Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136 results about "Ferroelectric polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

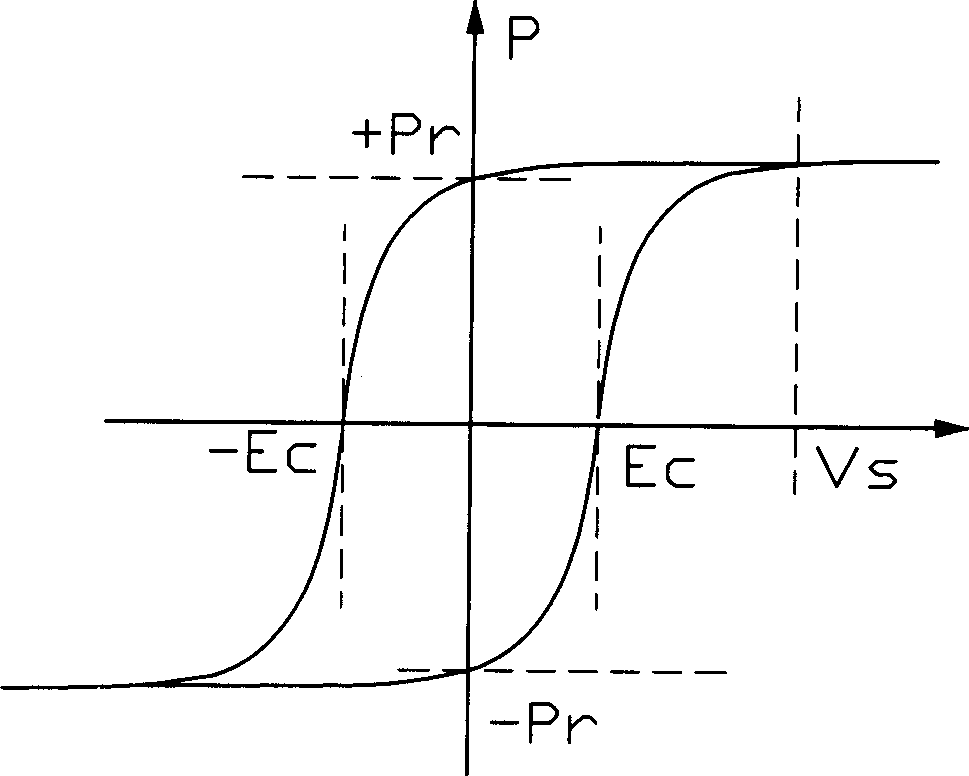

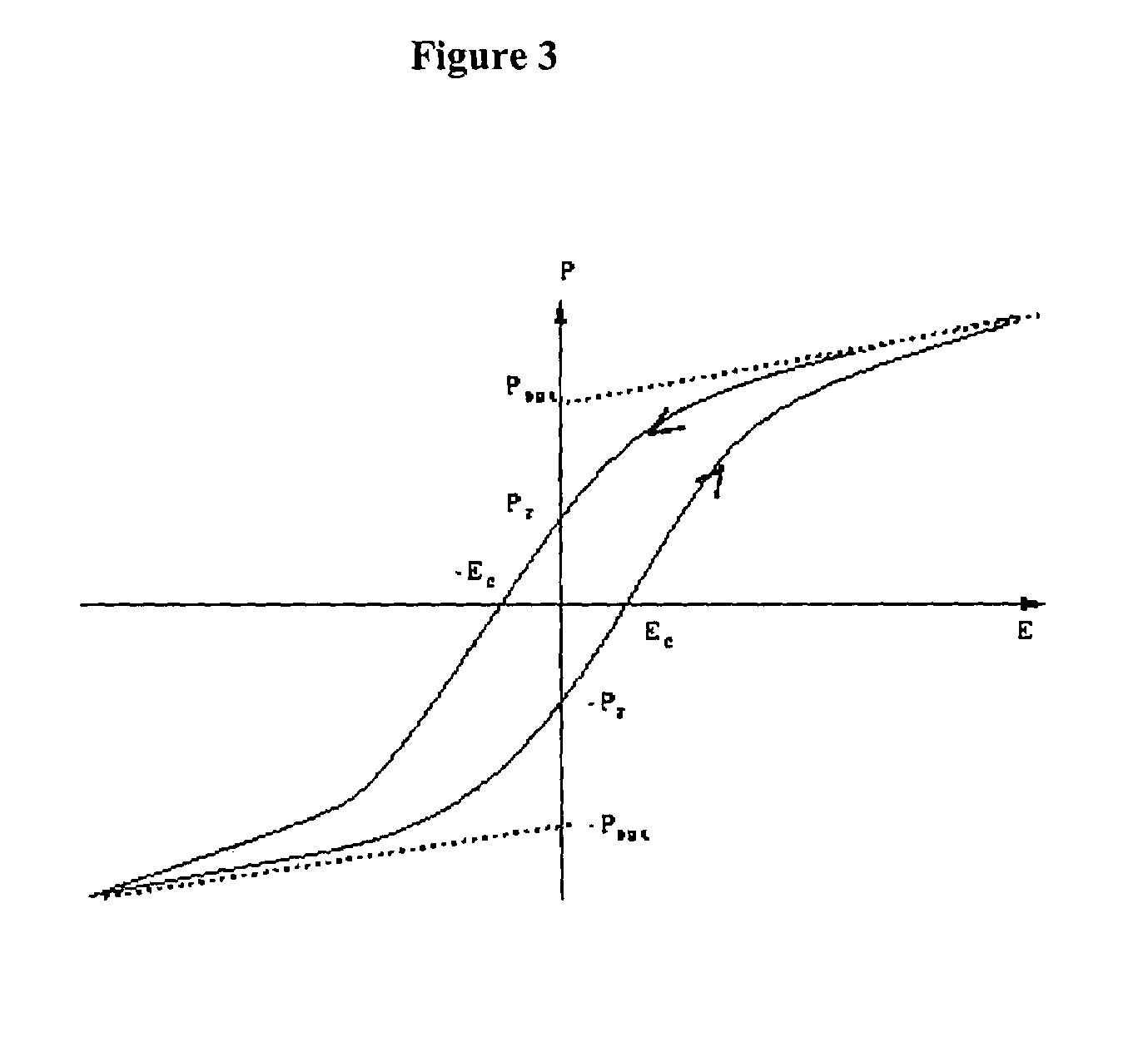

Ferroelectric polymers are a group of crystalline polar polymers that are also ferroelectric, meaning that they maintain a permanent electric polarization that can be reversed, or switched, in an external electric field.

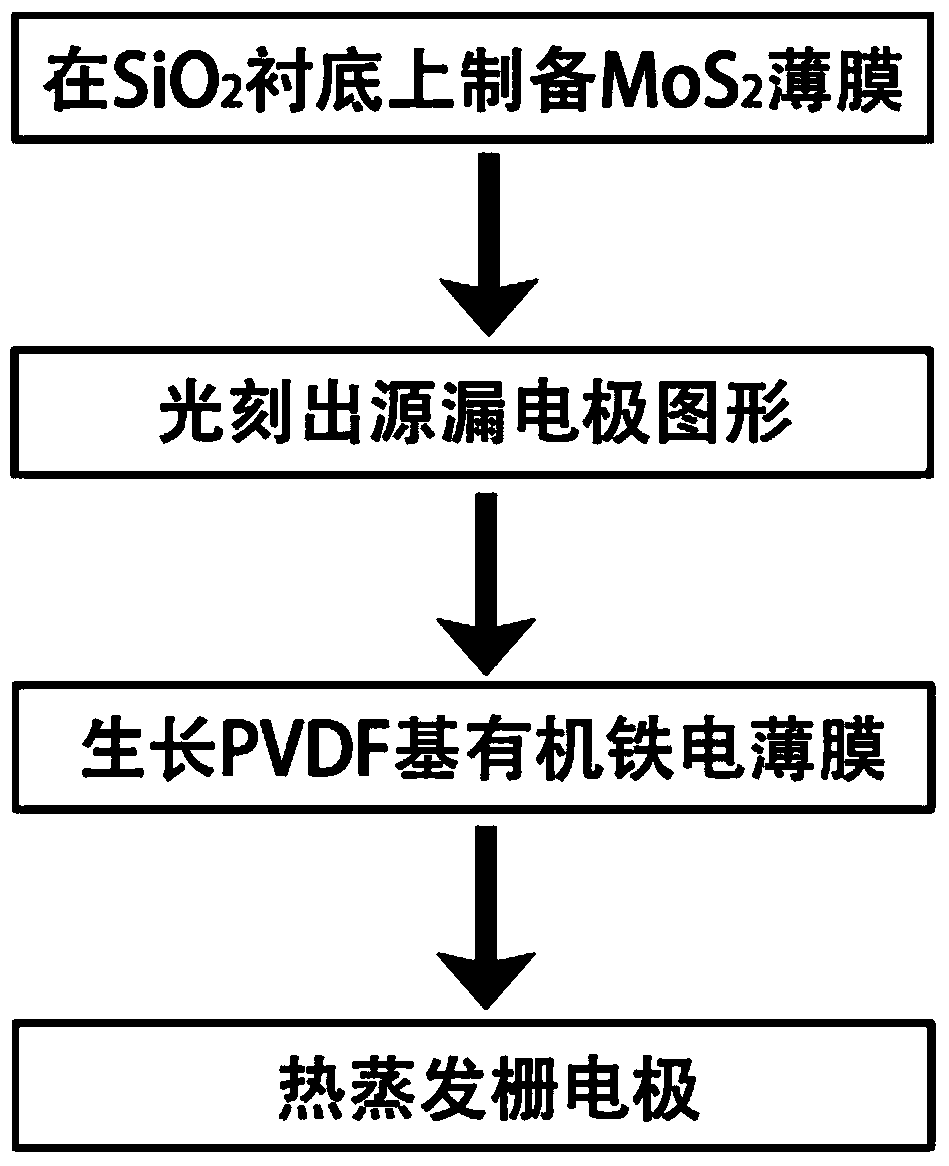

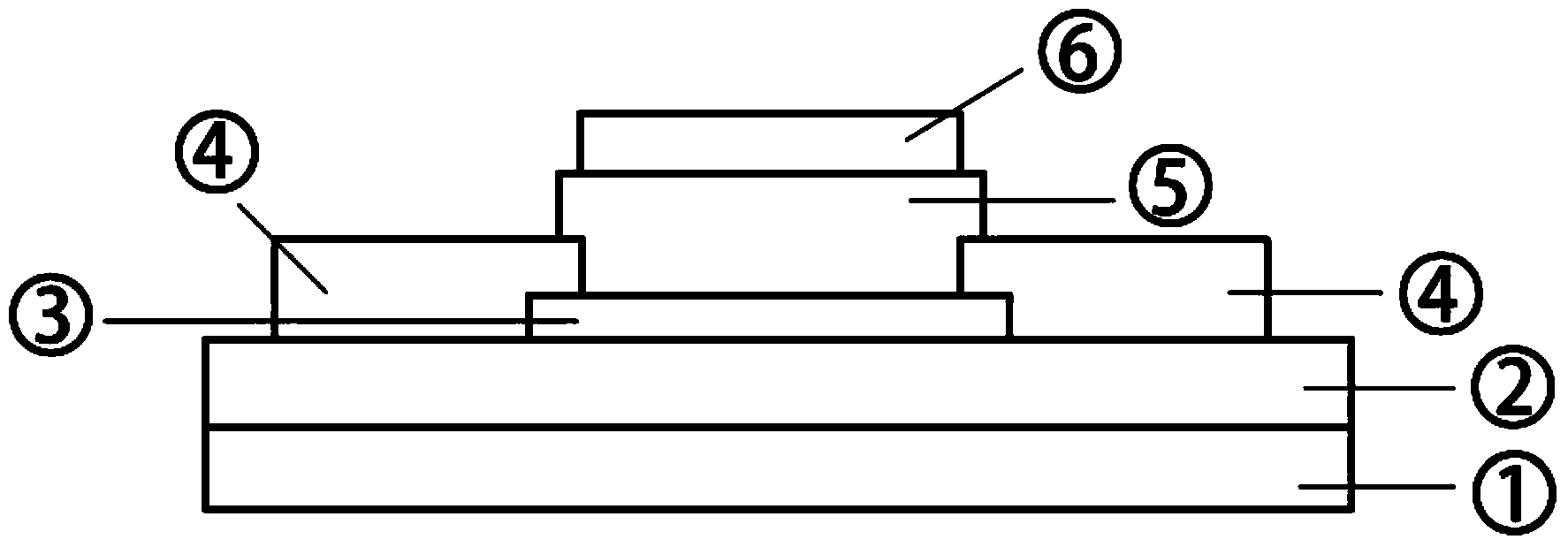

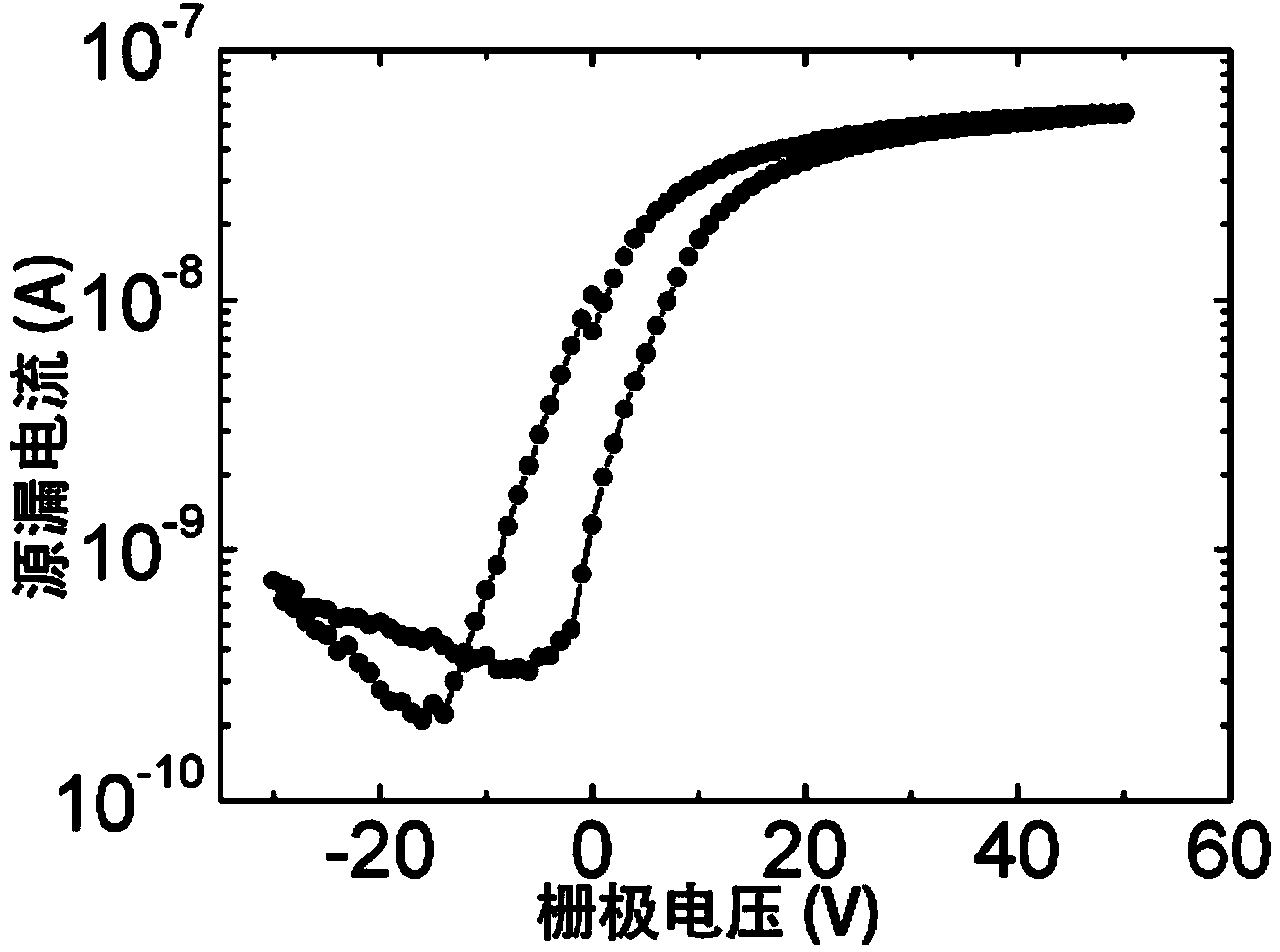

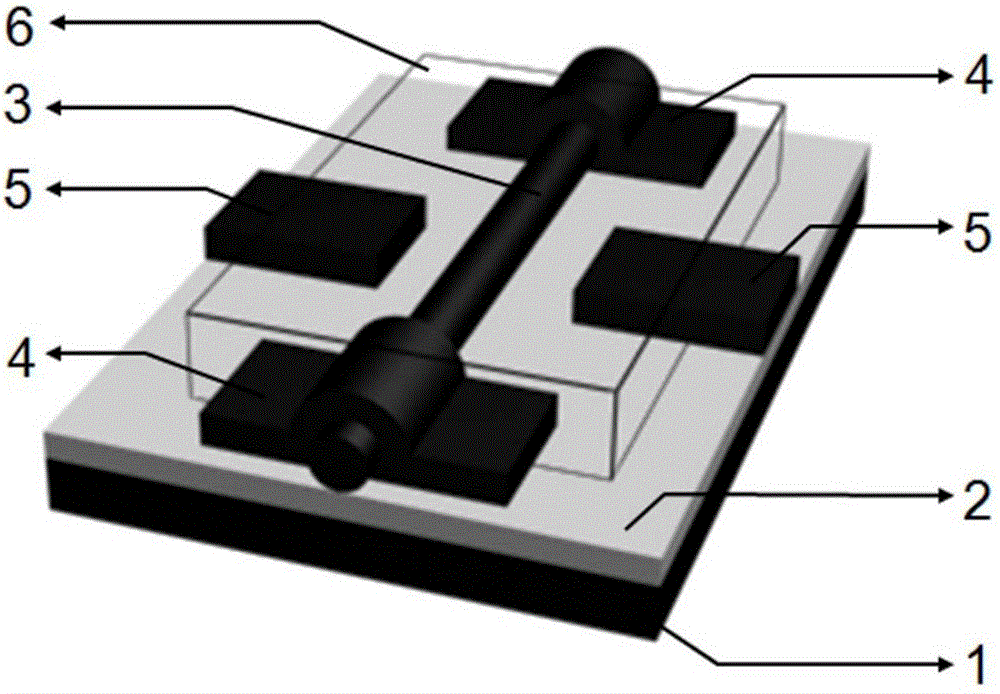

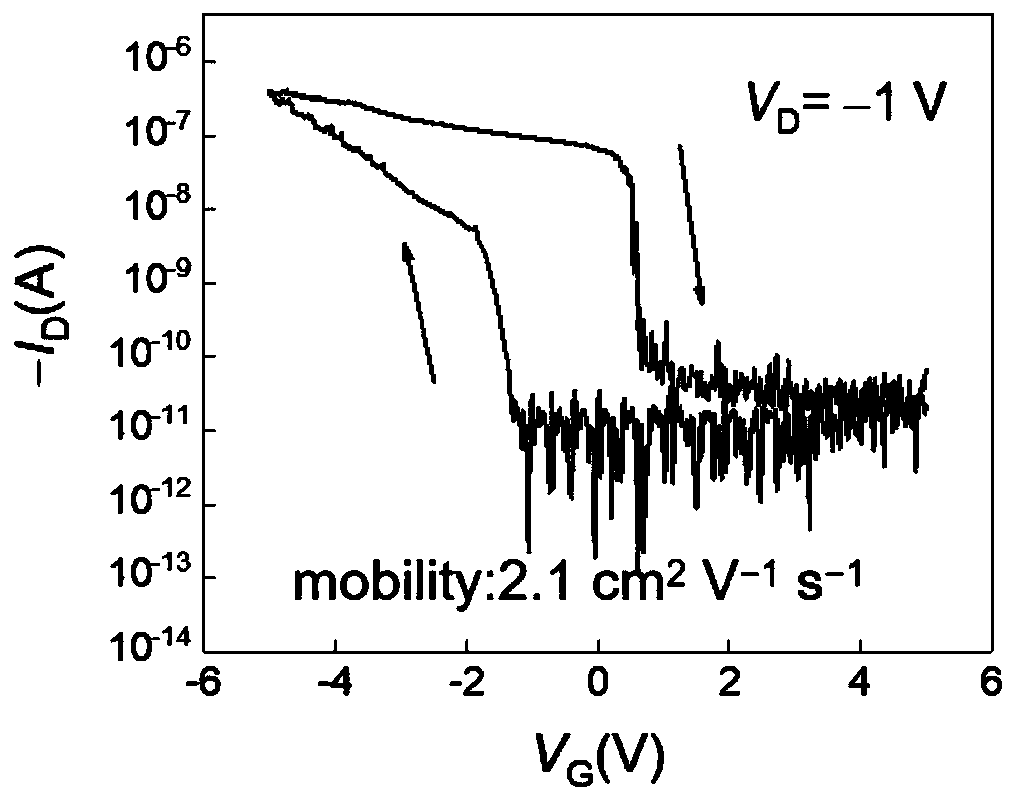

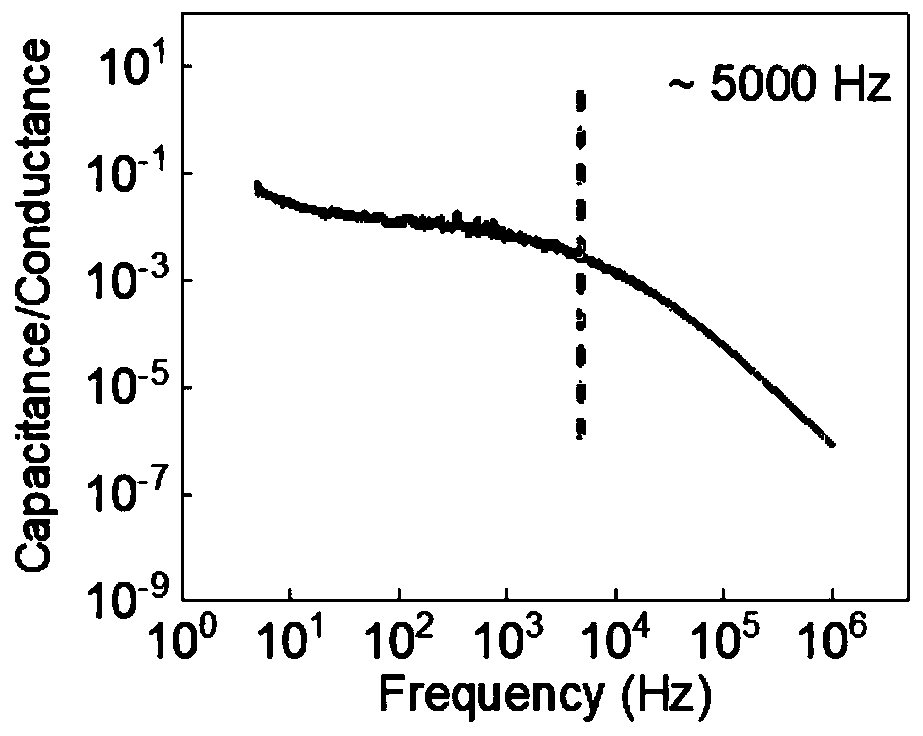

Production method of PVDF (polyvinylidene fluoride) ferroelectric field effect transistor based on molybdenum disulfide film

InactiveCN104362252AEasy to manufactureSimple processSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorSilicon dioxide

The invention discloses a production method of a PVDF (polyvinylidene fluoride) ferroelectric field effect transistor based on a molybdenum disulfide film. The production method is characterized by including producing the MoS2 (molybdenum disulfide) film on a Si (silicon) substrate of thermal oxide growth SiO2 (silicon dioxide), etching source and drain electrodes of a field effect transistor structure by photoetching and lift off methods, transfers a PVDF organic ferroelectric polymer film onto the MoS2 film with the source and drain electrodes, removing residual solvent on an interface and guaranteeing good crystallization characteristic of the film after annealing treatment, and finally, producing a metal gate electrode by photoetching and etching methods to produce a MoS2 ferroelectric field effect transistor device. The production method has the advantages that the production method for producing the organic ferroelectric field effect transistor structure is simple in technology and guarantees research on ferroelectric polarization control of electronic transport features, related photoelectric devices and related memory devices of MoS2.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

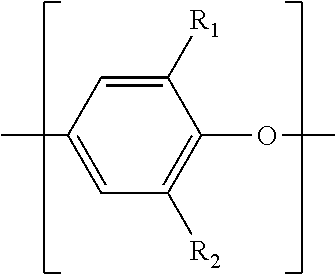

Adhesion promoter for ferroelectric polymer films

A silane adhesion promoter composition is useful in producing a ferroelectric polymer film that is especially suitable for use in a data processing device. Also disclosed is a film stack and a data processing device comprising a ferroelectric film produced using the silane adhesion promoter

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

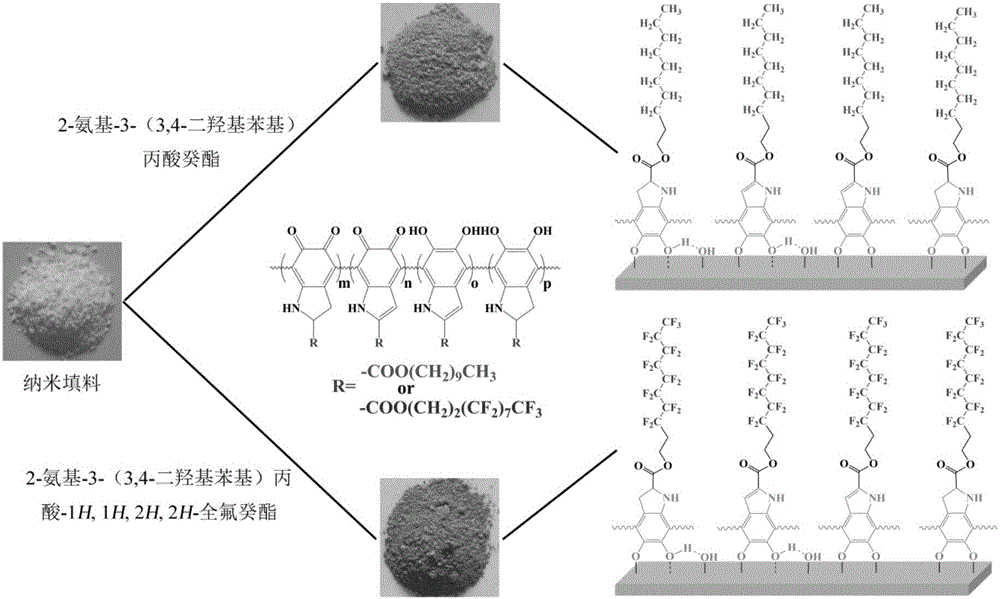

High-energy density polymer composite dielectric and preparation method thereof

The invention discloses a high-energy density polymer composite dielectric and a preparation method thereof. The composite dielectric comprises, by mass, 55-97.5% of a fluorine-containing ferroelectric polymer matrix and 45-2.5% of a dopamine modified high-dielectric constant nanofiller. The preparation method comprises solution blending, film casting and hot press molding. High-dielectric constant nanoparticles are grafted and modified with dopamine having a long chain structure, and the dopamine having a long chain structure improves the dispersion of the high-dielectric constant nanoparticles, has good compatibility with the fluorine-containing ferroelectric polymer matrix and enhances the interface combination force between the polymer matrix and the high-dielectric constant nanoparticle filler. The high-energy density polymer composite dielectric prepared in the invention has the characteristics of light weight, good flexibility and high energy density, and is suitable for producing high-energy density capacitors, embedded capacitors, field effect transistors and other advanced electronic and electric devices.

