Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Strong sense of leather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

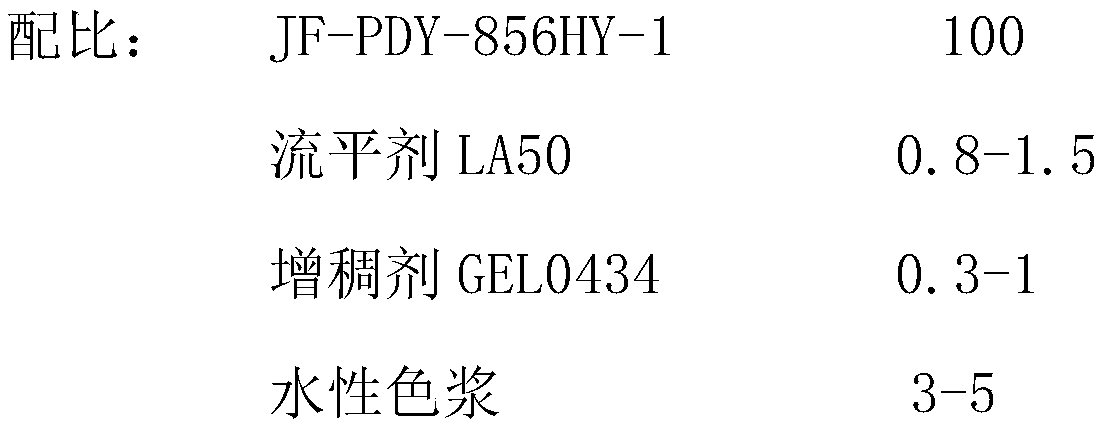

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Method for preparing sofa leather with strong wear resistant property and flame retardant property

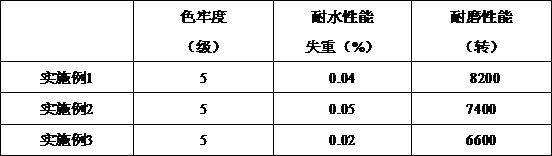

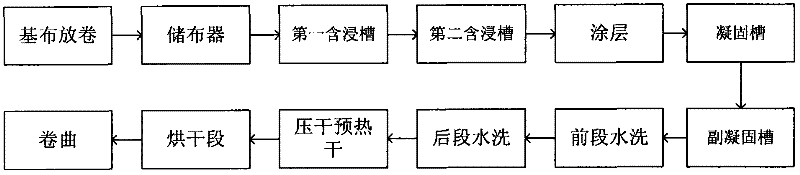

A high-wearing and fire-retardancy sofa leather is made by 1) wet condensing coating, molding in condensing groove, washing in water groove, drying and shaping and finally cooling and winding to become semi product wet process Bayes; 2) back spread coating with the semi product going through drawoff roller extraction shaping, dressing and spread coating, drying and baking and becoming fire-retardancy Bayes after cooling and winding; 3)nonaqueous shifting surface making, namely, separate paper shifting overlay; 4) kneading after treatment with pre-soaking of semi product sofa, squeezing out partial liquid, kneading and drying and finally batching on checking and final product packing. Apart from the major features of anti-friction and anti-retardancy, it can keep fine physical and mechanical performance and cosmetic styles with good quality and durable service.

Owner:HAININ JINDA COATING

Process for making high simulation ultra-fine fabric leather based cloth

One high simulation superfine fiber leather base cloth production method, uses the double component altogether to mix spinning production law produce island superfine fiber, then makes the adhesive-bonded base cloth material, first contains soaks half polyether polyurethane resin or the polyester polyurethane resin, then blows in base cloth the surface spreads gathers the carbonic ether polyurethane resin or the entire polyether polyurethane resin, then carries on coagulation processing using the DMF solution after the polyurethane resin, then uses the lukewarm water completely to wash DMF, use toluene solution island superfine fiber's in 'sea' ingredient extract comes out, then carries on alkali decrement processing. This invention produce base cloth which has thickness direction from trapezoidal density distribution structure, the dermis feeling is strong, may further enhance the artificial leather product the scale.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Synthetic leather prepared from non-woven fabric and slurry and its production method

A synthetic leather is prepared from non-woven fabric and slurry. Said non-woven fabric is prepared from the fibres of small-area leather and chemical fibres. Said slurry is prepared from polyurethane resin, solvent, assistant, pigment and wooden powder. Its preparing process includes such steps as immersing non-woven fabric in slurry, rolling, scrapping, coagulating, washing, squeezing, baking, grinding, wet coating, solidifying, water washing, baking, and coating film or polishing. Its advantages are high quality and low cost.

