Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

808 results about "Metal foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

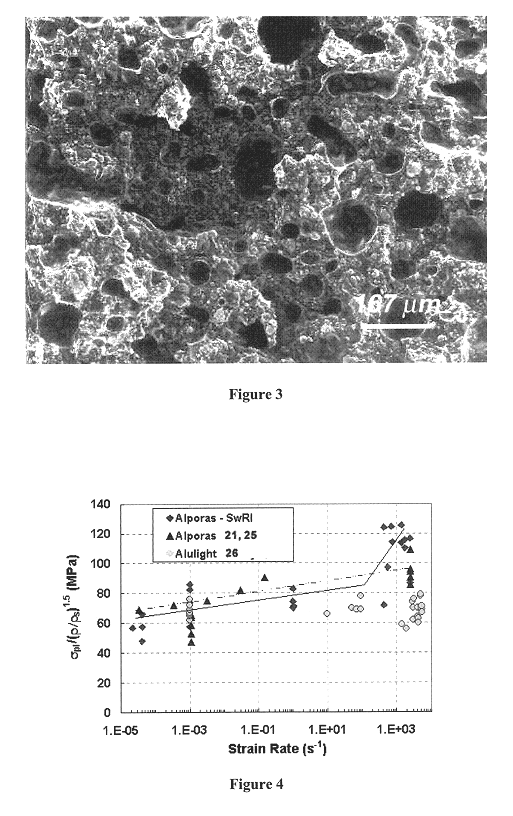

A metal foam is a cellular structure consisting of a solid metal (frequently aluminium) with gas-filled pores comprising a large portion of the volume. The pores can be sealed (closed-cell foam) or interconnected (open-cell foam). The defining characteristic of metal foams is a high porosity: typically only 5–25% of the volume is the base metal. The strength of the material is due to the square-cube law.

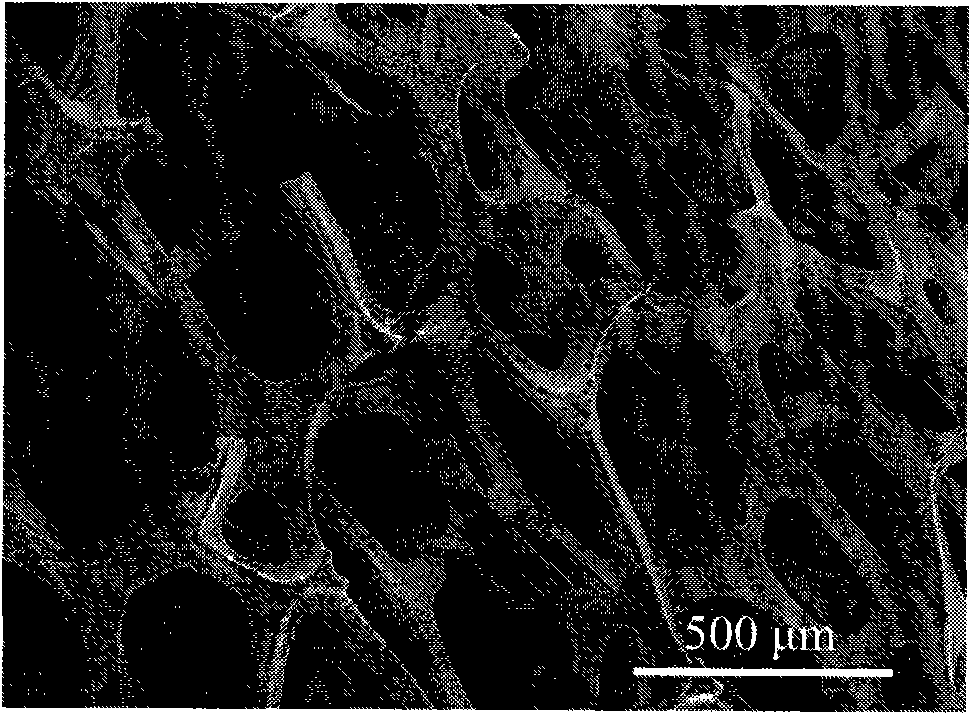

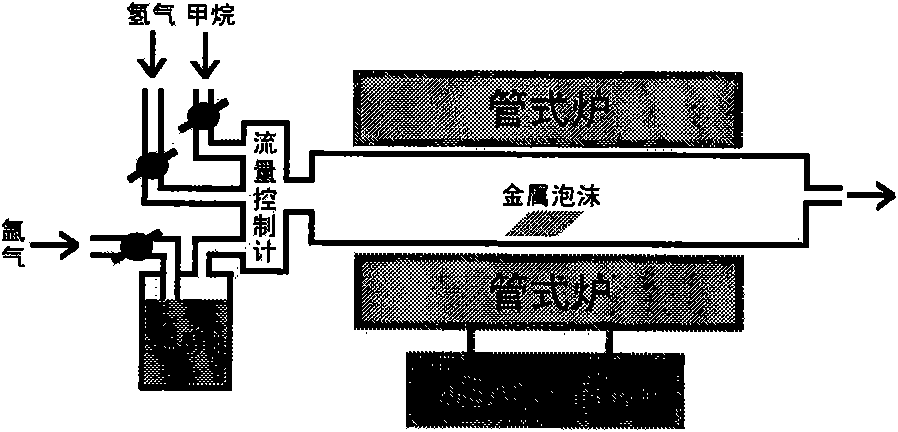

Grapheme foam and preparation method thereof

InactiveCN101831622AAvoid reunionHigh temperature resistantChemical vapor deposition coatingEtherConductive materials

The invention discloses grapheme foam and a preparation method thereof. The grapheme foam provided by the invention is prepared by the method comprising the following steps: 1) putting a metal foam material into a vacuum tube type furnace, and calcining the metal foam material under non-oxidizing atmosphere; 2) depositing grapheme on the calcined metal foam material by adopting a chemical vapor deposition method; and 3) removing foam metal from the obtained grapheme modified metal foam material, cleaning the obtained foam material by using deionized water, ethanol and ether in turn, taking the foam material out and drying the foam material to obtain grapheme foam. The grapheme foam material has a three-dimensional hollow porous netlike structure, the grapheme is on the netlike wall, and the structural characteristic effectively prevents the agglomeration of the grapheme; and the grapheme foam material integrates the characteristics of a foam material and a conductive material, and has the advantages of ultra-low density, ultra-high surface area, high heat conduction, high temperature resistance, corrosion resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

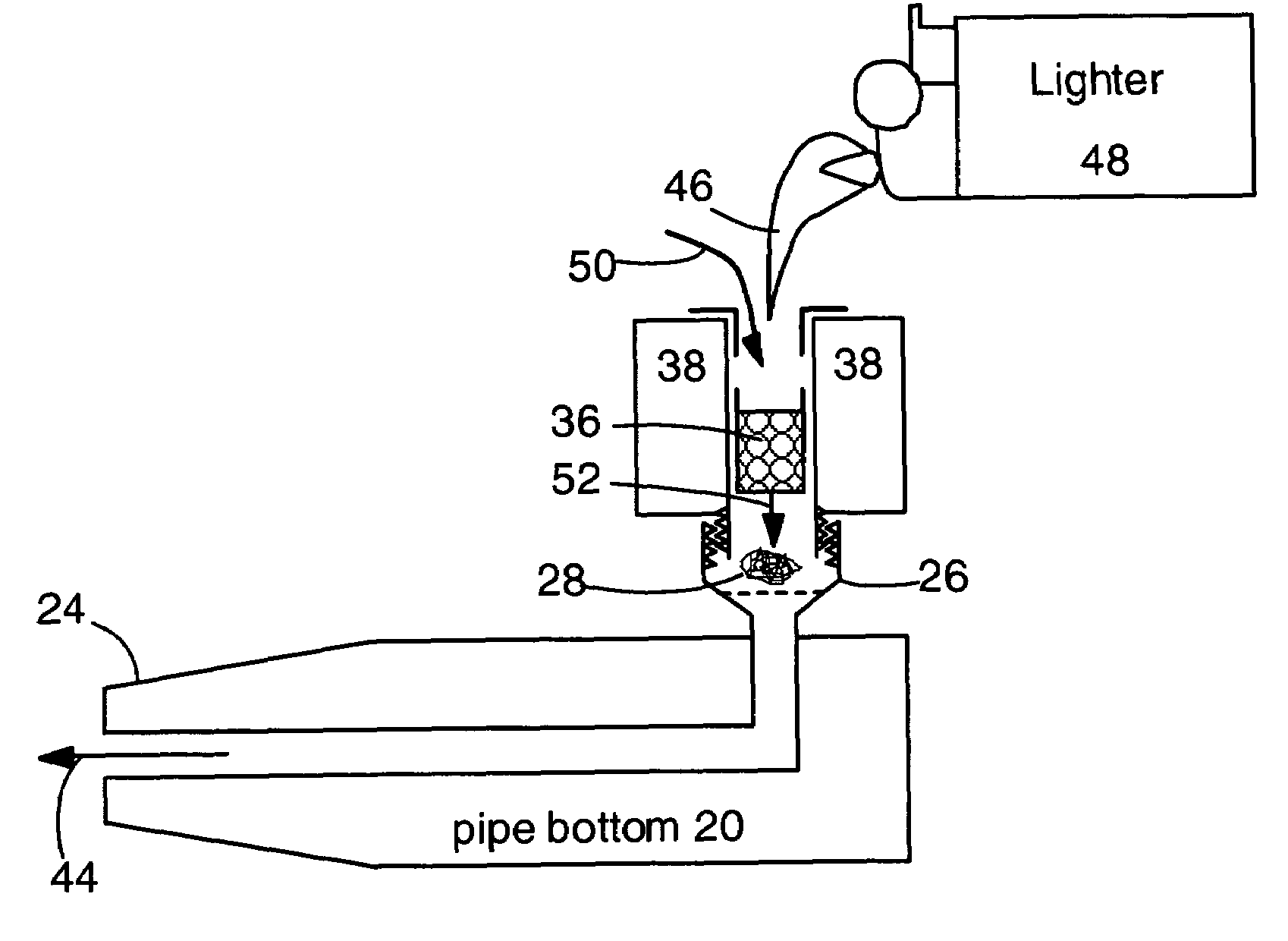

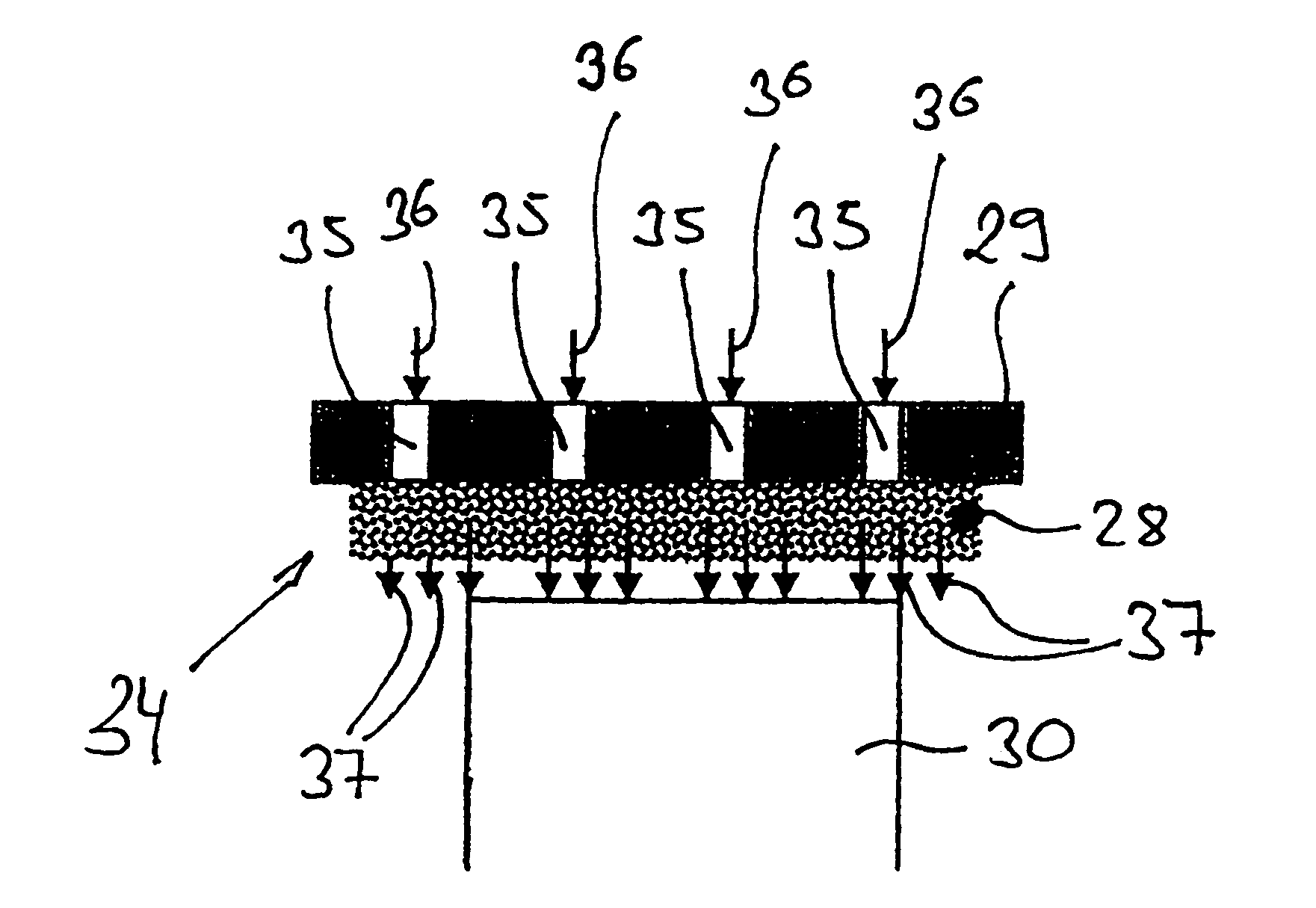

Vaporization pipe with flame filter

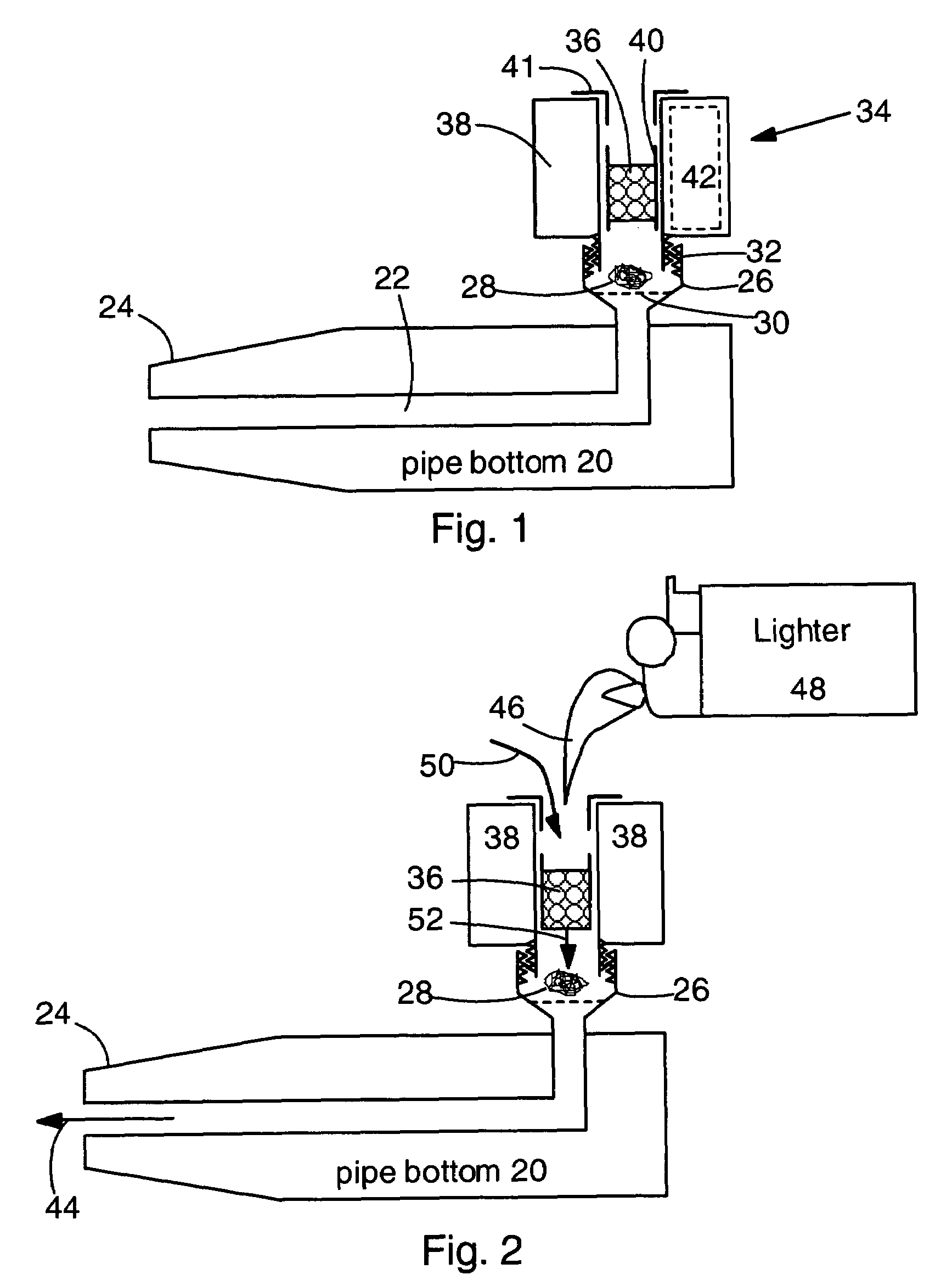

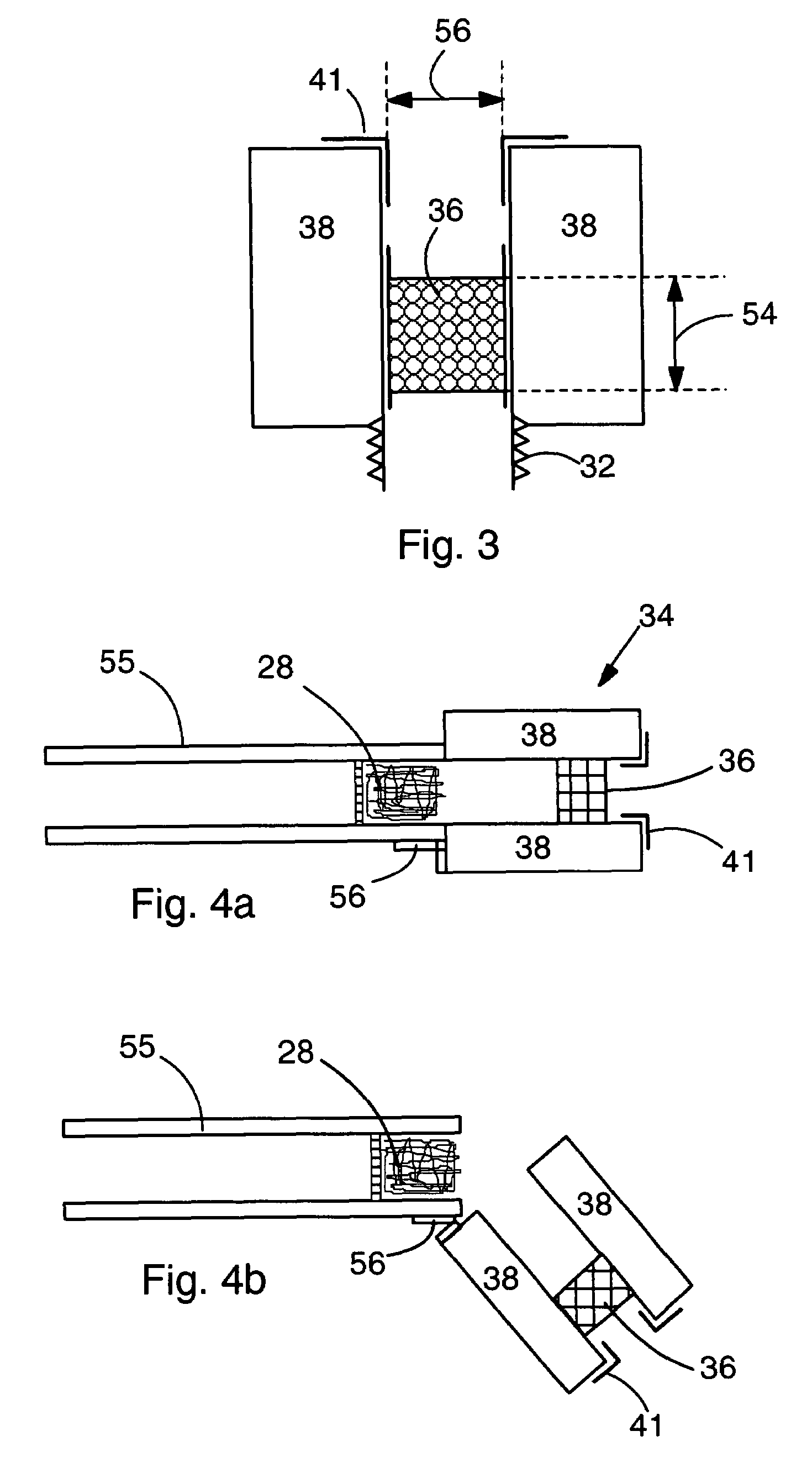

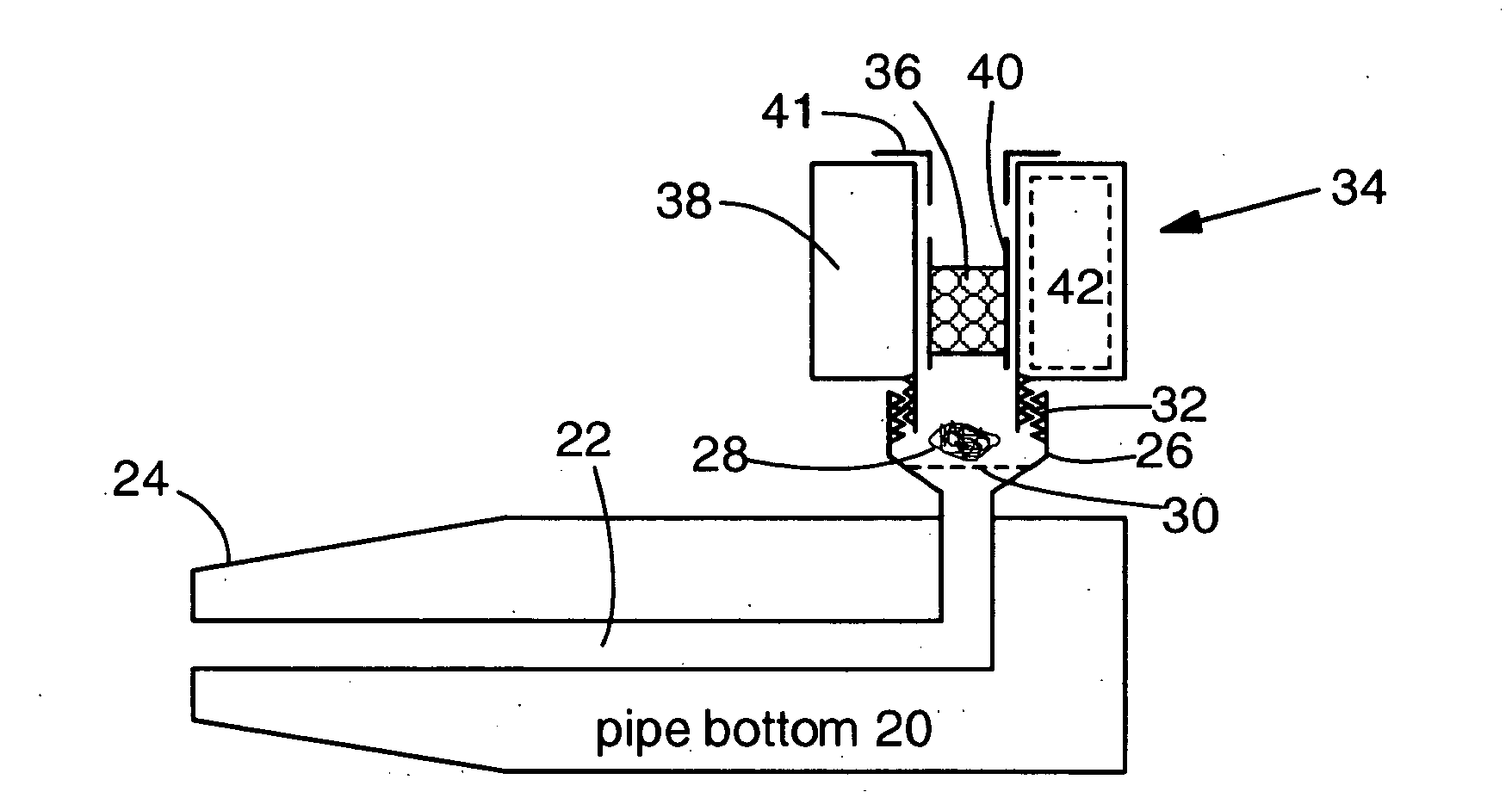

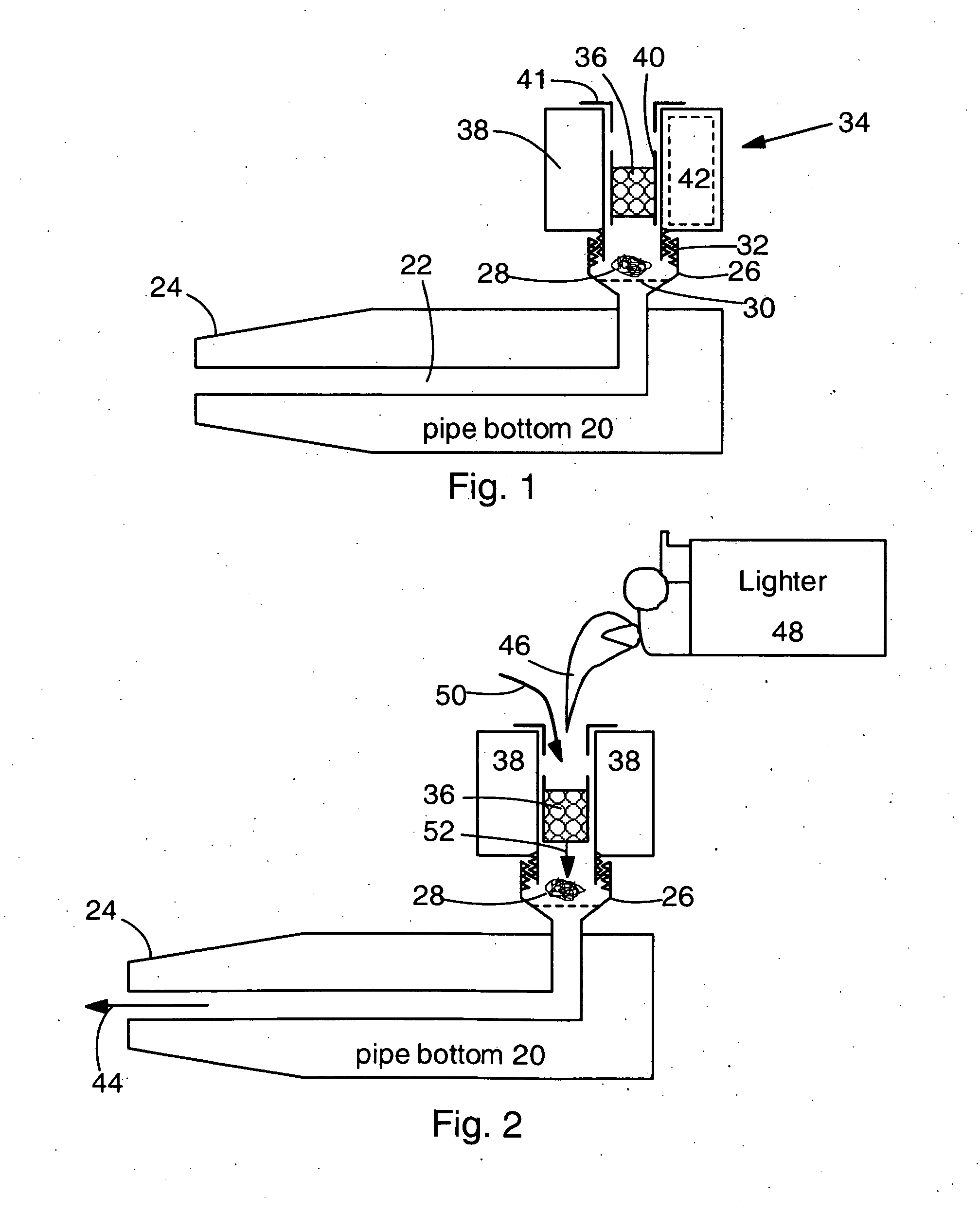

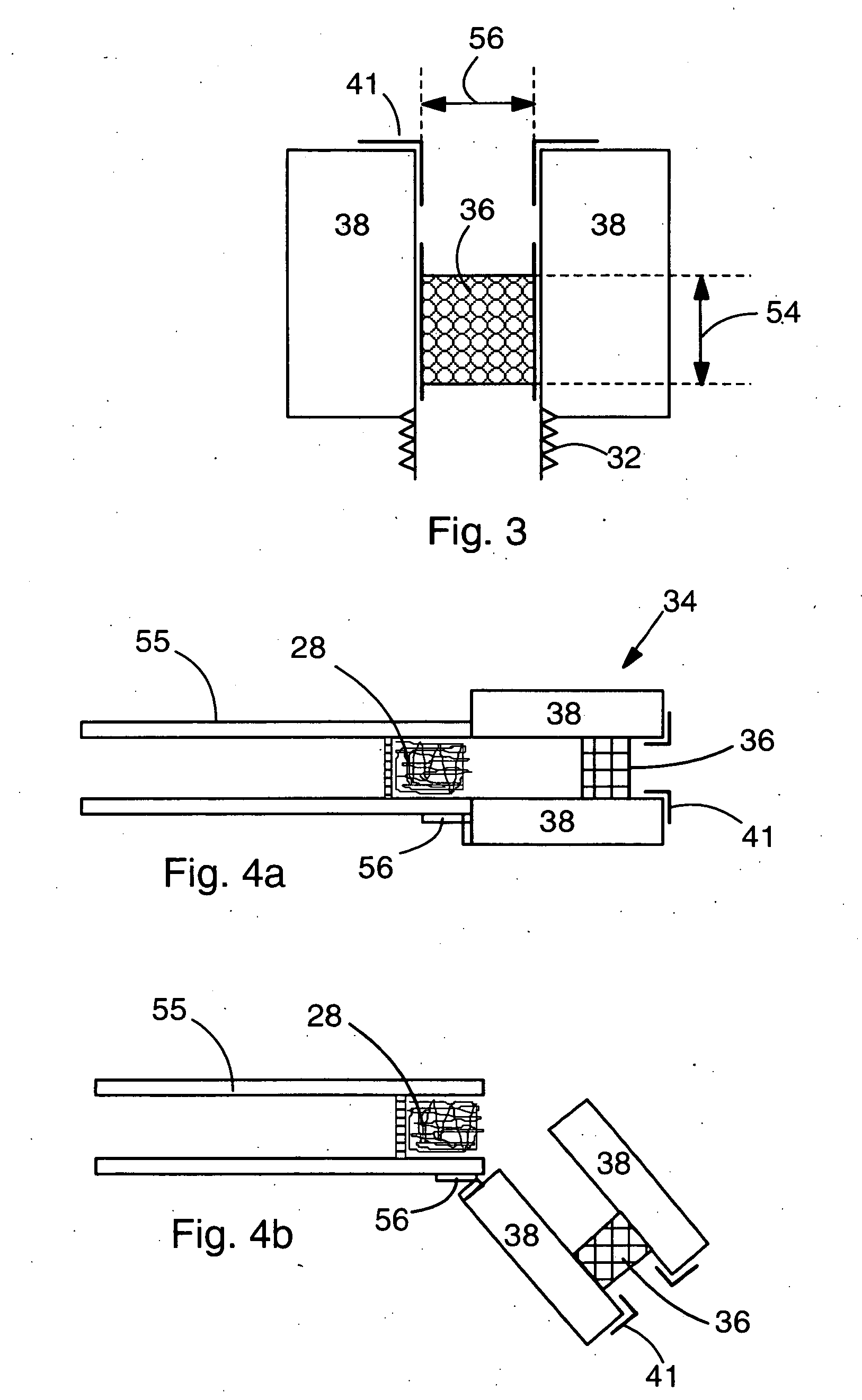

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material, but generally is not hot enough to burn the smoking material. The temperature of the air stream can be controlled by adjusting the amount of flame supplied to the flame filter 36.

