Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Ceramic polymer composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

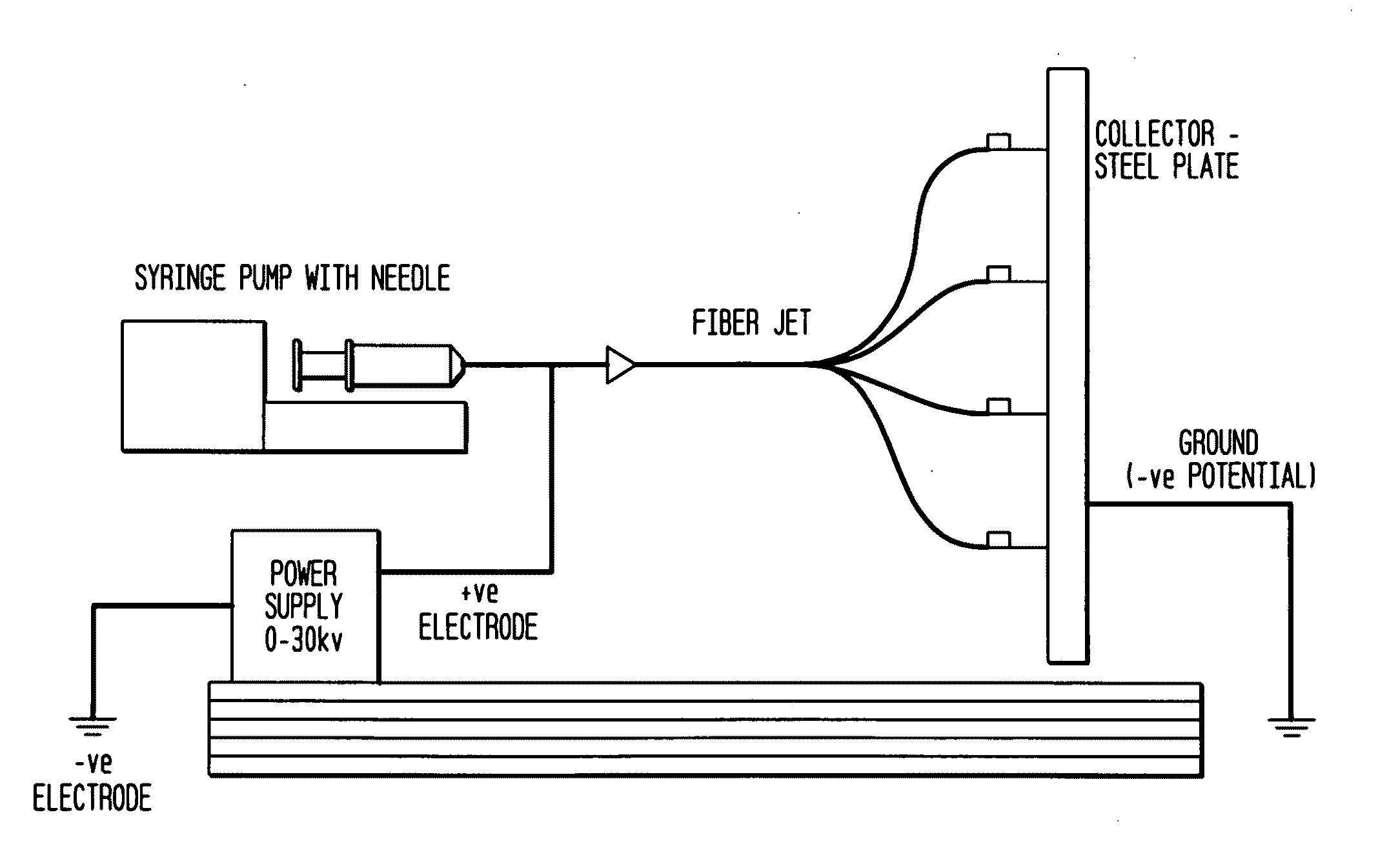

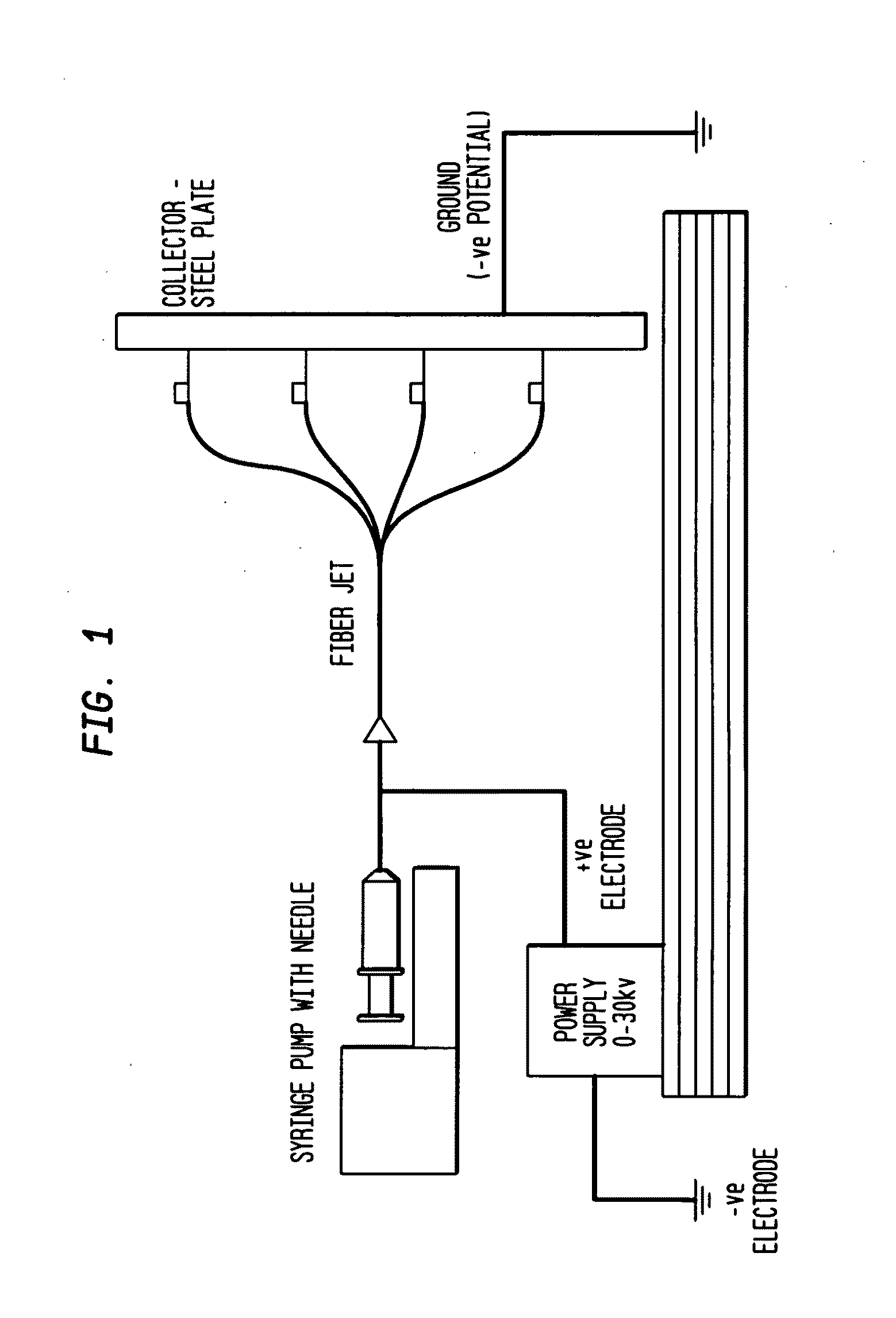

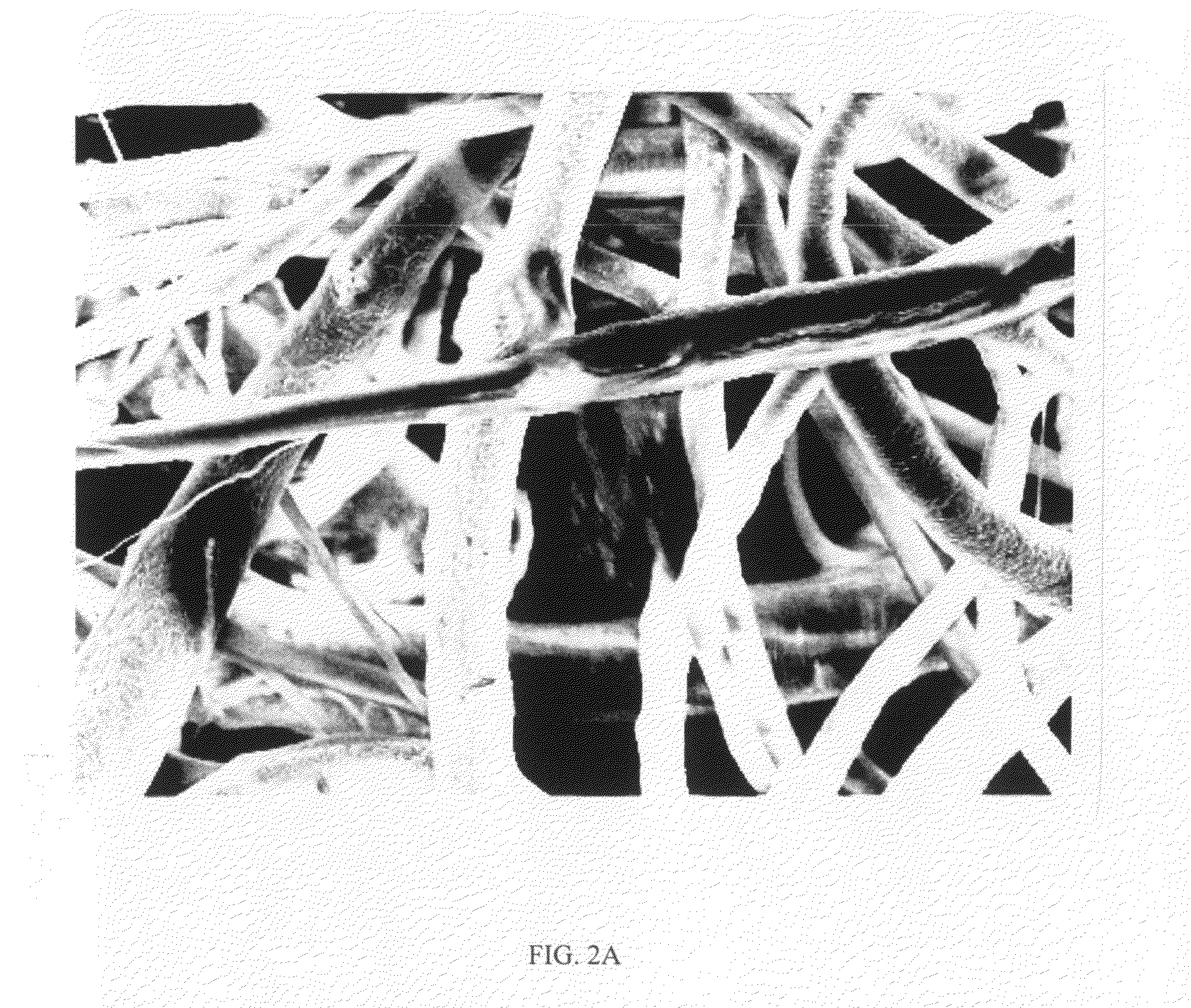

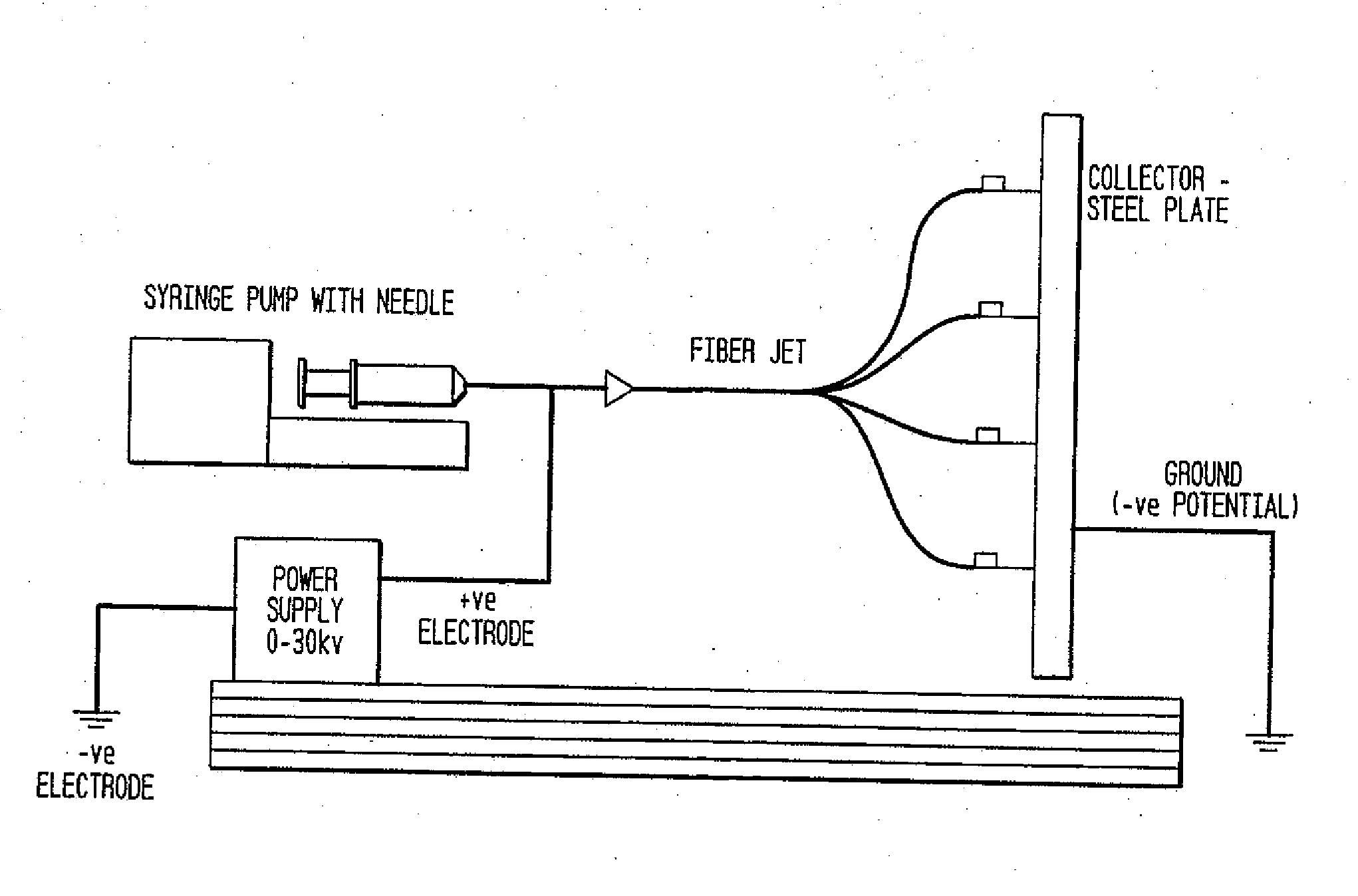

Electrospun Ceramic-Polymer Composite As A Scaffold For Tissue Repair

The present invention relates to compositions and methods of preparing a three-dimensional matrix of micron sized electrospun fibers, wherein