Owner:徐银松

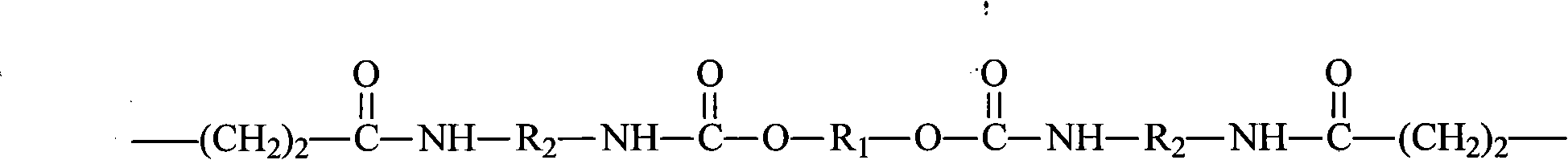

High springback wet method polyurethane resin for superfine fiber chemical leather

The invention relates to high resilience wet urethane resin for superfine fiber synthetic leather, which is mainly composed of polyether or polyester polyol, chain extenders and diisocyanate, and the mol ratio of the components is 1 of the polyester polyol, 1.5 to 3 of the chain extenders and 2.5 to 4 of diisocyanate. The high resilience wet urethane resin has the advantages that base cloth impregnated by the urethane resin has good resilience, strong real leather feeling, subtle lines of the base cloth after being reduced in weight, split, expanded, enlarged in size, dried, oiled and kneaded, the lines of the shoes made of shoe synthetic leather (especially for sports shoes and casual shoes) prepared by the base cloth, which are generated during wearing, can automatically restore due to the good resilience, the gauffer of the shoe upper is small, therefore the shoes can have good shape, and the quality is lifted to a higher level.

Owner:HUAFON MICROFIBER SHANGHAI

Resin composition for crazy horse leather

The invention relates to a resin compound for crazy horse leather, comprising urethane resin, dimethylformamide, stress color-changing wax powder, acetone and viscose fluff powder, wherein, the stress color-changing wax powder is hydroxide radical organic silicon. Compared with the prior level, the resin compound has better fluff scattering effect; therefore, after the made synthetic leather is kneaded, the fluff on the leather surface can grow, the fluff feeling is good and the fluff surface effect is good; after the leather surface is jacked up, the real leather feeling is great.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Oil coke-feeling treatment agent for synthetic leather and preparation method thereof

The invention relates to an oil coke-feeling treatment agent for synthetic leather and a preparation method of the oil coke-feeling treatment agent. The oil coke-feeling treatment agent is a mixture of the following materials in parts by weight: 55 to 65 of nitrocellulose (1 / 4 sec), 95 to 105 of aldehyde-ketone resin, 28 to 32 of silicon dioxide delusterant powder, 9 to 11 of color-change coke-forming wax powder, 9 to 11 of castor oil, 9.5 to 10.5 of dimethyl silicon oil, 9.7 to 10.3 of fluorine-based water repellents, 35 to 45 of dimethyl formamide, 115 to 125 of ethyl acetate and 240 to 250of methylal. The oil coke-feeling treatment agent is prepared by a preparation process comprising the following steps of: firstly uniformly dispersing and then grinding and filtering. The oil coke-feeling treatment agent has a novel formula design. The surface of the leather treated by the oil coke-feeling treatment agent has strong coke feeling and genuine leather feeling and good water resistance, is powdery and delicate, and has excellent glossy and coke feeling and good touch-feeling.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

Ultra-soft wet process embossing-type polyurethane resin and preparation method and application thereof

ActiveCN102010496AWork around limitationsSolve the costTextiles and paperPolyesterN dimethylformamide

The invention discloses ultra-soft wet process embossing-type polyurethane resin and a preparation method and application thereof, in particular to the ultra-soft wet process embossing-type polyurethane resin which adapts to the direct hot pressing and cold pressing process. The ultra-soft wet process embossing-type polyurethane resin is prepared from isocyanate, a polyester polyol mixture, a mixed chain extender prepared by matching a chain extender with a pendant group with an ethylene glycol chain extender and N, N-dimethylformamide as an organic solvent. A block structure containing ethylene glycol chain extension makes the polyurethane resin structure have the characteristics of high stripping strength and good embossing property by combining with the side chain action after the chain extender with the pendant group fully reacts, and therefore, a wet process base manufactured by the invention can adapt to direct embossing on the base, and the embossed grains are full and clear; and the base has soft and elastic hand feeling and approaches the true skin feeling. The invention solves the problems of grain restriction, complicated process flow, higher manufacturing cost and the like of the traditional process.

Owner:SHANGHAI HUIDE TECH CO LTD

Chromatophilous polyurethane resin for synthetic leather and preparation method of polyurethane resin

The invention relates to chromatophilous polyurethane resin for synthetic leather and a preparation method of the polyurethane resin. The polyurethane resin comprises the following components by mass percentage: 15-20% of polyester polyol EG1000, 3-5% of polyester polyol PCL2000, 15-20% of diphenyl-methane-diisocyanate (MDI), 0.1-0.2% of epoxy resin, 0.05% of triphenyl phosphite, 0.02% of dibutyltin dilaurate, 0.01% of silicone oil, 0.8-1.5% of glycol, 2-3% of 1,4-butanediol, 0.4-0.6% of alcohol, and the balance of solvent, wherein the solvent comprises the following components by mass percentage: 20-25% of dimethyl formamide (DMF), 15-20% of butanone, and the balance of methylbenzene. The chromatophilous polyurethane resin for the synthetic leather and the preparation method have the benefits that the polyurethane resin synthesized by the preparation method is chromatophilous, high in fixation, and uniform in coloring, and has good mechanical properties such as water resistance, solvent resistance, cold resistance and folding resistance after being produced into the leather.