Owner:SHANGHAI JIAO TONG UNIV

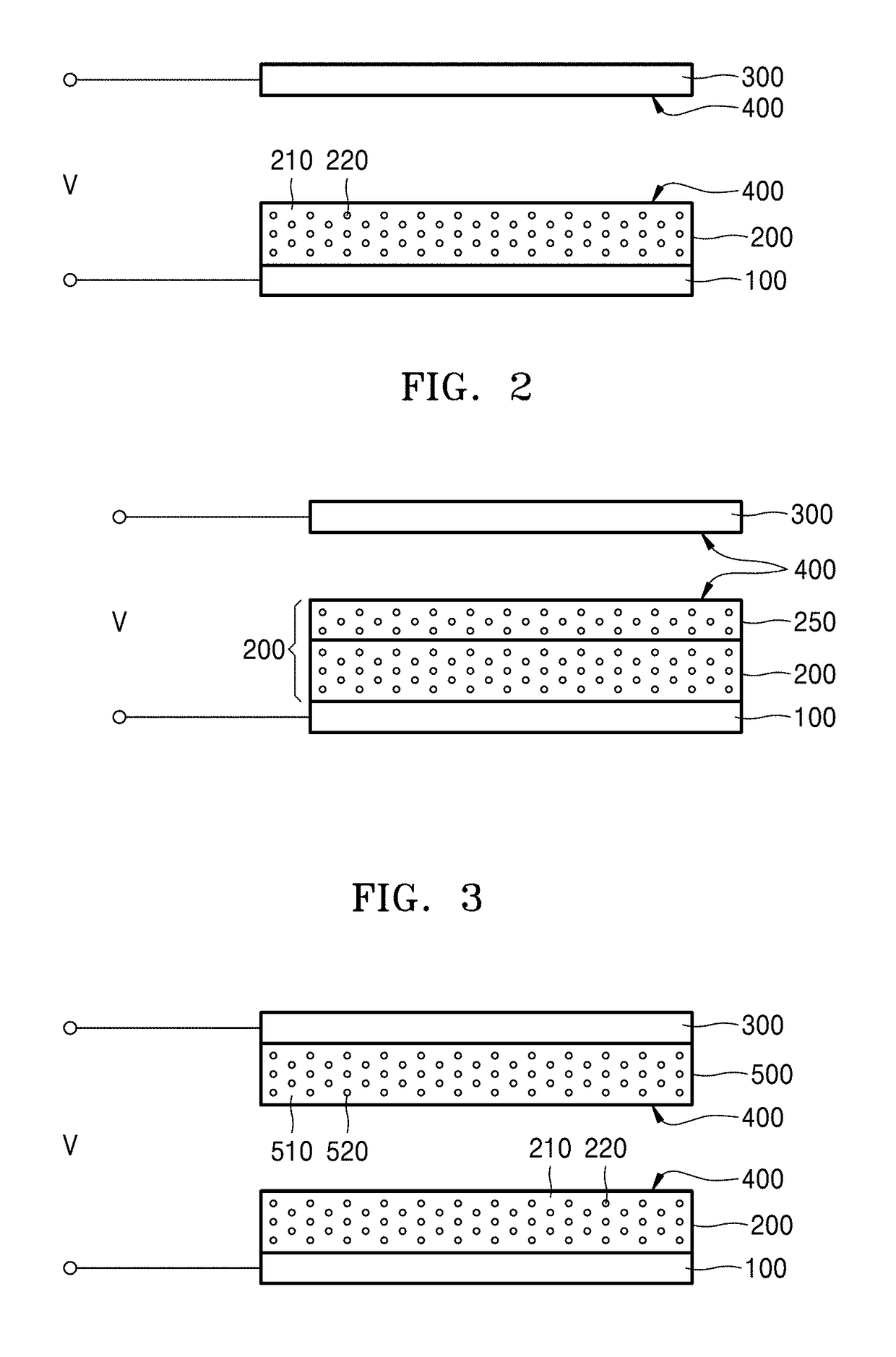

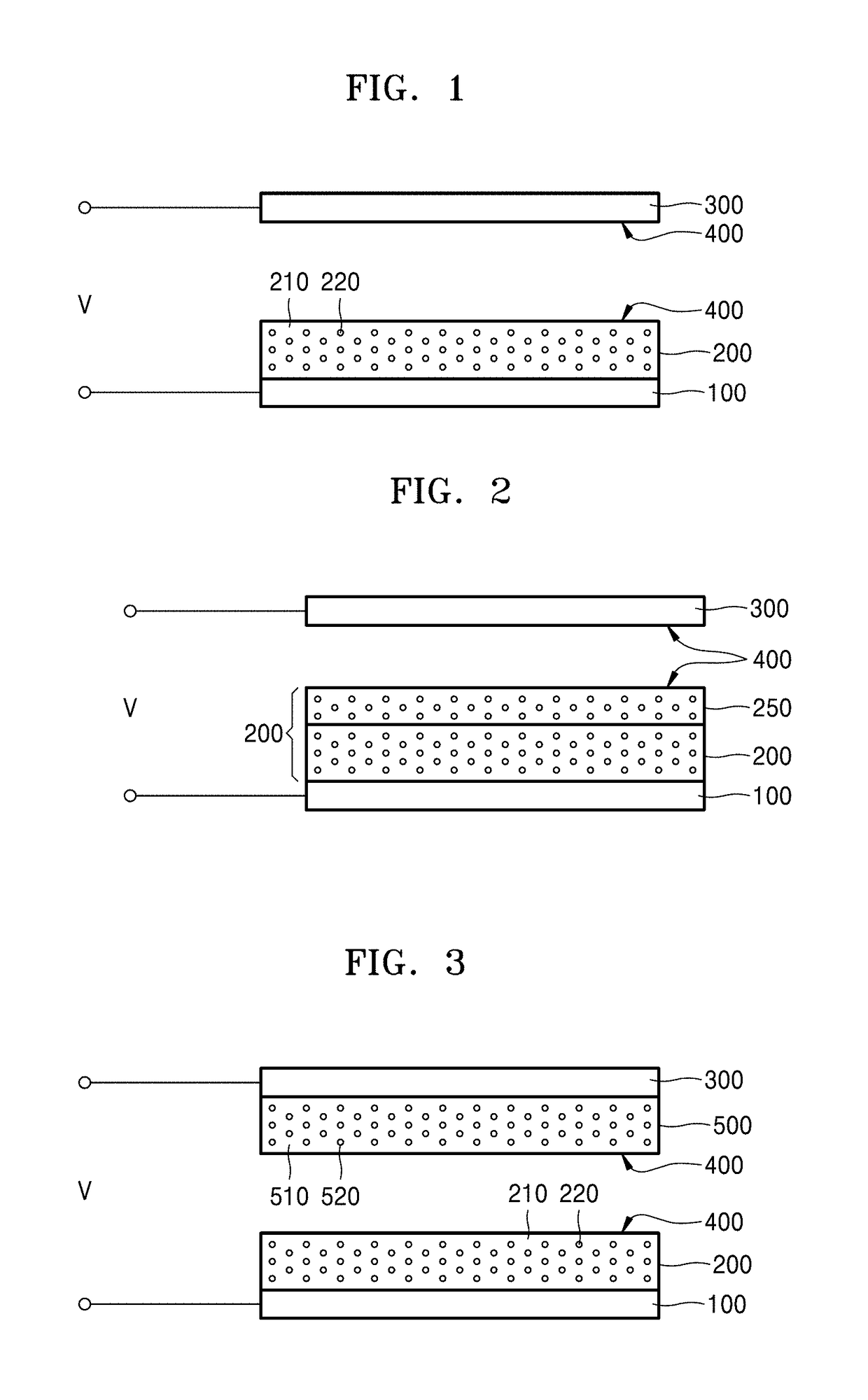

Triboelectric generation device

ActiveUS20180013359A1High outputIncrease productionNon-conductive material with dispersed conductive materialInfluence generatorsFerroelectric polymersInorganic particle

The present disclosure enables materials of a triboelectric charging member to exhibit a characteristic of increased surface charge density, thereby improving output of a triboelectric generating device. Accordingly, the present disclosure provides a triboelectric generating device showing improved output without increasing a size of the triboelectric generating device or without increasing amounts of materials required for the triboelectric generating device. An embodiment of a triboelectric generating device provided according to a first aspect of the present disclosure includes a first electrode; a first charging layer formed on the first electrode; and a second electrode disposed on the first charging layer, wherein the first charging layer and the second electrode are arranged such that an interface between the first charging layer and the second electrode forms a frictional interface, and the first charging layer includes a ferroelectric polymer matrix and ferroelectric inorganic particles dispersed in the ferroelectric polymer matrix.

Owner:SAMSUNG ELECTRONICS CO LTD +1

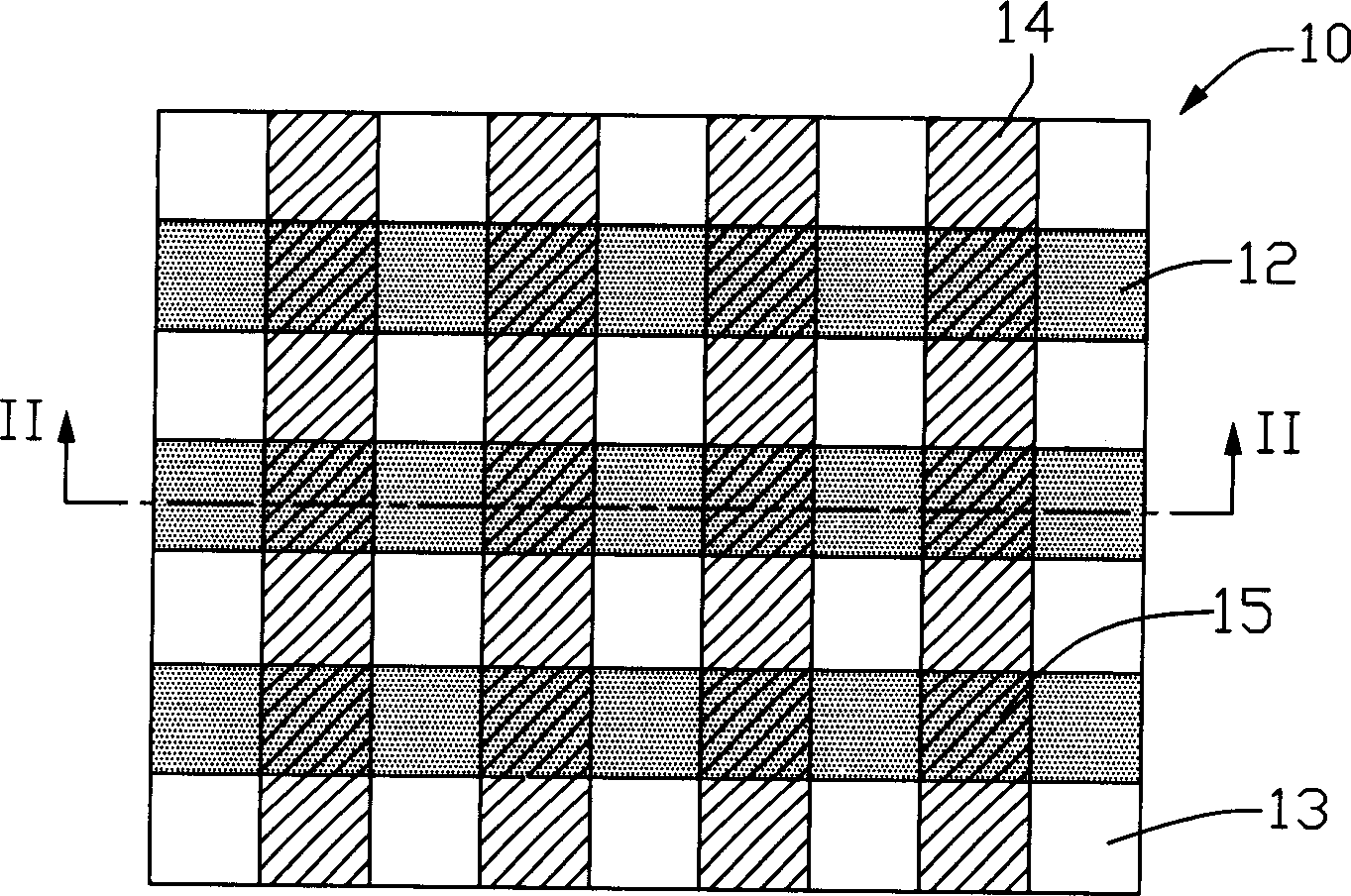

Ferroelectric memory device and manufacturing method thereof

InactiveCN1812105AGood subway electric effectQuick responseSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric polymersMatrix solution

This invention provides a kind of ferroelectric memory body unit. It concludes many parallel first electrodes; many secondly parallel electrodes that are perpendicular to the said first electrodes; ferroelectric memory body membrane that is located between the first and secondly electrodes. The ferroelectric memory body membrane is made from ferroelectric polymer, which is mixed from ferroelectric nanometer crystals and polymer matrix solution. The ferroelectric nanometer crystals disperse in the polymer evenly. It responses quickly to electric field and can avoid fatiguing effectively when repeated converting store status of the memory cell. It can embody ferroelectric well when the thickness is very thin.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

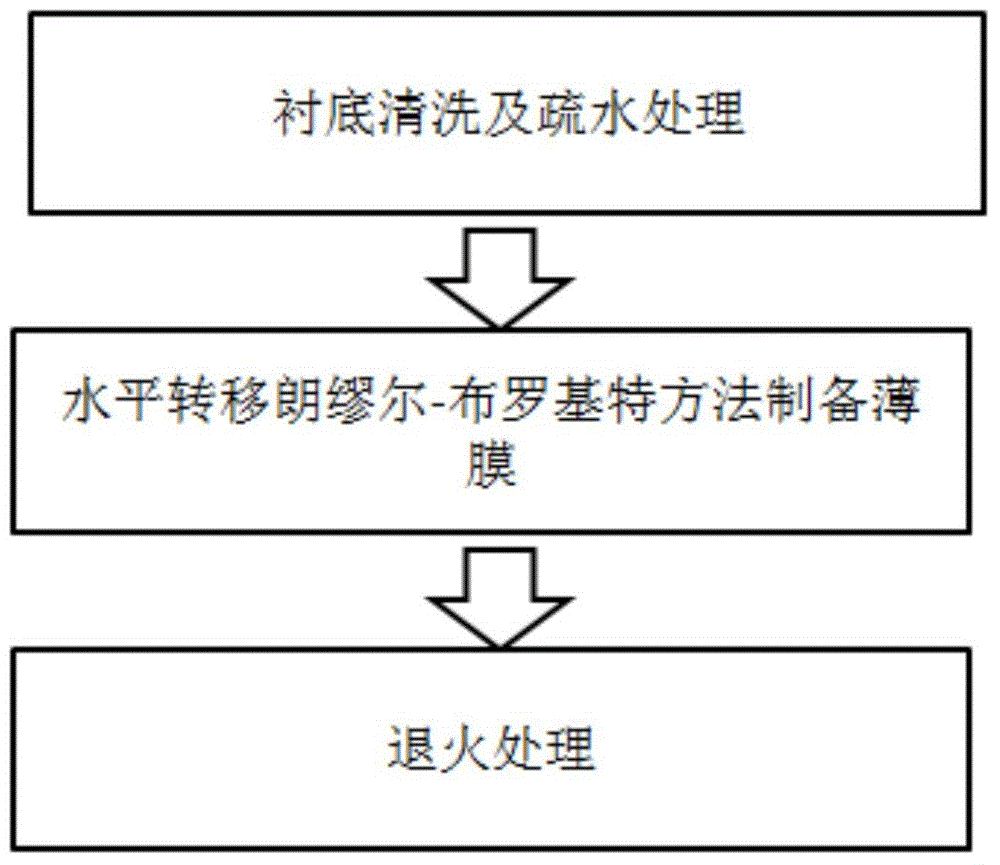

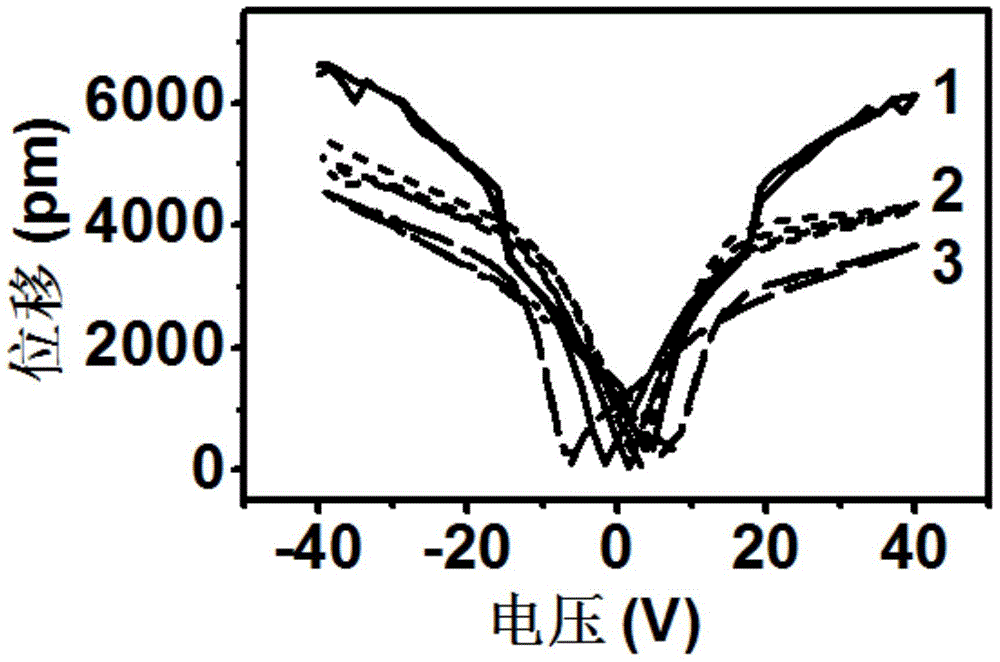

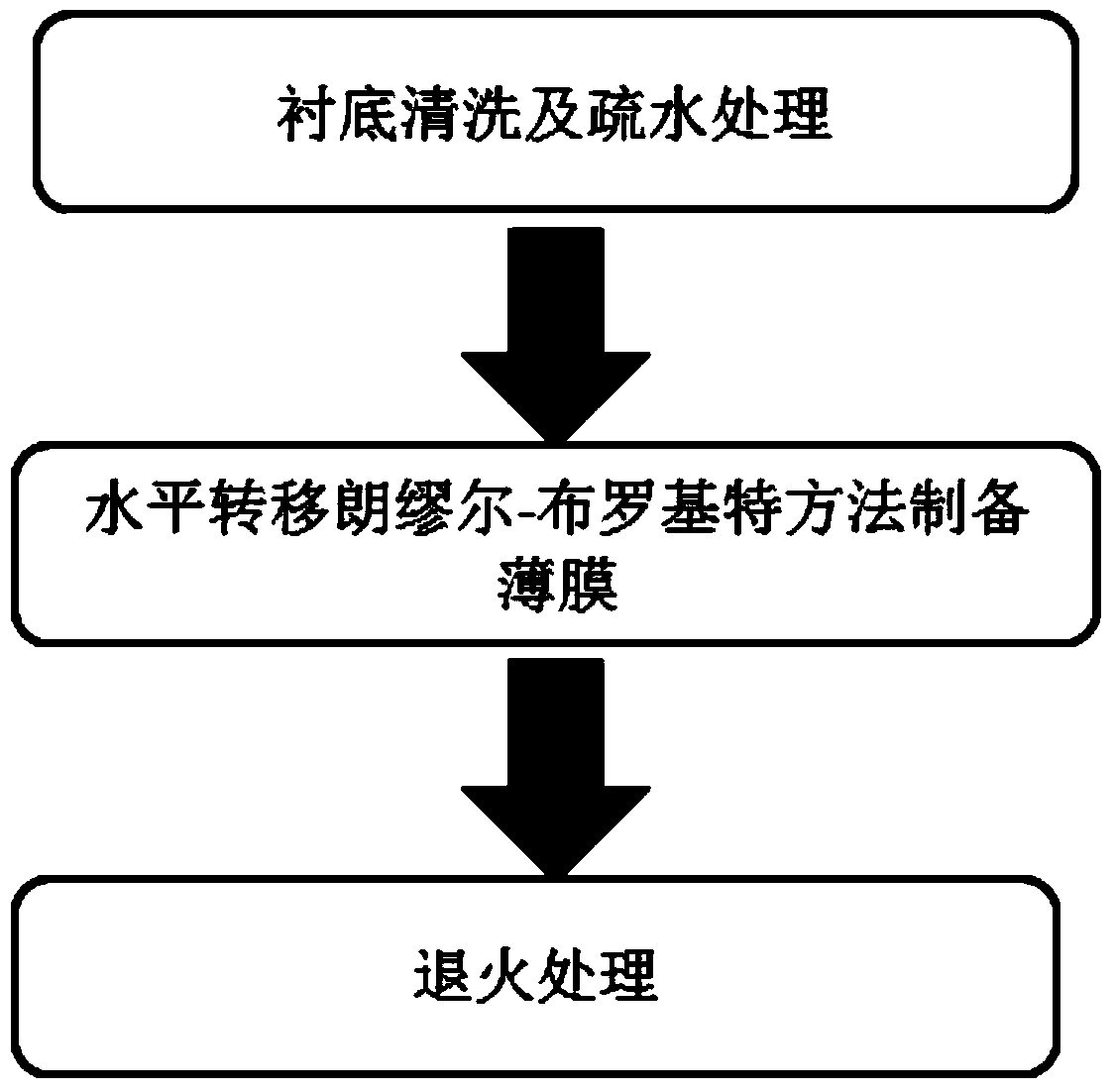

Preparation method for polyvinylidene fluoride (PVDF)-based high voltage coefficient thin film

InactiveCN104409626ALow costSimple processPiezoelectric/electrostrictive device manufacture/assemblyFerroelectric polymersCompound structure

The invention discloses a preparation method for a polyvinylidene fluoride (PVDF)-based high voltage coefficient thin film. The preparation method is characterized in that PVDF-based organic ferroelectric polymers are dissolved in a dimethyl sulfoxide solution; through a Langmuir-Blodgett method, different PVDF-based organic ferroelectric polymers are transferred to a substrate alternately layer by layer; and annealing treatment is performed to remove interface residual solvent and guarantee good crystalline characteristic of the thin film, so as to form a PVDF-based organic polymer compound structure. The preparation method for the PVDF-based high voltage coefficient thin film is simple, can control the thickness of a single layer of thin film precisely, and provides guarantee for research of piezoelectric property of the PVDF-based organic ferroelectric polymer compound structure. Experiments prove that the piezoelectric coefficient of the PVDF-based organic ferroelectric polymer compound structure is remarkably improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

