Peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades

A grinding wheel and peripheral technology, used in bonding grinding wheels, metal processing equipment, abrasives, etc., can solve the problems of high auxiliary time and labor intensity, the grinding wheel cannot meet its requirements, and the dressing tool wears quickly, etc. The effect of high bonding and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

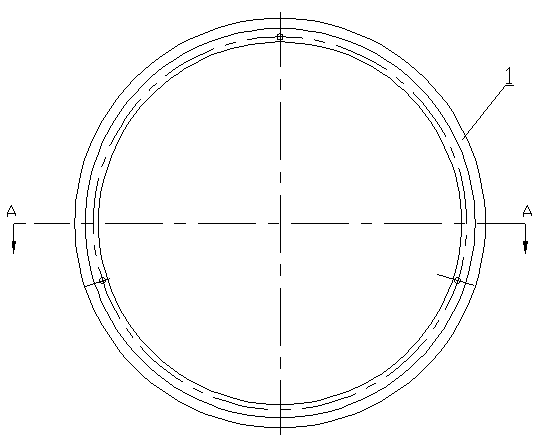

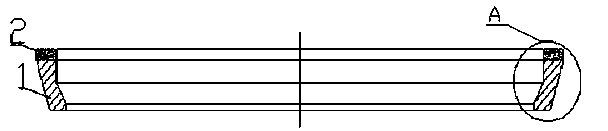

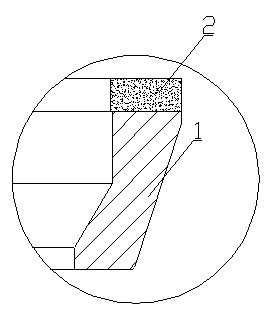

[0035] Embodiment one: see Figures 1 to 3 As shown, a peripheral grinding wheel for processing PCBN blades includes a grinding wheel base and an abrasive layer located on the grinding wheel base, and the abrasive layer is bonded and fixed to the base through epoxy resin glue.

[0036] The substrate is a circular steel substrate with a diameter of 400 mm and a thickness of 33 mm.

[0037] The abrasive layer is circular, with an outer diameter of 400 mm, a ring width of 15 mm, and a thickness of 7 mm.

[0038] The raw material composition and mass percentage of the abrasive layer are: 55% diamond, 32% vitrified bond, 8% pore forming agent, and 5% phenolic resin solution.

[0039] The abrasive layer has a porosity of 45% and a pore diameter of 60-80 μm.

Embodiment 2

[0040] Embodiment 2: A peripheral grinding wheel for processing PCBN blades, comprising a grinding wheel base and an abrasive layer located on the grinding wheel base, and the abrasive layer is bonded and fixed to the base by epoxy resin glue.

[0041] The base is a circular aluminum base with a diameter of 350 mm and a thickness of 77.5 mm.

[0042] The abrasive layer is circular, with an outer diameter of 350 mm, a ring width of 10 mm, and a thickness of 14.5 mm.

[0043] The raw material composition and mass percentage of the abrasive layer are: 64% diamond, 28% vitrified bond, 3% pore forming agent, and 5% phenolic resin solution.

[0044] The abrasive layer has a porosity of 37% and a pore diameter of 60-80 μm.

Embodiment 3

[0045] Embodiment 3: A peripheral grinding wheel for processing PCBN blades, comprising a grinding wheel base and an abrasive layer located on the grinding wheel base, and the abrasive layer is bonded and fixed to the base by epoxy resin glue.

[0046] The substrate is a circular aluminum substrate with a diameter of 400mm and a thickness of 14mm.

[0047] The abrasive layer is circular, with an outer diameter of 400 mm, a ring width of 12 mm, and a thickness of 8 mm.

[0048] The raw material composition and mass percentage of the abrasive layer are: 50% diamond, 35% vitrified bond, 10% pore-forming agent, and 5% phenolic resin solution.

[0049] The abrasive layer has a porosity of 48% and a pore diameter of 80-100 μm.

[0050] Referring to shown in table 1, carry out the part parameter contrast of identical machining process for peripheral grinding wheel of the present invention and existing emery wheel:

[0051] Table 1 Peripheral Grinding Wheel of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com