Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "High piezoelectric coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric Composite Material

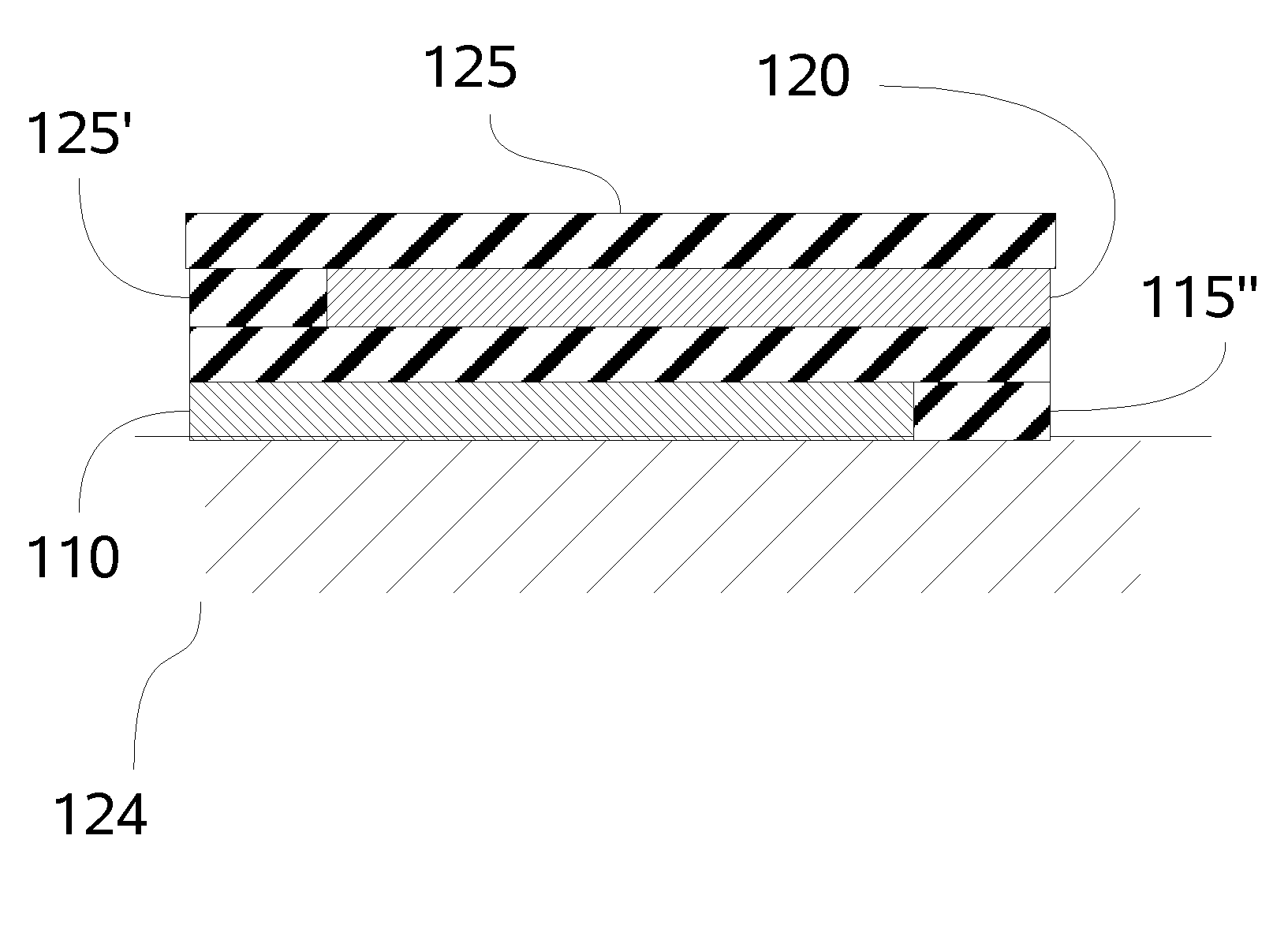

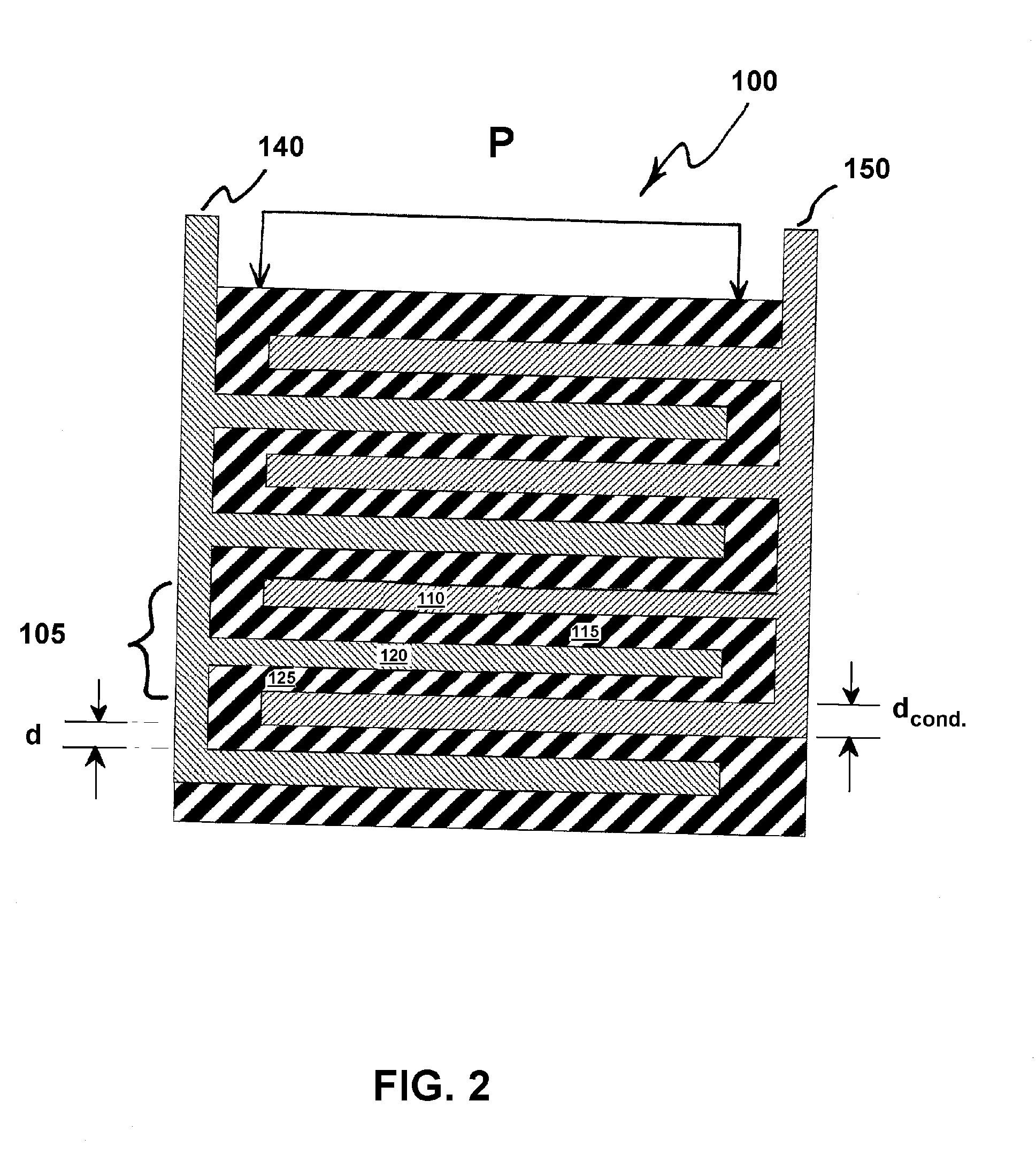

InactiveUS20070138905A1High piezoelectric coefficientMaterial nanotechnologyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorWork function

A composition of matter having multiple layers of different conductors separated by thin layers of dielectric materials has a high piezoelectric coefficient when the conductors are metals having a significant difference in work function and the dielectric materials have a low elastic modulus when the metal layers are connected to form a capacitive circuit. Alternatively, when the conductors are semi-conductors they should have a significant difference in Fermi levels.

Owner:PHYSICAL LOGIC

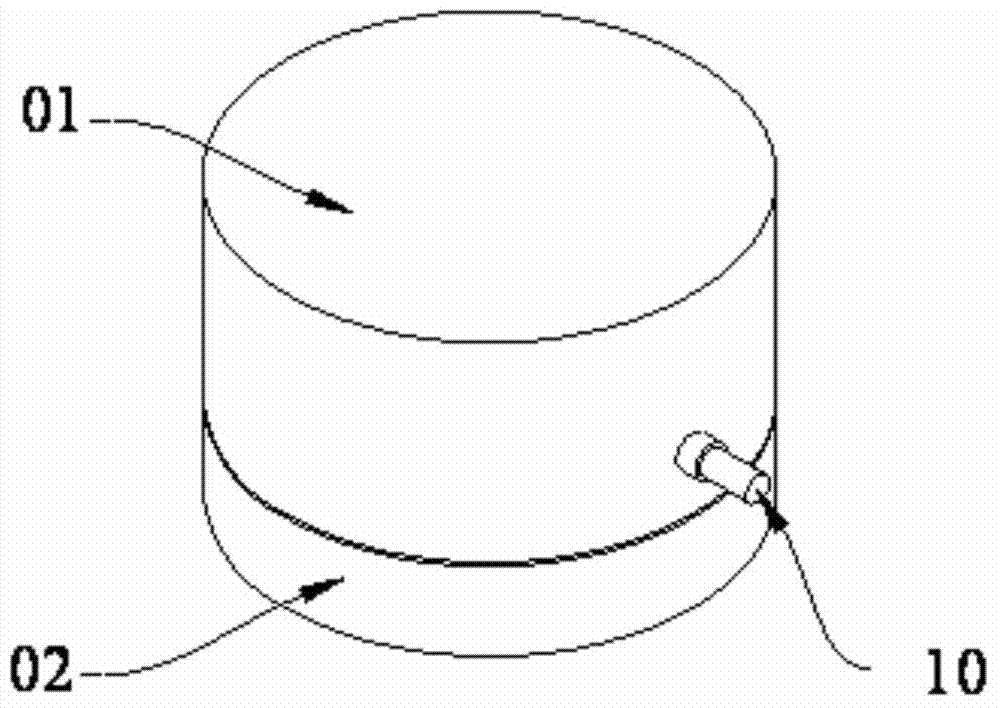

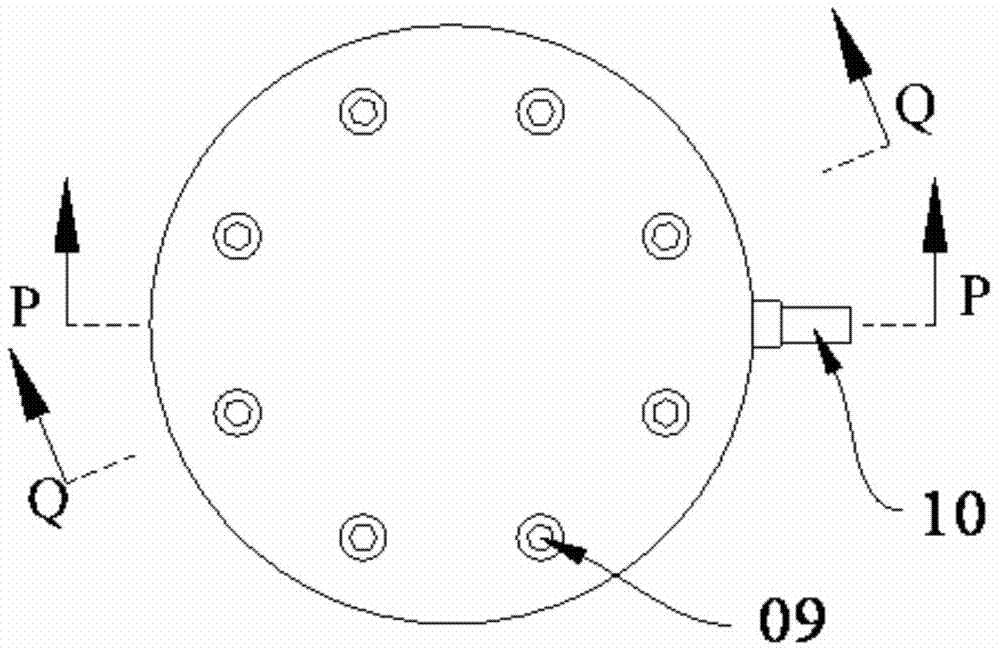

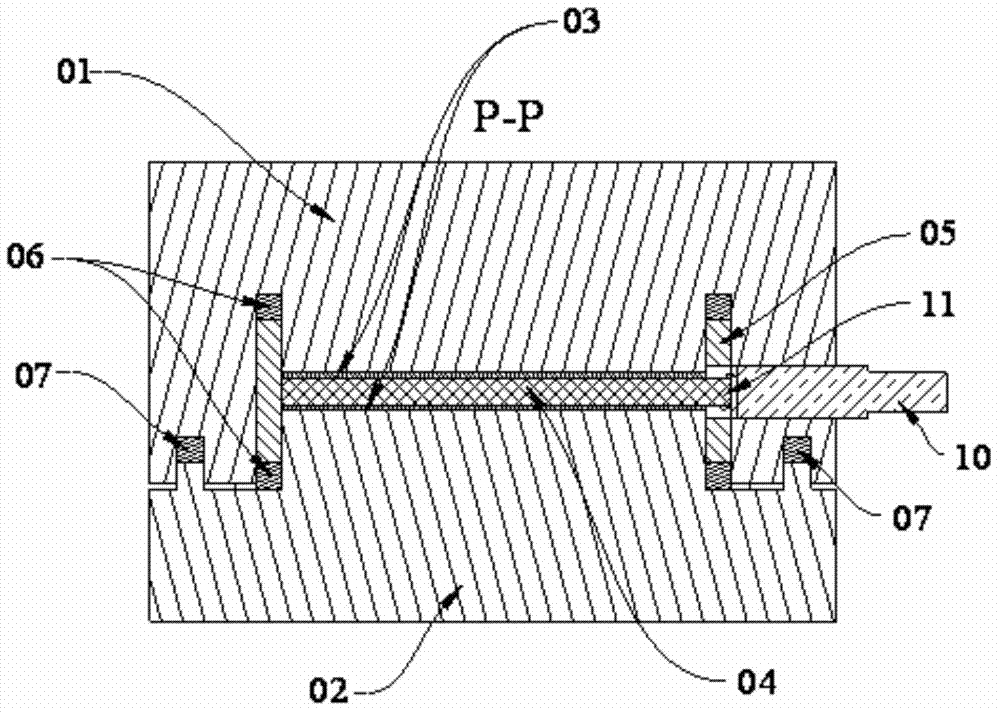

Concrete stress sensor by piezoelectric properties of PVDF (polyvinylidene fluoride) film

InactiveCN103674353AGood flexibilityHigh mechanical strengthForce measurement using piezo-electric devicesStrength propertiesPolyvinylidene difluorideEngineering

The invention discloses a concrete stress sensor by piezoelectric properties of a PVDF (polyvinylidene fluoride) film. The concrete stress sensor comprises an upper sensor shell, a lower sensor shell and the PVDF piezoelectric film, the upper sensor shell and the lower sensor shell are buckled together, the PVDF piezoelectric film is arranged between the upper sensor shell and the lower sensor shell, a nylon sleeve is sleeved on the periphery of the PVDF piezoelectric film, so that the PVDF piezoelectric film is positioned on a boss, insulating layers are respectively arranged on the upper end face and the lower end face of the PVDF piezoelectric film and closely contact with the upper sensor shell and the lower sensor shell, the nylon sleeve and the insulating layers form a sealed insulating space, so that a PVDF piezoelectric film and the sensor shells are separated in an insulating manner, and connection electrodes are respectively arranged on the upper surface and the lower surface of the PVDF piezoelectric film, so that piezoelectric signals are led to the outside of the sensor. The PVDF piezoelectric film is clamped between the two metal shells, a load is transmitted to the PVDF film by the aid of the sensor metal shells, the concrete stress sensor is sensitive in sensing, simple in structure, convenient to package and small in size, and can be embedded into concrete materials to finish an impact stress test.

Owner:CENT SOUTH UNIV

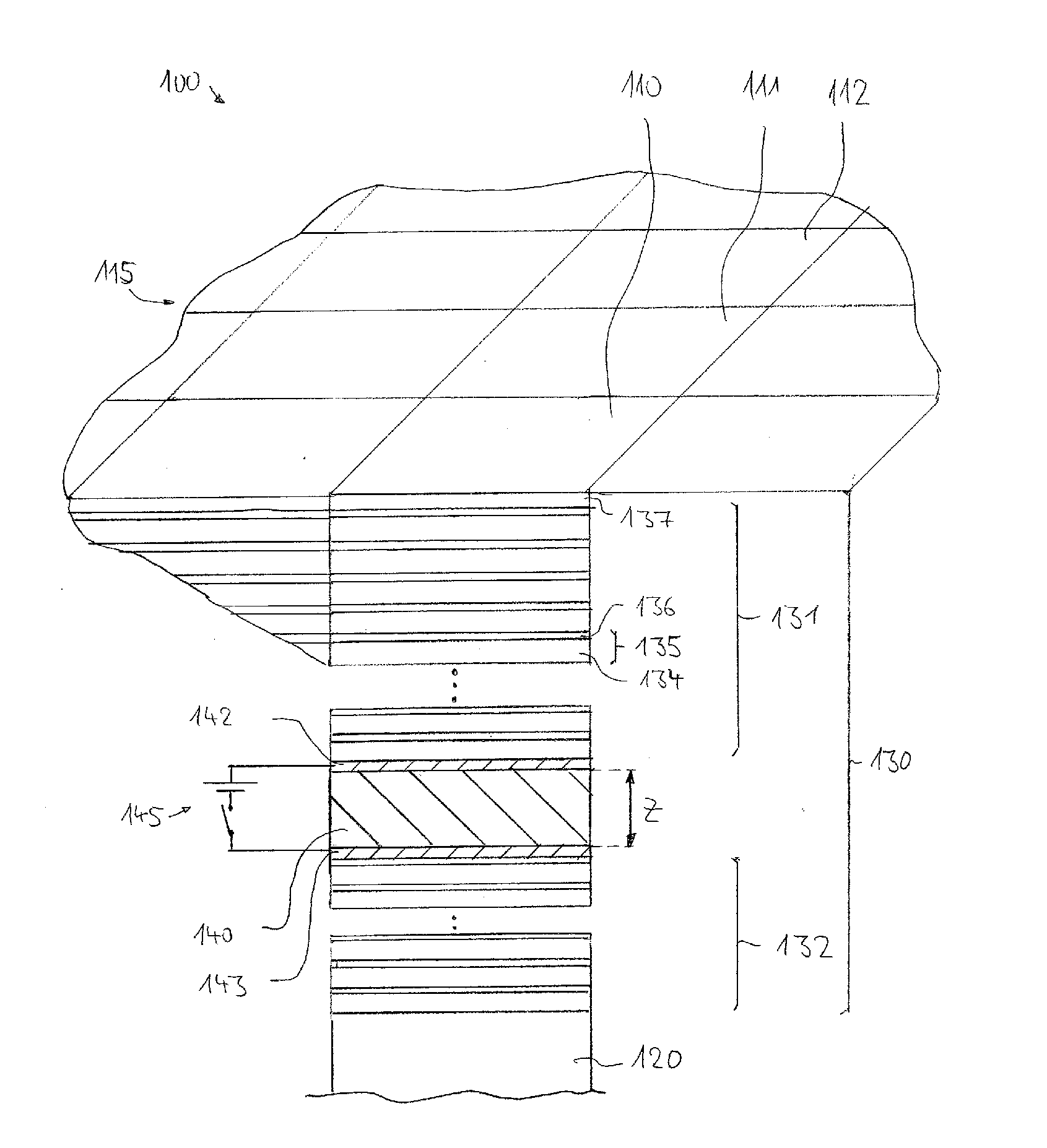

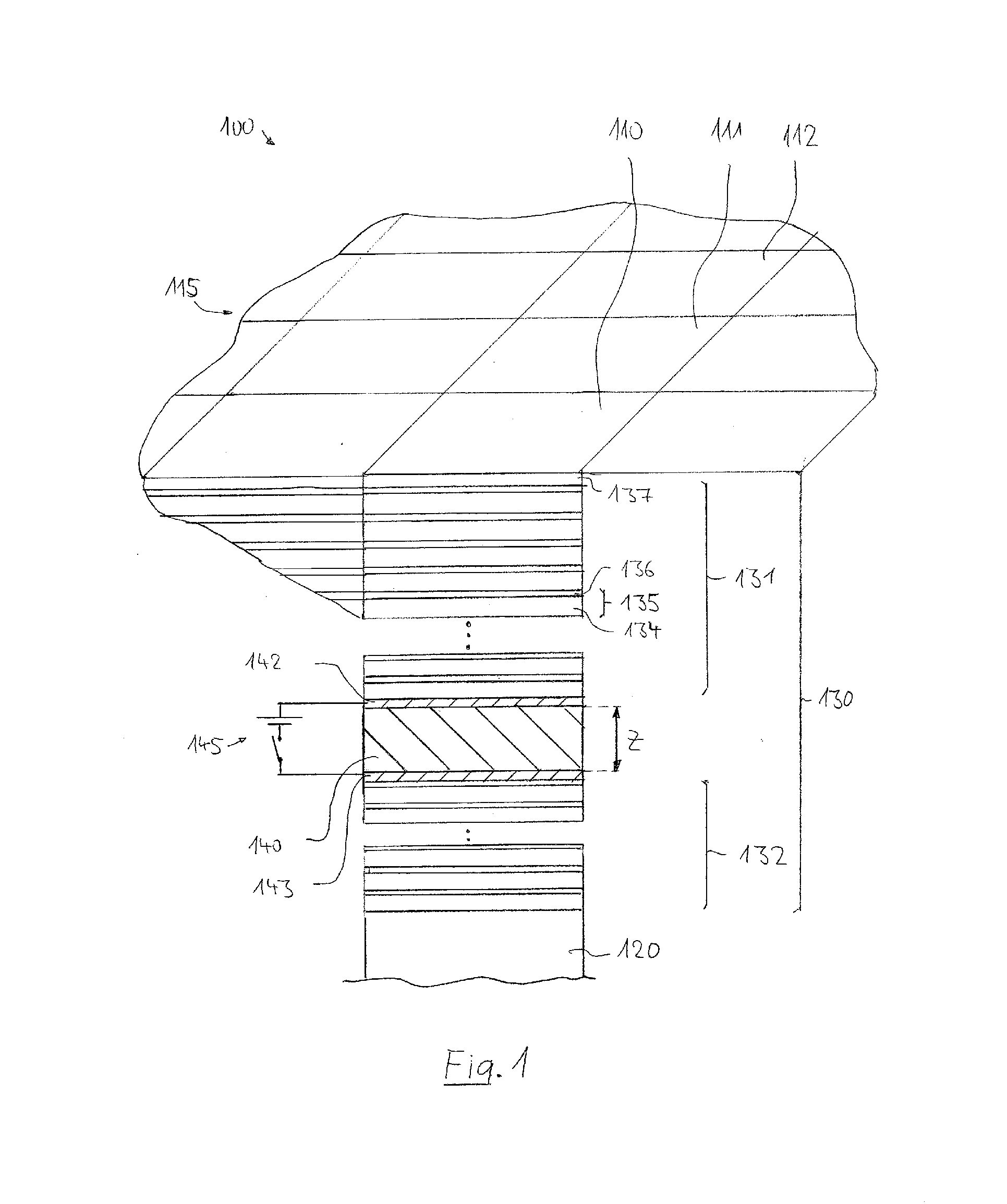

Euv-mirror arrangement, optical system with euv-mirror arrangement and associated operating method