Owner:JIANDE BAISHA CHEM

Resin composition for crazy horse leather resin composition

InactiveCN101284942ARubbing antique effect is goodStrong sense of leatherTextiles and paperEpoxyWear resistant

The invention relates to a resin compound used for crazy horse burnished leather, comprising polyurethane resin, dimethylformamide, floss powder, color-changing powder, acetone and epoxide resin, wherein, the color-changing powder is modified silicon dioxide and the melting point of the modified silicon dioxide is between 55 and 80 DEG C. Compared with the prior art, the crazy horse burnished leather prepared by the resin compound has good burnished archaizing effect, is close to corium, is smooth in the leather surface and has good scratch resistant and wear resistant performances.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based yangbuck with lustring effects and method for preparing water-based yangbuck

ActiveCN106436337AStrong sense of hierarchyClear texturePolyurea/polyurethane coatingsTextiles and paperWater basedEngineering

The invention provides a method for preparing water-based yangbuck with lustring effects. The method includes steps of 1), coating and scraping water-based wet base slurry on base cloth, transporting the base cloth into a coagulating tank, coagulating the base cloth and drying the base cloth by means of baking to obtain water-based base; 2), coating water-based yangbuck materials on release paper, drying the water-based yangbuck materials and the release paper to form yangbuck clinging surfaces, adhering the water-based base onto the yangbuck clinging surfaces, then drying the yangbuck clinging surfaces by means of baking, cooling the yangbuck clinging surfaces and peeling the release paper to obtain artificial leather by means of preparation; 3), placing the artificial leather in a baking oven and foaming the artificial leather at the high temperature to obtain yangbuck by means of preparation; 4), carrying out color change treatment on the yangbuck by the aid of a printing machine; 5), preparing lustring materials, adding the lustring materials into the printing machine and carrying out lustring treatment on the yangbuck. The method has the advantages that the surfaces of the water-based yangbuck are high in leather feeling and good in velvet feeling and feel soft, and the excellent lustring effects can be realized; the surfaces of the yangbuck are bulky, thick, smooth, straight and bright and have plump pile after lustring treatment is carried out on the yangbuck, and market requirements on high-grade yangbuck can be met.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Method of preparing back coated real leather intimating synthetic leather

The invention discloses a method for manufacturing back-coated skin-imitated synthetic leather. The method comprises: coating wet-process PU slurry onto the surface of base cloth to form a base green body; after solidifying and washing the base green body, coating foaming slurry on the back of the base green body; washing and drying the base green body and foaming the base green body to form wet-process crust leather; and finally grinding the back of the wet-process crust leather and carrying out dry-process release paper pattern transfer to the front of the wet-process crust leather, wherein the foaming slurry comprises foaming resin ST-1030 or ST-1040, dimethylformamide (DMF), a foaming agent and so on. The method uses the prior synthesis device and research on special foaming slurry to carry out once forming process of the skin-imitated synthetic leather, namely, the method simplifies the prior post processing processes for producing skin-imitated synthetic leather such as pile coating, real leather powder coating and suede foaming into a wet-process once forming process.

Owner:ANHUI ANLI MATERIAL TECH

Preparation method of soft and air-ventilating waterborne polyurethane clothes leather base

ActiveCN108755169AMeet needsSoft touchPolyurea/polyurethane coatingsTextiles and paperPolyvinyl alcoholLiquid state

The invention provides a preparation method of a soft and air-ventilating waterborne polyurethane clothes leather base. The preparation method comprises the following steps of preparing a PVA (polyvinyl alcohol) water solution, preparing a waterborne foaming slurry, treating a base cloth, coating, coagulating, washing and drying. The preparation method of the soft and air-ventilating waterborne polyurethane clothes leather base has the advantages that the waterborne polyurethane foaming holes and the PVA water solution are changed from the liquid state into the solid state in the shaping process, then the PVA is cleaned by hot water, and the foam holes are obtained; by adopting the physical double-layer foaming type, the foam holes are uniform and stable, so that the good air ventilating and moisture permeating properties of the clothes leather base are realized, the hand feel is soft, and the feel of real leather is strong; the requirements of synthetic leather market on the clothes leather base can be met.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

High-springback high-stretching clothing leather and preparation method thereof

InactiveCN105803813AHigh standardPromote environmental protectionCoatingsTextiles and paperSurface layerPulp and paper industry

