Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Porosity is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

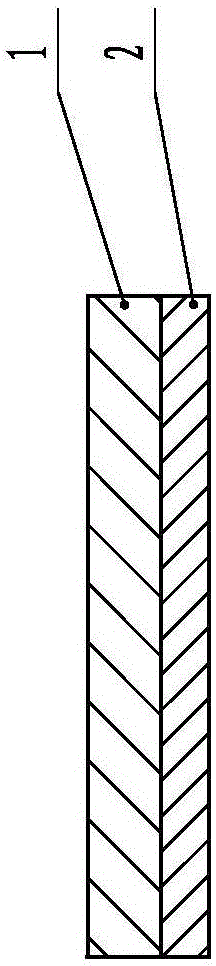

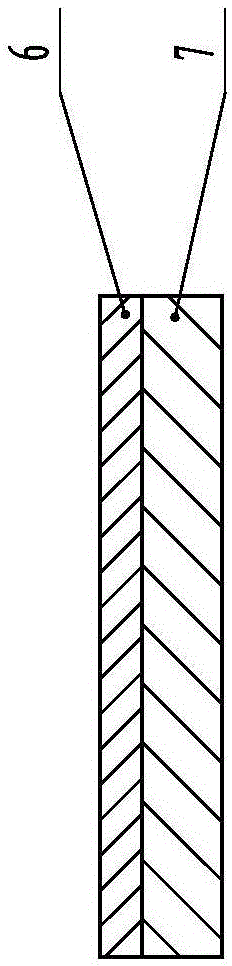

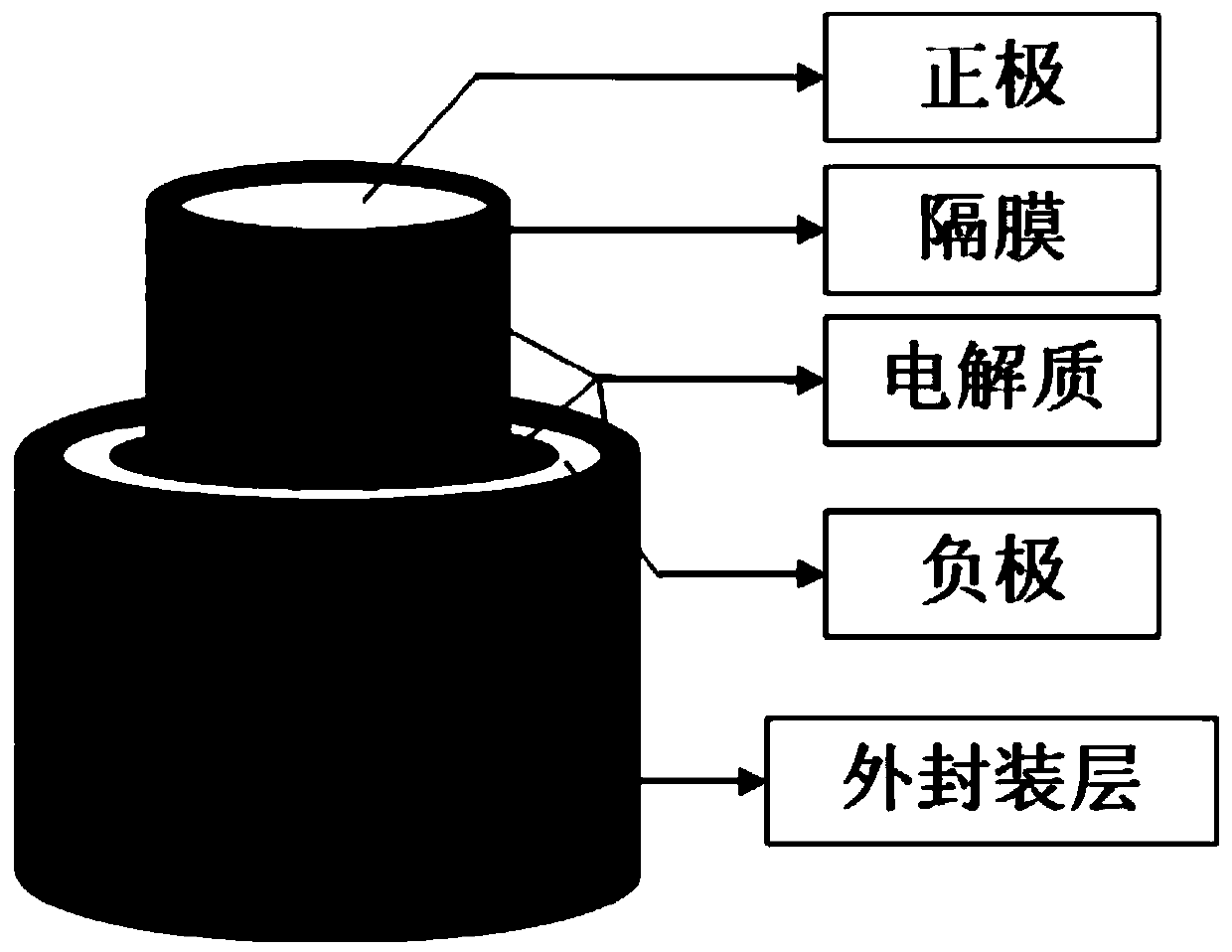

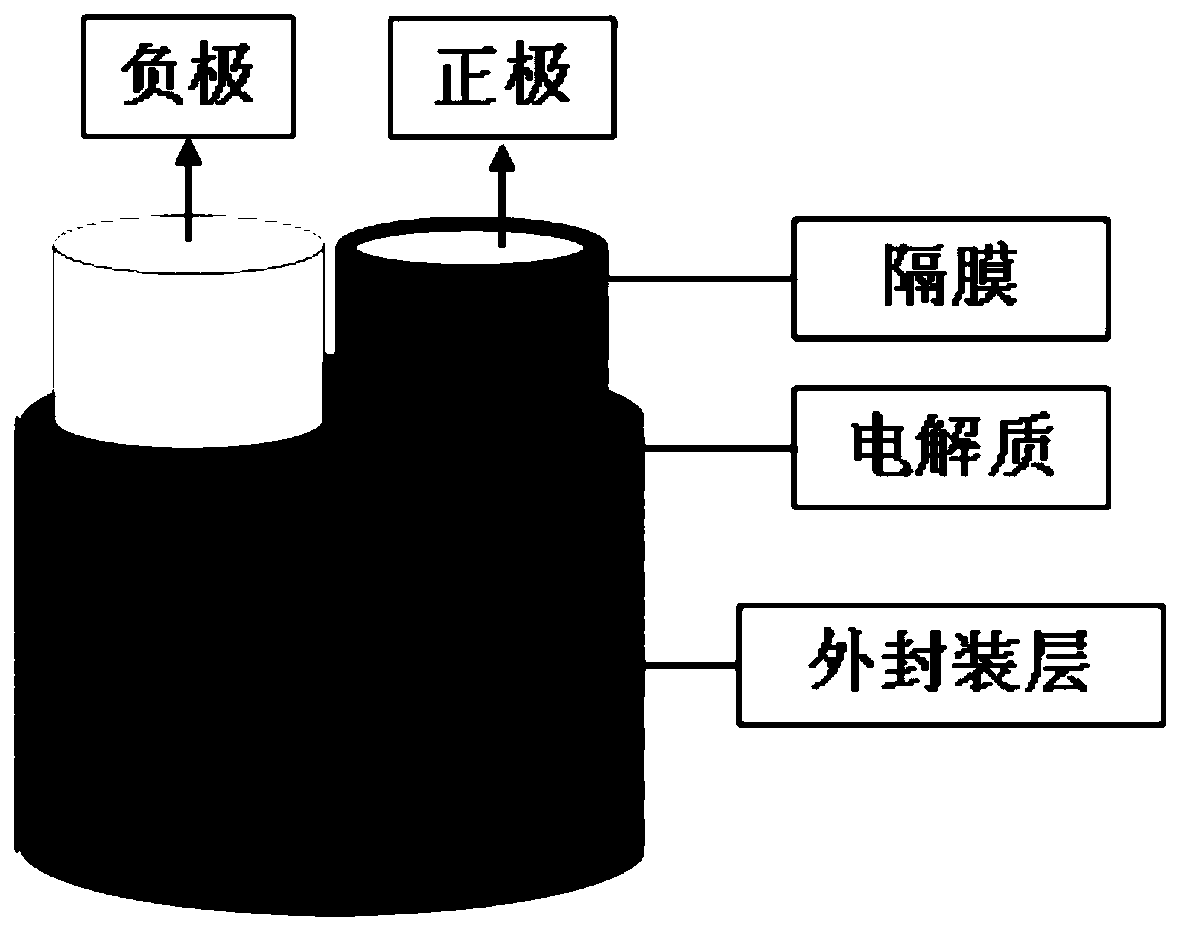

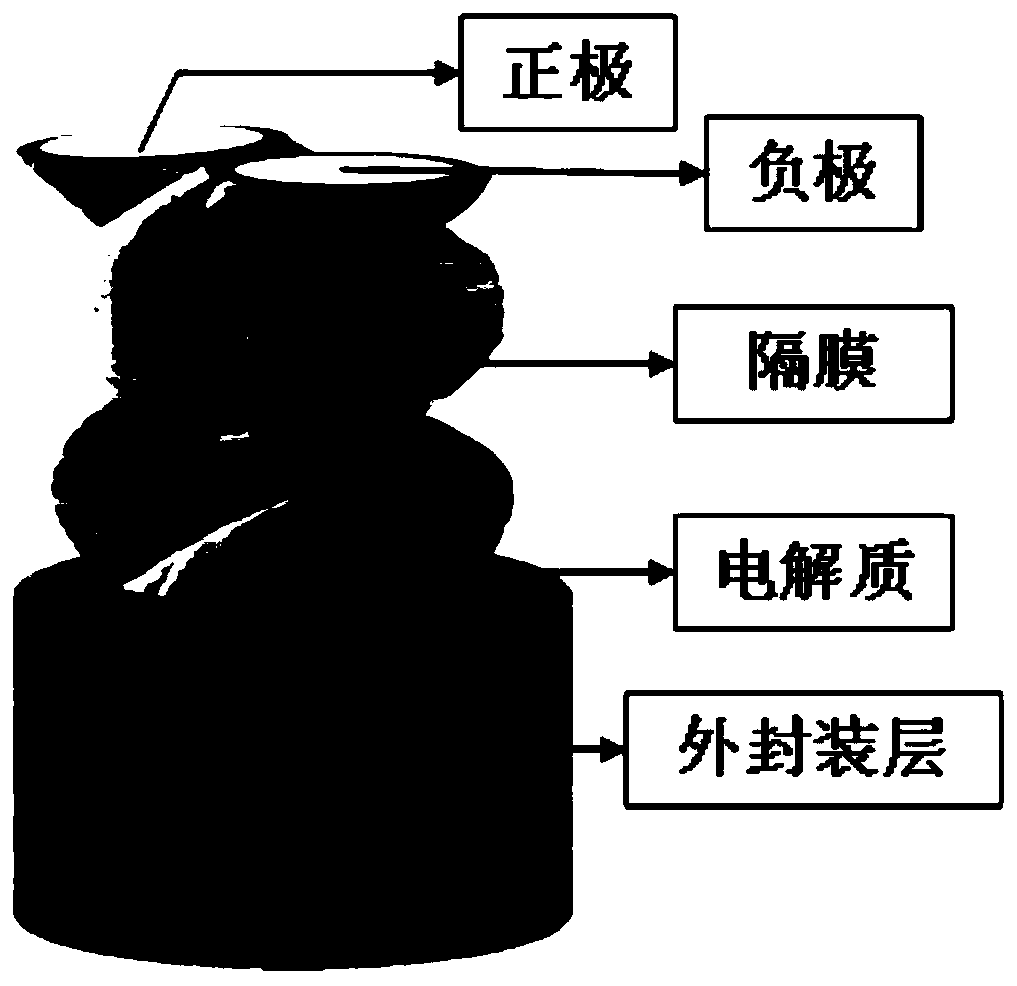

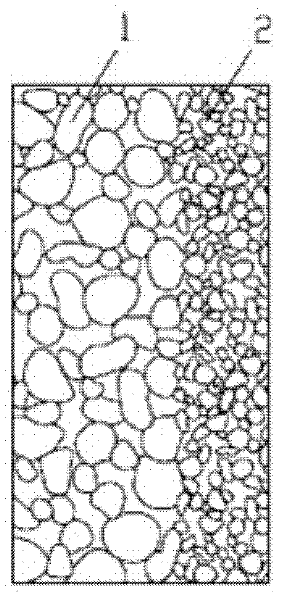

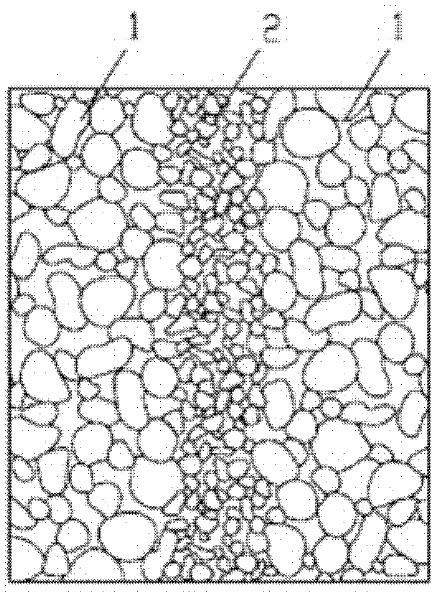

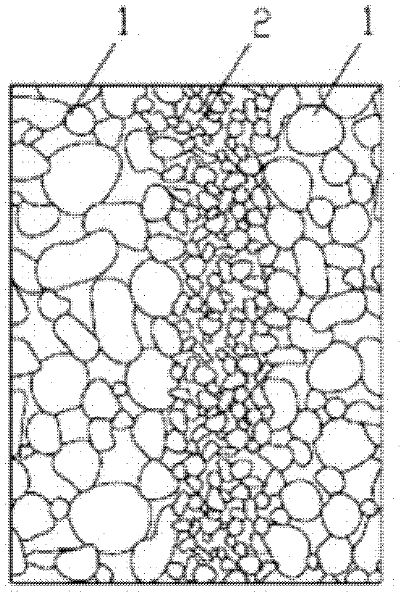

Lithium-ion battery diaphragm and preparation method thereof

InactiveCN105140451AUniform pore sizePorosity is easy to controlCell component detailsPorous coatingPorous substrate

The invention discloses a lithium-ion battery diaphragm. The lithium-ion battery diaphragm is prepared by coating the upper surface and the lower surface of a porous base material with one or more porous coatings, wherein the thickness of the porous base material is 4-80 microns; the porosity of the porous base material is 30%-90%; and each porous coating comprises the following raw materials in parts by weight: 30-100 parts of a polymer material, 0-70 parts of inorganic powder and a surface treating agent and 0-50 parts of a compatibilizer. The invention further discloses a preparation method of the lithium-ion battery diaphragm. The battery diaphragm disclosed by the invention is controllable in pore size and porosity and uniform in pore size; the finished diaphragm product is high in high-grade rate, good in wettability and high in safety; and the diaphragm is good in heat resistance, and has a thermal closing function.