Owner:VAPORGENIE

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

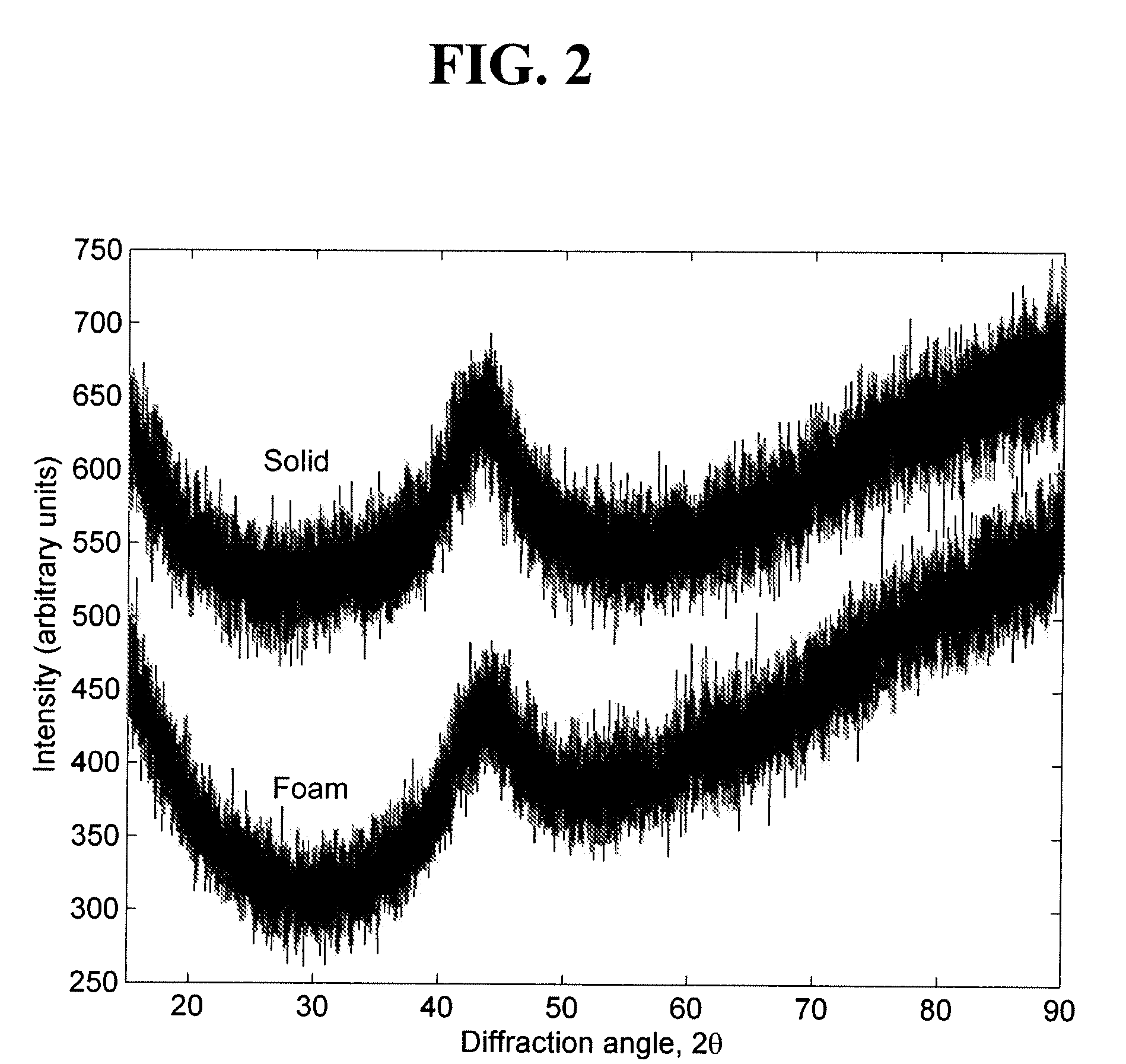

Amorphous fe and co based metallic foams and methods of producing the same

Amorphous Fe- and Co-based metal foams and methods of preparing the same are provided. The Fe- and Co-based foams are prepared from Fe- and Co-based metal alloys of low hydrogen solubility having an atomic fraction of Fe or Co greater than or equal to the atomic fraction of each other alloying element. A method for producing the Fe- and Co-based foams includes the in situ decomposition of a hydride in a molten Fe- or Co-based alloy.

Owner:CALIFORNIA INST OF TECH

Porous surface layers with increased surface roughness and implants incorporating the same

InactiveUS20110245930A1Improve surface roughnessIncrease roughnessBone implantPharmaceutical containersSurface layerMetallurgy

Owner:SMITH & NEPHEW INC

Metallic foam

Owner:ZEPHYROS INC

Method for preparation of metallic foam products and products made

InactiveUS6524522B2Cost-effectiveMinimal post-processing stepsAdditive manufacturing apparatusTransportation and packagingEnergy absorptionMetal foam

The present invention relates to the extrusion freeform fabrication of low cost, in situ, metallic foam components having oriented microstructures and improved mechanical properties such as energy absorption and specific stiffness. The present invention relates to the freeform fabrication of metallic foams to form parts having complex geometry that demonstrate superior mechanical properties and energy absorbing capacity.

Owner:ADVANCED CERAMICS

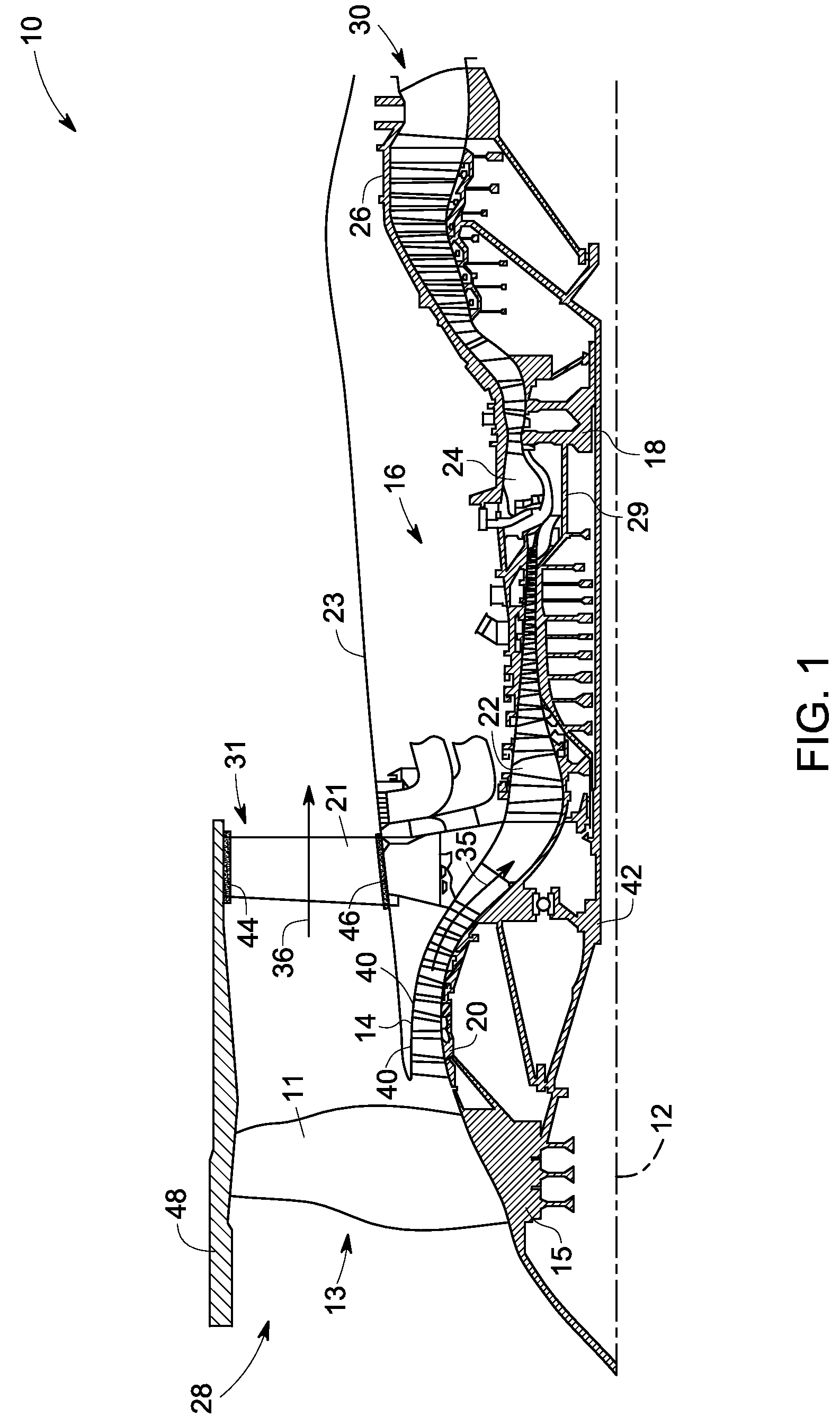

Combined acoustic absorber and heat exchanging outlet guide vanes

ActiveUS20090317238A1Improve heat transfer performanceImprove sound absorptionPump componentsEngine fuctionsSurface coolingAcoustic absorption

An outlet guide vane assembly for turbomachines is provided. The outlet guide vane assembly comprises one or more outlet guide vanes, wherein each of the one or more outlet guide vanes comprises a first surface and a second surface, and wherein the one or more outlet guide vanes are disposed between an inner wall and an outer wall of an engine and a surface cooler layer disposed on at least a portion of the first surface, the second surface, or both of the one or more outlet guide vanes, wherein the surface cooler layer comprises a metal foam, a carbon foam, or a combination thereof, wherein the metal foam, the carbon foam or the combination thereof is configured to augment heat transfer and enhance acoustic absorption.

Owner:GENERAL ELECTRIC CO

Porous metallic scaffold for tissue ingrowth

Owner:HOWMEDICA OSTEONICS CORP

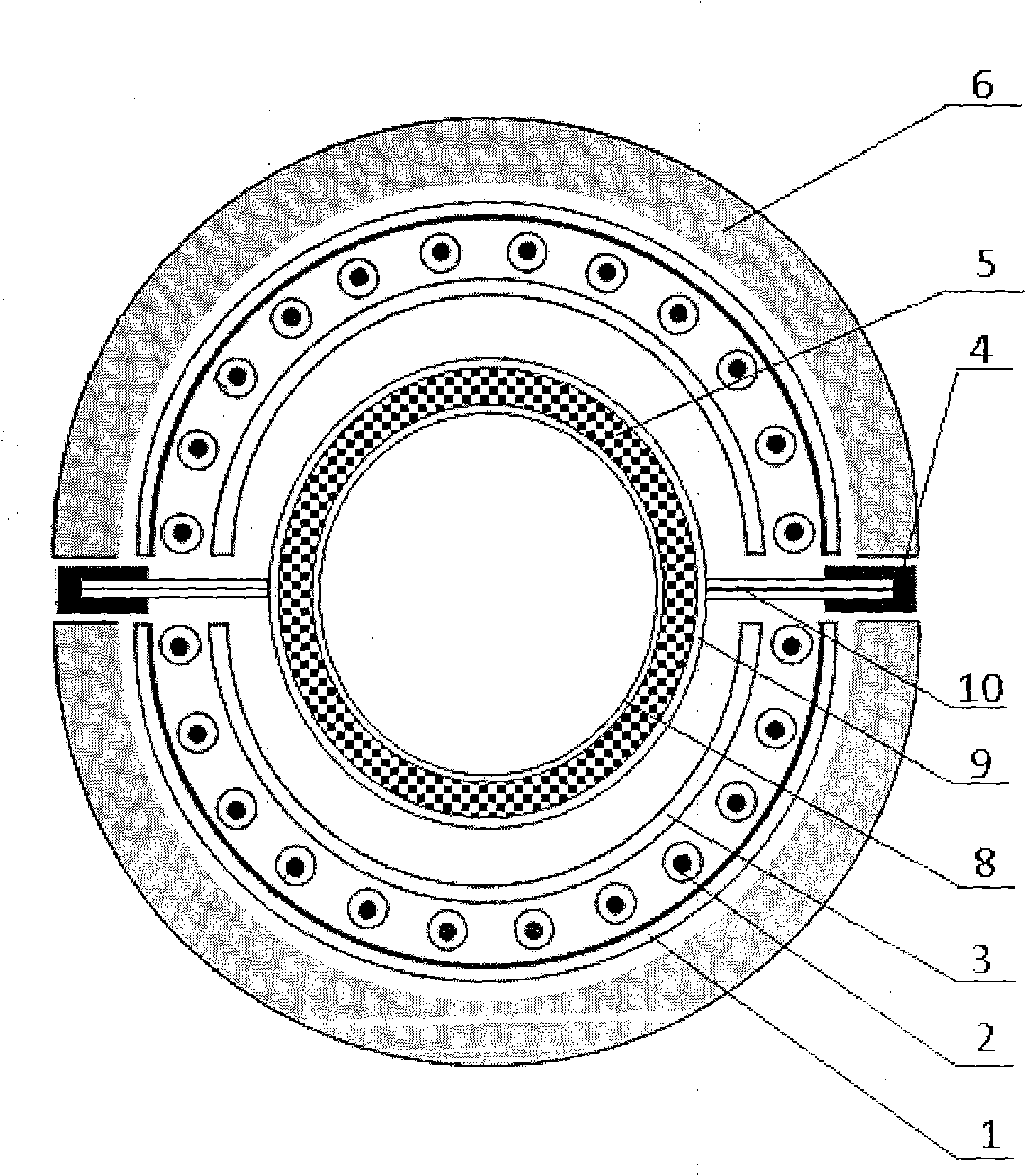

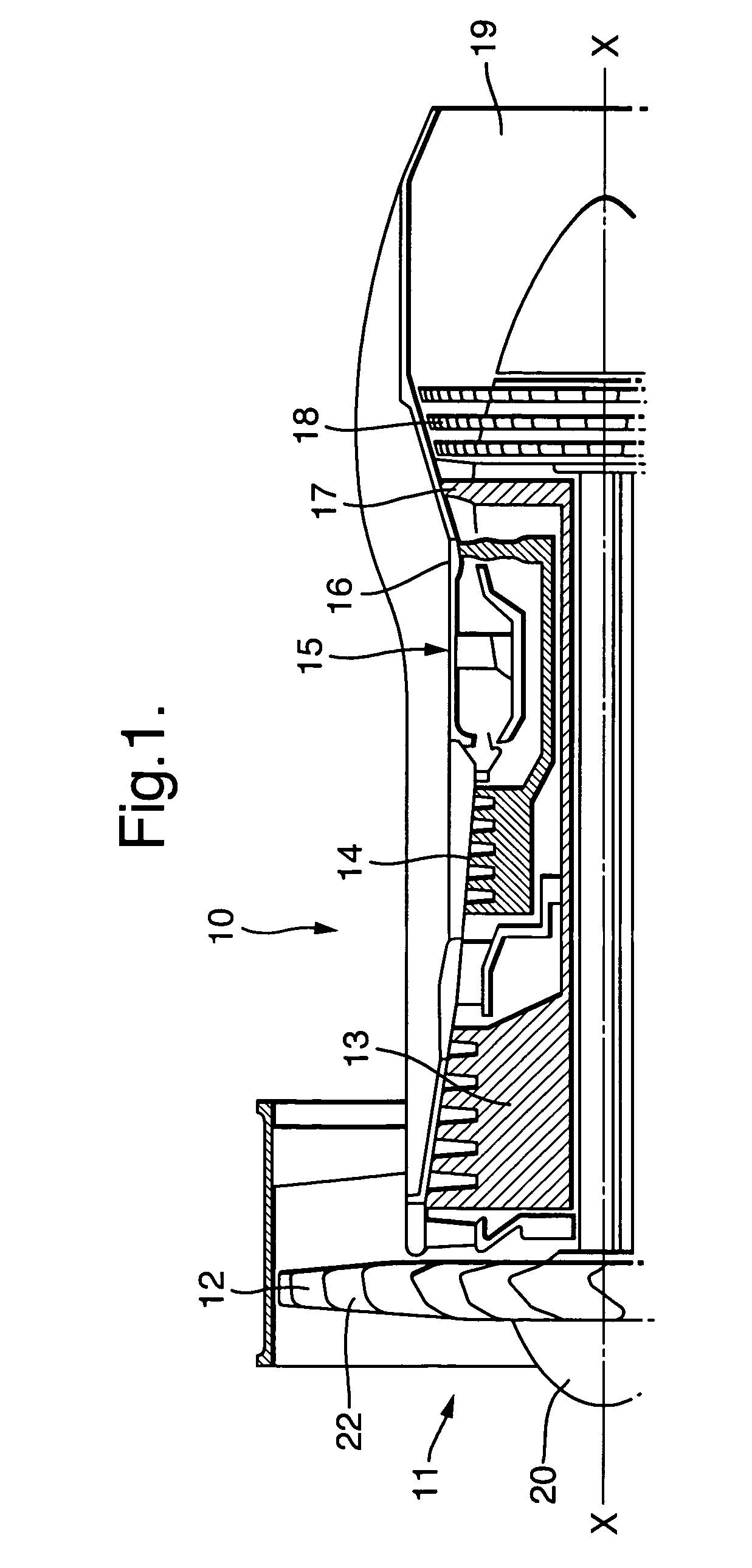

Plasma reactor with overhead RF electrode tuned to the plasma with arcing suppression

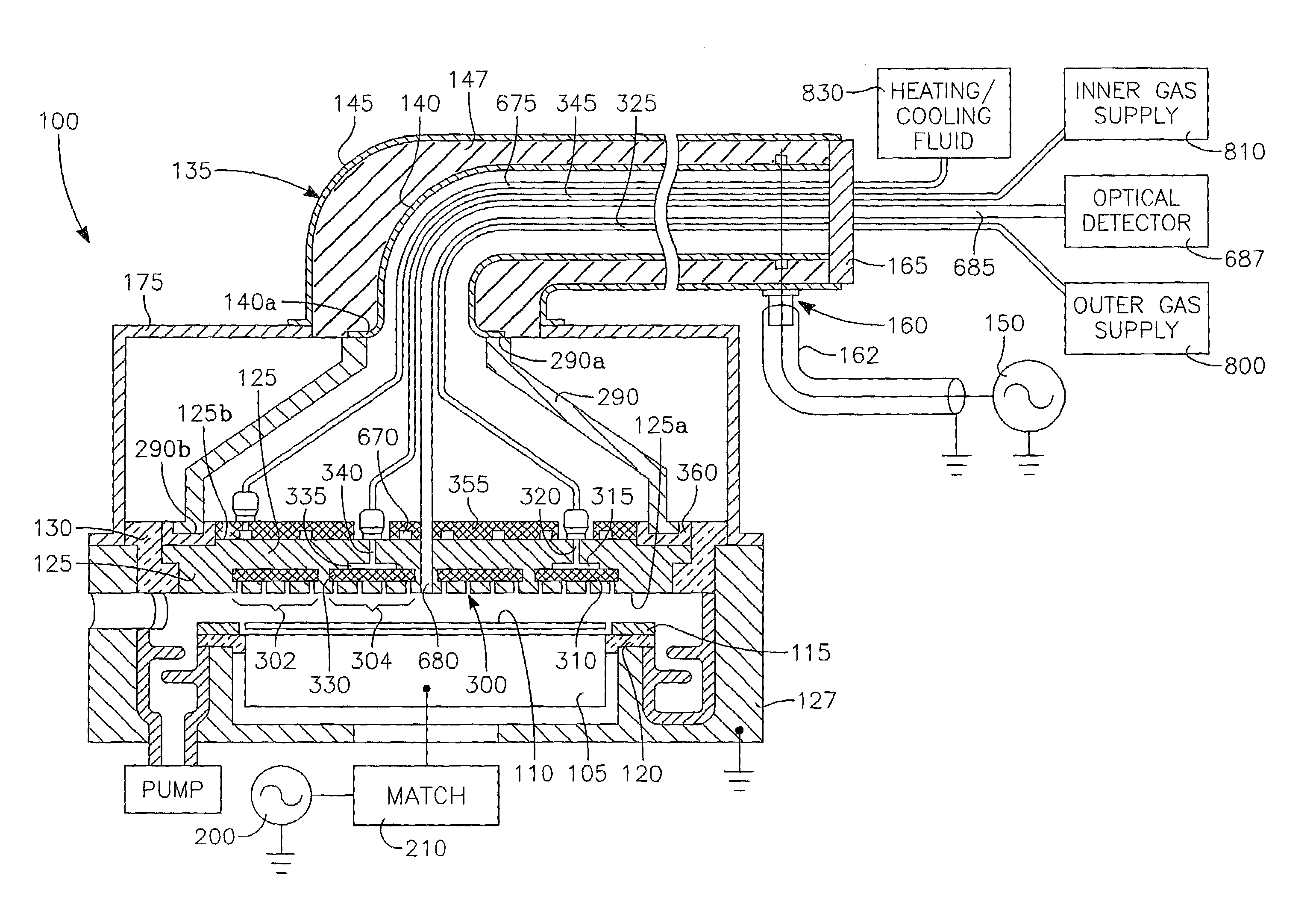

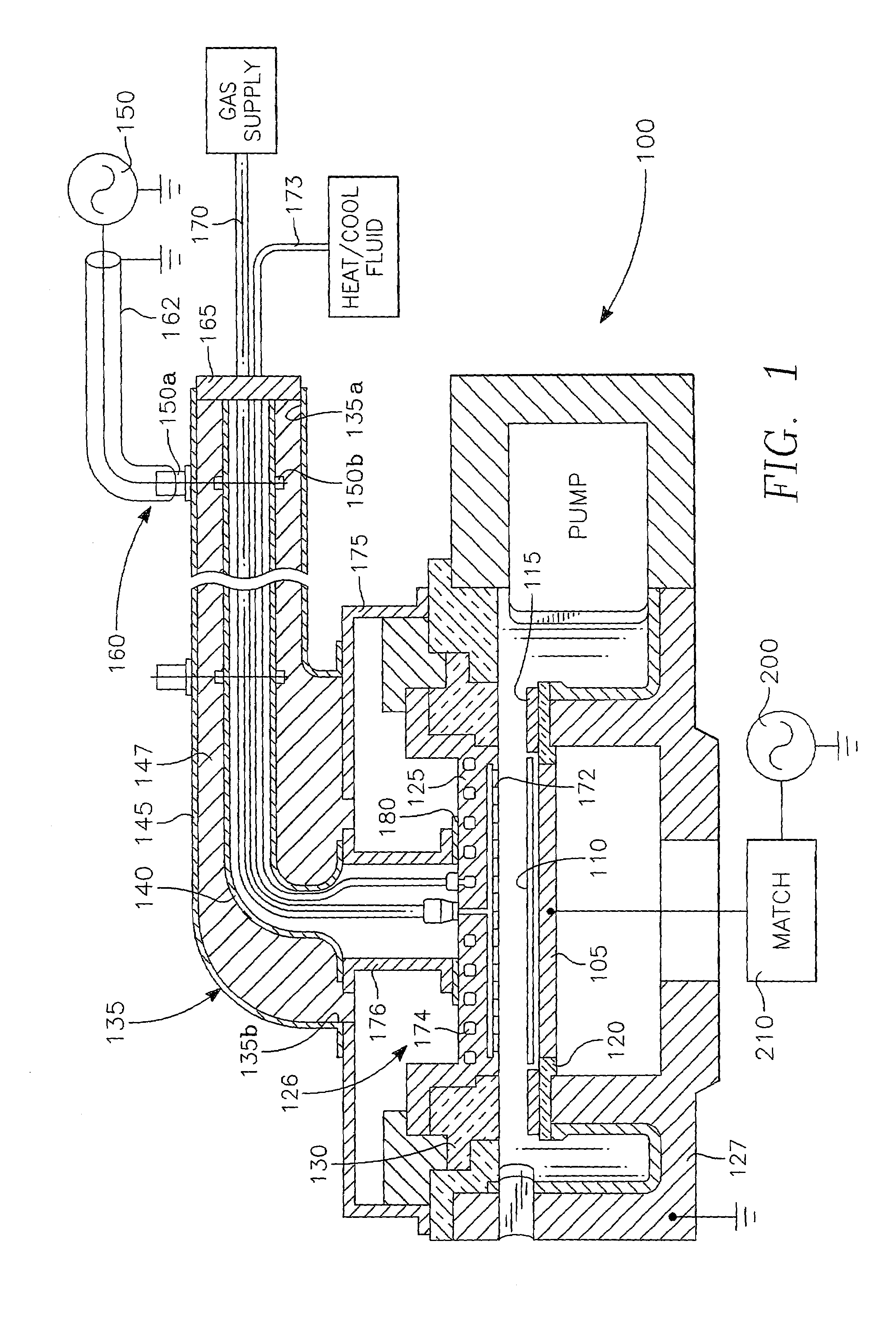

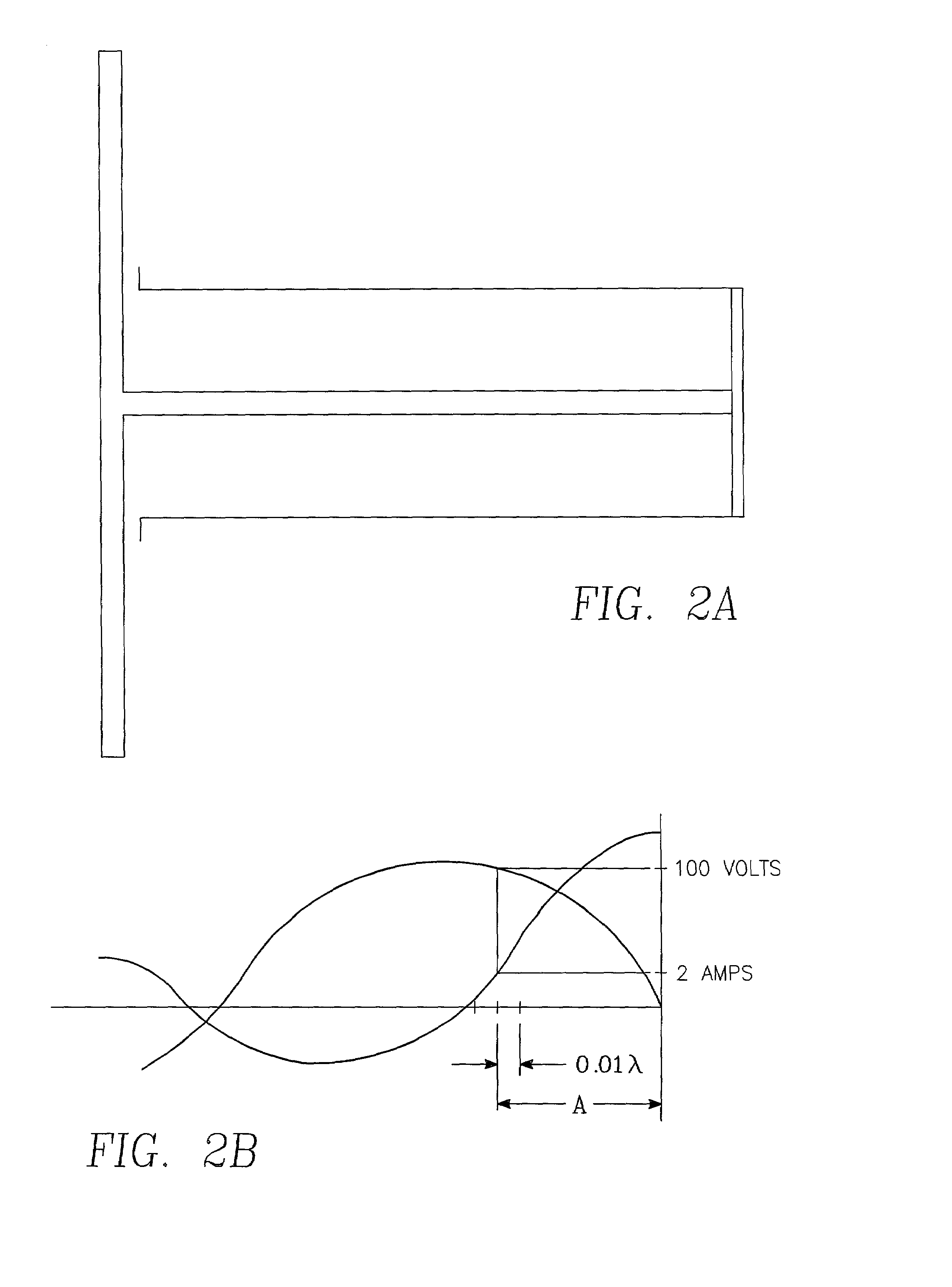

InactiveUS7030335B2Sufficient capacitanceAvoid insufficient thicknessCellsElectric discharge tubesCapacitanceIon density

A plasma reactor for processing a semiconductor workpiece, includes a reactor chamber having a chamber wall and containing a workpiece support for holding the semiconductor workpiece, an overhead electrode overlying said workpiece support, the electrode comprising a portion of said chamber wall, an RF power generator for supplying power at a frequency of said generator to said overhead electrode and capable of maintaining a plasma within said chamber at a desired plasma ion density level. The overhead electrode has a capacitance such that said overhead electrode and the plasma formed in said chamber at said desired plasma ion density resonate together at an electrode-plasma resonant frequency, said frequency of said generator being at least near said electrode-plasma resonant frequency. The reactor further includes an insulating layer formed on a surface of said overhead electrode facing said workpiece support, a capacitive insulating layer between said RF power generator and said overhead electrode, and a metal foam layer overlying and contacting a surface of said overhead electrode that faces away from said workpiece support.

Owner:APPLIED MATERIALS INC

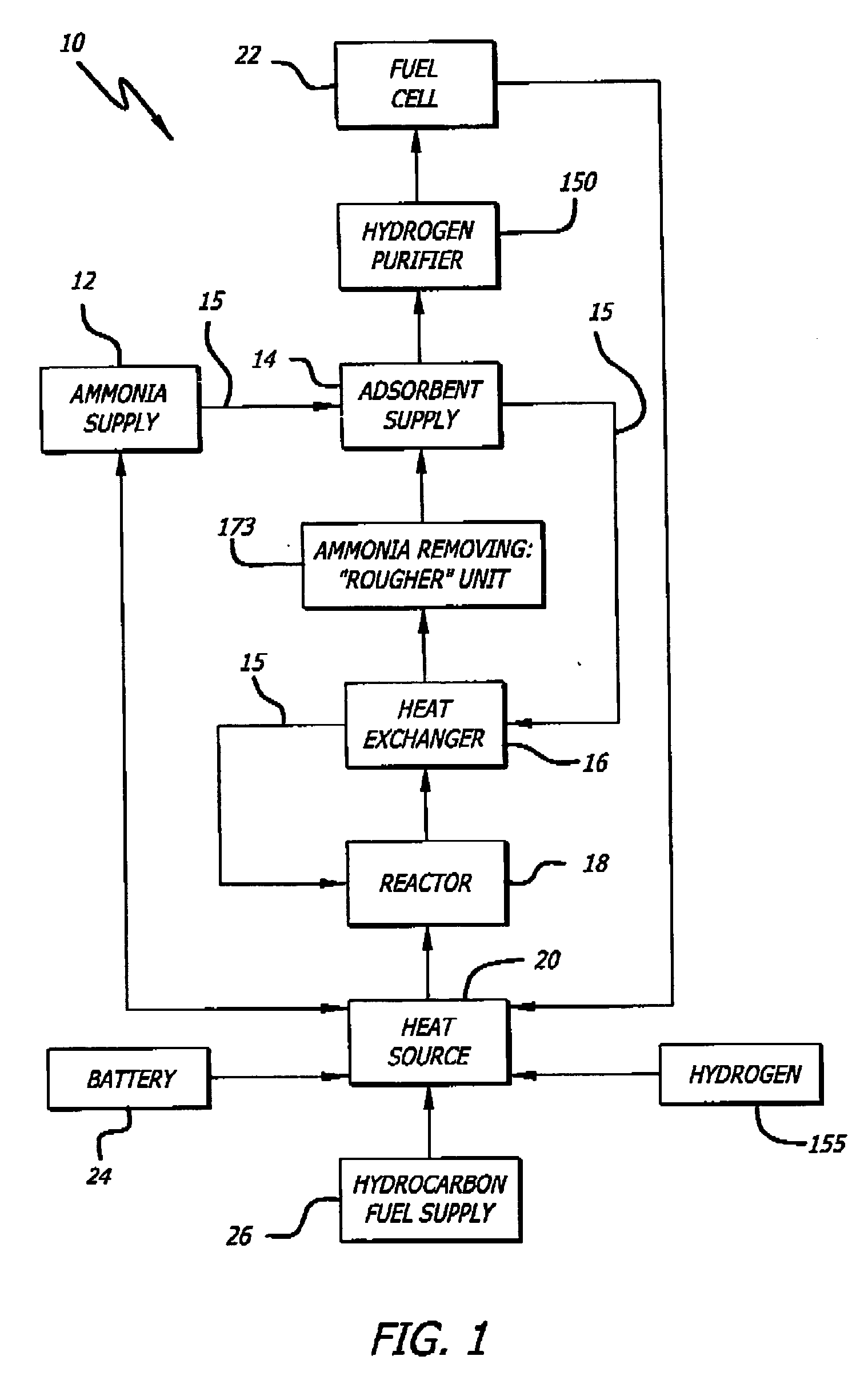

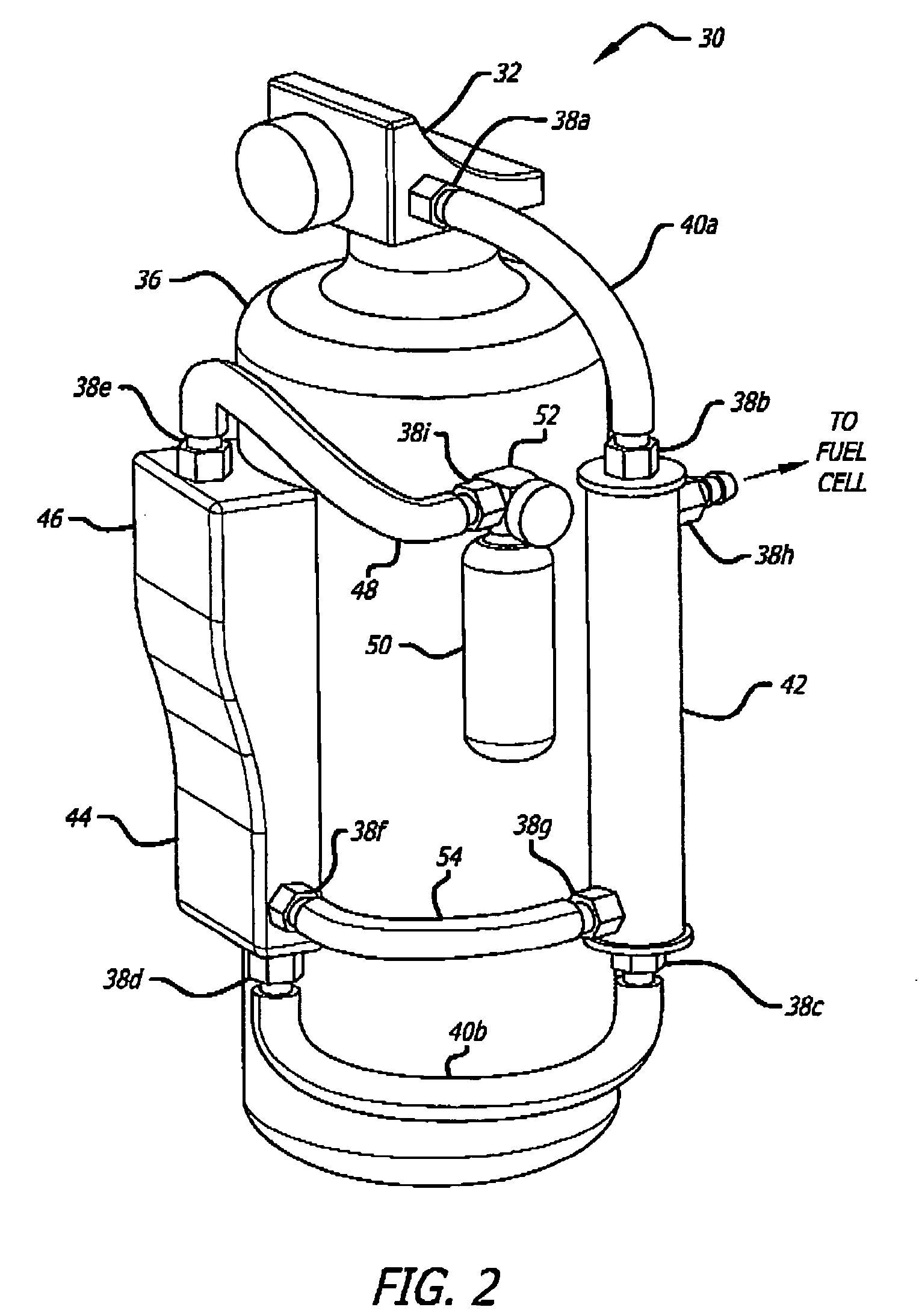

Ammonia-based hydrogen generation apparatus and method for using same

InactiveUS20060112636A1Reduce manufacturing costImprove heat transfer effectCyanogen compoundsNitrogen compoundsHydrogenCombustion chamber

The present disclosure provides teachings relating to ammonia-based hydrogen generation apparatus and associated methods of use. Exemplary methods and apparatus comprise a thermocatalytic hydrogen generation reactor which includes a reaction chamber containing a catalyst-coated substrate, and a combustion chamber containing a catalyst-coated substrate. Exemplary catalyst-coated substrates include, but are not limited to, metal foam, monolith, mesh, ceramic foam or ceramic monolith.