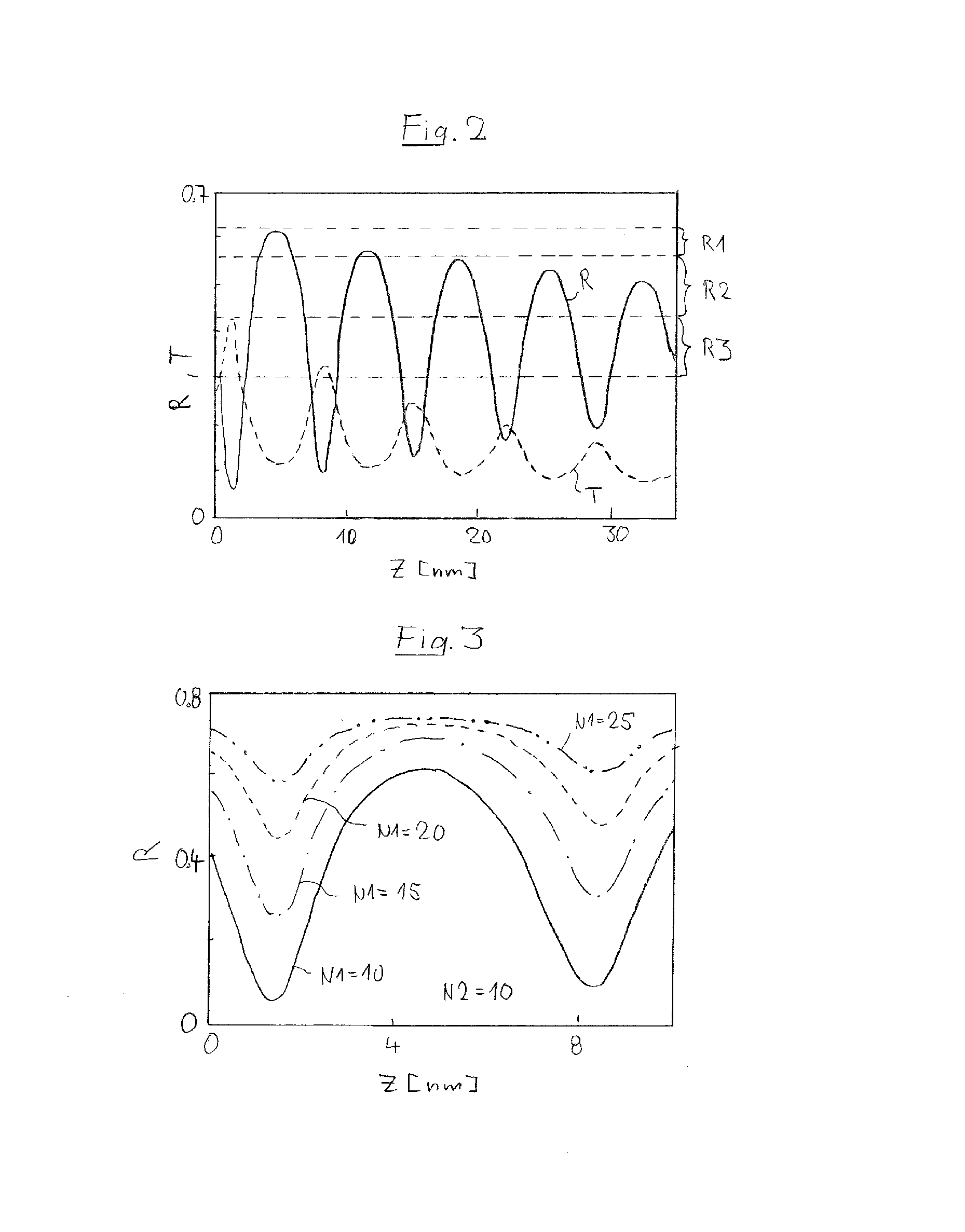

ActiveUS20140285783A1Little surface roughnessHigh piezoelectric coefficientMirrorsNanoinformaticsExtreme ultravioletElectric field

An EUV mirror arrangement (100) has a multiplicity of mirror elements (110, 111, 112) which are arranged alongside one another and jointly form a mirror surface of the mirror arrangement. Each mirror element has a substrate (120) and a multilayer arrangement (130) applied on the substrate and having a reflective effect with respect to radiation from the extreme ultraviolet range (EUV), said multilayer arrangement comprising a multiplicity of layer pairs (135) having alternate layers composed of a high refractive index layer material and a low refractive index layer material. The multilayer arrangement has an active layer (140) arranged between a radiation entrance surface and the substrate and consisting of a piezoelectrically active layer material, the layer thickness (z) of which active layer can be altered by the action of an electric field. For each active layer provision is made of an electrode arrangement for generating an electric field acting on the active layer.

Owner:CARL ZEISS SMT GMBH

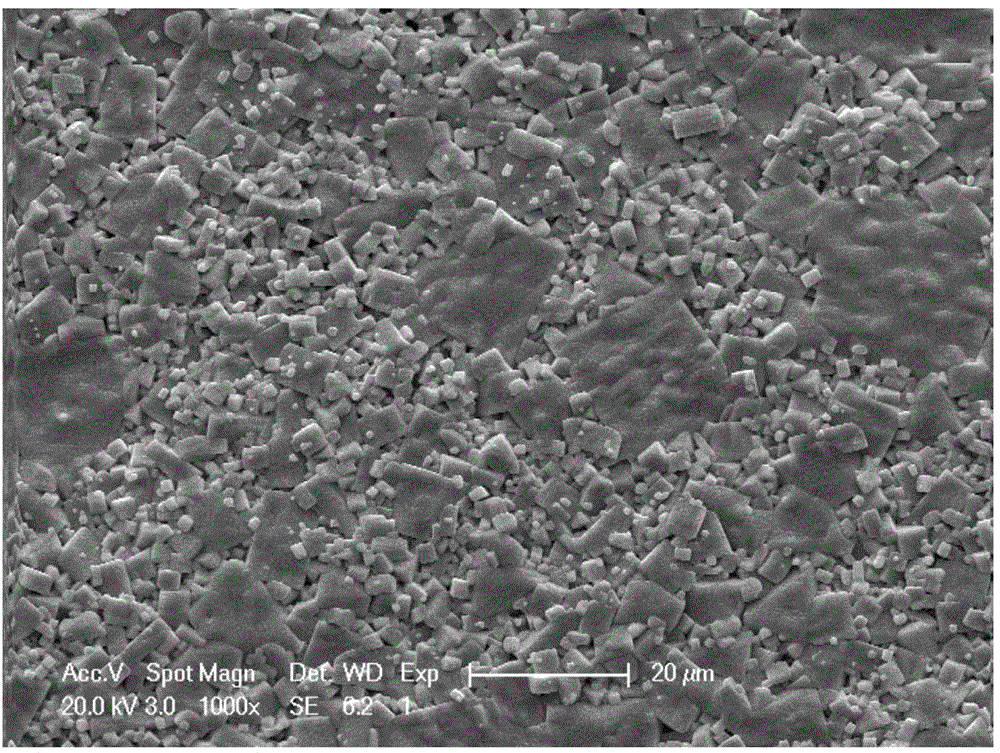

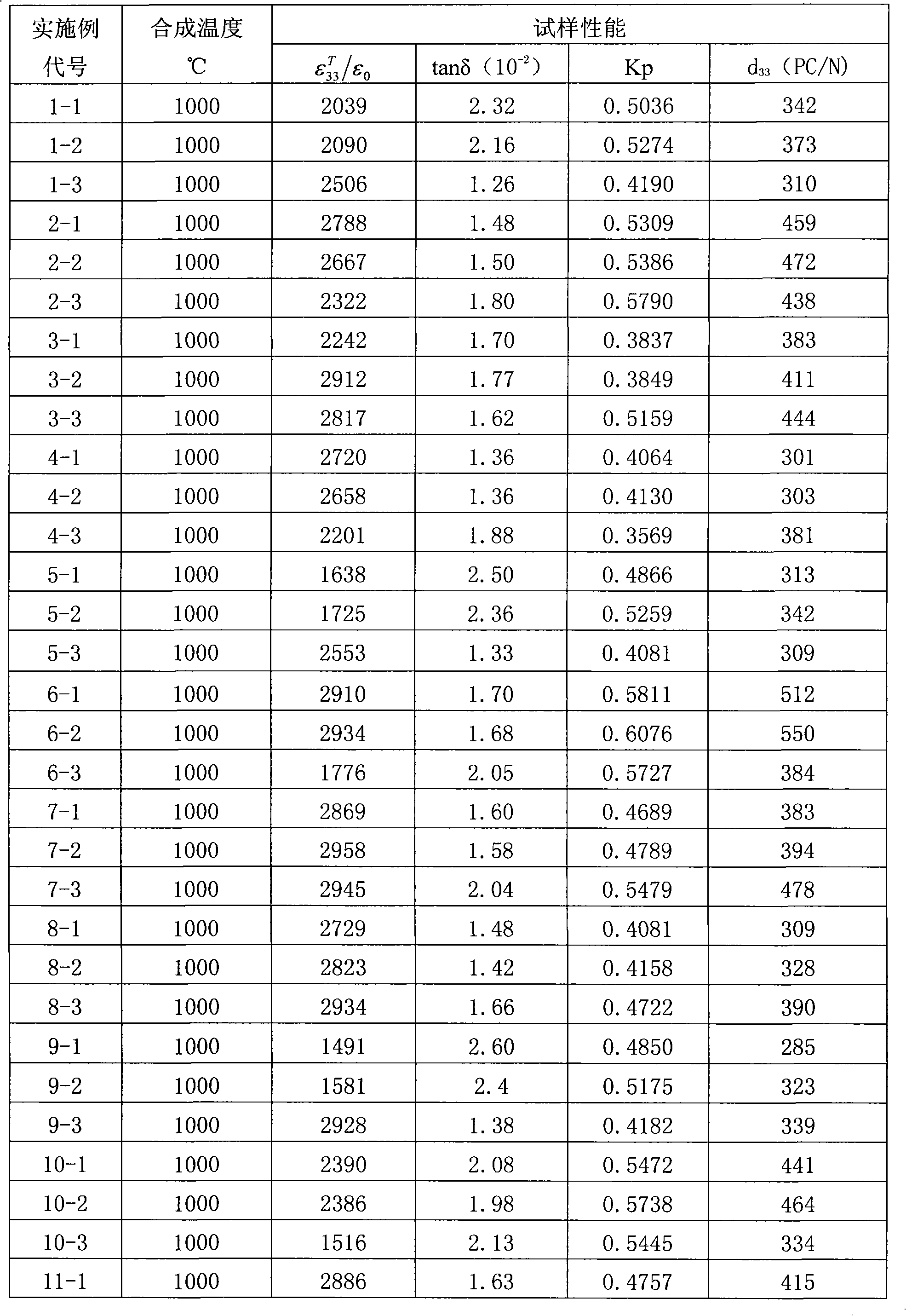

High-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics and preparation method thereof

InactiveCN104876567AReduce volatilityShorten the time of high temperature sinteringElectricityUltrasonic sensor

The invention relates to high-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics and a preparation method thereof. The raw material composition of the high-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics is (1-a)(K0.5Na0.5)-.95Li0.05Nb0.93Sb0.07-aMZrO3, wherein M is Ca, Sr or Ba, and a is within the range of 0.01 to 0.06; the following three-step sintering solid-phase synthesis preparation method is adopted: in the first step, the sintering temperature is within the range of 1100-1120 DEG C and the heat preservation time is 0 minute; in the second step, the sintering temperature is within the range of 1160-1210 DEG C and the heat preservation time is 0-5 minutes; in the third step, the sintering temperature is within the range of 1000-1100 DEG C and the heat preservation time is 2-20 minutes; consequently, a novel leadless piezoelectric ceramic material can be obtained, and the maximum piezoelectric coefficient d33 of the material is 410pC / N, wherein d*33 is 450. The leadless piezoelectric ceramic material is applied to a plurality of fields such as ultrasonic transducers, piezoelectric buzzers, drivers and resonators.

