180 DEG C, so that the strands are set by high temperature more fully, are not dispersed easily and do not have the phenomena of hair adhesion and nap collapse, and the style of flannel fabric is met; cotton fabric is substituted easily, so that the super-soft and super-fine polyester filament yarn has wide market prospect and remarkable economic benefit.

Owner:JIANGSU DELI CHEM FIBER CO LTD

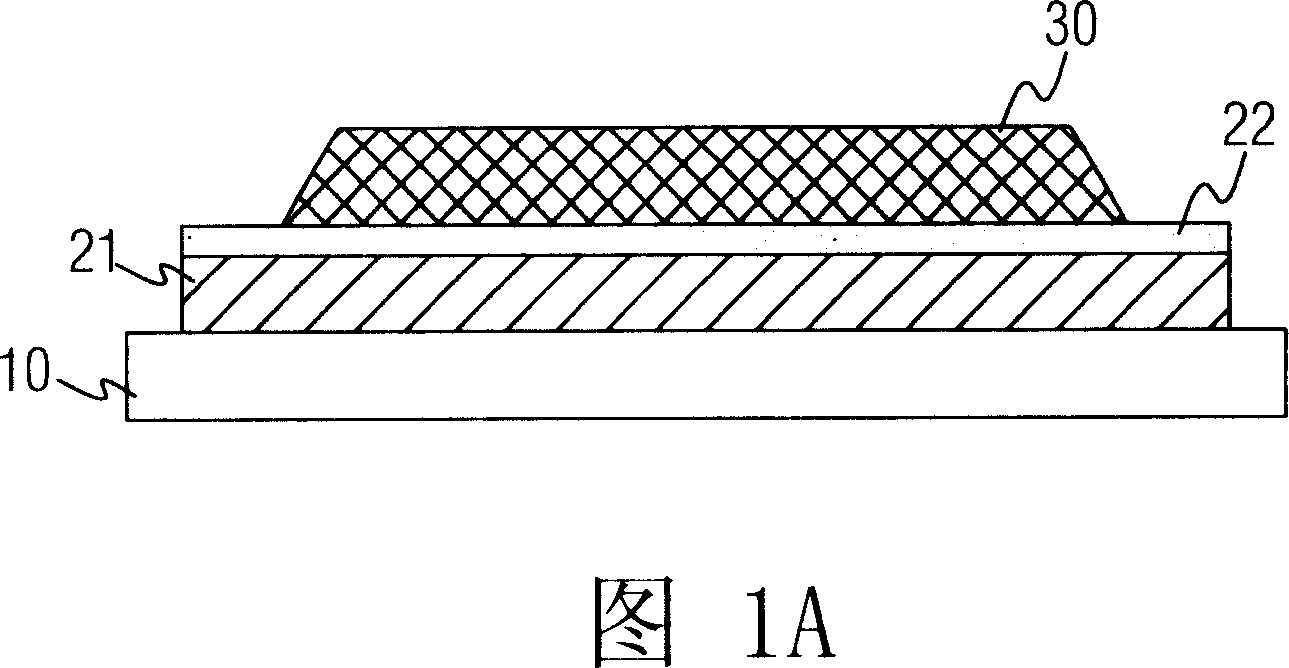

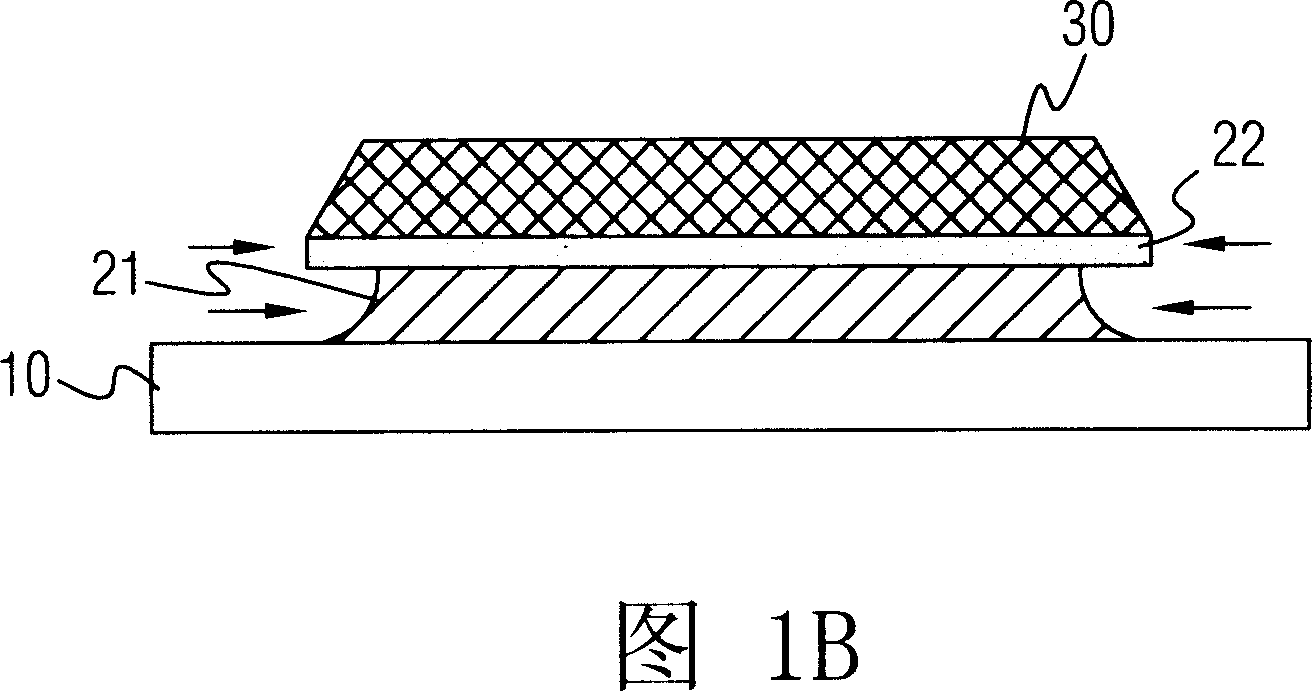

Film etching method

InactiveCN1992150AImprove and eliminate chamfering problemsAvoid failureSemiconductor/solid-state device manufacturingElectrical conductorEtching

This invention is a thin film etching method, being applied to a semiconductor or thin film transistor array (TFT Array) film process, to improve the undercut problem of existing etching, or make the etched film's shape more perfect. The film etching method divides the existing etching process into two stages, and between the two stages, inserting into a photoresist etching process, and through appropriate photoresist etching, it increases the contact area of the film and the etching materials, so that it can eliminate the existing etching problem that the undercut or file shape is not perfect.

Owner:CHUNGHWA PICTURE TUBES LTD

Fox pile knitted underwear

The present invention belongs to the field of textile technology, and is especially knitted fox fleece underwear. The knitted fox fleece underwear contains fox fleece in 1-100 wt%, preferably in 40-75 wt%, as well as polyurethane fiber, Jinlun, soybean protein fiber, Tencel, modal fiber or viscose fiber, shinkproof mercerized wool and / or long staple cotton. The knitted fox fleece underwear has the advantages of underwear of