The invention provides high-springback high-stretching clothing leather and a preparation method thereof.The method includes the following steps that 1, after release paper is directly coated with size of a surface layer, hot air drying is conducted, and cooling is conducted; 2, coating of size of a foaming middle layer is conducted, hot air drying is conducted, and cooling is conducted; 3, coating of size of a bottom layer is conducted, then base cloth is laminated through a laminating machine, then hot air drying is conducted, and cooling is conducted; 4, the release paper is stripped, and the high-springback high-stretching clothing leather is obtained.The obtained high-springback high-stretching clothing leather perfectly combines the elasticity of four-directional elastic fabric and the elasticity of a polyurethane layer, and the leather is soft in handfeel, resistant to wrinkling, high in real leather sense and especially sufficient in elastic force, and can meet the requirements of the clothing leather market for elastic clothing leather.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Preparation method of water-based superfine fiber synthetic leather

The invention discloses a preparation method of water-based superfine fiber synthetic leather. The preparation method comprises the steps of: 1, coating the surface of a sea-island fiber non-woven fabric with a water-based hydrophobic assistant and then carrying out drying curing to obtain a base fabric A subjected to surface hydrophobic pretreatment; 2, uniformly immersing the base fabric A intowater-based polyurethane impregnation resin, sufficiently impregnating the base fabric A by a roller, and then carrying out drying curing to obtain a composite base fabric B; 3, carrying out alkali decrement, washing, acid neutralization and drying treatment on the composite base fabric B, and removing a 'sea' component and the hydrophobic assistant in the composite base fabric B to obtain a superfine fiber base fabric C; and 4, carrying out sueding, dyeing and softening treatment on the superfine fiber base fabric C so as to obtain the water-based superfine fiber synthetic leather with polyurethane impregnation resin gradient distribution. In the invention, a density of the superfine fiber synthetic leather has an obvious gradient change; the surface of the superfine fiber synthetic leather is active and the inside of the superfine fiber synthetic leather is compact; sensuality elasticity and hand feel fullness of the product are improved; and a simulation effect is better.

Owner:ZHEJIANG TRANSFAR FUNCTIONAL NEW MATERIAL CO LTD +2

Production method for microfiber leather

InactiveCN106192441AGood flexibilityStrong sense of leatherFilament/thread formingLiquid/gas/vapor textile treatmentWater vapor permeabilityNonwoven fabric

The invention relates to a production method for microfiber leather. The production method comprises the following steps that firstly, composite fibers are spun; secondly, non-woven fabric is made; thirdly, the non-woven fabric is shaped; fourthly, a polyurethane resin working solution with high solid content and high viscosity is prepared; fifthly, a polyurethane resin working solution is smeared; sixthly, a polyurethane resin working solution with low solid content and low viscosity is prepared; seventhly, soaking and continuous rolling are carried out with the polyurethane resin working solution; eighthly, polyurethane is solidified; ninthly, methylbenzene decrement treatment is carried out. Compared with the prior art, the microfiber leather has the advantages of being good in hand touch and drape effect and high in air and water vapor permeability.

Owner:SHANDONG FRIENDSHIP MACHINERY

Water-based PU wiping-coke treating agent for synthetic leather and its preparation method

The invention relates to a water-based PU wiping-coke treating agent for synthetic leather. The treating agent consists of water-based PU resin varnish, modified PU emulsion, water, water-based silicone oil, modified polyamide wax powder, silicon dioxide matting agent, organosilicon leveling agent, organosilicon defoaming agent and water-based PU thickening agent. The invention also relates to a preparation method of the water-based PU wiping-coke treating agent for synthetic leather. The treating agent takes water as solvent to replace DMF, MEK and other toxic solvents, to achieve noninflammable, non-toxic and non-pollution characteristics, and fundamentally solve the toxic problem of solvent based resin paste for synthetic leather.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Manufacturing method of high-physical-property embossing dry-method environment-friendly sofa leather