Owner:郑少华

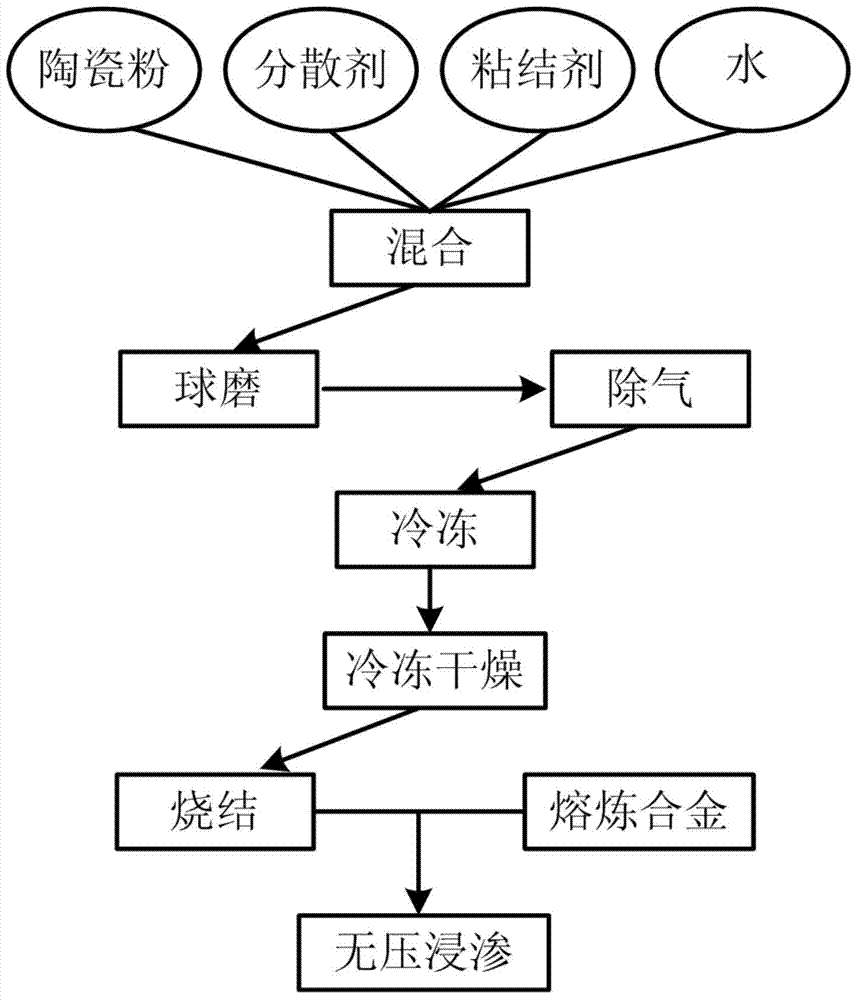

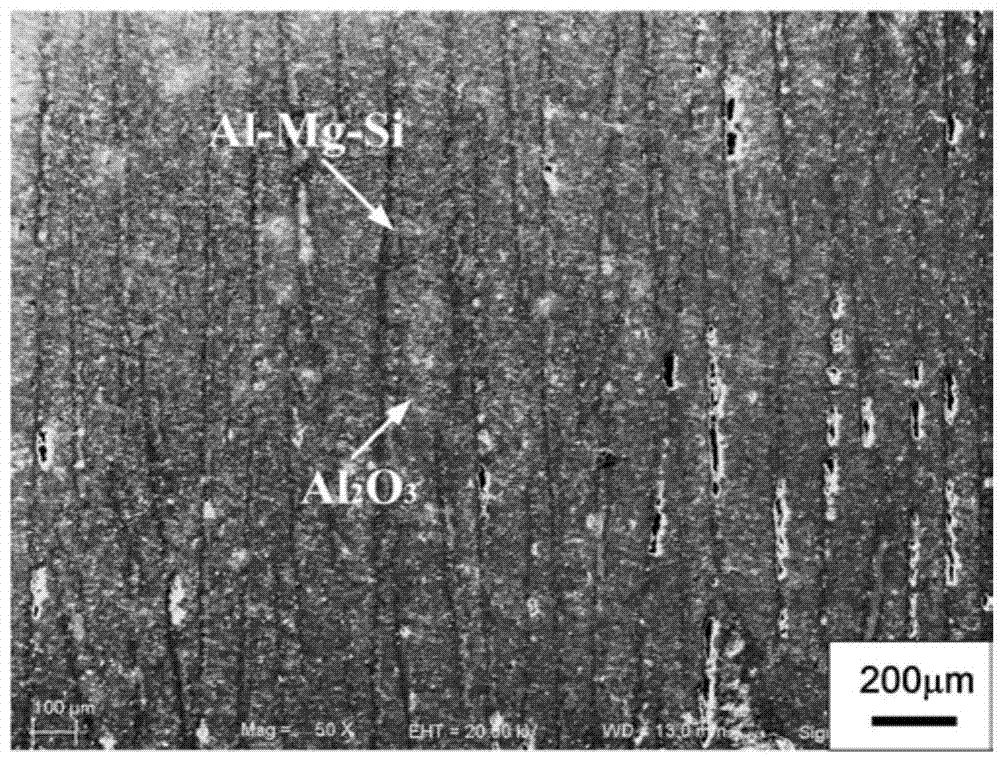

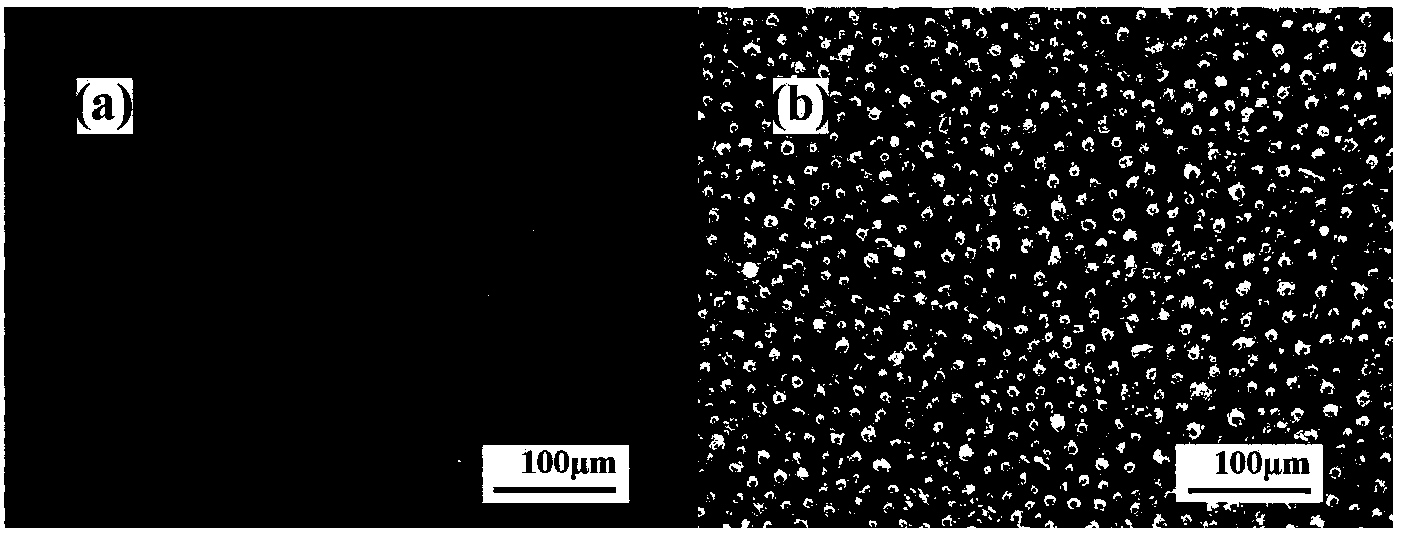

High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

InactiveCN103895285ANot easy to sinterEasy to manufactureCeramicwareMetal layered productsWater basedMass ratio

The invention discloses a high-strength lamellar Al-based metal ceramic composite material and a preparation method thereof, aiming at solving the problems of high preparation cost, complex operation, single type of reinforcement ceramic and low strength. The high-strength lamellar Al-based metal ceramic composite material, i.e., high-strength lamellar structure Al-Si-Mg / (Al2O3, SiC, TiC) composite material comprises ceramic powder and Al-Si-Mg alloy. The volume fraction of ceramic powder is 20%-40vol%; the volume fraction of Al-Si-Mg alloy is 80%-60vol%; the mass ratio of aluminum in the Al-Si-Mg alloy is 75-84wt%; the mass ratio of silicon is 10-15wt%; the mass ratio of magnesium is 6-10wt%. The preparation method of the high-strength lamellar Al-based metal ceramic composite material comprises the following steps: preparation of water-based ceramic slurry; directional solidification; freezing and drying; sintering of blanks; smelting of alloy; and non-pressure infiltration.