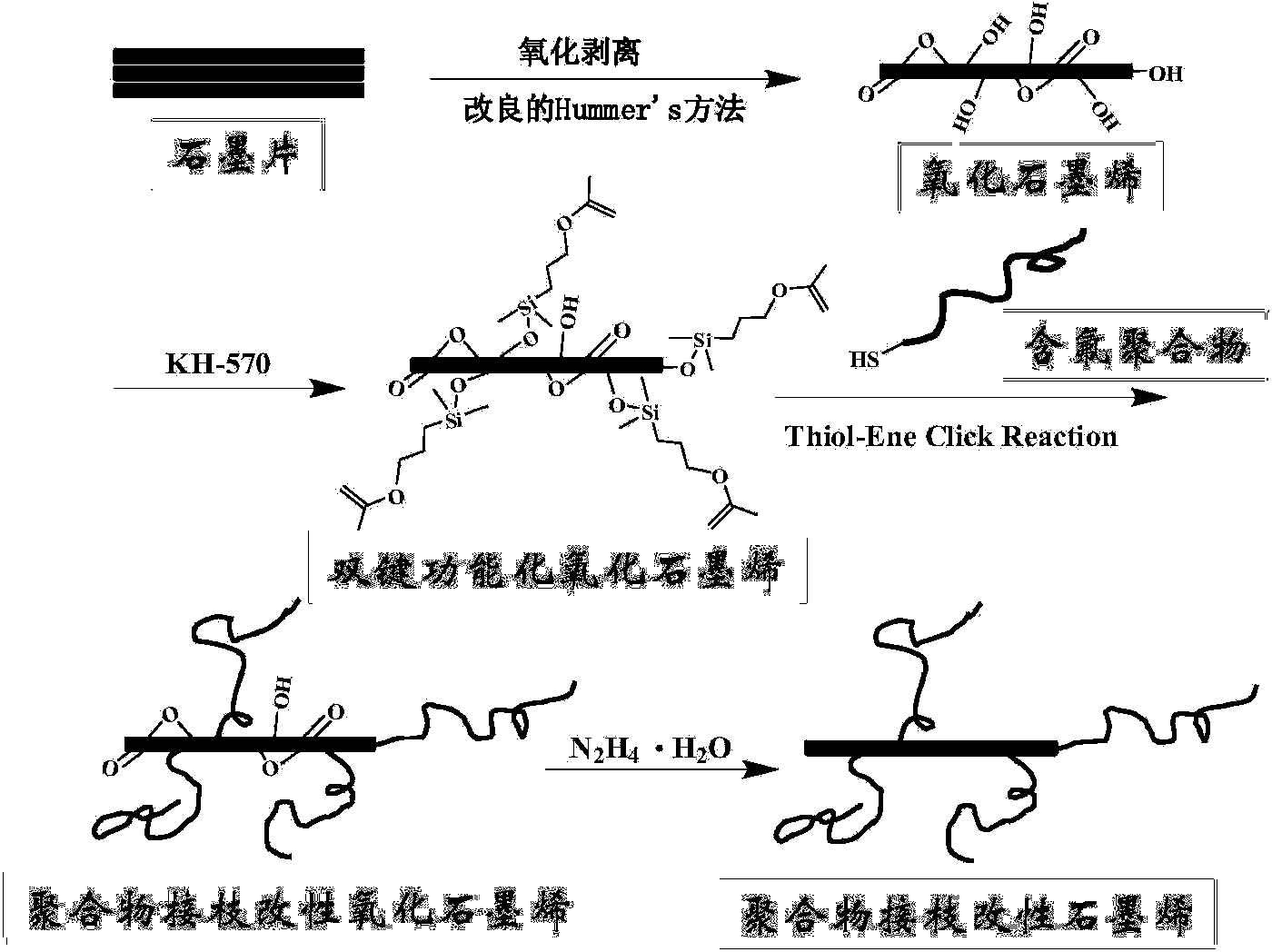

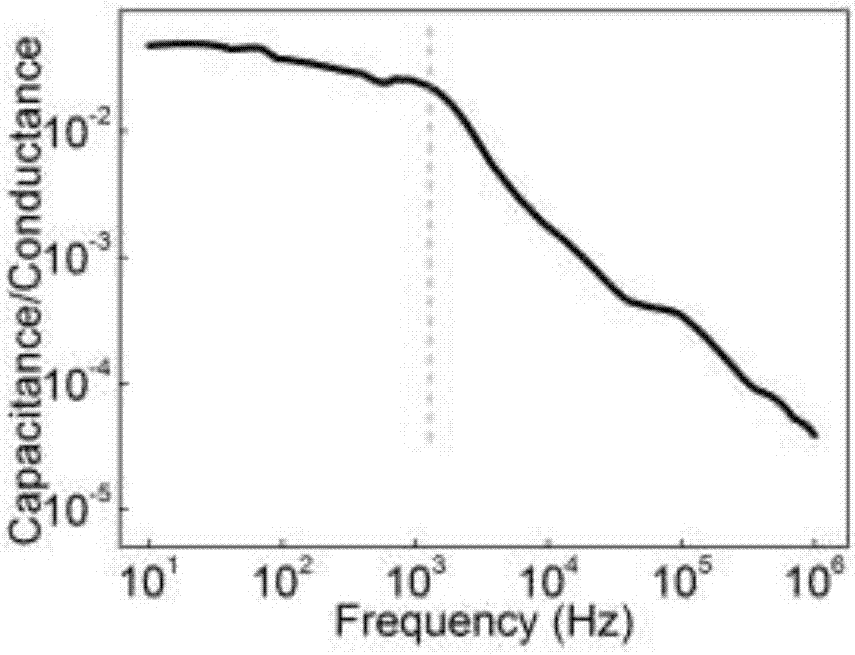

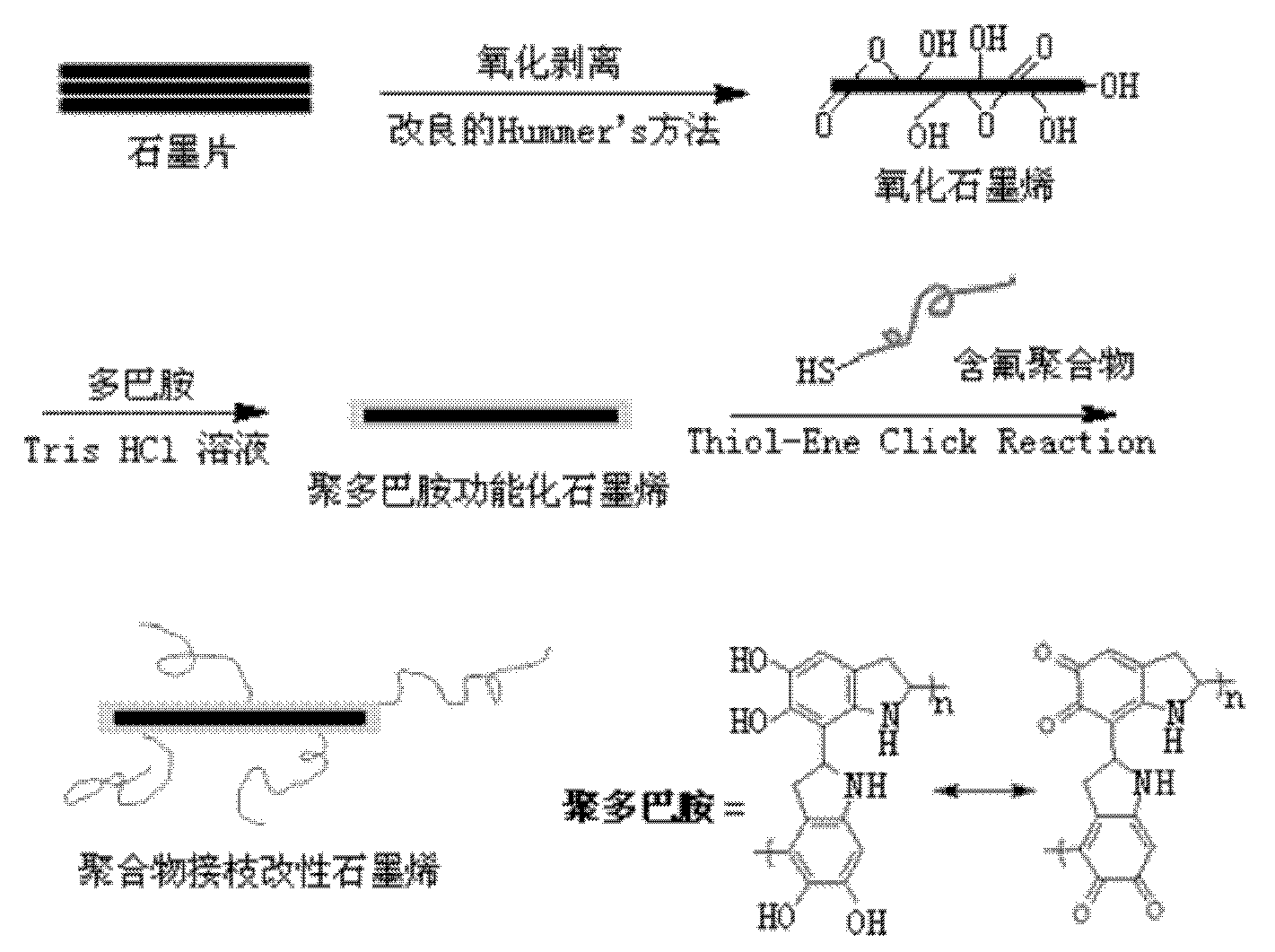

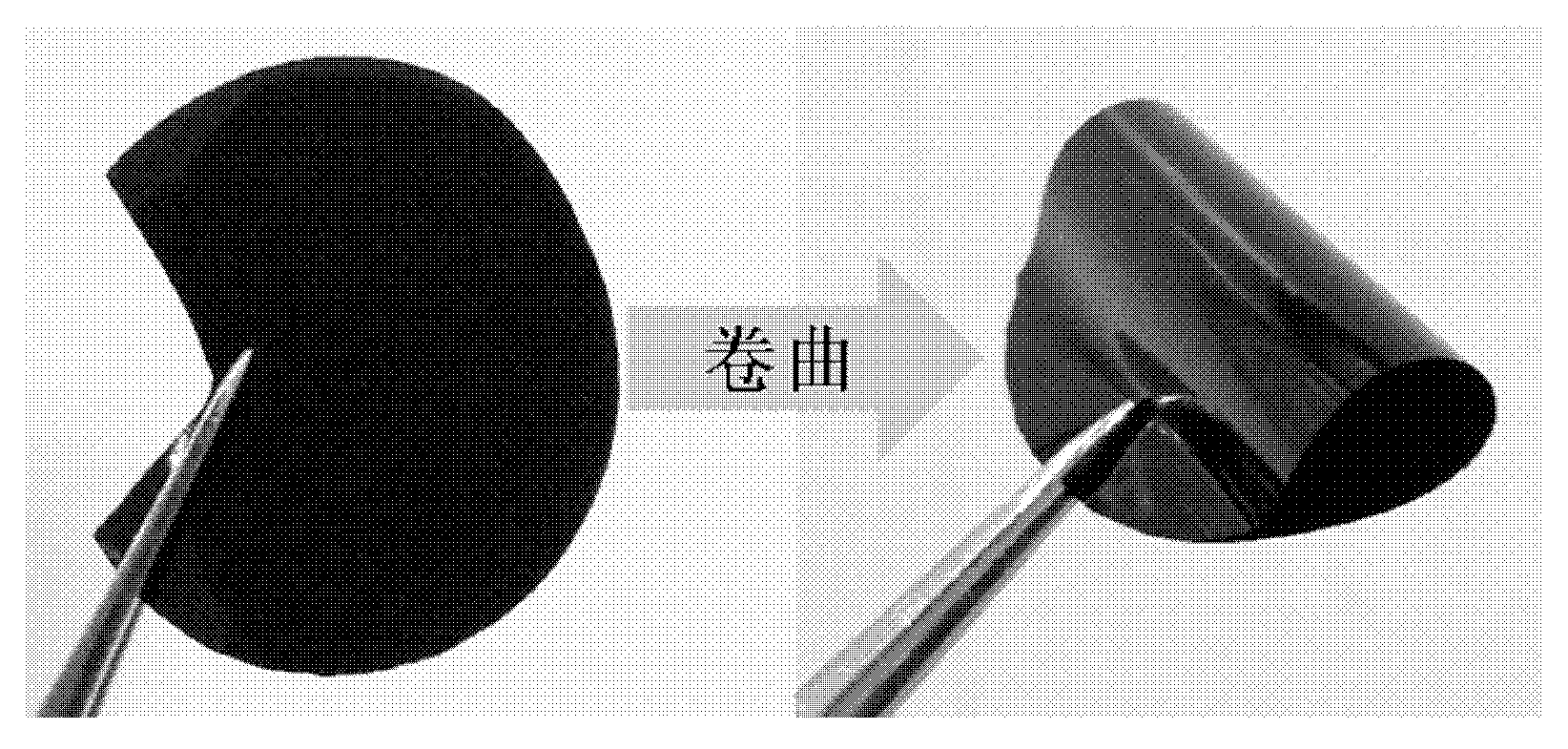

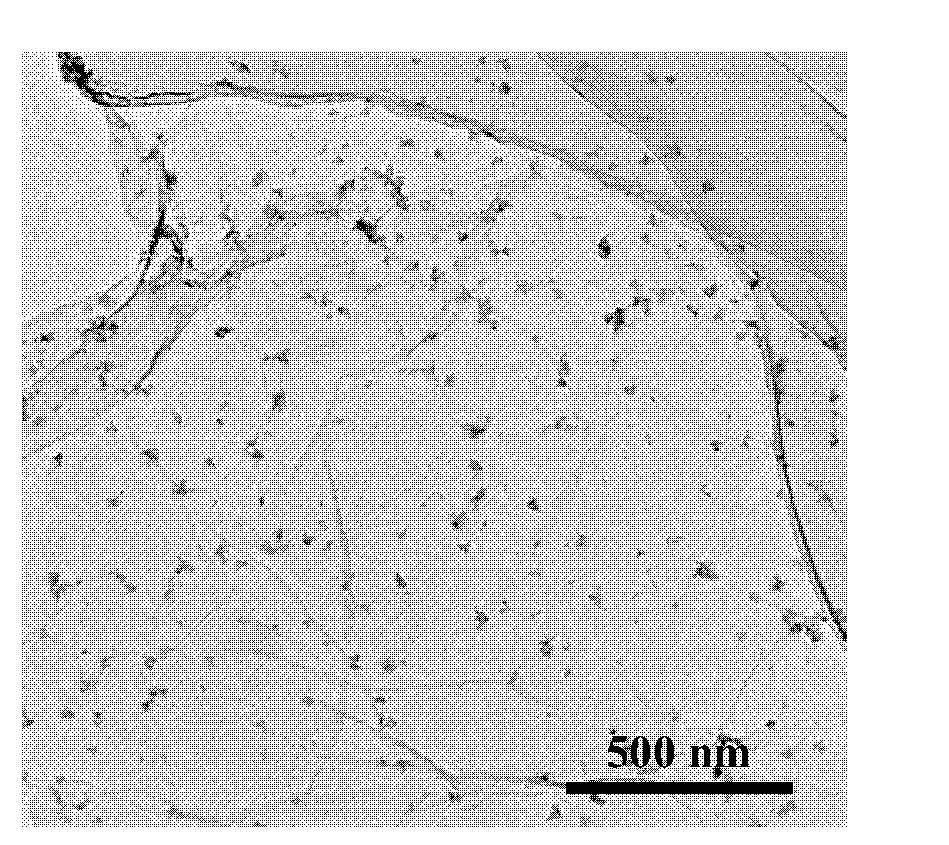

Flexible high-dielectric polymer composite material and preparation method thereof

The invention discloses a flexible high-dielectric polymer composite material and a preparation method thereof. The flexible high-dielectric polymer composite material disclosed by the invention is prepared by taking a fluorine-containing ferroelectric polymer as a basal body and modified graphene as a filler through processes such as liquor mixing, curtain-coating and film-forming, and hot-press molding, wherein the added graphene is grafted with the fluorine-containing polymer on the surface by adopting a click chemistry method and thermally reduced by hydrazine hydrate; the grafted fluorine-containing polymer not only can be used for improving dispersion of the graphene, but also can be well compatible with the fluorine-containing ferroelectric polymer basal body to strengthen the interface binding force between the polymer basal body and the graphene filler. The flexible high-dielectric polymer composite material prepared by the preparation method disclosed by the invention has the characteristics of being high in dielectric constant, low in dielectric loss, good in flexibility, excellent in mechanical performance, and the like, is suitable for manufacturing advanced electronic electrical appliance equipment such as an embedded type capacitor, a field-effect transistor, and the like.