Owner:TONGJI UNIV

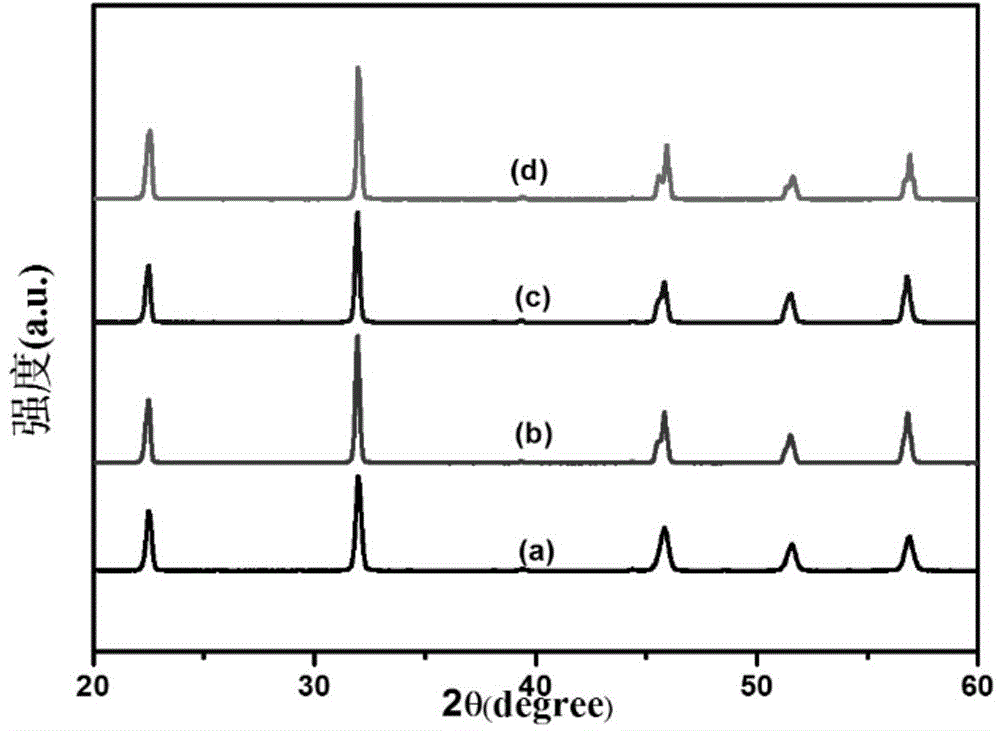

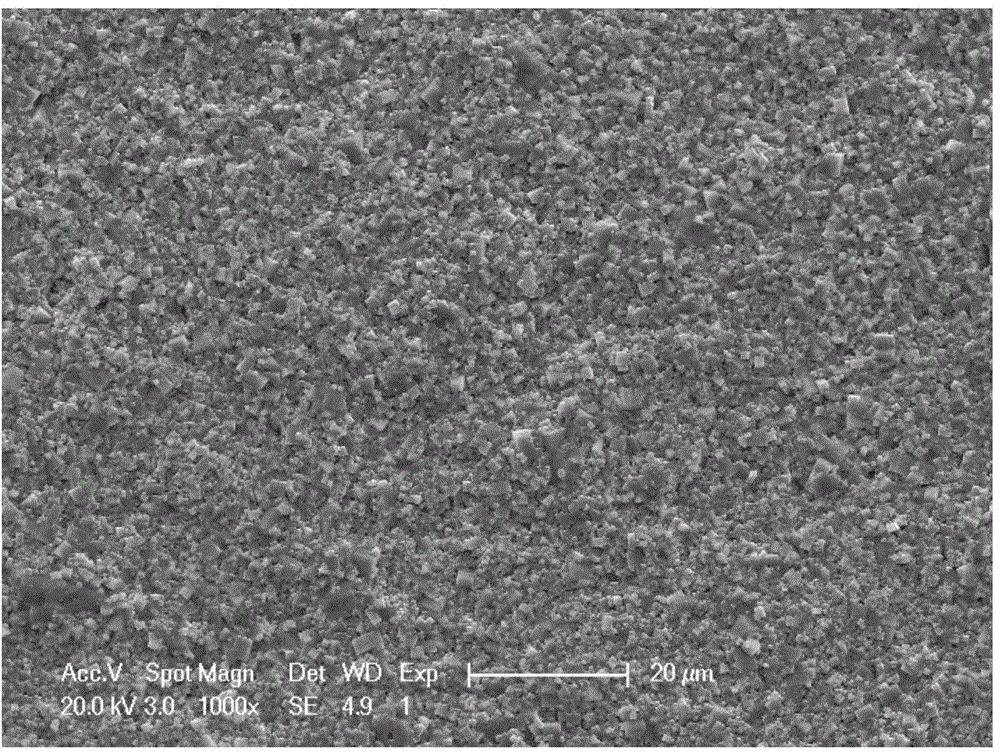

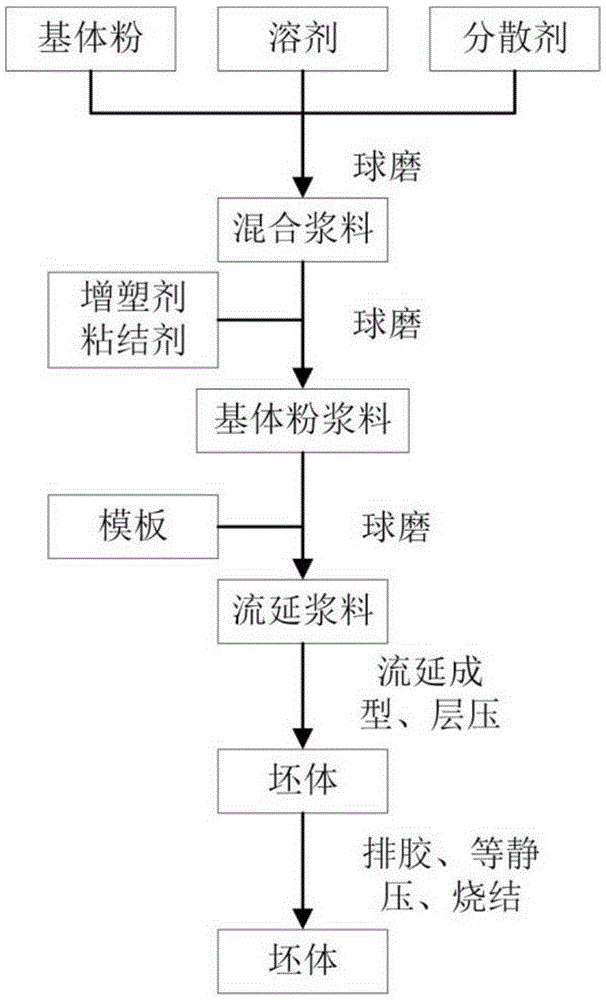

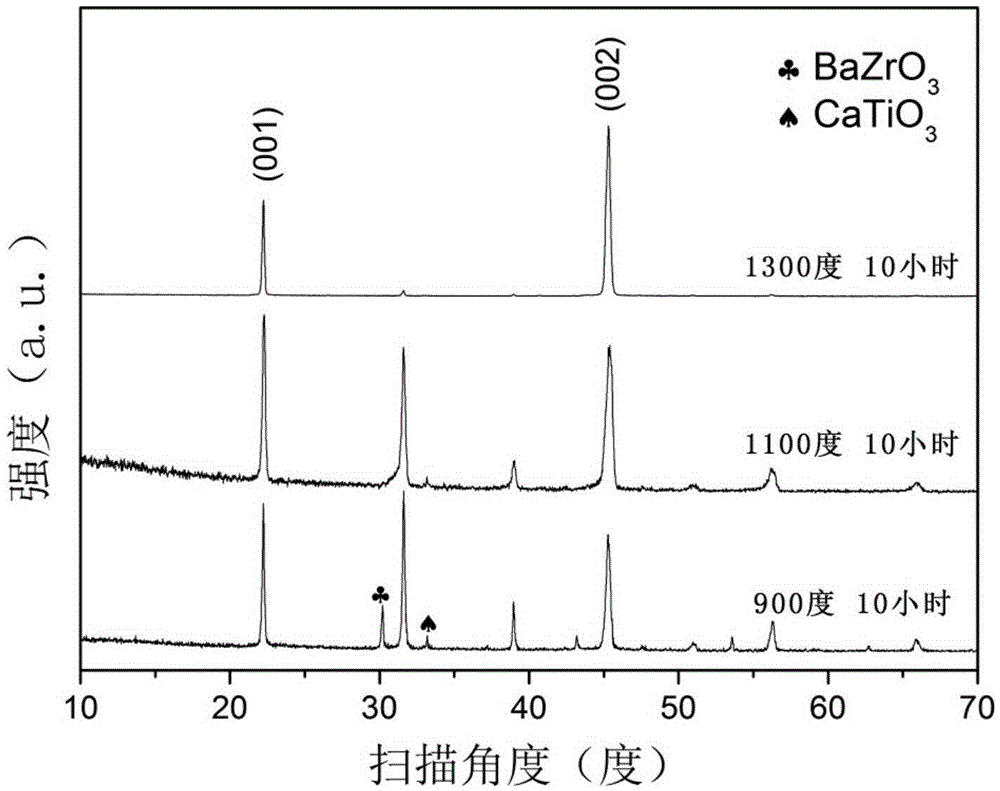

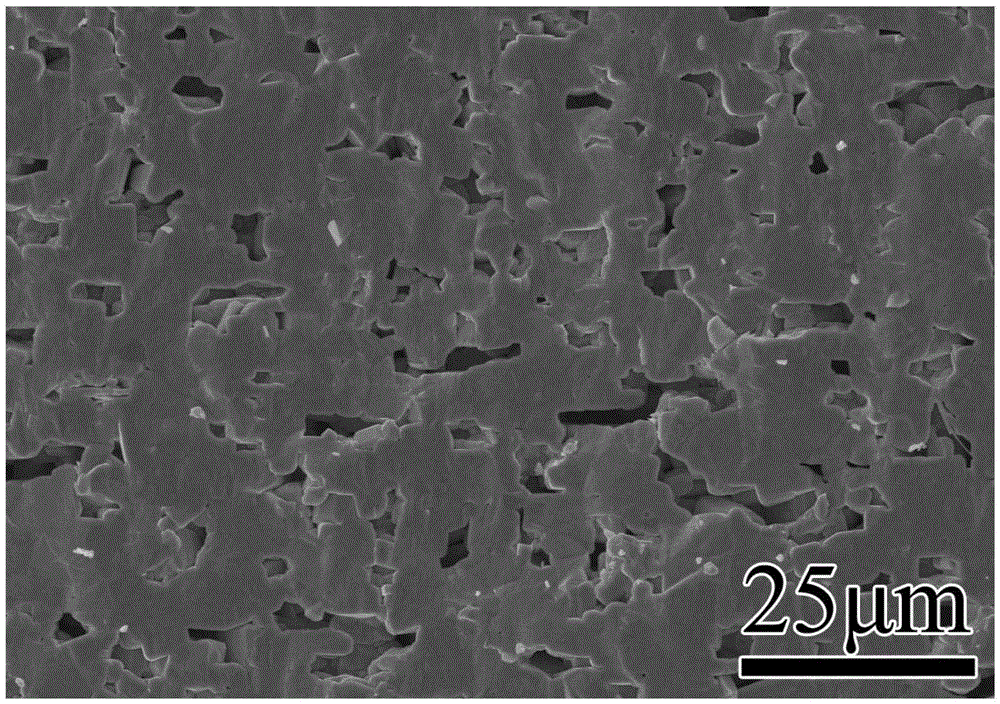

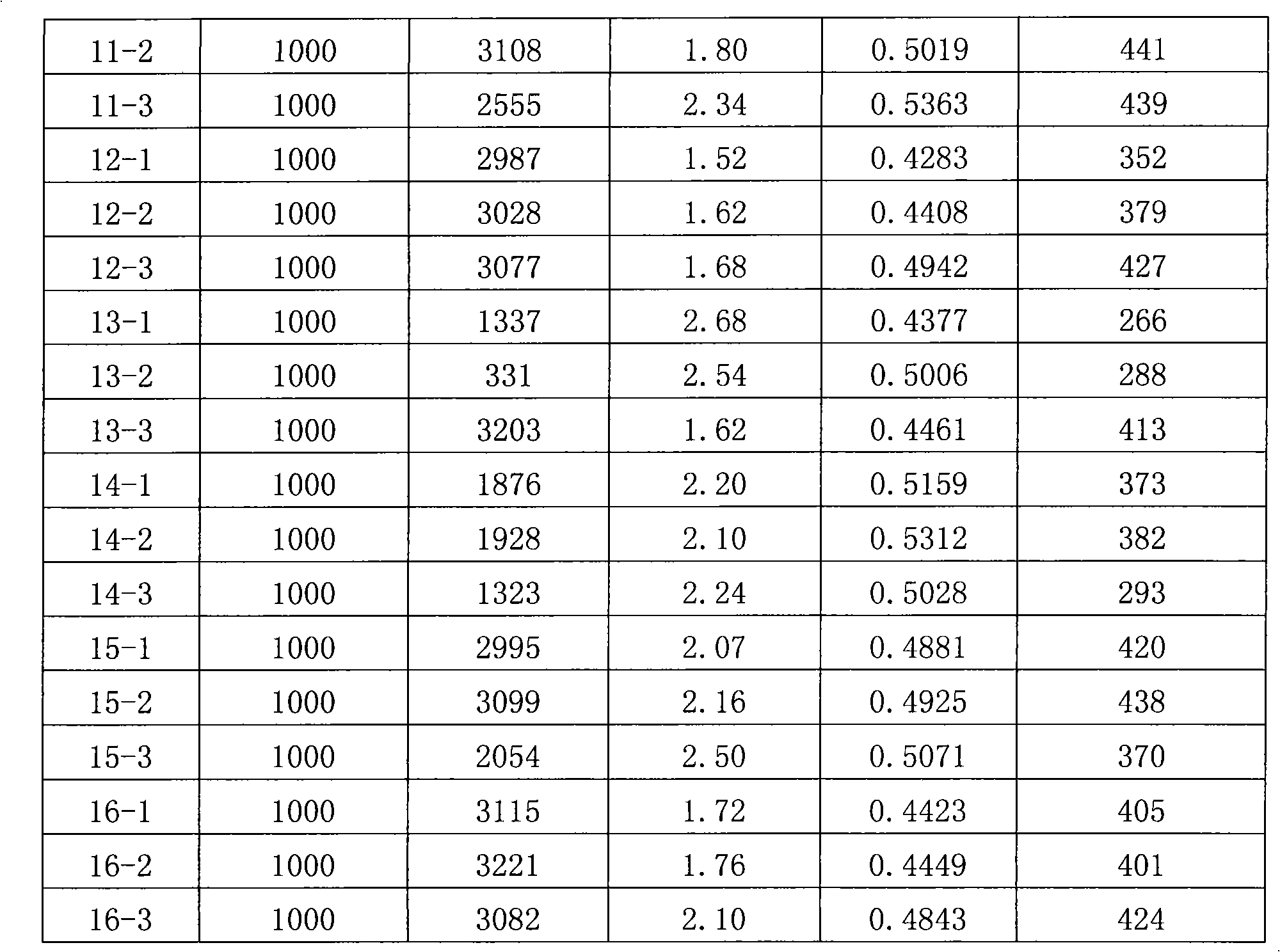

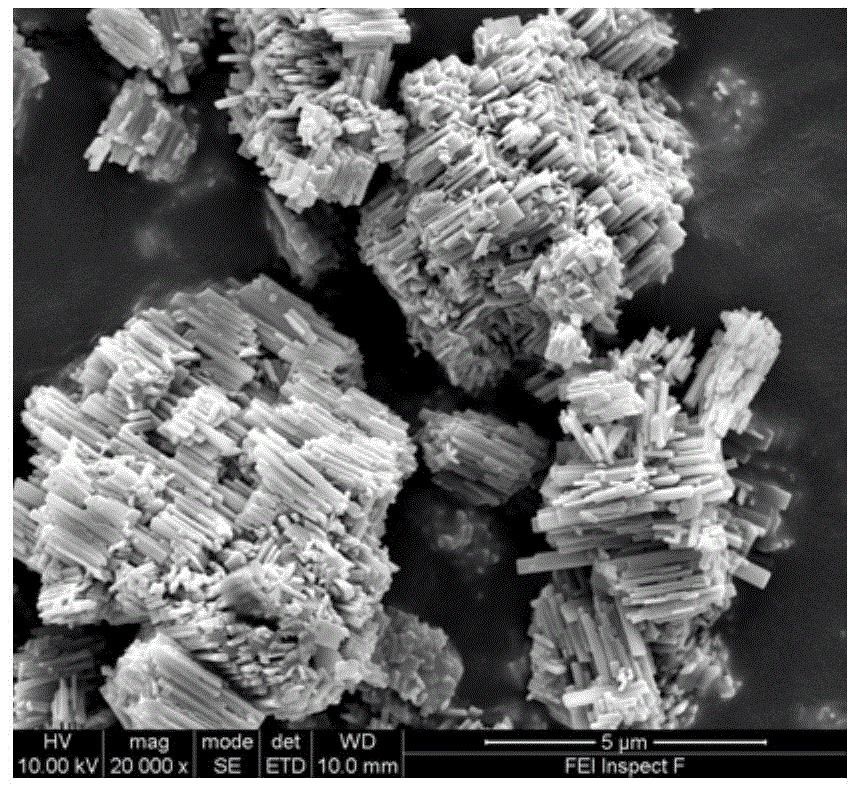

Preparation method of barium calcium zirconate titanate lead-free piezoelectric textured ceramic

The invention relates to a preparation method of a barium calcium zirconate titanate lead-free piezoelectric textured ceramic. The composition of the barium calcium zirconate titanate lead-free piezoelectric textured ceramic is Ba0.85Ca0.15Ti0.90Zr0.10O3. During preparation, no lead oxide is used, and the environmental requirement can be guaranteed to the utmost extent; and compared with the ceramic with the same components prepared in the prior art, XRD (X-ray diffraction) characterization proves that crystal particles of the ceramic are arranged along the <001> direction, so that a material can fully utilize the anisotropy of a piezoelectric material, the piezoelectric coefficient of the material is improved, the texture degree of the material is as high as 96%, and the piezoelectric constant of the material can be more than 290 pC / N. The preparation method of the barium calcium zirconate titanate lead-free piezoelectric textured ceramic can avoid separate preparation of a template and slurry, and unchanged material composition can be accurately guaranteed.

Owner:TIANJIN UNIV

Doped and modified lead zirconate-titanate piezoelectric ceramic and preparation method thereof

ActiveCN107986782ALower sintering temperatureHigh electromechanical coupling coefficientPiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateElectromechanical coupling coefficient

The invention discloses a doped and modified lead zirconate-titanate piezoelectric ceramic and a preparation method thereof. The doped and modified lead zirconate-titanate piezoelectric ceramic is shown in a following chemical formula I, namely xPb(Mg1 / 3Nb2 / 3)O3-yPb(Ni1 / 3Nb2 / 3)O3-(1-x-y)Pb(Ti1 / 2Zr1 / 2)O3+lSrCO3+mZnO+nQ, wherein Q is at least selected from Li2CO3 (lithium carbonate), CuO (copper oxide), SiO2 (silicon dioxide), MnO2 (manganese dioxide), Bi2O3 (bismuth oxide) and La2O3 (lanthanum oxide); l, m and n are respectively the mass percentages of SrCO3 (strontium carbonate), ZnO (zinc oxide) and Q in the compound Pb(Mg1 / 3Nb2 / 3)O3-Pb(Ni1 / 3Nb2 / 3)O3-Pb(Ti1 / 2Zr1 / 2)O3; x is greater than or equal to 0.10 and is smaller than or equal to 0.70, y is greater than or equal to 0.08 and is smallerthan or equal to 0.38, l is greater than 0 and is smaller than or equal to 0.5, m is greater than 0 and is smaller than or equal to 0.50, and n is greater than or equal to 0 and is smaller than or equal to 0.5. The doped and modified lead zirconate-titanate piezoelectric ceramic has the excellent properties of low sintering temperature, high electromechanical coupling coefficient, high piezoelectric strain coefficient, small dielectric loss and the like.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

La2O3-doped lead zinc niobate-lead zirconate titanate piezoelectric ceramic

InactiveCN101863660AHigh piezoelectric coefficientSmall dielectric lossPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateDielectric loss

The invention discloses an La2O3-doped lead zinc niobate-lead zirconate titanate (PZN-PZT) piezoelectric ceramic which comprises the following raw components in mol percent: 0.3Pb(Zn1 / 3Nb2 / 3)O3-0.7PbyLax (ZrzTim)O3, wherein x=0.01 to 0.07, y=1-x, z=0.5 to 0.53, m=1-z, and the sintering is carried out at 1230 to 1270 DEG C. In the invention, the ZnNb2O6 is firstly prepared by adopting a precursor method, and then, the piezoelectric ceramic with high piezoelectric coefficient, small dielectric loss and good comprehensive performance is provided by adopting the traditional preparation method. The invention is mainly applied to components of a piezoelectric ceramic driver, a piezoelectric transformer, an energy transducer, an automotive built-in vibration sensor, a controller shell buzzer, and the like.

Owner:TIANJIN UNIV

Lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and preparation method thereof

ActiveCN109608195ALower the holding temperatureHigh piezoelectric coefficientChemical compositionHigh pressure

The invention relates to a lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and a preparation method thereof. The chemical composition of the material accords with the chemical general formula (1-x)(K0.5Na0.5)0.98Ag0.02(Nb0.96Sb0.04) O3-x (Bi0.5Na0.5) ZrO3, wherein x represents the percentage of (Bi0.5Na0.5) ZrO3 in the potassium-sodium niobate-based lead-free piezoelectric ceramic, and x is more than or equal to 0.01 and less than or equal to 0.06. Compared with the prior art, the preparation method has the advantages of simplicity, good stability and low cost. The lead-free piezoelectric ceramic material obtained by the preparation method has excellent piezoelectric performance and electrogenerated strain, the d33 reaches 440 pC / N, thed33* reaches 553 pm / V, good temperature stability is shown, and the lead-free piezoelectric ceramic material can be used for piezoelectric sensors, piezoelectric motors and high-precision displacementcontrollers, the material has good application prospect.

Owner:TONGJI UNIV

Method of testing mechanical properties of coal in coal-rock composite under dynamic loading and combined static and dynamic loading

ActiveCN107314933AMeet the requirements of strain measurementOvercoming the conundrum of strainStrength propertiesStress variationStrain gauge

The invention discloses a method of testing mechanical properties of coal in coal-rock composite under dynamic loading and combined static and dynamic loading. An existing coal-rock composite test piece is used; starting from rock less prone to crushing, an SHPB (split Hopkinson pressure bar) test device is used, coal-rock composite loading test is performed by means of attaching a strain gauge, stress of coal is acquired according to stress at each end face of the coal test piece, and stress variation of the coal in the coal-rock composite under dynamic loading. Mechanical properties of coal in a certain surrounding rock environment are acquired, better guidance can be provided for field engineering practice, and the method has major guiding significance for disclosing true failure mechanism of engineering coal.

Owner:SHANDONG UNIV OF SCI & TECH

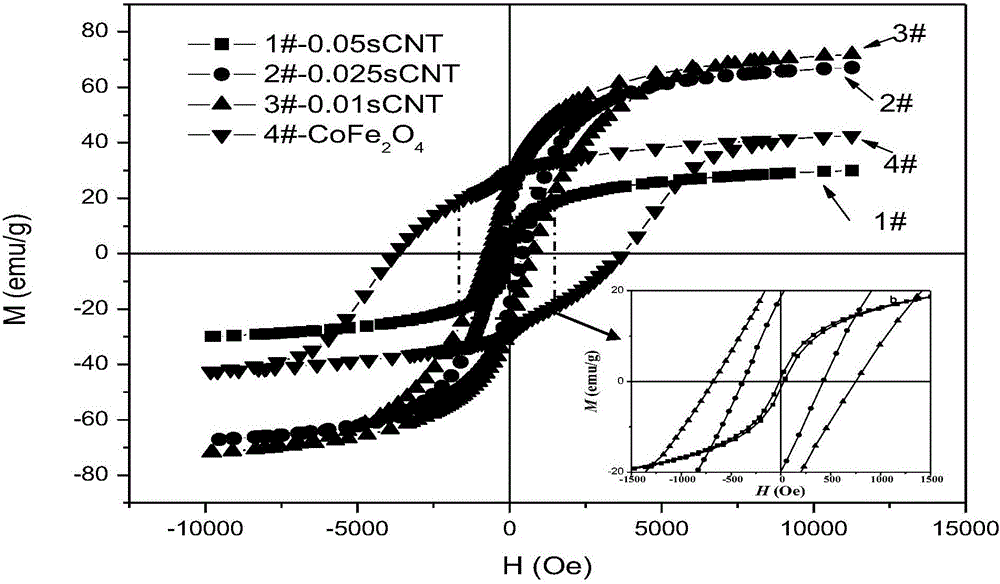

Polymer-based flexible composite material having both ferroelectric properties and ferromagnetic properties, and preparation method thereof

ActiveCN105949683AHigh piezoelectric coefficientHigh magnetoelectric coupling effectFerroelectric polymersMagnetite Nanoparticles

The invention relates to a polymer-based multiferroic magnetoelectric composite material having both ferroelectric properties and ferromagnetic properties. The composite material is characterized by being formed through mixing up one-dimensional OD-MFe2O4 ferromagnetic elements with the fluoropolymer cPVDF material. The one-dimensional OD-MFe2O4 ferromagnetic elements are obtained through growing an MFe2O4 ferromagnetic compound on the surface of a one-dimensional functionalized material, wherein M=Fe, Co, Ni, Mn and Zn. According to the technical scheme of the invention, ferrites (MFe2O4, M=Fe, Co, Ni, Mn and Zn) and magnetic nanoparticles are loaded on the surface of the one-dimensional functionalized material through the in-situ assembling process, so that the one-dimensional material-magnetic nano-material (OD-MFe2O4) of a specific dimension and a specific surface activity is automatically synthesized. Therefore, the uniform dispersion of ferromagnetic OD-MFe2O4 in a ferroelectric polymer matrix is realized through compounding the ferroelectric polymer matrix with ferromagnetic OD-MFe2O4. Meanwhile, the good integration of an inorganic phase and an organic phase is realized. As a result, a ferromagnetic phase is highly ordered in a composite system. The wholly new multiferroic magnetoelectric composite material having both ferroelectric properties and ferromagnetic properties is prepared.

Owner:WUHAN UNIV OF TECH

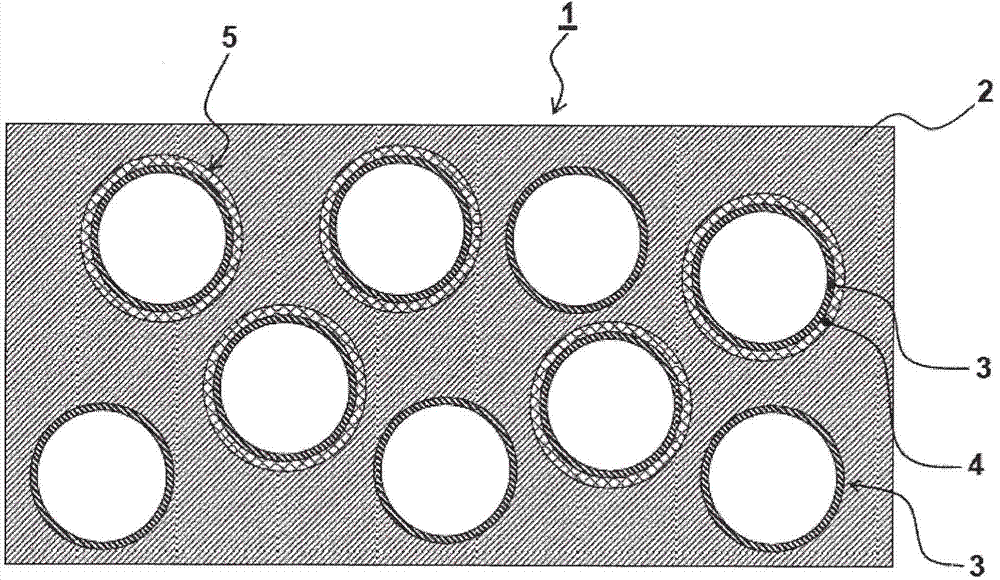

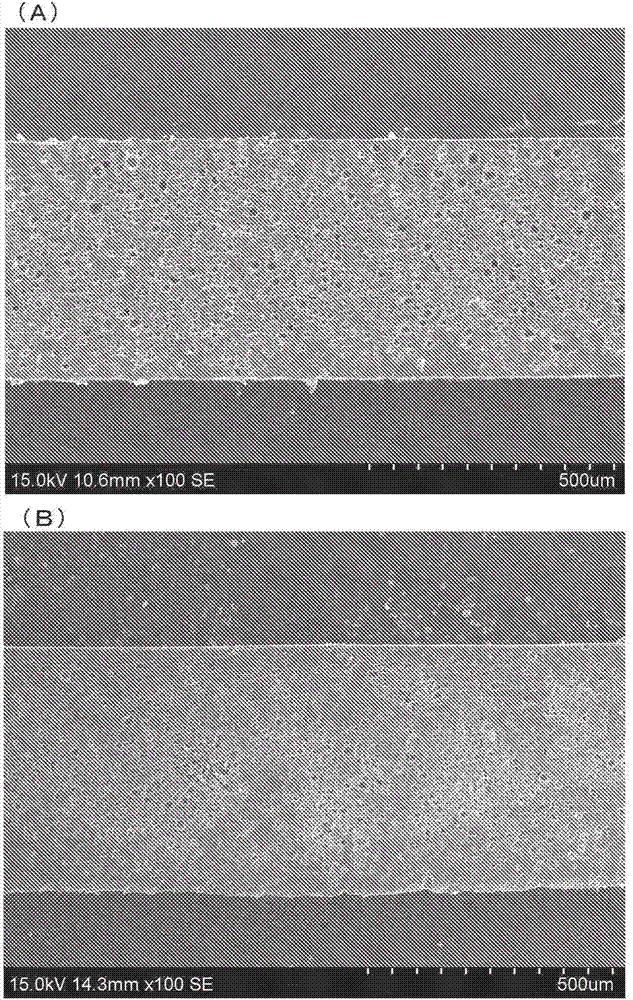

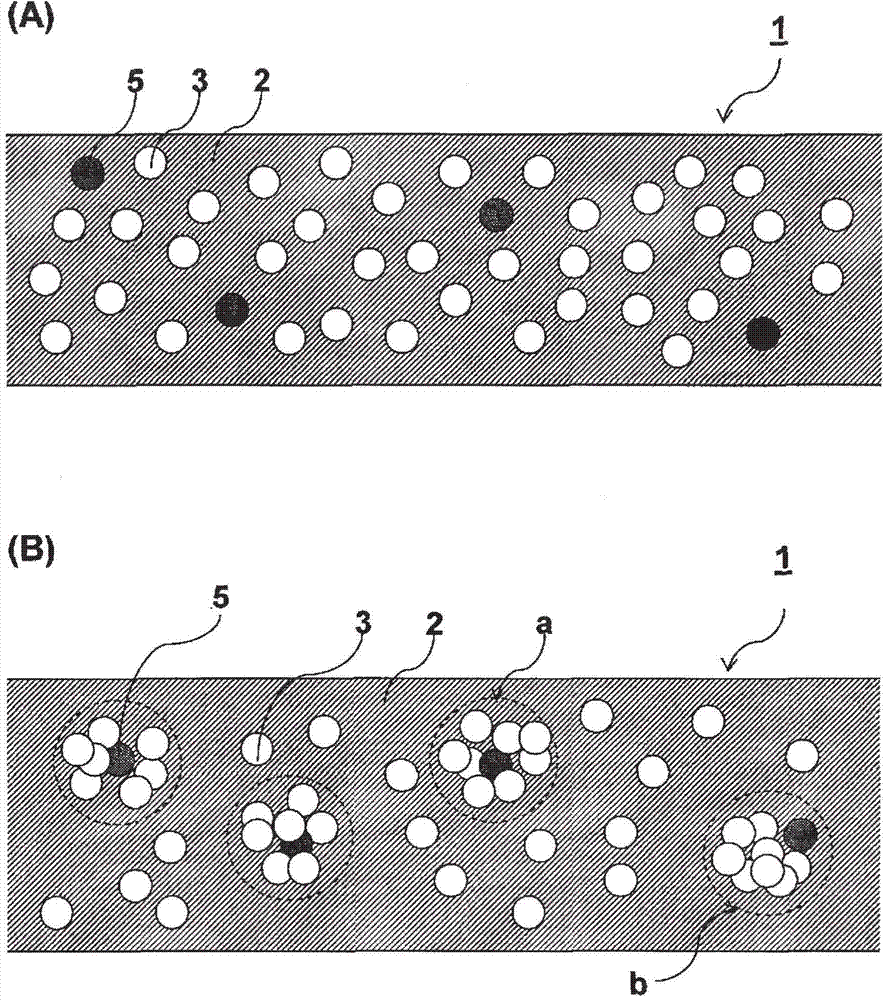

Piezoelectric stack

InactiveCN104756213AHigh piezoelectric coefficientInhibition attenuationPiezoelectric/electrostrictive device manufacture/assemblyElectretsElastic modulus

A piezoelectric stack having a porous resin sheet and a surface-coating layer stacked on the front and / or back surface of the porous resin sheet, which are the outside surfaces of the surface-coating layer, the volume resistivity of the surface-coating layer being at least 1 × 1013 Ω•cm, and the porous resin sheet and the surface-coating layer having different degrees of elasticity.