Owner:INTELLIGENT ENERGY INC

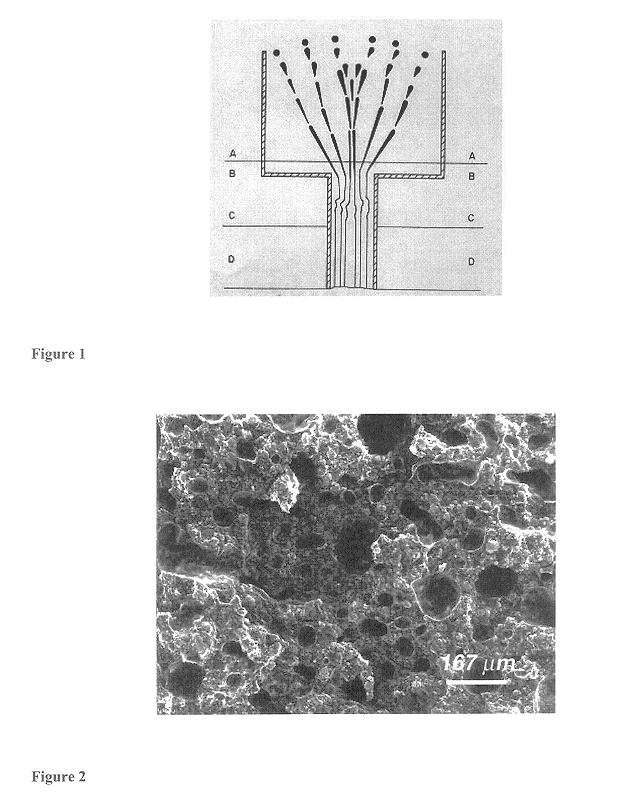

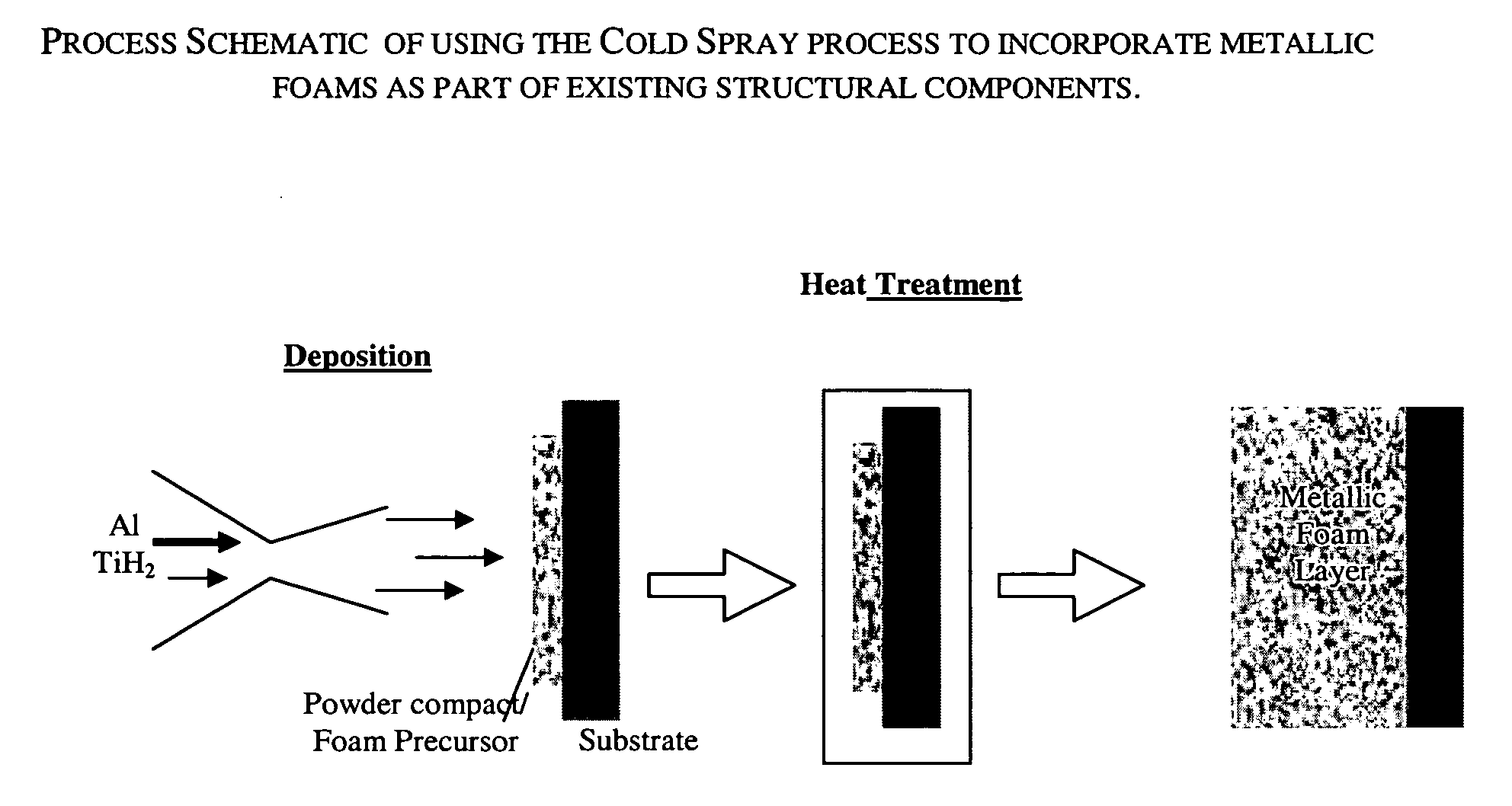

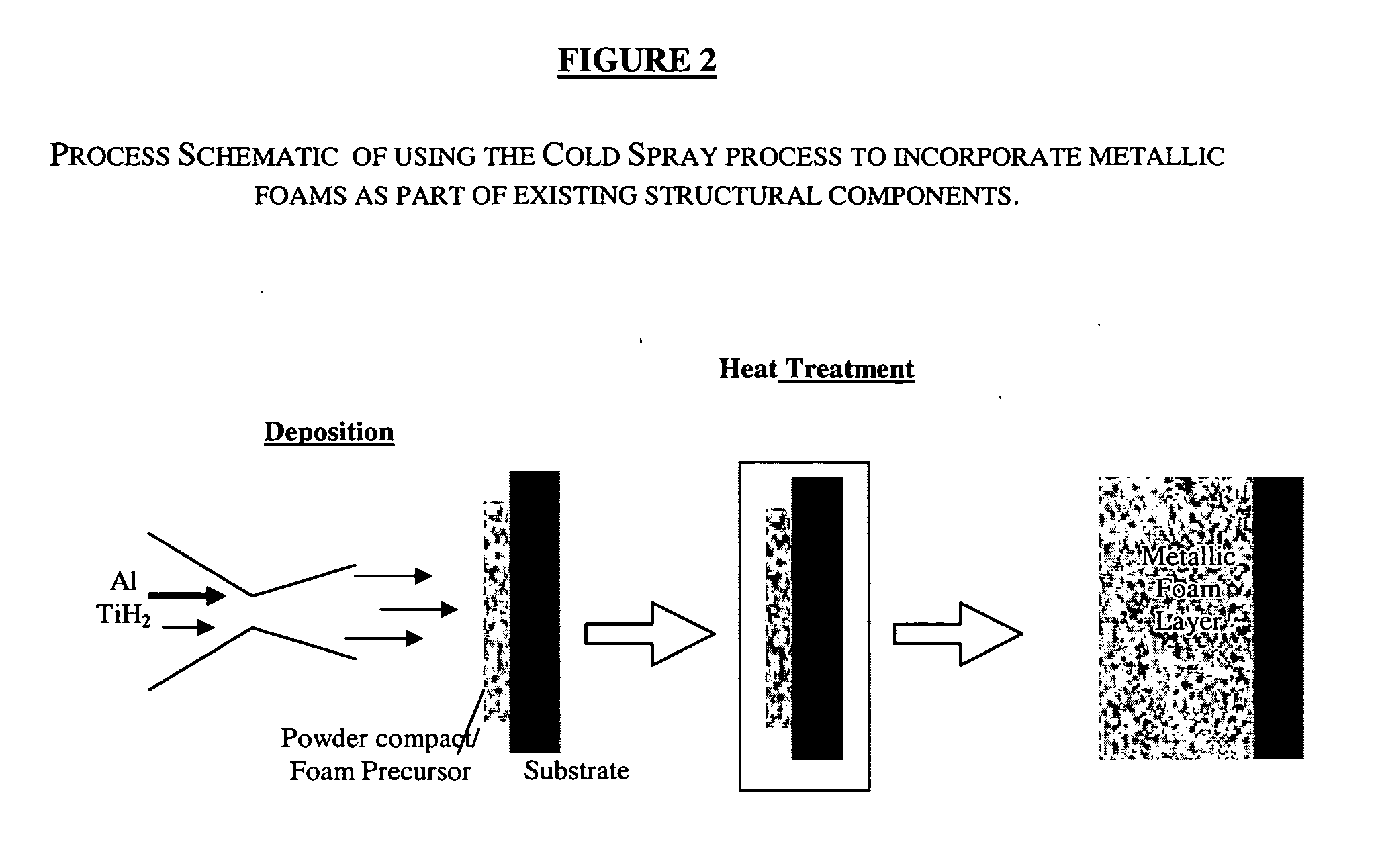

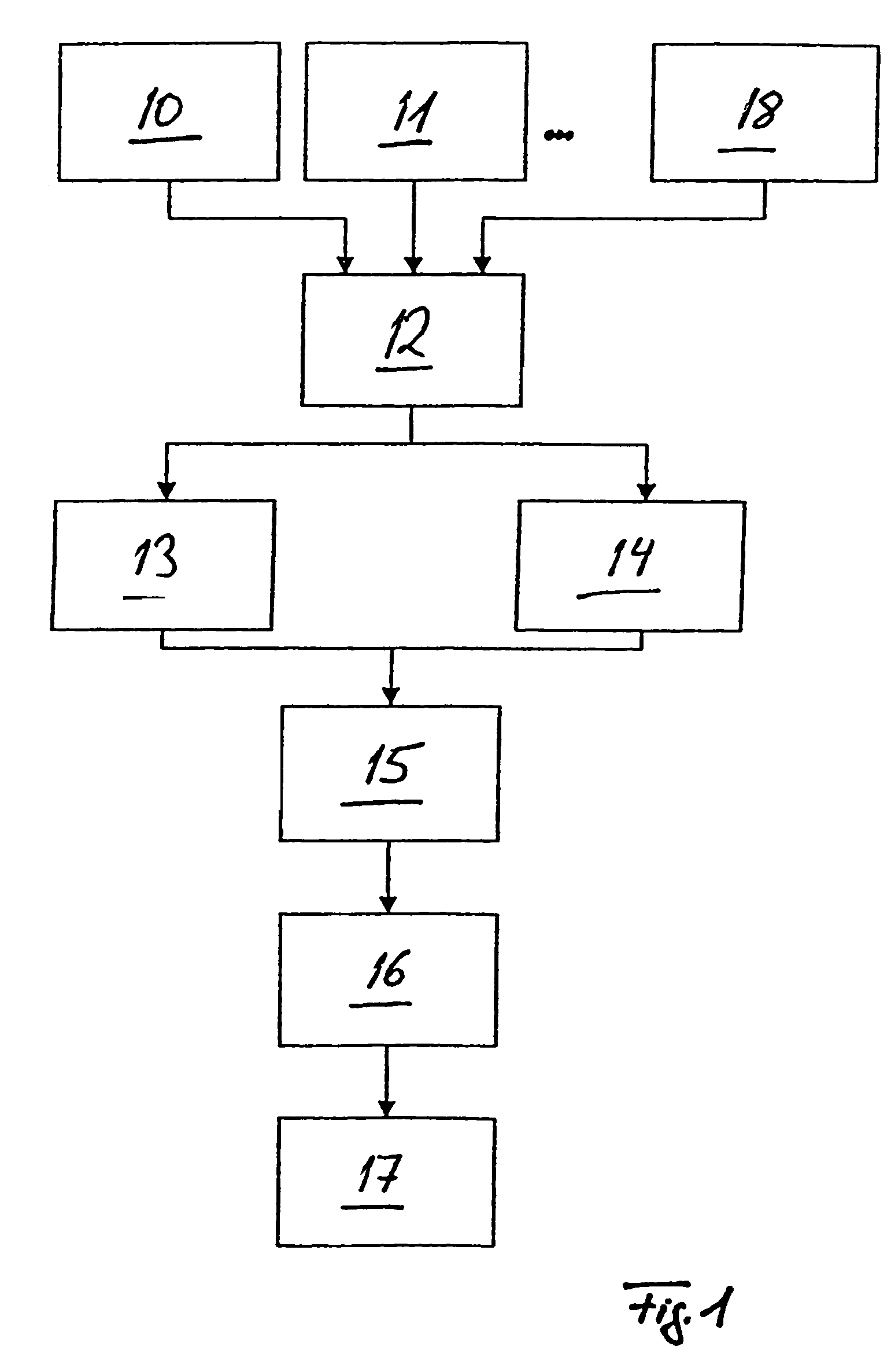

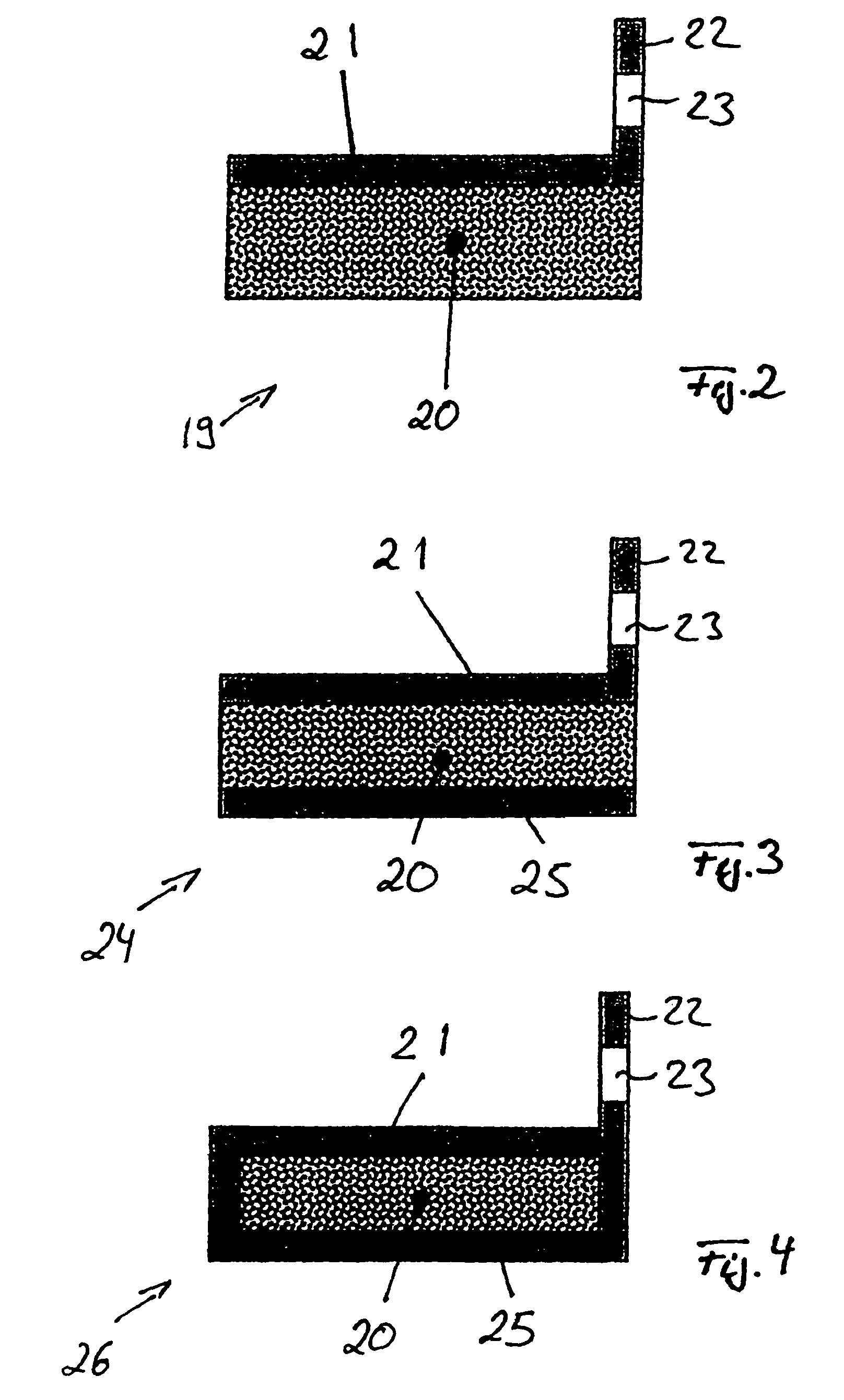

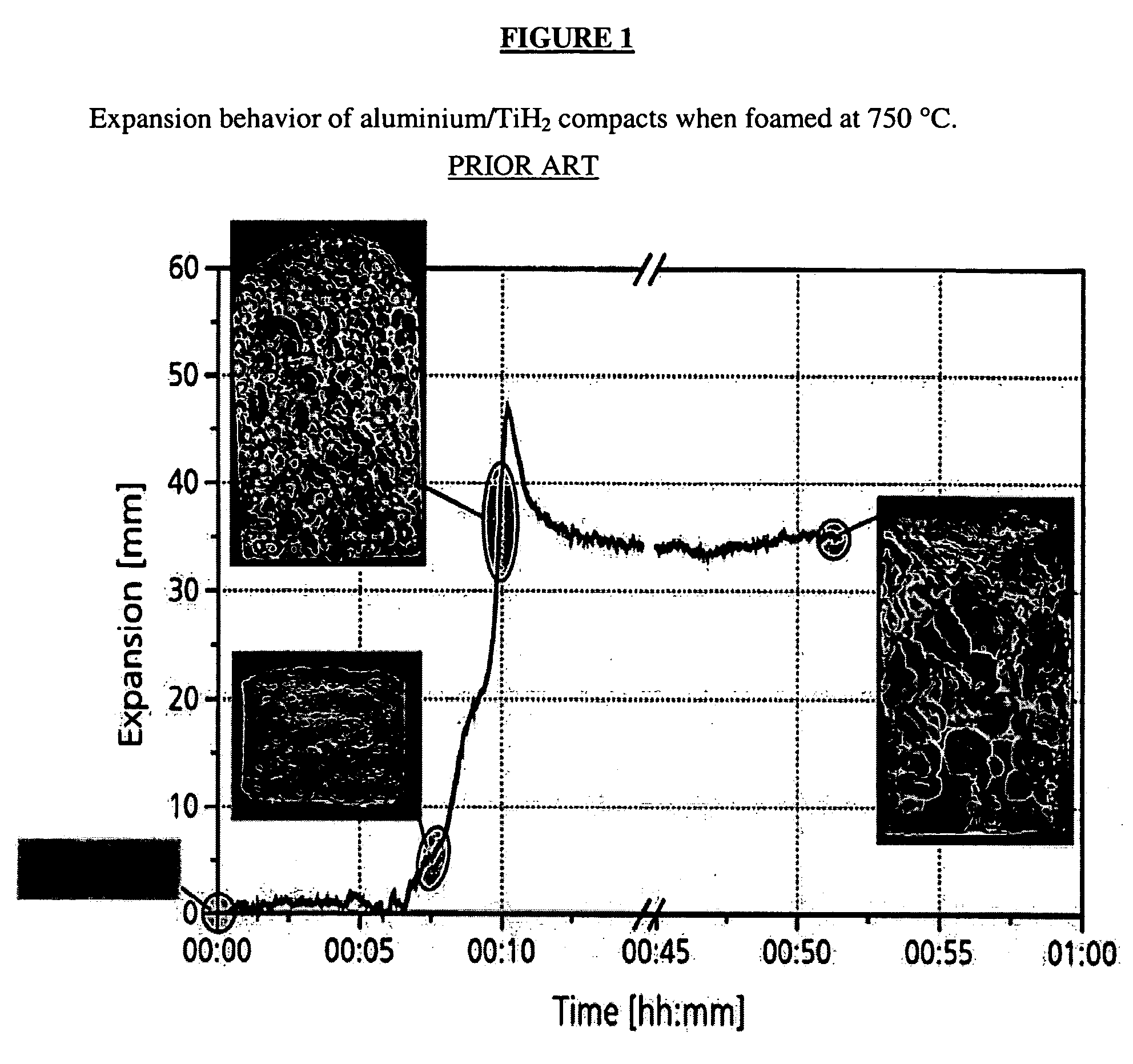

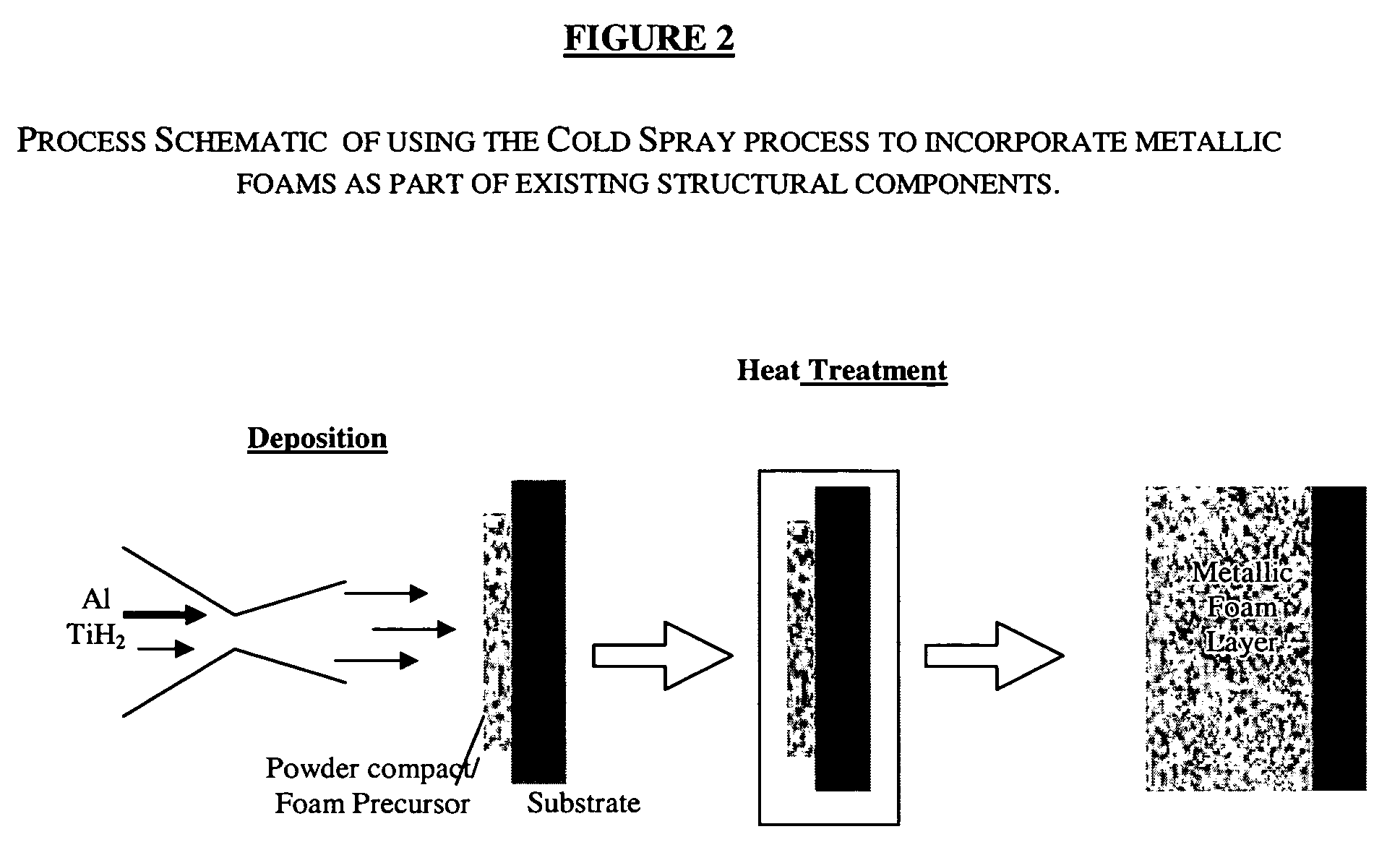

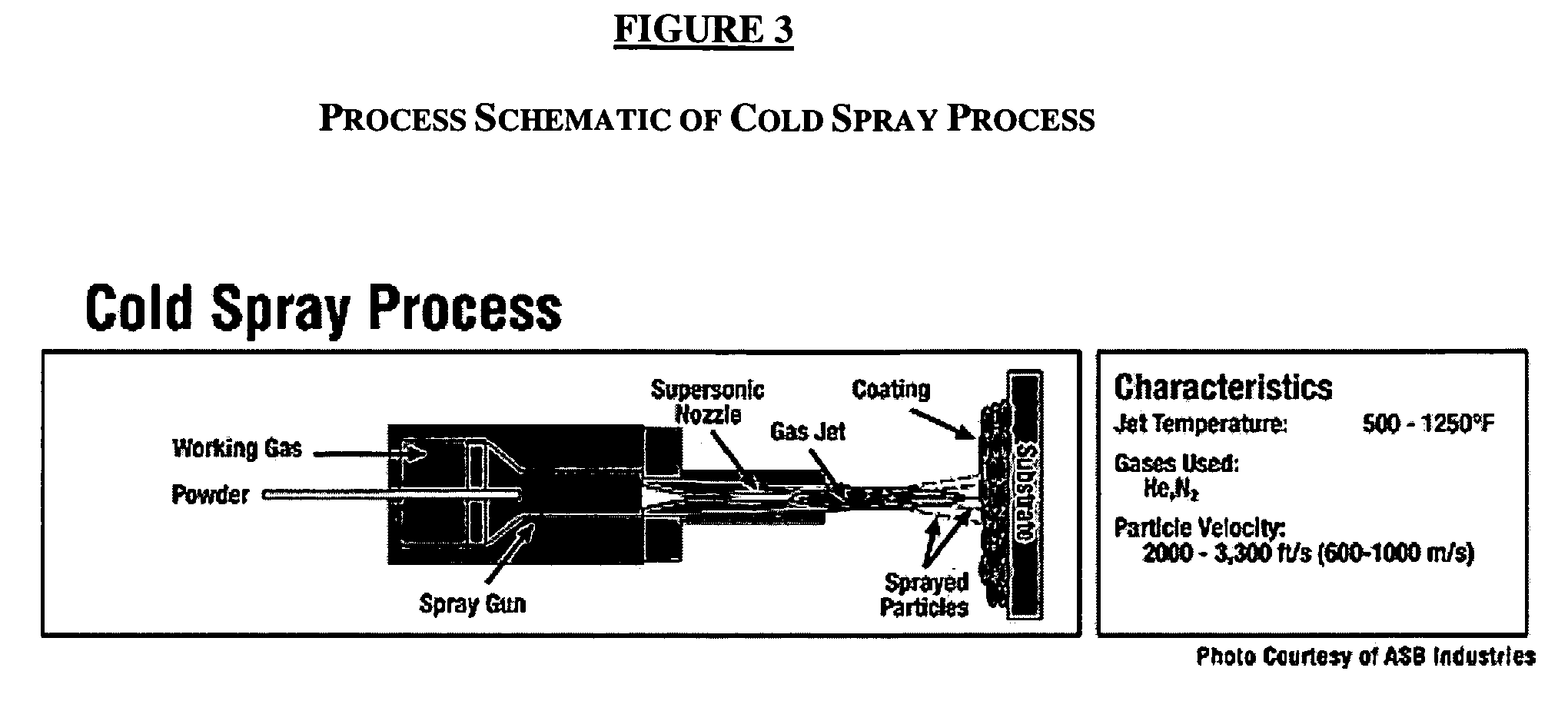

Method of forming metal foams by cold spray technique

The present invention relates to a method of forming metallic foams using cold spray processing. The method allows for the formation of metallic foams on existing substrates as a layer. The method includes the steps of providing a substrate for coating of a metallic foam; cold spraying a mixture of metal particles and a foaming agent onto the substrate to form a substrate coated with an unexpanded metallic layer; foam heat treating the substrate coated with an unexpanded metallic layer at a temperature above the decomposition temperature of the foaming agent for a time sufficient to form a heated substrate coated with an expanded metal foam layer; and cooling the heated substrate coated with an expanded metal foam layer to about ambient temperature to form a cooled substrate coated with an expanded metal foam layer. The method of forming metallic foams on substrates finds application in the oil, gas, and chemical industry by being an integral part of casings, pipelines, transfer lines, and other flow lines.

Owner:EXXON RES & ENG CO

Vaporization pipe with flame filter

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material. The filter unit and pipe can attach with a ground glass joint.

