Lithium-ion battery diaphragm and preparation method thereof

A lithium-ion battery and diaphragm technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as no shutdown function, unfavorable usability, and impact on battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

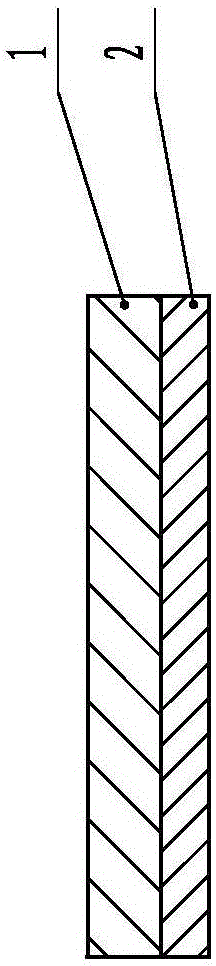

[0061] Lithium-ion battery separators were prepared by single-layer coating with the structure as figure 1 As shown, 1 is the coating, 2 is the porous substrate, the total thickness is 12 μm, the porosity is 48%, the thermal closing temperature is 125°C, and the liquid absorption rate is 180%.

[0062] A single-layer 7μm polyethylene diaphragm substrate is selected, with a melting point of 125°C, a porosity of 60%, and a liquid absorption rate of 50%.

[0063] The production steps are as follows:

[0064] a. The coated surface of the polyethylene diaphragm substrate is treated with corona, and the surface tension is 42dyn / cm.

[0065] b. Coating preparation:

[0066] The components of slurry A-1 include: 1 part of silane coupling agent (KH570), 10 parts of ethyl acetate, 19 parts of nano silicon dioxide (nano-SiO 2 ), 20 parts of propoxylated trimethylolpropane triacrylate (TMP3POTA), 10 parts of polyethylene glycol 1000 (PEG-1000), 10 parts of polyethylene glycol 200 (PEG-...

Embodiment 2

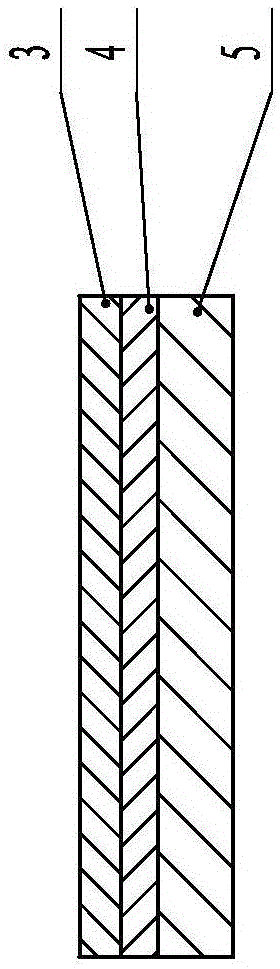

[0075] Preparation of Li-ion battery separator by single-sided two-layer stack coating, structure figure 2 As shown, 3 and 4 are coatings, 5 is a porous substrate, the total thickness is 20 μm, the porosity is 40%, the thermal closing temperature is 129°C, and the liquid absorption rate is 190%.

[0076] A single-layer dry-process polypropylene diaphragm substrate is selected, with a thickness of 12 μm, a porosity of 39%, and a liquid absorption rate of 36%. Coating 3 has a thickness of 4 μm and coating 4 has a thickness of 4 μm.

[0077] The production steps are as follows:

[0078] a. Substrate surface treatment:

[0079] The coated surface of the polypropylene separator substrate was treated with corona, and the surface tension was 40 dyn / cm.

[0080] b. Coating preparation:

[0081] The composition of slurry B-1 includes: 1 part of silane coupling agent (A187), 19 parts of tetraethyl orthosilicate (TEOS), 30 parts of ethyl acetate, 48.3 parts of ethylene glycol dimeth...

Embodiment 3

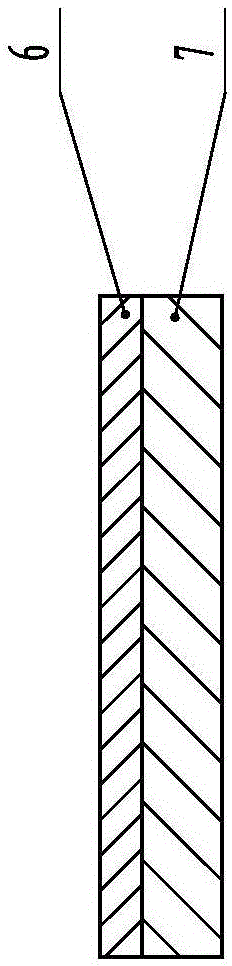

[0100] A lithium-ion battery separator is prepared by a single-sided single-layer coating method, and the structure is as follows image 3 As shown, 6 is the coating, 7 is the porous substrate, the total thickness is 25 μm, the porosity is 45%, and the liquid absorption rate is 150%.

[0101] A three-layered separator base film of polypropylene / polyethylene / polypropylene is used, with a thickness of 20 μm, a porosity of 46%, and a liquid absorption rate of 45%.

[0102] The production steps are as follows:

[0103] a. Substrate surface treatment: Flame treatment is carried out on the coated surface of the base film, and the surface tension is 41dyn / cm.

[0104] b. Coating preparation:

[0105] The components of slurry D-1 include: 0.5 parts of silane coupling agent (KH570), 49.5 parts of ethyl acetate, and 50 parts of porous alumina. The average particle diameter of the porous alumina is 5 μm, and the average pore diameter is 8 nm.

[0106] The preparation method of slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com