Owner:NIPPON VALQUA IND LTD +1

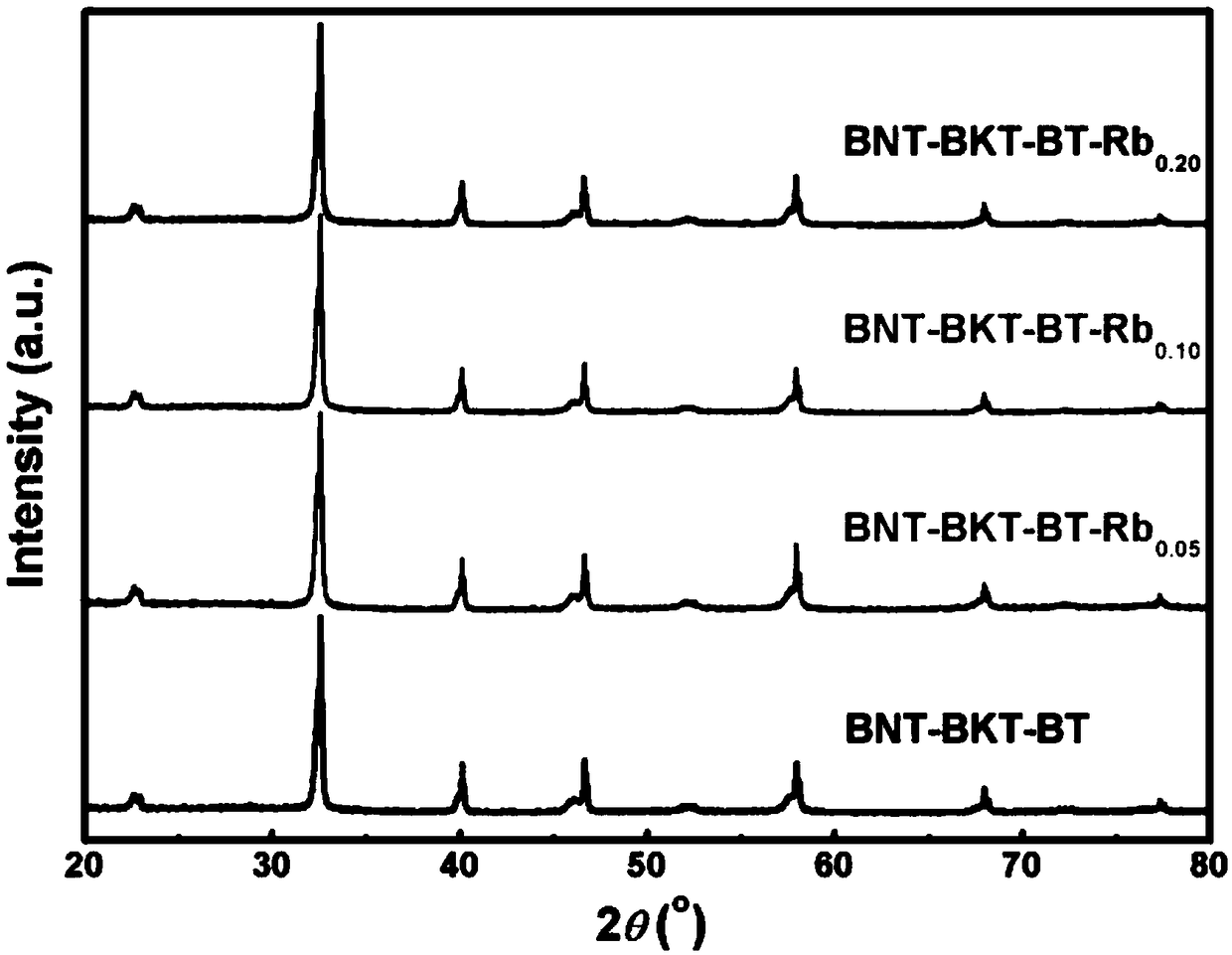

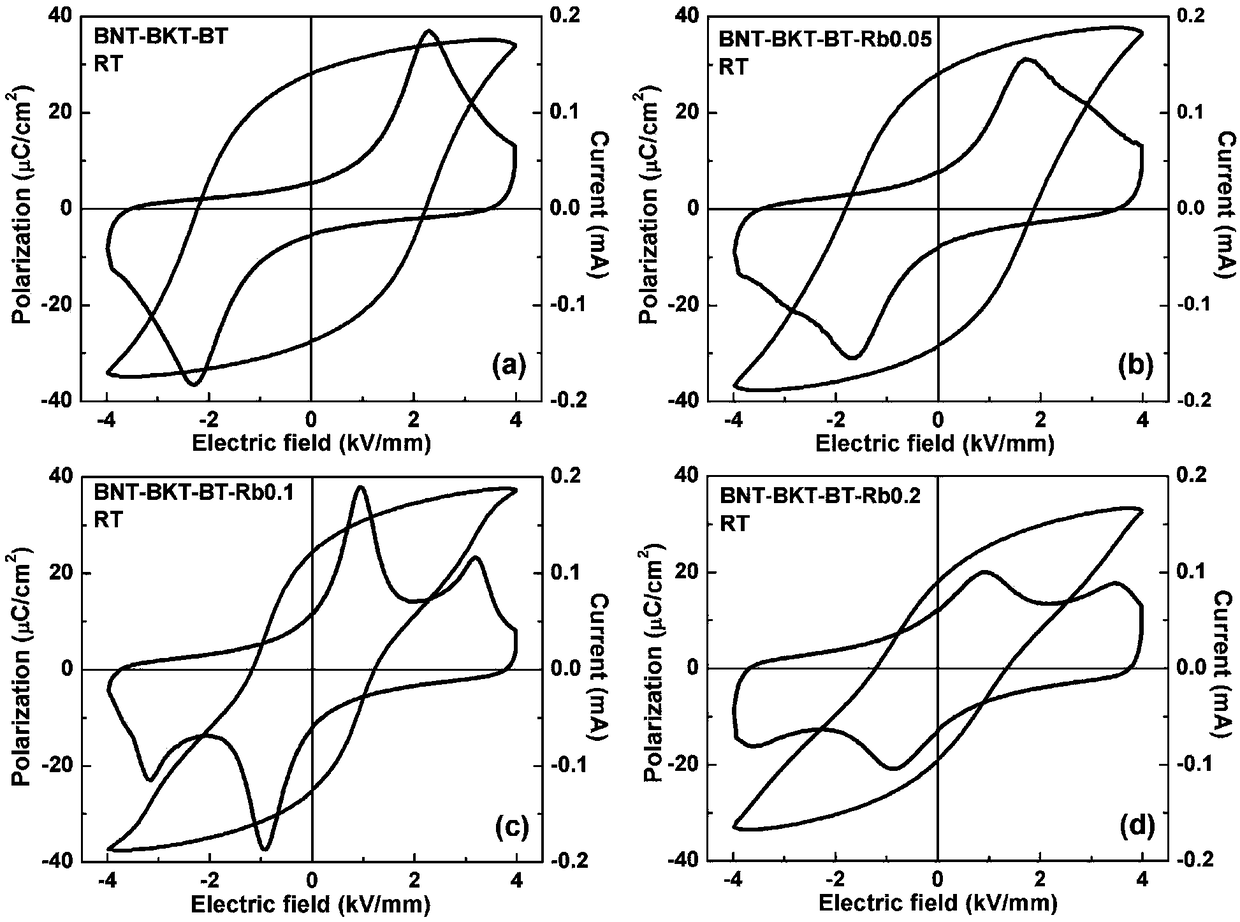

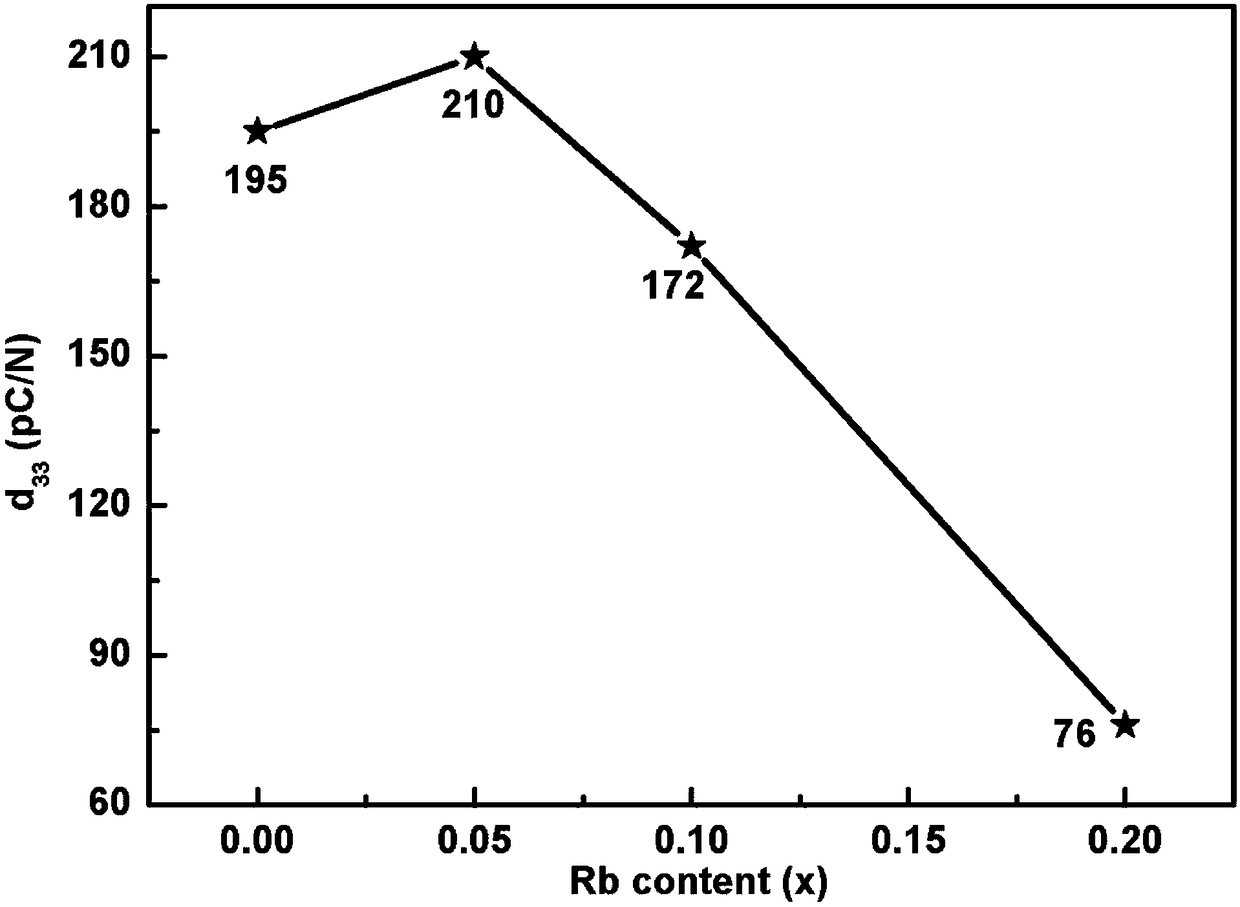

Sodium bismuth titanate based lead-free piezoelectric ceramic with high piezoelectric coefficient and method for preparing sodium bismuth titanate based lead-free piezoelectric ceramic

ActiveCN108147813AReduce manufacturing costExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyRubidiumActuator

The invention discloses sodium bismuth titanate based lead-free piezoelectric ceramic with a high piezoelectric coefficient and a method for preparing the sodium bismuth titanate based lead-free piezoelectric ceramic. A stoichiometric ratio of the sodium bismuth titanate based lead-free piezoelectric ceramic (BNT-BKT-BT-Rb<x>, wherein the x can be equal to 0, 0.05, 0.10 and 0.20) with the high piezoelectric coefficient is shown as 0.85Bi<0.5>Na<0.5>TiO<3>-0.11 Bi<0.5>K<0.5-x>Rb<x>TiO<3>-0.04BaTiO<3>. The method includes uniformly mixing Bi<2>O<3> powder, Na<2>CO<3> powder, K<2>CO<3> powder, BaCO<3> powder, Rb<2>CO<3> powder and TiO<2> powder with one another according to the stoichiometric ratio; carrying out ball-milling and drying and carrying out pre-burning at the temperature of 850 DEG C for 3 h to obtain pre-burned powder; carrying out secondary ball-milling, drying, granulating, compressing and glue discharging and then carrying out sintering at the temperature of 1160-1180 DEGC; carrying out silver firing and polarization to obtain the sodium bismuth titanate based lead-free piezoelectric ceramic. The sodium bismuth titanate based lead-free piezoelectric ceramic and the method have the advantages that rubidium elements are doped in the sodium bismuth titanate based lead-free piezoelectric ceramic, and accordingly the piezoelectric coefficient d33 of the sodium bismuthtitanate based lead-free piezoelectric ceramic can be increased; the piezoelectric coefficient of BNT-BKT-BT-Rb<0.05> ceramic can reach 210 pC / N, and the sodium bismuth titanate based lead-free piezoelectric ceramic which is a lead-free piezoelectric material can be effectively applied to diversified fields of actuators, sensors and the like.

Owner:广州光鼎科技集团有限公司

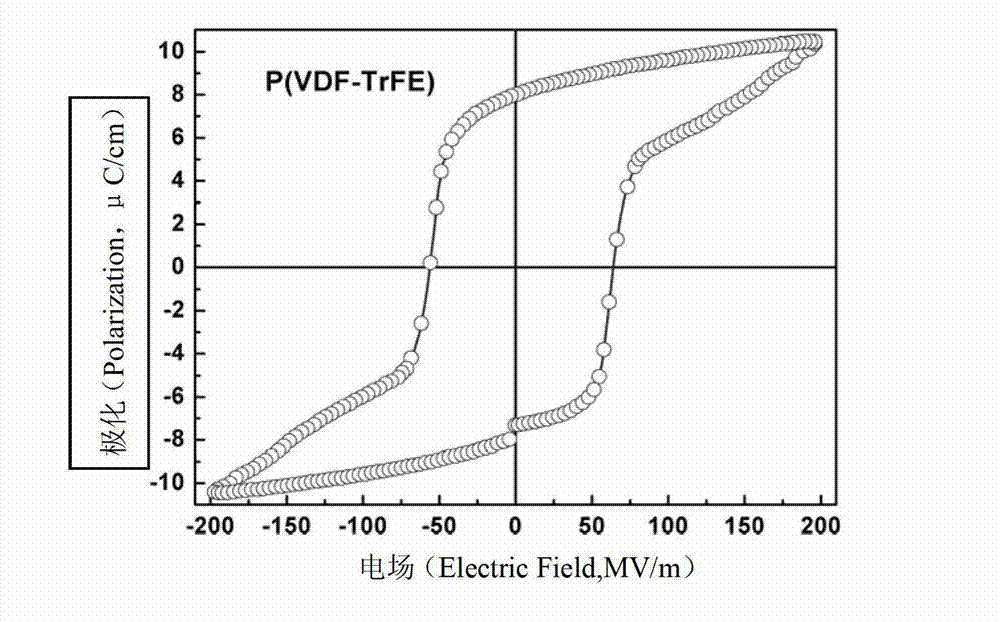

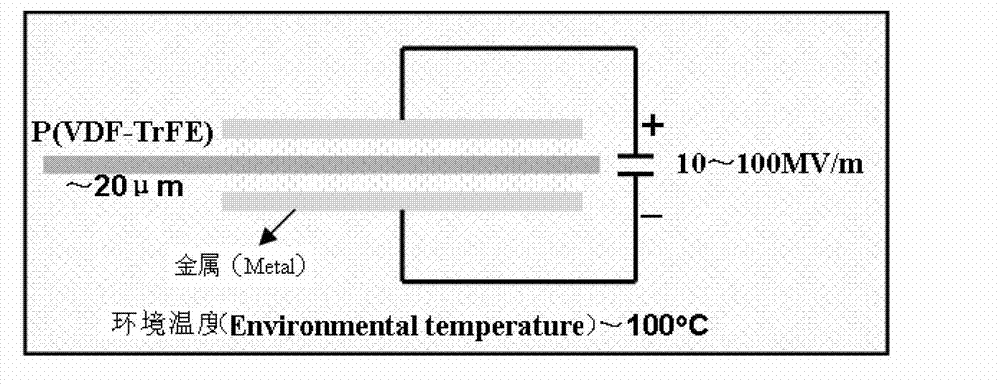

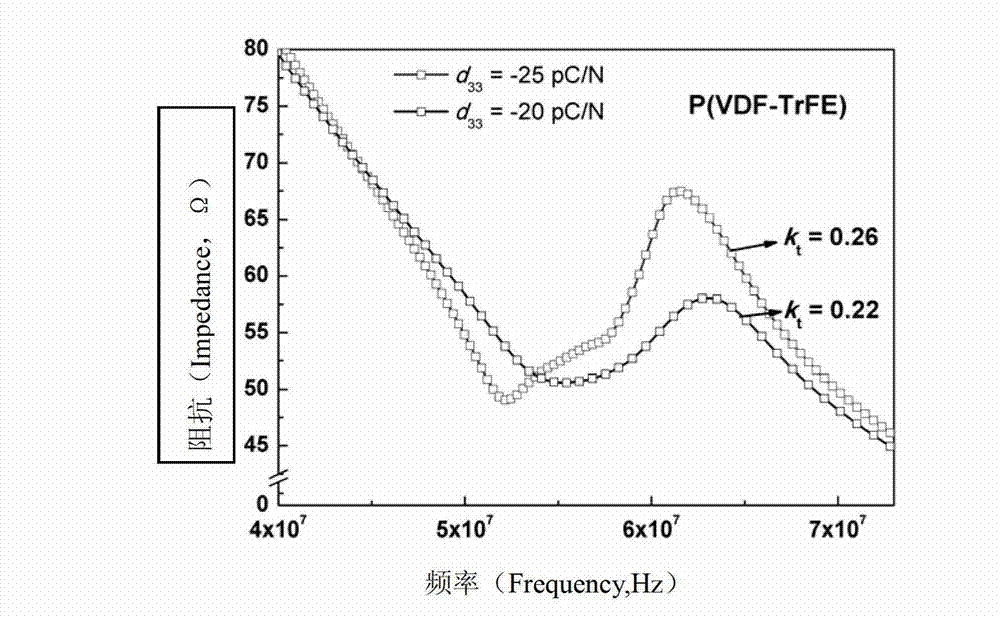

Application and method for preparing electret piezoelectric material from head-head connected hydrogenation P (VDF-TrFE)

ActiveCN102956812AHigh piezoelectric coefficientGood electromechanical coupling performancePiezoelectric/electrostrictive/magnetostrictive devicesChemistryElectric field

The invention discloses an application and a method for preparing an electret piezoelectric material from head-head connected hydrogenation P (VDF-TrFE). The hydrogenation P (VDF-TrFE) is prepared into a film, an electric field is heated and polarized, a polymer has an unexpected result, namely, the polymer has the advantages of high voltage coefficient and good electromechanical coupling performance and the like; a dipole moment formed by C-F and C-H bonds in a molecular chain is oriented along an electric field direction so that a chain alignment mode similar to TTTT is formed. The head-head connected hydrogenation P (VDF-TrFE) has the characteristics of safe operation, good stability and low raw material noxious property, and the method can greatly reduce the preparation cost of the P (VDF-TrFE); and the hydrogenation P (VDF-TrFE) is utilized to replace the existing PVDF piezoelectricity film and a direct interpolymer P (VDF-TrFE) so as to be used as the electret piezoelectric material, and the preparation cost of the electret piezoelectric material is greatly reduced.

Owner:西安德天励行新材料科技有限公司

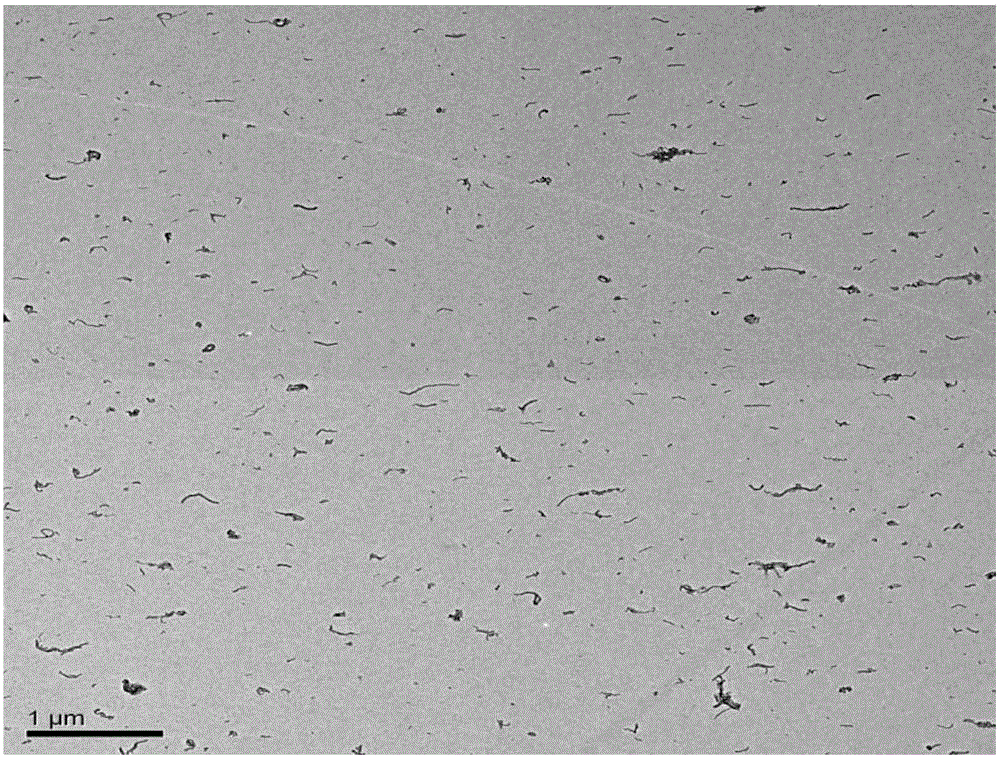

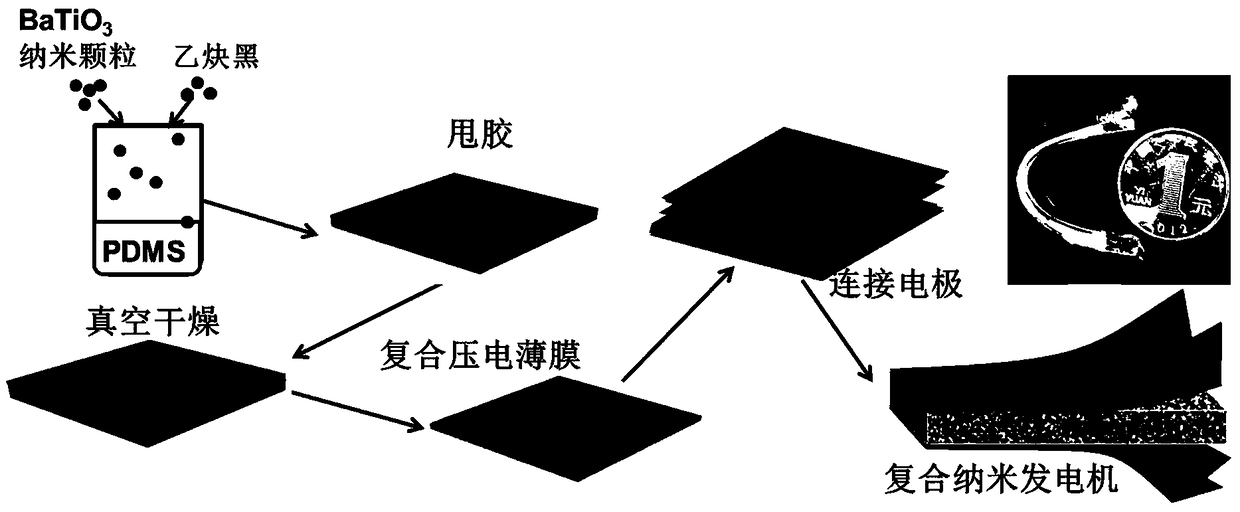

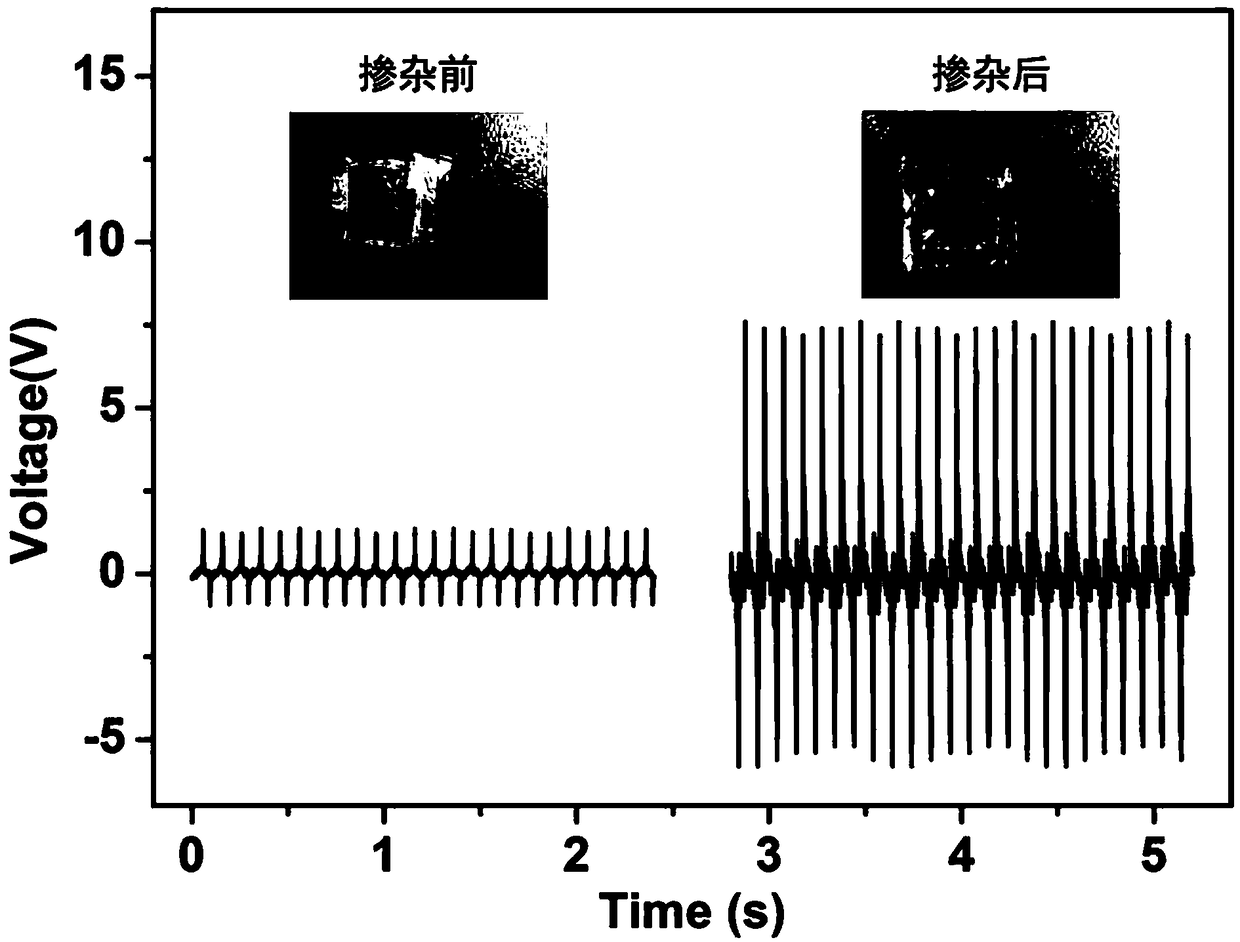

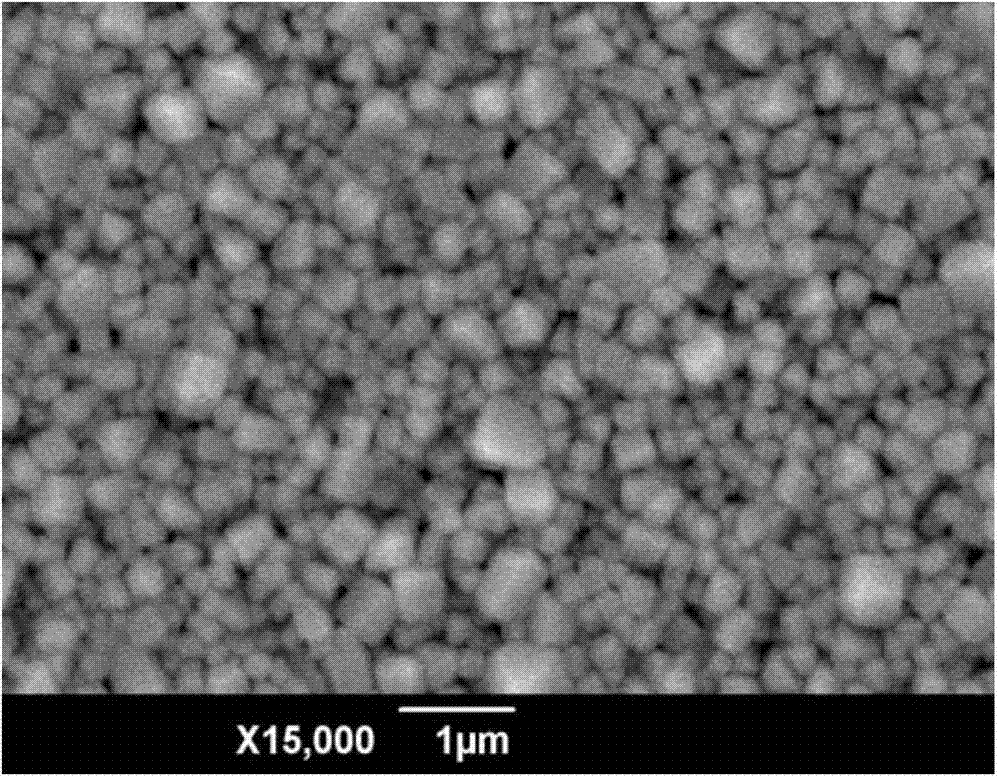

Preparation method of conductive material-doped nanometer piezoelectric composite thin film generator

InactiveCN108365085AGood flexibilityEasy to makeMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyElectricityComposite film

The invention belongs to the preparation field of a piezoelectric material modified nanometer composite thin film generator, relates to a preparation method of a conductive material-doped nanometer piezoelectric thin film generator, and solves the technical problems of low piezoelectric coefficient, insufficient output power and the like of the conventional nanometer thin film generator. Accordingto the preparation method of the conductive material-doped nanometer composite piezoelectric thin film generator, a piezoelectric nanomaterial, PDMS and a conductive material are combined to preparea flexible piezoelectric thin film with uniform granule distribution; and then through high voltage polarization to obtain the nanometer piezoelectric thin film generator with high piezoelectric coefficient and relatively high output power. The preparation method of the composite thin film is simple in process, short in period, and low in cost; the nanometer particles are uniformly dispersed, andthe thin film obtained by adhesive throwing is uniform in thickness; and the composite thin film is quite high in flexibility, not broken after suffering from impact of multiple times, high in piezoelectric coefficient, high in output power and high in stability.