Owner:STEINBERG DAN A

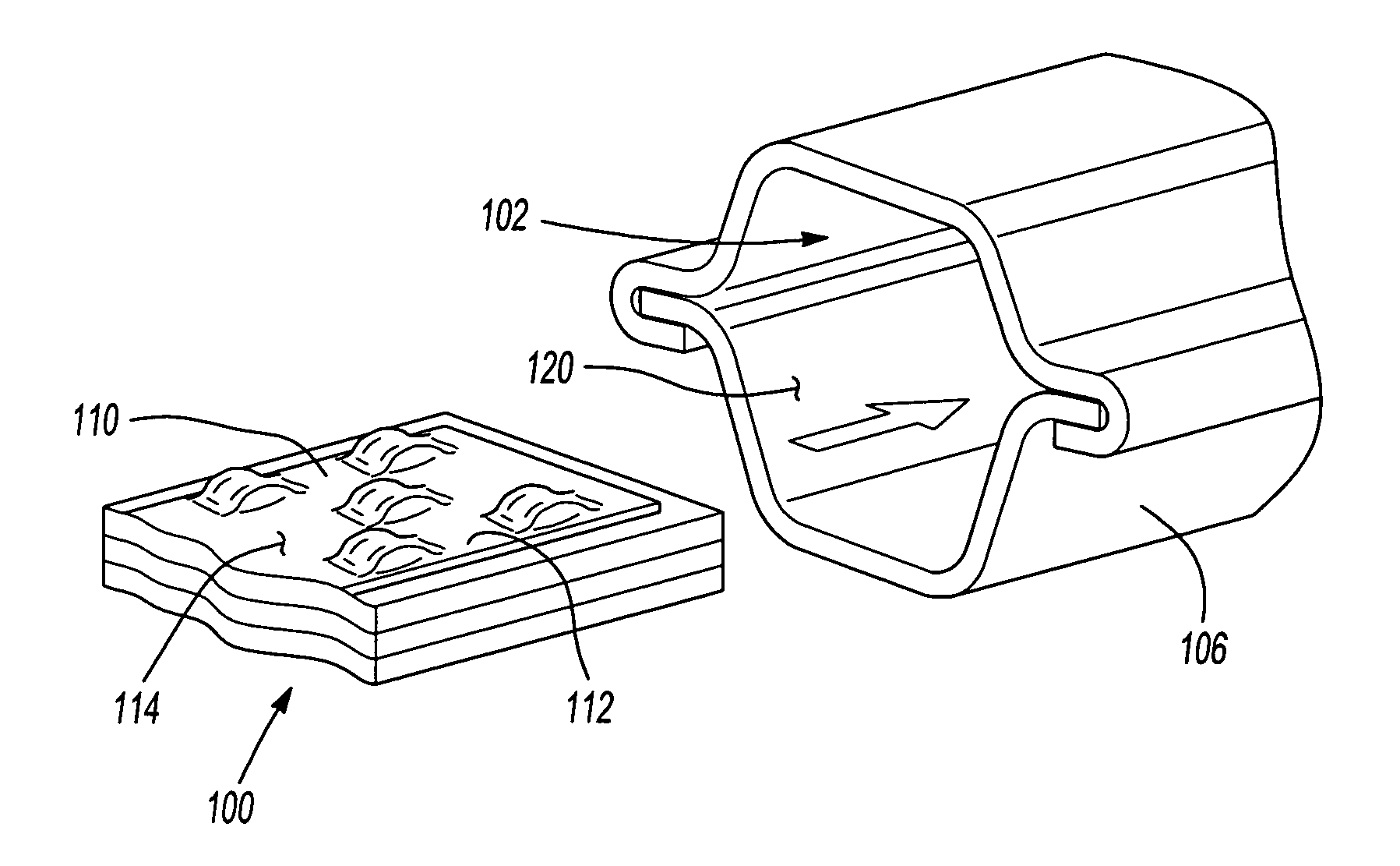

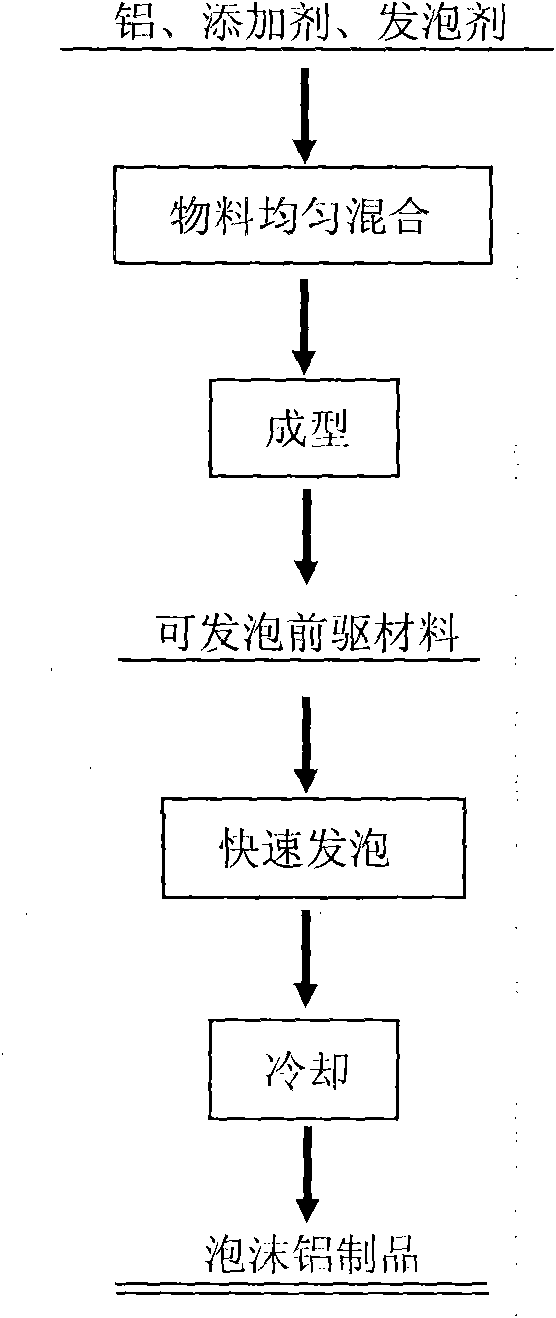

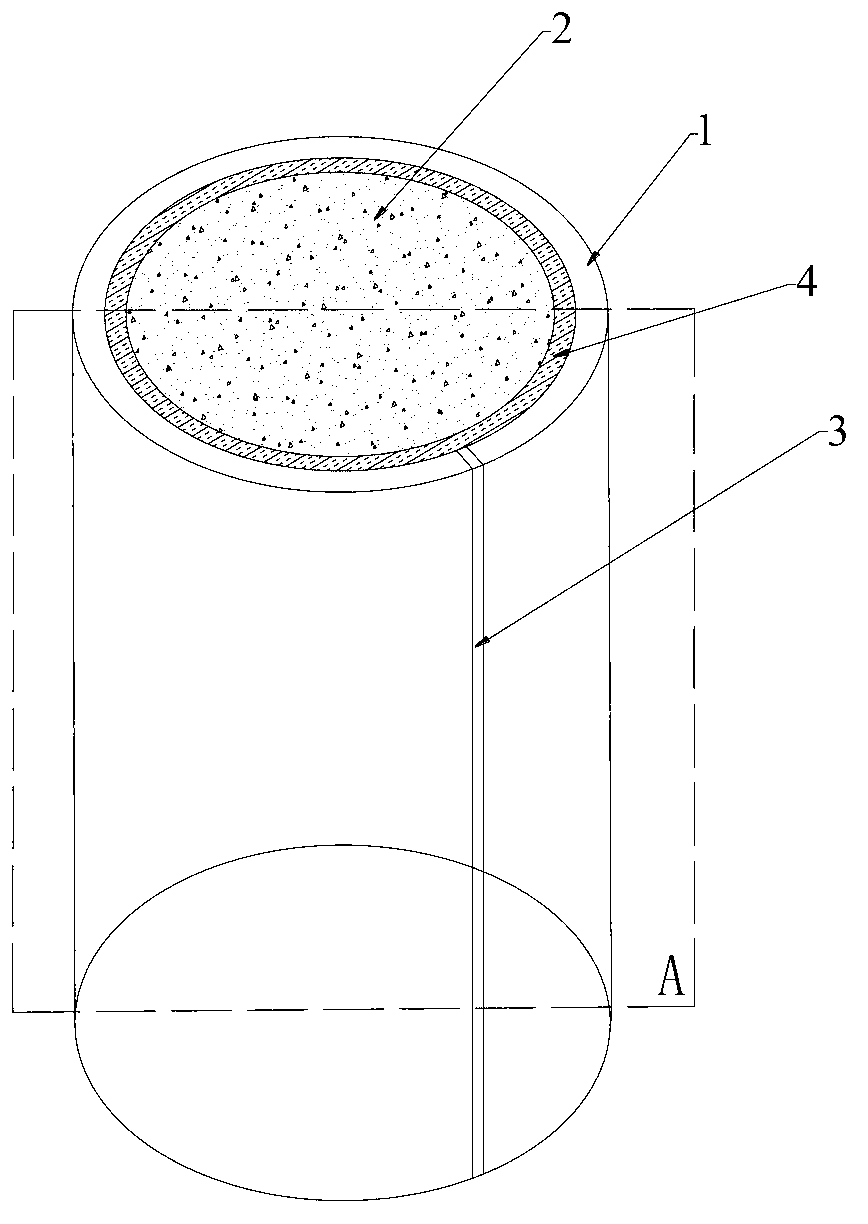

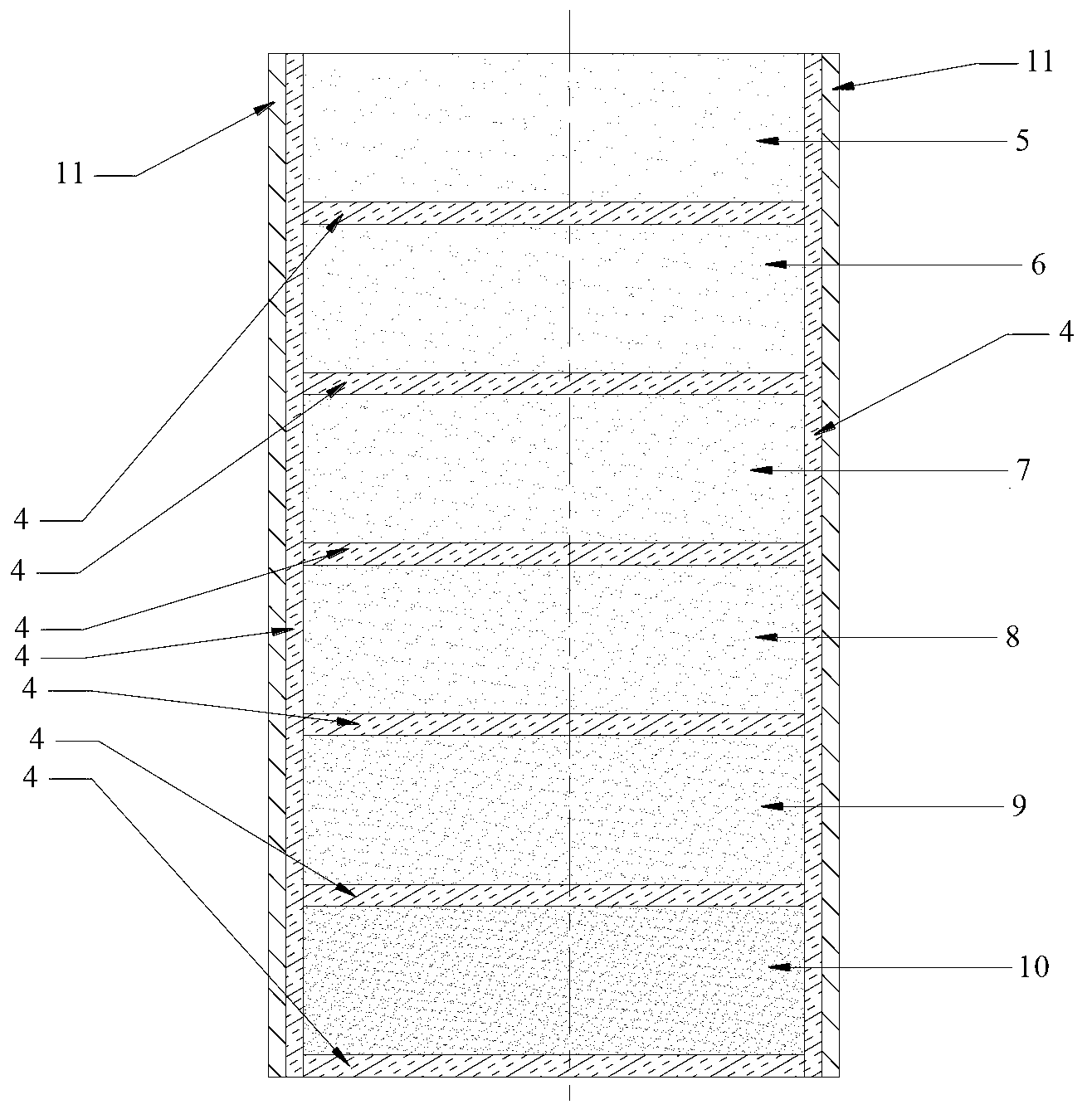

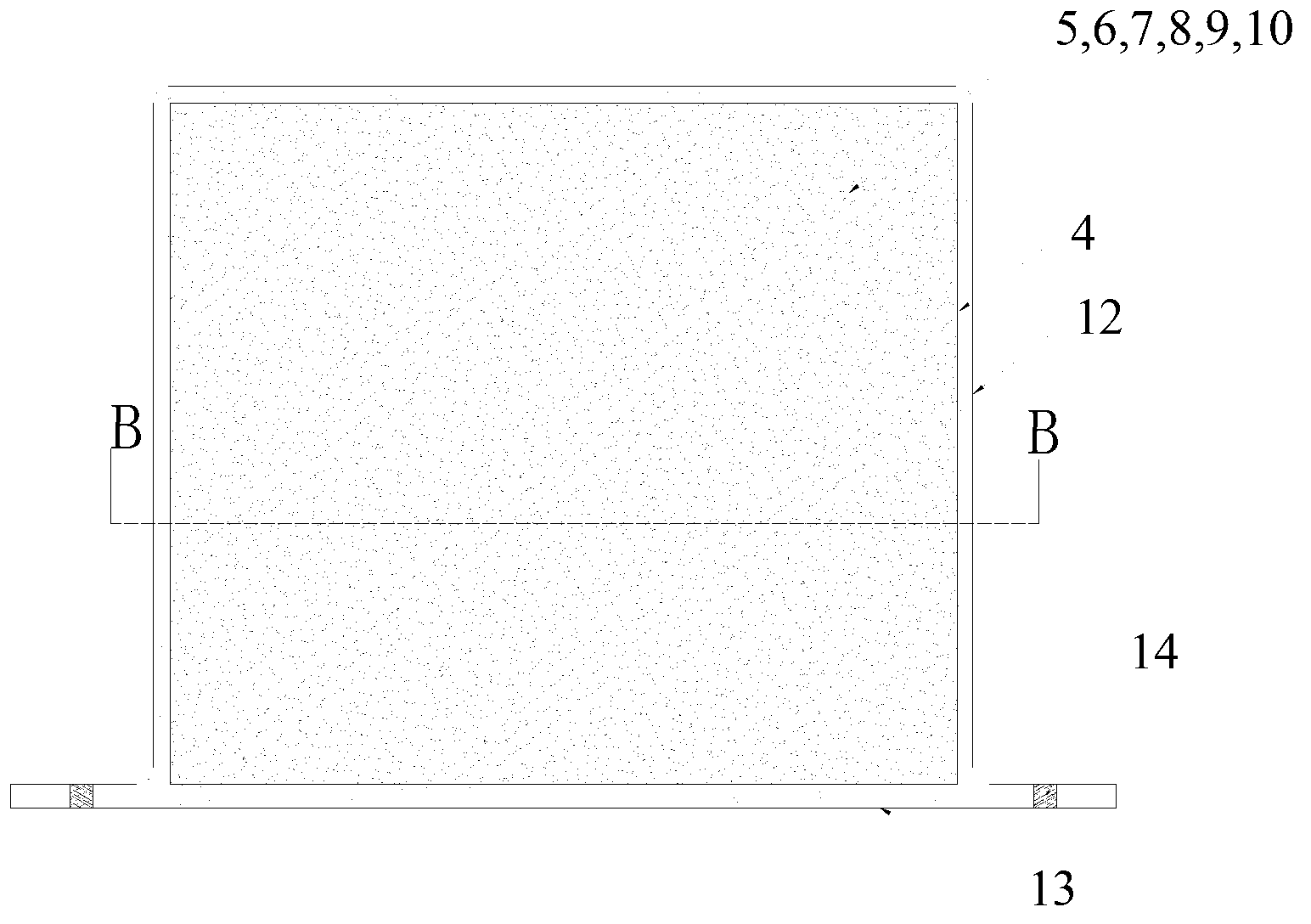

Preparation method and device of metal foam material

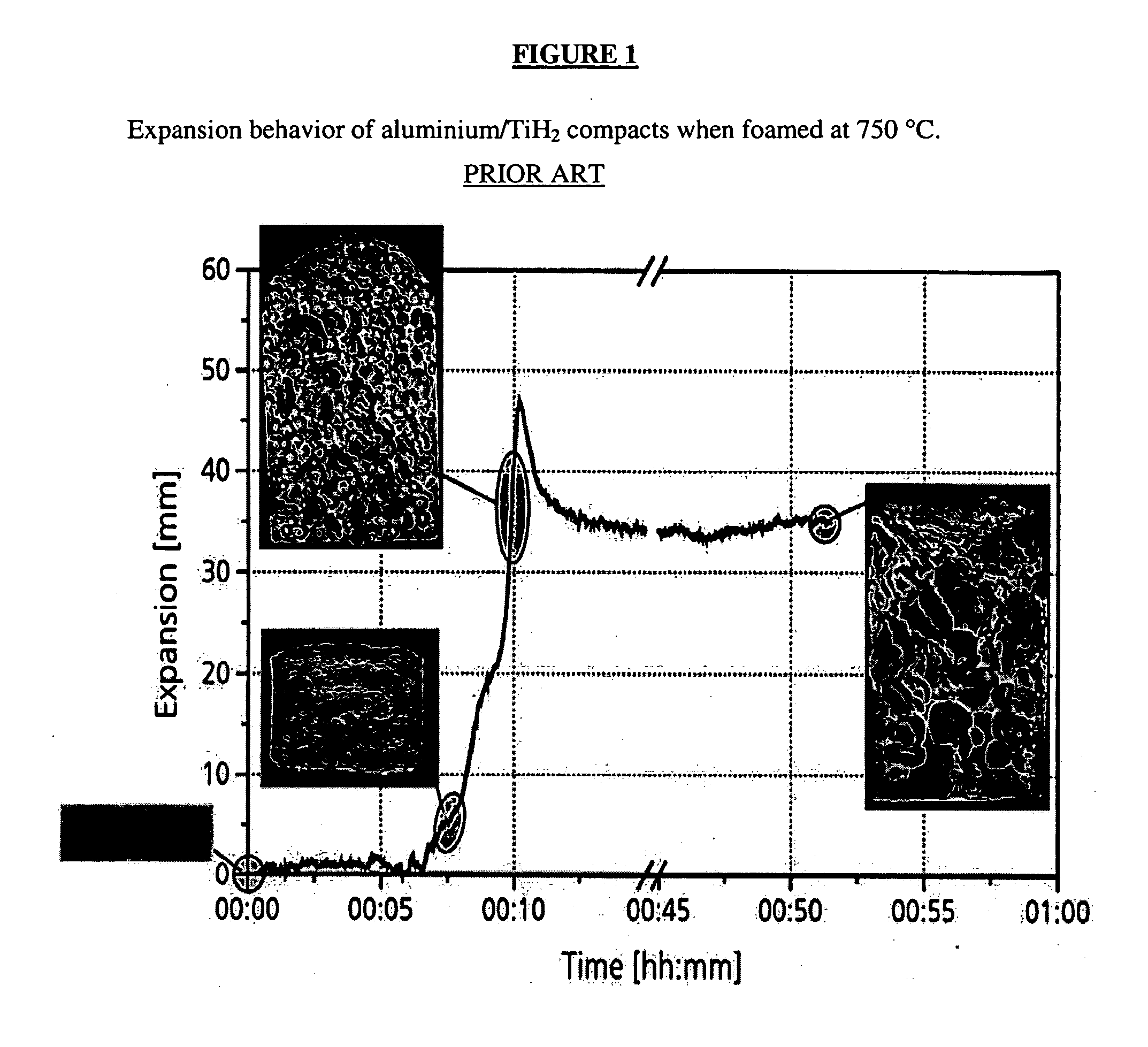

The invention discloses a preparation method and a device of a metal foam material. The preparation method comprises the following steps: mixing 93-99 wt% of aluminium matrix, 0.5-5 wt% of additive and 0.5-2 wt% of foaming agent uniformly to form a shaped foamable precursor material, putting the foamable precursor material in a foaming furnace with infrared heating to foam the foamable precursor material fast under infrared radiation, then taking the foam material out from the foaming furnace and cooling, wherein, the aluminium matrix is pure aluminium, aluminium powder or aluminium alloy, the foaming agent is titanium hydride, zirconium hydride, or calcium carbonate, and the additive is calcium, carborundum powder, or alumina powder. The device is a foaming furnace with infrared heating,has the advantages of fast foaming the precursor material, eliminating the hole gradient, easily controlling the foaming and cooling process, making the product have reproducibility and maneuverability, and improving cellular uniformity. According to the invention, metal foam sandwich panels can be prepared directly, and the mechanical properties of the aluminium-based foam material are improved.

Owner:NORTHEASTERN UNIV

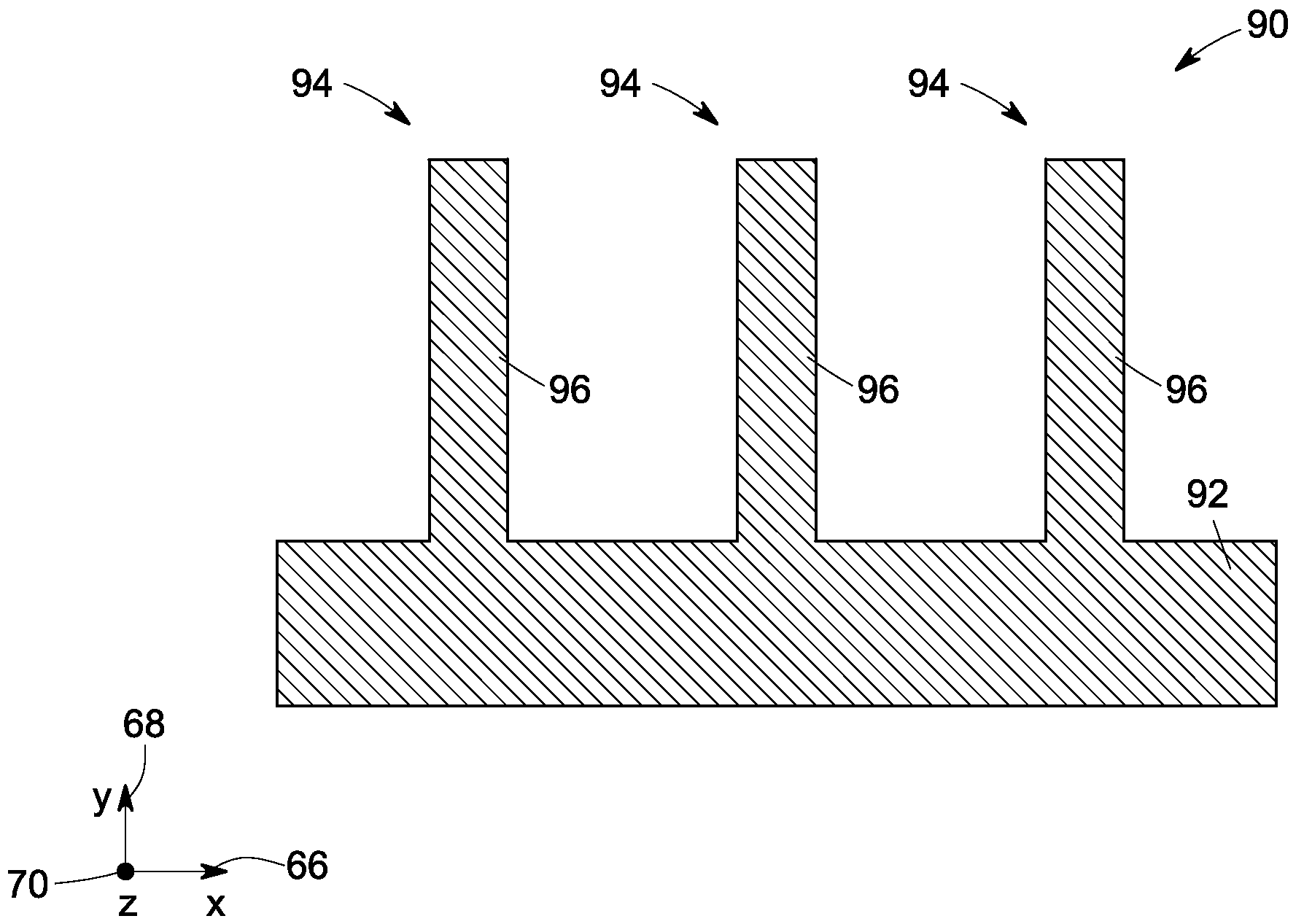

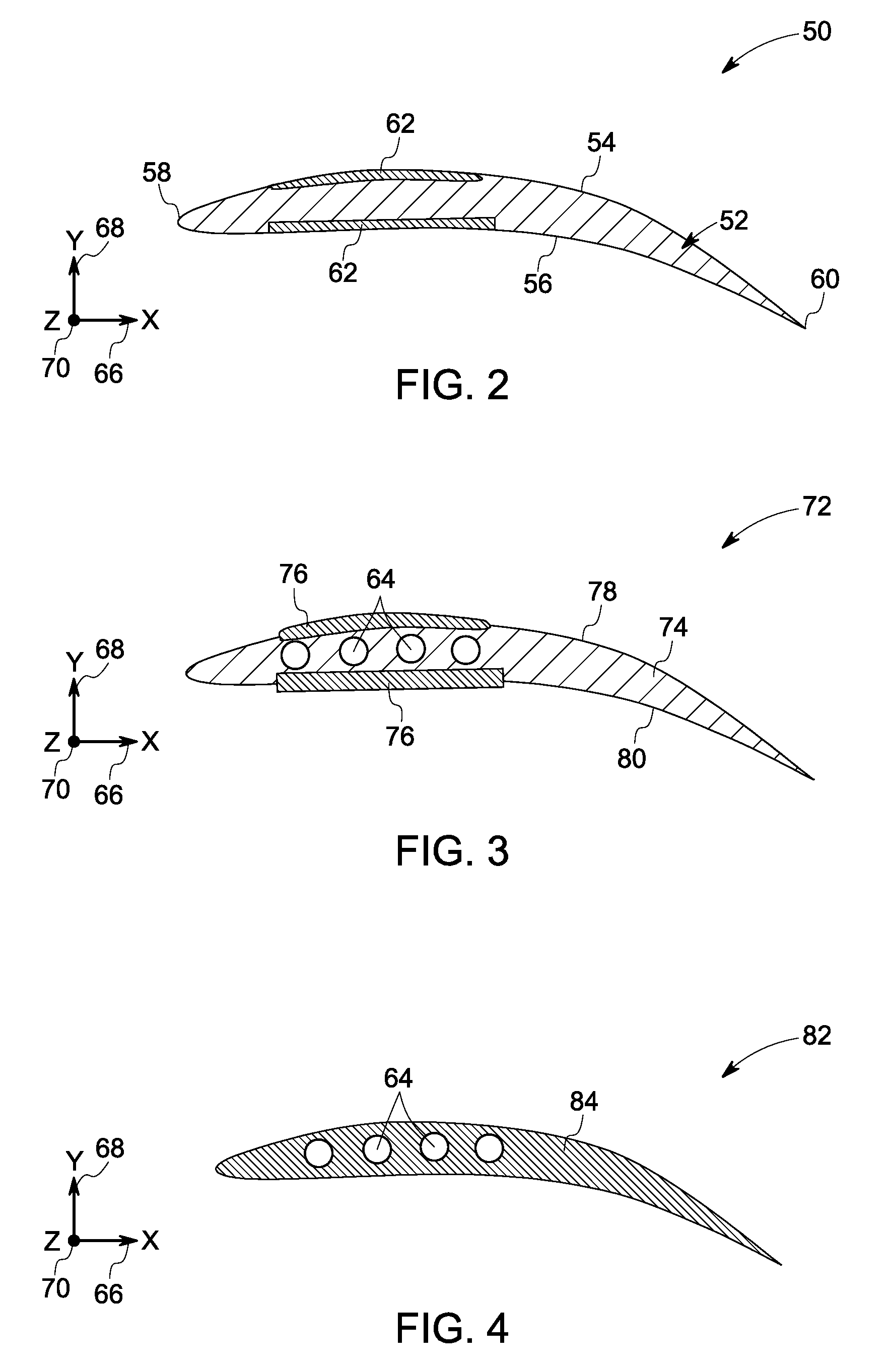

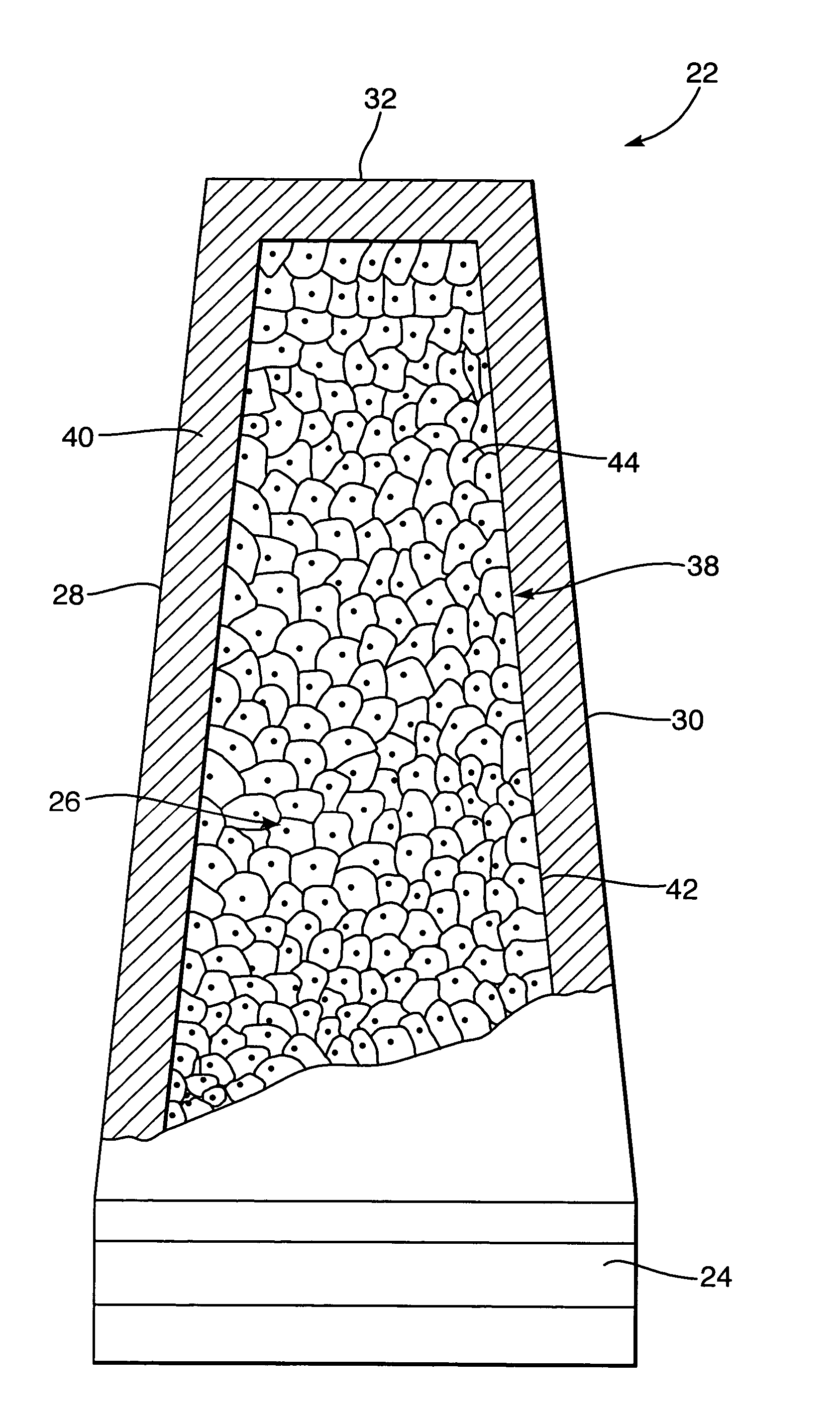

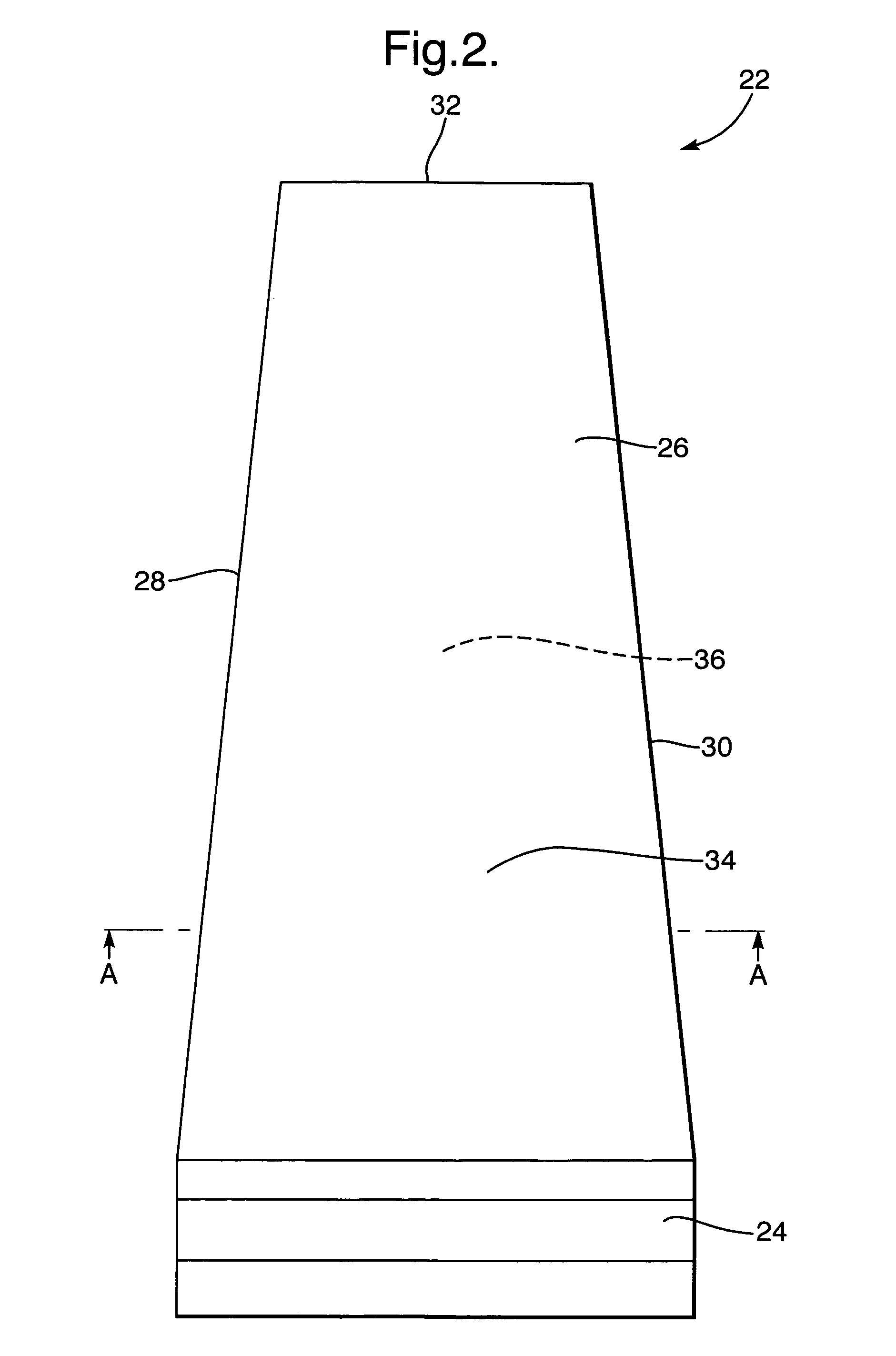

Aerofoils for gas turbine engines

An aerofoil 26 for a gas turbine engine (10, FIG. 1) comprises a cavity 38, a cellular material 42 located in the cavity 38 for stiffening the aerofoil 26, and a vibration damping medium 44 located in the cavity 38 for damping the aerofoil. The cellular material 42 is preferably a metal foam bonded to the inner surface 34a, 36a of the hollow aerofoil 26, and the vibration damping medium 44 is preferably a viscoelastic material. Various methods for fabricating the aerofoil 26 are also described.

