Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

857 results about "Sintered ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

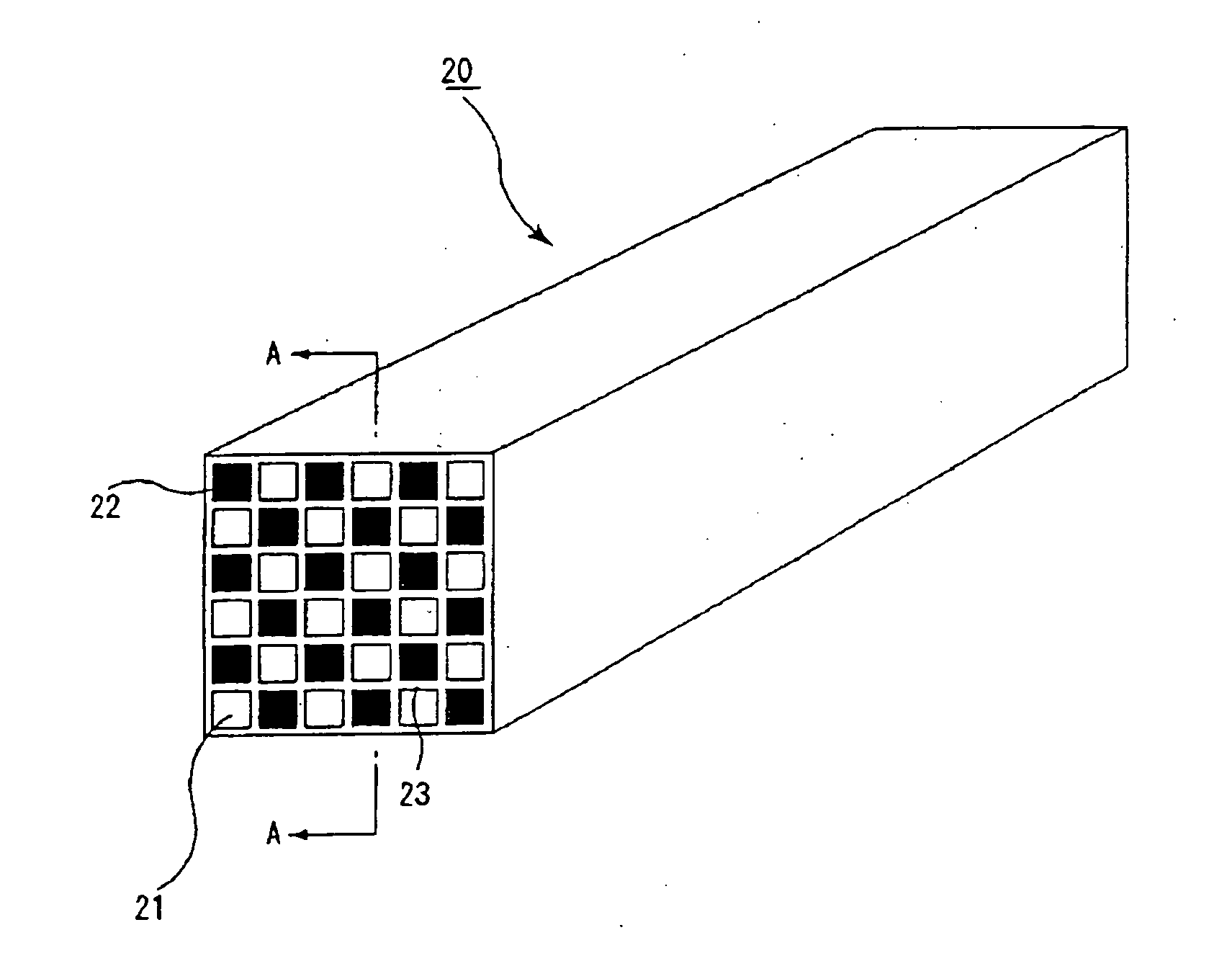

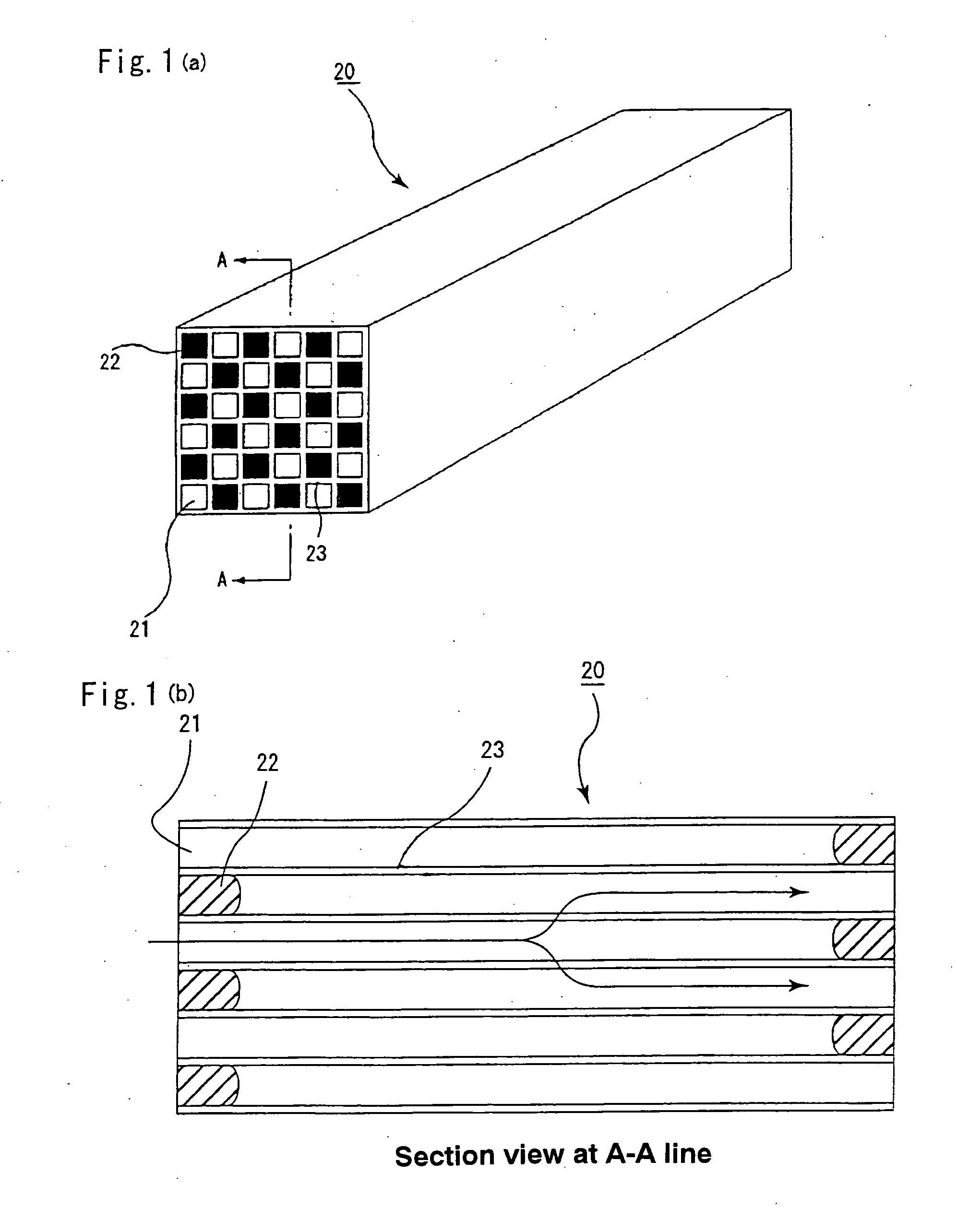

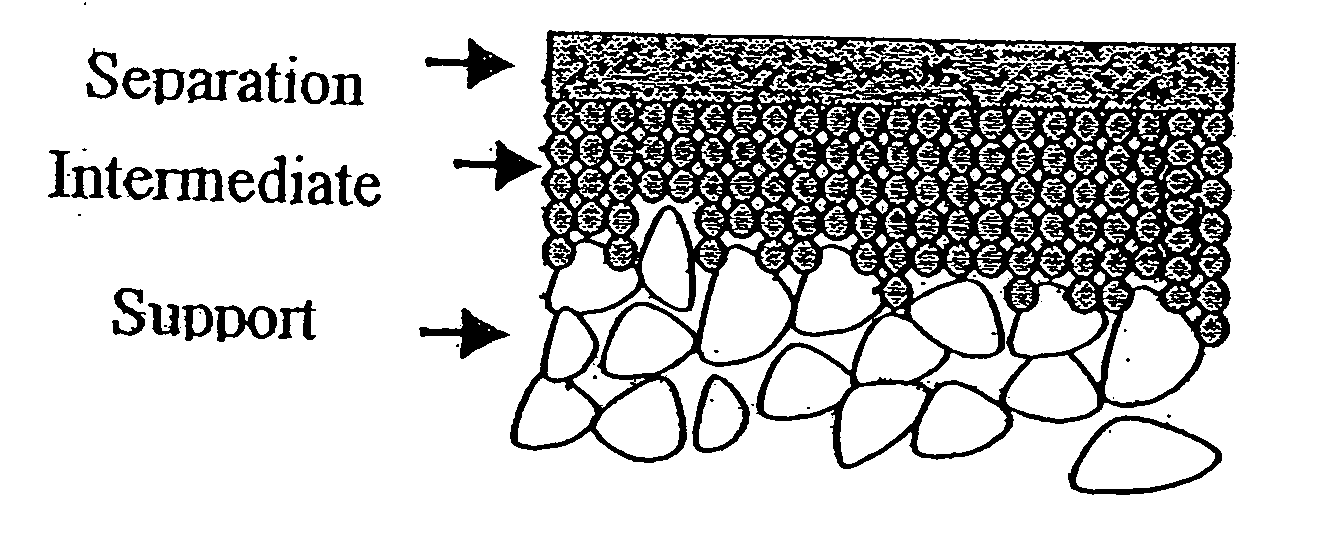

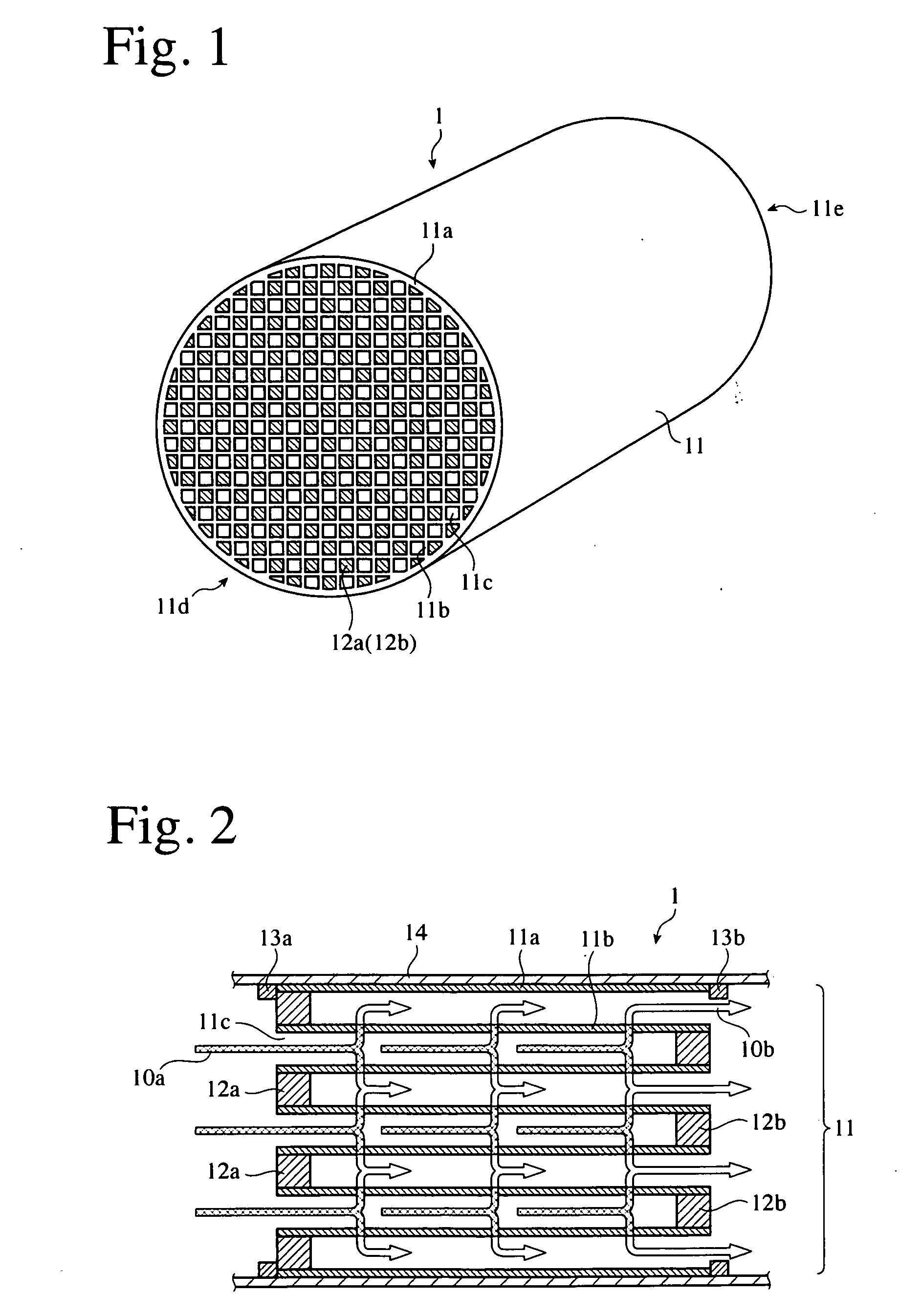

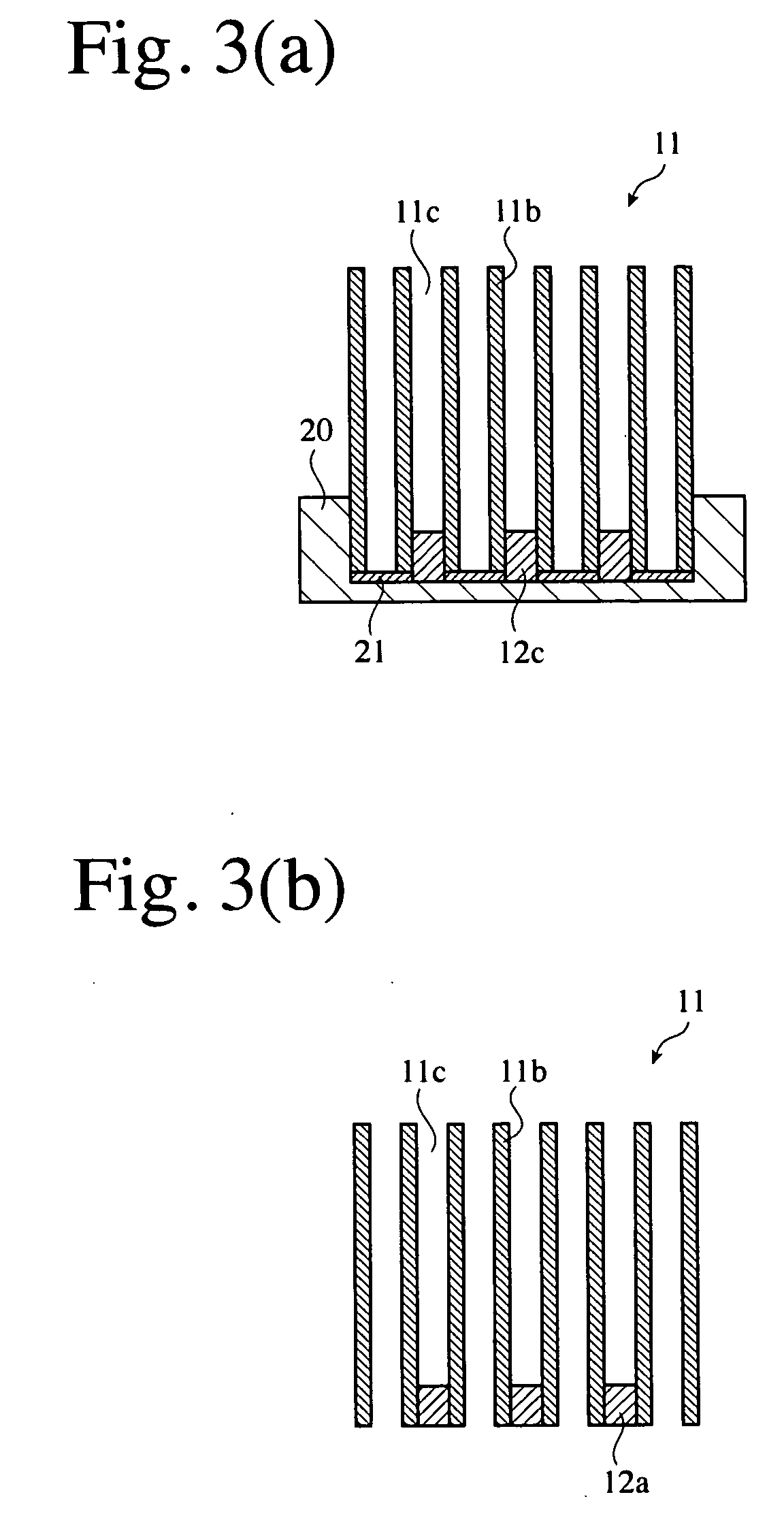

Sintered ceramic compact and ceramic filter

InactiveUS20060051556A1Shock mitigationAvoid micro cracksDispersed particle filtrationExhaust apparatusCeramic sinteringMetallurgy

The present invention provides for a ceramic sintered body and a ceramic filter having a long-term stability which can prevent cracks from occurring due to the breakage of ceramic particles when thermal stress is applied in regeneration process and the like, and can prevent catalyst carried from deteriorating when regeneration treatment is conducted repeatedly. The invention is a ceramic sintered body comprising ceramic coarse particles and porous bonding layers existing between the ceramic coarse particles to connect the particles and comprising ceramic fine particles having an average particle size smaller than that of the ceramic coarse particles and / or the aggregates thereof, and a ceramic filter prepared by using the ceramic sintered body.