Owner:TAIYUAN UNIV OF TECH

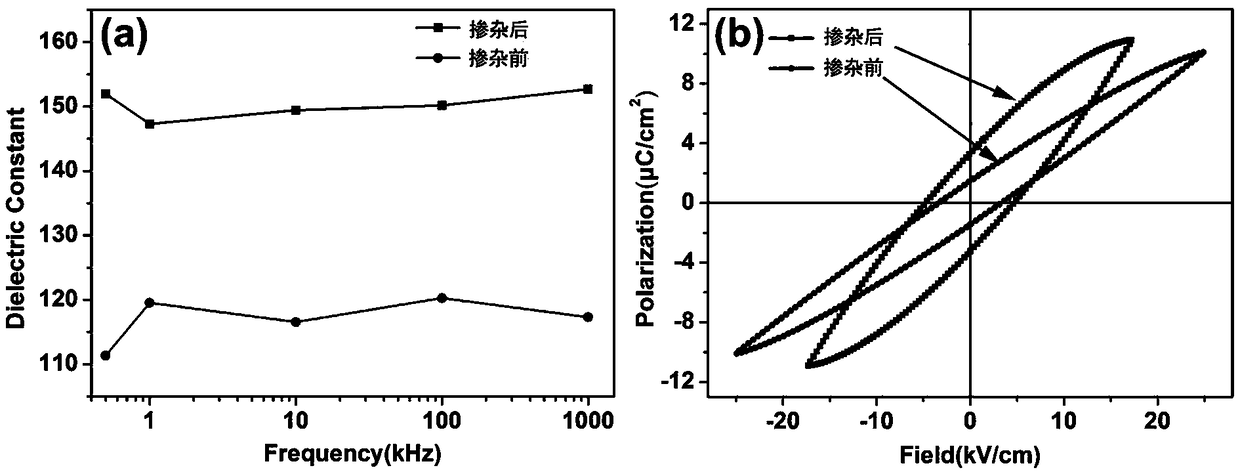

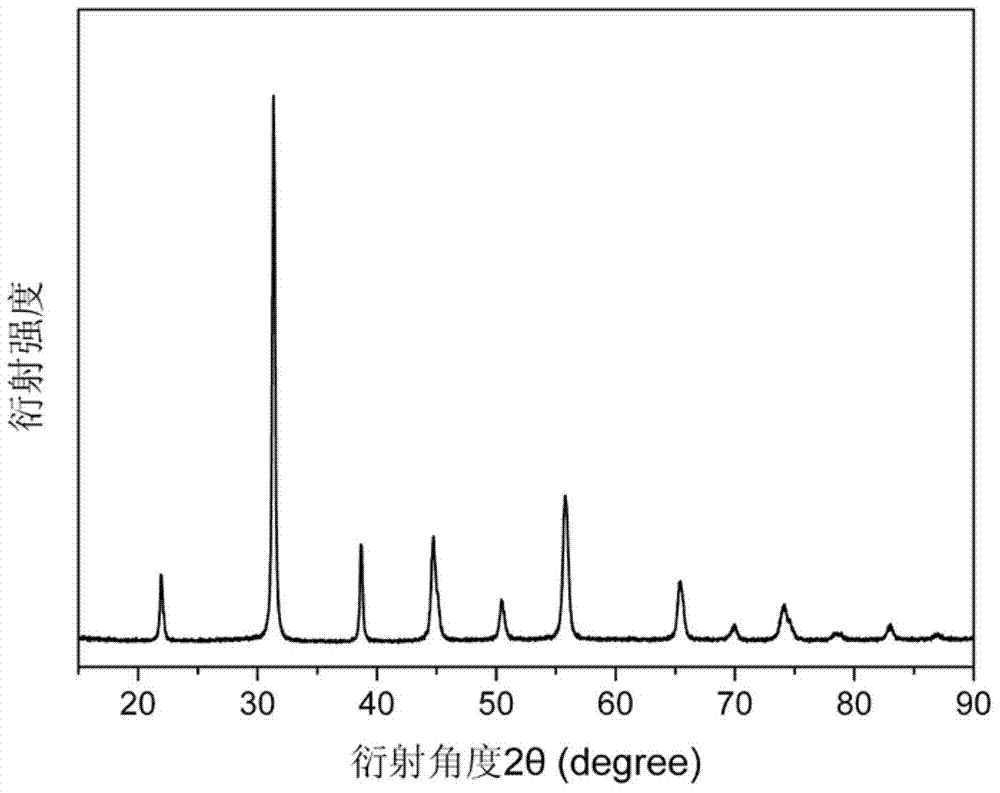

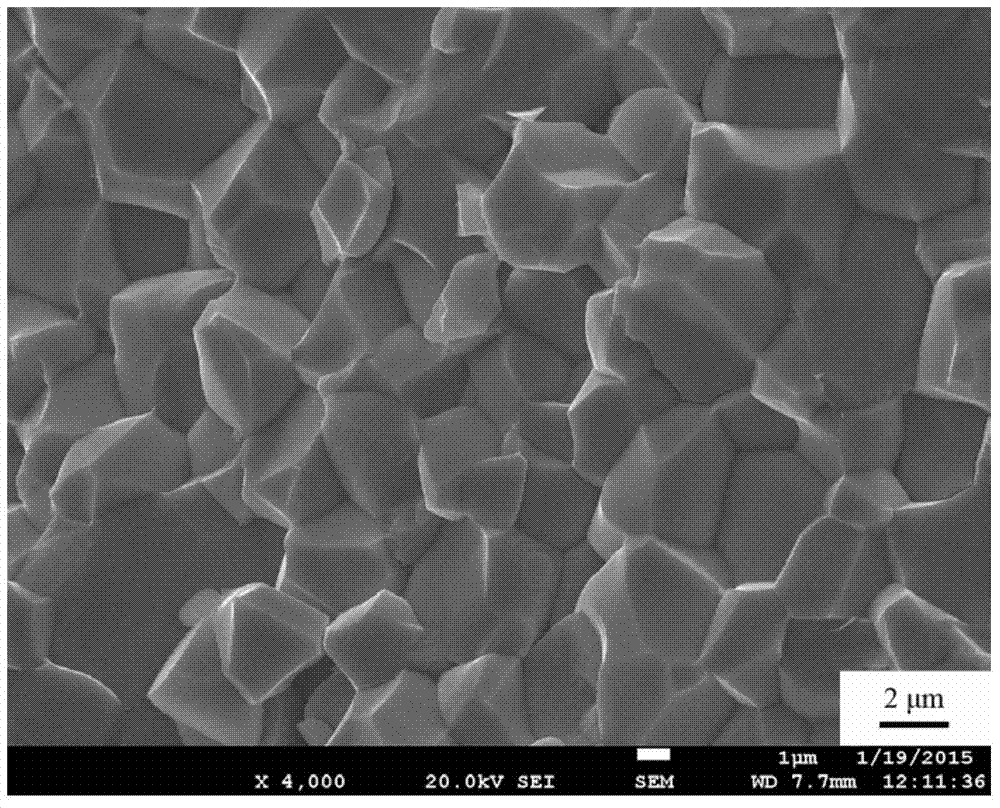

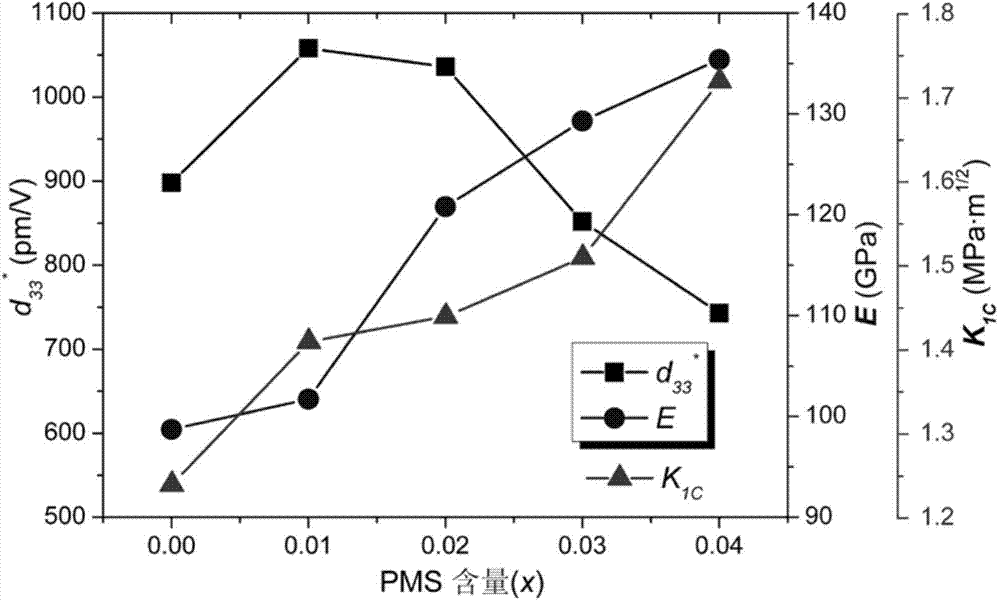

Lead manganate antimonate doped niobium nickel-lead zirconate titanate piezoelectric ceramic

ActiveCN104844202AHigh piezoelectric coefficientImprove mechanical propertiesLead zirconate titanateNiobium

The invention discloses a lead manganate antimonate (PMS) doped niobium nickel-lead zirconate titanate piezoelectric ceramic (PNN-PZT) having the raw material formula: (1-x)Pb(Ni[1 / 3]Nb[2 / 3])[0.5]Zr[y]Ti[0.5-y]O[3]-xPb(Mn[1 / 3]Sb[2 / 3])O[3], wherein in the formula, x and y represent the molar content and have numerical values respectively being x=0.0-0.06 and y=0.10-0.20. A traditional solid phase synthesis process is adopted, a pre-sintering temperature is 800-900 DEG C, a sintering temperature is 1000-1300 DEG C, and a novel piezoelectric ceramic material is obtained, wherein the material has high piezoelectric coefficient (d33<*>=1000 pm / V) and excellent mechanical properties (E=120 GPa, and K1C=1.44 Mpa.m<1 / 2>). The piezoelectric ceramic based on lead zirconate titanate has high piezoelectric coefficient and excellent mechanical properties. The novel piezoelectric ceramic is mainly used in the fields of micrometric displacement actuators, piezoelectric sensors, transducers and the like, and has great market values.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Preparation method of high grain orientation piezoceramic material

The invention relates to a preparation method of a high grain orientation piezoceramic material. The general chemical formula of the high grain orientation piezoceramic material is XaYbOc, wherein X and Y are respectively an element from Ca, Nd, Ti, Nb or Sr, and X is different from Y; O is oxygen; and a, b and c are all positive integer, and the number of positive and negative charges is balanced among a, b and c. The preparation method comprises the following steps: (1) a spheroidic powder XaYbOc is prepared by a solid phase method with the combination of a ball-milling technology; (2) a flaky powder XaYbOc is prepared by a molten salt method; (3) the spheroidic powder XaYbOc and the flaky powder XaYbOc are mixed and undergo hot-pressing so as to obtain the high grain orientation piezoceramic material XaYbOc. In comparison with a traditional grain orientation technology, the preparation method provided by the invention has the following characteristics: the high grain orientation piezoceramic material prepared by the preparation method has higher grain orientation degree and higher density; and the preparation technology is simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

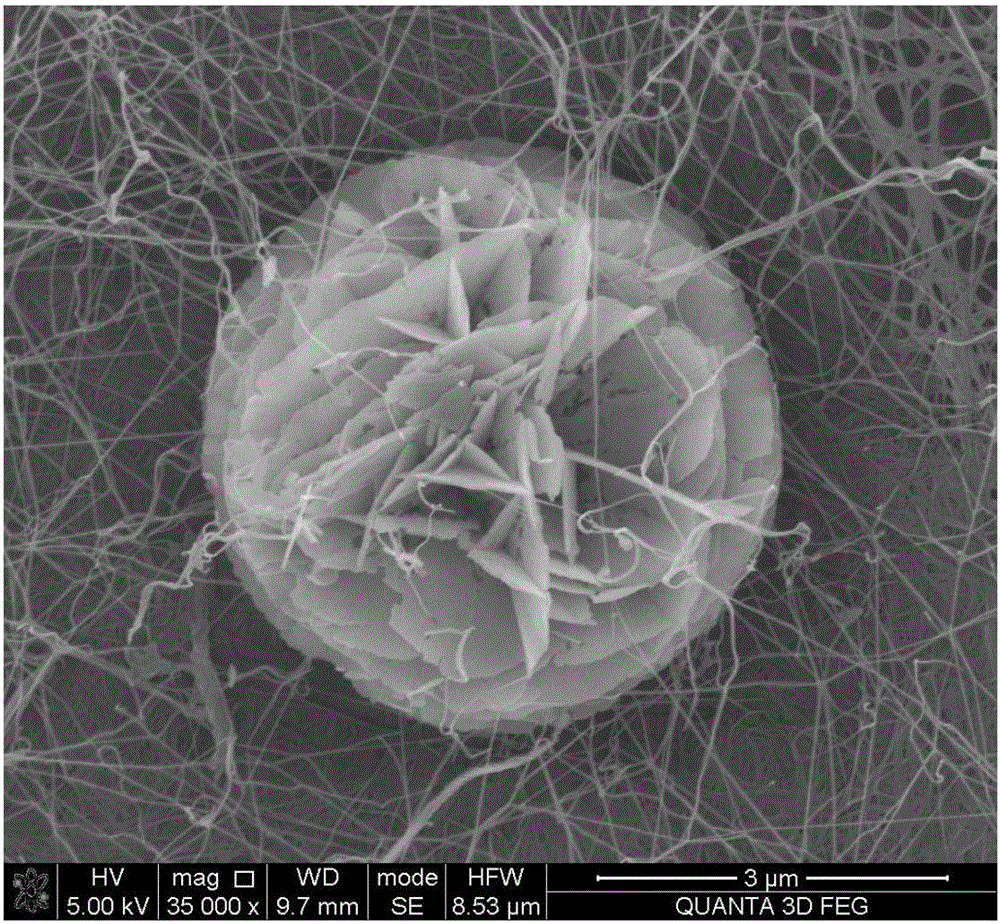

Bacterial cellulose flexible composite piezoelectric film and preparation method thereof

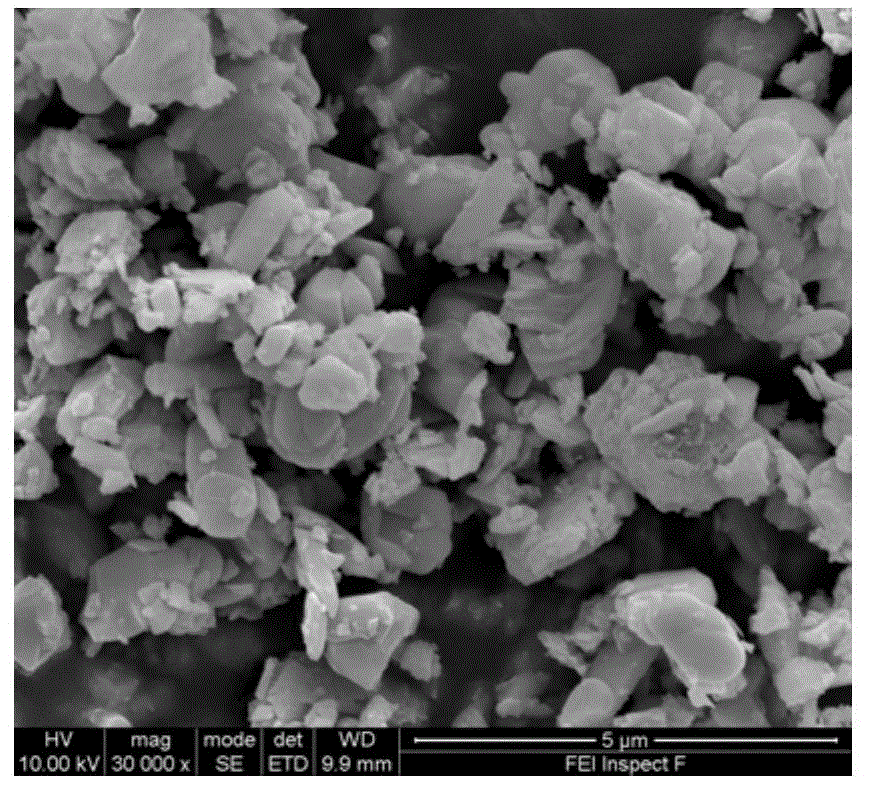

ActiveCN106784296AHigh piezoelectric coefficientWith ferroelectricityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionMaterials preparationVanadium doping

The invention mainly belongs to the technical field of composite piezoelectric material preparation and particularly relates to a bacterial cellulose flexible composite piezoelectric film and a preparation method thereof. The method comprises the steps of adopting bacterial cellulose as a matrix material of the composite piezoelectric film; and synthesizing vanadium-doped zinc oxide microflowers in situ in the bacterial cellulose through a solution reaction method, thereby obtaining the composite piezoelectric film with flexibility and piezoelectric property, wherein the vanadium-doped zinc oxide microflowers are formed by vanadium-doped zinc oxide nanosheets and are spherical in form and shape; the thicknesses of the vanadium-doped zinc oxide nanosheets are 10-100nm; and the sizes of the vanadium-doped zinc oxide microflowers are 1-10 microns. A piezoelectric nanostructure is uniformly filled into the composite piezoelectric film under the condition of not destroying the natural structure of the bacterial cellulose, and the filled vanadium-doped zinc oxide has a higher piezoelectric coefficient than pure zinc oxide and has the ferroelectric properties which the pure zinc oxide does not have.

Owner:UNIV OF SCI & TECH BEIJING

BTS (Ba2TiSi2O8) piezoelectric crystal cut type and application thereof

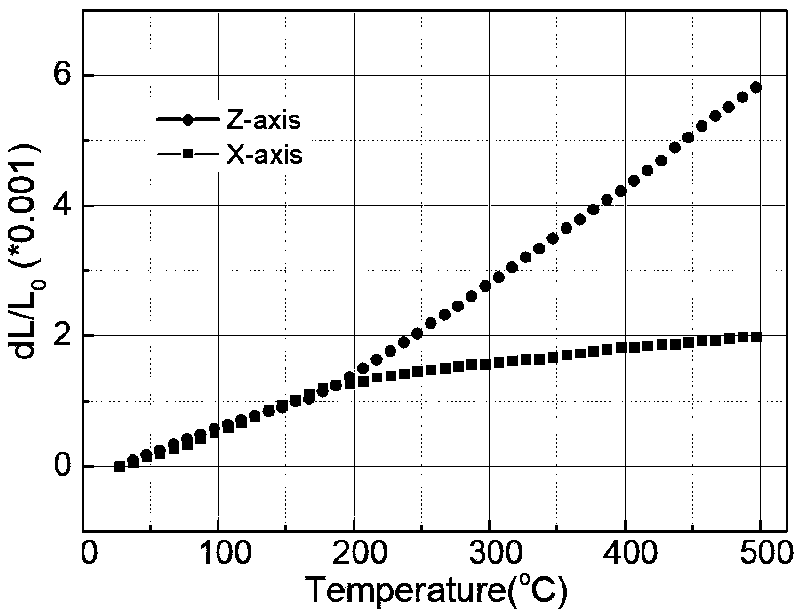

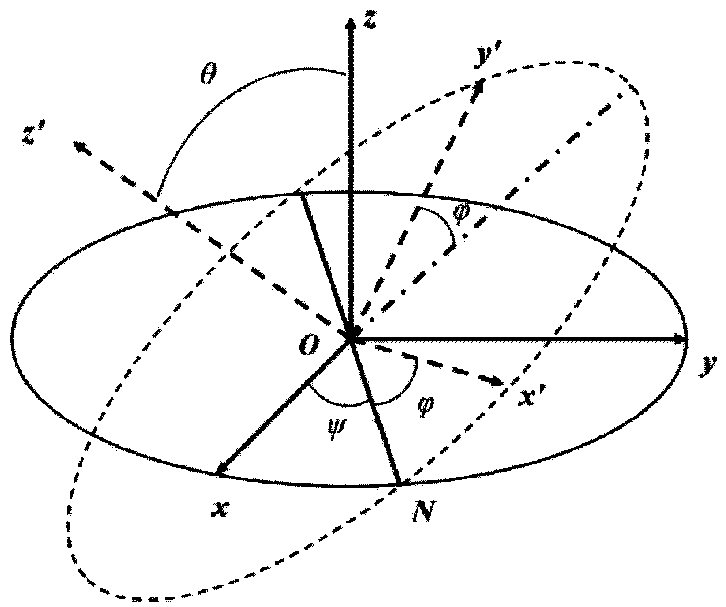

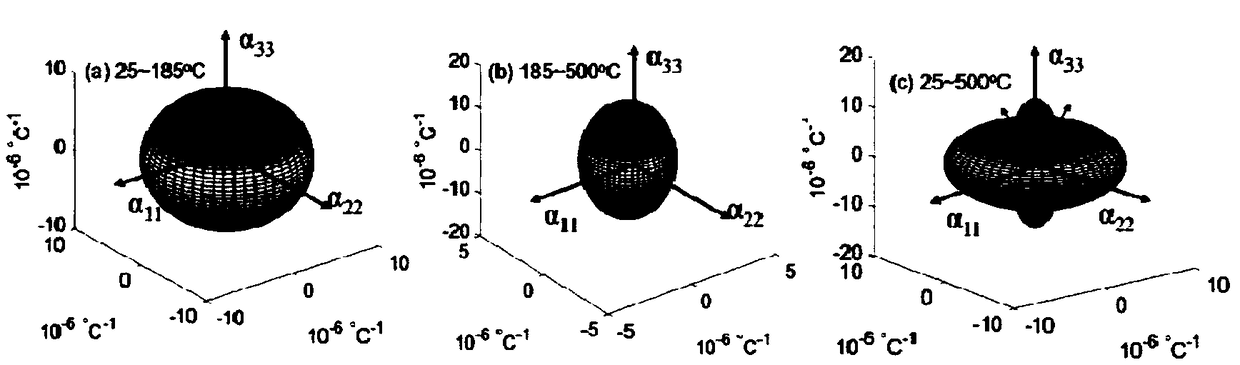

ActiveCN109338473AHigh piezoelectric coefficientExcellent linear thermal expansion coefficientPolycrystalline material growthSingle crystal growth detailsPhysicsRoom temperature

The invention relates to a BTS (Ba2TiSi2O8) piezoelectric crystal cut type. The BTS piezoelectric crystal cut type can be obtained by cutting along the direction deviating from theta angle of the Z axis randomly and has higher piezoelectric constant and linear thermal expansion coefficient, marked (theta, psi), wherein theta is larger than or equal to 45 degrees and smaller than or equal to 50 degrees and psi is larger than or equal to minus 180 degrees and smaller than or equal to 180 degrees. The cut type has the linear thermal expansion coefficient of 8.0-8.2 ppm / DEG C and the effective piezoelectric constant d<*>33 lager than 8.5 pC / N in the range of the room temperature to 500 DEG C and has the change rate lower than 13% in the range of the room temperature to 500 DEG C. The problem of mismatching of thermal expansion in application of BTS crystals is solved, besides, the temperature stability of the piezoelectric performance is improved, and the cut type is particularly suitableto be developed into a piezoelectric sensor device used in the wide temperature range.