Owner:SHANGHAI JIAO TONG UNIV

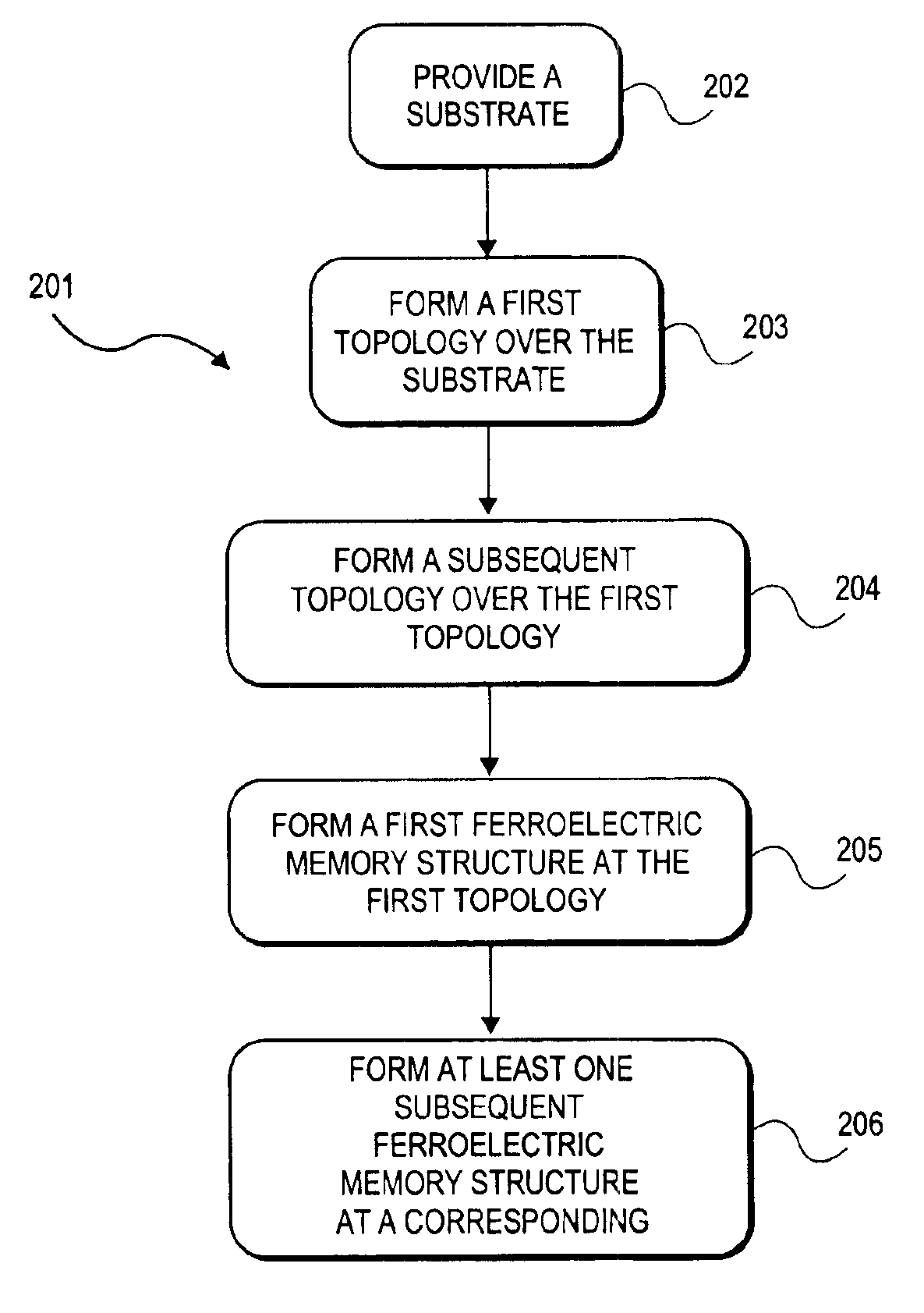

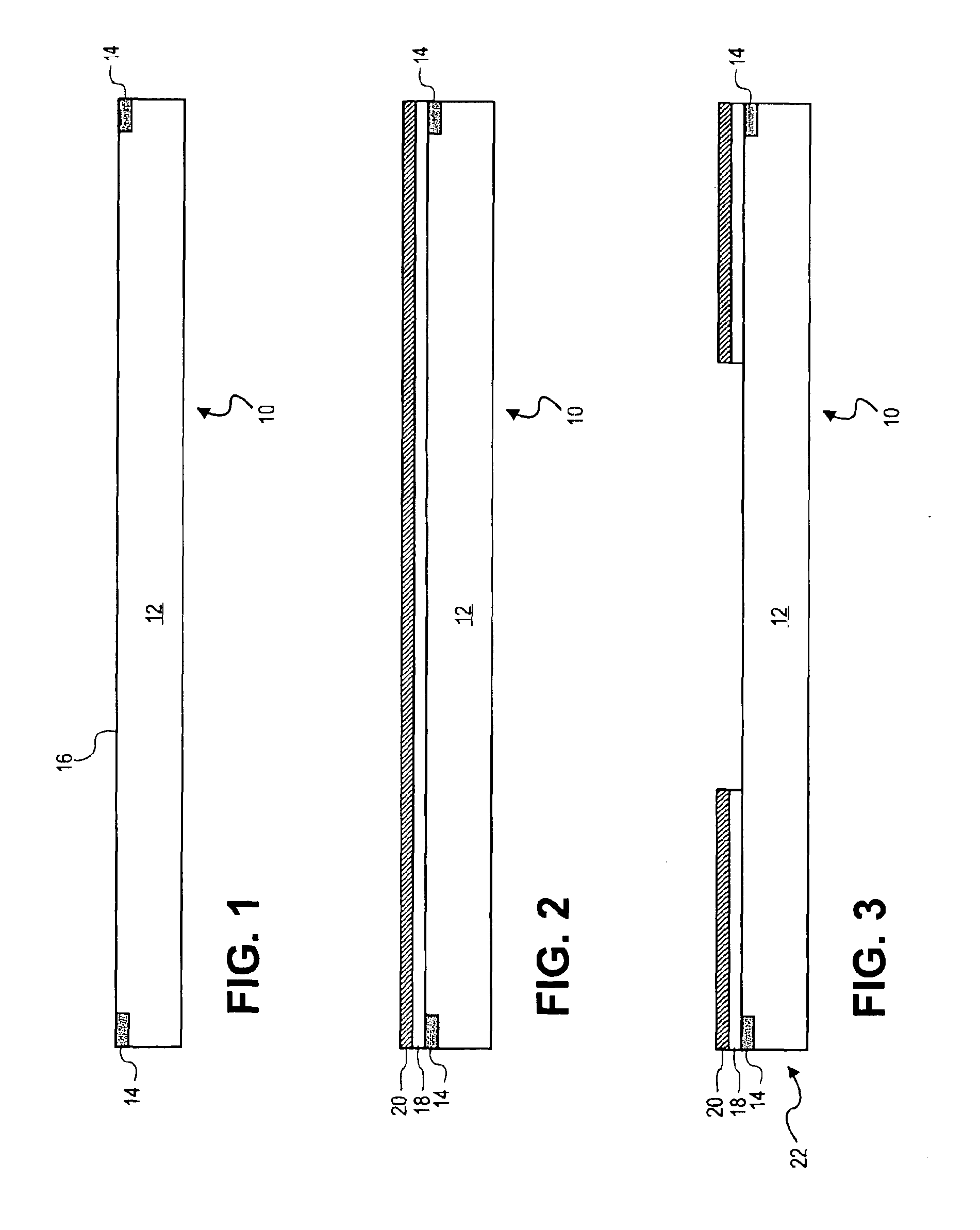

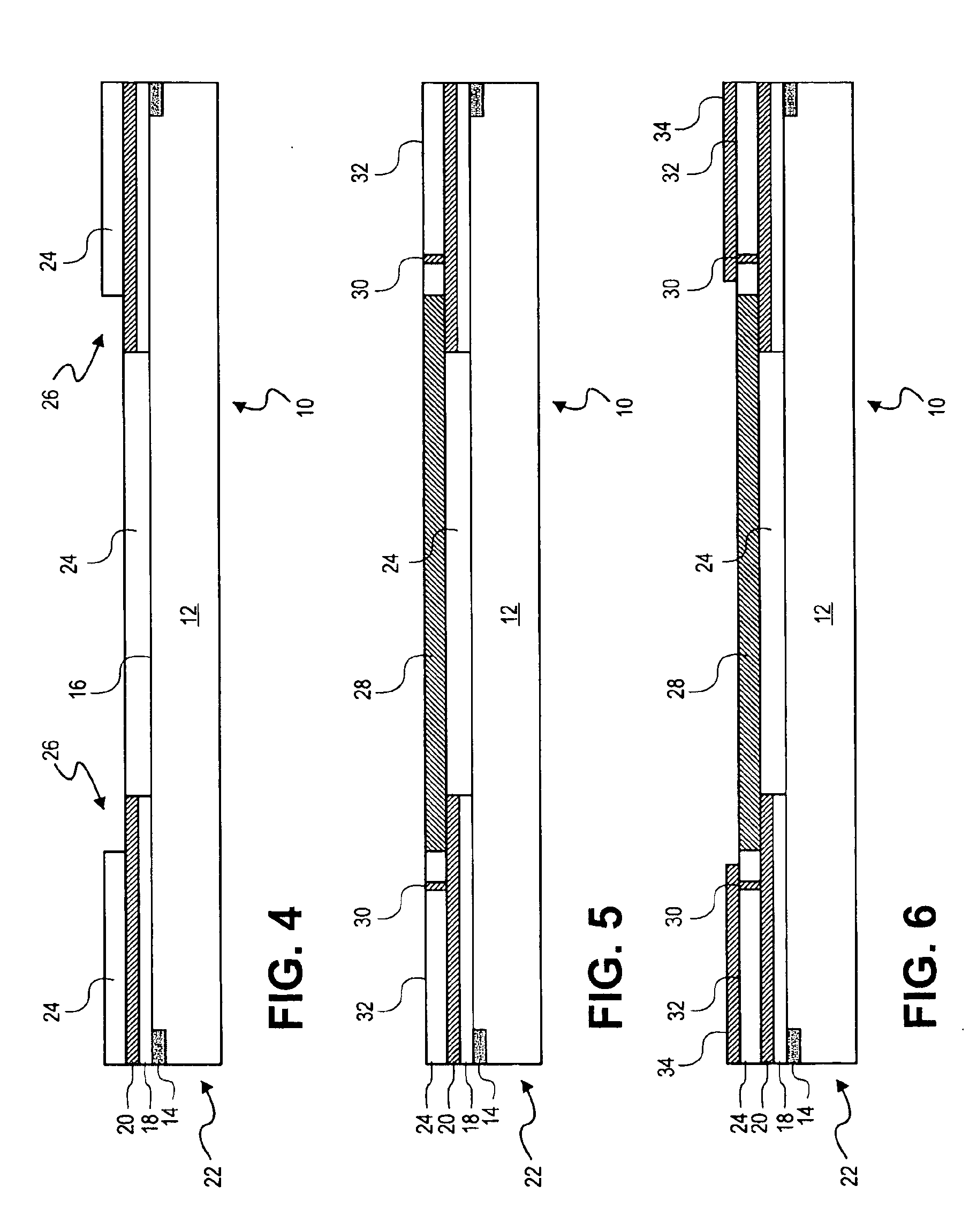

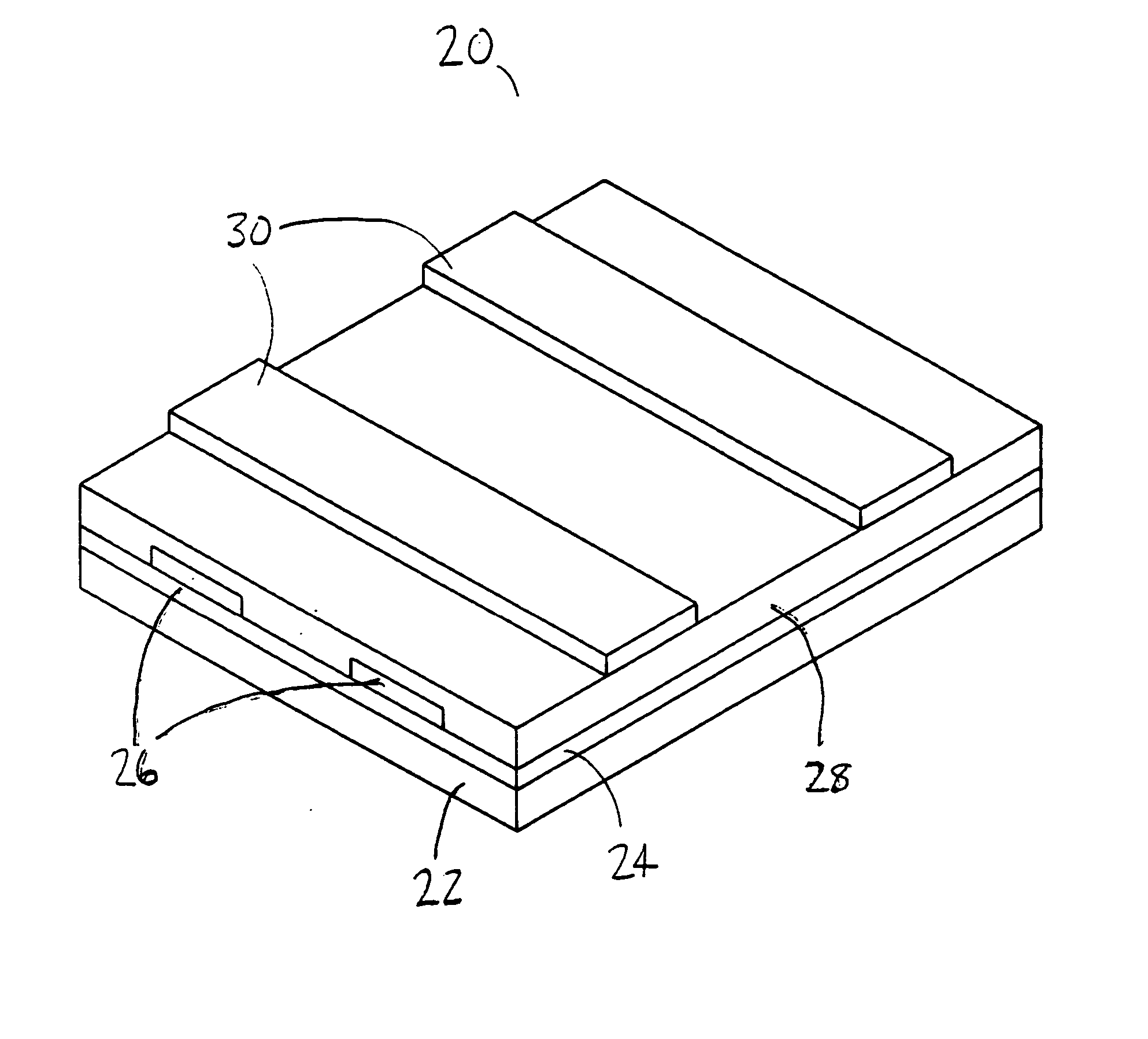

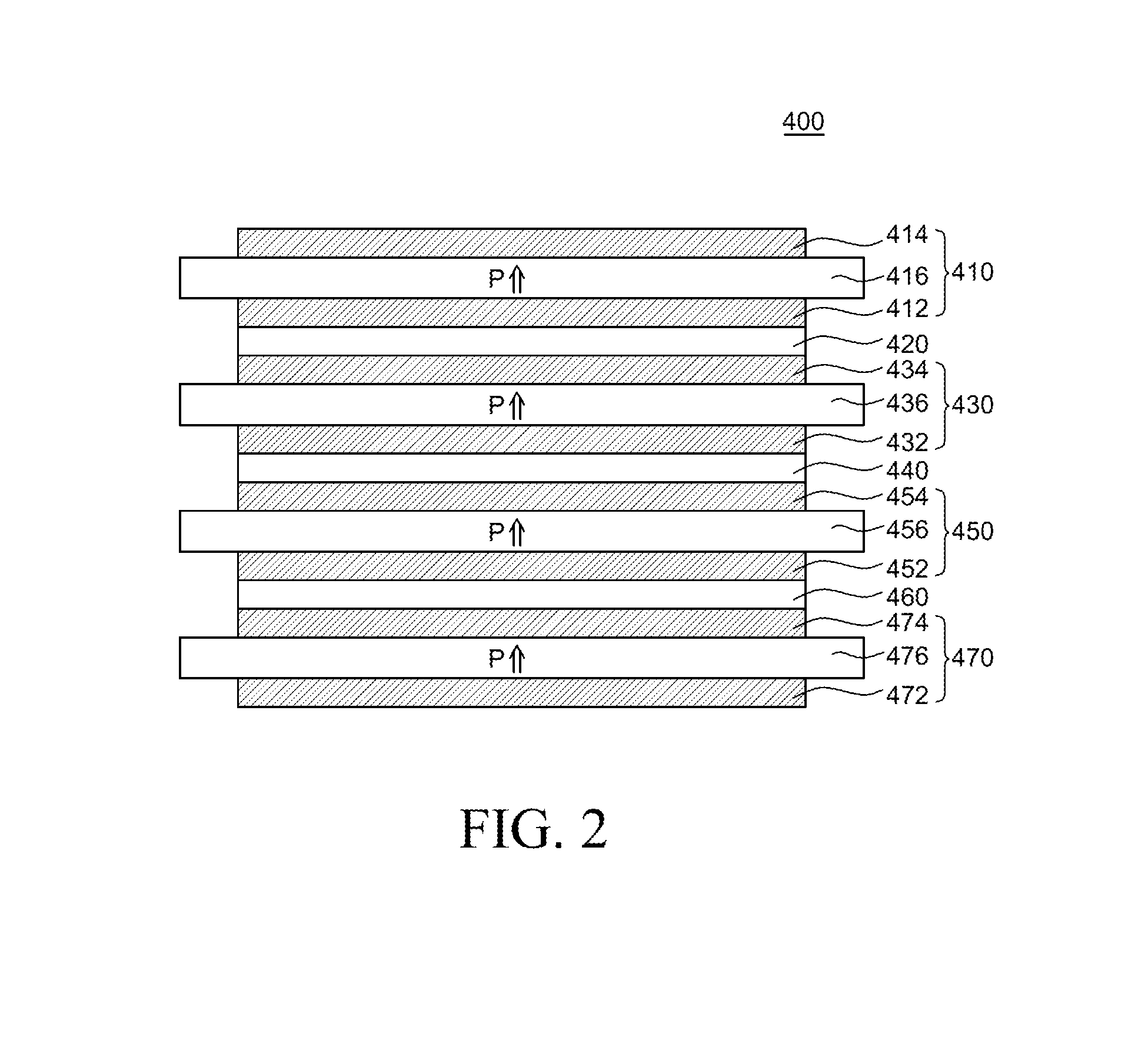

Stacked ferroelectric memory device and method of making same

InactiveUS6960479B2Rotary current collectorElectric discharge tubesFerroelectric polymersDielectric layer

The present invention relates to a ferroelectric polymer storage device including at least two stacked ferroelectric polymer memory structures that are arrayed next to at least two respective stacked topologies that are a pre-fabricated silicon substrate cavity that includes interlayer dielectric layers and via structures. Combining ferroelectric polymer and ferroelectric oxide layers on the pre-fabricated silicon substrate cavity forms a multi-rank structure.

Owner:INTEL CORP

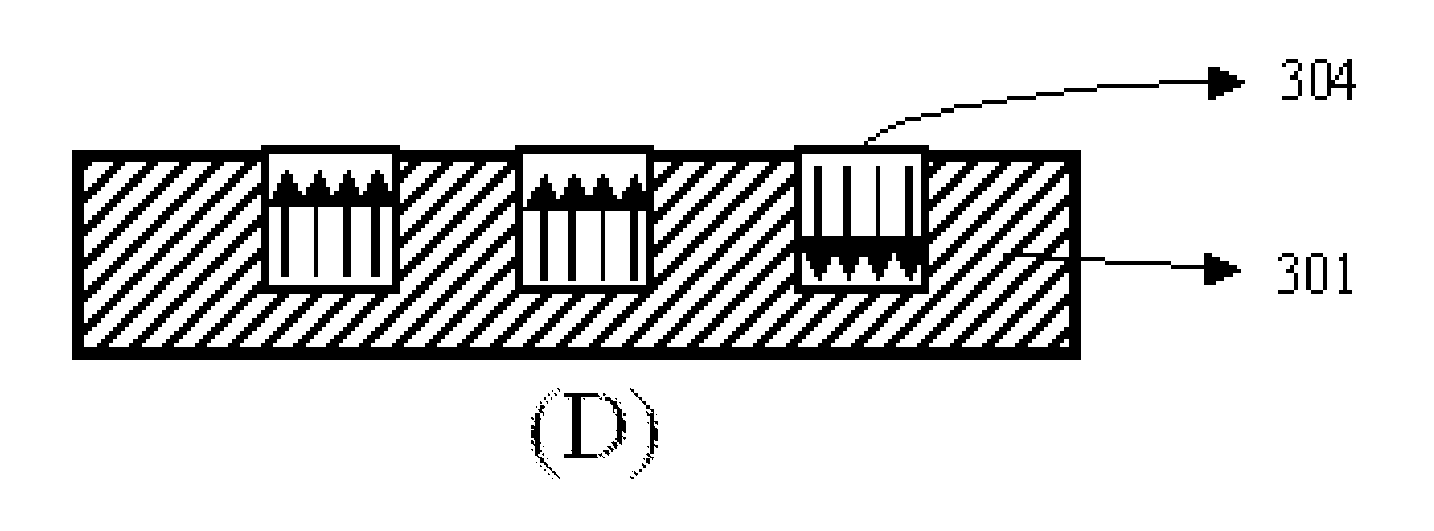

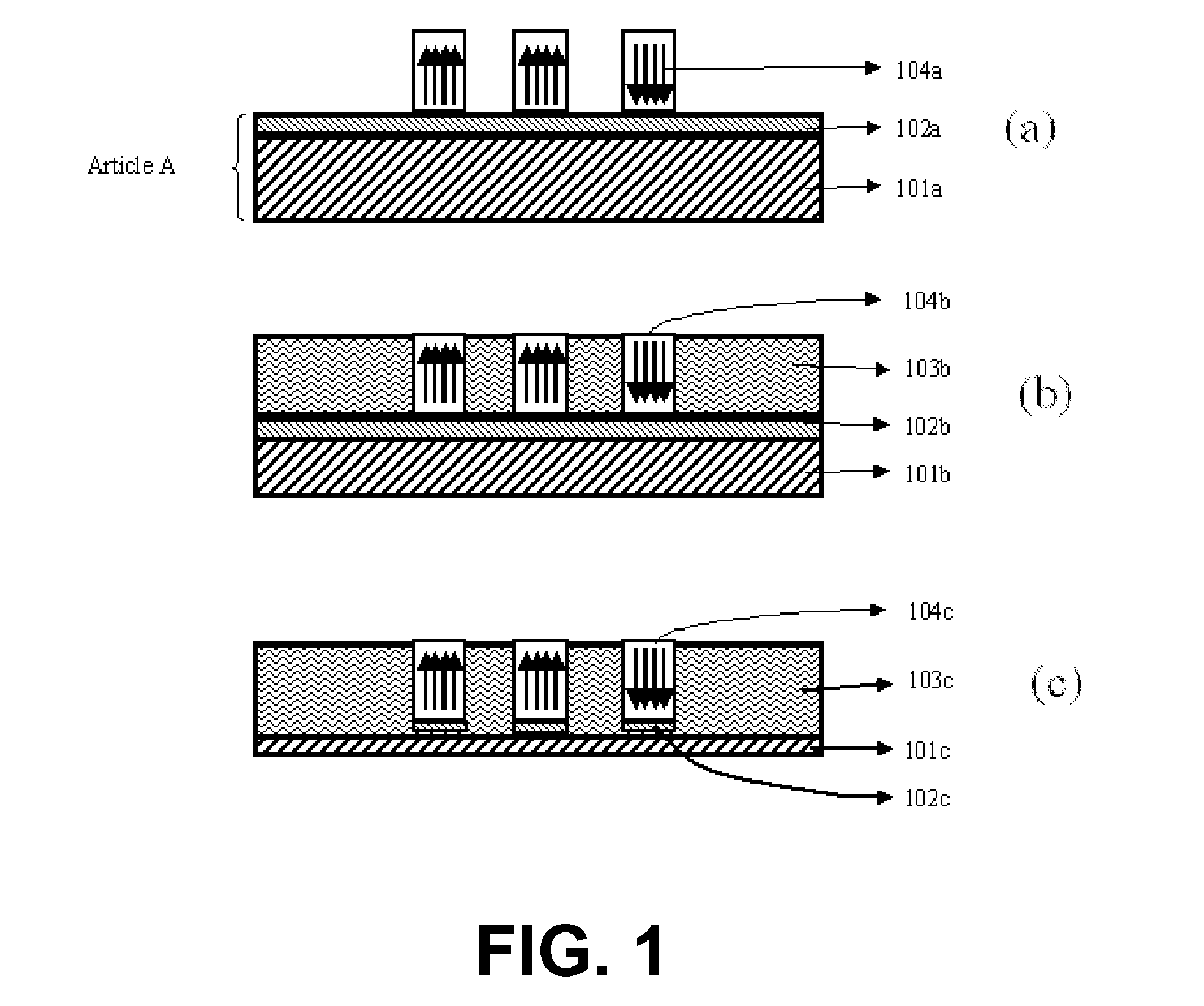

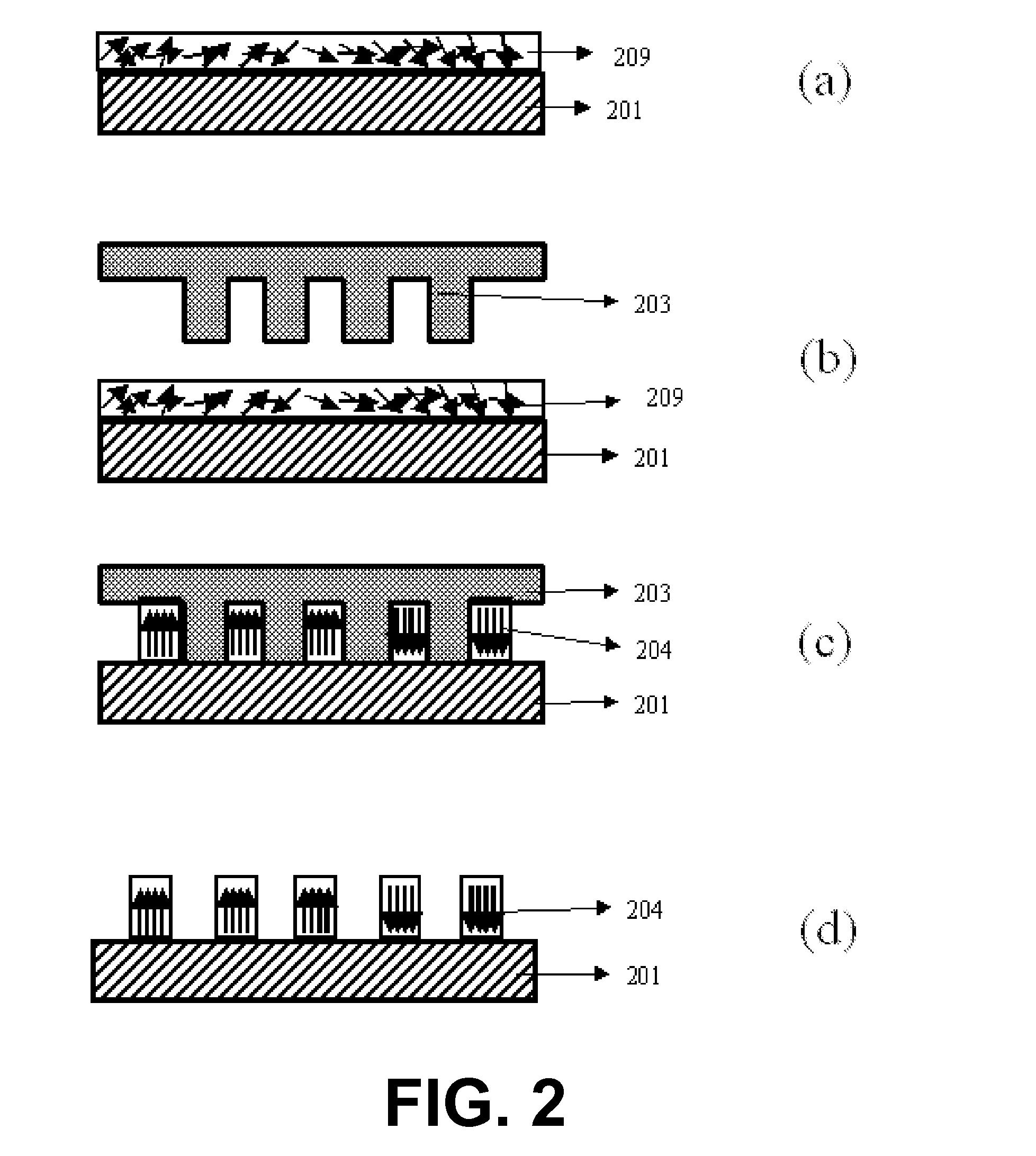

Ferroelectric organic memories with ultra-low voltage operation

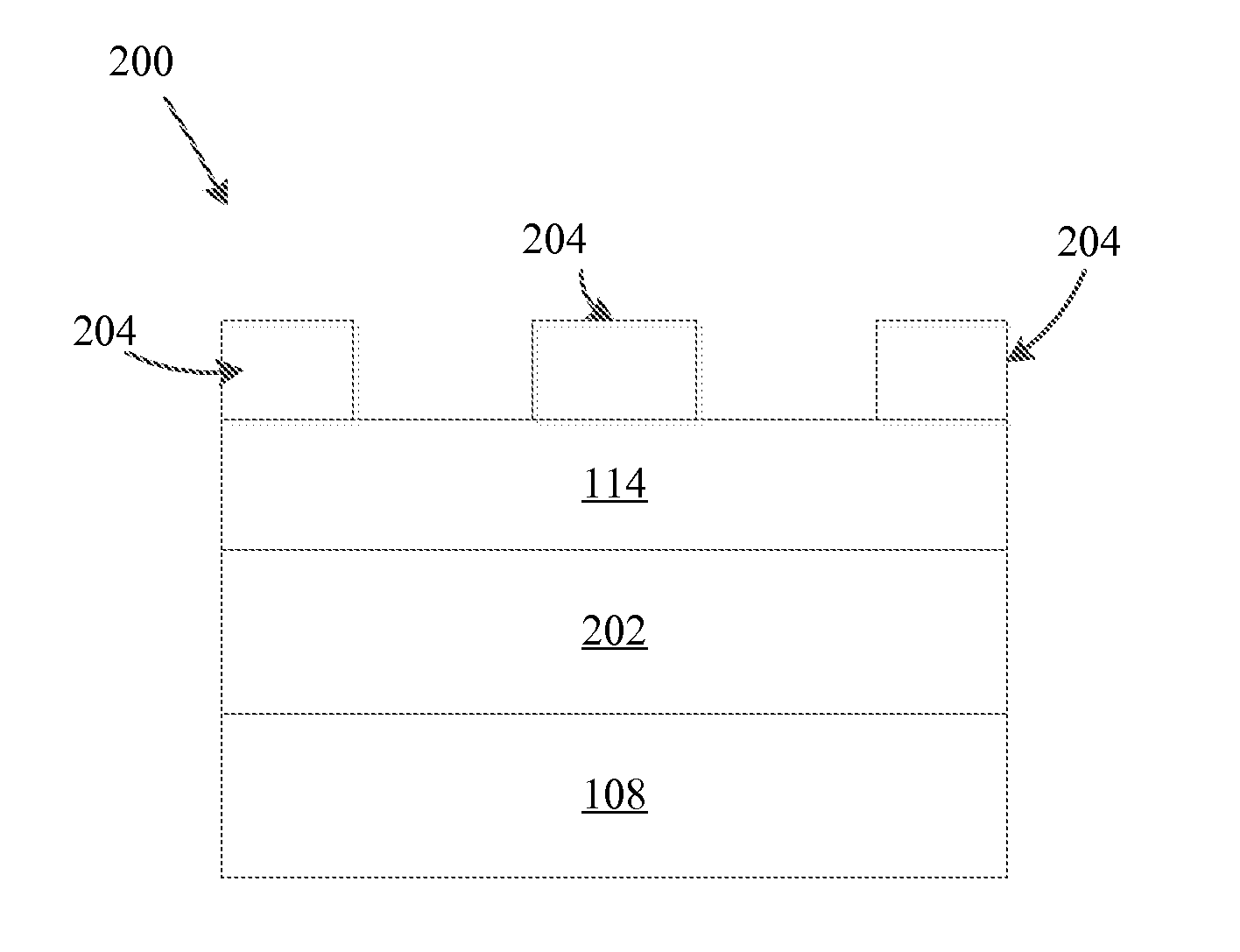

InactiveUS20110108899A1Good ferroelectric switching performanceLow working voltageSolid-state devicesSemiconductor/solid-state device manufacturingDielectricOrganic memory

A method of manufacturing a patterned ferroelectric polymer memory medium is disclosed, which includes forming an electrode on a substrate; forming a ferroelectric polymer thin film on the electrode; and patterning and orienting the polymer thin film into a plurality of nanostructures by embossing techniques. Also disclosed are two methods which include forming nanofeatures in an interlayer dielectric (ILD) layer deposited on a substrate; forming a ferroelectric polymer thin film on the ILD layer in the nanofeatures; and patterning and orienting the polymer thin film into a plurality of nanostructures by pressing. The patterning process followed by an annealing process promotes specific crystal orientation, which significantly reduces the operation voltage, and increases the signal-to-noise ratio. The invention also covers devices made of a ferroelectric polymer layer oriented by such an embossing method and the use of such devices at a coercive field of 10 MV / m or less.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN

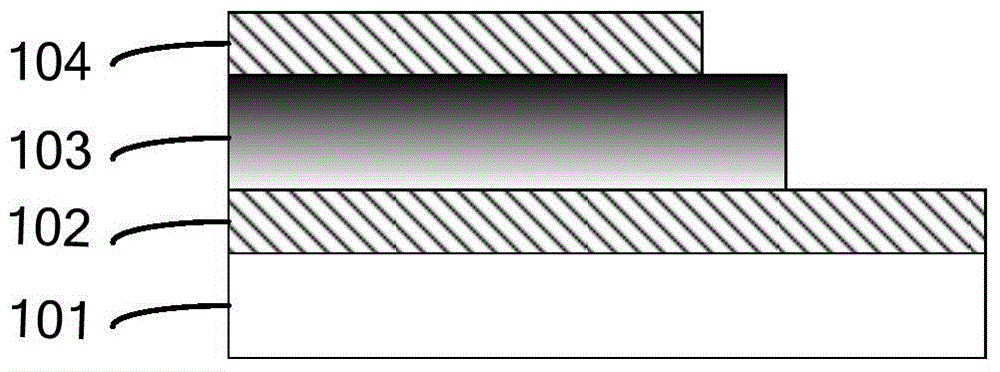

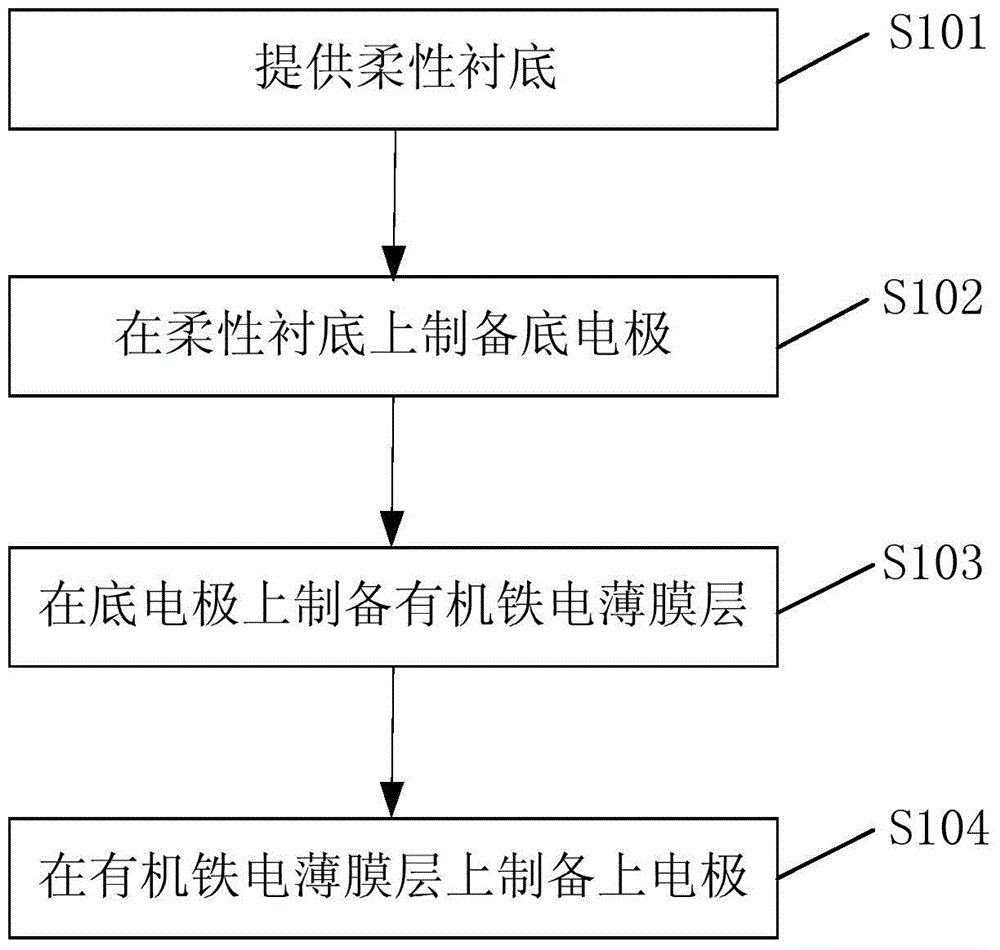

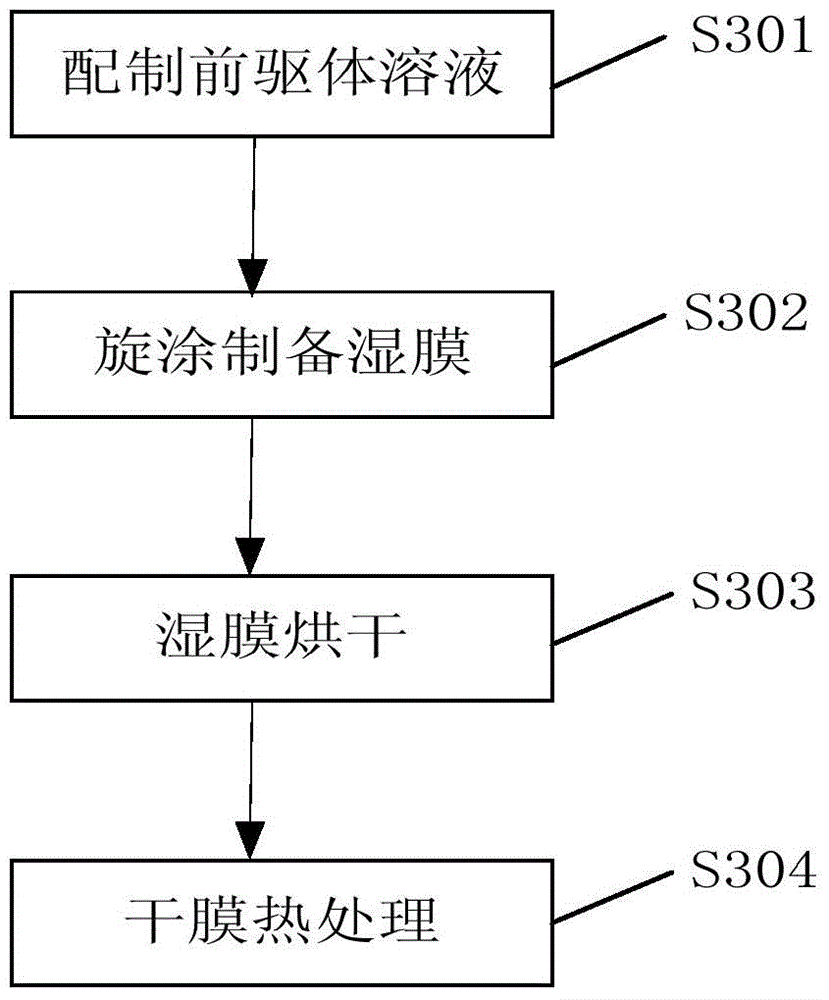

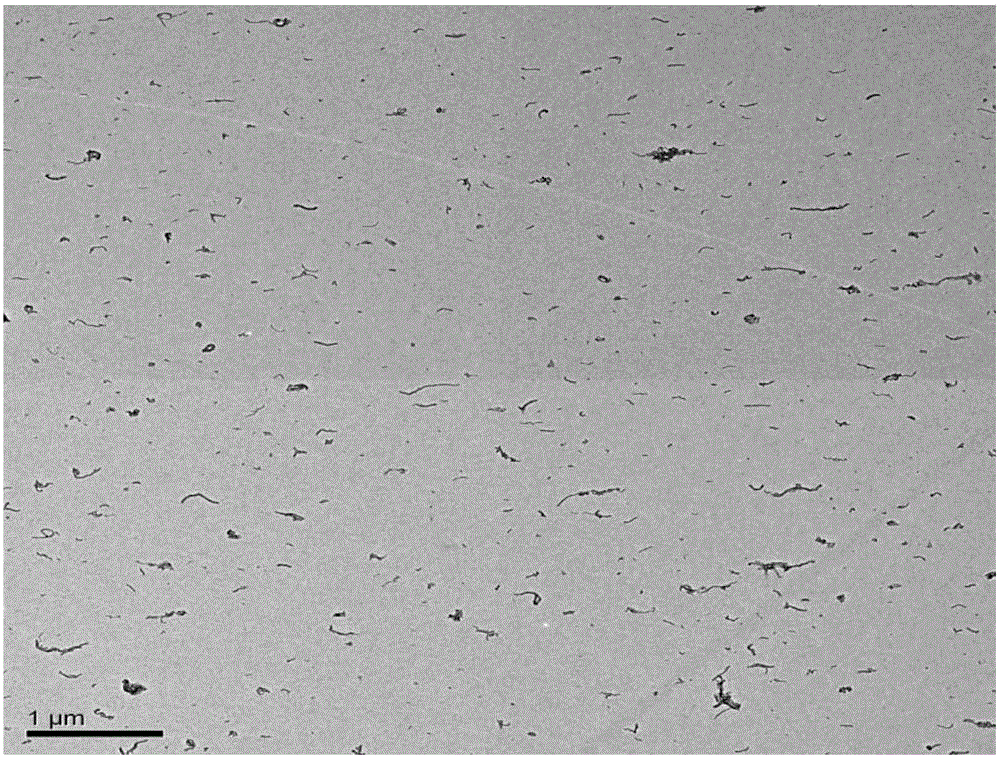

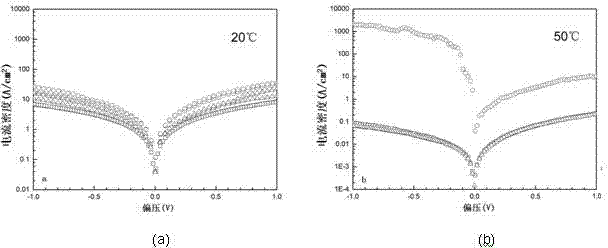

Memristor device based on organic ferroelectric film material and preparation method thereof

InactiveCN105702856AImprove ferroelectric propertiesResistor state changeElectrical apparatusFerroelectric polymersFluoride

The invention provides a memristor device based on an organic ferroelectric film material, comprising a flexible substrate, a bottom electrode formed on the flexible substrate, an organic ferroelectric film layer formed on the bottom electrode, and an upper electrode formed on the organic ferroelectric film layer, wherein the organic ferroelectric film layer is made of a vinylidene fluoride based ferroelectric polymer. The memristor device can achieve multi-state storage, has a memristive performance, has good mechanical property of being compatible with electronic skin, can simulate the functions of biological nerve synapses, has the advantages of small size, simple structure, low cost, non-volatility, quick reading and writing and the like, and provides the possibility of preparing a light, flexible and integrated artificial cognition equipment in the future. The invention further provides a method for preparing the memristor device based on an organic ferroelectric film material.

Owner:HUAWEI TECH CO LTD +1

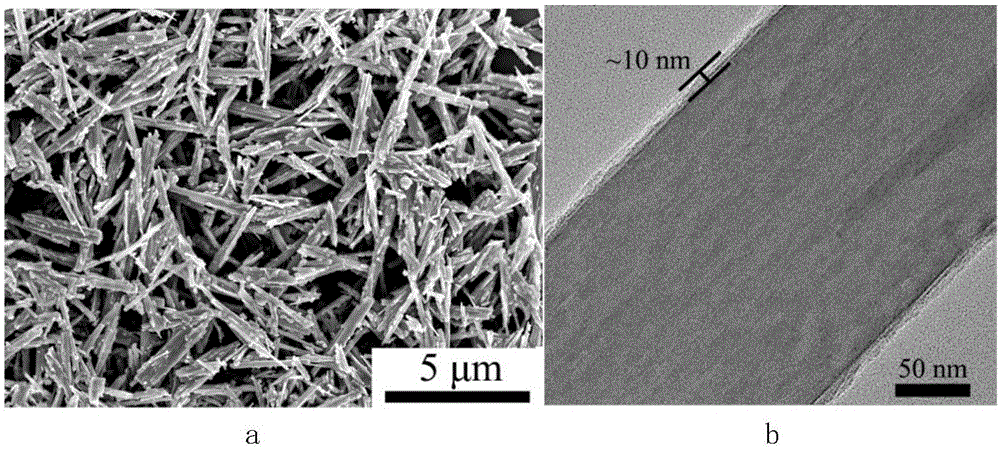

Polymer-based flexible composite material having both ferroelectric properties and ferromagnetic properties, and preparation method thereof

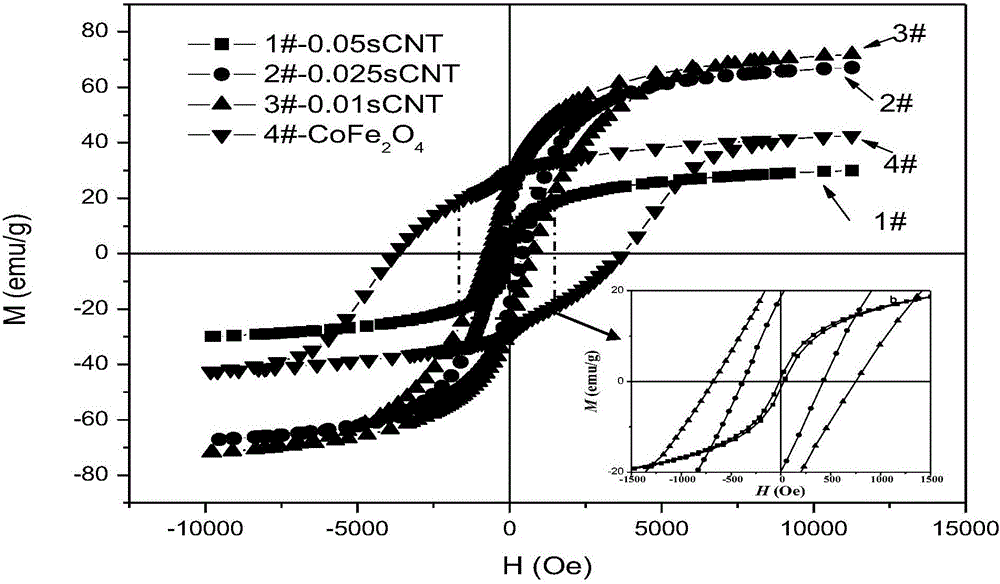

ActiveCN105949683AHigh piezoelectric coefficientHigh magnetoelectric coupling effectFerroelectric polymersMagnetite Nanoparticles

The invention relates to a polymer-based multiferroic magnetoelectric composite material having both ferroelectric properties and ferromagnetic properties. The composite material is characterized by being formed through mixing up one-dimensional OD-MFe2O4 ferromagnetic elements with the fluoropolymer cPVDF material. The one-dimensional OD-MFe2O4 ferromagnetic elements are obtained through growing an MFe2O4 ferromagnetic compound on the surface of a one-dimensional functionalized material, wherein M=Fe, Co, Ni, Mn and Zn. According to the technical scheme of the invention, ferrites (MFe2O4, M=Fe, Co, Ni, Mn and Zn) and magnetic nanoparticles are loaded on the surface of the one-dimensional functionalized material through the in-situ assembling process, so that the one-dimensional material-magnetic nano-material (OD-MFe2O4) of a specific dimension and a specific surface activity is automatically synthesized. Therefore, the uniform dispersion of ferromagnetic OD-MFe2O4 in a ferroelectric polymer matrix is realized through compounding the ferroelectric polymer matrix with ferromagnetic OD-MFe2O4. Meanwhile, the good integration of an inorganic phase and an organic phase is realized. As a result, a ferromagnetic phase is highly ordered in a composite system. The wholly new multiferroic magnetoelectric composite material having both ferroelectric properties and ferromagnetic properties is prepared.

Owner:WUHAN UNIV OF TECH

Production method for ternary ferroelectric polymer thin-film material

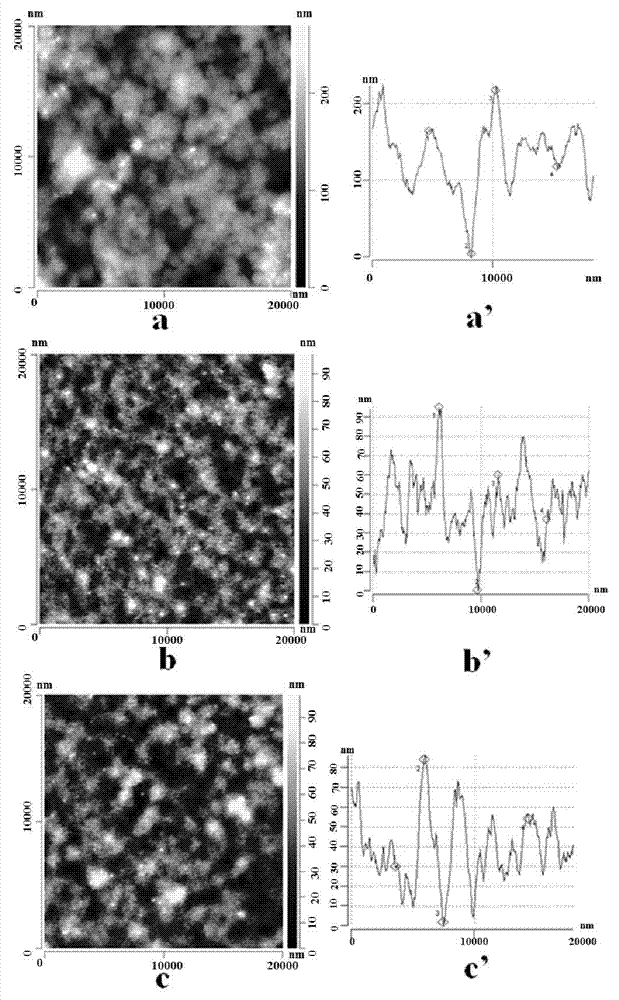

InactiveCN101471180AHighly orderedThin/thick film capacitorFixed capacitor dielectricFerroelectric polymersPolymer science

The invention discloses a preparing process of ternary ferroelectric polymer film material, which comprises preparing a precursor solution by using dimethyl sulfoxide as solvent and ternary polymer P (VDF-TrFE-CFE) as solute, and adopting horizontal dipping method to create films and heat-treat films on LB devices, thereby obtaining polymer films which are characterized by controllable nanometer scale, ordered arrangement level and high crystallinity. The film material processed according to the method provides a platform for studying the origin of relaxation ferroelectricity. The P (VDF-TrFE-CFE) ternary ferroelectric polymer films have the properties for studying practical energy memory devices.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

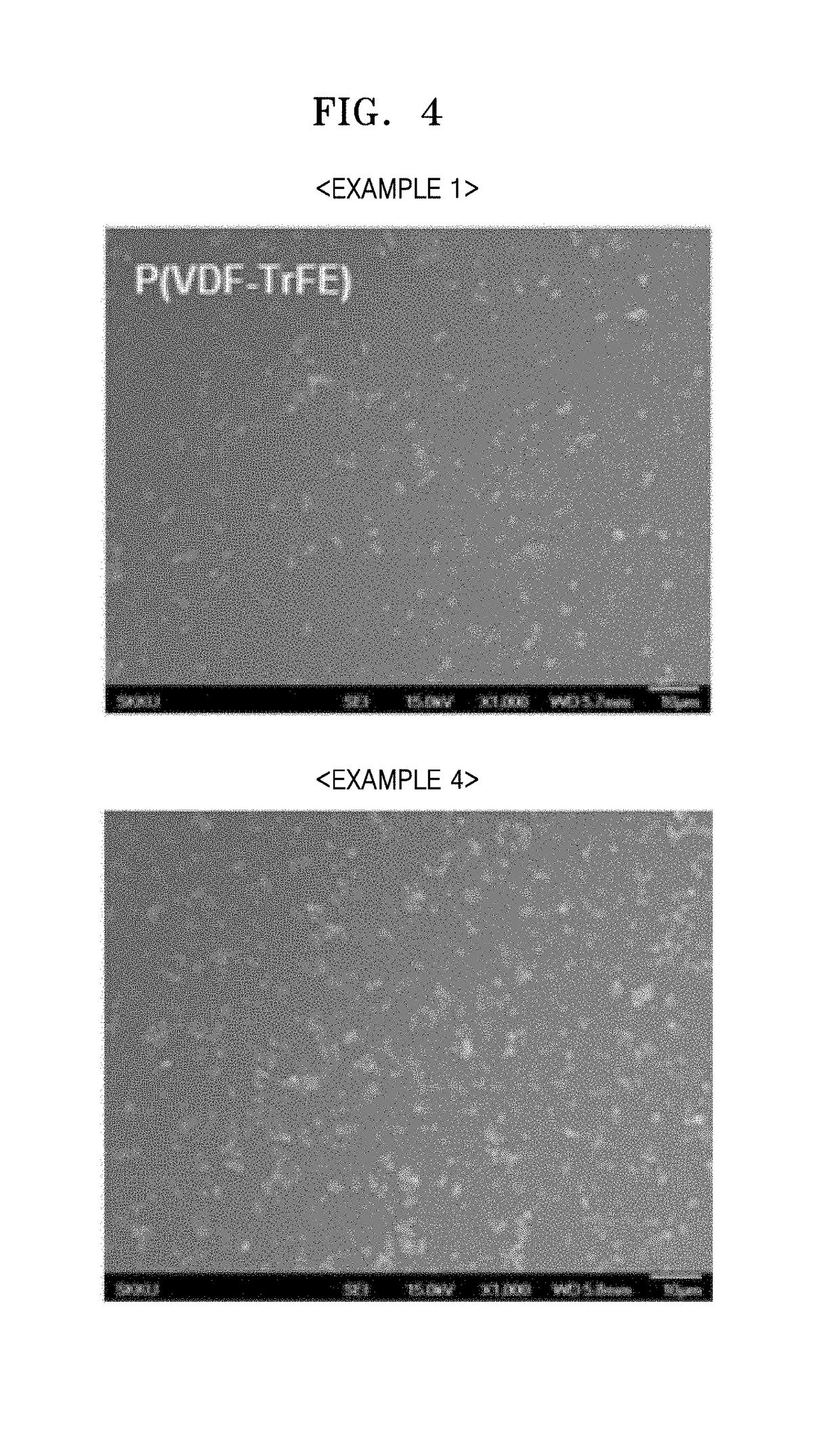

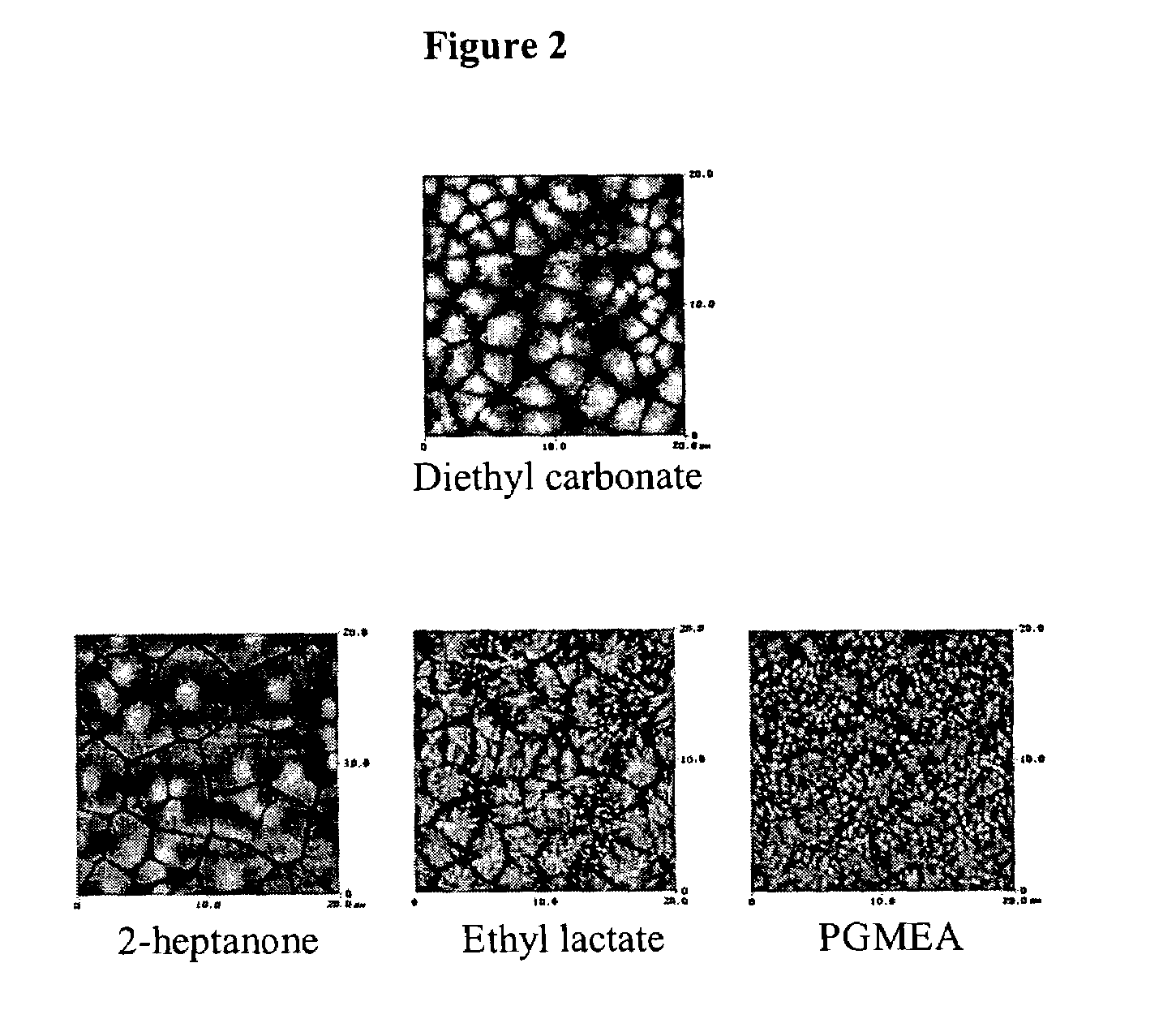

Use of ambient-robust solution processing for preparing nanoscale organic ferroelectric films

InactiveUS20160284714A1Desired optical propertyReduce the possibilitySolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric polymersBoiling point

Disclosed is a method for preparing a ferroelectric film having ferroelectric hysteresis properties, the method comprising (a) obtaining a composition comprising a solvent and an organic ferroelectric polymer solubilized therein, (b) heating the composition to above 75° C. and below the boiling point of the solvent, (c) depositing the heated composition onto a substrate; and (d) annealing the heated composition to form a ferroelectric film having ferroelectric hysteresis properties and a thickness of 400 nm or less.

Owner:SABIC GLOBAL TECH BV

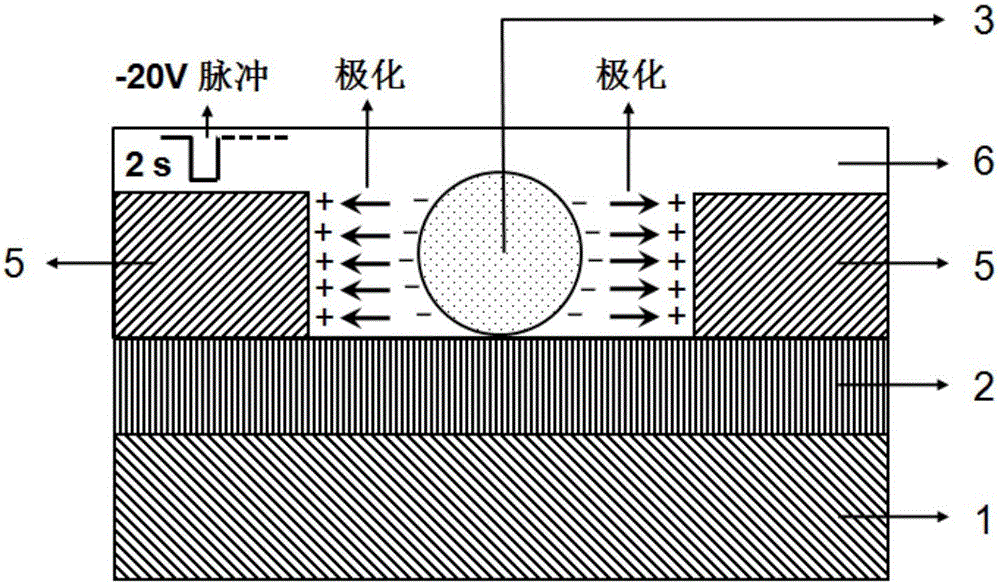

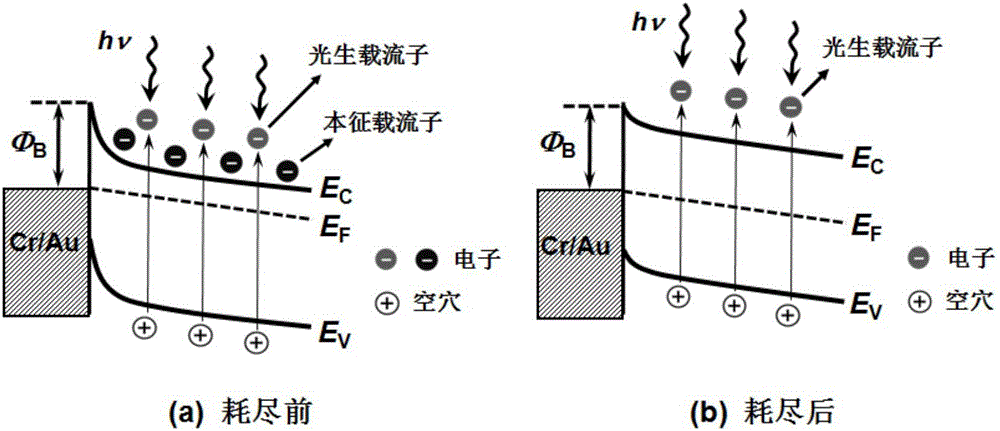

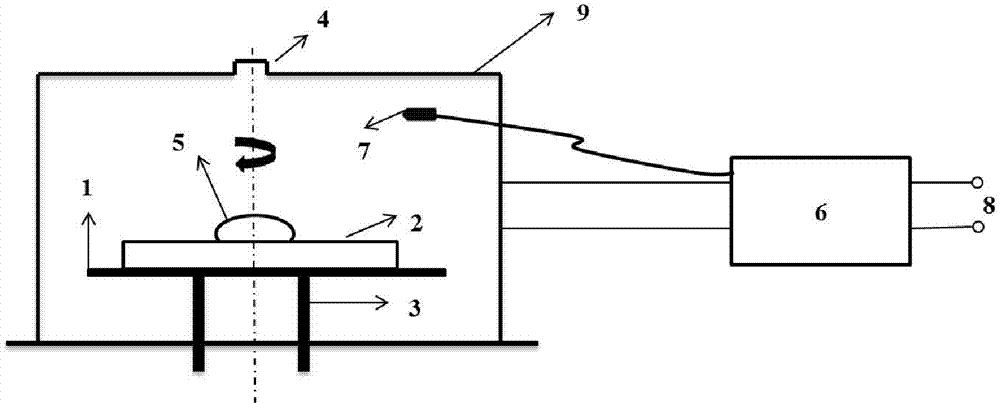

Fully depleted iron electric side gate single nanometer wire near infrared electro photonic detector and preparation method

ActiveCN106449854ASuppress dark currentHigh sensitivityFinal product manufactureSemiconductor devicesNanowireLow voltage

The invention discloses a fully depleted iron electric side gate single nanometer wire near infrared electro photonic detector and preparation method. The detector device has the preparation steps of physically transferring the CVD growth InP nanometer to the Si substratum of SiO2 oxide layer, utilizing the electronic beam exposure technique fabrication source and the drain side gate electrode, and spin coating the ferroelectric polymer membrane, and preparing into an iron electric side gate nanometer wire electro photonic detector with side railing structure. The electro photonic detector utilizes a unique side railing appliance item structure, and through the ferroelectric polymer material negative polarizes the produced ultra strong electrostatic field to completely deplete the intrinsic current carrier caused by defects or pits in the nanometer wire ditch way, thereby obviously lowers the dark current of the detector under gateless voltage, substantially increases the signal-noise ratio and detection ability of the appliance item. Single piece InP and CdS nanometer wire electro photonic detector under the control of ferroelectric materials both displays ultra high detection rate in a near infrared and visible optical band. The electro photonic detector has the advantage of low dark current, high detection rate, low voltage consumption and quick response.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

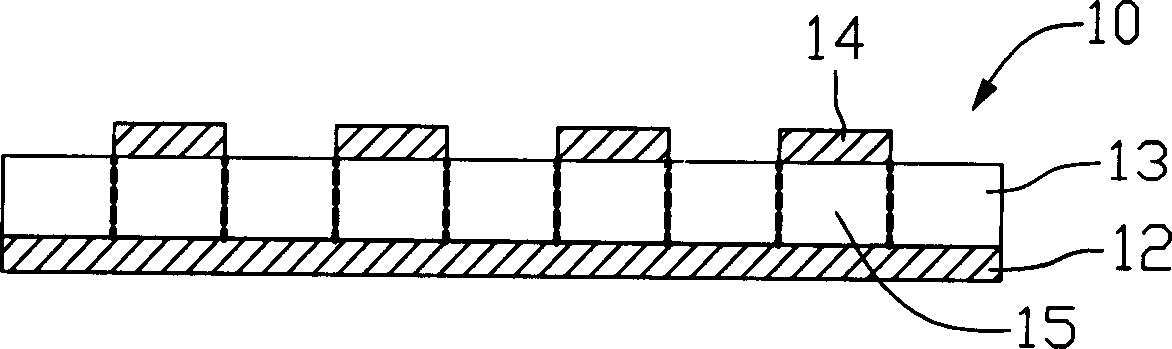

Ferroelectric polymer memory with a thick interface layer

InactiveUS20050070032A1NanoinformaticsSemiconductor/solid-state device manufacturingFerroelectric polymersInterface layer

According to one aspect of the invention, a memory array and a method of constructing a memory array are provided. An insulating layer is formed on a semiconductor substrate. A first metal stack is then formed on the insulating layer. The first metal stack is etched to form first metal lines. A polymeric layer is formed over the first metal lines and the insulating layer. The polymeric layer has a surface with a plurality of roughness formations. A second metal stack is formed on the polymeric layer with an interface layer, which is thicker than the heights of the roughness formations. Then the second metal stack is etched to form second metal lines. Memory cells are formed wherever a second metal line extends over a first metal line.

