Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239results about How to "Density controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

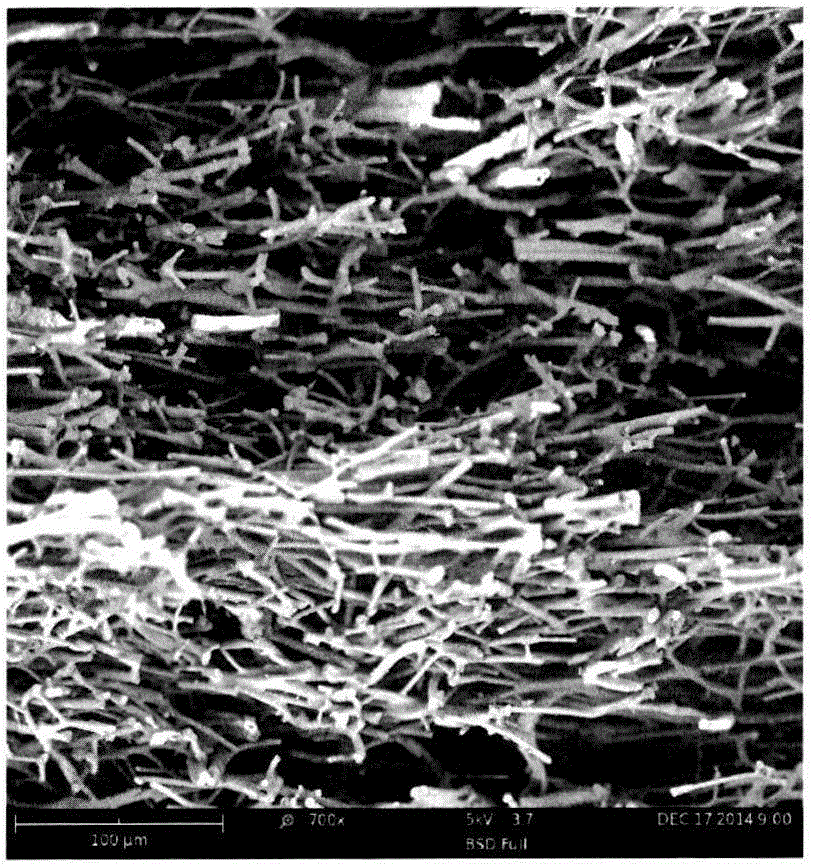

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing polylactic acid foam material

The invention relates to a preparation method for an expanded material of polylactic acid; the polylactic acid, a tackifying modifier, a chemical inhibitor, a vesicant, a foaming accessory ingredient, a abscess stabilizer and a parting agent are mixed under high temperature according to a certain proportion to obtain a basic mixture; then the basic mixture is arranged in a die to carry out moulding foaming on a vulcanizing machine with a certain temperature and a certain pressure to manufacture the foaming material of polylactic acid. The foaming material of polylactic acid manufactured by the method of the invention has excellent performances of being biodegradable, controllable density, easy processing as well as good barrier property, has similar foaming shaping performance and shock-absorbing capacity with polystyrene, can replace the foaming material of polystyrene, can be used as the materials for heat isolating, sound isolating and shock absorption and has broad application in the fields of cushion packaging, transportation, electric apparatus, refrigeration, agriculture and forestry and gardening.

Owner:SHANGHAI JIAO TONG UNIV

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Extrusion foaming thermoplastic polyurethane elastomer bead and preparation method thereof

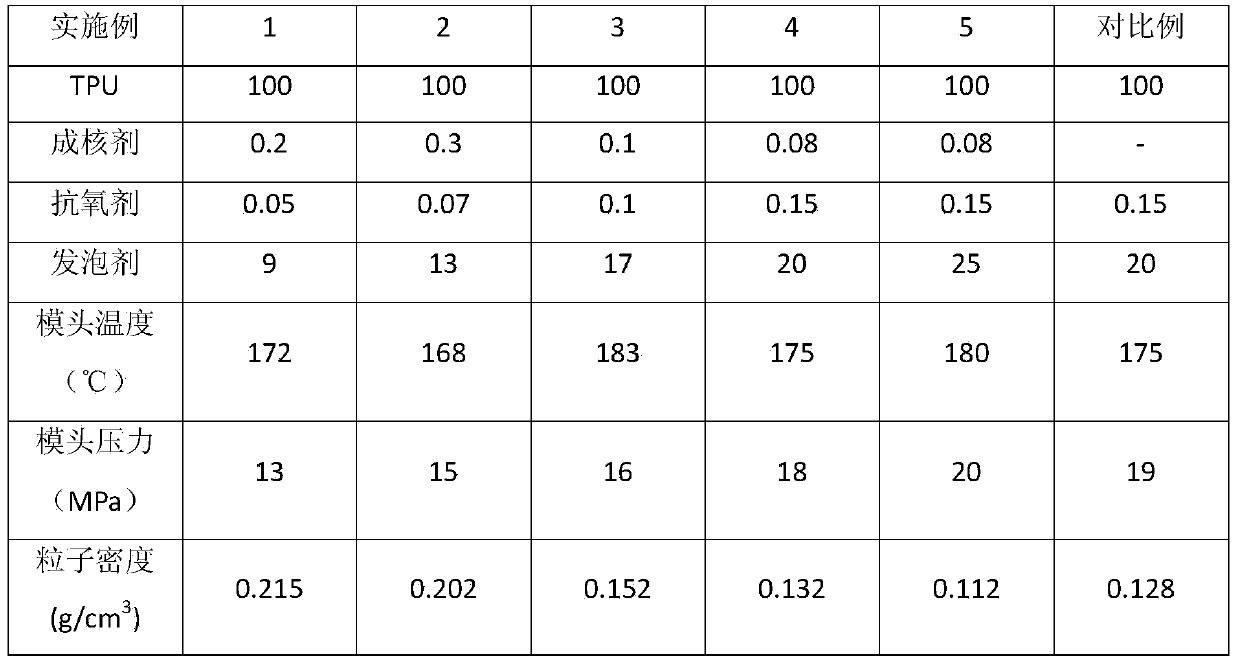

The invention discloses an extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead comprises the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 parts of a foaming nucleating agent, and 0.01-0.2 parts of an antioxidant, wherein a foaming process adopts supercritical fluid with the addition amount of 1-40 parts. The invention also discloses a preparation method of the extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead and the preparation method have the advantages that the foaming process does not cause environmental pollution; the obtained foaming material is stable in quality and high in foaming ratio; and the operation method in production is easy and suitable for continuous industrial production.

Owner:MIRACLL CHEM

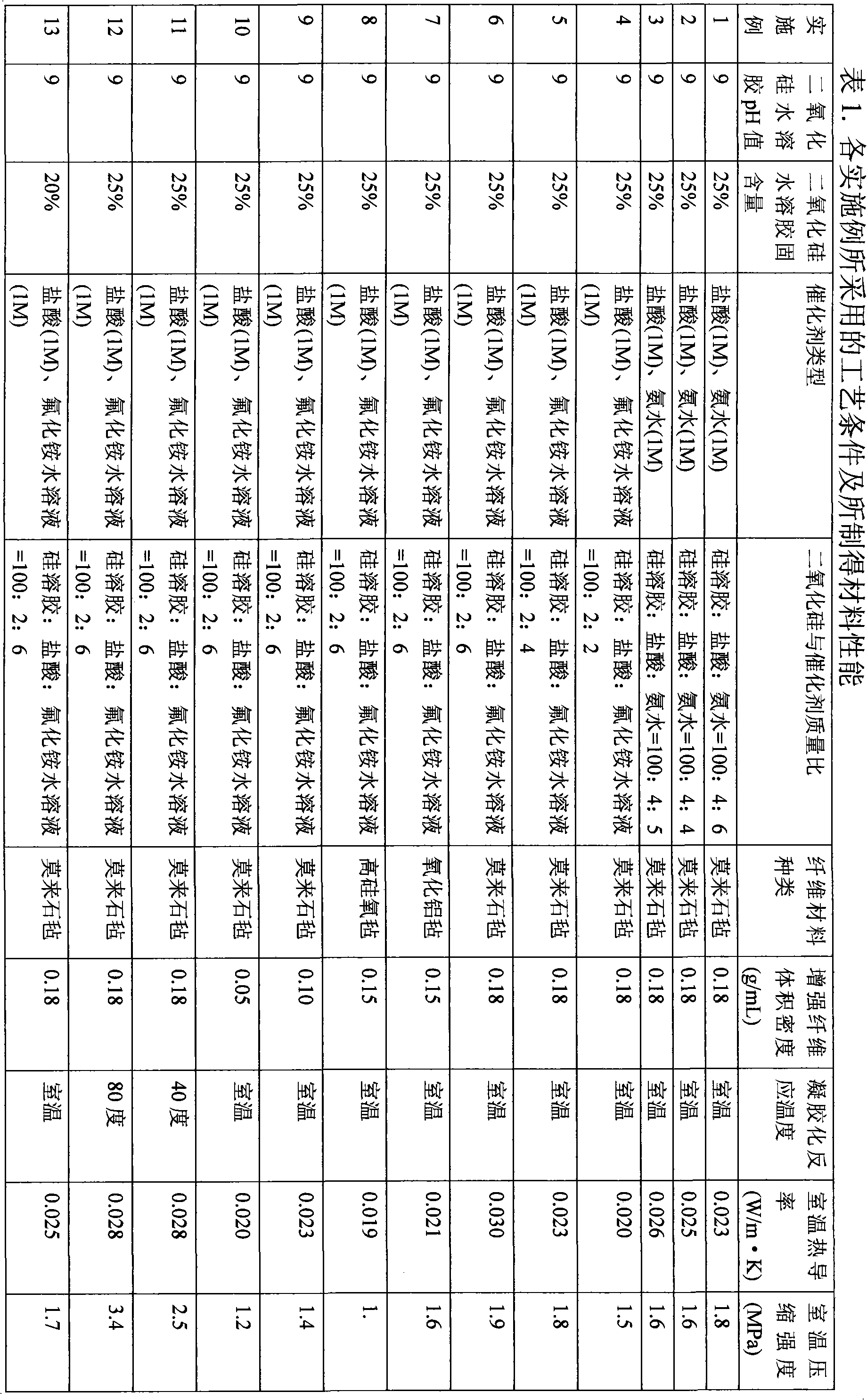

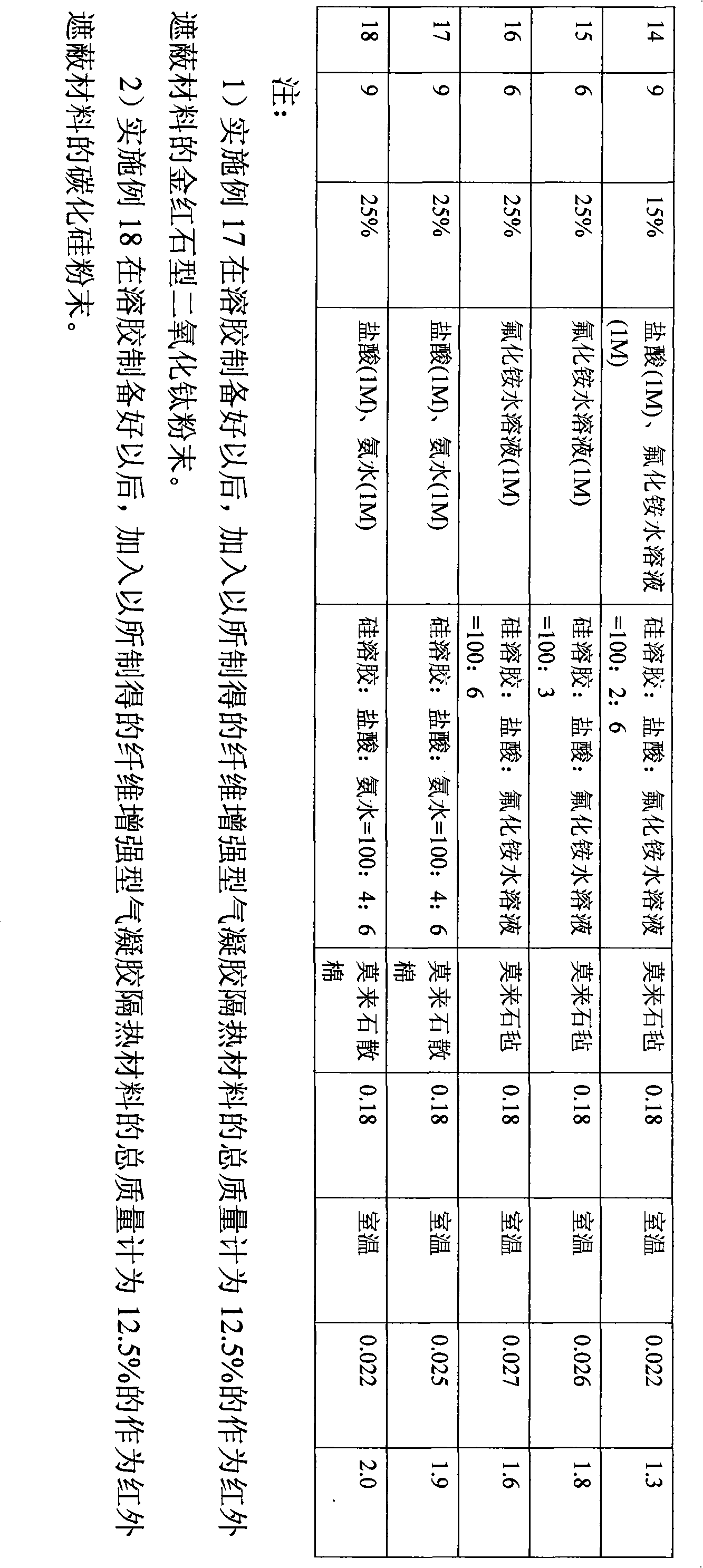

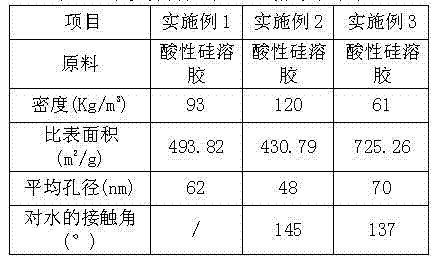

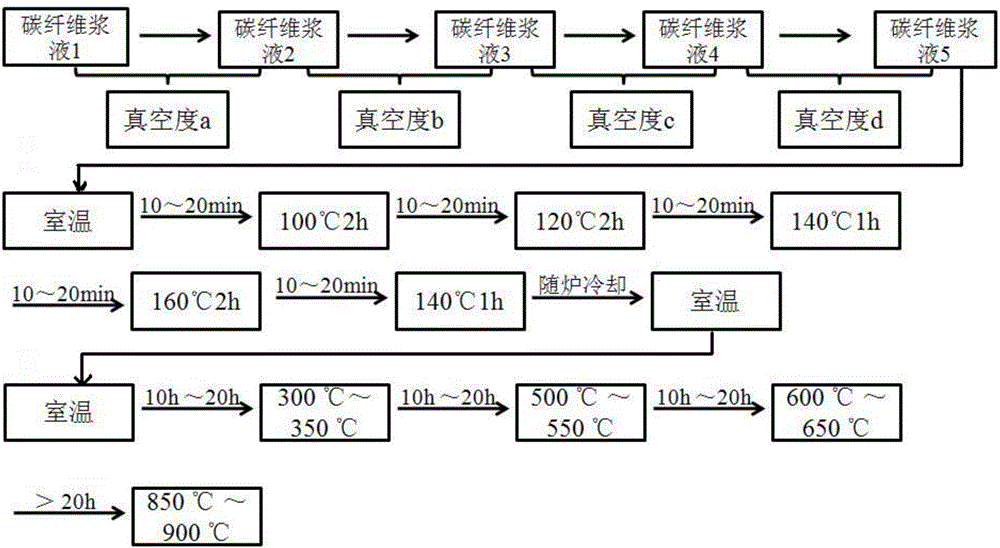

Method for preparing silicon dioxide aerogel by using acidic silica sol

ActiveCN102642842ALow cost of preparationSimple processSilicaBulk chemical productionSolventOrganosilicon

The invention discloses a method for preparing silicon dioxide aerogel by using acidic silica sol and belongs to the field of preparation of inorganic heat-insulating materials. The method comprises the following steps of: directly forming gel under actions of acid and alkali catalysts by using acidic silica sol as a raw material, wherein the process for preparing the gel does not involve organic solvent so as to improve the security of production; and preparing SiO2 aerogel through supercritical or constant pressure drying after the gel is subjected to solvent replacement and surface silylation. According to the method, the process for preparing the sol by using organic silicon as raw material and a complicated process for removing salt in water glass are avoided; and because the acidic silica sol with low cost and stable performance is used as the raw material, the method has the advantages that the process is simple, the production cycle is short, the reaction process is controlled, and the requirement and investment of the equipment are low, so that the industrial production of SiO2 aerogel can be realized.

Owner:纳诺科技有限公司

Polylactic acid foaming material and preparation method thereof

The invention provides a polylactic acid foaming material and a preparation method thereof. The polylactic acid foaming material is prepared from the following ingredients according to parts by weight: 45-93 parts of polylactic acid, 5-28 parts of toughener, 1-5 parts of nucleating agent and 1-10 parts of foaming agent. The polylactic acid is one of poly-L-lactic acid, poly-D-lactic acid and poly-DL-lactic acid or a mixture or a polymer thereof, and has the weight average molar mass of 0.8-3.5 million, molecular weight distribution of 1.2-2.5, and degree of crystallinity of 15-60 percent. The toughener is one of poly succinic acid butyl ester and poly adipate / butylene terephthalate or a mixture of two with random ratio. Other accessory ingredients can also be added. The preparation method comprises the following steps: evenly mixing the polylactic acid, the toughener, the nucleating agent, the foaming agent, the accessory ingredients and the like in a high mixing machine according to a certain proportion, then milling for 5-25 minutes at the temperature of 100-170 DEG C, and carrying out die pressing foaming on obtained materials at the temperature of 120-210 DEG C on a vulcanizing machine for 2-10 minutes to prepare the polylactic acid foaming material. The polylactic acid foaming material prepared by using the preparation method has the advantages of high resistance to shock, high elongation at break, high tensile strength and complete biodegradation after used.