the electrospun fibers are formed from a electrospun composite comprising a bioactive ceramic component and a polymer component. The matrix provides an osteoconductive and osteoinductive scaffold supporting osteogenesis and thereby facilitates bone repair.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

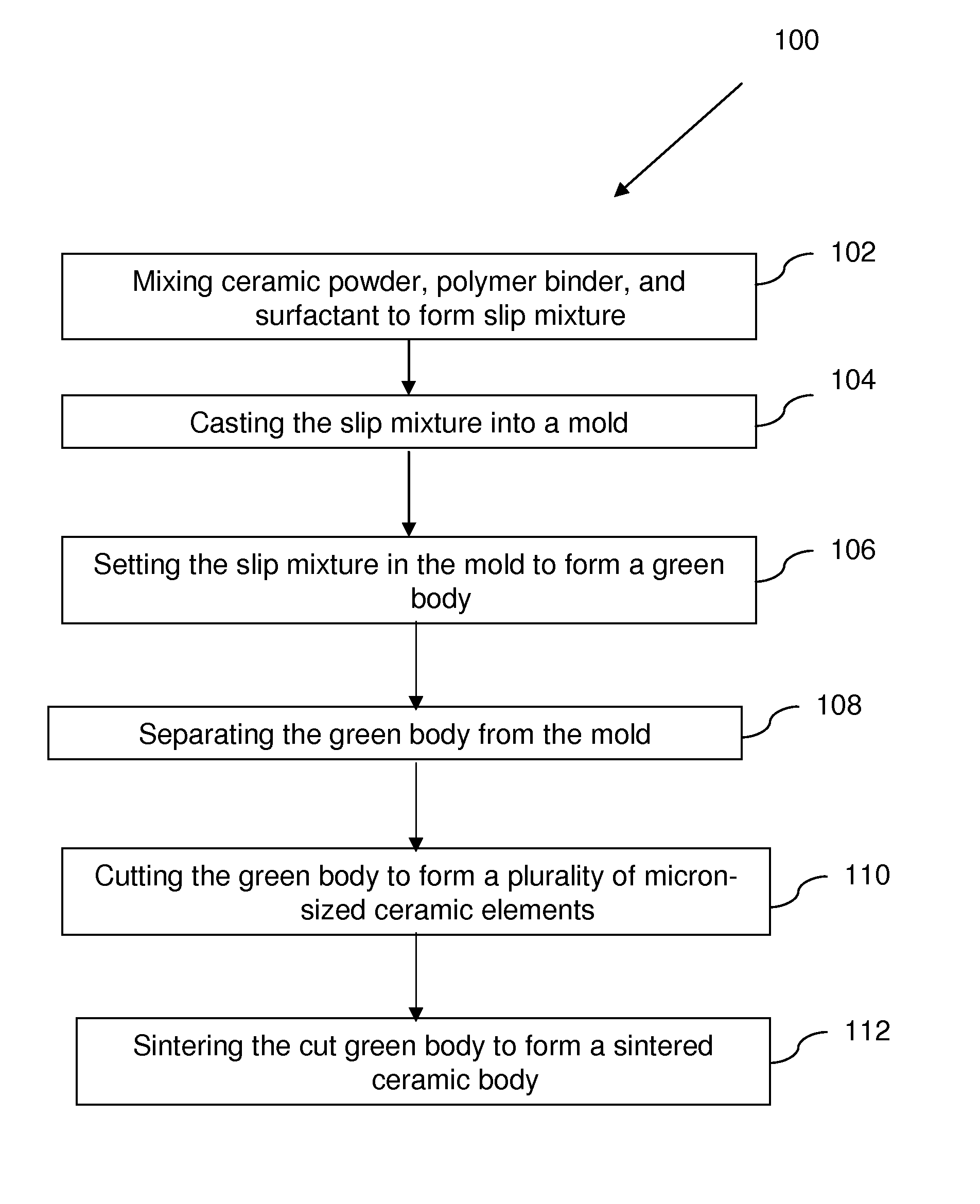

Method for manufacturing a piezoelectric ceramic body

ActiveUS8703040B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersMetallurgyTransducer

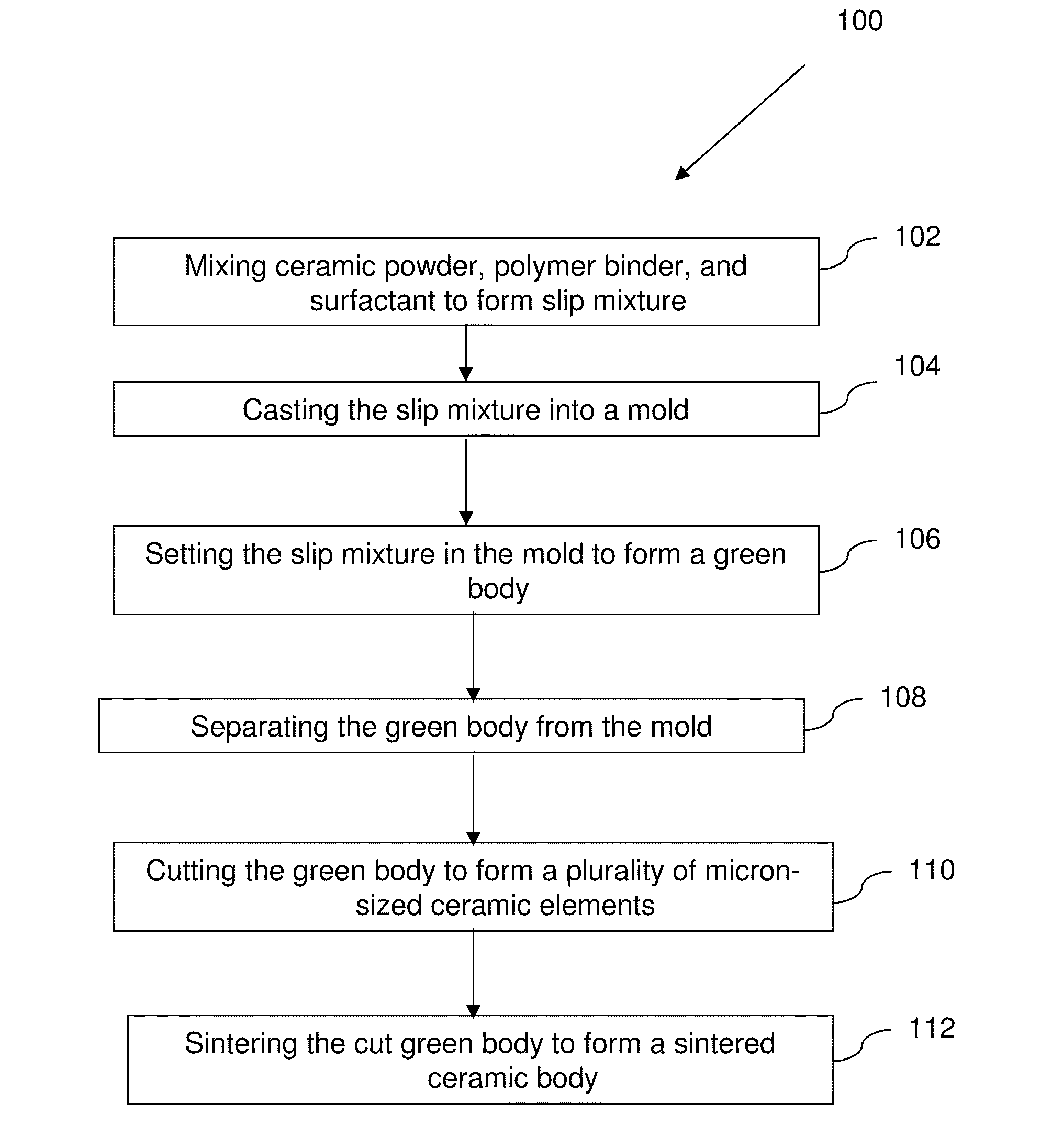

The present invention relates to a method of manufacturing a piezoelectric ceramic body and devices therefrom. The method comprises mixing a piezoelectric ceramic powder with a polymer binder and surfactant to form a slip mixture, casting the slip mixture into a mold and setting to the slip mixture in the mold to form a green body, cutting the green body to form a cut green body with an array of micron-sized ceramic elements and separation, and sintering the cut green body to form a sintered ceramic body. The sintered ceramic body can be further process to encasing in a polymer material to form a piezoelectric ceramic-polymer composite. The piezoelectric ceramic-polymer composite can be further processed to form devices such as acoustic transducers and sensors.

Owner:SONAVATION INC

Method for Manufacturing a Piezoelectric Ceramic Body

ActiveUS20110010904A1Easy to manufacturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersMetallurgyCeramic polymer composites

The present invention relates to a method of manufacturing a piezoelectric ceramic body and devices therefrom. The method comprises mixing a piezoelectric ceramic powder with a polymer binder and surfactant to form a slip mixture, casting the slip mixture into a mold and setting to the slip mixture in the mold to form a green body, cutting the green body to form a cut green body with an array of micron-sized ceramic elements and separation, and sintering the cut green body to form a sintered ceramic body. The sintered ceramic body can be further process to encasing in a polymer material to form a piezoelectric ceramic-polymer composite. The piezoelectric ceramic-polymer composite can be further processed to form devices such as acoustic transducers and sensors.

Owner:SONAVATION INC

Formulation of environment-friendly ceramic polymer composite material and preparation thereof

ActiveCN101580615AReduce temperature sensitivityExcellent physical and chemical propertiesSolid waste managementThermoplasticCross-link

The invention belongs to the field of building materials, an in particular relates to a formulation of an environment-friendly ceramic polymer composite material and a preparation thereof. The technical proposal is that the environment-friendly ceramic polymer composite material comprises thermoplastic plastics, bamboo powder, plasticizers, internal and external lubricants, cross-linking modifiers, bulking agents, fire retardants, pigments, and gray materials. The technical proposal is energy conservation and emission reduction and has the advantages that the materials are acid resistant and alkali resistant, the temperature sensitivity is low and the physical and chemical properties are superior. Various sectional materials prepared from the environment-friendly ceramic polymer composite material have the advantages of stable physical and chemical properties, high strength, no toxicity, tastelessness, acid and alkali resistance, and high and low temperature resistance; and after surface treatment, the sectional materials can generate woody feelings, and have high imitative degree and secondary processing properties of sawing, nailing, cutting or bolt fixing.

Owner:SHANDONG HUAZHIYE NEW MATERIAL TECH CO LTD

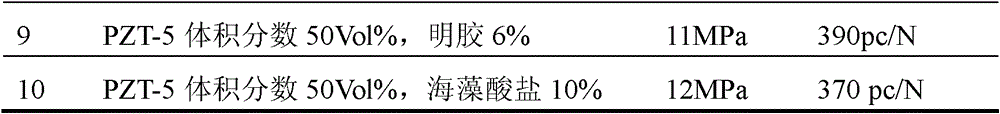

Piezoelectric ceramic-polymer composites preparation method and piezoelectric ceramic-polymer composites

InactiveCN103915561ANo wearImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionLaser processingRoom temperature

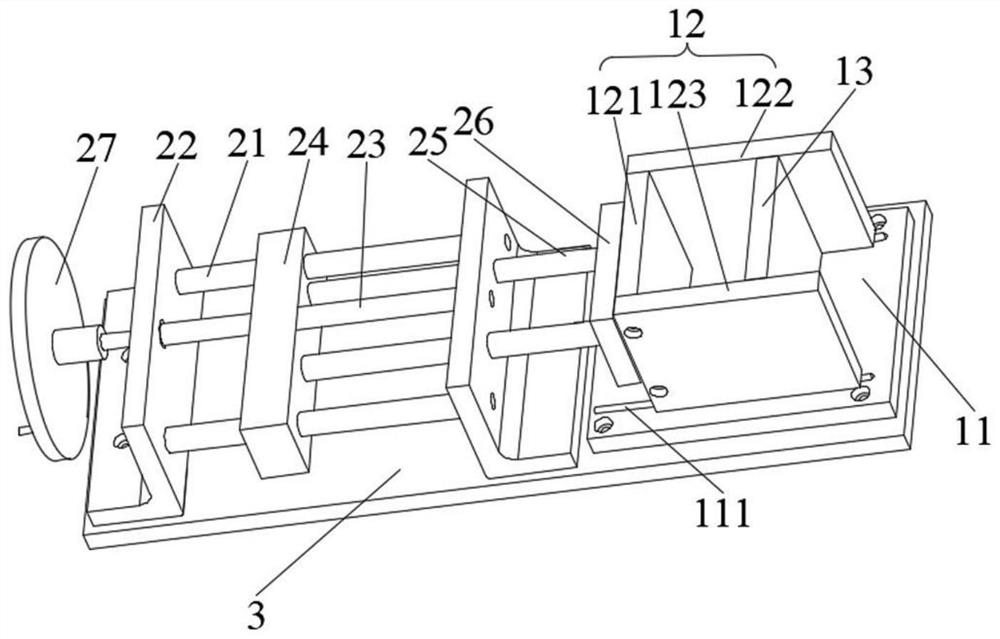

The invention discloses a piezoelectric ceramic-polymer composites laser processing preparation method. The method comprises a first step of fully mixing ceramic powder, a dispersant, an organic mono, a crosslinking agent and water to obtain a ceramic slurry, wherein the ceramic powder represents 45vol% to 53vol% of the slurry; a second step of putting the ceramic slurry obtained in the first step into a mold; a third step of initiating gel reaction at a certain temperature, curing and drying at a constant temperature, and obtaining a piezoelectric ceramic biscuit with the strength greater than 15MPa; and a fourth step of cutting and sintering the biscuit obtained in the third step using laser, then filling in polymers, cutting off a base after curing at a room temperature, and obtaining 1-3 or 2-2 piezoelectric ceramic-polymer composites. According to the invention, large-scale pressurized equipment required for preparing ceramic pieces through a traditional dry-pressed way is not needed, and a dense ceramic body of a large area can be prepared without external pressure; and the cutting efficiency is greatly improved, the operation is simple and easy to control, and a cutting path can be changed flexibly so that the structure can be controlled and the device performance can be improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Active acoustic array for ultrasonic biomedical applications