Owner:INTEL CORP

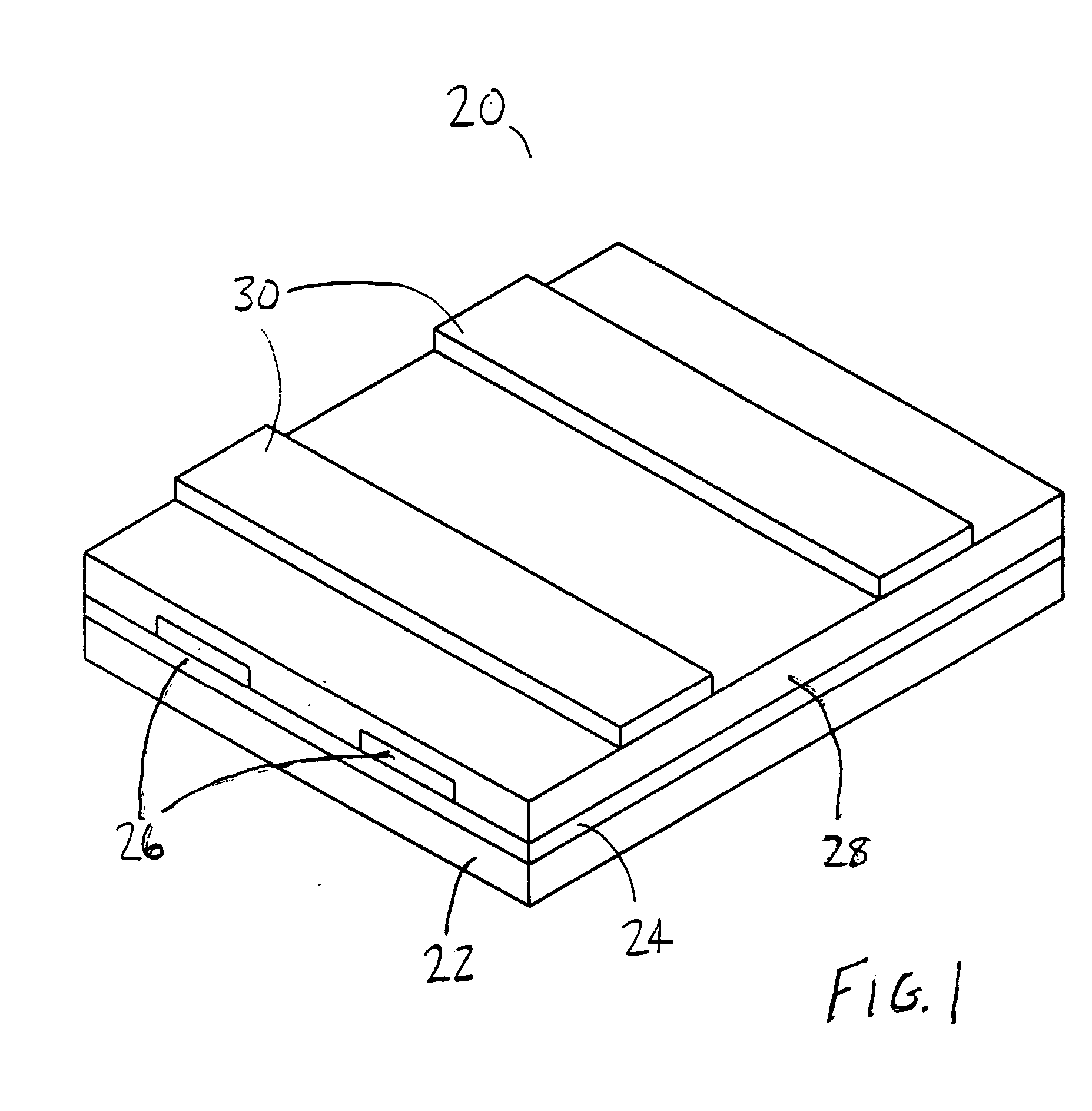

Preparation method of PVDF (polyvinylidene fluoride)-based organic ferroelectric polymer superlattice

InactiveCN103848997AEasy to manufactureSimple processSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric polymersPolymer science

The invention discloses a preparation method of a PVDF (polyvinylidene fluoride)-based organic ferroelectric polymer superlattice. The method comprises the steps of dissolving the PVDF-based organic ferroelectric polymer in dimethyl sulfoxide solution, alternately transferring different PVDF-based organic ferroelectric polymers with adjustable thickness onto a substrate through a Langmuir-Blodgett method, annealing the substrate, removing interface residual solvent to ensure that the superlattice has good crystallization characteristics, and forming a PVDF organic polymer superlattice stsructure. The prepared PVDF-based organic ferroelectric polymer superlattice is simple in method and process, the thickness of a single layer film can be precisely controlled, and the research on the unique phase changing, electric characteristics and optical characteristics of the PVDF-based organic ferroelectric polymer superlattice structure as well as relevant devices can be guaranteed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

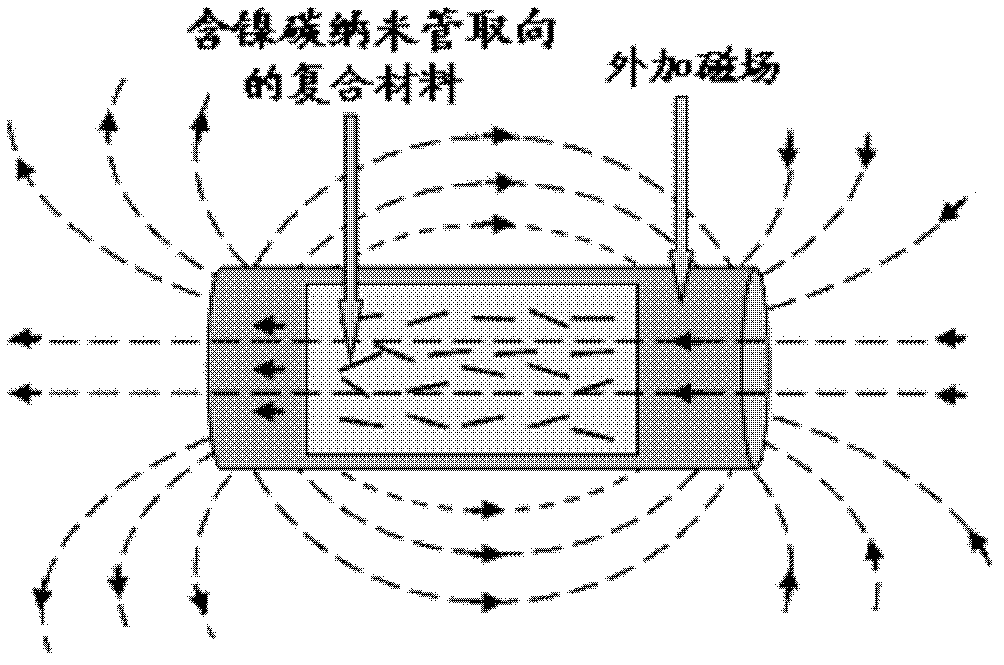

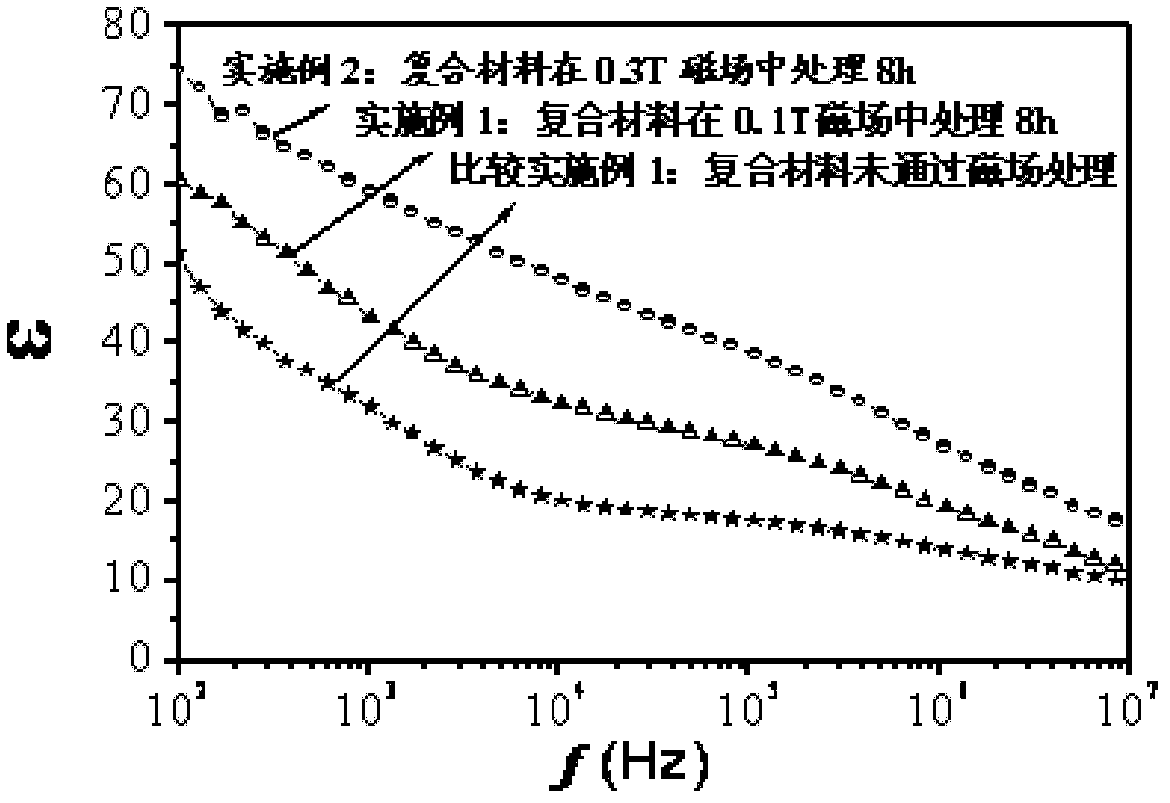

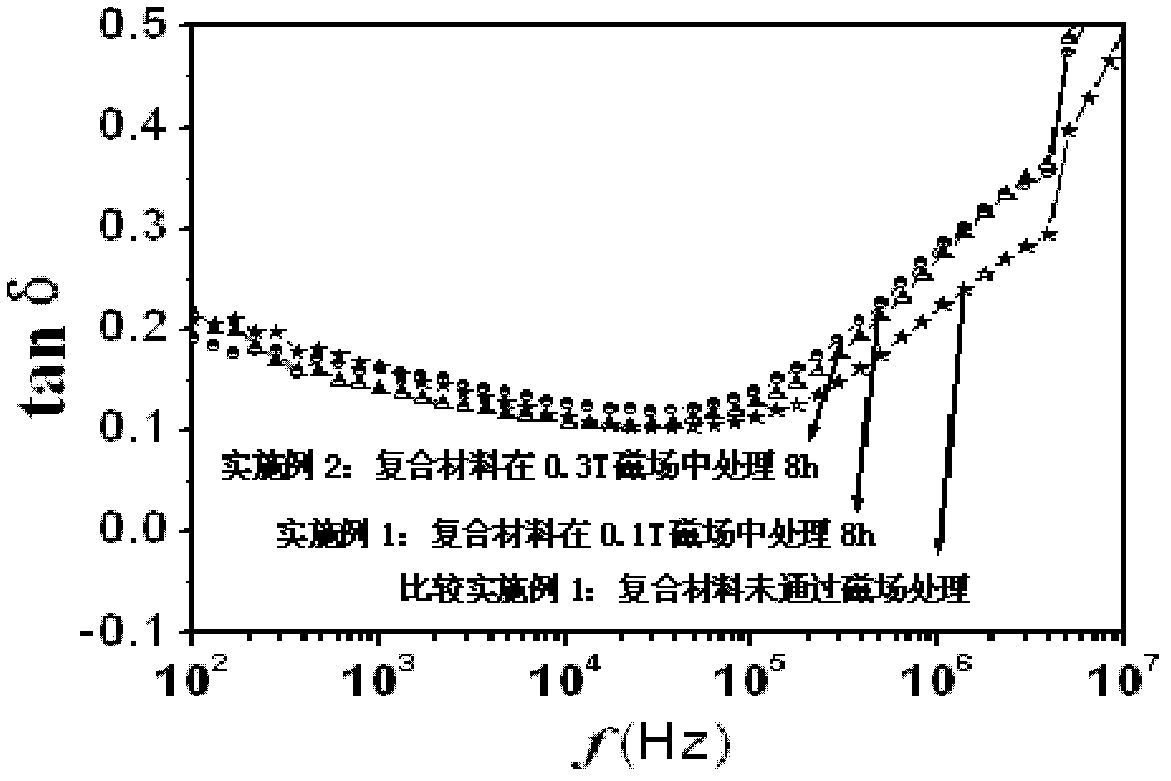

High-energy-storage density dielectric material and preparation method thereof

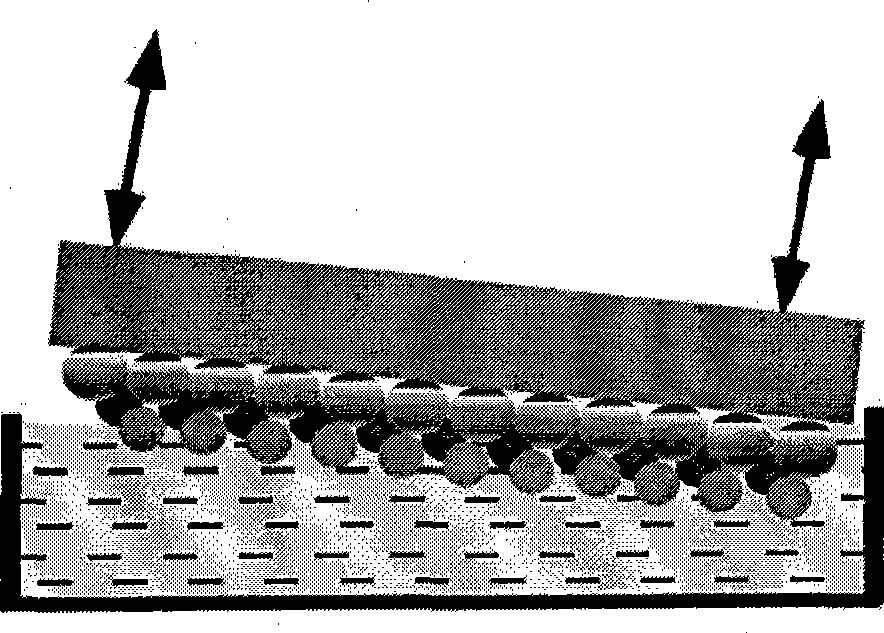

Provided is a preparation method of a high-energy-storage density dielectric material. The preparation method comprises firstly dispersing magnetic carbon nanotubes into dimethyl formamide (DMF) solvent for mechanical mixing for 1-3 hours, and performing ultrasonic processing for 1 hour to obtain carbon nanotube solution; independently dissolving ferroelectric polymers into the DMF solvent, and then pouring the prepared carbon nanotube solution into ferroelectric polymer solution for continuous mixing for 1 hour; pouring the compound solution into a glass culture dish made of non-magnetic permeability materials, and drying solvent in the compound solution in a dryer at the temperature of 80-100 DEG C until the compound can only flow when the culture dish inclines; placing the compound to a 0.1-0.5 T magnetic field for standing for 5-10 hours, and continuously drying the compound after being taken out in the dryer at the temperature of 80-100 DEG C to obtain a compound film of the carbon nanotubes solidified in the polymers; cutting the compound film and placing the cut compound film into a mould in an overlaying mode, and pressing the compound films into a sheet-shaped test sample through a hot press; and coating conductive silver paste at two ends of the test sample, processing for 2 hours in the dryer at the temperature of 120 DEG C, and stabilizing for 24 hours at the room temperature after cooling to obtain the high-energy-storage density dielectric material. By means of the preparation method, the high-energy-storage density dielectric material can be obtained. In addition, the shortcoming such as frigility caused by addition of ceramic powder can be avoided.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

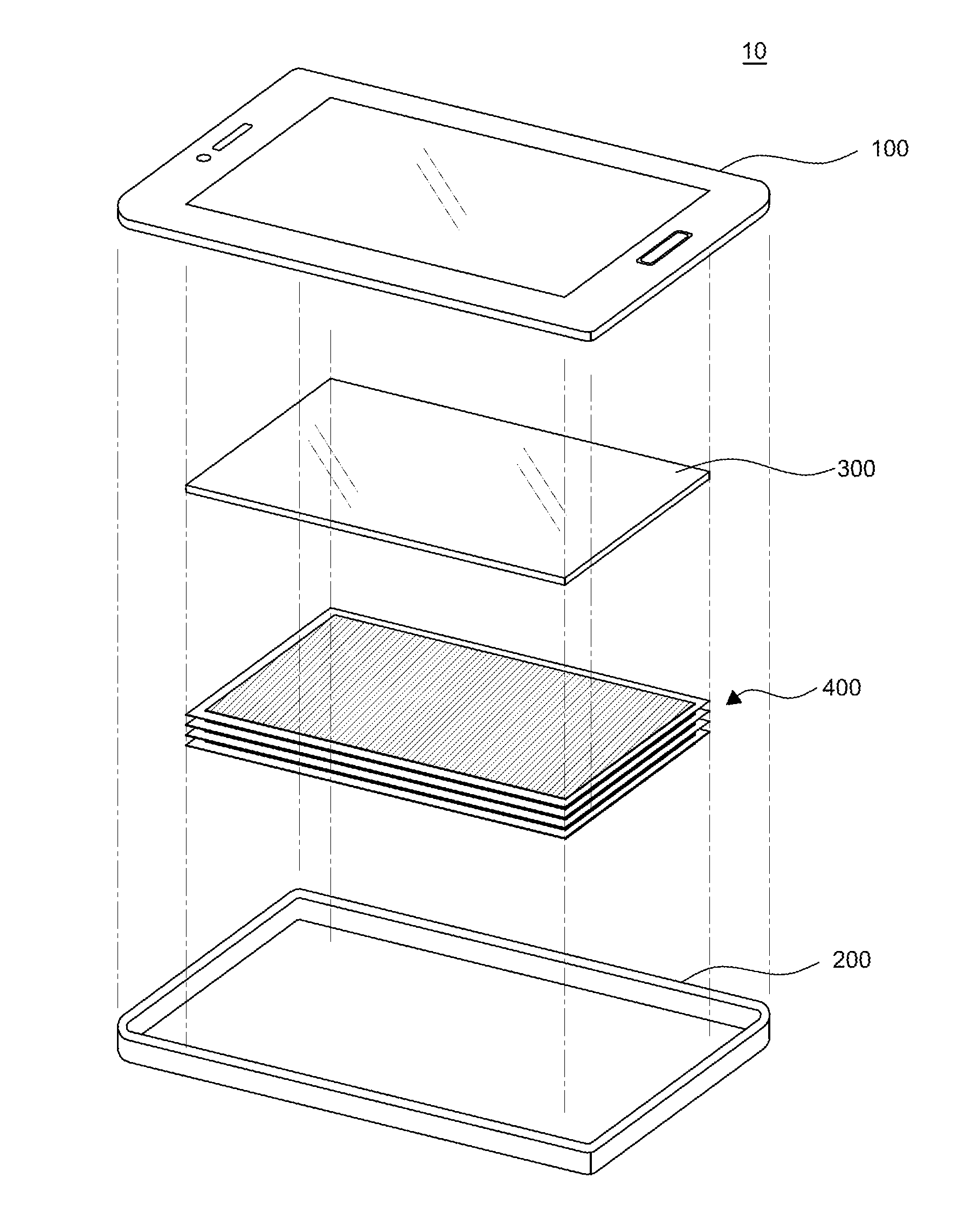

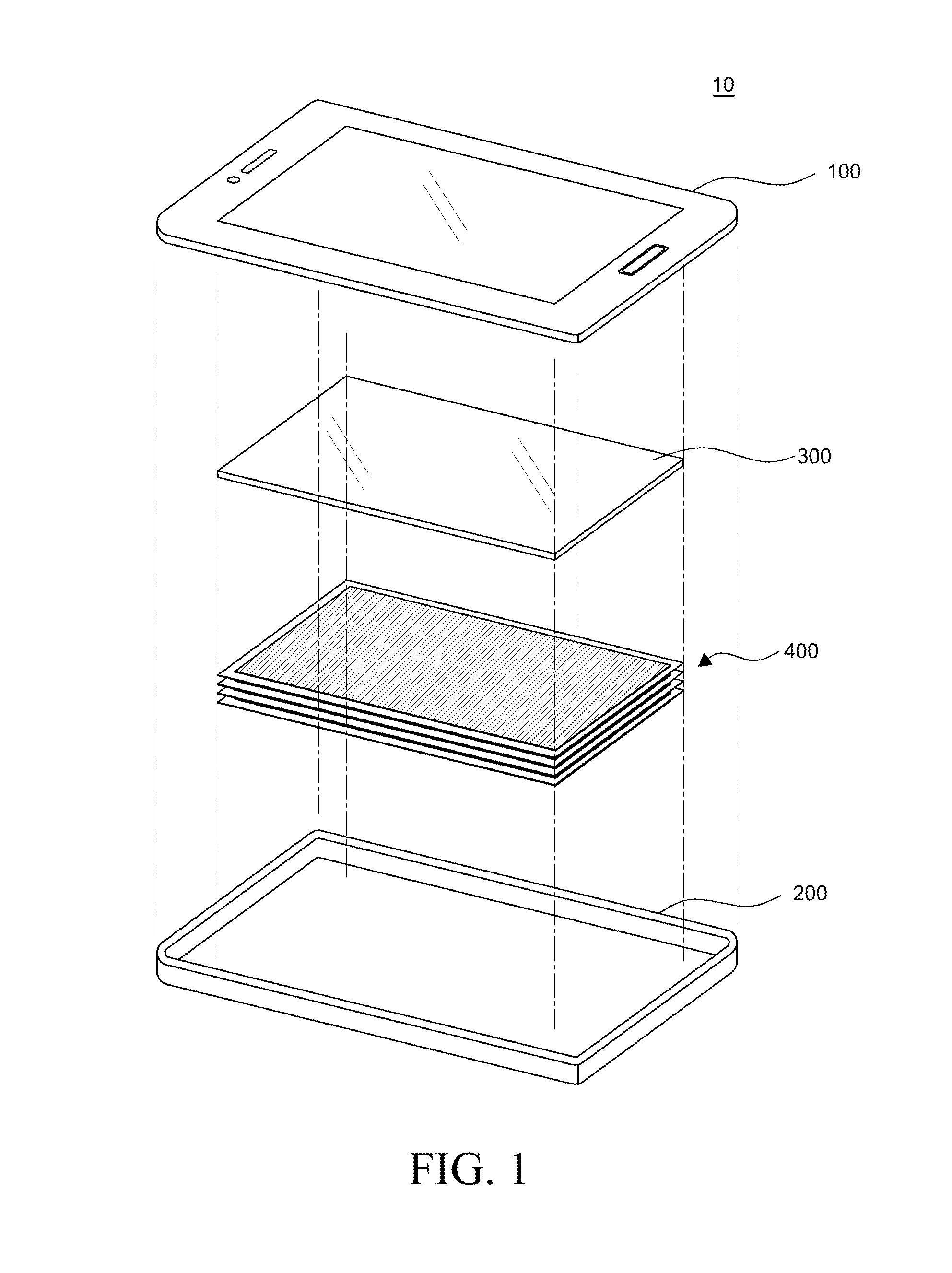

Multilayer actuator and display device comprising the same

InactiveUS20160190428A1Increase drive displacementIncrease displacementPiezoelectric/electrostriction/magnetostriction machinesPrinted circuit detailsFerroelectric polymersDisplay device