Owner:南京冠创生物科技有限公司

Extruded foaming thermoplastic polyurethane elastomer particles and preparation method thereof

The invention relates to extruded foaming thermoplastic polyurethane elastomer particles and a preparation method thereof. The particles comprise the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 part of foaming nucleating agent, and 0.01-0.2 part of antioxidant. The preparation method comprises steps of firstly, mixing the materials, then throwing the mixture into an extruder to prill to obtain a bead raw material suitable for foaming, finally, throwing the beads into a special extruder for foaming, and after foaming by an opening die, pelletizing underwater so as to prepare the particles. The thermoplastic polyurethane foaming particles are prepared through an extrusion method; by controlling the foaming technology conditions, the foaming particles are controllable in density and have uniform cell density; the whole production method is simple to operate, has no special limitation and requirement on the equipment, and is applicable to industrial continuous production.

Owner:MIRACLL CHEM

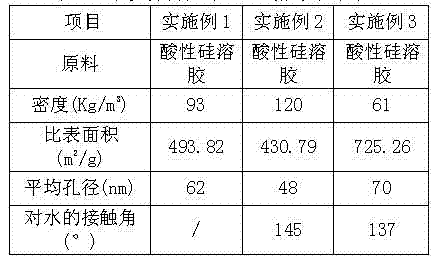

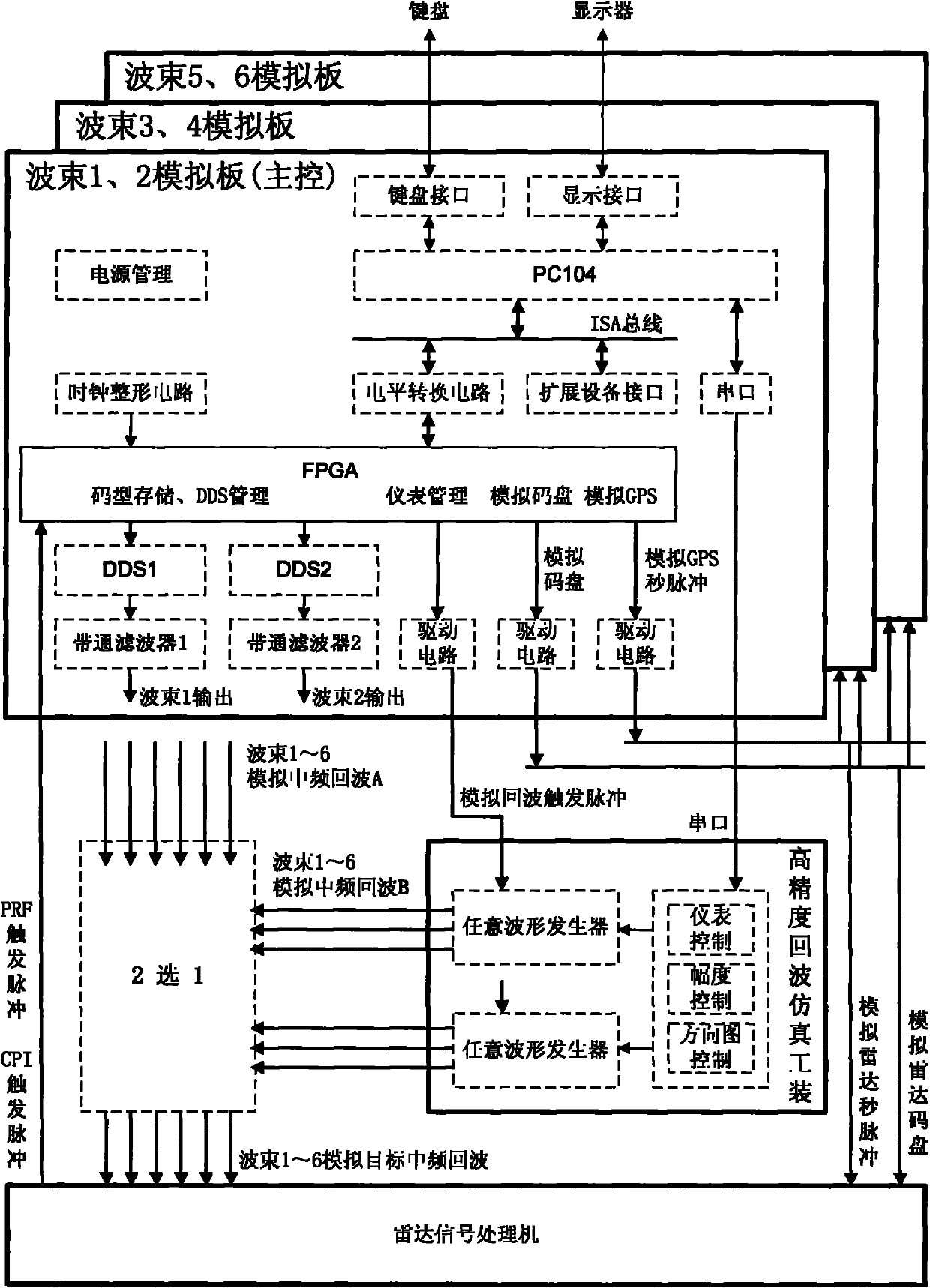

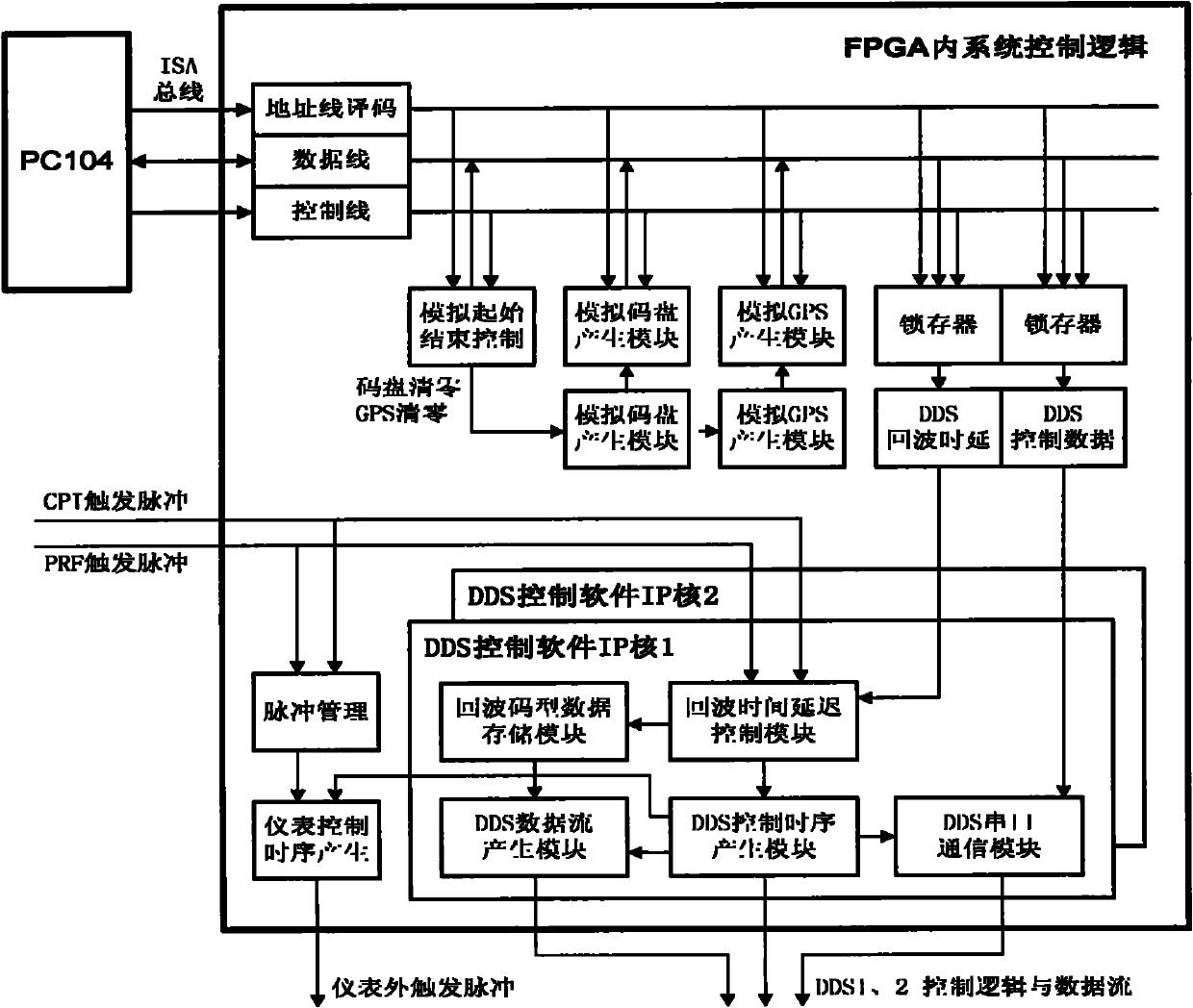

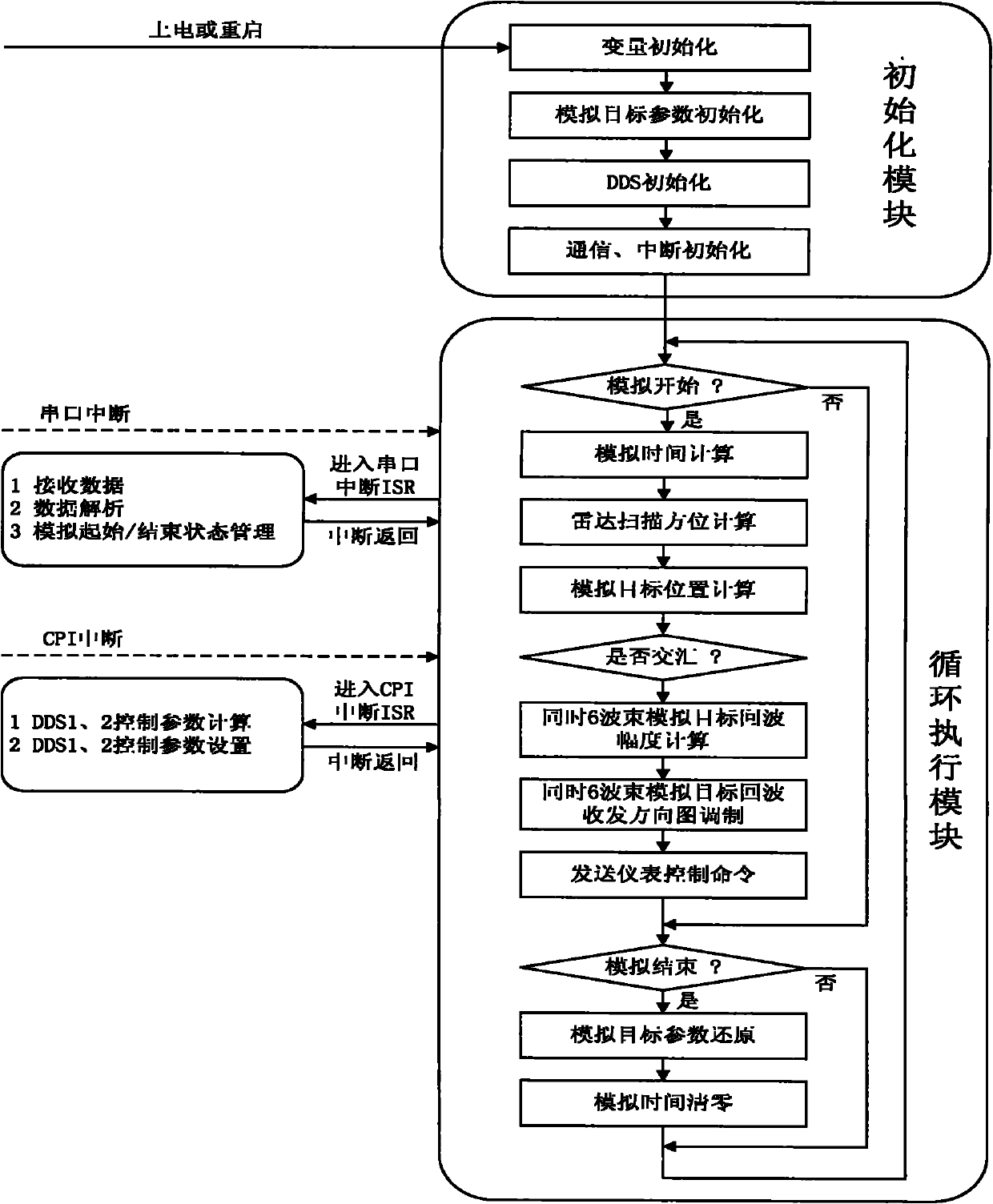

Radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and control method thereof

InactiveCN102023293AEasy to controlDensity controllableWave based measurement systemsIntermediate frequencyRadar signal processing

The invention relates to a radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and a control method thereof, relating to the field of radar target echo simulation. The system comprises three target echo simulation boards and an arbitrary waveform generator instrument fixture, wherein the echo simulation boards are designed with a computer module PC104, a field programmable gate array (FPGA), direct digital synthesis (DDS) technique and a simulation circuit as cores; and the arbitrary waveform generator instrument fixture is designed with instrument programming control as the core. According to the invention, simultaneous 6-channel simulated target IR echo simulation of the radar of the multi-beam amplitude-comparison angle measurement system is realized, parameters of the simulated target echo such as distance, delay, echo amplitude, Doppler shift, pattern, direction pattern modulation, noise superposition and the like can be controlled, single-channel switching and output of dual-beam echo is realized, and the test use requirement of the radar signal processor of the system is met. In the invention, the arbitrary waveform generator instrument frock is utilized, thus improving the amplitude precision of the output echo signals; and the control program in the FPGA in the target echo simulation boards is designed by the soft IP core, thus providing convenience for hardware transplanting and clipping.

Owner:中国兵器工业第二0六研究所

Preparation method of silica aerogel

ActiveCN102674374AWide variety of sourcesEasy to controlSilicon compoundsOrganic solventDesalination

The invention discloses a preparation method of silica aerogel, and belongs to the field of preparation of inorganic porous materials. The preparation method includes: allowing alkaline silica sol to form aerogel directly under the action of acid catalyst and base catalyst; performing solvent displacement and surface silylanizing; and supercritical or atmospheric drying to obtain SiO2 aerogel. Organic solvents are not used in sol formation, and accordingly dangers in sol formation are eliminated. The complex process of sol preparation by organosilicone and desalination by sodium silicate is omitted from the aerogel preparation, the alkaline silica sol low in cost and stable in performance is used as raw material, process is simple, production cycle is short, reaction process is controllable, equipment requirements and investment are low, and industrial production of SiO2 aerogel is achieved.