Owner:山东本源晶体科技有限公司

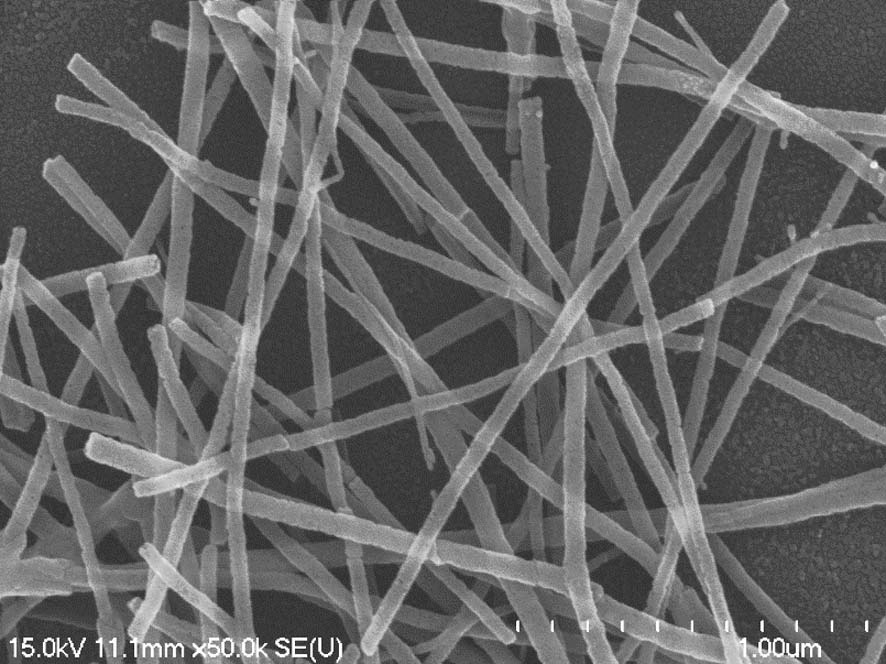

Vanadium-doped strontium titanate nanofiber and preparation method and application thereof

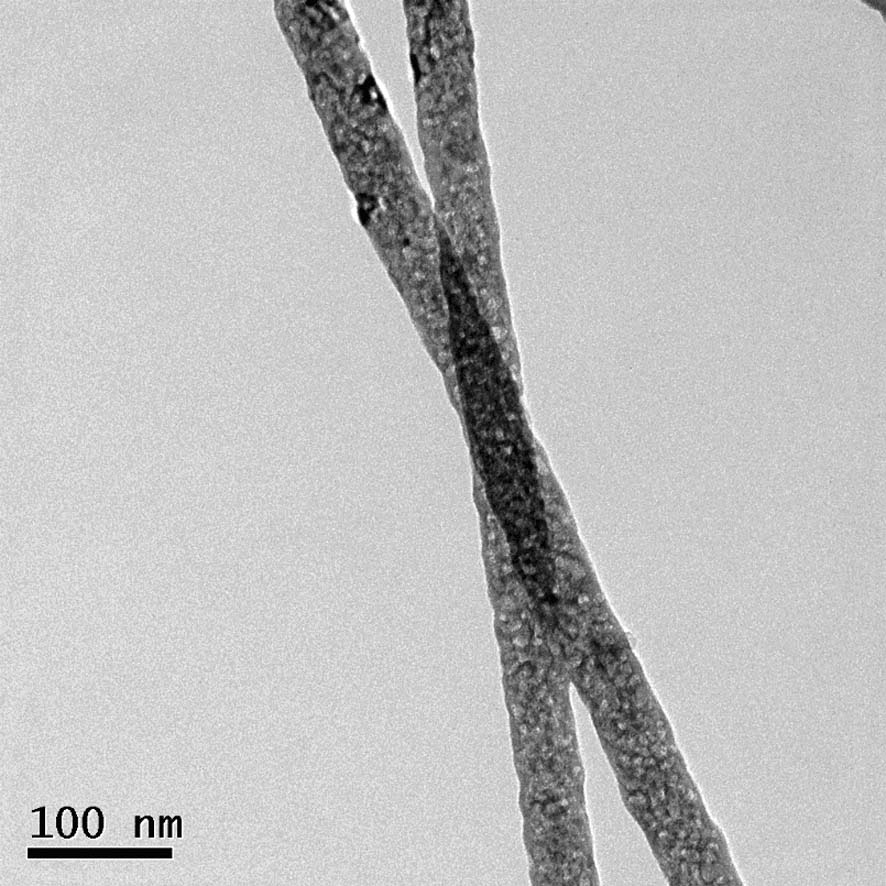

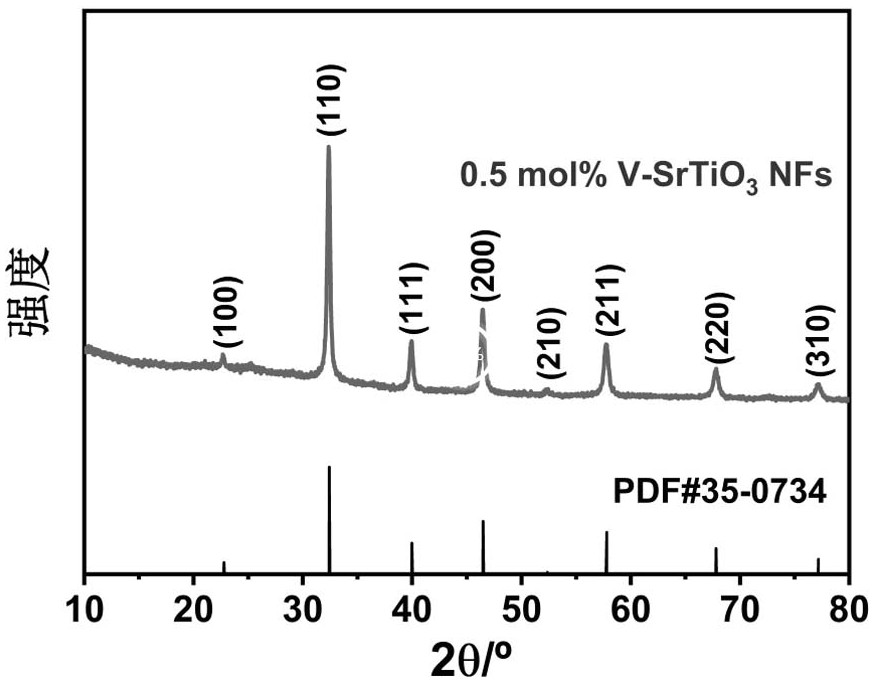

ActiveCN111996618AImprove piezoelectric performanceStrong piezoelectric catalytic activityMaterial nanotechnologyWater contaminantsStrontium titanateFiber

The invention discloses vanadium-doped strontium titanate nanofiber. A preparation method of the vanadium-doped strontium titanate nanofiber includes the following steps that electrostatic spinning isconducted on a vanadium-doped strontium titanate electrostatic spinning precursor solution to obtain a fiber film; and the fiber film is calcined, and the vanadium-doped strontium titanate nanofiberis obtained, wherein the vanadium-doped strontium titanate electrostatic spinning precursor solution includes vanadium salt, strontium salt, titanium salt, high polymers and solvent. In construction of piezoelectric catalysis nanometer materials, the vanadium-doped strontium titanate nanofiber piezoelectric material has a non-centrosymmetry structure, is an excellent ferroelectric material, has aninternal space charge layer, can effectively generate piezoelectric inductive charges and has good piezoelectric performance, and under external ultrasonic vibration, the material can effectively degrade and remove organic pollutant in a water body.

Owner:SUZHOU UNIV

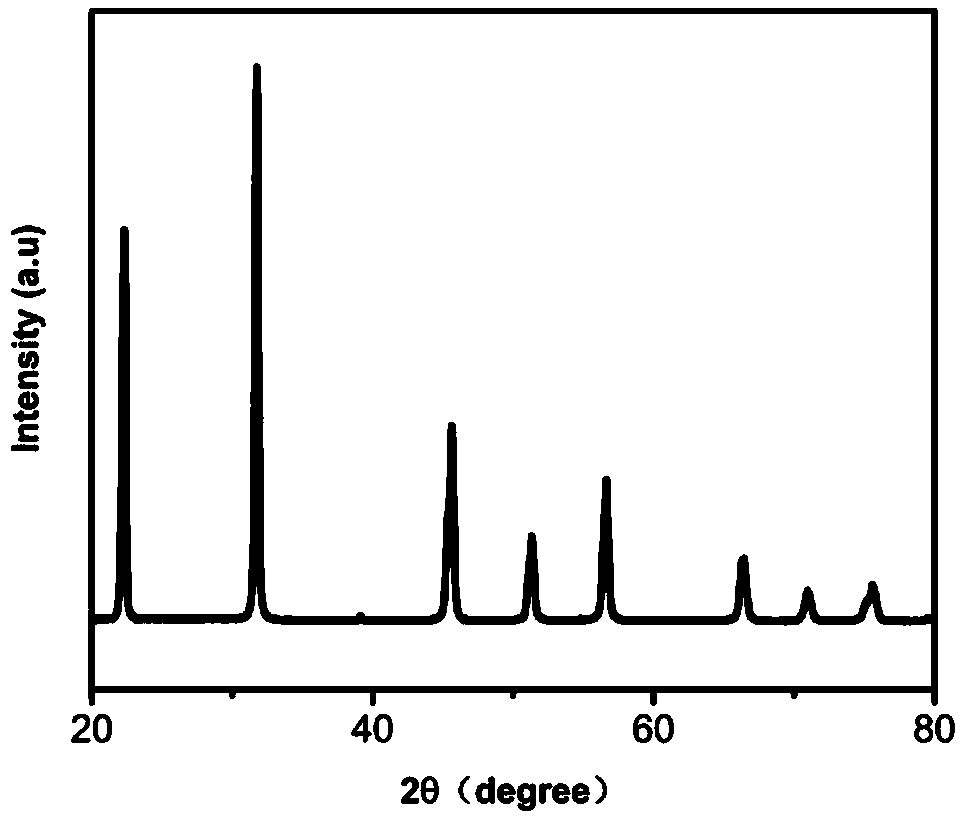

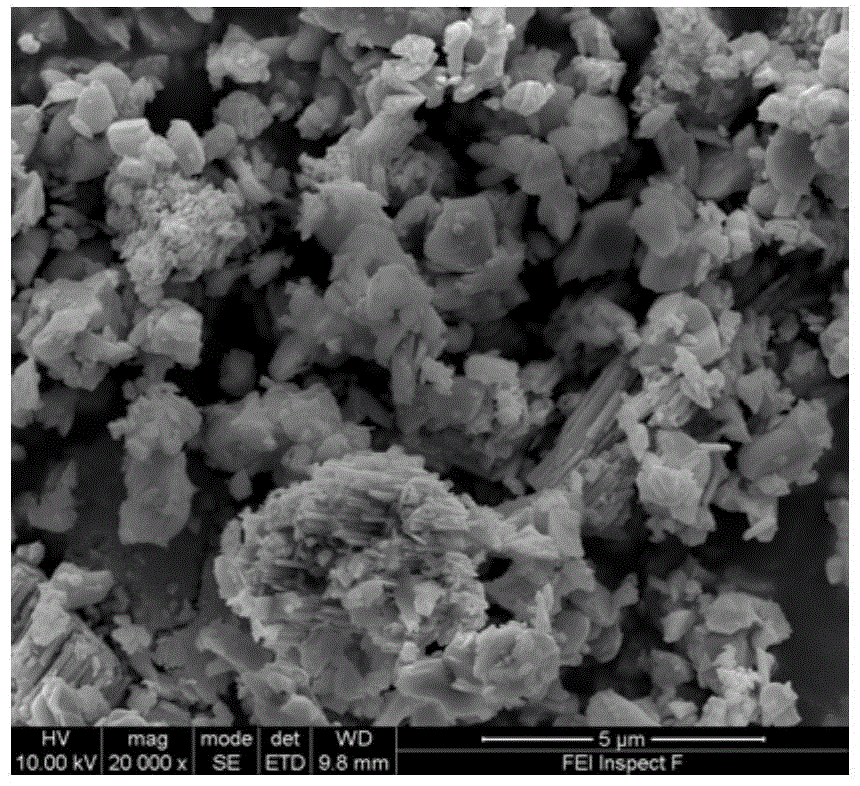

High-solid-solubility relaxation-type nano leadless piezoelectric ceramic and preparation method thereof

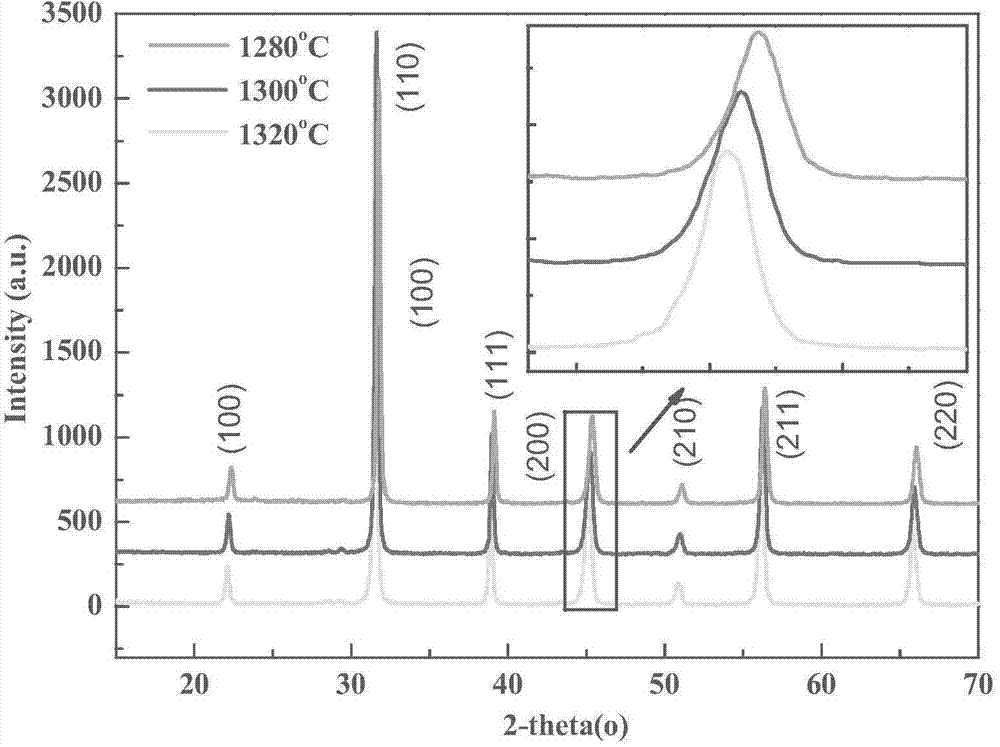

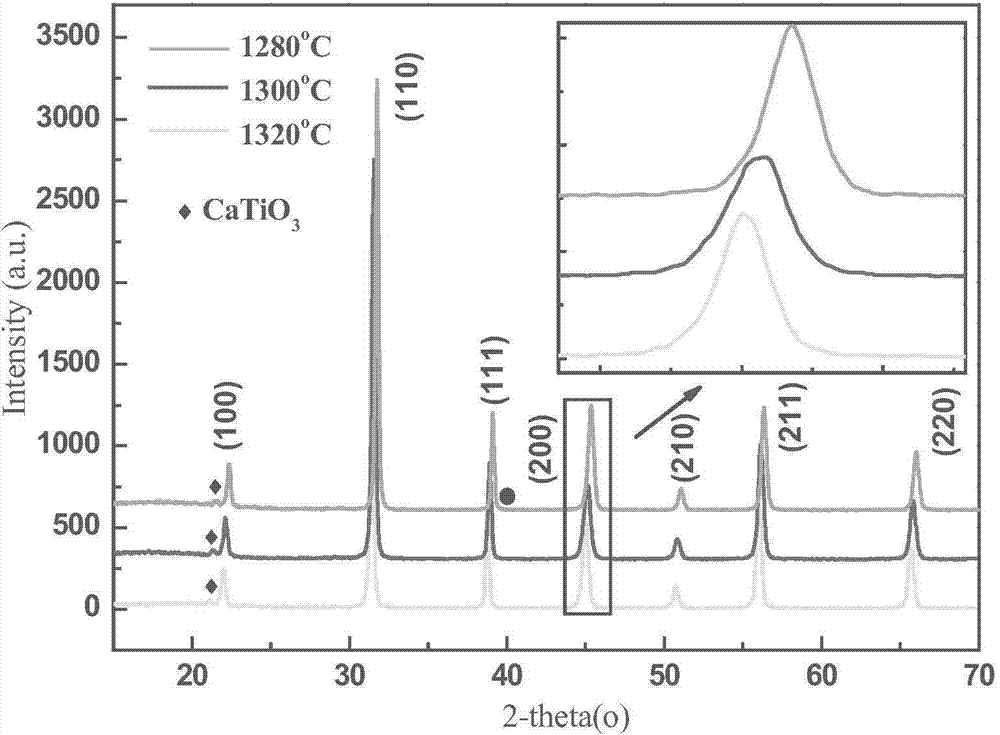

InactiveCN104496466AExcellent Dielectric Relaxation BehaviorHigh dielectric constantCurie temperatureMicrowave sintering

The invention relates to a high-solid-solubility relaxation-type nano leadless piezoelectric ceramic and a preparation method thereof. The method comprises the following steps: dissolving a soluble raw material in water according to the stoichiometric proportion of Ba0.8Ca0.2Ti0.9Zr0.1O3 to obtain a mixed solution; regulating the pH value of the mixed solution to obtain a powder precursor; reacting at 150-200 DEG C in a hydrothermal environment for 10-15 hours to obtain a billet; and carrying out microwave sintering on the billet at 1280-1320 DEG C to obtain the high-solid-solubility relaxation-type nano leadless piezoelectric ceramic. The ceramic, which is prepared by sintering the Ba0.8Ca0.2Ti0.9Zr0.1O3 ceramic powder at 1280-1320 DEG C, has the advantages of excellent dielectric relaxation behavior and high solid solubility for calcium ions, enhances the temperature stability of the material on the premise of effectively lowering the Curie temperature of the ceramic material, and still has excellent electric properties in some extreme environments.