Owner:IBIDEN CO LTD

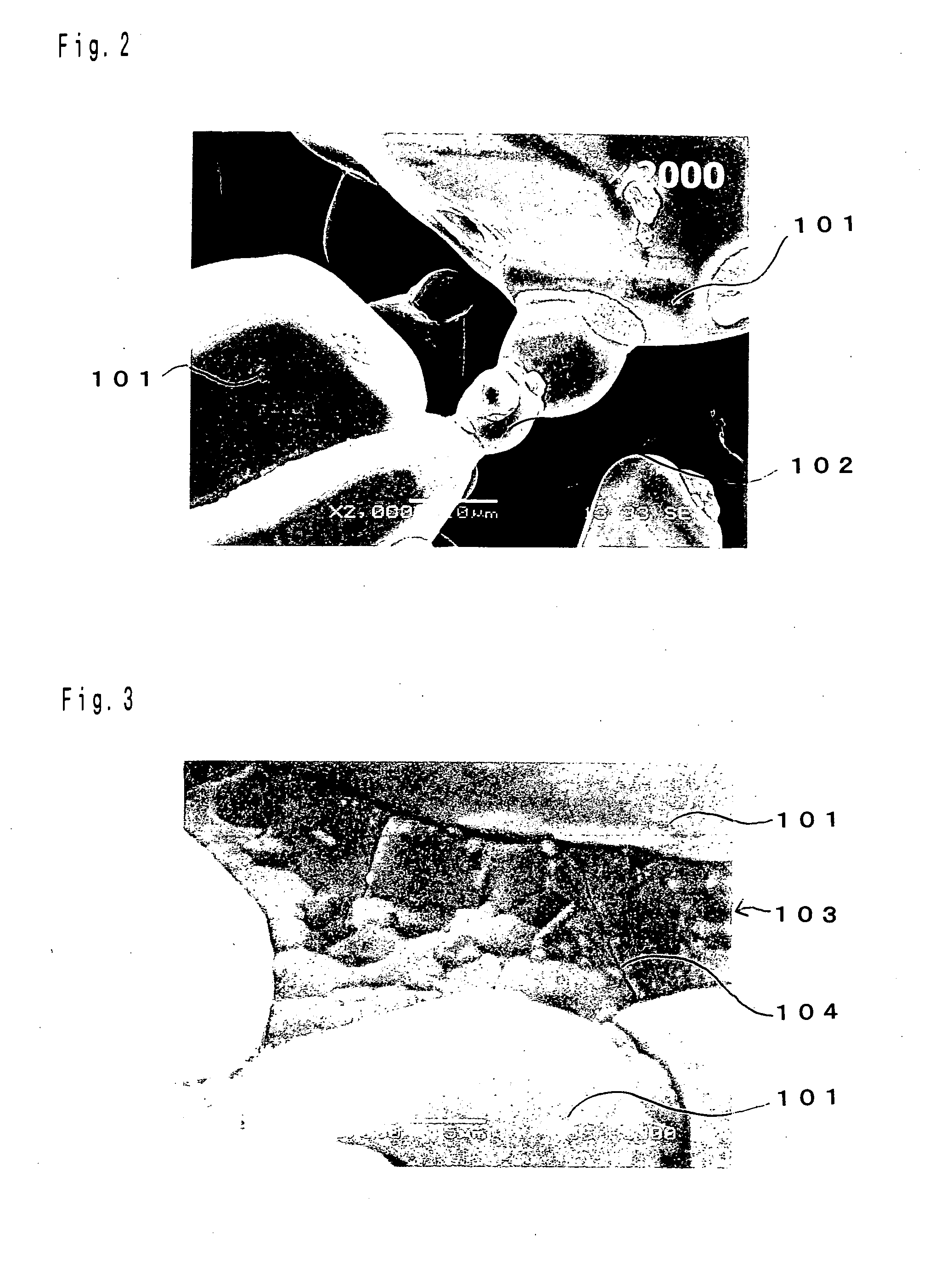

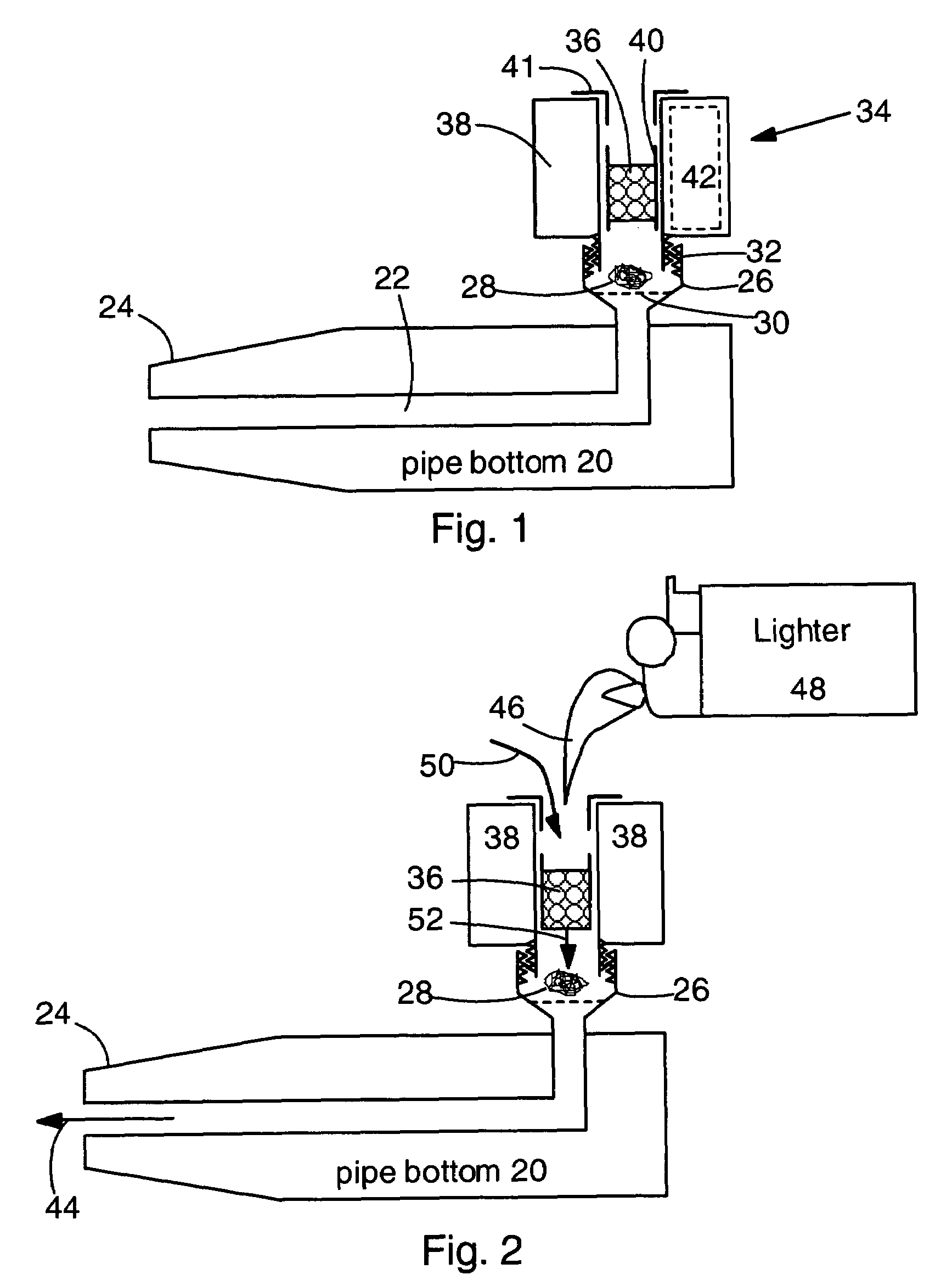

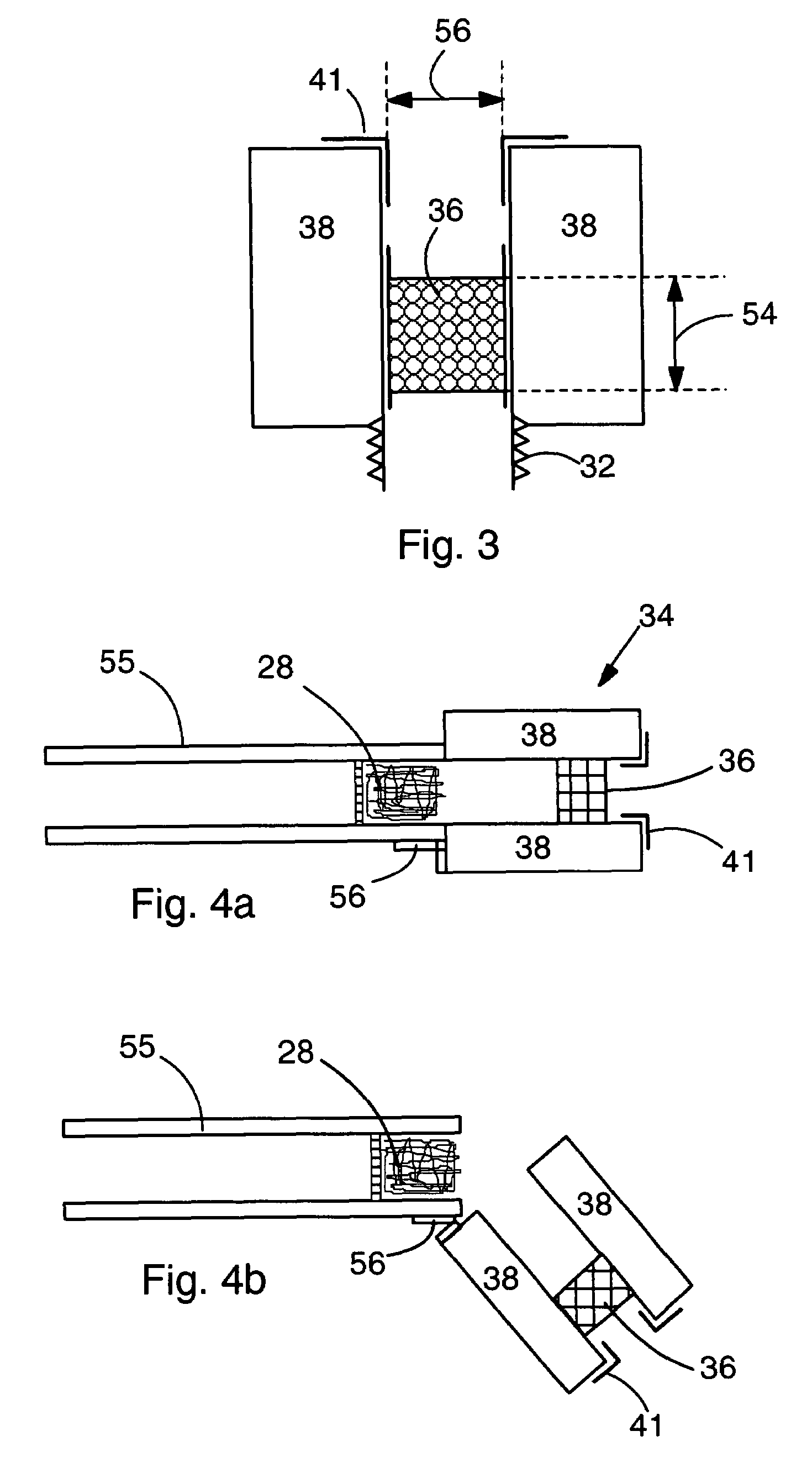

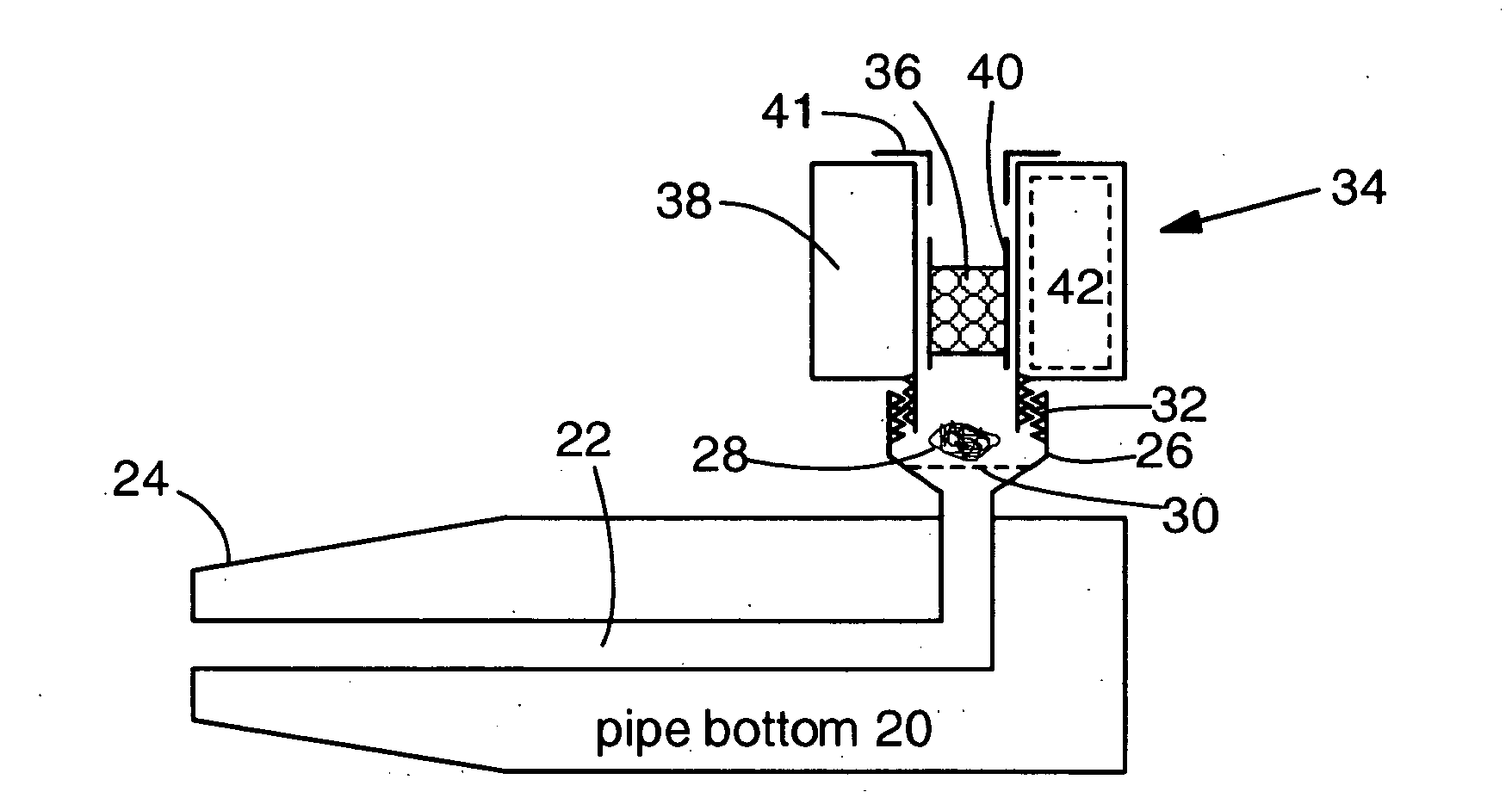

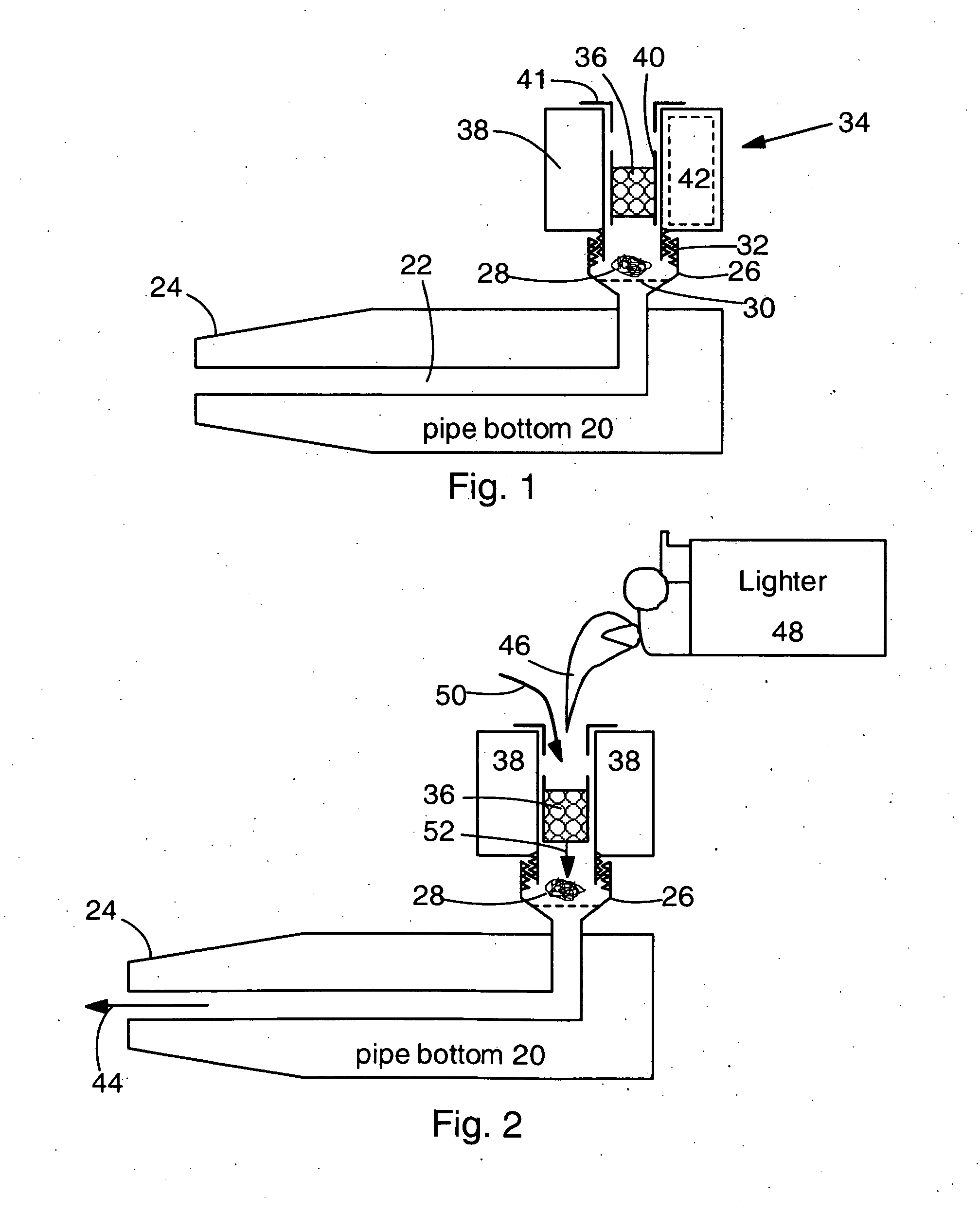

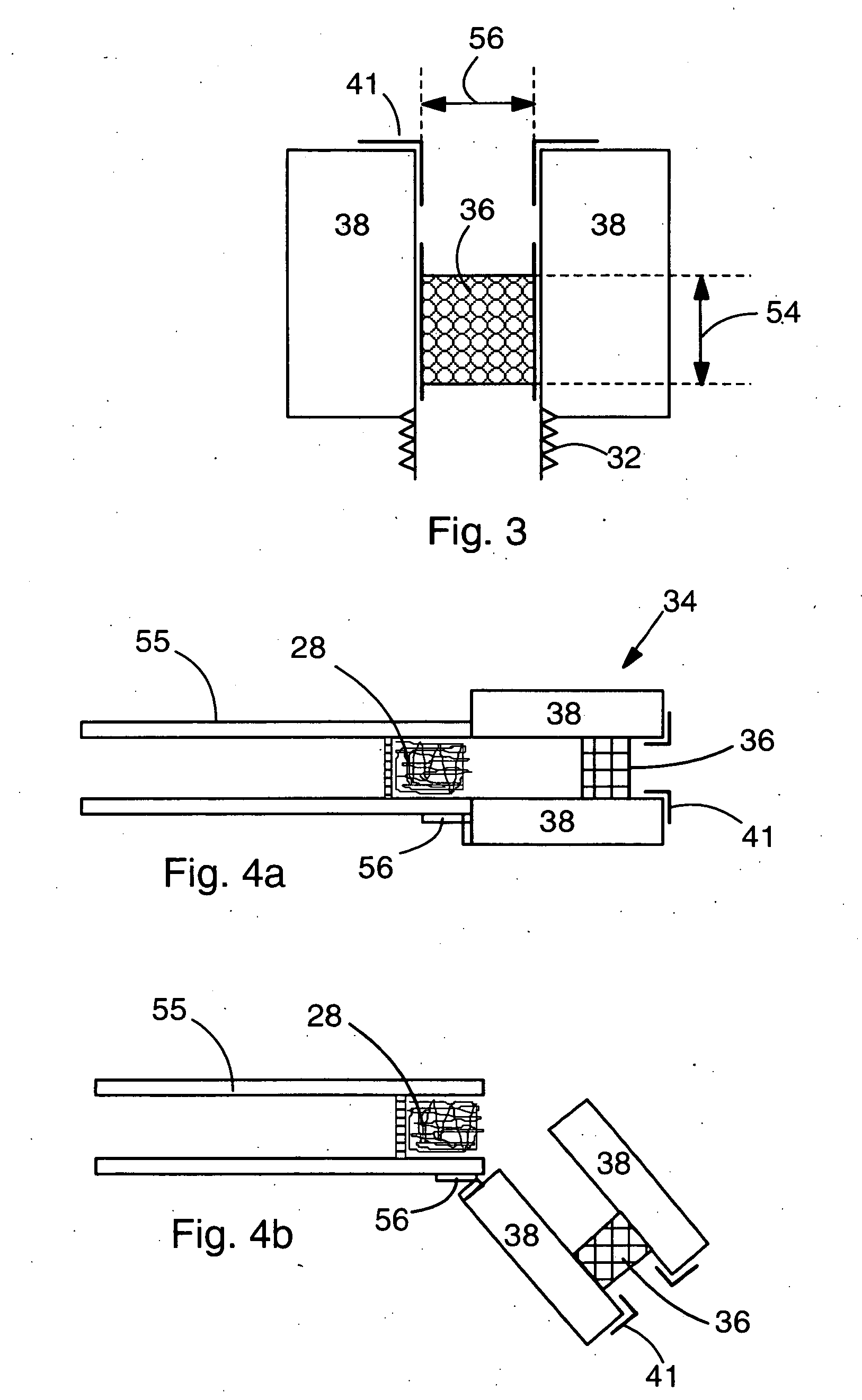

Vaporization pipe with flame filter

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material, but generally is not hot enough to burn the smoking material. The temperature of the air stream can be controlled by adjusting the amount of flame supplied to the flame filter 36.

Owner:VAPORGENIE

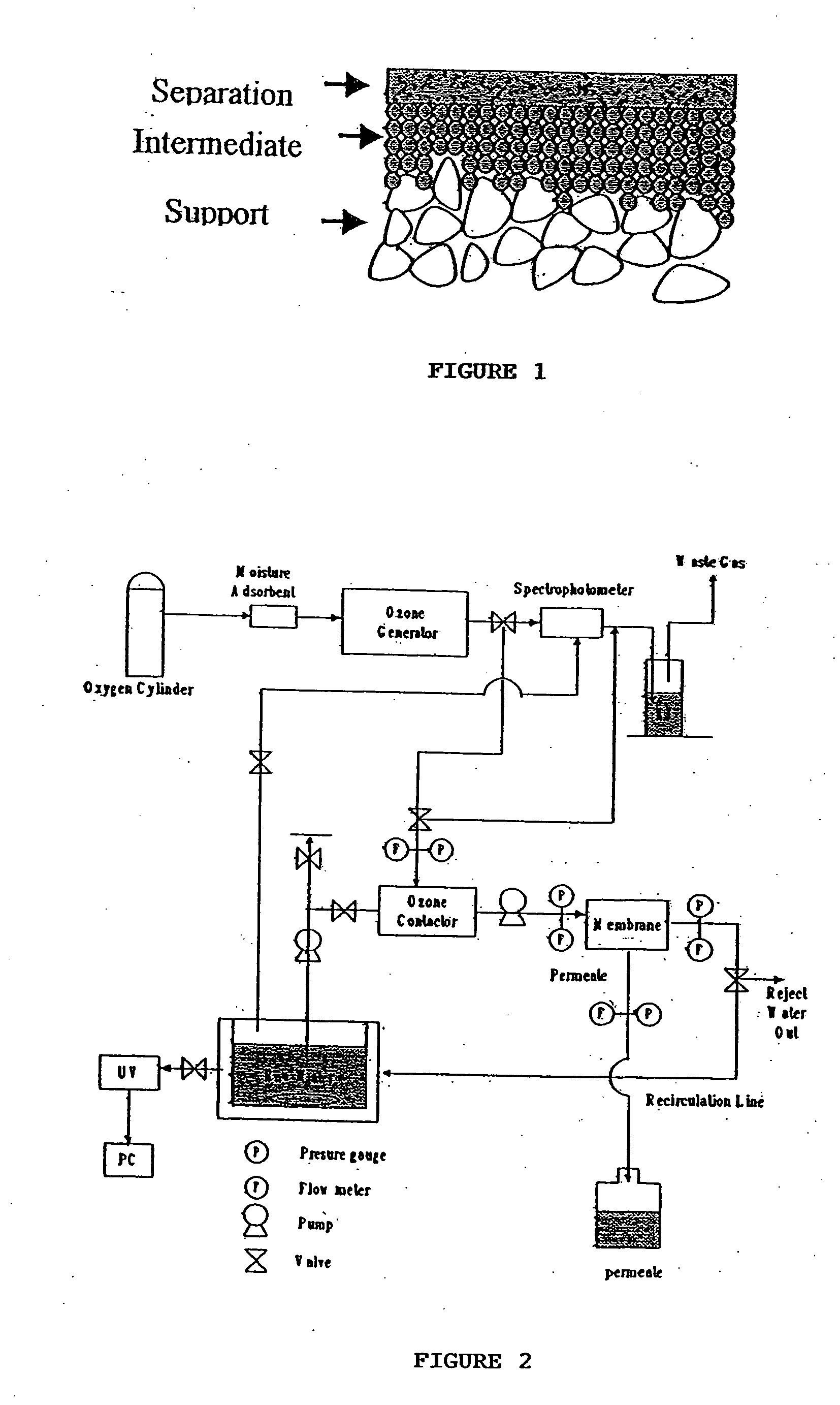

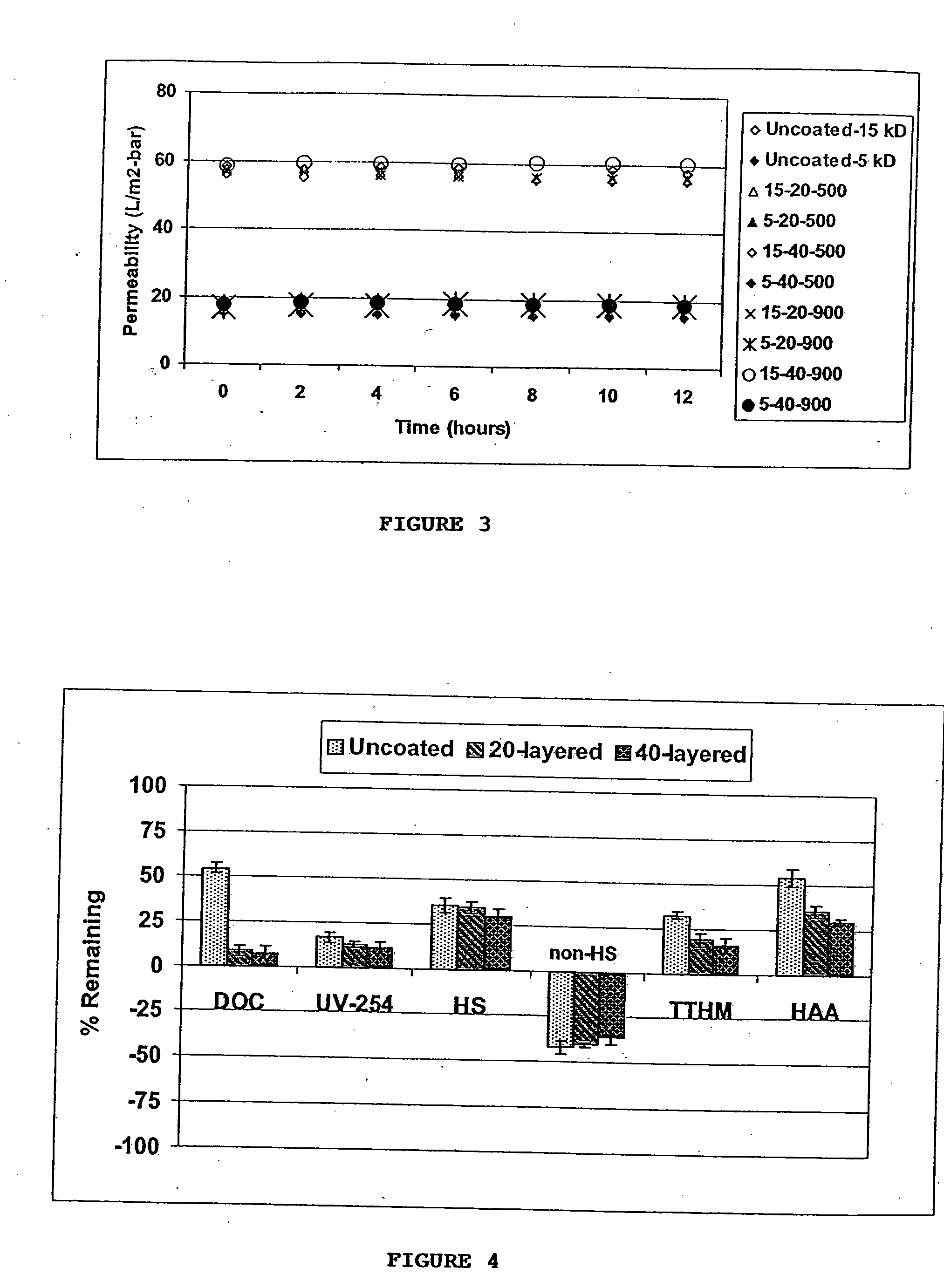

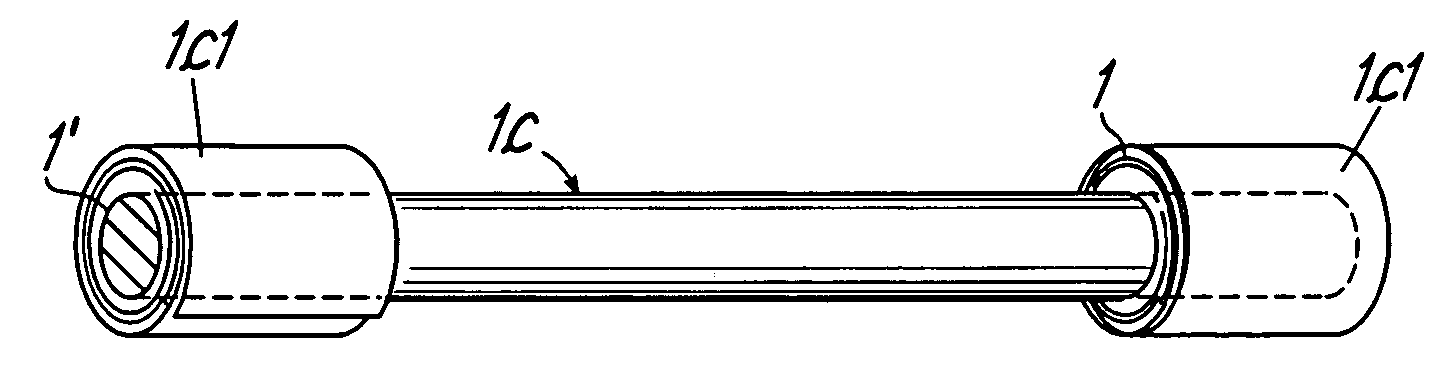

Ceramic membrane water filtration

A process for combined ozone degradation and filtration using a multi-layered, nanocrystalline, sintered ceramic, metal oxide catalyst and ceramic membrane filter is described. The process reduces fouling of the membrane and degrades ozone remaining in the water from ozonation of water to kill microorganisms.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

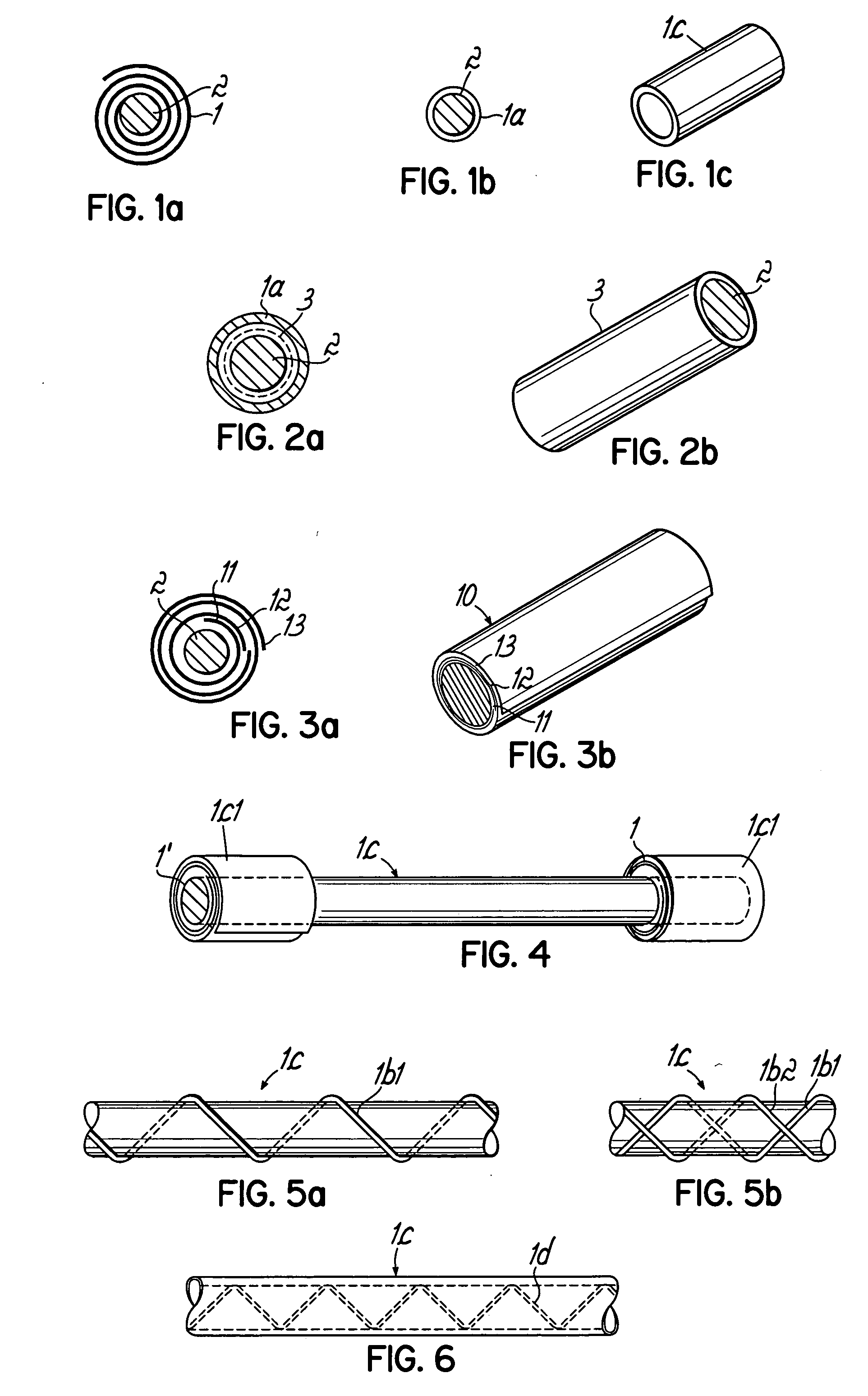

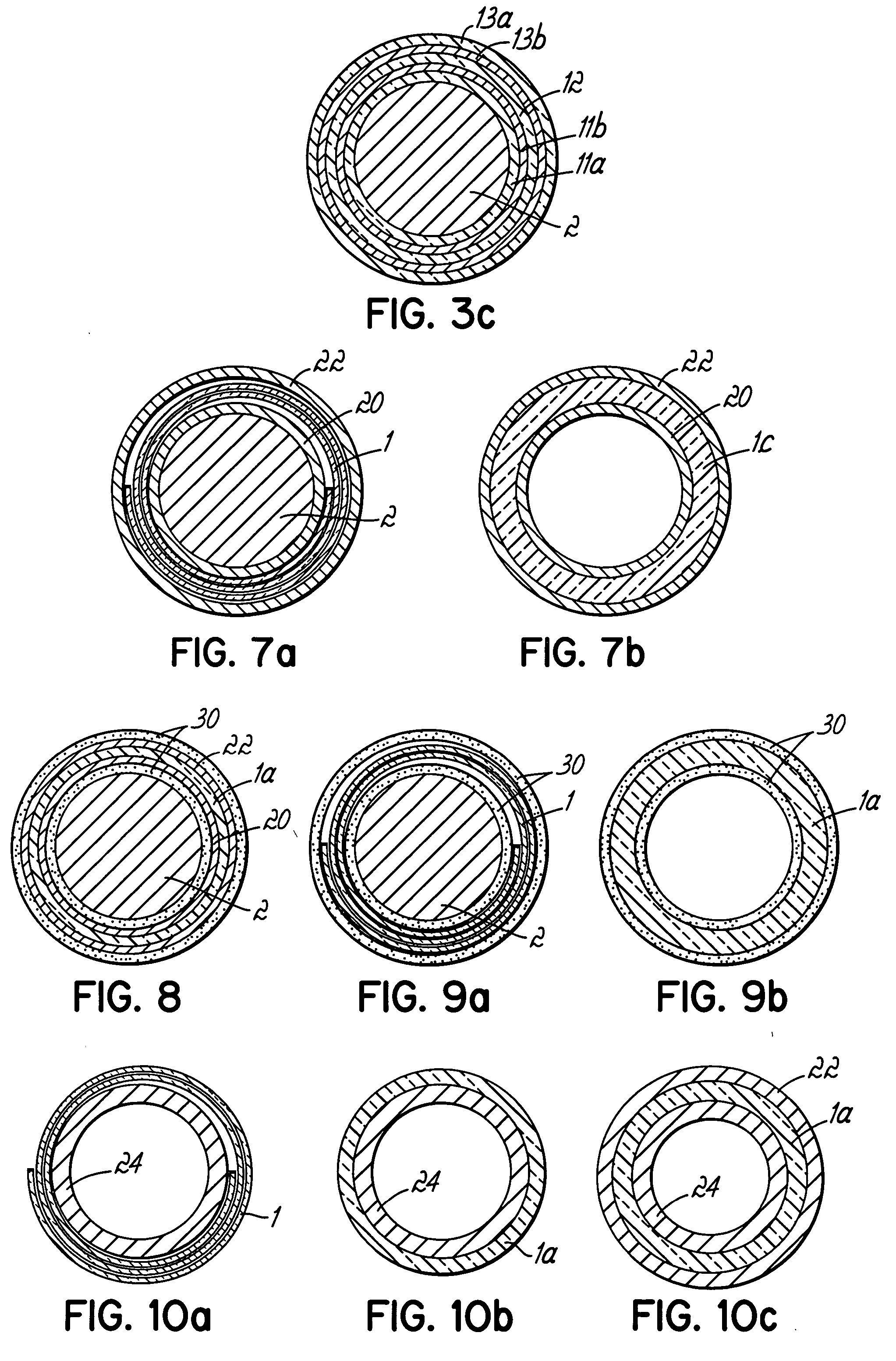

Method of making laminate thin-wall ceramic tubes and said tubes with electrodes, particularly for solid oxide fuel cells