Owner:ROLLS ROYCE PLC

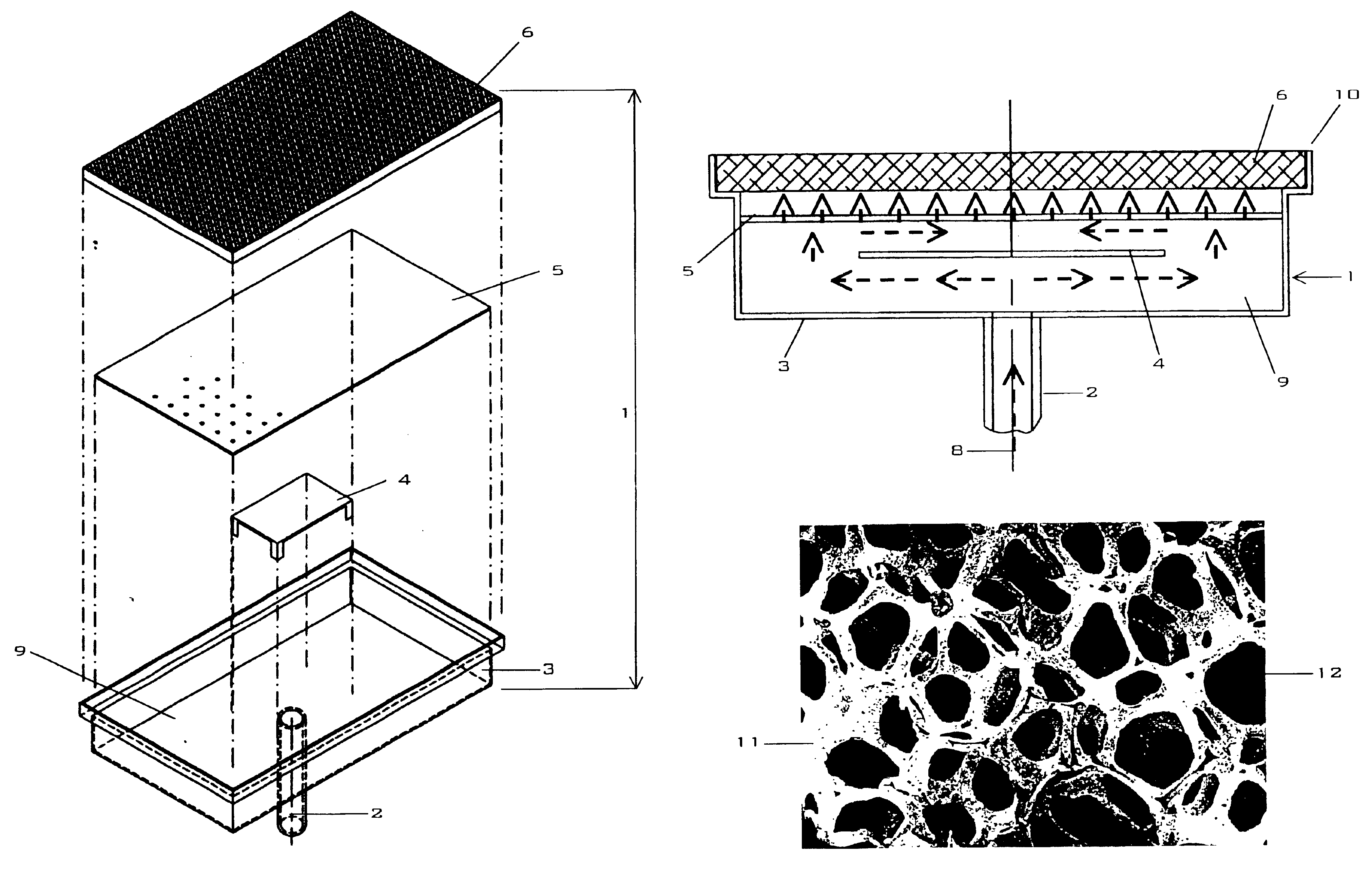

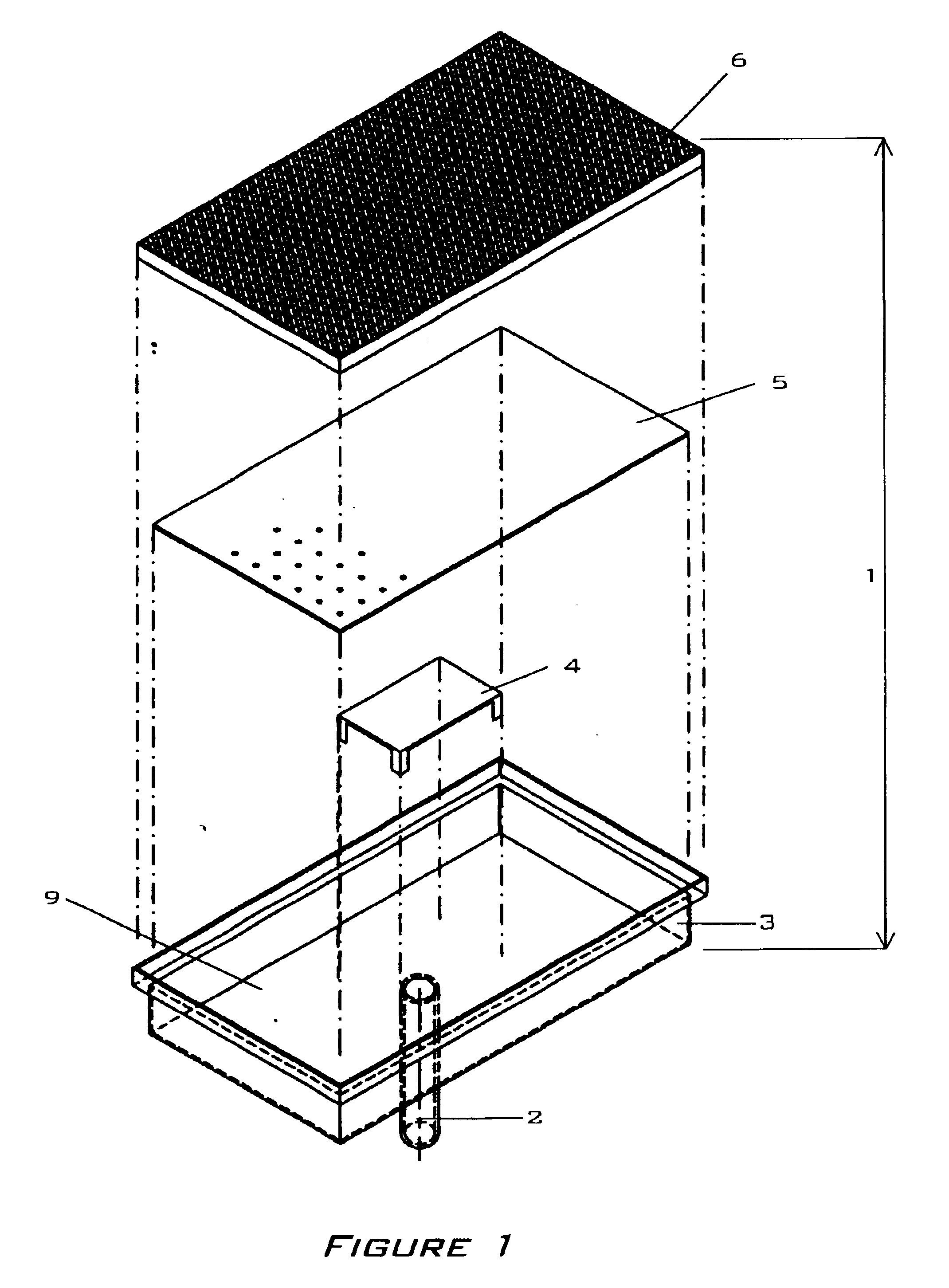

Radiator element

InactiveUS6896512B2Promotes efficient combustionEffective radiationDomestic stoves or rangesAir heatersCombustionMetal alloy

The present invention is a radiator element composed of a metal foam for use within a radiant burner. The radiator element is comprised of a homogenous network about a plurality of inter-connected cells thereby forming a gas-permeable metal foam. The homogeneous network may be composed of a metal or metal alloy capable of withstanding combustion temperatures typical of fuel-air reactions and resisting damage produced by flashback. Inter-connected cells include irregular-shaped voids, circular-shaped voids, and combinations thereof.

Owner:SOLEBURY TECHN

Radiator element

InactiveUS20030054313A1More to mechanical damagePromote combustionCapillary burnersBurner material specificationsCombustionMetal alloy

The present invention is a radiator element composed of a metal foam for use within a radiant burner. The radiator element is comprised of a homogenous network about a plurality of inter-connected cells thereby forming a gas-permeable metal foam. The homogeneous network may be composed of a metal or metal alloy capable of withstanding combustion temperatures typical of fuel-air reactions and resisting damage produced by flashback. Inter-connected cells include irregular-shaped voids, circular-shaped voids, and combinations thereof.

Owner:SOLEBURY TECHN

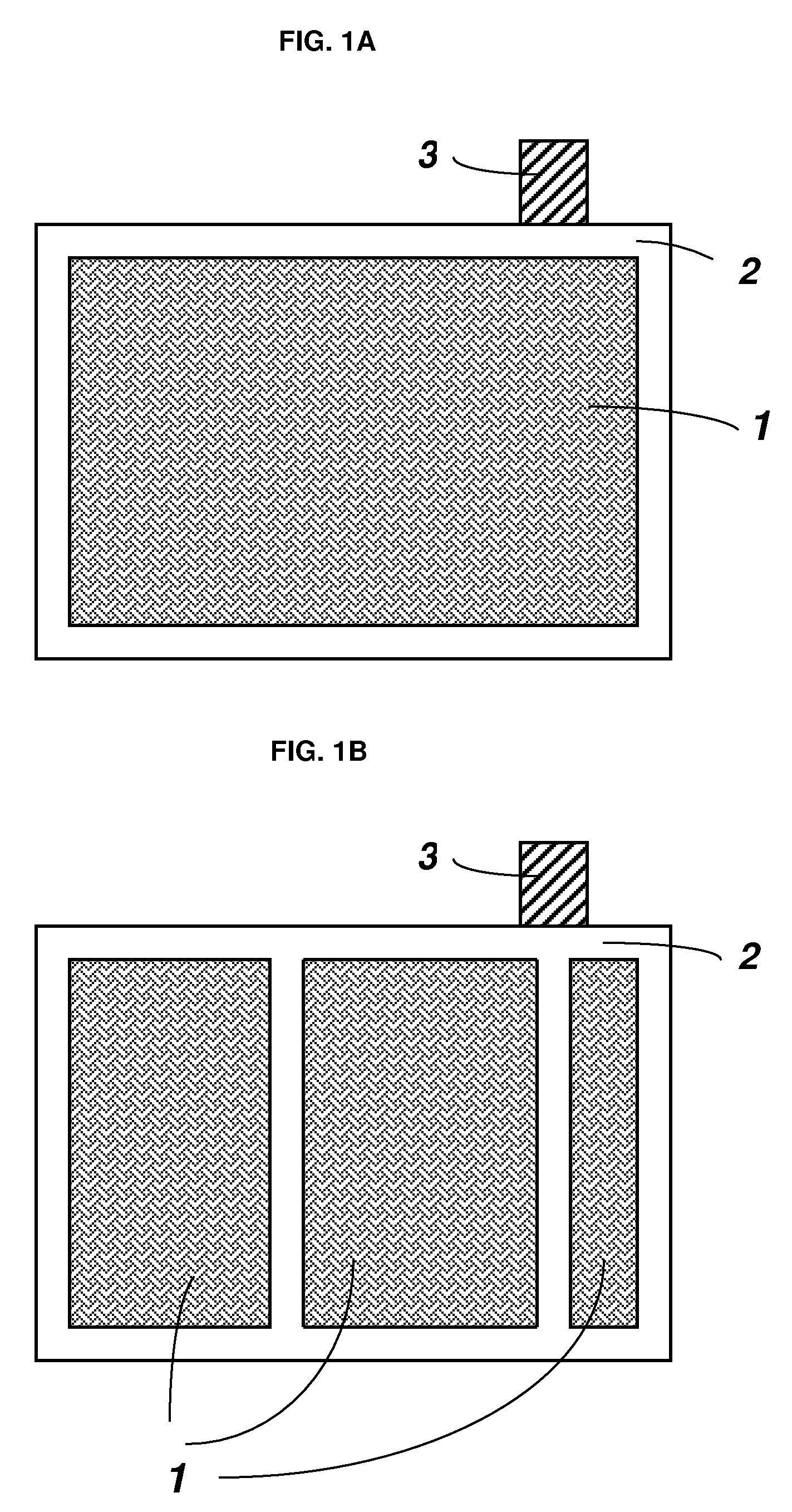

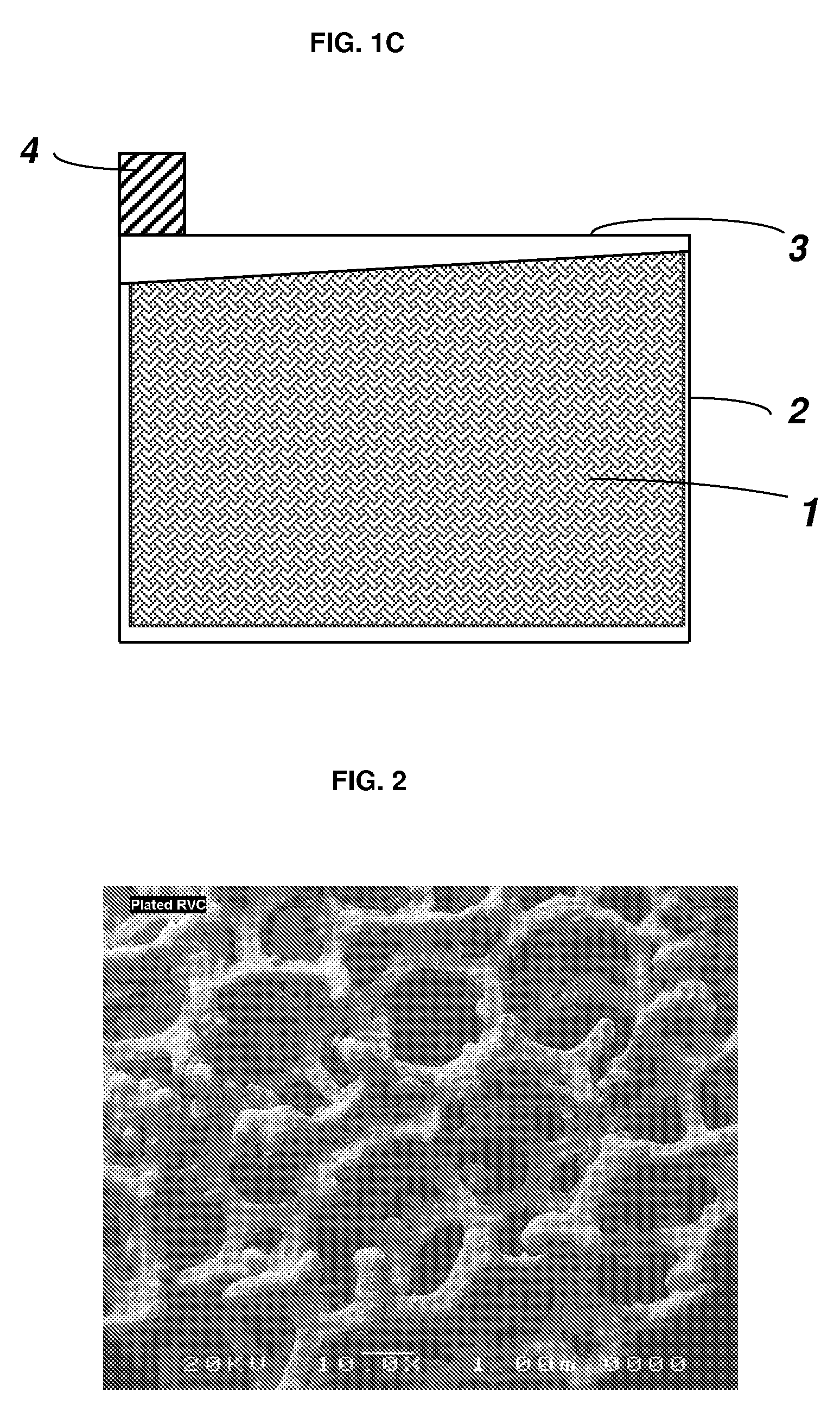

Current Collector Structure and Methods to Improve the Performance of a Lead-Acid Battery

InactiveUS20060292448A1Improve performanceAchieve recyclabilityElectrode carriers/collectorsLead-acid accumulator electrodesGraphiteMetal foam

A current collector of a battery includes a reticulated substrate having a circuitous network of pores and a metal applied to at least a portion of the reticulated substrate. The reticulated substrate may be a non-metal foam substrate, such as, for example, a carbon foam substrate, a reticulated vitreous carbon substrate or a graphite foam substrate.

Owner:GYENGE ELOD +2

Method of forming metal foams by cold spray technique

The present invention relates to a method of forming metallic foams using cold spray processing. The method allows for the formation of metallic foams on existing substrates as a layer. The method includes the steps of providing a substrate for coating of a metallic foam; cold spraying a mixture of metal particles and a foaming agent onto the substrate to form a substrate coated with an unexpanded metallic layer; foam heat treating the substrate coated with an unexpanded metallic layer at a temperature above the decomposition temperature of the foaming agent for a time sufficient to form a heated substrate coated with an expanded metal foam layer; and cooling the heated substrate coated with an expanded metal foam layer to about ambient temperature to form a cooled substrate coated with an expanded metal foam layer. The method of forming metallic foams on substrates finds application in the oil, gas, and chemical industry by being an integral part of casings, pipelines, transfer lines, and other flow lines.

Owner:EXXON RES & ENG CO

Process for producing metal foam and metal body produced using this process

The invention relates to a process for producing metal foam and to a metal body produced using this process.The object is achieved by a process for producing metal foam by adding a blowing agent to a metal melt, wherein the metal melt is introduced into the die cavity of a metal die-casting machine and is foamed using a blowing agent which releases gases and is solid at room temperature.