Owner:纳诺科技有限公司

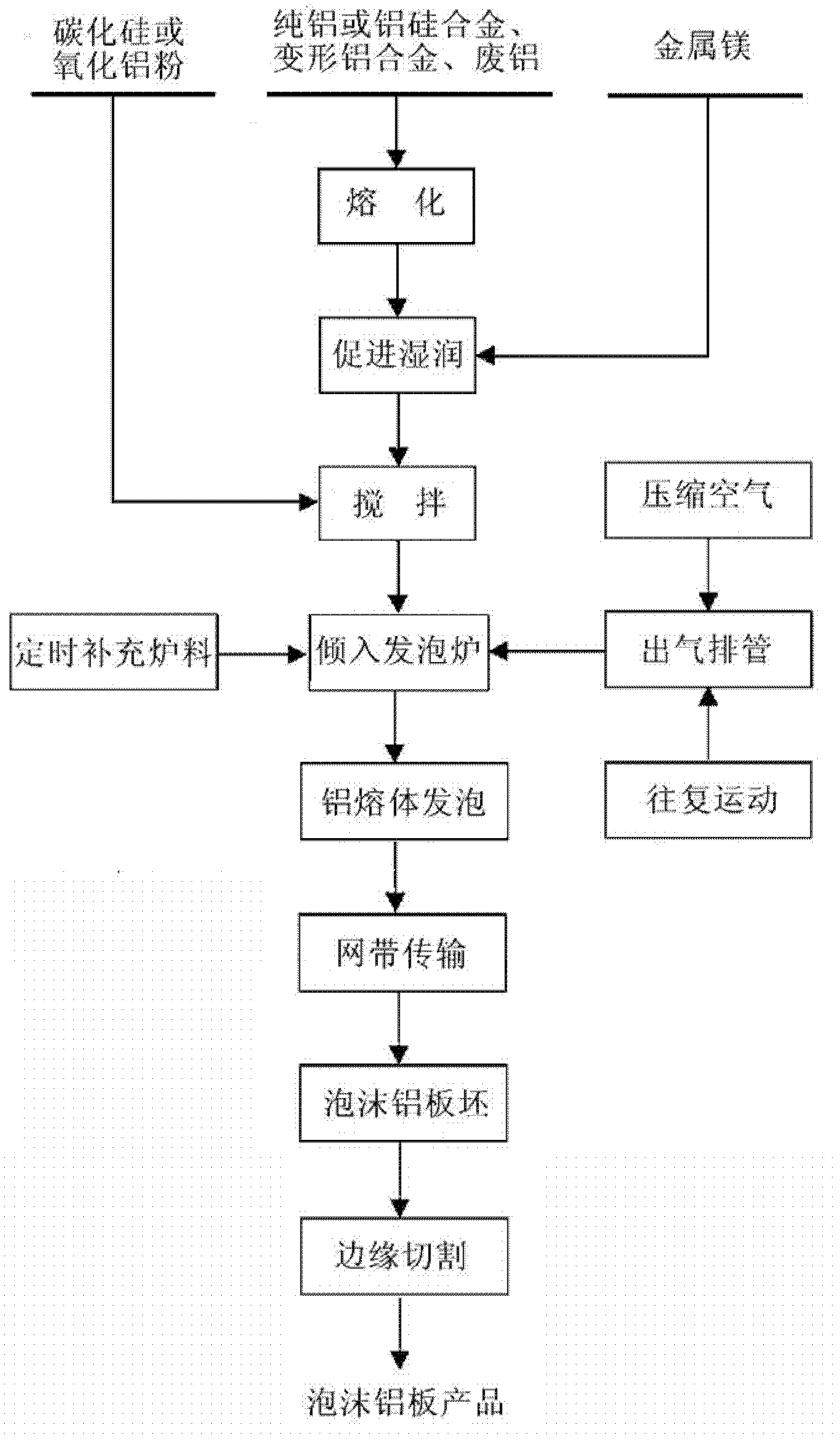

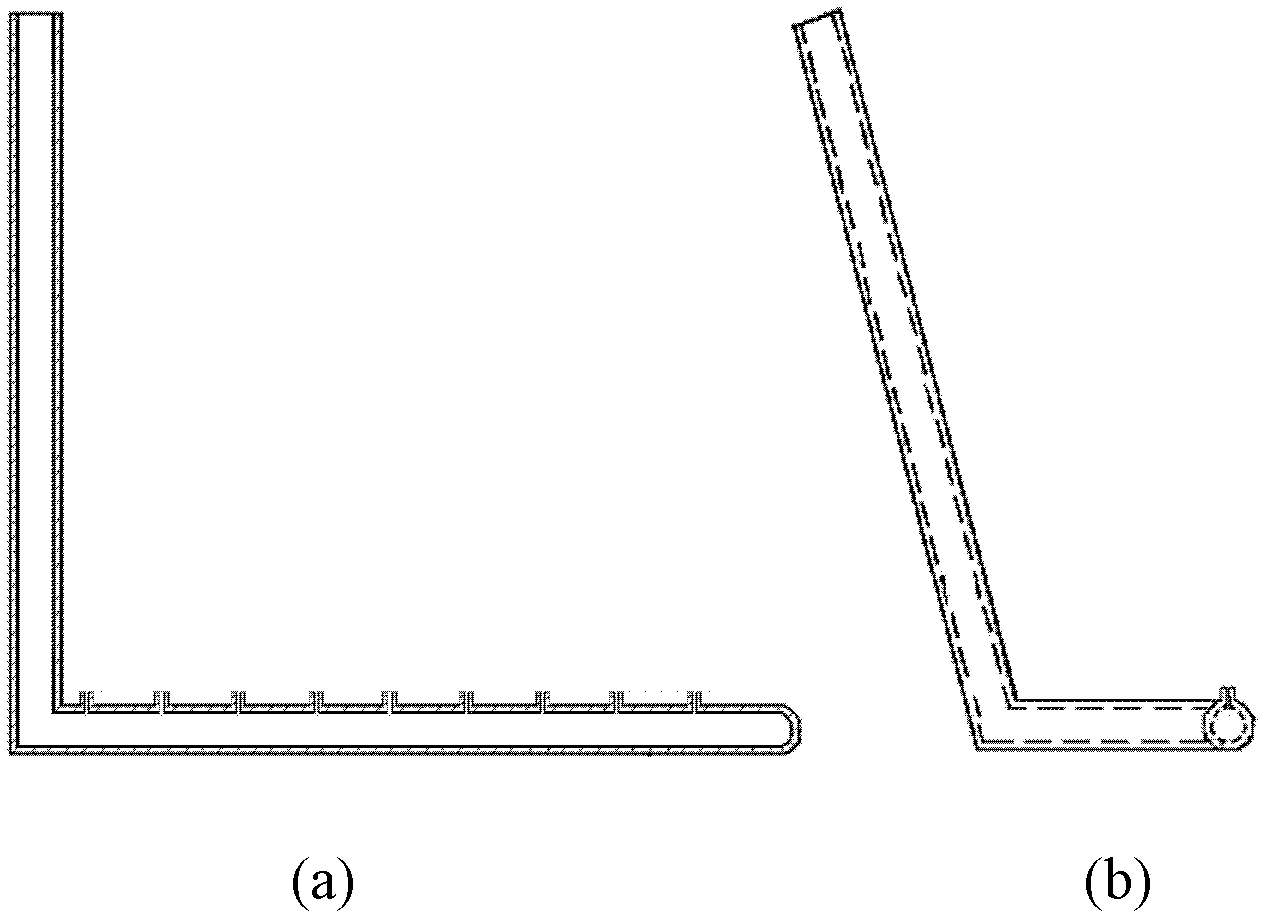

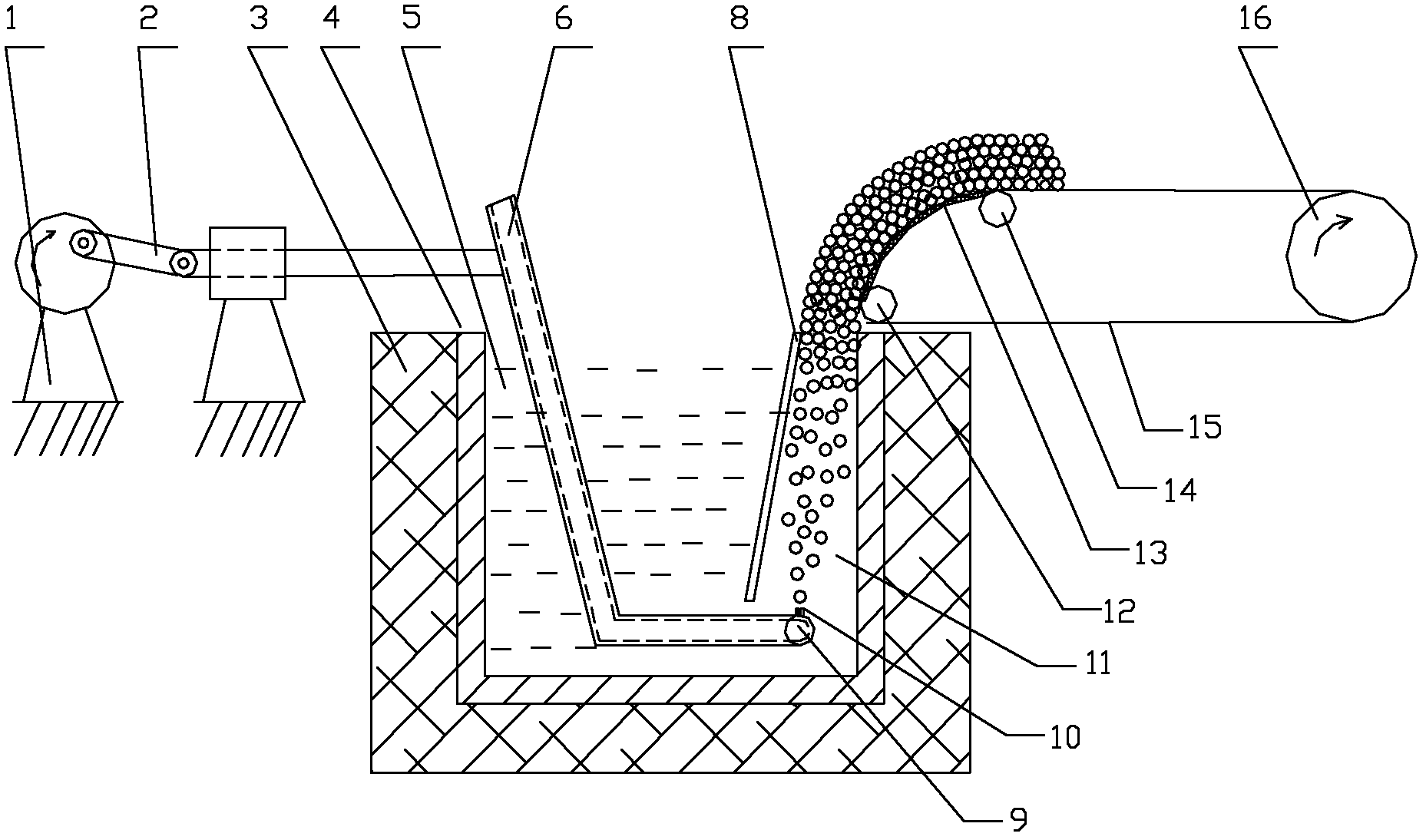

Process and apparatus for continuous production of closed-cell aluminum foam with blowing foaming

The invention relates to a process and an apparatus for continuous production of a closed-cell aluminum foam through blowing foaming. The process comprises the following steps: melting a raw material, adding with a ceramic tackifier and a moistening promoter, stirring to obtain molten aluminum with uniform component, carrying out continuous foaming with the apparatus for the continuous productionof the closed-cell aluminum foam with blowing foaming to obtain a molten aluminum foam with uniform foam size, and controllable density and productivity, and producing a foamed aluminum board by going through a net belt and transmitting with an arc transition mechanism and cutting. The apparatus is characterized in that: a simple crank link mechanism is adopted to realize the reciprocating motion of a horizontal outlet duct, and the arc transition mechanism allows the ascending lifting of the molten aluminum foam to be changed into horizontal transmission. According to the invention, the process and the apparatus are simple, the operation control is accurate, and a purpose that the pore size and the density of foamed aluminum products can be accurately controlled at a high efficiency anda low cost is realized because the foam size of the molten aluminum is adjusted by changing the frequency of the reciprocating motion of the outlet duct, the pressure and the flow of a compressed gasand the diameter of outlet micropores.

Owner:ANHUI NEOFOUND TECH

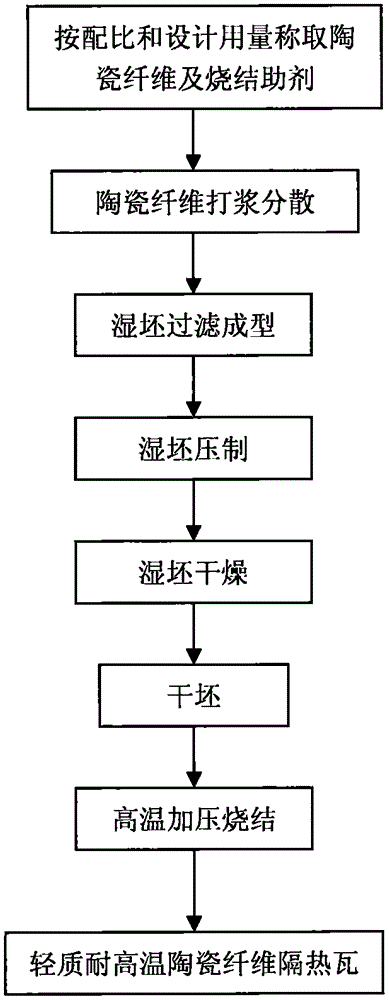

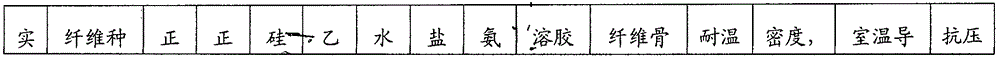

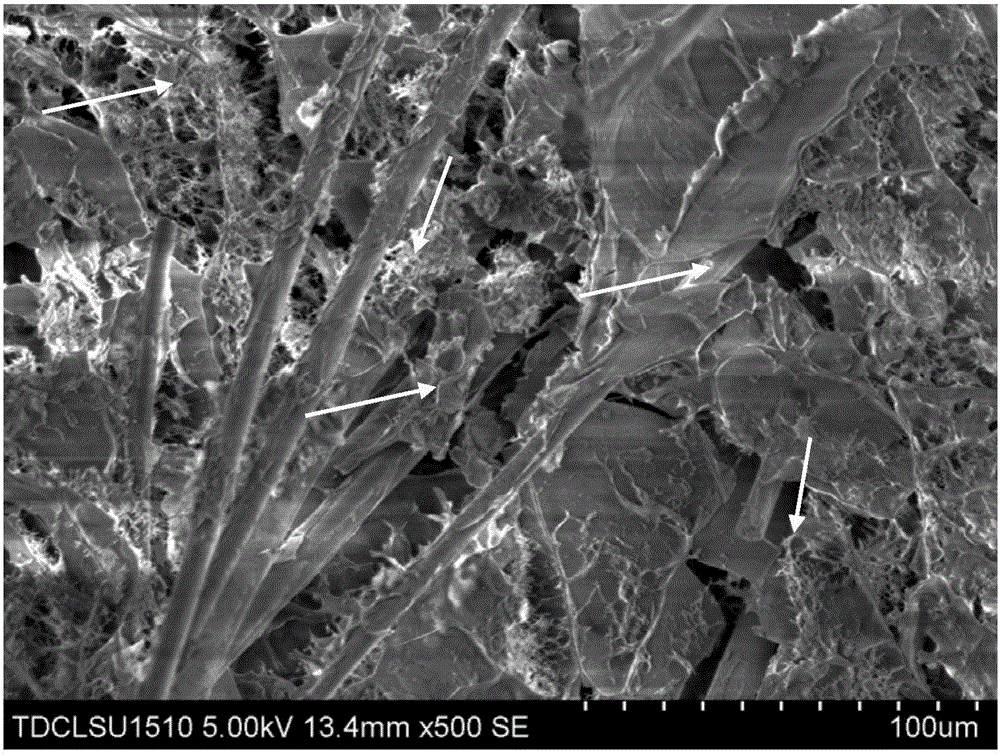

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

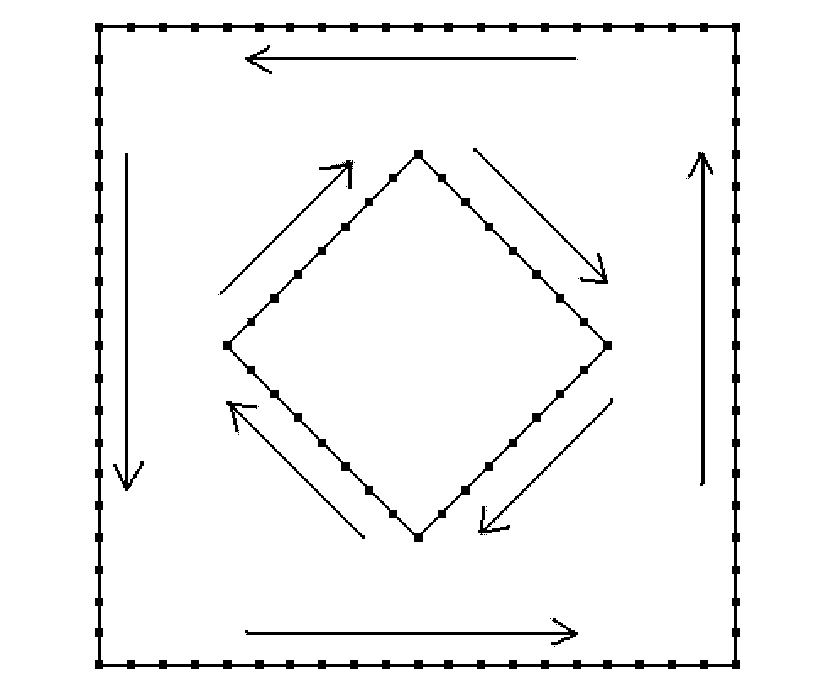

Generation method of quadrilateral grid of geometric model with any internal feature constraints

The invention relates to a generation method of quadrilateral grids of a geometric model with any internal feature constraints, which outstandingly enhances the generation quality and efficiency of the quadrilateral grids and has convenience and practicability. The generation method comprises the following steps of: (1.1) building an entitative geometric model according to an entity to be analyzed by utilizing a computer; and determining the shapes and the positions of constraint lines and density lines of the entitative geometric model, the positions of constraint points and density points and the range and the inner and outer boundaries of each region; (1.2) generating grid nodes on the inner and outer boundaries, the constraint lines and the density lines of the entitative geometric model according to grid size information set by a user, and numbering the grid nodes; viewing the constraint points and the density points as newly generated grid nodes, and numbering the newly generated grid nodes; (1.3) viewing the constraint lines, the density lines, the constraint points and the density points as internal cavities with areas of zero, generating node rings on the inner and outer boundaries of each region, and transforming a multiply connected region with the internal feature constraints into a simply connected region; (1.4) dividing the quadrilateral grids in each region; and finally generating the quadrilateral grids with the internal feature constraints.

Owner:SHANDONG UNIV

Water-foamed, antibacterial and air-permeable microporous film masterbatch, film and preparation method thereof

The invention relates to air-permeable microporous film masterbatch and further relates to a masterbatch containing plastic film and a preparation method thereof. The water-foamed, antibacterial and air-permeable microporous film masterbatch contains a polyolefin polymer, a modifier, a microporous water-absorbing inorganic expanded material, an initiator, a surfactant and a plastic antioxidant. The water-foamed, antibacterial and air-permeable microporous film contains the water-foamed, antibacterial and air-permeable microporous film masterbatch and blow-molded film plastics. The preparation method comprises the steps of granulating the masterbatch, then, carrying out water absorbing aging, adding the blow-molded film plastics, carrying out mixing, and adding the mixture into a foaming and extruding film blowing machine for extrusion, thereby preparing the film. The water-foamed, antibacterial and air-permeable microporous film provided by the invention has the characteristics of simple and stable preparation process, good processability and the like; a water foamer is adopted, is environment-friendly and safe and has an antibacterial function, and the extruded antibacterial and air-permeable film is controllable in micropore density, has the characteristics of fine and uniform open porous texture and cell size, and the like and has the characteristics of excellent comprehensive mechanical properties, environment-friendliness, easiness in recovery, and the like.