Owner:LG DISPLAY CO LTD

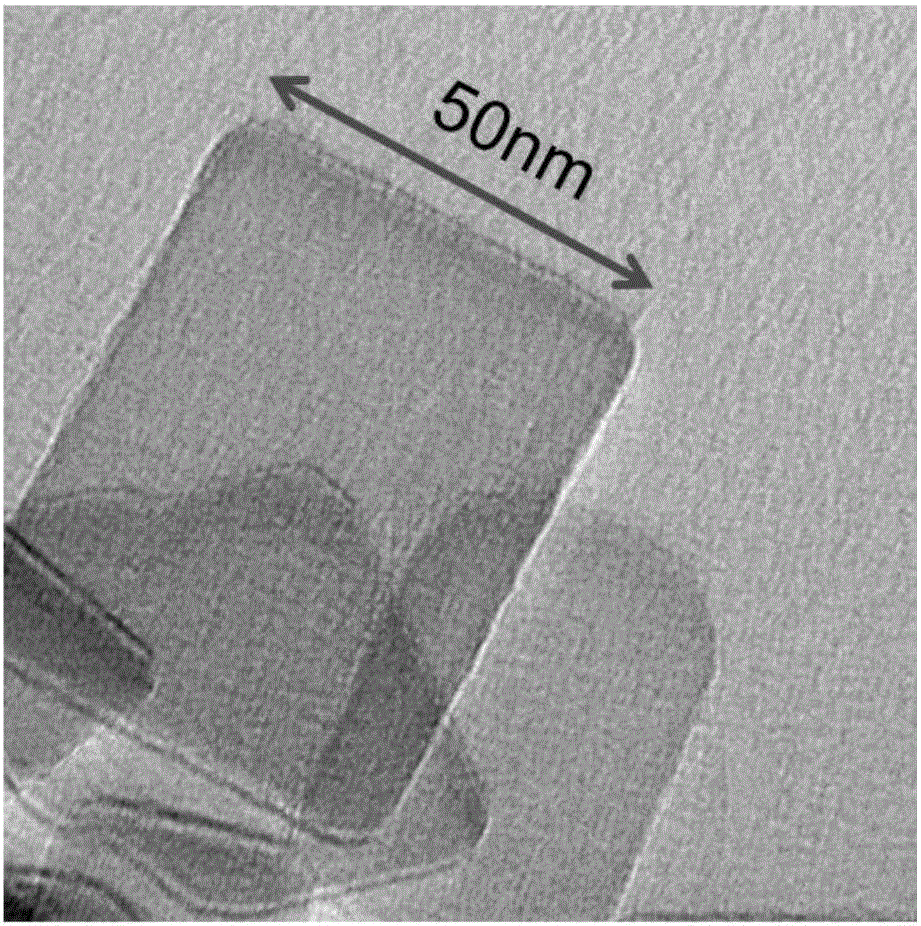

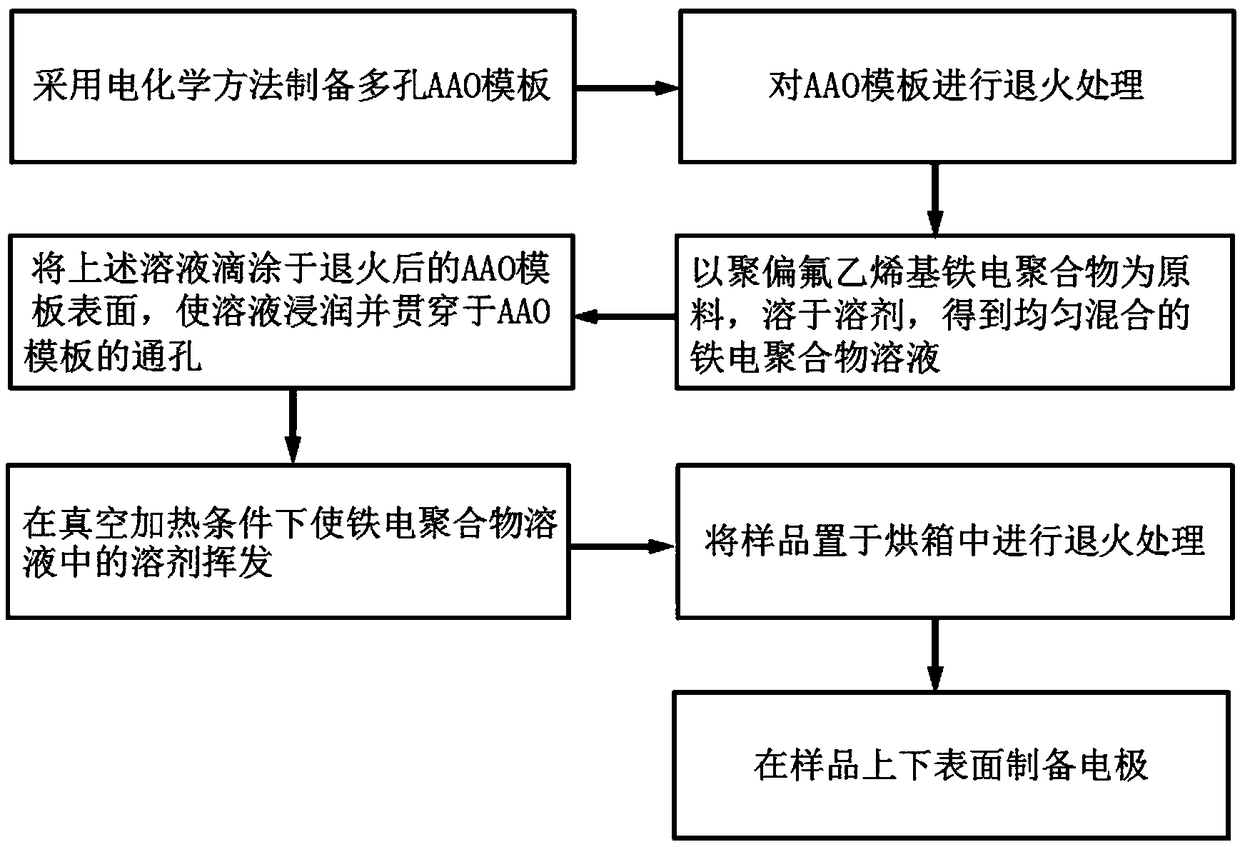

Ferroelectric polymer electric card material and preparation method thereof

InactiveCN108192247ASolve the problem of difficult heat conductionImprove the strength of the electric cardSurface reaction electrolytic coatingNanotechnologyFerroelectric polymersPolyvinylidene difluoride

The invention discloses a ferroelectric polymer electric card material and a preparation method thereof, wherein the ferroelectric polymer electric card material is a polyvinylidene fluoride (PVDF) based ferroelectric polymer electric card nanowire array; the PVDF based ferroelectric polymer electric card nanowire array is also embedded into a porous anodic aluminum oxide (AAO) template. Accordingto the preparation method, a PVDF based ferroelectric polymer electric card material is controlled to form the nanowire array; the nanowire array is also embedded into the porous anodic aluminum oxide AAO template; the ferroelectric polymer nanowire array is prepared in the porous anodic aluminum oxide AAO template through a solution infiltration method, and through improving the morphology, structure, internal microscopic joint construction and the like of a key ferroelectric polymer, in comparison with the prior art, the problems that the strength of a ferroelectric polymer electric card islow, the heat conduction in the electric card material is difficult and the refrigeration power density of an electric card device is low and the like are effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

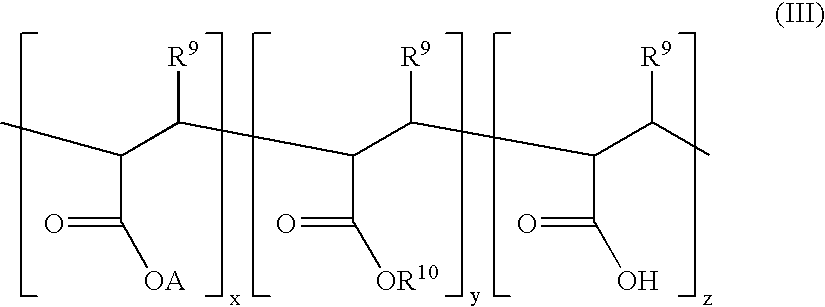

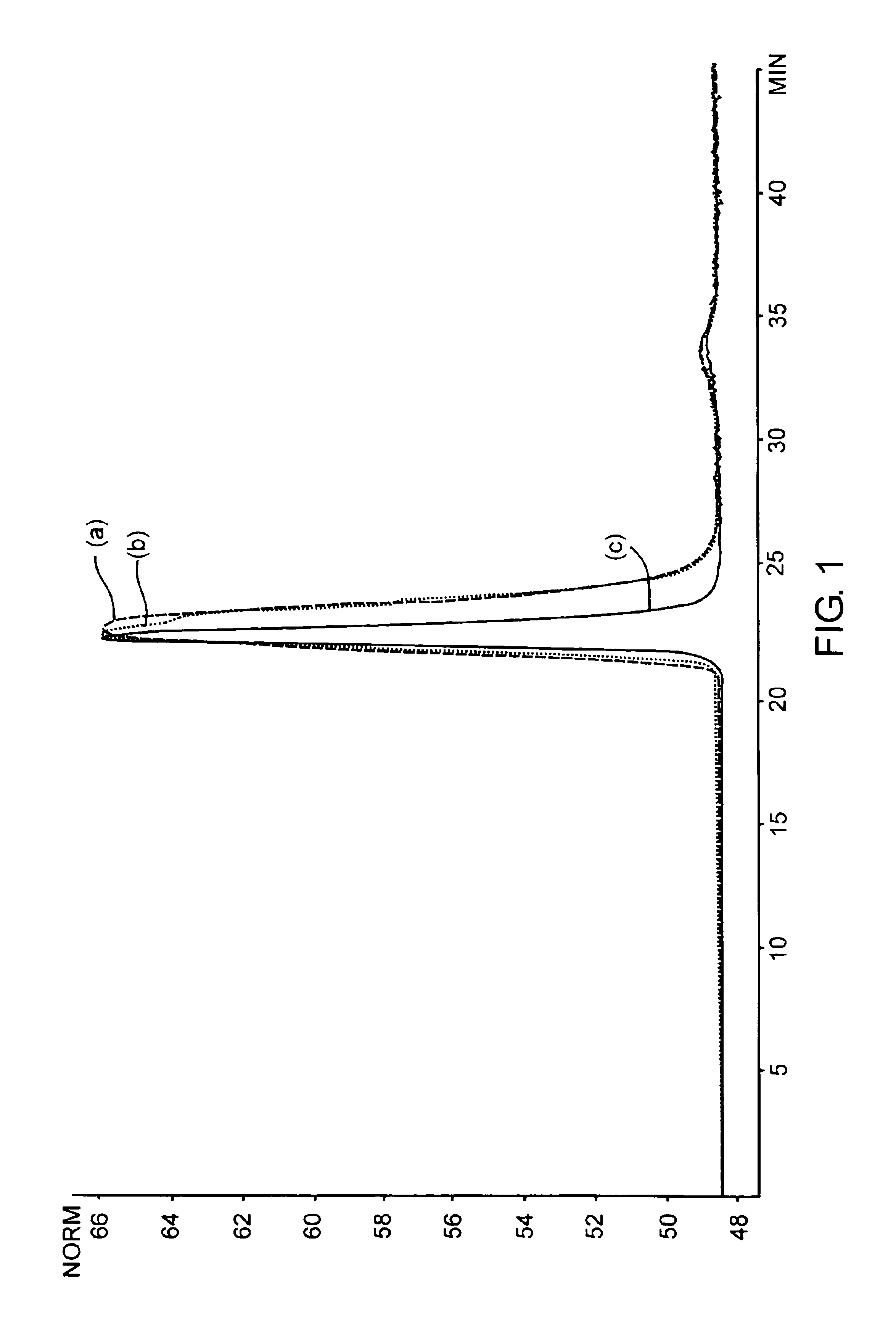

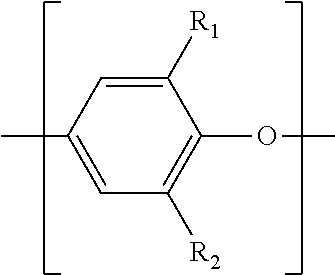

Process of fractionating polymers

Provided herein is a process of fractionating ferroelectric, preferably vinylidene fluoride polymers using a solvent having at least one polarizable functional group, and a precipitant. The composition of the fractionated ferroelectric polymers is selected so as to adjust the properties of a ferroelectric film made from the polymers. Films formed using the fractionated vinylidene fluoride polymers have improved properties, particularly with respect to roughness and crystal domain size, and suitability for use in data processing devices.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

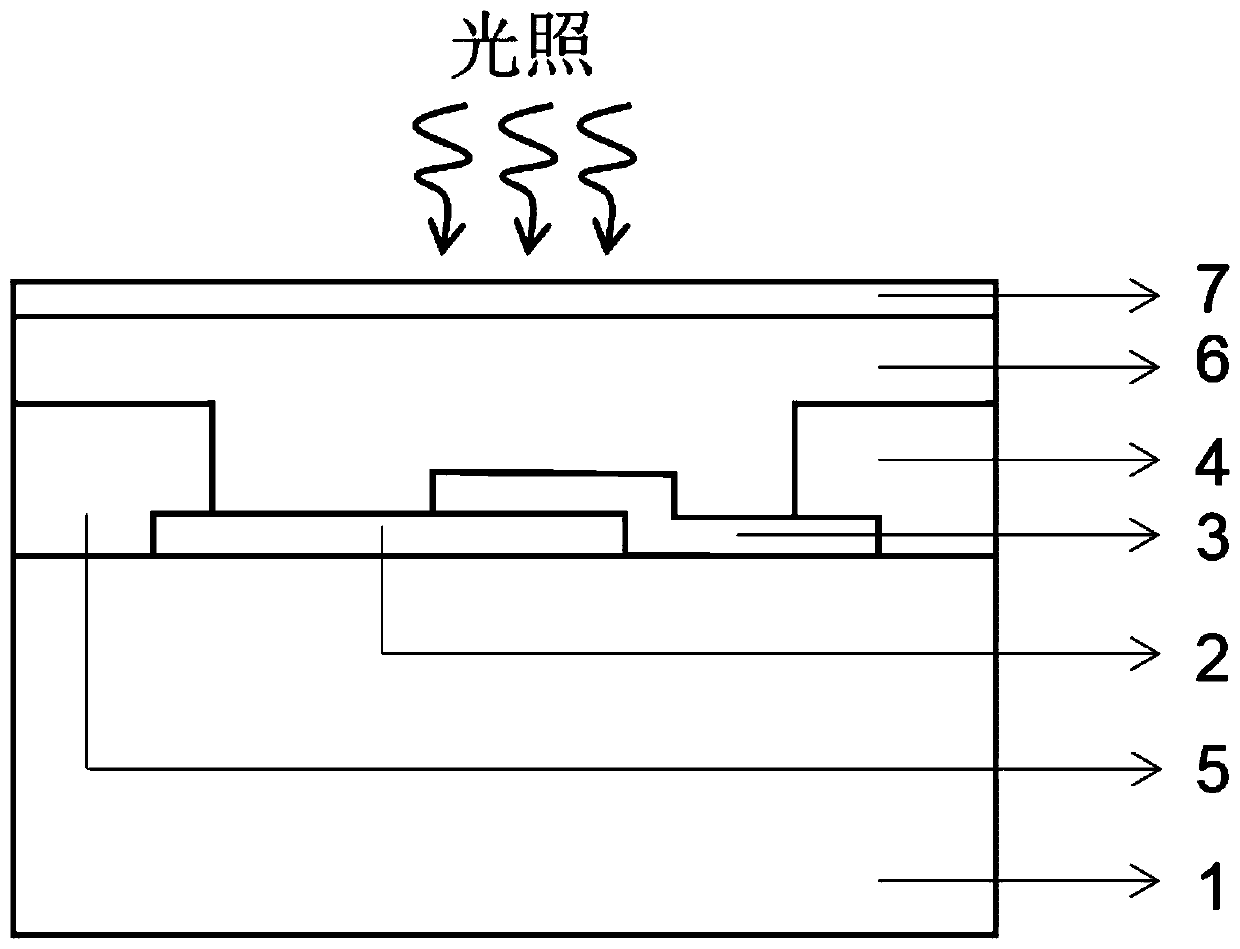

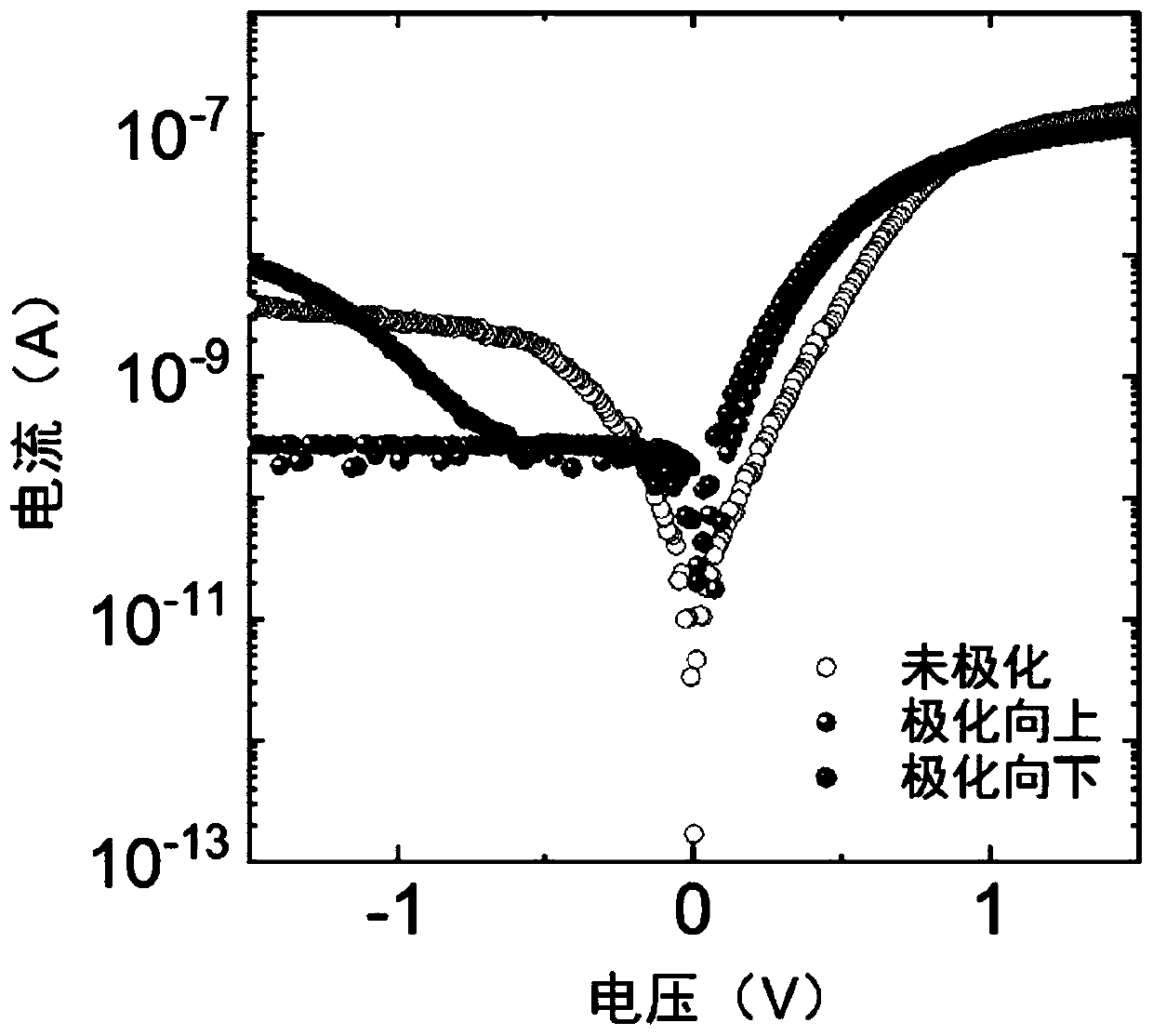

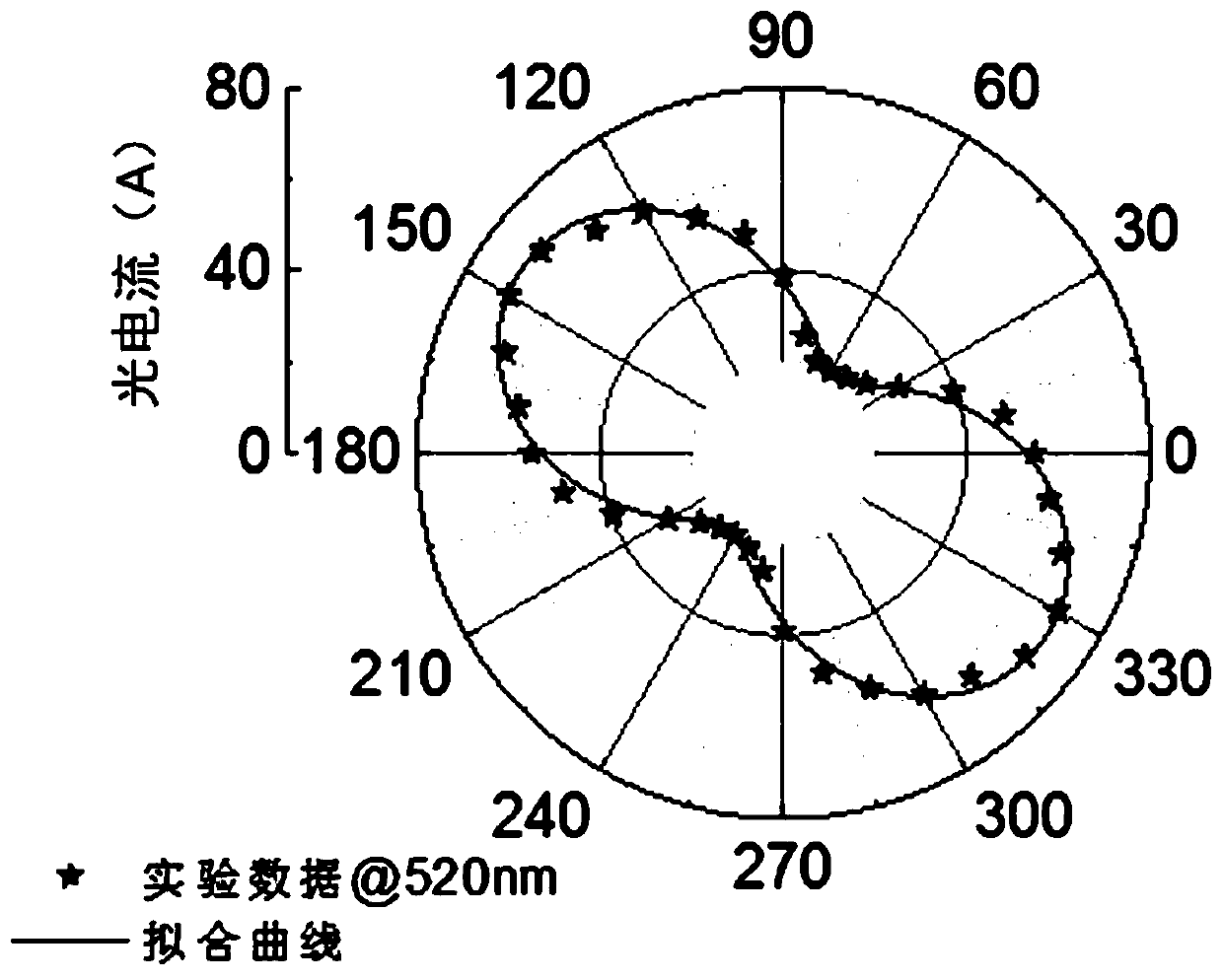

Ferroelectric enhanced van der Waals heterojunction polarization detector and preparation method thereof

PendingCN110808309AFinal product manufactureLight polarisation measurementHeterojunctionFerroelectric thin films

The invention discloses a ferroelectric enhanced van der Waals heterojunction polarization detector and a preparation method thereof. The ferroelectric enhanced van der Waals heterojunction polarization detector is characterized by comprising a substrate, a van der Waals heterojunction composed of two two-dimensional semiconductors, a metal source-drain electrode, a ferroelectric thin film, and atranslucent metal gate electrode in order from bottom to top. The preparation method comprises steps: firstly, preparing a two-dimensional semiconductor on the substrate; transferring another anisotropic two-dimensional semiconductor on this basis; combining the two semiconductors by Van der Waals force; preparing a metal electrode by electron beam lithography and lift-off technology; spin-coatinga ferroelectric polymer film to prepare a translucent metal electrode; and finally forming a ferroelectric local field enhanced polarization detector. Different from a heterojunction photoelectric detector, the structure can realize a polarization detector with a high dichroism ratio, low power consumption and fast response.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