InactiveUS20050000621A1Additional green thicknessHigh strengthPaper/cardboard wound articlesLayered productsFuel cellsMaterials science

A method of fabricating a ceramic tube with electrodes thereon suitable for use as a tubular reaction chamber for a fuel cell. In one embodiment, the method includes wrapping a first electrode material around a mandrel, then wrapping a green ceramic material over the first electrode material, and then wrapping a second electrode material over the green ceramic material. The wrapped layers are laminated together, and then removed from the mandrel and sintered, in either sequence, to produce the laminated ceramic tube having an inner first electrode and an outer second electrode. Alternatively, a first electrode tube is provided in place of the mandrel and around which the green ceramic material is wrapped. The outer second electrode may be produced by wrapping a second electrode material around the green ceramic material, before or after laminating, or by printing the electrode material onto the sintered ceramic tube. The present invention further provides a method of making a ceramic tube in which a sacrificial organic material is first wrapped around the mandrel to a desired thickness prior to wrapping the green ceramic material to increase the green material thickness. During sintering, the organic material is burned away leaving only a laminated ceramic tube, optionally with electrodes thereon.

Owner:PRESIDIO COMPONENTS

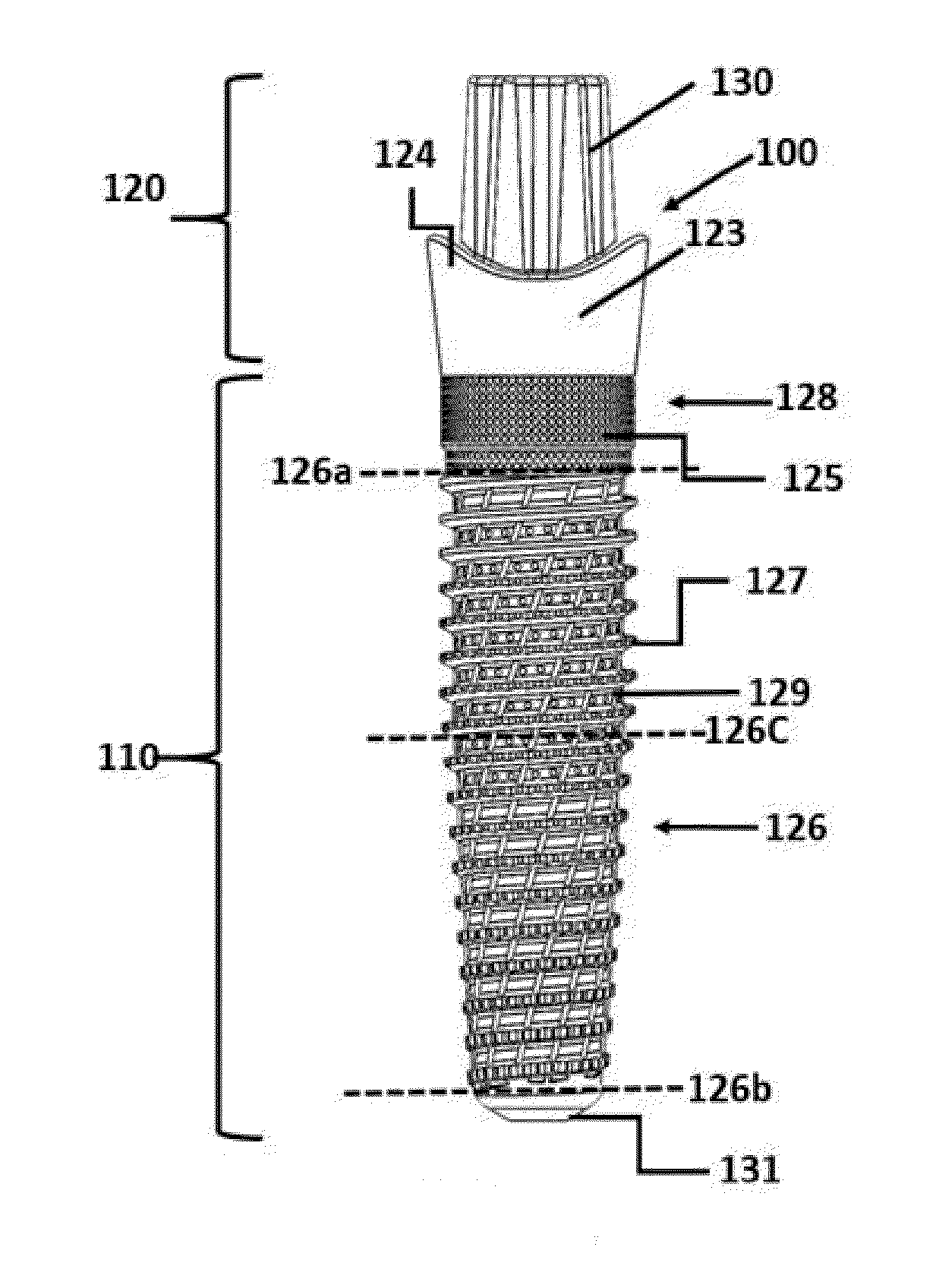

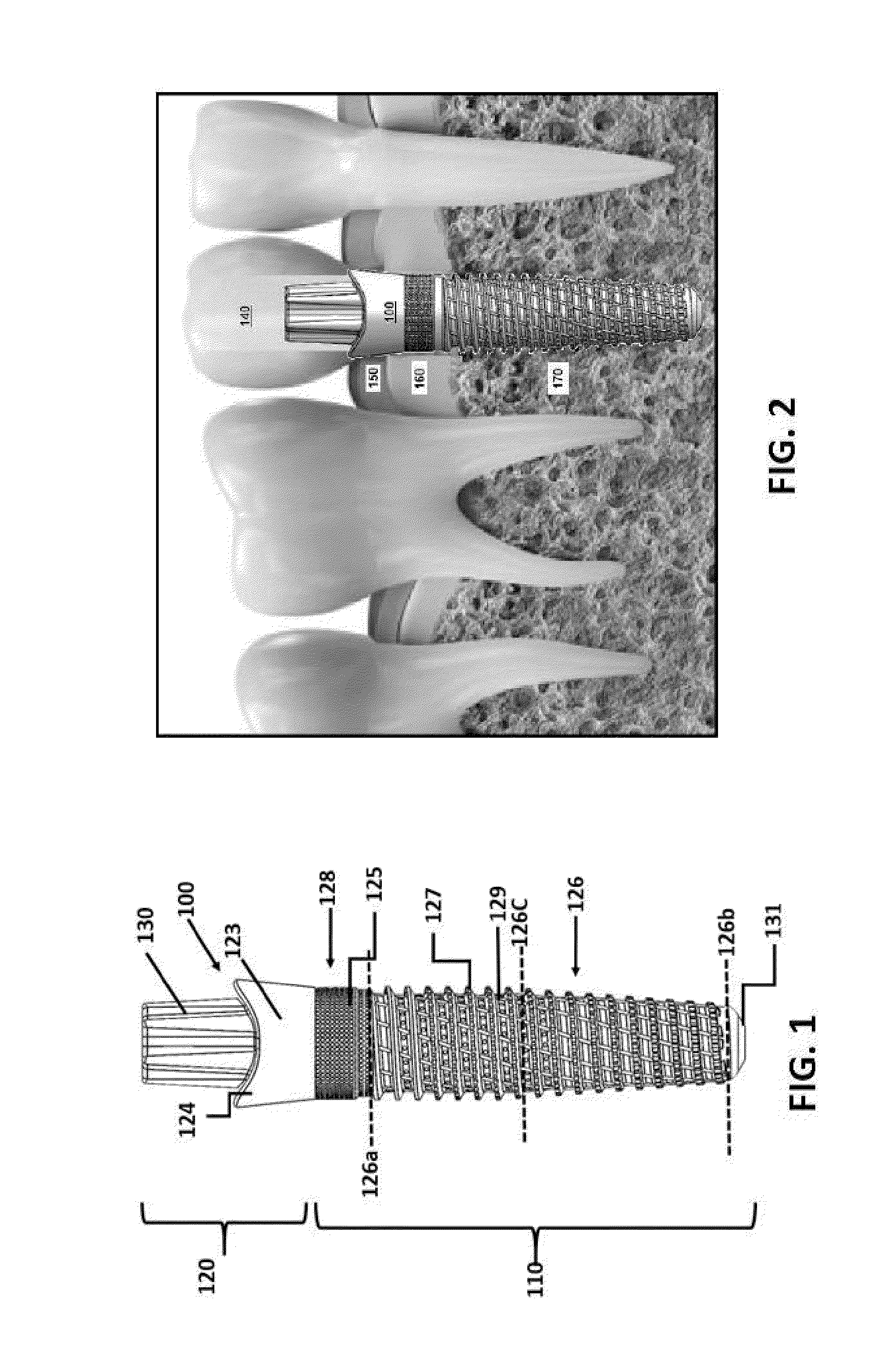

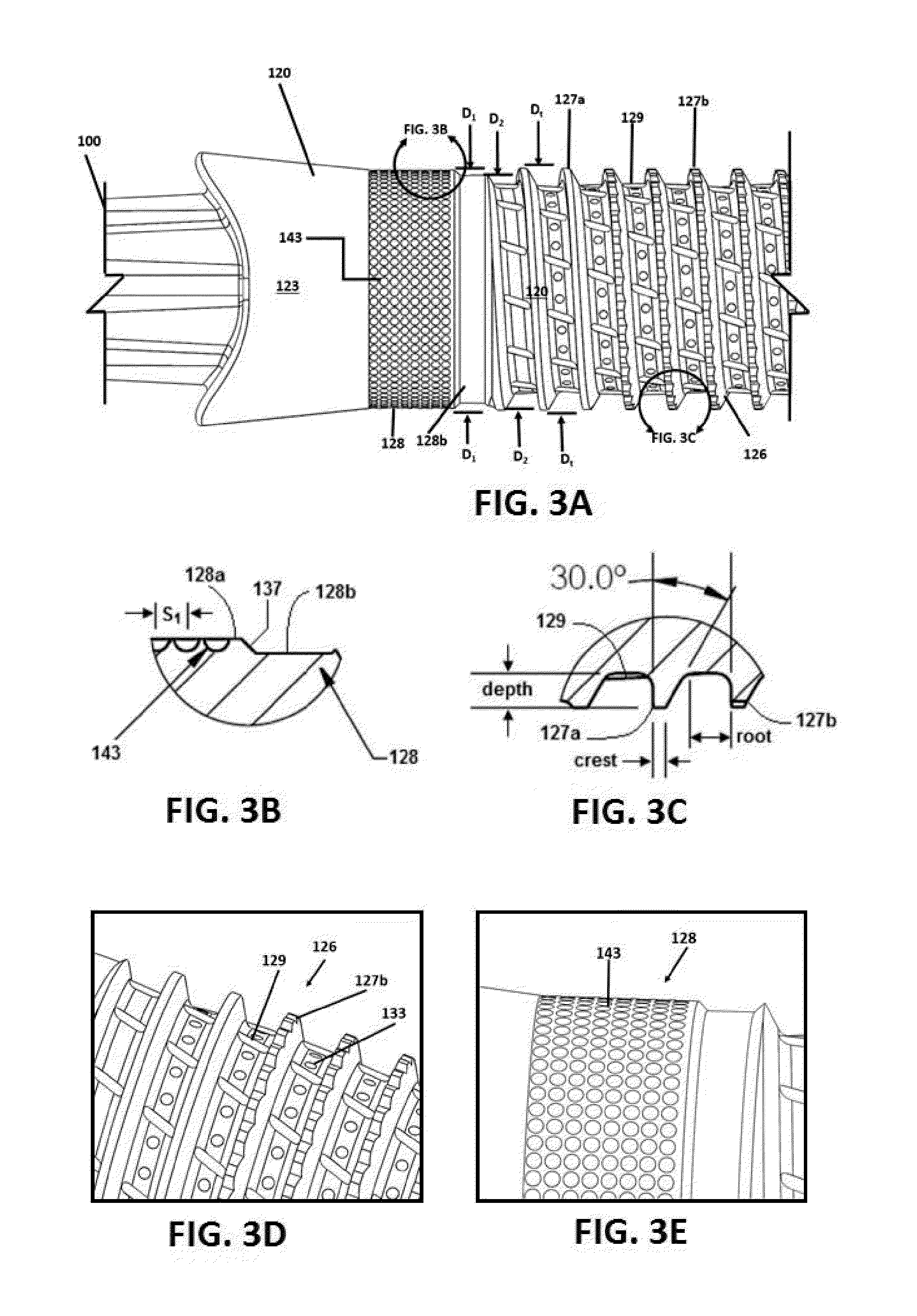

Osseointegrative surgical implant

InactiveUS20160015483A1Improve primary stabilityPromote healingSuture equipmentsDental implantsCeramic compositeSurgical implant

Embodiments of the present invention provide an osseointegrative implant and related tools, components and fabrication techniques for surgical bone fixation and dental restoration purposes. In one embodiment an all-ceramic single-stage threaded or press-fit implant is provided having finely detailed surface features formed by ceramic injection molding and / or spark plasma sintering of a powder compact or green body comprising finely powdered zirconia. In another embodiment a two-stage threaded implant is provided having an exterior shell or body formed substantially entirely of ceramic and / or CNT-reinforced ceramic composite material. The implant may include one or more frictionally anisotropic bone-engaging surfaces. In another embodiment a densely sintered ceramic implant is provided wherein, prior to sintering, the porous debound green body is exposed to ions and / or particles of silver, gold, titanium, zirconia, YSZ, α-tricalcium phosphate, hydroxyapatite, carbon, carbon nanotubes, and / or other particles which remain lodged in the implant surface after sintering. Optionally, at least the supragingival portions of an all-ceramic implant are configured to have high translucence in the visible light range. Optionally, at least the bone-engaging portions of an all-ceramic implant are coated with a fused layer of titanium oxide.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

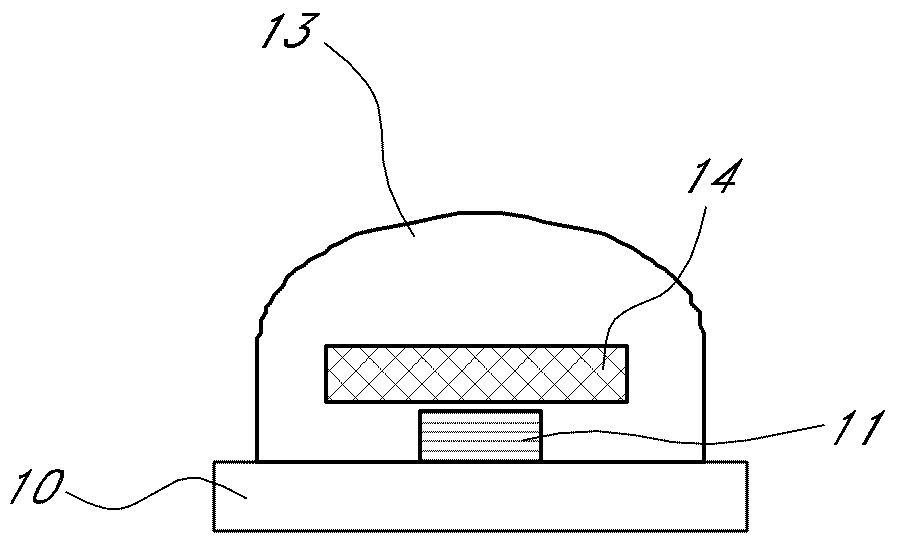

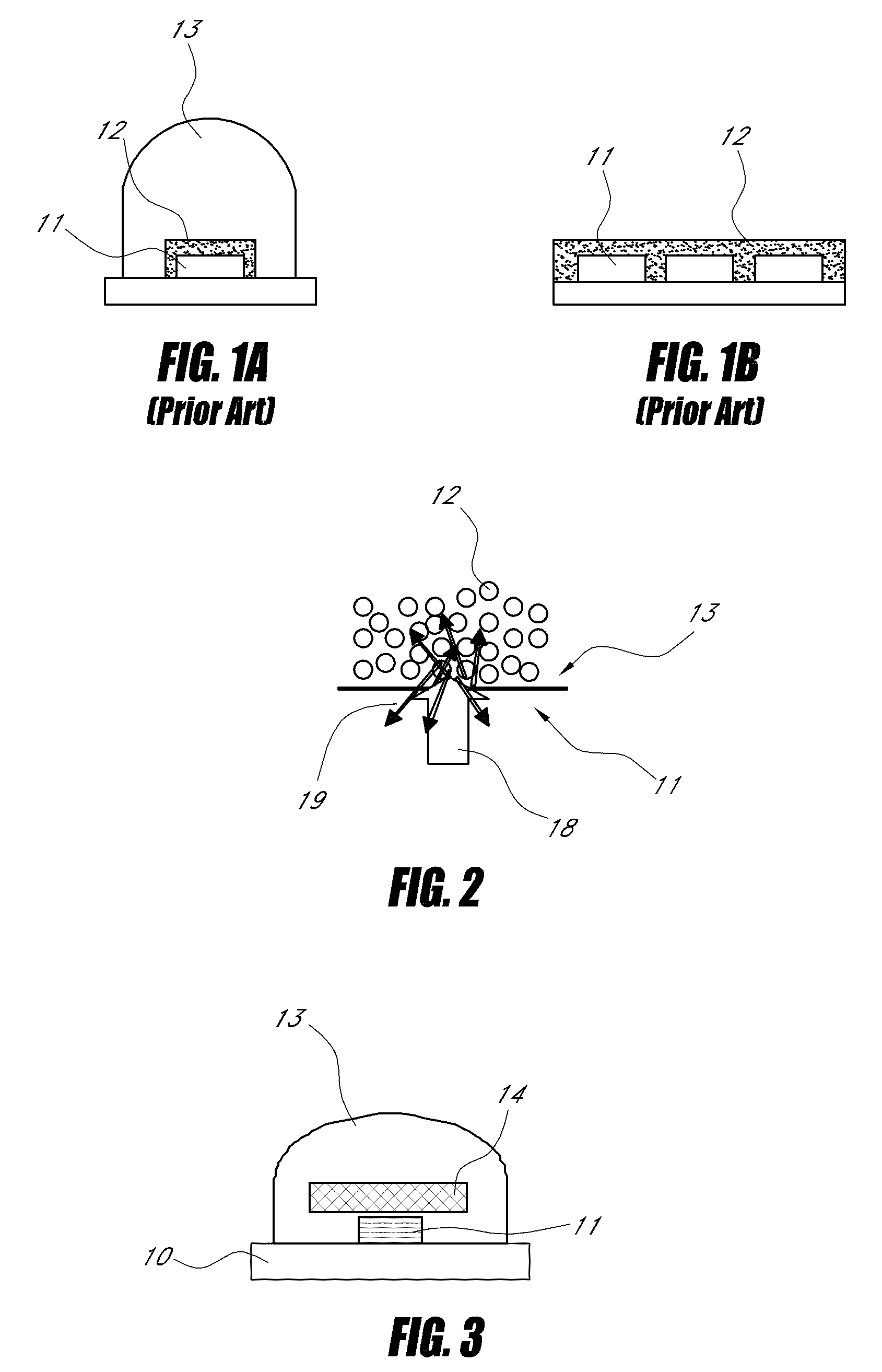

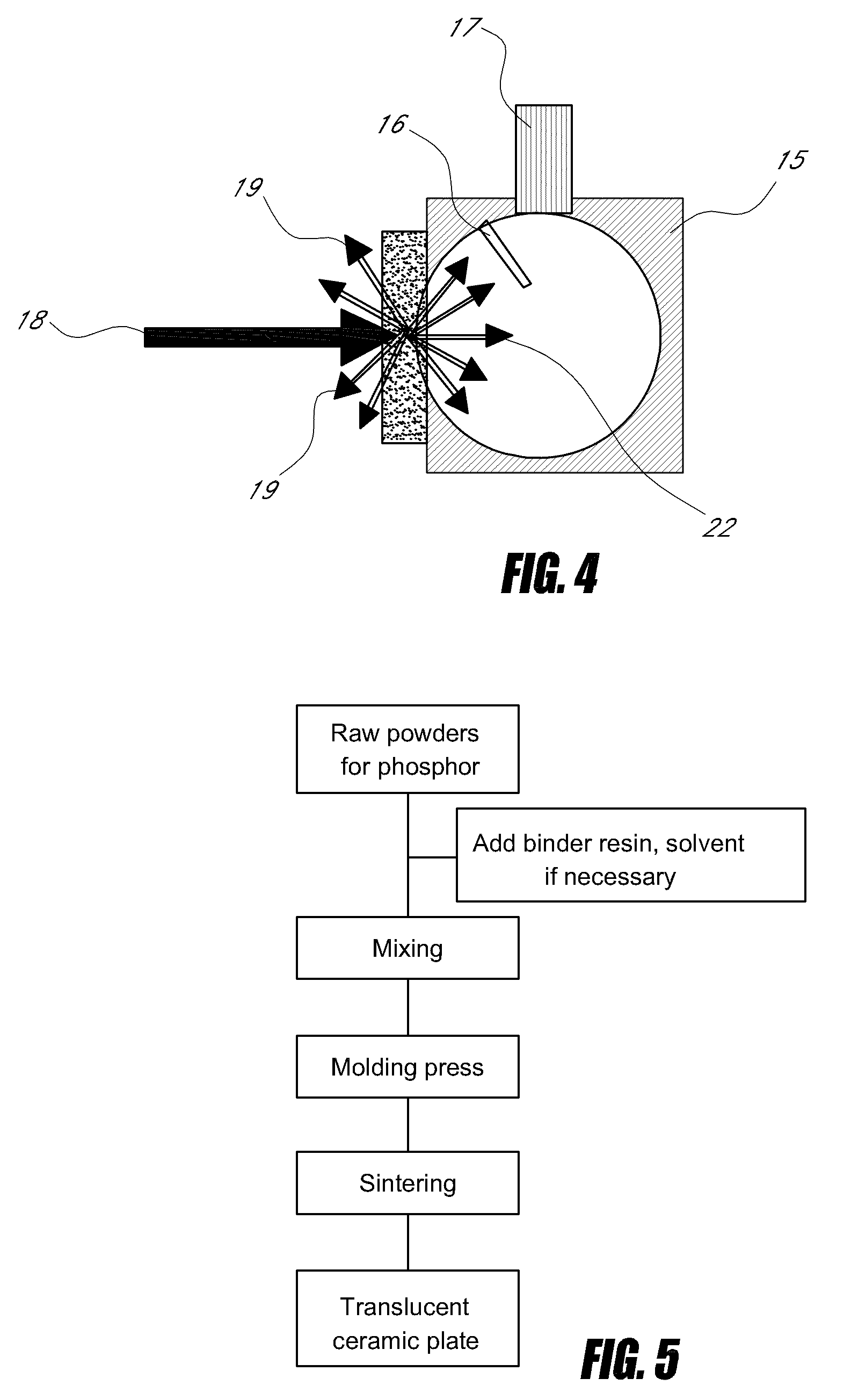

Light emitting device with translucent ceramic plate

ActiveUS20090212697A1Luminance intensity of lightHigh luminous intensityMaterial nanotechnologyIncadescent screens/filtersLuminous intensityTransmittance

A light emitting device comprising a light emitting component that emits light with a first peak wavelength, and at least one sintered ceramic plate over the light emitting component is described. The at least one sintered ceramic plate is capable of absorbing at least a portion of the light emitted from said light emitting component and emitting light of a second peak wavelength, and has a total light transmittance at the second peak wavelength of greater than about 40%. A method for improving the luminance intensity of a light emitting device comprising providing a light emitting component and positioning at least one translucent sintered ceramic plate described above over the light emitting component is also disclosed.