Owner:深圳市环美盛科技有限公司

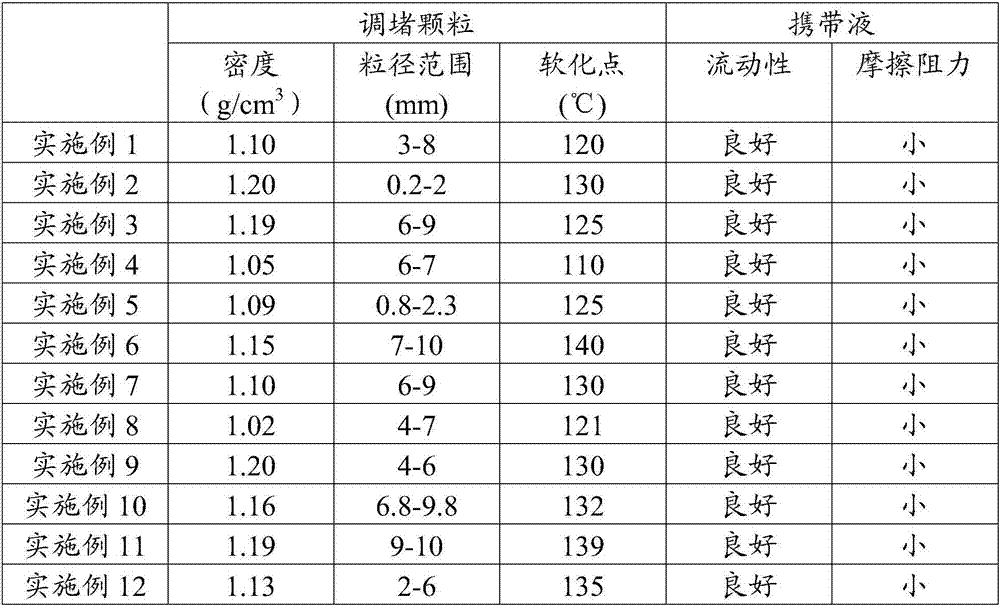

Flow channel regulation agent for fractured-vuggy oil reservoir and preparation method thereof

InactiveCN107474807AReduce frictional resistanceDensity controllableDrilling compositionWater flowOil production

The invention relates to a flow channel regulation agent for a fractured-vuggy oil reservoir. The flow channel regulation agent is prepared from a carrying solution and plugging regulation particles, wherein the carrying solution is prepared from a polymer and water at the ratio of (0 to 3) : (97 to 100); the plugging regulation particles are of an viscoelastic particle mixture, and are prepared from a high molecular polymer, calcium carbonate and bentonite at the ratio of (95 to 100) : (0 to 5) : (0 to 5); the ratio of the carrying solution to the plugging regulation particles is (10 to 100) : (0 to 90). The flow channel regulation agent for the fractured-vuggy oil reservoir, provided by the invention, is suitable for high-temperature and high-mineralization-degree flow channels of a reservoir stratum, and can realize layer-by-layer plugging from a water injection well to a preferred water flow channel of an oil production well, and the layer-by-layer plugging is a key point for realizing the implementation of the flow channel regulation agent for the fractured-vuggy oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing silicon dioxide aerogel by using acidic silica sol

ActiveCN102642842BWide variety of sourcesEasy to controlSilicaBulk chemical productionOrganic solventSolvent

The invention discloses a method for preparing silicon dioxide aerogel by using acidic silica sol and belongs to the field of preparation of inorganic heat-insulating materials. The method comprises the following steps of: directly forming gel under actions of acid and alkali catalysts by using acidic silica sol as a raw material, wherein the process for preparing the gel does not involve organic solvent so as to improve the security of production; and preparing SiO2 aerogel through supercritical or constant pressure drying after the gel is subjected to solvent replacement and surface silylation. According to the method, the process for preparing the sol by using organic silicon as raw material and a complicated process for removing salt in water glass are avoided; and because the acidic silica sol with low cost and stable performance is used as the raw material, the method has the advantages that the process is simple, the production cycle is short, the reaction process is controlled, and the requirement and investment of the equipment are low, so that the industrial production of SiO2 aerogel can be realized.

Owner:纳诺科技有限公司

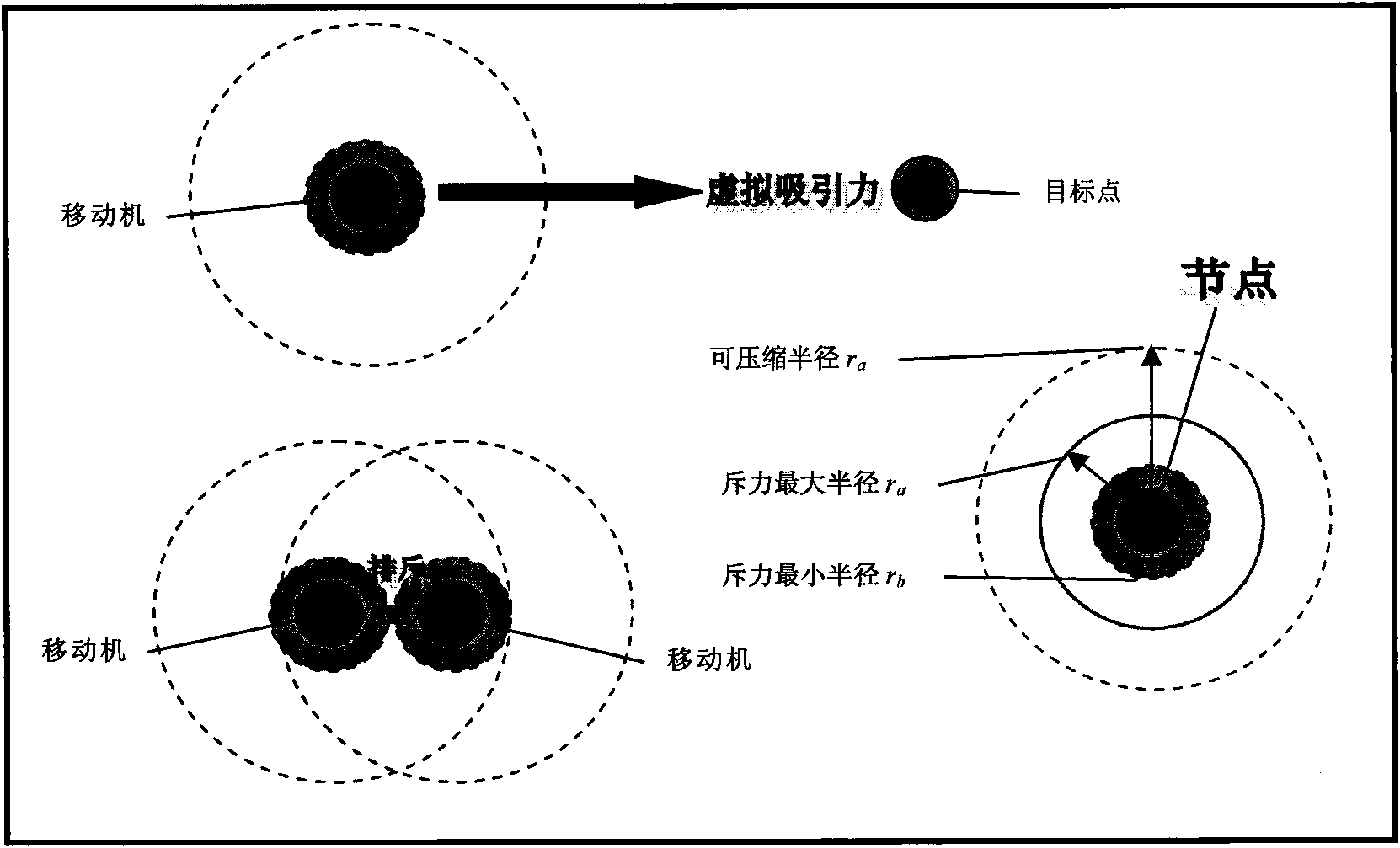

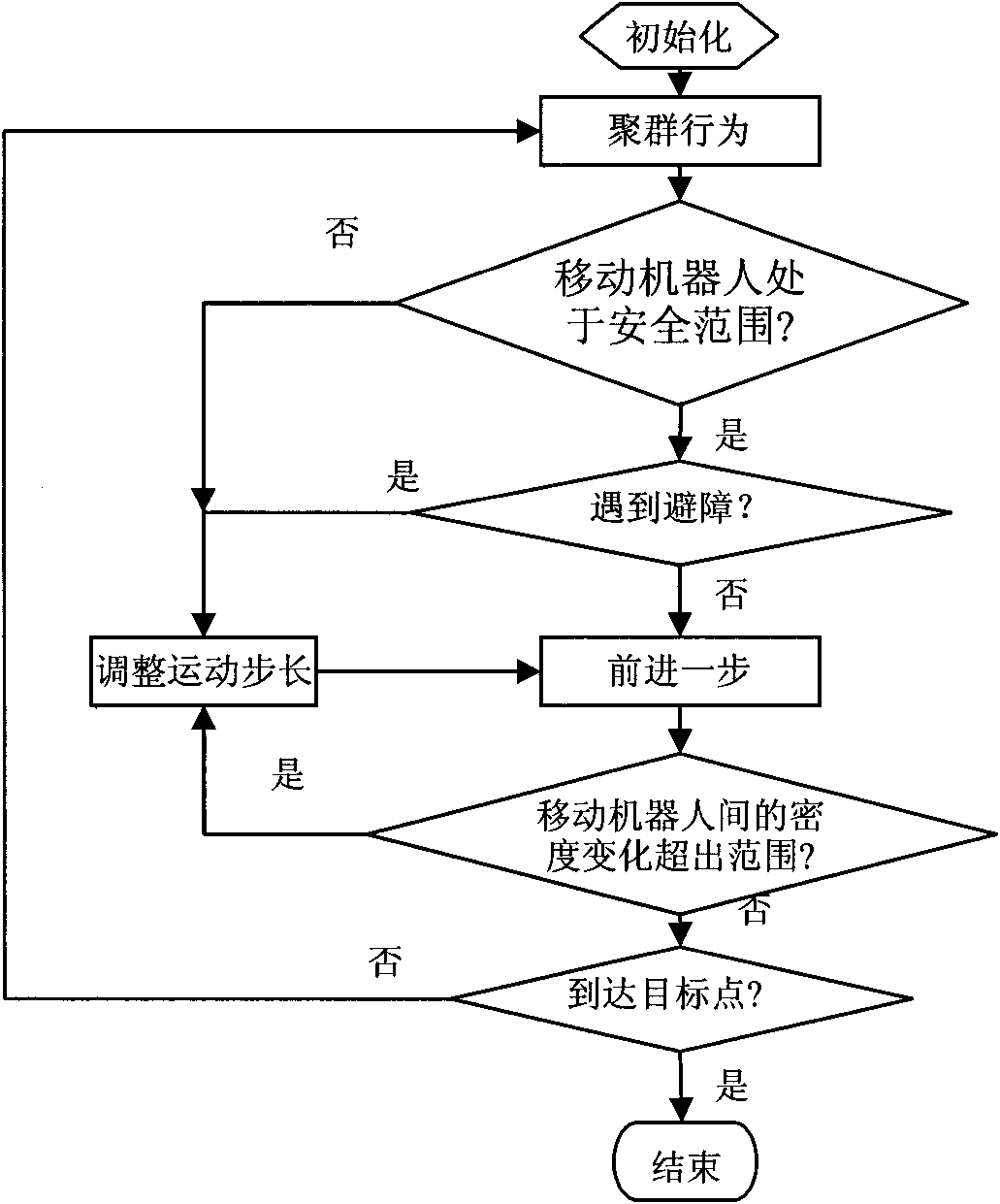

Method for controlling density of group mobile robots in any formation

InactiveCN102053621AUniform densityFacilitate communicationVehicle position/course/altitude controlPosition/direction controlSimulationCrowds

The invention discloses a method for controlling the density of group mobile robots in any formation, and belongs to the technical of mobile multiple robots. The method includes steps of grouping mobile robots, setting an advance destination point for the group mobile robots, and performing ground mobile adjustments to the robots till the destination is achieved. The invention adjusts the problem that the robots are too dispersive through a crowded factor, and adjusts the safety distance to solve the problem that the robots are too crowded or barriers are too close and cause collisions easily, through a robot spring model with a compressible range; and the formation of the group mobile robots is changed, but the method can efficiently ensure the communicating and sensing range of the group mobile robots, and overcome the phenomenon that one robot falls behind easily. The method enables the group mobile robots to be highly automated, the density of the group mobile robots can be controlled, and any formation can be formed according to movement environments, so that the method has the characteristics of keeping the density of the group mobile robots in an unknown environment and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