Owner:BUHLER DRUCKGASS AG

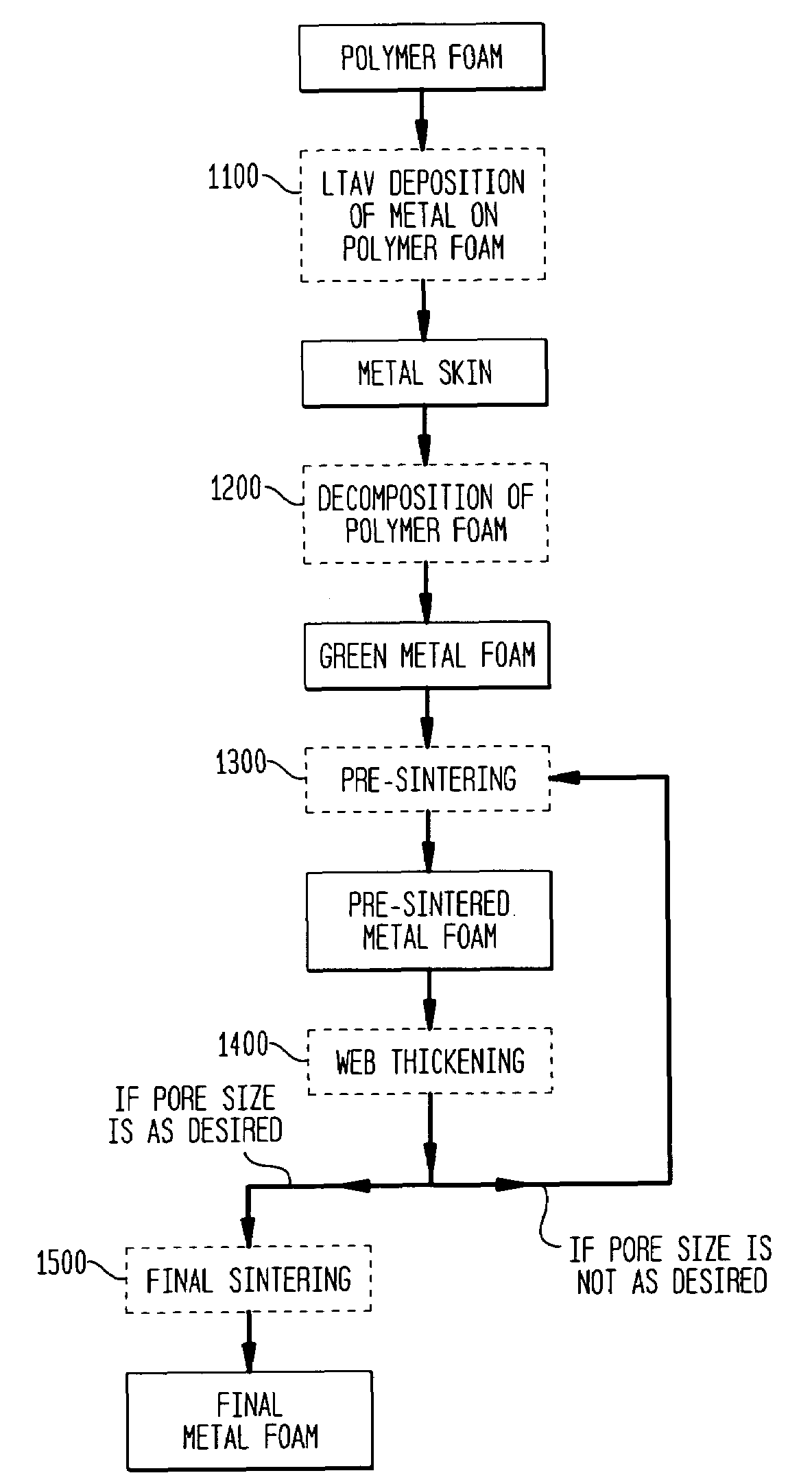

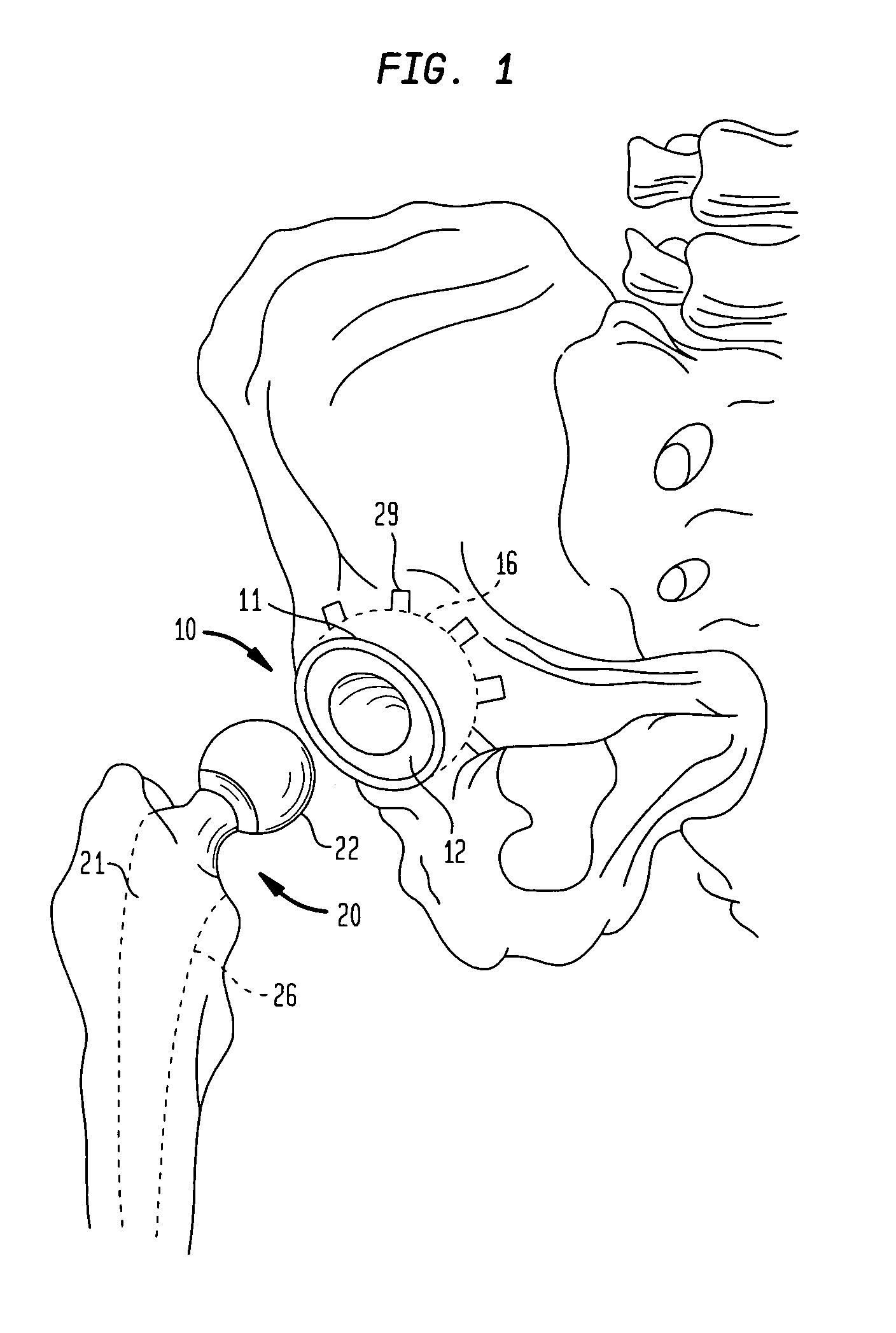

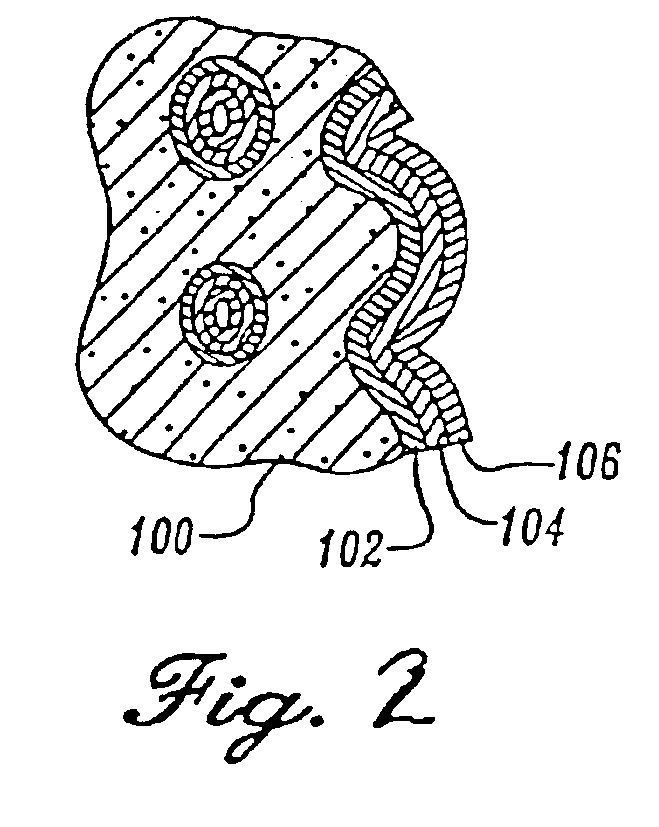

Porous metallic scaffold for tissue ingrowth

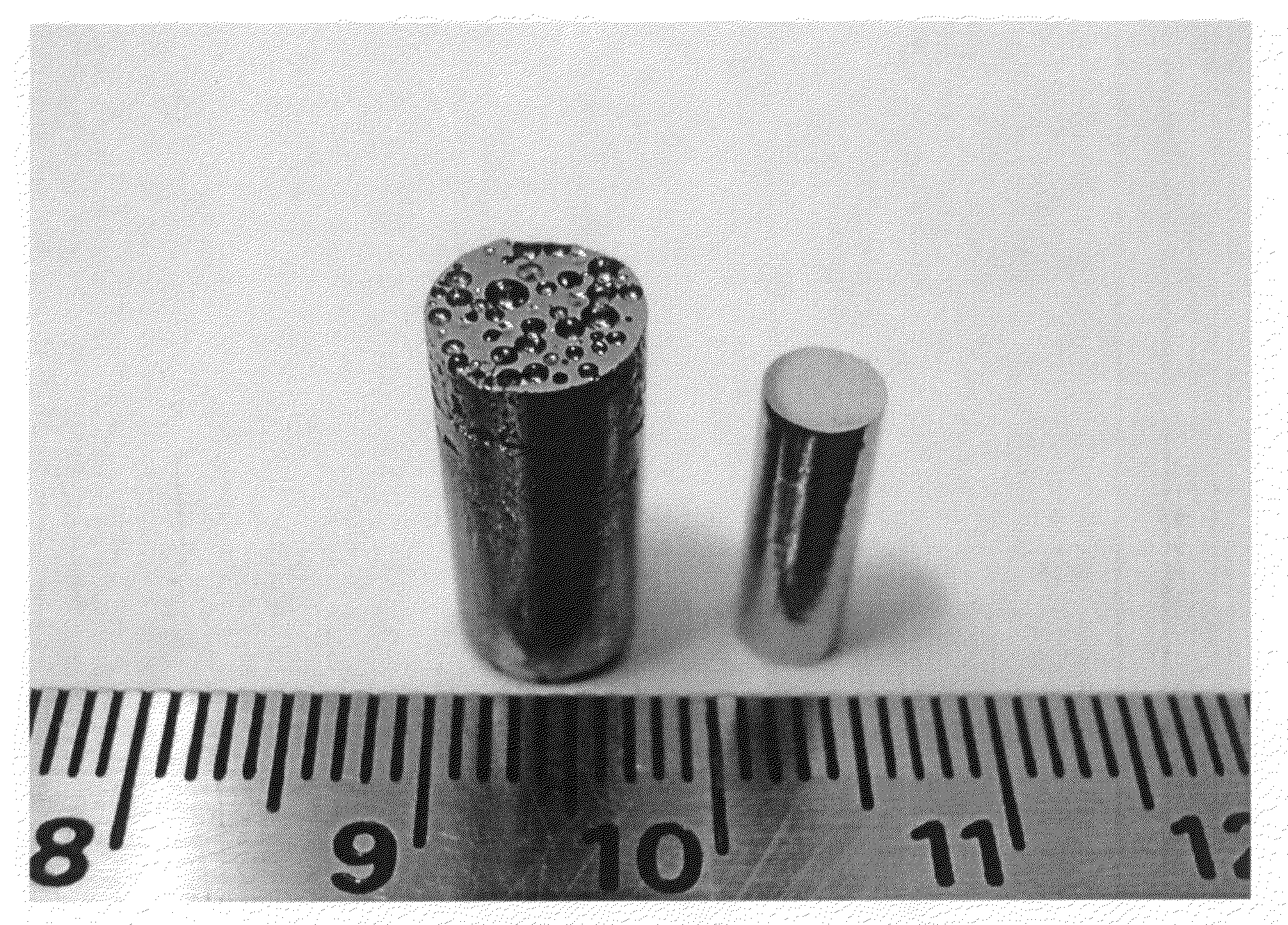

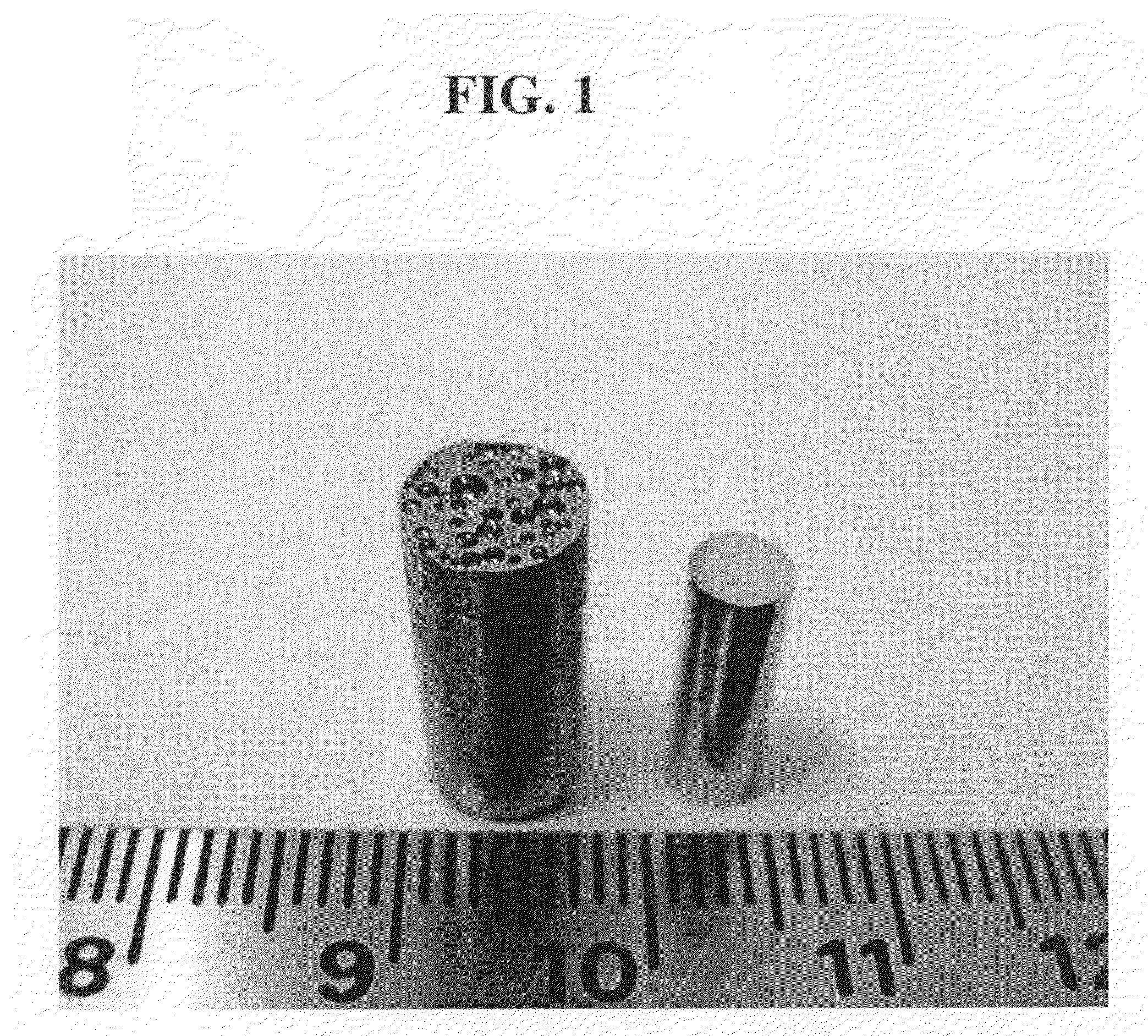

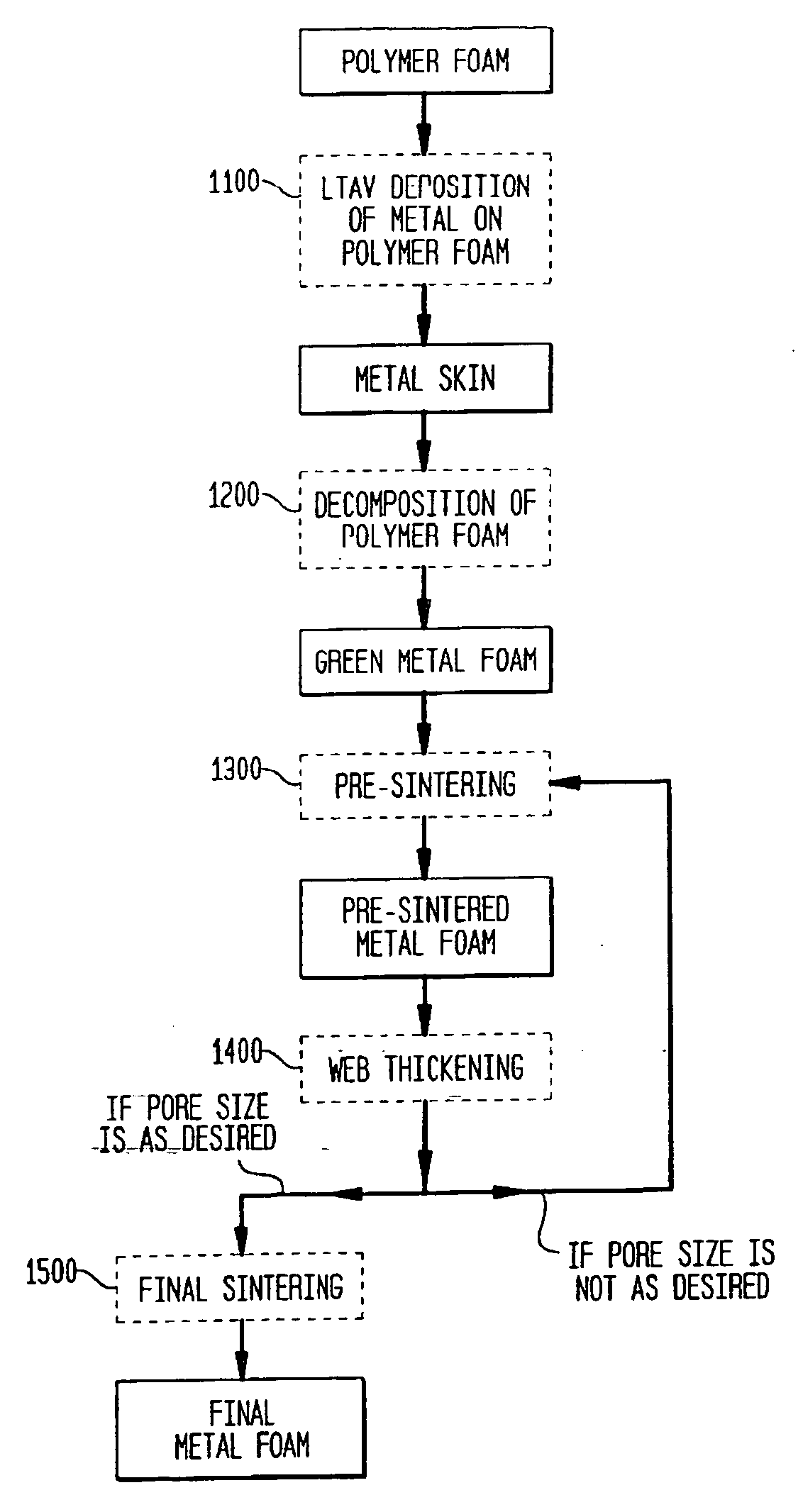

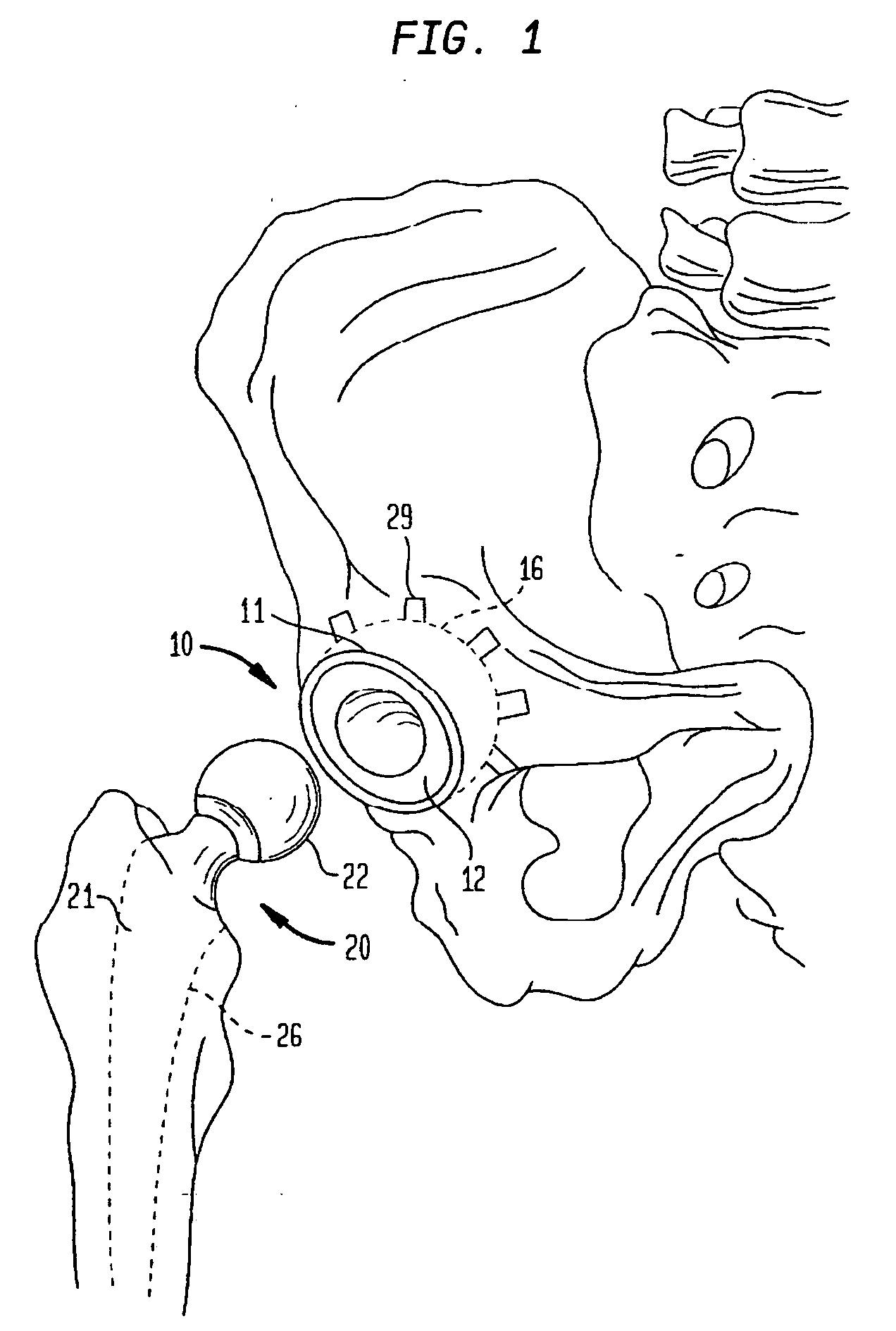

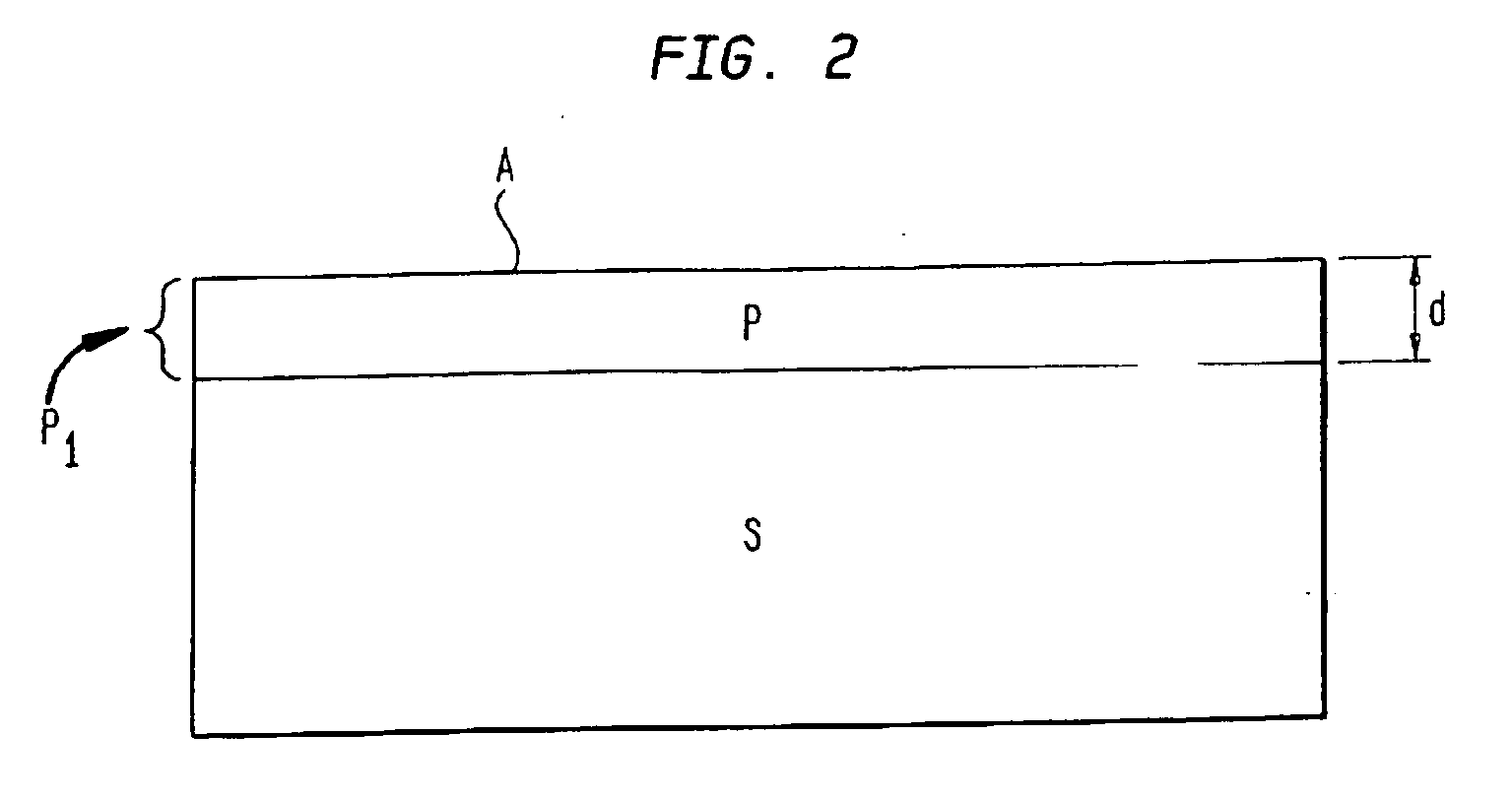

The invention relates to implantable medical devices, particularly, to porous structures for such devices. In one aspect, the invention provides a porous metal scaffold comprising a porous metal network having pores defined by metal webs, the metal webs covered with at least one layer of metal particles bonded to the metal webs. In other aspects, the invention provides methods of forming porous scaffolds. In one such aspect, the method includes providing a polymer foam; forming a skin of biocompatible metal on the polymer foam by low temperature arc vapor deposition; and heating the polymer foam and the metal skin above the decomposition temperature of the polymer foam in an inert gas atmosphere; thereby the polymer foam decomposes producing a green metal foam. In yet other aspects, the invention provides methods of improving stability of porous scaffolds.

Owner:HOWMEDICA OSTEONICS CORP

Water sensitive variable counterweight device driven by osmosis

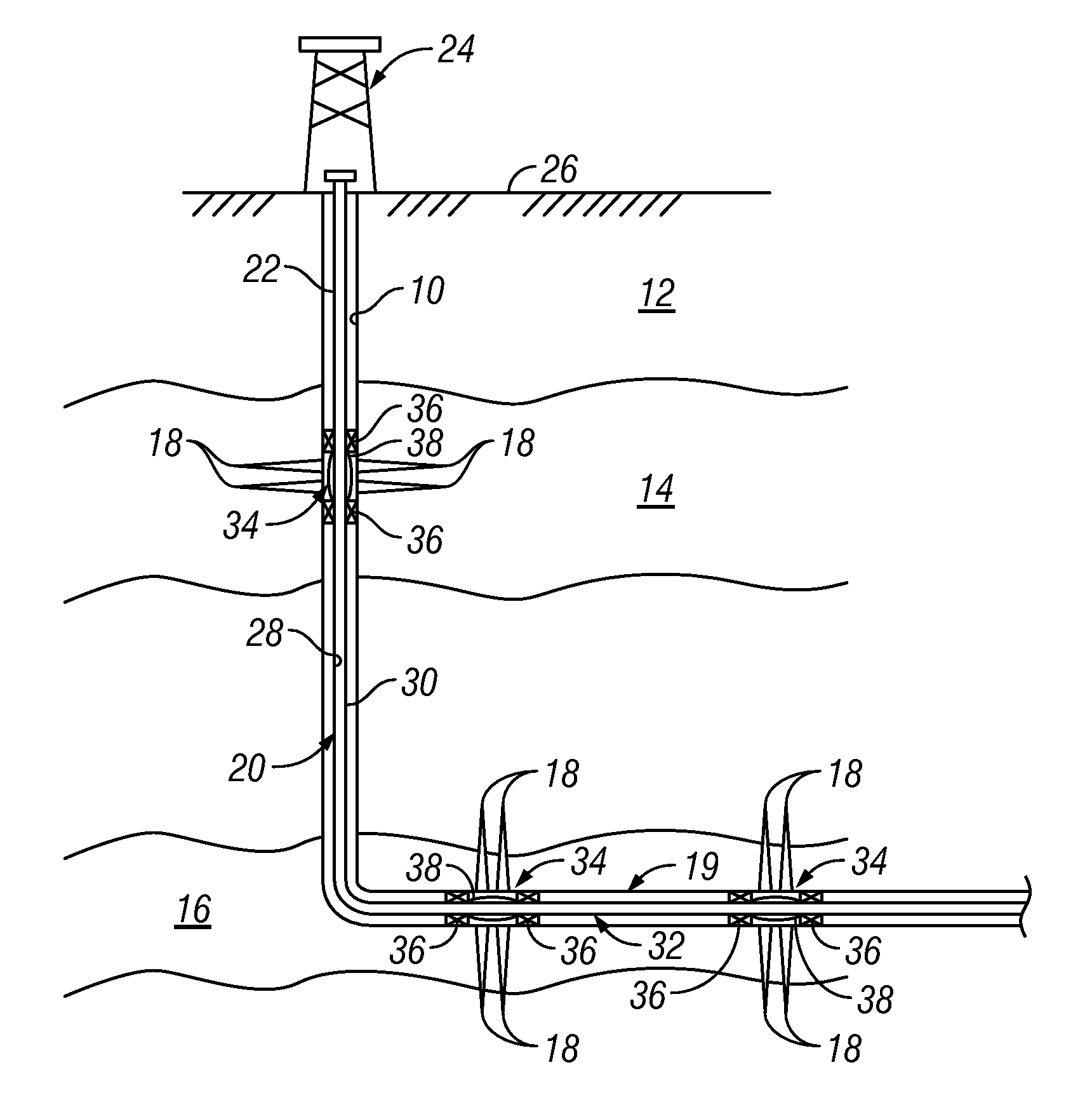

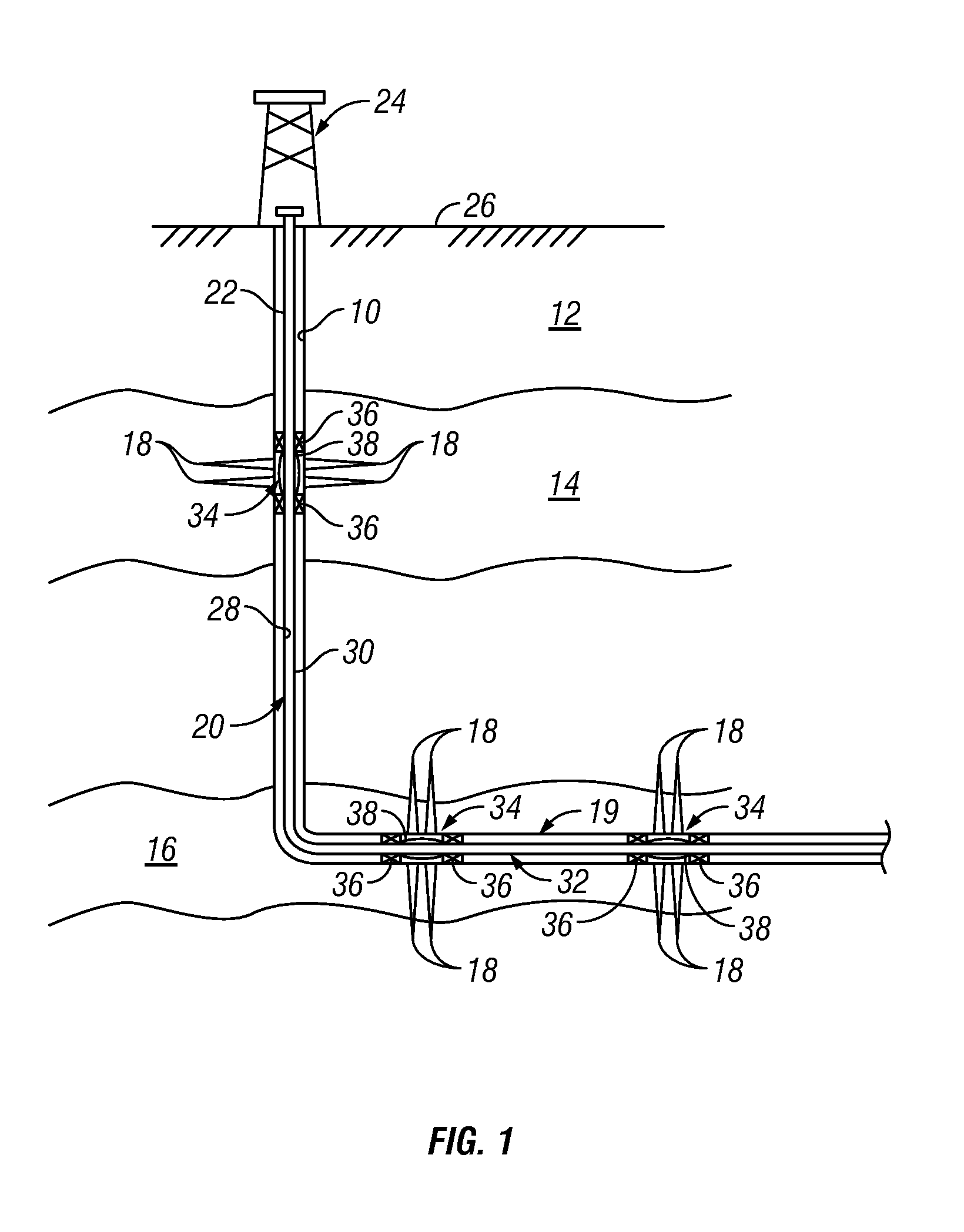

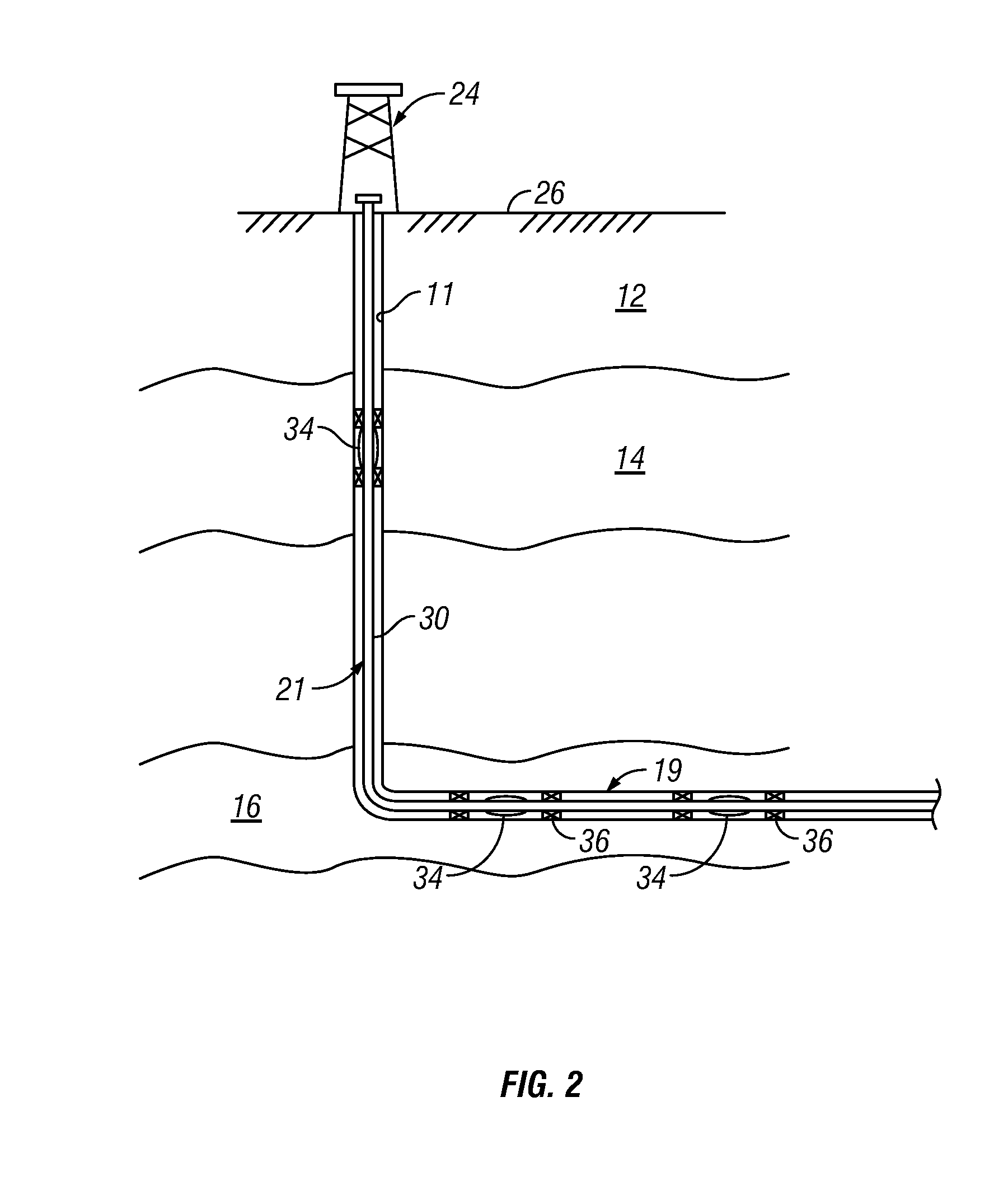

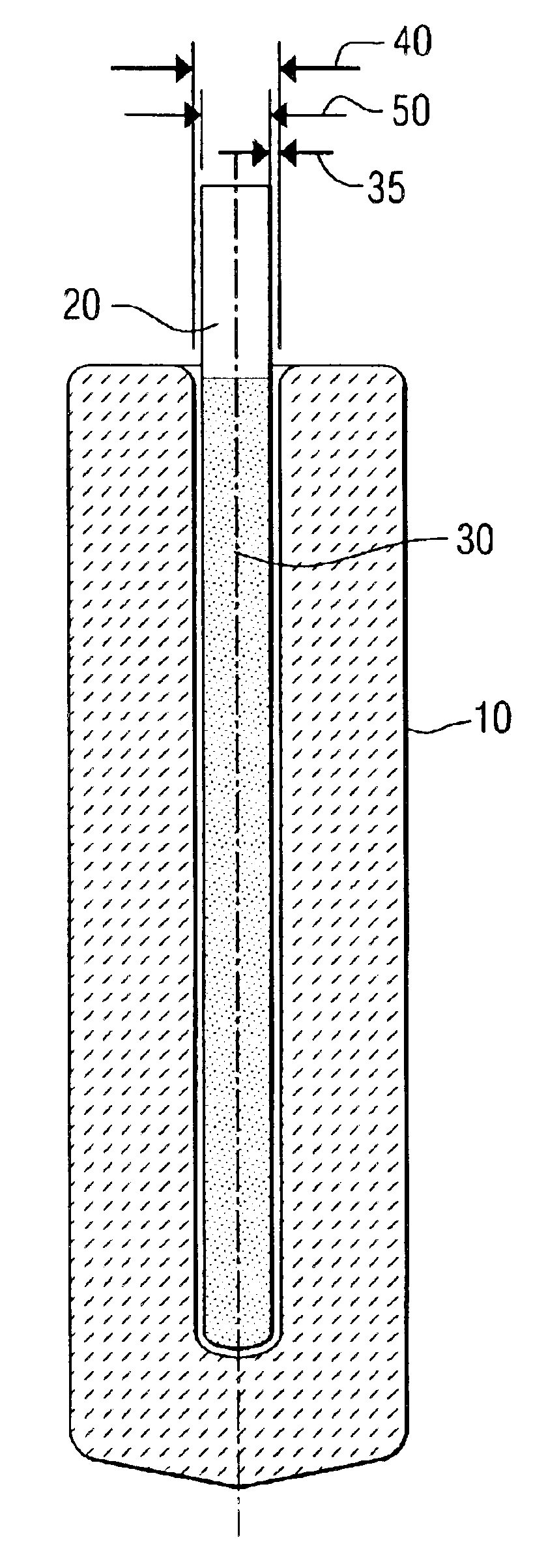

InactiveUS20090236102A1Fluid removalWell/borehole valve arrangementsControl flowHydrocotyle bowlesioides

A method for producing fluid from a subterranean formation includes configuring a body to at least partially fill with a selected fluid; and actuating a flow restriction element using the body. The selected fluid may be water. An apparatus for controlling flow of a fluid into a wellbore tubular may include a selectively buoyant body, and a flow restriction element responsive to a movement of the selectively buoyant body. The selectively buoyant body includes a membrane configured to block a flow of hydrocarbons into the selectively buoyant body. The flow restriction element may include a flapper, a sliding sleeve, and a poppet valve. The body may be at least partially filled with a permeable material, which includes, but is not limited to, open-cell foam, reticulated metal foam, shaped sintered powder and capillary tubes.

Owner:BAKER HUGHES INC

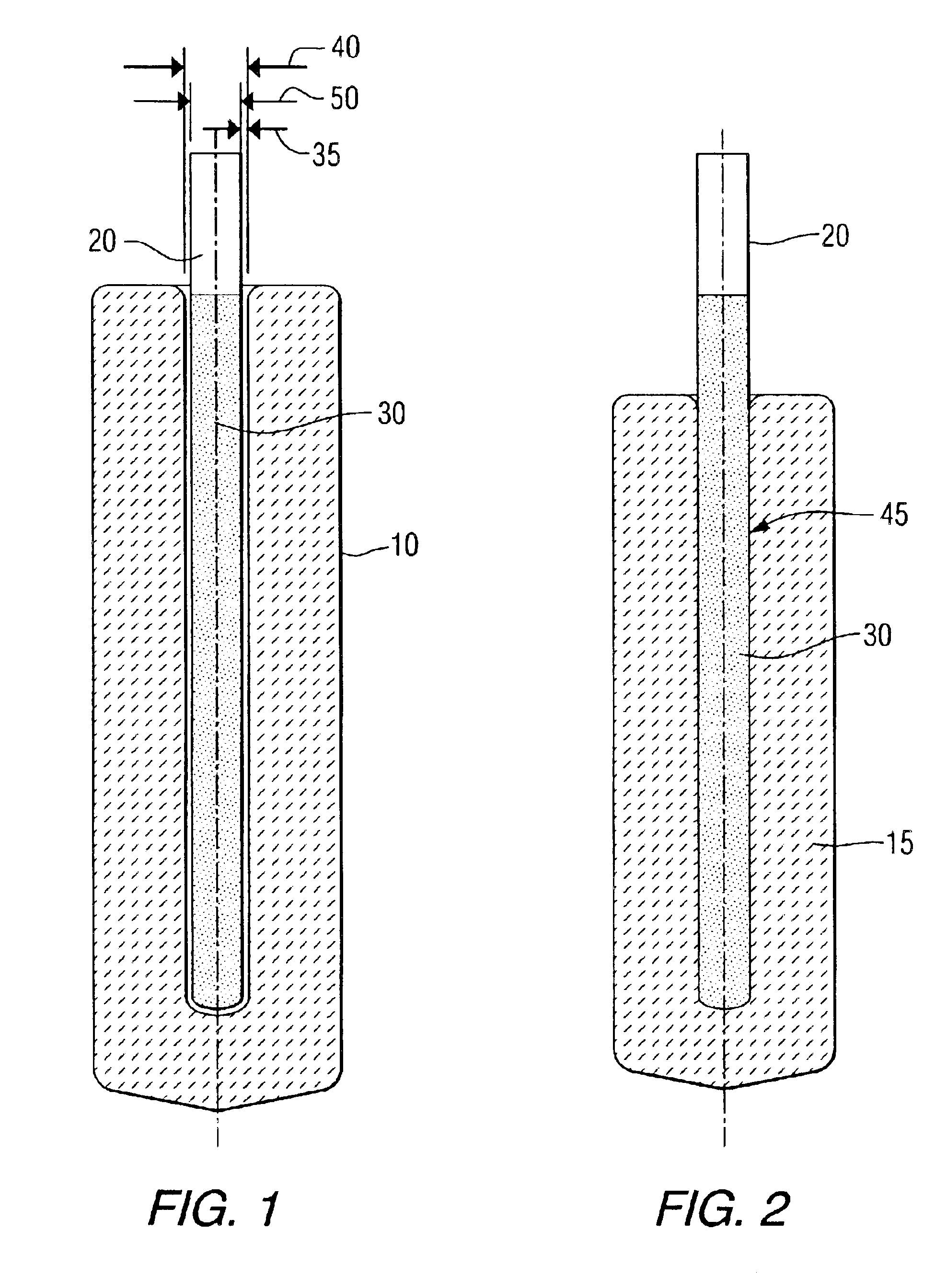

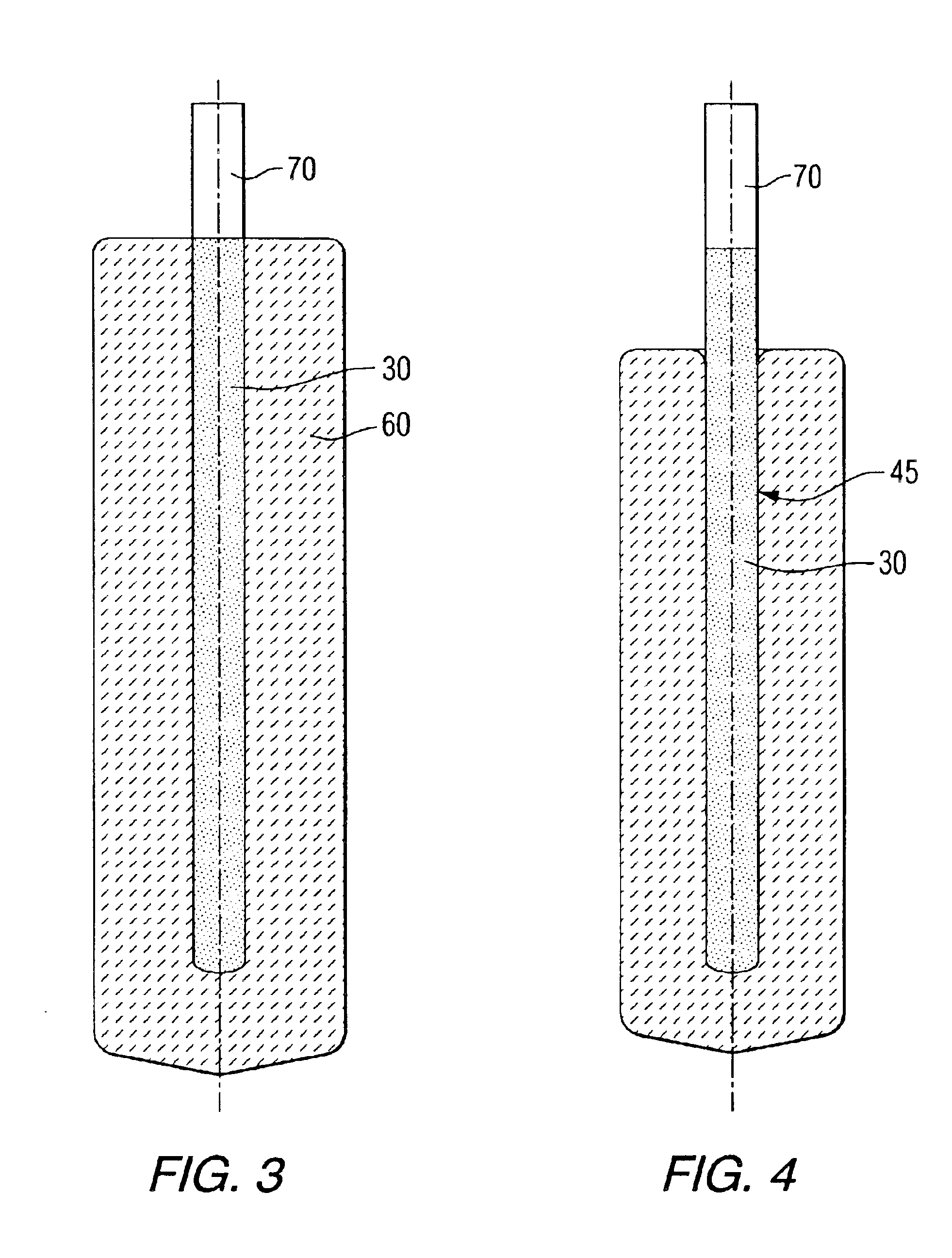

Sinter-bonded direct pin connections for inert anodes

InactiveUS6855234B2Reduce crackingStable electrical joint resistanceIsotope separationMetal working apparatusElectrical conductorMetallurgy

A sintered electrode assembly is made of an inert electrode (15) containing a sealed metal conductor (20) having a surface feature (30) such as a coating or wrapping which aids in bond formation with the inert electrode (15) at their interface (45), where the metal conductor (20) is directly contacted by and is substantially surrounded by the inert electrode (15) without the use of metal foam or metal powders.