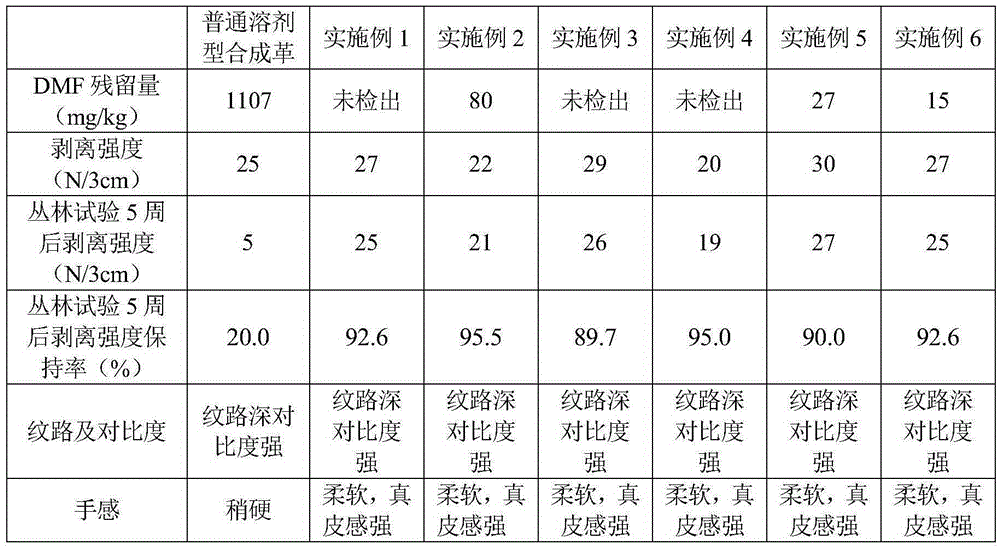

The invention provides a manufacturing method of high-physical-property embossing dry-method environment-friendly sofa leather. The manufacturing method includes the steps that 1, sofa leather base fabric including base fabric A and base fabric B is prepared; 2, the base fabric A is attached to the base fabric B through adhesive resin, the base fabric A is arranged on the base fabric B, microspheres foaming powder is added to the adhesive resin, and the composite base fabric is obtained after drying and foaming are conducted; 3, a piece of release paper is coated with a surface-layer sizing agent and then dried; 4, the release paper is coated with a middle-layer sizing agent and dried; 5, after the release paper is coated with bonding-layer resin, the composite base fabric is attached to the release paper, and the release paper is stripped after drying is conducted; 6, embossing and posttreatment are conducted, and a finished product is obtained. According to the method, base fabric of different knitting tightness is attached to one another through the adhesive resin, a tissue structure which is similar to natural leather and has a density gradient is obtained, and a product is high in genuine leather feeling; the excellent embossing property is obtained through the high-temperature molten deformation functions of a microspheres foaming layer, an adhesive layer and a dry-method layer; a wet-method coating is not used, hydrolysis resistance is improved, and residues of DMF are lowered.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Waterborne matte velour-wetting treatment agent for synthetic leather and preparation method thereof

InactiveCN103103782ANon-combustibleEnvironmentally friendlyFibre treatmentTherapeutic effectSilicon dioxide

The invention relates to a waterborne matte velour-wetting treatment agent for synthetic leather. The waterborne matte velour-wetting treatment agent is composed of the following components: waterborne polyurethane resin varnish, water, penetrant, silica extinction powder, an organosilicone levelling agent, an organosilicone defoamer and a waterborne polyurethane thickener. The invention further relates to a preparation method of the waterborne matte velour-wetting treatment agent for the synthetic leather. The waterborne matte velour-wetting treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the waterborne matte velour-wetting treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Synthesis method of hydrolysis-resistant and high-color-fastness waterborne polyurethane emulsion

The invention relates to the field of chemical engineering, and discloses a synthesis method of a hydrolysis-resistant and high-color-fastness waterborne polyurethane emulsion. The preparation method comprises the following steps: carrying out stepwise polymerization reaction on oligomeric dihydric alcohol, aliphatic diisocyanate, a vinyl modified Maya blue-like attapulgite hybrid pigment, an ethanolamine hydrophilic chain extender, an acrylic acid-2-hydroxyethyl ester cross-linking agent and a glycerol cross-linking agent to synthesize a polyurethane prepolymer modified by the Maya blue-like attapulgite hybrid pigment on a side chain; the preparation method comprises the following steps: preparing an ethanol amine functional group, adding an acid neutralizer to neutralize the ethanol amine functional group to form quaternary ammonium salt, self-emulsifying and dispersing the quaternary ammonium salt in metering water to obtain a Maya blue-like attapulgite hybrid pigment modified waterborne polyurethane dispersion liquid, and adding diamine for chain extension to prepare the hydrolysis-resistant high-color-fastness waterborne polyurethane emulsion. When the waterborne polyurethane emulsion is used for producing waterborne polyurethane coatings, synthetic leather and other products in the later period, the water resistance of the obtained waterborne polyurethane product can be effectively improved, and the mechanical performance, color fastness and the like of the obtained product are further improved.