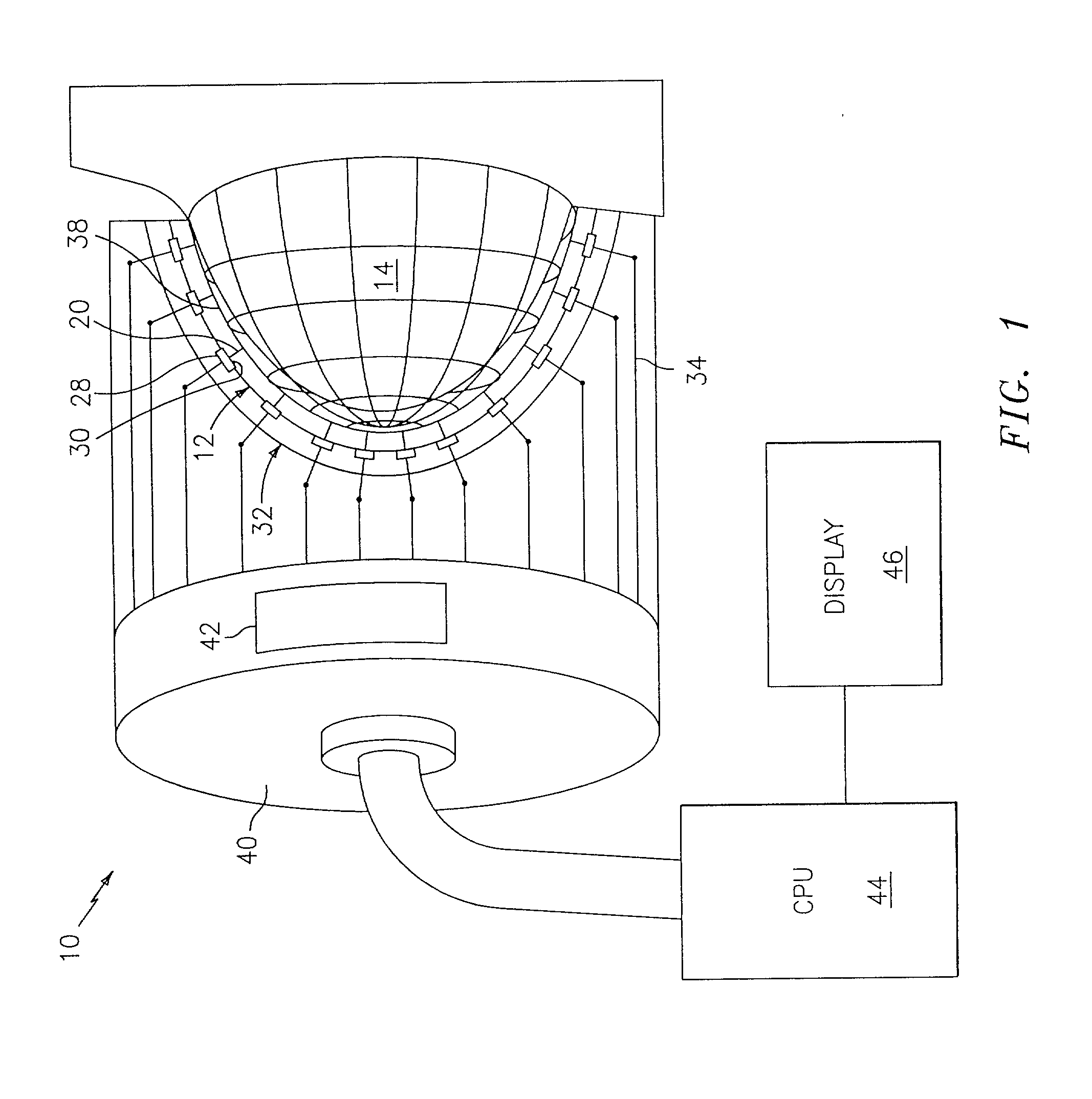

The present invention relates to a device for detecting cancer in human tissue. The device comprises an acoustic array shaped to conform to and surround a portion of the human anatomy and a material for acoustically coupling the acoustic array and the human anatomy portion. The acoustic array is formed from a plurality of doubly curved segments. Each segment is formed by a piezoelectric ceramic polymer composite material with an acoustic element pattern formed on one surface via the selective deposition of a conductive material. The acoustic element pattern contains a plurality of acoustic elements which act as both transmitters and receivers. The acoustic array further includes a backing material which provides a desired mechanical damping to each segment and defines the shape of the array. The device further includes a housing which includes signal conditioning electronics to condition signals received from the acoustic array. A central processing unit is provided to create cross sectional images of the human tissue under examination. A display unit is provided to display the cross sectional images.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Preparation method of piezoelectric ceramics-polymer composite material

InactiveCN102745996AImprove reliabilityImprove electrical performanceRoom temperatureCeramic polymer composites

The invention relates to a preparation method of a piezoelectric ceramics-polymer composite material. The method is characterized in that ceramic powder, a dispersant and a curing agent system are added are added in water for mixing, a reaction is initiated to prepare the piezoelectric ceramics biscuit with the strength greater than 10 MPa, and processes of cutting and sintering are carried out. The method comprises the following steps: 1) removing water of the ceramic powder, the dispersant, the curing agent system and fully mixing, defoaming, performing a gel reaction on the ceramic slurry under certain temperature and solidifying to obtain the piezoelectric ceramics gel biscuit with strength greater than 10MPa; and 2) cutting the piezoelectric ceramics biscuit from the step 1), sintering, then filling the polymer, solidifying under room temperature and cutting a pedestal to obtain 1-3 or 2-2 piezoelectric ceramics polymer composite material. The method has the advantages of high reliability, simple required equipment, simple operation, and can be used for preparing the ceramic-polymer piezoelectric composite material with large area and less defect crack.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Active acoustic array for ultrasonic biomedical applications

The present invention relates to a device for detecting cancer in human tissue. The device comprises an acoustic array shaped to conform to and surround a portion of the human anatomy and a material for acoustically coupling the acoustic array and the human anatomy portion. The acoustic array is formed from a plurality of doubly curved segments. Each segment is formed by a piezoelectric ceramic polymer composite material with an acoustic element pattern formed on one surface via the selective deposition of a conductive material. The acoustic element pattern contains a plurality of acoustic elements which act as both transmitters and receivers. The acoustic array further includes a backing material which provides a desired mechanical damping to each segment and defines the shape of the array. The device further includes a housing which includes signal conditioning electronics to condition signals received from the acoustic array. A central processing unit is provided to create cross sectional images of the human tissue under examination. A display unit is provided to display the cross sectional images.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Electrospun Ceramic-Polymer Composite As A Scaffold for Tissue Repair

The present invention relates to compositions and methods of preparing a three-dimensional matrix of micron sized electrospun fibers, wherein the electrospun fibers are formed from a electrospun composite comprising a bioactive ceramic component and a polymer component. The matrix provides an osteoconductive and osteoinductive scaffold supporting osteogenesis and thereby facilitates bone repair.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