Owner:SCHOTT AG

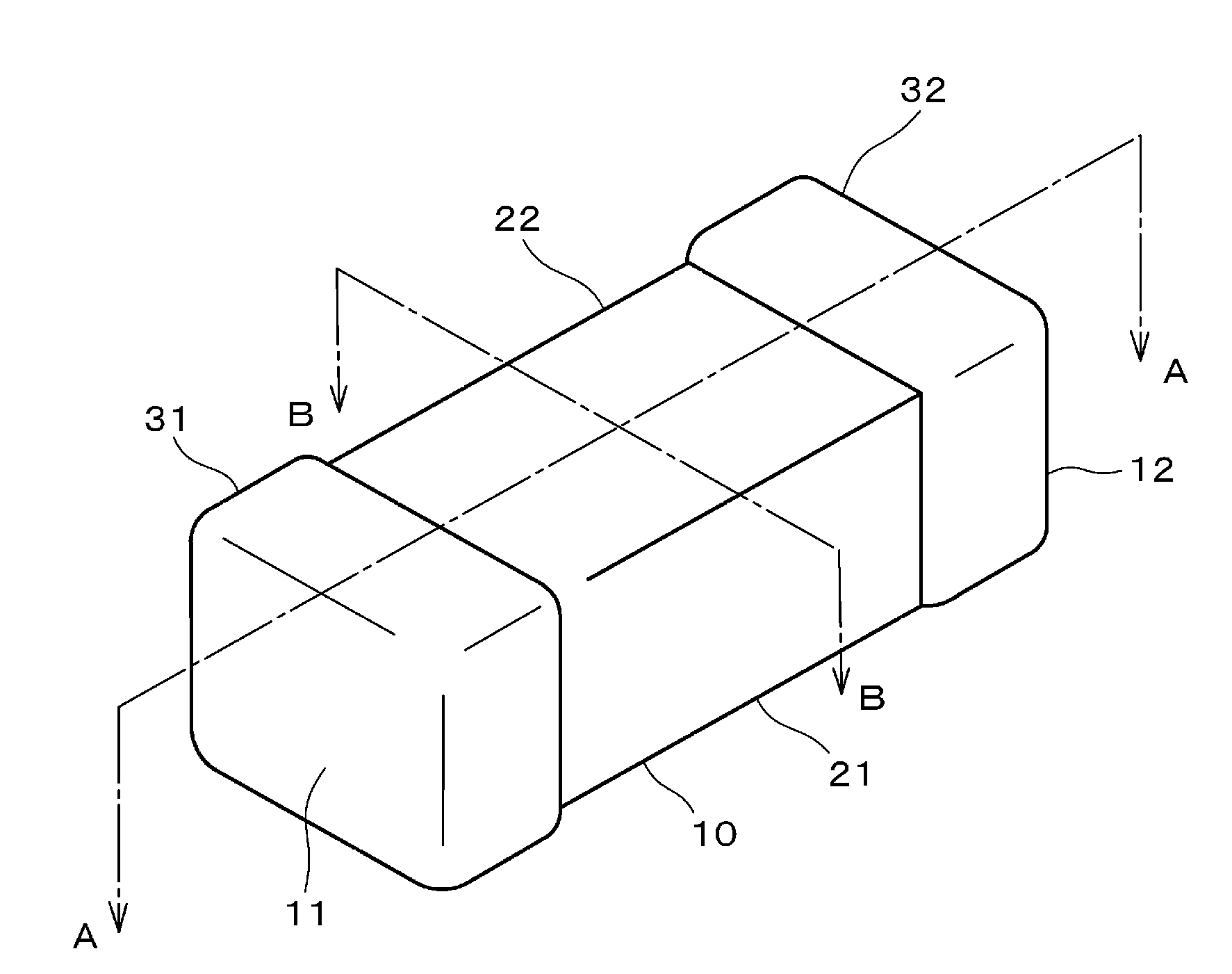

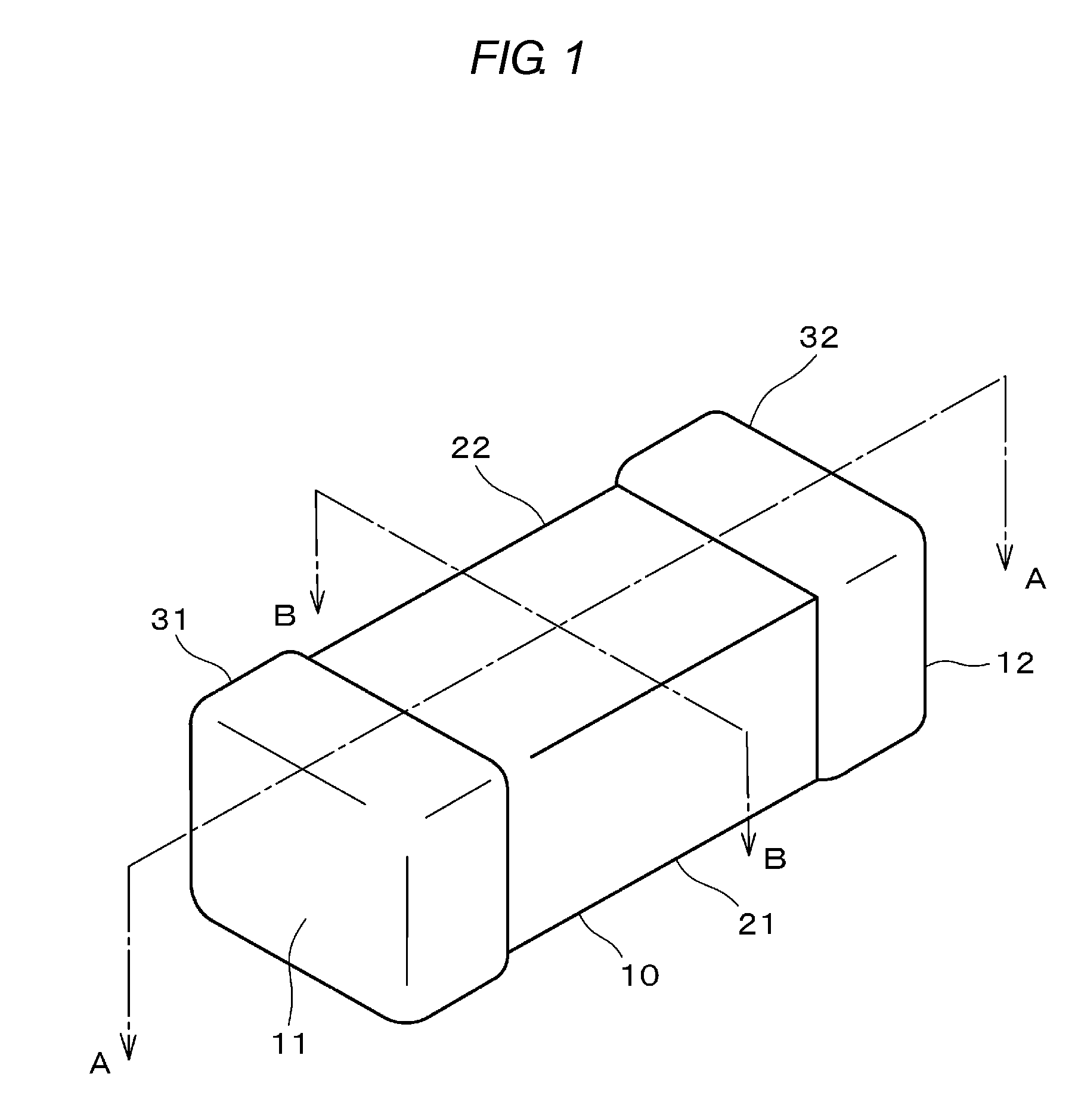

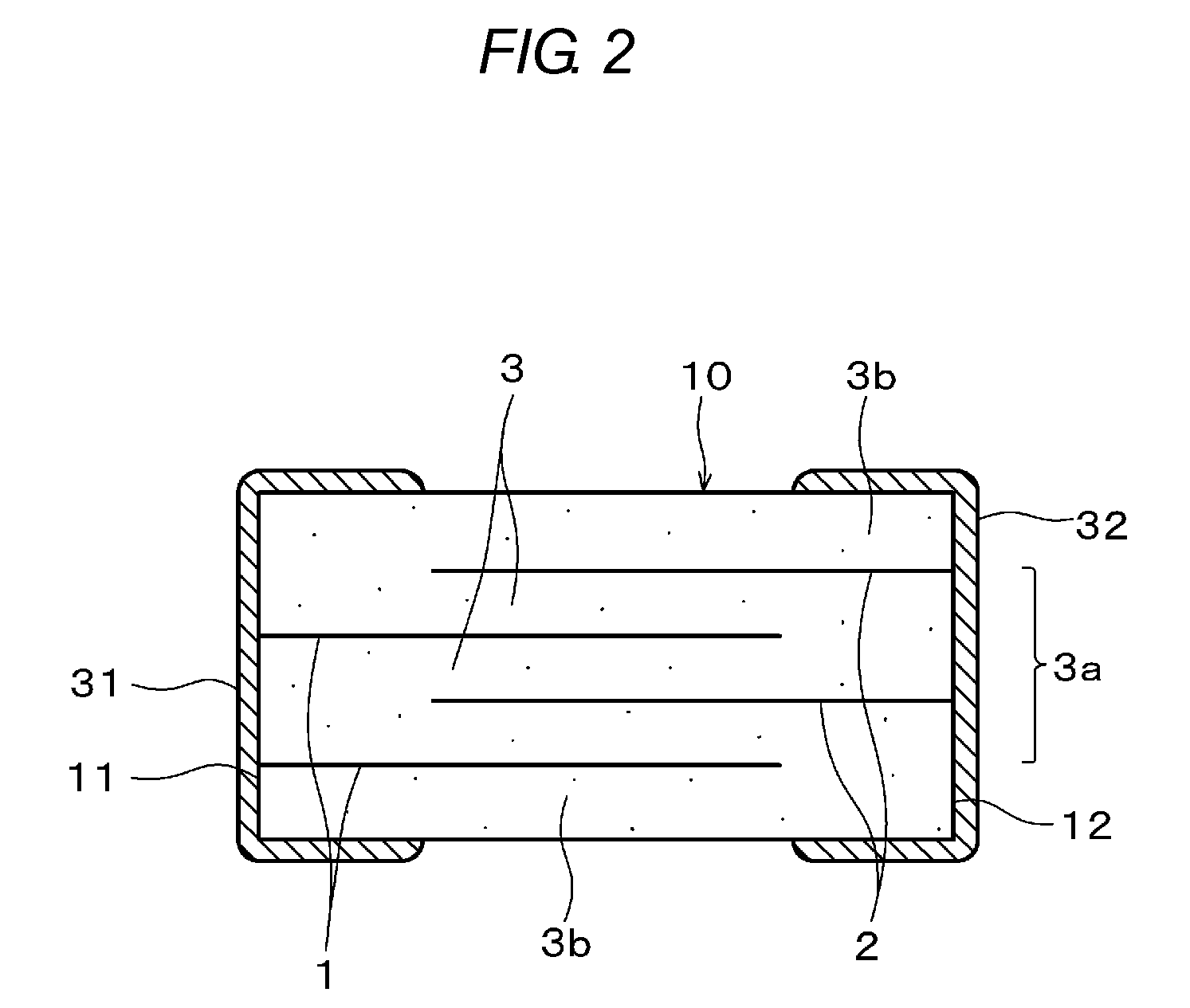

Multi-layered ceramic electronic component

ActiveUS20080304204A1Reliable moisture resistanceSmall sizeFixed capacitor electrodesFixed capacitor dielectricMetallurgyElectronic component

In a sintered ceramic body including side gap portions arranged between sides of first and second internal electrodes and first and second side surfaces of the sintered ceramic body and between sides of the effective layer portion and the first and second side surfaces of the sintered ceramic body, regions of the side gap portions at least adjacent to the first and second internal electrodes are Mg-rich regions each having a Mg concentration greater than that of the effective layer portion.

Owner:MURATA MFG CO LTD

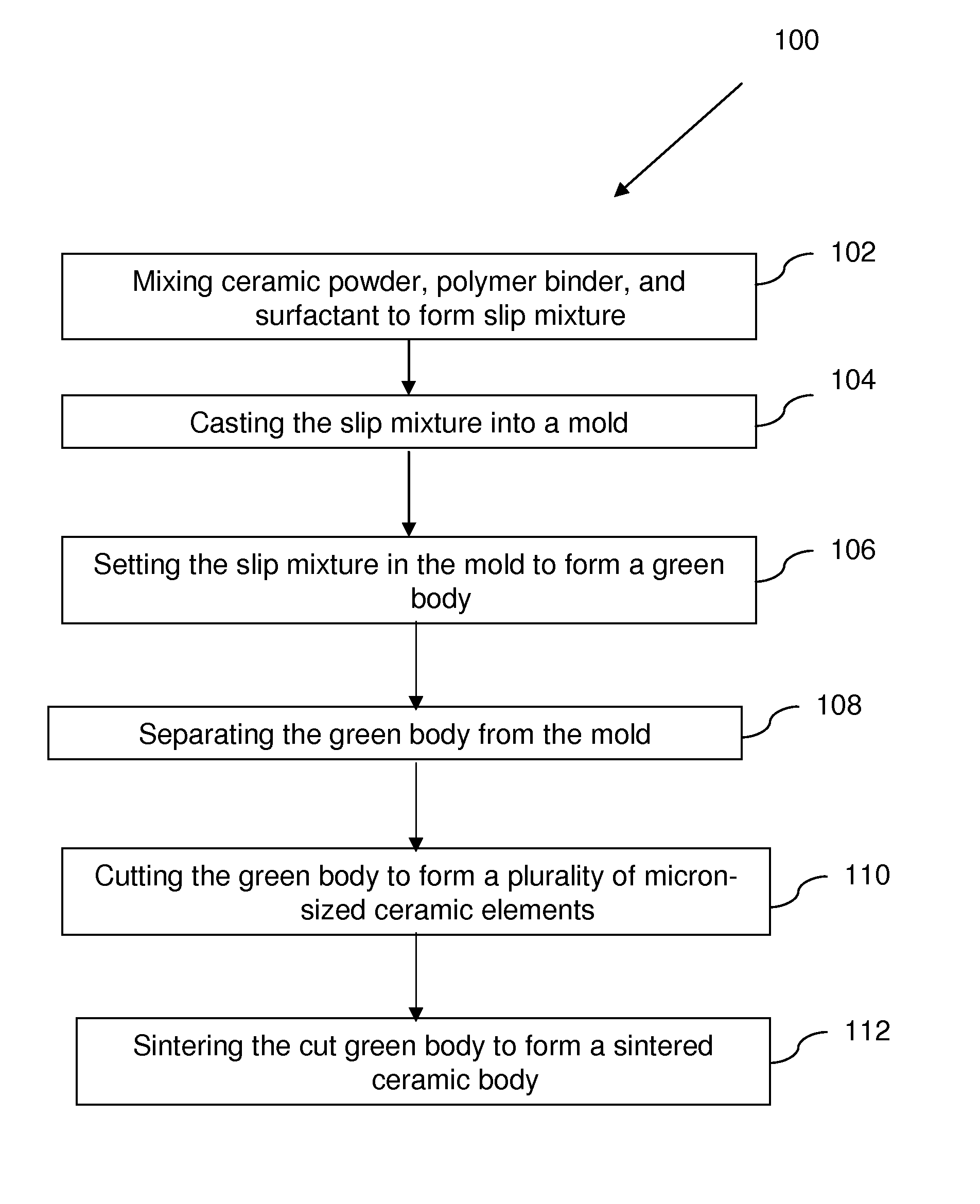

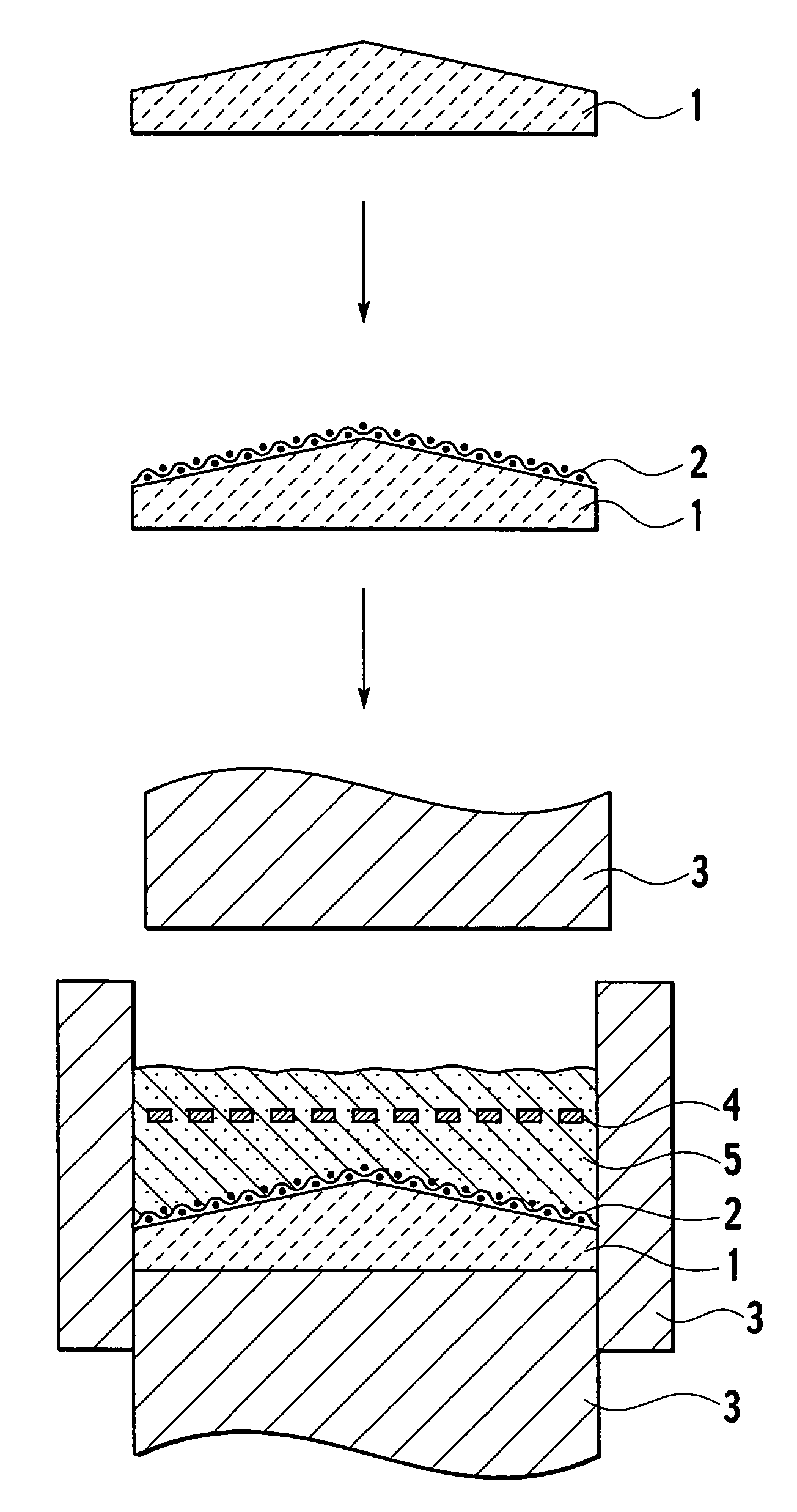

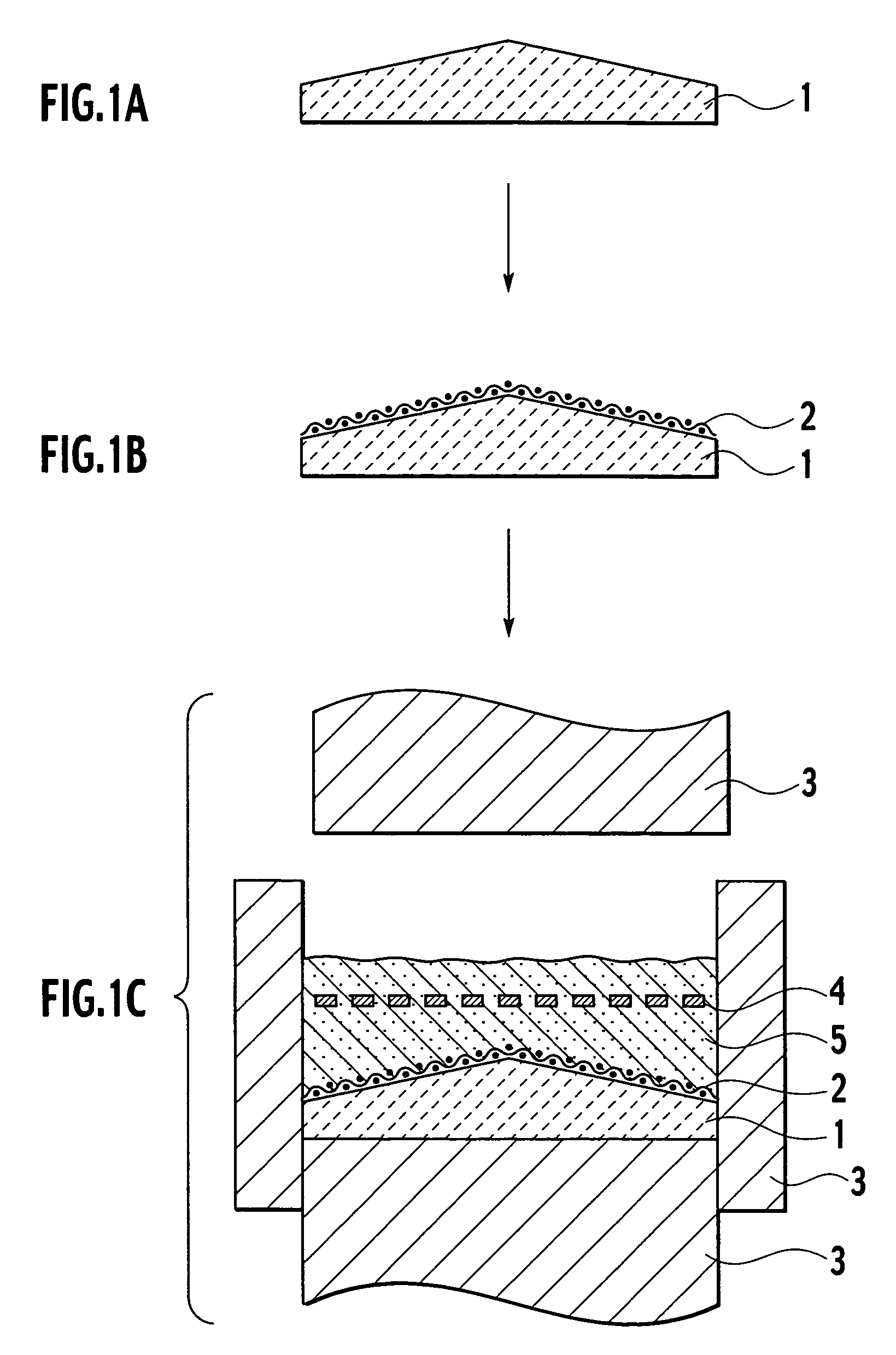

Method for manufacturing a piezoelectric ceramic body

ActiveUS8703040B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersMetallurgyTransducer

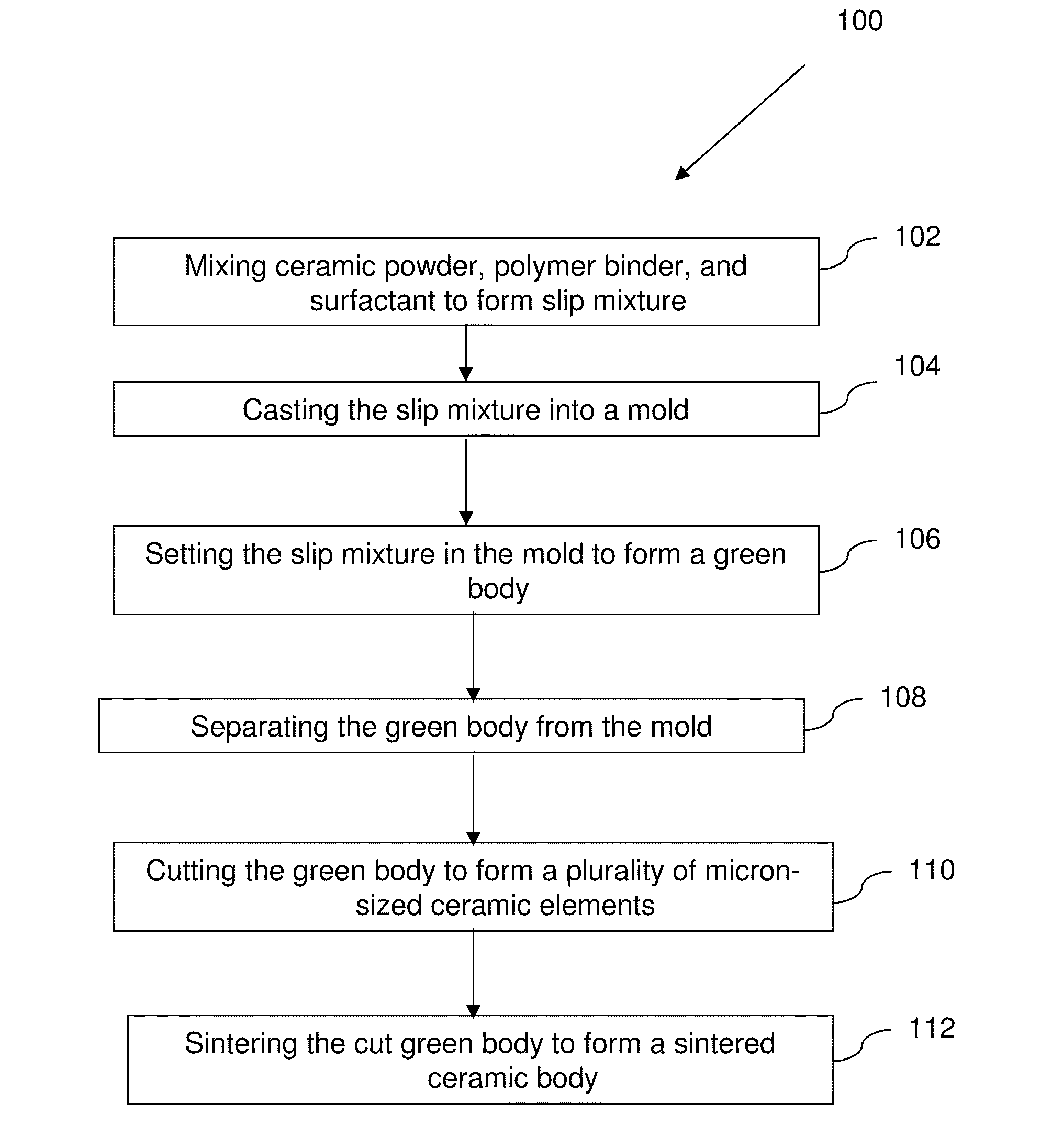

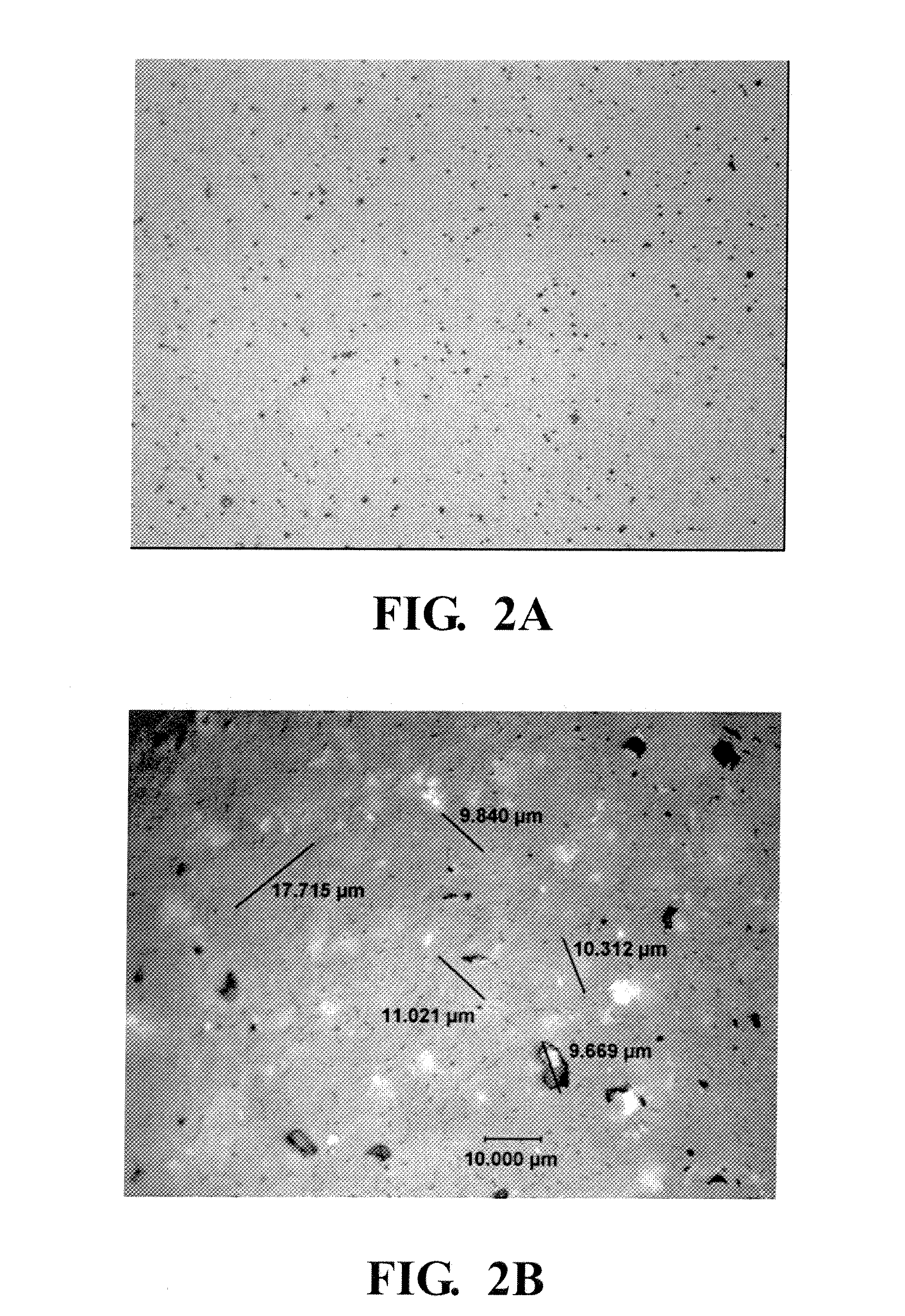

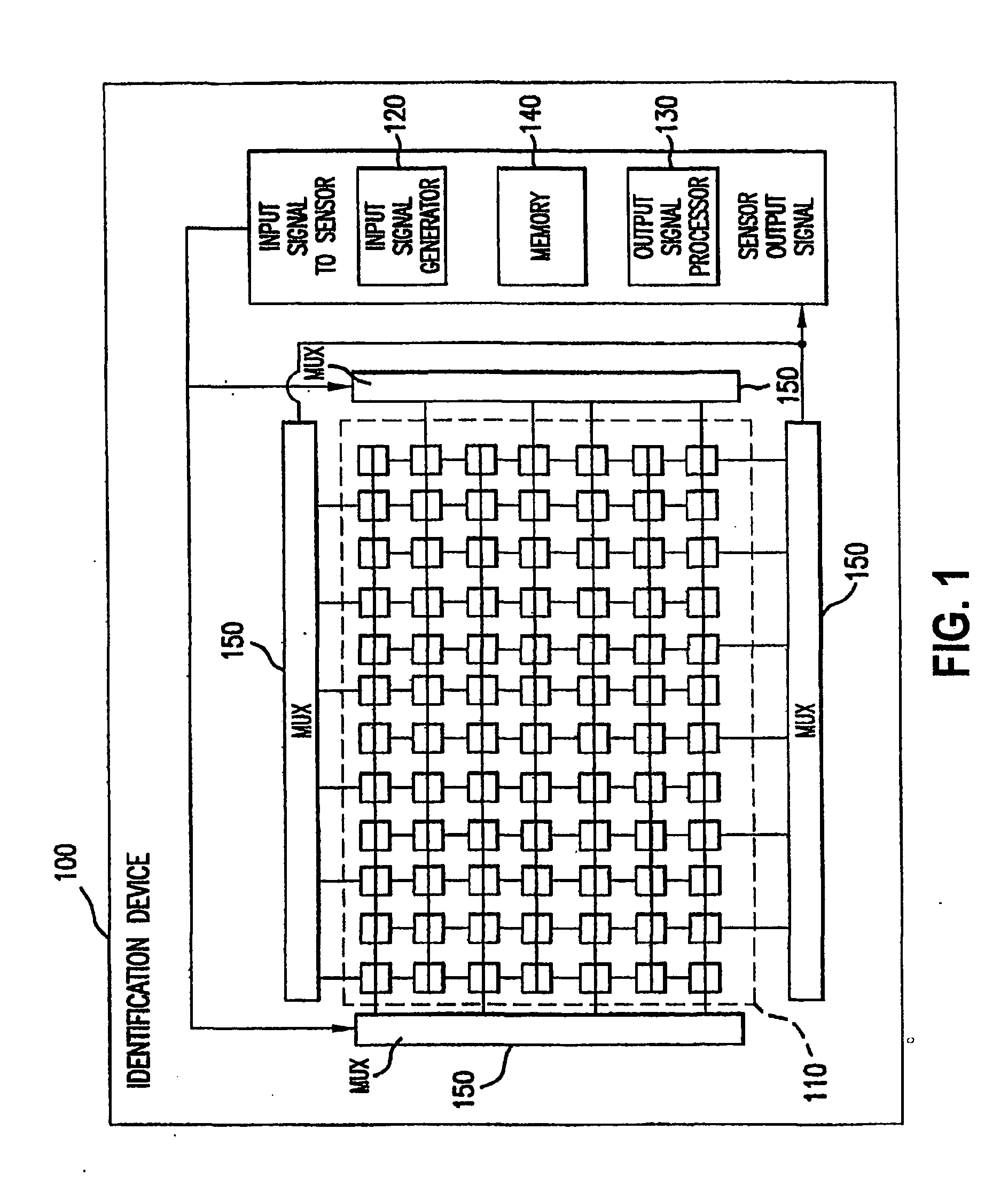

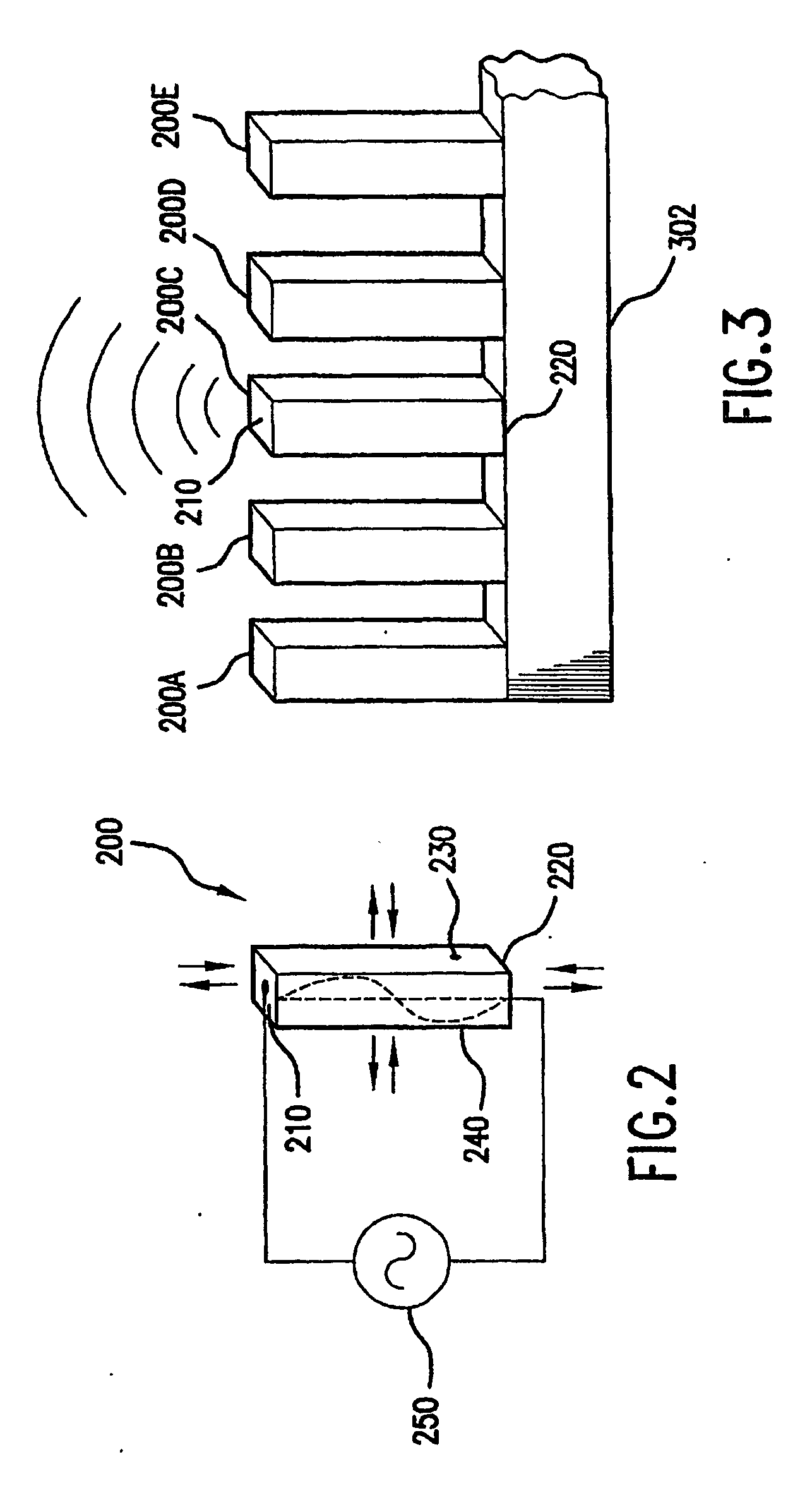

The present invention relates to a method of manufacturing a piezoelectric ceramic body and devices therefrom. The method comprises mixing a piezoelectric ceramic powder with a polymer binder and surfactant to form a slip mixture, casting the slip mixture into a mold and setting to the slip mixture in the mold to form a green body, cutting the green body to form a cut green body with an array of micron-sized ceramic elements and separation, and sintering the cut green body to form a sintered ceramic body. The sintered ceramic body can be further process to encasing in a polymer material to form a piezoelectric ceramic-polymer composite. The piezoelectric ceramic-polymer composite can be further processed to form devices such as acoustic transducers and sensors.

Owner:SONAVATION INC

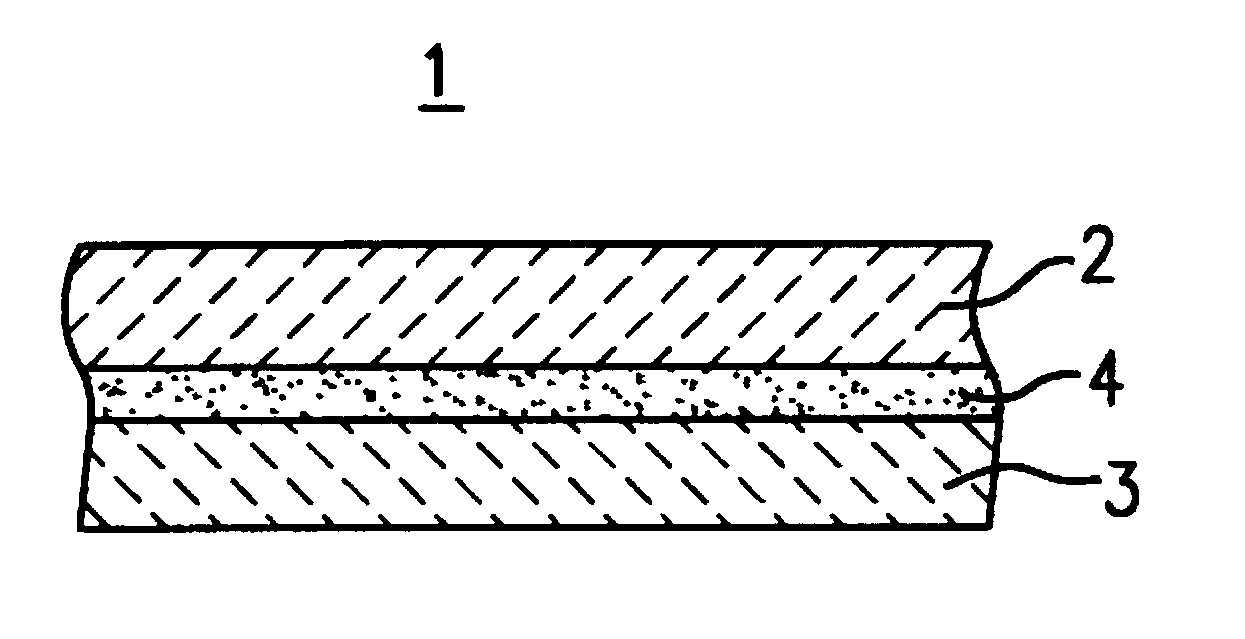

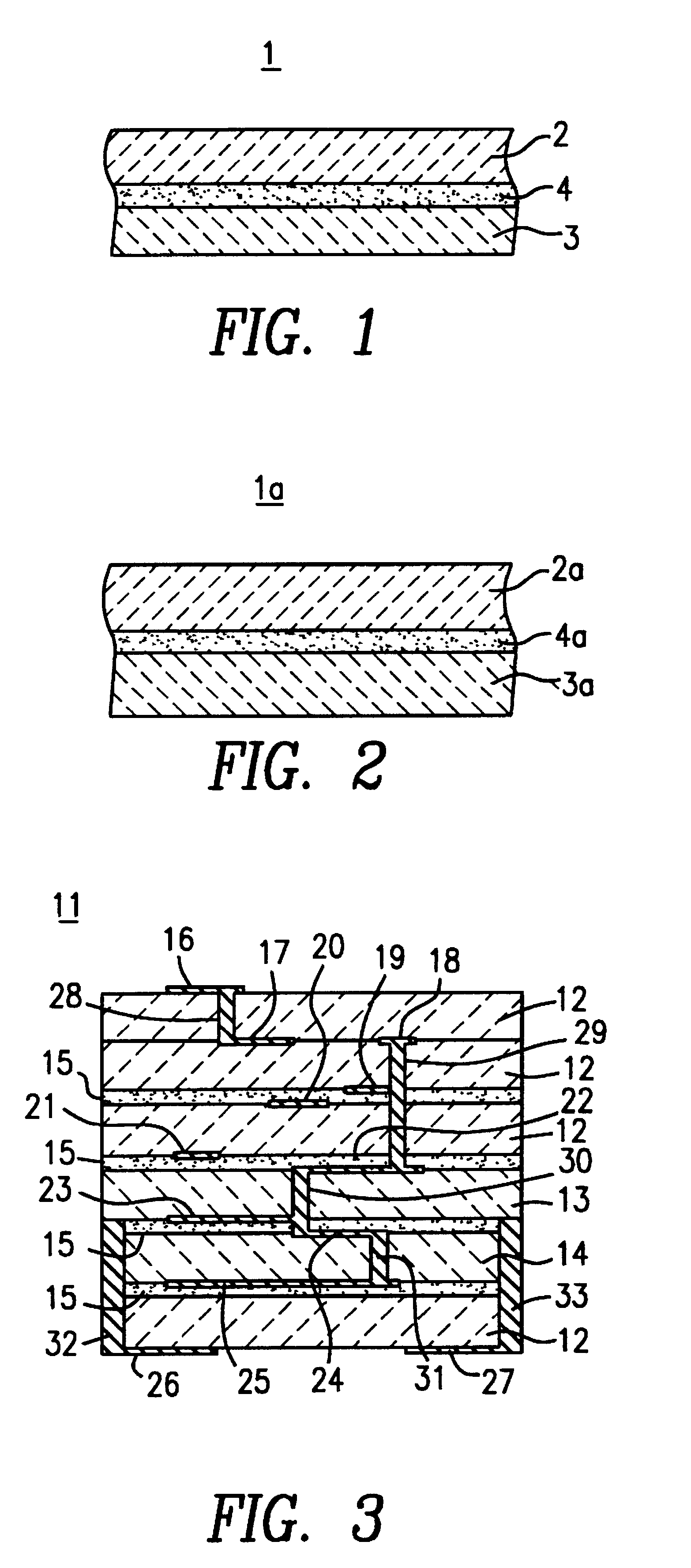

Multilayered ceramic substrate and method of producing the same

InactiveUS6337123B1Prevent of changePrevent of deteriorationSemiconductor/solid-state device detailsSolid-state devicesMetallurgyComposite laminates

A multilayered ceramic substrate which includes at least two types of ceramic layers respectively containing different ceramic materials, and which can be produced by simultaneous firing without causing layer peeling is described. A green composite laminated product is prepared in a state in which two substrate green sheets respectively contain different types of low-temperature sintered ceramic materials, and a shrinkage inhibiting green sheet containing an inorganic material which is not sintered at the sintering temperature of each of the low-temperature sintered ceramic material is arranged between the two substrate green sheets, followed by firing. In the firing step, the low-temperature sintered ceramic materials are sintered while inhibiting shrinkage of the substrate green sheets in the direction parallel to the main surfaces thereof by the shrinkage inhibiting green sheet, while the inorganic material remains unsintered and is fixed by glass supplied by firing the low-temperature sintered ceramic materials.

Owner:MURATA MFG CO LTD

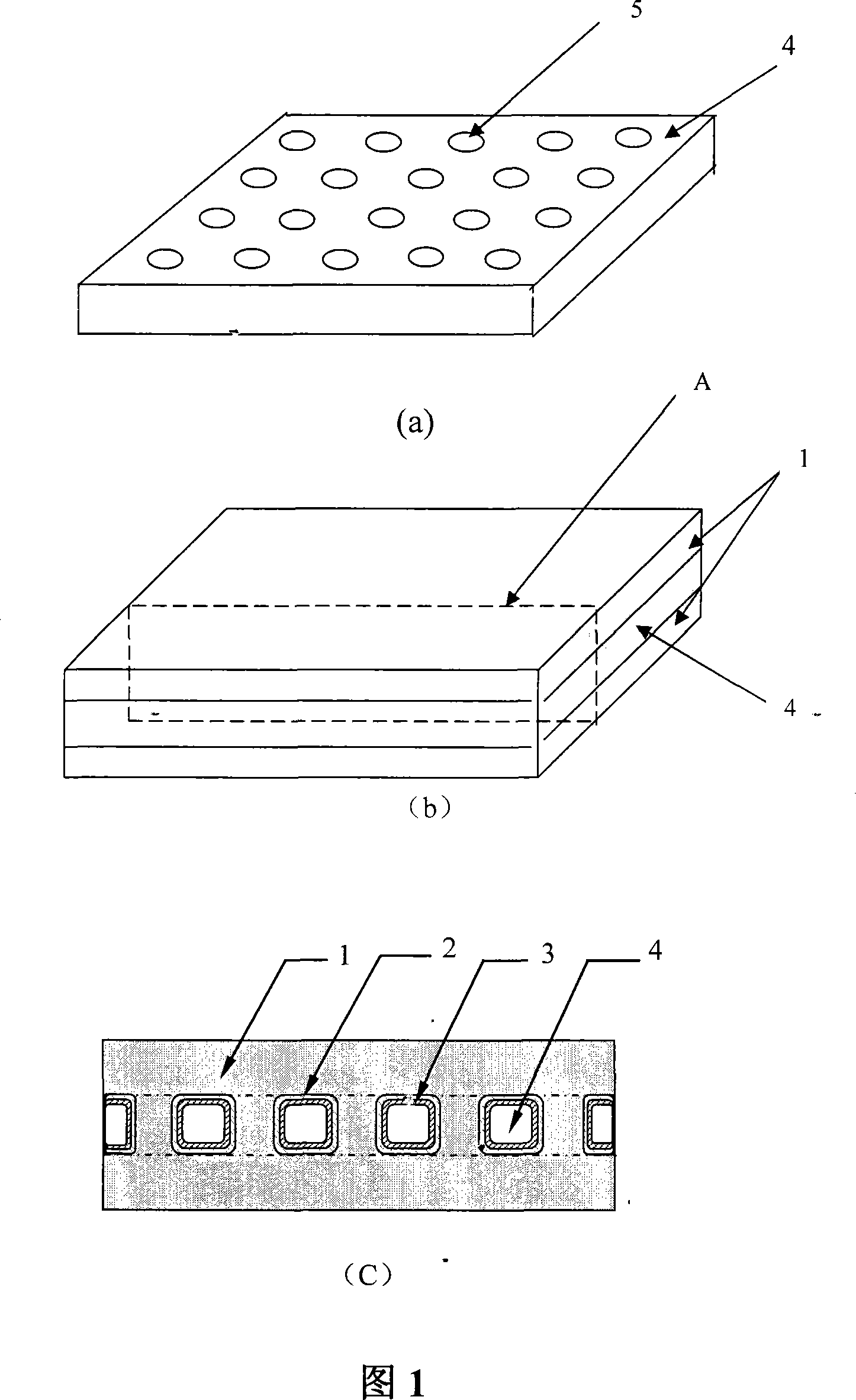

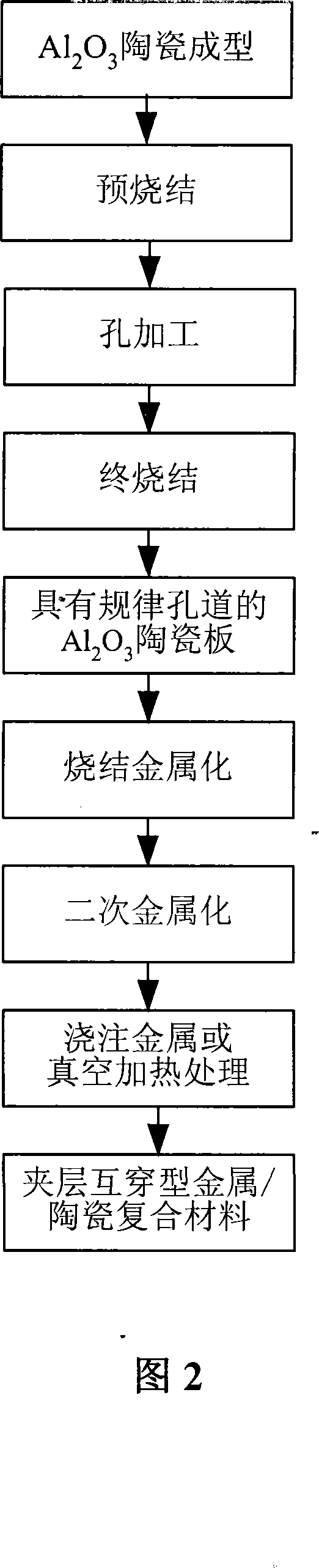

Armor of ceramic-metal composite and preparation method thereof

InactiveCN101158564AHigh hardnessStrong penetration resistanceArmour platesMolten stateCeramic composite

The invention discloses a metallic / ceramic composite armor and preparation method with ordered supporting structure of metallic materials as a framework and alumina ceramic materials as a core, and comprises the following steps: (1) a ceramic core plate with well-ordered pore canals is prepared and comprises working procedures such as forming, first sintering, hole machining and final sintering; (2) the ceramic core plate is sintered and metallized, all the surfaces of the finally sintered ceramic core plate is coated with Mo-Mn metal pastes, after being dried, the finally sintered ceramic core plate is metallized and sintered by being put under a protective atmosphere; (3) the metal is poured or vacuum heating treatment is made, the metal material is heated into a molten state, then poured into a die in which the ceramic core plate is arranged to have a thermostatic treatment, and finally cooled slowly to knock out. The invention can overcome weak binding of articulated connection and plane connection between the metal and the ceramic, etc., and realize high-strength binding between metallic / ceramic interfaces, moreover, the prepared metallic / ceramic composite armor with the sandwiches which can pass mutually is provided with the performance of light weight, high strength and impact resistance, thereby being suitable for a bulletproof composite armor plate and an armored panel on tanks and armored vehicles, etc.

Owner:XI AN JIAOTONG UNIV

Vaporization pipe with flame filter

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material. The filter unit and pipe can attach with a ground glass joint.

Owner:STEINBERG DAN A

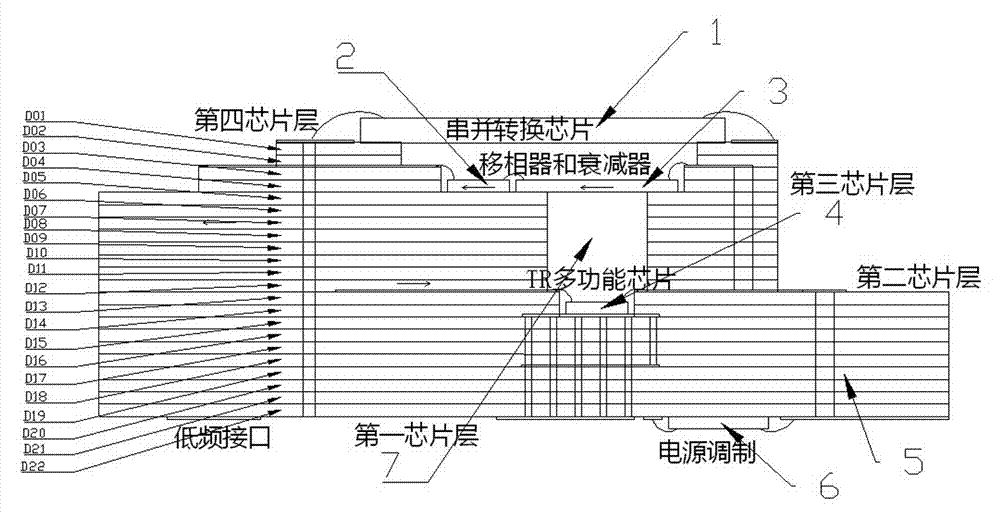

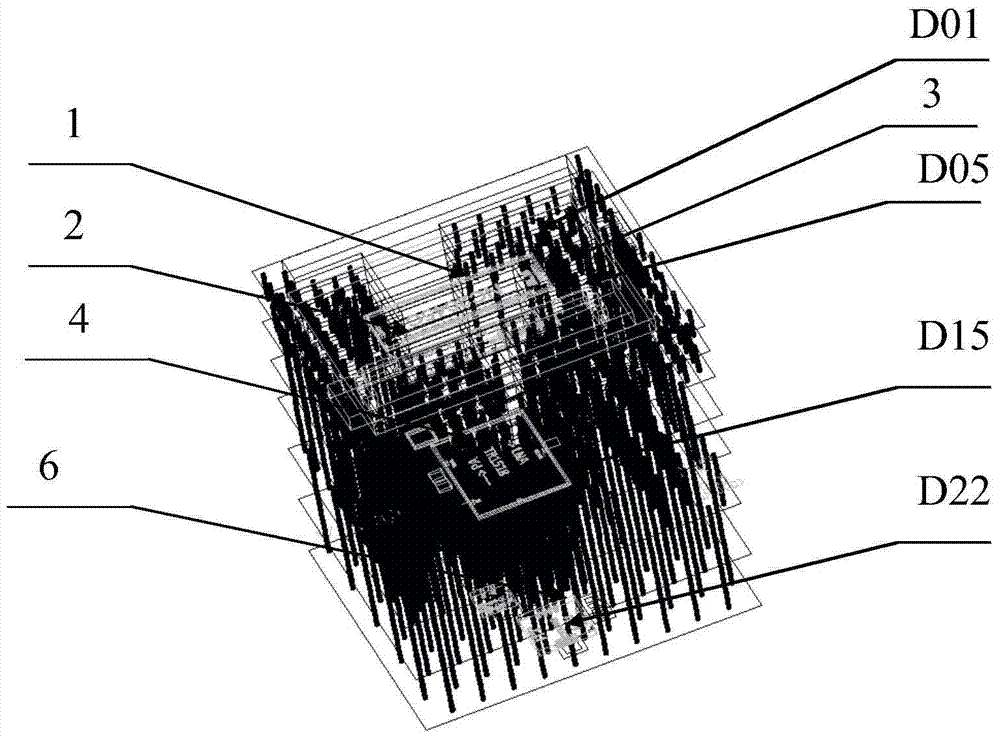

3D assembling method for integrally integrating chips of T/R assembly

InactiveCN104332413AHighly integratedLow costSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityThree-dimensional space

The invention provides a 3D assembling method for integrally integrating chips of T / R assembly, and aims to provide a T / R assembly which has advantages of reliable performance, higher density, more functions, high signal transmission speed, better performance and relatively lower cost. The 3D assembling method is realized through a solution which comprises the steps of performing z-direction expansion on a planar circuit with printed circuit patterns to a green ceramic chip laminate of a three-dimensional circuit through interlayer vertical interconnection; vertically packaging an active device in a rectangular chamber (7) of the green ceramic chip laminate (5), placing a power supply modulator on the back surface of the bottom of the green ceramic chip laminate, and inputting an outer signal from a low-frequency interface at the back surface of the green ceramic chip laminate to a pad of the green ceramic chip laminate (5); performing radio frequency connection among chips through a metal wire bonding vertical interconnection structure among the green ceramic chip laminates, accurately aligning and laminating the green ceramic laminates in a Z direction, and then sintering at a temperature of 900 DEG C, thereby preparing a three-dimensional circuit low-temperature co-sintered ceramic LTCC substrate which is used for high-density circuits with no three-dimensional space interference and is internally provided with a passive element and can be equipped with bare chips or package chips on the surface.