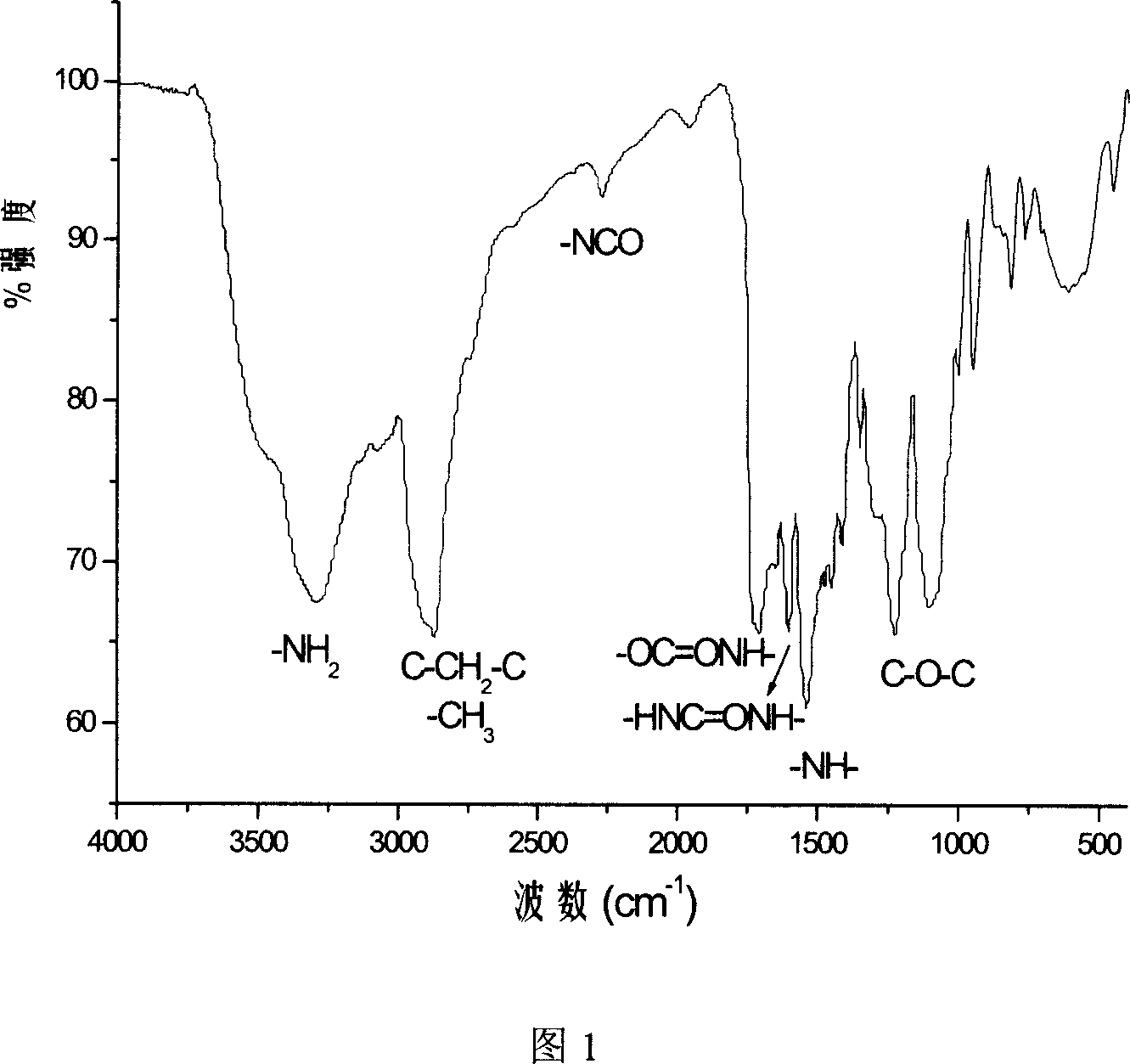

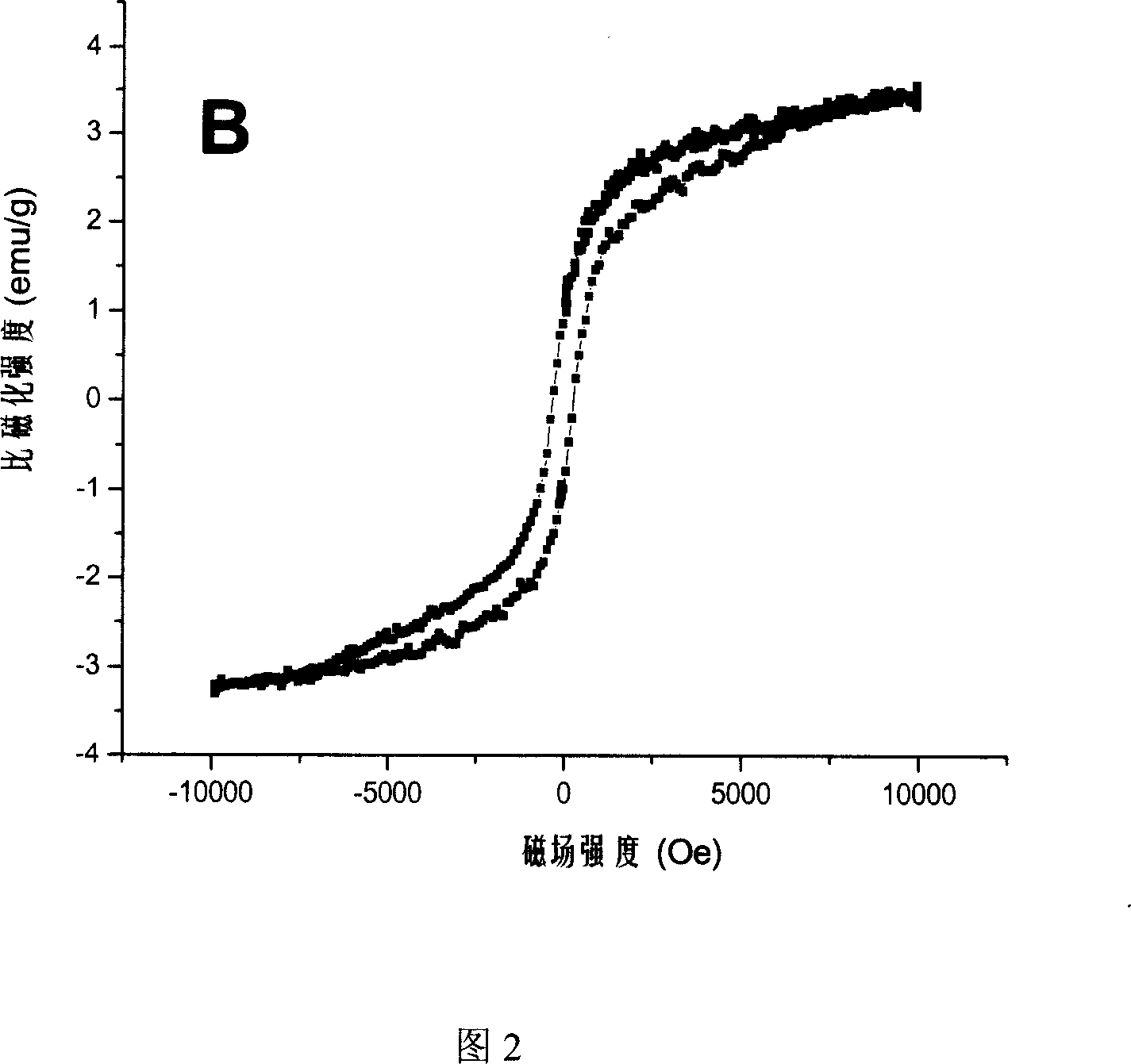

Core/shell type polyurethane magnetic compound microsphere, preparation method and use thereof

InactiveCN1966097ASimple manufacturing methodReduce manufacturing costImmobilised enzymesInorganic non-active ingredientsMicrosphereX-ray

The invention relates to a corn / case polyurethane magnetic composite micro ball, and relative preparation, wherein it uses inorganic magnetic particles as corn, uses polyurethane as case, while its diameter reaches 800micrometer; and its production comprises that: planting -NH and -NH2 groups on the surface of magnetic inorganic powder; than polymerizing into polyurethane prepolymer; forming stable oil / water suspension in the disperser solution; then polymerizing into magnetic inorganic / polyurethane magnetic composite micro ball. The inventive micro ball has X-ray contrast, high magnetic response and low density of polyurethane macromolecule, etc. And inventive production has simple process and low cost. Said micro ball can be used to prepare vessel plunge material and drug carrier.

Owner:WUHAN UNIV OF TECH

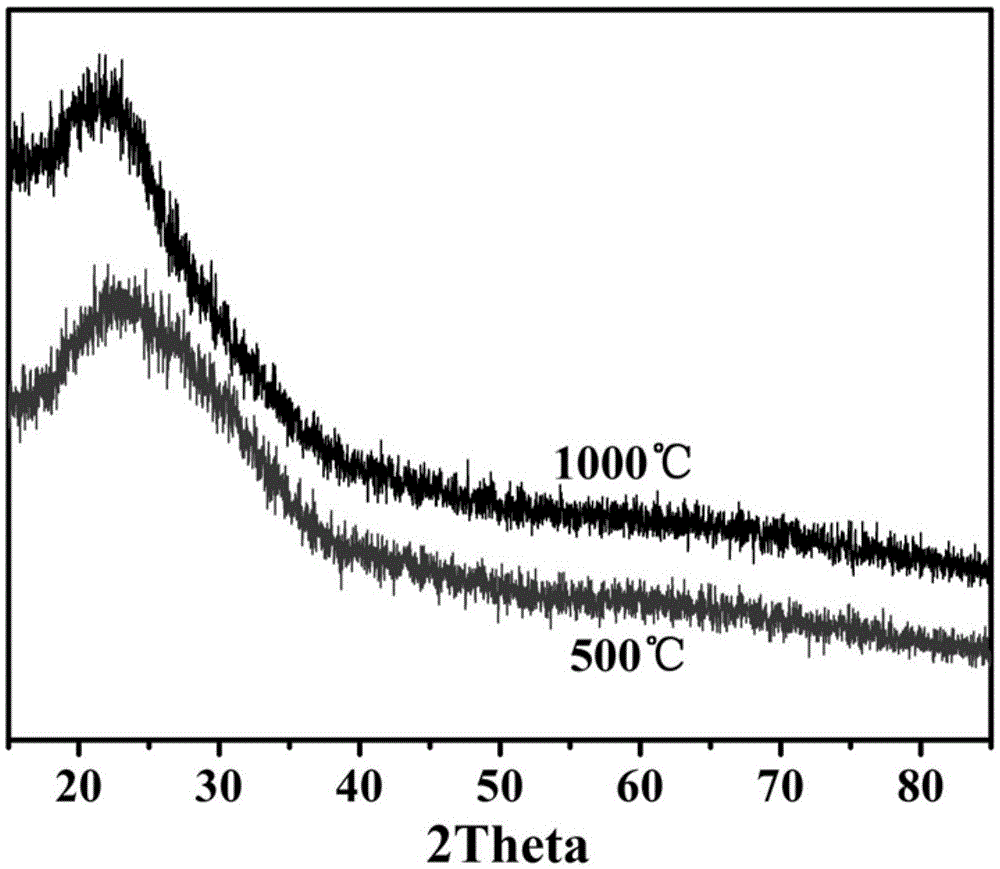

Silicon carbide aerogel and preparation method thereof

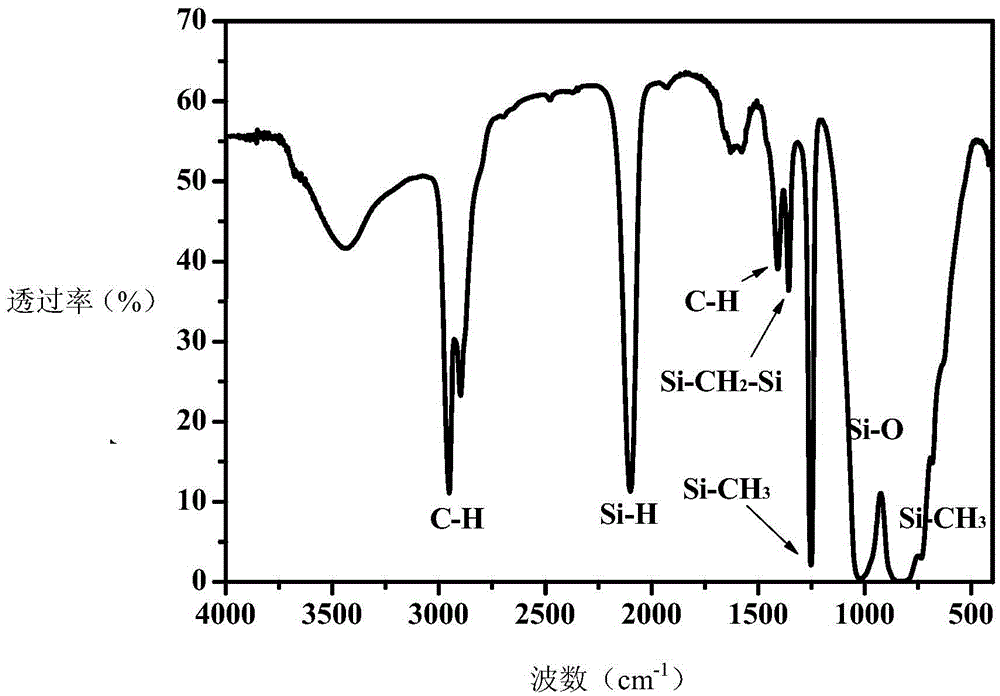

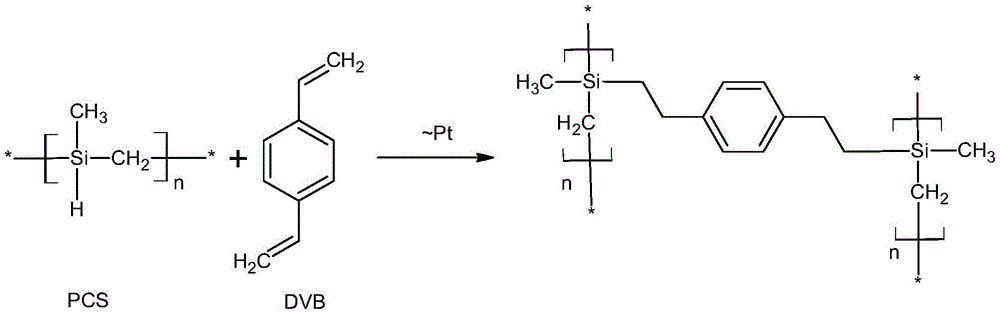

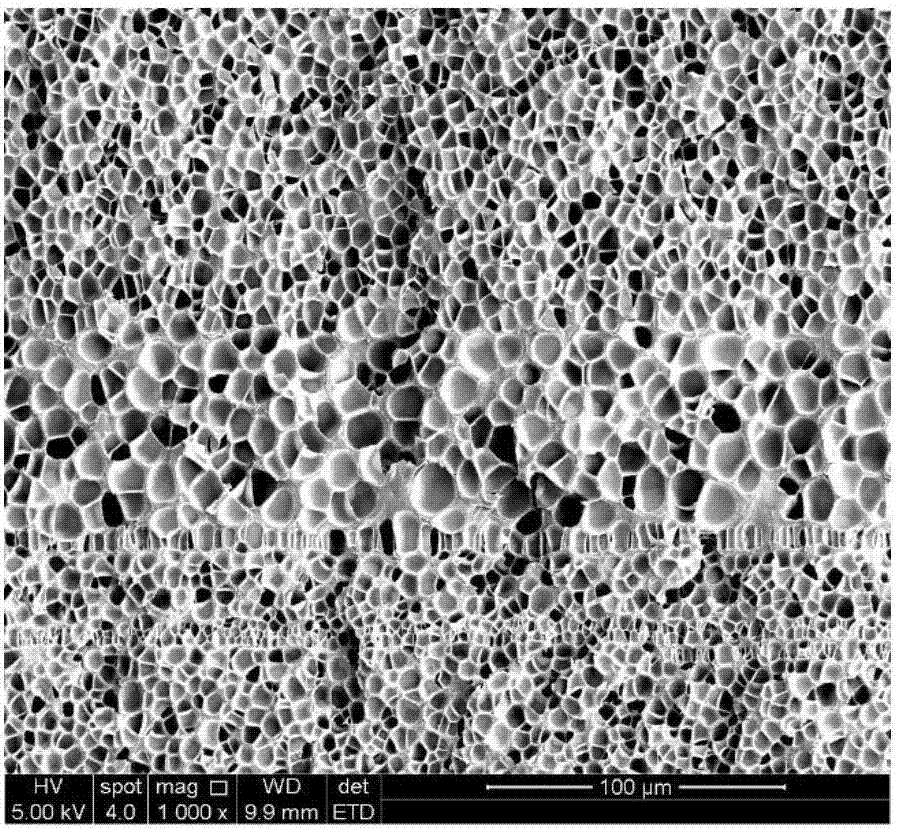

The present invention discloses a silicon carbide aerogel, which is prepared from polycarbosilane containing Si-H bond, divinylbenzene, a Pt catalyst and an organic solvent by a polymer precursor conversion ceramic preparation method and aerogel preparation method. The silicon carbide aerogel has a specific surface area of 50-400 m<2> / g, a porosity of 70-90% and density of 0.1-0.2 g / mL; the mass ratio of polycarbosilane to divinylbenzene is 1:08-1.2; and the Pt catalyst accounts for 0.1-0.5% of the total weight of polycarbosilane and divinylbenzene. The method utilizes polymer precursor conversion ceramic preparation method for preparation of SiC aerogel, and the conversion temperature is as low as 800 DEG C. The obtained SiC aerogel has low oxygen content, high purity, good quality, and controllable porosity and density; and the process is simple and controllable.

Owner:厦门纳美特新材料科技有限公司

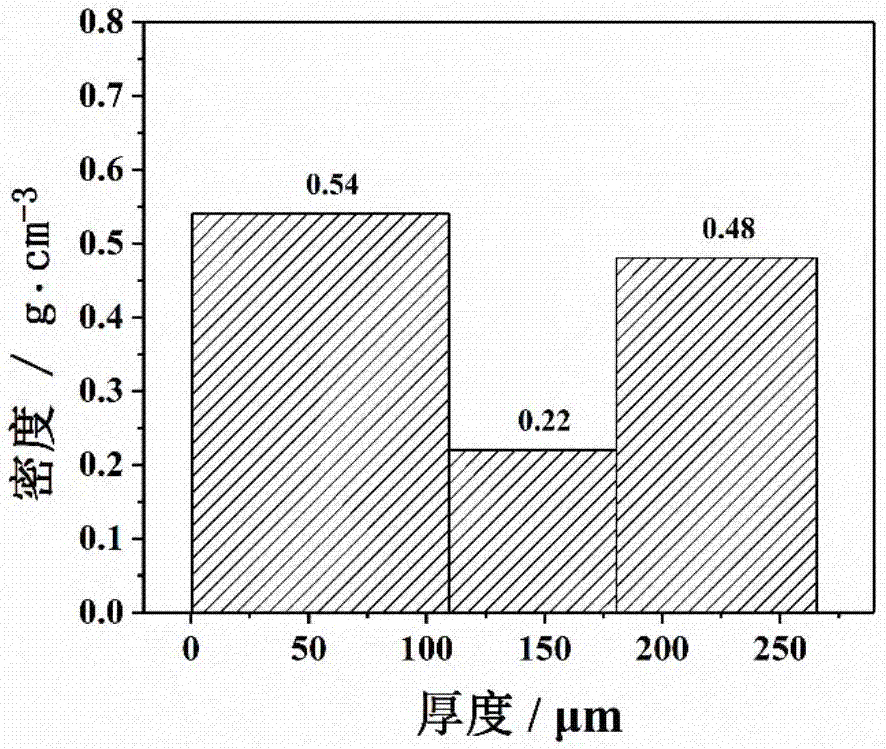

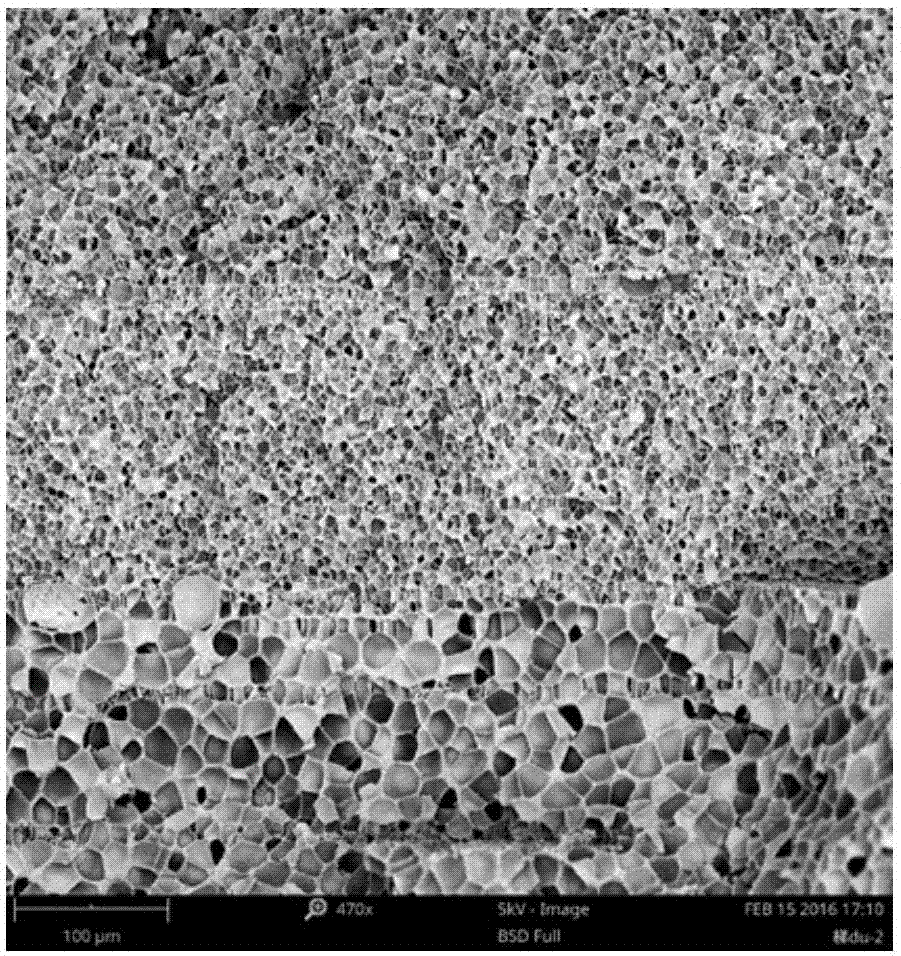

Preparation method for polymer-based density-gradient foam material

The invention discloses a preparation method for a polymer-based density-gradient foam material. The preparation method specifically comprises the following steps: firstly, mixing a mixed system of micron metal particles and a polymer through high-temperature mixing to obtain composite material melts with different densities; secondly, carrying out melting hot-pressing on the melts at a high temperature separately to obtain a density-gradient composite material; and finally, foaming the density-gradient composite material through supercritical carbon dioxide foaming to obtain the polymer-based density-gradient foam material. According to the preparation method disclosed by the invention, the polymer-based density-gradient foam material is prepared from combining a lamination hot-pressing process with a supercritical carbon dioxide foaming technology, the density of the material is adjustable in a range from 0.2g / cm<3> to 1.96g / cm<3>, and the density of a sample presents gradient change at different positions; the diameter of the material is in a micron scale, and the material is high in dimensional stability, structural controllability and mechanical strength, and has wide application prospects in the fields of cushion packaging, impact protection, aerospace, transportation, building energy conservation and the like.