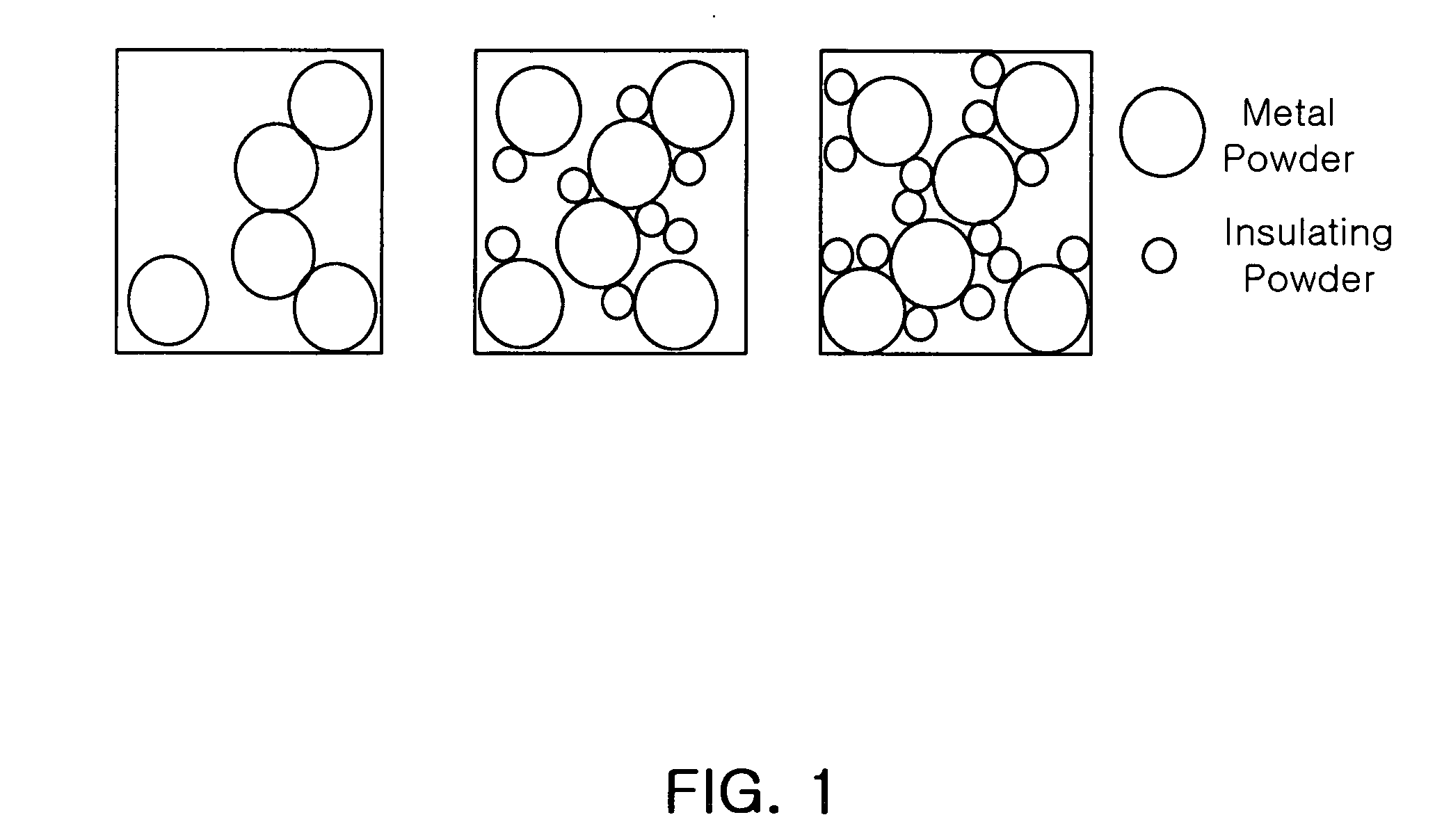

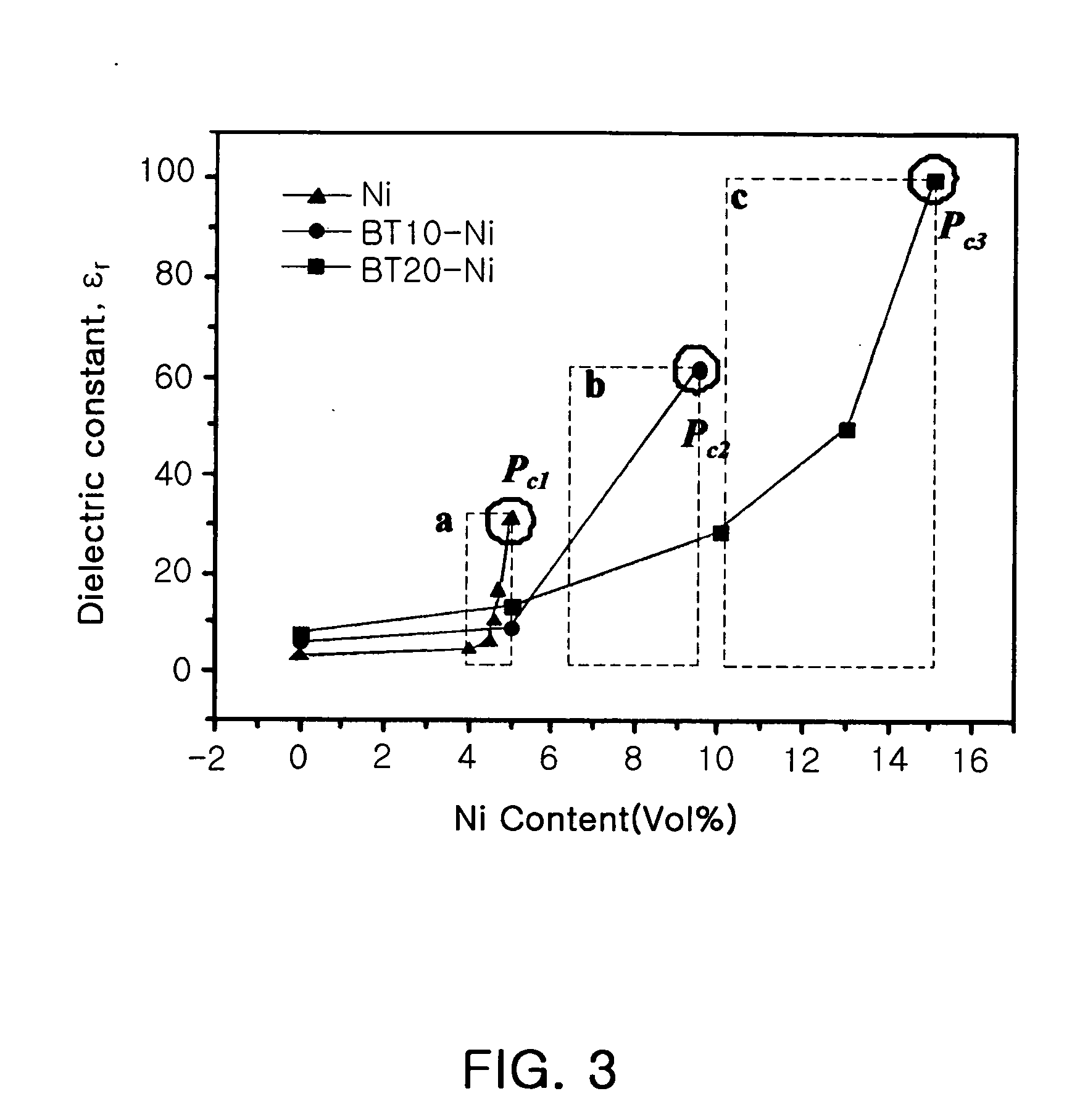

High-dielectric constant metal-ceramic-polymer composite material and method for producing embedded capacitor using the same

InactiveUS20060223931A1Avoid it happening againHigh metal contentFixed capacitor dielectricConductive materialCapacitanceCeramic polymer composites

The invention relates to a high-dielectric constant metal / ceramic / polymer composite material and a method for producing an embedded capacitor. As ceramic particles having a relatively small size are bound to the surface of metal particles having a relatively large size by mixing, the occurrence of percolation can be prevented without coating the metal particles, and at the same time, the capacitance of an embedded capacitor can be increased. In addition, a process for coating the surface of the metal particles can be omitted, thus contributing to the simplification of the overall preparation procedure.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Piezoelectric ceramics polymer composite materials with high ceramic content and preparation method thereof

ActiveCN104795488AImprove performanceSimple processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionCeramic polymer compositesPolymer composites

The invention provides a preparation method of the piezoelectric ceramics polymer composite materials. The method includes: preparing the piezoelectric ceramics polymer composite membrane through curtain coating-hot pressing or dry pressing-hot pressing firstly, conducting the intersecting lamination hot pressing on one layer or multiple layers of composite membranes and polymer silk screen membranes to form the piezoelectric ceramics polymer composite materials; or preparing the piezoelectric ceramics polymer composite materials through hot pressing after the curtain coating is conducted on the piezoelectric composite membrane directly on the polymer silk screen membrane through the curtain coating method. The piezoelectric ceramics polymer composite material with the high ceramic content is simple in technology, low in cost, capable of preparing the piezoelectric composite membrane with the excellent comprehensive performance and large size, applicable to the piezoelectric touchpad, and capable of realizing industrialization.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

Superhydrophobic and Oleophobic Ceramic Polymer Composite Coating

An article having a superhydrophobic or oleophobic ceramic polymer composite surface is formed by the coating of the surface with a fluid comprising a polymer, copolymer, or polymer precursor and a plurality of glass, ceramic, or ceramic-polymer particles. The particles have fluorinated surfaces and at least a portion of the polymer's repeating units that are fluorinated or perfluorinated. The composite can be a cross-linked polymer.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Preparation method of piezoelectric ceramic polymer composite material

InactiveCN105789431AExcellent piezoelectric propertiesSimple preparation processPiezoelectric/electrostrictive device manufacture/assemblyConductive polymerCeramic polymer composites

The invention relates to a piezoelectric ceramic polymer composite material, especially a preparation method of the piezoelectric ceramic polymer composite material. A conductive polymer layer is clamped between two piezoelectric material layers, and the piezoelectric ceramic polymer composite material of the integrated structure is formed via hot pressing. The conductive polymer layer is of a conductive particle polymer composite material, the piezoelectric material layer is of a 0-3 type piezoelectric ceramic polymer composite material, and the conductive polymer layer improves the flexibility of the 0-3 type composite material while having no influence on the piezoelectric performance of the 0-3 type composite material. The piezoelectric ceramic polymer composite material is simple in preparation technology, low in cost and high in comprehensive performance, can be used to prepare large-size piezoelectric composite films, and can be applied to a piezoelectric touch control plate and realize industrial production.

Owner:JIANGSU UNIV

A ceramic polymer composite material and a preparing method thereof

A ceramic polymer composite material is disclosed. The composite material comprises following components by mass: 47-85% of 3Y-ZrO2, 0-8% of polyethylene, 0-8% of polypropylene, 3-15% of paraffin, 0-10% of microcrystalline wax, 0.3-4% of a dispersant, 0-5% of a plasticizer, and 5-25% of graphite particles with the particle size of the graphite particles ranging from 1 [mu]m to 1 mm. The 3Y-ZrO2, the polyethylene, the polypropylene, the paraffin, the microcrystalline wax, the dispersant, the plasticizer and the graphite particles are sintered at a high temperature to obtain a ceramic material with a spongy porous crosslinking structure. The ceramic composite material with light weight and good toughness is formed by injecting the ceramic material with the spongy porous crosslinking structure into a polymer resin material. A preparing method of the ceramic polymer composite material is also disclosed.

