Method for preparing through-hole foamed metal of high factor of porosity

A metal foam and high porosity technology, applied in the field of metal foam preparation, can solve the problem of high process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

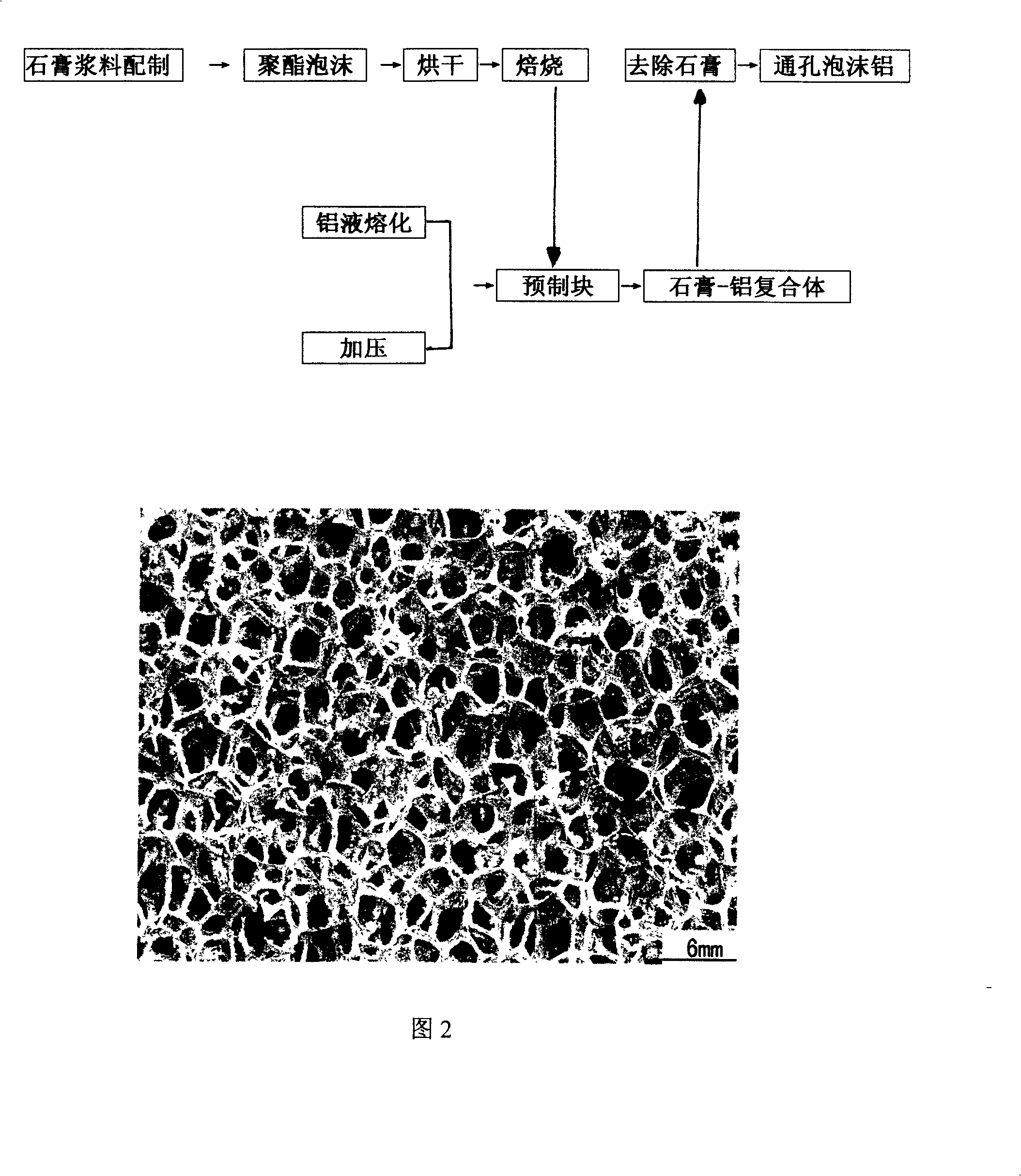

[0032] Put polyester foam with a diameter of 100mm and a height of 60mm and a porosity of 95% into the mold, and use materials such as α hemihydrate gypsum, tap water, industrial salt (particle size ≥ 100 mesh), calcium oxide (particle size ≥ 100 mesh) Prepare a uniform slurry according to (mass percentage) 45%: 20%: 30%: 5%, then inject the slurry into polyester foam and dry it naturally for 3 hours, then dry it at 55°C for 2 hours, and then dry it at 120°C respectively. °C, 260 °C and 550 °C for 3 hours each to burn off the polyester foam to form a porous skeleton. Put the porous skeleton into a mold, pour aluminum liquid at about 700°C on it, then infiltrate the aluminum liquid into the gaps of the porous skeleton at 1 to 2 atmospheres, and finally wash with water to remove gypsum and other materials, that is A through-cell aluminum foam with a porosity of 95% is available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com