cashmere, underwear of rabbit fleece and underwear of camel hair, and is superior to the later mentioned underwears. In addition, the fox fleece is the side product of fox fur processing, so that the present invention is the technology of reusing the resource.

Owner:济南元首针织股份有限公司

Cationic sliver and its making technology

InactiveCN1382845AInitial modulus reductionReduce intensityMonocomponent polyesters artificial filamentArtifical filament manufactureEngineeringVacuum drying

A technology for producing cationic sliver includes vacuum drying CDP chips with 0.23-0.3% of SIPM content which controlling the precrystallizing temp and time, screw smelting and spinning, cooling while winding to obtain primary fibres (7-17 dtex), bundling, oil-bath drafting, two-pass steam stretching, curling while finishing oil, thermal shape fixation, making ribbons (88 mm in average length), carding, and making sliver. Its advantages are soft handle, high antistatic nature, and high dyeability.

Owner:孔森根

Composite fabric

InactiveCN102008144AGood flexibilityGood skin affinityLayered productsWoven fabricsYarnSurface layer

The invention discloses a composite fabric, comprising a surface layer and an inner layer, which are both knitting fabrics, the surface layer is composed of beech yarns, and the inner layer is a milk protein fiber layer. The composite fabric disclosed by the invention has silky gloss, soft handle, good dyeability and bright color, still can keep the bright color after being washed for many times, and has good perspiration absorption performance and good air permeability after perspiration absorption, so that the composite fabric can keep dry and comfortable.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com