Owner:JILIN UNIV

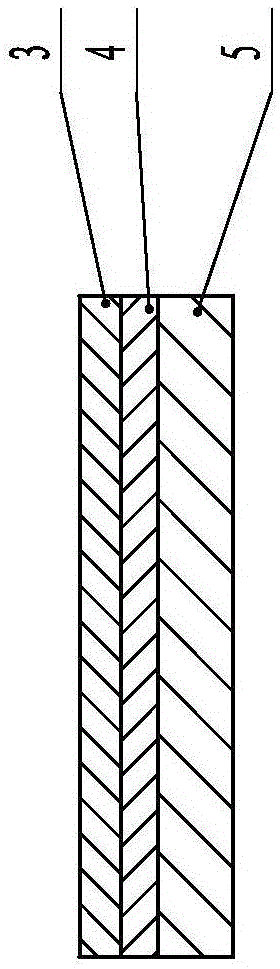

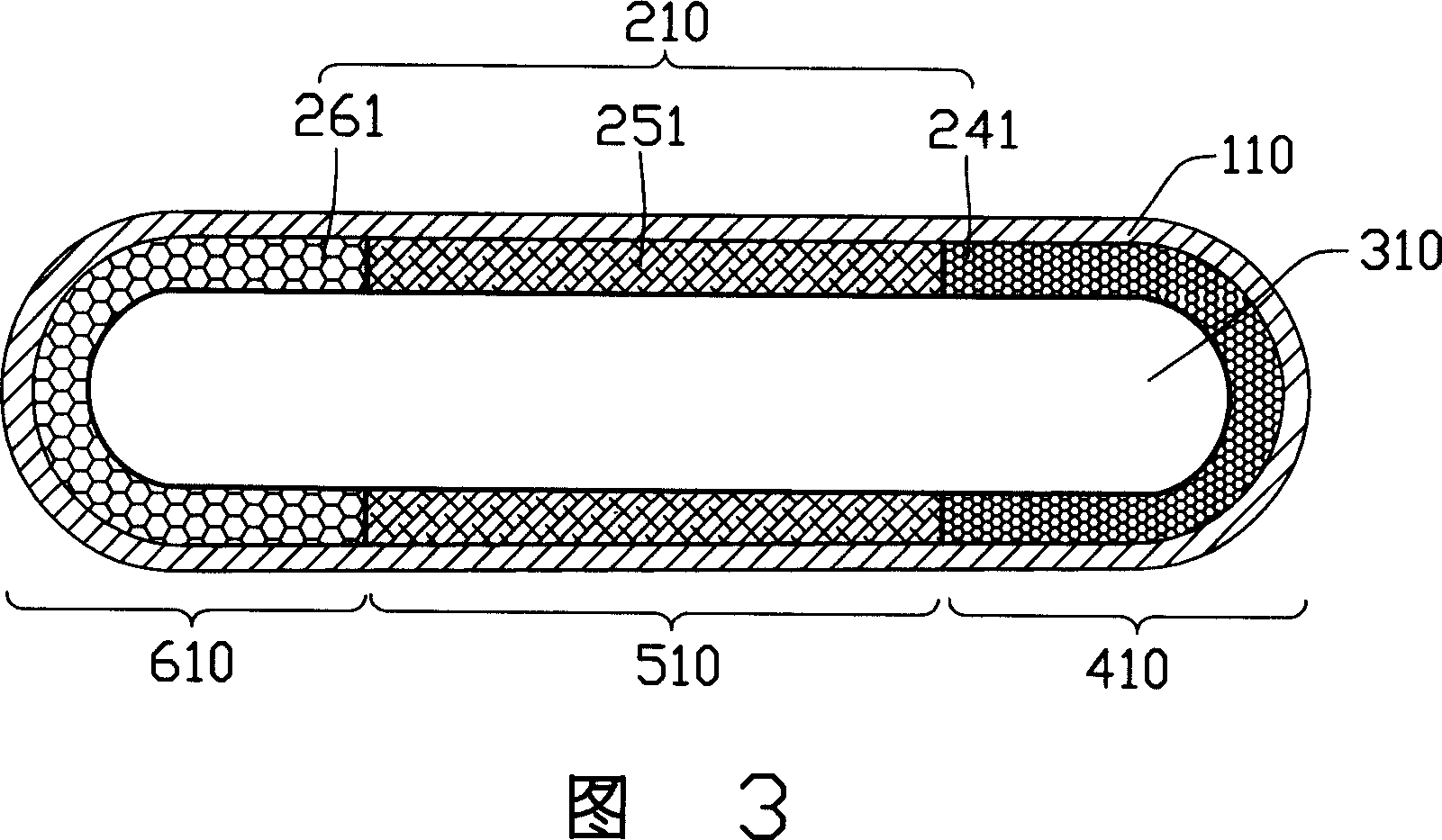

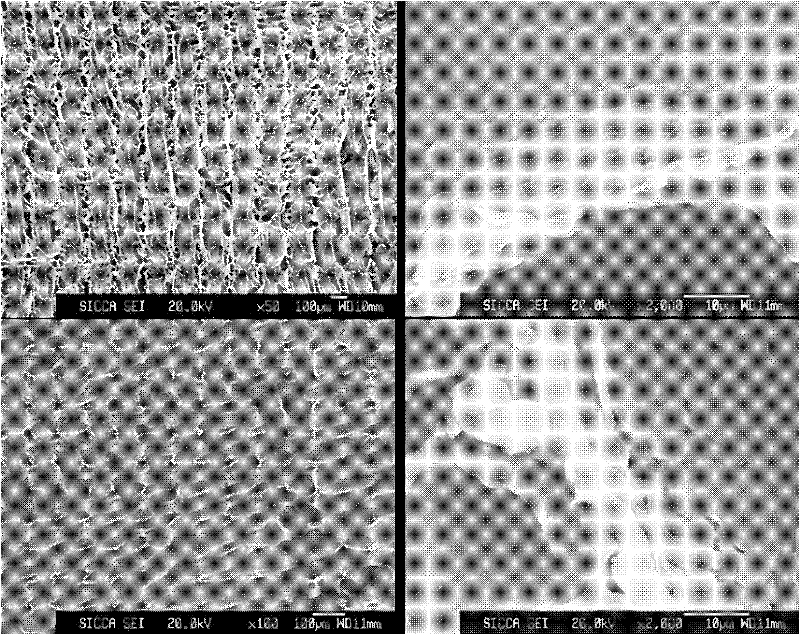

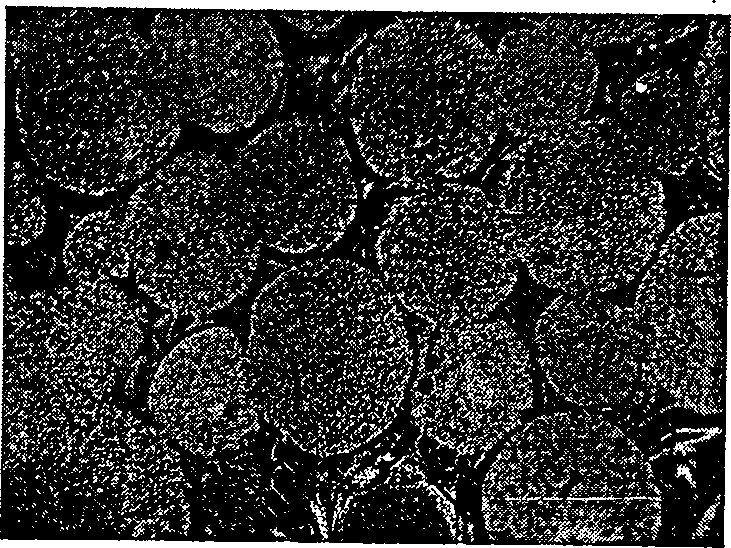

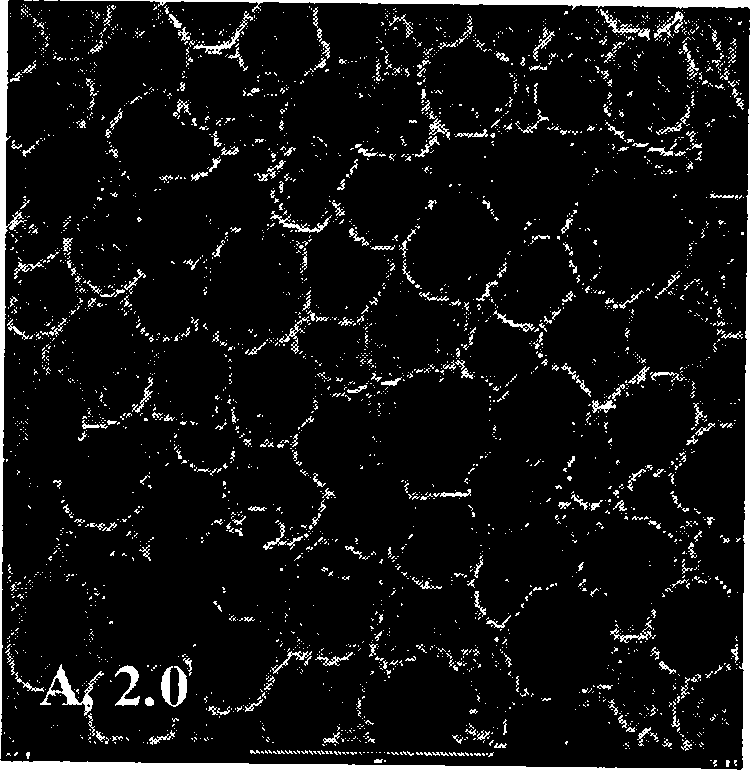

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

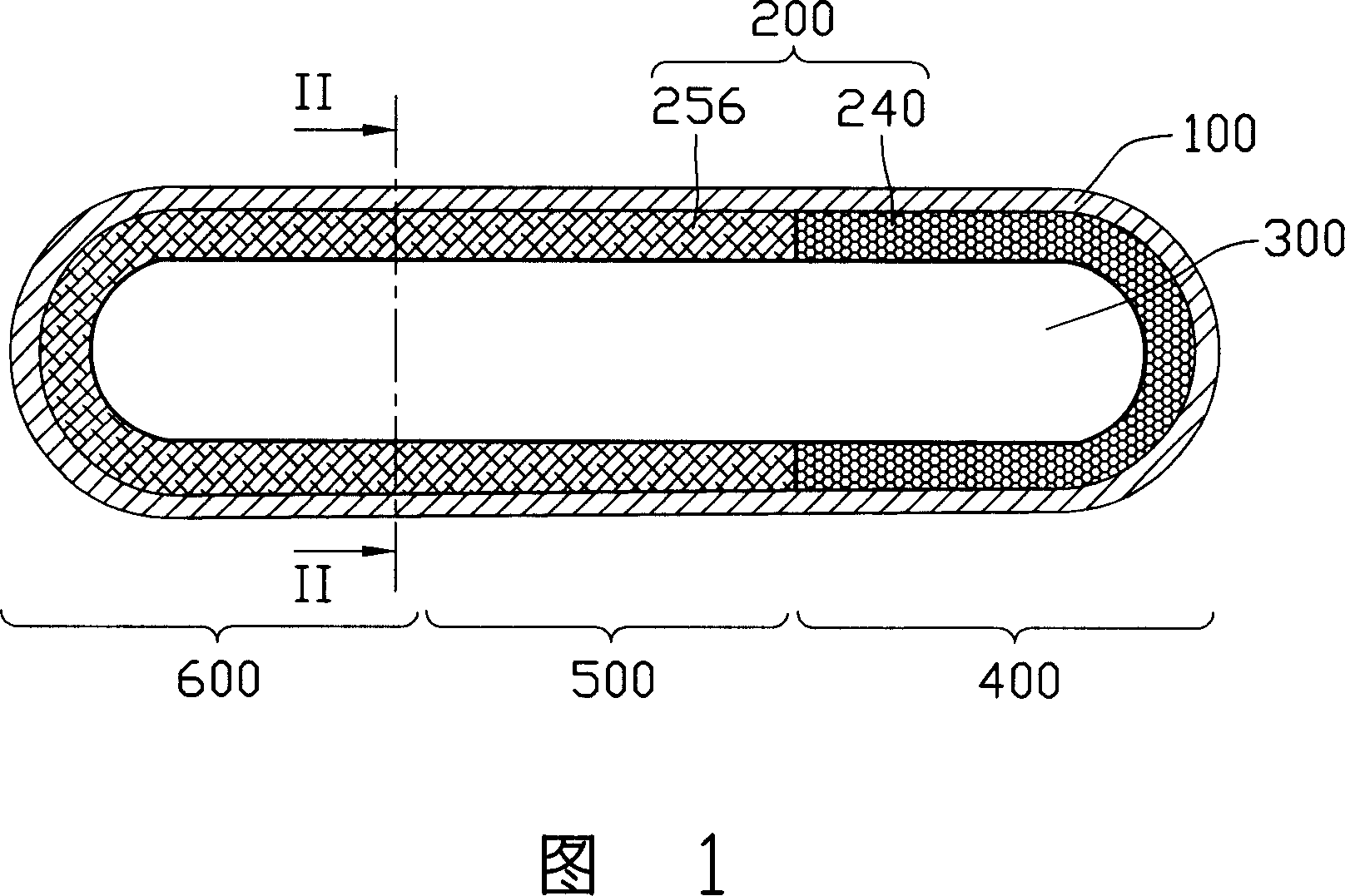

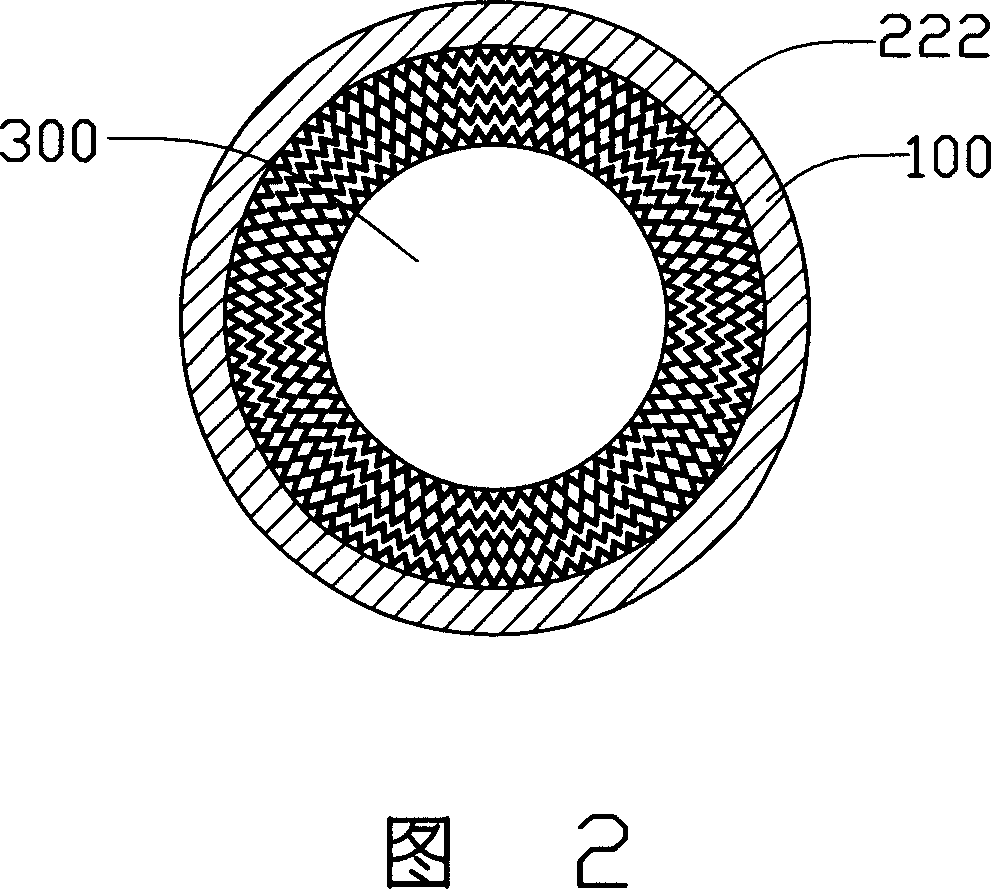

Heat pipe

Owner:FU ZHUN PRECISION IND SHENZHEN +1

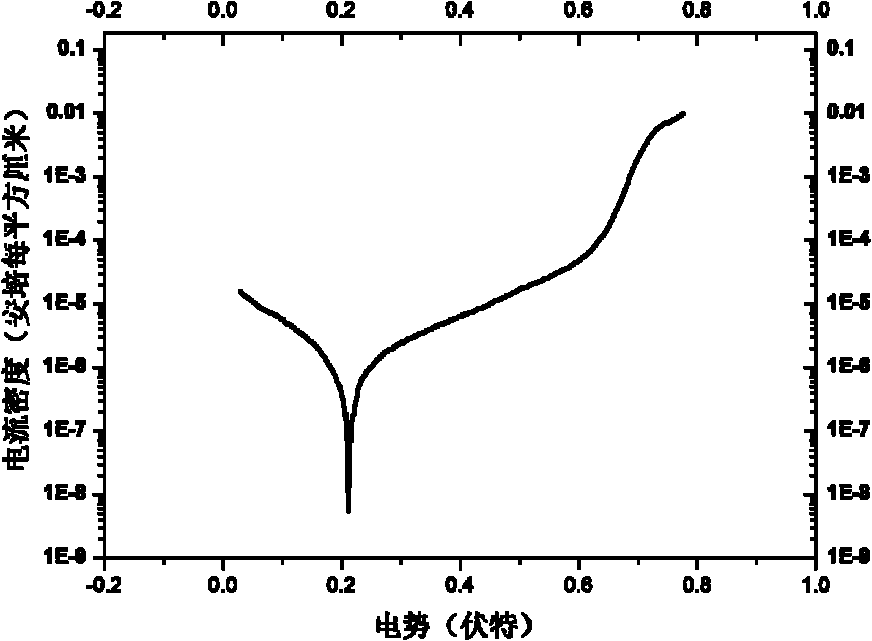

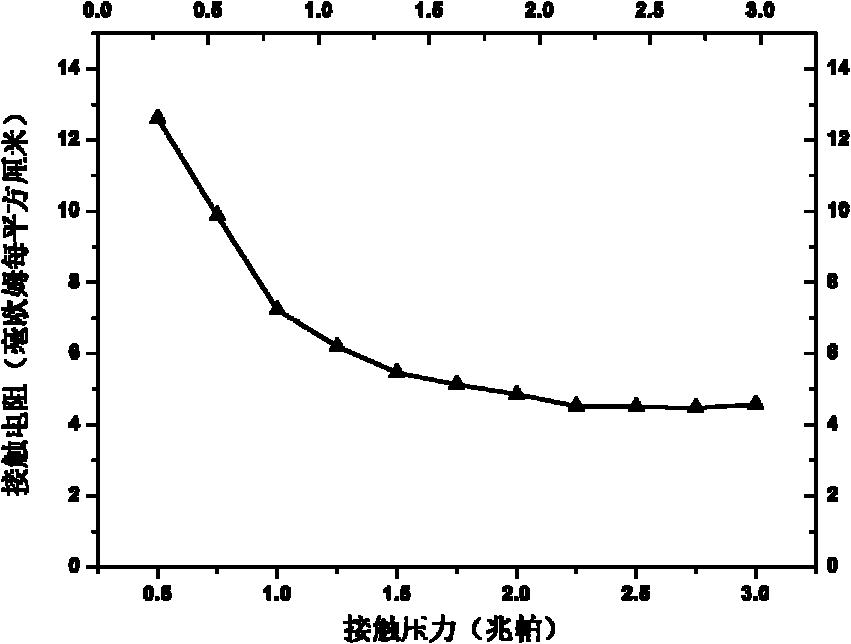

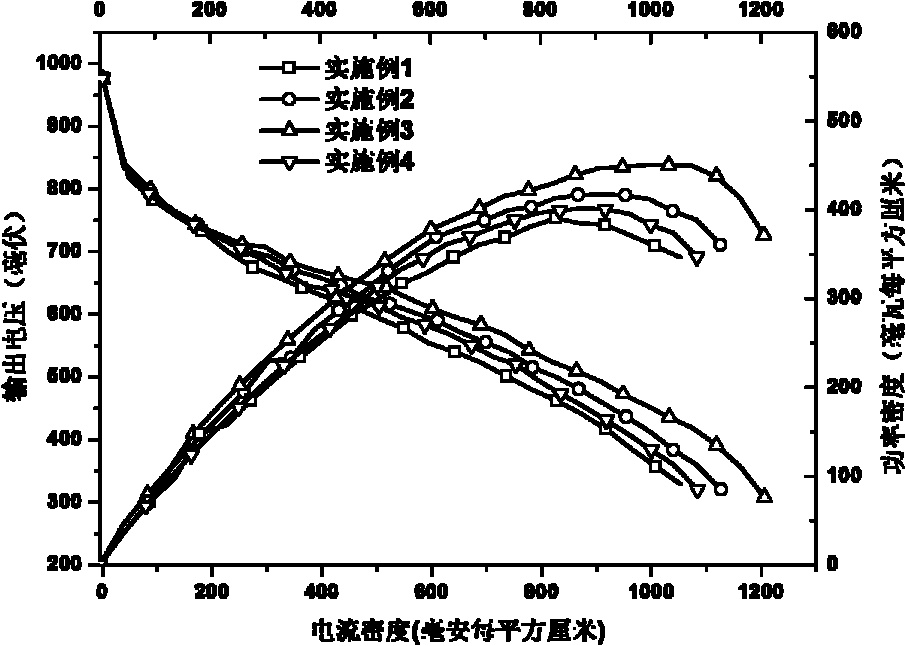

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277AImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:上海氢晨新能源科技有限公司

Preparation of porosity controllable porous titanium

The invention provides a preparation method of a porous titanium with controllable porosity, comprising the following steps: Ti powder and 1 wt.%-4 wt.% of binder are well mixed; urea particles are used as a pore forming agent and added into the mixture, the volume fraction between the pore forming agent and the mixture is 30-80 percent: 70-20 percent, and the mixture is mixed fully and evenly; and then the obtained mixture is one-direction pressed into blanks under the pressure of 100MPa to 250MPa; the obtained green compact is heated in a vacuum furnace with the vacuum degree kept between 10<-2> to 10<-3>Pa, thus obtaining porous metal members. The porosity can be determined by the quantity of added urea in the invention, and the size and shape of the pores can be determined according to the size (200Mum to 2mm) and shape of urea particles, thus realizing the target of controllable porosity, pore size and pore shape; the preparation method of the invention also has the advantages of simple technique, low equipment requirement, convenient operation and low cost.

Owner:CHONGQING UNIV

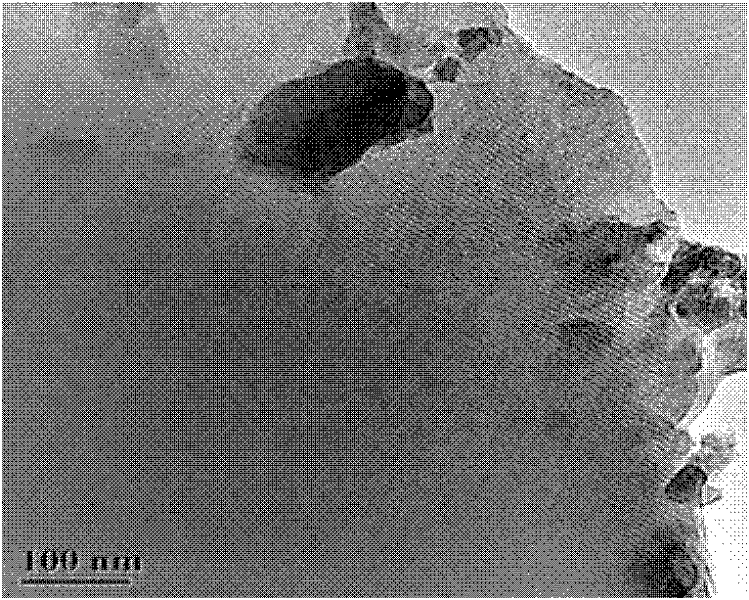

3D porous bracket with mesoporous biological glass coating and preparation method thereof

The invention relates to a 3D porous bracket with a mesoporous biological glass coating and a preparation method thereof. Polymer porous bracket substrate is prepared by utilizing freeze-extraction technique, by dipping precursory sol of the mesoporous biological glass and the approach of evaporation-induced self-assembly, a novel 3D porous bracket with a mesoporous biological glass coating for tissue engineering. The preparation method has the advantages of simple to carry out, low cost, high efficiency and easy operation. The 3D porous bracket with a mesoporous biological glass coating prepared by the invention is suitable for drug loading and releasing, sterilization, inducing the adhesion and proliferation of cells, with good application prospect in tissue engineering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Nano-silver porous silicone rubber/polyurethane-containing double-layer artificial skin and preparation method thereof

InactiveCN103948960ACapable of absorbing effusionWaterproofAbsorbent padsProsthesisFoaming agentSolvent