Owner:湖北国瓷科技有限公司

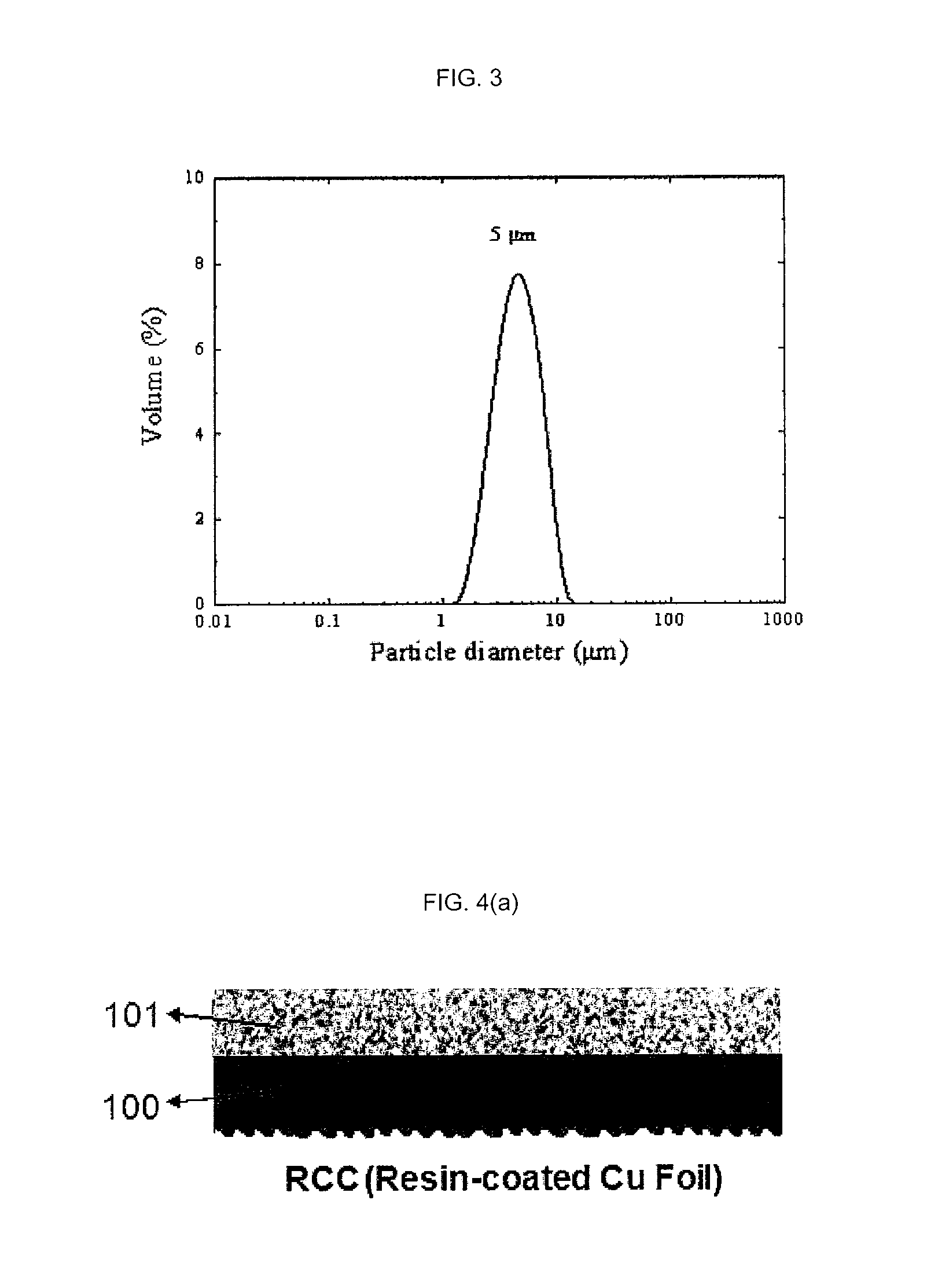

Thermally Conductive Ceramic-Polymer Composite and Method of Preparing the Same

ActiveUS20160046851A1Improve insulation performanceImprove thermal conductivityLamination ancillary operationsLaminationThermoplasticCeramic polymer composites

Provided are a thermally conductive ceramic-polymer composite in which thermoplastic polymers form a matrix, and planar fragments of thermally conductive ceramic or thermally conductive ceramic powder is uniformly dispersed on a grain boundary between thermoplastic polymer particles, thereby forming a thermal pathway, wherein the thermoplastic polymer particles are formed in a faceted shape, and the average size of the planar fragments of thermally conductive ceramic or thermally conductive ceramic powder is smaller than 1 / 10 of that of the thermoplastic polymer particles, and a method of preparing the same. Accordingly, since dispersion and interfacial affinity of a thermally conductive ceramic filler are maximized, excellent electrical insulation and excellent thermal conductivity can be exhibited even with a small content of the thermally conductive ceramic filler.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Method for manufacturing a microwave substrate

InactiveUS20060175740A1Evenly dispersedShorten the timeHigh frequency circuit adaptationsCeramic shaping apparatusMicrowave substrateAlcohol

A method for manufacturing a microwave substrate is disclosed. In particular, the method of the present invention uses the sol-gel process to form a ceramic-polymer composite microwave substrate. First, an alkoxy silane, water, a catalyst, an alcohol, and a polymer are mixed to form a sol-gel mixture. Next, the water and alcohol in the sol-gel mixture are removed by exerting a pressure. Finally, the sol-gel mixture is sintered to form a microwave substrate.

Owner:COMPAL ELECTRONICS INC

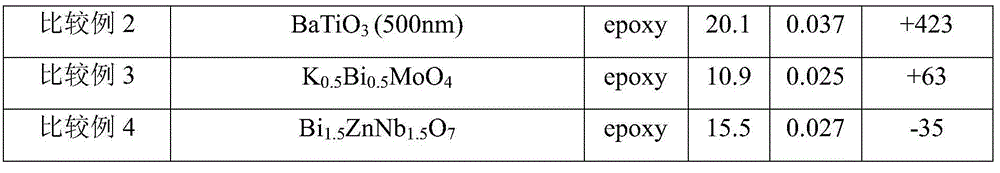

Ceramic-polymer composite material, preparation method therefor and use thereof

ActiveCN105086359AConvenience fillerAdjustable dielectric temperature coefficientFixed capacitor dielectricCapacitanceMetallurgy

The invention discloses a ceramic-polymer composite material. The ceramic-polymer composite material comprises a polymer matrix and microwave medium ceramic powder filler, wherein the ceramic powder filler is any one or a mixture of any two of (A0.5-2xBi0.5)BO4-x, (Bi1.5C0.5-y)ZnO.5Nb1.5O7-y and (A0.5-2xBi0.5)BO4-x@TiO2 or (Bi1.5C0.5-y)Zn0.5Nb1.5O7-y@TiO2 ceramic powder with a core-shell structure, which is formed by coating a ceramic surface with TiO2. The composite material has relatively low dielectric loss (tan sigma being less than or equal to 0.2) within a microwave frequency band, has a dielectric constant temperature coefficient adjustable within a range of + / -100ppm / DEG C, and is a very valuable embedded type composite material for capacitors.

Owner:GUANGDONG SHENGYI SCI TECH

Flame retardant ceramic polymer composite

InactiveCN104945838AReduce manufacturing costSimple anti-heat insulation structureFuranThermal insulation

The invention discloses a flame retardant ceramic polymer composite which comprises, by weight, 40-50% of thermosetting furan resin, 15-25% of synergism fire retardant, 25-35% of ceramic inorganic filler and 1-10% of compound additive. The flame retardant ceramic polymer composite can form a compact ceramic product within the temperature of 700-1100 DEG C, and the formed ceramic product has the good flame retardant property and high temperature mechanical performance, and has the good characteristic of common polymer composites. The flame retardant ceramic polymer composite has the advantages of being low in preparation cost, low in material heat conductivity and simple in thermal insulation structure.

Owner:SUZHOU KEMIAO NEW MATERIAL

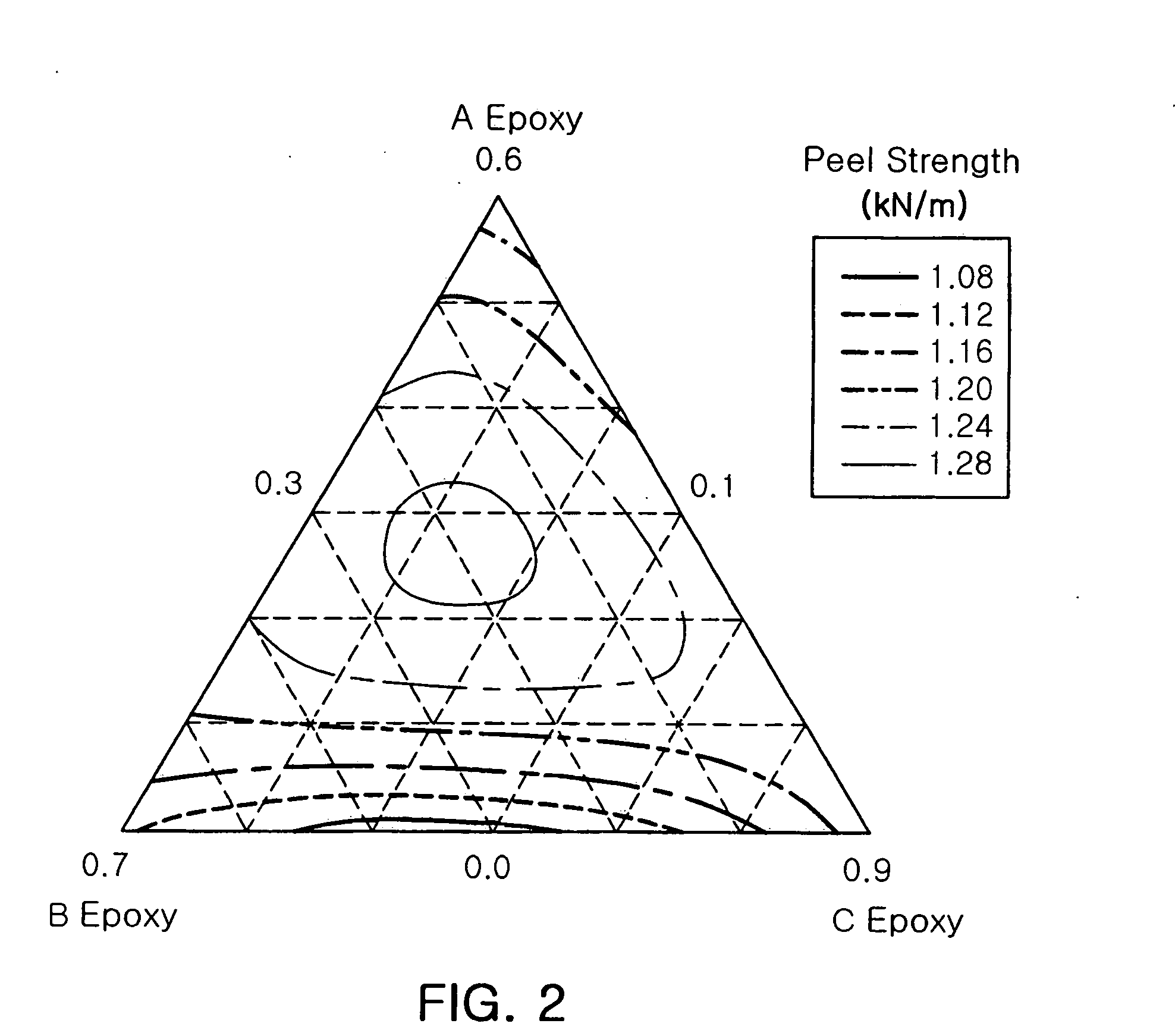

Resin composition for embedded capacitors having excellent adhesive strength, heat resistance and flame retardancy

