Manufacturing method of high-physical-property embossing dry-method environment-friendly sofa leather

A manufacturing method and technology of sofa leather, which is applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of dry hand feeling, low grade, and poor genuine leather feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

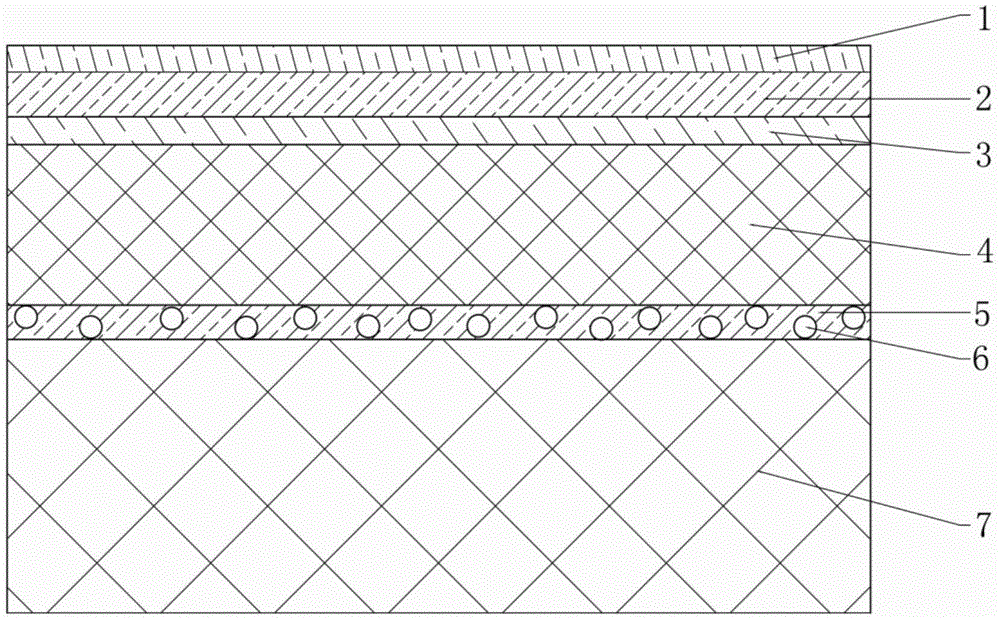

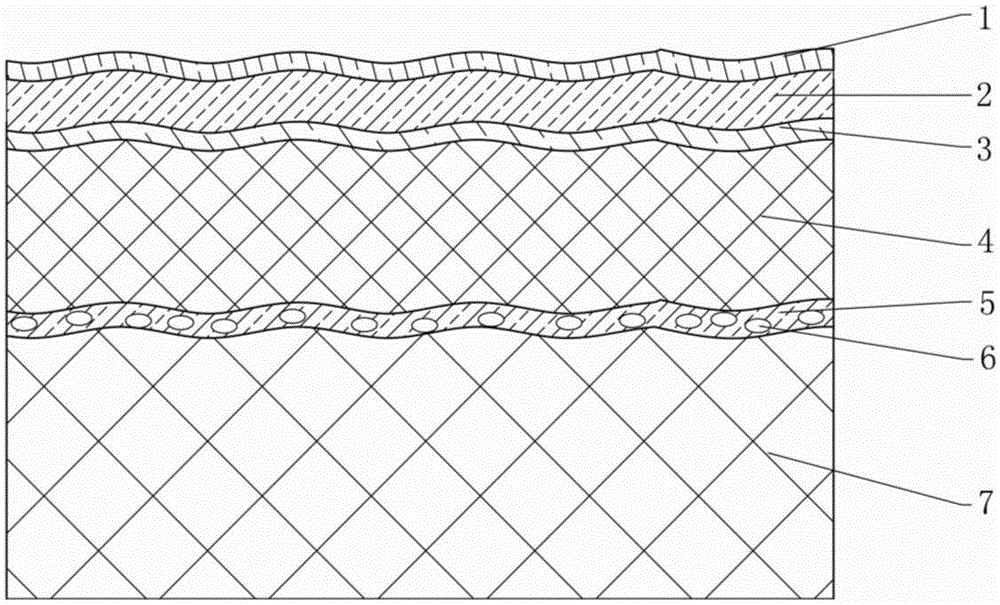

Method used

Image

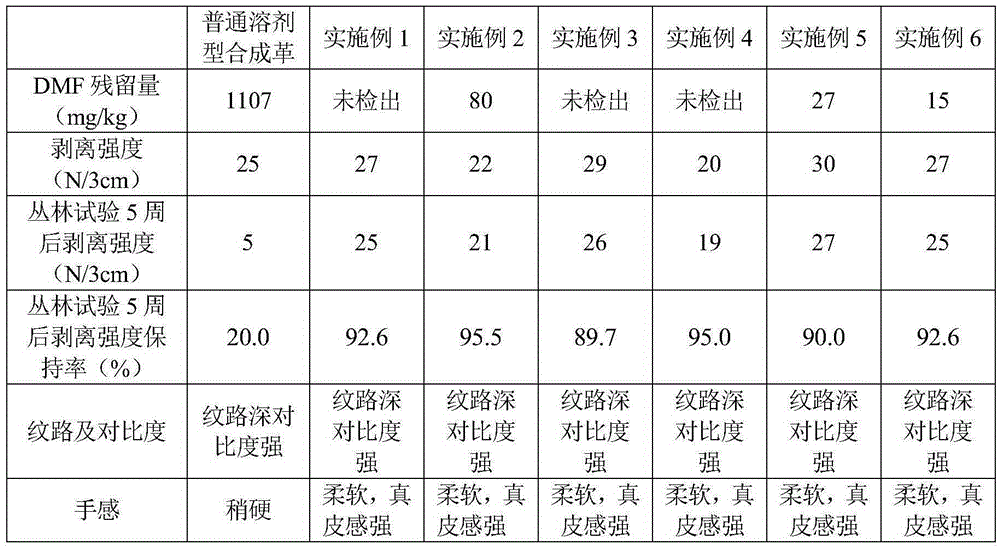

Examples

Embodiment 1

[0034] (a) Prepare sofa leather base fabric: A base fabric - 0.6mm, 190g / m 2 Woven fabric and B base fabric - 0.7mm, 180g / m 2 Raised knitted fabric on the back;

[0035] (b) Choose water-based polyurethane adhesive resin, and apply 40g / m on the back of A base fabric 2 The adhesive resin is bonded to the front of the B base fabric (the A base fabric is on the top, and the B base fabric is on the bottom), and the composite base fabric is obtained after drying;

[0036] The polyurethane adhesive slurry formula is:

[0037] Waterborne PU resin (Leasys3458, solid content 50%): 100g

[0038] Microsphere foaming powder (FN100D): 10g

[0039] Solvent: 0g

[0040] The maximum drying temperature is 140 degrees Celsius.

[0041] (c) drying after coating HX-6051 on the release paper;

[0042] (d) Coating 0.1mm middle layer HX-8028 on the surface layer slurry obtained in step c and then drying;

[0043] (e) After coating HX-930G on the intermediate layer slurry obtained in step d, ...

Embodiment 2

[0046] (a) Prepare sofa leather base fabric: A base fabric - 0.4mm, high tear paper, 150g / m 2 And B base fabric - 0.5mm, 200g / m 2 Microfiber synthetic leather base cloth;