Owner:10TH RES INST OF CETC

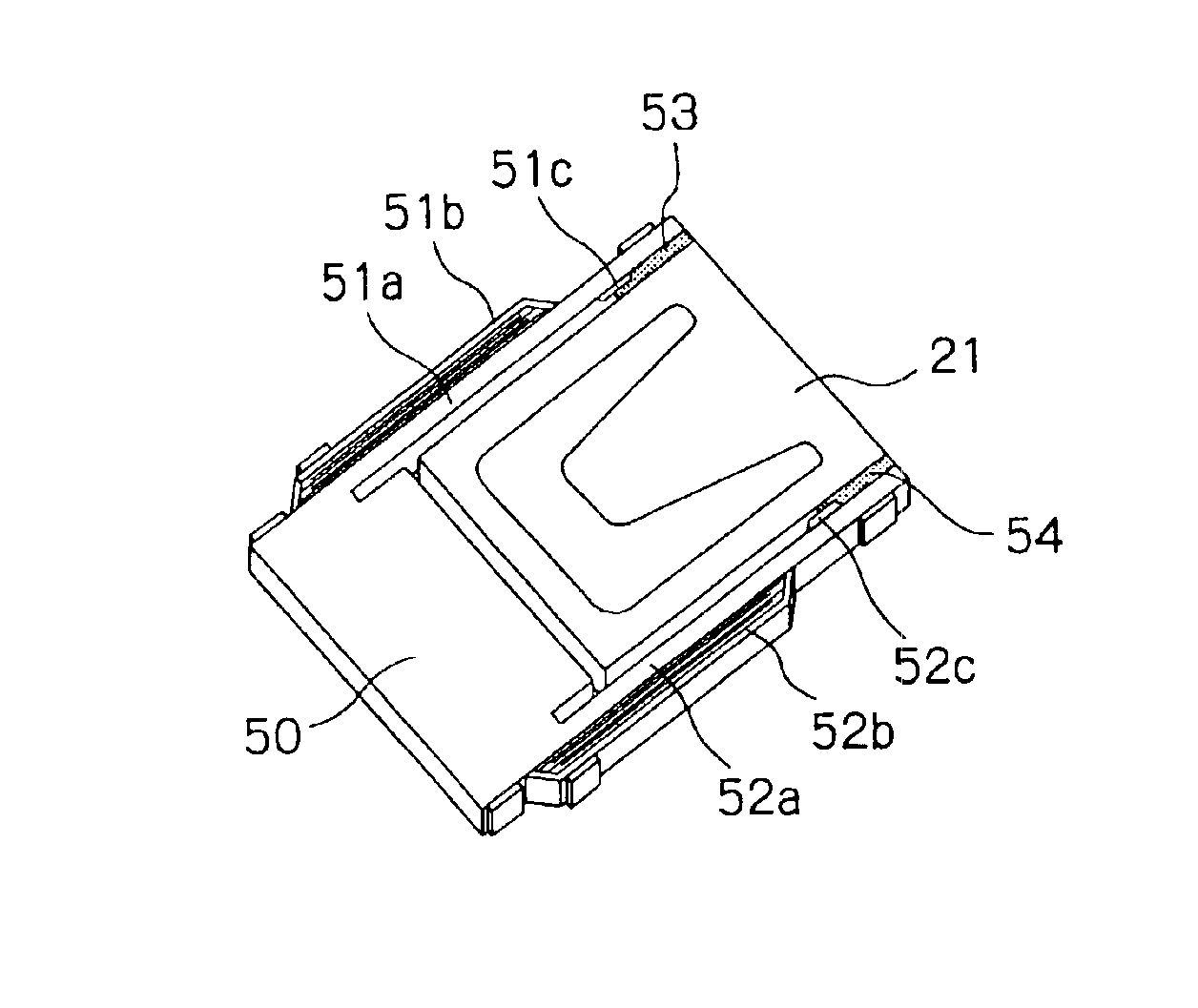

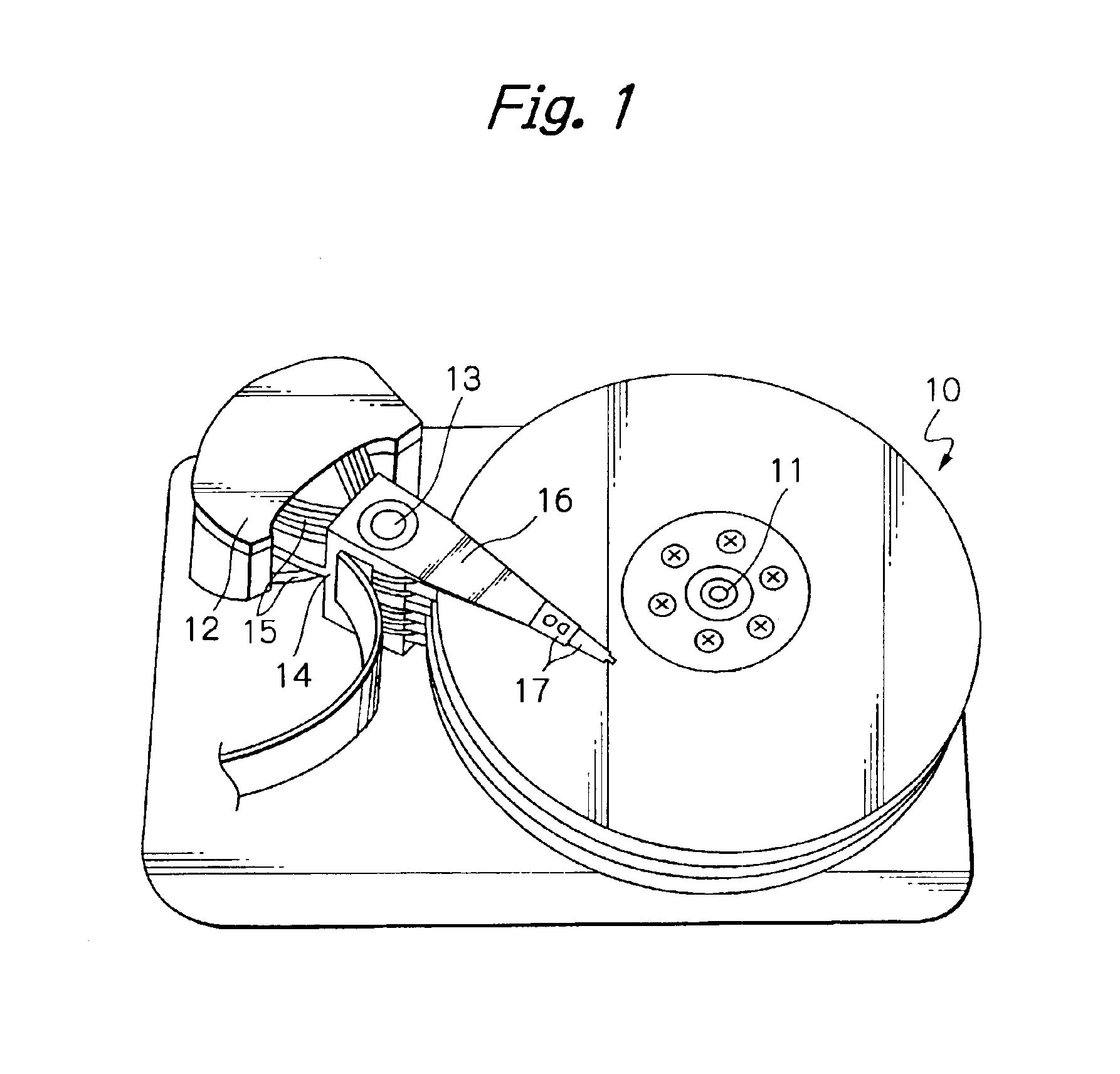

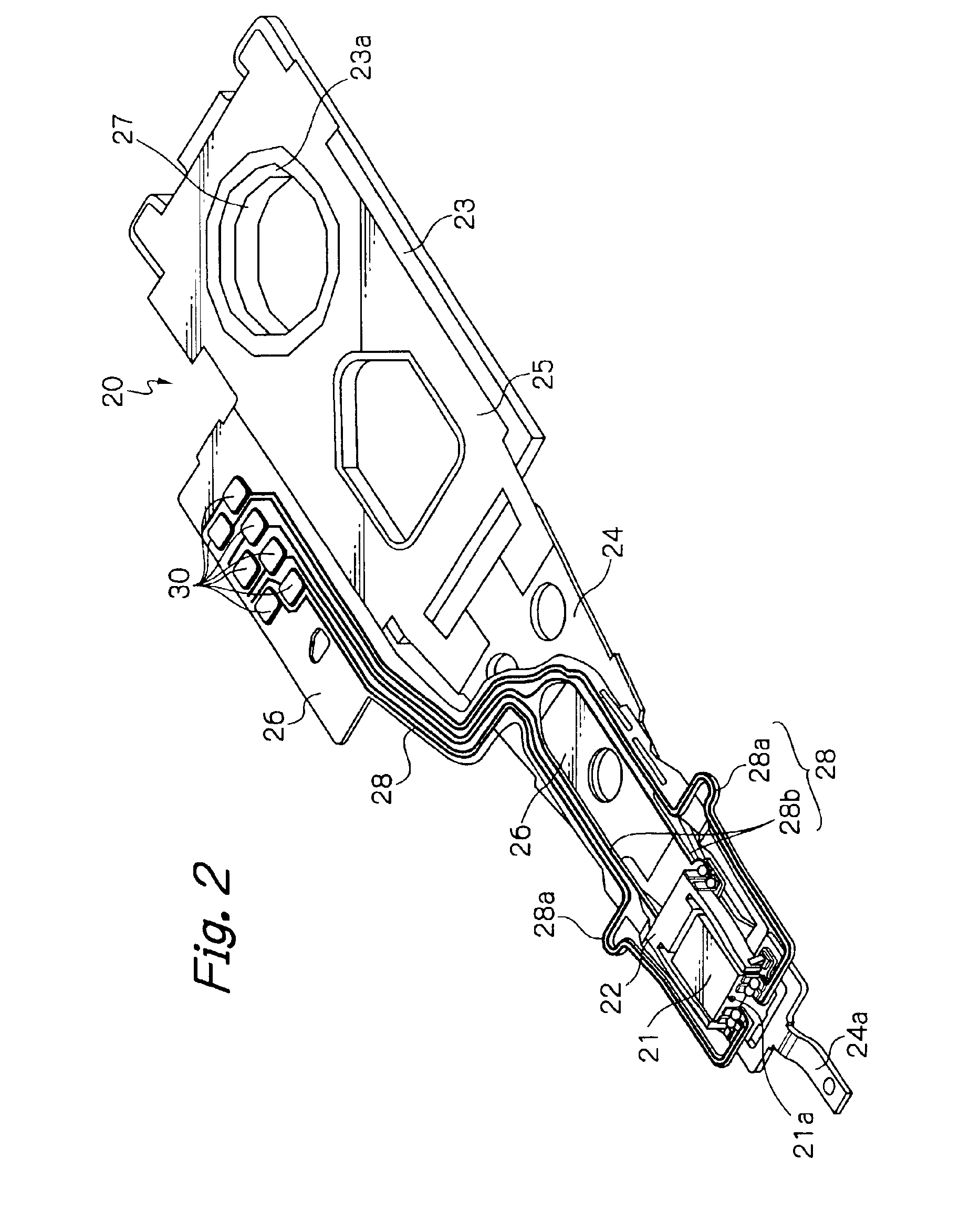

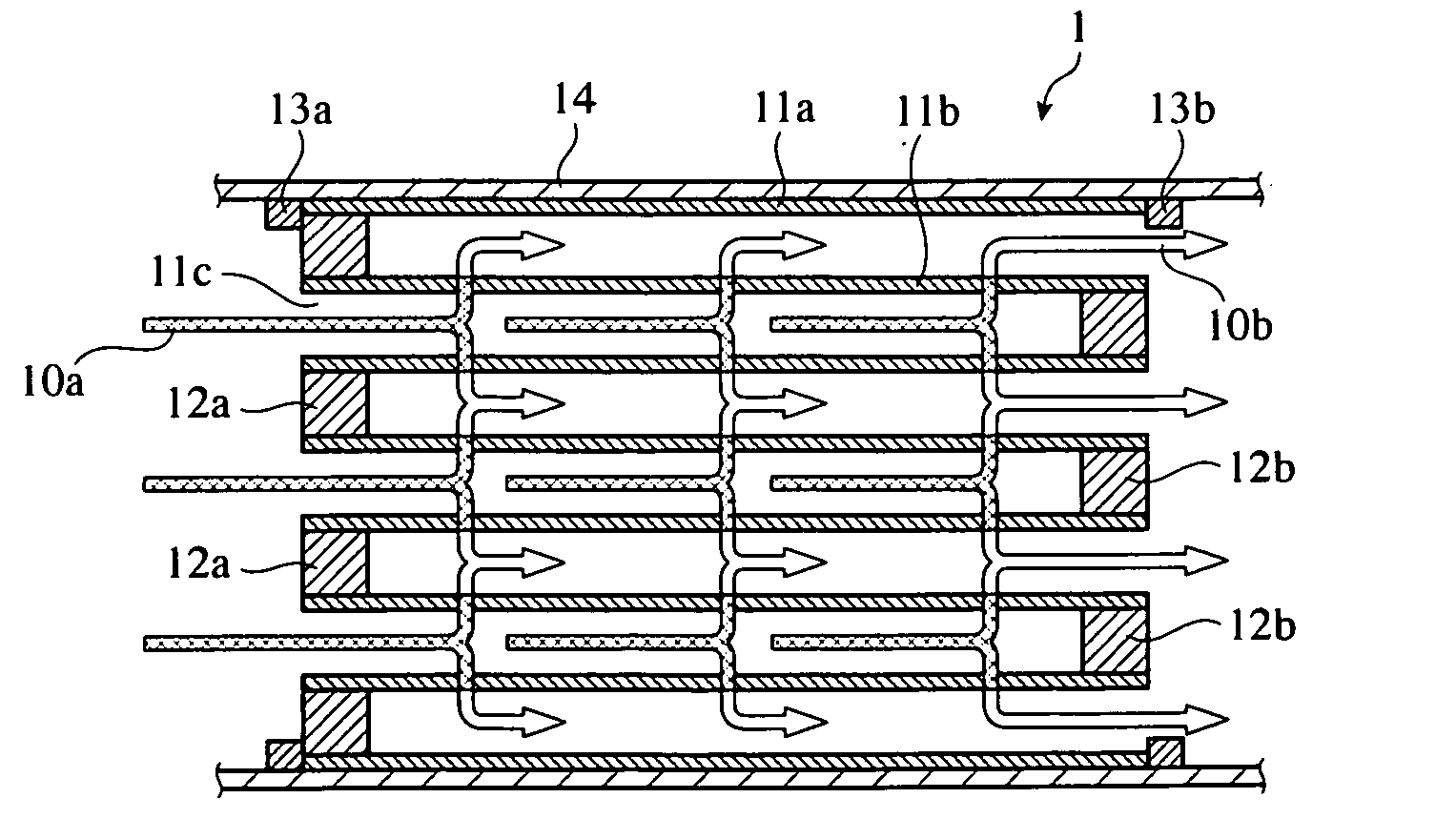

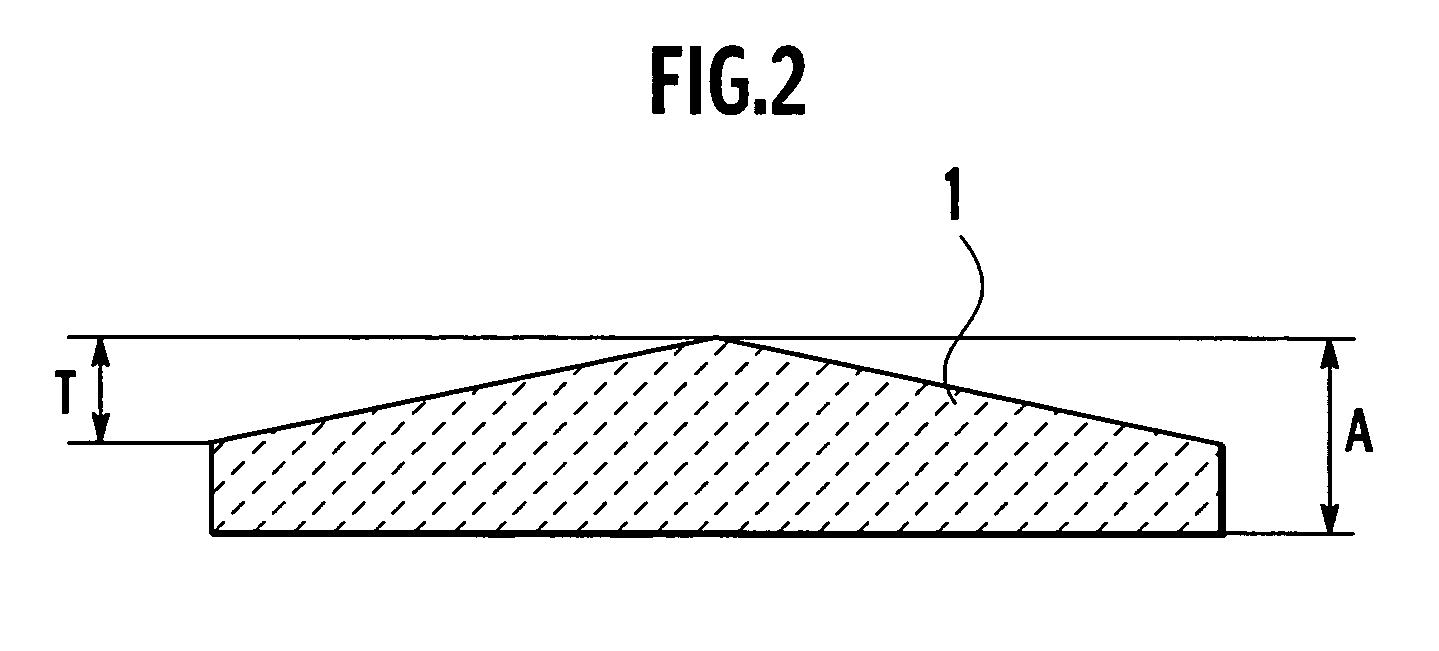

Precise positioning actuator for head element, head gimbal assembly with the actuator and disk drive apparatus with the head gimbal assembly

InactiveUS6934127B2Improve seismic performanceStable and reliable adhesionTrack finding/aligningRecord information storageEngineeringActuator

A precise positioning actuator for precisely positioning at least one head element is provided with a base and a pair of movable arms capable of displacing in response to a drive signal applied to the actuator. The pair of movable arms extend from the base for catching a head slider with at least one head element in a space between the pair of movable arms. Each of the pair of movable arms includes an arm member made of an elastic sintered ceramic and having substantially the same cross sectional shape from a root thereof to a top end thereof, a piezoelectric element formed on a side surface of the arm member and a protrusion additionally formed on an inside surface of the arm member near its top end section. The protrusion has tapered surfaces. Side surfaces of the head slider are adhered to the inside surfaces of the arm members at the protrusions and within regions between the protrusions and top ends of the arm members.

Owner:SAE MAGNETICS (HK) LTD

Building silt soil non-sintered ceramic aggregate and preparation method thereof

ActiveCN102617107ASimple technical processEasy accessSolid waste managementSolid componentEnvironmental resistance

The invention discloses a building silt soil non-sintered ceramic aggregate, which is characterized by comprising solid components and water, wherein every kilogram of solid components comprise the following components in percentage by weight: 60-80 percent of building silt soil, 2-5 percent of cement, 2-5 percent of quick lime, 2-5 percent of desulfurized gypsum, 2-7 percent of perlite, 2-8 percent of fly ash and 5-10 percent of water glass; and the amount of the water accounts for 45-60 percent of the total mass of the solid components. The invention also discloses a preparation method of the ceramic aggregate. The ceramic aggregate and the preparation method thereof have the characteristics of simple pretreatment of building silt soil, simple preparation process and capabilities of eliminating industrial wastes such as fly ash and desulfurized gypsum without large-sized calcining equipment and expanding the utilization approach of the solid waste material; and by adopting a non-sintering process, the ceramic aggregate and the preparation method thereof have the advantages of environmental protection effects such as energy conservation and low carbon compared with a roasting process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

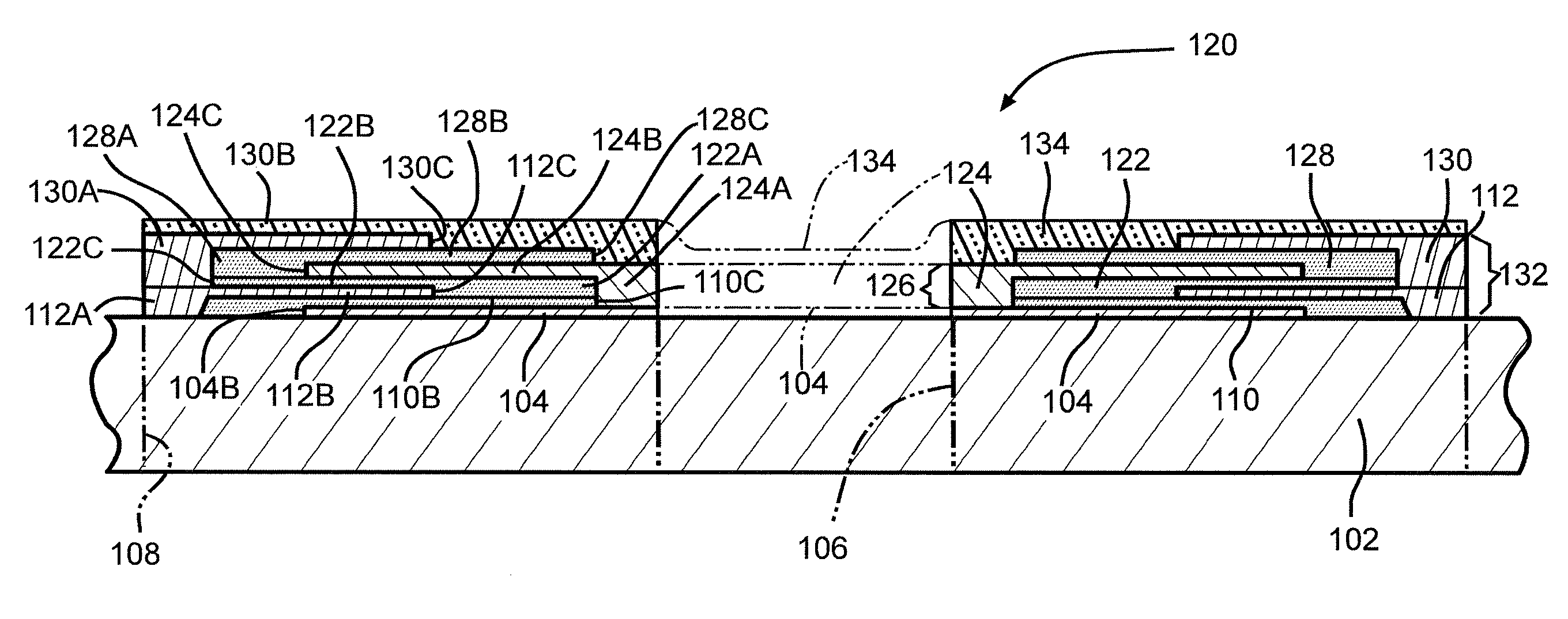

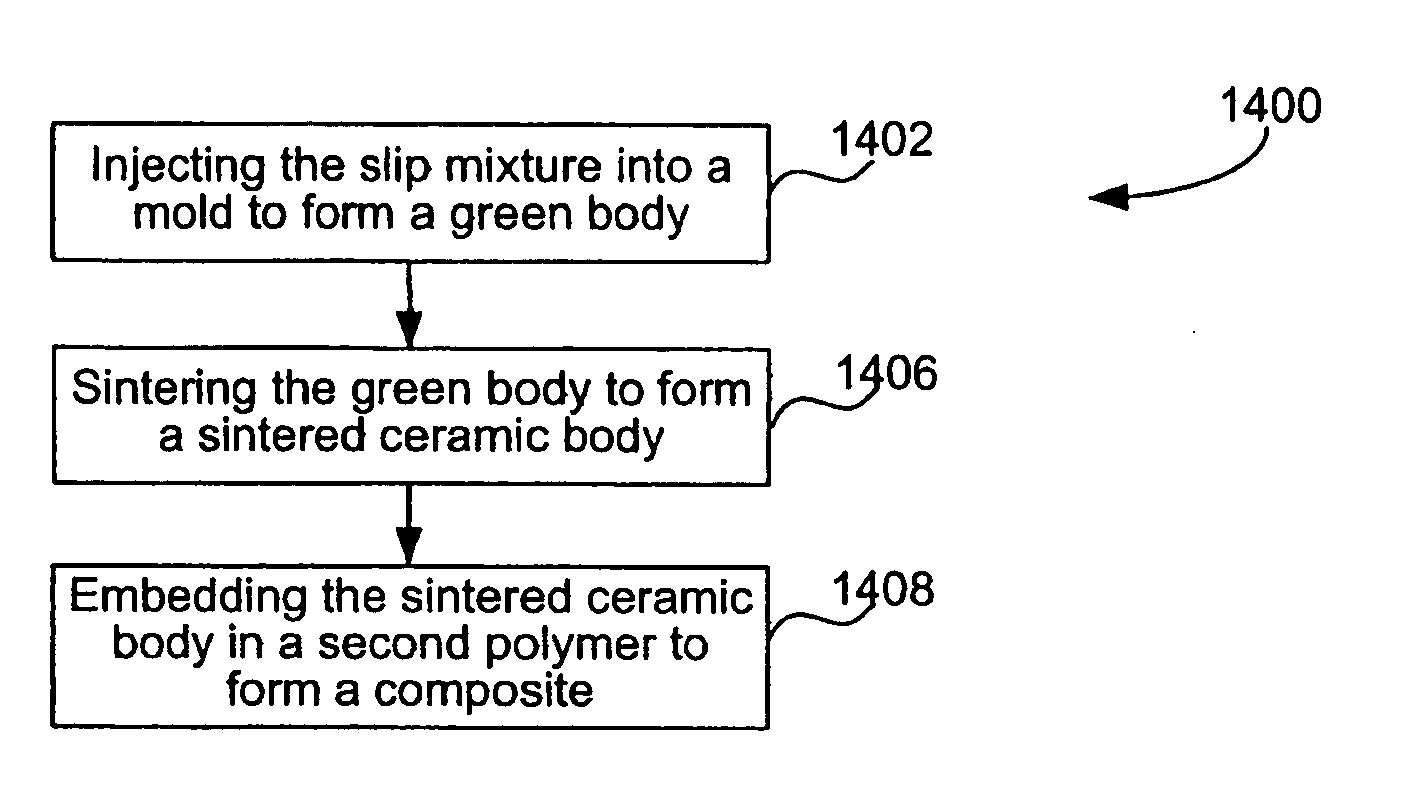

Method for Manufacturing a Piezoelectric Ceramic Body

ActiveUS20110010904A1Easy to manufacturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersMetallurgyCeramic polymer composites

The present invention relates to a method of manufacturing a piezoelectric ceramic body and devices therefrom. The method comprises mixing a piezoelectric ceramic powder with a polymer binder and surfactant to form a slip mixture, casting the slip mixture into a mold and setting to the slip mixture in the mold to form a green body, cutting the green body to form a cut green body with an array of micron-sized ceramic elements and separation, and sintering the cut green body to form a sintered ceramic body. The sintered ceramic body can be further process to encasing in a polymer material to form a piezoelectric ceramic-polymer composite. The piezoelectric ceramic-polymer composite can be further processed to form devices such as acoustic transducers and sensors.