The invention discloses a nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin and a preparation method thereof. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin is characterized in that the artificial skin contains a dermis and epidermis double-layer structure; a dermis layer is prepared from loose porous polyurethane; an epidermis layer is prepared from antibacterial agent-containing silicone rubber. A preparation method of the dermis layer comprises the following steps: dissolving the polyurethane, adding a pore-foaming agent, defoaming, carrying out curtain coating so as to form a film, volatilizing a solvent, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a porous polyurethane film. A preparation method of the epidermis layer comprises the following steps: dissolving a silicone rubber precursor, carrying out ultrasonic dispersion on a nano-silver solution, adding the pore-foaming agent, defoaming, carrying out blade coating or curtain coating so as to form a film, volatilizing a solvent, curing so as to obtain an embryonic film, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a silicone rubber microporous film. The preparation method of the double-layer artificial skin comprises the following steps: coating the polyurethane film with polyvinyl alcohol, acid liquor and a crosslinking agent, then covering the polyurethane film by using the silicone rubber film, volatilizing a solvent, and carrying out heat treatment so as to obtain the double-layer artificial skin. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin has the effects of water resistance, air permeability, bacterial inhibition, virus killing and effective absorption of hydrops.

Owner:SICHUAN UNIV +1

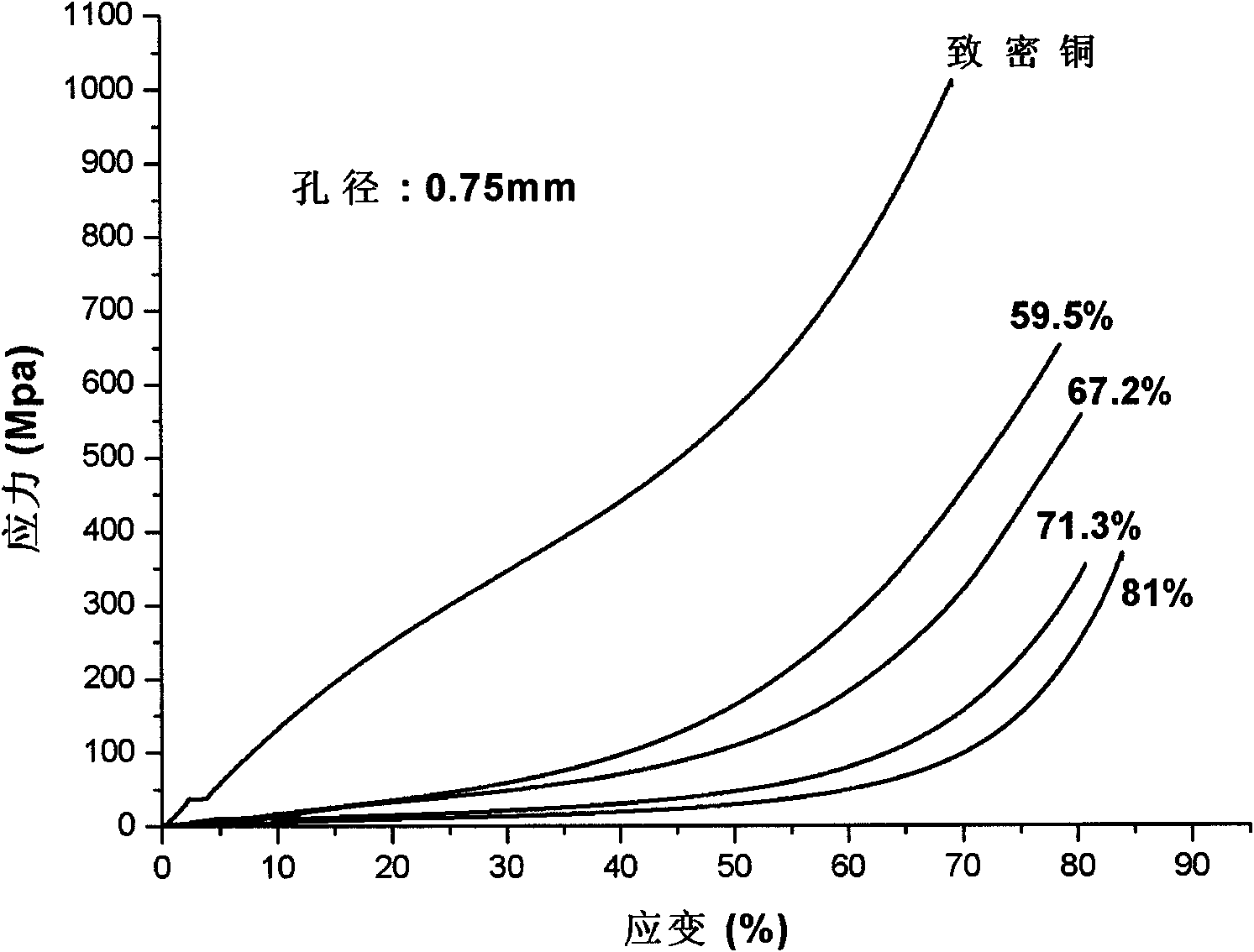

Method for preparing through-hole foam copper

The invention relates to a method for preparing through-hole foam copper, in particular to the manufacture of metal with an opened or a closed hole. Electrolytic copper powder and NaCl granules are taken as raw materials, and sintering-desolvation technology is adopted for preparing the through-hole foam copper; the NaCl granules, the electrolytic copper powder and additive are evenly mixed together and then pressed into green-ware; the obtained green-ware is sintered in a sintering furnace under the argon atmosphere, and the obtained product is placed into a circulating hot water device to dissolve and remove the NaCl granules and then washed by ultrasonic wave water bath, and cleaned by acetone; finally, the through-hole foam copper product which is provided with the hole formed by three-dimensional communicated space network, has the porosity of 50-81% and the average pore size of 0.2-4mm and is provided with microcosmic holes in a base body can be obtained. The obtained through-hole foam copper has controllable porosity and aperture, higher sintering quality and excellent energy absorbing performance.

