Film etching method

A thin film and etchant technology, applied in the field of thin film etching, can solve the problems of increased contact area, chamfering or imperfect film shape, etc., to achieve the effect of improving the coating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] As shown in FIG. 4 , it is a flowchart of an embodiment of a thin film etching method of the present invention. The thin film etching method is applied in the thin film manufacturing process of a semiconductor or a thin film transistor array, and comprises the following steps: providing a substrate on which at least one thin film is formed, and on the top of the uppermost layer of the thin film A photoresist is formed (step S1); the first stage etching is to use the first etchant to etch the film (step S2); the second stage etching is to use The second etchant etches the photoresist (step S3); and the third stage etching is to etch the film again with the first etchant after the second stage etching (step S4 ).

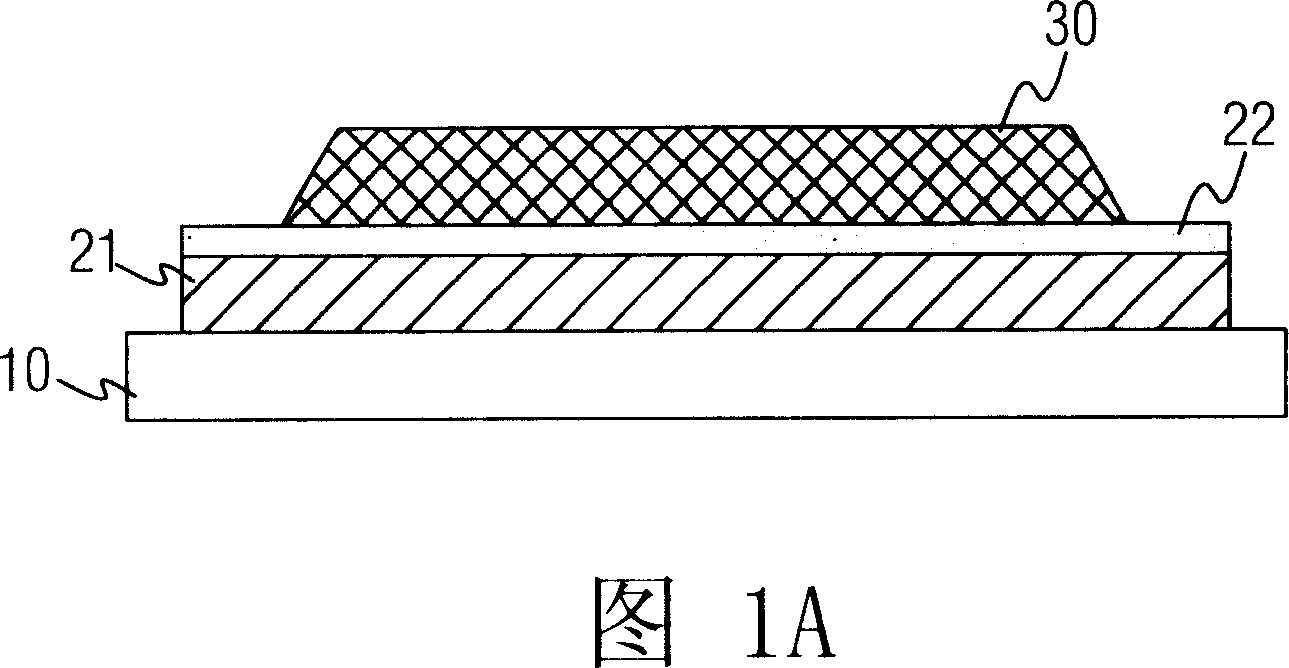

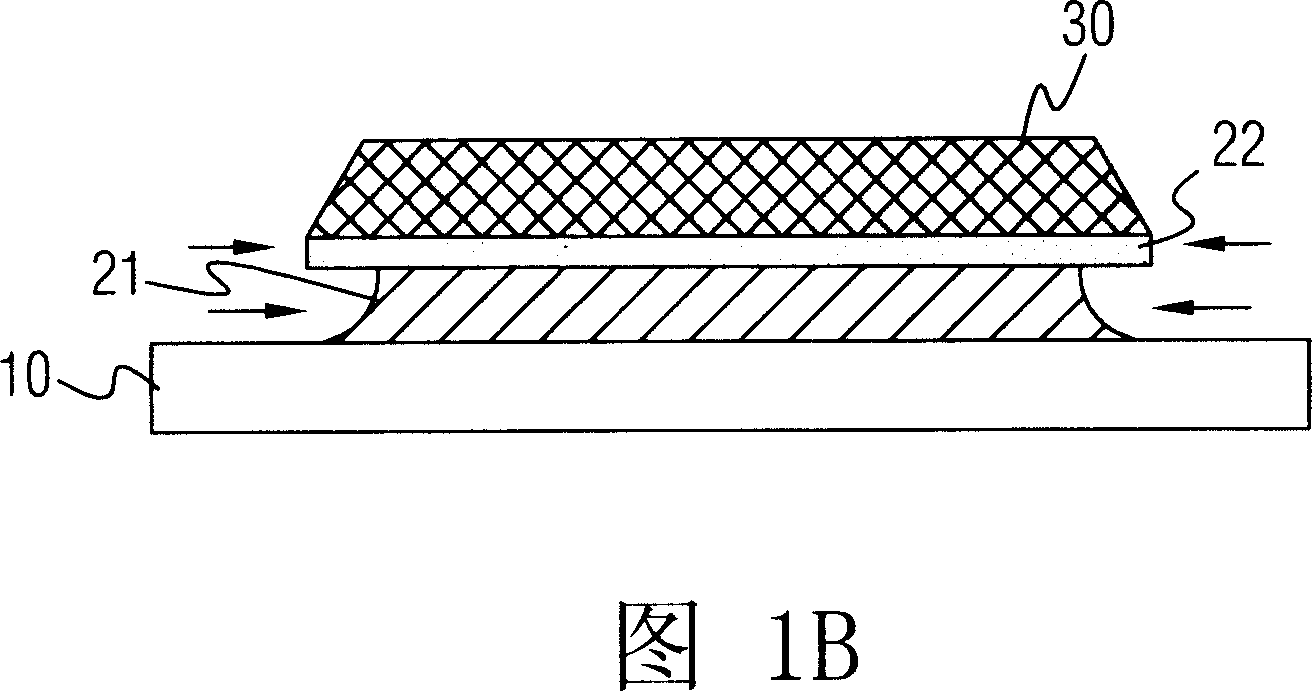

[0055] As shown in FIG. 5A , it is a schematic structural view of a double-layer film structure after photolithography. As shown in FIG. 5B , it is a schematic diagram of the first-stage etching for the double-layer film structure in FIG. 5A . As shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com