Owner:ARCONIC INC

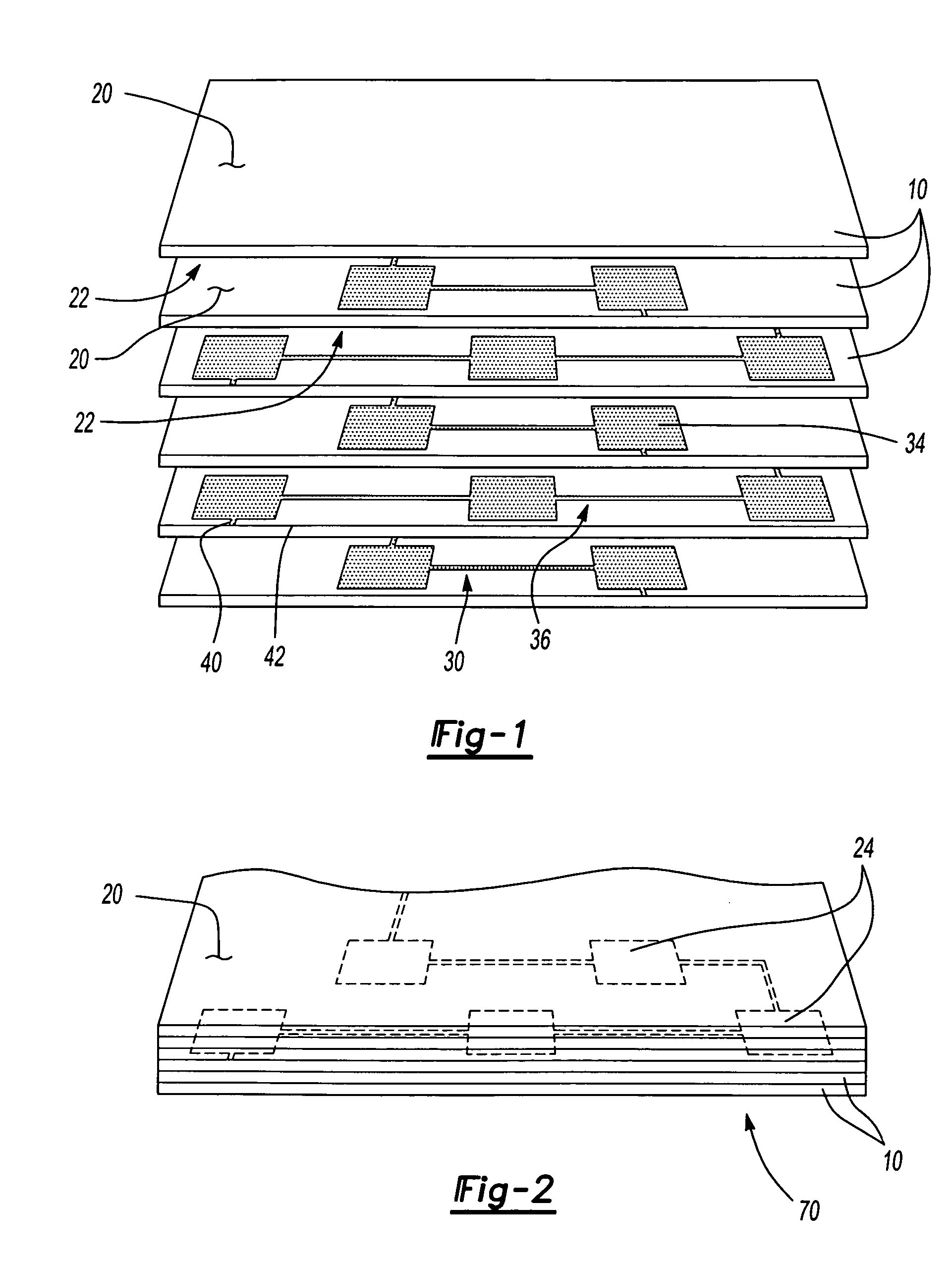

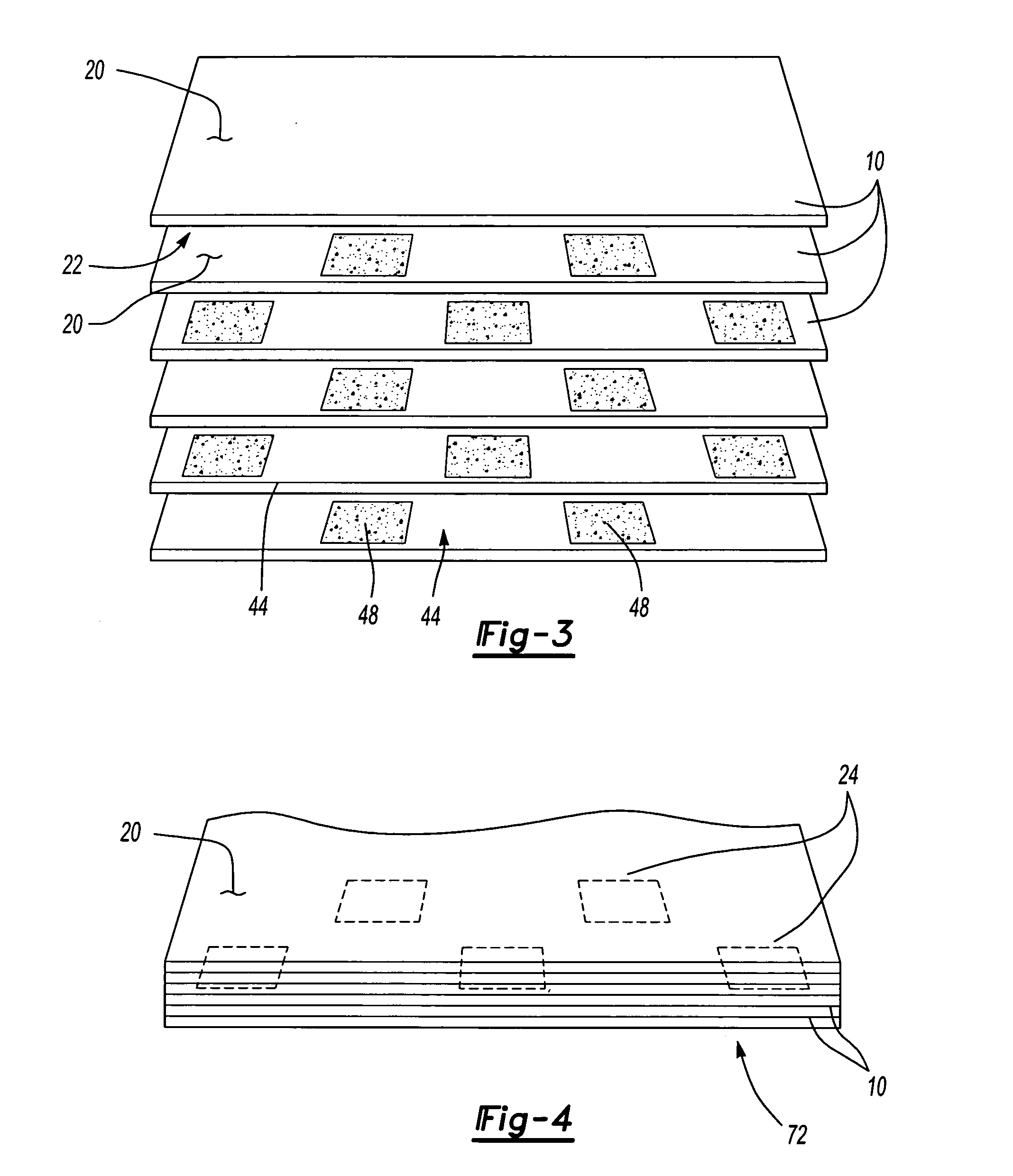

Heat dissipation plate for battery cell and battery module having the same

InactiveUS20130071718A1Efficiently dissipatedExtend the lifespanSafety devices for heat exchange apparatusCell temperature controlEngineeringMetal foam

Owner:HYUNDAI MOTOR CO LTD

Buffering energy-absorbing structure

The invention discloses a buffering energy-absorbing structure which comprises a hollow metal thin-wall structure, wherein a light metal foam material or metal cellular material is filled in the hollow metal thin-wall structure; the hollow metal thin-wall structure is fixedly connected with the filled light metal cellular material through binding or brazing, thereby forming the complete buffering energy-absorbing structure; the density of the filled metal foam material along the longitudinal direction is changed in a gradient form; and an aperture size or cellular wall thickness of the filled metal cellular material along the longitudinal direction is changed in the gradient form. Compared with the traditional energy-absorbing structure, the buffering energy-absorbing structure has the advantages that the deformation mode is more stable, the energy-absorbing efficiency is higher, the weight of the energy-absorbing structure is effectively reduced, the impact force during the whole energy-absorbing process is stable and the crashing safety of the energy-absorbing structure is greatly increased. The buffering energy-absorbing structure served as a direct impact energy-absorbing structure of an automobile can greatly increase the direct impact safety of the automobile and can reduce the casualties.