Owner:HEBEI UNIV OF TECH

Polyvinyl formal sponge material with uniform abscesses and rapid imbibition and preparation method thereof

ActiveCN102020816ASolution can not be reusedSolve the shortcomings of high closed cell rate and slow water absorption rate of the productPharmaceutical non-active ingredientsAbsorbent padsCross-linkLiquid waste

The invention discloses a polyvinyl formal sponge material with uniform abscesses and rapid imbibition and a preparation method thereof. The material comprises polyvinyl alcohol, a cross-linking agent, a catalyst and a pore-forming agent, wherein the cross-linking agent is formaldehyde or paraformaldehyde or formaldehyde solution. The preparation method comprises the following steps of: stirring 2-9 parts of polyvinyl alcohol in 100-200 parts of water of which the temperature is 60-98 DEG C to obtain solution, and adding 0.05-8 parts of pore-forming agent to the solution; fully emulsifying the pore-forming agent to form evenly dispersed continuous solution phase; then adding 1-26 parts of catalyst and 1-15 parts of cross-linking agent or 5-50 parts of recovered liquid waste, 1-8 parts of catalyst and 1-15 parts of cross-linking agent, and mixing; pouring the mixture into a mould after 1-60 min for cross-linking reaction for 0.1-2 hours to form the abscesses under the action of the pore-forming agent; and continuing to heat and cure for 2-18 hours to prepare the polyvinyl formal sponge material. The invention has the advantages of good hydrophily, high compression strength, high dry wetting rate, high imbibition ratio and the like.

Owner:克林纳奇(荆州)高分子科技有限公司

Method for improving hydrophilicity of polymer porous membrane by dentritic branching molecule

InactiveCN1799682AImprove hydrophilicityImprove hydrophilic abilitySemi-permeable membranesTemperature controlPolymer science

The invention discloses a method for using tree branching molecule to improve the hydrophilicity of polymer porous membrane. The method comprises following steps: (1) adding the tree branching molecule and polymer into solvent to be heated, mixed and dissolved; (2) laying casting liquid on the carrier of stainless steel plate or glass plate and using erasing knife to make it into a liquid film with a certain thickness; (3) dipping the carrier with casting liquid into coagulating bath via the lyotropic conversion process to make the liquid film into tree branching molecule to improve the property of polymer porous membrane. The invention can adjust the molecular weight, terminal group and added amount of tree branching molecule to control the surface property of polymer porous membrane; and adjust the components of casting liquid and coagulating bath and temperature to control the structure of porous membrane. The inventive method can effectively control the balance between hydrophilicity and dewatering of dewatering polymer; improve the dirt resistance and biocompatibility, which can improve the preparation and application of ultra and micro filtration film.

Owner:ZHEJIANG UNIV

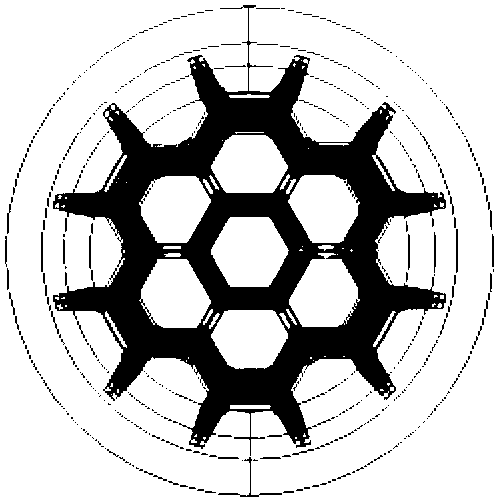

3D printing manufacturing technology of metal porous material with through hole structure

InactiveCN106891007APorosity is easy to controlSimple preparation processAdditive manufacturing apparatusTransportation and packagingManufacturing technologyMetallic materials

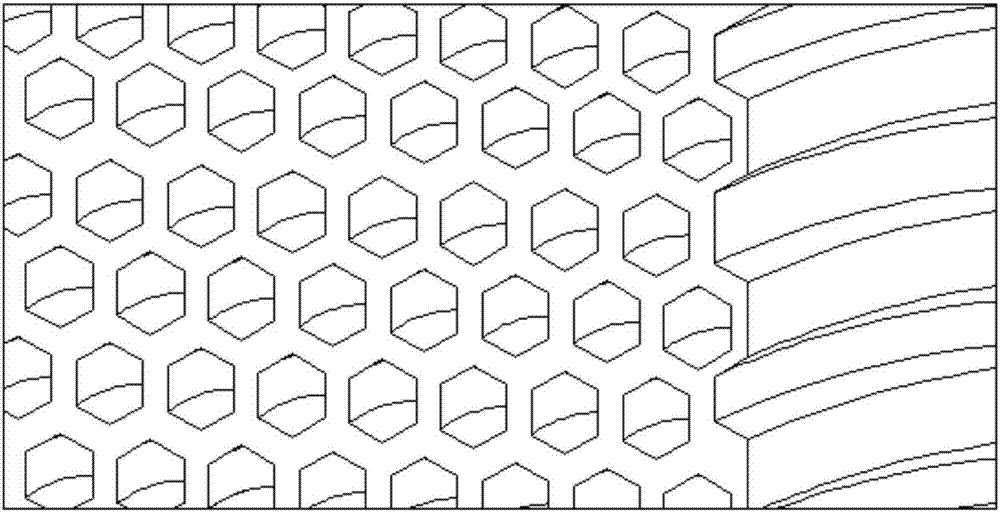

Disclosed is a 3D printing manufacturing technology of a metal porous material with a through hole structure. The 3D printing manufacturing technology of the metal porous material with the through hole structure comprises the following steps that S1, a 3D model of the porous material with the actual structure and the actual size is drawn; S2, 3D printing of a porous material blank is conducted; S3, thermosetting treatment of the porous material blank is conducted; S4, powder in the porous material blank is removed to form inner channels and pores; and S5, a required porous material product is manufactured through degreasing and sintering. The 3D printing manufacturing technology of the metal porous material with the through hole structure omits laser devices, has the advantages of being simple in manufacturing technology and low in manufacturing cost, can manufacture the structure with complex inner pore channels on the basis of a low-cost 3D printing technology, can be widely applied to manufacture of two porous materials including honeycomb-shaped metal porous materials and open-pore foam materials, and is broad in application prospect.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG

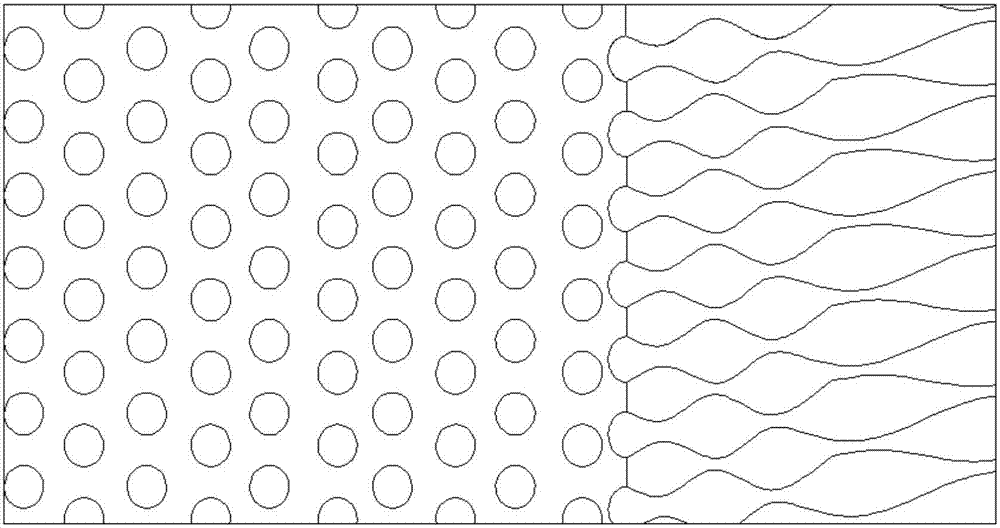

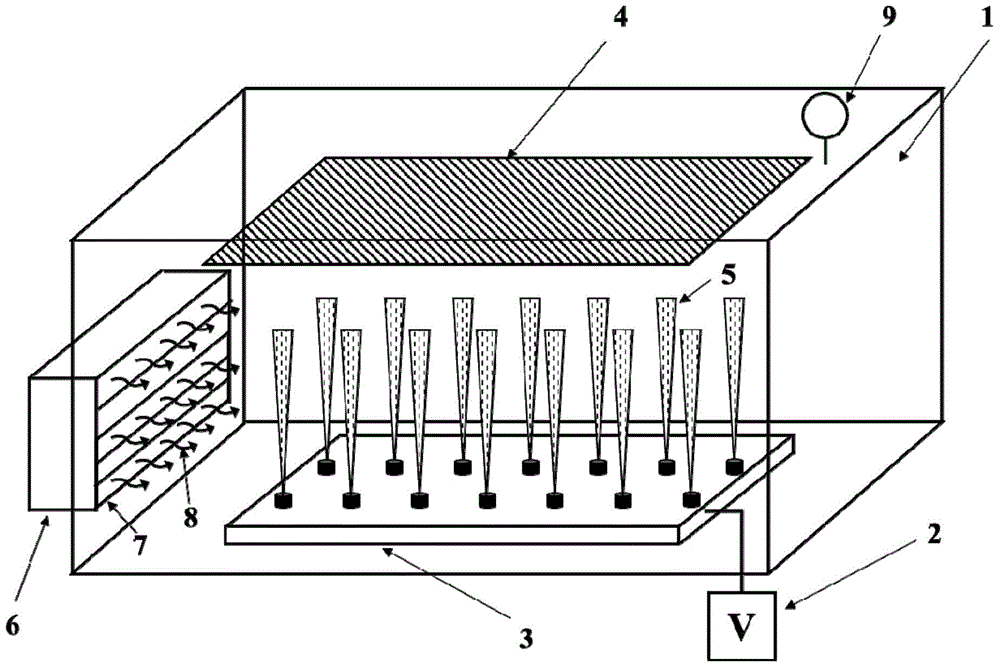

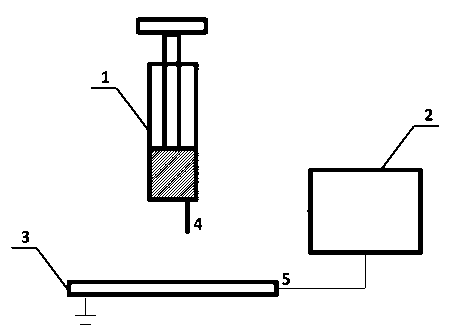

Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

ActiveCN104452109AGood waterproof and moisture permeabilityPorosity is easy to controlNon-woven fabricsPorosityFiber

The invention relates to an electrostatic spinning method and device of a fiber-based waterproof moisture-permeable film high in moisture-permeable flux. The electrostatic spinning method includes that during electrostatic spinning, polymer solution jet flow is injected at a certain included angle with air of a certain temperature and / or lateral air flow of non-solvent steam, and polymer molecules in the jet flow are quickened to be separated and solidified into fibers; water-pressure resistance of the electrostatic spinning film, namely the fiber-based waterproof moisture-permeable film high in moisture-permeable flux is greater than or equal to 100kPa, and the moisture-permeable flux is greater than or equal to 15000g / m<2> / d. The electrostatic spinning device is composed of an electrostatic spinning box, a high-voltage direct-current power supply, an electrostatic spinning hydraulic system, a spinning jet and a receiving base material, and a steam generation and air supply system is mounted on one side of the electrostatic spinning box. The fiber-based waterproof moisture-permeable film produced by the method has the advantages of small bore diameter, controllable adhesion degree and high porosity; the film is high in water-pressure resistance and moisture-permeable flux when used in the waterproof and moisture-permeable areas, and is wide in actual application prospect.