Owner:江苏华缘高科股份有限公司

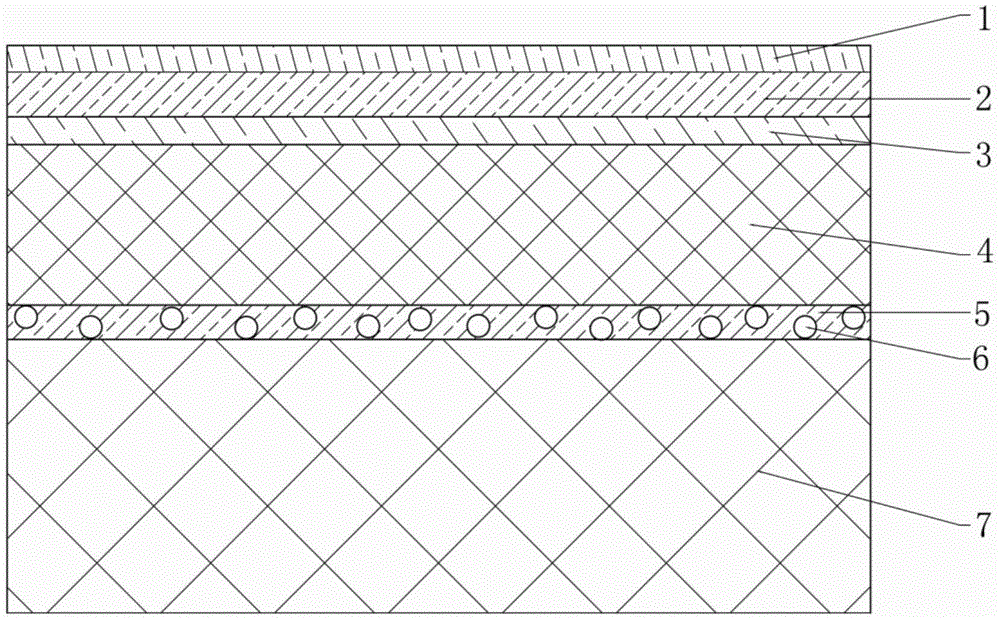

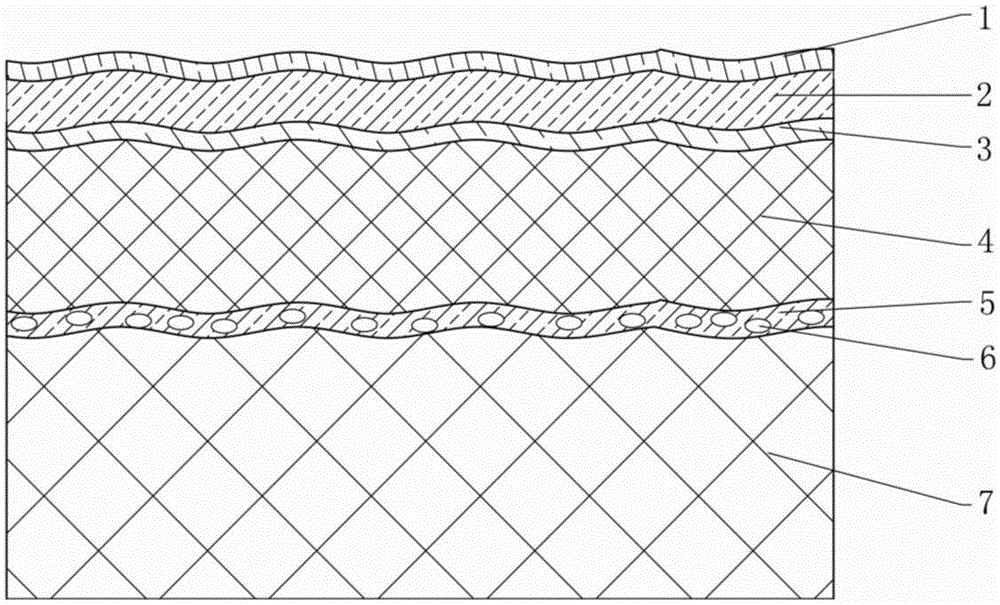

Skin-imitated synthetic leather, and manufacturing method and apparatus for same

InactiveCN102359021AImprove breathabilitySoft touchSynthetic resin layered productsTextiles and paperFoaming agentAnimal skin

The invention discloses skin-imitated synthetic leather, and a manufacturing method and apparatus for the same. The skin-imitated synthetic leather is prepared through the following steps: applying an impregnating material on a base cloth to form a bottom green body by using a wet method, preparing a base from a coating, and carrying out solidification, rinsing and drying to obtain the skin-imitated synthetic leather, wherein, the impregnating material comprises, by weight, 100 parts of a speciality resin, 180 to 250 parts of DMF (dimethyl formamide), 0.05 to 0.5 part of an anti-foaming agent, 0.5 part to 2 parts of a wetting agent and 2 to 5 parts of color paste. The skin-imitated synthetic leather provided in the invention has the advantages of good water resistance and air permeability, soft handle, authentic skin feel, low production cost compared to superfine fibrous leather and capacity of compensating for restriction on related manufacturing industries caused by scarcity of animal skin.

Owner:浙江元新实业有限公司

Imitation leather polishing treatment agent for synthetic leather and preparation method of imitation leather polishing treatment agent

InactiveCN102587143AStrong sense of leatherLow costFibre treatmentPolyurea/polyurethane coatingsPrepolymerDimethyl formamide

The invention relates to crystal slippery resin for synthetic leather and a preparation method of the crystal slippery resin. The crystal slippery resin is formed by preparing the following raw materials in part by weight: 35 to 50 parts of dimethyl formamide, 8 to 15 parts of polyether polyol, 4 to 8 parts of polyester polyol, 10 to 30 parts of diphenylmethane diisocyanate, 0.5 to 1.8 parts of 1,4-butanediol, 3 to 6 parts of ethanediol, 10 to 20 parts of toluene, 10 to 20 parts of acetic ether, 3 to 5 parts of silicone emulsion and 0.01 to 0.03 part of antioxidant. The preparation method comprises the following steps of: performing addition polymerization reaction of the polyether polyol, the polyester polyol and diisocyanate to form a prepolymer; performing chain extension reaction to form polymer with high relative molecular mass; and performing chain extension reaction of diol and polyol on the prepolymer to prepare the resin. The invention has the advantage that the problems of pastiness of gloss oil resin and poor temperature resistance can be solved, the crystal slippery resin is high-temperature-resistant, folding-resistant, anti-aging, simple in process, convenient to produce and low in cost and can be directly applied to the subsequent production process, and the process can employ three-plate printing or spraying.