Owner:HUNAN UNIV

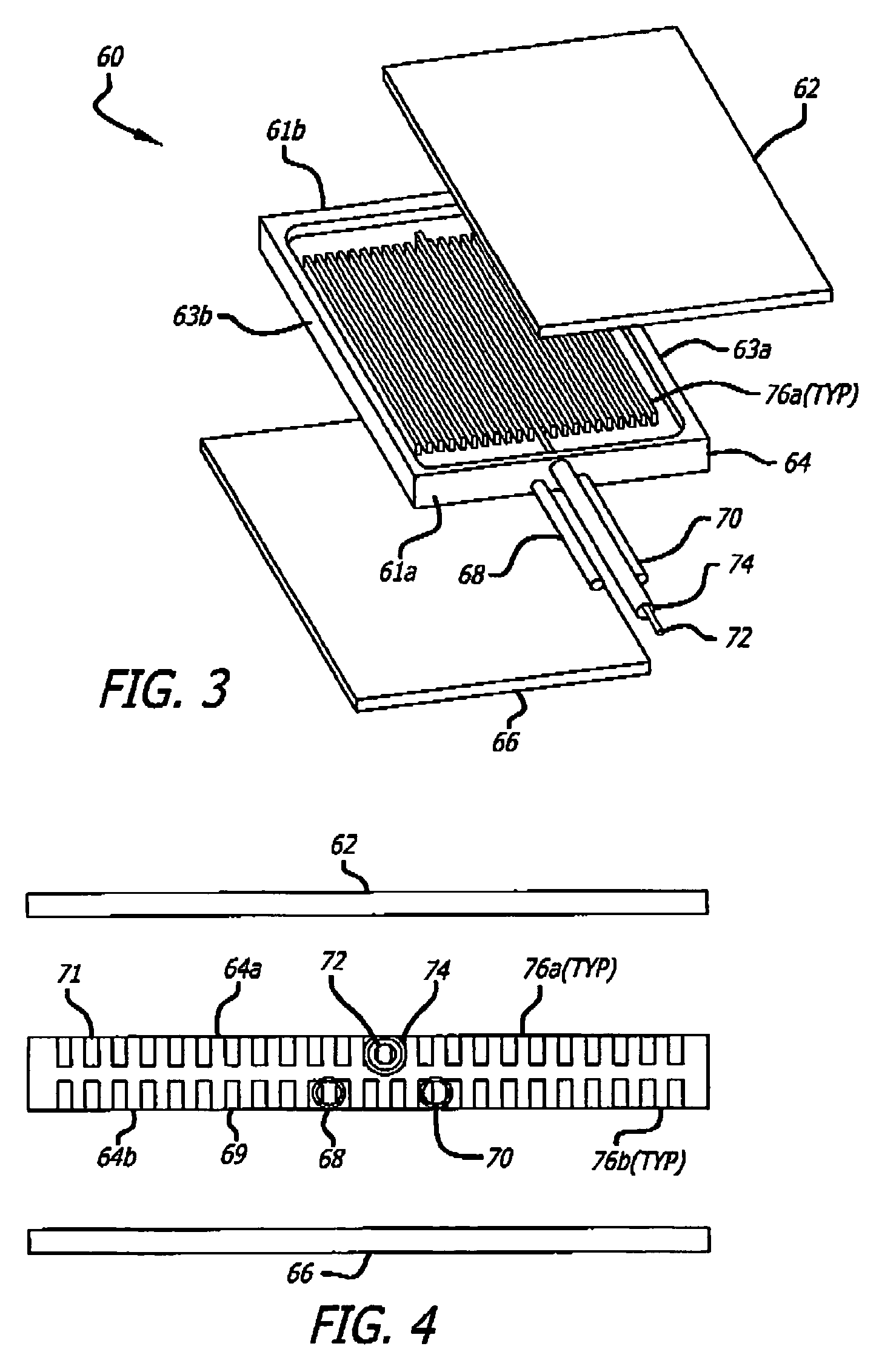

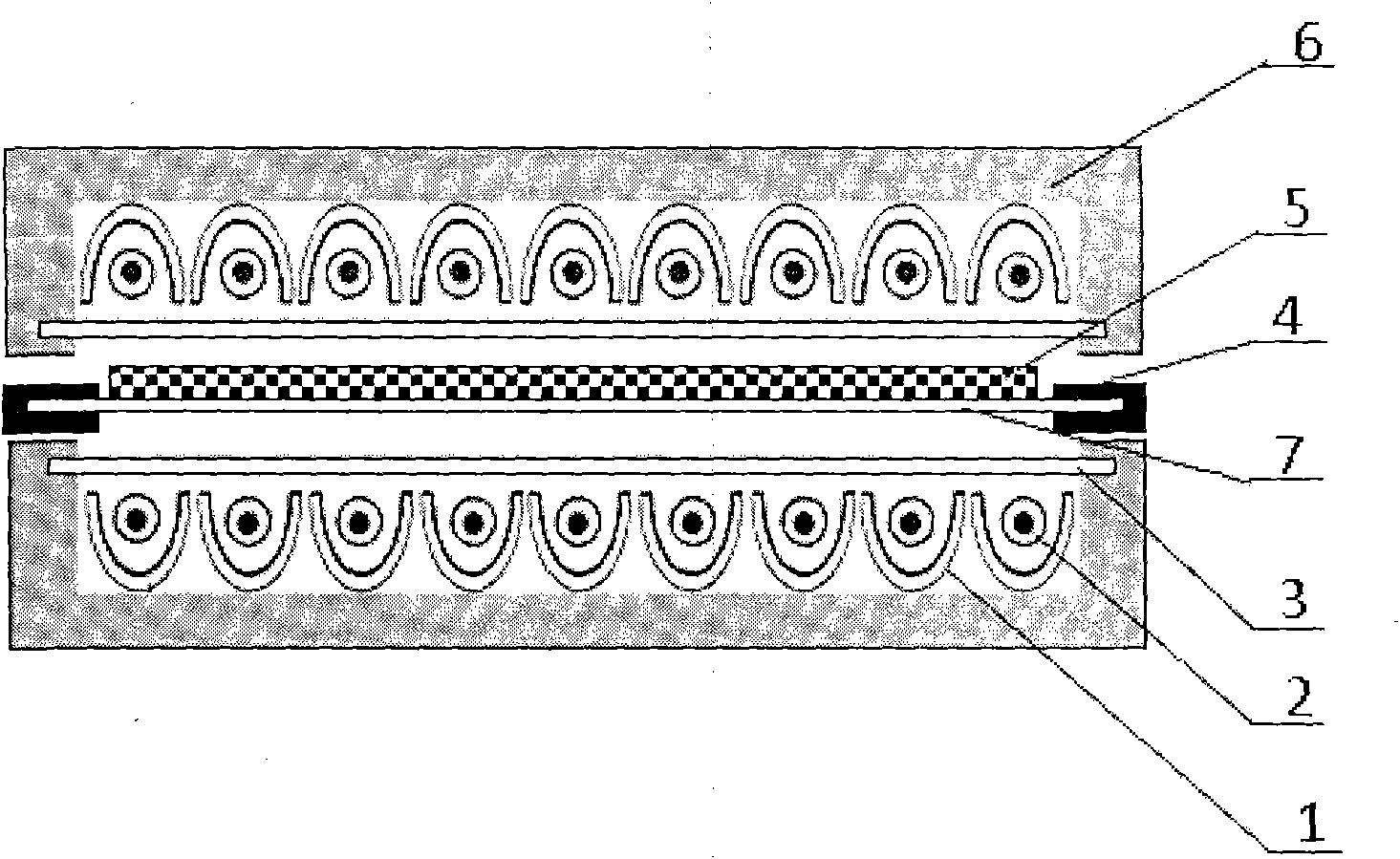

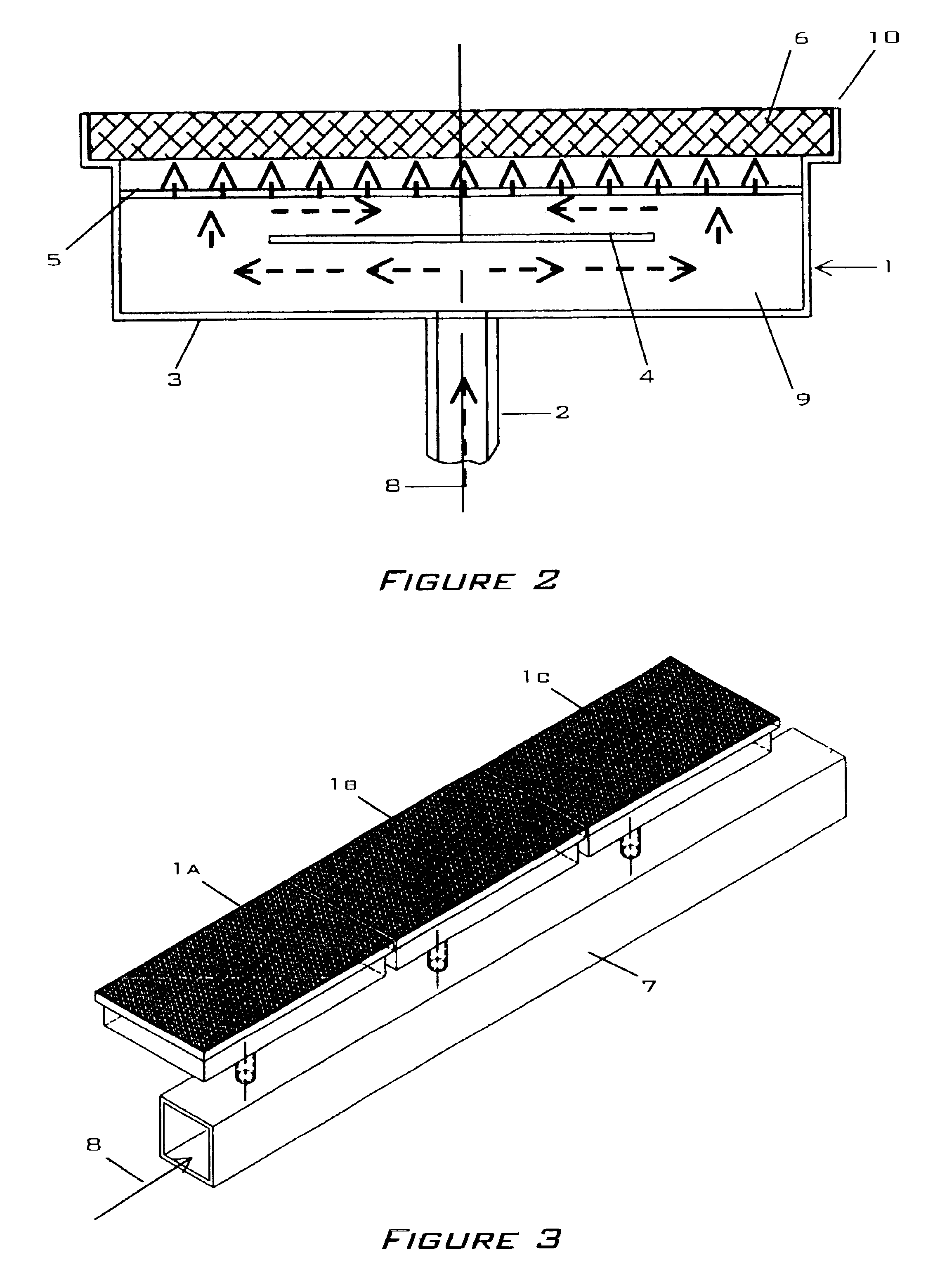

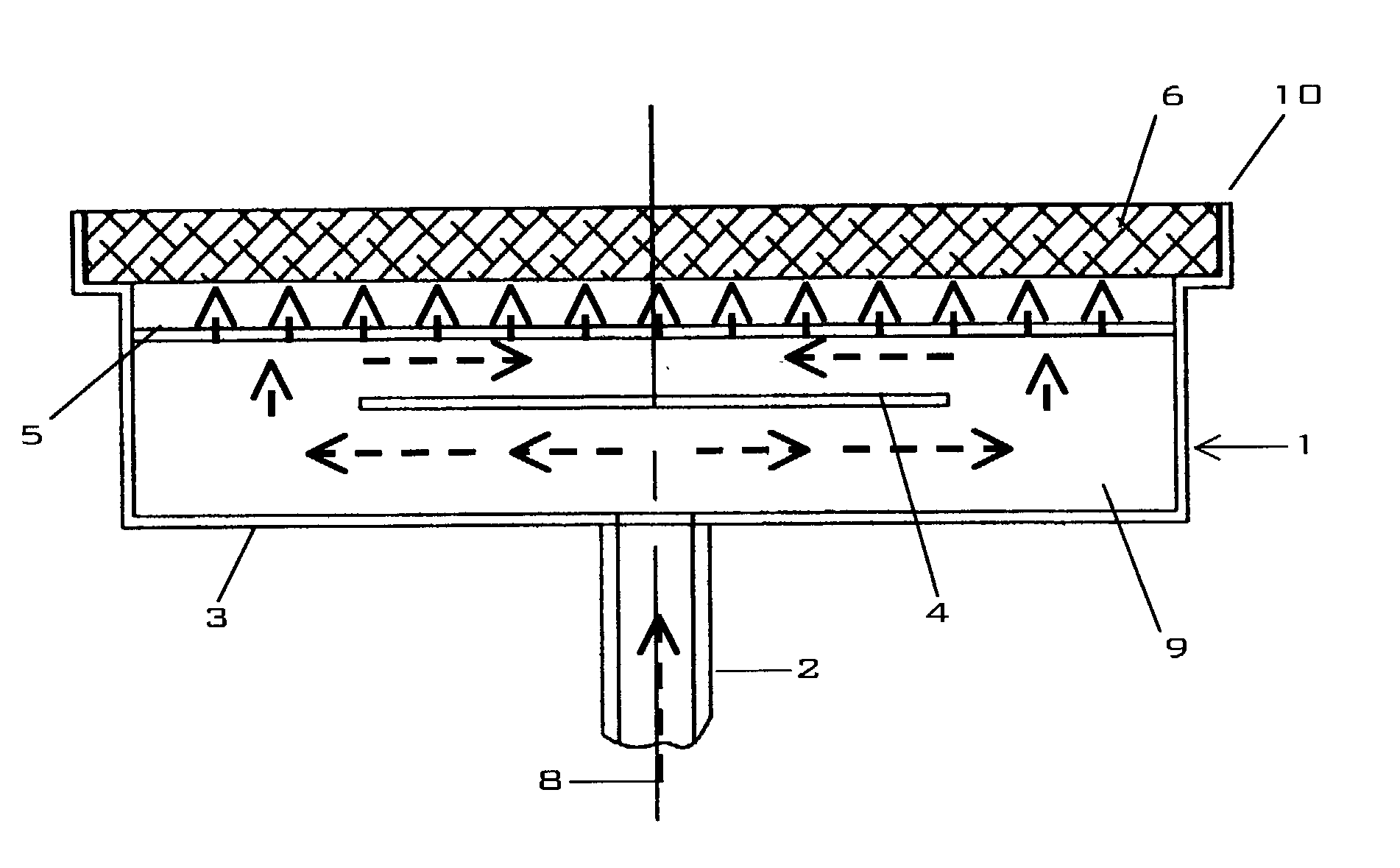

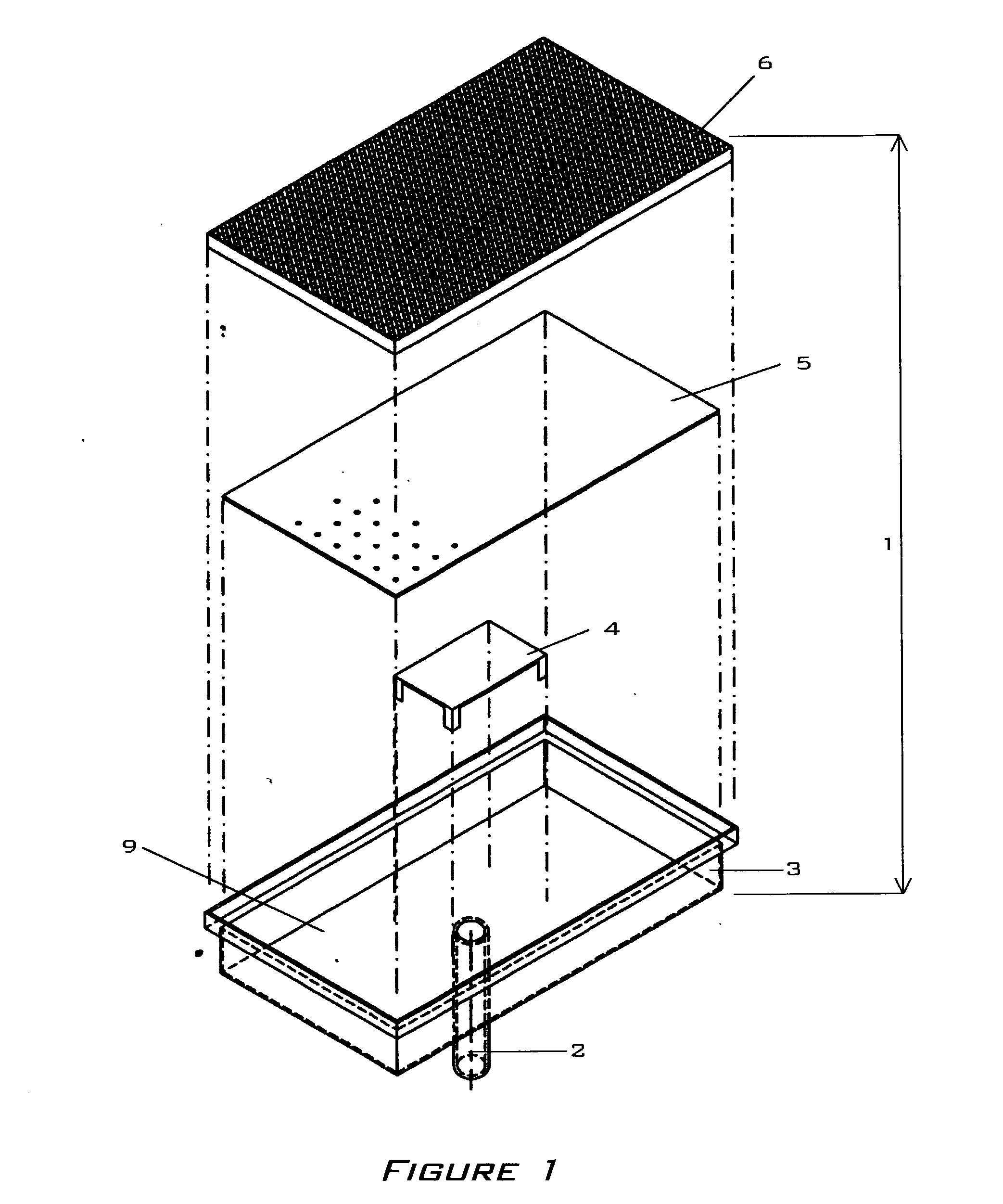

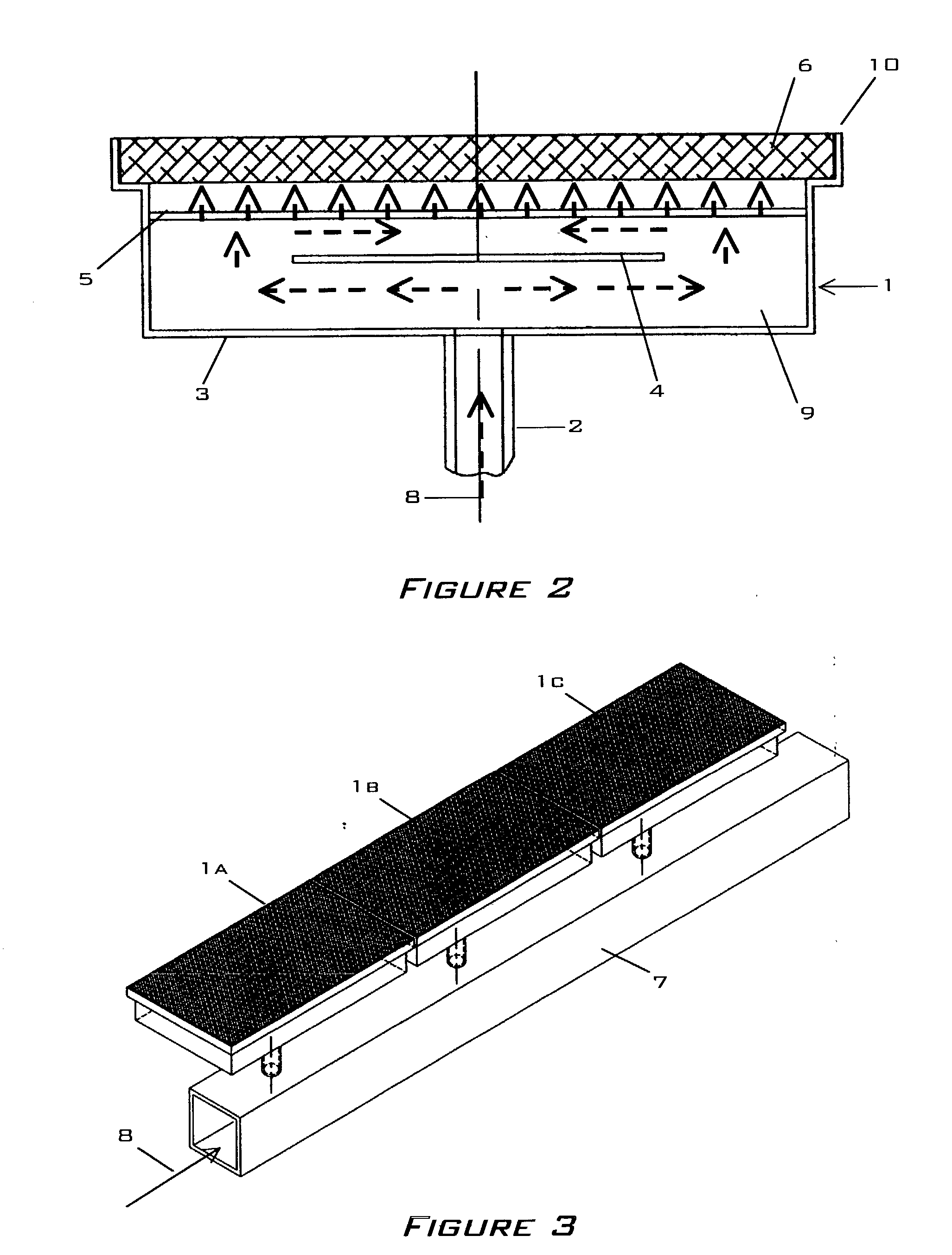

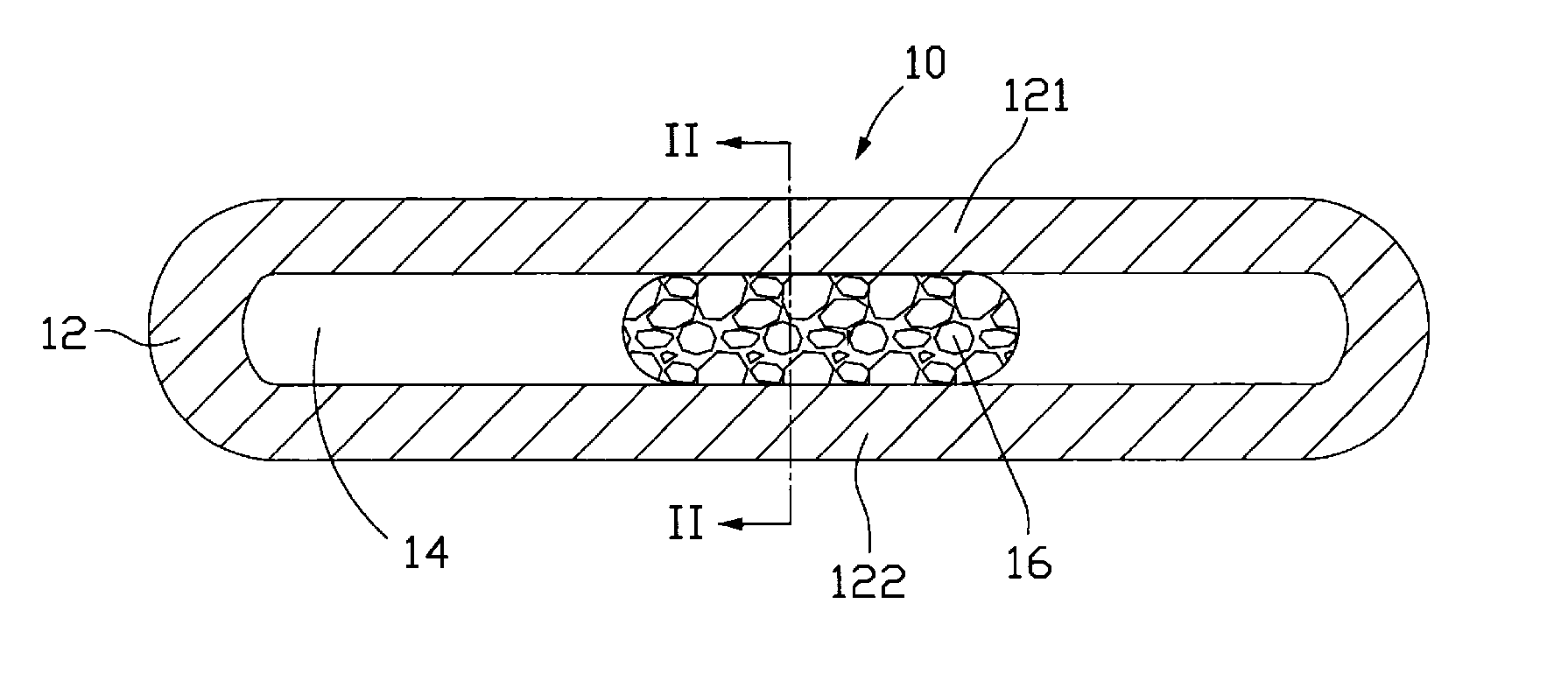

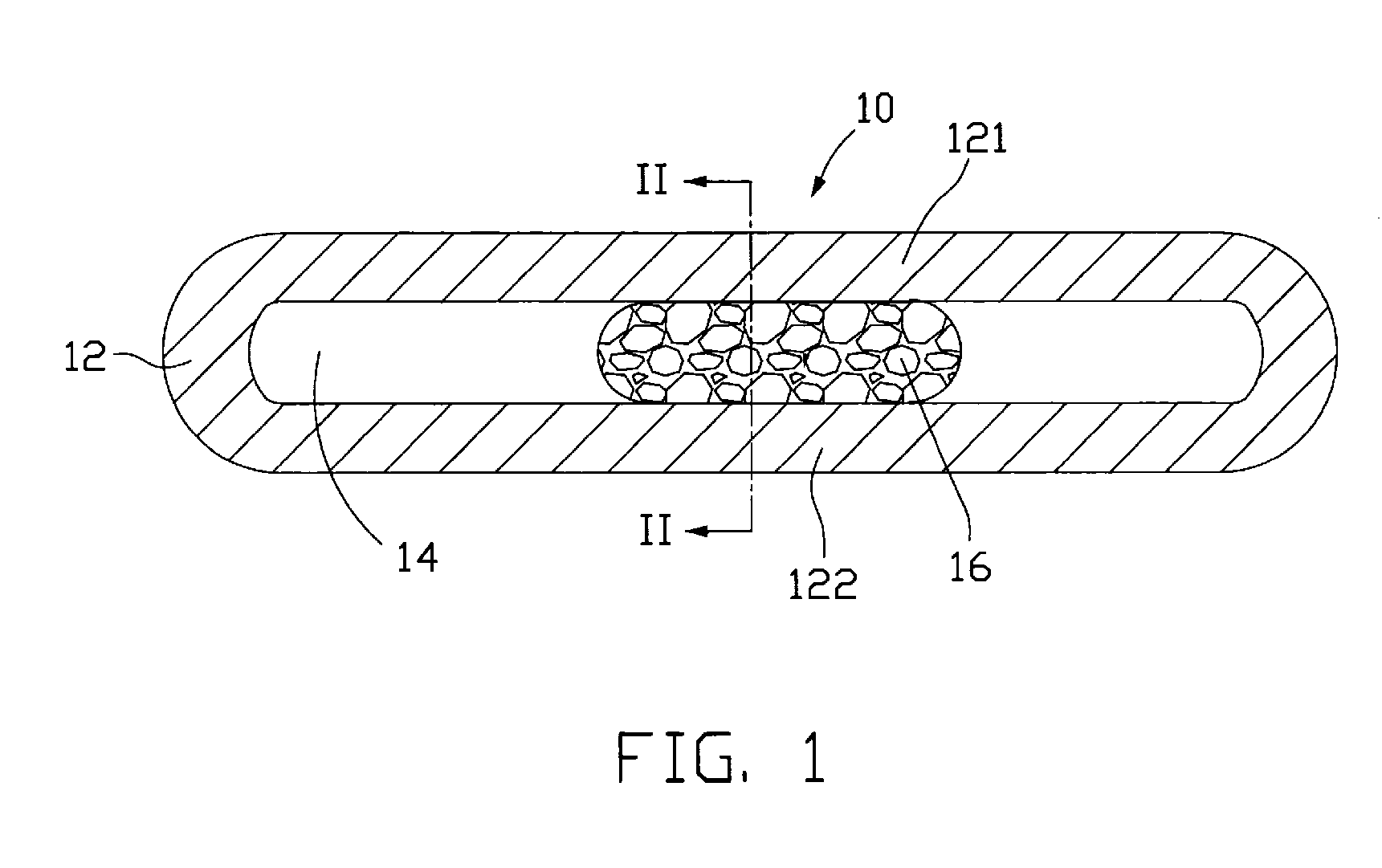

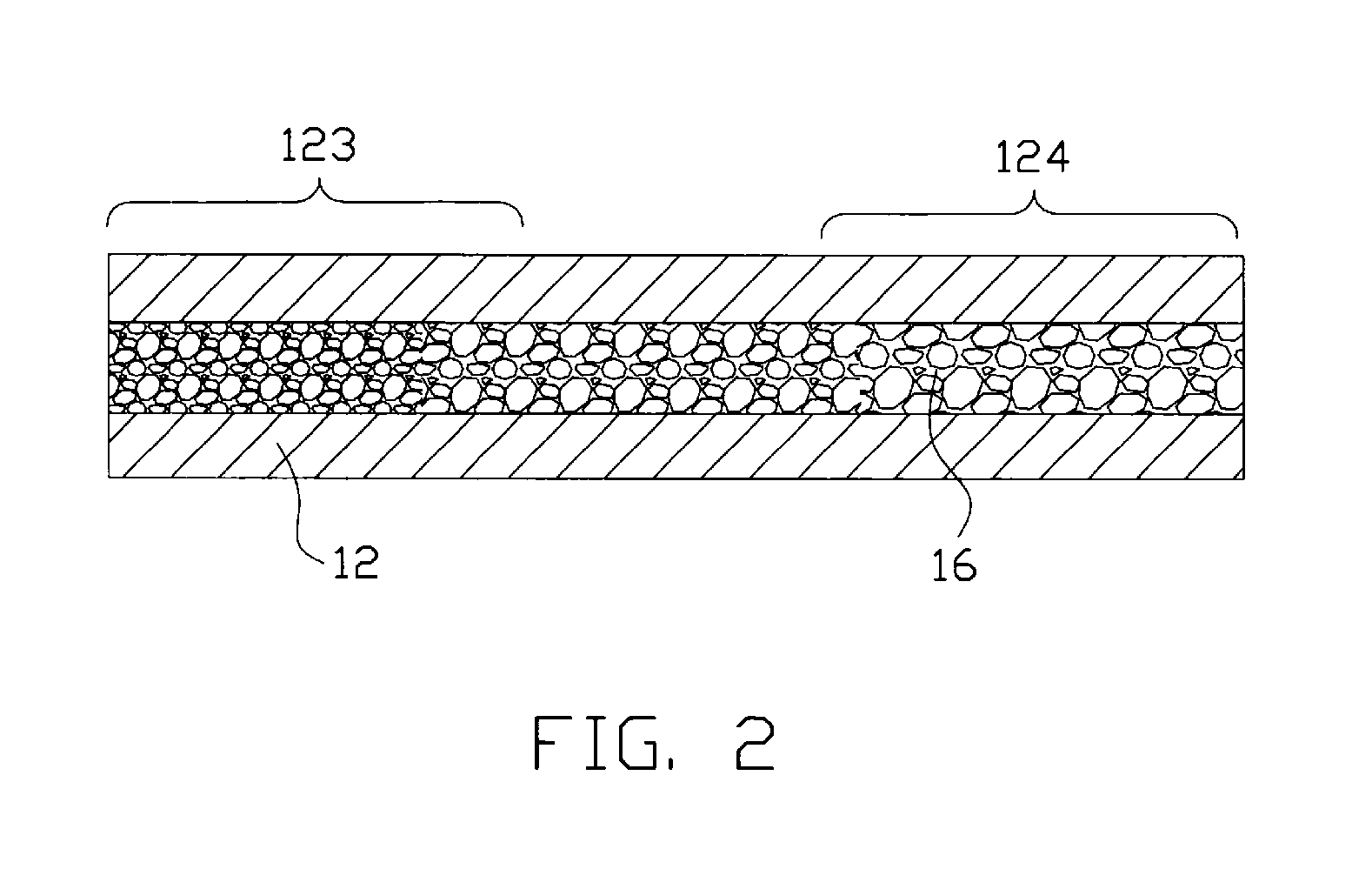

Flat type heat pipe

InactiveUS20070006993A1Lower resistanceIncrease capillary forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal foam

A flat type heat pipe (10) is disclosed which includes a metal casing (12) and a wick structure (16) arranged inside the metal casing. The metal casing has an evaporating section (123) and a condensing section (124). The wick structure extends from the evaporating section towards the condensing section of the metal casing and has a first section in conformity with the condensing section of the metal casing and a second section in conformity with the evaporating section of the metal casing. The first section has a pore size larger than that of the second section of the wick structure. The wick structure includes a metal foam.

Owner:HON HAI PRECISION IND CO LTD

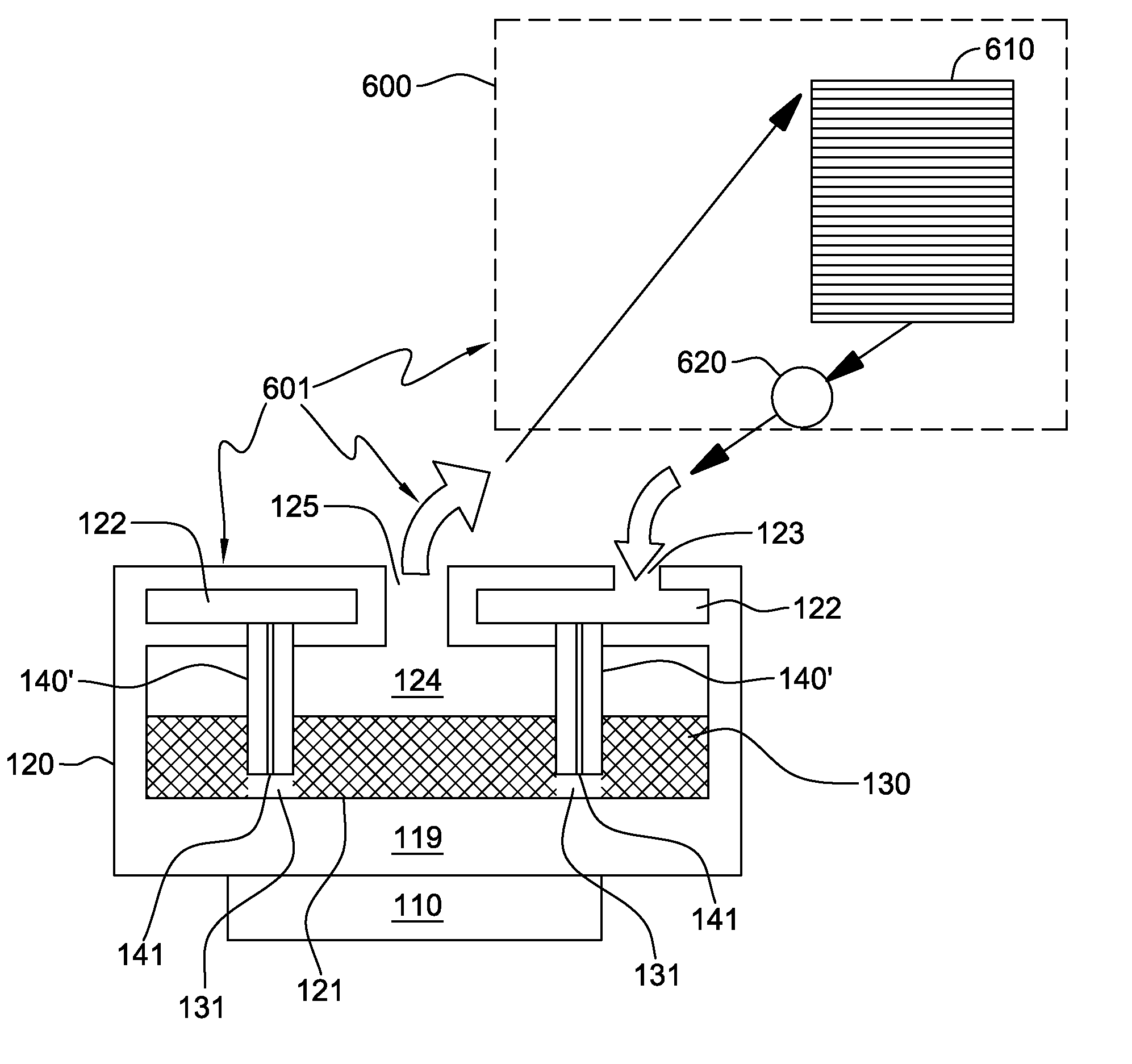

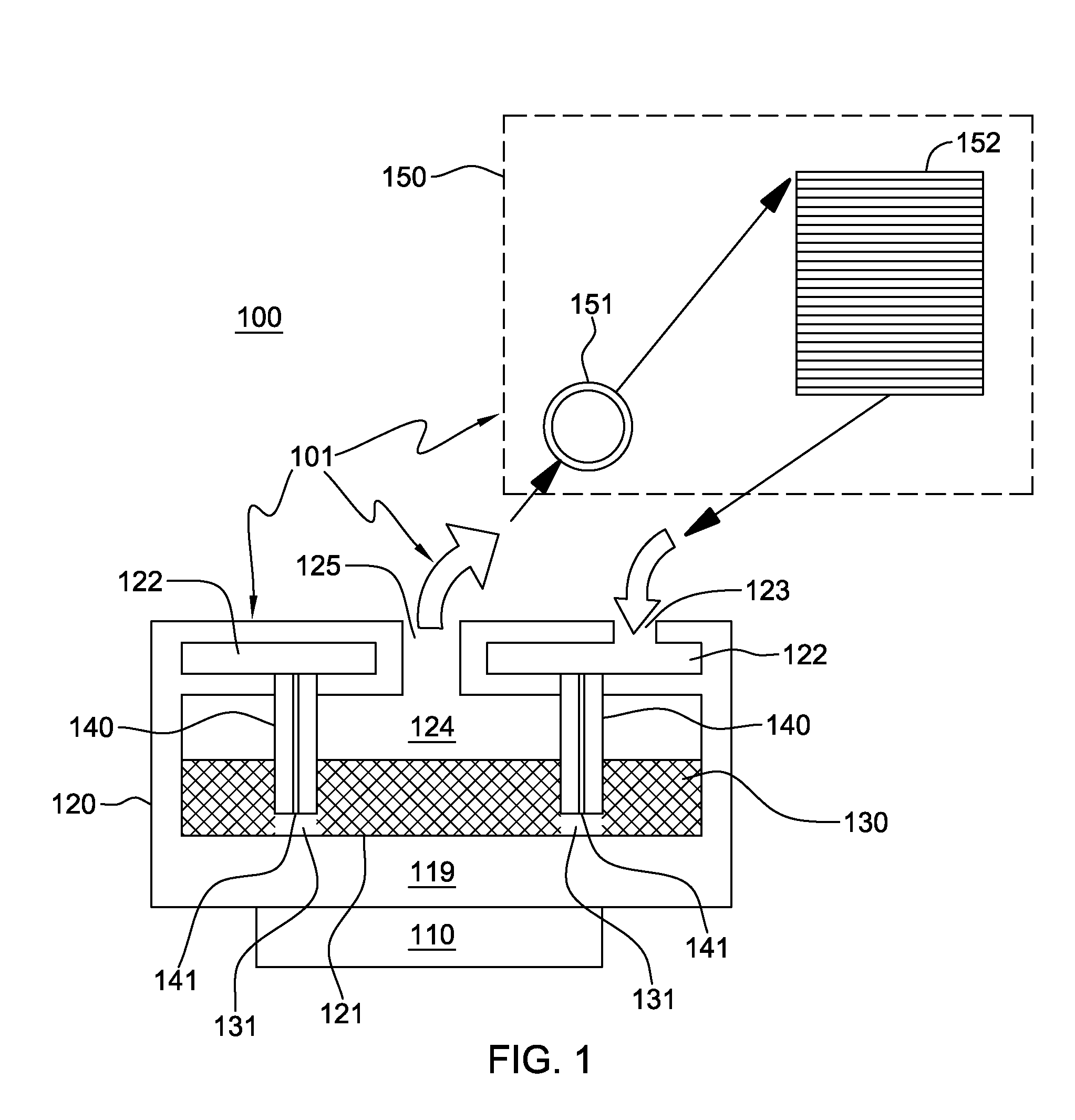

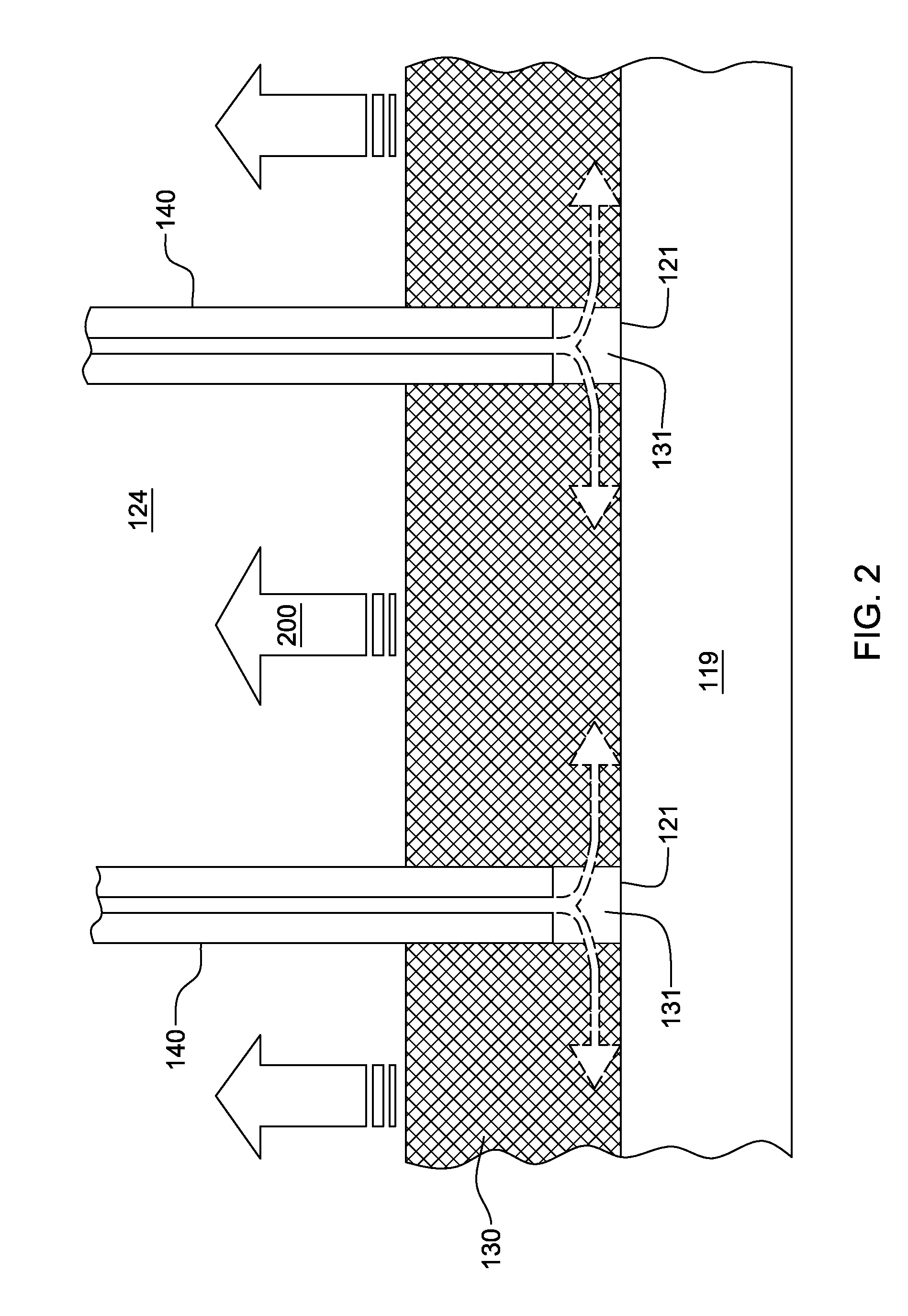

Cooling apparatus with thermally conductive porous material and jet impingement nozzle(s) extending therein

ActiveUS20100328888A1Overcomes shortcomingEnhanced advantageDigital data processing detailsSemiconductor/solid-state device detailsThermal contactMetal foam

A cooling apparatus and method of fabrication are provided for facilitating cooling of an electronic device. The cooling apparatus includes a thermally conductive porous material and a liquid coolant supply. The thermally conductive porous material (such as metal foam material) is coupled to a surface of the electronic device to be cooled, or a structure coupled to the electronic device. The liquid coolant supply includes a jet impingement structure, which includes one or more jet nozzles for directing liquid coolant onto the surface to be cooled. The jet nozzle(s) extends into the thermally conductive porous material, and facilitates delivery of liquid coolant onto the surface to be cooled. The thermally conductive porous material is in thermal contact with the surface to be cooled and facilitates cooling of the electronic device by boiling of the liquid coolant passing through the porous material.

Owner:LENOVO GLOBAL TECH INT LTD

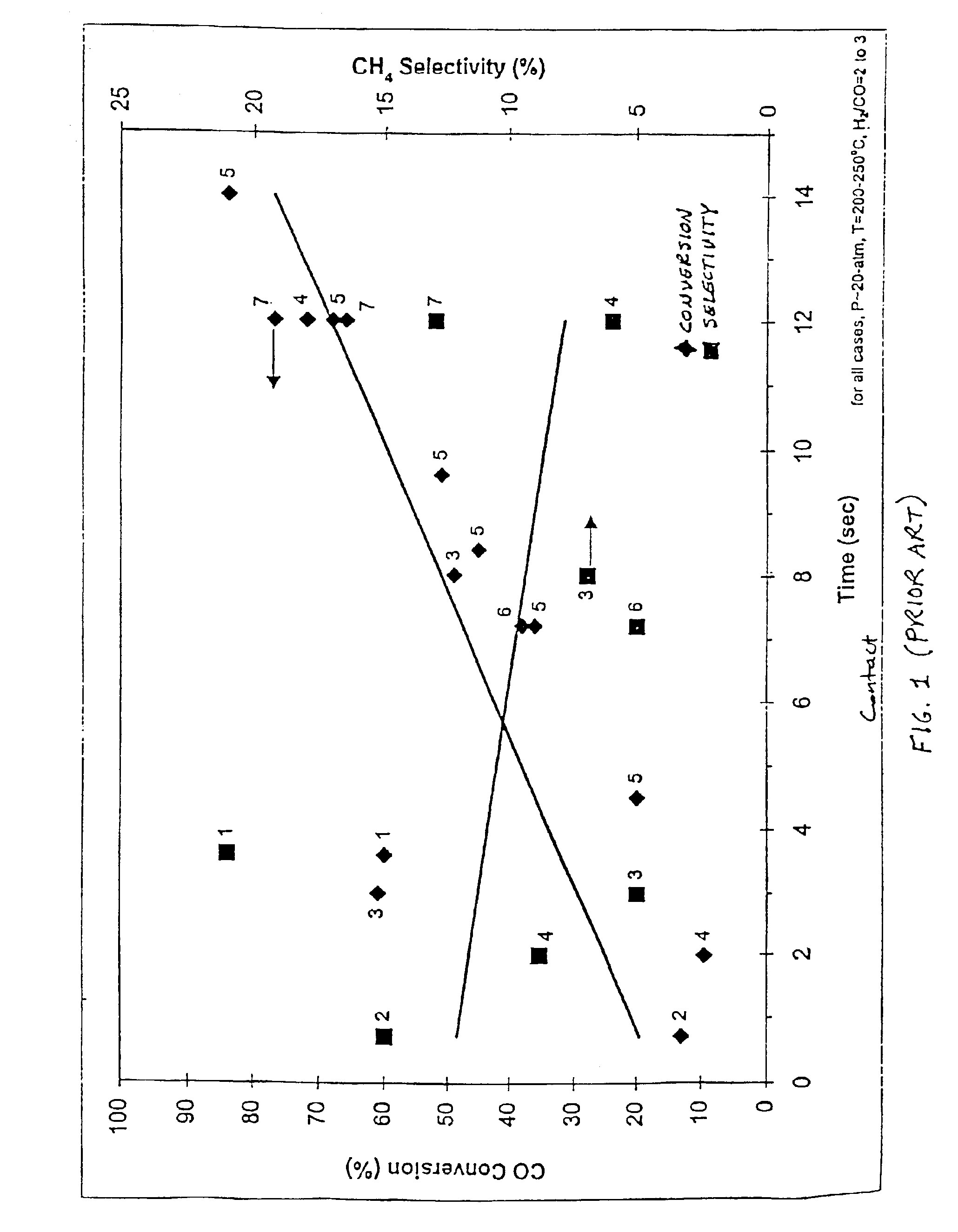

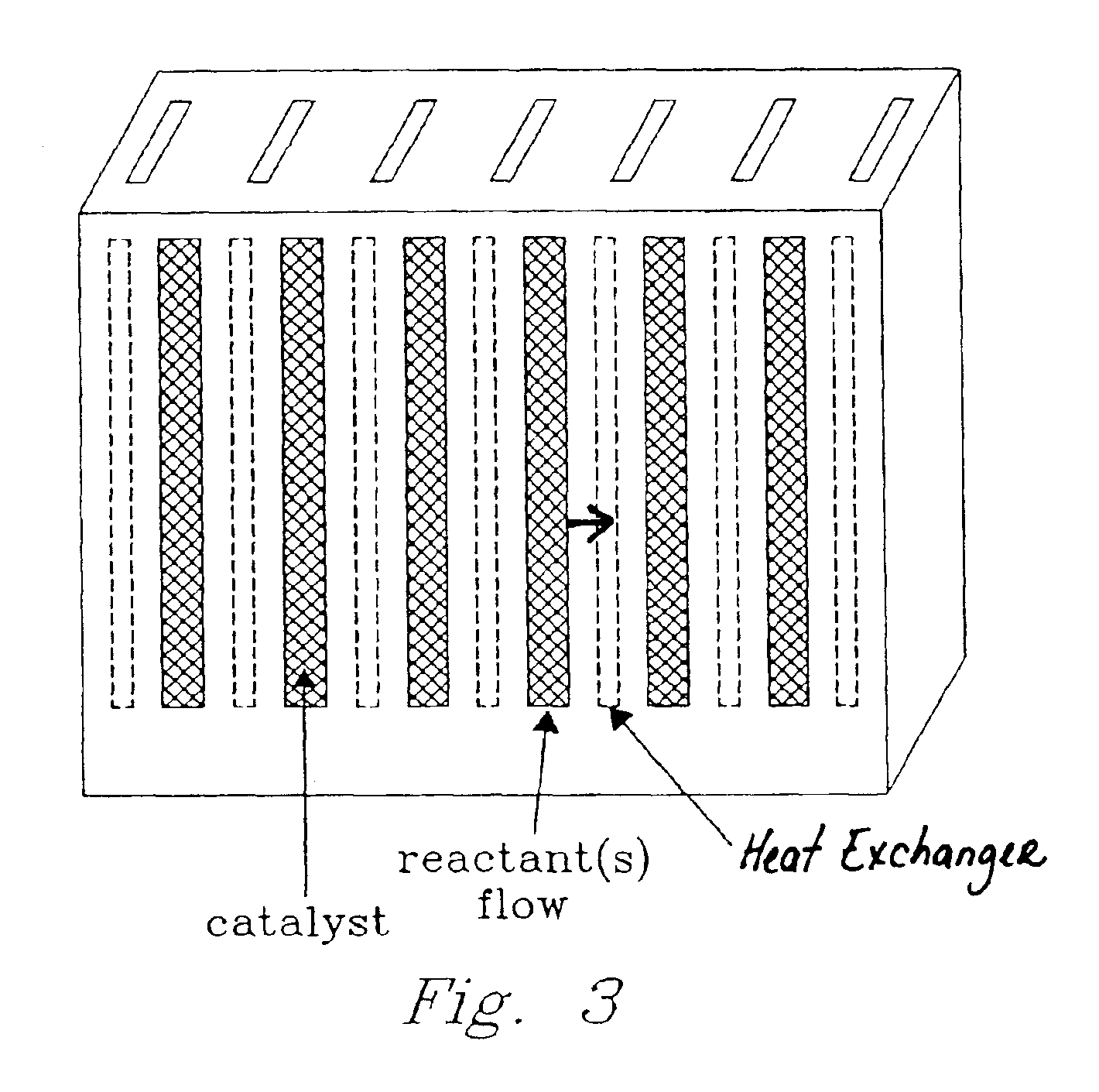

Catalyst structure and method of fischer-tropsch synthesis

InactiveUS6982287B2Speed up the conversion processHigh methane selectivityCombination devicesExhaust apparatusContact timeMetal foam

The present invention includes Fischer-Tropsch catalysts, reactions using Fischer-Tropsch catalysts, methods of making Fischer-Tropsch catalysts, processes of hydrogenating carbon monoxide, and fuels made using these processes. The invention provides the ability to hydrogenate carbon monoxide with low contact times, good conversion rates and low methane selectivities. In a preferred method, the catalyst is made using a metal foam support.

Owner:BATTELLE MEMORIAL INST

Process for producing metal foam and metal body produced using this process

The invention relates to a process for producing metal foam and to a metal body produced using this process. The object is achieved by a process for producing metal foam by adding a blowing agent to a metal melt, wherein the metal melt is introduced into the die cavity of a metal die-casting machine and is foamed using a blowing agent which releases gases and is solid at room temperature.

Owner:BUHLER DRUCKGASS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com