Silicon carbide aerogel and preparation method thereof

An airgel and silicon carbide technology, applied in the field of airgel, can solve the problems of complicated purification treatment, harsh preparation conditions, and long cycle, and achieve the effects of simple and controllable process, stable physical and chemical properties, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

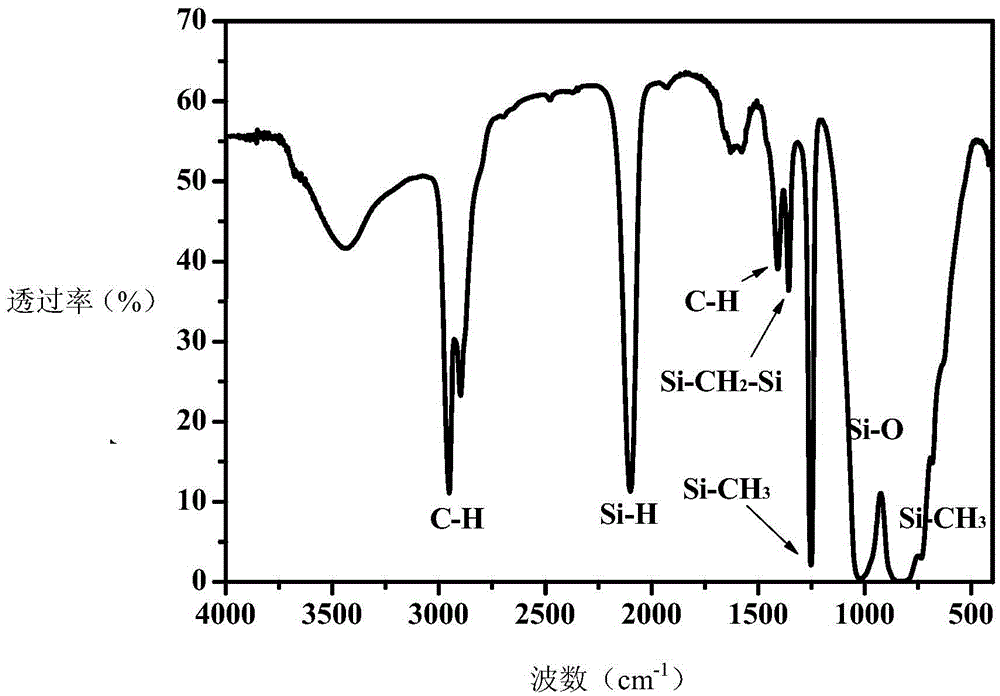

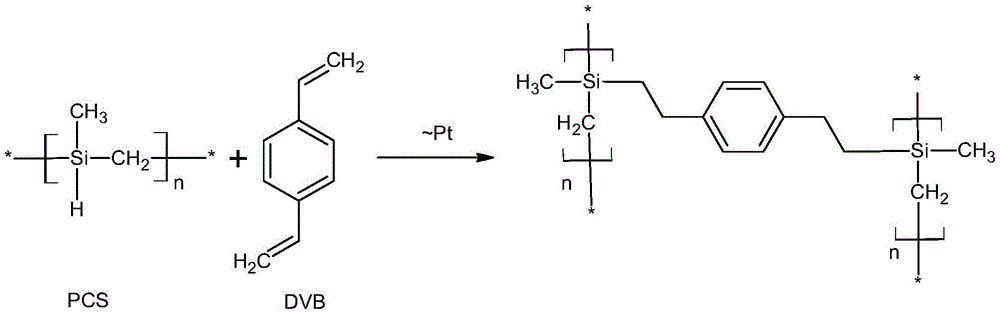

[0028] (1) 6.0gPCS (its infrared spectrum such as figure 1 Shown) powder is dissolved in 94.0g cyclohexane, the preparation concentration is 6.0% PCS solution; Add 6.0gDVB and 0.3g~Pt, stir well to form a homogeneous solution, then transfer to the polytetrafluoroethylene tank in the reaction kettle , and then transferred to a pressure reactor, and carried out hydrosilylation polymerization and crosslinking reaction at 150°C for a reaction time of 5 hours. After the reaction was completed, the reactor and materials were cooled to room temperature to obtain a precursor gel;

[0029] (2) Transfer the precursor gel to a supercritical drying kettle, first replace it with liquid carbon dioxide for 1-3 days, and then undergo supercritical drying (50°C, 20MPa) to obtain the precursor aerogel;

[0030] (3) Under an inert atmosphere, the precursor aerogel is kept at 200°C for 1h, and then heat-treated at 800°C (heating rate 2°C / min) for 1-3h to obtain amorphous SiC aerogel, which is tre...

Embodiment 2

[0033] The raw material PCS in Example 1 was changed to polycarbosilane PXCS containing heterogeneous elements (X includes elements such as aluminum, iron, yttrium), and following the above test process, silicon carbide airgel materials containing heterogeneous elements can be obtained for use in special field.

Embodiment 3

[0035] Preparation of SiC airgel material by drying under normal pressure: After the precursor gel obtained in Example 1 was sealed and aged, n-hexane was used as a replacement solvent to replace cyclohexane in the pores, and the replacement was performed 3 times for 24 hours each time. Then it is placed in a programmed temperature-controlled oven, and the drying program is as follows: heat up to 50°C (3°C / min) for 2 hours; heat up to 80°C (2°C / min) for 4 hours; heat up to 110°C (5°C / min) ) for 6 hours; natural cooling to obtain the precursor airgel, the subsequent steps are the same as in Example 1, and SiC airgel materials can also be obtained. SiC airgel porosity ~ 75%, specific surface area ~ 110m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com