Owner:WUHAN UNIV OF TECH

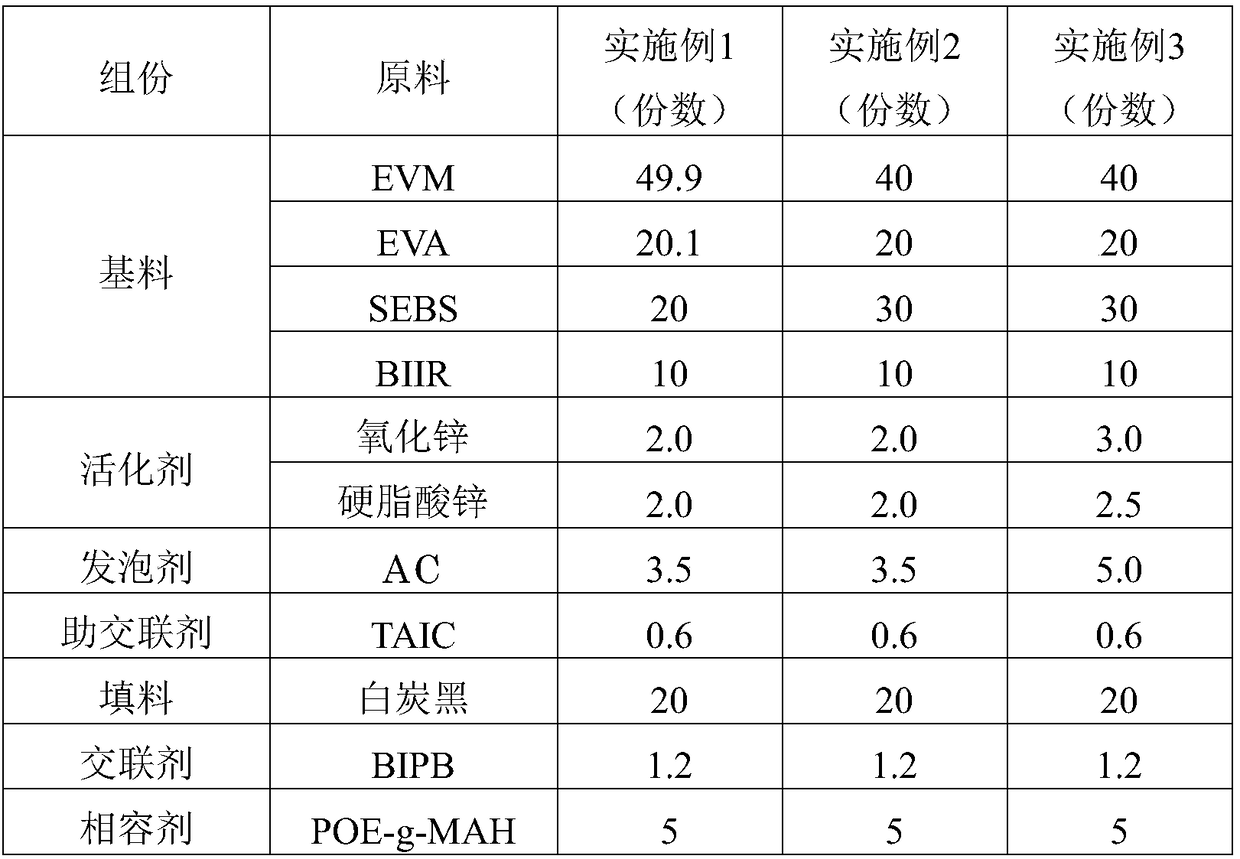

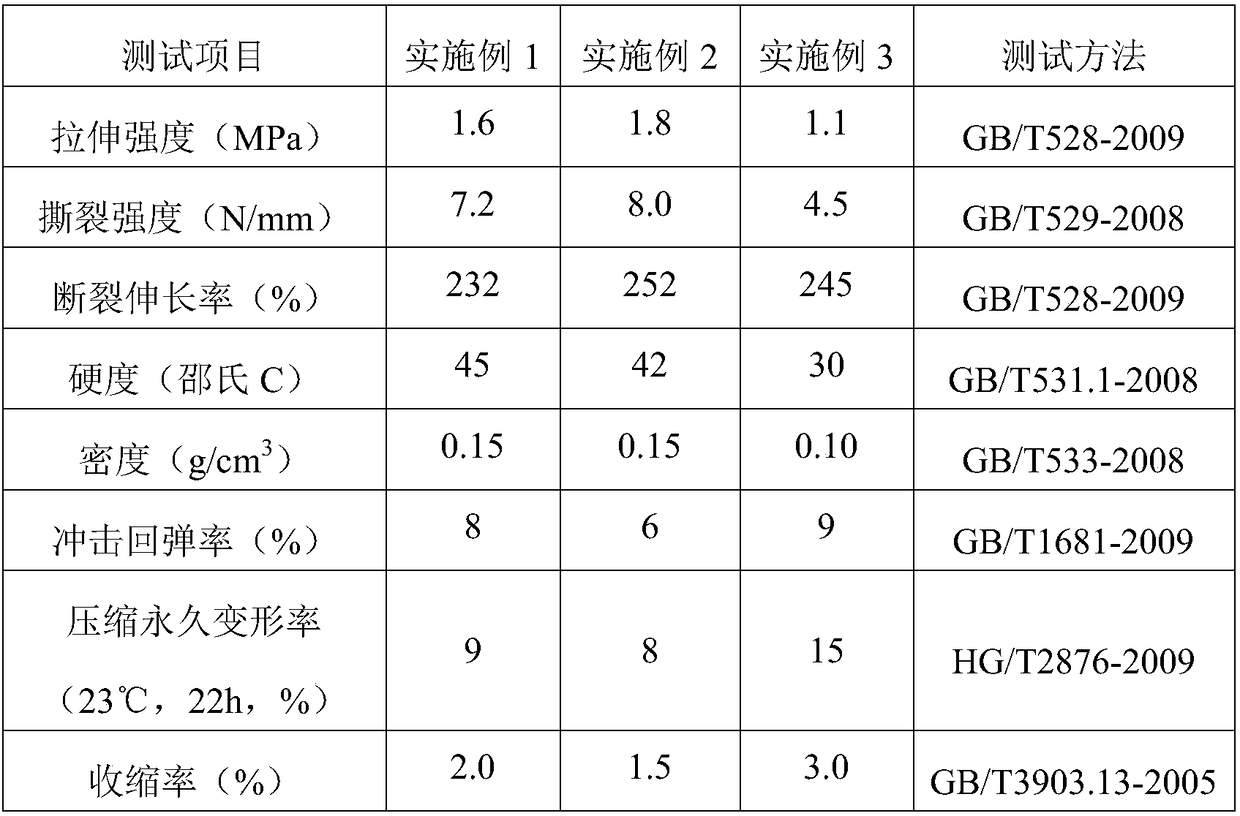

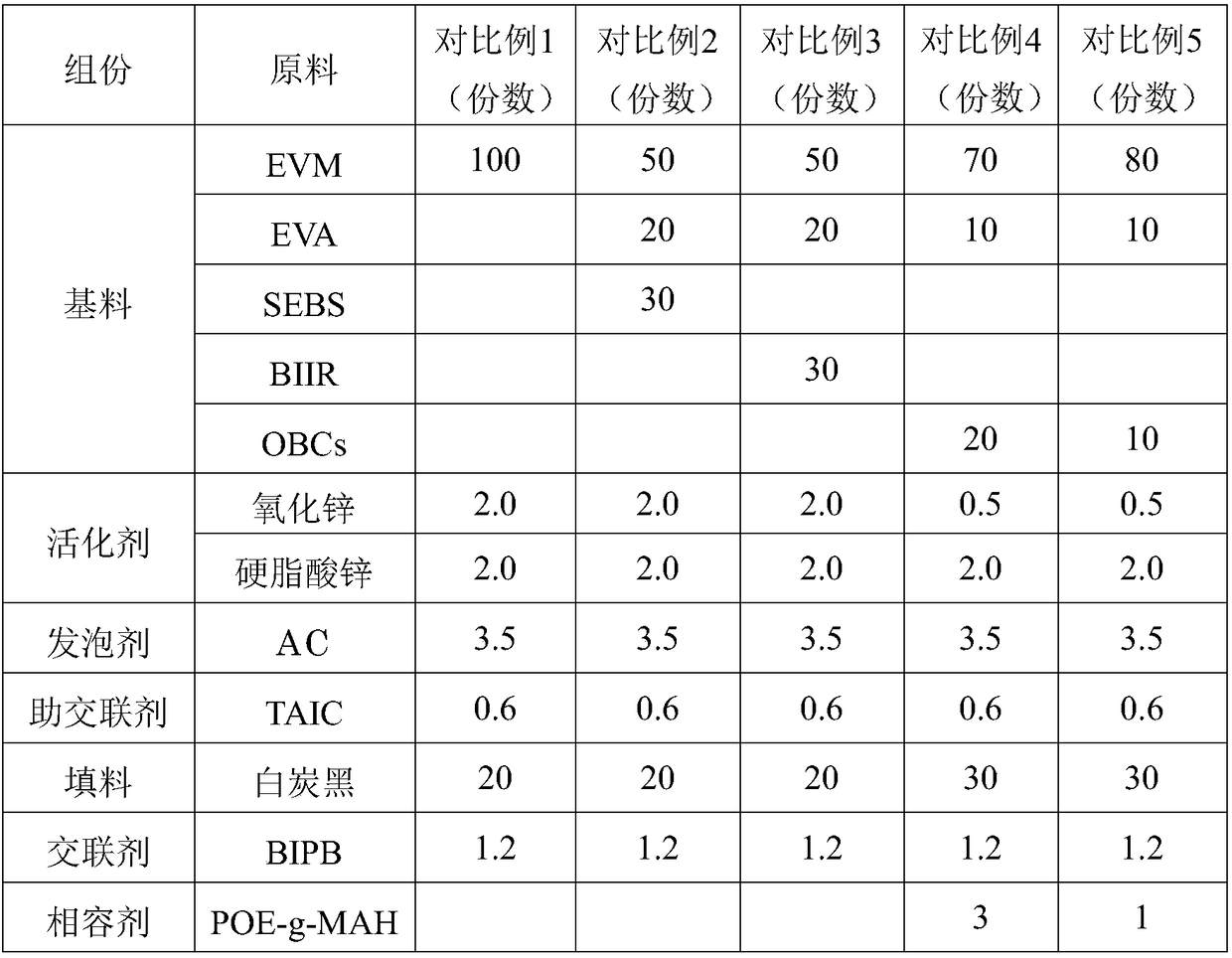

Foam material for shoes and preparation method thereof

ActiveCN108485143AImprove shock absorptionImprove deformation resistanceSolesFoaming agentShrinkage rate

The invention relates to a foam material for shoes and a preparation method thereof. The foam material for shoes comprises the following components in percentage by weight: base stock, a foaming agent, a crosslinking agent, an assistant crosslinker, an activating agent and a filler, wherein based on the total mass of 100%, the base stock comprises 30-49.9% of ethylene-vinylacetate rubber, preferably 35-45%, 10-30% of ethylene-vinyl acetate resin, preferably 15-25%, 20-40% of a styrene-ethylene-butene-styrene block copolymer, preferably 25-35%, and 5-30% of brominated butyl rubber, preferably 5-20%. The foam material for shoes, disclosed by the invention, is uniform in foam structure, has excellent shock absorption, deformation resistance, lightweight and low cost, and can achieve the aim of controlling the density, elasticity, hardness and hot-shrinkage rate according to different proportions of the various components.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST JINJIANG CO LTD +1

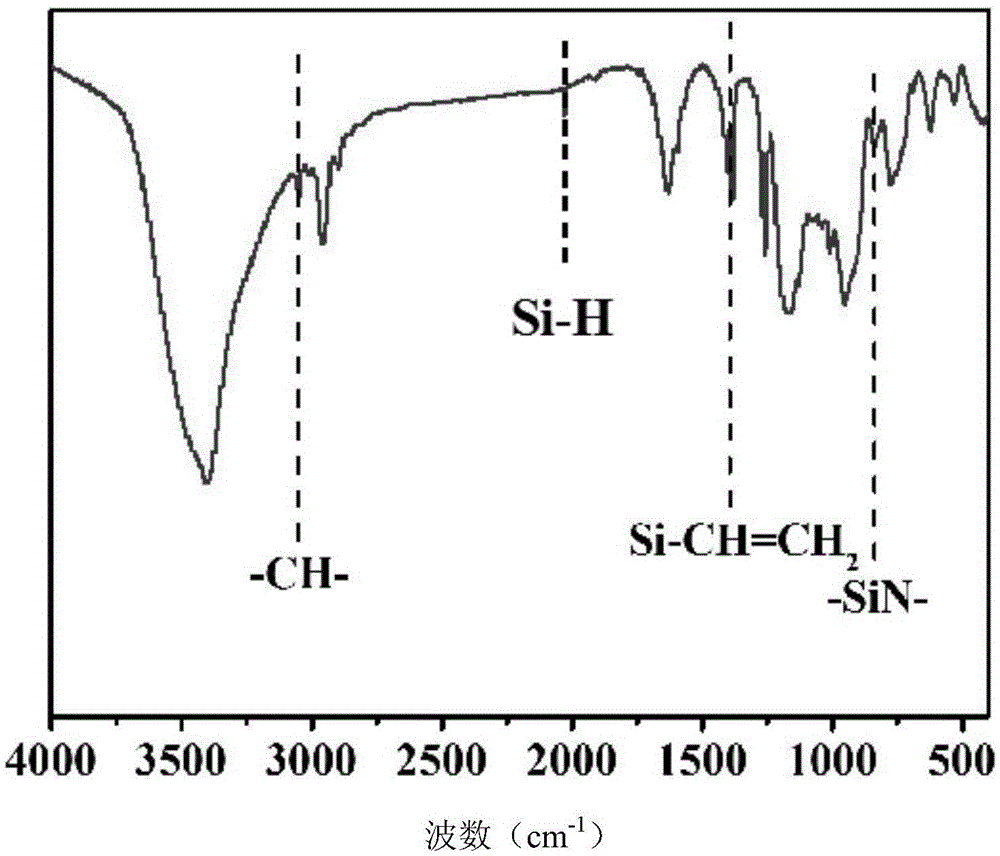

SiCN aerogel and preparation method thereof

The invention discloses a SiCN aerogel. The raw materials comprise polyvinyl silazane containing -CH=CH2 bond or also containing both -Si-H bond in the molecular structure, and divinylbenzene / dicumyl peroxide. A polymer precursor conversion ceramic preparation method and an aerogel preparation method are conduced to prepare the SiCN aerogel with specific surface area of 100-200 m<2> / g, porosity of 80-90% and density of 0.05-0.15 g / mL. The SiCN aerogel of the invention is a novel nano-porous ceramic material with extremely high porosity and specific surface area, and low density.