[0047] (b) Choose a solvent-based adhesive resin, and coat 60g / m on the front of the B base fabric 2 Adhesive resin is bonded to the back of A base fabric (A base fabric is on top, B base fabric is below), and a composite base fabric is obtained after drying;

[0048] The polyurethane adhesive slurry formula is:

[0049] Solvent-based PU resin (HX-9530, solid content 35%): 100g

[0050] Microsphere foaming powder (461DU20): 20g

[0051] Solvent DMF: 20g

[0052] The maximum drying temperature is 150 degrees Celsius.

[0053] (c) drying after coating HX-6081 on the release paper;

[0054] (d) drying after coating 1.8mmHX-9530 on the surface layer slurry obtained in step c;

[0055](e) After coating HX-9530 on the intermediate layer slurry obtained in step d, attach the base cloth, peel off the releas...

Embodiment 3

[0058] (a) Prepare sofa leather base fabric: A base fabric - 0.2mm, 100g / m 2 Knitted fabric and B base fabric - 0.9mm, 250g / m 2 Raised plain woven fabric on the back;

[0059] (b) Choose water-based adhesive resin and apply 80g / m on the back of A base fabric 2 The adhesive resin is bonded to the front of the B base fabric (the A base fabric is on the top, and the B base fabric is on the bottom), and the composite base fabric is obtained after drying;

[0060] The polyurethane adhesive slurry formula is:

[0061] Waterborne PU resin (ImpranilLPRSC1537, solid content 60%): 100g

[0062] Microsphere foaming powder (551DU40): 40g

[0063] Solvent: 0g

[0064] The maximum drying temperature is 130 degrees Celsius.

[0065] (c) drying after coating Leasys3458 on the release paper;

[0066] (d) drying after coating 1.0mmImpranilLPRSC1537 on the surface layer slurry of c step gained;

[0067] (e) After coating HX-9530 on the middle layer slurry obtained in step d, semi-dryly p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weaving density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com