Owner:SONAVATION INC

Alumina ceramic for spark plug insulator

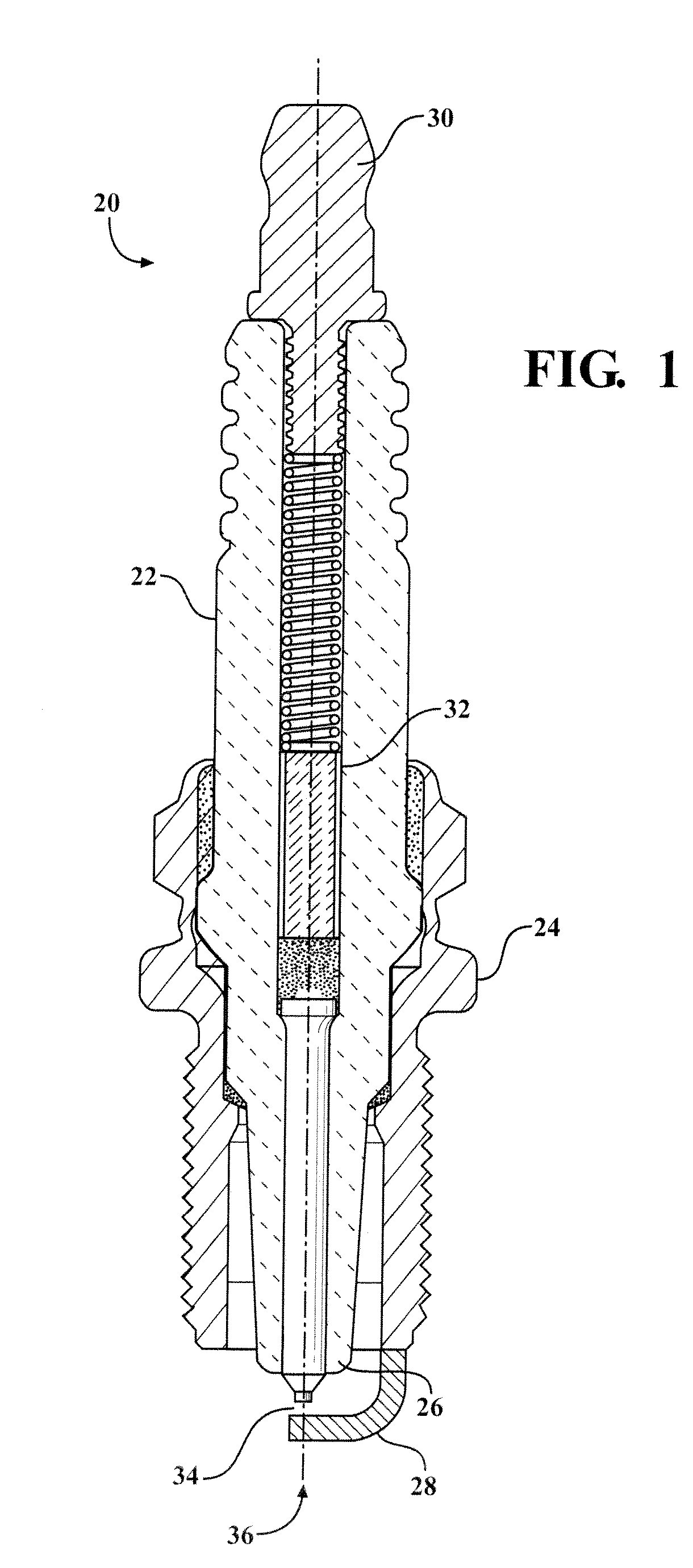

ActiveUS20110077141A1Improve conductivityHigh strengthElectric discharge tubesDischarge tube main electrodesAluminateMullite

A spark plug includes an insulator formed of a ceramic material. The ceramic material comprises Al2O3 in an amount of 98.00 wt % to 99.50 wt %; Group 2 oxides in an amount of 0.16 wt % to 0.70 wt %; SiO2 in an amount of 0.25 wt % to 0.75 wt %, Group 4 oxides in an amount of 0.01 wt % to 0.16 wt %, Group 1 oxides in an amount less than 0.0060 wt %, and P2O5 in an amount of less than 0.0040 wt %. The Al2O3 is formed of particles having a D50 median particle size by volume of 1.2 μm to 1.8 μm. The ceramic material is pressed, sintered, and formed to a predetermined shape. The sintered ceramic material includes a glass phase comprising the Al2O3, Group 2 oxides, and SiO2. The sintered ceramic material also includes secondary crystals of calcium hexa-aluminate (CaAl12O19) spinel (MgAl2O4), anorthite (CaAl2Si2O8), and mullite (Al6Si2O13).

Owner:FEDERAL MOGUL IGNITION

Method of pressureless sintering production of densified ceramic composites

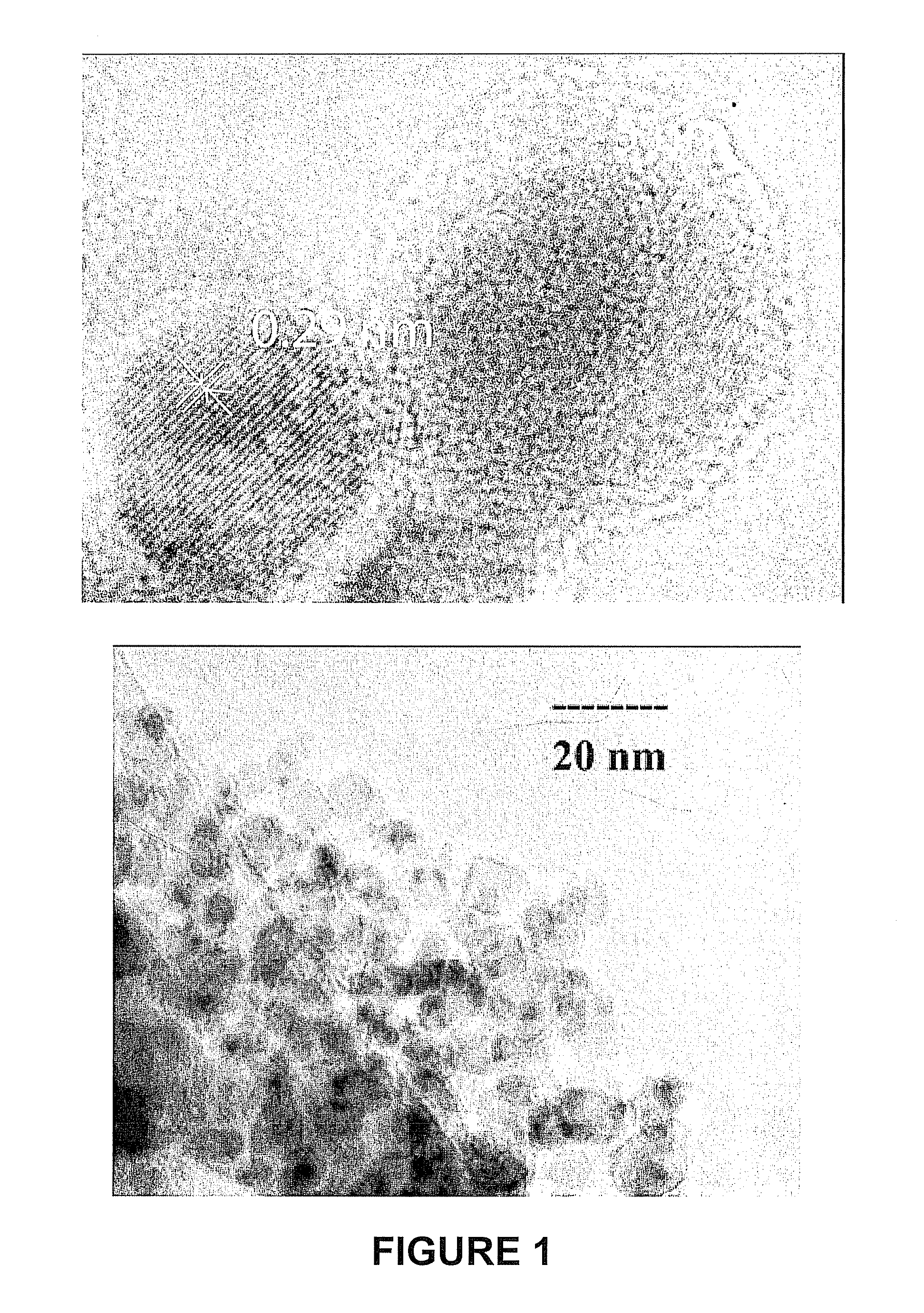

InactiveUS20100130346A1Material nanotechnologySpecial surfacesLiquid-feed flame spray pyrolysisCeramic composite

Methods of making and compositions of dense sintered ceramic nano- and micro-composite materials that are highly stable in a variety of conditions and exhibit superior toughness and strength. Liquid feed flame spray pyrolysis techniques form a plurality of nanoparticles (e.g., powder), each having a core region including a first metal oxide composition comprising Ce and / or Zr or other metals and a shell region including a second metal oxide composition comprising Al or other metals. In certain aspects, the core region comprises a partially stabilized tetragonal ZrO2 and the shell region comprises an α-Al2O3 phase. The average actual density of the ceramic after sintering is greater than 50% and up to or exceeding 90% of a theoretical density of the ceramic.

Owner:RGT UNIV OF MICHIGAN

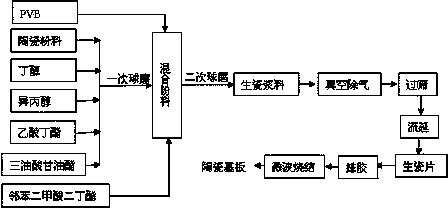

Borosilicate glass-spherical alumina low temperature co-fired ceramic green tape and preparation method thereof

The invention discloses a borosilicate glass-spherical alumina low temperature co-fired ceramic (LTCC) green tape and its preparation method. The green tape is composed of a glass-ceramic composite material and a casting medium. Specifically, the glass-ceramic composite material consists of borosilicate glass and spherical alumina. The casting medium consists of a mixed solvent, a monomer binder, a plasticizer and a dispersing agent. The low temperature co-fired ceramic green tape prepared in the invention has a level and smooth surface, a solid content up to 88-92wt%, and a firing shrinkage rate of 9-11%. The difference between the sintering shrinkage rate of each direction is small. And the green tape can achieve wiring co-firing with Au, Ag and other low melting point metals at 850DEG C. The raw material tape sintered ceramic body provided in the invention has excellent dielectric properties. Under the condition of less than 10GHz, the dielectric constant (epsilon r) of 7-8, the dielectric loss (Tan delta) is less than 2*10<-3>, and effectively solves the anisotropy problem of traditional LTCC green tape sintering shrinkage.

Owner:凤阳凯盛硅材料有限公司

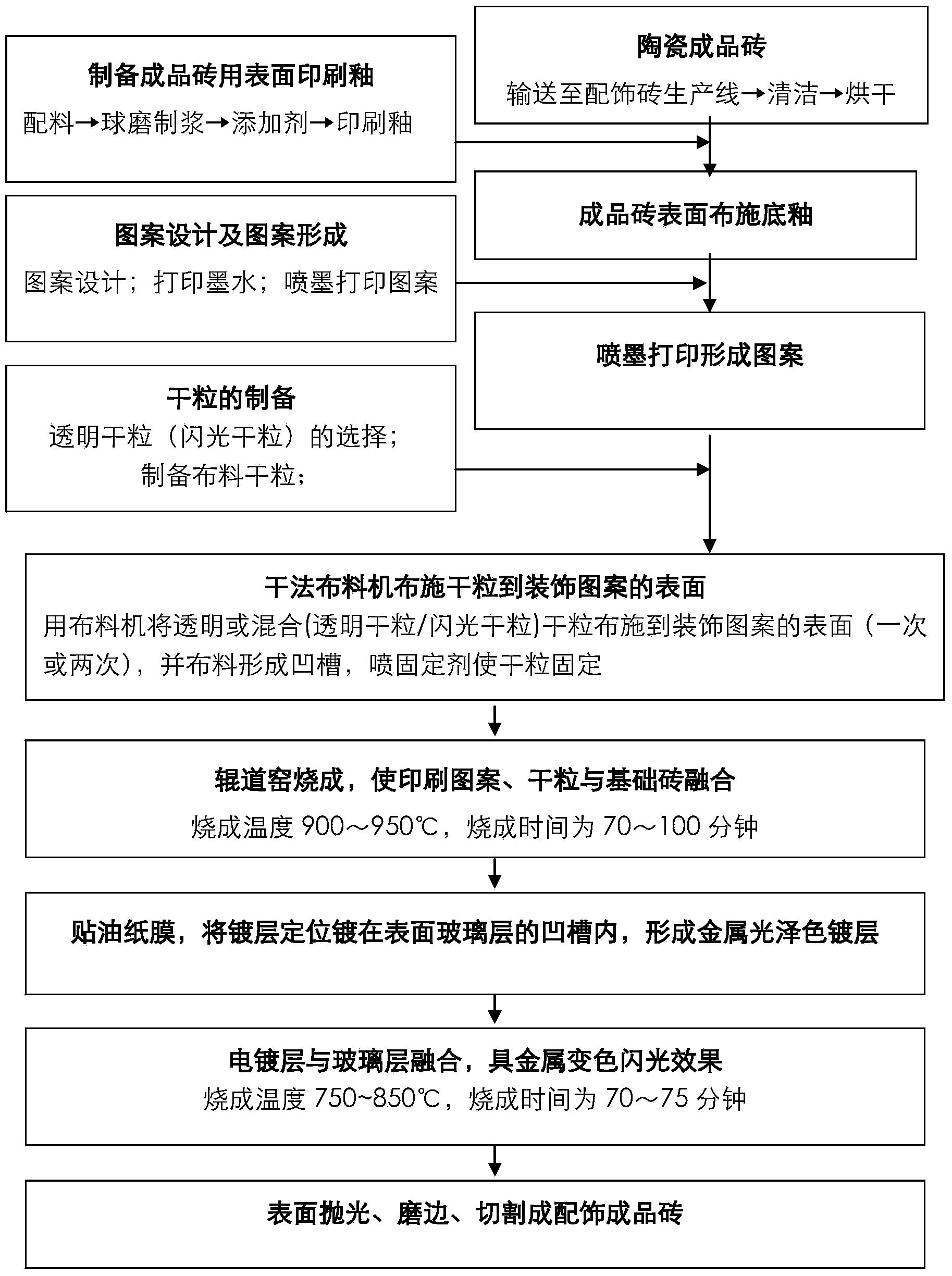

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

Ceramic honeycomb filter, its production method, and plugging material for ceramic honeycomb filter

ActiveUS20070039298A1Small differenceImprove thermal shock resistanceCombination devicesAuxillary pretreatmentParticulatesOxide matrix

A ceramic honeycomb filter comprising a sintered ceramic honeycomb body having porous partition walls defining flow paths, and plugs formed in predetermined flow paths for removing particulate matter from an exhaust gas passing through the porous partition walls, the sintered ceramic honeycomb body being formed by a cordierite-based ceramic material, at least part of the plugs comprising ceramic particles and an amorphous oxide matrix formed from colloidal oxide.

Owner:HITACHI METALS LTD

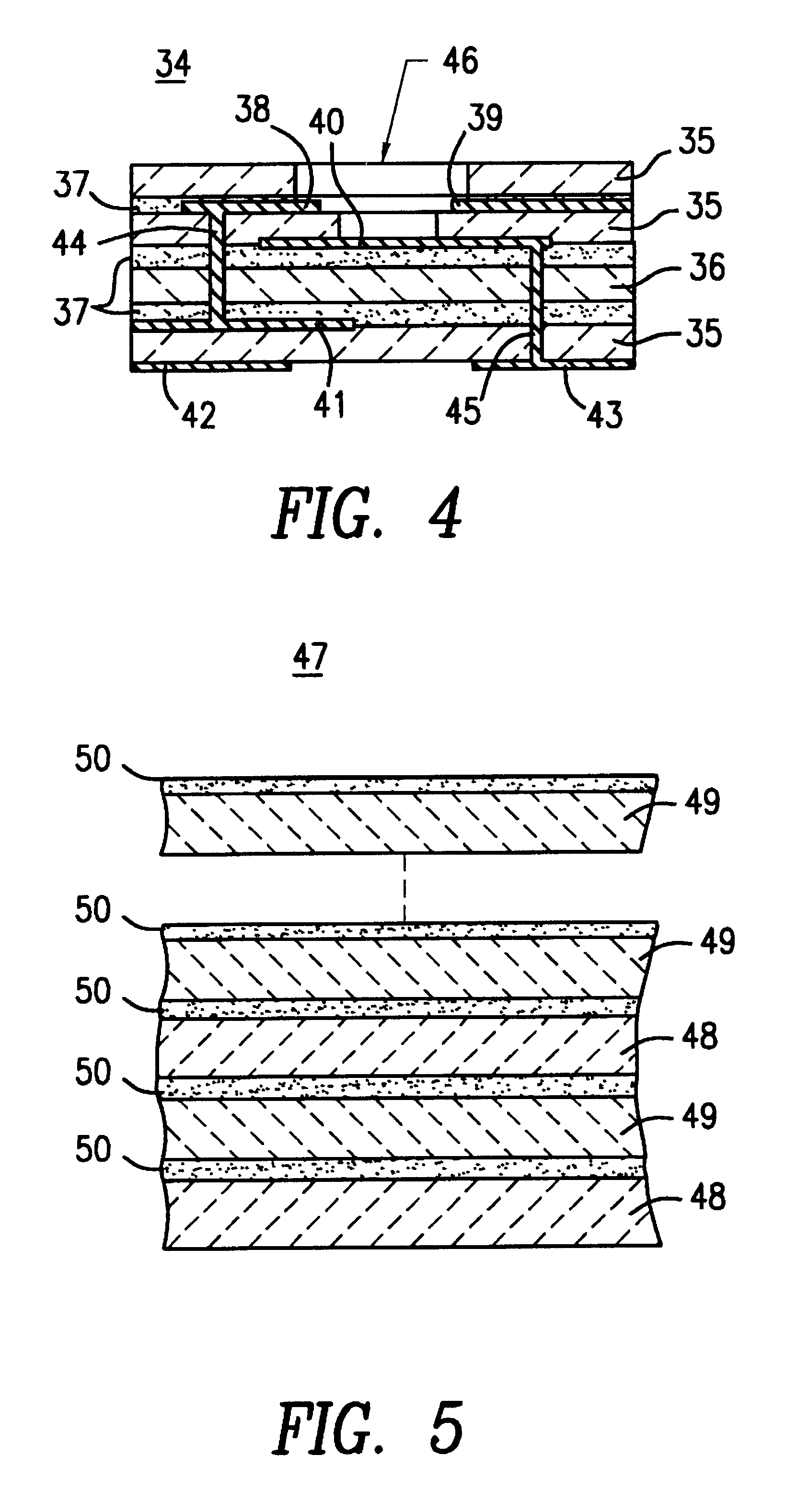

Screen-printed filter capacitors for filtered feedthroughs

InactiveUS7569452B2Prevent leakageAvoid spreadingAnti-noise capacitorsFeed-through capacitorsScreen printingDielectric layer

A filter capacitor comprising a pre-sintered substrate supporting alternating active and ground electrode layers segregated by a dielectric layer is described. The substrate is of a ceramic material that maintains its shape and structure dimensions even after undergoing numerous sintering steps. Consequently, relatively thin active and ground electrode layers along with the intermediate dielectric layer can be laid down or deposited by a screen-printing technique. Using a relatively thin over-glaze in comparison to a thick upper dielectric layer finishes the capacitor. Consequently, a significant amount of space is saved in comparison to a comparably rated capacitor or, a capacitor of a higher rating can be provided in the same size as a conventional prior art capacitor. The pre-sintered ceramic substrate is used instead of conventional tape cast technology for the base dielectric.

Owner:WILSON GREATBATCH LTD

Piezoelectric device and method of manufacturing same

InactiveUS20050156362A1Piezoelectric/electrostrictive device manufacture/assemblyCeramic shaping apparatusMetallurgySURFACTANT BLEND

The present invention relates to a device and methods of making the same. The method comprises contacting a ceramic powder with a first polymer and surfactant to form a slip mixture, mixing the slip mixture, injecting the slip mixture into a mold to form a green body, removing the mold from the green body, sintering the green body to form a sintered ceramic body, and embedding the sintered ceramic body in a second polymer to form a composite. An apparatus for forming a net shaped green body includes a mold, supplemental mold and mold assembly.