Owner:厦门纳美特新材料科技有限公司

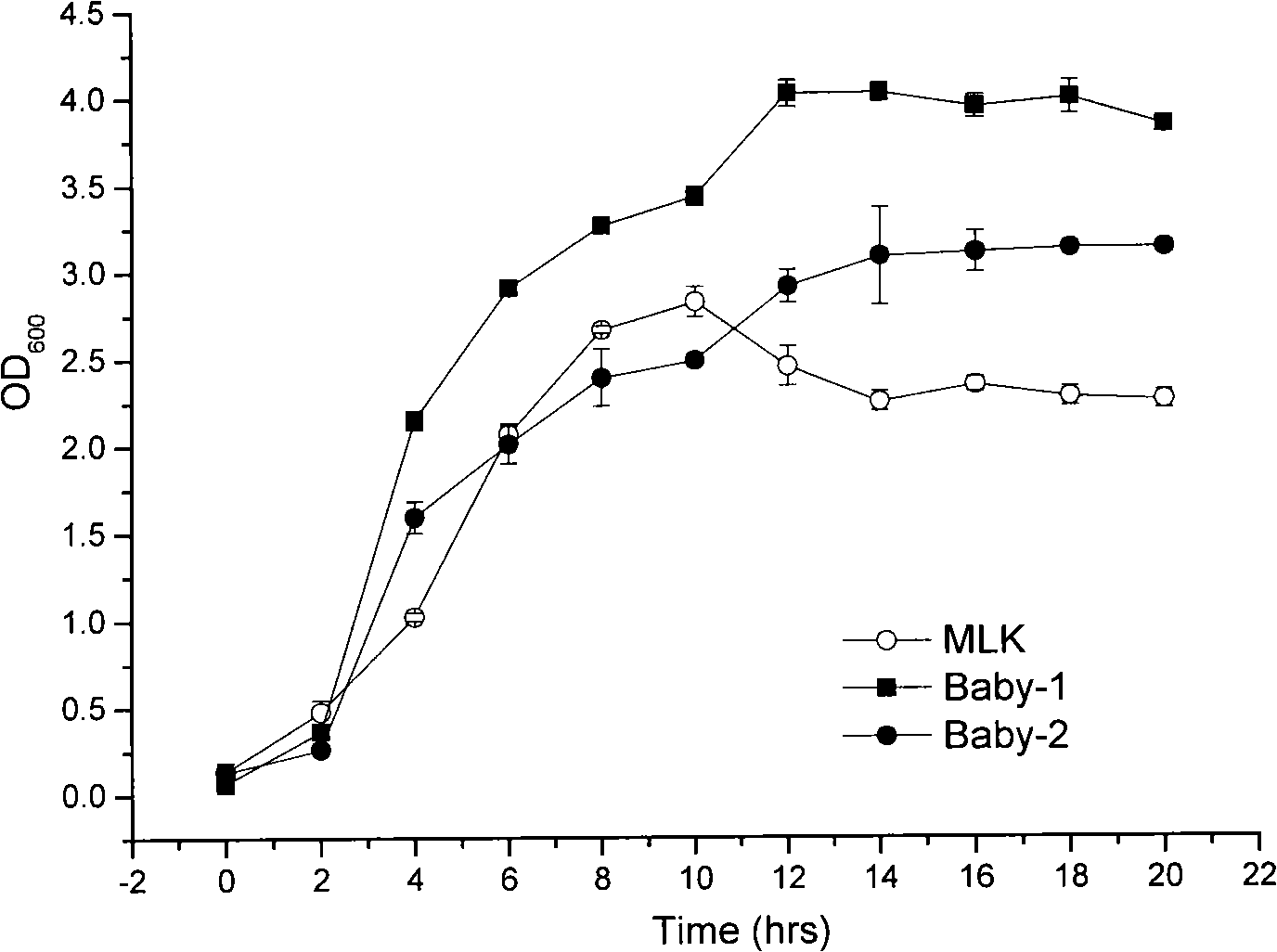

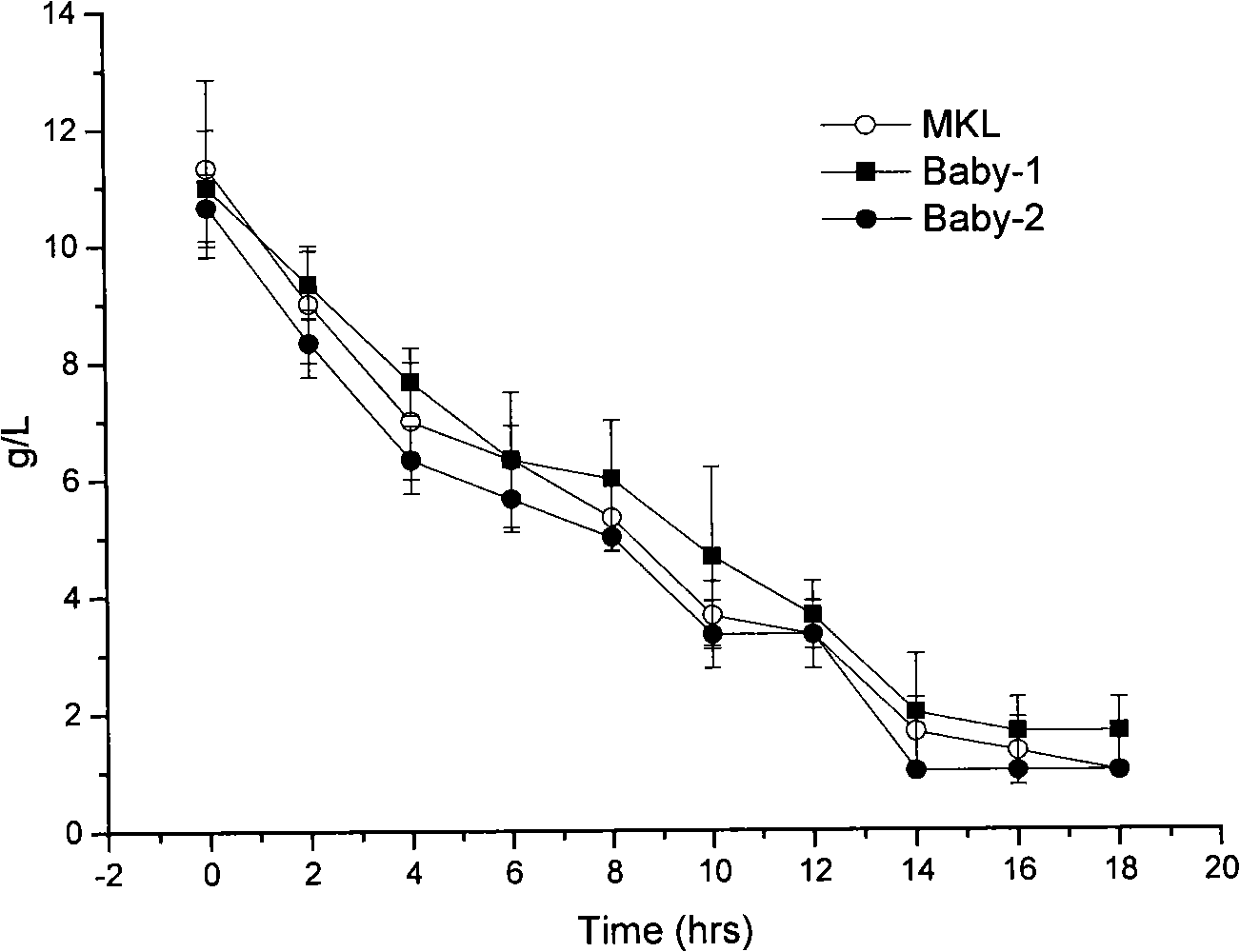

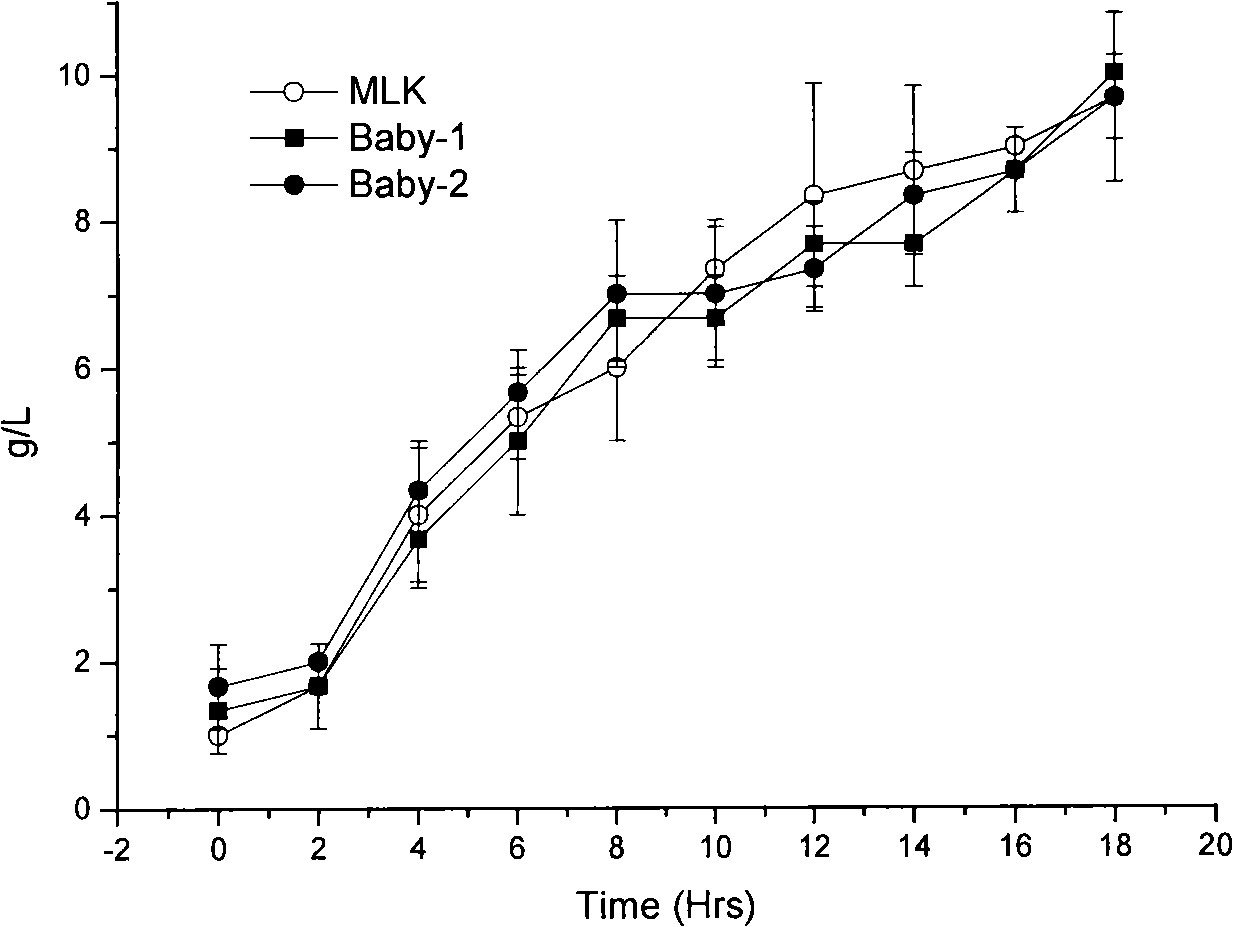

Enterococcus faecium microcapsule formulation and method for preparing same

InactiveCN101289648AImprove liquidityGood dispersionBacteriaMicroorganism based processesMicroorganismVolumetric Mass Density

The invention discloses micro-capsule preparation and a method for preparing the same, belonging to the microorganism field and the preparation field. The micro-capsule preparation uses sodium alginate as capsule material solution and CaCl2 as curing agent and contains Enterococcus Faecium the preservation number of which is CGMCC No.2516. The invention has the advantages that: the pre-embedding and after fermentation method is adopted, thereby thalli can be proliferated continuously under the micro-capsule microenvironment; the size of the cell density is controllable; the density of the micro-capsule thalli higher than that of the after embedding method can be reached; the pre-embedding method greatly reduces the utilization amount of cells during the encapsulization process, avoids the adverse factors of low encapsulization efficiency and productive rate due to impact of the cell density in the after embedding process, and more easily obtains encapsulated products with better shape and stability.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

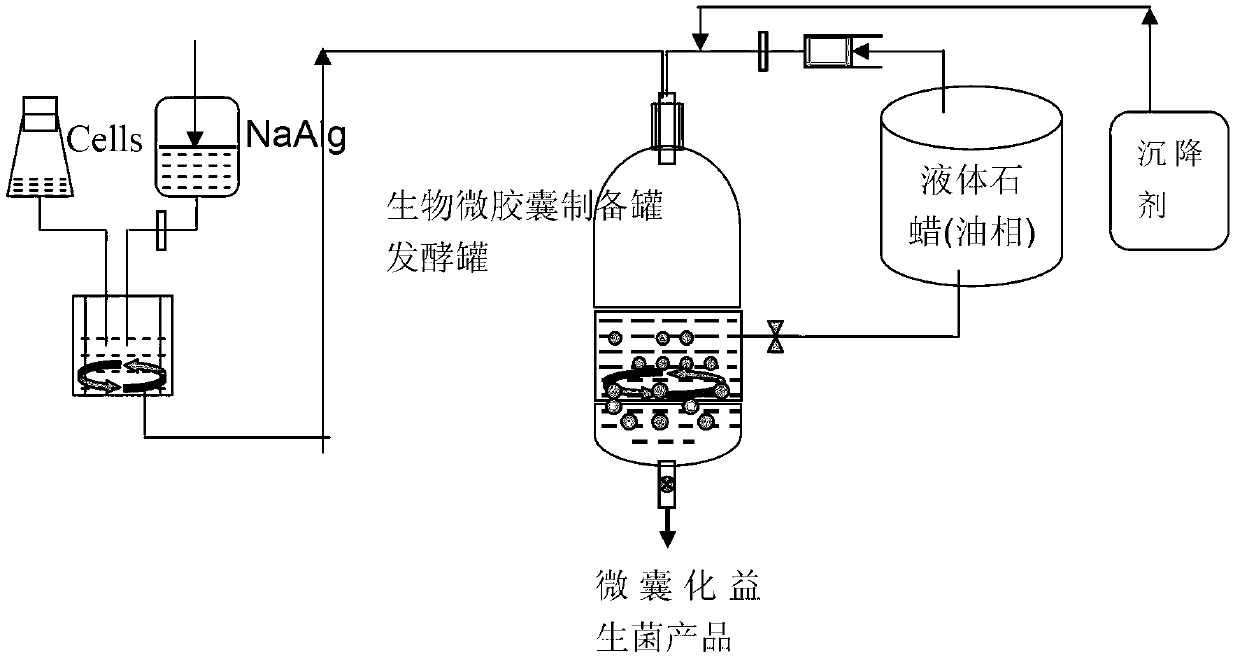

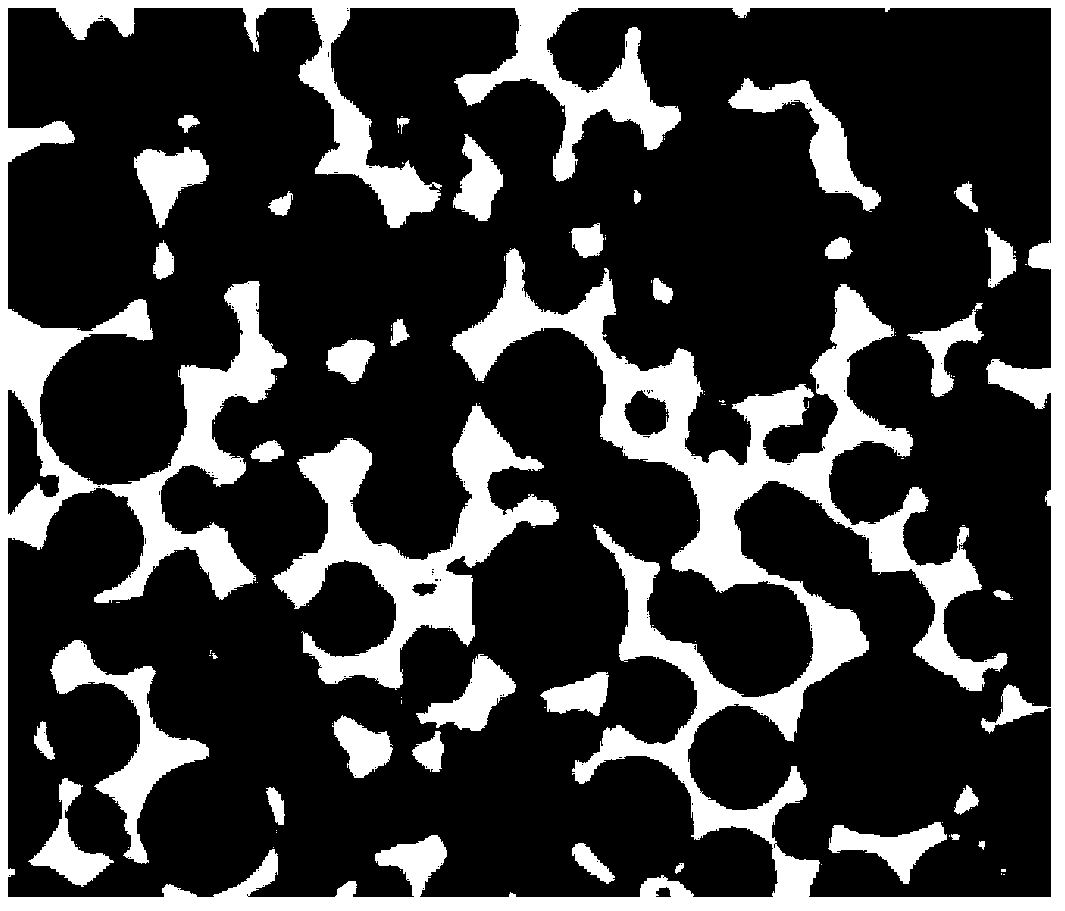

Method for preparing coating microcapsule before microbial fermentation by utilizing common fermentation tank

ActiveCN103275966AEasy to shapeImprove stabilityOn/in organic carrierOn/in inorganic carrierMicroorganismMicrometer

The invention discloses a method for preparing a coating microcapsule before microbial fermentation by utilizing a common fermentation tank. The method comprises steps of: preparation of a capsule material solution, preparation of an aqueous mixed solution, preparation of an oil mixed solution, preparation of a settling agent, preparation of microcapsules and culturing after coating, etc. By the method, microcapsules of which the diameter is 100-400 micrometers can be prepared, and the microcapsules have good sphericity degree and the yield of the product is higher than 95%. The innovation point of the method disclosed by the invention is that the method utilizes the general fermentation tank for preparation and fermentation of microcapsules without any modification, really realizes large-scale production of probiotic microcapsules, and has better product yield, sphericity degree and dispersibility than those of the existing industrial before-fermentation coating production method. The method disclosed by the invention is suitable for preparation of microorganism microcapsule in a plurality of fields such as fodders, foods and medicines, etc.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