InactiveUS20060183872A1Low peel strengthPrinted circuit aspectsSynthetic resin layered productsPolymer scienceCeramic polymer composites

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

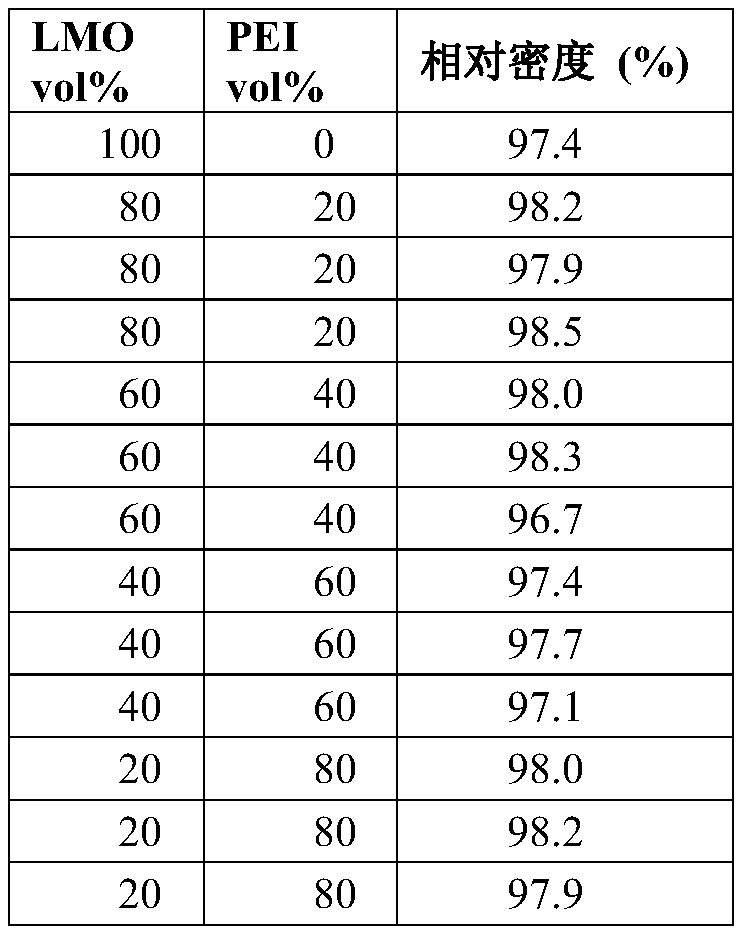

Ceramic-polymer composites obtained by a cold sintering process

Described herein are cold-sintered ceramic polymer composites and processes for making them from inorganic compound starting materials and polymers. The cold sintering process and wide variety of polymers permit the incorporation of diverse polymeric materials into the ceramic.

Owner:SABIC GLOBAL TECH BV

High dielectric constant ceramic-polymer composites, embedded capacitors using the same, and fabrication method thereof

Disclosed are ceramic-polymer composite consisting of aggregates of dielectric ceramic particles and polymer resin, and a fabrication method thereof, the method including aggregating dielectric ceramic particles to create aggregates, melting polymer resin in a solvent to prepare a polymer solution, dispersing the aggregates in the polymer solution to prepare a mixed solution, and hardening the mixed solution to obtain ceramic-polymer composites.

Owner:KOREA INST OF SCI & TECH

Ceramic-polymer composite material with high dielectric constant and preparation method thereof

ActiveCN104985896BImprove bindingAvoid clumpingSynthetic resin layered productsDielectric lossCeramic polymer composites

Owner:佛山国防科技工业技术成果产业化应用推广中心

Composite electrolyte material with electrochemical buffer layer, preparation method thereof and lithium metal battery

InactiveCN112635815AHigh capacity retentionSecondary cellsElectrolytesComposite electrolyteLithium metal

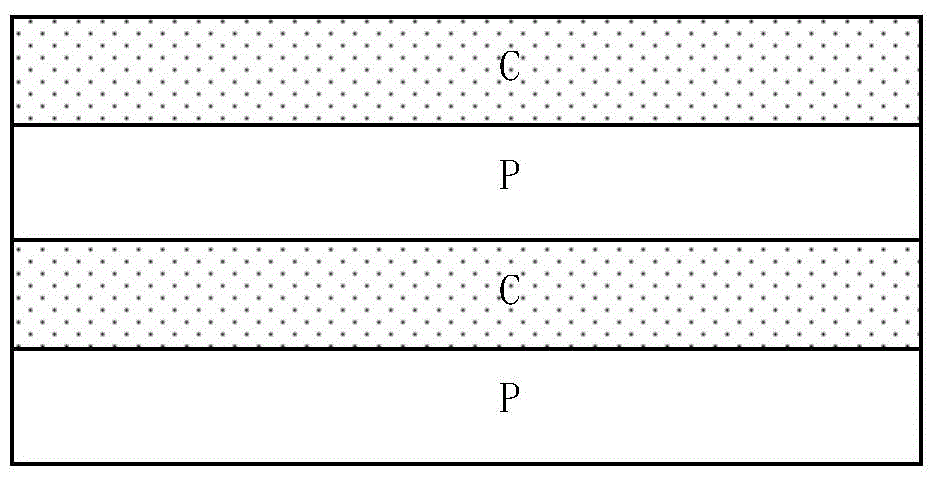

The invention provides a composite electrolyte material with an electrochemical buffer layer, a preparation method of the composite electrolyte material and a lithium metal battery. The composite electrolyte material with the electrochemical buffer layer comprises a three-layer structure, and the two sides of the ceramic polymer composite electrolyte are respectively provided with a specific positive electrode electrochemical buffer layer and a negative electrode electrochemical buffer layer, so that the interface contact between the ceramic polymer composite electrolyte material and an electrode can be effectively improved; the charge transfer impedance is reduced; meanwhile, the buffer layers on the two sides can also improve the tolerance to high and low pressure, play an electrochemical buffer role, stabilize an electrode / electrolyte interface, generate better chemical stability and reach a wider electrochemical window.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of piezoelectric ceramic polymer composite material

InactiveCN105185899AHigh dielectric constantHigh piezoelectric coefficientPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionElectricityElectrophoresis

The invention discloses a preparation method of piezoelectric ceramic polymer composite material. Compared with a common preparation technology, the dielectric constant of the piezoelectric composite material prepared by an electrophoresis auxiliary preparation technology is enhanced for about 50%, the piezoelectric coefficient is enhanced for about 50% and ferroelectric property is also substantially enhanced so that operation is easy, cost is low and the piezoelectric, dielectric and ferroelectric properties are substantially enhanced, and the preparation method has great actual application prospect in the field of intelligent sensing.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

Ceramic polymer composite material and preparation method thereof

ActiveCN114767940AHigh hardnessHigh strengthCeramic shaping apparatusTissue regenerationCeramic polymer compositesSlurry

The invention relates to a ceramic polymer composite material and a preparation method thereof. The composite material comprises the following components in percentage by volume: 18-85% of a ceramic skeleton and 15-82% of a polymer material, the ceramic skeleton comprises a layered structure, every two adjacent sheet layers in the layered structure form a bridging structure, and pores of the ceramic skeleton are filled with the high polymer material; the composite material is prepared by the following steps: mixing raw materials of a ceramic skeleton to obtain slurry, preparing the slurry into a green body with a stacked layered structure by adopting bidirectional freezing casting, placing the green body in a compression mold for volume compression, and sequentially performing degumming treatment and sintering treatment to obtain the ceramic skeleton, and the ceramic skeleton is infiltrated into liquid resin to obtain the composite material. The ceramic polymer composite material prepared by adopting the technical scheme provided by the invention has better mechanical properties and better light transmittance, and is more suitable for false tooth materials.

Owner:SHENZHEN TAOTAO TECH CO LTD

Ceramic polymer composite material and preparation method thereof

ActiveCN112960991AEven by forceGuaranteed work efficiencyCeramicwareNanowireCeramic polymer composites

Owner:SHENZHEN TAOTAO TECH CO LTD

Method for improving mechanical property of ceramic polymer composite material

ActiveCN113149514AImprove mechanical propertiesImprove thermal performanceStatic frictionMechanical property

The invention provides a method for improving the mechanical property of a ceramic polymer composite material, and the method comprises the following steps: carrying out plasticizing molding on corundum-type alumina particles and PPS engineering resin to obtain a composite material blank, and carrying out heat treatment to obtain the ceramic polymer composite material. The invention provides a material heat treatment method which is used for carrying out heat treatment on a high-strength ceramic polymer composite material containing ultrahigh-proportion ceramic powder and aims at eliminating static friction force and static pressure stored in the material forming process. The material has the advantages of ceramic and high polymer materials, has the characteristics of good mechanical strength, high thermal conductivity, good high temperature resistance, excellent processability and the like, and is very suitable for being applied to power PCBs (Printed Circuit Boards).