Owner:SHAANXI UNIV OF SCI & TECH

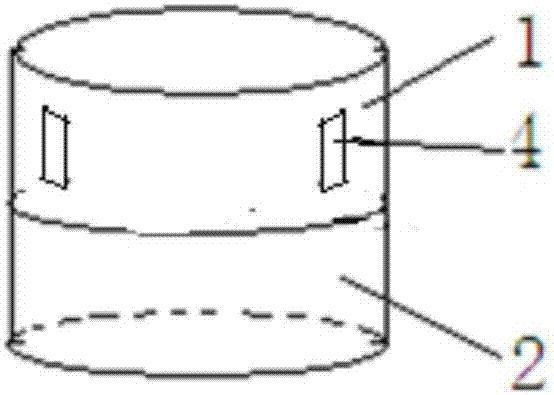

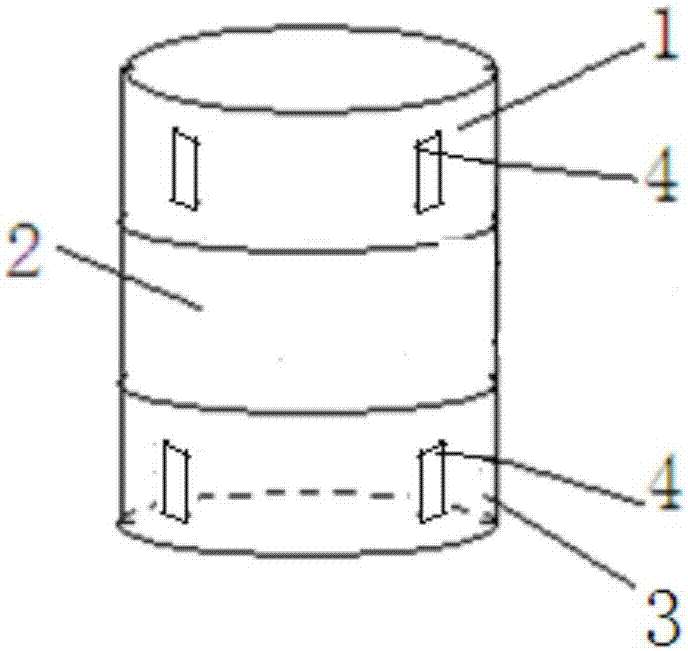

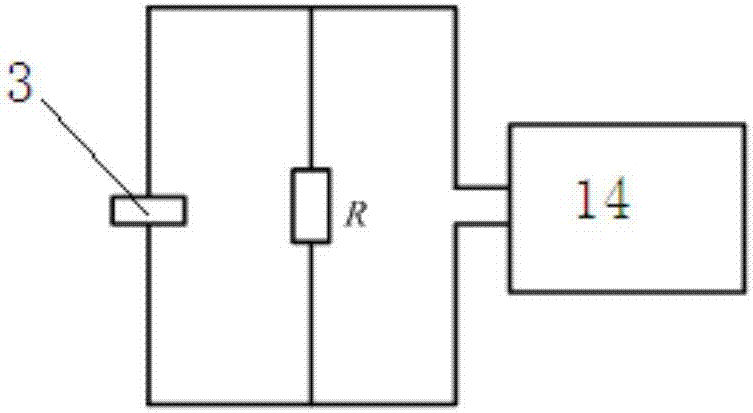

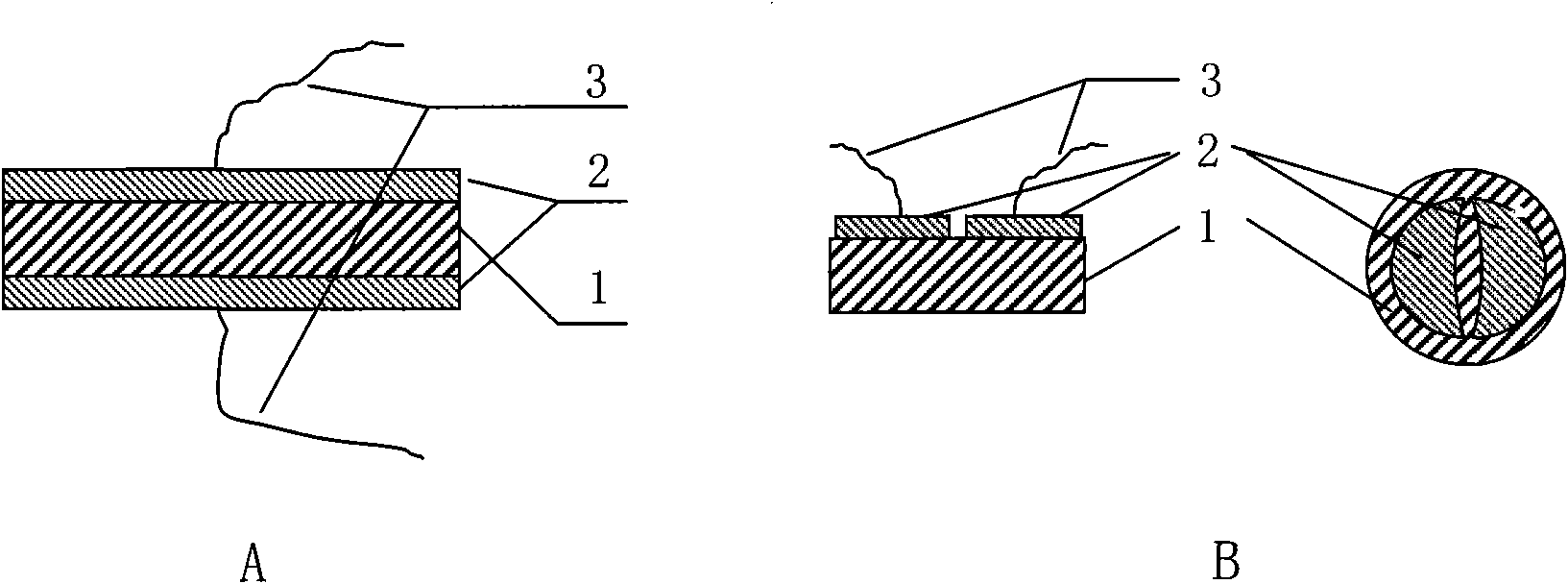

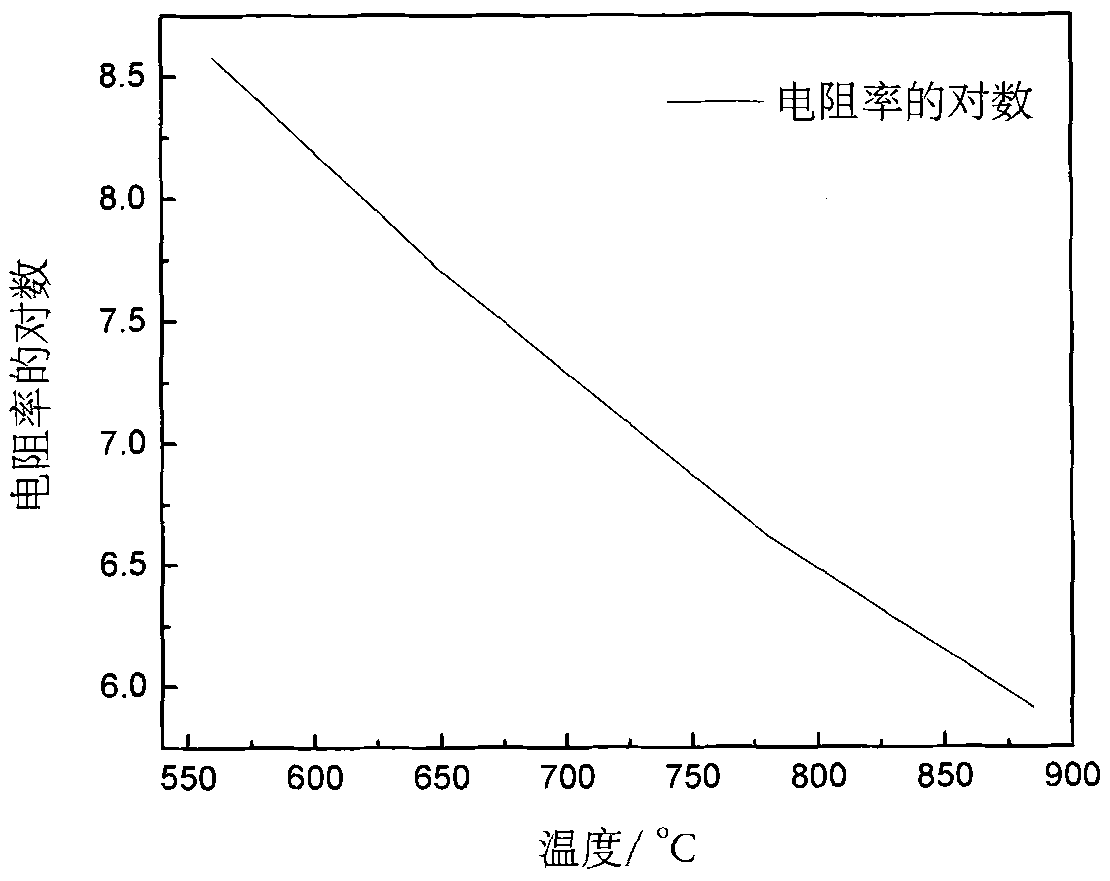

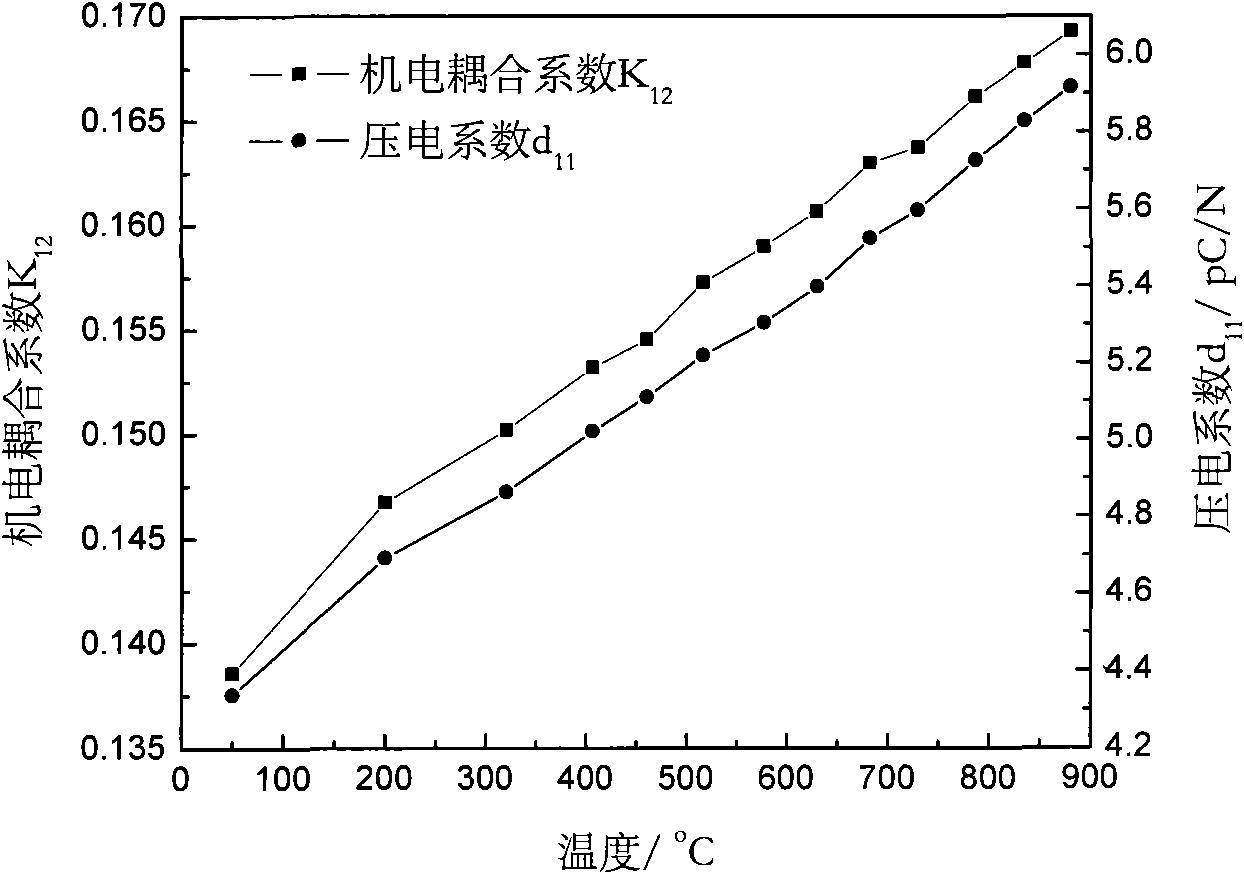

Piezoelectric crystal element

ActiveCN101834268AImprove stabilityHigh point coupling coefficientPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionElectromechanical coupling coefficientRoom temperature

The invention relates to a piezoelectric crystal element and belongs to the field of crystal elements. The piezoelectric crystal element comprises a piezoelectric crystalline material (1), an electrode layer (2) and a lead (3). A chemical formula of the piezoelectric crystal material is A3+xB1+yAl3+zSi2+mO14+n, wherein x is more than or equal to -0.2 and less than or equal to 0.2; y is more than or equal to -0.2 and less than or equal to 0.2; z is more than or equal to -0.2 and less than or equal to 0.2; m is more than or equal to -0.2 and less than or equal to 0.2; n is more than or equal to -1.4 and less than or equal to 1.4; A is Ca, Sr or combination of the two elements; and B is one of Ta, Nb or Sb, or combination of more of the three elements. The maximum service temperature of the piezoelectric crystal element can reach 1,000 DEG C; and the piezoelectric crystal element has the characteristics of large high temperature electrical resistivity, large piezoelectric coefficient, large electro-mechanical coupling factor, no phase change from the room temperature to a melting point, low price and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Two-dimensional layered perovskite ferroelectric multifunctional film and preparation process thereof

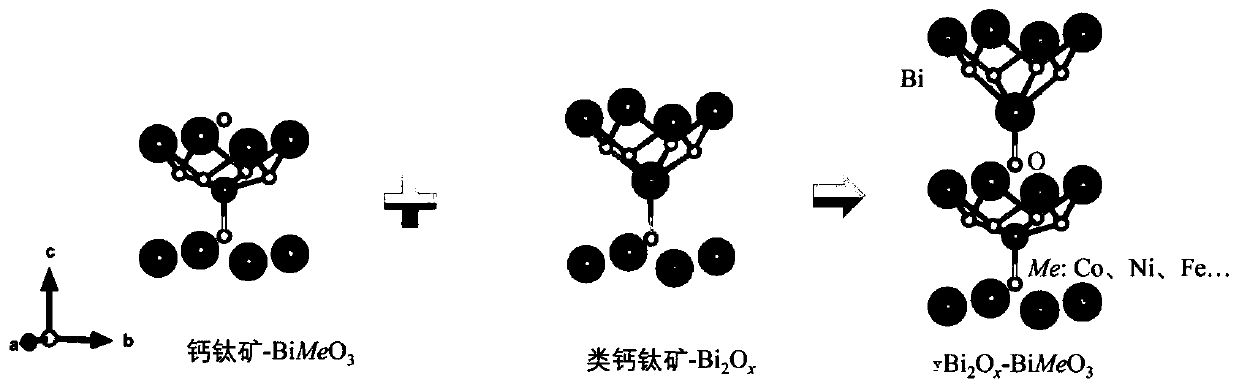

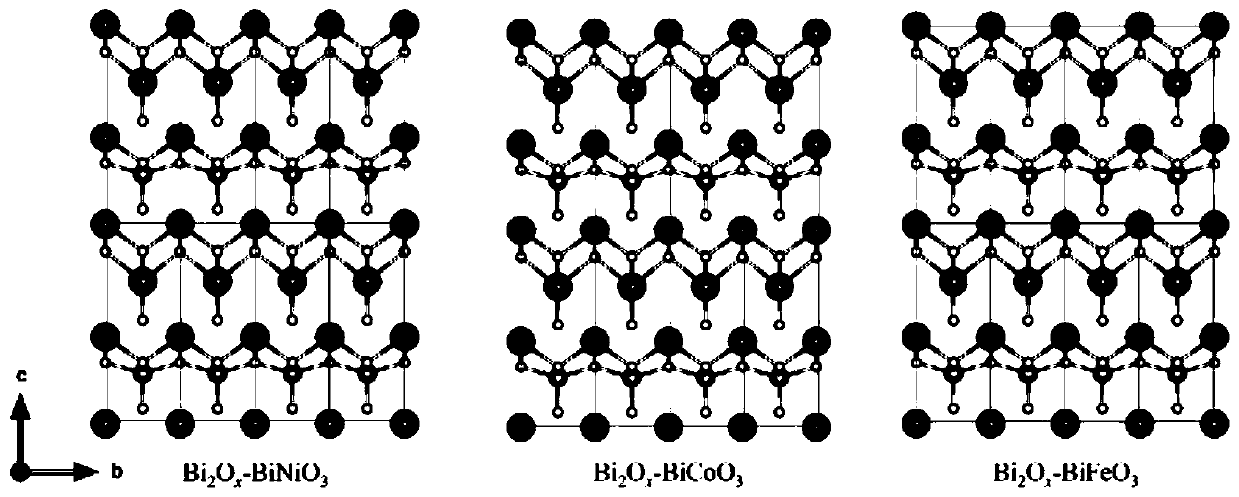

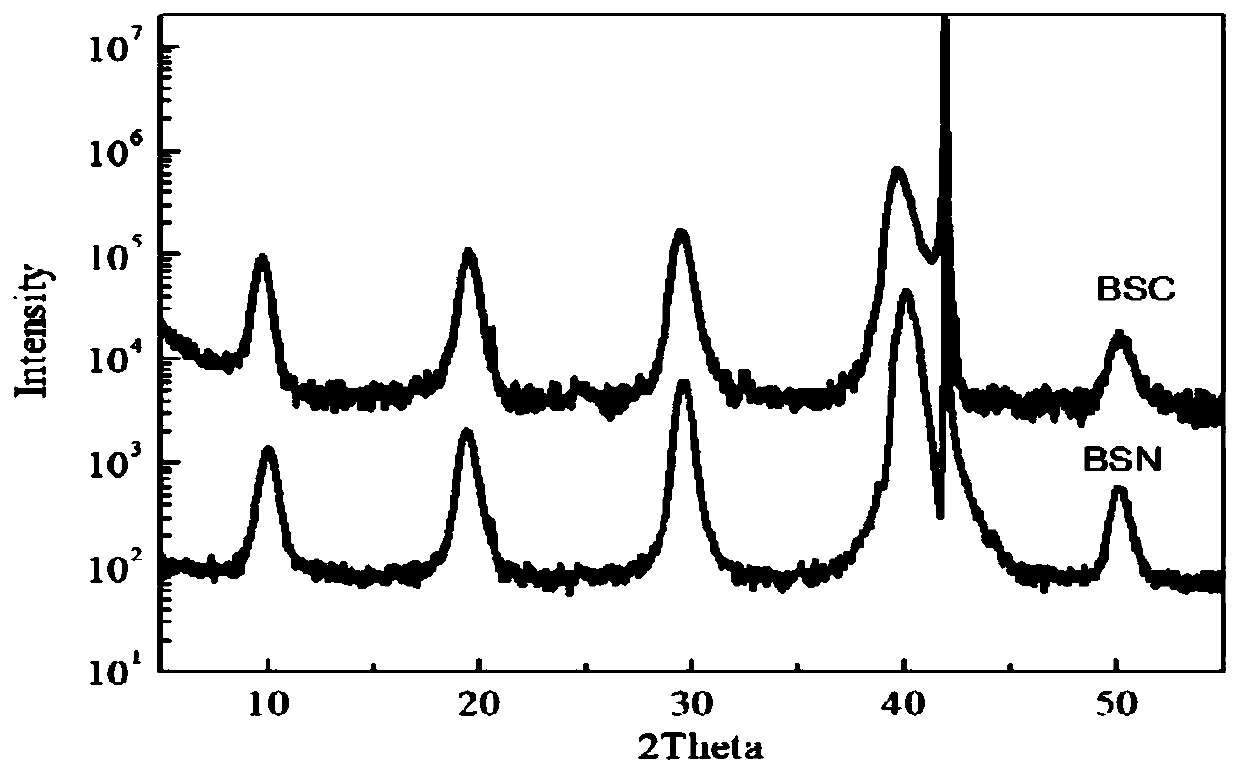

ActiveCN111416006AThickness is easy to controlImprove ferroelectric propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesPerovskite (structure)Physical chemistry

The invention belongs to the field of condensed state physics, functional films and nanotechnology, and relates to a two-dimensional layered perovskite ferroelectric multifunctional film and a preparation process thereof. The molecular formula of the two-dimensional layered perovskite ferroelectric multifunctional film is yBi2Ox-BiMeO3, 2<=x<=4, 1<=y<=4, and Me is a transition metal. The perovskite-like structure Bi2Ox and the perovskite-like structure BiMeO3 have similar crystal structures and matched lattice constants, and have a stable tetragonal phase-like supercell structure. The preparation process comprises the following steps: firstly, preparing a precursor solution of which the ratio of Bi to Me is 1-6 and the molar concentration is 0.1-0.4 M; and carrying out spin coating, drying, pyrolysis and annealing to obtain the two-dimensional layered perovskite ferroelectric multifunctional film. According to the invention, a crystal structure design and a sol-gel synthesis method areadopted to develop a film with a new structure, the components of the precursor solution are accurate and controllable, the synthesis conditions are simple, and finally the high-quality ferroelectricfilm with excellent performance is obtained.

Owner:UNIV OF SCI & TECH BEIJING

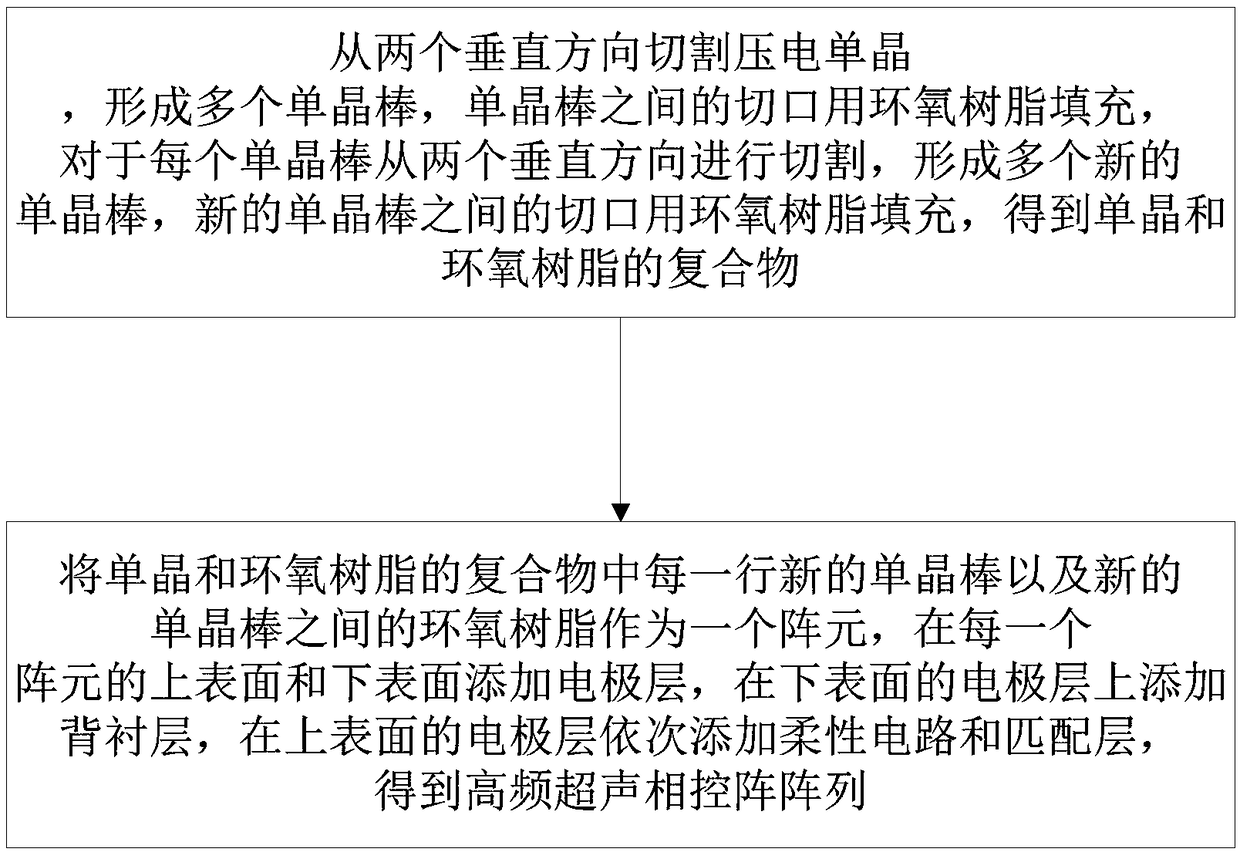

High-frequency ultrasonic phased array for ophthalmology and preparation method thereof

InactiveCN108903975AHigh electromechanical coupling coefficientImprove image qualityBlood flow measurement devicesEye diagnosticsEpoxyFlexible circuits

The invention discloses a high-frequency ultrasonic phased array for ophthalmology and a preparation method thereof, wherein the preparation method includes: cutting piezoelectric monocrystal from twovertical directions to form multiple monocrystal rods, filling cuts of the monocrystal rods with epoxy resin, cutting each monocrystal rod from two vertical directions to form a plurality of new monocrystal rods, and filling cuts of the new monocrystal rods with epoxy resin to obtain monocrystal-epoxy resin complex; using the new monocrystal rods of each row in the monocrystal-epoxy resin complexand the epoxy resin between the new monocrystal rods as an array element, adding electrode layers to upper and lower surfaces of each array element, adding a backing layer to an electrode layer of each lower surface, and adding a flexible circuit and a matching layer to the electrode layer of each upper surface so that the high-frequency ultrasonic phased array is obtained. The high-frequency ultrasonic phased array has high resolving power for imaging and can monitor fundal blood flow condition in real time.

Owner:HUAZHONG UNIV OF SCI & TECH

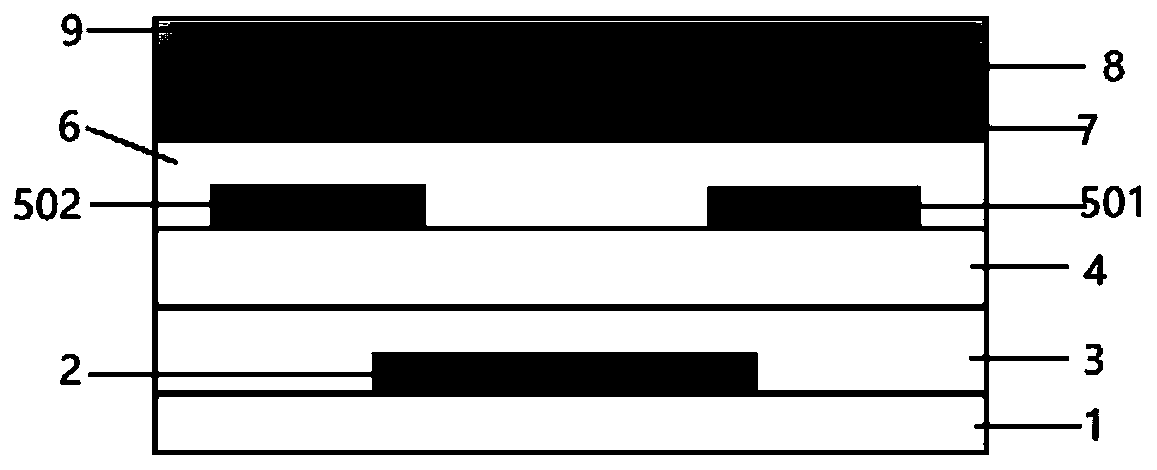

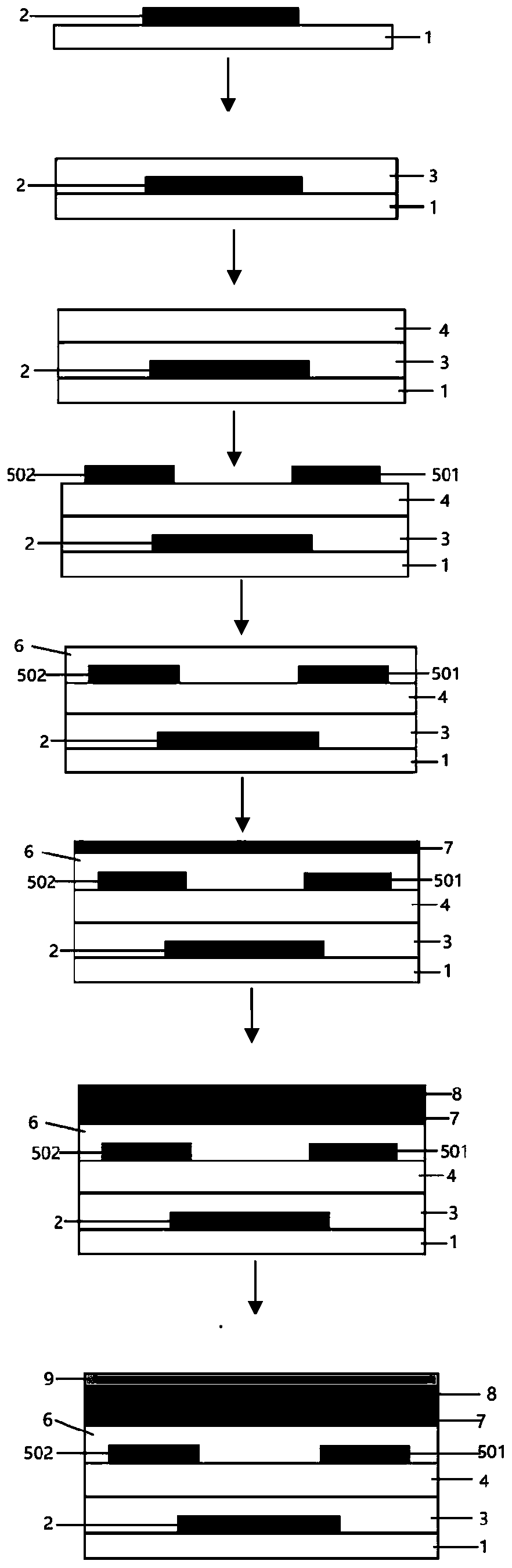

Piezoelectric integrated flexible tactile sensor and preparation method thereof

InactiveCN111060233AHigh sensitivityImprove signal-to-noise ratioPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyThin film sensorElectronic systems

The invention discloses a piezoelectric integrated flexible tactile sensor and a preparation method thereof. The piezoelectric integrated flexible tactile sensor comprises a double-gate structure metal oxide TFT, a piezoelectric film layer which is located on a top gate electrode layer of the double-gate structure TFT and contains zinc oxide nanowires, and an upper electrode located on the nano piezoelectric film layer. The top gate electrode layer, the zinc oxide nanowire or nanobelt piezoelectric film layer and the upper electrode form a nano piezoelectric sensitive unit. According to the flexible tactile sensor, the double-gate structure metal oxide TFT and a nano piezoelectric film sensor are integrated, the metal oxide TFT serves as a charge amplifier and also serves as an array element switch, and the advantages of high sensitivity, high resolution, high signal-to-noise ratio, high flexibility, high anti-interference capacity and adjustable sensitivity and measuring range are achieved. The preparation process is simple, the cost is low, large-area array preparation can be achieved, and the sensor can be widely applied to the fields of bionic electronic systems, wearable devices, robots, medical health and the like.