Owner:DONGHUA UNIV

Folding-resistant one-dimensional fibrous flexible energy storage device and preparation method thereof

ActiveCN109979763AImprove folding resistanceImprove electrochemical stabilityHybrid capacitor separatorsFinal product manufactureFiberEngineering

The invention discloses a folding-resistant one-dimensional fibrous flexible energy storage device and a preparation method thereof. The preparation method comprises the following steps: at least by adopting an electrostatic spinning mode or a 3D printing mode, a first nano-fiber membrane used as a diaphragm on a surface of a first electrode in situ is formed, and the first nano-fiber membrane isused to wrap the first electrode; and the first electrode provided with the diaphragm in a wrapped way is assembled and combined with matched electrolyte and a second electrode to form the flexible energy storage device. According to the invention, the nano-fiber membrane is wrapped on the electrode of the flexible energy storage device in situ by adopting the electrostatic spinning way, the 3D printing way, and so on, so that the structure and the composition height of the membrane are controllable, and the membrane has very strong adsorbability and high flexibility; and especially, after theflexible energy storage device is repeatedly folded, the membrane can still be tightly combined with the electrode, so that the problem of short circuit caused by mutual contact of the electrodes canbe prevented, and the folding resistance and the electrochemical stability of the flexible energy storage device are greatly improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for manufacturing composite material porosity detection comparison sample pieces

The invention belongs to composite material forming technologies and relates to a method for manufacturing multi-directional laid composite material porosity detection comparison sample pieces. The method comprises the following steps: when composite material prepreg is laid, adding a solvent which is soluble with resin and can easily volatile among prepreg layers; when laid laminated boards are solidified, adjusting the pressure and the pressure time to form pores, and enabling the pores to be uniformly formed in the laminated boards so as to manufacture the comparison sample pieces meeting composite material laminated board porosity detection. According to the method, a conventional mode that porosity comparison sample pieces need to be accumulated in the long-term production process is changed, the uniformly distributed porosity detection sample pieces with the controllable porosity can be manufactured within a short time, and urgent demands of a new generation aircraft on a porosity detection technology are met.

Owner:AVIC COMPOSITES

High heat conducting foam material of graphite, and fabricating method

This invention discloses a method for manufacturing high heat-conductive graphite foam material. The method comprises: (1) heating asphalt in a reactor at 1-5 deg.C / min to 260-400 deg.C; (2) pressurizing to 2-6 MPa; (3) heating at 1-2 deg.C / min to 350-550 deg.C; (4) keeping the temperature for 15-120 min, and discharging the gas to obtain asphalt foam material; (5) heating to 950-1100 deg.C under nitrogen protection to obtain carbonized asphalt foam material; (6) heating to 2600-3000 deg.C under nitrogen protection for carbonization, and cooling naturally to obtain high heat-conductive graphite foam material. The pore sizes are 80-800 mum, the density is 0.28-0.75 g / cu cm, the porosity is 55-85%, and the heat conductivity is 68-140 W / mK. The high heat-conductive graphite foam material can be widely used in radiator, heat exchanger, automobile, airplane brake block, catalyst carrier, gas adsorbent and composite material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

The invention relates to the porous ceramics material field, and concretely relates to a method for manufacturing high porosity and high strength yttrium-silicon-oxygen porous ceramics material through a foaming injection coagution process. According to the method, yttrium oxide and silicon oxide mixed power can be taken as a raw material, water is taken as a disperse medium, polyethyleneimine or ammonium citrate is selected as a dispersant, acrylamide or N-methylolacrylamide is taken as a monomer, a cross-linking agent N,N'-methylene bisacrylamide is added, a foaming agent sodium dodecyl sulfate, a peeling inhibitor polyoxyethylene, a catalyst N, N, N',N'-tetramethyl ethylenediamine and an initiator ammonium persulfate are added after stirring, and then injection mold solidification is carried out, drying is carried out for 24-48 hours at room temperature after demoulding, and then drying is carried out for 24-36 hours under the temperature of 60-90 DEG C, high temperature reaction sintering is carried out for 1.5-2.5 hours under the temperature of 1500-1550 DEG C finally, and the gamma-Y2Si2O7 porous ceramics can be finally manufactured. The manufactured gamma-Y2Si2O7 porous ceramics material having a multi-layer pore structure has controllable porosity with high porosity (75-85%) and high strength (3-8MPa).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of open pore foamed aluminum capable of easily removing pore-forming agent

The invention relates to a preparation method of an open pore foamed aluminum capable of easily removing a pore-forming agent. The preparation method of the open pore foamed aluminum comprises the following steps: firstly weighing ammonium bicarbonate and aluminite powder according to a volume ratio of (1-4) to 1, then uniformly mixing, subsequently adding absolute ethyl alcohol so as to improve the uniformity of mixed powder so as to obtain mixed powder sample, then pressing the mixed powder sample to obtain a cylindrical or strip-shaped pressed blank sample; putting the pressed blank sample in water bath for dipping to remove a spherical ammonium bicarbonate pore-forming agent, then drying the pressed blank sample in a drying oven; finally, sintering the pressed blank sample in vacuum, then cooling the pressed blank sample to the room temperature so as to obtain open pore foamed aluminum which is uniform in pore structure and controllable in porosity. The preparation method of the open pore foamed aluminum has the advantages that compared with the irregularly-shaped pore-forming agent, the foamed aluminum prepared by the spherical ammonium bicarbonate is capable of avoiding crack initiation to a great extent under the action of stress; the mechanical property of the foamed aluminum is improved; the pore-forming agent can be thoroughly removed; the corrosion of the residual pore-forming agent to an aluminum substrate can be avoided; the process period is shortened; the economic benefit is increased.

Owner:TONGJI UNIV

Paper protection method for sealing, protecting and reinforcing through high voltage electrostatic spinning film coating

InactiveCN103266537AThe method is simpleNo pollution in the processOld paper after-treatmentFiberPulp and paper industry

The invention discloses a method for reinforcing, sealing and protecting weak paper through a spinning film coating technology. High polymer sol generates micro / nano fiber membranes at normal temperature and normal pressure under the action of high voltage static to cover the paper surface so as to improve the tensile strength and elongation of the paper and effectively avoid secondary pollution of the paper generated by external pollutants such as dust mite, dust and mould. The method can be realized at normal temperature and normal pressure, thereby being simple and practicable, the spinning speed is high, the treatment process is free of pollution, and no obvious change occurs on the reinforced paper or the writing and pigments on the paper surface.

Owner:ZHEJIANG UNIV

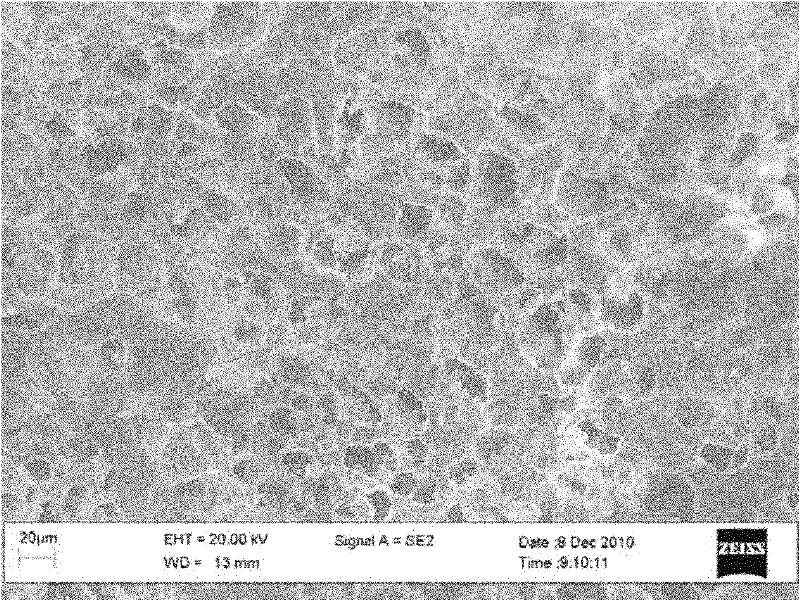

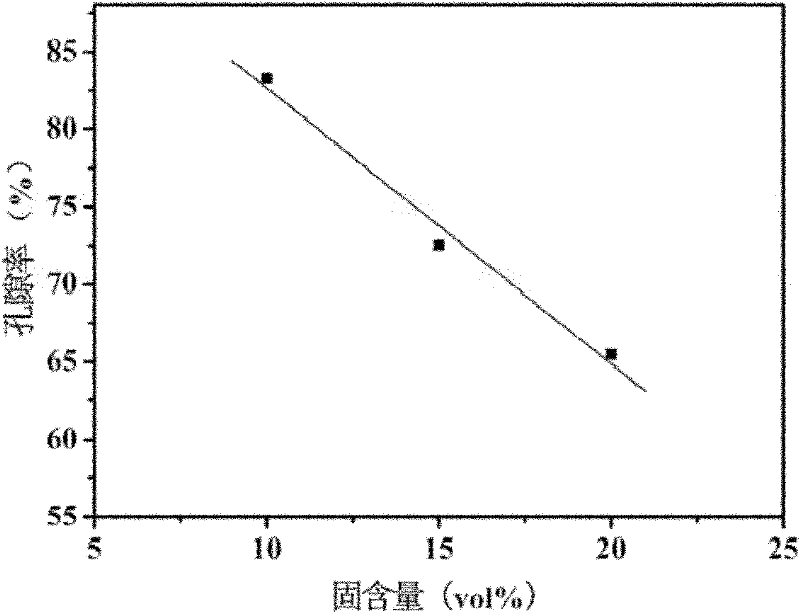

Method for preparing porous ceramic by using tertiary butanol-based freezing sublimation method

InactiveCN102531660ASimple selection of raw materialsSimple processCeramicwareOxide ceramicPolyvinyl butyral

The invention relates to the field of porous ceramics, in particular to a method for preparing a porous ceramic by using a tertiary butanol-based freezing sublimation method. The method disclosed by the invention basically has no restriction to an oxide material system and is generally suitable for engineering ceramics. The method comprises the following steps of: with oxide ceramic powder as a raw material, tertiary butanol as a solvent, citric acid as a dispersing agent and polyvinyl butyral as a binding agent, carrying out ball grinding on the raw material for 5-50h, pouring the uniformly-dispersed raw material into a polyethylene mold of which the bottom temperature is above 0 DEG C and the top temperature is room temperature, and cooling for 5min-2h; and demolding, then sublimating for 24-27h by using a water circulating pump under the condition of suction filtering, and heating to 1200-1600 DEG C in an air furnace and preserving the temperature for 5min-2h. According to the method disclosed by the invention, slurry of an organic system is prepared under the room temperature; and the obtained porous ceramic is distributed with directional holes, wherein the directional holes are polygonal holes and have the size distribution of below 100 microns and the longitudinal lengths of reaching millimeter-scale. According to the method disclosed by the invention, the porosity can be controlled by adjusting the solid content, and the porous ceramic material with ultrahigh porosity (more than 80 percent) can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

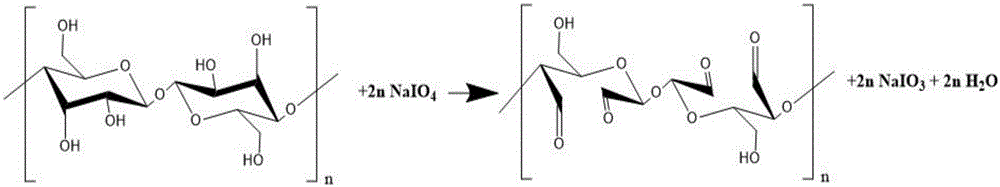

Self-crosslinked hydroformylated bacterial cellulose functional porous nano-material and preparation method thereof

ActiveCN106084302AGood moisture absorptionImprove water holding capacityPharmaceutical delivery mechanismAbsorbent padsWound dressingFoaming agent

The invention relates to a self-crosslinked hydroformylated bacterial cellulose porous nano-material and a preparation method thereof. The material comprises bacterial cellulose, polysaccharides or polypeptides, an antibacterial agent and a foaming agent. The preparation method comprises the following steps: dissolving the polysaccharides or polypeptides, stirring the polysaccharides or polypeptides to form a solution, adding a certain amount of dispersed hydroformylated bacterial cellulose, a certain amount of the antibacterial agent (or antibacterial sol) and a certain amount of the foaming agent to the solution, stirring all above materials to make bubbles uniformly exist in the obtained mixed solution, pouring the mixed solution to a die, quenching the above sample, placing the quenched sample in a vacuum lyophilizer, and carrying out vacuum drying to prepare the self-crosslinked degradable polysaccharide or polypeptide composite hydroformylated bacterial cellulose functional porous nano-material. The material has the inherent good mechanical performances of a porous material, also as the advantages of good biocompatibility, fast dry state wetting rate, good attachment to skins, and good antibacterial function, and can be used as various medical wound repairing materials, multifunctional wound dressings and novel tissue engineering scaffolds.

