Oil coke-feeling treatment agent for synthetic leather and preparation method thereof

A technology for treating agent and oil coke feeling is applied in the field of oil coke feeling treatment agent for synthetic leather and its preparation field, which can solve the problems of oily feeling, poor coke penetration, insufficient powder feeling, dull leather surface, etc. The retro style is outstanding, the powder feeling is delicate, and the leather feeling is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

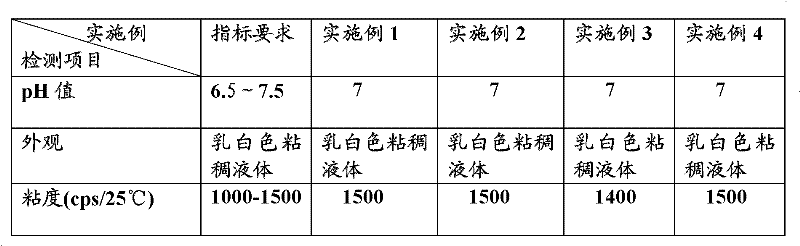

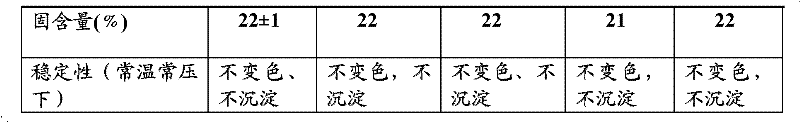

[0017] According to the oil scorching treatment agent for synthetic leather of the present embodiment, it is directly mixed by the following components by weight: 60 parts of nitrocellulose for a quarter of a second; 100 parts of aldehyde and ketone resin; 30 parts of silica matting powder ; 10 parts of discoloration rubbing wax powder; 10 parts of castor oil; 10 parts of dimethyl silicone oil; 10 parts of fluorine-based water repellent; See Table 1 for the technical specifications of the oil burn treatment agent, which meet the application requirements.

Embodiment 2

[0019] According to the oil scorching treatment agent for synthetic leather of this embodiment, its formula is the same as that of Example 1, but it is prepared by the following preparation method: add dimethyl to 60 parts of quarter second nitrocellulose and 100 parts of aldehyde and ketone resins After 40 parts of methyl formamide, 120 parts of ethyl acetate, 250 parts of methylal, 10 parts of castor oil, 10 parts of simethicone oil, and 10 parts of fluorine-based water repellent, stir at high speed until the dispersion is uniform, and then add two 30 parts of silicon oxide matting powder and 10 parts of discoloration scorching wax powder are uniformly dispersed, ground by a grinder and filtered to obtain the oily burn feeling treatment agent for synthetic leather. See Table 1 for the technical specifications of the oil burn treatment agent, which meet the application requirements.

Embodiment 3

[0021] According to the oil scorching treatment agent for synthetic leather of the present embodiment, it is directly mixed by the following components by weight: 56 parts of nitrocellulose for a quarter of a second; 100 parts of aldehyde and ketone resin; 30 parts of silica matting powder ; 10 parts of discoloration scorching wax powder; 10 parts of castor oil; 10 parts of dimethyl silicone oil; 10 parts of fluorine-based water repellent; See Table 1 for the technical specifications of the oil burn treatment agent, which meet the application requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com