Owner:建德市顺发化工助剂有限公司

Method for preparing powder fluff for electrostatic flocking from waste Cr-containing leather debris

ActiveCN106245253ADelicate and smooth feelExcellent imitation leather effectSucessive textile treatmentsTwo or more solvent application treatmentSodium bicarbonateOrganic solvent

The invention relates to a method for preparing powder fluff for electrostatic flocking from waste Cr-containing leather debris, and belongs to the technical field of leather. The method comprises steps as follows: the waste Cr-containing leather debris is ground into particles and dried; the particles are dried, left to stand for 95-105 days and screened; the particles are immersed in an organic solvent, a feeling agent is added in terms of the mass of a screened material, the mixture is stirred for 30-40 min, and a liquid is drained; the product is placed in a cylinder, and a degreasant is added for operation in terms of mass of the screened material, a penetrate is added for operation, sodium bicarbonate, sodium formate and sodium citrate are added for operation, dye is added, a color fixing agent is added for operation, sodium chloride is added for operation, a slipping agent is added for operation, the product is taken out of the cylinder, dehydrated and dried continuously, and the powder fluff for electrostatic flocking is obtained. The powder fluff for electrostatic flocking, prepared with the method, feels smooth and fluffy, and an electrostatic flock product is endowed with good leather feel.

Owner:滨州市科创孵化器有限公司

Rare earth complex containing leather composite coating agent

InactiveCN108148495AGood weather resistanceImprove water resistancePolyurea/polyurethane coatingsLeather surface finishingRare earthPhenol

The invention discloses a rare earth complex containing leather composite coating agent which is prepared from the raw materials of polyurethane emulsion, oxidized polyethylene wax emulsion, fluorinecontaining acrylic emulsion, alkyl phenol polyoxyethylene ether, sodium dodecyl benzene sulfonate, octadecyl dimethyl (3-methoxy silicyl propyl) ammonium chloride, a diluent, rare earth complex, 1,4-bi(bromoacetoxy)-2-butene, silicone oil, N-allyl isothiazolinone and compound filler, wherein the compound filler is prepared by mixing nano iron oxide, nano titanium dioxide, oxidized graphene, a 5A zeolite molecular sieve, nano zirconium oxide and silane coupling agent KH-570. The rare earth complex containing leather composite coating agent disclosed by the invention has excellent antibacterialproperty, water resistance and ageing resistance; when the rare earth complex containing leather composite coating agent is applied to leather products, the antibacterial property, water resistance and ageing resistance of the leather products are remarkably improved; meanwhile, the prepared leather products have the advantages of good glossiness and soft and full hand feeling.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

Leather patching method

InactiveCN109576420ASmooth grainIncrease coverageLeather surface finishingUltimate tensile strengthCoating

The invention relates to the technical field of leather chemistry and engineering and provides a leather patching method. A polyurethane foam resin material is introduced into a patching agent for patching to create a hollow-system patching agent, density of the patching agent is reduced while strength is excellent and stable, and accordingly an elastic stable object is formed. In addition, by combination of mechanical operations such as roller coating and press polishing, the patching agent can be firmly filled at defective or damaged parts of crust leather. The technical defects of lack of falling resistance and proneness to recessing of traditional patching coatings are overcome, a production cycle is shortened, and production efficiency is improved.

Owner:XINGYE LEATHER TECH CO LTD

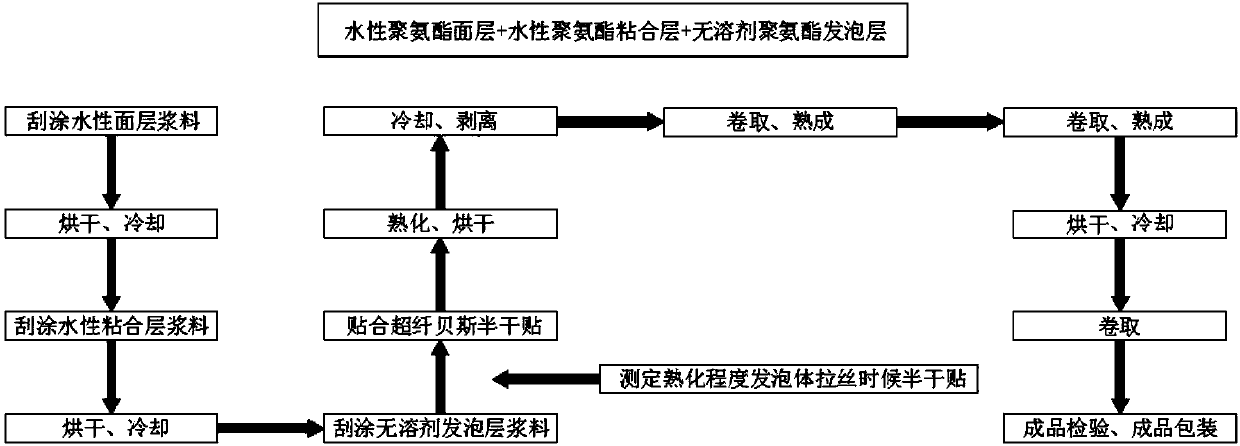

R&D (research and development) and production method of waterborne solvent-free polyurethane superfine fiber emulational leather