Owner:UNIV OF SCI & TECH BEIJING

Multi-layer porous polyimide film and preparation method of porous polyimide film

ActiveCN102582138AImprove integrityReduce resistanceSynthetic resin layered productsGranularityPolyamide

The invention provides a multi-layer porous polyimide film and a preparation method of the porous polyimide film. The film comprises a large-hole layer and a small-hole layer or is formed in the way that one small-hole layer is sandwiched between two large-hole layers, wherein the large-hole layer is 0.15-6 microns in hole diameter and 5-100 microns in thickness, and the small-hole layer is 0.01-0.15 microns in hole diameter and 1-5 microns in thickness. The preparation method of the film comprises the following steps of: synthesizing two or three kinds of composite polyamide resin solution, by using dianhydride, diamine and two or three kinds of pore-forming materials with different granularities; carrying out composite salivating to form a two / three-layer film, carrying out two-way stretch and imidization, pickling the film for removing the pore-forming materials, thus obtaining the multi-layer porous polyimide film. The molar ratio of dianhydride to diamine is 1:1, and the mass of the pore-forming materials is 0.25-2 times that of dianhydride and diamine. Various media can conveniently pass through the large-hole layer of the film and the strength of the film is ensured; the small-hole layer can be thinned to 1 micron and the transmittance is good. According to the method, the porosity and hole diameter of all layers in the film can be easily controlled, and the method is suitable for preparing porous film products.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

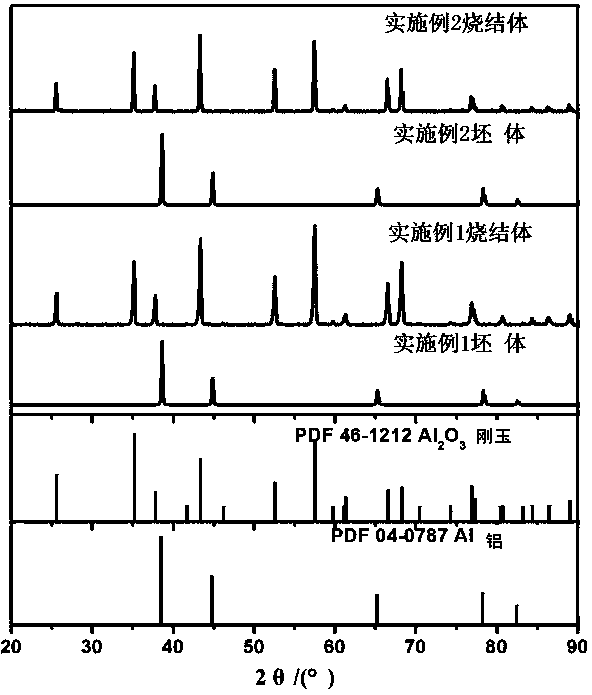

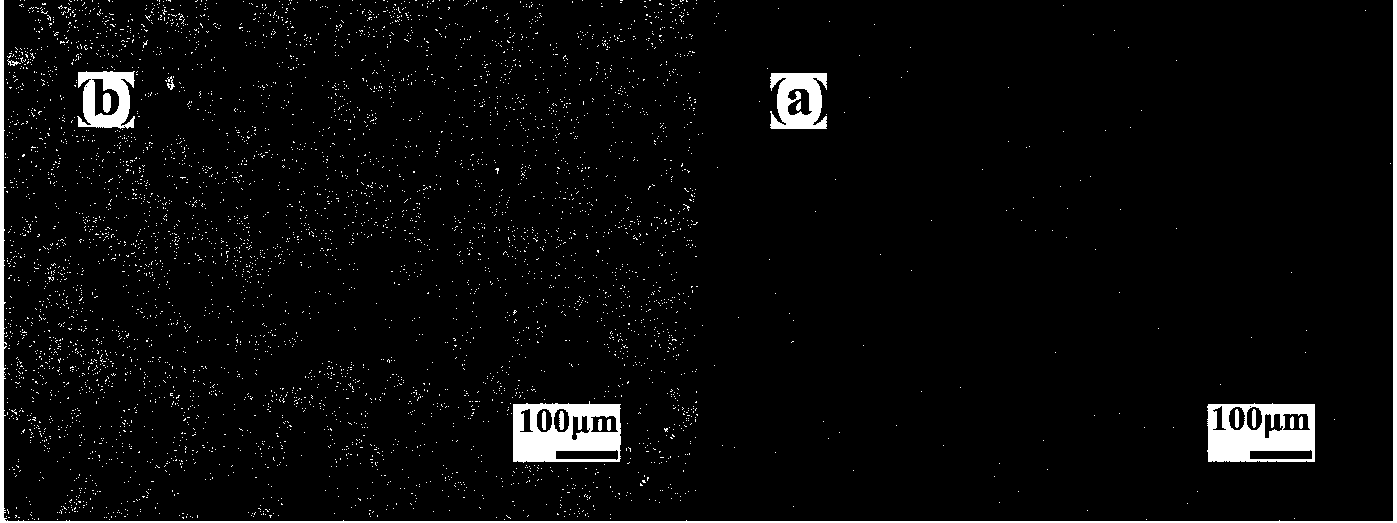

Method for preparing porous alumina ceramic material through combination of 3D printing and reactive sintering

The invention relates to a method for preparing a porous alumina ceramic material through combination of 3D printing and reactive sintering. The method comprises the following steps: 1) adding aluminium powder or aluminium alloy powder into a feeding box of a three-dimensional printer, and printing porous biscuit through the three-dimensional printer; 2) performing processes of solidification, debonding, oxidation and sintering in sequence on the porous biscuit prepared in the step 1) so as to obtain the porous alumina ceramic material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

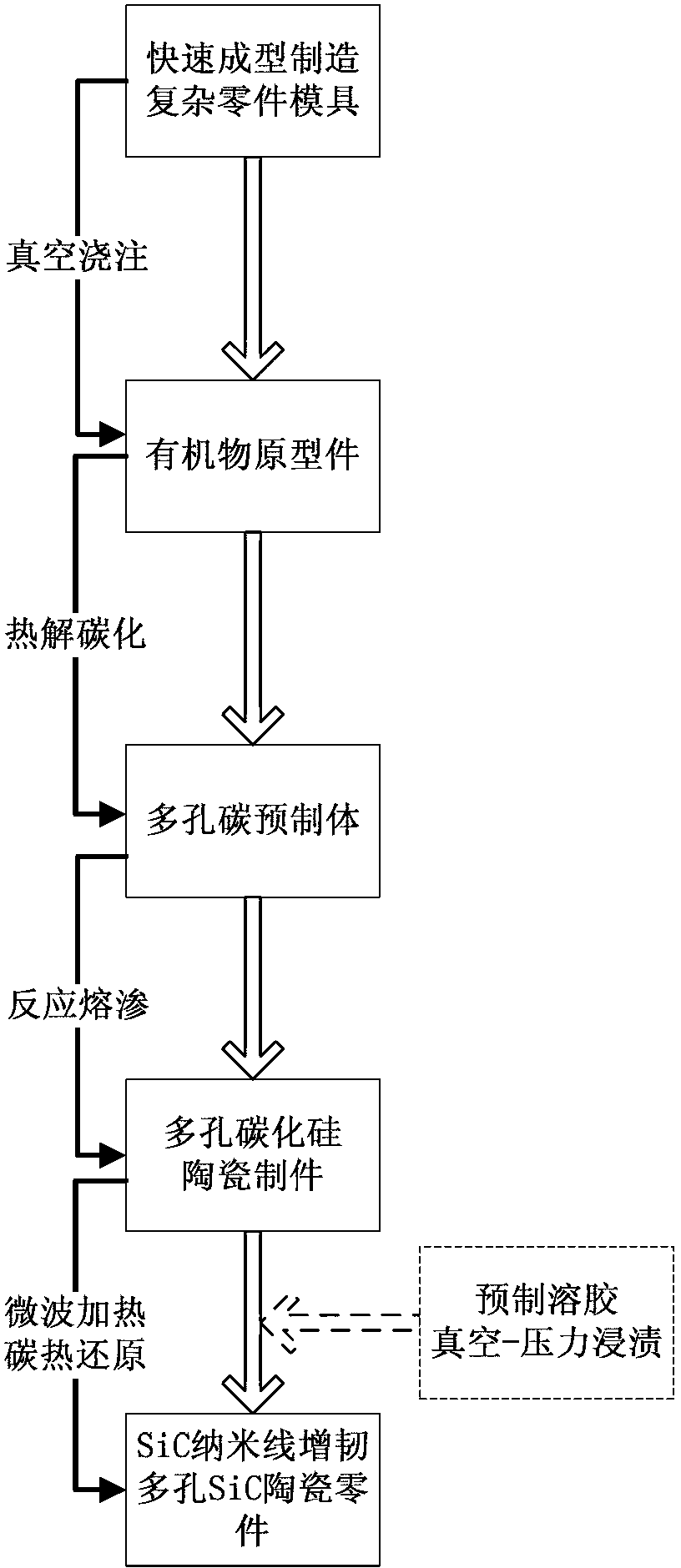

Making method of high-toughness porous SiC ceramic complex part

InactiveCN103130525AImprove part performanceExcellent flexural strengthCeramicwareTemperature resistanceOxidation resistant

The invention discloses a making method of a high-toughness porous SiC ceramic complex part. A light-cured rapid forming technology is adopted to make a resin die of the complex part, a high-residual carbon resin slurry is casted, cured and pyrolyzed to make a porous carbon perform, silicon-carbon reaction sintering and high-temperature vacuum silicon discharge technologies are adopted to make a porous SiC complex part, and matrix aperture internal SiC nanowires are made through a microwave heating process to realize the toughening purpose. The method has the advantages of free forming of the complex structure, uniform and controllable aperture, high specific surface area, high fracture toughness, high-temperature resistance, anti-oxidation and the like.

Owner:XI AN JIAOTONG UNIV

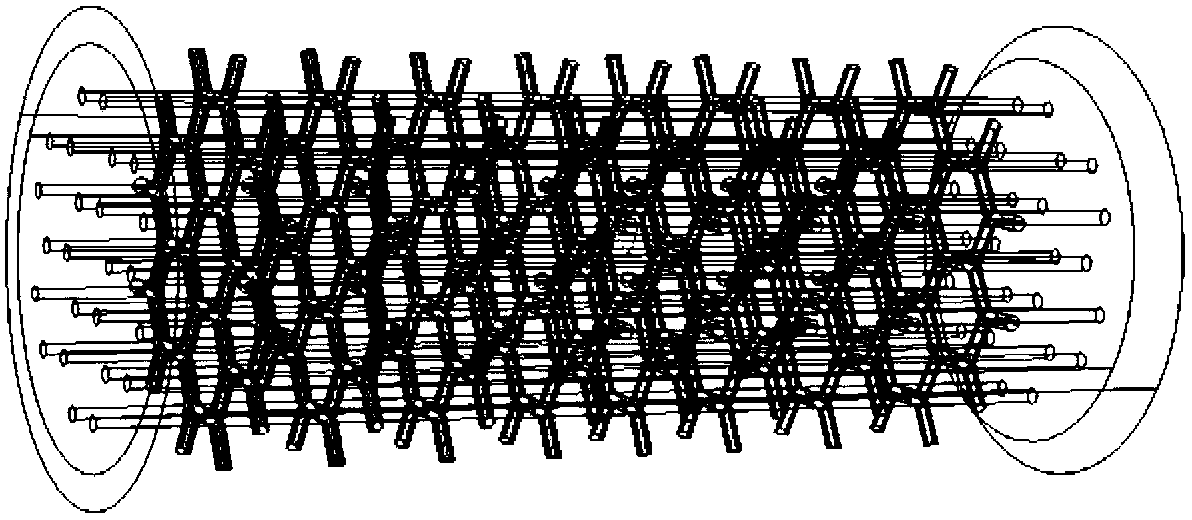

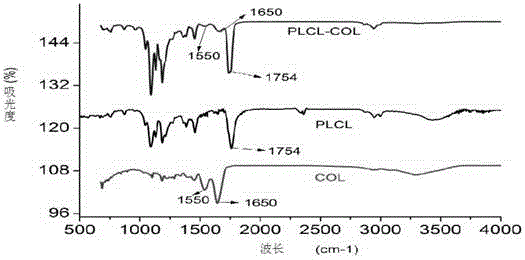

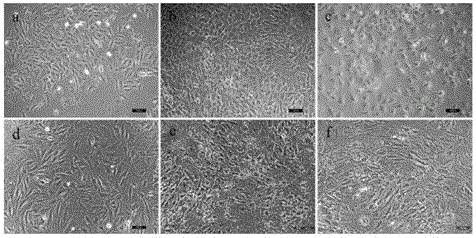

Poly-L-lactide-caprolactone copolymer (PLCL) three-dimensional porous scaffold, PLCL and collagen (PLCL-COL) composite scaffold and preparation methods of scaffolds

InactiveCN105343936ASimple structureHigh porositySurgeryTissue regenerationLow temperature depositionPoly-L-lactide

The invention is applicable to the field of biomedicine, and provides a poly-L-lactide-caprolactone copolymer (PLCL) three-dimensional porous scaffold, a PLCL and collagen (PLCL-COL) composite scaffold and preparation methods of the scaffolds. The preparation method of the PLCL three-dimensional porous scaffold, on the basis of a low-temperature deposition manufacturing technology, specifically comprises the following steps: implementing modeling pretreatment by virtue of CAD software, conducting hierarchical slicing by virtue of Aurora software, and implementing design of printing parameters of the PLCL three-dimensional porous scaffold by virtue of Cark software; dissolving the PLCL in an organic solvent, so that a PLCL homogenous liquid is prepared; smearing the organic solvent on a forming platform when forming room temperature drops to minus 25-35 DEG C, and printing and shaping after setting the shaping parameters by virtue of the Cark software, so that a PLCL three-dimensional porous scaffold prefabricated part is obtained; and taking out and freeze-drying the PLCL three-dimensional porous scaffold prefabricated part, so that the PLCL three-dimensional porous scaffold is obtained.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

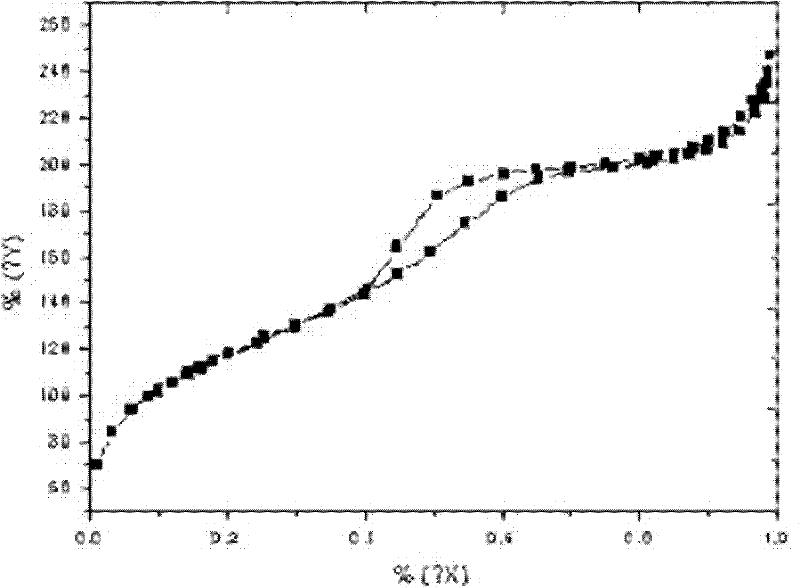

Method for preparing pore diameter controllable porous capillary core

InactiveCN102489706APorosity is easy to controlControllable pore size distributionCeramicwarePore diameterMaterials science

The invention relates to a method for preparing a pore diameter controllable porous capillary core. The method comprises the following steps of: uniformly mixing soluble salt powder which does not react with matrix powder in the matrix powder of capillary core sintering raw materials, and coldly molding the mixed powder into the capillary core with the needed shape; and performing pressureless sintering or pressure sintering on the molded raw materials under the protection of inert gases, and washing off the soluble salt to prepare the capillary core. The method has the advantages of simple preparation process, no need of a pore-forming agent and low cost, and the capillary core with high strength, controllable porosity and controllable pore size distribution is prepared.