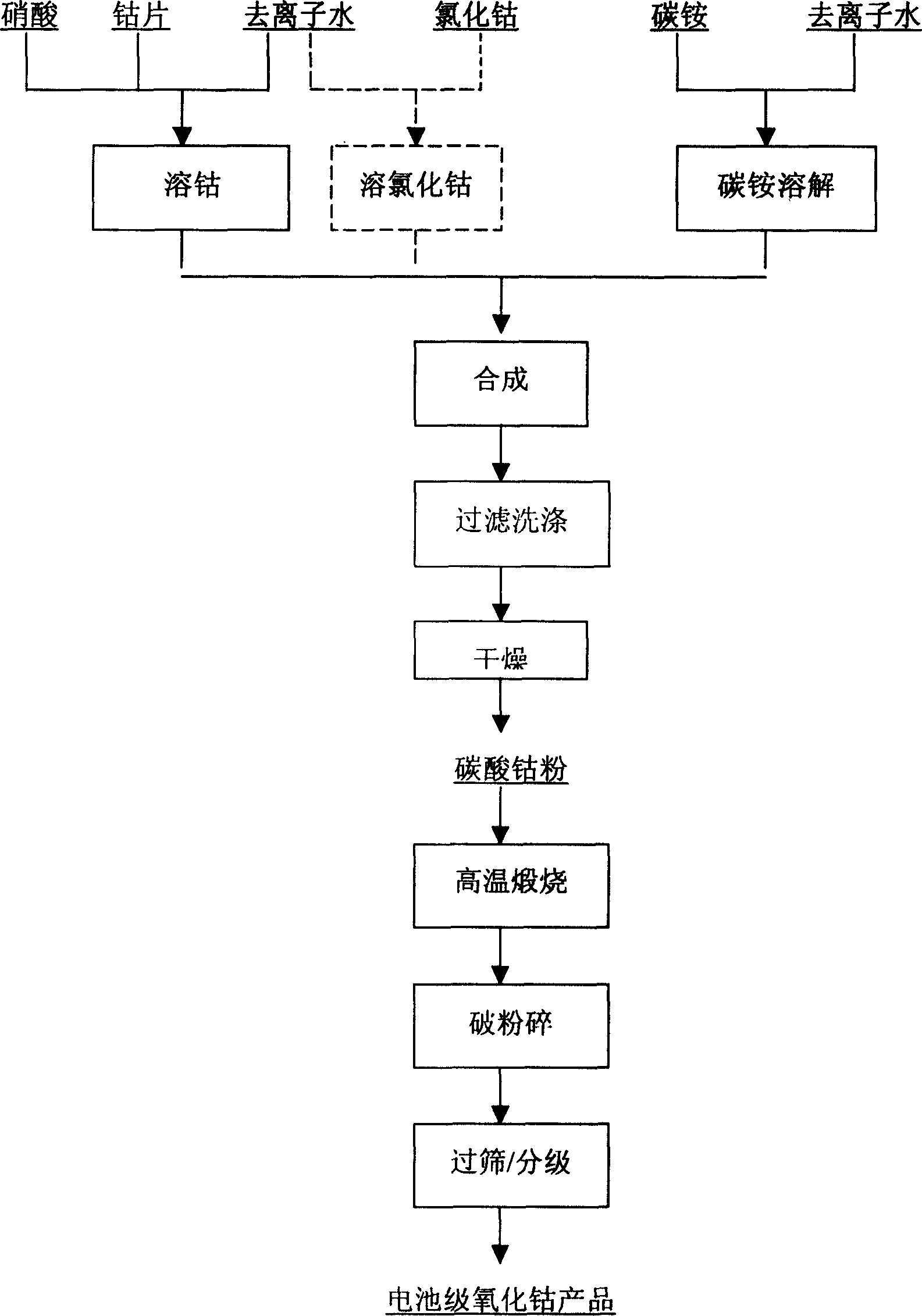

Cobalt oxide of lithium battery grade and its preparation method

ActiveCN1623909ANovel preparation processNo reportCobalt oxides/hydroxidesCobalt(II,III) oxideCarbonate

Owner:JIANGSU DANGSHENG MATERIAL TECH CO LTD

Forming method for ceramic hollow balls

InactiveCN106007781ADensity controllableThe size is easy to controlCeramicwarePeristaltic pumpWater baths

A method for forming ceramic hollow spheres. Ceramic micropowder, pore forming agent, sintering aid, dispersant and calcium salt are formulated into a uniform slurry in a certain proportion, and sodium alginate is precisely controlled by a precision peristaltic pump under heating and stirring in a water bath. The solution is added dropwise to solidify the slurry into balls. After all the slurry is formed into balls, it is filtered, dried, and then sintered into ceramic balls. The size of the obtained ceramic balls is controllable, the gap is adjustable, the roundness is good, and the quality is close to isostatic pressing. Technology, less equipment investment, easy operation, low cost, suitable for various ceramic materials into balls.

Owner:SHAANXI UDC MATERIALS TECH CO LTD

Detection method of tunnel lining crack based on mobile type three-dimensional laser scanning technique

ActiveCN109459439AQuick checkEasy to detectOptically investigating flaws/contaminationPoint cloudLaser scanning

The invention discloses a detection method of a tunnel lining crack based on a mobile type three-dimensional laser scanning technique. The detection method comprises the following steps of determiningthe length and the route change trend of the measuring route, and arranging a plurality of control points on a tunnel wall along the measuring route; when a scanning vehicle is moved, performing static self-calibrating collection on the cross section of a tunnel by a three-dimensional laser scanner, so as to obtain the data of the point cloud of the cross section of the tunnel; pre-treating the data of the point cloud of the cross section of the tunnel; when the scanning vehicle is moved, obtaining the coordinates of each control point through a total station, and controlling under the same coordinate system; projecting the pretreated data of the point cloud of the cross section of the tunnel onto the standard cross section of the tunnel to form an orthographic gray scale plan; accordingto the orthographic gray scale plan and the coordinates of each control point, measuring the data of crack at the tunnel lining surface, marking, calculating, and outputting. The detection method hasthe advantages that a large amount of point clouds at the tunnel lining surface can be obtained, and be treated and analyzed, so as to obtain the information of the crack at the tunnel lining surface;the tunnel lining crack can be more quickly and accurately detected.

Owner:SOUTHEAST UNIV

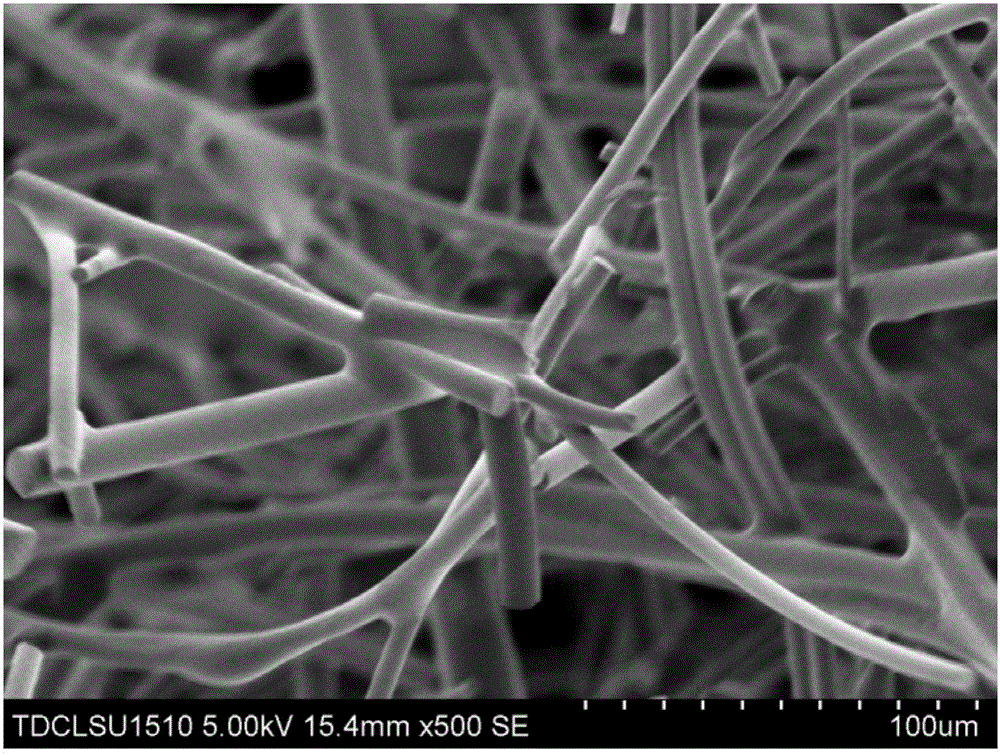

High pressure-resistant thermal insulation material and preparation method thereof

The embodiment of the invention provides a high pressure-resistant thermal insulation material and a preparation method thereof and relates to the technical field of thermal insulation materials. The preparation method is simple and convenient to operate and causes little pollution to the environment. The high pressure-resistant thermal insulation material has low heat conductivity coefficient and good temperature-resistant thermal insulation performance. The high pressure-resistant thermal insulation material is prepared by combining a fiber ceramic frame and sol and is subjected to drying and oven processing. The fiber ceramic frame is prepared by combining a fiber matrix and an enhancer and is subjected to drying and high-temperature processing. The fiber matrix is formed by dispersing at least one of quartz fiber, alumina fiber, mullite fiber and zirconia fiber to form a specific shape. The high pressure-resistant thermal insulation material is mainly used for aerospace industry, civil industry and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

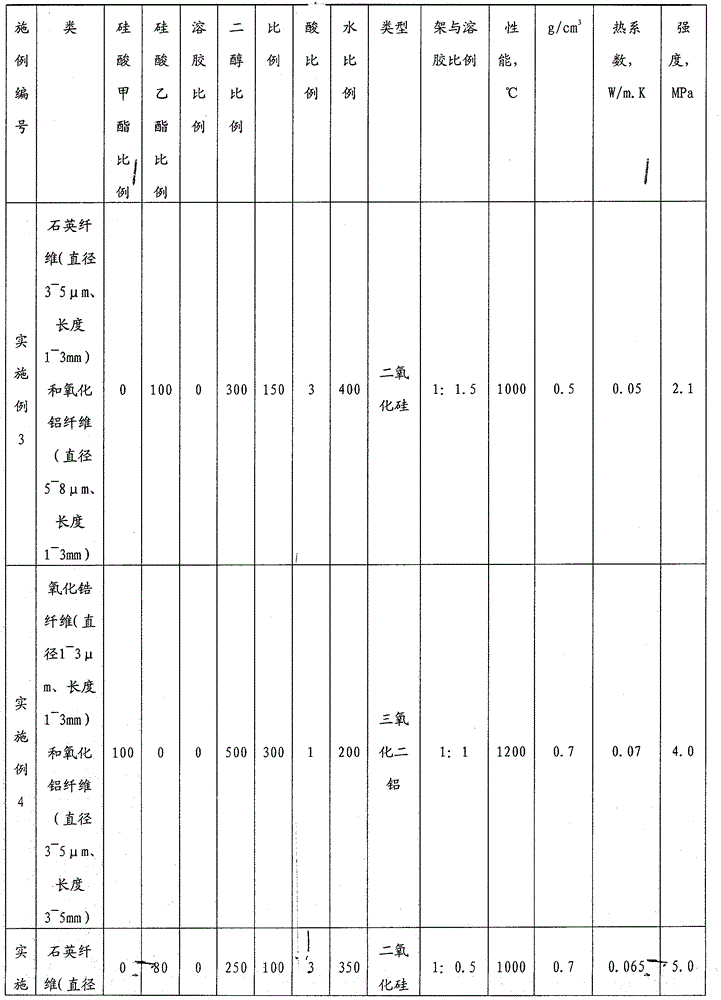

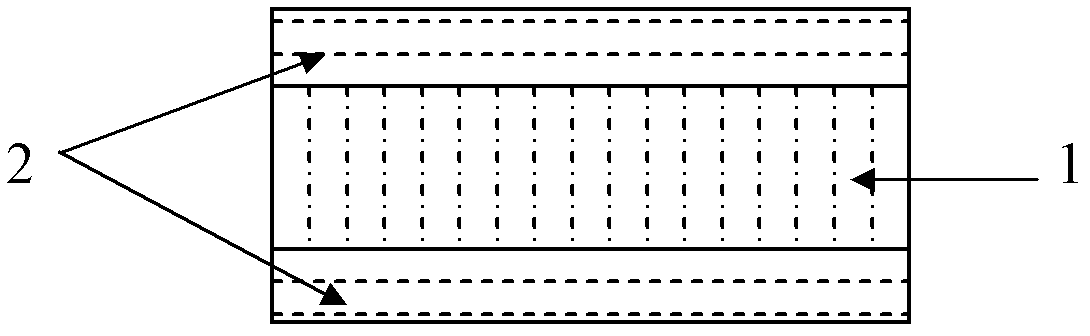

Continuous density gradient low-density porous carbon bonding composite material and preparing method thereof

The invention discloses a continuous density gradient low-density porous carbon bonding composite material.The composite material is prepared from, by mass, 12 parts of chopped viscose-based carbon fiber, 7-36 parts of fiber binder and 1.5-5 parts of fiber dispersing agent.A preparing method of the composite material comprises the steps of 1, preparing fiber size and conducting vacuum filtration formation on the fiber size; 2, heating and drying wet green obtained in the step 1 till weight does not change any more, and curing a mixture obtained after drying with the gradient curing technology under the vacuum condition; 3, conducting furnace cooling on the mixture obtained in the step 2 to indoor temperature, and then carbonizing the mixture obtained in the step 2 with the gradient carbonization treatment technology.The composite material has a high temperature resisting property and a heat insulating property, has a continuous density gradient feature in the thickness direction, and has high mechanical strength, anti-scouring performance and thermal protection / insulation efficiency.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method for mullite fiber porous thermal insulation material

The invention discloses a preparation method of a mullite fiber porous heat insulating material. The invention discloses a method for preparing a mullite fiber porous material by combining gel casting into a film and freeze-drying. The process is: first mix silica sol and agar powder, add deionized water to dilute and stir evenly under the condition of heating in a water bath at 78°C, then slowly add mullite fiber to the uniform mixture of silica sol and agar powder, and stir while adding , so that the mullite fiber is evenly dispersed in the sol; after stirring evenly, pour the obtained sol into a plastic beaker, put it in a 15°C water bath environment for gel treatment for 60s, and then freeze it at -196°C, and then put it into Drying in a freeze dryer; finally, heat-treating the dried body at 1500° C. for 2 hours to obtain a mullite fiber porous material. The invention has simple process and low energy consumption, and realizes the purpose of controlling the density of the prepared mullite fiber porous material, and prepares the mullite fiber porous material with low density and high specific strength.

Owner:TIANJIN UNIV

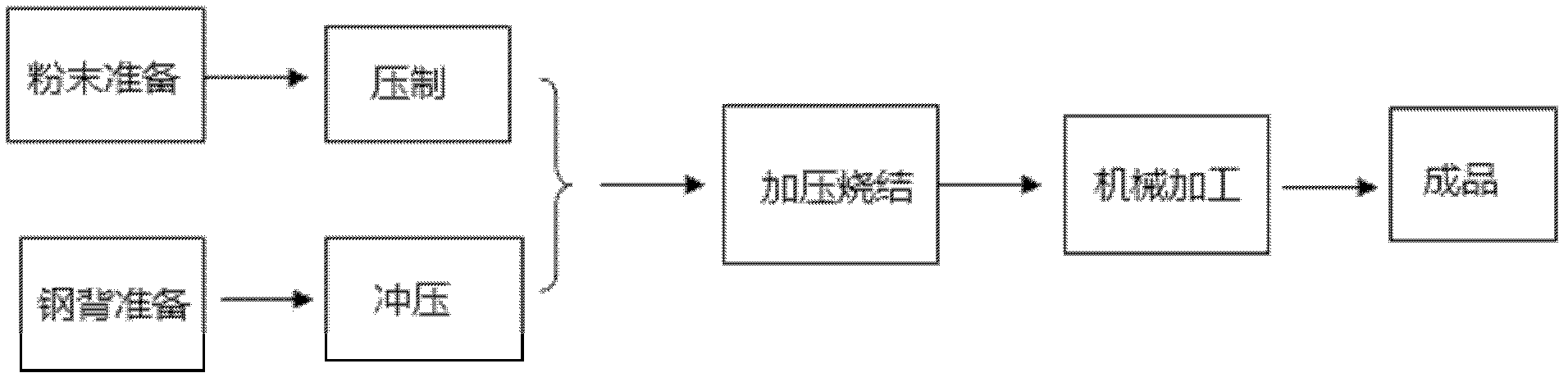

Sintered metal matrix friction sheet and deep processing production technology thereof

The invention discloses a deep processing production technology of a sintered metal matrix friction sheet and a sintered metal matrix friction sheet prepared by the production technology. The sintered metal matrix friction sheet comprises a steel backing layer and one or two friction layers. The production technology includes the steps of powder spread, primary sintering, primary rolling, secondary sintering, secondary rolling, annealing treatment, and stamping to obtain the sintered metal matrix friction sheet. The defects that prior sintered metal matrix friction materials are large in production technology investment, complicated in processing, low in production efficiency, unstable in product quality, uncontrollable and the like are overcome, the method can be applicable to the production of iron-based and copper-based friction materials, the thicknesses of the steel layer and the friction layers can be controlled respectively, the control accuracy is high, the finished product qualities of the friction sheets are stable, the device investment is small, the operation is simple, and the production efficiency is high.

Owner:SHANGHAI HEWEI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com