Owner:AUTHORIZER TECH INC

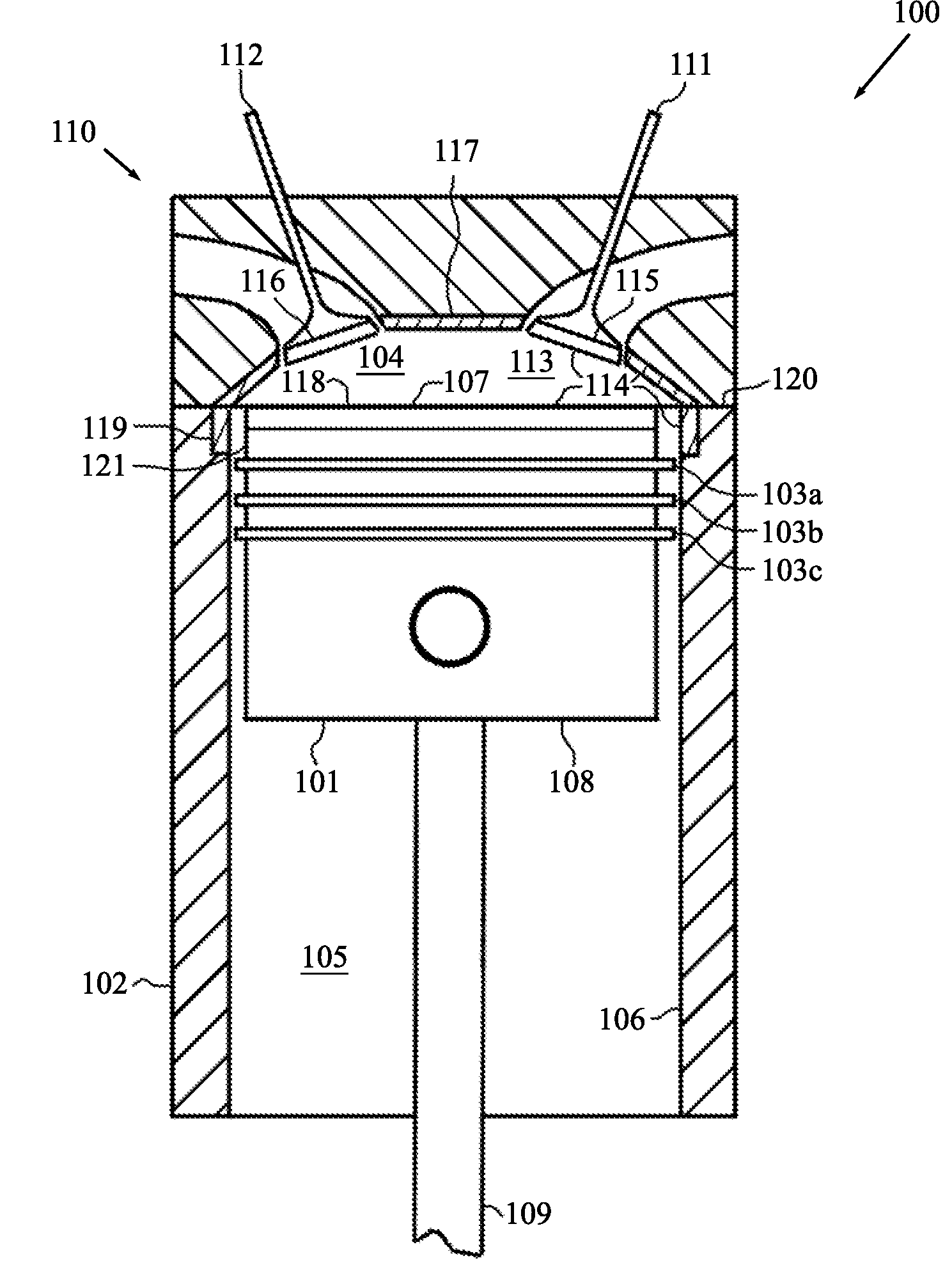

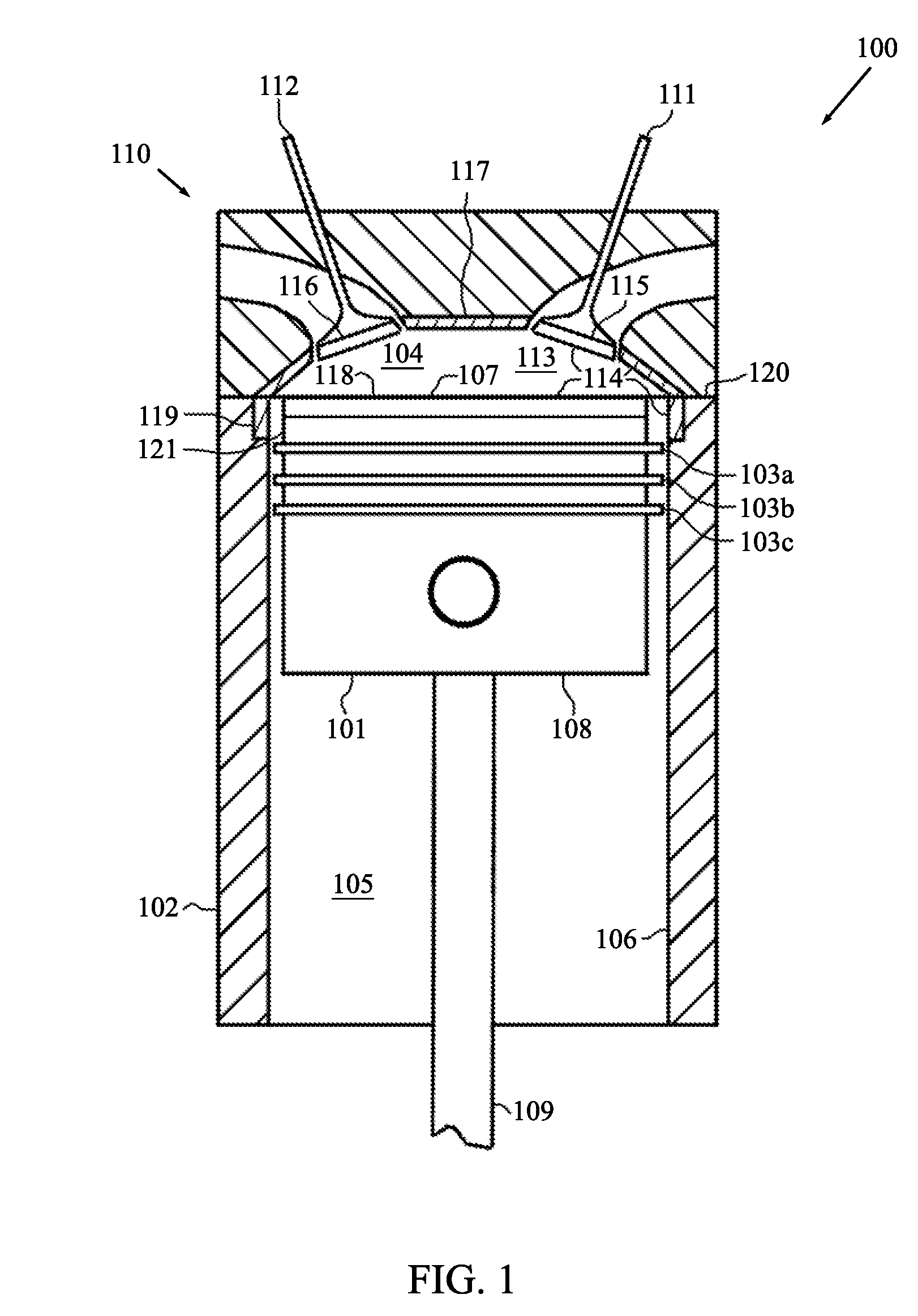

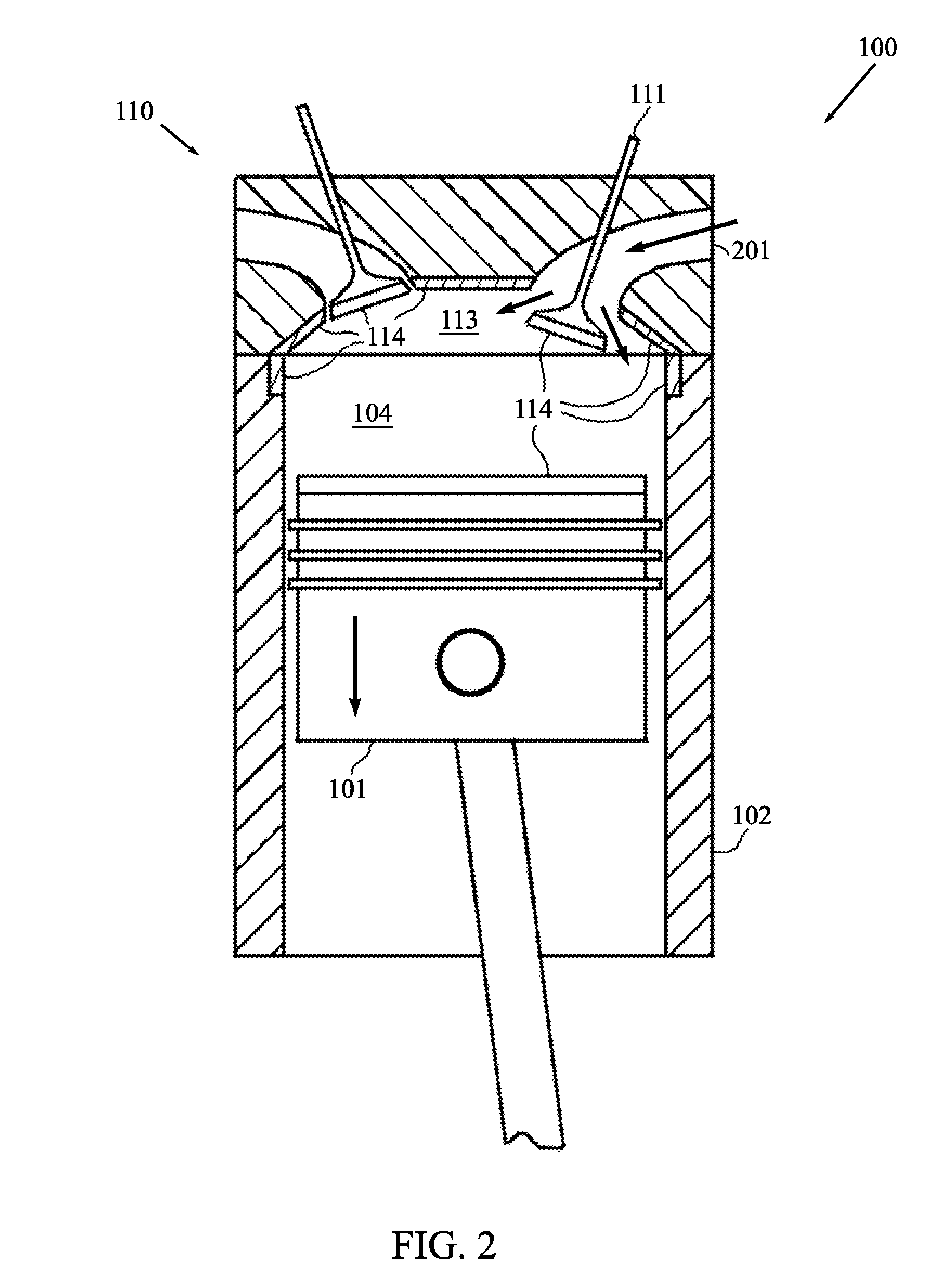

Low heat rejection high efficiency internal combustion engine

InactiveUS20090071434A1Improve efficiencyLow heat rejection rateCasingsInternal combustion piston enginesExternal combustion engineVariable valve timing

An internal combustion engine including a low thermal capacity, low thermal conductivity insulating liner is provided. The insulating liner may be positioned to line the combustion chamber and a portion of the cylinder wall. The insulating liner may comprise a high aspect morphology sintered ceramic material and may further include a surface coating. The internal combustion engine may be a four-stroke diesel engine with variable valve timing operating using an asymmetric cycle. Through the asymmetric cycle and insulative properties of the insulating liner, the heat loss of the disclosed internal combustion engine is significantly less than that of a similar conventional internal combustion engine, resulting in significant efficiency improvements.

Owner:DWIGHT ENGINE TECHNOLGIES

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

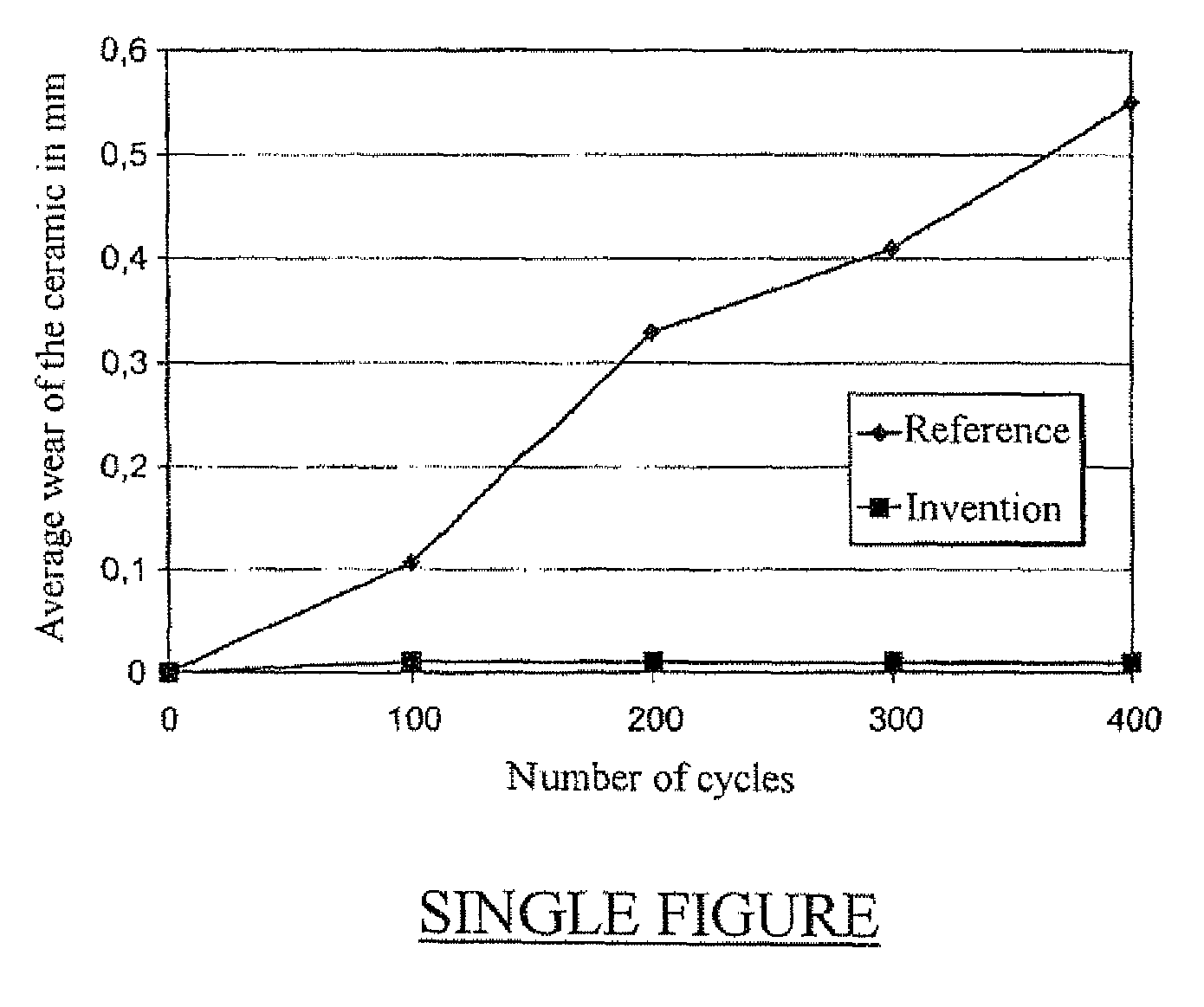

Transparent polycrystalline sintered ceramic of cubic crystal structure

ActiveUS20050164867A1Increased mechanical load capacityHigh hardnessMaterial nanotechnologyCrystal structureTransmittance

Transparent polycrystalline sintered ceramic of cubic crystal structure. The invention relates to the field of technical ceramic and relates to transparent polycrystalline sintered ceramics of cubic crystal structure for applications with increased mechanical stress, e.g., as protective or armoring ceramic. Provided are sintered ceramics that combine a high transmission of RIT>75% of the theoretical maximum value with a distinctly improved hardness. Transparent polycrystalline sintered ceramics of cubic crystal structure with a real in-line transmission RIT>75% of the theoretical maximum value measured on 0.8 mm-thick polished plates and for light of a wavelength between 600 and 650 nm, and with an average grain size D in the range of 60 nm<D<10 μm are provided.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method of manufacturing electrical resistance heating element

ActiveUS7275309B2Reducing range variationPrevent the sintered ceramicsEnvelope/housing resistor manufactureSemiconductor/solid-state device manufacturingMetalMelting point

A method of manufacturing an electrical-resistance heating element includes forming sintered ceramics or calcined ceramics, forming an electrode on the sintered ceramics or the calcined ceramics, and forming a ceramic base material having mainly a high melting point metal on the electrode embedded therein, thereby forming a heating element with built-in electrode.

Owner:NGK INSULATORS LTD

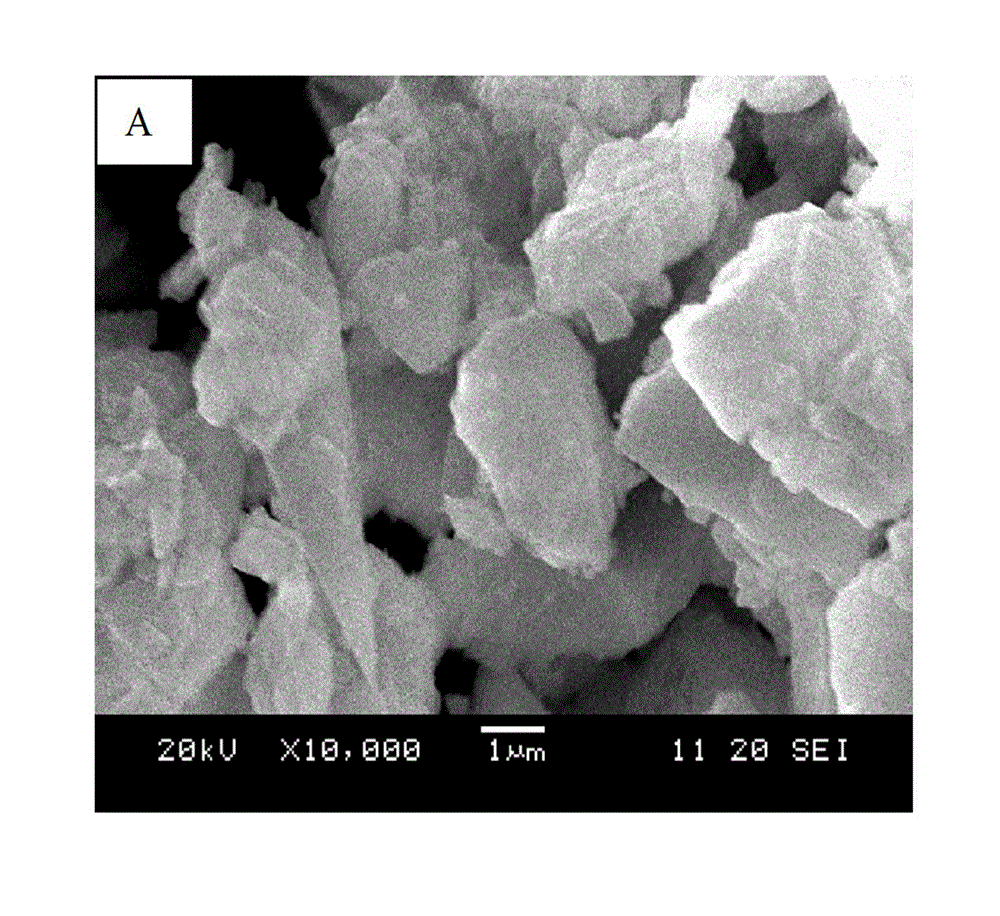

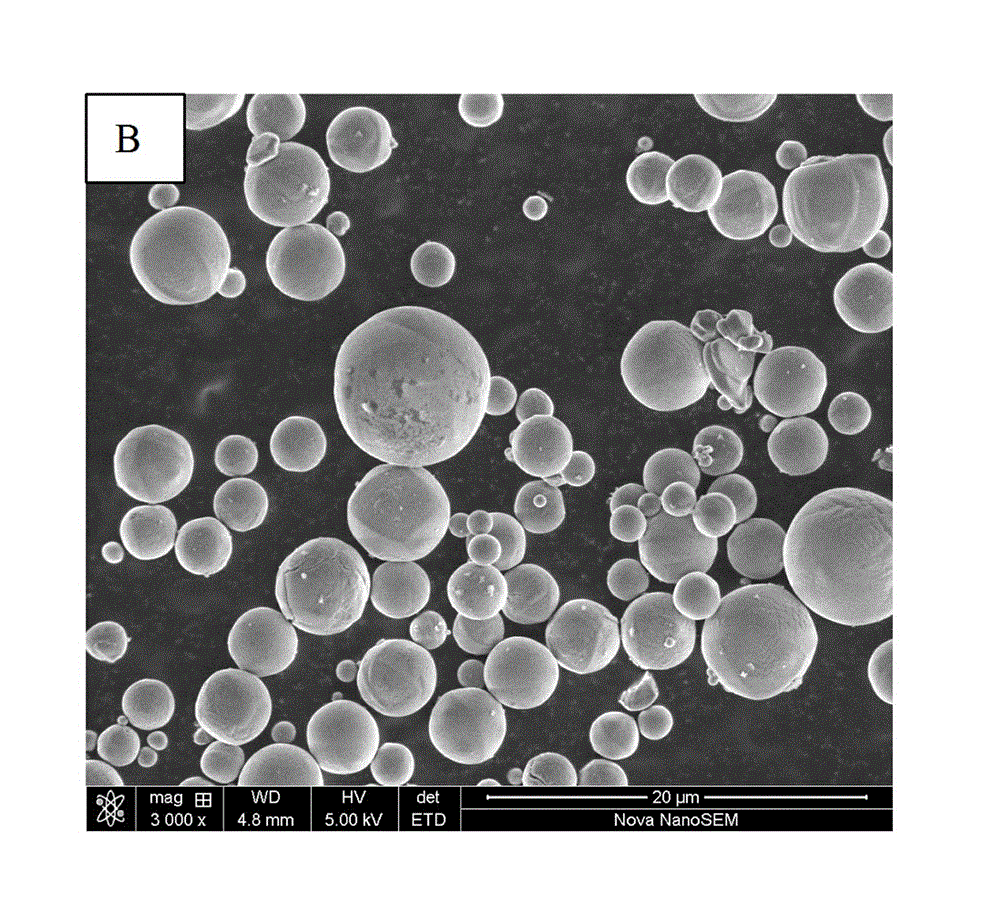

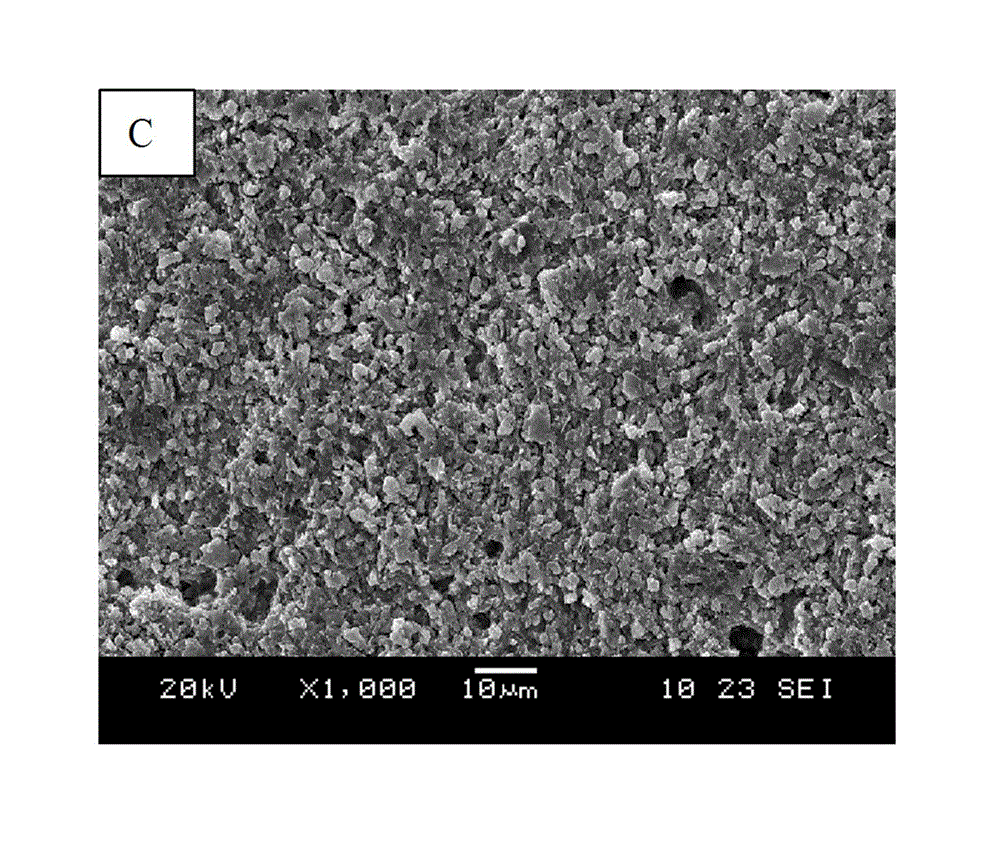

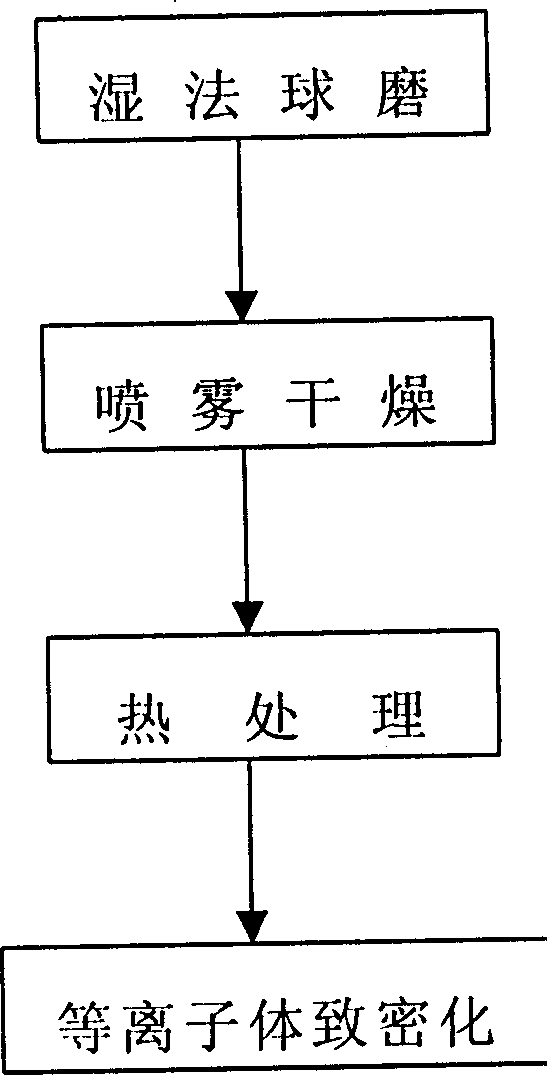

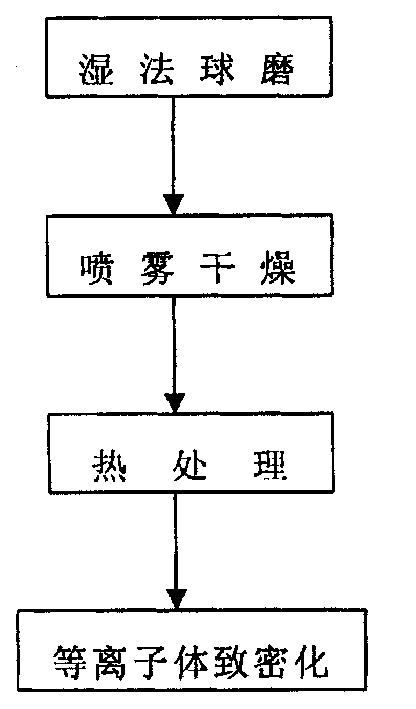

Method for producing and using large particle ball nano ceramic powder

InactiveCN1377857AUniform tissue structureImprove performanceCeramic layered productsThermal sprayingHigh density

The production process of nano ceramic powder includes the steps of: wet ball milling to obtain water-thinned nano colloid; spray drying to obtain large particle spheircal nano ceramic powder; heat treatment; and plasma densifying the large particle spherical nano ceramic powder after being heat treated. The nano ceramic powder thus produced has good flowability and high density and may be used through hot spray painting and sintering to form. The present invention reduce fragility of ceramic and raise the performance of hot spray painted and sintered ceramic products.

Owner:BAIFURUI MATERIAL HUNAN

Process for the preparation of a sintered ceramic spark plug

Process for the preparation of a ceramic wherein: 50% to 75% by weight of a compound intended to form a conductive phase, and 25% to 50% by weight of one or more materials allowing the formation of insulating phases composed of silicon nitride and modified silicon oxynitride are mixed in a receptacle containing a liquid after a thermal treatment leading to sintering of the ceramic; this mixture is subjected to grinding, drying and sieving operations; this mixture is pressed; and this mixture is sintered so as to obtain a ceramic with a porosity of between 0 and 30%. The sintering is carried out under a pressure of at least 50 bar of a gas which is inert towards the constituents of the mixture. Ceramic thus obtained and spark plug comprising it.

Owner:AEVA

Low-temperature sintered ceramic glazed tile and preparation method thereof

The invention discloses a low-temperature sintered ceramic glazed tile and preparation method thereof. The ceramic glazed tile comprises a tile blank, a top glaze layer, and a print glaze layer. In tile blank component raw materials, petalite (LiAlSi4O10) is adopted as a tile blank temperature-reducing material. A product is obtained through the steps of blending, ball milling and sieving, drying, press-molding, top glaze applying, roller printing, print glaze applying, and sintering. Sintering temperatures are that: sintering is carried out for 15-20min at a temperature of 970 DEG C when the material is delivered into a kiln; sintering is carried out for 20-25min at a temperature of 970-1150 DEG C; sintering is carried out for 5-10min at a temperature of 1150-1200 DEG C; temperature is maintained for 5-10min at 1200 DEG C; and sintering is carried out for 20-25min at a temperature of 1200-150 DEG C. According to the invention, lithium feldspar in lithium ore tailings is adopted as a tile blank temperature reducing material, such that defects of high sintering temperature and long sintering time of glazed tile in prior arts are overcome. Therefore, glazed tile low-temperature fast sintering is realized, energy consumption is reduced, and resource utilization rate is improved.

Owner:景德镇欧神诺陶瓷有限公司

Process for the preparation of a sintered ceramic, ceramic thus obtained and spark plug comprising it

Process for the preparation of a ceramic wherein:50% to 75% by weight of a compound intended to form a conductive phase, and 25 % to 50% by weight of one or more materials allowing the formation of insulating phases composed of silicon nitride and modified silicon oxynitride are mixed in a receptacle containing a liquid after a thermal treatment leading to sintering of the ceramic;this mixture is subjected to grinding, drying and sieving operations;this mixture is pressed;and this mixture is sintered so as to obtain a ceramic with a porosity of between 0 and 30%.The sintering is carried out under a pressure of at least 50 bar of a gas which is inert towards the constituents of the mixture.Ceramic thus obtained and spark plug comprising it.

Owner:AEVA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com