Owner:广州青苗新材料科技有限公司

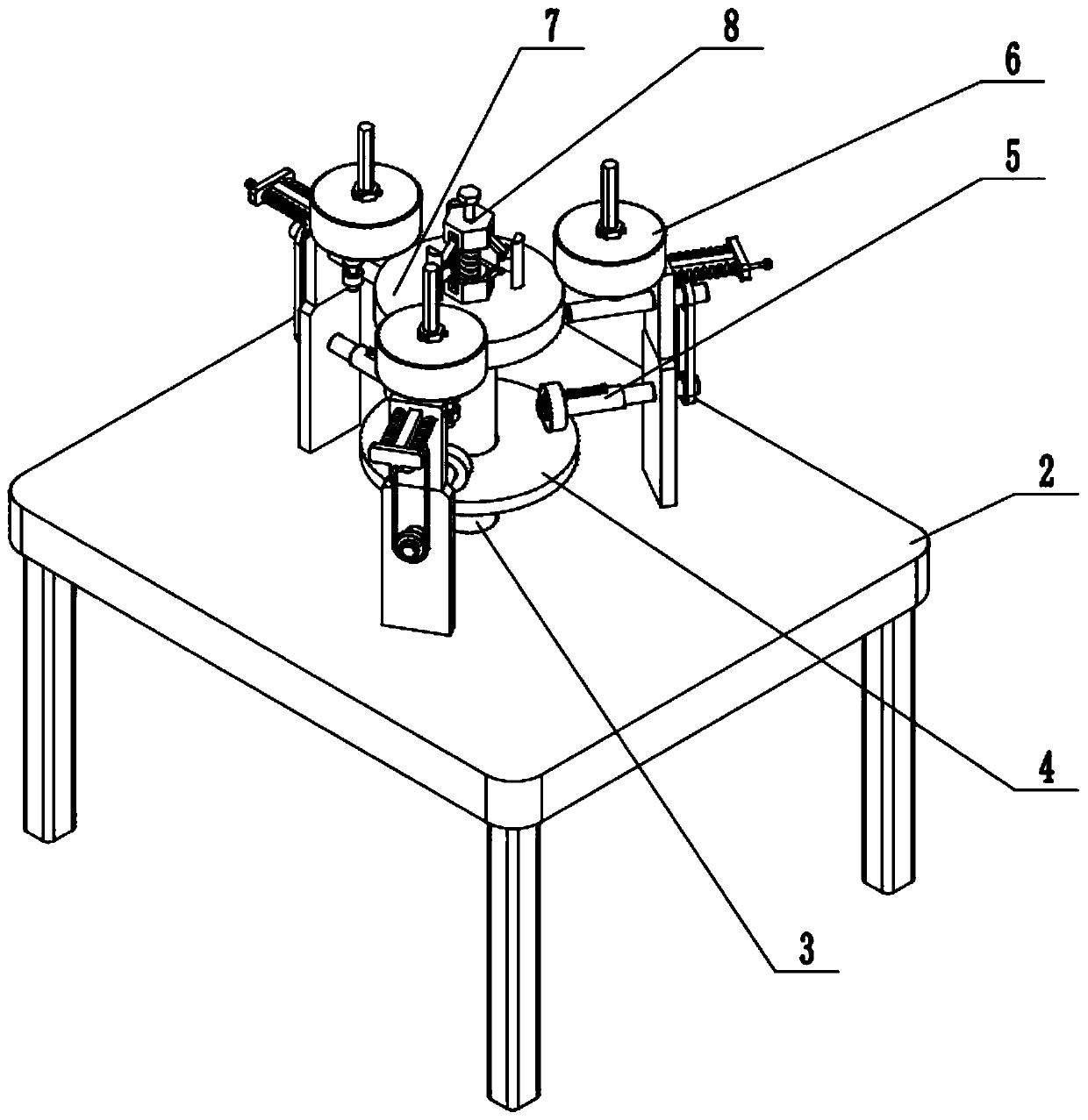

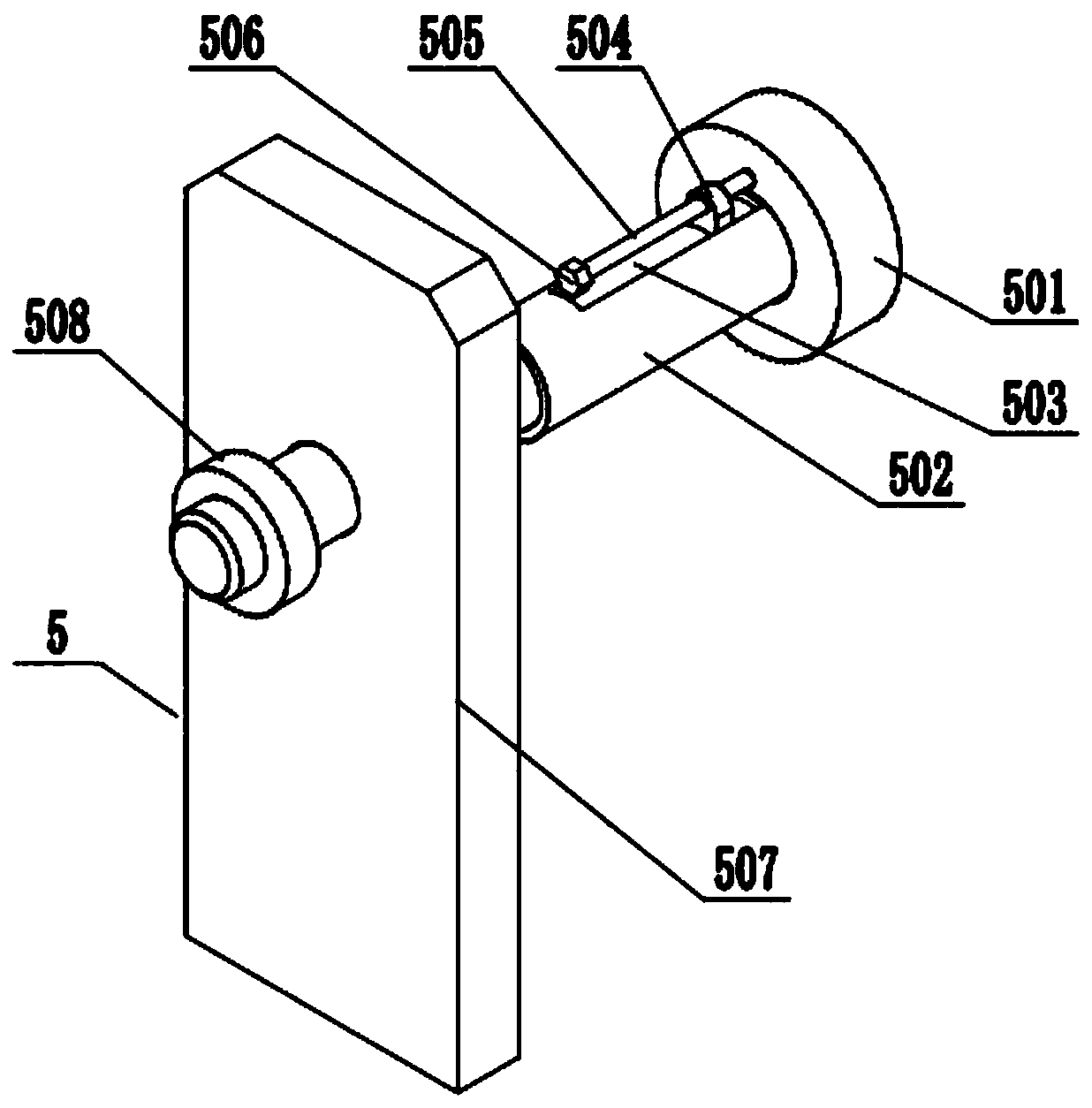

Processing equipment for piezoelectric ceramic polymer composite material

ActiveCN110640581APolished evenlyEasy to polishGrinding drivesGrinding machinesCeramic polymer compositesElectric machinery

The invention relates to the field of processing of piezoelectric ceramic polymer composite materials, in particular to processing equipment for a piezoelectric ceramic polymer composite material. Theprocessing equipment comprises a servo motor, a rack, a central shaft, a friction transmission disc, variable speed linkage parts, grinding parts, a bearing disc and a joint part. The servo motor isfixed to the rack through a motor base. The servo motor is in transmission connection with one end of the central shaft. The center shaft is rotationally connected to the rack. The friction transmission disc is fixedly connected to the central shaft. The friction transmission disc is in transmission connection with the three variable speed linkage parts. The three variable speed linkage parts areuniformly fixed to the rack in a surrounding manner. The three variable speed linkage parts each are in transmission connection with one grinding part. The three polishing parts are correspondingly fixed to the three variable speed linkage parts. The other end of the central shaft is fixedly connected with the bearing disc. The joint part is fixed to the middle of the bearing disc. By the adoptionof the processing equipment, a circular ring blank processed by the piezoelectric ceramic polymer composite material can be uniformly ground, and the grinding effect is good.

Owner:孙维涛

Novel ceramic polymer composite raw material formula and preparation technology

ActiveCN106495674AHigh surface finishImprove high temperature resistanceTitanium nitrideTemperature resistance

The invention relates to the technical field of ceramic polymer composite preparation, in particular to a novel ceramic polymer composite raw material formula and a preparation technology. The novel ceramic polymer composite raw material formula and the preparation technology achieve the technical purposes that the composite is high in strength, low in shrinkage and not likely to crack. The novel ceramic polymer composite is prepared from, by weight, 100-120 parts of aluminum oxide powder, 20-25 parts of hydrated magnesium silicate ultrafine powder, 10-15 parts of calcium carbonate powder and the like. The preparation technology comprises six steps. The surface smoothness of prepared ceramic is higher, the surface glossiness is better, the surface finishing degree of the ceramic is obviously improved, and due to addition of the titanium nitride powder, high temperature resistance, corrosion resistance, wear resistance and thermal shock resistance and other excellent properties of the ceramic can be improved.

Owner:德化县后井窑瓷业有限责任公司

Ceramic polymer composite pipe production process

The invention discloses a ceramic polymer composite pipe production process, and relates to the technical field of pipe fitting production. The ceramic polymer composite pipe production process comprises the following production processes of S1, coating or stringing wear-resistant ceramic patches or pipe fittings on a winding machine; S2, filling gaps between the ceramic patches or the pipe fittings are filled with a resin adhesive; and S3, soaking glass fiber cloth subjected to surface treatment in epoxy resin glue through a glue dipping tank for gluing, enabling the glue content of the adhesive plaster to be 35-45%, and winding 10-20 layers of adhesive plaster outside the wear-resistant ceramic patches or pipe fittings. According to the ceramic polymer composite pipe production process,a high polymer material is combined with wear-resistant ceramic to be cured into a composite component under specific conditions, and the metal high polymer material is combined with the ceramic, so that the strength is high, wear resistance and corrosion resistance are high, a metal pipeline can be replaced, the service life is long, and the ceramic polymer composite pipe production process is widely applied to industrial deslagging and exhaust pipeline systems such as metallurgy, mines, electric industry and chemical engineering.

Owner:扬州金鑫管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com