InactiveCN107700229ARealize non-toxic and harmlessImprove the physical indexTextiles and paperProduction lineSolvent free

The invention discloses an R&D (research and development) and production method of waterborne solvent-free polyurethane superfine fiber emulational leather. The leather is prepared by the following steps: bonding a waterborne polyurethane resin surface material and a middle material (bonding layers) and solvent-free polyurethane resin (A and B), and bonding an obtained layer and microfiber base with different thicknesses in a half-dry manner. According to the method, various difficulties in production of microfiber-related products and various problems in production technologies due to the limitation caused by the traditional out-dated production line and the traditional production technique and raw materials can be solved; a product produced by the method is smooth in surface without deadcrinkles, soft and elastic in hand feeling and extremely strong in dermic feeling and can meet the requirements of users and merchants on the product, so that the grade and the additional value of the product can be improved, and the foundation is laid for industrial upgrading and transformation of enterprises.

Owner:浙江瑞普实业有限公司

Waterborne matte polishing treatment agent for synthetic leather and preparation method thereof

InactiveCN103103786ANon-combustibleEnvironmentally friendlyFibre treatmentEmulsionTherapeutic effect

The invention relates to a waterborne matte polishing treatment agent for synthetic leather. The waterborne matte polishing treatment agent is composed of the following components: waterborne polyurethane resin varnish, modified polyurethane emulsion, water, silica extinction powder, methoxy silicone oil, penetrant, an organosilicone levelling agent, an organosilicone defoamer and a waterborne polyurethane thickener. The invention further relates to a preparation method of the waterborne matte polishing treatment agent for the synthetic leather. The waterborne matte polishing treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the waterborne matte polishing treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Manufacturing method of ecological environment protection polyurethane superfine fiber synthetic leather

InactiveCN106638017AIncrease elasticityStrong sense of leatherTextiles and paperFiberOrganic solvent

The invention relates to a manufacturing method of ecological environment protection polyurethane superfine fiber synthetic leather. The method comprises the following steps: (1) unwinding base fabric, wherein the base fabric is superfine fiber synthetic leather base fabric used for alkali decrement; (2) impregnating the base fabric into aqueous slurry containing dissoluble hole forming filler, wherein the aqueous slurry contains waterborne polyurethane and the dissoluble hole forming filler; (3) drying; (4) impregnating the dried product into an acid treatment solution, squeezing to dryness and then washing; (5) carrying out alkali decrement, and washing; (6) drying to obtain the finished product. The dissoluble hole forming filler can be dissolved by means of an acid treatment solution impregnation process or a direct hot alkali decrement process, so that a foam structure, which is obtained by wet solidification similar to solvent type polyurethane resin, is obtained from polyurethane resin; an organic solvent is not used in a production process, and methylbenzene is not used in the decrement process, so that ecological environment protection is realized in the production process, and the product is free from any dissolution residue; the product is soft, good in elasticity and strong in leather feeling.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Coarse cracking crazy-horse resin for synthetic leather and preparation method thereof

The invention discloses coarse cracking crazy-horse resin for synthetic leather and preparation method thereof. The resin is prepared from polyurethane resin, nitrocellulose resin, acetone, DMF, high-temperature resistant wax powder, high-temperature resistant silica color-changing wax powder, wood powder, silicone leveling agent and 0.2 brown fluff. The coarse cracking crazy-horse resin for synthetic leather has good adhesive force, good derma effect, prominent fur feel, and apparent effect. The synthetic leather applying the coarse cracking crazy-horse resin has good feeling, high-temperature resistance, and comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

High-efficiency water-proof anti-oil high temperature-resisting dedusting treating agent for synthetic leather

The invention discloses a high-efficiency water-proof anti-oil high temperature-resisting dedusting treating agent for synthetic leather, relating to a high temperature-resisting dedusting treating agent, comprising 18-25 parts of temperature-resistant resin, 7-12 parts of polyurethane bright resin, 23-32 parts of dimethyl formamide, 8-13 parts of ethyl acetate, 15-23 parts of butyl acetate, 2-4 parts of micronized organic polymer wax, 4-7 parts of micronized silicon dioxide, 2-7 parts of oily water-proof anti-oil aid, 1-3 parts of modified organosilicon aid, and 1-3 parts of grease. The dedusting treating agent disclosed herein has high temperature resistance, excellent water-proof anti-oil effect, charred feeling, extremely good handle, oil feel and waxy feel, and strong leather feeling.

Owner:HANGZHOU COLORICH CHEM MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com