Synthesis method of hydrolysis-resistant and high-color-fastness waterborne polyurethane emulsion

A water-based polyurethane, high color fastness technology, applied in the chemical field, can solve the problems of single color, water-based polyurethane material water resistance, wear resistance and other properties are not improved, etc., to achieve strong leather feeling, easy storage and transportation, improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

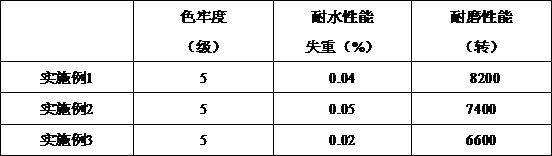

Examples

Embodiment approach 1

[0020] A method for synthesizing water-based polyurethane with hydrolysis resistance and high color fastness. Raw materials are taken by weight percentage: 20% diisocyanate, 15% oligomeric glycol, 5% vinyl-modified Maya blue-like hybrid pigment, acrylic acid -2-hydroxyethyl ester crosslinking agent 3%, ethanolamine hydrophilic chain extender 5%, glycerin crosslinking agent 0%-1%, small molecule acid neutralizer 2%, small molecule diamine extender 5% chain agent, 0.5% organic bismuth catalyst, 10% acetone, and the balance is water;

[0021] The synthesis steps are as follows:

[0022] (1) Preparation of vinyl-modified attapulgite-like hybrid pigments:

[0023] Take 2.0 g of indigo and 20.0 g of attapulgite and mix them in a ratio of 1:10, mix well and put them in an oven for 48 h at 130°C, take them out and cool to room temperature, disperse them in 200 ml of water, add 100 ml of isopropanol, 0.5 g sodium silicate, 3 g vinyltriethoxysilane and 0.5 ml hydrochloric acid (12 mol...

Embodiment approach 2

[0031] A method for synthesizing water-based polyurethane with hydrolysis resistance and high color fastness. The raw materials are taken by weight percentage: 25% of diisocyanate, 15% of oligomeric glycol, and 3% of vinyl-modified Mayan blue attapulgite hybrid pigment , 2-hydroxyethyl acrylate crosslinking agent 5%, ethanolamine hydrophilic chain extender 10%, glycerin crosslinking agent 0.5%, small molecule acid neutralizer 6%, small molecule diamine chain extender 8% agent, 1% organic bismuth catalyst, 10% acetone, and the balance is water;

[0032] The synthesis steps are as follows:

[0033] (1) Preparation of vinyl-modified attapulgite-like hybrid pigments:

[0034] Take 2.0 g of methyl red and 20.0 g of attapulgite and mix them according to the ratio of 1:10. After mixing well, put them in an oven for 48 hours at 130 ℃, take them out and cool to room temperature, disperse them in 200 ml of water, add 100 ml of isopropyl Alcohol, 0.5 g sodium silicate, 3 g vinyltrietho...

Embodiment approach 3

[0042] A method for synthesizing water-based polyurethane with hydrolysis resistance and high color fastness. The raw materials are taken by weight percentage: 30% diisocyanate, 20% oligomeric glycol, 1% vinyl-modified Maya blue-like hybrid pigment, acrylic acid -2-hydroxyethyl ester crosslinking agent 5%, ethanolamine hydrophilic chain extender 3%-15%, glycerol crosslinking agent 0%-1%, small molecule acid neutralizer 2%-10%, Small molecule diamine chain extender 3%-15%, organic bismuth catalyst 0%-1%, acetone 10%-20%, the balance is water;

[0043] The synthesis steps are as follows:

[0044] (1) Preparation of vinyl-modified attapulgite-like hybrid pigments:

[0045] Take 2.0 g of madder pigment and 20.0 g of attapulgite and mix them in a ratio of 1:10. After mixing well, put them in an oven and dry them at 130°C for 48 hours. Take them out and cool to room temperature, disperse them in 200 ml of water, and add 100 ml of isopropanol , 0.5 g sodium silicate, 3 g vinyltriet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com