Owner:SOUTH CHINA UNIV OF TECH

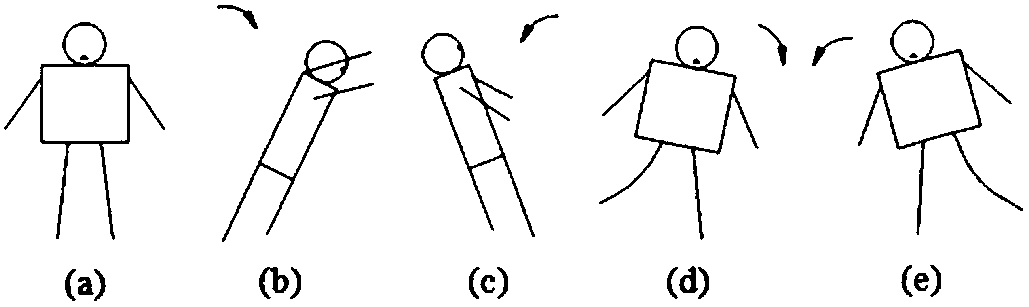

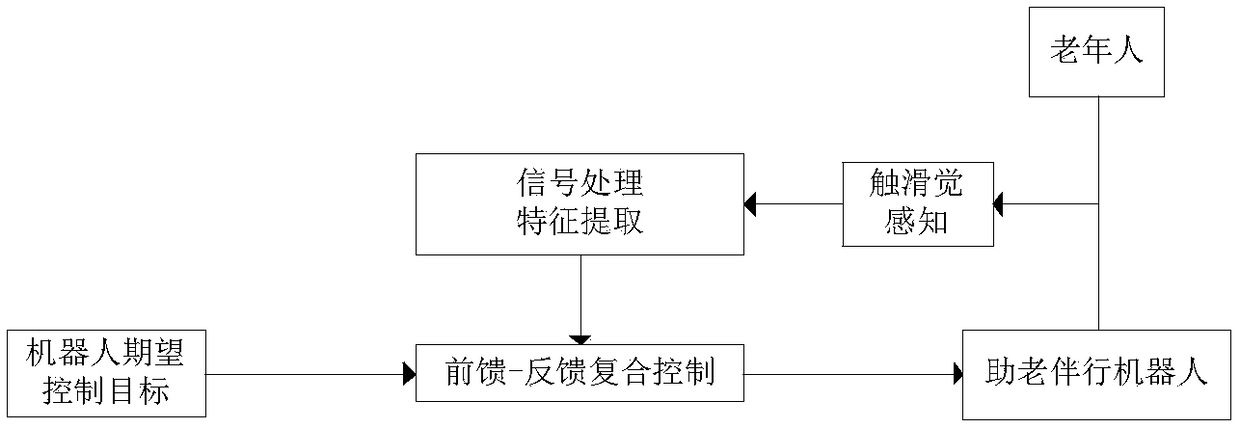

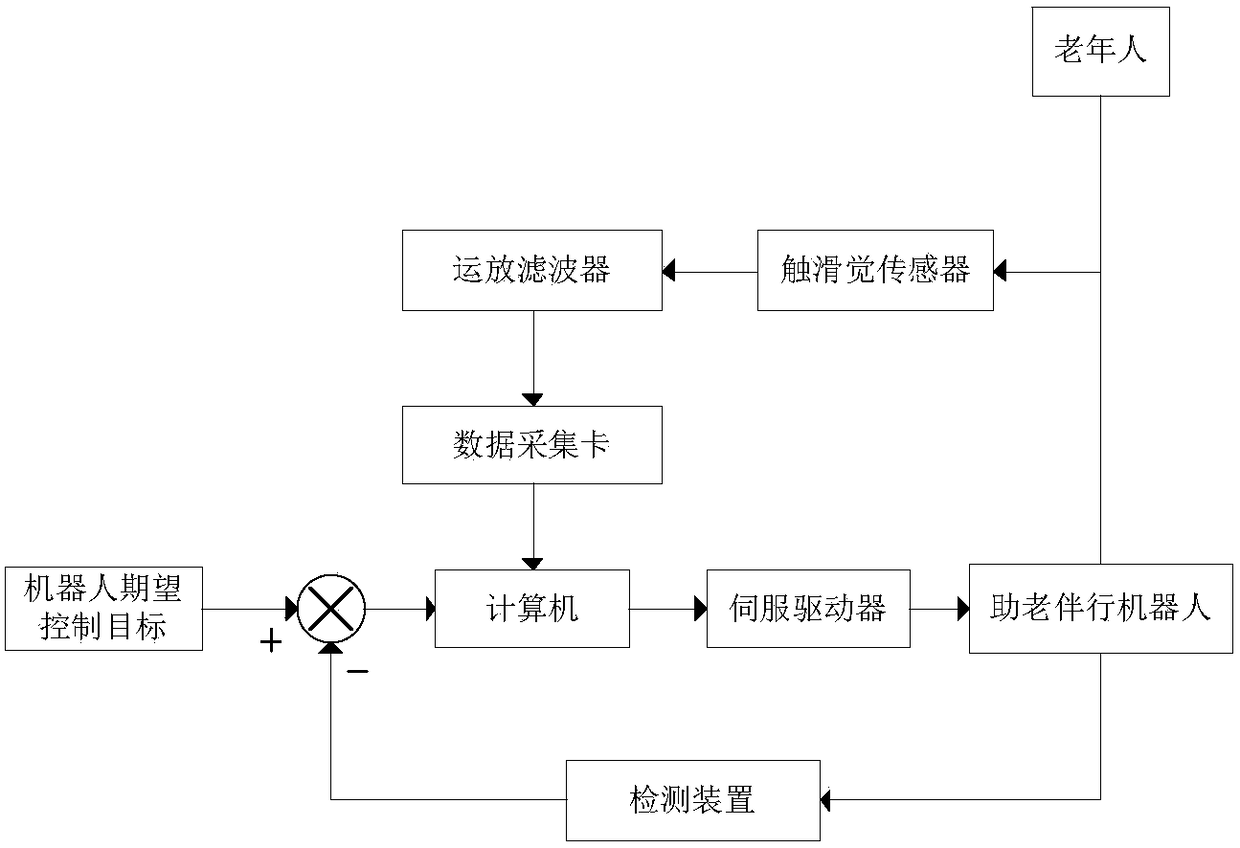

Human-machine cooperative control system for preventing fall of elderly person and control method thereof

ActiveCN108415250AHigh precisionRealize collaborative controlAdaptive controlCompanion robotHuman–machine system

The invention discloses a human-machine cooperative control system for preventing the fall of an elderly person and a control method thereof. A feedforward and feedback composite control method is used, expected control target parameters of an elderly person companion robot are taken as a whole control input, a time domain feature of a touch-sliding force signal applied to a handle of the elderlyperson companion robot by a hand of the elderly person after feature extraction is used as a feedforward compensation link, and the influence of touch-sliding force on the control target parameters ofthe elderly person companion robot is eliminated. The actually measured control target parameters of the elderly person companion robot are taken as a feedback link, the precision of the control target parameters of the elderly person companion robot is improved, and the human-machine cooperative control for preventing the fall of the elderly person is achieved. According to the system and the method, the cooperative control of the elderly person and the elderly person companion robot can be achieved, the control target parameters of the elderly person companion robot are detected in real time, the expected control target can be accurately achieved, the balance and stability of the human-machine system is achieved, and thus the purpose of preventing the fall of the elderly person is achieved.

Owner:XI AN JIAOTONG UNIV

Bismuth ferrite-barium titanate binary high-temperature piezoelectric ceramic material as well as preparation method and application thereof

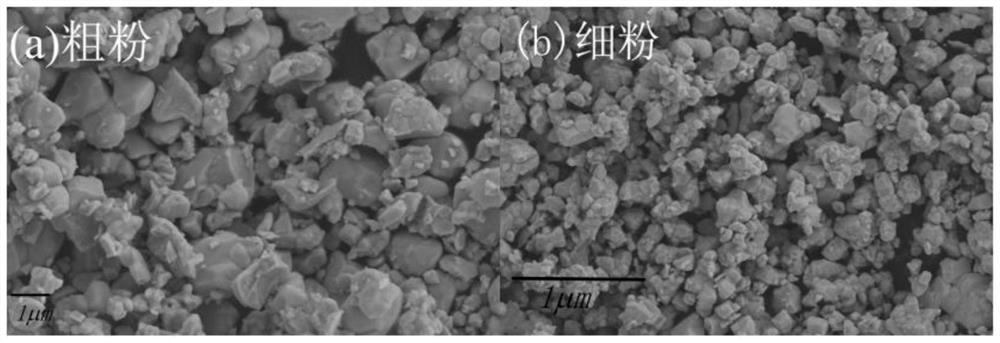

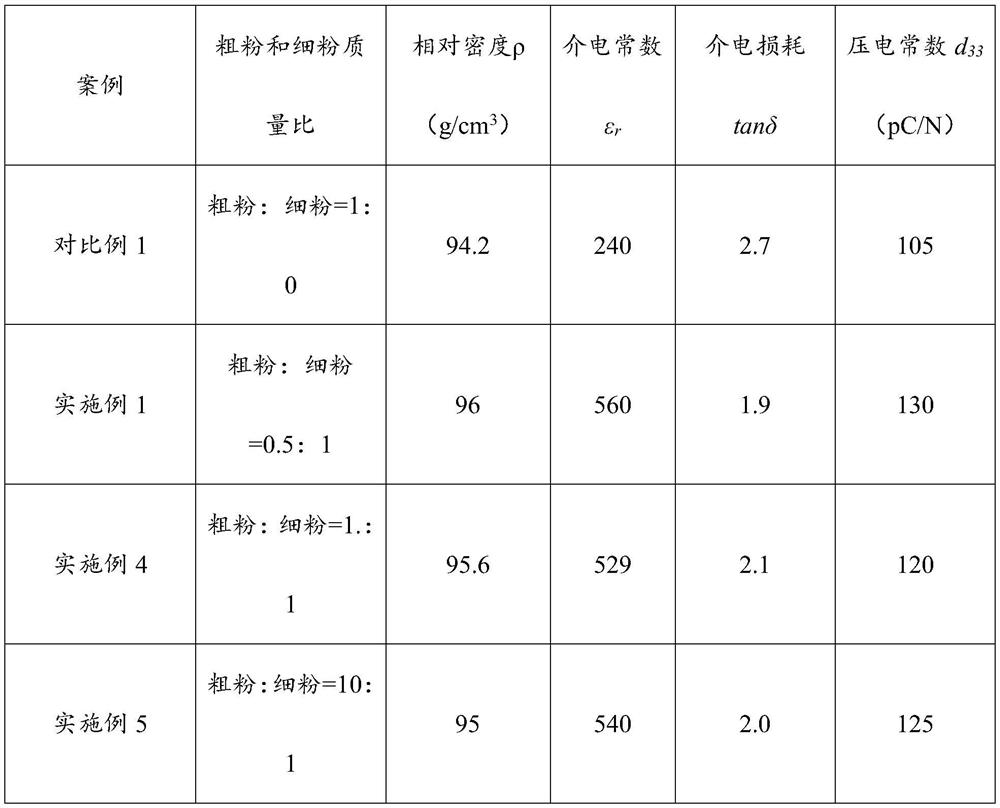

The invention provides a bismuth ferrite-barium titanate binary high-temperature piezoelectric ceramic material as well as a preparation method and application thereof, which belongs to the technical field of high-temperature piezoelectric materials. According to the method, the bismuth ferrite-barium titanate coarse powder and the bismuth ferrite-barium titanate fine powder with the particle size difference of 700 nm-1.2 mum are used as raw materials, the bismuth ferrite-barium titanate is prepared by using the mixed powder with different particle sizes, and due to the fact that the surface tension of large particles and small particles is larger than that of the same particles when the large particles and the small particles are in contact, growth of crystal grains is better facilitated, the relative density of the ceramic material is increased, the porosity is reduced, the dielectric constant and piezoelectric coefficient of the ceramic material are further improved, the dielectric property is improved, the dielectric loss tandelta is reduced, the insulating property of the ceramic is improved, the leakage current is reduced, and the ceramic material has excellent piezoelectric property. The result of the embodiment shows that the piezoelectric constant of the bismuth ferrite-barium titanate binary high-temperature piezoelectric ceramic material prepared by the preparation method disclosed by the invention reaches 200 pC / N.

Owner:SHANGHAI UNIV

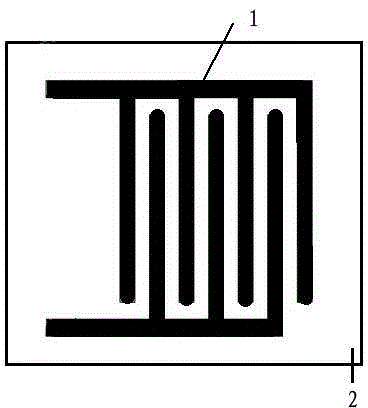

Surface acoustic wave (SAW) transducer

InactiveCN102983831AEasy to manufactureHigh piezoelectric coefficientImpedence networksElectromechanical coupling coefficientBoron nitride

The invention discloses a surface acoustic wave transducer which comprises a base and an interdigital transducer electrode, and is characterized in that the base adopts a diamond / ALN (Aluminium Nitride) / AL (Aluminum) / BN (Boron Nitride) multilayer film structure; and the interdigital transducer electrode adopts an AL / ALN double-layer film structure. The surface acoustic wave transducer can meet the requirements that the frequency is high, the propagation loss is low, the electromechanical coupling coefficient is high, and the service life of finger strips is long.

Owner:HUAINAN UNITED UNIVERSITY +3

Piezoceramic material and preparation method thereof

ActiveCN104402436AHigh piezoelectric coefficientHigh dielectric constantSpray GranulationCompression molding

The invention discloses a piezoceramic material and a preparation method thereof. The piezoceramic material is characterized by being prepared from the following components in parts by weight: 65-73 parts of ZrO2, 15-23 parts of CaCO3, 8-15 parts of BaCO3, 8-12 parts of PVA (Polyvinyl Acetate), 5-8 parts of myristyl alcohol, 2-4 parts of SiC, 1-2 parts of BaTiO3 and 1-1.2 parts of graphene. The invention further provides the preparation method of the piezoceramic material. The method comprises the following steps: (1) weighing 65-73 parts of ZrO2, 15-23 parts of CaCO3, 8-15 parts of BaCO3, 2-4 parts of SiC, and 1-2 parts of BaTiO3; (2) adopting a wet ball-milling method to mix the components uniformly, heating the mixture at 750-810 DEG C, adding 8-12 parts of PVA, 5-8 parts of myristyl alcohol, and 1-1.2 parts of graphene to the mixture, and performing spray granulation and compression molding; (3) at last sintering the molded substance in an inert atmosphere at 1150-1200 DEG C for 2-3 hours to obtain the piezoceramic material.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

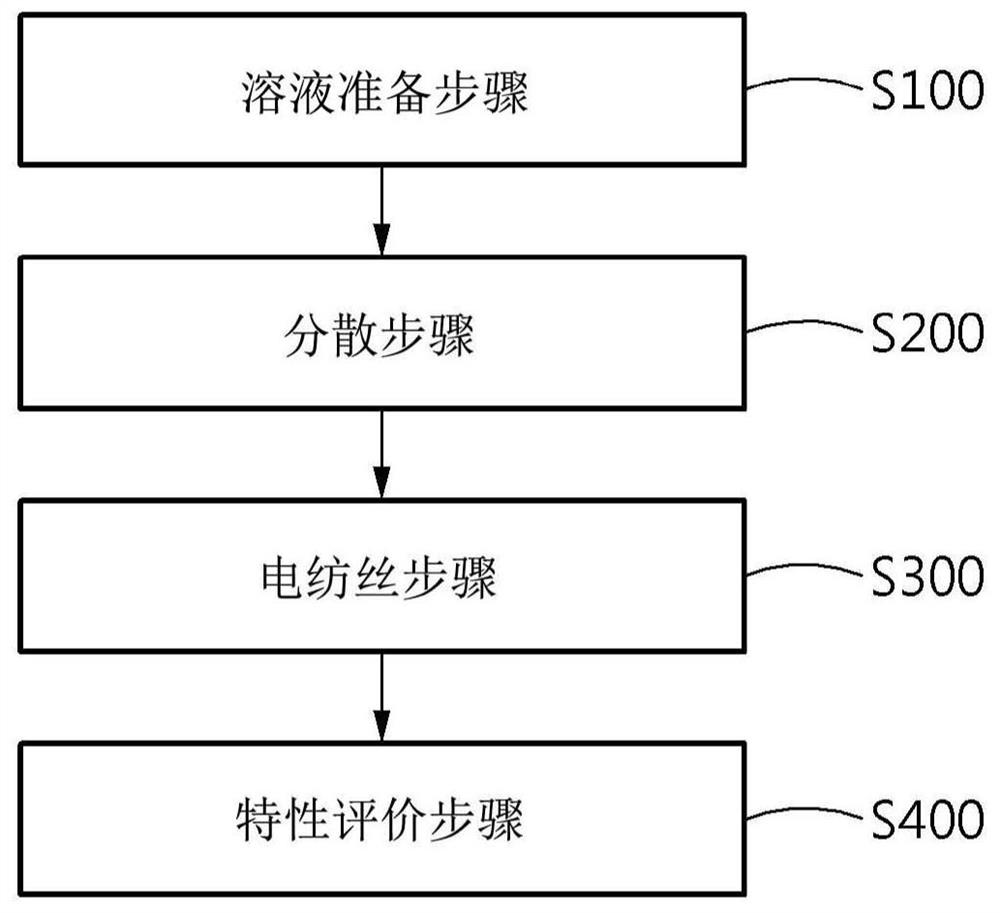

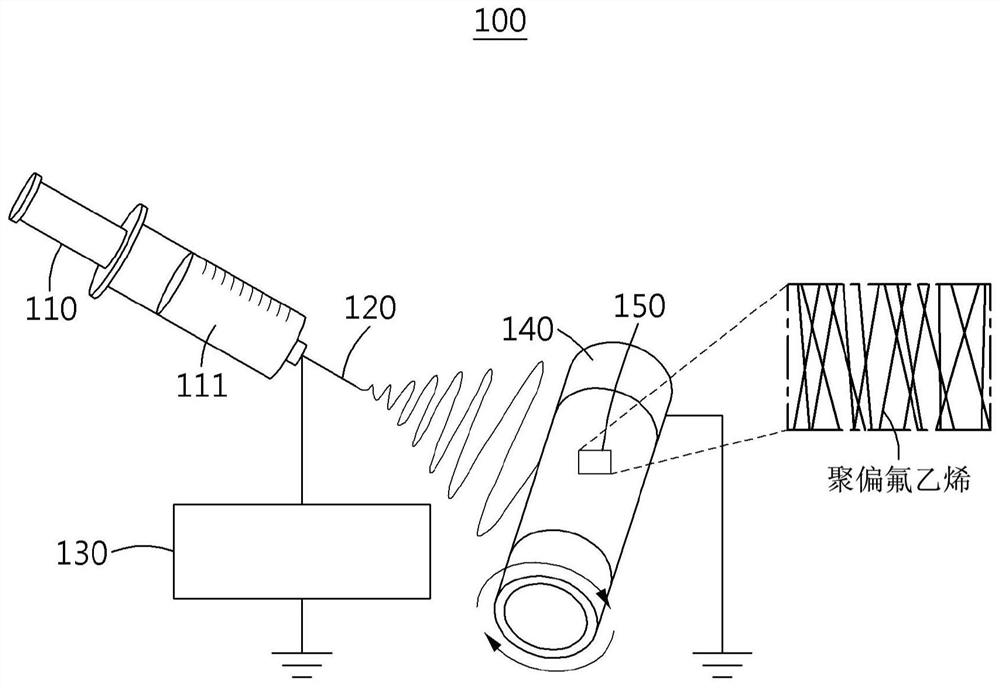

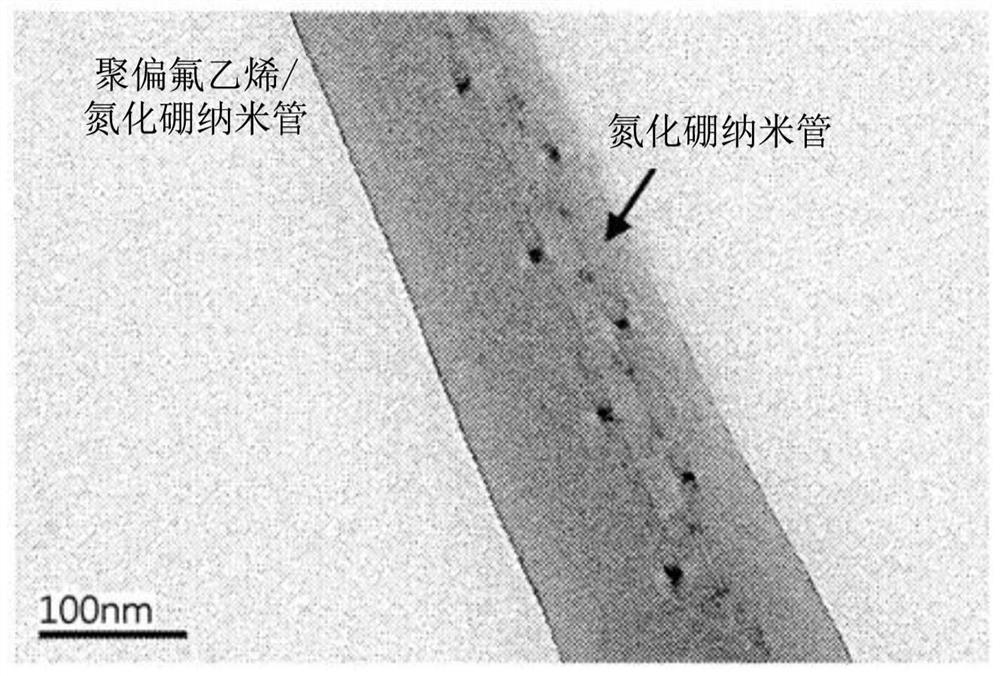

Method and apparatus for manufacturing polymer composite piezoelectric material having boron nitride nanotubes dispersed therein, and polymer composite piezoelectric material manufactured by the method

PendingCN112585774AExcellent piezoelectric propertiesMaximize the effect of polarizationMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyNanofiberBoron nitride

A method for manufacturing a polymer composite piezoelectric material having boron nitride nanotubes (BNNTs) dispersed therein, according to one embodiment of the present invention, may comprise: a solution preparation step for preparing a polymer solution; a dispersion step for dispersing BNNTs in the polymer solution; and an electrospinning step for, by using an electrospinning method, carryingout electrospinning on the polymer solution having the BNNTs dispersed therein, thereby producing a polymer composite piezoelectric material on a nanofiber.

Owner:ネイール テクノロジー

Preparation method of bismuth layer structure ferroelectric ceramic material with chemical formula srbi2ti2o9 for preparing thin film

InactiveCN102267811AEvenly dopedEasy to uniform quantitative dopingHigh voltage capacitorsStrontium acetate

The invention relates to a preparation method of a bismuth layer structured ferroelectric material, and concretely relates to a preparation method of a bismuth layer structured ferroelectric ceramic material of chemical formula of SrBi2Ti2O9 for preparing films. A purpose of the invention is to prepare the bismuth layer structured ferroelectric ceramic material which can replace a PZT material. The purpose of the invention is realized by adopting the following technical scheme that the material is synthesized by adopting a sol-gel process with tetrabutyl titanate, acetylacetone, bismuth nitrate, strontium acetate and glycol as raw materials. The preparation method of the present invention has advantages that: the material performs a high temperature dielectric property, high piezoelectriccoefficient and a good ferroelectric property, can replace lead ferroelectric materials under a high temperature, and can be applied to fields of high voltage capacitors, ferroelectric memories, piezoelectric ceramic oscillators and the like.

Owner:SHANDONG WOMENS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com