Owner:SHANDONG UNIV

Silicon carbide aerogel and preparation method thereof

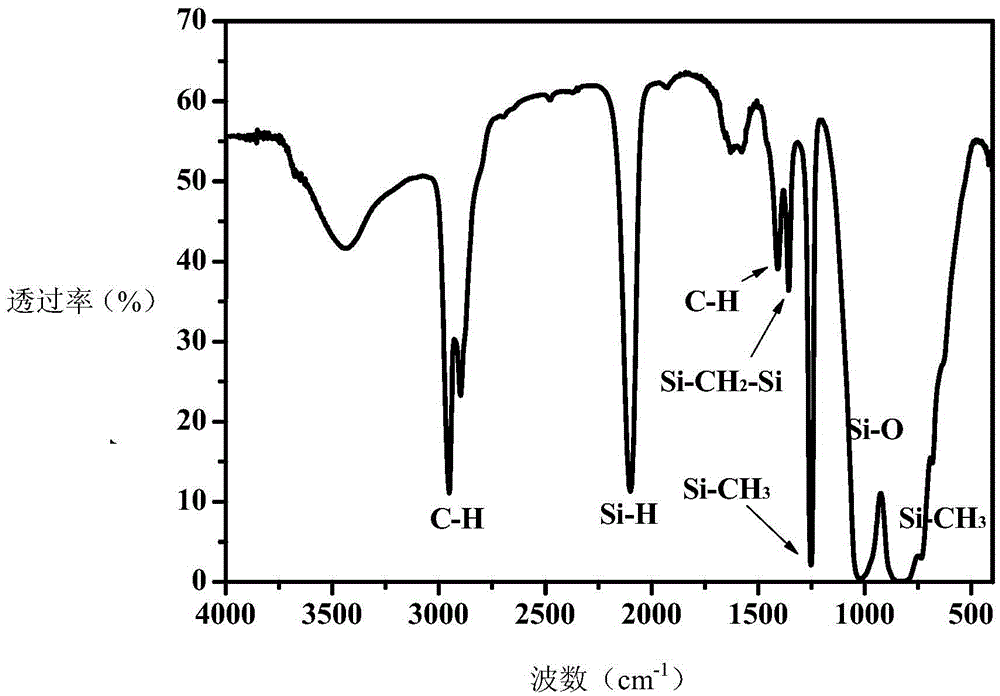

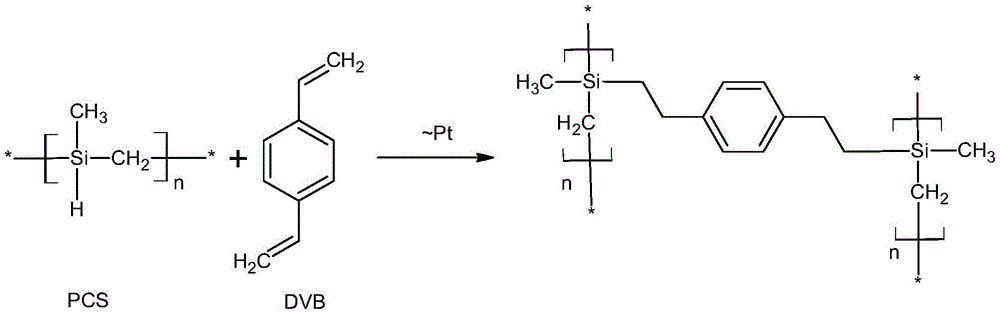

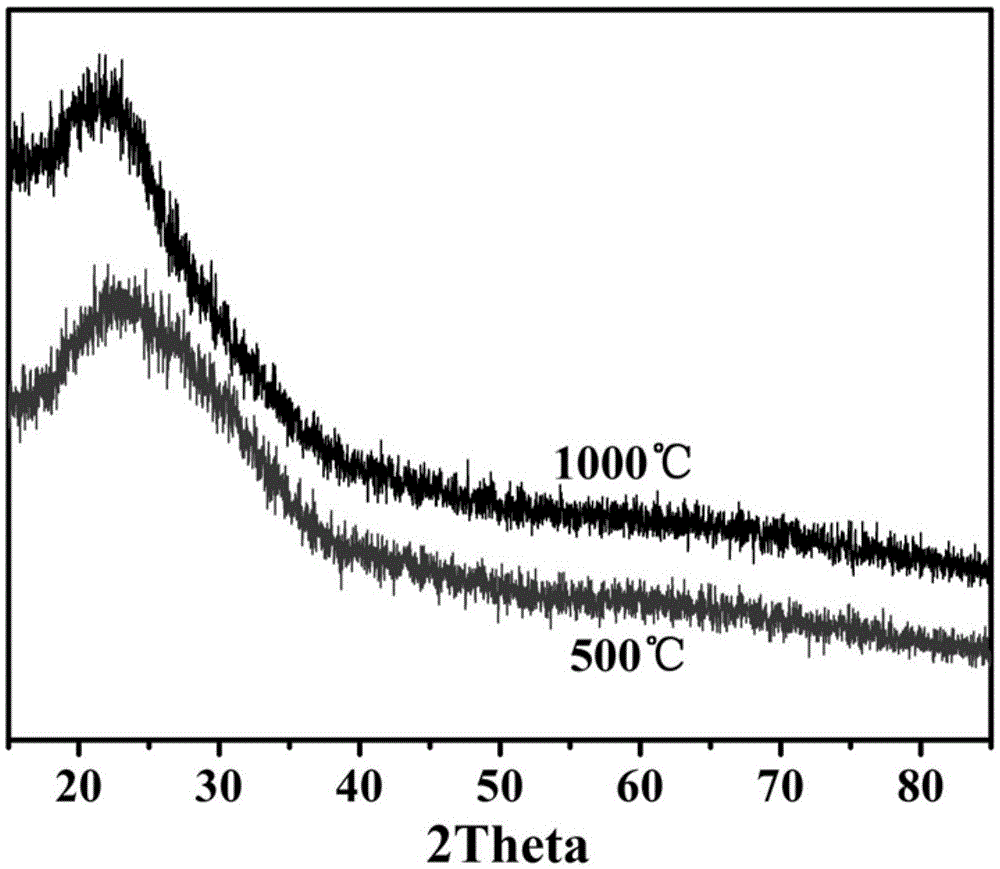

The present invention discloses a silicon carbide aerogel, which is prepared from polycarbosilane containing Si-H bond, divinylbenzene, a Pt catalyst and an organic solvent by a polymer precursor conversion ceramic preparation method and aerogel preparation method. The silicon carbide aerogel has a specific surface area of 50-400 m<2> / g, a porosity of 70-90% and density of 0.1-0.2 g / mL; the mass ratio of polycarbosilane to divinylbenzene is 1:08-1.2; and the Pt catalyst accounts for 0.1-0.5% of the total weight of polycarbosilane and divinylbenzene. The method utilizes polymer precursor conversion ceramic preparation method for preparation of SiC aerogel, and the conversion temperature is as low as 800 DEG C. The obtained SiC aerogel has low oxygen content, high purity, good quality, and controllable porosity and density; and the process is simple and controllable.

Owner:厦门纳美特新材料科技有限公司

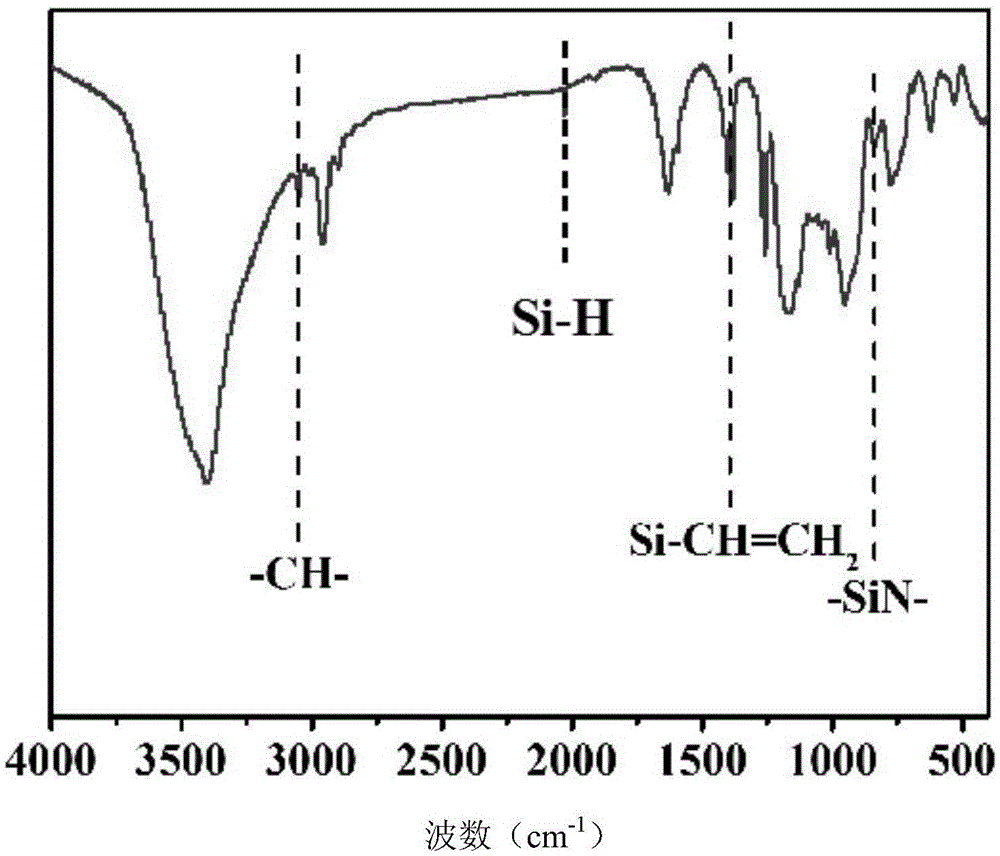

SiCN aerogel and preparation method thereof

The invention discloses a SiCN aerogel. The raw materials comprise polyvinyl silazane containing -CH=CH2 bond or also containing both -Si-H bond in the molecular structure, and divinylbenzene / dicumyl peroxide. A polymer precursor conversion ceramic preparation method and an aerogel preparation method are conduced to prepare the SiCN aerogel with specific surface area of 100-200 m<2> / g, porosity of 80-90% and density of 0.05-0.15 g / mL. The SiCN aerogel of the invention is a novel nano-porous ceramic material with extremely high porosity and specific surface area, and low density.

Owner:厦门纳美特新材料科技有限公司

Method for manufacturing high heat conducting foam material of graphite with even apertures

This invention discloses a method for preparing graphite foam material with uniform pore sizes and high heat conductivity. The method comprises: (1) placing mesophase pitch into a high-pressure reactor, adding surfactant, mixing uniformly, vacuumizing, heating to 260-350 deg.C, pressurizing to 2-6.0 MPa, heating to 450-650 deg.C, keeping for 15 min-2 h, cooling, and exhausting to obtain pitch foam; (2) heating the pitch foam at a heating rate not higher than 1 deg.C / min to 950-1100 deg.C, and carbonizing under nitrogen protection to obtain carbonized pitch foam; (3) heating the carbonized pitch foam at a heating rate not higher than 1 deg.C / min to 2500-3000 deg.C under Ar protection, and cooling naturally to obtain graphite foam material with high heat conductivity. The obtained graphite foam material can be widely used in radiators, heat exchangers, brake pads of automobiles and planes, catalyst carriers, and gas adsorbents.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for preparing high fatigue property porous Ti-6Al-4V bulk material

The invention relates to porous material preparation, in particular relates to a method for preparing a high fatigue property porous Ti-6Al-4V bulk material, which is used for solving the problem of low fatigue property of the porous Ti-6Al-4V bulk material of the prior art. The method is that an 'electron beam molten metal molding technology' is utilized to prepare the large Ti-6Al-4V bulk material with the porosity of 50%-95% at first, the porous material is then subjected to two steps of thermal treatment of annealing and aging at 400 DEG C and 1000 DEG C, and the Ti-6Al-4V porous material with high fatigue strength, low elasticity modulus of (0.1-20 GPa) and 'the ratio of fatigue strength / compressive strength' of 0.7 is obtained finally. According to the method, the mechanical performance of the porous Ti-6Al-4V pore wall material is controlled through a thermal treatment technology, and thus, a large titanium alloy porous material with excellent fatigue property is obtained and can be widely applied to the fields of aerospace, medical treatment and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com