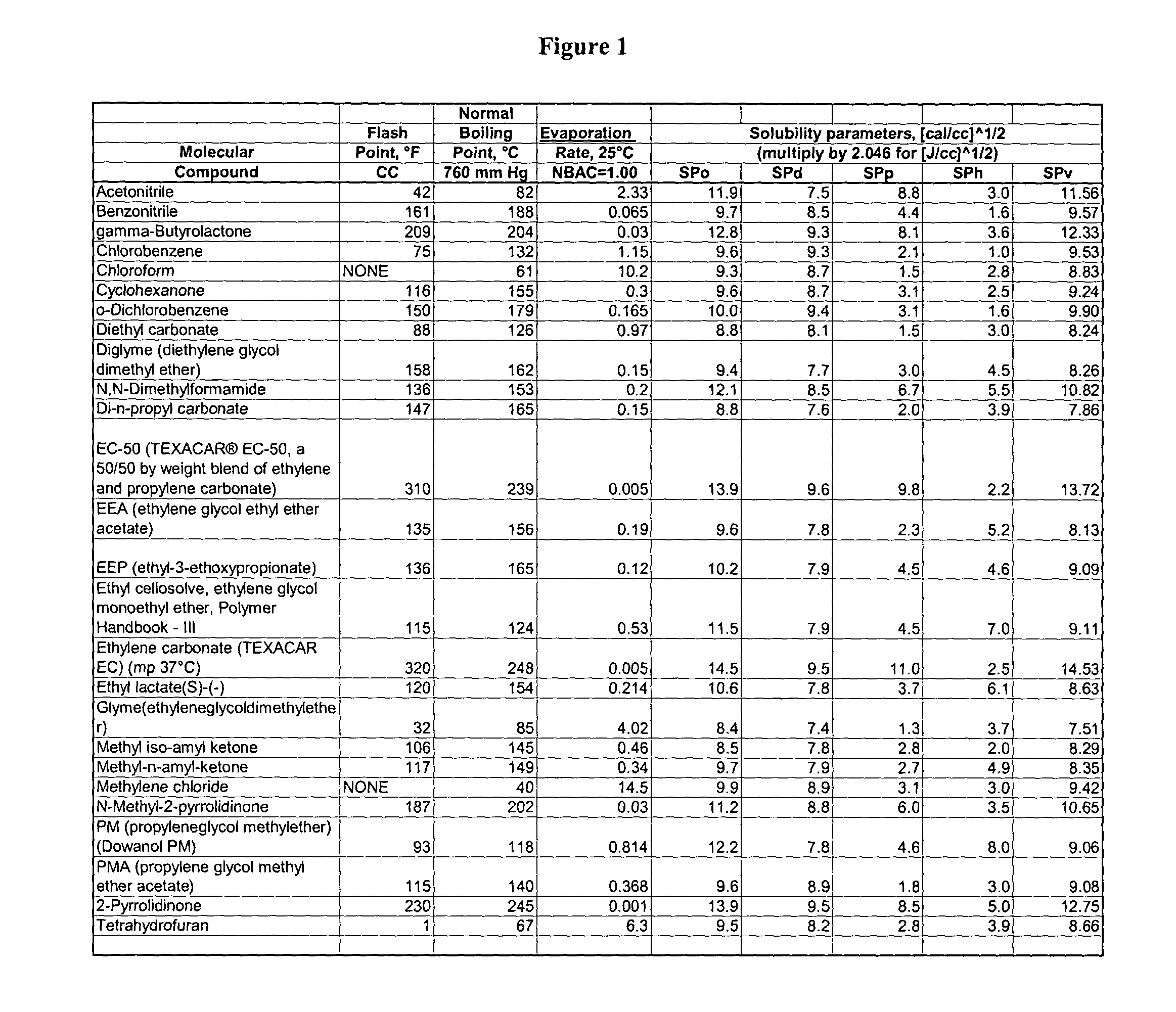

Process for selecting solvents for forming films of ferroelectric polymers

InactiveUS7214410B2Piezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsFerroelectric polymersPolymer

Owner:SHIPLEY CO LLC

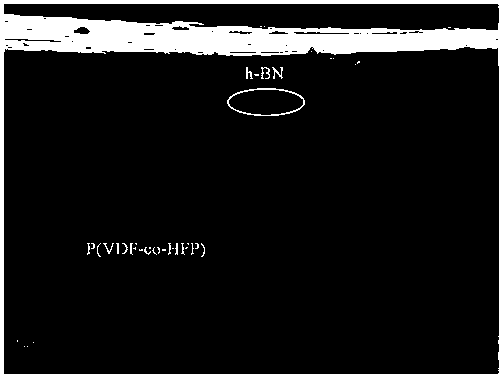

High energy storage efficiency ferroelectric polymer matrix dielectric film, preparation method of the same, and application of the same

ActiveCN107705985AImprove energy storage efficiencyImprove energy storage performanceFixed capacitor dielectricFerroelectric polymersPolymer science

The invention relates to a high energy storage efficiency ferroelectric polymer matrix dielectric film, a preparation method of the same, and an application of the same. The high energy storage efficiency ferroelectric polymer matrix dielectric film contains vinylidene fluoride-hexafluoropropene copolymer P(VDF-co-HFP) and hexagonal boron nitride h-BN, wherein by volume percentage, the proportionof the vinylidene fluoride-hexafluoropropene copolymer P(VDF-co-HFP) and the hexagonal boron nitride h-BN is (100x)%P(VDF-co-HFP)-x%h-BN, and 0< x<=7. The high energy storage efficiency ferroelectricpolymer matrix dielectric film has the advantages of being high in breakdown field strength, being high in energy storage density, being high in energy storage efficiency, being leadless and environmentally friendly, being excellent in energy storage performance, and being suitable for the high density energy storage field.

Owner:TSINGHUA UNIV

Ferroelectric Capacitor With Improved Fatigue and Breakdown Properties

ActiveUS20140268483A1Increased durabilityPoor durabilityDecorative surface effectsDuplicating/marking methodsFerroelectric polymersPolymer science

Disclosed is a ferroelectric material and methods for its use in capacitors that includes a polymer blend of at least two polymers, wherein the first polymer is a ferroelectric polymer and the second polymer has a low dielectric constant.

Owner:SAUDI BASIC IND CORP SA

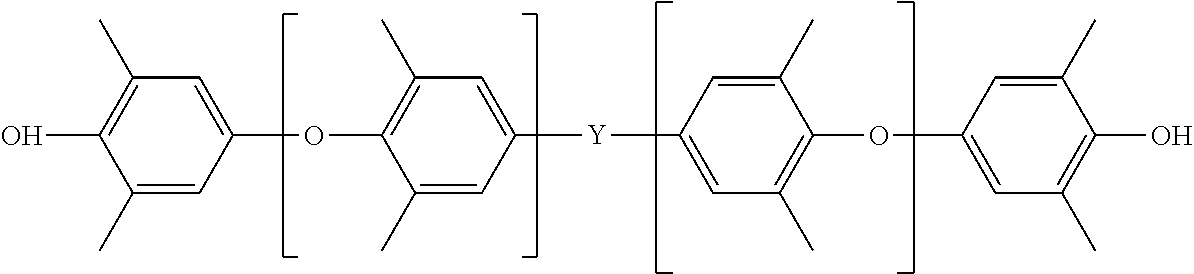

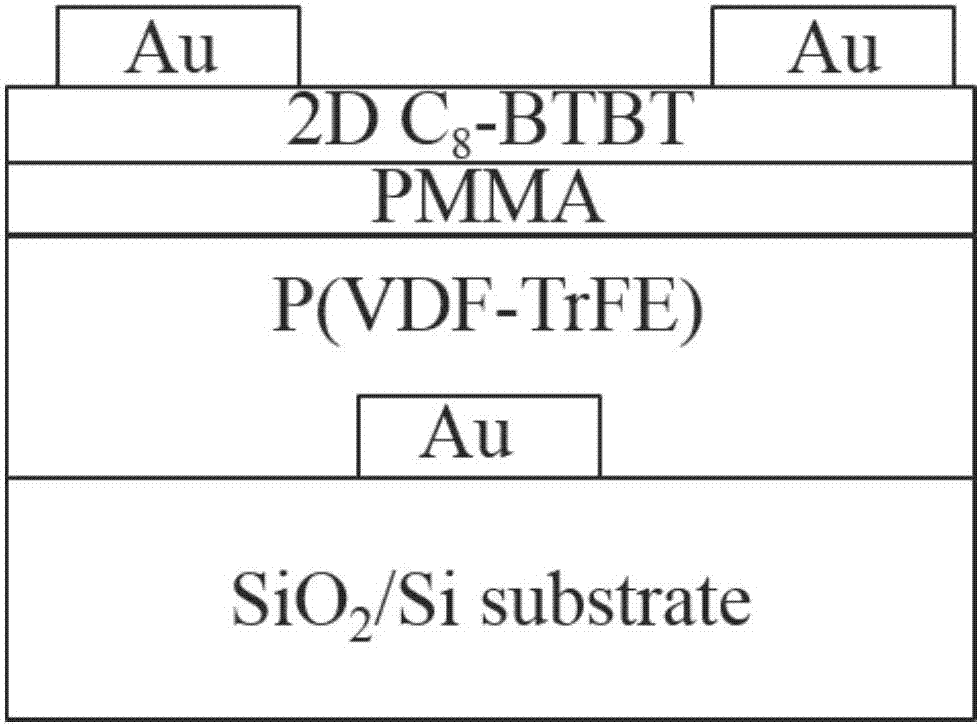

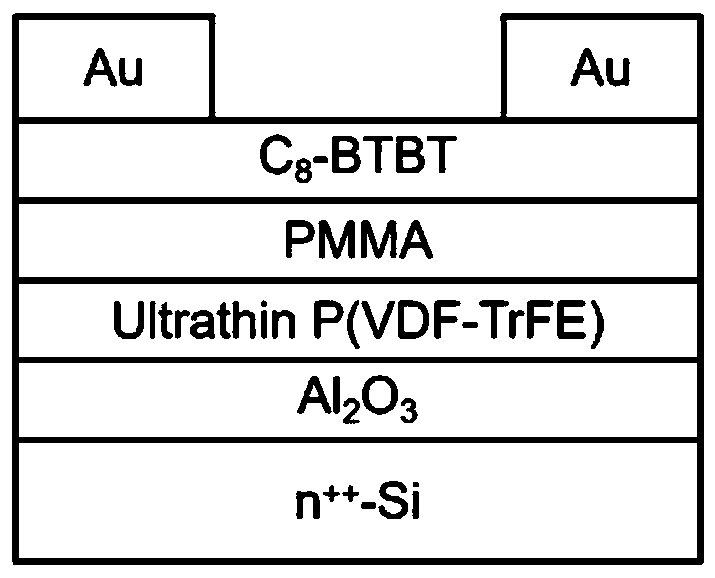

Fast ferroelectric transistor memory based on two-dimensional organic molecular semiconductors and preparation thereof

InactiveCN107275483AFast operationEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric polymersEvaporation

A fast ferroelectric transistor memory based on two-dimensional organic molecule semiconductors is prepared in a way that heavily doped p-type silicon is taken as a substrate and 50-250 nm silicon dioxide is grown and used as an insulating layer; a layer of 20-50 nm gold is prepared on the silicon dioxide by thermal evaporation and used as the gate, and then a layer of ferroelectric polymer material, poly (vinylidene fluoride-trifluoroethylene), is spin-coated on the gate; and a layer of untrathin polymethyl methacrylate (PMMA) with thickness of 2-10 nm and a dioctyl benzothiophene benzothiophene semiconductor layer (C8-BTBT) with thickness of 5-10 nm are grown respectively on P (VDF-TrFE) by the floating coffee effect and the phase separation method, wherein the passivation layer PMMA is under the two-dimensional semiconductor layer C8-BTBT, gold is deposited on the semiconductor layer as a source and a drain to prepare a two-dimensional organic molecular semiconductor ferroelectric transistor memory having a bottom gate top contact structure.

Owner:NANJING UNIV

Lightweight flexible polymer-based high-energy-density material and preparation method thereof

The invention discloses a lightweight flexible polymer-based high-energy-density material and a preparation method thereof. The lightweight flexible polymer-based high-energy-density material disclosed by the invention is prepared from a fluoride ferroelectric polymer as matrix and modified graphene as a filler by the processes of solution blending, film casting, hot-press molding and the like, wherein the added graphene is subjected to one-step process green reduction and functionalization by using dopamine, and then a fluorine-containing polymer is grafted onto the surface of the graphene by a clicking chemical method, the grafted fluorine-containing polymer can improve the dispersibility of the graphene, and also can be well compatible with fluoride ferroelectric polymer matrix, and the interface bonding force between the polymer matrix and the graphene filler is enhanced. The material prepared by the method has the characteristics of light weight, good flexibility, high energy density and the like, and is applicable to preparation of advanced electronic-electrical equipments such as high-energy-density capacitors, embedded capacitors, field effect transistors and the like.

Owner:SHANGHAI JIAO TONG UNIV

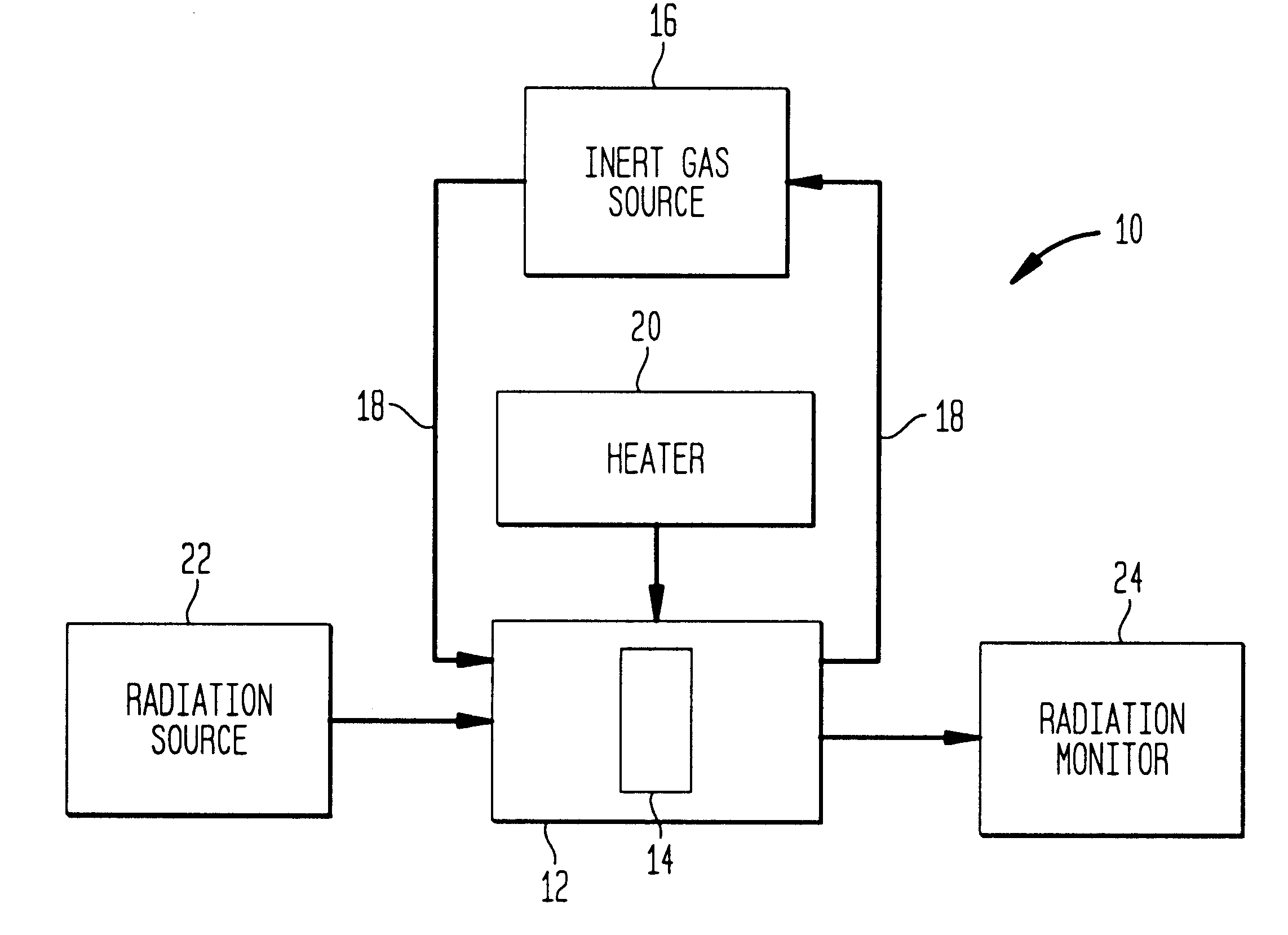

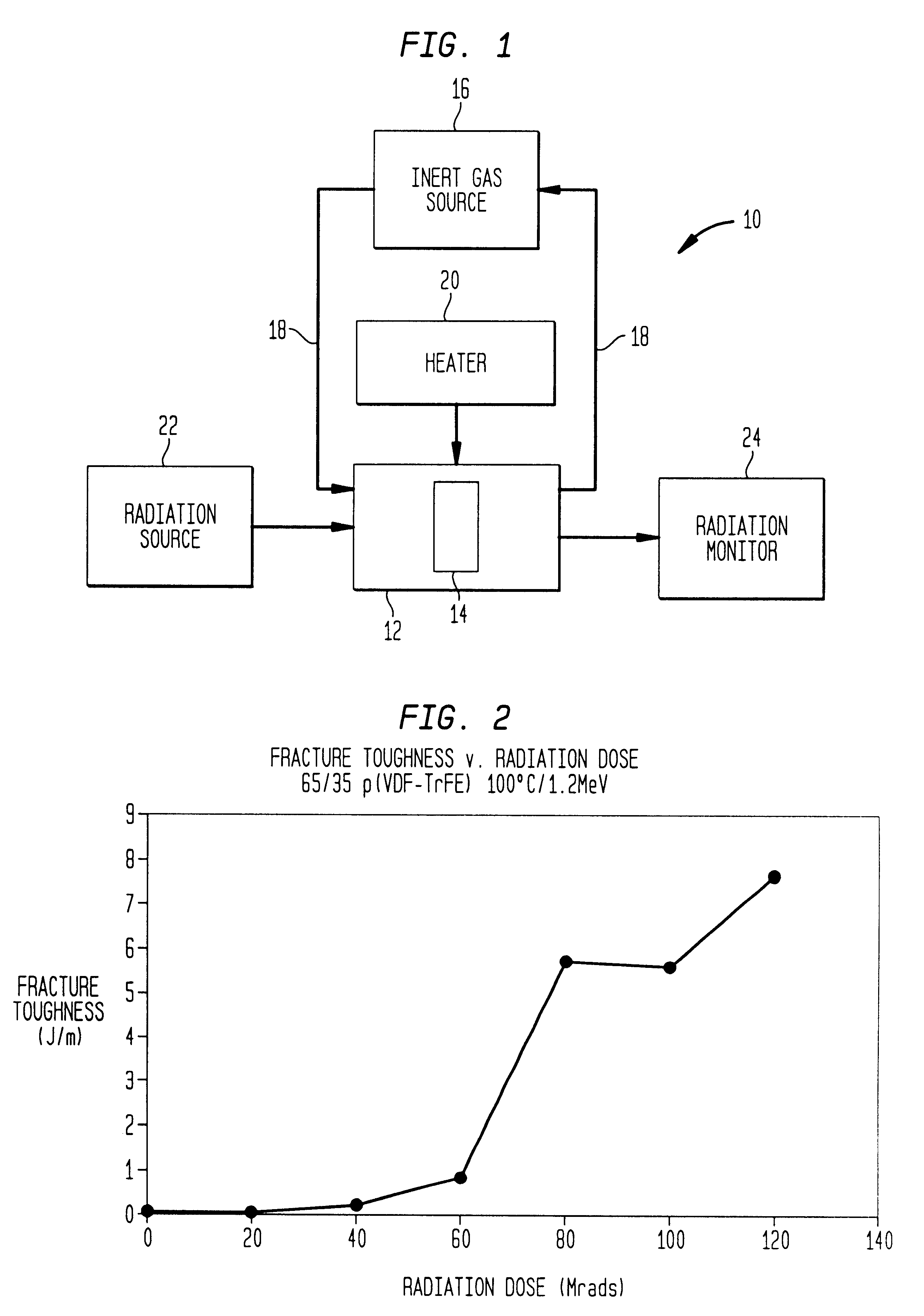

Method for increasing fracture toughness and reducing brittleness of ferroelectric polymer

InactiveUS6440755B1Piezoelectric/electrostrictive device manufacture/assemblySemiconductor/solid-state device manufacturingOxygenElectron

A method is provided that increases fracture toughness and reduces brittleness of a semi-crystalline ferroelectric polymer material while substantially maintaining ferroelectric properties of the material. The material is heated in an inert oxygen-free atmosphere to a temperature above the material's Curie transition but below its melting temperature. The material is then irradiated with beta particles to provide a desired level of fracture toughness that substantially maintains ferroelectric properties of the material. In the case of poly(vinylidene fluoride-trifluorethylene), the heating temperature is just above the material's Curie transition temperature, the beta particles have an energy level of approximately 2.5 mega electron volts (MeV), and the radiation dose should not exceed approximately 50 megarads (Mrads).

Owner:TOYOTA IND CORP +1

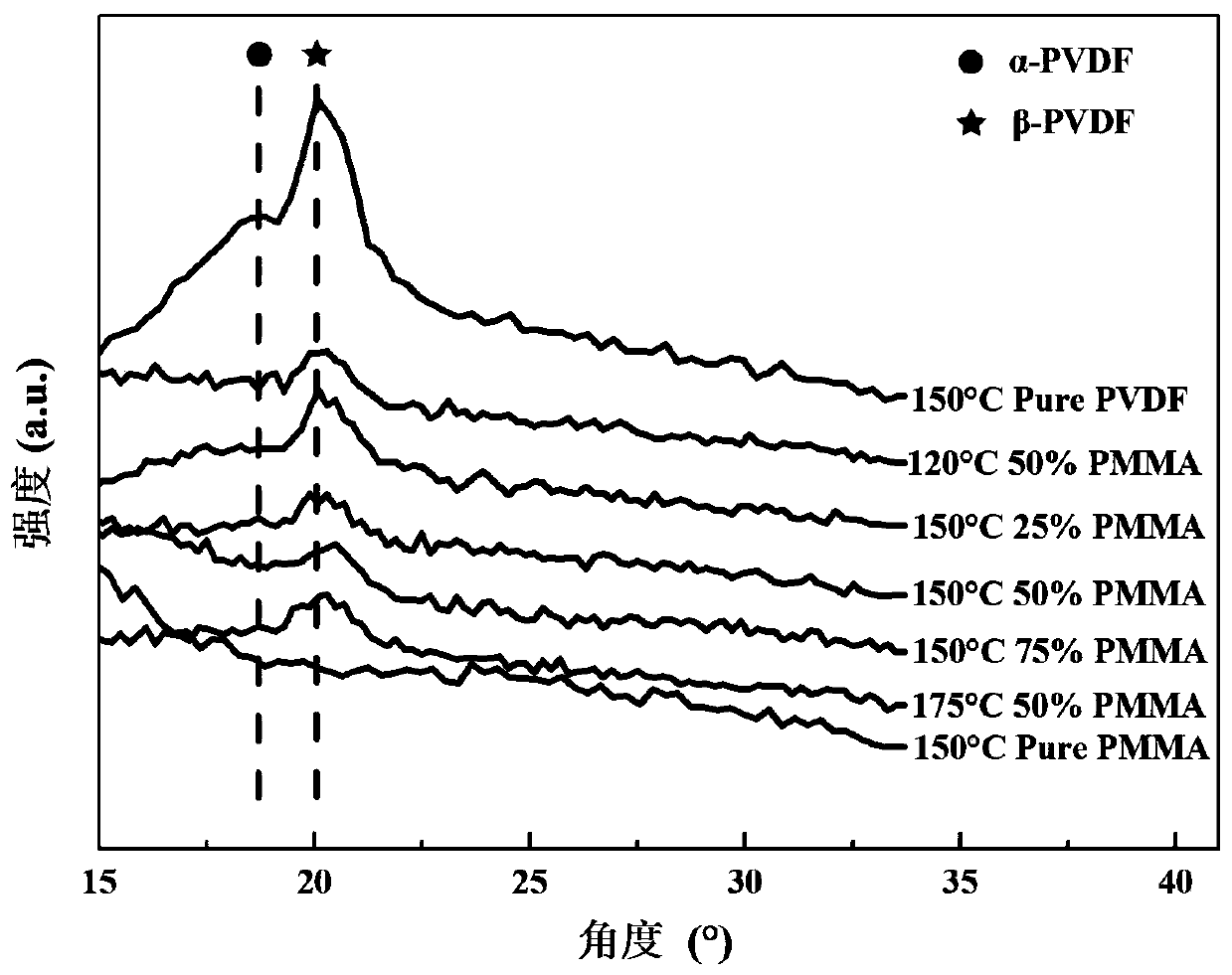

PMMA/PVDF composite film and preparation method thereof

InactiveCN110951195ABreakdown field strengthBreakdown field heightFlat articlesDielectricFerroelectric polymers

Owner:HARBIN UNIV OF SCI & TECH

Ultralow power consumption ferroelectric transistor type memory based on two-dimensional organic functional material and preparation method thereof

ActiveCN110047996ASimple deposition processGood workmanshipSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorLow voltage

The invention discloses an ultralow power consumption ferroelectric transistor type memory based on a two-dimensional organic functional material and a preparation method thereof. The method is as below: growing an aluminum oxide insulating layer on a substrate by an atomic beam deposition method; preparing a layer of ultrathin ferroelectric polymer crystalline film at room temperature by utilizing an anti-solvent assisted crystallization method; then simultaneously growing a layer of ultrathin polymethyl methacrylate and a layer of ultrathin dioctyl benzothiophene benzothiophene by utilizinga floating coffee ring effect and a phase separation method; and finally transferring a gold film onto a dioctyl benzothiophene layer as a source electrode and a drain electrode by utilizing a non-invasive gold film transfer process. A quasi-two-dimensional ferroelectric polymer crystalline film and a two-dimensional organic molecular crystal C8-BTBT are used as a dielectric layer to prepare the fast transistor memory, so that the power consumption of the ferroelectric organic field effect transistor memory can be greatly reduced, and meanwhile, the low-voltage operation capability and the fast storage capability are realized.

Owner:NANJING UNIV

Method for manufacturing organic semiconductor/ferroelectric composite resistance-variable film through temperature-controllable spin coating

InactiveCN103943777AReduce surface roughnessImprove resistance performanceSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric polymersComposite film

The invention relates to a method for manufacturing an organic semiconductor / ferroelectric composite film having a resistance-variable characteristic through a temperature-controllable spin coating technology. Ferroelectric polymers and an organic semiconductor are dissolved in butylene oxide to be prepared into a mixed solution, and at a specific spin coating environment temperature, the surface of a clean substrate is coated with the mixed solution in a dripping mode to form the film through spin coating. Through precisely adjusting and controlling the environment temperature in the spin coating process, the organic semiconductor / ferroelectric composite film which is low in surface roughness and high in resistance-variable performance can be manufactured.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com